Page 1

PROJECT EVEREST

DD65000 & DD67000

PRODUCT COMMENTARIES AND USER GUIDE

Page 2

Thank you for purchasing a

JBL Project Everest loudspeaker system.

Before using the system, please take the time

to read through this user guide to understand

this loudspeaker well and also to use it properly.

Page 3

TABLE OF

TC

CONTENTS

Preface: ....................................................................... 6

chaPter 1:

LEGACY .............................................................................. 8

chaPter 2:

THE PROJECT EVEREST DD65000 AND DD67000

LOUDSPEAKERS – A TRIUMPH IN ACOUSTICS

AND TECHNOLOGY ....................................................... 14

chaPter 3:

UNPACKING THE PROJECT EVEREST SYSTEM ............ 22

chaPter 4:

SELECTING SPEAKER WIRE ......................................... 26

chaPter 5:

AMPLIFIER RECOMMENDATIONS .................................. 28

chaPter 6:

PLACEMENT AND SETUP CONSIDERATIONS ............... 30

chaPter 7:

PROJECT EVEREST ADJUSTMENTS ............................. 32

chaPter 8:

PROJECT EVEREST CONNECTIONS ............................. 38

chaPter 9:

PROJECT EVEREST CARE AND MAINTENANCE ........... 44

troubleshooting and service guide: .................. 44

Project everest dd67000 system

sPecifications: ............................................................. 46

Project everest dd65000 system

sPecifications: ............................................................. 47

5

Page 4

PREFACE

Thank you for selecting a Project Everest DD65000 or DD67000

loudspeaker system. These loudspeakers represent the

culmination of our research and developmental efforts in sound

reproduction over the last half century. We have endeavored

to create loudspeaker systems with no acoustical or electrical

limitations whatsoever.

However, it is the level of your listening pleasure that ultimately

determines how successful we are in this endeavor. To ensure

a perfect listening experience, we ask you to carefully follow the

setup and operation procedures outlined in this Project Everest

User Guide.

This guide serves several purposes. It contains all necessary

background information and detailed instructions for setting up

your Project Everest loudspeaker system, including unpacking

the loudspeaker, selecting the correct location, choosing speaker

wire, wiring method and amplication, and connecting the

speakers to their associated electronics. This information is found

in Chapters 3 through 8. In addition, we have included a detailed

description of your Project Everest loudspeakers in Chapter 2,

so that you may become thoroughly acquainted with their unique

design and technical features.

Despite the formidable nature of Project Everest, the setup

procedure for these loudspeaker systems is relatively simple.

Again, we strongly urge you to read this guide thoroughly before

you begin, and then consult it frequently throughout the process.

Certain considerations must be made in placing the speakers;

their physical characteristics make it imperative that you become

familiar with the entire setup process in advance.

Also, we believe that the historical and technical information

included will add immeasurably to your complete enjoyment of

your system. As a loudspeaker, the Project Everest DD65000 and

DD67000 are unparalleled in the eld of sound reproduction. The

story and principles behind them are an interesting, informative

and tting start to a lifetime of musical enjoyment.

7

Page 5

LEGACY

THE HISTORICAL DEVELOPMENT OF

1

THE JBL PROJECT LOUDSPEAKERS

Of those who have sought perfection in sound reproduction, only a

few have actually come close. For one thing, it is a costly process.

It is rare indeed when an individual or group is able to triumph over

the constraints of economic and technological realities even once.

At JBL, this has happened nine times. In each case, our engineers

were told to build the speaker system they had always wanted

to build. Whatever resources were required would be made

available. Thus began an ongoing search for new frontiers in

sound reproduction, beginning in the mid-1950s and continuing

to the present day.

The products that have resulted from this venture are now known

as the JBL Project loudspeakers. Each represents the absolute

peak of every technological, material and engineering innovation

available at the time, combined into a single loudspeaker

system. They are Hartseld, Paragon, Everest DD55000, K2

S9500/7500, K2 S5500, K2 S9800, K2 S5800, Project Everest

DD66000 and K2 S9900.

Although differing in performance details and physical attributes,

all of the Project loudspeakers have shared a common objective

– to elevate sound reproduction to levels dened only by the

limitations of existing materials and technology. The fact that all

Project loudspeakers have many common features, despite

their having been created over a span of nearly sixty years, is a

testimony to the excellence of the technology and manufacturing

techniques upon which JBL was built.

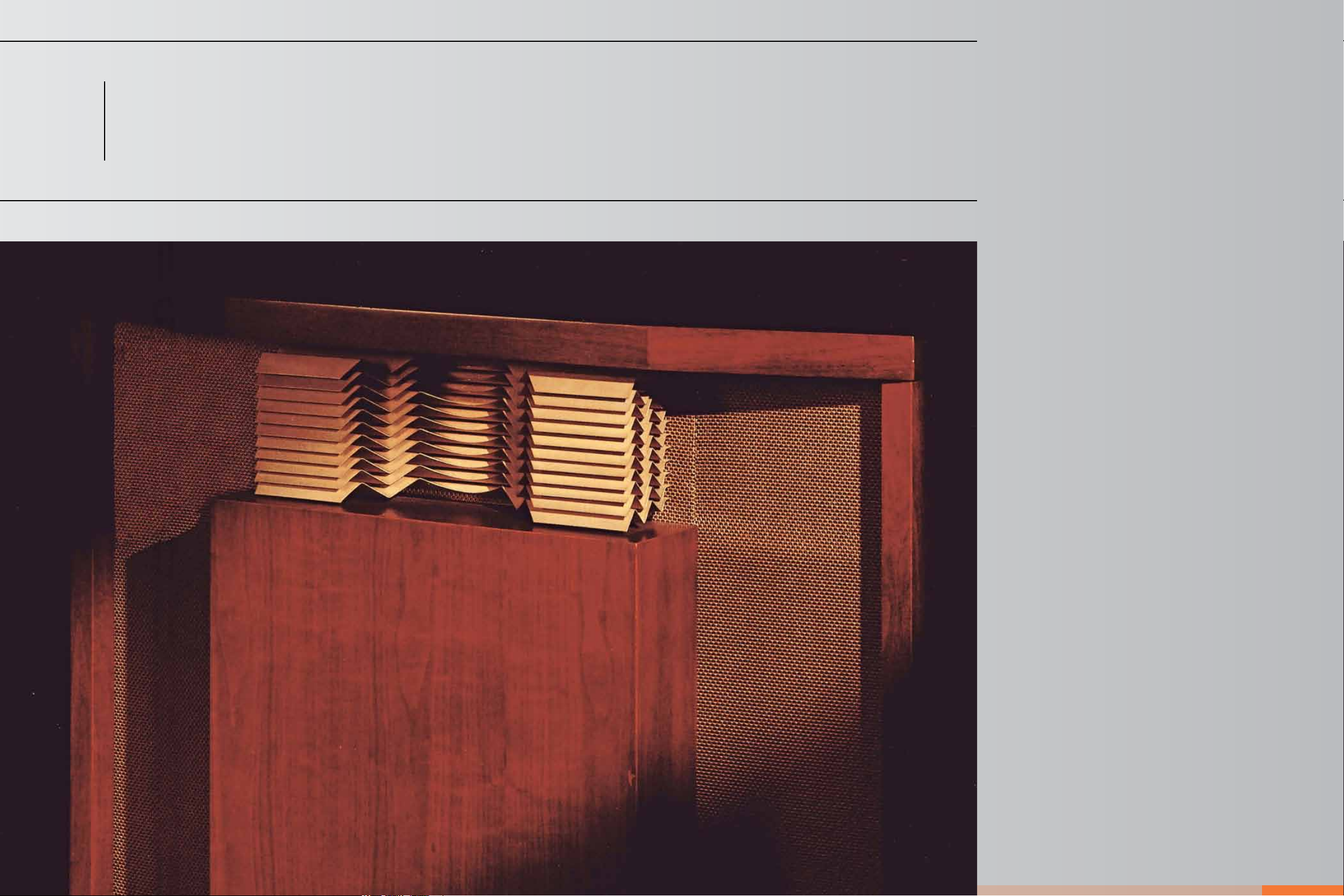

JBL Hartseld

DEFINING THE PROJECT CONCEPT

The Hartseld began a tradition at JBL that continues today. First,

engineer a product as close to perfection as possible. When it

reaches that level, make it better.

In 1954, the Hartseld was signicant in that it represented not new

technology, but rather a new level of technical manufacturing, in the

spirit of the approach pioneered by James B. Lansing some twenty

years before. Like its Project series successors, it was a high-

efciency system incorporating compression driver technology and

combining the qualities of high-output, low-distortion, exceptional

stereo imaging and fatigue-free listening. Most important, it was

the rst loudspeaker system available to consumers to do all this.

JBL’s president in 1954, William Thomas, described the Hartseld

as the “speaker system we have always wanted to build [with] the

nest components ever made available to serious listeners.”

9

Page 6

JBL-Ranger Paragon

®

Digital, DTS®, DVD-Audio and Super Audio CD (SACD™).

Dolby

Frequency responses to 50kHz, as well as three-digit dynamic

range and signal-to-noise ratio specications have now become

commonplace. To faithfully reproduce such robust sonic properties,

the loudspeaker needed to undergo drastic improvements to its

transducer, network and enclosure technologies.

The K2 S9800 employed a three-way design, incorporating

an ultrahigh-frequency (UHF) compression driver and horn

to reproduce high frequencies up to 50kHz. With the UHF

driver handling the higher frequencies, the high-frequency (HF)

transducer could then be upgraded to a new design using a

3-inch (75mm) diaphragm, which improved reproduction of

lower frequencies and blended better with the woofer than the

older generations’ 2-inch (50mm) diaphragm did. Both of these

new compression drivers utilized newly developed beryllium

diaphragms to provide the lowest distortion and attest frequency

response possible.

To recreate the extremely high dynamic range provided by

today’s audio sources, a brand-new low-frequency transducer

was developed from the ground up, utilizing an Alnico magnet, a

4-inch (100mm) edge-wound voice coil, and a 15-inch (380mm)

cone. Extensive computer-aided engineering and design effort

was necessary to develop the optimized port tuning employed

in Project K2 S9800, and resulted in a signicant advance in the

concept of state-of-the-art acoustic reproduction. As a result of

these efforts, a loudspeaker system with higher sensitivity and a

wider dynamic range became a reality without power compression

or distortion, even at extremely high drive levels.

He went on to describe the process behind the creation of the

Hartseld: “Most people who own and appreciate ne sound

reproduction equipment look forward to the day when they will

be able to assemble a system without limitation in just exactly

the way they think it should be done. Periodically a manufacturer

gets this same feeling. The science of acoustics has provided

us with the basic principles available to all for achieving precision

reproduction. It is only a matter of incorporating these methods into

a system design, and then taking every bit of trouble necessary to

build a system precisely to the design.”

He added, “It isn’t easy, but that’s the way it is done.”

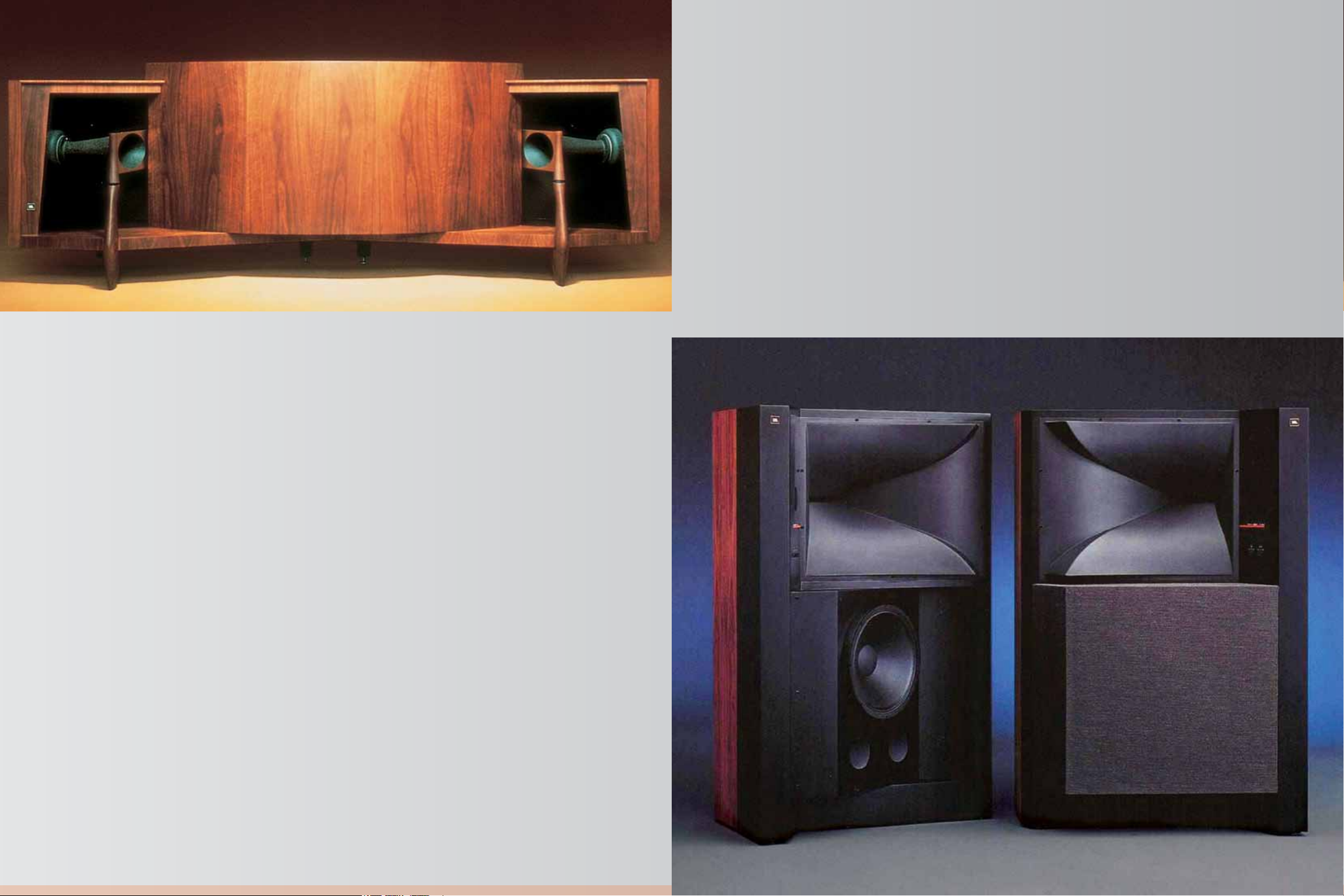

The Ranger-Paragon, JBL’s second Project system, was the rst

serious attempt at a reecting speaker system, and broke ground

in what was at the time, the new concept of stereo imaging.

Basically two independent full-range speaker systems installed in

a handsome, curved cabinet nearly 9 feet (2.7 meters) wide, the

Paragon’s enclosure was treated as an extension of its transducers.

In essence, the system had its own “built-in acoustics.” In many

respects, the Paragon anticipated loudspeaker developments

that would occur years and even decades later. This “built-in

acoustics” concept was present in the Project Everest DD66000

and has now been further rened in the DD65000 and DD67000.

For nearly 30 years, the Paragon remained one of the world’s

most highly-regarded home loudspeaker systems. Today, along

with the Hartseld, the Paragon is still the most sought-after

speaker in the world.

In 1986, JBL introduced a new Project system that retained the

Paragon’s overall sense of musicality while upgrading its character

by incorporating three decades’ worth of continuous development

in every facet of its design. Its name – Project Everest – reected

the pinnacle of achievement it represented. This was the original

Project Everest DD55000.

For the rst time, the rest of the sound reproduction chain – and

not the loudspeaker or its transducers – would impose limits on

overall system performance. Like the Paragon and Hartseld,

Project Everest was built around compression driver technology

and addressed a more rened stereo image than was previously

considered technically feasible.

Since the original Project Everest was introduced, sound recording

and playback technology has undergone a revolution of its own.

With the advent of the CD, extremely demanding recorded signals

became the rule rather than the exception – the typical source

material used by the average audio enthusiast became superior

to the best demonstration material of even just a few years

prior. In overall dynamics and transient response, transducers

became once again a potentially weak link in the high-end audio

reproduction chain.

It was in this environment that JBL set out to create its fourth and

fth Project loudspeakers, K2 S9500 and K2 S5500. As with

Hartseld, the simplicity of a two-way system was considered the

most promising design track. Advances in transducer design and

low-frequency alignment would make possible the construction of

a two-way system of unprecedented physical and acoustical scale.

Our engineers took the core components – the low-frequency and

high-frequency transducers – and optimized them by redesigning

their magnetic structures, diaphragms and framework for greater

linearity, dynamic capability and transient response.

In the years following the introduction of the K2 S9500 and K2

S5500, sound reproduction technology underwent another series

of revolutionary changes, with the introduction of DVD-Video,

JBL Everest DD55000

1110

Page 7

JBL K2 S9500 JBL K2 S9800

The development of the Project Everest DD66000 loudspeaker

system was undertaken as a celebration of JBL’s 60th

anniversary and as a realization of the potential engendered by

the breakthroughs discussed above. The stately character of the

Hartseld, exceptional wood craftsmanship of the Paragon, the

“built-in acoustics” which treat the enclosure as an extension of the

transducers, and the state-of-the-art transducer technologies that

were built up from two generations of the Project K2 developments

were all poured into this new challenge to extend the acoustic and

electrical possibilities in this Project Everest model.

Despite its 21st century power and sophistication, Project Everest

DD66000 was a synthesis of tradition and technology. It reected

the design, material, engineering and manufacturing expertise

developed and rened through nearly six decades of experience

that are the exclusive legacy of one loudspeaker builder – JBL.

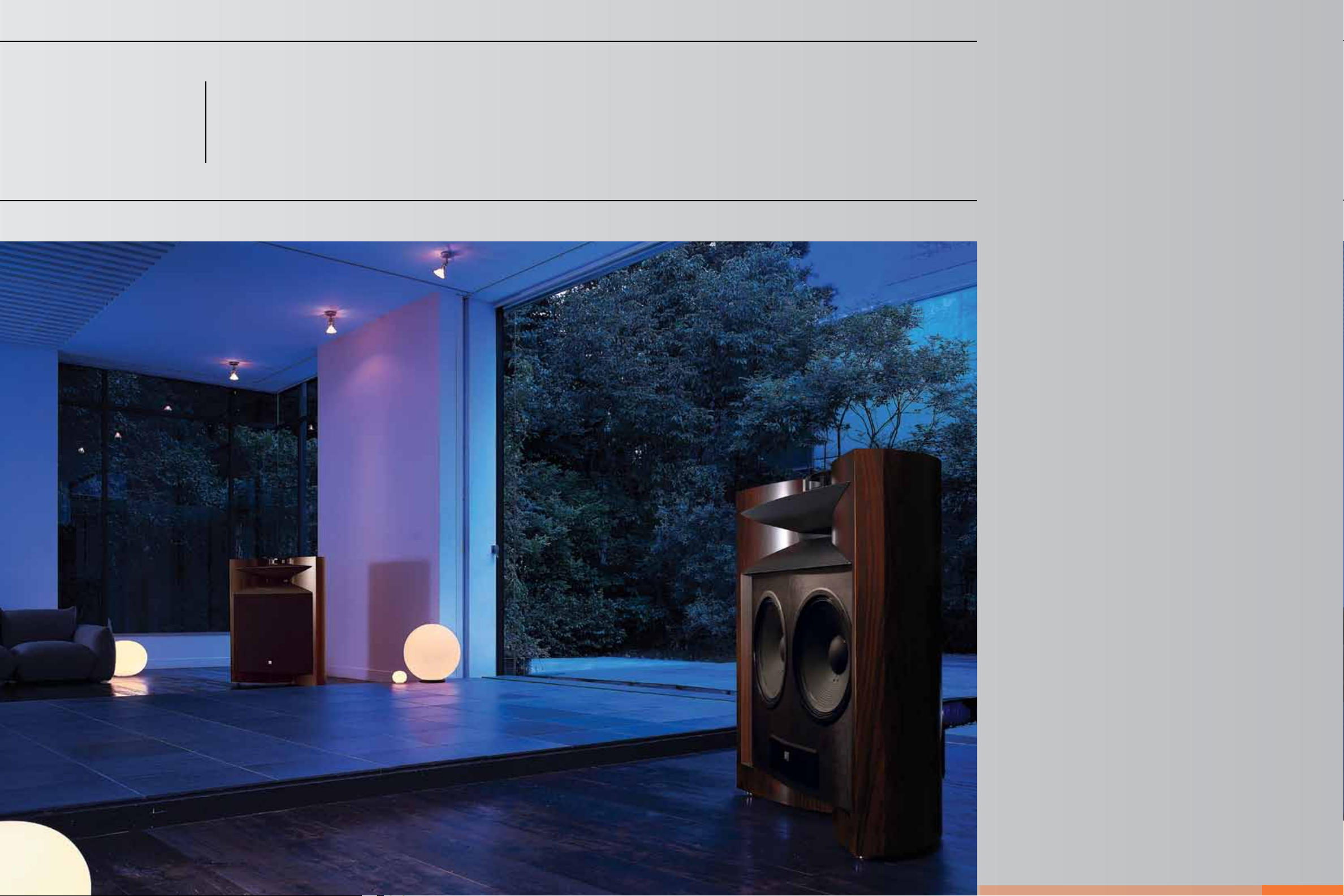

And now, with the introduction of the Project Everest DD65000

and DD67000 JBL presents additional renements that enable

these loudspeakers to outshine even the stellar performance

standard set by the DD66000 system.

JBL Project Everest DD66000

1312

Page 8

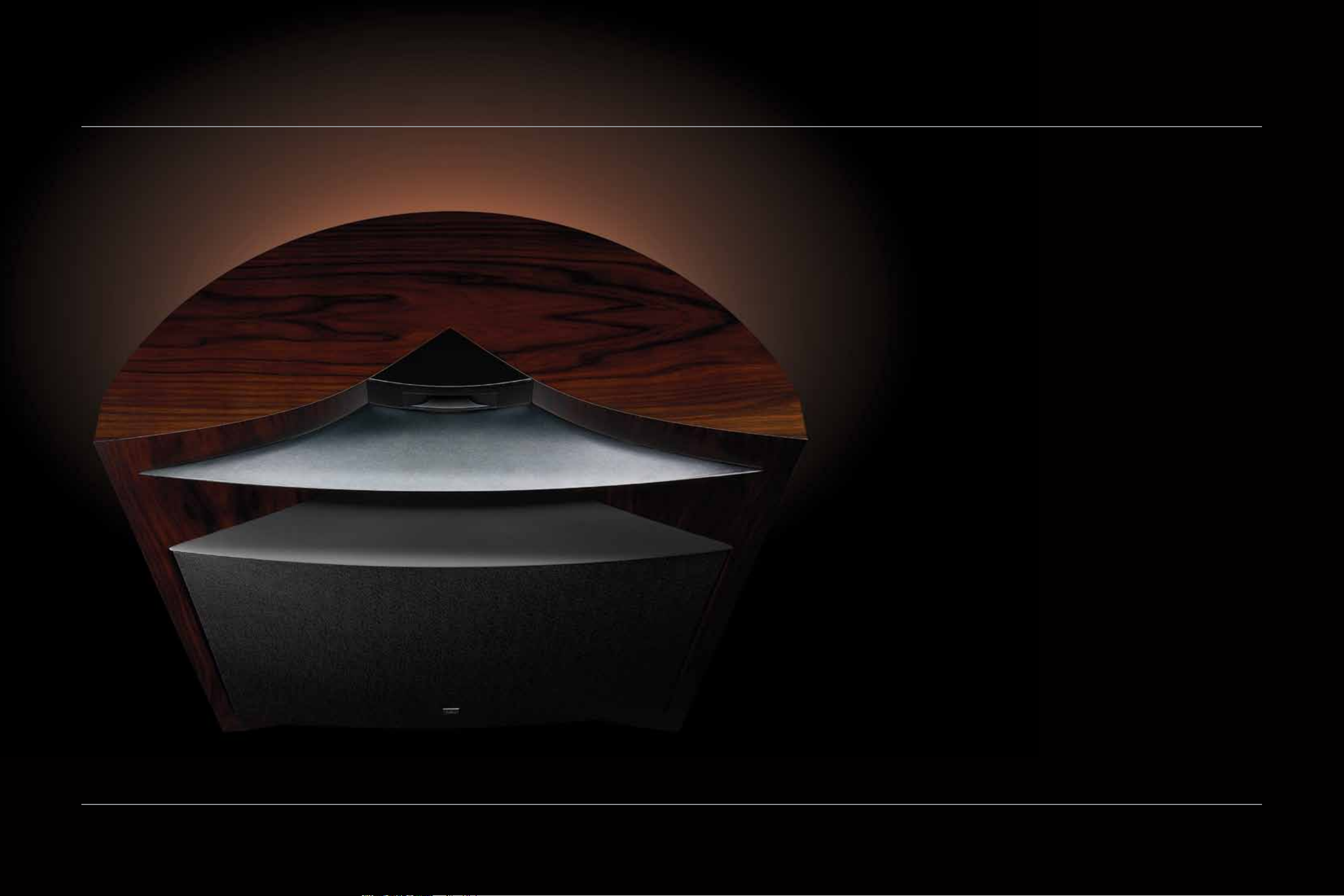

PROJECT EVEREST

A TRIUMPH IN ACOUSTICS

2

AND TECHNOLOGY

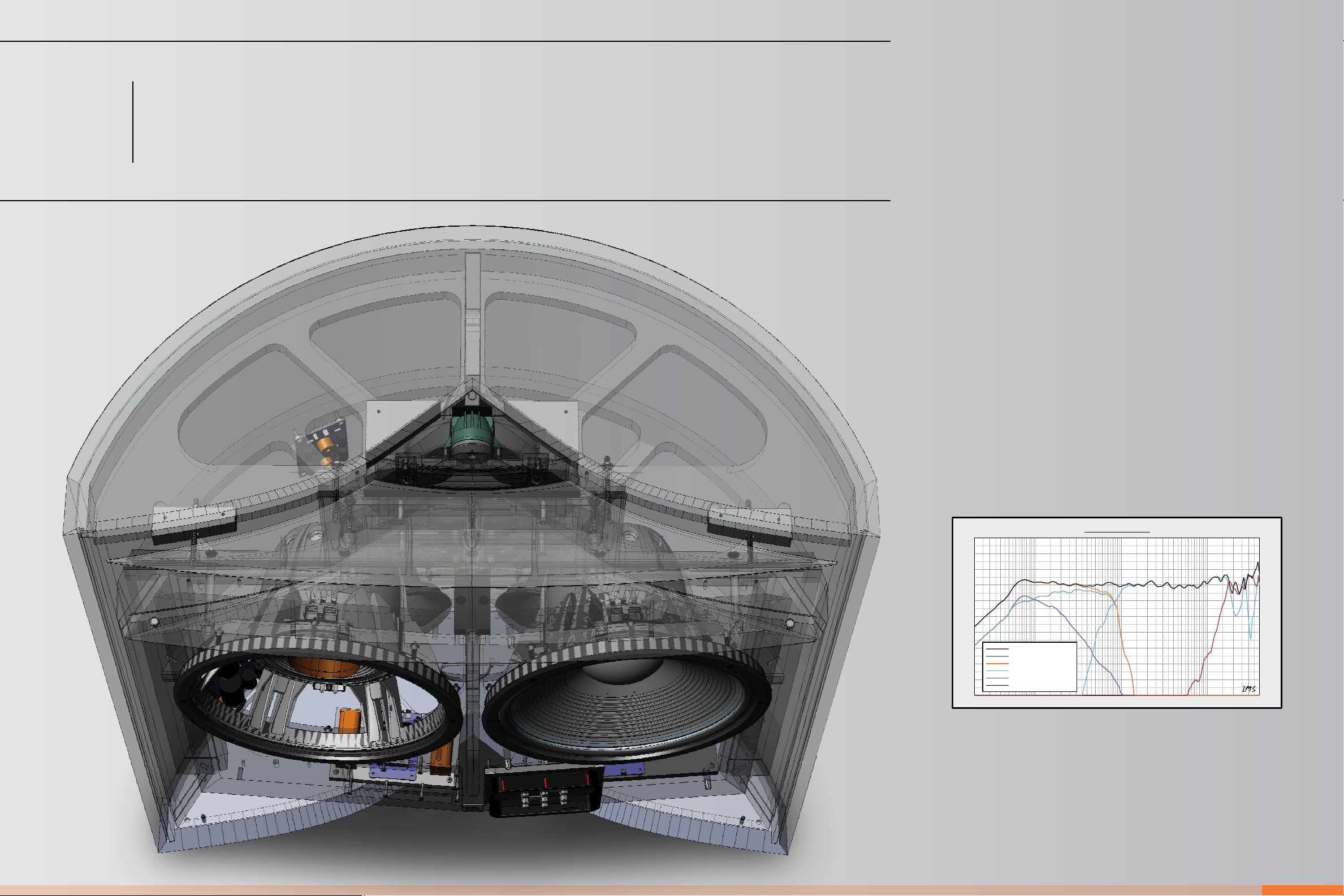

This chapter describes the primary features and components of the Project Everest

DD65000 and DD67000 loudspeaker systems.

The basic system conguration is what JBL historically has referred to as an “augmented

two-way”. In the 1950s and 1960s, JBL primarily built two-way systems with a 12-inch or

15-inch (305mm or 380mm) woofer crossed over to a large-format compression driver/

horn combination. Some of the systems would be “augmented” by a UHF device, usually

the 075 ring radiator which would operate above 8kHz. These systems would have only a

single crossover point in the middle of the audio range, to minimize any sonic degradation

caused by the dividing network.

The DD65000 and DD67000 both have a single midrange crossover point – the

DD65000 at 750Hz and the DD67000 at 850Hz – blending one 1501 woofer to the 476

compression driver and horn combination. The 045 UHF driver is brought in at 20kHz to

cover an octave and a half of ultrasonic frequencies. A second 1501 woofer operates in

the bass frequency range from below 30Hz to around 150Hz, where it is rolled off at a

gradual 6dB/octave. This rst-order slope ensures proper amplitude and phase summing

between the two woofers over their entire operating range. Both woofers operate below

150Hz, but only one of them extends up to the midrange crossover point. This is done

to achieve proper directivity control throughout the entire woofer operating range, while

delivering powerful and extended low-frequency performance. Above the midrange

crossover point, the HF compression driver and horn combination operates unassisted,

all the way to 20kHz (see graph, below).

dBSPL

110

105

100

95

90

85

80

75

70

65

60

20Hz 50 100 200 500 1k 2k 5k 10k 20k 40k

DD67000 LF1

DD67000 LF2

DD67000 LF Combined

DD67000 HF

DD67000 UHF

DD67000

SPL vs Freq

On-axis response of the DD67000 system and of each

transducer through its crossover network (2.83V @ 1m)

15

Page 9

The transducers, horns and crossover networks are housed

in a visually stunning enclosure that is reminiscent of both the

Hartseld and Paragon systems. The specially curved bafe

provides the sidewalls for the main high-frequency horn. The top

and bottom horn ares are accomplished by the attachment of

precision-molded SonoGlass

®

horn “lips” to the enclosure’s upper

surface. The UHF driver is mounted to a SonoGlass horn which is

itself mounted to a die-cast aluminum housing.

The entire Everest DD65000 and DD67000 enclosure is

constructed of MDF. The curved panels are formed out of two

thicknesses of MDF with an inner, outer and middle skin. The

MDF is internally grooved, allowing the panels to curve to the

desired dimensions. The voids in the material are lled with a

foam damping compound. The panels are held in place using

a complex internal bracing scheme and external xturing during

the curing process. The woofer bafe module is a six-sided 3/4

inch (19mm) thick shell, constituting an extremely rigid and secure

structure. The DD65000 has a 1 inch (25mm) thick veneer-

covered outer bafe, giving the total combined woofer bafe a

thickness of 1-3/4 inch (45mm). The DD67000 has an inner 3/4

inch (19mm) bafe constructed of Finland birch plywood and an

outer 1-inch thick bafe that is covered in carbon ber woven

cloth. The outer bafes of both models are removable (bolted from

the inside of the enclosure) to enable repair or replacement of the

covering surface, should that ever be necessary.

The system is ported on the rear with a tuning frequency of

32Hz for the DD65000 and 31Hz for the DD67000. Two large

4-inch (100mm)-diameter ared ports are combined with the

input connections on a massive three-piece die-cast aluminum

structure. The entire enclosure rests on four stainless-steel foot

assemblies. Stainless-steel coasters are included to protect

wood and tile oors from damage from the spiked feet. The grille

assembly is constructed of MDF and uses a thick, perforated

metal sheet to provide the curved shape. The grille securely

attaches to the enclosure with metal pins and rubber cups.

The low-frequency and high-frequency transducers for the Project

Everest systems are designed to be absolute minimum-distortion

drive units. Although they are capable of tremendous acoustic

output, they are designed to be nearly linear in every way, up to

a reasonably high drive level. This enables the system to sound

the same regardless of playback level. In addition, a great deal of

attention was paid to minimizing distortions and non-linear effects

occurring around signal zero-crossings. The result of this is that

Project Everest systems are able to play at very low levels and still

present realistic response and detail to a degree unattained by

other loudspeaker systems.

PROJECT EVEREST TRANSDUCERS

THE 1501AL FAMILY OF LOW-FREQUENCY

TRANSDUCERS

The 1501AL-1 (DD65000) and 1501AL-2 (DD67000) lowfrequency drivers are very similar to the 1501AL used in the

DD66000, and 1500AL and 1500AL-1 used in the K2 S9800 and

K2 S9900 systems. They all share a common motor assembly

and they all use a long 4-inch (100mm) diameter voice coil with

edge-wound aluminum wire. The 1501 family voice coil is wound

double impedance so that the pair of woofers in a Project Everest

system still allows an 8-ohm system impedance. Their voice coils

are completely immersed in an underhung radial magnetic eld

generated by an Alnico 5DG magnet. This underhung design is

a signicant feature because even at high output levels, the coil

will always see a constant drive force and will be more thermally

coupled to the motor than is possible with conventional designs.

Alnico was chosen for the magnet material because of its

stable operating point. This material is insensitive to temperature

changes and back EMF from the voice coil. JBL has overcome

Alnico’s tendency to demagnetize with high drive by utilizing

a massive shorting ring at the base of the motor assembly. In

addition to this, the top plate is constructed of alternating coppersteel laminations. The presence of the copper rings linearizes

the magnetic properties of the gap to all but eliminate both eddy

current distortion and local ux modulation.

A thick-wall, cast-aluminum frame is used to rigidly support the

motor structure. This fully vented frame and motor design also

serves to minimize the back pressure under the dome and spider,

helping to reduce harmonic distortion to even lower levels. JBL’s

Vented Gap Cooling™ (VGC) is incorporated within the motor

structure, and lowers the operating temperature of the coil during

moments of high power operation.

SonoGlass

UHF Horn

Adjustment

Panels

Crossover

Network

Die-Cast Aluminum Housing

045-Series 1" (25mm)

UHF Compression Driver

SonoGlass High-Frequency Horn

476-Series 4" (100mm)

HF Compression Driver

Crossover Network

1501AL-Series 15" (380mm)

LF Driver

Adjustment Panels

Crossover Network

Die-Cast Aluminum

Input Plate/Port Assembly

Spiked Foot Assembly

Project Everest DD65000/DD67000 System Major Components

Crossover Network

™

Vented Gap Cooling

Die-Cast Aluminum Motor Housing

Back Plate

Conductive Aluminum

Shorting Ring

Alternating

Copper/Steel Ring

Top Plate

Dual Inverted

®

Spiders

Nomex

Pure Pulp Sandwich

Cone with Foam Injection

Core (1501AL-2)

Pleated Cloth

Accordion Surround

(1501AL-2)

Polepiece

Alnico 5DG Magnet

4" Edge-Wound

Aluminum Voice Coil

Cooling Vents

5-Way Binding Post Connectors

Layered Paper-Pulp

Matrix Cone (1501AL-1)

Aquaplas Damping Material

Foamed Rubber Suspension

Aluminum Frame

(1501AL-1)

(1501AL-1)

Die-Cast

Vents

1501AL-Series Woofer Section View

1716

Page 10

The 1501AL-1 employs a pure pulp straight sided cone body

attached to an outer suspension made of special foamed rubber.

This suspension material has the longevity and frequency-response

characteristics of traditional rubber surrounds, but with a low density

very close to that of foam surrounds. This material was chosen to

preserve the transient detail of musical signals while still providing

the movement required for high output at low frequencies. Unlike

traditional foam surrounds, the foamed rubber has a very long

service life and will not deteriorate. The cone consists of a special

layered paper-pulp matrix with proprietary Aquaplas damping,

which offers more pistonic behavior throughout the woofer’s

operating bandwidth, and controlled cone breakup beyond it.

The 1501AL-2 uses an “accordion pleated” high strength Poly-

Cotton cloth outer suspension. This material is then coated with a

sealing/damping compound to render it air-tight and provide the

appropriate amount of damping control. This surround is attached

1501AL-1

(DD65000)

Layered Paper-Pulp

Matrix Cone with

Aquaplas Damping

to a composite cone body consisting of an inner and outer layer of

pure pulp stock with an inner foam injection core. This sandwich

construction creates an incredibly stiff, but still relatively light cone

body with extremely good distortion characteristics.

®

Both woofers employ dual inverted Nomex

spiders for the

cancellation of even-order distortion components. The design

and material of these spiders have been further optimized for the

DD65000 and DD67000 systems to offer even greater freedom

of motion and dynamic range, specically at low playback levels.

All suspension elements are tailored for maximum mechanical

displacement linearity.

All together, these design factors provide reduced harmonic

distortions at very low and very high acoustic output, improved

power handling, reduced power compression, and more

consistent spectral balance with varying input drive level.

1501AL-2

(DD67000)

3-Layer Pure Pulp

Sandwich Cone with

Foam Injection Core

476Mg, 476Be HIGH-FREQUENCY

COMPRESSION DRIVER

The 476 family of high-frequency compression drivers make

use of a 4-inch (100mm)-diameter formed diaphragm with a

4-inch (100mm) aluminum edge-wound voice coil, operating into

JBL’s existing rapid-are-type, coherent-wave phasing plug. The

476Mg (DD65000) has a 95% pure magnesium alloy diaphragm.

The 476Be (DD67000) has a 98% pure beryllium diaphragm.

The use of an efcient neodymium rare-earth motor structure

with a new copper-sleeved polepiece maintains maximum gap

ux and reduced coil inductance at a minimal size and weight.

The combination of these features has resulted in drivers that can

deliver superior sound quality with very little distortion and power

compression, regardless of acoustic power output.

A high-purity copper sleeve is used for the polepiece. This greatly

improves the electrical conductivity of the polepiece for lower coil

inductance and thus greater high-frequency output at 15kHz and

above. The copper-sleeved pole piece quickly wicks away heat

generated by the voice coil, thereby contributing to a reduction

in dynamic power compression. To compensate for the higher

resistance caused by the use of the copper-sleeved polepiece, a

new magnet with special high-grade and high-temperature-grade

neodymium has been used.

The phasing plug is of JBL’s traditional rapid-are, coherent-wave

four-slot design. This coherent-wave design shapes the wave

output, producing a truly coincident wave front as the sound

enters the Bi-Radial horn.

The diaphragm is formed of very high purity magnesium alloy

foil (476Mg, DD65000) or pure beryllium foil (476Be, DD67000)

that is manufactured with a proprietary high-temperature and

pressure-forming process. This process enables the integrated

JBL diamond-pattern surround to be formed as one piece with the

dome. Compared to other methods, forming the diaphragms out

of sheets of magnesium or beryllium foil yields greater reliability and

resistance to failure due to fatigue. If breakage ever does occur, the

diaphragm does not shatter into pieces or harmful dust. Beryllium

has a very high stiffness-to-density ratio of about ve times that

of aluminum, magnesium, titanium or iron. This maintains pistonic

behavior up to 20,000Hz, eliminating diaphragm modal breakup

and keeping the upper frequency response very smooth, with

minimal distortion spikes. Compared to the 475Nd compression

driver used in JBL’s original K2 S9500 system, this is about a 45

percent reduction in moving mass. With such a low mass, the

moving assembly is able to respond even more quickly to musical

transients, further enhancing the reproduction of musical detail

and microdynamic nuances.

Like the beryllium diaphragm in the 476Be, a proprietary thermal

forming process is used to form thin magnesium alloy sheets into

a 100mm magnesium dome shape of exacting dimensions for

the 476Mg. This includes the integrated JBL diamond surround.

The 95% pure magnesium alloy diaphragm of the 476Mg also

uses small percentages of aluminum, zinc, and other alloys to

improve characteristics such as diaphragm forming, fatigue

strength, corrosive and acoustic properties. Magnesium has very

low density, slightly lower than even beryllium, but with much lower

stiffness. However, with such a low density the thickness of the

magnesium alloy diaphragm can be increased to 130 microns,

greatly improving its stiffness. In fact, when compared to the

titanium diaphragms used in JBL’s original K2 S9500 and M9500

systems, this new magnesium alloy diaphragm is 2.5 times thicker

but maintains about the same moving mass of 3.4 grams. This is

benecial because with high stiffness, pistonic behavior extends

up to higher frequencies than is possible with current aluminum

or titanium diaphragms. Another benet of the magnesium alloy is

greater internal loss or damping when compared to aluminum or

titanium diaphragms. This greater internal loss quickly minimizes

the amplitude of resonances when the driver is asked to produce

frequencies beyond its acoustic limits.

Special Low-Density

Foamed Rubber

Half-Roll

Suspension

High-Strength Sealed

Poly-Cotton Cloth

Accordion-Pleated

Suspension

1501AL-1/1501AL-2 Cone and Suspension Comparison

Die-Cast Aluminum Front Cover

Diamond Surround

Top Plate

Neodymium Magnet

4" Edge-Wound

Aluminum Voice Coil

Copper-Sleeved

Pole Piece

Foam Damping Pad

Coherent-Wave, 4-Slot Phase Plug

Diaphragm Assembly

Acoustic Seal

Die-Cast Aluminum Back Cover

5-Way, Gold-Plated Terminals

476-series Compression Driver Section View

1918

Page 11

JBL’s proprietary diamond-pattern surround is utilized to maintain

proper control and tuning of the diaphragm’s second resonance

(the surround resonance mode). The proper control and

placement of this surround resonance is critical for good highfrequency shape, extension and level.

These features, when taken as a whole, create a new large-format

compression driver with the greatest high-frequency extension,

lowest distortion, smoothest response and greatest sonic detail.

045Be-1 AND 045Mg ULTRAHIGH-FREQUENCY

COMPRESSION DRIVER AND BI-RADIAL

®

HORN

Like the original 045Be used in the Everest DD66000, the 045Be1 used in the Everest DD67000 incorporates a 1-inch (25mm)

beryllium diaphragm and 2-inch (50mm) neodymium magnetic

structure. The pure-beryllium diaphragm is less than 0.04mm

thick and has a mass of only 0.1 gram. The single-layer aluminumribbon voice coil is wound without a former and is attached

directly to the diaphragm. This driver employs the smallest

annular-slit phasing plug that JBL has ever designed. The 045Be-

1 has been re-designed to improve manufacturing efciency and

consistency. Small changes have been made to the top plate and

some signicant improvements were made to the surround shape

and clamping methodology. As a result, the driver’s output above

30kHz has been increased by nearly 5dB.

Newly created for Everest DD65000, the 045Mg incorporates

a very high purity magnesium diaphragm – the same material

used on the 476Mg. This material was selected to maintain

acoustic consistency between the high-frequency and ultra-highfrequency drivers. Also new to the 045 family is a new precision

cast magnesium phasing plug. Compared with the plastic phasing

plug used in the previous design, this new magnesium phasing

plug offers improved stiffness and better ability to wick heat away

from the voice-coil/diaphragm assembly. The extremely low

mass of the moving system combined with the high magnetic ux

density and high rigidity of diaphragms produces response that is

very smooth from below 8kHz to beyond 50kHz in the DD65000,

and beyond 60kHz in the DD67000.

The response curve has a slight downhill tilt, due to the constantdirectivity nature of the horn used in this system. The Bi-Radial®

horn used with the 045-series driver is properly scaled to maintain

a coverage angle of 60 degrees in the horizontal plane and 30

degrees in the vertical plane over the frequency interval from

10kHz to 50kHz.

INTERNAL CROSSOVER NETWORK

The circuit topology, combined with the acoustic behavior of the

1501-series and 476-series transducers, provides a 24dB-peroctave transition at 750Hz in the DD65000 and at 850Hz in the

DD67000. This is the primary crossover point of the system.

Additionally, the 045-series transducer is active above 20kHz to

provide extended response to beyond 50kHz in the DD65000,

and beyond 60kHz in the DD67000. A second 1501AL woofer

is active from below 30Hz to around 150Hz, at which point it is

gently rolled off at 6dB per octave. The design intent is to use both

woofers in the bass frequencies and slowly transition to a single

woofer in the midrange. This technique allows a primary crossover

point between just two drivers and permits proper control of the

system’s directivity pattern, while providing tremendous power

and air movement capabilities at the lower frequencies. As a

result, the speed and power of the Project Everest systems are

unmatched from the lowest to the highest frequencies.

All of the electrical components are of the highest quality and exhibit

the lowest internal loss. Air core inductors are incorporated to avoid

nonlinear hysteresis effects. Capacitors are constructed using

polypropylene foil, which is known for having minimal distortion

caused by dielectric absorption nonlinearities. The mid-, high- and

ultrahigh-frequency networks employ DC voltage bias to operate

the capacitors effectively in a Class A mode. Every attempt is made

to present as smooth a system impedance as possible to the

driving amplier. This design element is often overlooked in many

loudspeaker systems, yet ampliers work their best when they are

given a smooth, level load impedance in which to deliver current.

The aggregate of these attributes allows the DD65000 and

DD67000 systems to translate the electrical signal from source

material into an accurate and unencumbered three-dimensional

sound eld. These systems can do this at any desired listening

level, from whisper-quiet to big-band loud, while at the same time

maintaining unchanged acoustic characteristics.

Surround

Back Plate/

Driver Exit

1" Edge-Wound

Aluminum Voice-Coil

Stainless-Steel

Mounting Bracket

Magnesium

Phase Plug

1" Diaphragm

Neodymium Magnet

Top Plate

Die-Cast

Aluminum-Alloy

Back Cover

Gold-Plated

Input Terminals

045-Series Compression Driver Section View

Ohm

50

45

40

35

30

25

20

15

10

5

0

20Hz 50 100200 5001k2k5k10k 20k

Impedance vs Freq

DD65000 System Impedance

2120

Page 12

UNPACKING THE

PROJECT EVEREST

3

SYSTEM

All components of the Project Everest system have been very carefully packed for

maximum protection against damage. As with any superior audio product, it is advisable

to keep the original packing materials, in case it is necessary to transport the Project

Everest system. Because of the bulk and weight of this loudspeaker, at least two people

are required to unpack it.

NOTE: Stainless-steel round feet are installed on the bottom of the speaker cabinet.

To avoid damage to your oor, we strongly advise unpacking the speakers on a wellprotected surface, such as a thick carpet or cardboard. (Note: Your loudspeaker system

is packed with a protective wrapping, but this is omitted for clarity in the drawings below.)

1. Cut the straps securing the carton with scissors or a knife. (Please be careful so that

the cut straps don’t spring up and hit your face or hand.)

2. a) Slowly lift the top cover up and remove it. b) If there is not enough room above the

box to pull off the top cover, carefully cut the side and top of it with a knife and pull

it horizontally.

A B

23

Page 13

3. Remove the cardboard and packing materials. Remember to

take the accessories out from the upper endpads.

Remove

Accessory

Package

6. Cut tapes at the corners of the bottom cardboard.

7. Slide the loudspeaker system together with bottom endpads

out toward you.

9. Remove the protective wrapping.

INSTALLING SPIKES

REMOVING THE GRILLES

Project Everest loudspeakers are shipped with their grilles installed

on the enclosures. You will need to remove the grilles to access

the adjustment panels when you set up your speakers. You can

remove the grilles with the following procedures.

1. Hold the lower part of the grille with both hands and push it up.

4. Remove the upper endpads.

5. Together with the bottom cardboard, slide the loudspeaker

system down from the bottom board

8. Lift the system slightly on the right and left, in turn, to remove

the bottom endpads.

Project Everest speakers are shipped with round-tipped feet on

the bottom of the cabinet. If you would like to use pinpoint spikes,

remove the round-tipped feet and replace them with the supplied

pinpoint spikes. If the round-tipped feet are hard to loosen, use an

11/16-inch (18mm) wrench.

IMPORTANT: To prevent damage (scratches, indentations, etc.)

to wood or linoleum oors due to the weight of these speakers,

always use the included coasters. Be especially sure to use the

coasters on tile surfaces to prevent cracking the tile.

Push bottom of grille UP

2. Pull the bottom of the grille toward you to remove the grille from

the lower pins on the enclosure.

Pull bottom of grille OUT

3. Pull the grille down and remove it from the enclosure.

Pull grille DOWN and remove

Repeat the above steps in reverse order in order to install the

grilles back on the enclosures.

2524

Page 14

SELECTING

4

SPEAKER WIRE

Speaker wire and interconnecting cables are an important

component in any audio system. With a system like Project

Everest, they assume an increased level of importance.

Project Everest loudspeakers are internally wired using highquality oxygen-free copper wiring. The same care that was

given to the selection of the loudspeakers’ internal system wiring

should be afforded to the selection and application of the wires

that will connect the Project Everest loudspeakers to your other

system components.

Many manufacturers produce audiophile speaker wire worth

considering for Project Everest loudspeakers. As with all electronics

and associated components, however, every manufacturer

offers products of varying quality to suit a range of budgets and

applications. We advise that you use high-quality wire and to

select the highest grade of wire available from the manufacturer.

Project Everest specialist dealers have the experience and

knowledge to recommend suitable speaker wire to best

complement your particular system. We recommend using an

audiophile-quality speaker wire of not less than 16-gauge for

connections of up to 15 feet (5 meters) as a minimum requirement.

For maximum signal purity, we advise that you place the

amplier(s) as close as possible to the loudspeakers, even if

this means that a longer distance will be needed between the

amplier(s) and preamplier.

The connections between the left and right ampliers and

speakers should be the same length. If the distance between one

speaker and its amplier(s) is greater than the distance between

the other speaker and its amplier(s), use the longer length of wire

for both connections.

For bi-wire connections, the same type of wires may be used for

both low-frequency and high-frequency sections to reduce wire

effects (resistance, inductance, etc.) and to avoid intermodulation

of low and high frequencies in the wires. Specialized wires for

low-frequency and high-frequency sections may yield excellent

results. Whatever wires you select, be sure that the low-frequency

wires are as short as possible, and that the left and right wires for

each section are the same length.

27

Page 15

AMPLIFIER

5

RECOMMENDA TIONS

No single type of amplier is specied for use with Project Everest

Loudspeaker systems. The speakers are highly efcient and will

operate adequately with an amplier or receiver of 70 – 100 watts.

However, the transient response and audio denition of a high-end

system such as Project Everest will expose all the inaccuracies

and distortion in the electronic chain that precedes it. For fullrange operation, Project Everest loudspeaker systems should not

be used with an amplier/receiver of less than 100 watts. Highquality ampliers/receivers of 100 – 500 watts will ensure optimal

system performance.

There is no effective limit to the power handling capabilities of

the Project Everest loudspeakers when driven by consumer audio

ampliers. No damage will occur when used with high-powered

components. The selected amplier(s) should have a very high

current capacity and must be capable of driving a low-impedance

load. Low output impedance is also an important criterion in

selecting an appropriate amplier.

For bi-wiring or bi-amplication applications, four identical ampliers

or two dual-channel units may be used, although specialized low-

frequency and high-frequency ampliers offer clear advantages.

(If four amplier channels are used, the high-frequency amplier

may be up to 6dB less powerful than the low-frequency amplier.

Due to the power-versus-frequency distribution of music, the

loudspeaker’s low-frequency section requires approximately four

times the power of the high-frequency section.)

Project Everest dealers can recommend amplication to best suit

your individual needs. In all cases, the left and right ampliers for

each section must be identical. When bi-amping or bi-wiring,

make sure that the input sensitivity of the two ampliers is equal

or that input level controls are provided to maintain the proper low

to mid/high balance. If two identical stereo ampliers are chosen,

each amplier may be located near a loudspeaker and drive low-

frequency and high-frequency sections through short wire runs.

If you are bi-amping the loudspeakers, a separate electronic

crossover network (not included) must be connected to the

outputs of the preamp/processor and to the inputs of the

ampliers that are powering the loudspeakers’ low-frequency and

high-frequency sections. Refer to HF Drive/LF Drive in Chapter 7,

for more information.

29

Page 16

PLACEMENT

6

AND SETUP

Project Everest loudspeaker systems are designed to be less affected

by room acoustics than conventional direct-radiator systems. However,

they are still sensitive to the overall symmetry of their locations relative to

the listening position, and their proximity to walls, ceilings and corners.

Ideally, any listening room should contain a combination of live surfaces

(e.g., walls and windows) and absorbent surfaces (e.g., drapes,

carpets, upholstery). If the distance between the oor and ceiling is

minimal, it is preferable that one surface has an absorbent covering.

To obtain the best stereo effect, each speaker should be placed an

equal distance from the listening position.

• The distance between the right and left speakers is determined by

the relationship between the distance from the listening position to

the speakers and the angles of the speakers. The Project Everest

loudspeakers’ imaging qualities enable them to be placed relatively

far apart from each other, but this weakens the imaging of sounds

such as vocals, that are typically mixed to the center of the stereo

soundstage. In such an installation, increasing the inward angle (toein) of the speakers toward the listener will improve the center imaging.

Less

Toe-In

40° – 60°

• The listener should be centered in front of the speakers, and furniture

should be of an appropriate height so that when the listener is sitting,

their ear level is about the same height as the high-frequency horn

(approximately 36 inches/91cm from the oor),

Approximately

36" (91cm)

• Placing the speakers closer to the wall behind them or to the side

walls will result in an abundance of bass, but placing them too close

will result in dull sounding bass. On the other hand, too much distance

between the loudspeakers and the nearest wall will reduce the bass

output but result in fast and sharp sounding bass. The loudspeakers’

low-frequency alignment feature enables placing the loudspeakers

near (or even in) a corner without producing an overabundance of

bass. This corner placement allows optimal performance, even in

small rooms. Careful listening using various source materials will

enable you to nd the most suitable location for your loudspeakers in

your listening room.

Each Project Everest loudspeaker in a stereo pair needs to be

designated as the right or left speaker, depending on its installed

location. Once speaker locations are decided upon, please refer to

System Orientation, in Chapter 7, to set them up.

More

Toe-In

60° – 90°

CAUTION: Project Everest is a massive loudspeaker, consisting of

materials chosen for their density, with its weight concentrated in

a relatively narrow area. Verify the integrity of the oor surface before

placing and setting up the speakers. See Floor Requirements (below).

Remember that these loudspeakers cannot be easily moved once they

are installed.

FLOOR REQUIREMENTS

The oor at the locations you select for your Project Everest loudspeakers

must be capable of supporting a load of 310 lb (141kg). Because

of the coupling effect of the stainless-steel feet, a at, hard surface

such as wood or linoleum is preferable. However, the design of the

loudspeakers’ coupling system, along with the speakers’ substantial

weight, should result in excellent performance on any surface, even

on carpets.

To prevent indentations on wood or linoleum oors caused by the

weight of the loudspeakers, always utilize the enclosed coasters.

IMPORTANT: Do not set up the Project Everest loudspeaker directly

on a ceramic tile oor; the concentrated weight might cause the tiles

to crack.

31

Page 17

PROJECT EVEREST

7

ADJUSTMENTS

The DD65000 and DD67000 have two control panels under the cover at the center

bottom of the front bafe. Shorting bars and switches on the control panels allow you to

switch orientation of the system, engage bi-amplication if desired and adjust woofer and

high-frequency levels. After removing the grille (see Removing the Grilles, in Chapter 3),

remove the control panel cover to expose the adjustments.

To change setups using shorting bars, use the supplied hexagonal driver to remove the

screws securing the bar. Move the bar according to the setup you require and then reinstall the screws.

ATTENTION: To avoid poor electrical contact caused by loose shorting bar mounting

screws, make sure that the screws are rmly installed. However, if you overtighten, there

is a risk of damaging the terminals themselves. Please use the supplied hexagonal driver

and tighten screws with reasonable torque, by hand only. DO NOT USE POWERED

SCREWDRIVERS OF ANY TYPE.

33

Page 18

The following adjustments are made using the above procedure:

HF DRIVE/LF DRIVE

SYSTEM ORIENTATION

As described earlier, the loudspeaker’s two low-frequency drivers

operate over different frequency ranges. For proper stereo

imaging, it is necessary that the midrange woofer (LF2) be in the

inboard position (closer to the other speaker). The proper setting of

the system orientation jumper bars can congure a single Project

Everest system as either a “left” or “right” system. It is necessary

that both bars be set in the same position. Improper sound will

result from staggering the bars. The bars select which woofer

receives the low-frequency signals and which woofer receives

the midrange signals. One system should be set to “left” and

positioned as the left speaker. The other system should be set to

“right” and positioned as the right speaker.

System Orientation:

Left Speaker

System Orientation:

Right Speaker

These jumper bars allow you to set the loudspeakers for normal

operation (using a single stereo amplier or pair of mono ampliers)

and bi-amp operation (using two sets of stereo ampliers and an

external dividing network). The shorting bars are set at the factory

for Normal (single-amplier) operation, so move the shorting bars

only if you are bi-amping the loudspeakers.

Normal Operation

Bi-Amp Operation

3534

Page 19

Setting the LF- and HF Drive shorting bars in the Bi-Amp position

bypasses the speaker’s crossover function for the full-range woofer

and the high-frequency driver. The low-frequency woofer and the

ultrahigh-frequency drivers are unchanged. Setting the shorting

bars in the Bi-Amp position requires the addition of an external

dividing network (electronic crossover) to provide the 750Hz

(DD65000) or 850Hz (DD67000) primary crossover point for the

system. The built-in attenuation and equalization for the 476-series

high-frequency driver remains in place. The high-frequency level

trim control remains operational, as does the diode biasing for both

the low-frequency and high-frequency network sections.

Normally, all three sets of shorting bars (two LF and one HF)

would be moved together to set the loudspeaker for bi-amping.

It is possible to operate the system with just the low-frequency

system or the high-frequency system set for bi-amping. In this

circumstance, it would be necessary to use a combination of an

external dividing network and the internal network. However, this

is not generally recommended.

The graphs below shows the low-frequency and high-frequency

voltage drive functions necessary to properly bi-amplify a

DD65000 or DD67000 system using an external dividing network

and two amplier channels. Neither the low-pass nor the high-

pass drive is a standard Butterworth alignment or, for that matter, a

standard alignment at all. The provided drive curves were derived

using the internal passive network and resulting acoustic low-pass

and high-pass shapes. Duplicating these shapes will result in the

same frequency response and directivity pattern as the passively

driven system. The low-pass section is made up of two cascaded

second-order sections and the high pass is a single high-pass

section. The values within a high-quality analog dividing network

can usually be modied to achieve these results. Recent digital

crossover units will have no problem duplicating these curves.

HF AND LF1 LEVEL SWITCHES

High-Frequency

Level Switch

LF1 Woofer

Level Switch

The HF Level switch adjusts the attenuation applied to the

476-series high-frequency transducer by approximately ±0.4dB

over the range of 1,000Hz to about 8,000Hz. The action is

accomplished by trimming the main attenuation resistors.

Midrange sound becomes softer by reducing the level and

stronger by increasing the level. No additional parts are inserted

in the signal path and there is no sonic deterioration by position or

adjustment functions.

There is also a level trim switch available for the LF1 woofer. LF1

is the low-range woofer (that operates up to 150Hz), and each

position will affect the output level in the range of 40Hz to 120Hz

by about ±0.5dB. The purpose of this adjustment is to allow ne-

tuning of the bass to mid-bass response of the system to better

integrate with different room characteristics. The adjustment is

accomplished by a change in value of a parallel damping resistor in

the LF1 woofer circuit. No insertion loss is caused by this control.

dBm

10

5

0

-5

24 dB/Oct

LP1: Fo = 430 Hz, Q =1

-10

LP2: Fo = 1100 Hz, Q = 1.4

Gain = 2 dB

-15

-20

-25

-30

20Hz 50 100 200 500 1k 2k 5k 10k 20k

Voltage vs Freq

12 dB/Oct

HP: Fo = 700 Hz, Q = 0.94

DD65000 Voltage Drive

dBm

10

5

0

-5

24 dB/Oct

LP1: Fo = 440 Hz, Q =0.71

-10

LP2: Fo = 700 Hz, Q = 1.8

Gain = 3 dB

-15

-20

-25

-30

20Hz 50 100 200 500 1k 2k 5k 10k 20k

Voltage vs Freq

12 dB/Oct

HP: Fo = 800 Hz, Q = 1.0

dBSPL

110

105

100

95

90

85

80

75

70

65

60

20Hz 50 100 200 500 1k 2k 5k 10k 20k

SPL vs Freq

= LF1 Adjustment Range

= HF Adjustment Range

DD65000 Control Adjustment Range

dBSPL

110

105

100

95

90

85

80

75

70

65

60

20Hz 50 100 200 500 1k 2k 5k 10k 20k 40k

SPL vs Freq

= LF1 Adjustment Range

= HF Adjustment Range

DD67000 Voltage Drive

DD67000 Control Adjustment Range

3736

Page 20

PROJECT EVEREST

8

CONNECTIONS

CAUTION: Turn off all ampliers before connecting or

disconnecting Project Everest loudspeakers. Making

connections while an amplier is operating could seriously

damage the loudspeaker system and void the warranty.

All ampliers must also be turned off before connecting or

disconnecting cables at the amplier or preamplier inputs.

All connections between the amplier(s) and the Project Everest

loudspeaker system are made at the terminals located on the

rear of the enclosure. The left-hand terminals (black rings and

black logos on the terminal knobs) are negative, and the righthand terminals (red rings and red logos on the terminal knobs)

are positive. Twisted-pair shorting straps connect the netative

terminals together and the positive terminals together.

Assign one of the two speaker wire conductors as the negative

conductor and the other as the positive conductor. These should

correspond to the negative and positive speaker terminals on

the speaker and amplier. Use these same designations for all

system wiring. Always connect the conductors of the speaker wire

appropriately to the corresponding negative and positive terminals

on all system components: amplier “+” to speaker “+”; amplier

“–” to speaker “–”. This will ensure that all components will work

together in proper polarity (sometimes referred to as “in phase”).

Refer to your receiver’s or amplier’s instruction manual to conrm

its connection procedures. Connecting the loudspeakers with

improper polarity (sometimes referred to as “out of phase”) will not

damage them but will result in reduced low-frequency output and

impaired stereo effect.

39

Page 21

Speaker wires may be fastened to the loudspeaker terminals by

several methods. The most positive connection is usually made

by directly connecting clean, bare wire (exposed by stripping the

insulation from the ends of the wire) to the terminal posts.

For this type of connection, loosen the knobs on the terminals to

expose the holes in the terminal shafts and insert the bare end

of each speaker wire into the hole exposed on the terminal shaft.

(Again, make sure to connect amplier “+” to speaker “+” and

amplier “–” to speaker “–”.) Tighten the knob on each terminal so

that a snug positive connection is achieved. Do not apply excessive

force and do not overtighten. To avoid a short circuit that could

damage the loudspeakers or your amplier(s), trim off any excess

wire that is not in contact with the binding post contact surfaces.

A B

C D

Project Everest loudspeaker terminals are also designed to accept

spade connectors or banana connectors, which are fastened to the

ends of the wires and, in turn, are attached to the terminal posts.

A B

C D

Spade Connection

A B C

Project Everest loudspeaker connector panels have two sets

of terminals that provide a choice of three different connection

methods: single-wire, bi-wire and bi-amp. Use the most suitable

method for your audio system.

SINGLE-WIRE CONNECTION METHOD

The single-wire method requires one amplier channel and one

set of wires for each loudspeaker. You can make the connections

to either the loudspeaker’s upper set of terminals or its lower set of

terminals. IMPORTANT: DO NOT REMOVE THE SHORTING

STRAPS. Make sure the conductors and sleeves of the shorting

straps are rmly fastened at the terminals.

Bare Wire Connection

Banana Connection

Receiver or Amplier

(one channel shown)

Use Either Set

Terminals

of

Speaker

Connector Panel

Single-Wire Connection Method

Note: Do Not Remove Shorting Straps

Do NOT Remove

Shorting Straps

4140

Page 22

BI-WIRE CONNECTION METHOD

BI-AMP CONNECTION METHOD

IMPORTANT: When you use the bi-wire or bi-amp connection

method, remove the shorting straps from the terminals (referring

to the gures below) and re-tighten the knobs on the terminals. If

the ampliers are connected to the Project Everest loudspeakers

in the bi-wire or bi-amp mode with the shorting straps still on,

the amplier outputs will be shorted, which could result in costly

amplier damage when power is switched on.

The bi-wire connection method requires one amplier channel and

two sets of speaker wires for each loudspeaker. After removing

the shorting straps, you can make connections to the individual

network sections using all four connectors, with one set of wires

to the upper (high-frequency) terminals and another set of wires to

the lower (low-frequency) terminals.

The bi-amp connection method requires two ampliers, one for

the low-frequency transducers and one for the high-frequency

transducers, and an external dividing network (electronic

crossover). After removing the shorting straps on the loudspeaker

connector panels, wires from the high-frequency amplier are

connected to the upper terminals, and wires from the low-

frequency ampliers are connected to the lower terminals.

Preamp/Processor

(one channel shown)

INPUT

OUTPUT

High-Frequency

Amplier

(one channel shown)

Low-Frequency

Amplier

(one channel

shown)

INPUT

HIGH-

FREQUENCY

OUTPUT

LOW-

FREQUENCY

OUTPUT

INPUT

Use Both

Set of

Terminals

Speaker

Connector Panel

Shorting Straps

Removed

Receiver or

Amplier

(one channel

shown)

Use Both Set

of Terminals

Speaker

Connector

Panel

Shorting Straps

Removed

Bi-Wire Connection Method

Note: Remove Shorting Straps

Electronic Crossover

(one channel shown)

Each of these connection methods described above has its own

advantages – your Project Everest loudspeaker system will deliver

superb performance with any of the methods described.

FINAL CHECKLIST:

• Connect all other system electronics and plug into AC

power outlets.

• Check all connections. In case of bi-amping or bi-wiring,

make sure both shorting straps are removed.

• Make sure the system orientation and HF/LF drive jumper

bars on the control panels are correctly set.

Bi-Amp Connection Method

Note: Remove Shorting Straps

The loudspeakers are now ready for use. The Project Everest

loudspeaker system is fully functional as soon as it is set up. There

may be subtle tonal changes in bass output over the rst week to

10 days of operation. These are caused as the movement of the

low-frequency drivers becomes more uid and the parts settle in.

This process is completely normal and natural with transducers of

this caliber. Even during this initial period, there is no restriction on

the amount of amplication that may be applied. Enjoy!

4342

Page 23

CARE AND

9

MAINTENANCE

Project Everest loudspeakers require no maintenance other than occasional dusting with

a soft, dry, lint-free cotton cloth. The horns may also be wiped with a soft cloth. Treat the

lacquered surface very carefully to avoid scratching the nish. To remove ngerprints and

smudges, apply a small amount of diluted ammonia-free or alcohol-free neutral detergent

to the cloth and gently clean the surface.

• Never use any abrasive cleaners or chemicals to clean the enclosure. If the enclosure

becomes noticeably scratched or otherwise damaged, consult a qualied furniture

repair shop.

• Do not spray insecticide near the cabinet.

• To remove dust from the grille fabric, use a vacuum cleaner set to low suction.

• Do not wash the grille in water, as water may fade the grille's color or make it uneven

• Never apply suction or pressurized air to the high-frequency or ultrahigh-frequency horn.

• If the surfaces of the low-frequency driver cones become dusty, you can carefully

sweep them clean with a soft, dry calligraphy brush or paint brush. Do not use a

damp cloth.

All wiring connections should be inspected and cleaned or remade periodically.

The frequency of maintenance depends on the metals involved in the connections,

atmospheric conditions, and other factors. Consult your Project Everest dealer for specic

recommendations.

TROUBLESHOOTING AND SERVICE GUIDE

Project Everest loudspeakers are designed to provide years of trouble-free service.

No maintenance is required.

If a problem occurs, make sure that all connections are properly made and clean. If a

problem exists in one loudspeaker, reverse the speaker wires to the left and right speakers.

If the problem appears in the opposite speaker, the cause is in another component or

cable. If the problem remains in the same speaker, then the fault is in the loudspeaker. In

this event, consult your Project Everest dealer for assistance.

45

Page 24

PROJECT EVEREST SYSTEM SPECIFICATIONS

DD65000

Low-frequency transducer: 15" (380mm) Layered paper/pulp matrix cone woofer (1501AL-1) x 2

High-frequency transducer: 4" (100mm) Magnesium compression driver (476Mg)

Ultrahigh-frequency transducer: 1" (25mm) Magnesium compression driver (045Mg)

Maximum recommended amplier power: 500 Watts

Frequency response (–6dB): 30Hz – 50kHz (half space), 40Hz – 50kHz (anechoic)

Nominal impedance: 8 ohms

5.0 ohms @ 80Hz

3.8 ohms @ 40kHz

Sensitivity (2.83V@1m): 96dB

Hor n directivity (horizontal x vertical)

High-frequency:

Ultrahigh-frequency:

Crossover frequency: 150Hz (LF1 6dB/octave)

100º x 60º

60º x 30º

750Hz (LF2 24dB/octave)

20kHz (UHF 24dB/octave)

DD67000

Low-frequency transducer: 15" (380mm) Pure pulp sandwich/foam core cone woofer (1501AL-1) x 2

High-frequency transducer: 4" (100mm) Beryllium compression driver (476Be)

Ultrahigh-frequency transducer: 1" (25mm) Beryllium compression driver (045Be-1)

Maximum recommended amplier power: 500 Watts

Frequency response (–6dB): 30Hz – 60kHz (half space), 45Hz – 60kHz (anechoic)

Nominal impedance: 8 ohms

5.0 ohms @ 85Hz

3.0 ohms @ 40kHz

Sensitivity (2.83V@1m): 96dB

Hor n directivity (horizontal x vertical)

High-frequency:

Ultrahigh-frequency:

Crossover frequency: 150Hz (LF1 6dB/octave)

100º x 60º

60º x 30º

850Hz (LF2 24dB/octave)

20kHz (UHF 24dB/octave)

Control functions: HF level control (Low, Mid, High)

LF level control (Low, Mid, High)

LF/HF drive mode bars (normal/bi-amp)

System orientation bars (left/right)

Dim ensions (H x W x D):

(including feet)

Weight: 302 lb (137kg) without grille

Package weight: 383 lb (174kg)

38" x 43-5/8" x 18-1/2" (965mm x 1109mm x 469mm)

312 lb (142kg) with grille

Control functions: HF level control (Low, Mid, High)

LF level control (Low, Mid, High)

LF/HF drive mode bars (normal/bi-amp)

System orientation bars (left/right)

Dim ensions (H x W x D):

(including feet)

Weight: 302 lb (137kg) without grille

Package weight: 383 lb (174kg)

38" x 43-5/8" x 18-1/2" (965mm x 1109mm x 469mm)

312 lb (142kg) with grille

4746

Page 25

Thank you for purchasing a

JBL Project Everest loudspeaker system.

Page 26

JBL AND HARMAN INTERNATIONAL

JBL is part of the HARMAN International, a group of companies with a common purpose: combining technology with a love of music to

manufacture audio products that provide new levels of satisfaction, performance and value.

To promote variety and creativity, JBL operates independently in research and development. When it comes to translating the results

of these efforts into actual consumer and professional products, JBL draws on the full combined strength of HARMAN International’s

resources, which include one of the world’s most advanced manufacturing facilities. The result of this teamwork is that JBL’s renowned

excellence in engineering is successfully carried through to each individual product, regardless of its application or price range.

As new audio concepts and technologies are pioneered, the partnership of JBL and HARMAN International guarantees that consumer

and professional audio users everywhere will be able to enjoy their full range of benets.

JBL continually engages in research related to product development and improvement. Because of this, new materials, production

methods and design renements may be introduced into existing products without notice. For this reason, any current JBL product

may differ in some respect from its published description, but will always equal or exceed the original design specications unless

otherwise stated.

HARMAN International Industries, Incorporated.

8500 Balboa Boulevard, Northridge, CA 91329 USA

© 2012 HARMAN International Industries, Incorporated. All rights reserved.

JBL, K2, SonoGlass and Bi-Radial are trademarks of HARMAN International Industries, Incorporated, registered in the

United States and/or other countries. Vented Gap Cooling is a trademark of HARMAN International Industries, Incorporated.

Dolby is a registered trademark of Dolby Laboratories.

DTS is a registered trademark of DTS, Inc.

Nomex is a registered trademark of E.I. du Pont de Nemours and Company.

SACD is a trademark of Sony Corporation.

Part No. JBLP4578 Rev: A www.jbl.com

Loading...

Loading...