Jenn-Air JGC8645ADB, JGC8645ADS, JGC8645ADW Installation Guide

JGC8430 AND JGC8645 403WESTFOURTHSTREET,NORTH. NEWTON,IA 502

SEALEDGAS COOKTOPS • JENN-AIR ol

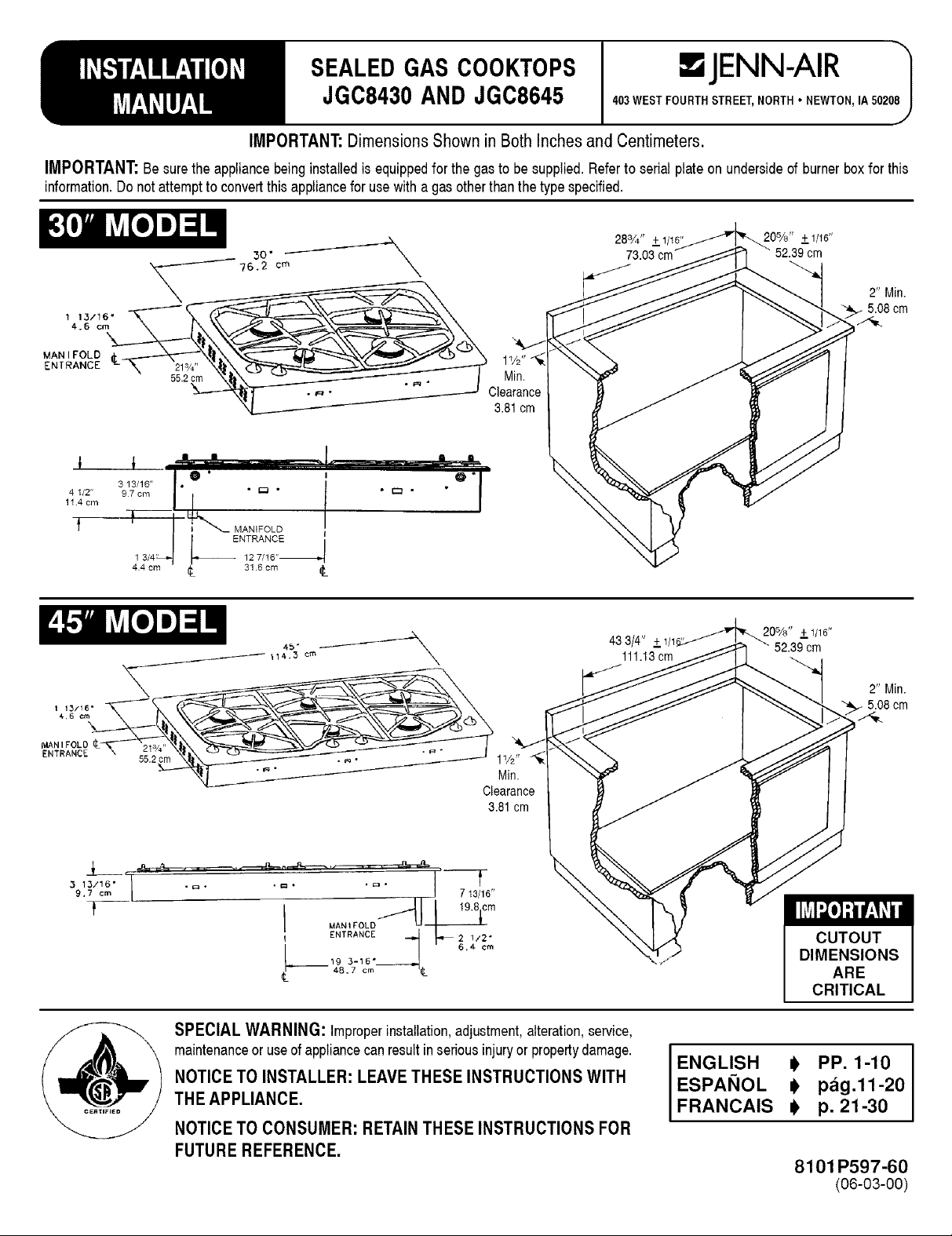

IMPORTANT:DimensionsShown in BothInchesand Centimeters.

IMPORTANT:Besurethe appliancebeinginstalledis equippedforthe gasto besupplied.Referto serial plateon undersideof burnerboxfor this

information.Donotattemptto convertthisappliancefor usewith a gasotherthanthetype specified.

28%" +1/15" 20%" +1/15"

73.03 cm 52.39 cm

2" Min,

5.08cm

1 13/16"

4.6 cm

76.2 cm

MANIFOLD

ENfRANCE

I

4 1/2" 97 cm I_

11.4 cm

313/16" t

1 12 7/t6"

44 cm I_ 31.6 cm I_.

_ 114.3 cm

X

ENTRANCE

NTRANCE_

11/2" "_.

Min.

Clearance

3.81 cm

I

@

43 3/4" +_

111.13cm

20%" +_1/15"

52,39 cm

2" Min.

5.08cm

Min.

Clearance

3.81 cm

.3 13/16" / - _ -

9,7 cm

/

I

SPECIAL WARNING: Improperinstallation,adjustment,alteration,service,

maintenanceor useofappliancecan resultinseriousinjuryor propertydamage.

NOTICETO INSTALLER: LEAVETHESEINSTRUCTIONSWITH

THE APPLIANCE.

NOTICETO CONSUMER:RETAINTHESEINSTRUCTIONS FOR

FUTURE REFERENCE.

ESPANOL

ENGLISH

FRANCAIS 0

PP. 1-10

pag.11-20

p. 21-30

8101 P597-60

(06-03-00)

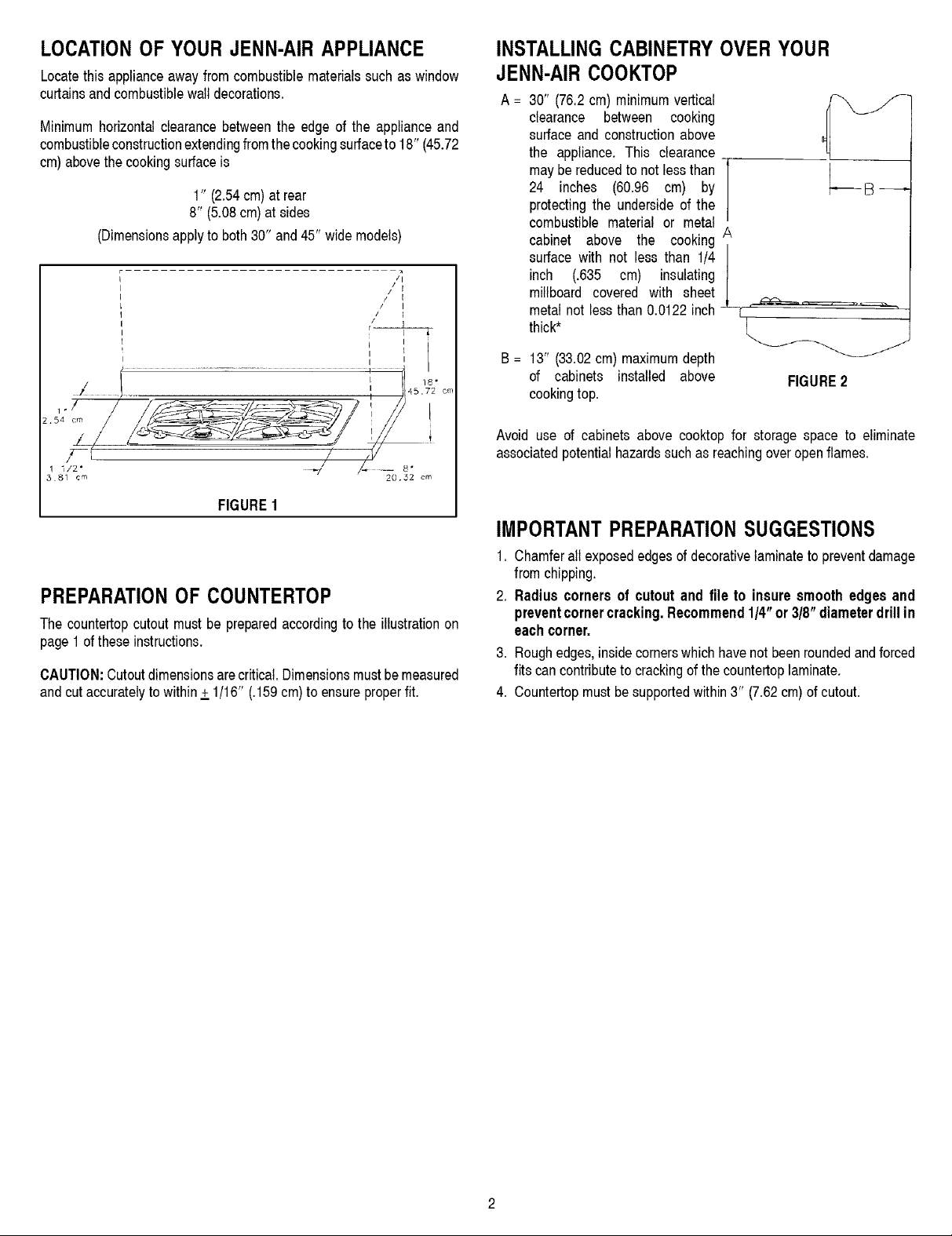

LOCATIONOF YOUR JENN-AIRAPPLIANCE

Locatethisapplianceawayfromcombustiblematerialssuchaswindow

curtainsandcombustiblewalldecorations.

Minimumhorizontalclearancebetweenthe edge of the applianceand

combustibleconstructionextendingfromthecookingsurfaceto 18"(45.72

cm)abovethecookingsurfaceis

1" (2.54cm)atrear

8" (5.08cm)at sides

(Dimensionsapplyto both30"and45" widemodels)

/I

/ I I

I I I

I I

I I

f / /_ _._--_ _ , t)

z. s4 om / , //

3.81 cm 20,_2 cm

FIGURE1

INSTALLINGCABINETRYOVER YOUR

JENN-AIRCOOKTOP

A = 30" (76.2cm) minimumvertical F"X /'-

clearance between cooking

surfaceand constructionabove

the appliance. This clearance

maybereducedto notlessthan I |

protectingthe undersideof the

24 inches (60.96 cm) by J _B

combustible material or metal

cabinet above the cookingA

surfacewith not less than 1/4 |

inch (.635 cm) insulating

millboard covered with sheet _ ....

metalnot lessthan 0.0122inch- T' " •

thick* ______/

B = 13" (33.02cm) maximumdepth

of cabinets installed above FIGURE2

cookingtop.

Avoid use of cabinetsabove cooktopfor storagespace to eliminate

associatedpotentialhazardssuchas reachingoveropenflames.

/

1

U

IMPORTANTPREPARATIONSUGGESTIONS

PREPARATIONOF COUNTERTOP

Thecountertopcutoutmustbe preparedaccordingtothe illustrationon

page1 oftheseinstructions.

CAUTION:Cutoutdimensionsarecritical.Dimensionsmustbemeasured

andcutaccuratelytowithin_+1/16" (.159cm)to ensureproperfit.

1. Chamferall exposededgesof decorativelaminatetopreventdamage

fromchipping.

2. Radius cornersof cutout and file to insure smoothedges and

preventcornercracking.Recommend114"or 318"diameter drill in

each corner.

3. Roughedges,insidecornerswhichhavenotbeenroundedandforced

fitscancontributeto crackingofthecountertoplaminate.

4. Countertopmustbesupportedwithin3" (7.62cm)of cutout.

INSTALLATIONOF APPLIANCE

Theinstallationof thisappliancemustconformwithlocalcodesor,inthe

absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1-LatestEdition,or, inCanada,CAN!CGA-B149InstallationCode,

LatestEdition.

This appliance, when installed, must be electrically grounded in

accordancewith localcodesor,inthe absenceof local codes,with the

NationalElectricalCodeANSI!NFPANo.70-LatestEdition,or, inCanada,

currentCSAStandardC22.1CanadianElectricalCode,Part1.

In The CommonwealthOf Massachusetts

Thisproductmustbeinstalledbya licensedplumberor gasfitterwhe_

installedwithintheCommonwealthofMassachusetts.

A"F" handletypemanualgasvalvemust beinstalledinthegassupply

linetothisappliance.

A flexiblegasconnector,whenused,mustnotexceeda lengthof

three(3)feet136 inches.

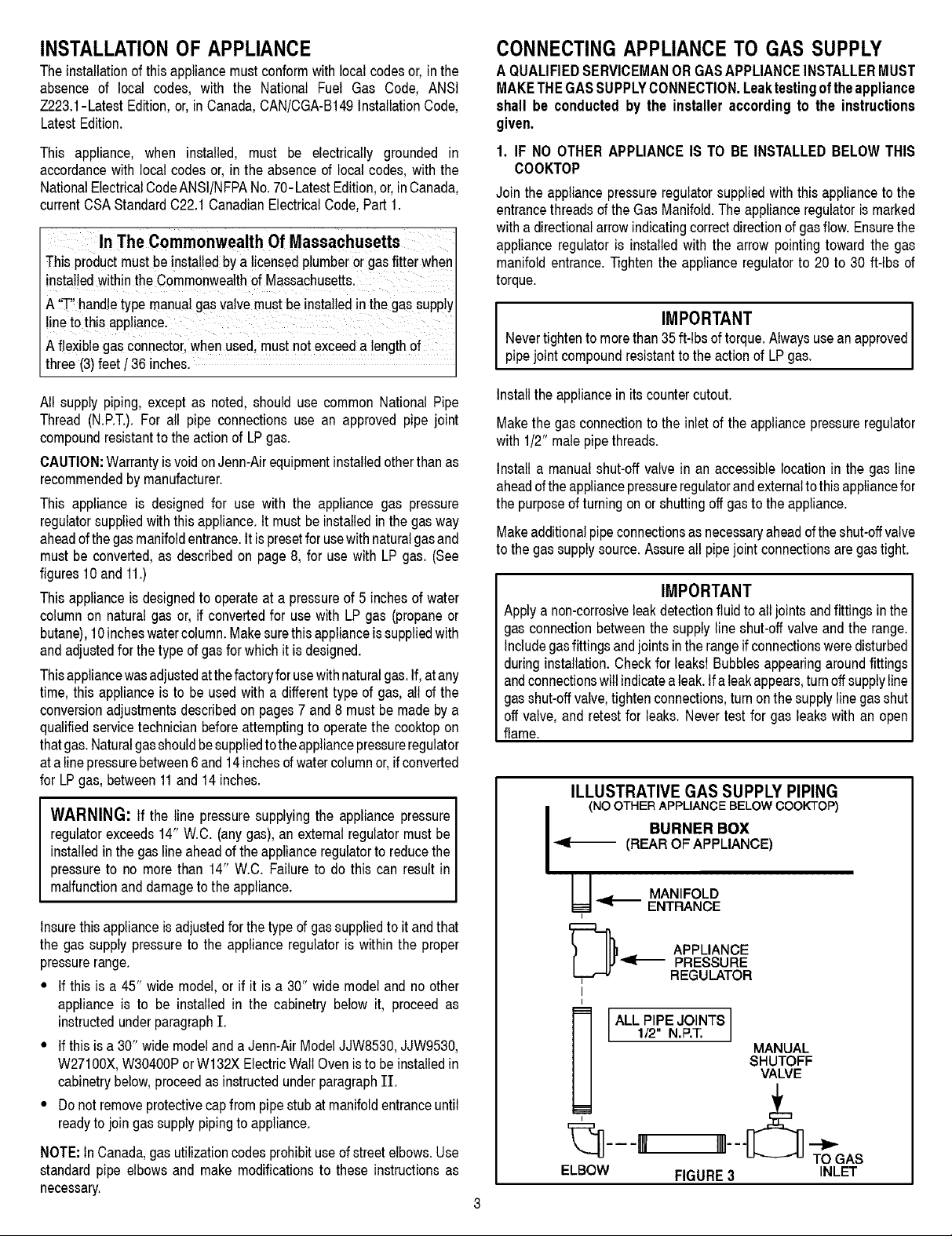

CONNECTINGAPPLIANCETO GAS SUPPLY

AQUALIFIEDSERVICEMANORGASAPPLIANCEINSTALLERMUST

MAKETHEGASSUPPLYCONNECTION.Leaktestingoftheappliance

shall be conductedby the installer accordingto the instructions

given.

1. IF NOOTHER APPLIANCEIS TO BE INSTALLEDBELOWTHIS

COOKTOP

Join theappliancepressureregulatorsuppliedwiththis applianceto the

entrancethreadsof theGasManifold.Theapplianceregulatorismarked

with adirectionalarrowindicatingcorrectdirectionof gasflow. Ensurethe

applianceregulatoris installedwith the arrowpointingtoward the gas

manifoldentrance.Tightenthe applianceregulatorto 20 to 30 ft-tbs of

torque.

Nevertightento morethan35ft-lbsof torque.Alwaysusean

I IMPORTANT approved

pipejointcompoundresistantto theactionof LPgas.

All supply piping,exceptas noted, shoulduse commonNational Pipe

Thread (N.RT.).For all pipe connectionsuse an approved pipejoint

compoundresistantto theactionof LPgas.

CAUTION:Warrantyisvoid onJenn-Airequipmentinstalledotherthanas

recommendedbymanufacturer.

This applianceis designedfor use with the appliancegas pressure

regulatorsuppliedwiththis appliance.It mustbeinstalledinthe gasway

aheadofthe gasmanifoldentrance.Itispresetforusewithnaturalgasand

mustbe converted,as describedon page8, for usewith LP gas. (See

figures10and11.)

This applianceis designedto operateat a pressureof 5 inchesofwater

columnon naturalgas or, if convertedfor usewith LPgas (propaneor

butane),10incheswatercolumn.Makesurethisapplianceis suppliedwith

andadjustedfor thetype ofgasforwhich itisdesigned.

Thisappliancewasadjustedatthefactoryforusewithnaturalgas.If,atany

time,this applianceis to be usedwith a differenttype of gas, all of the

conversionadjustmentsdescribedon pages7 and8 mustbe madeby a

qualifiedservicetechnicianbeforeattemptingto operatethe cooktopon

thatgas.Naturalgasshouldbesuppliedto theappliancepressureregulator

atalinepressurebetween6 and14inchesofwatercolumnor,ifconverted

for LPgas,between11and 14inches.

WARNING: If the line pressuresupplyingthe appliancepressure

regulatorexceeds14"W.C. (anygas),anexternalregulatormustbe

installedinthegaslineaheadof theapplianceregulatorto reducetheI

pressureto no morethan 14" W.C. Failureto do this can result in

mafunctonanddamagetothe app ance.

Insurethisapplianceisadjustedforthetypeof gassuppliedto itandthat

the gas supplypressureto the applianceregulatoris within the proper

pressurerange.

• Ifthisis a 45" wide model,or if it is a 30" widemodeland noother

applianceis to be installed in the cabinetry below it, proceed as

instructedunderparagraphf.

• Ifthisis a 30" widemodelandaJenn-AirModelJJW8530,JJW9530,

W27100X,W30400PorW132XElectricWallOvenistobe installedin

cabinetrybelow,proceedas instructedunderparagraphIf.

• Donotremoveprotectivecapfrompipestubat manifoldentranceuntil

readyto joingassupplypipingto appliance.

Installthe appliancein itscountercutout.

Makethe gasconnectionto the inletof the appliancepressureregulator

with 1/2"malepipethreads.

Installa manualshut-offvalvein an accessiblelocationin the gasline

aheadof theappliancepressureregulatorandexternaltothisappliancefor

the purposeofturningonor shuttingoffgastothe appliance.

Makeadditionalpipeconnectionsas necessaryaheadoftheshut-offvalve

to thegassupplysource.Assureallpipejointconnectionsaregastight.

IMPORTANT

Applya non-corrosiveleakdetectionfluidto alljointsandfittingsinthe

gasconnectionbetweenthe supplylineshut-offvalveandthe range.

Includegasfittingsandjointsintherangeifconnectionsweredisturbed

duringinstallation.Checkfor leaks!Bubblesappearingaroundfittings

andconnectionswill indicatealeak.Ifaleakappears,turnoffsupplyline

gasshut-offvalve,tightenconnections,turnonthe supplylinegasshut

offvalve,and retestfor leaks.Nevertestfor gas leakswith an open

flame.

ILLUSTRATIVEGAS SUPPLYPIPING

BURNER BOX

i (NO OTHER APPLIANCE BELOW COOKTOP)

U MANIFOLDENTRANCE

(REAROF APPLIANCE)

APPLIANCEPRESSURE

i REGULATOR

I

I

1/2 N.P.T.

ALL PIPEJOINTS

I

MANUAL

SHUTOFF

VALVE

NOTE:In Canada,gasutilizationcodesprohibituseof streetelbows.Use

standardpipeelbowsand make modificationsto these instructionsas

necessary.

ELBOW

TOGAS

FIGURE3 INLET

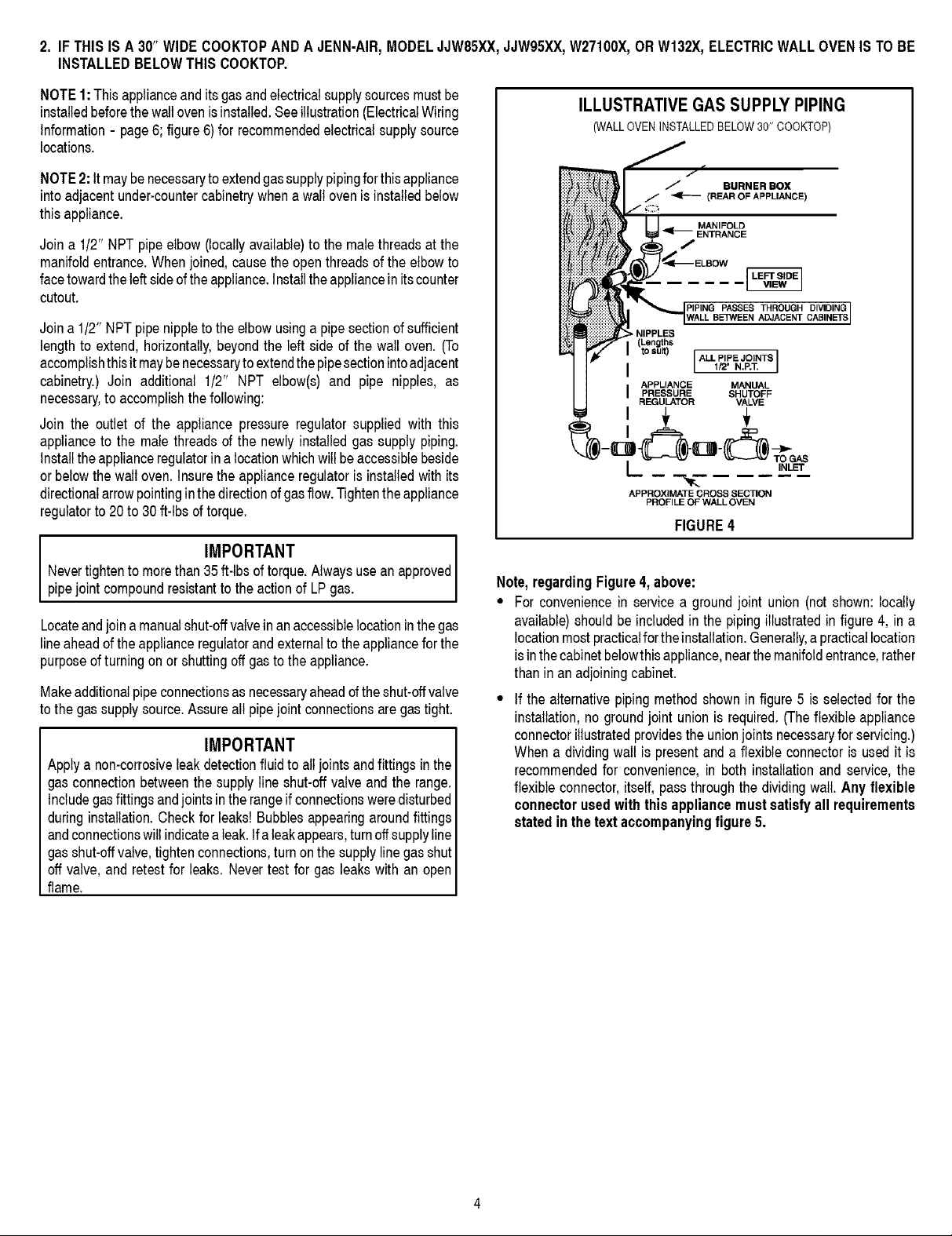

2.IFTHISISA30"WIDECOOKTOPANDAJENN-AIR,MODELJJW85XX,JJW95XX,W27100X,ORW132X,ELECTRICWALLOVENISTOBE

INSTALLEDBELOWTHISCOOKTOR

NOTE1:Thisapplianceanditsgasandelectricalsupplysourcesmustbe

installedbeforethewaltoven isinstalled.Seeillustration(ElectricalWiring

Information- page6;figure6)for recommendedelectricalsupplysource

locations.

NOTE2:Itmaybenecessaryto extendgassupplypipingforthisappliance

intoadjacentunder-countercabinetrywhenawallovenisinstalledbelow

thisappliance.

Joina 1/2" NPTpipeelbow(locallyavailable)to themalethreadsatthe

manifoldentrance.Whenjoined,causetheopenthreadsof the elbowto

facetowardtheleftsideoftheappliance.Installtheappliancein itscounter

cutout.

Joina 1/2"NPTpipenippleto theelbowusinga pipesectionofsufficient

lengthto extend,horizontally,beyondthe left sideof thewall oven. (To

accomplishthisitmaybenecessarytoextendthepipesectionintoadjacent

cabinetry.)Join additional 1/2" NPT elbow(s) and pipe nipples, as

necessary,to accomplishthefollowing:

Join the outlet of the appliance pressureregulatorsuppliedwith this

applianceto the malethreadsof the newlyinstalledgassupplypiping.

Installtheapplianceregulatorina locationwhichwillbeaccessiblebeside

or belowthewall oven.Insurethe applianceregulatorisinstalledwith its

directionalarrowpointinginthedirectionofgasflow.Tightentheappliance

regulatorto20to 30ft-tbsoftorque.

ILLUSTRATIVEGAS SUPPLYPIPING

(WALLOVENINSTALLEDBELOW30" COOKTOP)

J BURNER BOX

J _ (REAROF APPLIANCE)

MANIFOLD

_I[_ENTRANCE

J

PIPING PASSES THROUGH DIVIDING

• NIPPLES

(Lengths

I to suit)

I I ALL PIPE JOINTS1/2 N.RT,

I PRESSURE SHUTOFF

APPROXIMATE CROSS SECTION

_IALL BE3_NEEN ADJACENT CAB NETS

APPLIANCE MANUAL

REGULATOR VALVE

INLET

PROFILE OF WALL OVEN

FIGURE4

Nevertightento morethan35ft-tbsoftorque.Alwaysusean

I IMPORTANT approved

pipejointcompoundresistanttotheactionof LPgas.

Locateandjoinamanualshut-offvalveinanaccessiblelocationinthegas

lineaheadoftheapplianceregulatorandexternalto theapplianceforthe

purposeofturningonor shuttingoffgasto theappliance.

Makeadditionalpipeconnectionsas necessaryaheadoftheshut-offvalve

tothegassupplysource.Assureallpipejointconnectionsaregastight.

IMPORTANT

Applya non-corrosiveleakdetectionfluidto all jointsandfittingsinthe

gasconnectionbetweenthesupplyline shut-offvalveandthe range.

Includegasfittingsandjointsintherangeif connectionsweredisturbed

duringinstallation.Checkfor leaks!Bubblesappearingaroundfittings

andconnectionswiltindicatealeak.Ifa leakappears,turnoffsupplyline

gasshut-offvalve,tightenconnections,turnonthesupplylinegas shut

off valve,and retestfor leaks. Nevertest for gasleakswith an open

flame.

Note,regardingFigure4,above:

• For conveniencein servicea groundjointunion (notshown:locally

available)shouldbeincludedinthe pipingillustratedin figure4, ina

locationmostpracticalforthe installation.Generally,apracticallocation

isinthecabinetbelowthisappliance,nearthe manifoldentrance,rather

thaninanadjoiningcabinet.

• If the alternativepiping methodshowninfigure5 isselectedfor the

installation,no groundjoint unionis required.(Theflexibleappliance

connectorillustratedprovidestheunionjointsnecessaryforservicing.)

Whena dividingwall ispresentand a flexibleconnectoris usedit is

recommendedfor convenience,inboth installationand service,the

flexibleconnector,itself,passthroughthe dividingwall.Any flexible

connectorusedwiththis appliancemustsatisfyall requirements

statedin the text accompanyingfigure 5.

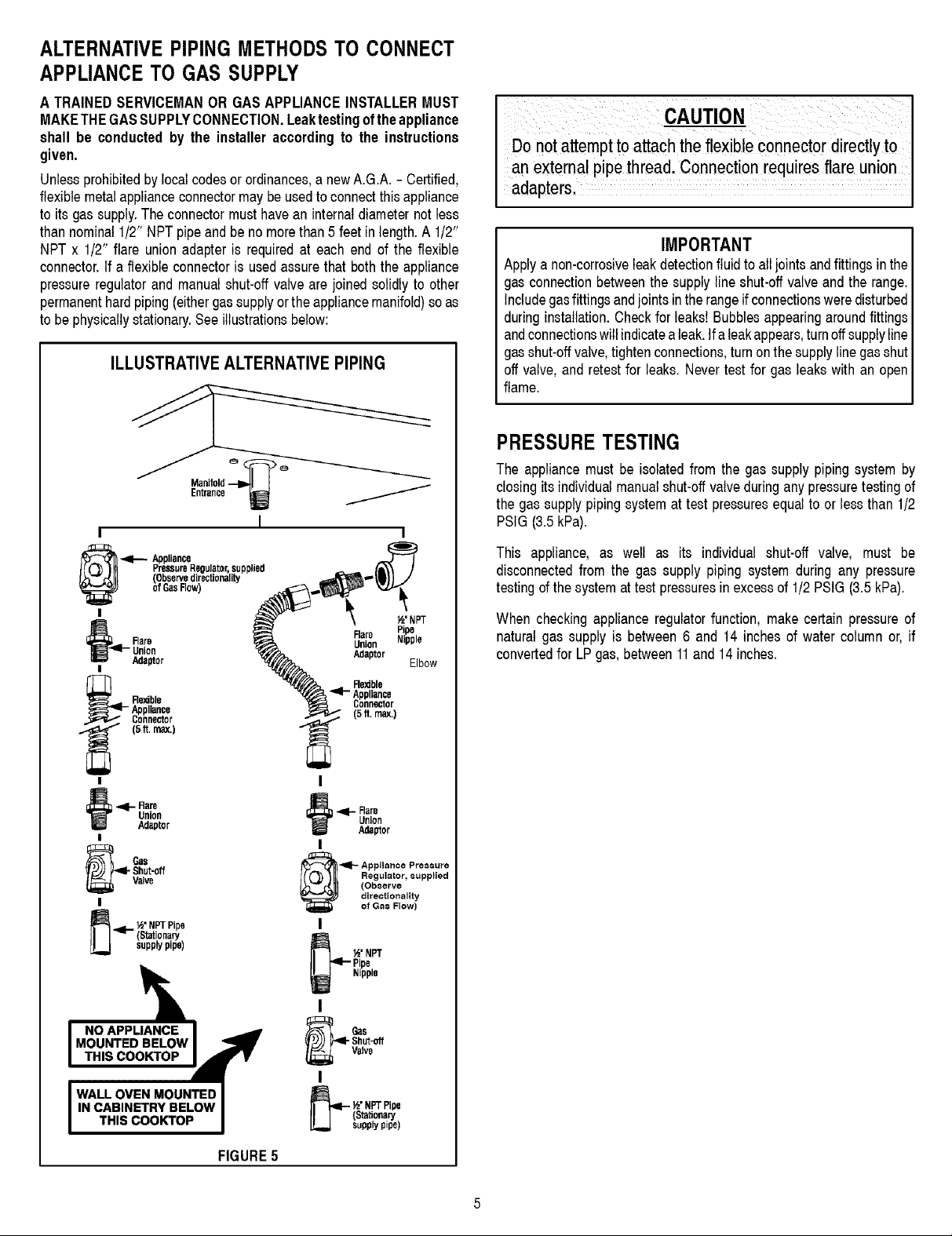

ALTERNATIVEPIPING METHODSTO CONNECT

APPLIANCETO GAS SUPPLY

A TRAINEDSERVICEMANOR GASAPPLIANCEINSTALLERMUST

MAKETHEGASSUPPLYCONNECTION.Leaktestingoftheappliance

shall be conductedby the installeraccordingto the instructions

given.

Unlessprohibitedbylocalcodesorordinances,a newA.G.A.- Certified,

flexiblemetalapplianceconnectormaybeusedto connectthisappliance

to itsgassupply.Theconnectormusthavean internaldiameternot less

thannominal1/2"NPTpipeandbenomorethan5feet inlength.A 1/2"

NPT x 1/2" flare union adapteris requiredat each end of the flexible

connector.If a flexibleconnectoris usedassurethat boththe appliance

pressureregulatorandmanualshut-offvalveare joined solidlyto other

permanenthardpiping(eithergassupplyortheappliancemanifold)soas

to bephysicallystationary.Seeillustrationsbelow:

ILLUSTRATIVEALTERNATIVEPIPING

Do notattempttOattachthe flexible connector directlyto

anexternalpipethread.Connection requiresflare union

IMPORTANT

Applya non-corrosiveleakdetectionfluidto alljointsandfittingsinthe

gasconnectionbetweenthesupplylineshut-offvalveand therange.

Includegasfittingsandjointsin therangeifconnectionsweredisturbed

duringinstallation.Checkforleaks!Bubblesappearingaroundfittings

andconnectionswillindicatealeak.Ifaleakappears,turnoffsupplyline

gasshut-offvalve,tightenconnections,turnonthesupplylinegasshut

offvalve,and retestforleaks. Nevertestforgasleakswith an open

flame.

PRESSURETESTING

The appliancemustbe isolatedfrom the gas supplypiping systemby

closingits individualmanualshut-offvalveduringanypressuretesting of

the gassupplypipingsystemattest pressuresequalto or lessthan1/2

PSIG(3.5kPa).

I

_ -',9- Rare

NO APPLIANCE

MOUNTED BELOW

THIS COOKTOP

WALL OVEN MOUNTED

IN CABINETRY BELOW

Union

Adaptor

I

Valve

!

.,_._ " Ngr Pipe

(Stationary

supplypips)

THIS COOKTOP

I

I_ _=1--Flare

Union

Adaptor

I

_1_._ Appliance Pressure

Regulator, supplied

direetionMity

of Gas Flow)

I

Nipple

I

Valve

I

1'- "NPTPipe

(Stationary

supplypipe)

This appliance, as well as its individual shut-off valve, must be

disconnectedfrom the gas supply pipingsystemduring any pressure

testingofthesystemat testpressuresinexcessof1/2 PSIG(3.5kPa).

When checkingapplianceregulatorfunction,make certainpressureof

naturalgas supply is between6 and 14 inchesof water columnor, if

convertedfor LPgas,between11and 14inches.

FIGURE5

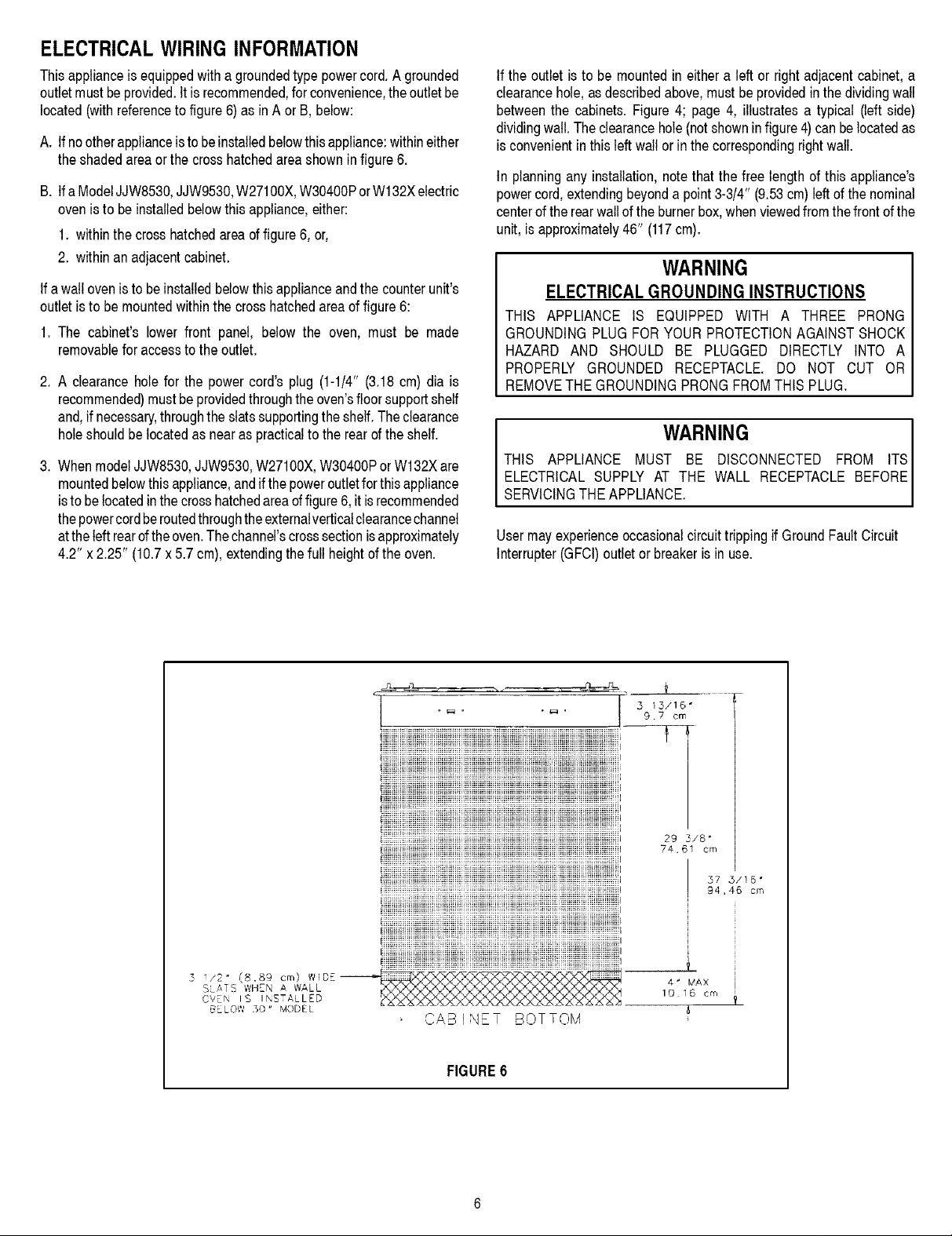

ELECTRICALWIRINGINFORMATION

Thisapplianceis equippedwitha groundedtypepowercord,A grounded

outletmustbeprovided,ttisrecommended,forconvenience,theoutletbe

located(withreferencetofigure6)as inA orB,below:

A. Ifnootherapplianceis tobeinstalledbelowthisappliance:withineither

theshadedareaorthe crosshatchedareashowninfigure6.

B. Ifa ModelJJW8530,JJW9530,W27100X,W30400PorW132Xelectric

ovenisto beinstalledbelowthisappliance,either:

1. withinthe crosshatchedareaoffigure6, or,

2. withinanadjacentcabinet.

If awallovenisto beinstalledbelowthisapplianceandthecounterunit's

outletisto be mountedwithinthecrosshatchedareaoffigure6:

1. The cabinet's lower front panel, belowthe oven, must be made

removablefor accesstothe outlet.

2. A clearancehole for the powercord's plug (1-1/4" (3.18cm)dia is

recommended)mustbeprovidedthroughtheoven'sfloorsupportshelf

and,if necessary,throughtheslatssupportingthe shelf.Theclearance

holeshouldbelocatedasnearas practicalto therearof theshelf.

3. When modelJJW8530,JJW9530,W27100X,W30400Por W132Xare

mountedbelowthisappliance,andif thepoweroutletforthisappliance

isto belocatedinthe crosshatchedareaoffigure6,itisrecommended

thepowercordberoutedthroughtheexternalverticatclearancechannel

atthe leftrearoftheoven.Thechannel'scrosssectionisapproximately

4.2" x2.25" (10.7x5.7cm),extendingthefull heightoftheoven.

If the outlet isto be mountedin eithera left or rightadjacentcabinet,a

clearancehole,asdescribedabove,mustbeprovidedin the dividingwall

betweenthe cabinets.Figure4; page 4, illustratesa typical (left side)

dividingwatt.Theclearancehole(not shownin figure4)canbelocatedas

isconvenientinthisleftwall orinthe correspondingrightwall.

In planningany installation,notethatthe freelengthof thisappliance's

powercord,extendingbeyonda point3-3/4"(9.53cm)leftof the nominal

centerof therearwalloftheburnerbox,whenviewedfromthe frontofthe

unit,is approximately46" (117cm).

WARNING

ELECTRICALGROUNDING INSTRUCTIONS

THIS APPLIANCE IS EQUIPPED WITH A THREE PRONG

GROUNDINGPLUGFORYOUR PROTECTIONAGAINSTSHOCK

HAZARD AND SHOULD BE PLUGGED DIRECTLY INTO A

PROPERLY GROUNDED RECEPTACLE, DO NOT CUT OR

REMOVETHEGROUNDINGPRONGFROMTHISPLUG.

WARNING

THIS APPLIANCE MUST BE DISCONNECTED FROM ITSI

ELECTRICALSUPPLY AT THE WALL RECEPTACLEBEFORE

SERVC NGTHEAPPLANCE.

Usermayexperienceoccasionalcircuittrippingif GroundFaultCircuit

Interrupter(GFCI)outletor breakeris in use.

5 i/2" (8.89 cm) WIOE

S_ATS WHEN A WALL

CVEN IS INSTALLED

BELOW 50 _ MODEL

c

ilili]ii iii;iiiiiiiiiii{i]ii]iiiiiifiiiiiiiii]iiii]ili]_iili_iil]iliiiii_iiiil]i]]_iiiiiil]iiJ]_iJiiiil]]iih

il]iiiii i_!i!!i!i!iP,illi!]il]i:i]ili!!!iii!iiiiiiiiii]iiiiiiii!!IHIB]illIIIW@iiiiiiii!ii]iiii_

_ii]i]]i]] i[iiiiii]]iii]iii]ii]]]i]i]]]]iii] i]]i]]]ii iii iiiii ]i]]i]:.iiiii;ii_]_H__]]]_]]i(::_i]]iiiii]i ]]]l

iii]iiii:Ji]iiiiiiiii!ill!iiiii]iiiiiii!iiiiiiiiiiiii!!iiiiiiiii!iiiiiiiii]iii]iiiiiii]iiiiiili]]iii]iii!iiii

!;iiii;ii}_i_i_iiiii:_:_i::iiiiiiiiii:_iiiii;;iiii;i:_i::iiiiiiiiii:4:_ii}i:_iii:J:i,i}iii:_i_i::_i_:_iiiiiiiiii;!S

_i_ _ilqi_i$1iii!iiiiiiiiiiiiiiiiiiiiiiii iiiiiiiiiiiiiiiiiiiiiiiiiiiiii_iil}iiiiiiii{_iiii

__;!!!:_::!!::;_;;i;;;i_;ii;iii iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii;i;iii;iiii;ii]iiiiill

__ _::_iiiiiiiii;ii_iil]ililii;iiiiii]iii!iii]iiii_;!]il!!iii]iii]iiiiii::iiii]i]iiii]iiiHi!!i!iill

I.......................]._L i._...LLi2 ii.iiiiiil;iiiii'

_!!iii!!i!!i!!!!!! i!!i!ii! i !!iiiii!!iii!ii iiliiiiiiiiii::i

...............i..iii!iii_,i!!i!!!!!!iiii!iiii!i!iiiiii!i!i!!!i!!!!!ii!iii!ii!i!i::!!!!iiiiiiii$iiiiiii!!!_

_ii_iiiiWii_iiiii!!H!!__!!!!!!!!! !_!!!!!i!!!!H!!_!!!!!!!!!!!!_!!!!!!!!!!!!!!!!!_iiii_i_i_

_iiiiiii!ii!ii!£i!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!i!!_i_!]_iiii_]_]_i_]iiliiiiiiiiiiiiiii

i_ii_i_iiiiiiiii:_iiiilililB:_ii:,iiiiiiiiiiiiiiiiiii'_:_'_

8ii!i!!iiiii!i_ii!!!i! :.!!!!!!i:.::.!!!i!!!!:!:iii:.!iiiii!iii::!!!i!!!_:_!IIW:II:ii!iiiii:.':::

.........i ':':iiiiii',ii:":iiiiiii',::ill::::ii:i::iii::ii_::iiiiiiii iiiiiiiiiiiiiiiiiiii_

_!!iii!ii!i]!!!!i]iii _]_!ii_i!iiii_iiiiii!ii_iii!i!iii_ii!ii!i iiiiiii]!i!i!_ii!i!!!ii!!ii!!!!!!_!_iiii_i_!!ii_i

r_

_A_INET BOTTOM

FIGURE6

ii

5 15/16"

9.7 crn

74.6! cm

1016 cm

29 _/8"

57 5/16"

94.46 cm

4" MAX i

CONVERTINGAPPLIANCE FOR USE

WITH LP GAS

WARNING

PropaneconversionistobeperformedbyaJENN-AIRAUTHORIZED

SERVICER (or other qualified agency) in accordance with the

manufacturer'sinstructionsand alt codes and requirementsof the

authorityhavingjurisdiction.Failureto followinstructionscouldresultin

seriousinjuryor propertydamage.Thequalifiedagencyperformingthis

workassumesresponsibilityfor thisconversion.

WARNING

Electrical power and gas must be turned off prior to

conversion.

This appliancewas adjustedat the factoryfor usewithnaturalgas. To

convertit forusewith LP gas(propaneorbutane),eachof thefollowing

modificationsmustbeperformed:

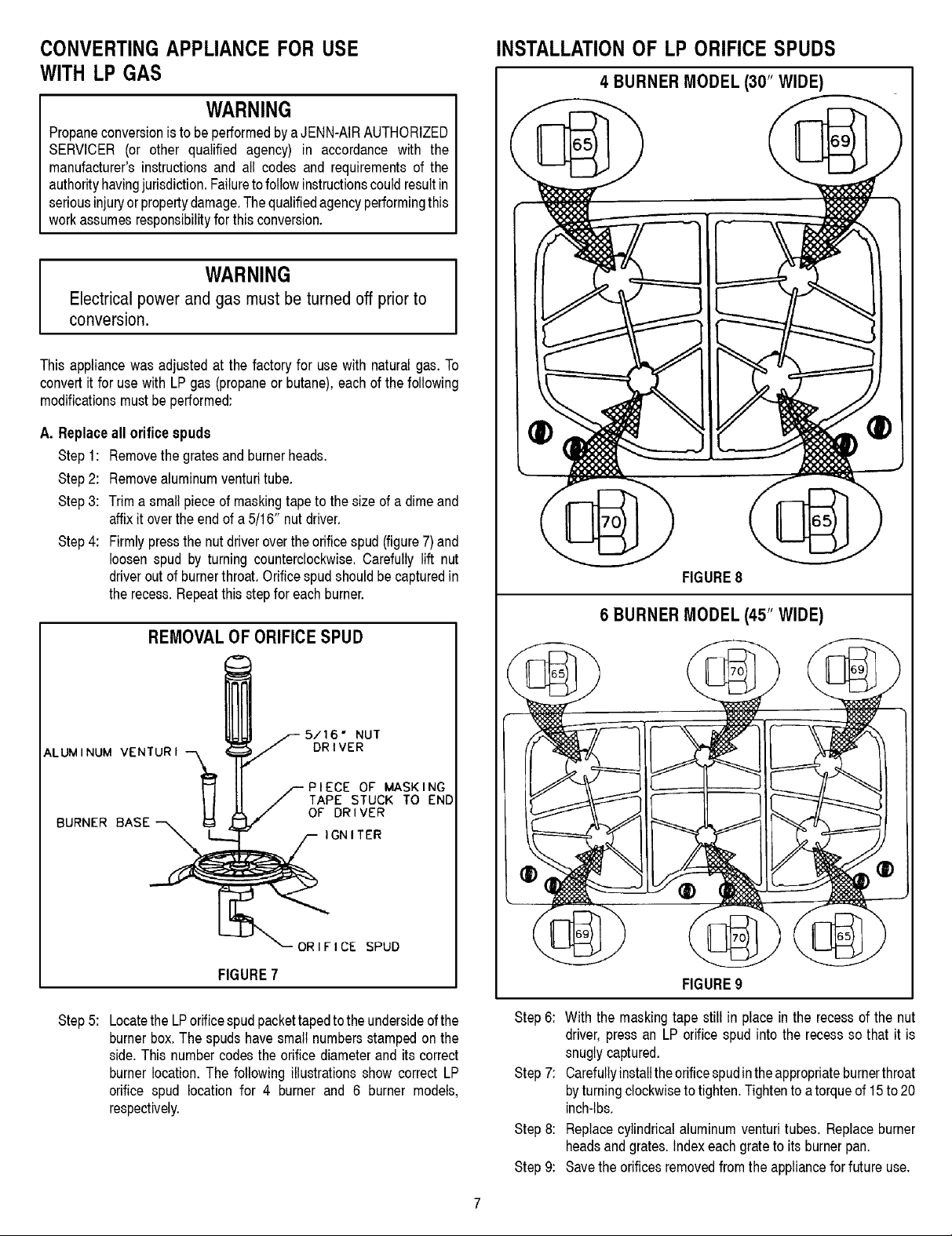

A. Replaceallorificespuds

Step1: Removethegratesand burnerheads.

Step2: Removealuminumventuritube.

Step3: Trima smallpieceof maskingtapeto thesizeof a dimeand

affixit overthe endof a 5/16" nutdriver.

Step4: Firmlypressthe nutdriveroverthe orificespud(figure7)and

loosenspud by turning counterclockwise.Carefully lift nut

driverout ofburnerthroat.Orificespudshouldbecapturedin

therecess.Repeatthisstepforeach burner.

REMOVALOF ORIFICESPUD

INSTALLATIONOF LP ORIFICE SPUDS

4 BURNER MODEL (30" WIDE)

i

6 BURNER MODEL (45" WIDE)

5/16" NUT

ALUMINUM VENTURI

BURNER BASE

FIGURE 7

DRIVER

PIECE OF MASKING

TAPE STUCK TO END

OF DRIVER

IGNITER

ORIFICE SPUD

Step5: LocatetheLPorificespudpackettapedtotheundersideofthe

burnerbox.Thespudshavesmall numbersstampedon the

side.This numbercodesthe orificediameterand its correct

burner location.Thefollowing illustrationsshow correctLP

orifice spud location for 4 burner and 6 burner models,

respectively.

FIGURE9

Step6: With the maskingtapestill in placein the recessof the nut

driver,pressan LP orificespudinto the recesssothat it is

snuglycaptured.

Step7: Carefullyinstalltheorificespudintheappropriateburnerthroat

byturningclockwisetotighten.Tightentoatorqueof 15to20

inch-tbs.

Step8: Replacecylindricalaluminumventuritubes. Replaceburner

headsandgrates.Indexeachgratetoits burnerpan.

Step9: Savetheorificesremovedfromthe appliancefor futureuse.

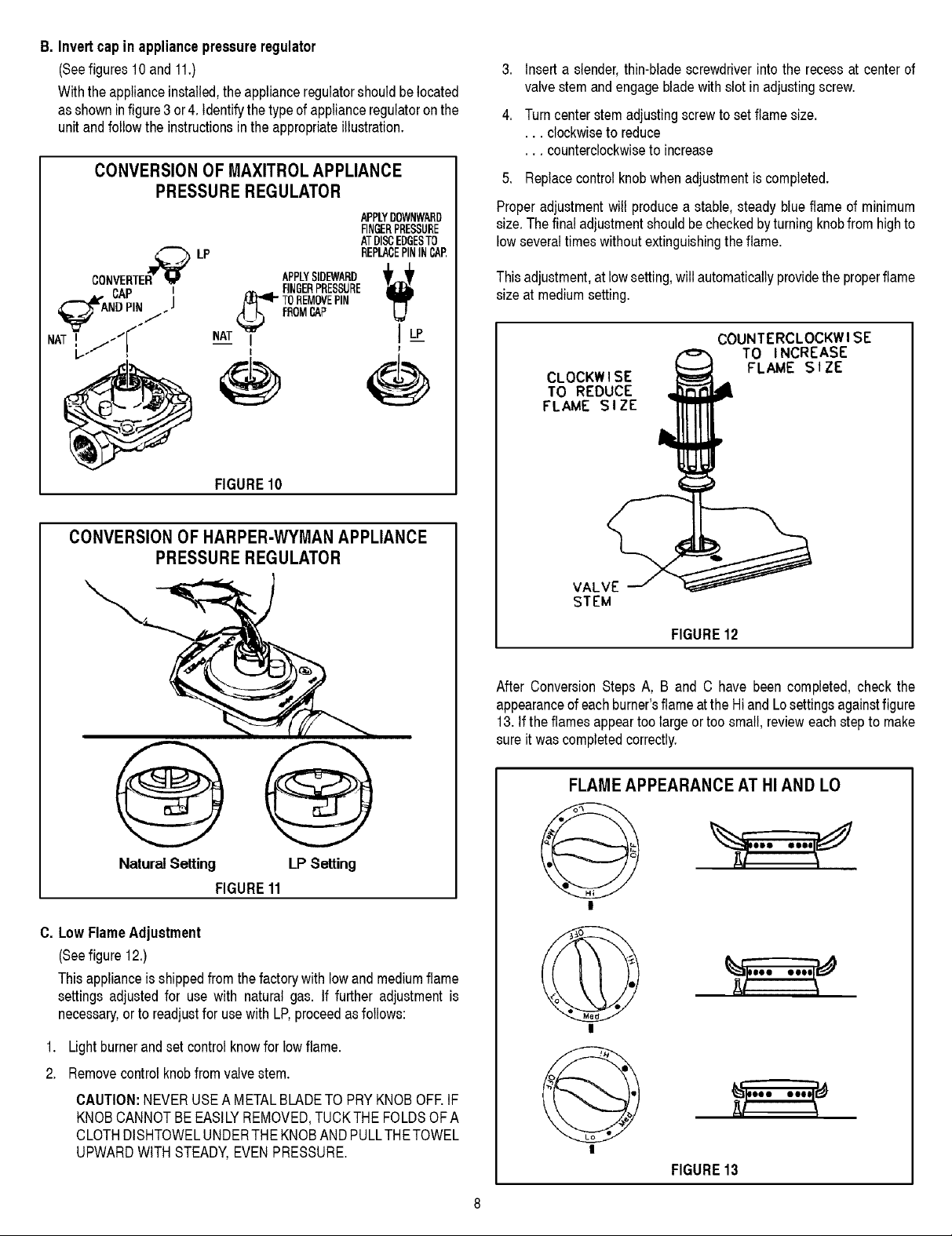

B. Invertcap inappliancepressureregulator

(Seefigures10and11.)

Withtheapplianceinstalled,theapplianceregulatorshouldbelocated

asshowninfigure3or4. Identifythetypeofapplianceregulatoronthe

unitandfollowthe instructionsintheappropriateillustration.

CONVERSIONOFMAXITROL APPLIANCE

PRESSURE REGULATOR

APPLYDOWNWARD

FINGERPRESSURE

ATDISCEDGESTO

REPLACEPININ_1_

CONVERTER_ _ LP

_t.A CAP I

NAT ! /-"¢

NDPIN . J

.J

NAT IL_P

FIGURE10

FINGERPRESSURE

APPLYSIDEWARD

FROMCAP

I_T0 REMOVEPIN

3. Inserta slender,thin-bladescrewdriverintothe recessat centerof

valvestemandengagebladewithslot in adjustingscrew.

4. Turncenterstemadjustingscrewtosetflamesize.

... clockwiseto reduce

... counterclockwiseto increase

5. Replacecontrolknobwhenadjustmentiscompleted.

Properadjustmentwill producea stable,steadyblueflame of minimum

size.Thefinaladjustmentshouldbecheckedbyturningknobfromhighto

lowseveraltimeswithoutextinguishingthe flame.

Thisadjustment,atlowsetting,willautomaticallyprovidetheproperflame

sizeat mediumsetting.

COUNTERCLOCKWISE

TO INCREASE

CLOCKWISE

TO REDUCE

FLAME SIZE

FLAME SIZE

CONVERSIONOFHARPER-WYMAN APPLIANCE

PRESSURE REGULATOR

i

O

NaturalSetting

FIGURE11

C. LowFlameAdjustment

(Seefigure12.)

This applianceisshippedfromthefactorywith lowandmediumflame

settingsadjustedfor use with naturalgas. If further adjustmentis

necessary,orto readjustfor usewithLP,proceedasfollows:

LPSetting

VALVE

STEM

FIGURE12

After ConversionStepsA, B and C have been completed,checkthe

appearanceofeachburner'sflameatthe HiandLosettingsagainstfigure

13.Ifthe flamesappeartoo largeortoo small,revieweachstepto make

sureitwascompletedcorrectly.

FLAMEAPPEARANCE ATHIAND LO

I

1. Lightburnerandset controlknowfor lowflame.

2. Removecontrolknobfromvalvestem.

CAUTION:NEVERUSEA METALBLADETOPRYKNOBOFF.IF

KNOBCANNOTBEEASILYREMOVED,TUCKTHEFOLDSOFA

CLOTHDISHTOWELUNDERTHEKNOBANDPULLTHETOWEL

UPWARDWITHSTEADY,EVENPRESSURE.

!

FIGURE13

TO CONVERTAPPLIANCE FOR USE WITH

NATURALGAS

INSTALLATIONOF NATURALGAS

ORIFICESPUDS

WARNING

Electrical power and gas must be turned off prior to

conversion.

If this appliancehas been convertedfor usewith LP gas, each ofthe

following modificationsmust be performedto convertthe unit back to

naturalgas.

A. Replaceallorificespuds

PerformSteps 1through4on page7.

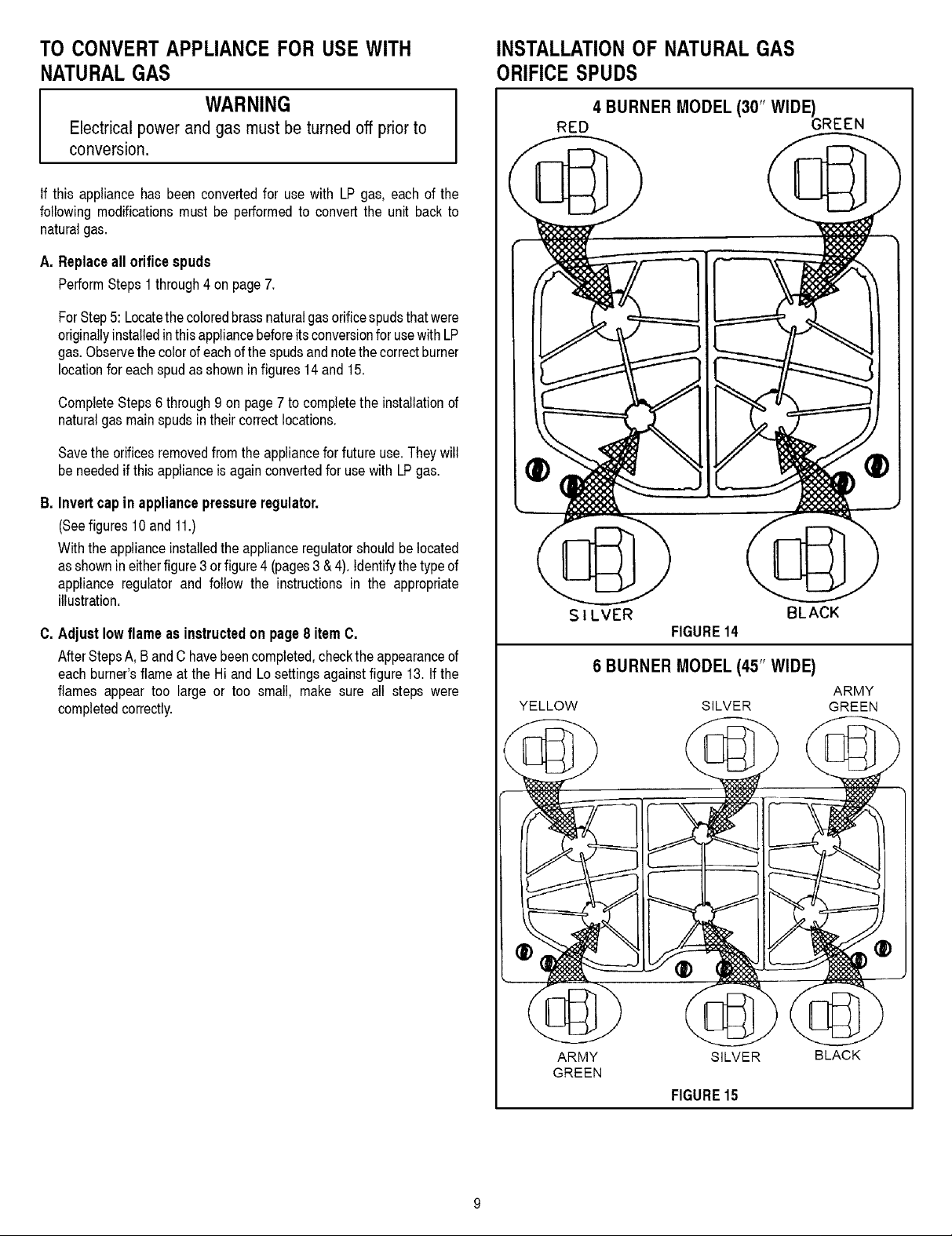

ForStep5:Locatethecoloredbrassnaturalgasorificespudsthatwere

originallyinstalledinthisappliancebeforeitsconversionfor usewithLP

gas.Observethecolorofeachofthespudsandnotethecorrectburner

locationfor eachspudasshowninfigures14and15.

CompleteSteps6through9 on page7 to completethe installationof

naturalgasmainspudsintheircorrectlocations.

Savethe orificesremovedfromthe applianceforfutureuse.Theywill

beneededifthis applianceisagainconvertedforusewithLPgas.

B. Invertcapin appliancepressureregulator.

(Seefigures10and11.)

Withtheapplianceinstalledtheapplianceregulatorshouldbelocated

asshownin eitherfigure3orfigure4 (pages3 &4). Identifythetypeof

applianceregulatorand followthe instructionsin the appropriate

illustration.

C. Adjustlowflameas instructedon page8 itemC.

AfterStepsA,BandChavebeencompleted,checktheappearanceof

eachburner'sflameat theHi andLosettingsagainstfigure13.If the

flamesappear too large or too small, makesure all steps were

completedcorrectly.

4 BURNER MODEL (30" WIDE)

RED GREEN

SILVER BLACK

FIGURE14

6 BURNER MODEL (45" WIDE)

ARMY

YELLOW SILVER GREEN

ARMY SILVER BLACK

GREEN

FIGURE 15

Loading...

Loading...