Page 1

SEALEDGAS COOKTOPS

CCG2423AND CCG2523

JGC7430 AND JGC7536

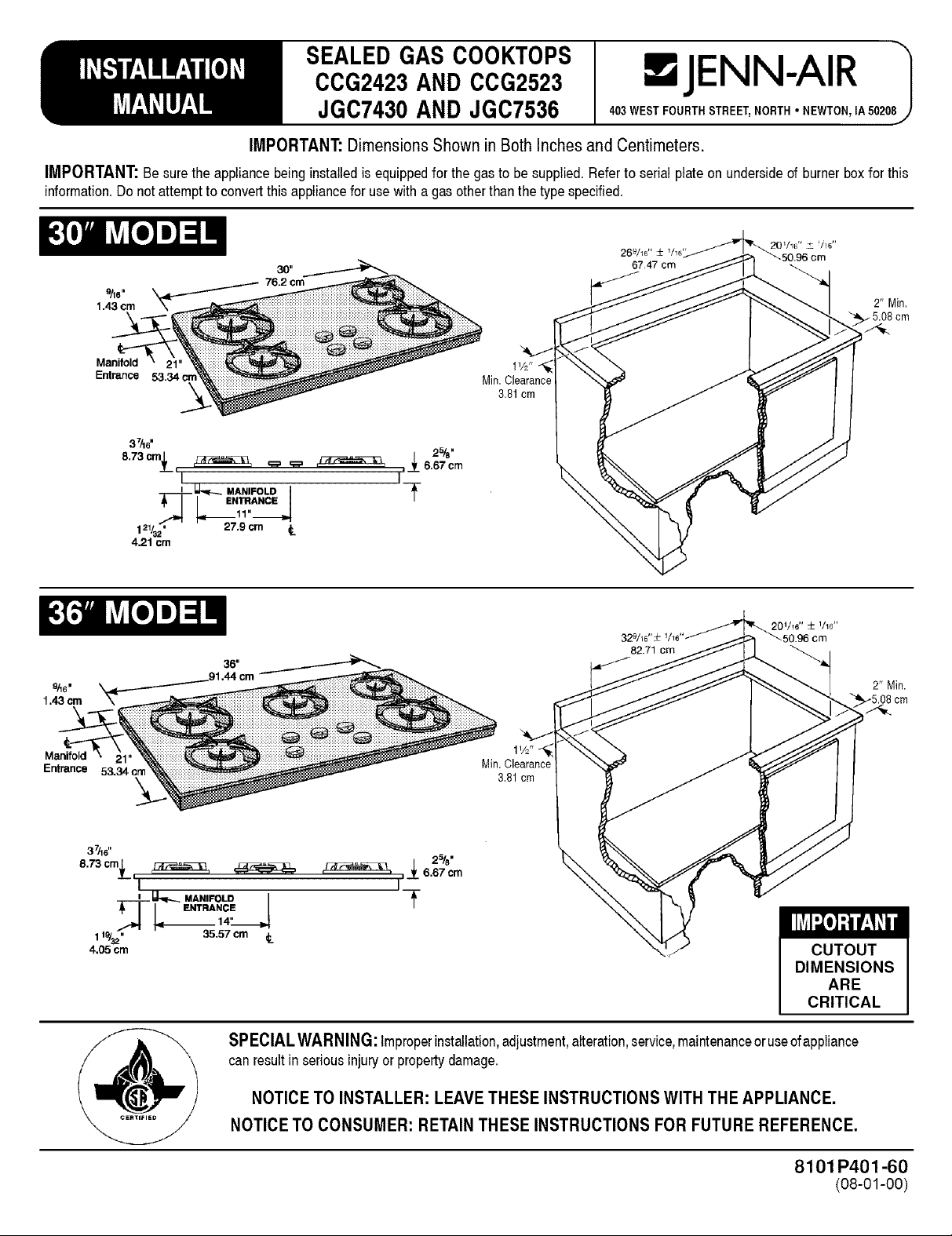

IMPORTANT:DimensionsShown in BothInchesand Centimeters.

IMPORTANT:Besurethe appliancebeinginstalledis equippedforthegasto besupplied.Referto serialplateon undersideofburnerboxfor this

information.Donotattemptto convertthis appliancefor usewitha gasotherthanthetype specified.

76.2 cm

"4

Manifold 1 V21' _

Entrance Min. Clearance

3.81cm

=JENN-AIR

403WEST FOURTHSTREET,NORTH° NEWTON,IA50208

2" Min.

5.08cm

37&6"

8.73__¢m_k,i_ _ _ _ ,_6.67cm

4.21 cm

9/16=

1.43cm

Manifold

Entrance 53.34 cm

37/16"

8.73 cmL, _

T-[-I ENTeNtE I

119/_.. 35.57 cm

4,05 cm

......_t_,_.._ MAN,FO_I

*II ENTRANClEJ

121/32" -- 27.9 cm

I

I _ MANIFOLD I

2%"

Lf

2%"

/

,,__ 6.67 cm

3.81cm

32_

82.71 cm

2" Min.

SPECIALWARNING:Improperinstallation,adjustment,alteration,service,maintenanceoruseofappliance

canresultinseriousinjuryor propertydamage.

NOTICETO INSTALLER:LEAVETHESE INSTRUCTIONSWITH THE APPLIANCE.

NOTICETO CONSUMER: RETAINTHESE INSTRUCTIONS FORFUTURE REFERENCE.

8101 P401-60

(08-01-00)

Page 2

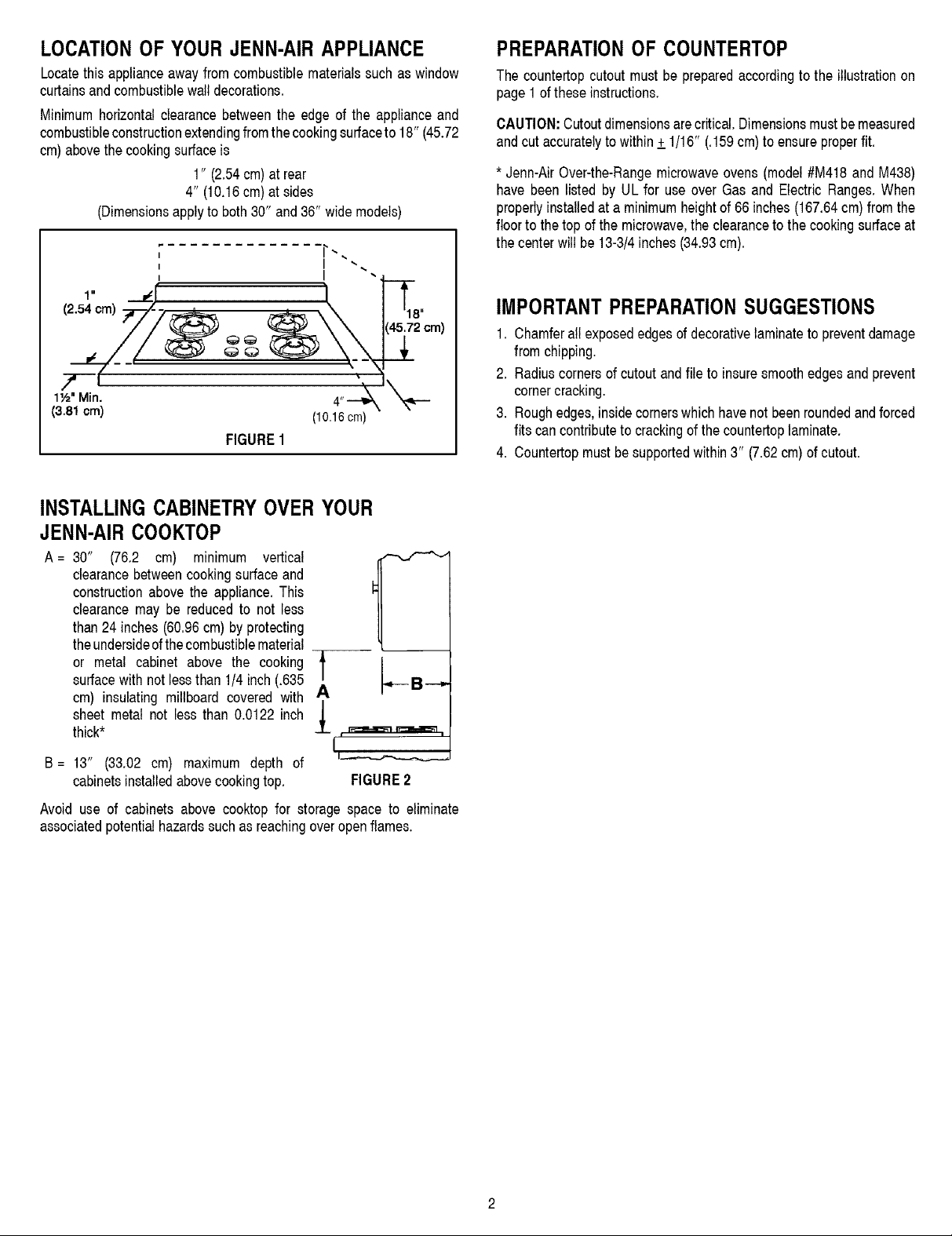

LOCATIONOF YOUR JENN-AIRAPPLIANCE

Locatethisapplianceawayfromcombustiblematerialssuch aswindow

curtainsandcombustiblewalldecorations.

Minimumhorizontalclearancebetweenthe edge of the applianceand

combustibleconstructionextendingfromthe cookingsurfaceto 18"(45.72

cm)abovethecookingsurfaceis

1" (2.54cm)atrear

4" (10.16cm) atsides

(Dimensionsapplyto both30" and36" widemodels)

I

I

I

I a

(2.54 cm)

1½" Min.

(3.81 cm)

FIGURE 1

(10.16cm)

PREPARATIONOF COUNTERTOP

The countertopcutoutmustbe preparedaccordingto the illustrationon

page1oftheseinstructions.

CAUTION:Cutoutdimensionsarecritical.Dimensionsmustbemeasured

andcutaccuratelytowithin+_1/16" (.159cm)to ensureproperfit.

* Jenn-AirOver-the-Rangemicrowaveovens(model#M418and M438)

have been listed by UL for use over Gasand ElectricRanges.When

properlyinstalledataminimumheightof66 inches(167.64cm) fromthe

floorto thetop ofthe microwave,the clearanceto the cookingsurfaceat

the centerwillbe 13-3/4inches(34.93cm).

IMPORTANTPREPARATIONSUGGESTIONS

1. Chamferall exposededgesof decorativelaminatetopreventdamage

fromchipping.

2. Radiuscornersof cutoutandfile to insuresmoothedgesandprevent

cornercracking.

3. Roughedges,insidecornerswhichhavenot beenroundedandforced

fitscancontributeto crackingofthecountertoplaminate.

4. Countertopmustbesupportedwithin3" (7.62cm)of cutout.

INSTALLINGCABINETRYOVERYOUR

JENN-AIRCOOKTOP

A= 30" (76.2 cm) minimum vertical

clearancebetweencookingsurfaceand

constructionabovethe appliance.This

clearancemaybe reducedto not less

than24inches (60.96cm)byprotecting

theundersideofthecornbustibiematerial

or metal cabinet above the cooking

surfacewithnotlessthan 1/4inch(.635

cm) insulatingmillboard covered with

sheet metal not less than 0.0122inch

thick*

B = 13" (33.02 cm) maximum depth of

cabinetsinstalledabovecookingtop.

Avoid use of cabinets abovecooktop for storage space to eliminate

associatedpotentialhazardssuchas reachingoveropenflames.

A

I

FIGURE2

Page 3

INSTALLATIONOF APPLIANCE

Theinstallationofthisappliancemustconformwithlocalcodesor,inthe

absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1-LatestEdition,or, inCanada,CAN!CGA-B149InstallationCode,

LatestEdition.

This appliance, when installed, must be electrically grounded in

accordancewith localcodesor,inthe absenceof local codes,with the

NationalElectricalCodeANSI!NFPANo.70-LatestEdition,or,inCanada,

currentCSAStandardC22.1CanadianElectricalCode,Part1.

All supply piping,exceptas noted, shoulduse commonNationalPipe

Thread (N.P.T.).For all pipe connectionsuse an approvedpipe joint

compoundresistantto theactionof LPgas.

CAUTION:Warrantyisvoid onJenn-Airequipmentinstalledotherthanas

recommendedbymanufacturer.

This applianceis designedfor use with the appliance gas pressure

regulatorsuppliedwiththis appliance.It mustbeinstalledinthe gasway

aheadofthe gasmanifoldentrance.Itispresetforusewithnaturalgasand

mustbe converted,asdescribedon page6, for usewith LP gas. (See

figures10and11.)

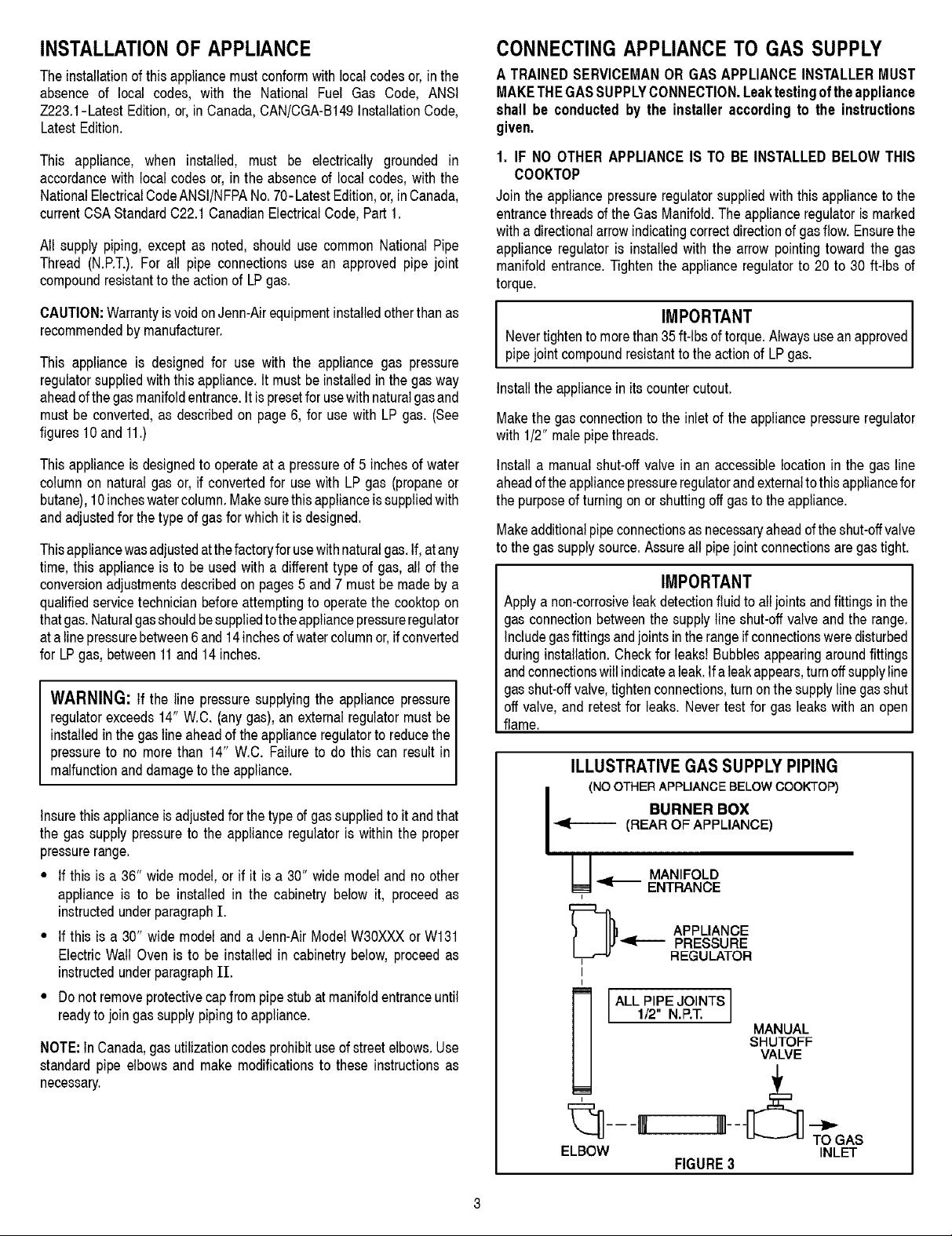

CONNECTINGAPPLIANCETO GAS SUPPLY

A TRAINEDSERVICEMANORGAS APPLIANCEINSTALLERMUST

MAKETHEGASSUPPLYCONNECTION.Leaktestingoftheappliance

shall be conductedby the installer accordingto the instructions

given.

1. IF NO OTHERAPPLIANCEIS TO BE INSTALLEDBELOWTHIS

COOKTOP

Join theappliancepressureregulatorsuppliedwiththis applianceto the

entrancethreadsof theGasManifold.Theapplianceregulatorismarked

with adirectionalarrowindicatingcorrectdirectionof gasflow.Ensurethe

applianceregulatoris installedwith the arrowpointingtoward the gas

manifoldentrance.Tightenthe applianceregulatorto 20 to 30 ft-tbs of

torque.

Nevertightento morethan35ft-lbsof torque.Alwaysusean

I IMPORTANT approved

pipejointcompoundresistantto the actionof LPgas.

Installthe appliancein itscountercutout.

Makethe gasconnectionto the inletof the appliancepressureregulator

with 1/2"malepipethreads.

This applianceis designedto operateat a pressureof 5 inchesofwater

columnon naturalgasor, if convertedfor usewith LPgas (propaneor

butane),10incheswatercolumn.Makesurethisapplianceis suppliedwith

andadjustedfor thetype ofgasforwhich itisdesigned.

Thisappliancewasadjustedatthefactoryforusewithnaturalgas.If,atany

time,this applianceis to be usedwitha differenttypeof gas,all of the

conversionadjustmentsdescribedon pages5 and7 mustbe madeby a

qualifiedservicetechnicianbeforeattemptingto operatethe cooktopon

thatgas.Naturalgasshouldbesuppliedtotheappliancepressureregulator

atalinepressurebetween6and14inchesofwatercolumnor,ifconverted

for LPgas,between11and 14inches.

WARNING: If the line pressuresupplyingthe appliancepressure

regulatorexceeds14"W.C. (anygas),anexternalregulatormustbe

installedinthegaslineaheadof theapplianceregulatorto reducetheI

pressureto no morethan 14" W.C. Failureto do this can resultin

mafunctonanddamagetothe app ance.

Insurethisapplianceisadjustedforthetypeof gassuppliedto itandthat

the gas supplypressureto the applianceregulatoris within the proper

pressurerange.

• Ifthis is a 36" wide model,or if it is a 30" wide modeland no other

applianceis to be installed in the cabinetrybelow it, proceedas

instructedunderparagraphI.

• Ifthis is a 30"wide modelanda Jenn-AirModelW30XXXorW131

ElectricWall Ovenis to be installedin cabinetrybelow,proceedas

instructedunderparagraph11.

• Donotremoveprotectivecapfrompipestubatmanifoldentranceuntil

readyto joingassupplypipingto appliance.

NOTE:In Canada,gasutilizationcodesprohibituseof streetelbows.Use

standardpipeelbowsand make modificationsto these instructionsas

necessary.

Installa manualshut-offvalvein an accessiblelocationin the gasline

aheadof theappliancepressureregulatorandexternaltothisappliancefor

the purposeofturningonor shuttingoffgastotheappliance.

Makeadditionalpipeconnectionsasnecessaryaheadoftheshut-offvalve

to thegas supplysource.Assureallpipejointconnectionsaregastight.

IMPORTANT

Applya non-corrosiveleakdetectionfluidto alljointsandfittingsinthe

gasconnectionbetweenthe supplylineshut-offvalveand the range.

Includegasfittingsandjointsintherangeifconnectionsweredisturbed

duringinstallation.Checkforleaks!Bubblesappearingaroundfittings

andconnectionswillindicatealeak.Ifaleakappears,turnoffsupplyline

gasshut-offvalve,tightenconnections,turnonthesupplylinegasshut

offvalve,and retestfor leaks.Nevertestfor gas leakswith an open

flame.

ILLUSTRATIVEGAS SUPPLYPIPING

BURNER BOX

i (NO OTHER APPLIANCE BELOW COOK'TOP)

(REAROF APPLIANCE)

U MANIFOLDENTRANCE

APPLIANCEPRESSURE

i REGULATOR

I

I

1/2 N.P.T.

ALL PIPEJOINTS

I

MANUAL

SHUTOFF

VALVE

!1---_ _

ELBOW

FIGURE3

TOGAS

INLET

Page 4

2. IFTHISISA 30"WIDE COOKTOPAND AJENN-AIR,MODEL

W30XXXORW131,ELECTRICWALLOVENISTOBE INSTALLED

BELOWTHISCOOKTOP.

NOTE1:Thisapplianceandits gasandelectricalsupplysourcesmustbe

installedbeforethe wallovenisinstalled.Seeillustration(ElectricalWiring

Information- page4;figure6)for recommendedelectricalsupplysource

locations.

NOTE2:Itmaybenecessarytoextendgassupplypipingforthisappliance

intoadjacentunder-countercabinetrywhen awallovenisinstalledbelow

thisappliance.

Joina 1/2" NPTpipeelbow(locallyavailable)to themalethreadsatthe

manifoldentrance.Whenjoined,causetheopenthreadsof the elbowto

facetowardtheleftsideoftheappliance.Installtheapplianceinitscounter

cutout.

Joina 1/2"NPTpipenippleto theelbowusinga pipesectionofsufficient

lengthto extend,horizontally,beyondthe left sideof the wall oven. (To

accomplishthisitmaybenecessaryto extendthepipesectionintoadjacent

cabinetry.)Join additional 1/2" NPT elbow(s) and pipe nipples, as

necessary,to accomplishthe following:

Join the outlet of the appliancepressureregulatorsuppliedwith this

applianceto the matethreadsof the newlyinstalledgassupplypiping.

Installtheapplianceregulatorina locationwhichwill beaccessiblebeside

or belowthewall oven.Insurethe applianceregulatorisinstalledwith its

directionalarrowpointinginthedirectionofgasflow.Tightentheappliance

regulatorto20to 30ft-tbsoftorque.

ILLUSTRATIVEGASSUPPLY PIPING

(WALLOVENINSTALLEDBELOW30" OOOKTOP)

/ BURNER BOX

.J _ (REAROF APPLIANCE)

MANIFOLD

f

PIPING PASSES THROUGH DIVIDING

• NIPPLES

(Lengths

I tosuit)

I I ALL PIPE JOINTS1/2 N.P.T.

I PRESSURE SHUTOFF

APPROXIMATE CROSS SECTION

_VALL BETWEEN ADJACENT CAB NETS

APPLIANCE MANUAL

REGULATOR VALVE

INLET

PROFILE OF WALL OVEN

FIGURE4

Nevertightento morethan35ft-tbsoftorque.Alwaysusean

pipejointcompoundresistantto theactionof LPgas.

IMPORTANT approved

Locateandjoinamanualshut-offvalveinanaccessiblelocationinthe gas

lineaheadoftheapplianceregulatorandexternalto theappliancefor the

purposeofturningonor shuttingoffgasto theappliance.

Makeadditionalpipeconnectionsasnecessaryaheadoftheshut-offvalve

tothegassupplysource.Assureallpipejointconnectionsaregastight.

IMPORTANT

Applya non-corrosiveleakdetectionfluidto all jointsandfittingsinthe

gasconnectionbetweenthesupply lineshut-offvalveandthe range.

Includegasfittingsandjointsintherangeif connectionsweredisturbed

duringinstallation.Checkforleaks!Bubblesappearingaroundfittings

andconnectionswiltindicatealeak.Ifaleakappears,turnoffsupplyline

gasshut-offvalve,tightenconnections,turnonthesupplylinegasshut

off valve,and retestfor leaks. Nevertest for gasleakswith an open

flame.

Note,regardingFigure4,above:

• Forconveniencein servicea groundjointunion (notshown: locally

available)shouldbeincludedin the pipingillustratedin figure4, ina

locationmostpracticalfortheinstallation.Generally,a practicallocation

isinthecabinetbelowthisappliance,nearthemanifoldentrance,rather

thaninanadjoiningcabinet.

• Ifthe alternativepipingmethodshownin figure5 is selectedfor the

installation,no groundjoint unionis required.(Theflexibleappliance

connectorillustratedprovidestheunionjointsnecessaryforservicing.)

Whena dividingwall is presentand a flexibleconnectoris usedit is

recommendedfor convenience,in both installationand service,the

flexibleconnector,itself, passthroughthe dividingwall. Any flexible

connectorusedwiththis appliancemustsatisfyall requirements

statedin the text accompanyingfigure 5.

Page 5

ALTERNATIVEPIPING METHODSTO CONNECT

APPLIANCETO GAS SUPPLY

A TRAINEDSERVICEMANOR GASAPPLIANCEINSTALLERMUST

MAKETHEGASSUPPLYCONNECTION.Leaktestingofthe appliance

shall be conductedby the installeraccordingto the instructions

given.

Unlessprohibitedbylocalcodesorordinances,a newA.G.A.- Certified,

flexiblemetalapplianceconnectormaybeusedto connectthisappliance

to itsgassupply.Theconnectormusthavean internaldiameternotless

thannominal1/2"NPTpipeandbenomorethan5feet inlength.A 1/2"

NPT x 1/2" flare union adapteris requiredat each end of the flexible

connector.If a flexibleconnectoris usedassurethat boththe appliance

pressureregulatorandmanualshut-offvalveare joined solidlyto other

permanenthardpiping(eithergassupplyortheappliancemanifold)soas

to bephysicallystationary.Seeillustrationsbelow:

ILLUSTRATIVEALTERNATIVEPIPING

CAUTION:Donotattemptto attachthe flexibleconnectordirectlyto an

externalpipethread.Connectionrequiresflareunionadapters.

IMPORTANT

Applya non-corrosiveleakdetectionfluidto alljointsandfittingsinthe

gasconnectionbetweenthe supplylineshut-offvalveand the range.

Includegasfittingsandjointsintherangeifconnectionsweredisturbed

duringinstallation.Checkforleaks!Bubblesappearingaroundfittings

andconnectionswillindicatealeak.Ifaleakappears,turnoffsupplyline

gasshut-offvalve,tightenconnections,turnonthesupplylinegasshut

offvalve,and retestfor leaks.Nevertestfor gas leakswith an open

flame.

PRESSURETESTING

The appliancemustbe isolatedfrom the gas supplypiping systemby

closingits individualmanualshut-offvalveduringanypressuretestingof

the gassupplypipingsystemattest pressuresequalto or lessthan1/2

PSIG(3.5kPa).

This appliance, as well as its individual shut-off valve, must be

disconnectedfrom the gas supply piping systemduring any pressure

testingofthesystemat testpressuresinexcessof1/2 PSIG(3.5kPa).

When checkingapplianceregulatorfunction,make certainpressureof

naturalgas supply is between6 and 14 inchesof water columnor, if

convertedfor LPgas,between11and 14inches.

I

_ -'<1- Rare

NO APPLIANCE

MOUNTED BELOW

THIS COOKTOP

WALL OVEN MOUNTED

IN CABINETRY BELOW

Union

Adaptor

I

Valve

!

.,_._ " Ngr Pipe

(Stationary

supplypips)

THIS COOKTOP

FIGURE5

I

I_ _=l-- Flare

Union

Adaptor

I

-,91--- ppliancePressu

Regulator,suppli_

(Observe

directionality

of6as Flow)

I

Nipple

I

Valve

I

1-- " NPTPipe

(Stationary

supplypipe)

Page 6

ELECTRICALWIRINGINFORMATION

Thisapplianceis equippedwithagroundedtypepowercord.Agrounded

outletmustbeprovided,ttisrecommended,forconvenience,theoutletbe

located(withreferencetofigure6)as inAorB,below:

A. Ifnootherapplianceisto beinstalledbelowthisappliance:withineither

theshadedareaorthe crosshatchedareashowninfigure6.

B. If a ModelW30XXXorW131 electricovenisto beinstalledbelowthis

appliance,either:

1. withinthecrosshatchedareaoffigure6, or,

2. withinanadjacentcabinet.

CABINET BO'i-rOM

FIGURE6

DimensionA:

W30XXX:5-1/2" (13.97cm)

W131:4" (10.16cm)

If awallovenisto beinstalledbelowthisapplianceandthecounterunit's

outletisto be mountedwithinthe crosshatchedareaoffigure6:

1. The cabinet'slower front panel, belowthe oven, must be made

removableforaccesstothe outlet.

2. A clearanceholefor the powercord's plug(1-1/4"(3.18cm) dia is

recommended)mustbeprovidedthroughtheoven'sfloorsupportshelf

and,ifnecessary,throughtheslatssupportingtheshelf.Theclearance

holeshouldbelocatedas nearas practicaltothe rearofthe shelfand

(iftheovenismodelW30XXX)asnearaspracticaltotheleftrearcorner.

3. WhenmodetW30XXXismountedbelowthisappliance,andifthepower

outletfor this applianceis to be locatedinthe crosshatchedarea of

figure 6, it is recommendedthe powercord be routed throughthe

externalverticalclearancechannelat the left rear of the oven.The

channel'scrosssectionisapproximately4.2" x 2.25" (10.7x5.7cm),

extendingthe full heightof the oven.(ModelW131providesasimilar,

butlarger,verticalchannelnearthecenterofthe mainbackoftheoven.)

If the outlet isto be mountedineither aleft or rightadjacentcabinet,a

clearancehole,asdescribedabove,mustbe providedinthedividingwall

betweenthe cabinets.Figure4; page 3, illustratesa typical (left side)

dividingwall.Theclearancehole(notshownin figure4)canbelocatedas

isconvenientinthisleftwall or inthecorrespondingrightwall.

In planningany installation,notethat the freelength of this appliance's

powercord,extendingbeyonda point3-3/4"(9.53cm)leftof thenominal

centerof therearwallof theburnerbox,whenviewedfromthe frontofthe

unit,isapproximately46" (117cm).

WARNING

ELECTRICALGROUNDING INSTRUCTIONS

THIS APPLIANCE IS EQUIPPED WITH A THREE PRONG

GROUNDINGPLUGFORYOUR PROTECTIONAGAINSTSHOCK

HAZARD AND SHOULD BE PLUGGED DIRECTLY INTO A

PROPERLY GROUNDED RECEPTACLE. DO NOT CUT OR

REMOVETHEGROUNDINGPRONGFROMTHISPLUG.

WARNING

THIS APPLIANCE MUST BE DISCONNECTED FROM ITSI

ELECTRICALSUPPLY AT THE WALL RECEPTACLEBEFORE

SERVC NGTHEAPPLANCE.

Page 7

CONVERTINGAPPLIANCE FOR USE

WITH LP GAS

WARNING

Propaneconversionistobe performedby aJENN-AIRAUTHORIZED

SERVICER (or other qualified agency) in accordance with the

manufacturer'sinstructionsand all codes and requirementsof the

authorityhavingjurisdiction.Failuretofollowinstructionscouldresultin

seriousinjuryor propertydamage,The qualifiedagencyperformingthis

workassumesresponsibilityforthisconversion.

WARNING

Electrical power and gas must be turned off prior to

conversion.

INSTALLATIONOF LP ORIFICESPUDS

4 BURNER MODEL (30"WIDE)

OO

This appliancewas adjustedat the factoryfor usewithnaturalgas.To

convertit forusewithLP gas(propaneor butane),eachof thefollowing

modificationsmustbeperformed:

A. Replaceallorificespuds

Step1: Removethegratesand burnerheads.

Step2: Removealuminumventuritube.

Step3: Trima smallpieceof maskingtapeto thesizeof a dimeand

affixit overthe endof a 5/16" nutdriver.

Step4: Firmlypressthenutdriverovertheorificespud(figure7)and

loosenspud byturningcounterclockwise.Carefully lift nut

driveroutofburnerthroat.Orificespudshouldbecapturedin

therecess.Repeatthisstepforeachburner.

REMOVALOF ORIFICESPUD

ALI_MH',IUM VENTURI _/_ 5,/16"NUT DRIVER

OO

FIGURE8

5 BURNER MODEL (36"WIDE)

©©©

O O

7" ICNITER

FIGURE7

Step5: LocatetheLPorificespudpackettapedtotheundersideofthe

burnerbox.Thespudshavesmall numbersstampedon the

side.This numbercodestheorifice diameterand its correct

burner location.Thefollowing illustrationsshow correctLP

orifice spud location for 4 burner and 5 burner models,

respectively.

A_T #9219 991-0

FIGURE9

Step6: With the maskingtapestill in placein the recessof the nut

driver,pressan LP orificespudinto the recesssothat it is

snuglycaptured.

Step7: Carefullyinstalltheorificespudintheappropriateburnerthroat

byturningclockwisetotighten.Tightentoatorqueof 15to20

inch-lbs,

Step8: Replacecylindricalaluminumventuritubes, Replaceburner

headsandgrates,Indexeachgratetoits burnerpan,

Step9: Savetheorificesremovedfromthe applianceforfutureuse.

Page 8

B. Invertcap inappliancepressureregulator

(Seefigures10and11.)

Withtheapplianceinstalled,theapplianceregulatorshouldbelocated

asshowninfigure3or4. Identifythetypeofapplianceregulatoronthe

unitandfollowtheinstructionsintheappropriateillustration.

CONVERSIONOF MAXITROL APPLIANCE

PRESSURE REGULATOR

APPLYDOWNWARD

FINGERPRESSURE

ATDISCEDGESTO

REPLACEPININ_1_

CONVERTER_ _ LP

_z,.A CAP I

NAT ! /-_'[_

NDPIN . J

.J

NAT IL_P

FINGERPRESSURE

APPLYSIDEWARD

FROMCAP

I_T0 REMOVEPIN

3. Inserta slender,thin-bladescrewdriverintotherecessatcenterof

valvestemandengagebladewithslot inadjustingscrew.

4. Turn centerstemadjustingscrewto setflamesize.

... clockwisetoreduce

... counterclockwiseto increase

5. Replacecontrolknobwhenadjustmentiscompleted.

Properadjustmentwill producea stable,steadyblueflame of minimum

size.Thefinaladjustmentshouldbecheckedbyturningknobfromhighto

lowseveraltimeswithoutextinguishingtheflame.

Thisadjustment,atlowsetting,willautomaticallyprovidetheproperflame

sizeat mediumsetting.

I

COUNTERCLOCKWISE

TO INCREASE FLAME

;IZE

CLOCKWISE

TO REDUCE

FLAME SIZE

1

FIGURE10

CONVERSIONOF HARPER-WYMAN APPLIANCE

PRESSURE REGULATOR

i

O

NaturalSetting

FIGURE11

C. LowFlameAdjustment

(Seefigure12.)

This applianceis shippedfromthefactorywith lowandmediumflame

settingsadjustedfor use with naturalgas. If furtheradjustmentis

necessary,orto readjustfor usewith LP,proceedas follows:

LPSetting

VALVE

STEM

FIGURE12

After ConversionStepsA, B and C have been completed,checkthe

appearanceof eachburner'sflameattheHiandLosettingsagainstfigure

13.Ifthe flamesappeartoo largeortoo small,revieweach stepto make

sureitwascompletedcorrectly.

FLAMEAPPEARANCE ATHIAND LO

Mad

LO_ HI

LO_ HI

Off

1. Lightburnerandsetcontrolknowfor lowflame.

2. Removecontrolknobfromvalvestem.

CAUTION:NEVERUSEA METALBLADETOPRYKNOBOFF.IF

KNOBCANNOTBEEASILYREMOVED,TUCKTHEFOLDSOFA

CLOTHDISHTOWELUNDERTHEKNOBANDPULLTHETOWEL

UPWARDWITHSTEADY,EVENPRESSURE.

Mad

LO_ HI

011

FIGURE13

Page 9

TO CONVERTAPPLIANCE FOR USE WITH

NATURALGAS

INSTALLATIONOF NATURALGAS

ORIFICESPUDS

WARNING

Electrical power and gas must be turnedoff prior to

conversion.

If this appliancehas been convertedfor use with LP gas, eachof the

following modificationsmust be performedto convertthe unit back to

naturalgas.

A. Replaceallorificespuds

PerformSteps 1through4on page5.

ForStep5:Locatethecoloredbrassnaturalgasorificespudsthatwere

originallyinstalledinthisappliancebeforeitsconversionfor usewithLP

gas.Observethecolorofeachofthespudsandnotethecorrectburner

locationfor eachspudasshowninfigures14and15.

CompleteSteps6through9 on page5 to completethe installationof

naturalgasmainspudsintheircorrectlocations.

Savethe orificesremovedfromthe applianceforfutureuse.Theywill

beneededifthis applianceisagainconvertedforusewithLPgas.

B. Invertcapin appliancepressureregulator.

(Seefigures10and11.)

With theapplianceinstalledtheapplianceregulatorshouldbelocated

as shownin eitherfigure 3 or figure 4 (page3). Identifythe type of

applianceregulatorand follow the instructionsin the appropriate

illustration.

4 BURNER MODEL (30"

OO

QO

FIGURE14

5 BURNER MODEL (36" WIDE)

C. Adjustlowflameas instructedon page6itemC.

AfterStepsA,BandChavebeencompleted,checktheappearanceof

eachburner'sflameat theHi andLosettingsagainstfigure13.tf the

flames appear too large or too small, make sure all steps were

completedcorrectly.

OO

O O

FIGURE15

)

Page 10

BURNERIGNITIONAND AUTO-REIGNITION

This applianceis equippedfor electronicauto-reignitionby meansof a

sparkigniterlocatedatthe rearofeachburner.The burnersaredesigned

tolightatanyvalverotationthatadmitssufficientgasflowtosupportaflame

andto automaticallyretightfollowingalossofflamedueto adraftorother

adversecondition.Thisfeatureisprovidedas a convenienceandis not

intendedas asafetyfeature.

CAUTION:Neverusea metalbladeto pryoff a controlknob.tf a knob

cannotbeeasilyremovedtuckthe folds of a clothdishtowelunderand

aroundtheknobandpullthe towelupwardwith steadyevenpressure.

CAUTION:Nevercovercontrolknobsorsurroundingcontrolsurfacewith

utensils,towels,orotherobjects.Neverobstructfreeairpassagepastthe

controlknobs.The knobopeningshavebeensizedto properlycontrolair

entrytotheinterioroftheapplianceduringoperation.

This appliance has no air shutters. Primary air adjustments are

unnecessary.Theburnersaredesignedtoprovideoptimumaerationforall

gases without air shutters. When operatingproperly,burners should

produceclearlydefined,evenblueflames.Iftheflameshaveyellowtipsor

arehazyandotherwiseappearto haveinsufficientair,obtaintheservices

ofa qualifiedservicetechnician.

Specifiedinputratesareasshowninfigures16and 17,below.

4 BURNER MODEL

TOP GRATEREPLACEMENT

Thetopgratesonthiscooktophaveundersideprojectionlugsdesignedto

nestin matchingdepressionsinthespillovertrays.Duringgrateplacement

alwayspositiongratestomakethisengagement.Correctindexingof grates

aboveburnerportswill preservethe grates'appearanceandhelpassure

longlife.

DETENT

WITH

INDENTATION

REQUIREDADJUSTMENTSAT TIME

OF INSTALLATION

Theinstallationofthis appliancemustconformwithlocalcodes,orinthe

absenceof localcodes,with the latesteditionof the NationalFuelGas

Code ANSI Z223.1 USA or currentCAN!CGA-B149INSTALLATION

CODE.

BURNER

LOCATION

RightFront

RightRear

LeftFront

LeftRear

BURNER

LOCATION

RightFront

RightRear

Center

LeftFront

LeftRear

FIGURE16

INPUTRATES- NATURALGAS(BTU/HR)

Hi Lo

12,000 1,500

9,100 1,050

6,500 830

10,500 1,500

5 BURNER MODEL

FIGURE17

INPUTRATES- NATURALGAS(BTU/HR)

Hi Lo

12,000 1,500

9,100 1,050

6,500 830

9,100 1,050

10,500 1,500

D Thisappliancewasmanufacturedfor usewithNaturalGas.If LPgas

isthefuelofchoice,followtheconversionto LPprocedurefoundinthe

installationinstructions.

D Testall externalconnectionsfor gasleaks.Nevertest forgas leaks

withanopenflame.

D Testallelectricalconnections.

10

Loading...

Loading...