Page 1

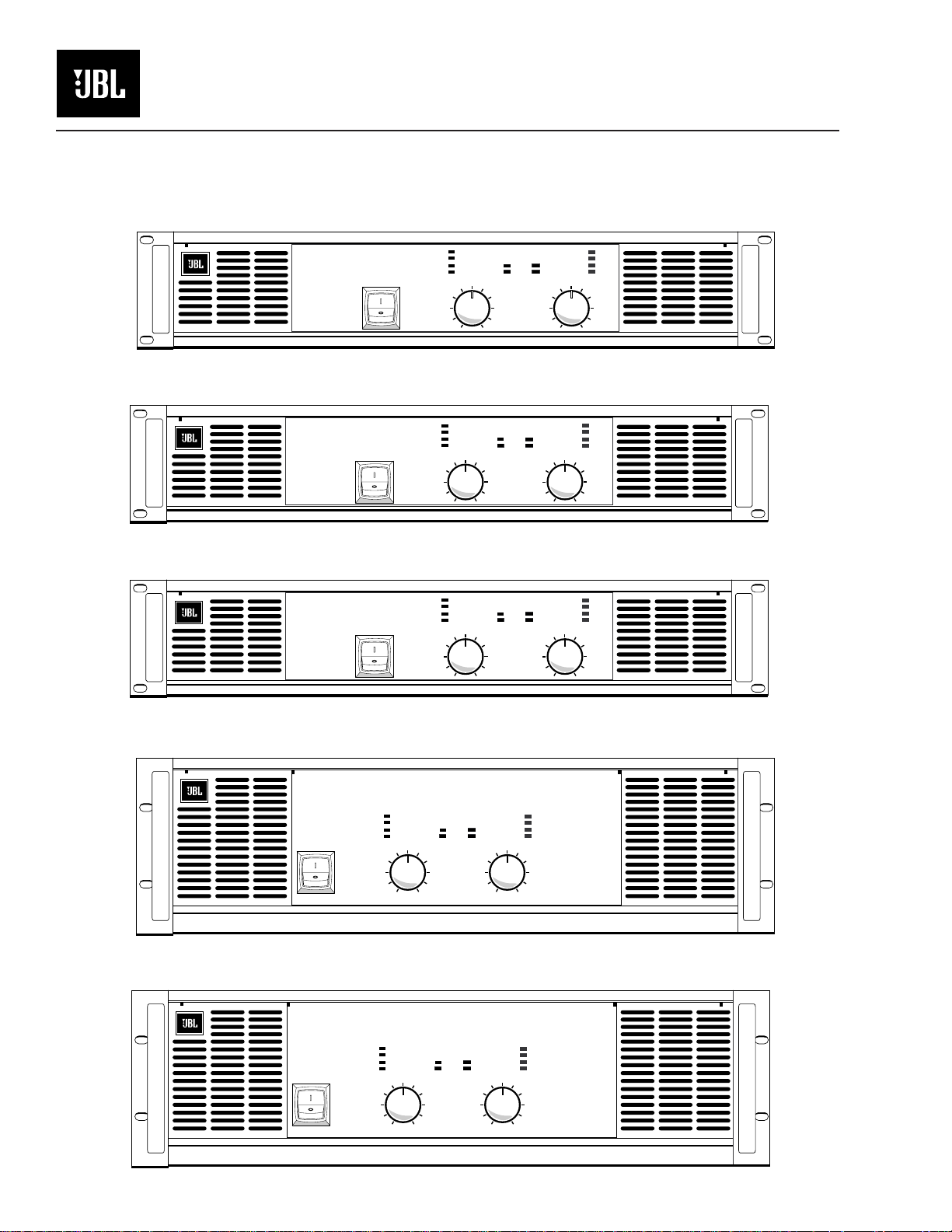

MPA Series

Power Amplifiers

Owner’s Manual

MPA275

MPA400

MPA275

MPA400

MPA600

P r o f e s s i o n a l A m p l i f i e r

P r o f e s s i o n a l A m p l i f i e r

P r o f e s s i o n a l A m p l i f i e r

Clip

-10dB

-20dB

Signal Present

10

12

14

18

24

48

Clip

-10dB

-20dB

Signal Present

10

12

14

18

24

48

Clip

-10dB

-20dB

Signal Present

10

12

14

18

24

48

8

0

8

6

2

0

8

6

2

0

6

4

2

1-CHANNEL-2

Protect

Power

4

1-CHANNEL-2

Protect

Power

4

1-CHANNEL-2

Clip

14

18

24

14

18

24

14

18

24

Signal Present

12

48

Signal Present

12

48

Signal Present

10

12

48

Clip

-10dB

-20dB

10

Clip

-10dB

-20dB

10

-10dB

-20dB

8

6

4

2

0

8

6

4

2

0

8

6

4

2

0

Protect

Power

MPA600

MPA750

MPA750

MPA1100

P r o f e s s i o n a l A m p l i f i e r

Clip

-10dB

-20dB

Signal Present

10

8

12

14

18

6

24

2

48

0

P r o f e s s i o n a l A m p l i f i e r

Clip

-10dB

-20dB

Signal Present

10

8

12

14

18

6

24

4

2

48

0

Protect

Power

4

1-CHANNEL-2

Protect

Power

1-CHANNEL-2

14

18

24

14

18

24

Signal Present

12

48

Signal Present

10

12

48

Clip

-10dB

-20dB

10

8

6

4

2

0

Clip

-10dB

-20dB

8

6

4

2

0

MPA1100

Page 2

Cautions

Sicherheitsvorschriften

Rack Mounting Precautions

To avoid damage to the amplifier mounting ears

and/or rack rails, the amplifier must be supported at all

four corners when used in portable racks.

Consult JBL Service Dept for availability of Rear

Support Brackets.

Lifting Precautions

In order to safely move or install the amplifier, it is

recommended that two persons share the weight when

lifting and positioning the unit.

CAUTION

TO AVOID ELECTRIC SHOCK, DO NOT INSERT FINGERS

OR OBJECTS INTO ANY OPENINGS IN THE CABINET.

WARNING: TOPREVENTFIREORELECTRIC

SHOCK

, DONOTEXPOSETHISEQUIPMENTTORAIN

ORMOISTURE

.

Explanation of Graphical Symbols

The lightning flash with arrowhead symbol, within an equilateral triangle, is intended to alert the user to the presence

of uninsulated “dangerous voltage” within the product’s

enclosure that may be of sufficient magnitude to constitute

a risk of electric shock to humans.

The exclamation point within an equilateral triangle is

intended to alert the users to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the product.

Sicherheitsvorschriften für den Einbau in ein Gestell

Um Schäden auf den Befestigungsleisten des

Verstärkers und/oder den Gestellschienen zu vermeiden, muß der Verstärker beim Einbau in ein tragbares Gestell an allen vier Ecken gestützt werden.

Erkundigen Sie sich bei der JBLKundendienstabteilung nach Stützen für die

Rückseite des Verstärkers.

Sicherheitsvorschriften beim Hochheben

Um den Verstärker sicher zu verschieben oder

einzubauen, wird empfohlen, das Gewicht des

Verstärkers beim Hochheben und Verschieben gleichmäßig auf zwei Personen zu verteilen.

VORSICHT

UM ELEKTRISCHEN SCHLAG ZU VERMEIDEN, KEINE

FINGERN ODER GEGENSTÄNDE IN ÖFFNUNGEN DES

WARNUNG:

ELEKTRISCHENSCHLÄGENDASGERÄTNICHMITREGEN

ODERFEUCHTIGKEITINBERÜHRUNGBRINGEN

Erklärung der graphischen Symbole

Der Blitz mit nach unten zeigendem Pfeil in einem gleichseitigen

Dreieck weist den Benutzer auf das Vorhandensein einer

unisolierten, “gefährlichen Spannung” im Gehäuse hin, die stark

genug sein kann, einer Person einen elektrischen Schlag zu versetzen.

Das Ausrufezeichen in einem gleichseitigen Dreieck weist den

Benutzer auf nichtige Betriebs - und Wartungsvorschriften in den

Beiliegenden Unterlagen des Geräteshin.

GEHÄUSES STECKEN.

ZURVERMEIDUNGVONFEUERODER

.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TOREDUCETHERISKOFELECTRIC

SHOCK, DONOTREMOVETHECOVER. NOUSER-

SERVICEABLEPARTSINSIDE. REFERSERVICINGTO

QUALIFIEDSERVICEPERSONNEL

.

CAUTION

RISK OF ELECTRIC SHOCK:

OPEN ONLY IF QUALIFIED

AS SERVICE PERSONNEL

To reiterate the above warnings: servicing instructions are for use by qualified personnel only. To avoid

electric shock, do not perform any servicing other than

that contained in the Operation Instructions unless you

are qualified to do so. Refer all servicing to qualified

service personnel

VORSICHT

GEFAHR EINES ELEKTRISCHEN

SCHLAGES NICHT ÖFFNEN

VORSICHT:

SCHLAGESZUVERMINDERN

ENTFERNEN

INNERN

BEDIENUNGSPERSONAL

UMDASRISIKOEINESELEKTRISCHEN

,

KEINEBENUTZERBEDIENUNGSTEILEIM

.

.

BEDIENUNGNURDURCHQUALIFIZIERTES

ABDECKUNGNICHT

.

VORSICHT

GEFAHR EINES ELEKTRISCHEN SCHLAGES: NUR VON

QUALIFIZIERTEM WARTUNGSPERSONAL ZU ÖFFNEN

Eindrigliche Warnung: Wartungsvorschriften dienen

nur der Benutzung durch qualifiziertes Personal. Zur

Vermeidung eines elektrischen Schlages keine anderen

als die in den Betriebsvorschriften beschriebenen

Wartungsarbeiten ausführen, es sei denn, Sie sind dafür

qualifiziert. Wartungsarbeiten sind von qualifiziertem

Wartungspersonal auszuführen.

1

Page 3

2

Cautions .................................................................................................................1

Unit Description ....................................................................................................3

General Information....................................................................................................3

Open Input Architecture™ Slots.................................................................................3

Feature Identification...................................................................................................4

Installation.............................................................................................................5

Inputs ...........................................................................................................................5

Outputs ........................................................................................................................5

Input Connections.......................................................................................................6

Changing XLR Polarity.................................................................................................7

To Parallel the Inputs..................................................................................................7

Bridged Mono Mode ...................................................................................................8

AC Power Connection.................................................................................................9

Operation .............................................................................................................10

Controls......................................................................................................................12

Gain Control Lockout................................................................................................12

Displays......................................................................................................................12

Typical Power Up, Operation, Power Down Behavior...........................................12

Maximum Long-Term Output Power........................................................................14

Protection Circuits......................................................................................................14

Specifications.......................................................................................................16

Power Output Ratings ...............................................................................................17

Troubleshooting ..................................................................................................19

Illustrations

Figure 1. Open Input Architecture Slots.....................................................................3

Figure 2. Rear and Front Views of 2-Space High Amplifiers ....................................4

Figure 3. Rear and Front Views of 3-Space High Amplifiers ....................................4

Figure 4. Neutrik Speakon Connector Wiring for Speaker Outputs.........................5

Figure 5. Typical Unbalanced Connection.................................................................6

Figure 6. Portable Balanced System ...........................................................................6

Figure 7. Installed Balanced System...........................................................................6

Figure 8. Ground Bus Connection..............................................................................6

Figure 9. Jumper Positions for XLR Polarity Reversal................................................7

Figure 10. Switch Settings for Bridged Mono Operation...........................................7

Figure 11. Connection Options of Speaker Load for Bridged Mono ......................8

Figure 12. Speakon Connection Details for Bridged Mono Operation. ...................8

Figure 13. Gain Control Lockout...............................................................................12

Figure 14. LED Displays During Normal Operation................................................13

Figure 15. LED Displays During Abnormal Operating Conditions .........................13

Tables

Table 1. JBL MPA Series AC Power Consumption

versus Load Impedance With 110, 115 & 120 V Mains ..............................9

Table 2. JBL MPA Series AC Power Consumption

versus Load Impedance With 220, 230 & 240 V Mains.............................10

Table 3. LED Display Operation...............................................................................11

Table 4. Output Ratings With 110, 115 and 120 V Mains........................................16

Table 5. Output Ratings With 110, 115 and 120 V Mains........................................17

Table of Contents

Page 4

3

The MPA275, MPA400, MPA600, MPA750 and MPA1100 are high-efficiency professional power amplifiers, with two independent channels, respectively capable of delivering 275, 400, 600, 750 and 1100 watts into a four ohm load (per channel), and

substantially more power into lower impedance loads. Semi-toroidal power transformers (one per channel in the MPA750 and MPA1100) are mounted in each front

corner, as close as possible to the rack ears and rails. The rear panels are 16.9 inches

behind the front mounting plane, so an extra rack depth allowance (i.e., more than

18 inches) will be needed to clear XLR or Speakon connections. The built-in fan

cooling takes air in the rear, exhausting through front vents. Due to the flow-through

cooling, amplifiers may be racked with zero clearance in between, which also helps

support the weight. Rear support within the rack must be used in portable applications.

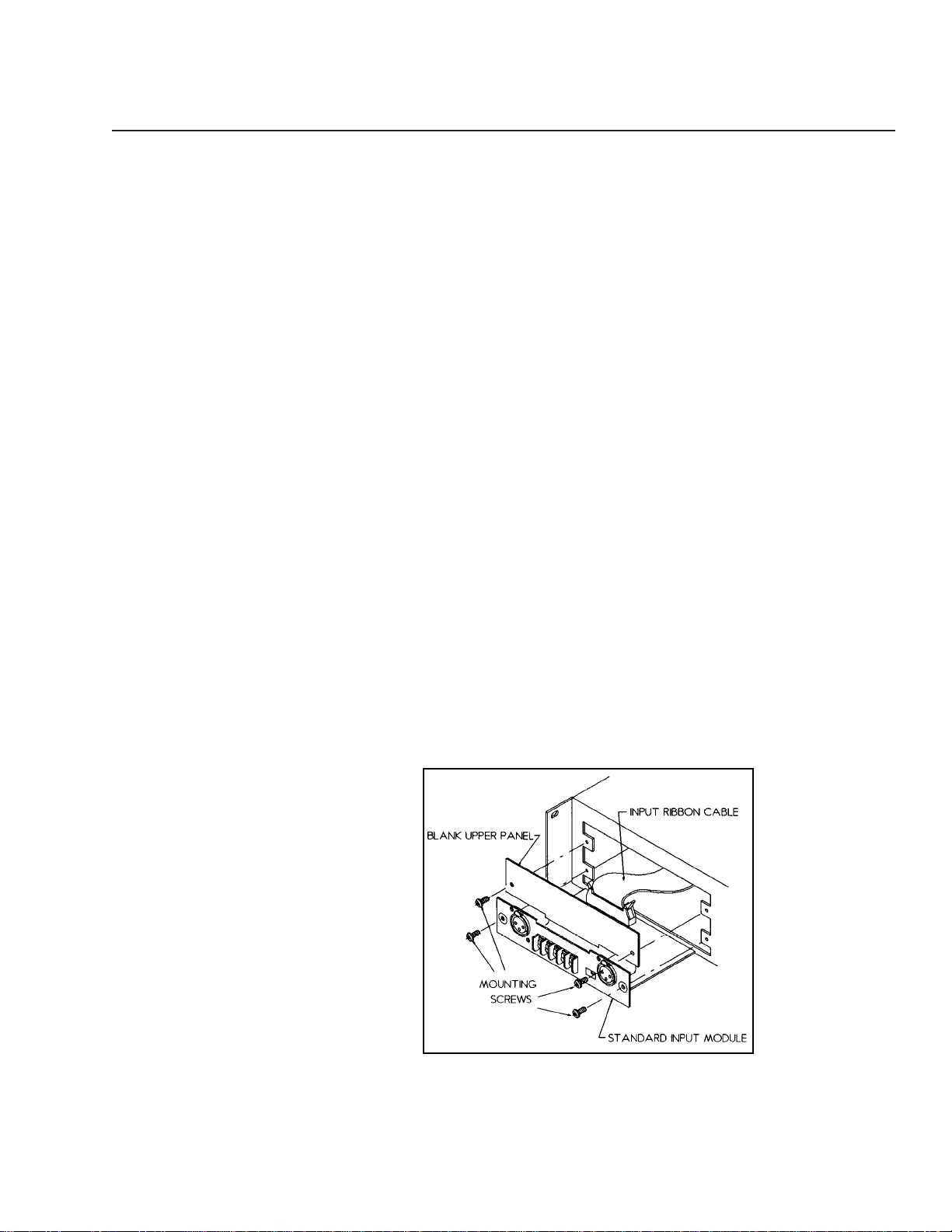

Open Input Architecture™ Slots

Provided with each MPA Series amplifier is a standard input module. This module

and the upper input cover panel can be removed, permitting future upgrades.

Internally, a ribbon cable runs behind both of these “slots.” The ribbon cable connects to the rest of the amplifier and carries several levels of DC power, and (for each

channel) the input signals, speaker output monitor, muting status, clip activity, thermal status, and power-on status. These signals are provided to support future remote

control and monitoring schemes as they become available. The JBL Marketing department will be happy to entertain suggestions for input modules.

The “standard input board” which is shipped with each amplifier has balanced

XLR and barrier strip inputs, bridging and input-parallel switches, and footprints for

passive rolloffs and popular input isolation transformers (more info is available on

request).

Unit Description

Figure 1. Open Input Architecture Slots.

Page 5

4

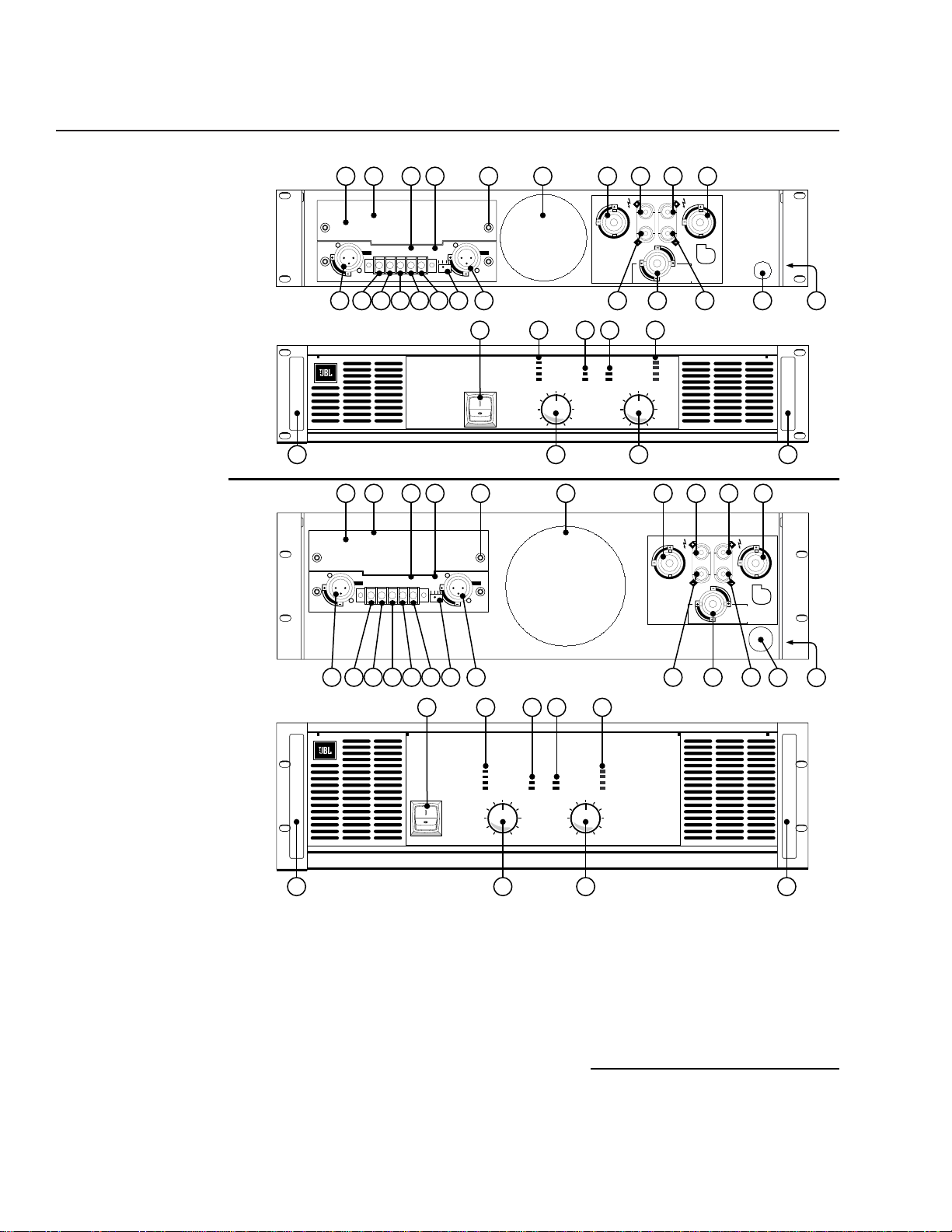

Figure 2. Rear and

Front Panel for

2–Space High

Models (MPA275,

MPA400 & MPA600)

Figure 3. Rear and

Front Panel for

3–Space High

Models (MPA750

and MPA1100)

Rear Panel Features

1. Upper Input Slot

2. Upper Input Cover Panel

3. Slot Product Mounting Screws

4. Lower Input Slot

5. Standard Input Board

6. Channel 2 XLR Input Connector

7. Channel 1 XLR Input Connector

8. Channel 2 (+) Terminal Block Input

9. Channel 2 (–) Terminal Block Input

10. Channel 1 & 2 Ground Terminal

11. Channel 1 (–) Terminal Block Input

12. Channel 1 (+) Terminal Block Input

13. Configuration Selector Switch

14. Fan

15. Channel 2 Speakon Output Connector

16. Channel 1 Speakon Output Connector

17. Channel 2 (+) Binding Post *

18. Channel 2 (–) Binding Post *

19. Channel 1 (+) Binding Post *

20. Channel 1 (–) Binding Post *

21. Dual-Channel Out Speakon Connector

22. Rear Rack Support (Left and Right)

23. Power Cord

Front Panel Features

24. Unit Power Switch

25. Channel 1 Level Display

26. Channel 2 Level Display

27. Channel 1 Power & Protection Display

28. Channel 2 Power & Protection Display

29. Channel 1 Gain Control

30. Channel 2 Gain Control

31. Handle (Left and Right)

*Banana output for 100–115 VAC Units Only

Unit Description

1 2 4 5 3 14 15 1617 19

CHANNEL 2

OUTPUT

– BRIDGED MONO +

CHANNEL 1

OUTPUT

GND

P1

P3

CHANNEL 2

INPUT

GND

+– –+

11

MPA600

P2

PARALLEL

STEREO

BRIDGE

CHANNEL 1

126 7

13

GND

P1

P3

DUAL CHANNEL

OUTPUT CONNECTOR

STEREO

4 OHM MIN PER CH

18 20211098

24 27 28 26

P r o f e s s i o n a l A m p l i f i e r

25

18

14

24

Clip

-10dB

-20dB

Signal Present

10

12

48

8

0

6

4

2

1-CHANNEL-2

Protect

Power

29

18

14

24

CH 2

Signal Present

10

12

48

30 3131

Clip

-10dB

-20dB

8

6

4

2

0

P2

SENSITIVITY

1 VOLT

IMPEDANCE

20K BAL

10K UNBAL

1 2 4 5 3 14 15 1617 19

CHANNEL 2

OUTPUT

P3

CHANNEL 2

GND

P1

INPUT

GND

+– –+

11

P2

GND

P1

PARALLEL

STEREO

BRIDGE

CHANNEL 1

MPA1100

P3

126 7

13

24 27 28 26

25

P r o f e s s i o n a l A m p l i f i e r

Clip

-10dB

-20dB

Signal Present

10

8

12

14

6

18

4

24

2

48

0

Protect

Power

1-CHANNEL-2

18

14

24

Signal Present

12

48

DUAL CHANNEL

OUTPUT CONNECTOR

STEREO

4 OHM MIN PER CH

Clip

-10dB

-20dB

10

8

6

4

2

0

P2

SENSITIVITY

1 VOLT

IMPEDANCE

20K BAL

10K UNBAL

CH 1

+

BRIDGED MONO

8 OHM MIN

–

23 22

CH 1

BRIDGED MONO

8 OHM MIN

+

–

CHANNEL 1

OUTPUT

23 22

– BRIDGED MONO +

CH 2

18 20211098

29

30 3131

Page 6

5

Installation

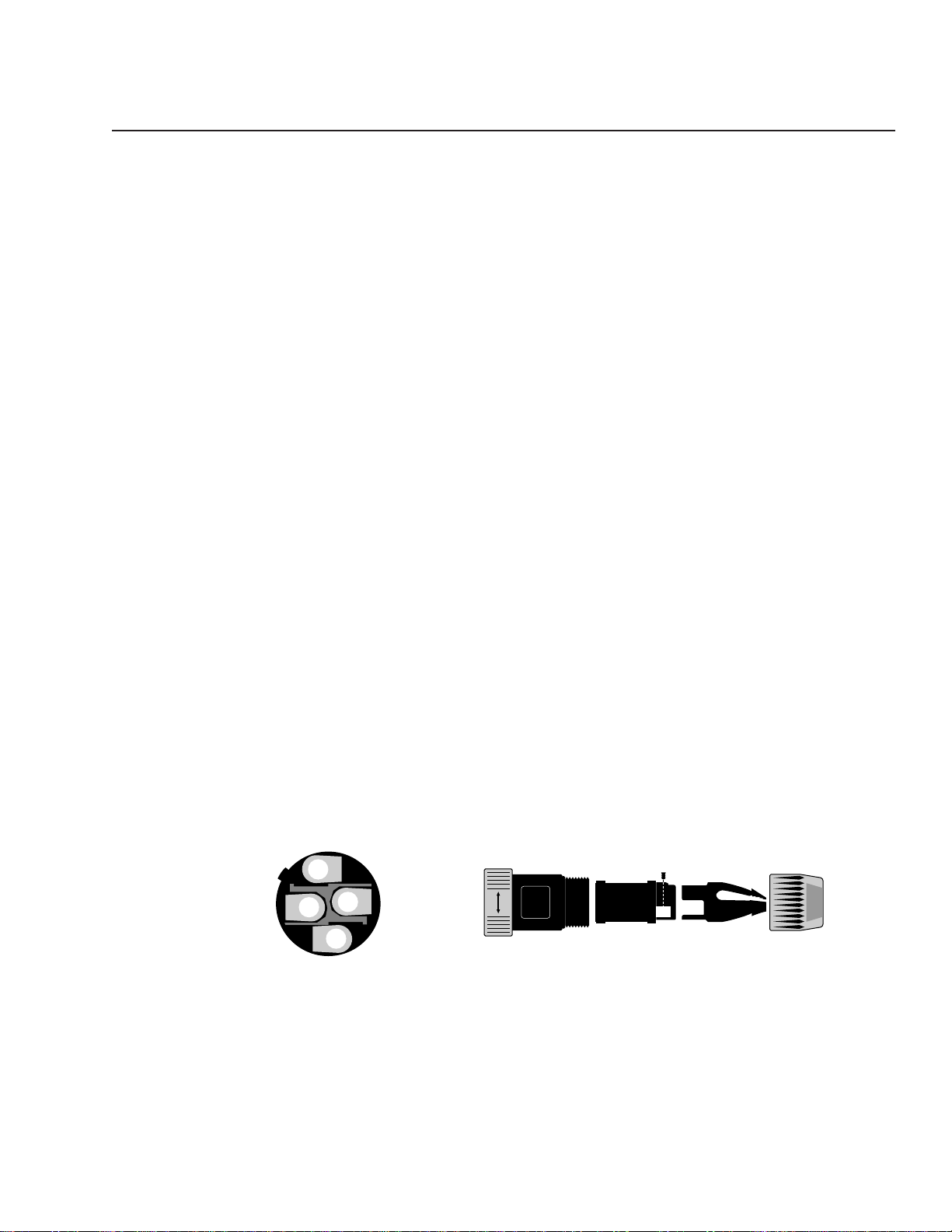

Figure 4. Neutrik Speakon Connector Wiring for Speaker Outputs

Exploded view (side)

Connection Terminals

Inputs

Balanced input connections are available via barrier strip or XLR connectors. The unit

is shipped with pin 2 high (see subsequent instructions to change polarity). As usual,

for unbalanced inputs, the unused terminal should be terminated to ground (the

negative input terminals on the barrier strip are located adjacent to the ground terminal for this purpose).

Input sensitivity is 1 Vrms, and impedance is 20 kilohm balanced, 10 kilohm

unbalanced, as is typical of JBL amplifiers.

The input jacks are located on a removable panel which has a toggle switch for

(1) bridged-mono (2) normal stereo, or (3) paralleling the inputs. See page 2 for more

information about the Open Input Architecture slots.

Outputs

Speaker connections are made via standard red/black 5-way binding posts, or by

Neutrik NL4FC Speakon connectors. The Speakon for each channel uses the standard

wiring of:

Pin 1- = Speaker Ground

Pin 1+ = Speaker Hot

Pin 2- = [Not used]

Pin 2+ = [Not used]

In addition, a central Speakon is provided with the standard stereo wiring of:

Pin 1- = Ch 1 Ground

Pin 1+ = Ch 1 Hot

Pin 2- = Ch 2 Ground

Pin 2+ = Ch 2 Hot

2–

2+

1+

1–

NEUTRIK

SPEAKON

NL4FC

SWISS MADE

Page 7

Xx

6

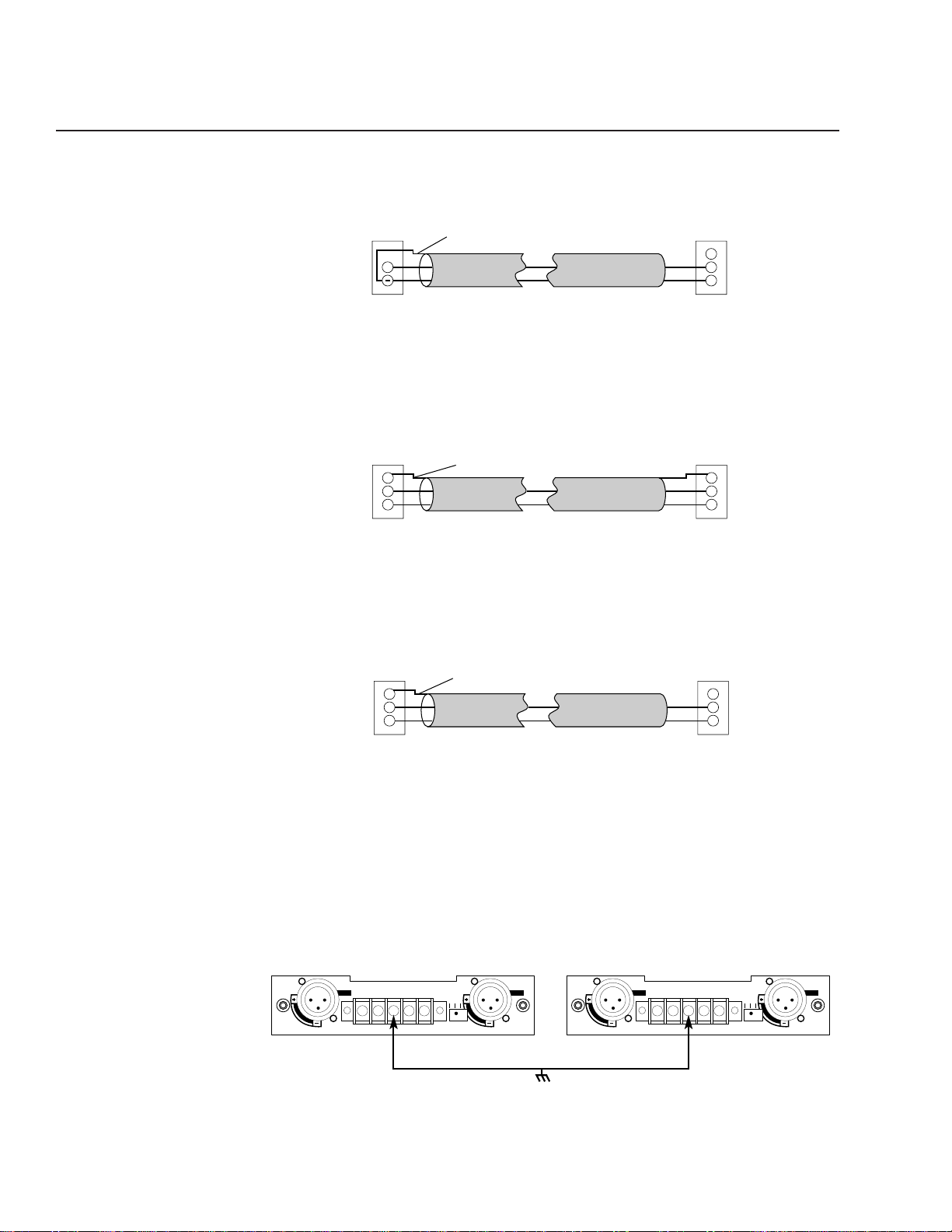

Input Connections

Figure 5. Typical Unbalanced Connection

To connect an unbalanced source to the input of an MPA amplifier, “+” should be

connected to pin 2, and “-” to pin 3 The “-” terminal should also be connected to the

shield at the source only. Pin 1 should not be connected at the amplifier.

Figure 6. Portable Balanced System

In a portable system using a source unit with balanced outputs, a standard XLR cable

wired pin to pin (with pin 1 connected to the shield at both ends) should be used.

Figure 7. Installed Balanced System

In an installed system using a source unit with balanced outputs, pin 1 should be

connected to the shield at the source, with no connection to pin 1 at the amplifier.

If, after wiring the input as shown above, any hum or buzzing is present, connect

the GND terminals of all amplifiers together. This bus should then be connected to a

stable earth ground. It may also be necessary to connect the chassis of the input

source device to the ground bus, particularly when using an unbalanced source.

Figure 8.

Output

(Source)

+

Unbalanced

Shield

MPA Input

1

2

3

Balanced

Output

(Source)

1

2

3

Balanced

Shield

MPA Input

1

2

3

Balanced

Output

(Source)

1

2

3

Balanced

Shield

MPA Input

1

2

3

Balanced

SENSITIVITY

1 VOLT

IMPEDANCE

20K BAL

10K UNBAL

P2

P3

CHANNEL 2

INPUT

+– –+

GND

P1

CHANNEL 1

PARALLEL

P2

GND

STEREO

BRIDGE

P1

P3

GND

SENSITIVITY

1 VOLT

IMPEDANCE

20K BAL

10K UNBAL

P2

P3

CHANNEL 2

INPUT

+– –+

GND

P1

CHANNEL 1

PARALLEL

P2

GND

STEREO

BRIDGE

P1

P3

GND

Page 8

Installation

Caution:

The XLR polarity changes

as outlined on this page

should only be done by

qualified personnel with

“board level” soldering

experience.

Changing the XLR polarity

The MPA275, MPA400, MPA600, MPA750 and MPA1100 are shipped with XLR polarity

set at pin 2 high. To convert to pin 3 high:

1. Remove the Standard Input Module and input ribbon cable. (See Figure 1).

2. Find the soldered jumpers W303, W304 (Ch 1) and W403, W404 (Ch 2), located

behind each XLR jack. These are soldered in positions marked “PIN 2 HI”.

3. Desolder each jumper, and move it lengthwise 0.2 inches to its alternate mounting position (the end marked “PIN 3 HI”), and resolder. Each jumper should fit

in its new position evenly without changing its length. All four must be moved

or the input signal will not be properly connected. (See Figure 5).

4. Label the outside of the Input panel to show that pin 3 is now High.

NOTE: THIS ADJUSTMENT DOES NOT ALTER THE POLARITY OF THE

BARRIER STRIP, which remains as marked on the rear panel.

5. Install the input ribbon cable and remount the Standard Input Module securely.

Jumper positions for

“Pin 2 High”

W303

XLR POLARITY

PIN 2 HI PIN 3 HI

W304

Jumper positions for

“Pin 3 High”

W303

XLR POLARITY

PIN 2 HI PIN 3 HI

W304

Figure 9. Jumper Positions for XLR Pin 2 High (factory preset), and Pin 3 High.

Note: Both channels must be modified for proper polarity reversal.

To Parallel the Inputs

1. Locate the selector switch adjacent to the CHANNEL 1 input XLR connector ,

and set it to the PARALLEL position (see Figure 6 below, left).

+

CHANNEL 1

PARALLEL

STEREO

P2

BRIDGE

GND

P1

P3

Parallel CH 1 & CH 2 Inputs,

Dual Mono Outputs Mode

+

CHANNEL 1

Shared CH 1 (Polarity Reversed) Input,

Bridged Output Mono Mode

PARALLEL

STEREO

P2

BRIDGE

GND

P1

P3

Figure 10. To Parallel the Input Jacks or for Bridged Mono,

Set the Toggle Switch on the Standard Input Module as Shown Here.

7

Page 9

Installation

With paralleled inputs, the signal may be looped through (or “daisy-chained”)

by going in one channel’s inputs and out the other. The amplifier Gain settings will

not affect the level at the input jacks.

BRIDGED-MONO

MODE CAUTION:

Output voltages up to 200

volts rms are available

between the MPA1100’s

bridged terminals (140

volts into an 8 ohm load).

Even on the MPA600, 150

volts rms are available

between the bridged

terminals (103 volts into

an 8 ohm load). Fully

insulated CLASS ONE

wiring must be used, and

the load must be rated up

to 2400 watts (8 ohms)

on the MPA1100, 1500

watts on the MPA750, and

1330watts (8 ohms) on

the MPA600. While the

MPA400 and MPA275

develop somewhat less

power, precautions should

be observed nonetheless.

Bridged-Mono Mode

1. Locate the selector switch adjacent to the CHANNEL 1 input XLR connector, and

set it to the BRIDGE position (see Figure 6, right side, on page 6).

2. Connect inputs to Ch 1 only. Do not connect anything to Ch 2 inputs.

3. Set Ch 2 Gain on FULL and regulate Gain with Ch 1 Gain only. Both channels

should display the same LEVEL readouts.

4. A single speaker load is used. The positive lead may be connected to Ch 1 red

binding post, and the negative lead to Ch 2 red binding post, but due to the

high voltage present (see caution note) we recommend the use of the fully

insulated Speakon connector. Both wiring options are shown in Figure 7.

–

+

–

+

2–

2+

1+

1–

CH 1

BRIDGED MONO

8 OHM MIN

CHANNEL 1

+

–

OUTPUT

CONNECT ONE

SPEAKER LOAD ONLY.

Use Either Binding Posts

or Stereo Speakon,

but not both.

CHANNEL 2

OUTPUT

DUAL CHANNEL

OUTPUT CONNECTOR

STEREO

4 OHM MIN PER CH

– BRIDGED MONO +

CH 2

Figure 11. Connection Options of Speaker Load for Bridged Mono Operation.

Speakon wiring for bridged mono, using the third, or

“stereo” Speakon:

Connect speaker positive to pin 1+.

Connect speaker negative to pin 2+.

Figure 12. Speakon Connection Details for Bridged Mono Operation.

VORSICHT BEIM ÜBERBRÜCKTEN MONO-MODUS:

Zwischen den überbrückten Terminals des MPA1100 (140 Volt bei einer Belastung von 8 Ohm) besteht eine Ausgangsspannung mit

einem quadratischen Mittelwert von bis zu 200 Volt. Selbst beim MPA600 besteht eine Ausgangsspannung mit einem quadratischen

Mittelwert von 15j0 Volt zwischen den überbrückten Terminals (103 Volt bei einer Belastung von 8 Ohm). Zu verwenden ist voll

isolierte Verdrahtung der US-Klasse Eins, und die angeschlossene Belastung muß für bis zu 2400 Watt (8 Ohm) beim MPA1100,

1500 Watt beim MPA750 und 1330 Watt (8Ohm) beim MPA600 ausgelegt sein. Obwohl die Leistung beim MPA400 und MPA275

etwas geringer ist, sind die Sicherheitsvorschriften dennoch einzuhalten.

8

Page 10

Installation

AC Power Connection

AC Connection is made through a standard Schuko or NEMA grounded plug. While

all models meet Safety Agency requirements for current consumption of less than 12

amp, 120Vac during “normal” operation, peak current consumption can be higher

on the MPA1100 or MPA750.

The amplifiers can be wired for 100, 120, or 220–240 Vac, 50–60Hz.

Some background on AC ratings is necessary to fully understand the limitations

on current draw. Essentially, there are three ratings of interest: (1) the legal operating

current as measured by the Safety Agencies, (2) the maximum expected average

under worst-case program material, and (3) the peak current draw at full output

power.

All major safety agencies around the world measure amplifier current and

temperature rise under the same “normal operating conditions” using a pink noise

signal with an average power equal to one eighth of maximum power. This was in

response to industry complaints that the former test level of one third power was

unrealistic for high-quality professional amplifiers. To put these levels in perspective,

music played at one third average power will be in a state of constant clipping, and

this power level is about the greatest one can obtain without completely obliterating

the program under clipping. The one eighth power level is about as loud as you can

play music while making some attempt to avoid obvious clipping.

We had to satisfy the following conditions:

1. Meet the safety agency requirements for “normal” current draw.

2. Remain within the functional limits of the plug for “severe program levels.”

3. Avoid unsafe conditions at full output power.

The AC consumption for each power level and load impedance is shown in

Table1 and Table 2 (see pages 9 and 10).

The safety agencies are concerned with the current levels shown under the one

eighth power column. This is because building codes prohibit the connection of a

single load which exceeds 80% of the capacity of the branch circuit.

JBL Engineering standards call for ability to operate at one third power, in order

to meet the demands of “worst-case” heavily compressed, clipped program material.

This will use the AC current shown in the one third power column. The amplifier’s

protective circuits will not permit long-term operation at full power into 2 ohms.

9

Page 11

Operation

Operation With 110 VAC, 60 Hz Power Mains

2 CH Load Max Power AC Current AC Current AC Current AC Current

Model (Ohms) (Midband) Full Power 1/3 Power 1/8 Power Idle

8+8 740 x 2 23.0 A 10.2A 5.4 A

MPA1100 4+4 1000 x 2 38.0 A 16.0 A 7.8 A 0.9 A

2+2 1300 x 2 54.0 A 23.0 A 11.4 A

8+8 480 x 2 18.0 A 9.6A 4.6 A

MPA750 4+4 700 x 2 29.0 A 14.4 A 6.4 A 0.7 A

2+2 950 x 2 38.0 A 21.0 A 10.0 A

8+8 400 x 2 15.2 A 8.4 A 3.4 A

MPA600 4+4 550 x 2 22.0 A 13.5 A 5.4 A 0.5 A

2+2 675 x 2 32.0 A 15.2 A 8.0 A

8+8 275 x 2 11.2 A 6.6 A 2.6 A

MPA400 4+4 400 x 2 16.0 A 9.6 A 4.6 A 0.4 A

2+2 525 x 2 22.0 A 13.2 A 5.4 A

8+8 180 x 2 7.6 A 5.4 A 3.6 A

MPA275 4+4 275 x 2 12.0 A 7.2 A 5.2 A 0.4 A

2+2 425 x 2 18.2 A 11.2 A 7.0 A

Operation With 115 VAC, 60 Hz Power Mains

8+8 770 x 2 24.0 A 10.4 A 5.6 A

MPA1100 4+4 1100 x 2 39.0 A 16.6 A 8.0 A 1.0 A

2+2 1400 x 2 56.0 A 23.4 A 11.8 A

8+8 510 x 2 18.6 A 9.8A 4.8 A

MPA750 4+4 760 x 2 30.0 A 14.8 A 6.8 A 0.8 A

2+2 1000 x 2 39.4 A 21.4 A 10.6 A

8+8 425 x 2 13.6 A 8.6 A 3.6 A

MPA600 4+4 610 x 2 23.0 A 13.4 A 5.6 A 0.6 A

2+2 750 x 2 33.0 A 15.6 A 8.6 A

8+8 290 x 2 11.6 A 6.8 A 2.8 A

MPA400 4+4 425 x 2 17.0 A 9.8 A 4.8 A 0.4 A

2+2 575 x 2 23.0 A 13.6 A 5.6 A.

8+8 190 x 2 7.8 A 5.6 A 3.8 A

MPA275 4+4 300 x 2 13.6 A 7.6 A 5.6 A 0.4 A

2+2 450 x 2 19.2 A 11.6 A 7.4 A

Operation With 120 VAC, 60 Hz Power Mains

8+8 800 x 2 25.0 A 10.8 A 5.8 A

MPA1100 4+4 1200 x 2 40.0 A 17.0 A 8.4 A 1.0 A

2+2 1500 x 2 58.0 A 24.0 A 12.0 A

8+8 550 x 2 19.0 A 10.0 A 5.0 A

MPA750 4+4 825 x 2 31.0 A 15.2 A 7.4 A 0.8 A

2+2 1100 x 2 41.0 A 22.0 A 11.0 A

8+8 450 x 2 16.0 A 9.0 A 4.0 A

MPA600 4+4 675 x 2 24.0 A 14.0 A 6.0 A 0.6 A

2+2 825 x 2 34.0 A 16.0 A 9.0 A

8+8 300 x 2 12.0 A 7.0 A 3.0 A

MPA400 4+4 450 x 2 18.0 A 10.0 A 5.0 A 0.4 A

2+2 650 x 2 24.0 A 14.0 A 6.0 A.

8+8 200 x 2 8.0 A 6.0 A 4.0 A

MPA275 4+4 325 x 2 13.0 A 8.0 A 6.0 A 0.4 A

2+2 500 x 2 20.0 A 12.0 A 8.0 A

Table 1. JBL MPA-Series AC Power Consumption vs Load Impedance With 110, 115 and 120V Mains

10

Page 12

11

Operation

Table 2. JBL MPA-Series AC Power Consumption vs Load Impedance With 220, 230 and 240V Mains

2 CH Load Max Power AC Current AC Current AC Current AC Current

Model (Ohms) (Midband) Full Power 1/3 Power 1/8 Power Idle

8+8 740 x 2 11.5 A 5.1A 2.7 A

MPA1100 4+4 1000 x 2 19.0 A 8.0 A 3.9 A 0.5 A

2+2 1300 x 2 27.0 A 11.5 A 5.7 A

8+8 480 x 2 9.0 A 4.8A 2.3 A

MPA750 4+4 700 x 2 14.5 A 7.2 A 3.2 A 0.4 A

2+2 950 x 2 19.0 A 10.5 A 5.0 A

8+8 400 x 2 7.6 A 4.2 A 1.7 A

MPA600 4+4 550 x 2 11.0 A 6.5 A 2.7 A 0.3 A

2+2 675 x 2 16.0 A 7.6 A 4.0 A

8+8 275 x 2 5.6 A 3.3 A 1.3 A

MPA400 4+4 400 x 2 8.0 A 4.8 A 2.3 A 0.2 A

2+2 525 x 2 11.0 A 6.6 A 2.7 A

8+8 180 x 2 3.8 A 2.7 A 1.8 A

MPA275 4+4 275 x 2 6.0 A 3.6 A 2.6 A 0.2 A

2+2 425 x 2 9.1 A 5.6 A 3.5 A

Operation With 220 VAC, 50 Hz Power Mains

8+8 770 x 2 12.0 A 5.2 A 2.8 A

MPA1100 4+4 1100 x 2 19.5 A 8.3 A 4.0 A 0.5 A

2+2 1400 x 2 28.0 A 11.7 A 5.9 A

8+8 510 x 2 9.3 A 4.9A 2.4 A

MPA750 4+4 760 x 2 15.0 A 7.4 A 3.4 A 0.4 A

2+2 1000 x 2 19.7 A 10.7 A 5.3 A

8+8 425 x 2 7.8 A 4.3 A 1.8 A

MPA600 4+4 610 x 2 11.5 A 6.7 A 2.8 A 0.3 A

2+2 750 x 2 16.5 A 7.8 A 4.3 A

8+8 290 x 2 5.8 A 3.4 A 1.4 A

MPA400 4+4 425 x 2 8.5 A 4.9 A 2.4 A 0.2 A

2+2 575 x 2 11.5 A 6.8 A 2.8 A.

8+8 190 x 2 3.9 A 2.8 A 1.9 A

MPA275 4+4 300 x 2 6.3 A 3.8 A 2.8 A 0.2 A

2+2 450 x 2 9.6 A 5.8 A 3.7 A

Operation With 230 VAC, 50 Hz Power Mains

8+8 800 x 2 12.5 A 5.4 A 2.9 A

MPA1100 4+4 1200 x 2 20.0 A 8.5 A 4.2 A 0.5 A

2+2 1500 x 2 29.0 A 12.0 A 6.0 A

8+8 550 x 2 9.5 A 5.0 A 2.5 A

MPA750 4+4 825 x 2 15.5 A 7.6 A 3.7 A 0.4 A

2+2 1100 x 2 20.5 A 11.0 A 5.5 A

8+8 450 x 2 8.0 A 4.5 A 2.0 A

MPA600 4+4 675 x 2 12.0 A 7.0 A 3.0 A 0.3 A

2+2 825 x 2 17.0 A 8.0 A 4.5 A

8+8 300 x 2 6.0 A 3.5 A 1.5 A

MPA400 4+4 450 x 2 9.0 A 5.0 A 2.5 A 0.2 A

2+2 650 x 2 12.0 A 7.0 A 3.0 A.

8+8 200 x 2 4.0 A 3.0 A 2.0 A

MPA275 4+4 325 x 2 6.5 A 4.0 A 3.0 A 0.2 A

2+2 500 x 2 10.0 A 6.0 A 4.0 A

Operation With 240 VAC, 50 Hz Power Mains

Page 13

Operation

Controls

The front-mounted Gain controls have 11 detents for easy matching of levels. The

Gain scale showsdB of attenuation from full gain, with positions for 0 (full), -2, -4,

-6, -8, -10, -12, -14, 18, -24, and ∞(full off). Attenuation is accurate within 1dB

(down to -14dB).

Gain Control Lockout

Provided with each amplifier are two lockout knob caps. Carefully remove the Gain

control knob (A), as shown in Figure 9. Cover the opening by snapping in the lockout knob cap (B). The Gain control can no longer be adjusted.

Displays

The LED displays for each channel operate as follows:

LED Label Color Behavior

Power Green Main power supply active on this channel.

Figure 13. Gain

Control Lockout

Installation

Signal Present Green Triggers at -36 dB below full output.

-20 dB Green Triggers at -23 dB.

-10 dB Yellow Triggers at -11 dB.

Clip Red Shows activity of Limiting circuit, which responds to

both clipping and to thermal overload.

Protect Red Flashes as amplifier approaches maximum tempera-

ture. Illuminated steadily plus flashing during thermal

muting. Illuminated steadily during non-thermal

muting.

Table 3. LED Display Operation

Typical Power Up, Operation, Power Down Behavior

When the amplifier is first turned on, the green POWER displays will light up for

both channels, and there will be a 3 second turn-on delay, during which all red LEDs

will be bright (PROTECT and CLIP). If a channel will not come out of muting, it may

be responding to an excessive high frequency level at the input (see page 12,

“ProtectionCircuits”). Turning down the Gain controls (before you power up the amp

is best) allows the muting to release, and is always a good idea to prevent an unexpected input signal from overdriving the load.

Signal Level will be shown as the green Signal Present, -20dB and the yellow

-10dB display illuminate with increasing signal level (see Figure 10 on next page).

When the amplifier is turned off, muting should be virtually instantaneous, with

all red LEDs illuminated until the power supply discharges.

12

Page 14

Operation

NO SIGNAL

Clip

-10dB

-20dB

Signal Present

SIGNAL PRESENT (-30 dB)

Clip

-10dB

-20dB

Signal Present

LEVEL -20 dB

Clip

-10dB

-20dB

Signal Present

LEVEL -10 dB

Clip

-10dB

-20dB

Signal Present

CLIPPING

Clip

-10dB

-20dB

Signal Present

Protect

Power

Protect

Power

Protect

Power

Protect

Power

Protect

Power

ON/OFF MUTING

Clip

-10dB

-20dB

Signal Present

SHORTED LOAD

Clip

-10dB

-20dB

Signal Present

CLIPPING

Clip

-10dB

-20dB

Signal Present

OVERHEATING

Clip

-10dB

-20dB

Signal Present

THERMAL MUTING

Clip

-10dB

-20dB

Signal Present

Protect

Power

Protect

Power

Protect

Power

Protect

Power

Protect

Power

CLIP is illuminated at full brightness when the output is muted

(PROTECT LED is on, too).

If CLIP is illuminated at less than

full LEVEL display, the load is

shorted or abnormal. PROTECT

may flash, too.

CLIP flashing at full LEVEL

display indicates the amp has

reached full power (clipping)

and the limiter is acting to

prevent severe overdrive.

A steady CLIP glow after the

flashing PROTECT display has

started indicates the onset of

thermal limiting.

PROTECT flashes as the amplifier approaches max temperature.

Full brightness plus flashing

indicates thermal muting.

Figure 14. LED Displays

During Normal Operation

Key to LED representations:

Figure 15. LED Displays DuringAbnormal Operating Conditions

Not Illuminated

Full Brightness

Variable or

Occasional Flashing

Flashing

Full Bright

& Flashing

13

Page 15

Operation

Maximum Long-Term Output Power

In most cases, the desired sound level can be obtained without using the full power

output of the amplifier. The level displays are then used to confirm that both channels are working as desired.

If the amplifier is operated at extreme power levels, it may overheat or the

speakers may be damaged. The following guidelines will help you determine how

much power can be delivered to the speakers without thermal limiting (which is

indicated by flashing of the red PROTECT display).

8 Ohm Loads

The amplifier can be played at practically any volume without overheating.

However, if the amplifier is pushed into continuous triggering of the CLIP display, the

average output power can reach higher levels than more most speakers will take.

4 Ohm Loads

The amplifier’s maximum long-term power capacity will be reached when the

LEVEL -10 is on almost all the time, with occasional flashing of the CLIP display. If

the CLIP display is on half the time, the amplifier is liable to start indicating thermal

limits are being approached in a few minutes (full brightness flashing of the PROTECT LED).

14

2 Ohm Loads

To avoid overheating on those models rated at 2 ohms (see Specifications), the

LEVEL -10 display should not be on more than about half the time, with only occasional clipping.

Protection Circuits

The essence of high-efficiency, lighter-weight designs is to control more power with

fewer or smaller load-bearing components. The MPA275, MPA400, MPA600, MPA750

and MPA1100 represent a considerable step forward, with high efficiency due to the

multi-step power supplies. Because of the higher power flow, effective protection

circuits become even more important.

The inputs are resistively buffered for overload and RF protection. Chassis

bypass capacitors are installed at inputs and outputs to further improve RF rejection.

All models have short circuit protection that is based on averaging the output

power. This protection circuit permits full output current into resistive or reactive

2 ohm loads, but if the output is shorted, the current is cut back to a safe level of about

25%.

Turn-on/off muting prevents transients from the amplifier or preceding devices

from reaching the speakers. The MPA275, MPA400, MPA600, MPA750 and MPA1100

use simultaneous relay and electronic muting to guarantee minimum possible on/off

noise. The limiter (see subsequent paragraphs) is fully activated during muting, so

that its release time cushions the onset of full volume. The turn-on delay has been

Page 16

Operation

extended somewhat, and the turn-off muting has been quickened, to ensure muting

even of poorly designed preceding components. On/off muting is equally effective

whether the amplifier is turned off with its own switch or with a remote switch.

Inrush current is limited by an NTC resistor (Negative Temperature Coefficient)

which starts at a high resistance and then diminishes after turn-on to avoid loss of

power. The amplifier’s inrush current is no more severe than amplifiers of one half to

one third its power rating.

DC Fault protection uses a load grounding relay.

Careful attention has been paid to thermal tracking and response. Sensors are

located on each power transformer, as well as each channel’s heat sink, so that

overheating of either component will trigger the thermal defenses. Instead of an

abrupt amplifier shutdown at the temperature limit, we now have 4 levels of

response. At temperatures of 50°to 65°C, the fan speed is elevated from slow to full,

to improve cooling as needed with the minimum possible noise. At temperatures of

about 75°C, the red PROTECT LED begins to flash at a gradually increasing rate. At

85°C, the limiter circuit begins to reduce gain, which is shown by progressively

brighter illumination of the red CLIP LED. At 90°C, gain is reduced by the maximum

amount of 15dB. If this does not arrest the temperature rise (in case of an output

short or blocked ventilation), the amplifier will finally enter full muting, which causes

full shutdown of the output bias circuit. Thermal tracking can be monitored at the

input slot (see below).

Clipping activates a “Clip-Limit” circuit. This permits the amp to reach the point

of clipping without premature limiting, for exceptional headroom capability.

However, once clipping is reached (for any reason), input volume is then limited to

prevent gross clipping. This circuit limits distortion caused by clipping to about 1%

to10% (depending on degree of overdrive), which is audible but not severe.

An ultrasonic detector mutes the amplifier in case of gross overloads above

20kHz, to prevent load or amplifier burnout. The amplifier will reproduce high

frequencies into normal loads without muting, but if the amp is turned on with highlevel, high frequency input above 10 kHz, the amplifier will not come out of turn-on

muting (this applies to full-level pink noise as well). This feature is intended to protect high frequency drivers from accidental burnout due to high frequency system

oscillations, etc.

While not a protection feature in its own right, the remote monitoring capability

built into the input slot provides the foundation for computer control and monitoring

as such systems become available. The input slot has lines to read the status (for

each channel) of power-on, input level, speaker level, thermal level, clip, protect,

and mute status.

15

Page 17

Specifications

General Specifications

DISTORTION

FREQUENCY RESPONSE

DAMPING FACTOR

DYNAMIC HEADROOM

NOISE

SENSITIVITY

VOLTAGE GAIN

INPUT IMPEDANCE

CONTROLS

INDICATORS

(each channel)

CONNECTORS

(each chan., except one stereo Speakon)

COOLING

AMPLIFIER PROTECTION

LOAD PROTECTION

OUTPUT CIRCUIT TYPE

POWER REQUIREMENTS

POWER CONSUMPTION

SMPTE-IM, less than 0.05 %

20Hz to 20kHz, ±0.1dB

8Hz to 100kHz, +0/-3dB

Greater than 200

3dB at 4 ohms (2 dB for MPA275)

100dB below rated output (20Hz to 20kHz)

1 Vrms for rated power (8 ohms)

MPA1100: 80 (38 dB)

MPA750: 63 (36 dB)

MPA600: 56 (35 dB)

MPA400: 45 (33 dB)

MPA275: 35.5 (31 dB)

10 kilohms unbalanced, 20 kilohms balanced

Front: AC switch, Ch 1 & Ch 2 Gain (2dB detents). Rear: One toggle switch for

paralleling inputs and for bridged output configuration

POWER: Green LED

SIGNAL PRESENT: Green LED

LEVEL -20: Green LED

LEVEL -10: Yellow LED

CLIP: Red LED

PROTECT: Red LED (flashes for over-temp)

Input: Barrier strip and XLR

Speakers:

Continuously variable speed fan, rear-to-front air flow

Full short circuit†, open circuit, ultrasonic, and RF protection, thermal limit-

ing/muting; stable into reactive or mismatched loads

On/off muting, clip limiting, DC-fault load grounding relay with internal fault

fuses

Complementary linear, high-efficiency outputs: 3-step on MPA1100; 2-step on

MPA750, MPA600 & MPA400; 1 step on MPA275

100, 120, 220–240 Vac, 50–60Hz

See Charts on pages 9 and 10.

5-way binding posts, Speakon connectors, st. Speakon**

16

DIMENSIONS

WEIGHT

48.3 cm (19") rack mounting,

45.5 cm (17.9") deep (rear support ears),

MPA1100 &MPA750 are 13.3 cm (5.25") high (3 spaces);

MPA600, MPA400 &MPA275 are 8.9 cm (3.5") high (2 spaces)

MPA1100:29 kg (64 lbs) net, 31.8 kg (70 lbs) shipping

MPA750: 24.9 kg (55 lbs) net, 26.8 kg (59 lbs) shipping

MPA600: 20 kg (44 lbs) net, 22.2 kg (49 lbs) shipping

MPA400: 19.1 kg (42 lbs) net, 21.2 kg (47 lbs) shipping

MPA275: 18.1 kg (40 lbs) net, 20.4 kg (45 lbs) shipping

** For mating cable, use Neutrik NL4FC connector.

†Output Averaging™ short circuit protection (US Patent 4,321,554).

Continued

Page 18

Specifications

Load & Measurement Conditions

8 ohms/channel

20 Hz – 20 kHz

0.1% THD

8 ohms/channel

20 Hz – 15 kHz *

0.1% THD

4 ohms/channel

20 Hz – 20 kHz

0.1% THD

4 ohms/channel

20 Hz – 15 kHz *

0.1% THD

8 ohms/channel

1 kHz

1% THD

4 ohms/channel

1 kHz

1% THD

2 ohms/channel

1 kHz

0.1% THD, ±1 dB

8 ohms bridged mono

20 Hz – 20 kHz

0.1% THD

8 ohms bridged mono

20 Hz – 15 kHz *

0.1% THD

4 ohms bridged mono

1 kHz

0.1% THD, ±1 dB

60 Hz AC

Power Mains

110 VAC

115 VAC

120 VAC

110 VAC

115 VAC

120 VAC

110 VAC

115 VAC

120 VAC

110 VAC

115 VAC

120 VAC

110 VAC

115 VAC

120 VAC

110 VAC

115 VAC

120 VAC

110 VAC

115 VAC

120 VAC

110 VAC

115 VAC

120 VAC

110 VAC

115 VAC

120 VAC

110 VAC

115 VAC

120 VAC

Output RMS Power in Watts

MPA1100 MPA750 MPA600 MPA400 MPA275

660

690

720

900

1000

1100

740

770

800

1000

1100

1200

1200

1300

1400

1800

2000

2200

2400

2600

2800

450

475

500

650

700

750

480

510

550

700

760

825

900

950

1000

1300

1400

1500

1800

1900

2000

350

375

400

500

550

600

400

425

450

550

610

675

650

725

800

1000

1100

1200

1300

1450

1600

250

260

275

350

375

400

275

290

300

400

425

450

500

550

600

700

750

800

1000

1100

1200

160

170

175

225

250

275

180

190

200

275

300

400

350

375

400

450

500

550

700

750

800

Table 4. Output Power Ratings When Used With 110, 115 & 120 VAC 60 Hz Mains

17

Page 19

Specifications

Load & Measurement Conditions

8 ohms/channel

20 Hz – 20 kHz

0.1% THD

8 ohms/channel

20 Hz – 15 kHz *

0.1% THD

4 ohms/channel

20 Hz – 20 kHz

0.1% THD

4 ohms/channel

20 Hz – 15 kHz *

0.1% THD

8 ohms/channel

1 kHz

1% THD

4 ohms/channel

1 kHz

1% THD

2 ohms/channel

1 kHz

0.1% THD, ±1 dB

8 ohms bridged mono

20 Hz – 20 kHz

0.1% THD

8 ohms bridged mono

20 Hz – 15 kHz *

0.1% THD

4 ohms bridged mono

1 kHz

0.1% THD, ±1 dB

50 Hz AC

Power Mains

220 VAC

230 VAC

240 VAC

220 VAC

230 VAC

240 VAC

220 VAC

230 VAC

240 VAC

220 VAC

230 VAC

240 VAC

220 VAC

230 VAC

240 VAC

220 VAC

230 VAC

240 VAC

220 VAC

230 VAC

240 VAC

220 VAC

230 VAC

240 VAC

220 VAC

230 VAC

240 VAC

220 VAC

230 VAC

240 VAC

Output RMS Power in Watts

MPA1100 MPA750 MPA600 MPA400 MPA275

660

690

720

900

1000

1100

740

770

800

1000

1100

1200

1200

1300

1400

1800

2000

2200

2400

2600

2800

450

475

500

650

700

750

480

510

550

700

760

825

900

950

1000

1300

1400

1500

1800

1900

2000

350

375

400

500

550

600

400

425

450

550

610

675

650

725

800

975

1075

1175

1300

1450

1600

250

260

275

350

375

400

275

290

300

400

425

450

500

550

600

675

725

775

1000

1100

1200

160

170

175

225

250

275

180

190

200

275

300

325

350

375

400

425

475

525

700

750

800

Table 5. Output Power Ratings When Used With 220, 230 & 240 VAC 50 Hz Mains

*Amplifier’s output protective circuitry prevents full power output above 15kHz.

Specifications subject to change without notice.

18

Page 20

19

Channel will not come out of muting:

A. If reducing Gain to zero does not release muting, the channel is defective or

overheated (see below).

B. If reducing Gain releases the muting, advance Gain slowly while watching the

LEVEL displays (in case there is an abnormal signal which could blow the

speakers).

No sound is heard:

A. Is the channel in muting? (PROTECT is bright, see below).

B. If the LEVEL displays are active, (1) the speaker is open (blown), (2) there is an

open circuit in the speaker wiring, or (3) there is an open circuit in the internal

output wiring of the amplifier. (Consult a JBL dealer for service.)

C. If there is no LEVEL (SIGNAL PRESENT, -20dB, -30dB) or CLIP displays, (1)

there is no input signal, or (2) the ribbon cable to the input module may not be

seated well.

D. If the CLIP display is bright or peaking with little or no LEVEL display, this

indicates shorted speaker line (especially if PROTECT starts flashing).

Channel goes into muting (temp-protect LED is on):

A. If flashing of the PROTECT display is visible, amplifier has muted due to

extreme overheating. Fan should be running at full speed, and unless ventilation is blocked, operation should resume within one minute.

B. The amplifier will mute in response to extreme high frequency overdrive, and

output will not be restored until the frequency or level is lowered. Try turning

down the Gain control to release muting, and determine the source of abnormal

frequencies.

C. Muting which does not respond to either condition suggests DC shutdown or

other amplifier fault.

Hum Problems:

A. Ground lift of the signal is not available in these amplifiers due to the design

which utilizes grounded-collector transistor mounting to improve thermal efficiency. Low-emission AC transformers are used, and balanced inputs afford

hum rejection. If hum persists despite the balanced inputs, check the tightness

of the rear panel screws which hold the input panel in place (two outer screws,

and two screws holding barrier strip). If the input wiring is near SCR (silicon

controlled rectifier) dimmers, transformer-isolated inputs may be necessary

because of the exceptionally high noise field voltages generated by SCRs.

Troubleshooting

Page 21

20

Troubleshooting

Overheating:

A. If ventilation is blocked, or if the amplifier is overdriven into low impedance

loads, it can overheat. The thermal protection system’s normal response to

rising temperatures is as follows:

25–50° C: Fan runs on low speed.

50–60° C: Fan Speed rises gradually from slow to full.

75° C: PROTECT LED starts flashing.

85° C: PROTECT flash rate increases, and CLIP starts to glow steadily. The

limiter will begin to reduce amplifier gain, up to 15 dB.

90° C: Full muting occurs, as indicated by bright CLIP display and bright

PROTECT display (with rapid flashing superimposed). Full muting

should occur only if the load is shorted, ventilation is completely

blocked, or the fan fails.

Page 22

For Further Assistance

General information or Technical Assistance

For more information on JBLproducts, including these power amplifiers, contact your

nearest JBL professional products dealer or the JBL factory at the address below.

Repairs

Please do not ship your amplifier(s) to JBL or a JBL authorized repair facility without

prior authorization. You may obtain that authorization by contacting the factory or

repair facility directly. Please ship amplifiers in original packing materials or equivalent to prevent further damage during shipment, and insure the shipment adequately.

Mark the return materials authorization number (RMA) clearly on the outside of the

package and on any correspondence.

JBL Incorporated

8500 Balboa Boulevard

Northridge, California 91329 USA

Telephone (818) 893-8411

21

Page 23

JBL Incorporated

8500 Balboa Boulevard

Northridge, California 91329USA

A Harman International Company

Part No. TD-007500-OB/PS137-2

Loading...

Loading...