Page 1

Downdraft

Ducting

Guide

T

HE

S

IGN OF A

G

REAT

C

OOK

®

®

Downdraft

Ducting

Guide

Page 2

Important Information

Dealer

Installer

Model and Serial Numbers

Equivalent Length

Fittings Required

Questions

Page 3

When considering the location for a Jenn-Air product, environmental influences that can affect ventilation performance must be considered.

Make-Up Air - The air that is exhausted by the unit

must be replaced. If a room or house is too “tight”,

the unit may not vent properly. If a house or room is

too tight, it will be necessary to introduce more air

into the environment. Some air conditioning and

heating units allow for make-up air.

Air Movement - Any other air movement devices

such as, ceiling fans, air conditioner registers, etc.

can create air currents which interfere with downdraft ventilation.

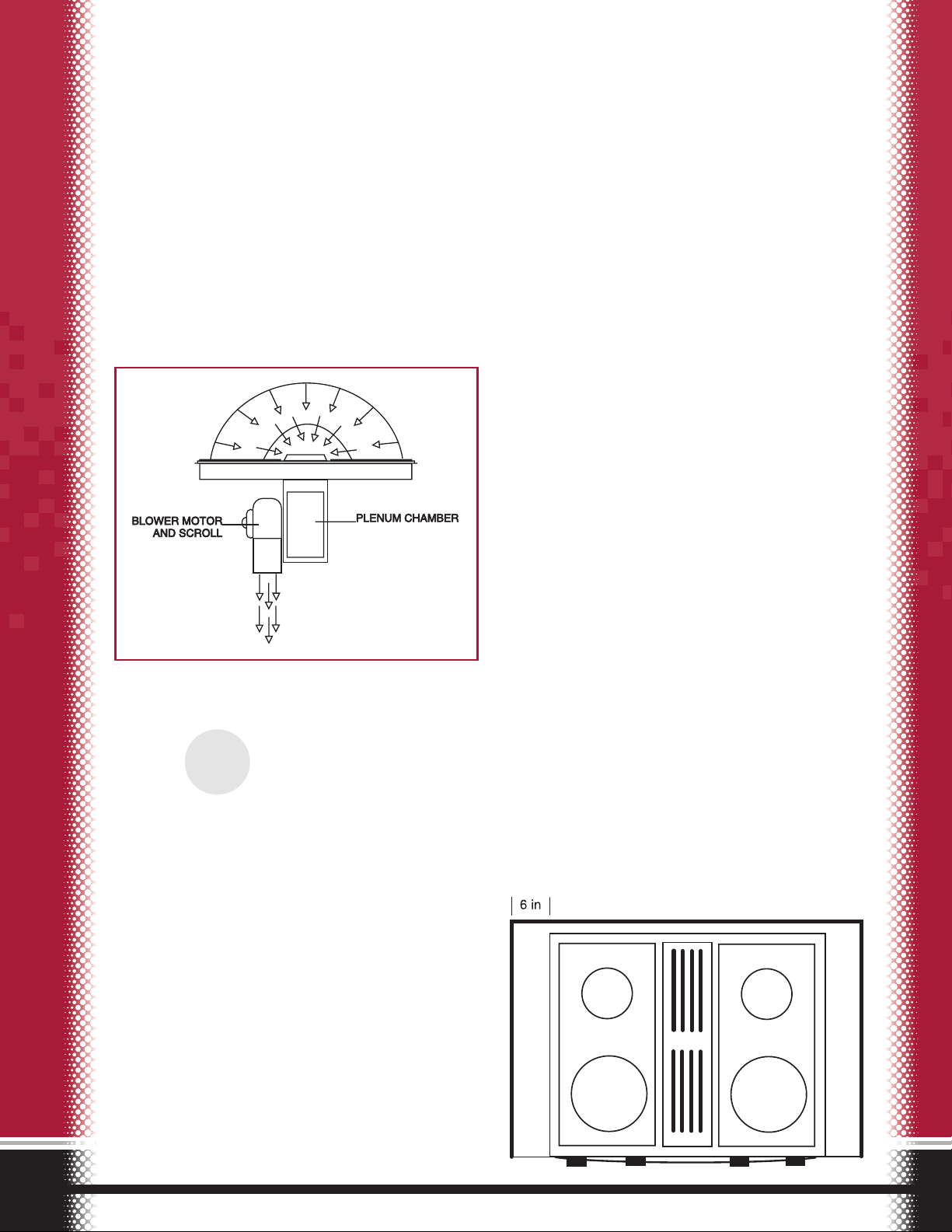

Adjacent Cabinets - Cabinets that are closer than

the minimum distance allowed can create dead air

pockets that impair performance. For maximum

performance, the recommended distance to adjacent

cabinets or walls is 6”. However, the minimum

clearance can be from 2 inches for cooktops to 1

inch for ranges. Please refer to the installation

instructions for the particular product.

Jenn-Air downdraft ranges and cooktops will adapt

to various installation locations. The blower assembly is capable of duct runs up to 60 equivalent feet.

When planning a particular installation, please refer

to this guide to ensure that all of the ducting needs

will be met. Always refer to the product and ducting installation instructions included with the JennAir product.

Jenn-Air downdraft ventilation systems are

designed to move air at a high rate of speed. High

speed air flow will ensure the exhausting of smoke

and fumes and will hold grease and moisture in suspension until exiting the home.

The downdraft cooking system operates on the

principle of localized or “proximity” ventilation.

This system creates a high velocity exhaust air pattern near the cooking surface. The air movement is

created by a blower motor and squirrel cage fan

blade encapsulated by a blower scroll. This scroll is

aligned with a plenum chamber. On cooktops, the

scroll is attached directly to the plenum chamber.

On ranges it mounts remotely under the range.

Since this system differs from the familiar forced-air

heating and air conditioning system you may have

in your home that uses low velocity air flow, the

Jenn-Air system will require different duct work

design techniques.

This guide will take you step-by-step through the

planning process and will assist you in determining

the types of materials needed to properly install a

Jenn-Air product.

The goal of the system is to maintain the proper

amount of airflow to efficiently pull smoke and

other cooking fumes to the outside without pulling

excessive air across the cooking surface. Too little air

movement will result in a smoke filled kitchen

while too much air movement will result in prolonged cooking times due to cooled off food.

The equipment design is flexible enough that the

ducting can be done simply with up to three turns

(elbows) and not rely on fancy sheet-metal work.

Proximity Ventilation Cooktop Example

Introduction

1

STEP

Environment

Page 4

Downdraft Ranges - Blower mounts to floor and has a flexible

connection to the range.

Rear Duct (Inside Wall) to the roof

Through the wall in back of the grillrange directly to the outside

Down through the floorF, along the

floor joists and through the foundation

or an outside wall

5” Dia. Duct

5” Dia. Duct

5”

Wall

Cap

6” Wall

Cap

The ability to rotate the blower 90 degrees provides

great flexibility to most installation types. On

ranges, the blower is positioned on the floor.

On cooktops, it is positioned under the cooking surface. The following graphics depict common installation types.

Cooktops - Blower mounted to cooktop (Expression

®

Collection examples shown)

5” to 6”

Transition

5” to

3-1/4” x 10”

Transition

Elbow

Jenn-Air Roof Rack

Up Inside Wall to

Roof or Overhang

Inside Wall Cabinet

Maximum of 54’

of 3-1/4” x 10”

Duct

5” to 3-1/4” x

10” Elbow

Directly to Outside

Outside Wall Cabinet

Thru Cabinet Toe Space

Peninsula

(no wall behind)

3-1/4” x 10”

Transition

Elbow

Between Floor Joist

Peninsula or island

6” Elbow

Maximum

of 51-1/2’

of 6" Duct

Jenn-Air 6”

Wall Cap

5” to 6”

Transition

Notes:

A.For venting up to the equivalent of 60’, use standard aluminum or steel

ducting and elbows.

B. IMPORTANT: See installation instructions shipped with product before

selecting island cabinetry, making cutouts or beginning installation. For

best performance, it is suggested that no more than three 90 degree elbows be used with 6" or 3-

1

/4" x 10"

duct. Each foot of metal flex duct counts as two feet of rigid metal duct. Each flex elbow counts as two

metal elbows. For longer duct runs of 31' to 60', the restricter ring on the blower inlet housing must be

removed. 6" round or 3-1/4" x 10" duct must be used for ducting beyond 10' (up to 60'). Failure to follow

ducting recommendations or use recommended ducting accessories may result in substandard performance.

C. Count each 90 degree elbow as 5' of duct.

D.When venting electric ranges or cooktops, 5" diameter round duct may be used to vent straight out the

back of appliance and directly through the wall for runs of 10' or less.

E. When venting dual-fuel ranges and gas cooktops, 5" diameter round duct must be used for runs of 10'

or less.

F. When installing through a slab, it is essential that the system be properly calculated, designed and

installed before the house is built, when the slab is poured.

Duct Length Recommendations

A

(Maximum)

B

5” Diameter

C

All Electric

D

All Gas

E

10’

10’

60’

60’

6” Diameter

or 3-1/4” x 10”

C

Installation Types

2

STEP

Page 5

DO NOT EXCEED

60 EQUIVALENT FEET

Example

5˝ to 6˝ Transition 1 ft

2 ft of 6˝ Round + 2 ft

6˝ Elbow + 5 ft

4 ft of 6˝ Round + 4 ft

6˝ Elbow + 5 ft

6 ft of 6˝ Round + 6 ft

Jenn-Air Wall Cap + 0 ft

23

EQUIVALENT

FEET

5˝, 6˝ or 3 1/4˝ x 10˝ 90 Degree Elbow

6˝ Diameter, 5˝ Diameter or

3

1

/4˝ x 10˝ Straight Duct

5 Feet

(5˝) 580357

(6˝) 580356

(3

1

/4˝x 10˝) 580359

(5˝) 580362

(6˝) 580361

A456

701944

701944

(no MCS #)

701945

701945

580360

(3

1

/4˝x 10˝) A403

(5˝) A405

Roof Cap 701943

708786

21/2Feet

1 Feet

5 Feet

9 Feet

6 Feet

1 Feet

4

1

/2Feet

12 Feet

0 Feet

2 Feet

1 Foot per Foot

(Metal Flex= 2

Feet per Foot)

Duct Fitting

Equivalent

Length

No. of

Fittings

Total Equivalent

Lengh-Fitting

Use Table Below to Calculate Total Systems

5˝ or 6˝ 45 Degree Elbow

5˝, 6˝ Transition

6˝ to 3

1

/4˝ x 10˝ Transition Elbow

6˝ to 3

1

/4˝ x 10˝ Transition Elbow

5˝ to 3 1/4˝ x 10˝ Transition Elbow

6˝ to 3 1/4˝ x 10˝ Transition

6˝ to 3

1

/4˝ x 10˝ Transition

3

1

/4˝ x 10˝ Flat Elbow

Jenn-Air Wall or Roof Jack

Jenn-Air Thermal Break

System Equivalent Length:

Equivalent Length Calculation Table

Since fittings such as elbows and transitions affect

air flow through the ducting, they must be accounted for in calculating a duct run. This is done by utilizing a formula that deducts an equivalent length

from the duct run. The following table depicts these

equivalent lengths and may be used as a worksheet

to determine your equivalent length deductions.

3

STEP

Calculating the Duct Length

(6˝) A406

Air Flow

in this Direction

Not Recommended

Air Flow

Air Flow in

this Direction

Only!

Air Flow

Air Flow

Air Flow

5˝ to 6˝ Transition

2´ of 6˝ Round

6˝ Elbow

4´ of 6˝ Round

6˝ Elbow

16´ of 6˝ Round

6˝ Wall Cap

Page 6

Sketching Area

Recommended Materials Include:

■ 3

1

/4in. X 10 in., ALUMINUM\STEEL

(For runs greater than 10 ft. )

■ 6 in. ROUND, ALUMINUM\STEEL

(For runs greater than 10 ft.)

■ 5 in. ROUND, ALUMINUM\STEEL

(For runs under 10 ft.)

Note: 5 in. MUST be used on Gas or Dual-Fuel

Ranges with runs less than 10 ft.

■ 6 in. PVC (Limited to under Concrete Slab. Subject

to Local Codes!)

Note: PVC Elbows count as 10 equivalent feet.

Non-Recommended Materials:

■ Metal Flex Duct (May be used for short runs only)

Note: If Metal Flex is used, multiply equivalent feet

by 2.

■ Vinyl Flex Duct (NEVER!)

■ Any material with less than 5” diameter (NEVER!)

e.g. Dryer Ducting

4

STEP

Use Recommended Ducting Material

3 1/4 in. x 10 in.

5 or 6 in. Round

P.V.C.

Metal Flex

Page 7

We hope this planner has assisted you in your planning for your new Jenn-Air Downdraft product.

Each installation is unique and requires insight and

careful planning. For further product information,

contact your Jenn-Air Dealer or call us at 1-800-6881100 or in Canada, 1-800-688-2002.

Thank You

DO

■ Use recommended wall caps and ducting material

■ Tape and seal all seams and connections

■ Use only professional elbows, fittings and crimps on ducting

■ Duct system to the outdoors

■ Maintain 12 inches from the bottom of the wall cap to the ground

■ Understand environmental influences on air movement

■ Calculate equivalent feet

■ Refer to installation instructions packed with the product

DON’T

■ Cause any restrictions

One of the most common and severe duct restrictions is caused by putting two elbows or fittings next to each other. Frequently, this

configuration is an attempt to get past a floor joist or other obstacle. Elbows and fittings cause turbulence in the air stream. This turbulence carries down the ducting for a considerable distance before it smoothes out again. Putting elbows or fittings together can create a

higher than desired resistance to the air movement.

To prevent this, it is required that a straight duct run be placed between the fittings. As a rule of thumb, this straight section should be at

least two and one half times the diameter of the duct.

Example

: For 6” diameter ducting the straight section should be at least 15 inch-

es ( 2

1

/2x 6” ).

■ Use non-recommended ducting materials

Another commonly found source of poor performance is the use of inadequate ducting material. Their size and configuration effect the

air movement within them. Choose the ducting material carefully and use only those that are Jenn-Air

®

recommended and comply with

Federal and Local building codes.

■ Use screws to attach ducting together

The ventilation system is designed to hold grease and smoke in suspension until it reaches the outdoors where it will condense. If the

duct has any open holes or seams in it, the suspended grease may condense in an undesirable location.

■ Reduce the size of the duct

While the mixing of ducting material is acceptable, you should NEVER reduce the duct size down. If 6” material is used, a reduction to 5”

will create a restriction in the air flow that cannot be overcome. The mixing of 3

1

/4” x 10” with 6” material is acceptable and will not hin-

der performance.

■ Use too many elbows or fittings

The number of elbows should be limited to three per duct run. Due to the restriction each elbow or fitting creates, performance will be

sacrificed if more than three are used.

■ Use a common duct for more than one downdraft

If installing more than one downdraft, each blower assembly will require its own dedicated duct run. If two systems are sharing a common run, some performance situations may occur. Smoke and odor will come out of the unit not operating and poor ventilation performance if both units are operated at the same time. Common duct runs NEVER should be used.

5

STEP

Do’s and Don’ts of Ducting

Page 8

403 West Fourth Street North

Newton, Iowa 50208

Specifications subject to change without notice.

© 1998 Maytag AppliancesPart No. 16009426

T

HESIGN OF AGREATCOOK

®

Loading...

Loading...