Page 1

JBL PERFORMANCE™SERIES

P81

P941

HIGH-PERFORMANCE

IN-WALL LOUDSPEAKERS

OWNER’S GUIDE

Page 2

81/P941 IN-WALL

P

OUDSPEAKERS

L

OCUMENTATION

D

ONVENTIONS

C

3 Documentation Conventions

Introduction

4

4 Highlights

4 Product Registration

Unpacking

5

6 Loudspeaker Overview

6 Driver Complement

7 Filter Network

Input Panel

7

8 Installation Considerations

8 Loudspeaker Placement

Installation Instructions

9

11 Making Connections

12 Optimizing Performance

13 Loudspeaker Volume

14 Specifications

14 Dimensions

14 Obtaining Service

15 Index

This document contains general safety,

nstallation, and operation instructions

i

or the JBL

f

®

erformance

P

™

eries P81

S

and P941 In-Wall Loudspeakers. It is

important to read this document before

attempting to use your loudspeakers.

ay particular attention to safety

P

instructions.

WARNING

Calls attention to a procedure, practice,

ondition, or the like that, if not correctly

c

performed or adhered to, could result

in injury or death.

CAUTION

Calls attention to a procedure, practice,

condition, or the like that, if not correctly

performed or adhered to, could result

in damage to or destruction of part or

all of the product.

NOTE

Calls attention to information that is

essential to highlight.

®

3

Page 3

NTRODUCTION

I

Thank you for purchasing the JBL

erformance Series P81/P941 In-Wall

P

oudspeakers. Designed for discerning

L

audiophiles, the P81 and P941 offer versatile, easily integrated in-wall loudspeakers that provide the superior,

ncolored sound that is the hallmark of

u

JBL loudspeakers. The P81 and P941

reproduce realistic, accurate signals

with minimal coloration and distortion,

making them perfect complements to

BL Performance front speakers in

J

multichannel setups. Proprietary transducers, sophisticated filter networks,

and user-adjustable compensation controls allow the P81/P941 to achieve

remarkable sound quality and performance befitting the most demanding

home entertainment systems.

The P81 and P941 are also perfectly

suited as front and surround speakers

in complete in-wall setups, or as stereo

pairs in secondary listening spaces, or

for integration with flat-screen television home theater installations. Unlike

freestanding loudspeakers, the P81 and

P941 speakers occupy no space in living areas and will not detract from the

décor of the listening room. They are

easily mounted in either pre-existing or

new construction projects.

A critical aspect of loudspeaker design,

transducers convert electrical signals

into audible sounds, profoundly affecting

speaker performance. Combining superior form and function, the P81 and P941

transducers feature a distinctive design

that allows for smoother frequency

response. The cones are constructed

with Organic Ceramic Composite cone

material to reduce dis

spiders are constructed

®

Nomex

blend with optimized geometry

tortion, while the

of a high-strength

for increased linearity.

A two-way design, the P81 transducers

effectively cover a broad range of frequencies. A 7-1/2-inch (191mm) woofer

delivers highly refined and dynamically

authoritative low frequencies down to

the very lowest octaves. Also, a 1-inch

(25mm) titanium-dome tweeter repro

duces high frequencies well above

audible levels, with wide dispersion for

open, airy treble.

A three-way design, the P941, in addi

tion to its 9-inch (229mm) woofer and

1-inch (25mm) tweeter

, also features

a 3-1/2-inch (89mm) midrange, which

handles critical mid-band frequencies

ith natural tonal balance over a wide

w

perating range.

o

An advanced midrange (P941 only)

motor structure includes two high-

rade neodymium magnets placed

g

t the center of the motor structure,

a

inside the voice coil, for improved

magnetic shielding. Inside the motor, a

black-plated steel-shield cup facilitates

eat dissipation for higher power han-

h

dling. An integrated aluminum fluxstabilization ring minimizes modulation

inside the motor’s static gap flux field,

reatly reducing distortion. A copper ring

g

inside the motor’s gap reduces distortion

even further. Both rings are optimally

sized and placed to maintain constant

linear voice coil inductance with

forward and backward motions.

The P81 has a high-order filter at

2.8kHz. In the P941, high-order filters at

300Hz and 2kHz optimize loudspeaker

on- and off-axis response, helping

to ensure smooth octave-to-octave

balance and timbral accuracy. The P81

and P941 feature gold-plated binding

posts that accommodate two connection methods, while separate HighFrequency Tilt, Low-Frequency Boundary

Compensation, High-Frequency Level

and Listener Axis controls compensate

for less-than-ideal listening room

acoustics and loudspeaker placement.

For more than 50 years, JBL has stood

at the forefront of loudspeaker design.

With extensive research and design

facilities, the JBL Performance Series

P81 and P941 loudspeakers benefit

from cutting-edge tools such as a multichannel listening lab for double-blind

listening tests; a laser interferometer

for detailed driver analysis; real ane

choic chambers for precise tests and

measurements; finite element analysis

for advanced loudspeaker modeling;

and a stereo lithography apparatus for

design verification.

Adding to the proud lineage of JBL’s

Performance Series loudspeakers, the

P81 and P941 further advance JBL

’s

reputation as the leading designer

and manufacturer of high-quality,

high-performance loudspeakers.

P81/P941 HIGHLIGHTS

n Exceptional accuracy

n Proprietary 7-1/2-inch (191mm)/9-inch

229mm) Organic Ceramic Composite

(

woofer

n Proprietary 3-1/2-inch (89mm)

rganic Ceramic Composite

O

midrange (P941 only)

roprietary 1-inch (25mm) titanium-

n P

dome tweeter

n High output with low distortion

n Gold-plated binding posts

igh-Frequency Level control

n H

n High-Frequency Tilt control

n Low-Frequency Boundary

Compensation control

n Listener Axis control

n Advanced woofer and midrange

(P941 only) motor structure

n Large voice coils for wide dynamic

range without compression

n Wall-mounting frame which features

spring-loaded clamps to securely

anchor loudspeaker into wall opening

n Optional rough-in bracket for stud-

mounting prior to drywall installation

(not included)

PRODUCT REGISTRA

Please register the P81/P941 as soon

as possible after purchase. To do so,

register online at www.jbl.com. The

product registration serves no warranty

purposes. Retain the original, dated

sales receipt as proof of warranty

coverage.

TION

4

Page 4

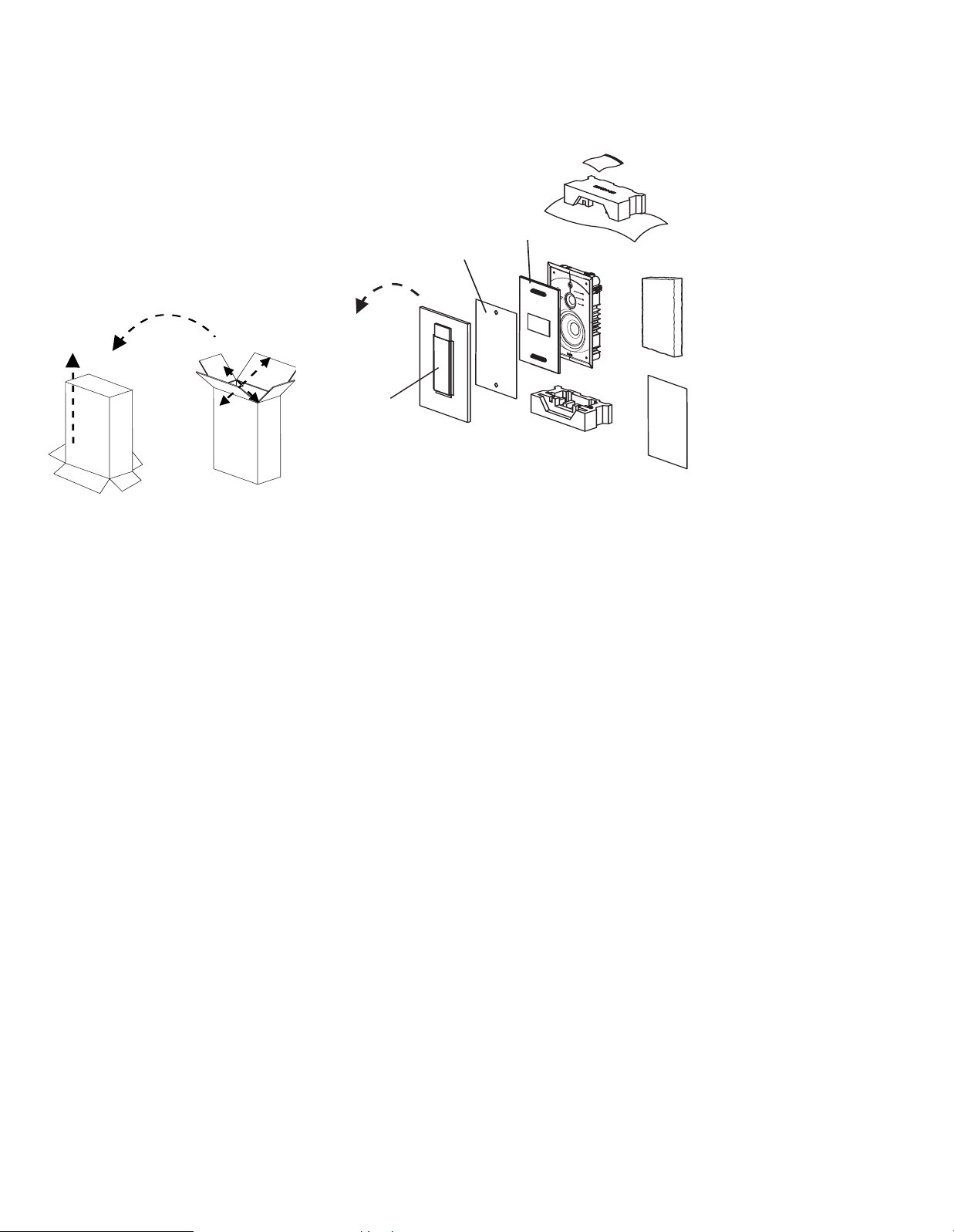

NPACKING

Top Pad

Bottom Pad

Frame

Alignment Tool

Paint Mask

Protective

Cloth

Grille

Allen Keys/Spacer Shim

Fiberglass

Insulation

Wall Template

Replacement

Scrim Cloth

Figure 2: Packing Materials

F

igure 1: Unpacking the P81/P941

¡

™

£

U

The P81 and P941 require special care

nd handling during unpacking. Pay

a

articular attention to the precautions

p

that appear in this section and to other

precautions that appear throughout this

owner’s manual.

hen unpacking, save all packing

W

materials for possible future shipping

needs. Refer to the Obtaining Service

section on page 14 for additional

nformation.

i

Figure 1: Unpacking the P81/P941

Figure 2: Packing Materials

To Unpack the P81 and P941:

1. Place the packing carton in the

upright position and fully open the top

flaps, as shown in Step 1 of Figure 1.

2. Without allowing the top flaps to

close, move the outer packing carton

into an inverted position, as shown in

Step 2 of Figure 1.

3. Lift the packing carton off of the

loudspeaker, as shown in Step 3

of Figure 1. Use caution to avoid

damaging the loudspeaker or frame

clamps. At this point, the loudspeaker

will be upside-down.

4. Remove the bottom pad, and then

remove the frame alignment tool

and grille from the grille filler

items are identified in Figure 2.

5. Set aside the wall template, paint

mask, fiberglass insulation, spacer

shim, replacement scrim cloth and

Allen keys.

6. Invert speaker so it is in the upright

position.

When the P81/P941 is in the upright

7.

position, remove the top pad.

8. Leave the loudspeaker upright in the

bottom pad until ready to install.

. These

5

Page 5

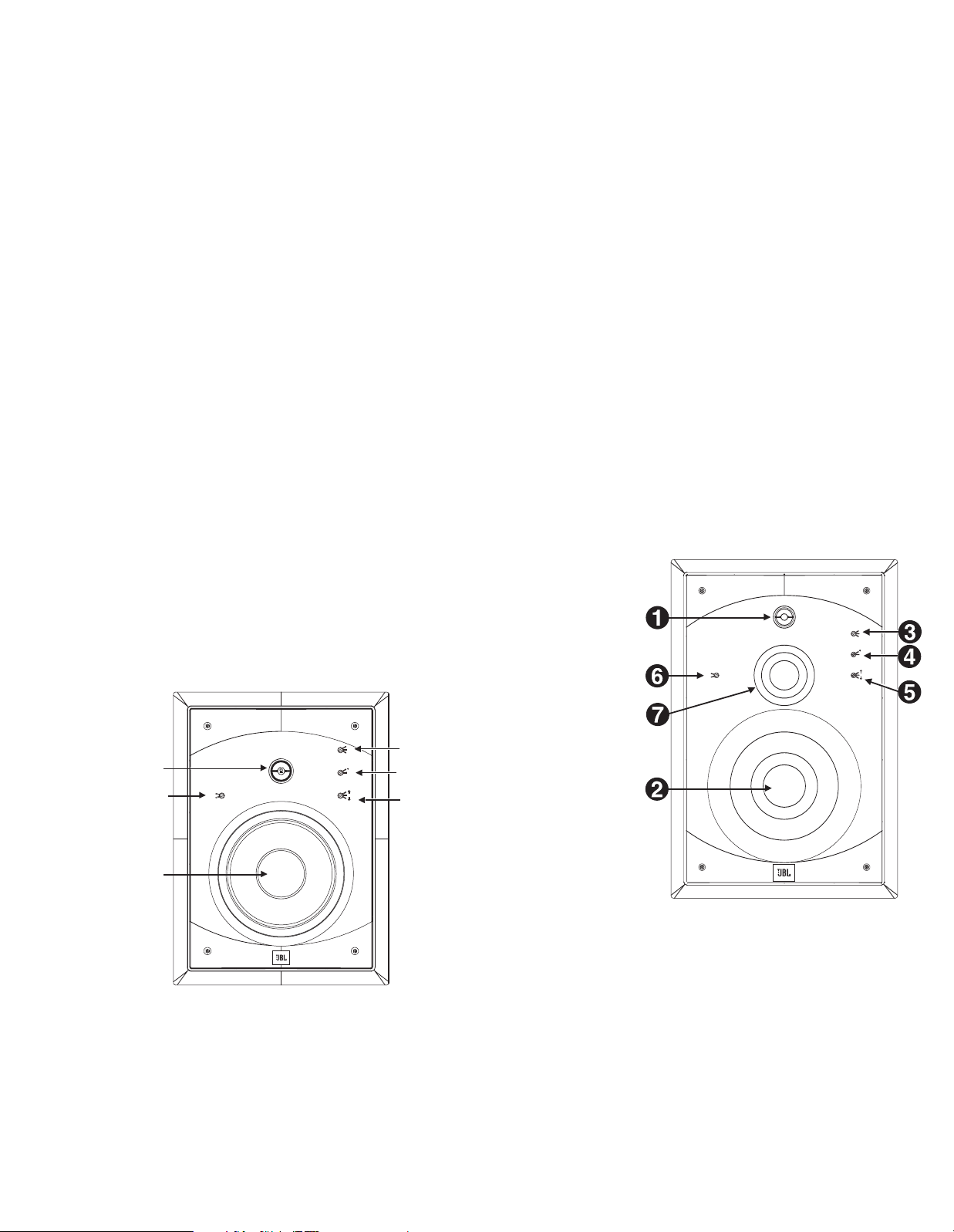

OUDSPEAKER OVERVIEW

¡

™

£

¢

∞

§

Figure 3: P81 Speaker (Front View)

on

off

Low Frequency

Boundary

Compensation

High Frequency Level (dB)

Listener Axis

High Frequency Tilt

on axis

0

+1

0

–1

Figure 4: P941 Speaker (Front View)

on

o

ff

Low Frequency

Boundary

Compensation

High Frequency Level (dB)

L

istener Axis

H

igh Frequency Tilt

o

n axis

0

+1

0

–1

L

P81/P941 DRIVER COMPLEMENT

he numbers in Figure 3 correspond to

T

the numbered items in this section.

1. Tweeter

1-inch (25mm) titanium dome

•

Underhung with copper-clad alu-

•

minum wire for low distortion

Ferrofluid for high-power handling

•

with reduced compression

2. Woofer

7-1/2-inch (191mm)/9-inch (229mm)

•

cones constructed with Organic

Ceramic Composite cone material for

low distortion

rue pistonic operation for increased

T

•

freedom from coloration

Symmetrical Field Geometry (SFG™)

•

design for low overall distortion

Aluminum ring for flux stabilization

•

greatly reduces distortion at low frequencies

Butyl rubber surround for large, linear

•

excursion capabilities

Carbon composite aluminum (CCA)

•

flatwire voice coil wound on a 1-1/2inch (38mm) fiberglass bobbin for low

mass and higher power handling

Vented center pole for improved heat

•

dissipation and low compression

The numbers in Figure 3 correspond to the

numbered items in the Driver Complement

section.

Figure 3: P81 Speaker (Front View)

6

3. High-Frequency Level (dB) Control

rovides a shift in the output level of

P

the tweeter or overall high-frequency

response (active above approximately

2.5kHz). The options are –1dB, 0dB

nd +1dB.

a

4. High-Frequency Tilt Control

Adds a ”tilt“ to the high-frequency

esponse. The tilt will become active

r

above approximately 8kHz (depart

from nominally flat response) and will

increase to 3dB – 4dB at 20kHz. This

will offer an improved high-frequency

response for installations where the

primary listening position is located

significantly off the tweeter axis (for an

effect almost like adding ”toe in“ towards

the listening position). The added

highfrequency contour helps to offset perceived reduction of high-frequency

response for off-axis listeners due to

the increase in directivity of the system

(tweeter beaming) above 8kHz.

5. Listener Axis Control

inverted speaker installations. Refer to

he Notes on page 9 and the Optimizing

t

erformance (page 12) section for addi-

P

tional information.

6. Low-Frequency Boundary

ompensation Control

C

Compensates for less-than-ideal

speaker placement near adjacent walls

or boundaries.

Select the “off” setting if the speaker

•

is mounted at least 4 feet away from

adjacent walls or boundaries.

elect the “on” position if the

S

•

speaker is less than 4 feet from one

(or possibly two) or more adjacent

walls or boundaries. In the ”on“

position, system output is reduced

below approximately 400Hz to offset

the increased low-frequency support,

due to the boundary.

NOTE: Refer to the Optimizing

Performance section on page 12 for

more information about the front-panel

controls.

All loudspeakers sound best when the

listener is positioned at optimal angles

relative to the speaker placement. This

is a fixed angle for most loudspeakers,

but the P81 and P941 provide compensation for much greater placement

flexibility. The listener axis control,

used in conjunction with the placement

of the speaker, can obtain excellent

results in a very wide range of circumstances. This control optimizes system

response for installations in which the

listening positions are lower than,

higher than, or directly level with the

tweeter. This switch will be active

in the network transition regions

between the woofer and tweeter

(in the P81) and the midrange and

tweeter (in the P941).

Select the “high” (up arrow) setting

•

if the speaker is mounted so that the

listener is at tweeter level or above.

Select the “on axis” setting if the

•

listener position is located directly

on axis with the tweeter level.

Select the “low” (down arrow) set-

•

ting if the speaker is mounted so that

the listener is below tweeter level.

NOTE: In some circumstances, such

as when the speaker is to be mounted

high on the wall towards the ceiling, it

may be desired to invert the speaker in

order to place the tweeter axis closer

to the listener’s ear level. The Listener

Axis Control will also optimize these

The numbers in Figure 4 correspond to the

numbered items in the Driver Complement

section.

Figure 4: P941 Speaker (Front View)

7. Midrange (P941 Only)

3-1/2-inch (89mm) cone constructed

•

with Organic Ceramic Composite

material

Die-cast basket to eliminate col-

•

oration from resonances

True pistonic operation for increased

•

freedom from coloration

Page 6

Two high-grade neodymium magnets

P81

P941

Figure 5: Rear of P81/P941

•

laced inside the voice coils for opti-

p

al magnetic shielding

m

Symmetrical Field Geometry (SFG™)

•

design for low overall distortion

1-1/2-inch (38mm) voice coil wound

•

on a fiberglass bobbin for high-power

handling and low distortion

Copper cap stabilizes inductance and

•

controls flux modulation, dramatically

reducing distortion

Optimized and shielded magnetic cir-

•

cuits to minimize harmonic distortion

and prevent video monitor interference

FILTER NETWORK

Optimizes loudspeaker on- and off-axis

response with a high-order filter at

2.8kHz for the P81, and high-order

filters at 300Hz and 2kHz for the P941,

helping to ensure smooth octave-tooctave balance and timbral accuracy.

Gold-plated binding posts accommodate heavy speaker cables, while

separate Low-Frequency Boundary

Compensation, High-Frequency Level,

High-Frequency Tilt and Listener Axis

controls provide precise balance to

compensate for less-than-ideal listening room acoustics and loudspeaker

placement.

INPUT PANEL

umber 1 in Figure 5 corresponds to

N

the numbered item below.

1. Input Connectors

Provide input connections from the

associated power amplifier/receiver(s).

One positive (+) gold-plated binding

ost and one negative (–) gold-plated

p

binding post are available. Refer to

the Making Connections section on

page 11 for additional information.

Figure 5: Rear of P81 and P941

7

Page 7

Front

Right

TV

Front

Left

Left

Surround

Right

Surround

Subwoofer

(optional)

Primary Listening Position

Couch

Figure 7:

Figure 6:

Two Channel Placement

Left

Channel

Right

Channel

Primary Listening Position

(Couch)

I

Front

Right

TV

Front

Left

Left

Side

Surround

Right

Side

Surround

Left

Back Surround

Right

Back Surround

Couch

6.1/7.1-Channel System

Loudspeaker fidelity depends on the

f

•

•

•

Advanced JBL design features allow the

P81 and P941 to achieve exceptional

a

placement and listening room acoustics

have a significant impact on the performance of the P81 and P941.

C

•

•

LOUDSPEAKER PLACEMENT

The P81 and P941 are designed to offer

excellent performance in any listening

room or home theater system. Abide by

the following placement suggestions

for optimal results.

2-Channel or Front Left and Front Right

in a Home Theater System

The bulleted items that begin below

indicate important loudspeaker placement considerations for 2-channel or

front left and right installations.

•

•

•

NSTALLATION CONSIDERATIONS

ollowing three factors:

Loudspeaker accuracy

Loudspeaker placement

Listening room acoustics

coustical precision. However, proper

AUTION:

The P81 and P941 should be installed

by a professional.

Installers must adhere to local building codes to ensure a proper installation. JBL is not responsible for any

possible damages caused by improper

installation.

The speakers should be equidistant

from the primary listening position

and placed at least 4 feet away from

the side walls.

It is recommended that the angle

formed between the speakers and the

listening area be between 45° and 60.°

For example, if the speakers are 8

feet apart, the listening position

should be 8 to 12 feet from each

. Refer to Figure 6.

speaker

When used as part of a home theater

system, excellent results can also be

obtained when the speakers must be

placed further apart due to a screen.

Figure 6: 2-Channel Placement

Surround Channels in a Home Theater

System

The bulleted items that begin below

indicate important loudspeaker placement considerations for surround channel installations for home theaters.

When used as part of a 5.1-channel

•

music or home theater system, the

surround speakers should be placed

slightly behind the primary listening

position. Refer to Figure 7.

If there are several rows of seating,

•

place the speakers perpendicular

to, or slightly behind, the last row of

seating.

When used as part of a 6.1/7.1-

•

channel music or home theater system, place the side speakers at the

sides of the main listening position.

If there are several rows of seating,

•

place the speakers perpendicular to

the middle row of seating.

Figure 8: Surround Channels

6.1/7.1-Channel System

The back surround speakers should

•

be placed along the rear wall facing

the front of the room. Each side

surround speaker should be about

one-third of the way forward of the

rear wall, as shown in Figure 8.

8

Figure 7: Surround Channels

(5.1-Channel System)

Page 8

Baffle

Mounting Frame

Carpenter's Level

Utility Knife

Figure 10: Cut wall opening

Place Woofer

a

t 1/3 the

height of

Stud Bay

1/3 the height

of Stud Bay

(measured

from the

Fire Block)

1/3 the height

of Stud Bay

(measured

from the

Fire Block)

Fire Block

1/3 of

Height

1/3 of

Height

1/3 of

Height

C

BA

F

igure 11: Ideal Height of Woofer

At least

1-inch

At least

1-inch

Figure 9: Use wall template

NSTALLATION INSTRUCTIONS

I

For installations in new construction

rojects, use the JBL P81/P941 In-Wall

p

ough-In Bracket, which should be

R

installed by a professional. Refer to the

JBL P81/P941 In-Wall Rough-In Bracket

Installation Instructions for more infor-

ation.

m

The JBL P81 and P941 in-wall speakers

were designed to be easily installed

into existing walls. It is recommended

hat they be professionally installed.

t

The following tools are required for

installation:

4) Allen-head screws (included)

(

•

5/32-inch Allen key (included)

•

1/16-inch Allen key (included)

•

cardboard installation template

•

(included)

pencil

•

Phillips-head screwdriver

•

measuring tape

•

utility knife

•

carpenter’s level

•

flat-blade screwdriver

•

stud finder

•

To Install the P81/P941:

1. Locate the wall studs.

2. Use the supplied template to trace an

outline to mark the desired location

to mount the speaker system. Use

caution to cut the hole approximately

centered between wall studs, allowing at least 1 inch between the

cutout and wall studs, as shown in

Figure 9. Use a carpenter’s level to

ensure a level measurement.

NOTES:

he height of the woofer within the

T

•

stud bay relative to the entire height

of the bay is critical because of

standing waves within the cavity.

Before installation, determine the

•

height of the cavity. (There might be a

fire block that makes it shorter than

the entire height from the floor to the

eiling.) Avoid placing the woofer at

c

the very top or bottom of the stud bay,

as this would cause a serious cancellation of low frequency output.

The ideal location for the woofer

•

(whether the speaker is mounted

upright or inverted) is at the one-third

distance point, as shown in example

of Figure 10. If that is not feasible,

A

then two-fifths, or one-fifth of the

height are the next best alternatives.

The least desirable position to place

the woofer is at one-half or onefourth of the height. If a fire block

is completely dividing the bay, the

measurement would be from the fire

block – not the floor or ceiling – as

shown in example B of Figure 10.

Example C shows an inverted speaker

placement.

3. With a utility knife, cut the wall

pening, as shown in Figure 11.

o

Use caution not to cut into any

•

electrical wiring or plumbing. Run

the wiring from your system to the

ole. (Be sure to comply with local

h

iring codes.)

w

The measurements of the open-

•

ing(s) required to mount the JBL

n-wall frames are listed below:

i

JBL P81

•

Width: 10-1/2 inches (267mm)

Height: 14-7/8 inches (378mm)

JBL P941

•

Width: 12-1/2 inches (318mm)

Height: 19-1/8 inches (486mm)

4. The speakers are shipped with the

baffle assembly attached to the

mounting frame at its four corners.

Unscrew the four screws and carefully lift the baffle assembly out of

the mounting frame, as shown in

Figure 12.

Figure 9: Use W

all T

emplate

Figure 10: Ideal Height of Woofer

Figure 11: Cut Wall Opening

Figure 12: Remove Baffle From

Mounting Frame

5. (Optional) It is recommended that the

frame be painted before it is mounted.

For instructions on painting the frame

and grille, refer to page 12.

6. The mounting frame has spring-

loaded clamps around its perimeter,

which are designed to fold shut as

the mounting frame is placed into the

wall opening and spring open once

inside, anchoring the mounting frame

in the wall opening. See Figures 13

and 14. Loosen all clamp screws until

the clamps are fully extended.

9

Page 9

7. Be sure to run the speaker wire in

F

igure 17:

Tighten Allen screws with Allen key wrench

Mounting Frame

Clamp

Frame

Alignment

T

o ol

Figure 15:

Frame Alignment Tool

A

C

lamp

Screw

B

C

Insert frame into

wall opening

Wall

Figure 14:

Clamp Mechanism

Note how the clamp

springs open

CLAMP

F

igure 13: Clamp Closeup

Figure 16: Install the Insulation and Baffle

Baffle

Assembly

Thread Speaker Wires

Fiberglass Insulation

Allen Head

Screws

hrough the rear opening before

t

einstalling the baffle assembly.

r

8. Insert the mounting frame into the

cutout until the clamps snap into

lace.

p

14. Make speaker wire connections.

efer to the Making Connections

R

ection on page 11 for instructions.

s

15. Slide the baffle into place in the

mounting frame.

Figure 13: Clamp Close-Up

Figure 15: Frame Alignment Tool

9. Insert the frame alignment tool

horizontally into the center of the

frame. This tool functions as a

frame spreader, while the clamps

are being tightened, as shown in

Figure 15.

10. Starting from the lower right corner

and working in a diagonal torque

sequence, use a power screwdriver

to tighten each of the clamp screws

(only until almost snug). If needed,

adjust the mounting frame so it is

level and centered in the cutout.

11. Perform a final torque sequence.

Hand-tighten frame screws and

check each screw at least twice to

make sure they are fully tightened

to prevent rattles.

12. Remove the frame alignment tool.

Place the included fiberglass insula-

13.

tion in the back of the mounting

frame, as shown in Figure 16. Cut an

“x” into the insulation and thread

the wire(s) through.

Figure 17: Tighten Allen Screws With

Allen Key Wrench

Be sure that the speaker wires

NOTE:

are clear of the woofer basket and not

too close to the woofer cone. Make

sure the wires are not pinched

between the baffle and the mounting

frame. Refer to Figure 16.

16. Use the spacer shim to center the

baffle inside of the frame while

securing with four 10-32 x 2-1/4-inch

screws. Loosely tighten the screws

while using the spacer on the bottom

side. Remove spacer and gauge the

other three sides before starting

final torque sequence. Proper centering of the baffle is critical to the

grille fitting properly.

Use the included 5/32-inch Allen key

17.

to tighten until snug, as shown in

Figure 17.

Figure 14: Clamp Mechanism

10

Figure 16: Install the Insulation and Baffle

Page 10

I

nsert Speaker Wire

Te rminal Connectors

Insert

Banana Plug

h

ere if desired

E

xposed Binding Post (connector removed)

B

inding

Post

Figure 18: Making Connections

MAKING CONNECTIONS

The P81 and P941 feature gold-plated

inding posts that allow for two meth-

b

ds of connecting the speaker wires.

o

CAUTION: Never make or break connections unless all system components

are powered off.

Before making connections, note the

ollowing:

f

Make all connections observing the

•

proper polarity, positive-to-positive (+)

and negative-to-negative (–). Connec-

ions that do not observe the proper

t

polarity will cause poor stereo imaging and diminished bass response.

With the advent of multichannel surround systems, maintaining proper

polarity remains equally important to

preserve the correct ambience and

directionality of the program material.

Use high-quality loudspeaker cable

•

with a maximum total loop resistance

of 0.07 ohms or less (for each wire

run). Refer to the table below to

determine the appropriate maximum

wire gauge.

All in-wall speaker wires must be UL

•

listed for use in in-wall applications.

CAUTION: Be sure to comply with local

wiring codes. JBL is not responsible for

any damage or injuries that may result

from faulty wiring.

Maximum Wire Gauge

Gauge Length Length

(AWG) (Feet) (Meters)

6

7 69 21

8 58 18

9 43 13

10 34 10

11

12 22 7

13

14 14 4

15 11 3

16

17 7 2

18 5 2

NOTE: High loop resistances that

exceed 0.07 ohms (for each wire run)

will cause the filter network to misterminate, resulting in considerable

degradation of sound quality.

87 27

27

17 5

9

5. Repeat Steps 1 to 4 to connect the

econd P81 or P941 to a separate

s

mplifier/receiver output channel.

a

An alternative connection method,

instead of those described in Steps 1 to

, is to attach standard banana plugs to

3

he speaker wires and plug them into

t

the ends of the speaker connectors.

The hole in the center of each collar is

ntended for use with banana-type con-

i

nectors. To comply with European CE

certification, these holes are blocked

with plastic inserts at the point of

anufacture. The use of banana-type

m

Figure 18: Making Connections

connectors requires the removal of

the inserts. Do not remove these

inserts if you are using the product

Contact an authorized JBL dealer for

•

information about the suitability of

power amplifier/receiver components

before connecting the P81 or P941

to the associated power amplifier/

receiver.

Review the owner’s manuals for asso-

•

in an area covered by the European

CE certification.

If using a back box or if limited by

installation depth, the banana plugs

can also be inserted through the sides

of the binding posts. See Figure 18.

ciated audio components to determine their connection procedures.

Connections are made between one

pair of P81 or P941 input connectors

and one amplifier/receiver output

channel, as described below.

To Make Connections:

1. Loosen the terminal connectors by

hand (counterclockwise) on the

speakers’ positive (+) and negative

(–) binding posts until the holes in

their threaded posts are visible.

Insert the stripped ends of the

2.

wires through the holes, as shown

in Figure 18.

3. Retighten the connectors by hand

(clockwise) to secure the wire. Be

8

sure no stray strands of wire from

one binding post touch the other

binding post, as this will short-out the

signal and may damage the amplifier.

4. In the manner described above, con-

3

nect one pair of loudspeaker wires

to the P81 or P941 input connectors.

Then connect the same pair of loudspeaker wires to the desired amplifier/

receiver output channel.

11

Page 11

OPTIMIZING PERFORMANCE

Figure 19: Listener Axis Control Upright Speaker Placement

Tweeter

Tweeter

Tweeter

Tweeter

Woofer

Woofer

Woofer

Set Listener Axis Switch to “High” if

listening position is at tweeter level

or above.

Set Listener Axis Switch to “Low”

if listening position is below

tweeter level.

Set Listener Axis Switch to “High”

if listening position is below tweeter.

Set Listener Axis Switch to “Low”

if listening position is at tweeter

level or above.

Inverted Speaker Placement (woofer is above tweeter)

Woofer

Set Listener Axis Switch to “on axis”

if listening position is directly at

tweeter level.

Tweeter

Woofer

Woofer

Tweeter

Set Listener Axis Switch to “on axis”

if listening position is directly at

tweeter level.

Wall

It is highly recommended that you

ake front-panel control adjustments

m

efore installing the grille. Experiment

b

with settings and carefully listen to

ensure that the proper adjustments

have been made.

o optimize the P81 and P941 for best

T

performance:

1. Refer to the Loudspeaker Placement

ection on page 8 for information

s

about loudspeaker installation.

2. Set the High-Frequency Level control

to 0 (different listening rooms may

require other High-Frequency Level

control settings).

3. Set the Low-Frequency Boundary

Compensation control to the appropriate position.

Select the “off” setting if the speak-

•

er is mounted at least 4 feet away

from adjacent walls or boundaries.

Select the “on” setting if the speak-

•

er is mounted close to one (or possibly two) or more adjacent walls

or boundaries. In the “on” position,

system output is reduced below

approximately 400Hz to offset the

increased low-frequency support

due to the boundary.

4. Begin playback of a familiar music or

film source.

5. Listen from the primary listening

osition, increasing volume to a

p

omfortable level.

c

6. Adjust the High-Frequency Level

con-

trol on each P81 or P941 to change

igh-frequency balance and timbre.

h

7. Adjust the Listener Axis control

depending on the position of the

primary listening location. Refer to

igure 19.

F

Select the “high” (up arrow) setting

•

if the speaker is mounted so that

the listener is above the tweeter

level.

Select the “on axis” setting if the

•

listener location is directly on axis.

Select the “low” (down arrow) set-

•

ting if the speaker is mounted so

that the listener is significantly

below the tweeter.

When the loudspeaker has been

mounted upside-down, (with the

woofer higher than the tweeter), refer

to Figure 19. The listener axis control

settings function in the opposite manner

as normal operation:

Select the “low” setting if the

•

speaker is mounted so that the listener is at tweeter level or above.

Select the “high” setting if the

•

speaker is mounted so that the

listener is below the tweeter.

8. Set the High-Frequency Tilt switch to

+” if your listening position is far off

“

he tweeter axis; otherwise, leave it

t

at “0.”

9. Repeat these steps to optimize per-

ormance of the second P81 or P941.

f

NOTE: For best results, set the HighFrequency Level, High-Frequency Tilt,

and the Listener Axis controls to the

ame positions on both loudspeakers.

s

Painting the Frame

Proper surface preparation is critical

for best results. Use spray, roller

(smooth), or a pad to apply the paint.

Clean and prime the frame surface

prior to painting.

1. Place frame on a protected work

surface.

2. Install plastic paint mask (included)

into the frame.

3. Clean front edges of frame face by

gently rubbing with a soft rag dampened with rubbing alcohol.

4. Apply one coat of white or neutral

color water-based primer and let dry.

5. Apply one to two coats of paint for

desired finish.

12

Figure 19: Listener Axis Control Upright Speaker Placement

Page 12

Grille

1/16-inch Allen key

Frame

Painting the Grille

or best results, it is recommended

F

that the grille be painted with a spray

applicator to enable the paint to be

evenly applied to the inside edges of

he grille’s perforations.

t

The following items are required to

paint the grille:

the grille (included)

•

replacement scrim cloth (included)

•

pray paint

s

•

paint thinner (and cloth)

•

ubbing alcohol (and cloth)

r

•

white or neutral color water-based

•

primer

masking tape

•

spray adhesive

•

CAUTION: The grille must be painted

before it is attached to the frame.

To Paint the Grille:

1. Remove the grille from the grille filler.

2. Remove the scrim cloth on the inside

surface of the grille. If necesssary,

slightly peel up the lower inside

edges of the black felt strips to

remove the scrim.

3. Inspect the inside surface of the

grille to ensure that there are no

remnants of the scrim cloth. If necessary, remove any remnants by rub

bing with a cloth dampened with

paint thinner.

4. Clean the front grille surface with a

cloth dampened with rubbing alcohol.

Apply masking tape over the black

5.

felt strips around the grille perimeter

to shield them from paint. Be sure to

mask only the felt and not the outer

metal edges of the grille, so that they

will be painted.

6. Apply one coat of the primer and let

it dry.

7. Thin the paint before application.

8. Apply one to two coats of spray

paint. Use a varied spraying angle

when spraying, to ensure paint is

applied to the inside edges of the

grille perforations.

After the paint is dried, install the

replacement scrim cloth, if desired.

To Attach the Replacement Scrim Cloth:

. Place the grille face down on a soft

1

surface.

2. If paint thinner was used to remove

crim remnants, apply a light coating

s

of a spray adhesive to the inside

grille surface. Avoid spraying adhesive onto the felt strips. If too much

adhesive is used, it could wick into

he cloth and degrade the sound.

t

3. Place the replacement scrim cloth

in the grille with the cardboard side

facing upward (so that the cardboard

is not visible through the front of the

grille).

4. Tuck the outer edges of the scrim

cloth cardboard frame under the

black felt strips and gently smooth

the scrim cloth over the grille surface

to remove any wrinkles.

Figure 20: Removing the Grille

AUTION:

C

grille out using the Allen key (or any

other object) as a pry bar against the

plastic frame.This will cause damage

to the frame and mar the paint.

o not attempt to pry the

D

Speaker Frame Removal

Attaching the Grille to the

Frame

To Attach the Grille:

1. Line the grille up to the frame and

press the grille in only partially at

first.

2. Push gently at multiple points around

the outer edges to slowly ease it into

position.

NOTE: Configure the four front-panel

-

controls and experiment until optimal

results are achieved, before installing

the grille.

Grille Removal

To Remove the Grille:

Insert the small end of the included

1.

1/16-inch Allen key into one of the

metal mesh holes in the top corner

of the grille, as shown in Figure 20.

2. With the end of the Allen key in the

grille hole approximately 1/8 inch,

with thumb and forefinger close to

the grille, pull up on the Allen key to

wedge it into the grille hole.

3. Gently pull the Allen key to partially

pop out the corner of the grille.

4. Repeat Steps 1 to 3 for the other top

corner.

Apply Steps 1 to 4 for the bottom

5.

corners.

6. When all corners are partially

popped out, the grille can easily

be removed.

To remove the speaker frame from wall

opening:

1. Fully unscrew all of the clamps

around the speaker housing. The

clamp screws have an acorn nut

attached on their end to prevent

accidental disassembly.

2. Move the speaker housing away

from the wall enough to wedge your

hand behind and pinch a clamp shut.

3. While the clamp is shut, work the

speaker housing forward enough to

catch the shut clamp in the wall

opening.

ork around the perimeter

W

4.

closing each clamp and then slowly

pull the speaker housing from the

wall.

, carefully

LOUDSPEAKER VOLUME LEVELS

High-order filters include steep cut-offs

to reduce potential damage from “outof-band” frequencies. Combined with

carefully selected transducers and fil

ter network components, this approach

helps the P81/P941 to maintain its performance under extreme operating

conditions.

However, all loudspeakers have limits

when it comes to continuous playback.

To extend these limits, avoid playback

at volume levels that distort or strain

sound.

-

13

Page 13

81/P941 SPECIFICATIONS

P

P81 P941

W

oofer:

-1/2 inches (190.5mm) 9 inches (228.6mm)

7

Midrange: N/A 3-1/2 inches (89mm)

Tweeter: 1 inch (25.4mm) 1 inch (25.4mm)

System Frequency 40Hz – 20kHz 32Hz – 20kHz

Response (±3dB):

ensitivity:

S

7dB 89dB

8

Recommended 15 to 150 Watts 15 to 200 Watts

Amplifier Power Range:

ominal Impedance:

N

Ohms 8 Ohms

8

Crossover Frequency(ies): 2.8kHz, 24dB/octave 300Hz, 2kHz, 24dB/octave

Width: 13 inches (330mm) 14-7/8 inches (377.8mm)

Height: 17-7/8 inches (454mm) 22-1/8 inches (562mm)

Depth: 3-1/2 inches (89mm) 3-1/2 inches (89mm)

Wall Cutout Width: 10-1/2 inches (266.7mm) 12-1/2 inches (317.5mm)

Wall Cutout Height: 14-7/8 inches (377.8mm) 19-1/8 inches (485.8mm)

All features and specifications are subject to change without notice.

OBTAINING SERVICE

Before returning a product for warranty

or non-warranty service, contact JBL

Customer Support to determine the

extent of the problem and to obtain a

Return Authorization (RA) number. No

products will be accepted without an

RA number issued by JBL.

If a product must be returned for repair,

JBL will assume no responsibility for

the product during shipment from the

customer to JBL or its authorized service station, whether the product is or is

not covered under warranty

All Returns Must Be:

• well-packaged using the original

packing materials (if possible)

properly insured and consigned

•

• pre-paid to a reliable shipping agent

To Contact Customer Support:

Call 516.255.4JBL or visit www.jbl.com.

.

JBL is a registered trademark of Harman International Industries, Incorporated.

Nomex is a registered trademark of E.I. du Pont de Nemours and Company.

14

Page 14

NDEX

I

2-Channel Installations 8

5.1-Channel Installations 8

6.1-/7.1-Channel Installations 8

bout the P81/P941 4

A

ighlights 4

H

Product Registration 4

Unpacking 5

Allen Key 5, 9, 10, 13

Aluminum Ring 4, 6

mplifier Power Range

A

Recommended 14

Baffle Assembly 9, 10

Baffle, Centering of 10

Banana Plugs 11

Binding Post 4, 7, 11

Butyl Rubber Surround 6

Carbon Composite Aluminum (CCA) 6

Caution 3, 8, 11, 13

Clamps 10, 13

Compression 4, 6

Cones 4, 6

Connections 4

Input 7

Making 11

Connectors 11

Depth 14

Distortion, Reducing 4, 6

Documentation Conventions 3

Dome (see Cones)

Driver Complement 6–7

Dynamic Range 4

Ferrofluid 6

Fiberglass Bobbin 6, 7

Fiberglass Insulation 5, 10

Filter Network 7, 11

Filters 4, 7

Fire Block 4

Flux-Stabilization Ring 4, 6

Frame Alignment Tool 5, 10

Grille 13

Grille Installation 13

Grille Removal 13

Heat Dissipation 4, 6

Height 9, 14

High-Frequency Level 4, 6, 12

High-Frequency T

ilt 4, 6, 12

Highlights 4

Home Theater 4, 8

Ideal Height of Woofer 9

In-Wall Placement 9

Input Panel 7

nstallation Considerations 8

I

nstallation Instructions 9–10

I

Inverted Speaker 9, 12

Listener Axis 4, 6, 7, 12

Listening Room 8, 12

Loudspeaker Cable 11

oudspeaker Overview 6

L

Loudspeaker Placement 8, 9, 12

Loudspeaker Volume Levels 13

Low-Frequency Boundary

Compensation 4, 6, 12

Magnetic Shielding 4

Making Connections 11

Maximum Wire Gauge 11

Midrange 4, 6–7, 14

Mounting Frame 9–10

Neodymium Magnets 4, 6–7

Nomex Spiders 4

Nominal Impedance 14

Obtaining Service 14

On-Axis Response 4, 6, 12

Optimizing Performance 12

Organic Ceramic Composite

Cone Material 4, 6

Packing Carton 5, 14

Packing Materials 5, 14

Paint Mask 5, 13

Painting the Frame 12

Painting the Grille 13

Polarity 11

Primary Listening Position 8, 12

Product Registration 4

Rear Speakers 8

Room Placement 8

Rough-In Bracket 4, 9

Scrim Cloth 5, 13

Sensitivity 14

Shipping 5, 14

Spacer Shim 5, 10

peaker Frame Removal 13

S

peaker Wire 10, 11

S

Specifications 14

Spider 4

Steel-Shield Cup 4

Stereo Imaging 11

tud Bay 9

S

Surround Channels 8

Symmetrical Field Geometry (SFG

Terminal Connectors 7, 11

Timbre 4, 12

Titanium Domes 4, 6

Transducers 4, 6

Tweeter 4, 6, 12, 14

UL Listed 11

Unpacking 5

Vented Center Pole 6

Voice Coil 4, 6–7

Volume Levels 12, 13

Wall Cutout Height 9, 14

Wall Cutout Width 9, 14

Wall Openings 9

Wall Studs 9

Wall Template 5, 9

Web Site 14

Width 13, 14

Wire Connections 11

Wire Gauge 11

Wire Resistance 11

Wiring Codes 11

W

oofer 4, 6, 14

Woofer Height 9

™

) 6, 7

15

Page 15

JBL Consumer Products

A Harman International Company

A Harman International Company

A Harman International Company

250 Crossways Park Drive

Woodbury, New York 11797 USA

.jbl.com

www

2005 Harman International Industries,

©

Incorporated

Part No. 355087-001 2/05

®

Loading...

Loading...