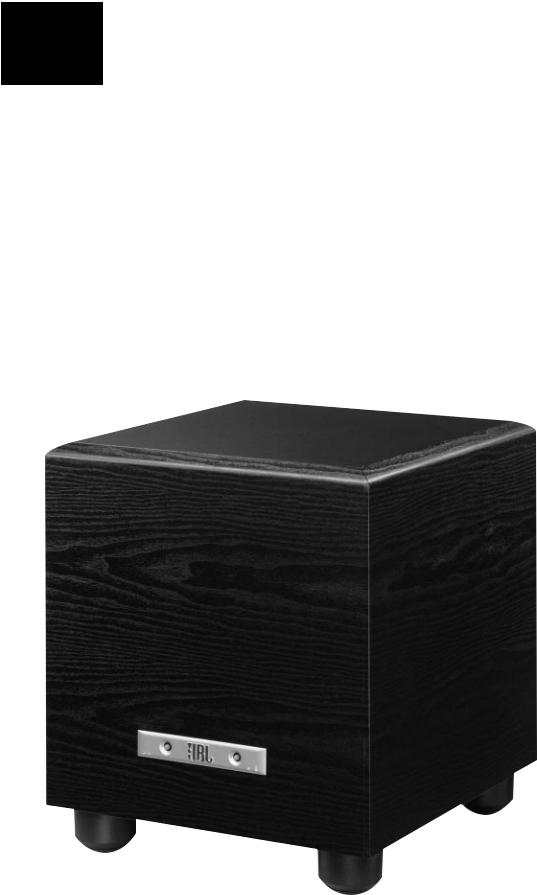

JBL PB-12 Mk3 Service manual

PowerBass™ Series

PB12 Subwoofer

SERVICE MANUAL

JBL, Incorporated

250 Crossways Park Drive |

REV 3 5/02 |

Woodbury, New York 11797

PB12

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 Basic Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Detailed Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Controls and their Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 Speaker Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 Test Setup and Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 Service Bulletin JBL 2001-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 Service Bulletin JBL 2001-04 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 Service Bulletin JBL 2001-05 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 Service Bulletin JBL 2001-07 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 Exploded and Packaging Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 Amplifier Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 Amplifier Faceplate/Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 Integrated Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 Testing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 Block Diagram Revision 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 Electrical Parts List (PCB version 6.3 – 7.0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 Electrical Parts List (PCB version 7.2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 Electrical Parts List Revision 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 Printed Circuit Boards (PCB version 6.3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 Printed Circuit Boards (PCB version 6.4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44 Printed Circuit Boards (PCB version 7.2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 Preamp Schematics (PCB version 6.3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48 Power Amp Schematics (PCB version 6.0 – 6.3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49 Power Amp Schematics (PCB version 7.0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 Preamp Schematics (PCB version 7.2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 Power Amp Schematics (PCB version 7.2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52 Preamp Schematics (Revision 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53 Power Amp Schematics (Revision 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

PB12 – DIFFERENCES IN REVISION 1 AND REVISION 2

REVISION 1 |

REVISION 2 |

|

|

Amplifier faceplate says “Made in Canada” |

|

|

|

Amplifier serial number starts with “AM” |

Amplifier serial number starts with “HA” |

|

|

Black (or silver) potted, non-serviceable output module |

Output transistors in the open, on a large black heatsink |

|

|

|

Large plastic cup enclosing the rear of the amp assembly |

|

|

|

Main PCB, bottom, solder-side contains all SMD devices |

|

|

|

“Made in Mexico” label on outer part of cabinet |

|

|

BOTH VERSIONS OF THESE AMPLIFIERS ARE NOT CONSIDERED INTERCHANGEABLE; THEY ARE NOT A DROP-IN REPLACEMENT IN THE CABINET OF THE OTHER VERSION.

2

PB12

SAFETY INFORMATION

Warning

Any person performing service of this unit will be exposed to hazardous voltages and the risk of electric shock. It is assumed that any person who removes the amplifier from this cabinet has been properly trained in protecting against avoidable injury and shock. Therefore, any service procedures are to be performed by qualified service personal ONLY!

Caution

Before the amplifier is plugged in, be sure its rated voltage corresponds to the voltage of the AC power source to be used. Incorrect voltage could cause damage to the amplifier when the AC power cord is plugged in. Do not exceed rated voltage by more than 10%: operation below 90% of rated voltage will cause poor performance or may shut the unit off.

Leakage/Resistance Check

Before returning the unit to the customer, perform a leakage or resistance test as follows:

Leakage Current. Connect the unit to its rated power source. Using an ammeter, measure the current between the neutral side of the AC supply and chassis ground of the unit under test. If leakage current exceeds 0.5mA, the unit is defective. Reverse the polarity of the AC supply and repeat.

Resistance. Measure the resistance from either side of the line cord to chassis ground, If it is less than 500k ohms, the unit is defective.

WARNING! DO NOT return the unit to the customer if it fails one of these tests until the problem is located and corrected.

Critical Components

All components identified with the IEC symbol in the parts list and schematic diagram designate components in which safety can be of special significance when replacing a component identified with. Use

only the replacement parts designated in the parts list or parts with the same rating of resistance, wattage or voltage.

List of Safety Components

Requiring Exact Replacements

|

Revision 1 |

Revision 2 |

Description |

|

|

F1 - 80117 |

093-105202-300 |

Line Fuse Slo Blo 2.0A |

|

|

PWRCORD |

083-041802-009 |

250V UL approved |

|

80105 |

|

SPT-2 or better with |

||

|

|

|

polarized plug, UL |

|

|

|

|

approved wired with the |

|

|

|

|

hot side to fused side. |

|

|

|

|

Use with factory |

|

|

|

|

replacement panel strain |

|

|

|

|

relief (70305) only. |

|

|

TRX |

042-010053-003 |

Power Transformer. Use |

|

|

80116 |

|

only factory replacement. |

|

|

BR RECT |

BR1 |

Bridge diode. Use only |

|

|

50100 |

052-400080-000 |

factory replacement. |

|

|

C1,2 |

C6,8 |

Large electrolytic filter |

|

|

(2200uF 100V) |

(3300uf 80v) |

caps. Be sure |

|

30710 |

034-470745-200 |

replacement part is at |

||

|

|

|

least the same working |

|

|

|

|

voltage and capacitance |

|

|

|

|

rating. |

|

|

|

|

Also the lead spacing is |

|

|

|

|

important. Incorrect |

|

|

|

|

spacing may cause |

|

|

|

|

premature failure due to |

|

|

|

|

internal cabinet pressure |

|

|

|

|

and vibration. |

|

|

C10 |

Does not apply |

4.7uF, 100 volt NPE low |

|

30718 |

|

df radial. |

||

|

|

|

(On Power amp PCB) |

|

|

S64AMI |

Does not apply |

Power output module. |

|

60302 |

|

Use only factory |

||

|

|

|

replacement |

|

|

Faceplate |

n/a |

Use only factory |

|

|

70325 |

|

replacement |

|

|

Rear Amp Cover |

063-531808-000 |

Use only factory |

|

|

Does not apply |

|

replacement |

|

|

Inductor |

Does not apply |

CMC - Use only factory |

|

|

80100 |

|

replacement |

|

|

Inductor |

Does not apply |

L1 - Use only factory |

|

|

80121 |

|

replacement |

|

|

Does not apply |

Inductor |

L2 - Use only factory |

|

|

|

043-300101-000 |

replacement |

|

|

Does not apply |

Inductor |

L3 - Use only factory |

|

|

|

043-700101-000 |

replacement |

|

3

PB12

BASIC SPECIFICATIONS PB12 Subwoofer

Output Power

Driver

Frequency Response

Inputs

Outputs

Low-Pass Frequency

High-Pass Frequency

Dimensions (H x W x D)

Weight

250 watts RMS

12" Woofer

25Hz ñ Low-Pass Frequency setting

Line Level (option: LFE); Speaker Level

Speaker level fixed frequency 150Hz

Variable from 50Hz ñ 150Hz

150Hz when using Speaker Level Output

15 1/2" x 15" x 16"

394mm x 381mm x 406mm (with feet) 17 1/2" x 15" x 16" 445mm x 381mm x 406mm

40 lb/18.2kg |

00261-1 |

|

Refinements may be made on occasion to existing products without notice but will always meet or exceed original specifications unless otherwise stated.

PowerBass is a registered trademark of JBL, Incorporated.

4

PB12

DETAILED SPECIFICATIONS PB12 Subwoofer

JBL PB12 |

250W Powered Sub Amp |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LINE VOLTAGE |

|

Yes/No |

Hi/Lo Line |

Nom. |

Unit |

|

Notes |

|

US 120vac/60Hz |

Yes |

108-132 |

120 |

Vrms |

Normal Operation |

|

|

|

EU 230vac/50-60Hz |

Yes |

207-264 |

230 |

Vrms |

Normal operation, MOMS required |

|

||

|

|

|

|

|

|

|

|

|

Parameter |

|

Specification |

Unit |

QA Test |

Conditions |

|

Notes |

|

|

|

|

|

Limits |

|

|

|

|

Amp Section |

|

|

|

|

|

|

|

|

Type (Class AB, D, other) |

D |

n/a |

n/a |

|

|

|

|

|

Load Impedance (speaker) |

5.6 |

Ohms |

n/a |

Nominal |

|

|

|

|

Rated Output Power (120VAC) |

250 |

Watts |

140 |

|

Domestic version only 120 VAC-60 Hz |

|

||

Rated Output Power (230VAC) |

250 |

Watts |

130 |

|

EU Version only |

230 VAC-50 Hz |

|

|

THD @ Rated Power |

0.3 |

% |

1 |

22k filter |

145 Watts |

|

|

|

THD @ 1 Watt |

|

0.1 |

% |

0.5 |

22k filter |

|

|

|

DC Offset |

|

10 |

mV-DC |

20 |

@ Speaker Outputs |

|

|

|

Damping factor |

|

>50 |

DF |

35 |

Measured at amplifier board |

At spkr cable. 150 Watts @ THD < 0.1 % @ 50 Hz |

||

|

|

|

|

|

|

|

|

|

Input Sensitivity |

|

|

|

|

|

|

|

|

Input Frequency |

|

50 |

Hz |

50 |

Nominal Freq. |

|

|

|

L&R |

|

240 |

mVrms |

±2dB |

To 150 Watts |

Single input driven |

|

|

LFE input |

|

240 |

mVrms |

±2dB |

To 150 Watts |

Single input driven, LFE switch ON |

|

|

Speaker/Hi Level Input |

2.4 |

Vrms |

±2dB |

To 150 Watts |

Single input driven |

|

|

|

|

|

|

|

|

|

|

|

|

Signal to Noise |

|

|

|

|

|

|

|

|

SNR-A-Weighted |

|

90 |

dBA |

70 |

relative to rated power |

A-Weighting filter |

|

|

SNR-unweighted |

|

85 |

dBr |

70 |

relative to rated power |

22k filter |

|

|

SNR rel. 1W-unweighted |

65 |

dBr |

60 |

relative to 1W Output |

22k filter |

|

|

|

Residual Noise Floor |

1 |

mVrms |

3 |

Volume @max, using RMS reading |

Line level inputs must be terminated using |

1KOHM |

||

|

|

|

|

|

DMM/VOM (or A/P) BW=20 Khz. |

|

|

|

|

|

|

|

|

|

|

||

Residual Noise Floor |

1.5 |

mVrms(max) |

3 |

Volume @max, w/ A/P Swept |

Line level inputs must be terminated using |

1KOHM |

||

|

|

|

|

|

Bandpass Measurement (Line freq.+ |

|

|

|

|

|

|

|

|

harmonics) (BW=20 Khz) |

|

|

|

|

|

|

|

|

|

|

|

|

Input Impedance |

|

|

|

|

|

|

|

|

Line Input (L, R,LFE) |

20K |

ohms |

n/a |

Nominal |

|

|

|

|

Speaker/Hi Level Input |

4.7K |

ohms |

n/a |

Nominal |

|

|

|

|

|

|

|

|

|

|

|

|

|

Filters |

|

|

|

|

|

|

|

|

LP filter 4th order fixed |

60-180 |

Hz |

± 10 |

|

2nd order variable + 2nd order fix-24 db/Octave |

|||

Subsonic filter (HPF) 3rd Order |

Fixed |

|

|

|

|

|

|

|

LFE Low pass 2nd order |

200>LP<1K |

Hz |

|

LFE input driven only |

|

|

|

|

HP speaker out connector |

200 |

Hz |

± 10 |

Speaker input driven - 4 Ohms |

|

|

|

|

|

|

100 |

Hz |

± 10 |

Speaker input driven - 8 Ohms |

|

|

|

|

|

|

|

|

|

|

|

|

Features |

|

-- |

|

|

|

|

|

|

Volume pot Taper (lin/log) |

LOG |

-- |

functional |

|

A Taper |

|

|

|

HP Speaker out |

|

YES |

|

functional |

|

Refer to Filter section |

|

|

Phase switch |

|

0-180 |

deg |

functional |

|

|

|

|

LP Filter defeat switch |

YES |

|

functional |

|

Disables LP filter, intended for LFE |

|

||

|

|

|

|

|

|

|

|

|

Input Configuration |

|

|

|

|

|

|

|

|

Line In (L,R) & LFE |

YES |

-- |

functional |

|

Dual RCA jack |

|

|

|

Spkr/Hi Level In |

|

YES |

-- |

functional |

|

Binding post connector L&R |

|

|

|

|

|

|

|

|

|

|

|

Signal Sensing (ATO) |

|

|

|

|

|

|

|

|

Auto-Turn-On (yes/no) |

YES |

|

functional |

|

|

|

|

|

ATO Input test frequency |

50 |

Hz |

functional |

" |

|

|

|

|

ATO Level LFE Input |

4 |

mV |

functional |

" |

Maximum acceptable level. |

|

||

ATO Level Speaker in |

50 |

mV |

functional |

" |

Maximum acceptable level. |

|

||

ATO Turn-on time |

|

5 |

ms |

functional |

Amp connected and AC on, then input |

|

|

|

|

|

|

|

|

signal applied |

|

|

|

Auto Mute/ Turn-OFF Time |

15 |

minutes |

15 |

T before muting, after signal is |

Auto turn of time (T) |

must be 5 > T < 15 Minutes |

||

|

|

|

|

|

removed |

|

|

|

|

|

|

|

|

|

|

|

|

Power on Delay time |

3 |

sec. |

4 |

AC Power Applied |

|

|

|

|

|

|

|

|

|

|

|

|

|

Transients/Pops |

|

|

|

|

|

|

|

|

ATO Transient |

|

5 |

mV-peak |

n/a |

@ Speaker Outputs |

|

|

|

Turn-on Transient |

|

50 |

mV-peak |

2v-pp |

@ Speaker Outputs |

AC Line cycled from OFF to ON |

|

|

Turn-off Transient |

|

50 |

mV-peak |

2v-pp |

@ Speaker Outputs |

AC Line cycled from ON to OFF |

|

|

|

|

|

|

|

|

|

|

|

Efficiency |

|

65 |

% |

64 |

|

Nominal Line voltage 120 VAC |

|

|

Stand-by Input Power |

24 |

Watts |

26 |

@ nom. line voltage |

Maximum allowable input power under nominal |

|||

|

|

|

|

|

|

Input voltage and frequency, HOT or COLD |

|

|

|

|

|

|

|

|

operation. |

|

|

Power Cons. @ rated power |

234 |

Watts |

240 |

@ nom. line voltage |

150 Watts @ 5.6 Ohms nominal line voltage |

|

||

|

|

|

|

|

|

|

|

|

Protection |

|

|

|

|

|

|

|

|

Short Circuit Protection |

YES |

|

functional |

Direct short at output |

Amplifier should resume operation after short circuit |

|||

|

|

|

|

|

|

condition removal |

|

|

Thermal Protection |

|

YES |

|

functional |

@1/8 max unclipped Power at 1.06 |

|

|

|

|

|

|

|

|

times the input voltage |

|

|

|

DC Offset Protection |

YES |

|

- |

DC present at Speaker Out leads |

|

|

|

|

Line Fuse Rating |

|

|

|

|

|

|

|

|

USA-Domestic |

|

2 |

Amps |

|

Type-T or Slo Blo-250 V |

|

|

|

EU |

|

1.25 |

Amps |

|

Type-T or Slo Blo-250 V |

External fuse with UL/SEMKO rated holder |

|

|

5

PB12

PB12 Subwoofer Controls and Their Function

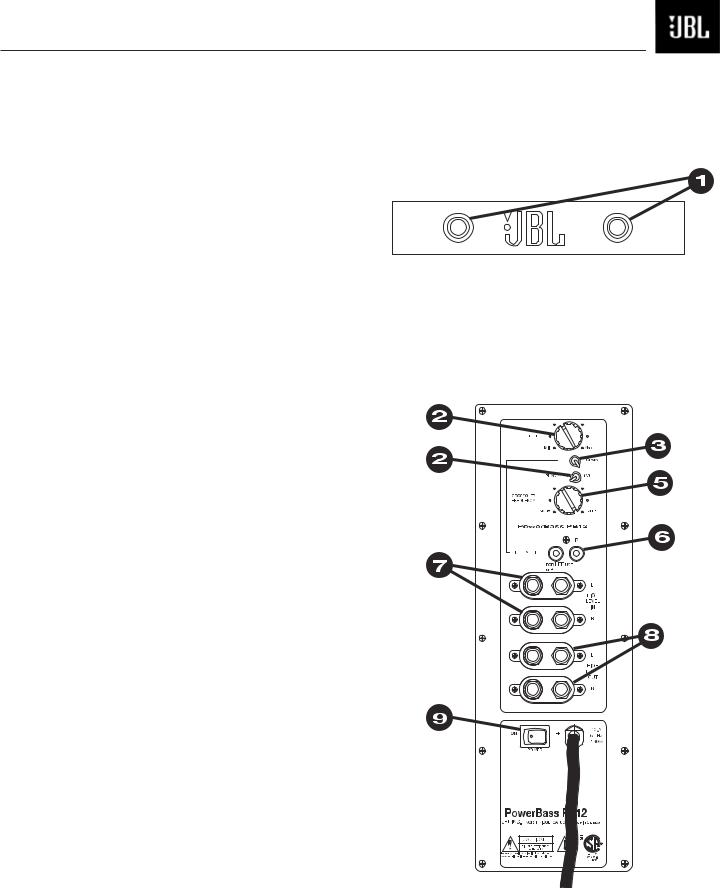

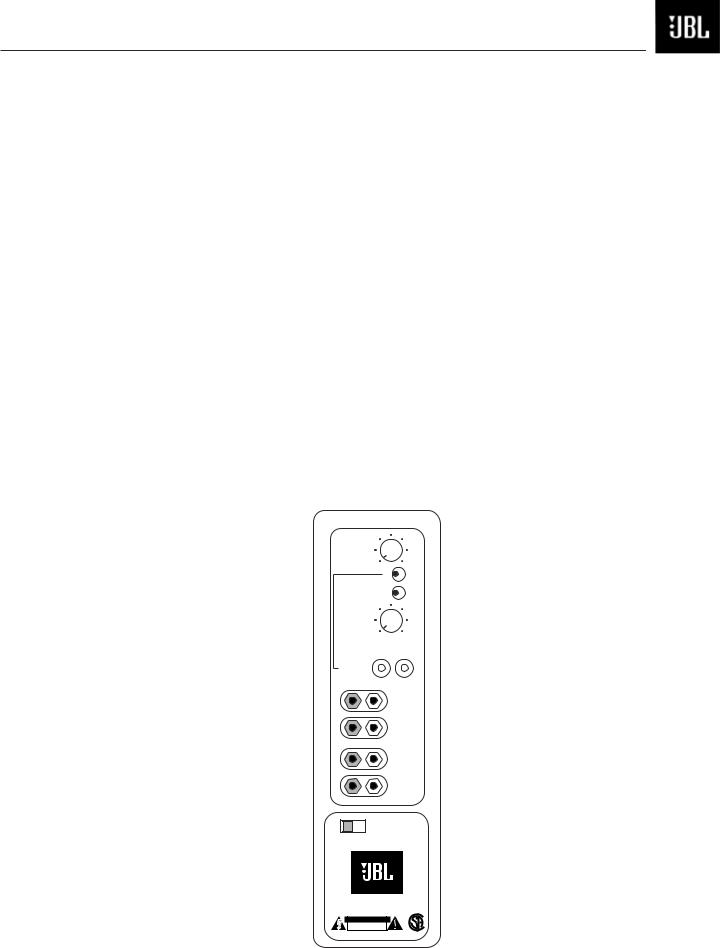

1. |

Power - These lights will be red when the unit is |

Front Panel |

|

plugged in and not receiving a signal; when the PB12 |

|

|

receives a signal, the lights will cycle to GREEN. If no |

|

|

signal is received after 10-15 minutes the lights will |

|

|

cycle back to RED (standby) until a signal is present |

|

|

again. |

|

2. |

Level Control - The subwoofer Level Control, PB12, |

|

|

(located on the rear panel) adjusts the volume of the |

|

|

subwoofer relative to the rest of the system. |

|

3. |

LFE/Normal Switch - Ordinarily placed in the Normal |

|

|

position - but switch to LFE when playing Dolby® |

|

|

Digital, DTS® or other digital surround modes - see |

|

|

page 9. |

|

4. |

Phase Switch - Changes the subwoofer’s output to |

|

|

be in phase or 180 degrees out of phase with the |

Rear Panel |

|

program material. |

|

5. |

Crossover Frequency - Sets the highest frequency |

|

|

the subwoofer will reproduce. |

|

6. |

Line Input - Main Input connection to subwoofer |

|

|

(preferred). |

|

7. |

Speaker In Jacks - Main Input connection to |

|

|

subwoofer when line level, subwoofer, or pre-amp |

|

|

output connectors are not available, or when a high |

|

|

pass filter (set at 150Hz) to main loudspeakers is |

|

|

desired through the Speaker Output Jacks. |

|

8. |

Speaker Out Jacks - Connected to main |

|

|

loudspeakers when the Speaker Input Jacks are used. |

|

9. |

Power Switch - Turns the PB12 on or off. |

|

6

PB12

Speaker Connection

When we designed the PB12 powered subwoofers, our goal was to offer the user the best possible performance combined with the most flexible and complete installation options. Please look over the following three examples to determine which

description best matches your system and follow the corresponding hookup instructions.

To use the binding-post speaker terminals with bare wire, unscrew the collar until the hole through the center-

post is visible under the collar.

Insert the bare end of the wire through the hole in the post, then screw the collar back down until the connection is tight. The holes in the center of the collars are intended for banana-type connectors.

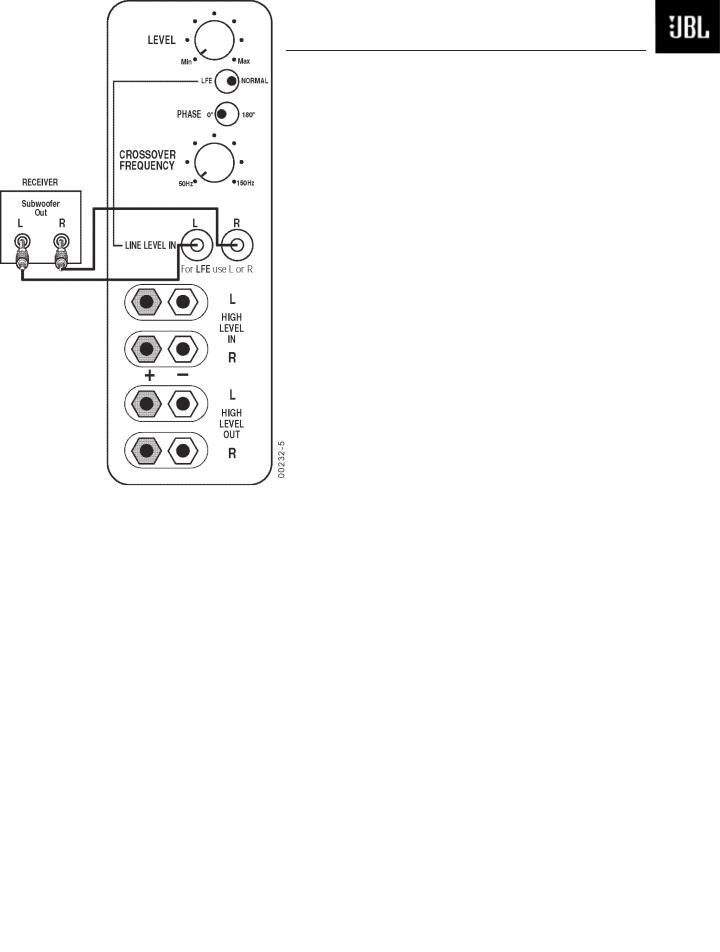

Dolby Pro Logic (Non-Digital) – Speaker Level

Use this installation method for Dolby Pro Logic applications (not Dolby Digital, DTS or other digital processing), where the receiver/processor does not have a subwoofer output or a volume-controlled preamp (line-) level output:

Connect your receiver or amplifier’s front left and right speaker terminals to the left and right terminals on the subwoofer that are marked “High Level In.” Connect the left and right terminals on the subwoofer that are marked “High Level Out” to the corresponding terminals on the back of your front left and right speakers.

Connect your receiver or amplifier’s center, left and right surround-speaker terminals to the corresponding terminals on the back of your center, left and right surround speakers.

7

PB12

Dolby Pro Logic (Non-Digital) – Line Level

Use this installation method for Dolby Pro Logic applications (not Dolby Digital, DTS or other digital processing), where the receiver/processor is equipped with a subwoofer output or a volume-controlled preamp (line-) level output:

Use RCA-type patch cords to connect the line-level subwoofer outputs on your

receiver or amplifier to the linelevel inputs on the subwoofer. IMPORTANT: Make sure that the LFE toggle switch on the subwoofer is in the “Normal” position. Do not use the “LFE”

position with Dolby Pro Logiconly processors.

Note: If your receiver or amplifier only has one subwoofer output jack, then you may connect the subwoofer output on your

receiver/preamplifier to either the left or right line-level input on the subwoofer. It makes no difference which jack you choose.

Connect each speaker to the corresponding speaker terminals on your receiver or amplifier.

Make sure your receiver or processor is configured correctly: Make sure that the subwoofer is configured as “On.”

Note for advanced users: If your receiver/processor has a built-in low-pass crossover

filter for the subwoofer output, then the LFE switch should be set to the “LFE” position to bypass the subwoofer’s internal crossover.

8

PB12

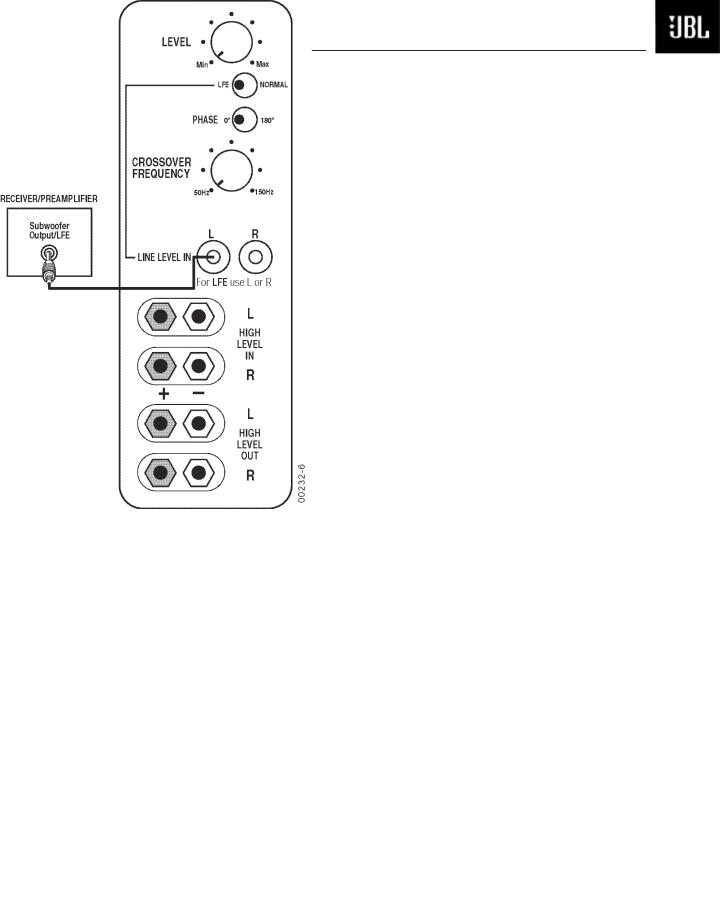

Dolby Digital or DTS (or Other Digital Surround Mode) Connection

Use this installation method for Dolby Digital, DTS or other digital surround processors:

IMPORTANT: Make sure that the LFE toggle switch on the subwoofer is in the “LFE” position. Use the line-level input jacks for the LowFrequency Effects channel. Connect these jacks to the LFE output or subwoofer output on your receiver or amplifier.

Note: If your receiver or amplifier only has one subwoofer output jack, then you may connect the subwoofer output on your

receiver/preamplifier to either the left or right line-level input on the subwoofer. It makes no difference which jack you choose.

Connect each speaker to the corresponding speaker terminals on your receiver or amplifier.

Make sure that you have configured your surroundsound processor for “Subwoofer On” or “LFE On.” The front left, front right, center and rear speakers should be set to “Small” or “Large” depending on their size and frequency response. Consult your receiver’s or processor’s owner’s manual.

9

PB12

OPERATION

Power

When the unit is plugged in and the power switch is on and no signal is received, the LEDs on the front of the unit will turn red. When a signal is present, the LEDs will turn green.

Note: It will take several minutes for the LEDs to turn from green to red after the input signal to the subwoofer is removed. Due to JBL’s unique, high-output, high-efficiency amplifier design, power consumption is minimal when the subwoofer is not receiving a signal.

Level Control

The subwoofer Level Control adjusts the volume of the subwoofer relative to the rest of the system. Proper level adjustments depend on several variables such as room size,

subwoofer placement, type of main speakers and listener position. Adjust the subwoofer level so that the volume of the bass information is pleasing to you.

Crossover Adjustments

The Crossover Frequency Control determines the highest frequency at which the subwoofer reproduces sounds. If your main speakers can comfortably reproduce some low-frequency sounds, set this control to a lower frequency setting, between 50Hz – 100Hz. This will concentrate the subwoofer’s efforts on the ultradeep bass sounds required by today’s films and music. If you are using smaller bookshelf speakers that do not extend to the lower bass frequencies, set the low-pass crossover control to a higher setting, between 120Hz – 150Hz. This control is not used when the LFE switch is in the “LFE” position.

LEVEL

Min |

Max |

LFE |

NORMAL |

PHASE 0º |

180º |

CROSSOVER

FREQUENCY

50Hz 150Hz

PowerBass PB12

L R

LINE LEVEL IN

For LFE use L or R

L

HIGH

LEVEL

IN

+ |

– |

R |

|

L |

|||

|

|

||

|

|

HIGH |

|

|

|

LEVEL |

|

|

|

OUT |

|

|

|

R |

|

ON |

OFF |

120V |

|

POWER |

|

||

|

60Hz |

PowerBass PB12

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

10

PB12

Phase Control

The Phase Control determines whether the subwoofer’s piston-like action moves in and out in phase with the main speakers or opposite the main speakers. There is no correct or incorrect setting. Proper phase adjustment depends on several variables such as subwoofer placement and listener position. Adjust the

phase switch to maximize bass output at the listening position.

Remember, every system, room and listener is different. There are no right or wrong settings; this switch offers the added flexibility to adjust your subwoofer for optimum performance for your specific listening conditions without having to move your speakers.

If at some time in the future you happen to rearrange your listening room and move your speakers, you should experiment with the phase switch in both positions, and leave it in the position that maximizes bass performance.

TROUBLESHOOTING

If you used the high-level (speaker) inputs and there is no sound from any of the speakers:

•Check that receiver/amplifier is on and a source is playing.

•Check that powered subwoofer is plugged into an active electrical outlet and is switched on.

•Check all wires and connections between receiver/amplifier and speakers. Make sure all wires are connected. Make sure none of the speaker wires are frayed, cut or punctured.

•Review proper operation of your receiver/amplifier.

If there is low (or no) bass output:

•Make sure the connections to the left and right “Speaker Inputs” have the correct polarity (+ and –).

•Make sure that the subwoofer is plugged into an active electrical outlet and switched on.

•Adjust the crossover point.

•Flip the Phase Control switch to the opposite position.

•If you are using a Dolby Digital/DTS receiver or processor, make sure that the subwoofer adjustments on the receiver/processor are set up correctly.

•Slowly turn the Level Control clockwise until you begin to hear the desired amount of bass.

If you used the line-level inputs and there is no sound from the subwoofer:

•Check that receiver/amplifier is on and a source is playing.

•Check that powered subwoofer is plugged into an active electrical outlet and is switched on.

•Check all wires and connections between receiver/ amplifier and subwoofer. Make sure all wires are connected. Make sure none of the wires are frayed, cut or punctured.

•Review proper operation of your receiver/amplifier.

•Slowly turn the Level Control clockwise until you begin to hear the desired amount of bass.

•Make sure that you have configured your receiver/ processor so that the subwoofer/LFE output is on.

11

PB12

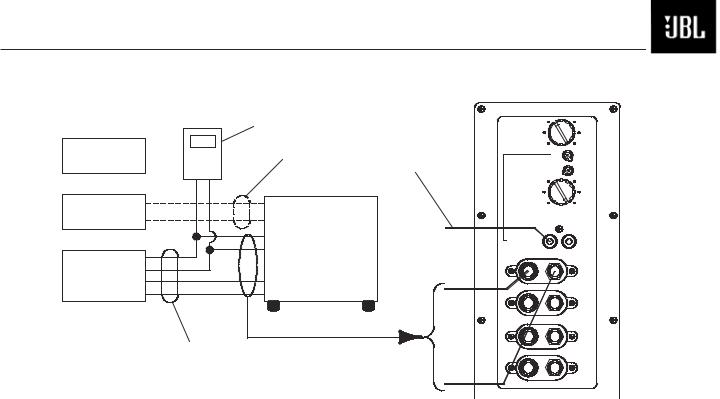

PB12 TEST SETUP AND PROCEDURE

AC VOLT

METER (6V)

|

|

|

LEVEL |

|

|

|

LINE LEVEL |

FROM |

Min |

|

Max |

CD PLAYER |

LINE-LEVEL |

|

LFE |

NORMAL |

|

|

|

||||

|

|

SOURCE |

PHASE |

0 |

180 |

|

|

|

|||

|

|

|

CROSSOVER |

|

|

|

|

|

FREQUENCY |

|

|

|

|

|

50 Hz |

|

150 Hz |

PRE AMP |

|

|

PowerBass PB12 |

||

|

|

|

|||

|

PB12 |

|

L |

R |

|

|

|

|

|

|

|

|

UNDER TEST |

|

LINE LEVEL IN |

|

|

|

|

|

|

|

|

|

|

|

FOR LFE USE |

L or R |

|

AMPLIFIER |

|

|

|

|

L |

|

|

|

|

HIGH |

|

|

|

|

|

|

|

|

|

|

|

|

LIVEL |

|

|

|

|

|

IN |

|

|

|

|

|

R |

|

|

|

|

|

L |

SPEAKER |

|

SPEAKER |

|

|

HIGH |

|

|

|

LIVEL |

||

LEVEL |

|

OUTPUT |

|

|

OUT |

|

|

|

|

||

FROM |

R |

|

|

AMPLIFIER |

|

00229

General Function

UUT = Unit Under Test

1.Connect one line level input cable (RCA) from signal generator to either Right or Left Level input on UUT. VOLUME control should be full conterclockwise. Make sure the LFE/Normal switch is in the NORMAL position.

2.Turn on generator, adjust to 100mV, 50Hz.

3.Plug in UUT; Turn Main Power switch ON. LED’s on the front panel may be either Red or Green. Turn VOLUME control full clockwise. Low Pass control should be set fully clockwise (150Hz).

4.LED should turn Green; immediately bass response should be heard and felt from port tube opening.

5.Turn off generator, turn VOLUME control fully counterclockwise, disconnect RCA cables.

6.Connect one pair of speaker cables to either high level input terminal on UUT. Cables should be connected to an integrated amplifier fed by the signal generator.

7.Turn on generator and adjust so that speaker level output is 1.0V, 50Hz. Turn VOLUME control full clockwise.

8.Green LED should light, immediate bass response should be heard and felt from the port tube opening.

Sweep Function

1.Follow steps 1-4 above, using a sweep generator as a signal source.

2.Sweep generator from 20Hz to 300Hz. Listen to the cabinet and drivers for any rattles, clicks, buzzes or any other noises. If any unusual noises are heard, remove driver and test.

Driver Function

1.Remove driver from cabinet; detach + and – wire clips.

2.Check DC resistance of driver; it should be 4.8 ohms.

3.Connect a pair of speaker cables to driver terminals. Cables should be connected to an integrated amplifier fed by a signal generator and adjust so that speaker level output is 5.0V.

4.Sweep generator from 20Hz to 1kHz. Listen to driver for any rubbing, buzzing, or other unusual noises.

12

PB12

Service Bulletin

Service Bulletin JBL2001-03 Rev1 – January 2002 |

This is considered a Minor repair |

To: All JBL Service Centers

Models: PB10, PB12 (Revision 1 only)*

Subject: Unit Will Not Switch to Standby Mode

When the power cord of the PB series subwoofer is plugged into a wall outlet (and for the PB12 only, the power switch is on), and an audio signal is present, the LED’s on the cabinet face will turn green, indicating the subwoofer is in the ON mode. With the audio signal removed, it will take 10 - 15 minutes for the LEDs to turn from green to red, indicating the subwoofer is now in the STANDBY mode. Power consumption is minimal in this mode.

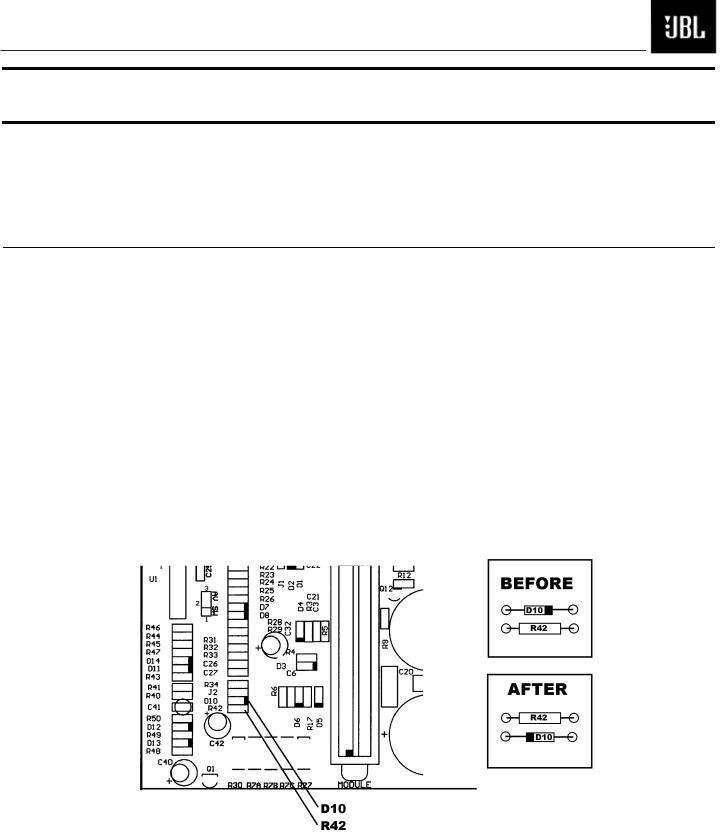

In the event you receive a PB10 or PB12 subwoofer with the complaint: “The unit will not switch to standby mode, even when the audio signal is removed” (indicated by the subwoofer’s green LED’s remaining on), perform the following modification:

1)Set the unit on a padded surface and remove all external cables.

2)On the amplifier faceplate, remove the (10) Phillips mounting screws around the perimeter.

3)Remove the amplifier assembly from the enclosure. If the amp is turned and supported correctly, no other connectors need to be unplugged.

4)Locate Zener Diode D10 and Resistor R42 (22kΩ). See illustration. These parts must be “swapped”, i.e., R42 soldered into the D10 location, and D10 soldered into the R42 location. VERY IMPORTANT: Observe polarity on D10 in new location.

5)Replace amplifier; test subwoofer to assure the unit goes into the standby mode 10 - 15 minutes after removing the Audio input signal.

|

|

|

|

|

|

|

|

Model |

Serial number |

Status |

Action |

|

|

|

|

|

|

Swap locations: |

|

|

|

PB10 * |

All serial numbers |

Unit may not switch to Standby mode |

Zener Diode D10, |

|

|

|

PB12 * |

affected |

|

Resistor R42 (22kΩ). |

|

|

|

|

|

|

|

||

|

|

|

|

Observe D10 polarity. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* Revision 1 of the PB10/12: Amplifier faceplate says “Made in Canada”; Amplifier serial number starts with “AM” |

||||||

|

|

Black (or silver) potted, non-serviceable S53/64AMI output module. PB10 only – No Power switch |

||||

13

PB12

|

Service Bulletin |

|

|

|

|

|

|

Service Bulletin JBL2001-04 Rev1 – January 2002 |

|

|

|

|

This is considered a Minor repair |

|

|

To: All JBL Service Centers |

|

|

|

Models: PB10, PB12 (Revision 1 only)* |

|

|

|

Subject: Hum, Buzz or “Thumping” |

|

|

|

In the event you receive a PB10 or PB12 subwoofer complaint: “There is an audible hum or buzz”, or the subwoofer “thumps” or “pops” every 10 seconds, then review the conditions below to determine the most effective solution:

A)Audible Hum with unit on, Green LED is ON, hum disappears completely when the connecting input cables (RCA or Speaker-Level) are disconnected:

Very long runs of line-level input cables, particularly in parallel with AC power cords, may induce hum in the audio cables. Check audio cables for defects, broken ground connections, or replace low quality cables. Try plugging the AC power cord from the subwoofer into a different AC service outlet other than the outlet the rest of the audio equipment is plugged into.

B)Mild Audible Hum under all circumstances when power cord is plugged in outlet. Hum level does not change whether the LED’s are Red or Green, or input cables are connected or disconnected. Level control adjustments do not change the hum level.

This is a mechanical hum caused by the power transformer. Note that a slight hum, within design limits, may be noticeable in a very quiet room, when you are close to the unit. This is acceptable within the PB10’s product and price category to most customers, but not to others. If the mechanical hum is unacceptable to the customer, then replace Power Transformer. PB10: JBL part# 80135. PB12: JBL part# 80116

C)Loud Hum, under all circumstances. It may be louder when LED’s are Green vs. Red ; it may be affected by the position of the Level control. The subwoofer may “thump” or “pop” approximately every 10 seconds.

Reset the digital subwoofer amplifier by unplugging the AC power cord. Wait 30 seconds, then plug the cord back in. Repeat this 2-3 times if necessary.

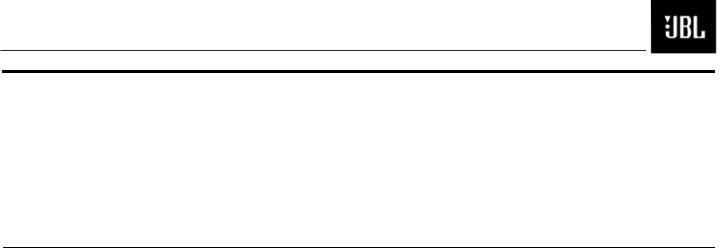

For #C only - If the unit still does not function correctly, then replace Power Amp Module S53/64AMI as per instructions below: PB10: JBL part# 60301 PB12: JBL part# 60302

1)Set the unit on a padded surface and remove all external cables.

2)On the amplifier faceplate, remove the (10) Phillips mounting screws around the perimeter.

3)Remove the amplifier assembly from the enclosure. If the amp is supported correctly, no other connectors need to be unplugged.

4)Locate the Power Amp Module S53/64AMI, see location on the following page. It is the large black or gray component with a metal case. On the solder side of the circuit board are 28 soldered connections. NOTE: See special handling instructions for S53/64AMI on the following page.

5)Replace the amplifier assembly back into the cabinet; replace the screws.

6)Test the unit and confirm the original problem has been corrected. NOTE: THE PB10/12 REVISION 1 AMPLIFIER MUST ALWAYS BE TESTED WITH A WOOFER OR 4 OHM RESISTIVE LOAD.

|

|

|

|

|

|

|

MODEL |

Serial Number (120v) |

STATUS |

ACTION |

|

|

|

Serial numbers are located on the cabinet directly |

|

|

|

|

|

below the amplifier faceplate. |

|

|

|

|

PB10 |

See serial numbers on Page 3 for factory |

Hum, Buzz or “Thumping” |

Replace Power Amp Module S53AMI |

|

|

|

modified units |

|

for symptoms described in #C only |

|

|

|

|

|

|

|

|

PB12 |

|

Hum, Buzz or “Thumping” |

Replace Power Amp Module S64AMI |

|

|

|

|

|

for symptoms described in #C only |

|

|

|

|

|

|

|

|

|

|

|

|

|

* Revision 1 of the PB10/12: Amplifier faceplate says “Made in Canada”; Amplifier serial number starts with “AM”

Black (or silver) potted, non-serviceable S53/64AMI output module. PB10 only – No Power switch

14

PB12

PB10/12 Revision 1 Only

S53AMI/S64AMI - Power Amp Module SAFETY PART

+6V |

15 |

|

|

|

|

|

1 |

|

|

+6V |

|

NOTE: THE FOLLOWING PROCEDURES MUST BE |

||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

FOLLOWED WHEN INSTALLING NEW S53AMI/S64AMI |

||||||

|

16 |

|

|

|

|

|

2 |

|

|

|

|

AMP MODULES: |

||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

FAILURE TO FOLLOW ONE OR MORE OF THESE STEPS |

||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MAY RESULT IN THE INSTANT DESTRUCTION OF THE |

V+ |

17 |

|

|

|

|

|

3 |

|

|

V+ |

|

|||

|

|

|

|

|

|

|

|

MODULE WHEN POWERED UP. |

||||||

|

|

|

18 |

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Align white indent marker on Amp Module with indent |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||||

O/P |

19 |

|

|

|

|

|

5 |

|

|

O/P |

|

marker on main PCB; alternately observe position of label |

||

|

|

|

|

|

|

|

|

on top of the Module; incorrectly replacing the Module |

||||||

|

20 |

|

|

|

|

|

6 |

|

|

|

|

180° in the PCB slot will result in its destruction. |

||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

2. All AC powered test instruments (meters, oscilloscopes, |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

etc.) must have a floating ground, i.e., be connected to |

V- |

21 |

|

|

|

|

|

7 |

|

|

V- |

|

|||

|

|

|

|

|

|

|

|

an isolation transformer. |

||||||

|

|

|

22 |

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. Align and position the Amp Module before soldering. |

||

|

|

|

|

|

|

|

|

|

|

|

||||

+15V |

23 |

|

|

|

|

9 |

|

|

+15V |

|

4. Attach the Amp Module with the mounting screws before |

|||

|

|

|

|

|

|

|

|

|||||||

SD |

24 |

|

|

|

|

|

10 |

|

SD |

|

soldering or powering up. |

|||

|

|

|

|

|

|

|

5. Use only rosin-core or non-acid core solder; thoroughly |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FR |

25 |

|

|

|

|

|

11 |

|

FR |

|

de-flux the surfaces after soldering. |

|||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|||||||

I/P |

26 |

|

|

|

|

|

12 |

|

I/P |

|

If the new S53AMI/S64AMI Amp Module has larger mounting |

|||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

hole(s) in the case, and the stock screws no longer will fit, |

|||||||

GND |

27 |

|

|

|

|

|

13 |

|

GND |

|

and screws of the proper type cannot be obtained locally |

|||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

order: |

|||||||

-15V |

28 |

|

|

|

|

|

14 |

|

-15V |

00228 |

(2) part# 60301S (screws) |

|||

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(2) part# 60301N (nuts) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15

PB12

|

Service Bulletin |

|

|

|

|

|

|

Service Bulletin JBL2001-05 Rev2 - February 2002 |

|

|

|

|

This is considered a Minor repair |

|

|

To: All JBL Service Centers |

|

|

|

Models: PB12 (Revision 1 only)* |

|

|

|

Subject: Popping Every Few Seconds During Play |

|

|

|

In the event you receive a PB12 subwoofer with the complaint: “The subwoofer “thumps” or “pops” every few seconds of play”, follow the procedure below:

Probable Cause:

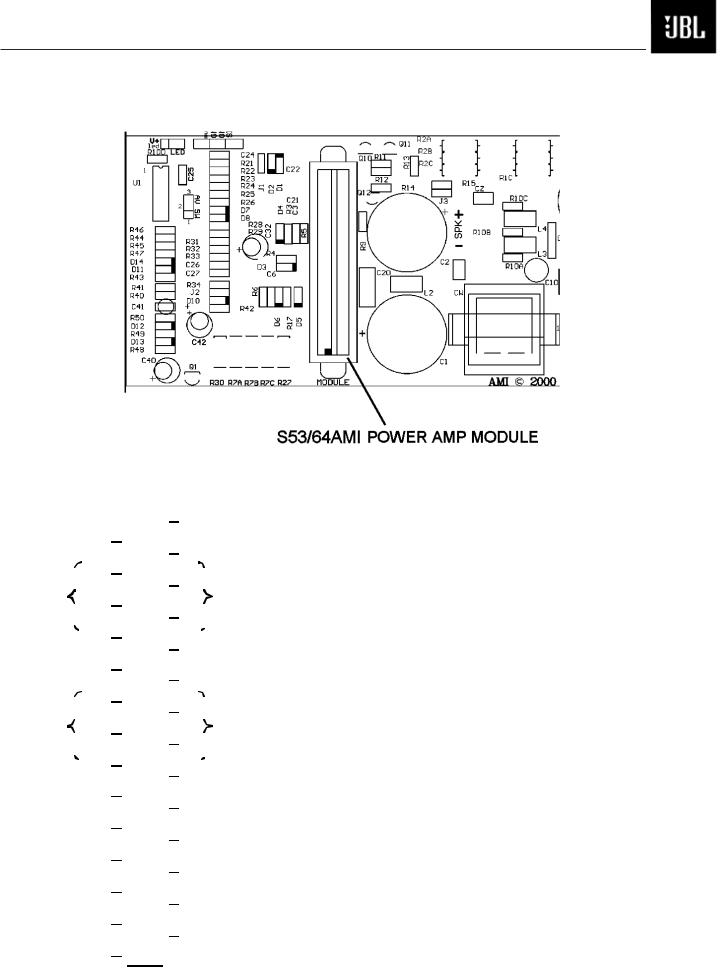

Inductor L1 (220uH) may be damaged.

Check and Replace L1 if necessary:

1)Set the unit on a padded surface and remove all external cables.

2)On the amplifier faceplate, remove the (10) Phillips mounting screws around the perimeter.

3)Remove the amplifier assembly from the enclosure. If the amp is supported correctly, no other connectors need to be unplugged.

4)Locate Inductor L1 on the main PCB. If the windings appear charred or burnt, it must be replaced.

5)Order JBL part# 80121 and replace L1.

6)Replace the amplifier assembly back into the cabinet; replace the screws.

7)Test the unit and confirm the original problem has been corrected.

|

|

|

|

|

|

|

Model |

Serial number (120V) |

Status |

Action |

|

|

PB12 * |

AM0035-24318 and below |

L1 may be damaged |

Replace L1 |

|

|

|

|

if experiencing above symptoms |

with JBL part# 80121 |

|

|

PB12 * |

AM0035-24319 and above |

Modified by factory |

None required |

|

|

|

|

|

|

|

* Revision 1 of the PB12: Amplifier faceplate says “Made in Canada”; Amplifier serial number starts with “AM” Black (or silver) potted, non-serviceable S64AMI output module.

16

PB12

Service Bulletin

Service Bulletin JBL2001-07 Rev1 - February 2002 |

This is considered a Minor repair |

To: All JBL Service Centers

Model: PB12 (Revision 1 only)*

Subject: Possible Missing Diode D4

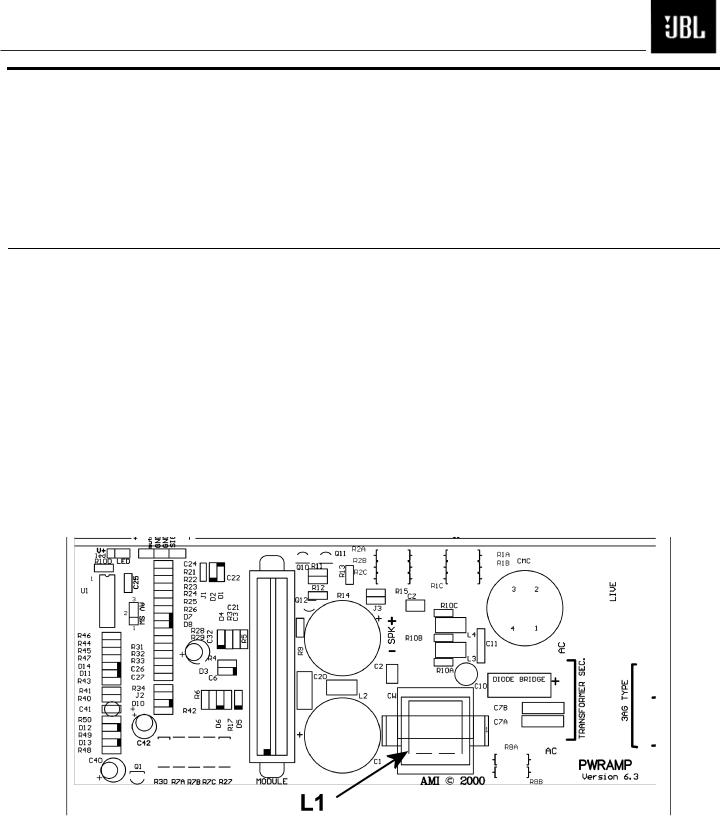

In the event you receive a PB12 subwoofer for any servicing reason, check for the presence of diode D4 on the Main PCB close to the Power Amp Module (see illustration). If D4 is missing or has been “cut out” of the circuit, it should be replaced; add JBL part# 50115. Observe polarity.

Note: The presence or absence of D4, in itself, does not contribute to, or solve, an amplifer failure. Purpose of D4 is to reduce the possibility of an occasional Turn-OFF pop noise.

Reference for general location only; all parts or designators may not conform exactly to this drawing.

* Revision 1 of the PB12:

Amplifier faceplate says “Made in Canada”; Amplifier serial number starts with “AM” Black (or silver) potted, non-serviceable S64AMI output module.

17

Loading...

Loading...