INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

INSTALLATION MANUAL

Dual Fuel 30-inch Wide Free-Standing Range

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

THE MANUAL IS INTENDED TO ASSIST IN THE INITIAL INSTALLATION AND ADJUSTMENTS OF THE RANGE.

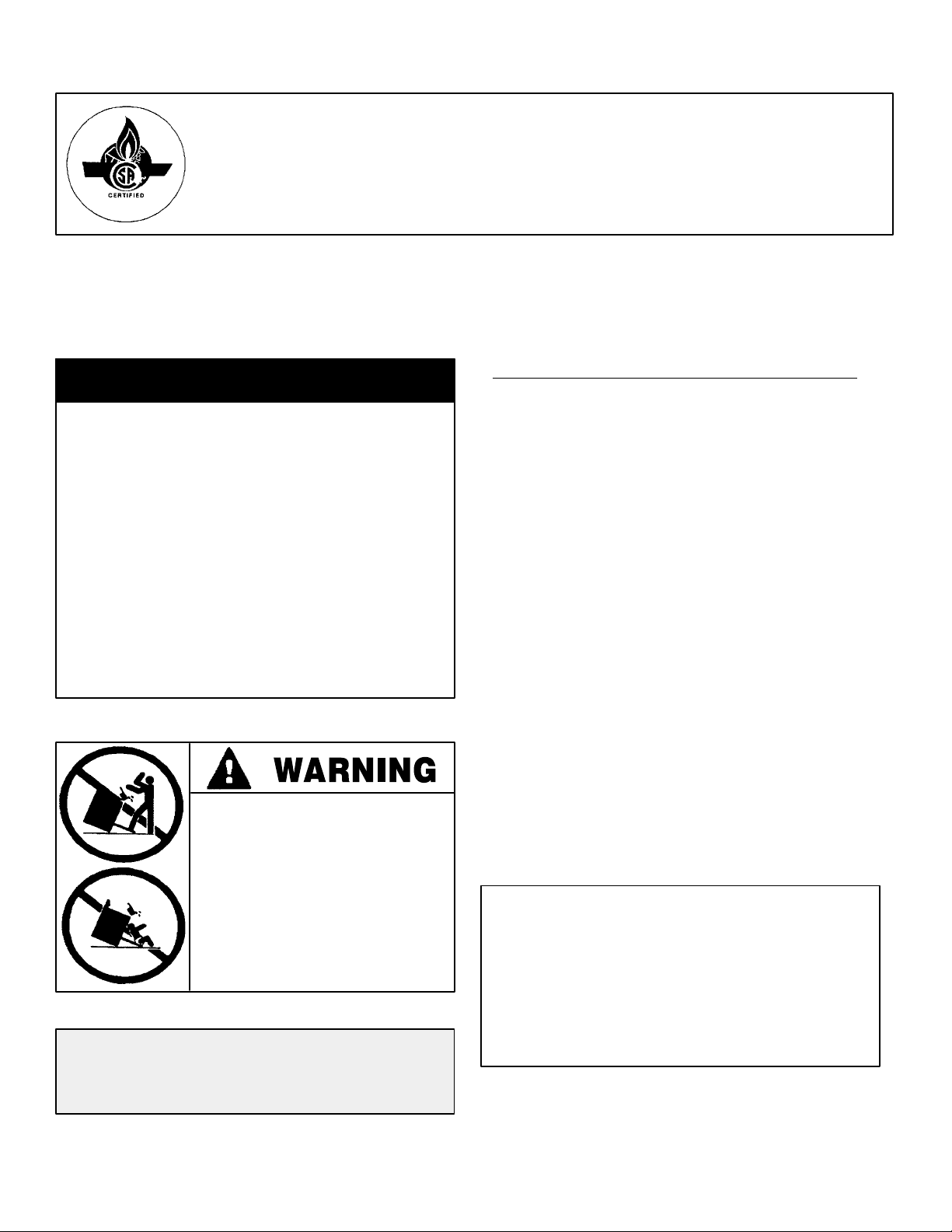

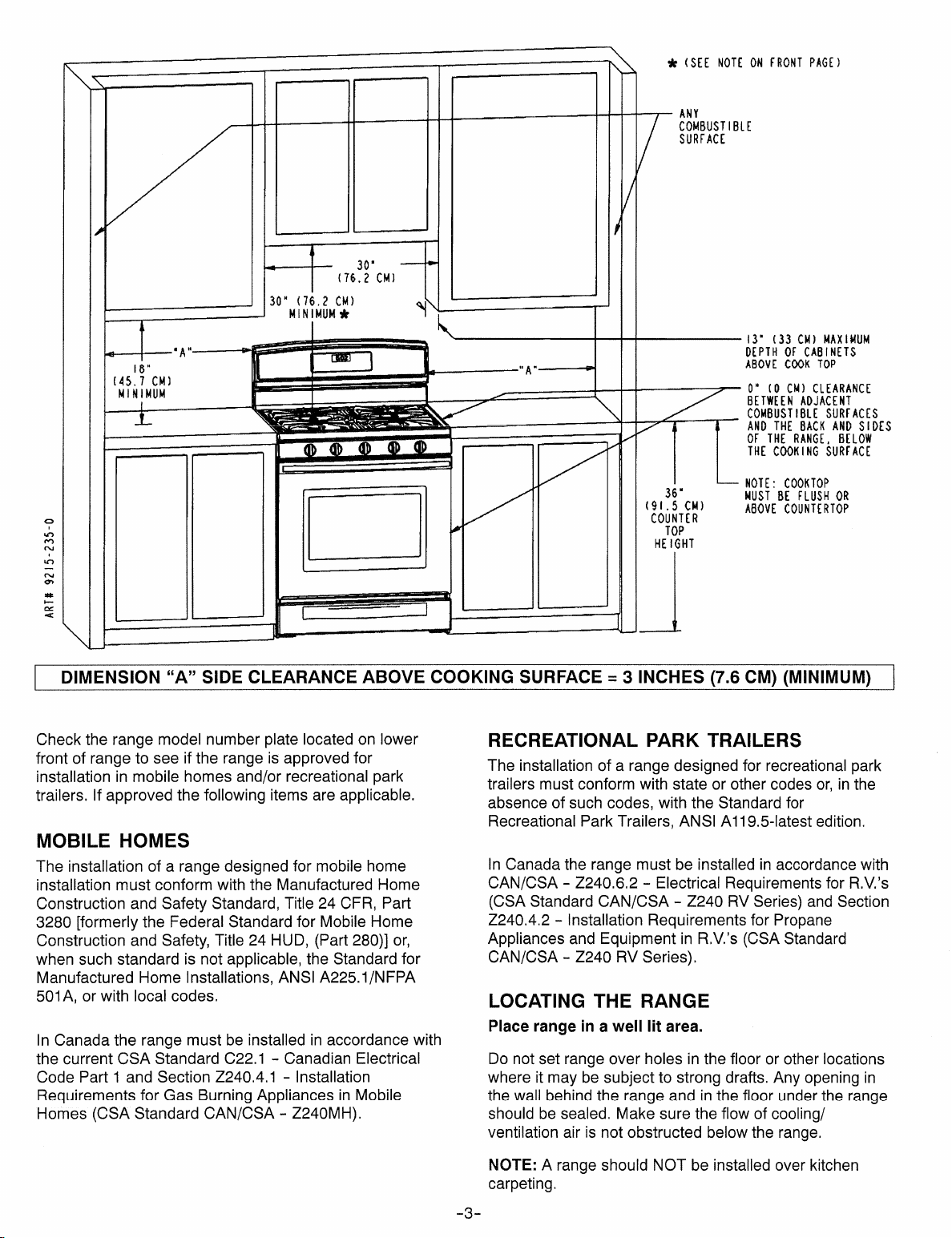

CLEARANCE DIMENSIONS

SPECIAL WARNING

Only qualified personnel should

install or service this range.

Read “Safety Instructions” in the

Use & Care book before using

range.

Range may be installed with zero inches clearance

adjacent to (against) combustible construction at the rear

and on the sides below the cooktop. For complete

information in regard to the installation of wall cabinets

above the range and clearances to combustible wall

above the cooking top see the installation drawings. For

SAFETY CONSIDERATIONS do not install a range in any

combustible cabinetry which is not in accord with the

installation drawings.

Improper installation, adjustment,

alteration, service, maintenance or

use of range can result in serious

injury or property damage.

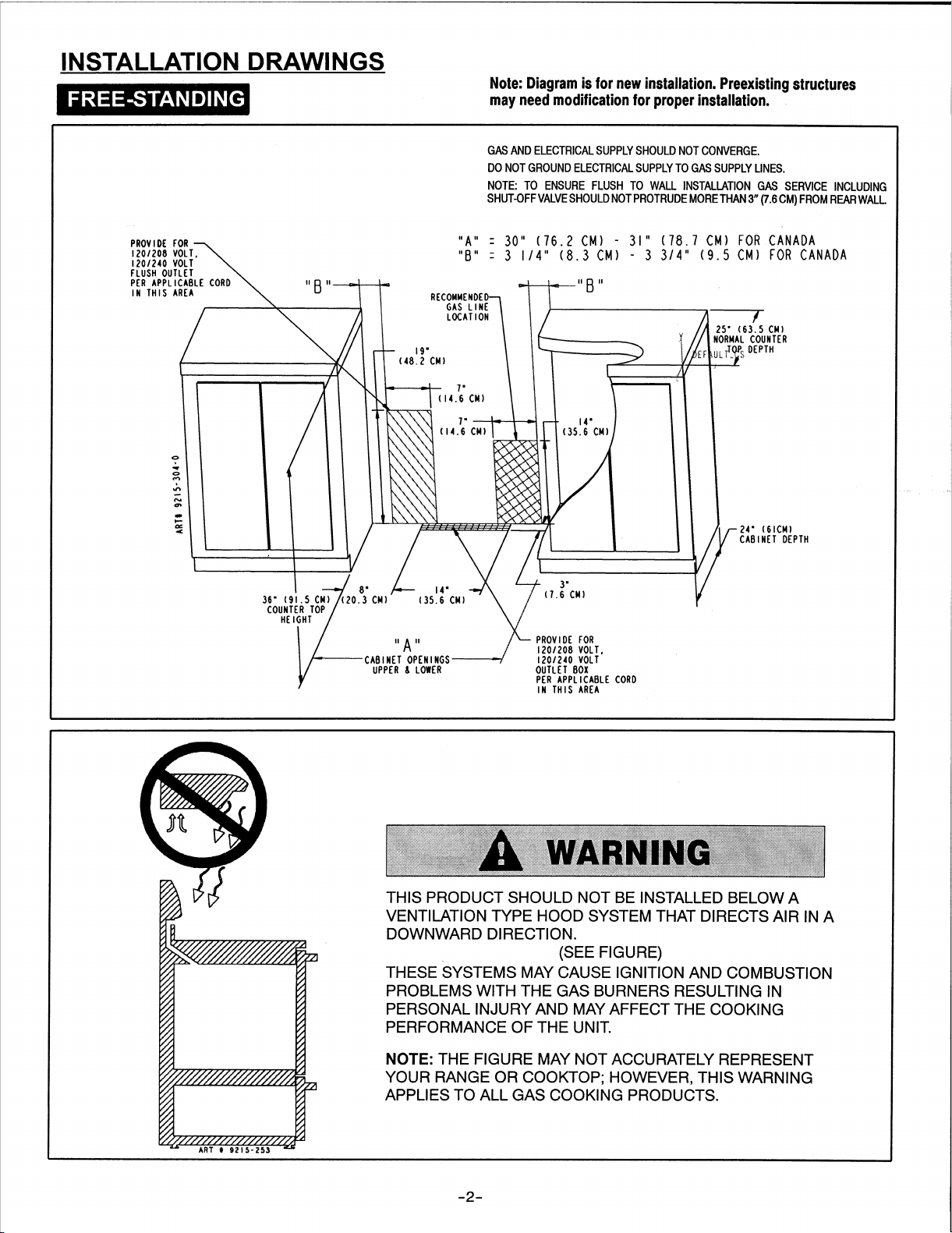

• ALL RANGES CAN TIP AND

CAUSE INJURIES TO PERSONS.

• INSTALL ANTI-TIP DEVICES

PACKED WITH RANGE.

• FOLLOW ALL INSTALLATION

INSTRUCTIONS.

Your range may not be equipped with

some of the features referred to in this

manual.

* NOTE: The 30 inch (76.2 cm) dimension may be

reduced to not less than 24 inches (61 cm) when the wall

cabinets in a domestic home are protected with fireproof

materials in accordance with American National

Standards -- National Fuel Gas Code or in mobile homes

when they are protected with fireproof materials in

accordance with the Federal Standard for Mobile Home

Construction and Safety.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches (13 cm) beyond the bottom of the

cabinets.

CAUTION: This range has been designed in

accordance with the requirements of various safety

agencies and complies with the maximum allowable

wood cabinet temperatures of 194°F. If this range is

installed with cabinets that have a lower working

temperature than 194°F, discoloration, delamination

or melting may occur. Contact Customer Service

for associated cabinet dimensions and installation

accessories.

8101P729-60

(03-06-00)

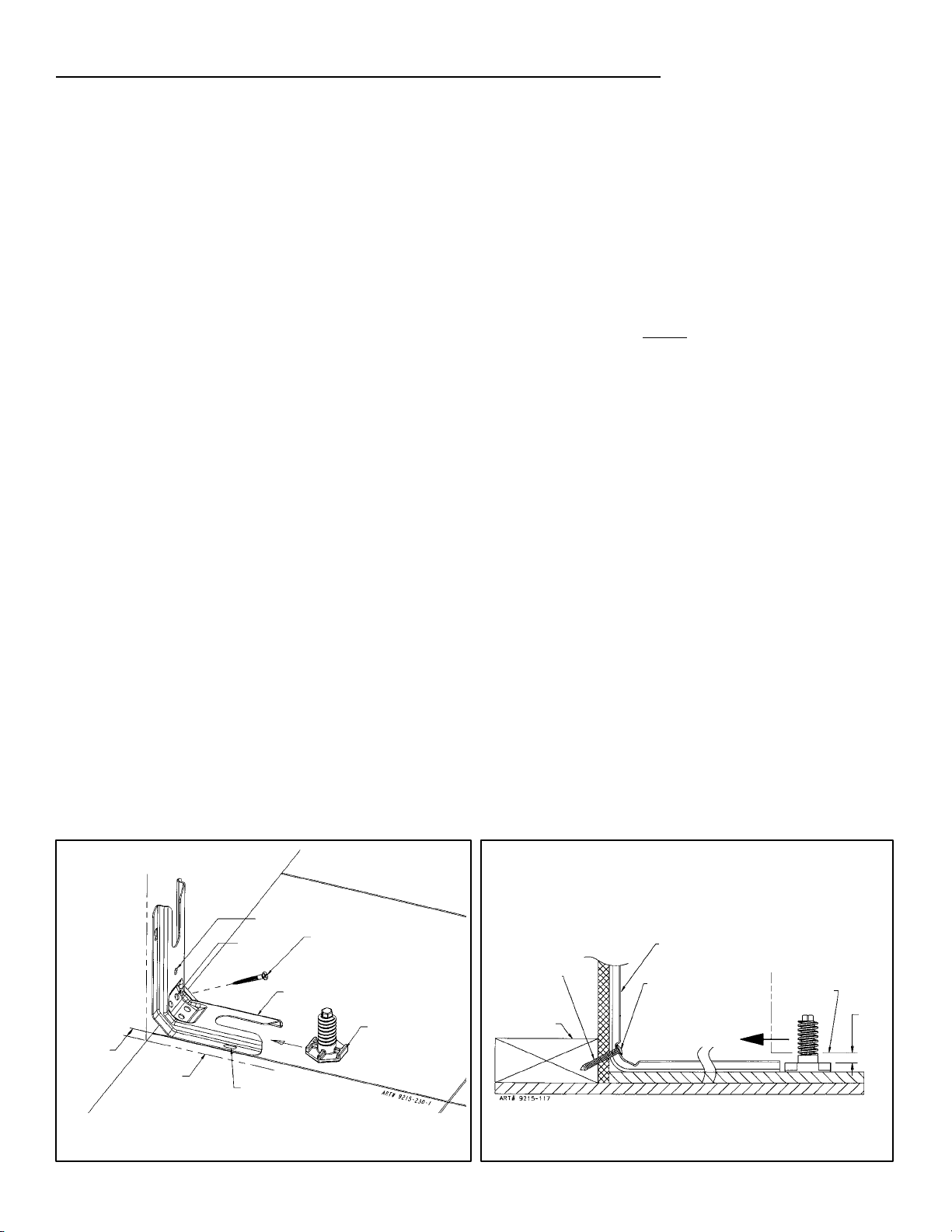

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

NOTE: A risk of range tip over exists if the appliance is

not installed in accordance with the installation

instructions provided. The proper use of this device

minimizes the risk of TIP-OVER. In using this device the

consumer must still observe the safety precautions as

stated in the USE and CARE MANUAL and avoid using

the oven door and/or lower drawer as a step stool.

Installation instructions are provided for wood and cement

in either floor or wall. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the ANTI-TIP

bracket to the floor or wall.

STEP 1 -- Locating The Bracket (see figure 1)

A. Determine where either the right or left rear “edge” of

the range will be located and mark the floor or wall.

B. Place the BRACKET 9/16″ (14.5 mm) from the

marked “EDGE” toward center of opening and against

the back wall as shown in figure 1, with orientation

hole against wall.

C. Use the bracket as a template and mark the required

holes, as shown in figure 1 for the type of construction

you will be using.

STEP 2 -- Anti-Tip Bracket Installation

A. Wood Construction:

1. Floor: Locate the center of the two holes identified

in figure 1 as “HOLES FOR FLOOR”. Drill a 1/8″

(3 mm) pilot hole in the center of each hole (a nail

or awl may be used if a drill is not available).

Secure the ANTI-TIP bracket to the floor with the

two screws provided. Proceed to STEP 3.

2. Wall: Locate the center of the two holes identified

in figure 1 as “HOLES FOR WALL. Drill an angled

1/8″ (3 mm) pilot hole in the center of each hole

as shown in figure 2. (A nail or awl may be used if

a drill is not available). Secure the ANTI-TIP

bracket to the wall with the two screws provided

as shown in figure 2. Proceed to STEP 3.

B. Cement or Concrete Construction:

1. Suitable screws for concrete construction can be

obtained at a hardware store. Drill the required

size hole for the screws obtained into the

concrete at the center of the holes identified in

figure 1 as “HOLES FOR FLOOR”. Secure the

ANTI-TIP bracket to the floor. Proceed to STEP 3.

STEP 3 -- Range Installation

A. For safety considerations as well as optimum

performance, adjust the range so it is level and to

desired height prior to installing in cabinet opening.

NOTE: Cooktop MUST

be flush or above

countertop.

Levelness may be checked by placing a spirit level or

a large pan of water on the cooktop or oven rack.

Adjust the range by tipping it forward or back and

rotate the leveling feet as required.

NOTE: A minimum clearance of 1/4″ (6 mm) is

required between the range and the leveling foot that

will engage the anti-tip bracket, (see figure 2).

CAUTION: Damage to the range may occur if range

is moved or lifted by grasping the main top, backguard

or door handles.

B. Align the range to its designated location and prepare

to slide it back into position. Connect gas line and

plug in power cord to outlet following guidelines

outlined in connecting the range and remainder of

installation instructions.

C. Slide range in place visually inspecting to verify that

power cord and gas line are freely routed and

contained within recessed area of back panel.

D. To check the range for proper installation of the

anti-tip bracket, use a flashlight and look underneath

the bottom of the range to see that one of the rear

leveling feet is engaged in the bracket slot.

9/16”

(14.5 mm)

FROM EDGE

OF RANGE

MARKED EDGE

OF RANGE

NOTE: USE A MINIMUM OF (2) SCREWS

TO INSTALL ANTI-TIP BRACKET

TO THE WALL OR FLOOR.

ORIENTATION

HOLE

HOLES FOR

WALL

HOLES FOR

FLOOR

(EACH SIDE)

ATTACH ANTI-TIP BRACKET WITH A

MINIMUM OF TWO (2) LONG SCREWS

TO THE WALL OR FLOOR.

ANTI-TIP

BRACKET

LEVELING

FOOT

SCREWS MUST

ENTER WOOD

OR METAL.

WALL PLATE

ANTI-TIP

BRACKET

SCREW BRACKET

TO WALL

SLIDE IN

TO SECURE

FIGURE 1 FIGURE 2

-- 4 --

RANGE

BOTTOM

1/4”

(6mm)

MIN.

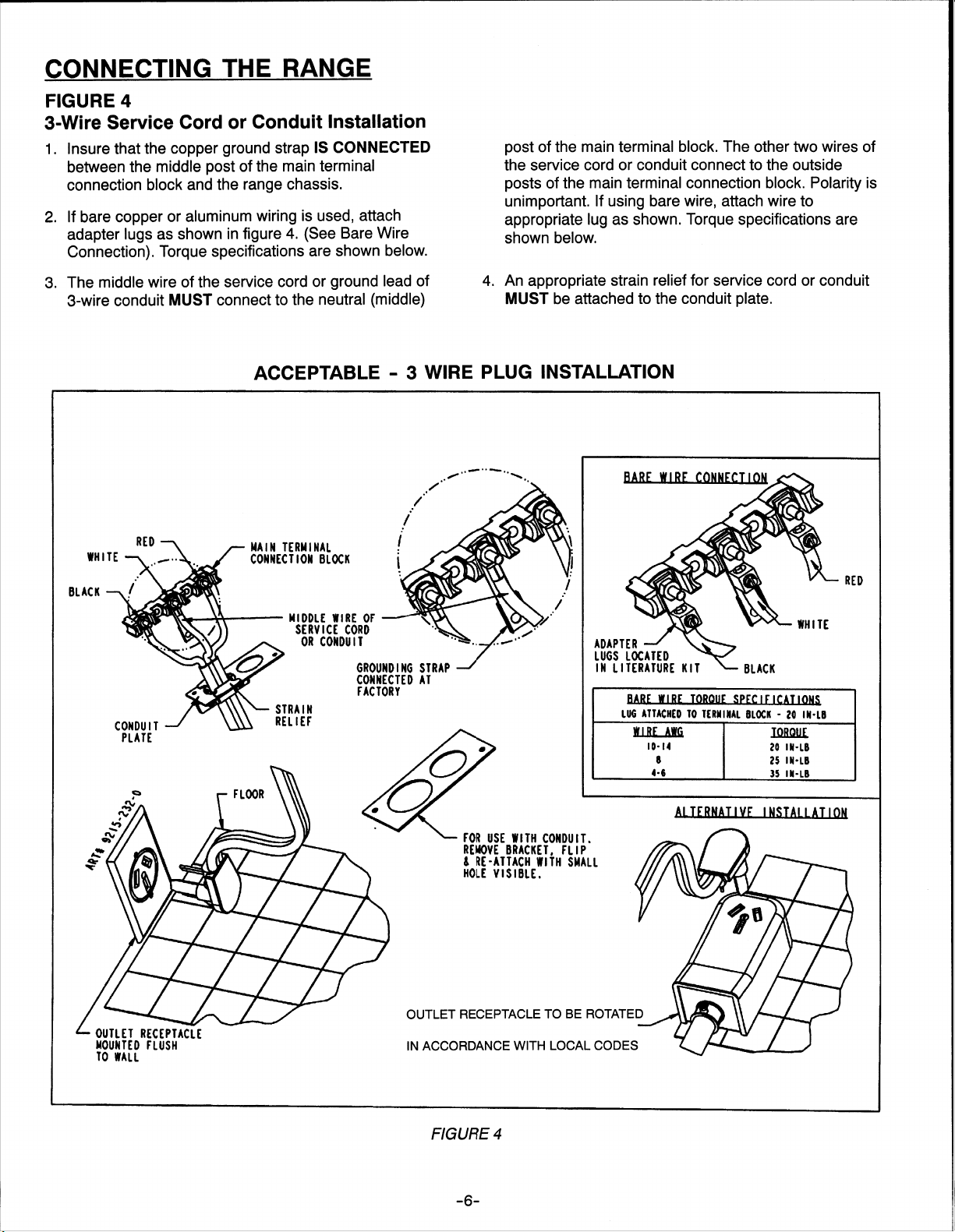

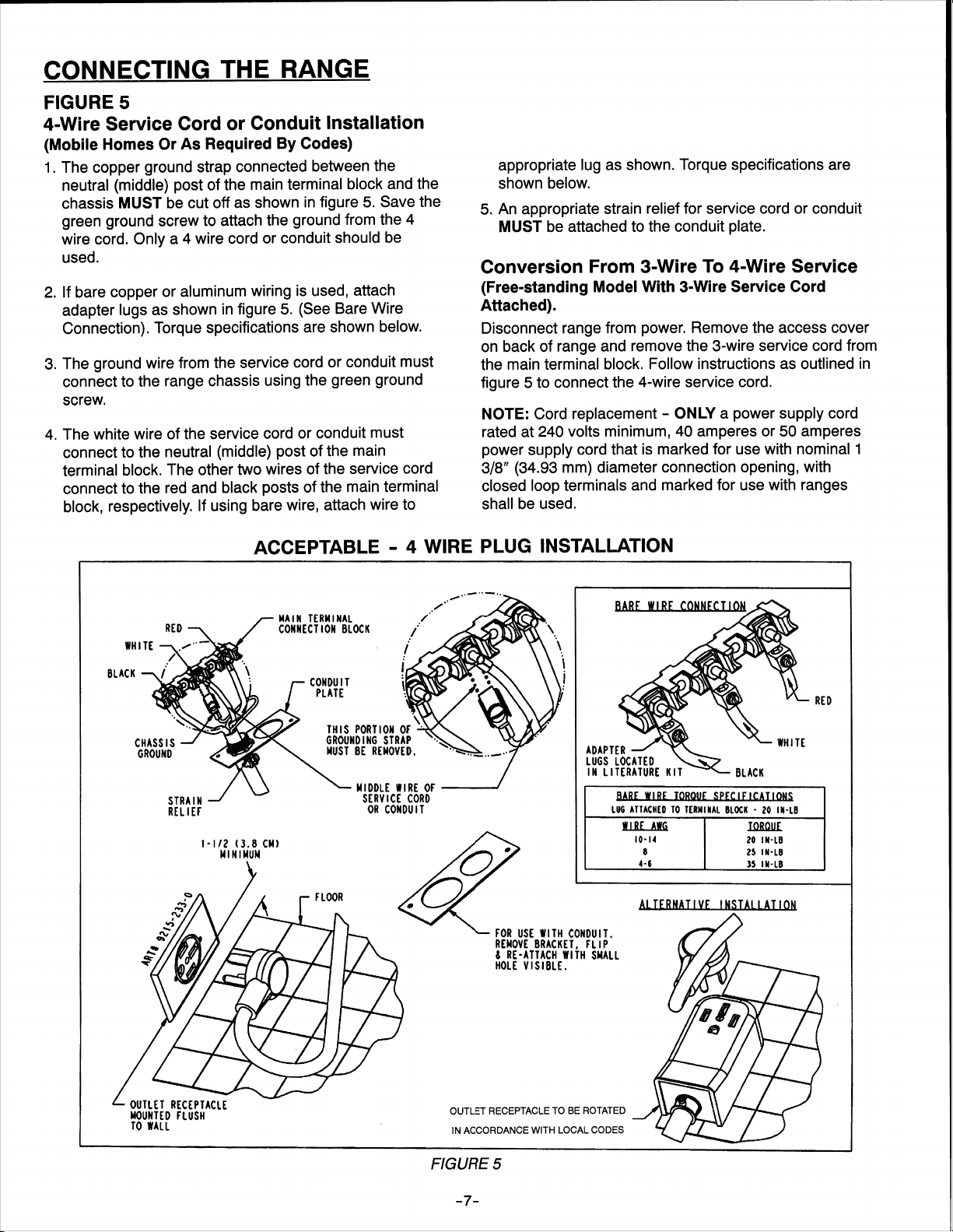

CONNECTING THE RANGE

ELECTRIC SUPPLY

The range must be installed in accordance with Local and

National Electric Code (NEC) ANSI/NFPA No. 70-latest

edition. See rating plate for total connected KW rating.

ELECTRIC SUPPLY (Canada)

The range must be installed in accordance with Local and

Canadian Electric Code CSA STD.C22.1 latest edition.

See rating plate for total connected KW rating.

OUTSIDE WIRING

Your local utility company will tell you whether the present

electric service to your home is adequate. It may be

necessary to increase the size of the wiring to the house

and service switch to take care of the electrical load

demanded by the range. The kilowatt rating for the range

is specified on the rating plate located on front of range.

HOUSE WIRING

Most local Building Regulations and Codes require that all

electrical wiring be done by licensed electricians. All

wiring should conform to Local and National Electrical

Codes. This range requires a single phase three wire

120/240 or a 120/208 volt, 60 Hz, AC circuit. Wiring codes

require a separate circuit be run from the main entrance

panel to the range and that it be equipped with separate

disconnect switch and fuses, either in the main entrance

panel or in a separate switch and fuse box. In some

communities, a solid or flexible continuous armored

conduit must be used from main entrance panel to the

terminal box on the rear of the range. Others will permit

the termination of the range circuit at a polarized three or

four wire plug-in outlet placed at a convenient point near

the back of the range. The range is then connected to this

outlet through an approved range connector (pigtail)

fastened securely to the terminal block with proper strain

relief at the range and a three or four pronged plug at the

opposite end.

by local code. USE COPPER OR ALUMINUM

CONDUCTORS. Main terminal block is recognized for

Copper or Aluminum conductors. If a flexible power cord

is required, it is recommended a cord no longer than 4 ft.

be used. Make connections as explained below and with

reference to the appropriate illustration (see figures 6 and

7). After installation, insure tightness of all electrical

connections and replace all covers.

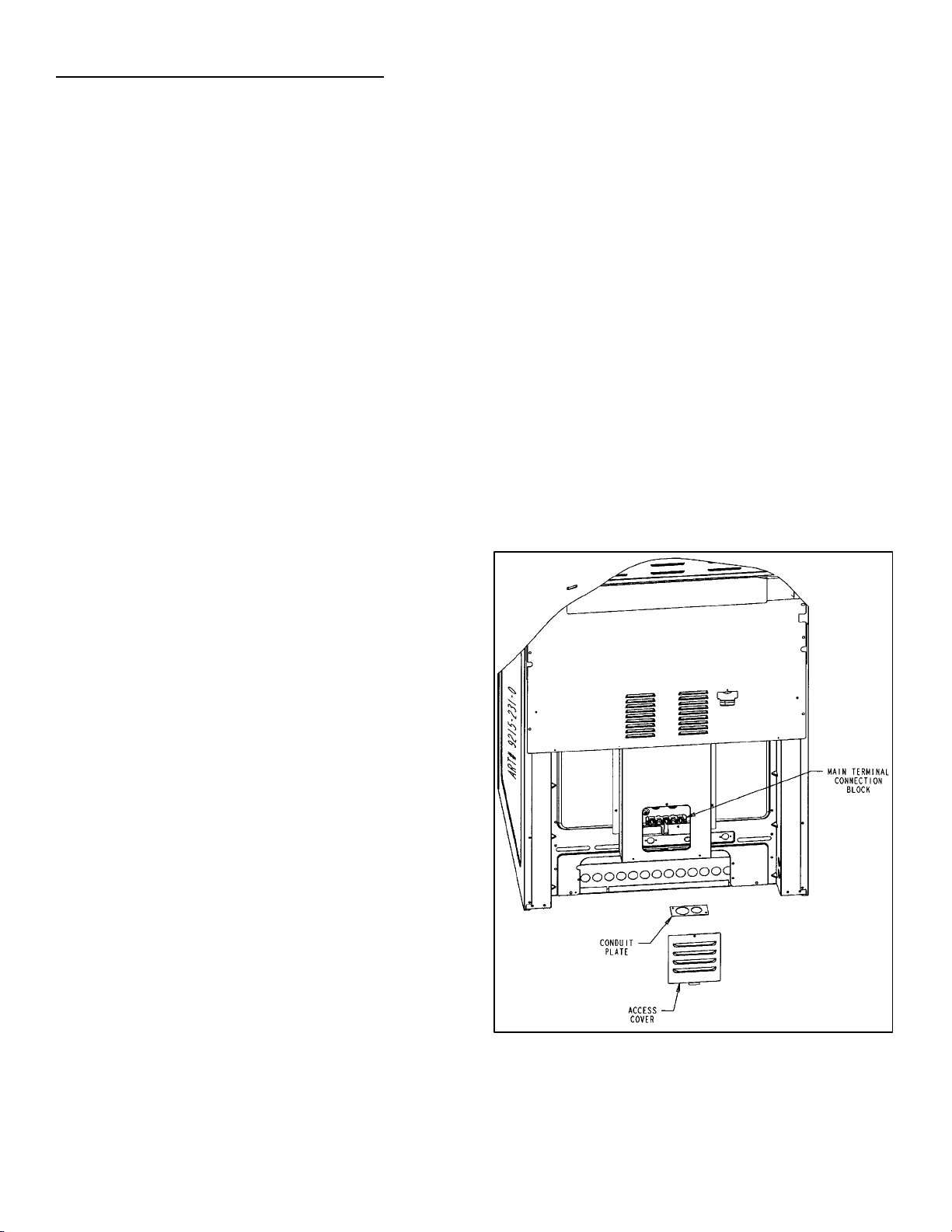

Remove terminal block access cover from range back.

(See figure 5).

RANGE CONNECTIONS (Canada)

This model was shipped direct from the factory with

service cord (pigtail) attached. There are no range

connections necessary. Just plug into the range outlet.

NOTE: Cord replacement -- ONLY a power supply cord

rated at 240 volts minimum, 40 amperes or 50 amperes

power supply cord that is marked for use with nominal

13/8″ (34.93 mm) diameter connection opening, with

closed loop terminals and marked for use with ranges

shall be used.

RANGE CONNECTIONS

Some models are shipped direct from the factory with

service cords (pigtails) attached. There are no range

connections necessary on these models. Just plug into

the range outlet. On models not provided with a service

cord, connection to the power supply is necessary.

REMEMBER -- only a 4--conductor cord is to be used on

new branch--circuit installations (1996 NEC), mobile

homes, recreational vehicles, or in an area where local

codes prohibit grounding through the neutral conductor.

Hence, 4--wire service MUST be provided for such

installations. 3--wire service may be used when permitted

FIGURE 3

-- 5 --

CONNECTING THE RANGE

Gas Supply

Installation of this range must conform with local codes or,

in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1-latest edition.

In The Commonwealth Of Massachusetts

This product must be installed by a licensed plumber or

gas fitter when installed within the Commonwealth of

Massachusetts.

A “T” handle type manual gas valve must be installed in

the gas supply line to this appliance.

A flexible gas connector, when used, must not exceed a

length of three (3) feet / 36 inches.

In Canada the range must be installed in accordance with

the current CGA Standard CAN/CGA--B149 -- Installation

Codes for Gas Burning Appliances and Equipment and/or

local codes.

Gas leaks may occur in your system and result in a

dangerous situation. Gas leaks may not be detected

by smell alone. Gas suppliers recommend you

purchase and install an UL approved gas detector.

Install and use in accordance with the manufacturer’s

instructions.

excess of 1/2 lbs./sq. in. (3.5 kPa) (13.8 in. water

column).

2. The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 lbs./sq. in. (3.5 kPa) (13.8 in. water column).

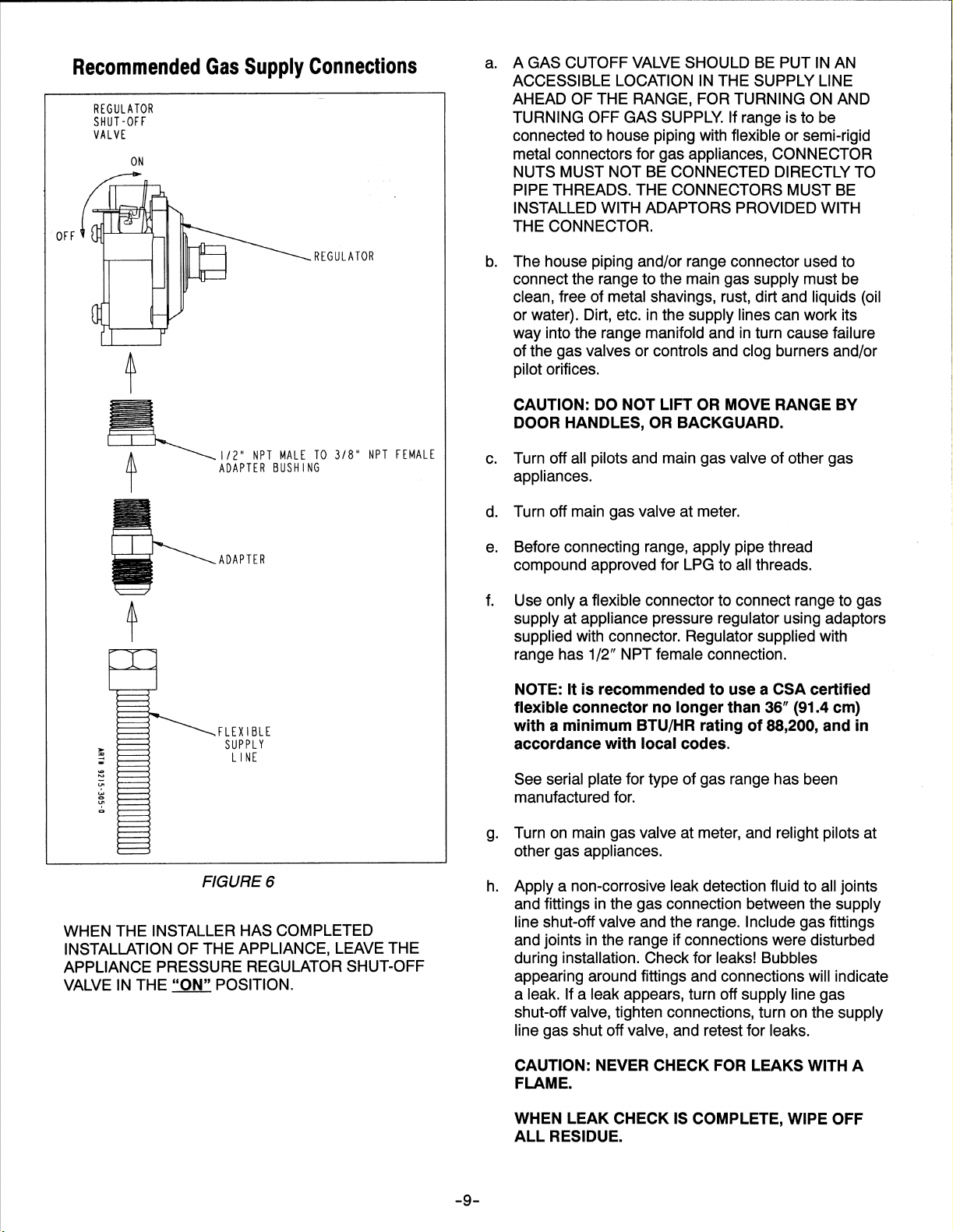

Gas Supply Connection (See figure 3)

A QUALIFIED SERVICEMAN OR GAS APPLIANCE

INSTALLER MUST MAKE THE GAS SUPPLY

CONNECTION. Leak testing of the appliance shall be

conducted by the installer according to the

instructions given in section h.

NATURAL GAS SUPPLY LINE MUST HAVE A NATURAL

GAS SERVICE REGULATOR. INLET PRESSURE TO

THIS APPLIANCE SHOULD BE REDUCED TO A

MAXIMUM OF 14 INCHES WATER COLUMN (0.5

POUNDS PER SQUARE INCH (P.S.I.). LIQUEFIED

PETROLEUM (L.P.)

MUST HAVE A L.P. GAS PRESSURE REGULATOR.

INLET PRESSURE TO THIS APPLIANCE SHOULD BE

REDUCED TO A MAXIMUM OF 14 INCHES WATER

COLUMN (0.5 P.S.I.). INLET PRESSURES IN EXCESS

OF 0.5 P.S.I. CAN DAMAGE THE APPLIANCE

PRESSURE REGULATOR AND OTHER GAS

COMPONENTS IN THIS APPLIANCE AND CAN RESULT

IN A GAS LEAK.

NOTE: This range is shipped from the factory set for

Natural Gas at 4″ water column pressure.

/PROPANE GAS SUPPLY LINE

Checking Pressure Of House Piping

System

1. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

Gas supply pressure for testing regulator must be at

least 1″ water column pressure above manifold

pressure shown on serial plate.

If conversion to LP Gas is required, convert appliance

before installation.

-- 8 --

RANGE ADJUSTMENTS

Top Section -- Electric Ignition

To operate, push and turn top burner knob to the LITE

position. The top burner will light. To turn OFF spark after

the top burner has ignited, turn knob to HI setting.

NOTE: Top burners are not adjustable.

Air Shutter -- Bake/Broil Burner

NOTE: If oven burner does not ignite, check oven gas

shut-off position at the regulator.

a. The approximate length of the flame of oven burner is

a 1/2 inch distinct inner blue flame, figure 7.

GAS CONVERSION

SEE INSTRUCTIONS FOR GAS CONVERSION

LOCATED ON THE BACK OF THE RANGE.

FIGURE 7

b. Bake/broil burner flame can be checked as follows:

1. Yellow flame on burner -- open burner air shutter

to the widest opening that will not cause the flame

to lift or blow off the burner when cold. (See #2 on

figure 8). Some yellow tipping on LP is normal.

2. Distinct blue flame but lifting -- close burner air

shutter to the point where it will not cause the

flame to lift or blow off the burner when cold. (See

#2 on figure 8).

FIGURE 8

-- 1 0 --

INSTALADOR: DEJE ESTAS INSTRUCCIONES CON EL ELECTRODOMÉSTICO

MANUAL DE INSTALACIÓN

Combustible dual independiente convencional de

76 cm (30 pulgadas) de ancho

CONSERVE ESTE MANUAL COMO REFERENCIA FUTURA

EL MANUAL TIENE LA FINALIDAD DE AYUDARLE EN LA INSTALACIÓN Y LOS AJUSTES INICIALES

DE LA ESTUFA.

ADVERTENCIA ESPECIAL

Solamente el personal calificado

deberá instalar o dar servicio a esta

estufa.

Lea las “Instrucciones de

seguridad” en el libro de Uso y

cuidado antes de usar la estufa.

La instalación, los ajustes, el

servicio, el mantenimiento o el uso

incorrectos, así como las

alteraciones de la estufa pueden

causar lesiones graves o daños

materiales.

DIMENSIONES DEL ESPACIO

LIBRE

La estufa puede instalarse con un espacio libre de cero

centímetros adyacente (contra) a la construcción

combustible en la parte posterior y en los lados debajo de

la superficie para cocinar. Para obtener la información

completa relacionada con la instalación de gabinetes de

pared encima de la estufa y los espacios libres a las

paredes combustibles por encima de la parte superior de

la superficie para cocinar, vea los dibujos de instalación.

Por MOTIVOS DE SEGURIDAD no instale la estufa en

ningún gabinete combustible que no esté de acuerdo con

los dibujos de instalación.

* NOTA: La dimensión de 76.2 cm (30”) no puede redu--

cirse a menos de 61 cm (24”) cuando los gabinetes de

pared en una casa están protegidos con materiales contra

incendios de acuerdo con las Normas Nacionales Esta-dounidenses – el Código Nacional de Gas Combustible o

en casas móviles cuando están protegidas con materiales

contra incendios de acuerdo con la Norma Federal para

Construcción y Seguridad de Casas Móviles.

ADVERTENCIA

• TODAS LAS ESTUFAS PUEDEN

VOLTEARSE Y CAUSAR

LESIONES A LAS PERSONAS.

• INSTALE LOS DISPOSITIVOS

ESTABILIZADORES EMPACADOS CON LA ESTUFA.

• SIGA TODAS LAS INSTRUCCIONES DE INSTALACIÓN.

Su estufa podría no estar equipada

con algunas de las características

mencionadas en este manual.

Para eliminar el riesgo de quemaduras o incendios al

atravesarse por encima de las unidades calientes de la

superficie, debe evitarse el almacenaje en los gabinetes

por encima de las unidades de la superficie. Si se va a

proporcionar almacenaje, puede reducirse el riesgo

instalando una campana de estufa que sobresalga

horizontalmente cuando menos 12.7 cm (5”) más que los

gabinetes inferiores.

PRECAUCIÓN: Esta estufa ha sido diseñada de

acuerdo con los requisitos de varias agencias de

seguridad y cumple con las temperaturas máximas

permitidas para los gabinetes de madera de 90°C

(194°F). Si esta estufa se instala en gabinetes que

tienen una tolerancia más baja a las temperaturas,

podría ocurrir decoloración, pérdida del laminado o

derretimiento. Póngase en contacto con el servicio

de atención al cliente para obtener las dimensiones

del gabinete asociado y los accesorios de

instalación.

INSTRUCCIONES DE INSTALACIÓN DEL DISPOSITIVO ESTABILIZADOR

NOTA: Existe el riesgo de que la estufa se voltee si el

electrodoméstico no se instala de acuerdo con las

instrucciones de instalación provistas. El uso correcto de

este dispositivo reduce el riesgo de VOLTEO. Cuando se

use este dispositivo el propietario debe aún observar las

precauciones de seguridad según se indican en el

MANUAL DE USO Y CUIDADO y evitar usar la puerta del

horno o el cajón inferior como banquillo.

Se proporcionan las instrucciones para madera y

cemento tanto para piso como para pared. Cualquier otro

tipo de construcción podría requerir técnicas de

instalación especiales según se determine necesario para

proporcionar un anclaje adecuado del soporte

ESTABILIZADORalpisooalapared.

PASO 1 – Ubicación del soporte (vea la figura 1)

C. Determine la ubicación del “borde” derecho o

izquierdo de la estufa y marque el piso o la pared.

D. Coloque el SOPORTE a 2.4 cm (9/16”) del “BORDE”

marcado hacia el centro del hueco y contra la pared

posterior, según se muestra en la figura 1, con el

orificio de orientación contra la pared.

E. Use el soporte como plantilla y marque los orificios

necesarios, según se muestra en la figura 1, para el

tipo de construcción que usará.

PASO 2 – Instalación del soporte estabilizador

I. Construcción de madera:

1. Piso: Ubique el centro de los dos orificios que se

identifican en la figura 1 como “ORIFICIOS PARA

EL PISO”. Taladre un orificio piloto con una broca

de 3 mm (1/8”) en el centro de cada orificio

(puede usar un clavo o un punzón si no tiene un

taladro disponible). Asegure el soporte

ESTABILIZADOR al piso con los dos tornillos

provistos. Continúe con el paso 3.

2. Pared: Ubique el centro de los dos orificios que

se identifican en la figura 1 como “ORIFICIOS

PARA LA PARED”. Taladre un orificio piloto en

ángulo con una broca de 3 mm (1/8”) en el centro

de cada orificio como se muestra en la figura 2.

(Puede usar un clavo o un punzón si no tiene

disponible un taladro.) Asegure el soporte

ESTABILIZADOR a la pared con los dos tornillos

provistos según se muestra en la figura 2.

Continúe con el PASO 3.

J. Construcción de cemento o concreto:

1. Puede obtenerse tornillos apropiados para la

construcción de concreto en una ferretería. Con

el taladro haga el orificio del tamaño requerido

para el tipo de tornillos que haya obtenido, en el

concreto, en el centro de los orificios identificados

en la figura 1 como “ORIFICIOS PARA EL PISO”.

Asegure el soporte ESTABILIZADOR al piso.

Continúe con el paso 3.

PASO 3 – Instalación de la estufa

A. Por motivos de seguridad así como para obtener el

desempeño óptimo, ajuste la estufa de manera que

esté bien nivelada y a la altura deseada antes de

instalarla en el hueco del gabinete.

NOTA: La superficie para cocinar DEBE

estar al

ras o por encima del mostrador.

La nivelación puede revisarse colocando un nivel de

burbuja de aire o un recipiente grande con agua en la

superficie para cocinar o en la parrilla del horno.

Ajuste la estufa ladeándola hacia delante o hacia

atrás y girando la pata niveladora según sea

necesario.

NOTA: Se requiere un espacio libre de cuando

menos 6 mm (1/4”) entre la estufa y la pata niveladora

que se enganchará al soporte estabilizador, vea la

figura 2.

PRECAUCIÓN: La estufa puede dañarse si se mueve

o levanta tomándola por la parte superior principal o

por el protector posterior o por las asas de la puertas.

B. Alinee la estufa en su ubicación final y prepárela para

deslizarla hacia atrás en su lugar. Conecte la tubería

de gas y enchufe el cordón eléctrico a un tomaco-rrinte siguiendo las normas indicadas en la conexión y

el resto de las instrucciones de instalación.

C. Deslice la estufa en su lugar inspeccionando visual--

mente para comprobar que el cordón eléctrico y la

tubería de gas estén libremente colocadas y conteni-das dentro del área ahuecada del panel posterior.

D. Para revisar que el soporte estabilizador de la estufa

esté bien instalado, use una linterna y vea por debajo

de la estufa para comprobar que una de las patas

niveladoras esté enganchada en la hendidura del

soporte.

NOTA: USE CUANDO MENOS DOS (2)

TORNILLOS PARA INSTALAR EL

SOPORTE ESTABILIZADOR A LA

PARED O AL PISO.

14.5 MM

(9/16”)

DEL

BORDE DE

LA ESTUFA

BORDE

MARCADO DE

LA ESTUFA

ORIFICIO DE

ORIENTACIÓN

ORIFICIOS

PARA LA

PARED

ORIFICIOS PARA

EL PISO (EN

CADA LADO)

SUJETE EL SOPORTE ESTABILIZADOR

CON UN MÍNIMO DE DOS (2) TORNILLOS

LARGOSALAPAREDOALPISO.

SOPORTE

ESTABILIZADOR

PATA

NIVELADORA

LOS

TORNILLOS

DEBEN

PENETRAR EN

LA MADERA O

EL METAL.

PLACA DE

PARED

SOPORTE

ESTABILIZADOR

ATORNILLE EL

SOPORTE A LA PARED

DESLICE PARA

ASEGURAR

FIGURA 1 FIGURA 2

-- 4 --

FONDO

DEL

HORNO

6MM

(1/4”)

MÍN.

CONEXIÓN DE LA ESTUFA

SUMINISTRO ELÉCTRICO

La estufa debe instalarse de acuerdo a los Códigos

Eléctricos Locales y Nacionales (NEC) ANSI/NFPA No.

70--última edición. Vea la placa de clasificación para

obtener la clasificación total de KW conectados.

SUMINISTRO ELÉCTRICO (Canadá)

La estufa debe instalarse de acuerdo a los Códigos

Eléctricos Canadienses y Locales CSA STD.C22.1 última

edición. Vea la placa de clasificación para obtener la

clasificación total de KW conectados.

CABLEADO EXTERIOR

La compañía local de servicios públicos le informará si es

adecuado el servicio eléctrico actual a su casa. Podría

ser necesario aumentar el tamaño del cableado a la casa

y el interruptor de servicio para poder con la carga

eléctrica que la estufa demanda. La clasificación de

kilovatios para la estufa está especificada en la placa de

clasificación que se ubica al frente de la estufa.

CABLEADO DE LA CASA

La mayoría de los Códigos y Reglamentos locales para

edificios exigen que todo el cableado eléctrico lo instale

un electricista con licencia. Todo el cableado debe estar

en conformidad con los Códigos Eléctricos Nacionales y

Locales. Esta estufa requiere un circuito de CA

monofásico de tres o cuatro cables de 120/240 o de

120/208 voltios, 60 Hz. Los códigos de cableado

requieren que se tenga un circuito separado del tablero

principal de entrada a la estufa y que esté equipado con

fusibles y con un interruptor de desconexión, ya sea en el

tablero principal de entrada o en un interruptor y caja de

fusibles separados. En algunas comunidades, debe

usarse un conductor flexible o sólido acorazado continuo

del tablero principal de entrada a la caja terminal en la

parte posterior de la estufa. Otros permitirán que el

circuito de la estufa termine en un tomacorriente de

conexión polarizada de tres o cuatro cables colocado en

un lugar conveniente cerca de la parte posterior de la

estufa. Entonces se puede conectar la estufa a este

tomacorriente mediante un conector de la clasificación

aprobada (cable flexible de conexión) asegurado con

firmeza al bloque terminal, con el protector contra tirones

apropiado, a la estufa y a un enchufe de tres o cuatro

puntas en el otro extremo.

mediante el conductor neutro. Por lo tanto, DEBE

proveerse un servicio de 4 alambres en dichas

instalaciones. El servicio de 3 alambres puede usarse

cuando lo permitan los códigos locales. USE

CONDUCTORES DE COBRE O ALUMINIO. El bloque

terminal principal está indicado para uso con conductores

de cobre o aluminio. Si se necesita un cordón de

suministro eléctrico, se recomienda usar un cordón que

no sea más largo de 4 pies. Haga las conexiones según

se explica a continuación y consulte las ilustraciones

correspondientes (vea las figuras 6 y 7). Después de la

instalación, asegúrese de que todas las conexiones

eléctricas estén bien ajustadas y coloque todas las

cubiertas.

Quite la cubierta de acceso del bloque terminal de la parte

posterior de la estufa. (Vea la figura 5).

CONEXIONES DE LA ESTUFA (en Canadá)

Este modelo se embarcó directamente de fábrica con el

cordón de servicio (cable flexible de conexión). No es

necesario hacer ninguna conexión en la estufa.

Sencillamente conéctela en el tomacorriente de la estufa.

NOTA: Reemplazo del cordón, SOLAMENTE se deberá

utilizar un cordón de suministro eléctrico de clasificación

mínima de 240 voltios, 40 ó 50 amperios que esté

marcado para usarse con una abertura nominal de

conexión de 1 3/8″ (34.93 mm) de diámetro, con

terminales de lazo cerrado y que estén marcados para

utilizarse con estufas.

BLOQUE DE

CONEXIÓN

DEL

TERMINAL

PRINCIPAL

CONEXIONES DE LA ESTUFA

Algunos modelos se envían directamente de fábrica con

los cordones de servicio (cables flexibles de conexión)

sujetos. No es necesario hacer ninguna conexión en

estos modelos de estufa. Sencillamente conéctelos en el

tomacorriente de la estufa. En los modelos que no vienen

con el cordón de servicio, es necesario hacer la conexión

al suministro de energía. RECUERDE -- solamente debe

usarse un cordón de 4 conductores en las instalaciones

nuevas de circuitos derivados (1996 NEC), áreas en

donde los códigos locales prohiben la conexión a tierra

PLACA CONDUCTORA

CUBIERTA DE ACCESO

FIGURÀ 3

-- 5 --

CONEXIÓN DE LA ESTUFA

FIGURA 5

INSTALACIÓN DEL CORDÓN DE SERVICIO DE 4

CABLES O DEL CONDUCTOR

(COMO LO REQUIEREN LAS CASAS MÓVILES O LOS

CÓDIGOS LOCALES)

1. La tira de conexión a tierra de cobre que está

conectada entre el poste neutro (medio) del bloque del

terminal principal y el bastidor DEBE cortarse según se

muestra en la figura 5. Conserve el tornillo verde de

conexión a tierra para sujetar la tierra del cordón de 4

cables. Solamente debe utilizarse un cordón de 4

cables o conductor.

2. Si se usa alambrado desnudo de cobre o aluminio,

sujete la lengüeta de conexión del adaptador según se

muestra en la figura 5. (Vea Conexión de alambre

desnudo). Las especificaciones de torsión se muestran

a continuación.

3. El cable de conexión a tierra del cordón de servicio o

del conductor debe conectarse al bastidor de la estufa

usando el tornillo verde de conexión a tierra.

4. El cable blanco del cordón de servicio o del conductor

debe conectarse al poste neutro (medio) del bloque del

terminal principal. Los otros dos cables del cordón de

servicio o del conductor se conectan a los postes rojo y

negro del bloque del terminal principal, respectivamente. Si va a usar alambre desnudo, sujete el

alambre a la lengüeta de conexión correspondiente

según se muestra. Las especificaciones de torsión se

muestran a continuación.

5. Debe colocarse a la placa del conductor un protector

contra tirones apropiado en el cordón de servicio o el

conductor.

CONVERSIÓN DE SERVICIO DE 3 CABLES A 4

CABLES

(Modelo individual con cordón sujeto de servicio de 3

cables)

Desconecte la estufa de la energía eléctrica. Quite la

cubierta de acceso en la parte posterior de la estufa y

quite el cordón de servicio de 3 cables del bloque del

terminal principal. Siga las instrucciones a continuación

según se indica en la figura 5 para conectar el cordón de

servicio de 4 cables.

NOTA: Reemplazo del cordón, deberá utilizarse

SOLAMENTE un cordón de suministro de energía con

clasificación mínima de 240 voltios, 40 ó 50 amperios que

esté marcado para utilización con aberturas nominales de

13/8″ (34.93 mm) de diámetro, con terminales de lazo

cerrado y marcados para utilización con estufas.

ROJO

BLANCO

NEGRO

CONEXIÓN A

TIERRA DEL

CHASIS

PROTECCIÓN

CONTRA TIRONES

INSTALACIÓN ACEPTADA DE UNA CLAVIJA DE CUATRO CABLES

BLOQUE DE CONEXIÓN

DEL TERMINAL

PRINCIPAL

PLACA DEL

CONDUCTOR

DEBE QUITARSE

ESTA PORCIÓN

DE LA CORREA

DE TIERRA.

ALAMBRE EN

MEDIO DEL

CORDÓN DE

SERVICIO O DEL

CONDUCTOR

1--1/2″ (3.8 CM) MÍNIMO

PISO

PARA EL USO CON

CONDUCTOR. QUITE EL

SOPORTE, VOLTÉELO Y

VUELVA A SUJETARLO

CON EL ORIFICIO

PEQUEÑO A LA VISTA.

CONEXIÓN DE

ALAMBRE

LENGÜETAS DE CONEXIÓN

DEL ADAPTADOR UBICADAS

EN EL PAQUETE DE MATERIALES IMPRESOS

ESPECIFICACIONESDE TORSIÓN DEL ALAMBRE DESNUDO

LENGÜETA DE CONEXIÓN SUJETA AL BLOQUE TERMINAL -- 20 PULG/LIBRAS

CALIBRE DEL ALAMBRE

DESNUDO

ROJO

BLANCO

NEGRO

DE

TORSIÓN

10--14

8

4--6

20 PULG/LIBRAS

25 PULG/LIBRAS

35 PULG/LIBRAS

INSTALACIÓN ALTERNATIVA

RECEPTÁCULO DEL

TOMACORRIENTE

MONTADO AL RAS

DE LA PARED

RECEPTÁCULO DEL

TOMACORRIENTE A

ROTARSE SEGÚN SE

MUESTRA SI NO ESTÁ AL

RASDELAPARED

FIGURA 5

-- 7 --

CONEXIÓN DE LA ESTUFA

Suministro de gas

La instalación de esta estufa debe estar en conformidad

con los códigos locales o, si no existieran, con la última

edición del Código Nacional de Gas Combustible, ANSI

Z223.1

En el estado de Massachusetts

Este producto debe instalarlo un plomero certificado o

un ajustador de gas cuando se instale dentro del estado

de Massachusetts.

Debe instalarse una válvula manual con asa tipo “T” en

la tubería de suministro de gas al electrodoméstico.

Los conectores flexibles de gas, cuando se usen, no

deben sobrepasar una longitud de 91.44 cm (36 pulg).

En Canadá la estufa debe instalarse de acuerdo con la

Norma actual CAN/CGA--B149 de CGA – Códigos de

instalación para electrodomésticos y equipos que queman

gas y con los códigos locales.

ADVERTENCIA

Podrían ocurrir fugas de gas en el sistema y causar

una situación peligrosa. Las fugas de gas podrían no

detectarse sólo por el olor. Los proveedores de gas

recomiendan que compre e instale un detector de

gas aprobado por UL. Instale y use de acuerdo con

las instrucciones del fabricante.

2. El electrodoméstico debe estar aislado del sistema de

suministro de gas cerrando la válvula de cierre

individual durante las pruebas de presión de ese

sistema a presiones iguales o menores de 3.5 kPa (1/2

libra por pulgada cuadrada) (35 cm (13.8 pulgadas) de

columna de agua).

Conexión del suministro de gas (vea la figura 3)

LA CONEXIÓN DE GAS DEBE REALIZARLA UN

TÉCNICO CALIFICADO DE SERVICIO O UN

INSTALADOR DE ELECTRODOMÉSTICOS DE GAS.

Las pruebas de fugas del electrodoméstico debe

realizarlas el instalador de acuerdo con las

instrucciones indicadas en la sección h.

LA TUBERÍA DE SUMINISTRO DE GAS DEBE TENER

UN REGULADOR DE SERVICIO DE GAS NATURAL. LA

PRESIÓN DE ENTRADA A ESTE

ELECTRODOMÉSTICO DEBE REDUCIRSE A UN

MÁXIMO DE 35.5 cm (14 PULGADAS) DE COLUMNA

DE AGUA (0.5 LIBRAS POR PULG CUADRADA (PSI).

LA TUBERÍA DE SUMINISTRO DE GAS

PROPANO/PETRÓLEO LÍQUIDO (LP) DEBE TENER UN

REGULADOR DE PRESIÓN DE GAS LP. LA PRESIÓN

DE ENTRADA A ESTE ELECTRODOMÉSTICO DEBE

REDUCIRSE A UN MÁXIMO DE 35.5 cm

(14 PULGADAS) DE COLUMNA DE AGUA (0.5 PSI).

LAS PRESIONES DE ENTRADA SUPERIORES A 0.5

PSI PUEDEN DAÑAR EL REGULADOR DE PRESIÓN Y

OTROS COMPONENTES DE GAS DEL

ELECTRODOMÉSTICO Y PROVOCAR FUGAS DE GAS.

NOTA: Esta estufa se embarca de fábrica lista para

usarse con gas natural a una presión de 10.16 cm (4”) de

columna de agua.

Para revisar la presión del sistema

de presión de la casa

1. El electrodoméstico y su válvula de cierre individual

deben estar desconectados del sistema de suministro

de gas durante las pruebas de presión de ese sistema

a presiones que sobrepasen 3.5 kPa (1/2 libra por

pulgada cuadrada) (35 cm (13.8 pulgadas) de columna

de agua).

La presión del suministro de gas para probar el

regulador debe ser de cuando menos 2.54 cm (1”) de

presión de columna de agua por encima de la presión

del múltiple que se indica en la placa de datos.

Si se necesita la conversión a gas LP, convierta el

electrodoméstico antes de iniciar la instalación.

-- 8 --

AJUSTES DE LA ESTUFA

Sección superior – Encendido electrónico

Para que funcione, empuje y gire la perilla del quemador

superior a la posición de encender “LITE”. El quemador

superior se encenderá. Para APAGAR la chispa después

de que se haya encendido el quemador superior, gire la

perilla al ajuste alto “HI”.

NOTA: Los quemadores superiores no se ajustan.

Obturador de aire – Quemador de

horneado/asado

NOTA: Si no se enciende el quemador, revise la posición

de la válvula de cierre del gas del horno en el regulador.

a. La longitud aproximada de la llama del quemador del

horno es una llama cónica con el interior azul, bien

definida de 1.27 cm ( 1/2”), figura 7.

CONVERSIÓN DE GAS

CONSULTE LAS INSTRUCCIONES PARA LA

CONVERSIÓN DE GAS QUE SE ENCUENTRA

EN LA PARTE POSTERIOR DE LA ESTUFA.

FIGURA 7

LLAMA CON CONO INTERNO

DE 1.27 CM (1/2”)

b. La llama del quemador de horneado/asado puede

revisarse de la manera siguiente:

2. Llama amarilla en el quemador – abra el

obturador de aire del quemador a la posición más

abierta que no cause que se apague ni levante la

llama cuando el quemador esté frío. (Vea el

número 2 de la figura 8.) Las puntas algo

amarillentas en el gas LP son normales.

3. Llama azul bien definida pero se levanta -- cierre

el obturador de aire hasta el punto en donde no

cause que se levante o apague la llama cuando

el quemador esté frío. (Vea el número 2 de la

figura 8.)

OBTURADOR DE AIRE

CAMPANA DE ORIFICIO

FIGURA 8

TORNILLO DE SEGURIDAD

-- 1 0 --

INSTALLATEUR: VEUILLEZ LAISSER CES INSTRUCTIONS AVEC L’APPAREIL

MANUEL DE MISE EN SERVICE

Cuisinière autonome à DEUX ÉNERGIES de 76,2 cm

(30 po)

VEUILLEZ CONSERVER CE MANUEL POUR RÉFÉRENCE

ULTÉRIEURE

CE MANUEL EST DESTINÉ À FACILITER LA MISE EN SERVICE ET LE RÉGLAGE INITIAUX DE LA CUISINIÈRE.

DÉGAGEMENT NÉCESSAIRE

AVERTISSEMENT SPÉCIAL

La mise en service et le dépannage de

cette cuisinière doivent être réalisés

uniquement par du personnel qualifié.

Lire les « Mesures de sécurité » dans

le manuel de l’utilisateur avant de

l’utiliser.

Une mauvaise réalisation de la mise

en place, du réglage, de toutes

modifications ou réparations ou de

l’entretien de la cuisinière ou son

usage incorrect peuvent entraîner

des blessures ou des dégâts graves.

La cuisinière peut avoir un dégagement nul (0 po/cm) par

rapport aux parois en matériaux combustibles à l’arrière et

sur les côtés au--dessous de la surface de cuisson (elle

peut être contre ces parois). Pour tous renseignements

concernant la pose d’armoires murales au--dessus de la

cuisinière et des dégagements à respecter par rapport

aux parois combustibles se trouvant au--dessus de la

surface de cuisson, se reporter aux schémas

d’installation. Pour des RAISONS DE SÉCURITÉ, ne pas

monter la cuisinière dans une armoire en matériau

combustible non conforme aux schémas d’installation.

*REMARQUE : La dimension de 76,2 cm (30 po) peut

être réduite à 61 cm (24 po) si les armoires murales d’un

logement sont pro-tégées par des matériaux ininflammables conformément

aux normes American National Standards -- National Fuel

Gaz Code ou, dans le cas de maisons mobiles, si les

armoires murales sont protégées par des matériaux

ininflammables conformément aux règlements du Federal

Standard for Mobile Home Construction and Safety.

AVERTISSEMENT

• TOUTES LES CUISINIÈRES

PEUVENT BASCULER ET

PROVOQUER DES BLESSURES.

• POSER LES DISPOSITIFS DE

STABILISATION FOURNIS AVEC

CETTE CUISINIÈRE.

• SUIVRE TOUTES LES CON -SIGNES DE MISE EN SERVICE.

Votre cuisinière peut ne pas être dotée

de toutes les fonctions mentionnées

dans ce manuel.

Pour éliminer tout risque de brûlure ou d’incendie en

essayant d’atteindre un objet placé au--dessus d’éléments

brûlants, éviter d’avoir un espace de rangement

au--dessus de la surface de cuisson. S’il doit y avoir une

armoire au--dessus de la table de cuisson, l’installation

d’une hotte dépassant d’au moins 13 cm (5 po) de sa

partie inférieure réduira les risques liés à ce type

d’entreposage.

ATTENTION : Cette cuisinière satisfait aux règles

de divers organismes de protection et aux normes

relatives à la température maximum permise de

90 ° C (194 ° F) pour les armoires en bois. Si cette

cuisinière est adjacente à des armoires pouvant

supporter une température inférieure à 90 ° C

(194 °5 F) seulement, celles--ci peuvent se

décolorer, se délaminer ou fondre. Prenez contact

avec le service à la clientèle pour obtenir les

dimensions de l’armoire et les accessoires

d’installation.

ANTI-MISE EN PLACE DU SUPPORT DE STABILISATION

REMARQUE : La cuisinière risque de basculer si elle

n’est pas mise en place conformément aux instructions

fournies. Si le dispositif de stabilisation est utilisé

correctement, il réduit le risque que la cuisinière ne BASCULE. Même si le dispositif est utilisé correctement,

le consommateur doit observer les précautions indiquées

dans le MANUEL D’UTILISATION ET D’ENTRETIEN et

éviter d’utiliser la porte du four et/ou le tiroir inférieur

comme un tabouret.

Les instructions sont prévues pour un plancher ou un mur

en bois ou en ciment. Un autre matériau pourra requérir

des techniques spéciales, qu’il conviendra de déterminer,

pour assurer la fixation d u SUPPORT DE STABILISATION

au mur ou au plancher.

ÉTAPE 1 -- Emplacement du support (voir figure 1)

A. Déterminer où le « bord » gauche ou droit de la

cuisinière se trouvera une fois celle--ci en place et le

marquer d’un repère sur le plancher.

B. Placer le SUPPORT à 14 mm (9/16 po) de la marque

« BORD » en allant vers le centre de l’ouverture et

contre le mur arrière tel qu’indiqué à la figure 1, le trou

d’orientation étant contre le mur.

C. Utiliser le support comme gabarit et marquer

l’emplacement de tous les trous pour le type de

matériau sur lequel le support doit être fixé, tel

qu’indiqué à la figure 1.

ÉTAPE 2 -- Pose du support de stabilisation

A. Bois :

1. Plancher : Déterminer le centre des deux trous

identifiés par « TROUS POUR PLANCHER » à la

figure 1. Percer un trou de positionnement de

3 mm (1/8 po) au centre de chaque trou (un clou

ou un poinçon peut également être utilisé si une

perceuse n’est pas disponible). Fixer le support

de STABILISATION au plancher à l’aide des deux

vis fournies. Passer à l’ÉTAPE 3.

2. Mur : Déterminer le centre des deux trous

identifiés par « TROUS POUR MUR » à la figure

1. Percer un trou de positionnement de 3 mm

(1/8 po) au centre de chaque trou (un clou ou un

poinçon peut également être utilisé si une

perceuse n’est pas disponible) tel qu’indiqué à la

figure 2. Fixer le support de STABILISATION au

mur à l’aide des deux vis fournies tel qu’indiqué à

la figure 2. Passer à l’ÉTAPE 3.

B. Ciment ou béton :

1. On trouve des vis convenant au ciment ou au

béton dans les quincailleries. Percer les trous de

positionnement de la grandeur correspondant à

celle des vis obtenues en quincaillerie au centre

des trous identifiés « TROUS POUR PLAN-CHER » à la figure 1. Fixer le support de STABI-LISATION au plancher. Passer à l’ÉTAPE 3.

ÉTAPE 3 -- Mise en place de la cuisinière

A. Pour des raisons de sécurité et pour obtenir des

résultats optimums à la cuisson, régler la cuisinière de

façon à ce qu’elle soit de niveau et à la hauteur

voulue avant de la mettre en place dans l’ouverture.

REMARQUE : La surface de cuisson DOIT

être au

même niveau que le comptoir ou légèrement plus

haute.

Pour vérifier le niveau, mettre un niveau à bulle ou

une grande casserole d’eau sur la surface de cuisson

ou sur la grille du four. Régler le niveau en la

basculant vers l’avant ou l’arrière et en tournant les

pieds de mise à niveau autant que nécessaire.

REMARQUE : Un dégagement minimum de 6 mm

(1/4 po) est exigé entre la cuisinière et le pied de mise

à niveau qui va s’insérer dans le support de

stabilisation (voir figure 2).

ATTENTION : La cuisinière peut être abîmée si elle

est déplacée et soulevée par le dessus, à l’aide du

dosseret ou par les poignées de porte.

B. Placer la cuisinière de façon à ce qu’elle puisse entrer

dans l’ouverture où elle sera encastrée et se préparer à

la pousser en place. Raccorder au gaz et brancher le

cordon d’alimentation dans la prise en suivant les

indications fournies pour le raccordement de la cuisinière

et dans le reste des consignes de mise en service.

C. Glisser la cuisinière en place en l’inspectant

visuellement pour s’assurer que le cordon

d’alimentation et la conduite de gaz ne se trouvent

pas coincés et qu’ils s’insèrent dans la partie en creux

du panneau arrière.

D. Pour vérifier si le support de stabilisation est

correctement en place, regarder sous la cuisinière et

s’assurer qu’un des pieds arrière est bien inséré dans

la fente du support.

REMARQUE: UTILISER UN MINIMUM DE DEUX

(2) VIS POUR FIXER LE SUPPORT

AU MUR OU AU PLANCHER.

14,5 MM

[9/16 PO] DU

BORD DE LA

CUISINIÈRE

REPÈRE DU

BORD DE LA

CUISINIÈRE

TROU

D’ORIENTATION

TROUS

POUR MUR

SUPPORT DE

STABILISATION

TROUS POUR LE

PLANCHER (DE

CHAQUE CÔTÉ)

FIXER LE SUPPORT DE

STABILISATION AU PLANCHER OU

AU MUR AVEC UN MINIMUM DE DEUX

(2) LONGUES VIS.

PIED DE

RÉGLAGE

LES VIS

DOIVENT

PÉNÉTRER

DANS LE BOIS

OU LE MÉTAL.

PLAQUE

MURALE

SUPPORT DE

STABILISATION

FIXER LE

SUPPORT AU MUR

GLISSER DANS LE SUPPORT

POUR STABILISER

FIGURE 1 FIGURE 2

-- 4 --

BAS DE LA

CUISINIÈRE

6MM

(1/4

PO)

MIN.

RACCORDEMENT DE LA CUISINIÈRE

ALIMENTATION ÉLECTRIQUE

Lors de la mise en service, la cuisinière doit être installée

conformément aux normes NEC ANSI/NFPA n°

70--édition la plus récente du code d’électricité local et

national. Voir la plaque signalétique de la cuisinière pour

en connaître la puissance raccordée totale (en kW).

ALIMENTATION ÉLECTRIQUE (Canada)

Lors de la mise en service, la cuisinière doit être installée

conformément aux normes ACN STD.C22.1 de l’édition la

plus récente du code d’électricité canadien. Voir la plaque

signalétique de la cuisinière pour en connaître la

puissance raccordée totale (en kW).

RACCORDEMENT AU SECTEUR

La compagnie d’électricité locale vous indiquera si votre

branchement est prévu pour fournir la puissance exigée

par l’appareil. Il pourra être nécessaire d’augmenter la

grosseur des câbles amenant l’électricité à la maison et

au panneau de distribution électrique. La puissance

électrique de la cuisinière (en kW) est spécifiée sur la

plaque signalétique qui se trouve à l’avant de la

cuisinière.

INSTALLATION ÉLECTRIQUE DE LA

MAISON

La plupart des codes et règlements relatifs à la

construction exigent que l’installation électrique d’une

maison soit réalisée par un électricien qualifié. Le câblage

doit être conforme aux codes d’électricité local et national.

Cette cuisinière requiert un circuit alternatif monophasé

trifilaire de 120/240 V ou 120/208 V et 60 Hz. Les codes

exigent que la cuisinière soit dotée d’un circuit séparé

partant du panneau de distribution électrique et que

celui--ci soit protégé par un sectionneur et des fusibles, au

niveau du panneau de distribution électrique ou dans un

coffret électrique séparé. Dans certaines municipalités,

une gaine blindée flexible ou rigide doit être utilisée entre

le panneau de distribution électrique et le boîtier de

raccordement se trouvant à l’arrière de la cuisinière.

D’autres municipalités autorisent le branchement de la

cuisinière sur une prise murale polarisée à trois ou quatre

fils placée dans un endroit pratique près de l’arrière de la

cuisinière. La cuisinière est branchée sur cette prise à

l’aide d’une fiche à trois ou quatre broches avec cordon

d’alimentation (spirale) homologué pour cuisinière

solidement fixé au bornier de la cuisinière par une retenue

mécanique appropriée.

par le neutre. Dans ce cas, une installationà4filsest

OBLIGATOIRE.Uneinstallationà3filspeut être utilisée

si les codes locaux le permettent. UTILISER DES

CONDUCTEURS EN CUIVRE OU EN ALUMINIUM. Le

bornier est prévu pour des conducteurs en cuivre ou en

aluminium. Si un cordon d’alimentation flexible est exigé,

il est recommandé de ne pas utiliser de cordon d’une

longueur supérieureà4pi.Siuncordond’alimentation

flexible est exigé, il est recommandé de ne pas utiliser de

cordon d’une longueur supérieureà4pi.Réaliserles

connexions tel qu’indiqué ci--dessous en se référant aux

illustrations appropriées (voir les figures 6 et 7). Une fois

l’installation effectuée, vérifier que toutes les connexions

n’ont pas de jeu et remettre tous les couvercles.

Enlever le couvercle d’accès au bornier à l’arrière de la

cuisinière (voir figure 5).

CONNEXIONS DE LA CUISINIÈRE (Canada)

Ce modèle est doté d’un cordon d’alimentation (spirale)

installé en usine. Aucune connexion n’est nécessaire. Il

suffit de la brancher.

REMARQUE : Pour remplacer le cordon d’alimentation,

utiliser UNIQUEMENT un cordon d’alimentation pour

cuisinière calibré à 240 volts minimum et 40 ou 50

ampères prévue pour une utilisation avec une ouverture

pour raccordement nominale de 1 3/8 po (35 mm) de

diamètre et muni de serre--fils.

BORNIER

CONNEXIONS DE LA CUISINIÈRE

Certains modèles ont un cordon d’alimentation (spirale)

installé en usine. Dans ce cas, il n’y a aucune connexion

à réaliser au niveau de la cuisinière. Il suffit de brancher la

fiche dans la prise murale. D’autres modèles ne sont pas

munis d’un cordon d’alimentation et dans ce cas, le

raccordement à l’alimentation électrique de la maison est

nécessaire. NE PAS OUBLIER -- seul des cordons à

quatre fils peuvent être utilisés avec les circuits de

dérivation nouvellement installés (NEC 1996), les

maisons mobiles, les véhicules de loisir ou dans toute

région où les codes locaux interdisent la mise à la terre

PLAQUE DE SUPPORT

DE GAINE

COUVERCLE D’ACCÈS

FIGURE 3

-- 5 --

FIGURE 5

INSTALLATION D’UN CORDON

D’ALIMENTATION OU D’UNE GAINE À 4

FILS

(MAISONS MOBILES OU SI LES CODES L’EXIGENT)

1. La barrette de mise à la terre en cuivre reliant la borne

neutre (celle du milieu) du bornier et le châssis DOIT

être enlevée tel qu’indiqué à la figure 5. Garder la vis

de mise à la terre verte pour fixer le fil de terre du

cordonà4fils.Utiliser uniquement un cordon

d’alimentationouunegaineà4fils.

2. Si du câblage nu en aluminium ou en cuivre est utilisé,

attacher les cosses d’adaptation tel qu’indiqué à la

figure 5. (Voir Connexion à fils nus). Les couples sont

indiqués ci--dessous.

3. Le fil de terre du cordon d’alimentation ou de la gaine

doit être relié au châssis de la cuisinière en utilisant la

visdemiseàlaterreverte.

4. Le fil blanc du cordon d’alimentation ou de la gaine doit

être connecté à la borne neutre (celle du milieu) du

bornier. Les deux autres fils du cordon sont connectés

aux bornes de même couleur (rouge et noire) du

bornier. Pour une connexion avec du fil nu, attacher le

fil à la cosse correspondante tel qu’indiqué. Les

couples sont indiqués ci--dessous.

5. Placer la retenue mécanique à bride sur le dessus de

la plaque support de gaine tel qu’indiqué et la serrer

sur le cordon d’alimentation ou la gaine.

CONVERSION D’UNE INSTALLATION 3 FILS

À UNE INSTALLATION 4 FILS

(Modèles amovibles avec cordon d’alimentation en

place)

Débrancher la cuisinière du secteur. Enlever le couvercle

du bornier se trouvant à l’arrière de la cuisinière et

déconnecter le cordon d’alimentationà3filsdubornier.

Suivre les instructions données à la figure 5 pour

connecter le cordonà4fils.

REMARQUE : Pour remplacer le cordon d’alimentation,

utiliser UNIQUEMENT un cordon d’alimentation pour

cuisinière calibré à 240 volts minimum et 40 ou 50

ampères prévu pour une utilisation avec une ouverture

pour raccordement nominale de 1 3/8 po (35 mm) de

diamètre et muni de serre--fils.

ROUGE

BLANC

NOIR

MISEÀLA

MASSE AU

CHÂSSIS

RETENUE MÉCANIQUE

1 1/2 PO (3,8 CM) MINIMUM

INSTALLATION ACCEPTABLE -- FICHE À QUATRE FILS

CONNEXION À FILS NUS

BORNIER

PLAQUE DE

SUPPORT DE

GAINE

Cettepartiedela

barrettedemiseà

la terre doit être

coupée.

FIL DU MILIEU

DU CORDON

OU DE LA

GAINE

PLANCHER

À UTILISER AVEC UNE

GAINE. ENLEVER LE

SUPPORT, RETOURNER ET

FIXER À NOUVEAU AVEC

LE PETIT TROU VISIBLE.

COSSES D’ADAPTA TION

AVEC LA DOCUMENTATION

SPÉCIFICATIONS DE COUPLE POUR FILS NUS

CÂBLE AWG

10--14

INSTALLATION ALTERNATIVE

COSSE AU BORNIER -- 20 PO--LB

8

4--6

NOIR

BLANC

COUPLE

20 PO--LB

25 PO--LB

35 PO--LB

ROUGE

DE

PRISE ENCASTRÉE

DANS LE MUR.

TOURNER LA PRISE DANS

L’AUTRE SENS TEL

QU’INDIQUÉ SI ELLE

N’EST PAS ENCASTRÉE

FIGURE 5

-- 7 --

RACCORDEMENT DE LA CUISINIÈRE

Alimentation en gaz

La mise en service de cette cuisinière doit être conforme

aux codes locaux ou, en l’absence de tels codes, avec la

norme ANSI Z223.1, dernière édition, du National Fuel

Gas Code.

Dans le « Commonwealth of

Massachusetts »

Ce produit doit être mis en service par un plombier ou

un monteur d’installations au gaz porteur d’une licence

pour toute mise en service à l’intérieur du

« Commonwealth of Massachusetts ».

Un robinet d’arrêt de gaz manuel de type à poignée en

T doit être posé sur la conduite de gaz de cet appareil.

Un raccord de gaz flexible devra, s’il est utilisé, ne pas

être d’une longueur supérieure à 91,4 cm (3 pi/36 po).

Au Canada, la mise en service de la cuisinière doit être

conforme à la norme ACG CAN/ACG--B149 en vigueur

relative aux codes de mise en service d’appareils à gaz

et/ou aux codes locaux.

AVERTISSEMENT

Des fuites de gaz peuvent se produire et aboutir à une

situation dangereuse. Les fuites de gaz ne peuvent

pas être détectées simplement à l’odeur. Les

fournisseurs de gaz recommandent d’acheter et de

poser un détecteur de gaz homologué UL. Le poser et

l’utiliser conformément aux consignes du fabricant.

2. L’appareil à gaz doit être coupé des conduites de gaz

en fermant son robinet de gaz individuel pendant toute

vérification de la pression dans les conduites de gaz à

des pressions égales ou inférieures à 0,5 lb/po

kPa (13,8 po de colonne d’eau).

2

/3,5

Raccordement à l’alimentation au gaz de

réseau (voir la figure 3)

LE RACCORDEMENT AU GAZ DOIT ÊTRE EFFECTUÉ

PAR UN TECHNICIEN AYANT REÇU LA FORMATION

APPROPRIÉE OU PAR UN INSTALLATEUR

D’APPAREILS À GAZ. La vérification de l’absence de

fuites sera effectuée par l’installateur conformément

aux directives fournies à la section h.

LA CONDUITE DE GAZ NATUREL DOIT ÊTRE

ÉQUIPÉE D’UN DÉTENDEUR POUR GAZ NATUREL. LA

PRESSION À L’ARRIVÉE DE CET APPAREIL DOIT

ÊTRE DÉTENDUE DE FAÇON À NE PAS ÊTRE

SUPÉRIEURE À 0,5 LB/PO

COLONNE D’EAU). LA CONDUITE DE GAZ DE

PÉTROLE LIQUÉFIÉ (GPL)/PROPANE DOIT ÊTRE

ÉQUIPÉE D’UN DÉTENDEUR POUR GPL. LA

PRESSION À L’ARRIVÉE DE CET APPAREIL DOIT

ÊTRE DÉTENDUE DE FAÇON À NE PAS ÊTRE

SUPÉRIEURE À 0,5 LB/PO

COLONNE D’EAU). UNE PRESSION À L’ARRIVÉE

SUPÉRIEURE À 3,5 KPA (0,5 LB/PO

ENDOMMAGER LE DÉTENDEUR DE L’APPAREIL ET

LES AUTRES COMPOSANTS DE CET APPAREIL ET

POURRAIT PROVOQUER DES FUITES DE GAZ.

REMARQUE : La cuisinière est réglée au gaz naturel

pour une pression de gaz naturel de 1,25 kPa (4 po de

colonne d’eau) en usine.

2

/3,5KPA(14PODE

2

/3,5KPA(14PODE

2

) PEUT

Vérification de la pression des

conduites du logis

1. L’appareil à gaz et son robinet d’alimentation doivent

être désolidarisés des conduites de gaz pendant toute

vérification de la pression à des pressions supérieures

à 0,5 lb/po

2

/3,5 kPa (13,8 po de colonne d’eau).

La pression de gaz nécessaire pour vérifier le

détendeur doit être au moins 0,25 kPa (1 po de

colonne d’eau) au--dessus de la pression de rampe

indiquée sur la plaque signalétique.

Si la conversion au gaz GPL est nécessaire, convertir

l’appareil avant la mise en place.

-- 8 --

RÉGLAGES DE LA CUISINIÈRE

Partie supérieure -- Allumage électrique

Pour allumer un brûleur de la surface de cuisson, pousser

sur le bouton de commande correspondant et le mettre

sur la position LITE. Le brûleur s’allume. Pour CESSER la

production d’étincelles une fois le brûleur allumé, tourner

le bouton sur le réglage HI.

REMARQUE : Les brûleurs de la surface de cuisson ne

sont pas réglables.

Obturateur d’air -- Brûleur du four et du gril

REMARQUE : Si le brûleur du four ne s’allume pas,

vérifier la position du robinet d’arrêt.

a. La hauteur approximative de la flamme d’un brûleur

du four doit présenter une partie bleue distincte de

13 mm (1/2 po) (voir la figure 7).

CONVERSION À UN GAZ DIFFÉRENT

VOIR LES CONSIGNES DE CONVERSION À

UN TYPE DE GAZ DIFFÉRENT À L’ARRIÈRE

DE LA CUISINIÈRE.

FIGURE 7

CÔNE INTÉRIEUR DE LA

FLAMME DE 1,3 CM (1/2 PO)

b. Pour vérifier la flamme du brûleur du four/gril :

1. Flamme jaune -- ouvrir l’obturateur d’air afin

d’assurer son ouverture maximum tout en ayant

une flamme qui ne se soulève pas du brûleur ou

qui s’éteigne lorsque le brûleur est froid. (Voir

l’élément 2 de la figure 8.) Il est normal que la

flamme présente une pointe légèrement jaune

avec le GPL.

2. Flamme avec partie bleue distincte mais qui se

soulève du brûleur -- fermer l’obturateur d’air

jusqu’à ce qu’il produise une flamme qui ne se

soulève pas du brûleur ou s’éteigne lorsque le

brûleur est froid. (Voir l’élément 2 de la figure 8.)

OBTURATEUR

D’AIR

CAPUCHON D’ORIFICE

FIGURE 8

VISDEBLOCAGE

-- 1 0 --

Loading...

Loading...