Page 1

18” Quilting Machine

Instruction Manual

Page 2

Congratulations on your purchase of a Janome Quilt Maker Pro 18

from Janome!

Congratulations on your purchase of the Janome Quilt

Maker Pro and welcome to the Janome family.

Our mission is to produce machines which inspire

creativity and innovation, yet are simple to use. The

better your tools, the more inventive and pleasurable

your sewing experience. We know the most important

thing about our products is not the machines

themselves, but what you create with them. That’s why

we design our machines for performance, but also for

comfort, quality, and intuitive ease of operation.

Package Contents

Please keep your original box and packaging

As a leader in the sewing industry, we keep striving to

provide best-in-class products and services which enable

sewists’ creativity and innovation. Please be sure to

register your warranty on janome.com. Your registration

allows us to communicate with you regarding machine

updates and other product information. In addition, our

website offers tutorials, quilting patterns, videos, and

more educational materials for your Quilt Maker Pro.

Remember, if you ever have questions, your local

Janome Dealer can help you. For general questions,

please use the General Inquiries Form on janome.com

or call Monday through Friday 8:30AM - 5:00PM EST,

1-800-631-0183 option 3.

Contents of Package

1. Bobbins (5 pieces, one in machine)

2. Needle (135x5) size 16 (pack of 10)

3. Needle (135x5) size 18 (pack of 10)

4. Bobbin Case

5. Thread Mast

6. Pin Oiler

7. Lint Brush

8. Screwdriver

9. Power Cord

10. 2.5 mm L Allen tool

11. Laser Stylus and Clamp

12. Laser Stylus Post

13. Open-toe Foot

14. User Manual

15. Quilt Maker Pro 18 Quilting Machine

Optional Accessories

1. 18” Machine Ruler Base

2. 11’ Leader Set

3. Set of 8 Casters

4. Hand Wheel Kit

5. Channel Locks

6. Couching Feet Set

7. Glide Foot

8. Echo Feet Set

9. Horizontal Spool Pin

10. Bobbin 8 Pack

11. Bobbin Case

Page 2

Quilt Maker Pro 18 User Manual

201704

Page 3

Table of Contents

Safety ................................................................................................................................................................................................................... 4

Components (Front Side View) ................................................................................................................................................................. 7

Components (Back Side, Rear and Front Views) ............................................................................................................................... 8

Installation (Frames) ......................................................................................................................................................................................9

Installation (Handlebars) .............................................................................................................................................................................. 9

Installation (Power Cord) ........................................................................................................................................................................... 10

Inserting Needle .............................................................................................................................................................................................11

Changing the Feet .........................................................................................................................................................................................12

Laser Stylus ......................................................................................................................................................................................................13

Installation (Thread Mast) .......................................................................................................................................................................... 14

Threading the Machine ................................................................................................................................................................................15

Horizontal Spool Pin .....................................................................................................................................................................................17

Bobbin and Thread Tension Adjustments .............................................................................................................................................17

Easy-Set Tension™ Adjustment ................................................................................................................................................................ 19

Maintenance (Oiling and Lubricating) ................................................................................................................................................... 19

Touch Screen Displays ............................................................................................................................................................................... 20

System Information ......................................................................................................................................................................................27

Diagnostics Tests ..........................................................................................................................................................................................28

Janome Stitch Regulator Operation .......................................................................................................................................................31

Getting Started Quilting ............................................................................................................................................................................. 32

Quilt Maker Pro 18 Troubleshooting .......................................................................................................................................................33

Bobbin Winder ...............................................................................................................................................................................................39

Warranty Information .................................................................................................................................................................................. 52

janome.com

Page 3

Page 4

Safety Section

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired

operation.

Please note: Do not operate your Janome Quilt Maker

®

Pro 18

the information contained in this manual. Please keep all

packaging and order information for warranty purposes.

IMPORTANT SAFETY INSTRUCTIONS

Read all instructions before using this machine.

When using this machine, basic safety precautions

should always be followed, including the following:

DANGER — To reduce the risk of electric shock:

• A quilting machine should never be left unattended

WARNING — To reduce the risk of burns, fire, electric

shock, or injury to persons:

• The Janome Quilt Maker Pro 18

• Always unplug the Janome Quilt Maker Pro 18

• Do not unplug by pulling on cord. To unplug, grasp

• Keep fingers away from all moving parts. Use caution

• Change the needle often. Do not use bent or dull

• Switch the machine to the symbol off, or 0, position

• Never drop or insert foreign objects into any

• The Janome Quilt Maker Pro 18

• The Janome Quilt Maker Pro 18

• Use the Janome Quilt Maker Pro 18

• To disconnect from the wall outlet, push the switch

quilting machine until you have completely read

when plugged in. Always unplug the machine from

the electrical outlet immediately after using and

before cleaning.

®

is heavy. Never

attempt to lift it alone. Always use two people when

lifting. Always lift from the throat of the machine, not

from the handlebars.

®

from the electrical outlet when performing any

maintenance, changing the needle, removing thread

locks, or when left unattended.

the plug, not the cord.

around the needle or sharp external components.

needles. “Every quilt deserves a new needle”.

to turn it off when making any adjustments in the

needle area, such as threading needle, changing

needle, threading bobbin, changing hopping foot,

and so forth.

opening.

®

should only be used

indoors away from moisture.

®

should not be stored

or used in extreme temperatures.

®

only for its

intended use as described in this manual.

to the off position, then remove the plug from outlet

pulling from the plug, not the cord. Never operate the

Janome Quilt Maker Pro 18

®

if the cord is damaged

or not working correctly. If a mechanical or electrical

problem is encountered, return the Janome Quilt

Maker Pro 18

®

to the nearest authorized service

center or the manufacturer for examination, repair,

electrical, or mechanical adjustment.

• It is not recommended that the Janome Quilt Maker

®

Pro 18

quilting machine be used with any machine

quilting frame other than those recommended by

Janome.

• Use this quilting machine only for its intended use

as described in this manual. Use only attachments

recommended by the manufacturer as contained in

this manual.

• Never operate the machine with any air openings

blocked. Keep ventilation openings of the machine

free from the accumulation of lint, dust, and loose

cloth.

• Do not operate where aerosol (spray) products are

being used or where oxygen is being administered.

• Do not pull or push the machine across the fabric

excessively while stitching. It may deflect the needle

enough to cause it to break.

• Use only needles designed for free motion quilting

and recommended by Janome for this machine.

Other types of needles may be break during normal

quilting.

• Children shall not play with the machine. Close

attention is necessary when this machine is used by

or near children.

• This sewing machine may be used by children age 8

years and above and persons with reduced physical,

sensory, or mental capabilities or lack of experience

and knowledge if they have been given supervision

or instruction concerning use of the machine in a safe

way and understand the hazards involved.

• Cleaning and user maintenance shall not be made by

children without supervision.

Save these instructions.

This machine is intended for household or commercial

use.

Disclaimer

Janome and its Representatives are in no way legally

responsible or liable for damage to the Janome Quilt

Maker Pro 18 when used improperly or not in accordance

with the guidelines stated in this manual or when used

on machine quilting frames not recommended by

Janome.

Page 4

Quilt Maker Pro 18 User Manual

201704

Page 5

To use the machine safely

1. Carefully watch the needle when sewing. Do not

touch the hand wheel, take up lever, needle, or other

moving parts.

2. Turn the machine off and unplug the cord in the

following cases:

• when you have stopped using the machine

• when you replace or remove the needle or any

other part

• when you check or clean the machine

• when you leave the machine unattended

3. Connect the machine directly to the wall outlet or to

a surge protector that connects directly to the wall

outlet. Do not use extension cords.

To increase the life of your machine

1. Do not store this machine in areas exposed to direct

sunlight or high humidity. Never use or store the

machine near a heater, an iron, a halogen lamp or

other hot things.

2. Use only neutral soaps or detergents to clean the

machine. Benzene, solvents and scouring powders

can damage the case and the machine and therefore

should never be used.

3. Do not drop or bump the machine.

4. Always consult the manual to replace or fix the

hopping foot, needle or any other part of the

machine. If necessary contact an authorized Janome

representative or Janome technical support.

General Specifications

The Janome Quilt Maker Pro 18 utilizes high-tech

electronics and an innovative touch-pad user interface

to offer greater functionality and ease of operation to

home quilters than ever before conceived in the quilting

industry. The Janome

is a high quality machine that incorporates very robust

design features and is very easy to service.

Sewing Opening Dimensions:

Sewing Speed:

Stitches-Per-Inch:

Needle System:

Needle Sizes (recommended):

Hook System:

Bobbin Type:

Bobbin Case:

Motor Ty pe:

Needle Positioning:

Electrical Power:

LED Power Consumption:

Sew Foot Stroke/Lift:

Needle Bar Stroke:

Take-Up Stroke:

Lubrication, main components:

Lubrication of hook:

Quilt Maker Pro 18 quilting machine

(245 mm X 610 mm) 8.25” X

18”

Manual Mode:

Min 90spm, Max 2,200spm

Regulated Mode:

Min 0spm, Max full speed

4spi – 22spi

134 (135 X 7)

12/80 - 20/125

Rotary, Horizontal axis, M-class

bobbin

Aluminum, Class M

Type MF

Brushless DC

Up and down, walking stitch

100 – 240 VAC, 50 - 60Hz,

300W peak

(1.69A@100/.9A@240)

8 W

5 mm

35.3 mm

73 mm

Kluber Lube, permanent

Velocite 10, Texaco 22

janome.com

Disclaimer

Janome and its Representatives are in no way legally

responsible or liable for damage to the Janome

Quilt Maker Pro 18 when used improperly or not in

accordance with the guidelines stated in this manual

or when used on Machine Quilting Frames not

recommended by Janome.

Page 5

Page 6

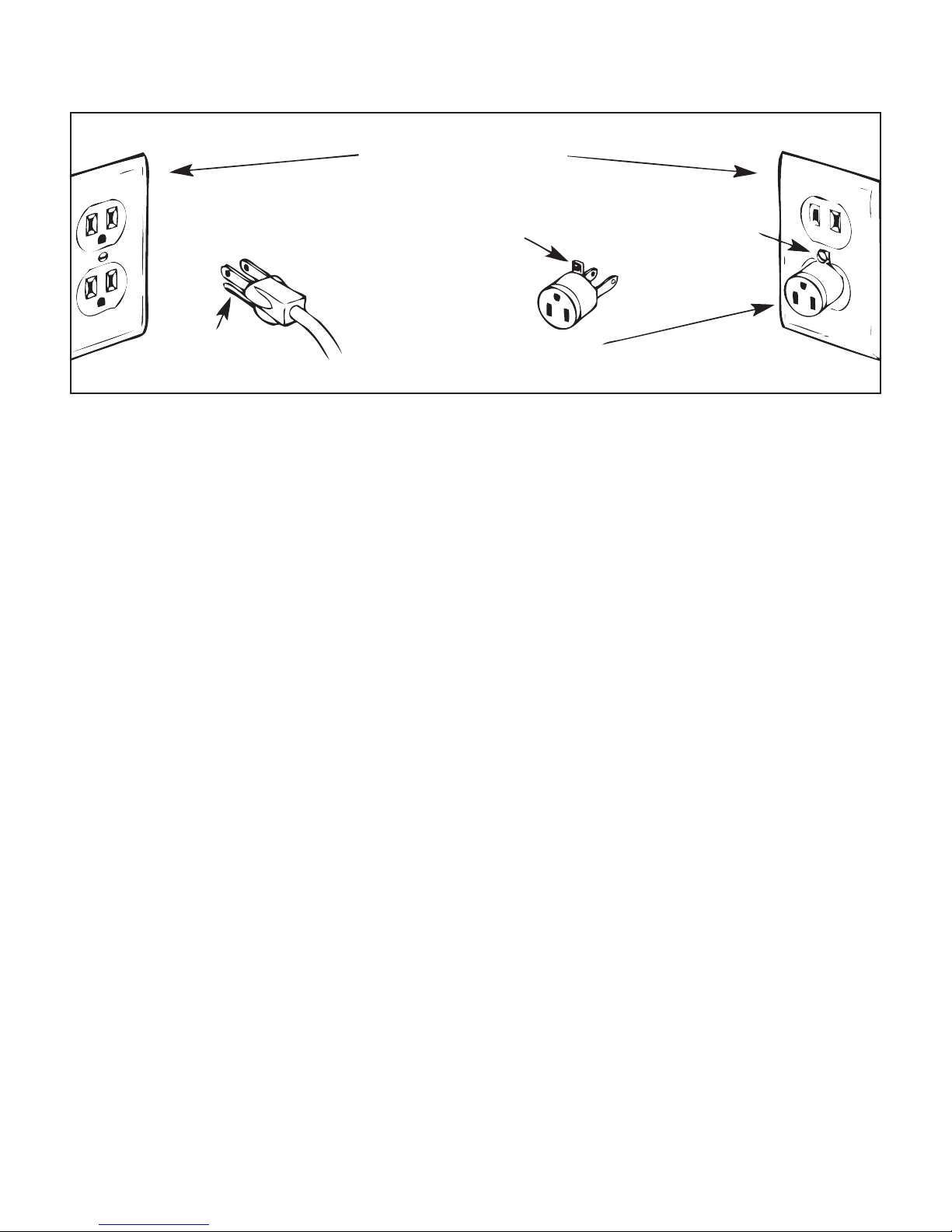

Optional U.S. Grounding

for Customers with 120 VAC Connections

GROUNDED OUTLET

BOXES

TAB FOR

GROUNDING

SCREW

GROUNDING

PIN

(A)

This product is for use on a nominal 120 V or nominal 220 V circuit, and has a grounding plug that looks like the

plug illustrated in sketch A above. A temporary adapter, which looks like the adapter illustrated in sketches B and

C, may be used to connect this plug to a 2-pole receptacle as shown in sketch B if a properly grounded outlet is

not available. The temporary adapter should be used only until a properly grounded outlet can be installed by a

qualified electrician. The green colored rigid ear, lug, and the like, extending from the adapter, must be connected to

a permanent ground such as a properly grounded outlet box cover. Whenever the adapter is used, it must be held in

place by the metal screw.

ADAPTER

(B)

METAL

SCREW

(C)

IMPORTANT: In Canada, the use of a temporary adapter is not permitted by the

Canadian Electric Code.

To repair or adjust the machine

If the machine breaks down or needs adjustment, first check the troubleshooting chart in the appendix to inspect

and adjust the machine yourself.

For more product information and updates, visit our website at www.janome.com/qmp18.

The contents of this manual and product specifications are subject to change without prior notice.

Check for updated manuals at www.janome.com/qmp18.

Page 6

Quilt Maker Pro 18 User Manual

201704

Page 7

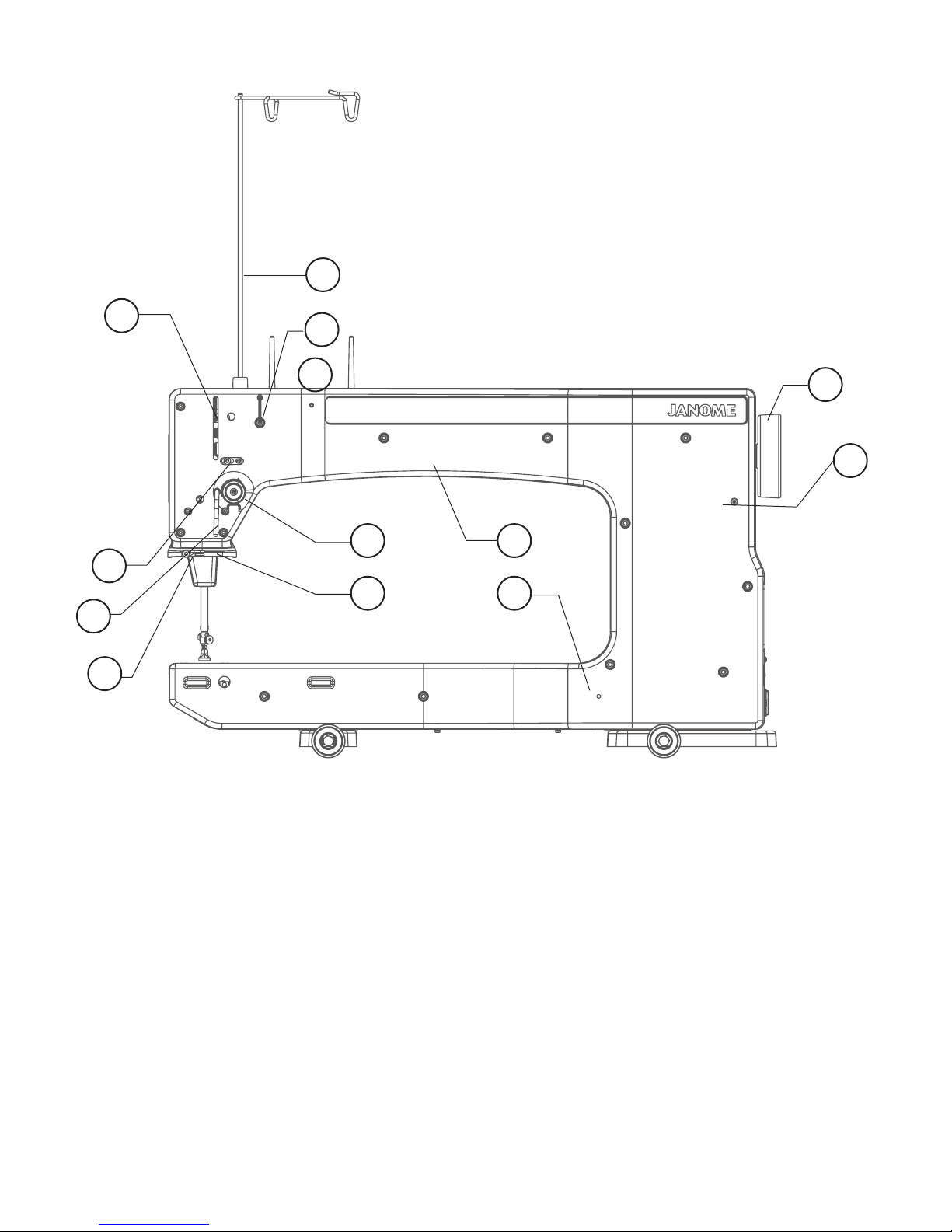

Janome Quilt Maker Pro 18 Components

Front Side View

1

8

4

6

7

3

2

5 10

8 12

11

13

1. Thread Mast

2. Thread Guide A

3. Three Hole Thread Guide B

4. Thread Guide C

5. Tension Assembly

6. Stirrup Thread Guide D

7. Thread Guide E

8. Take-Up Lever

9. Thread Guide F

10. Front Casing/Frame

11. Handwheel

12. Side Laser Stylus Post Hole

13. Laser Stylus Power Connector

janome.com

Figure 1

Page 7

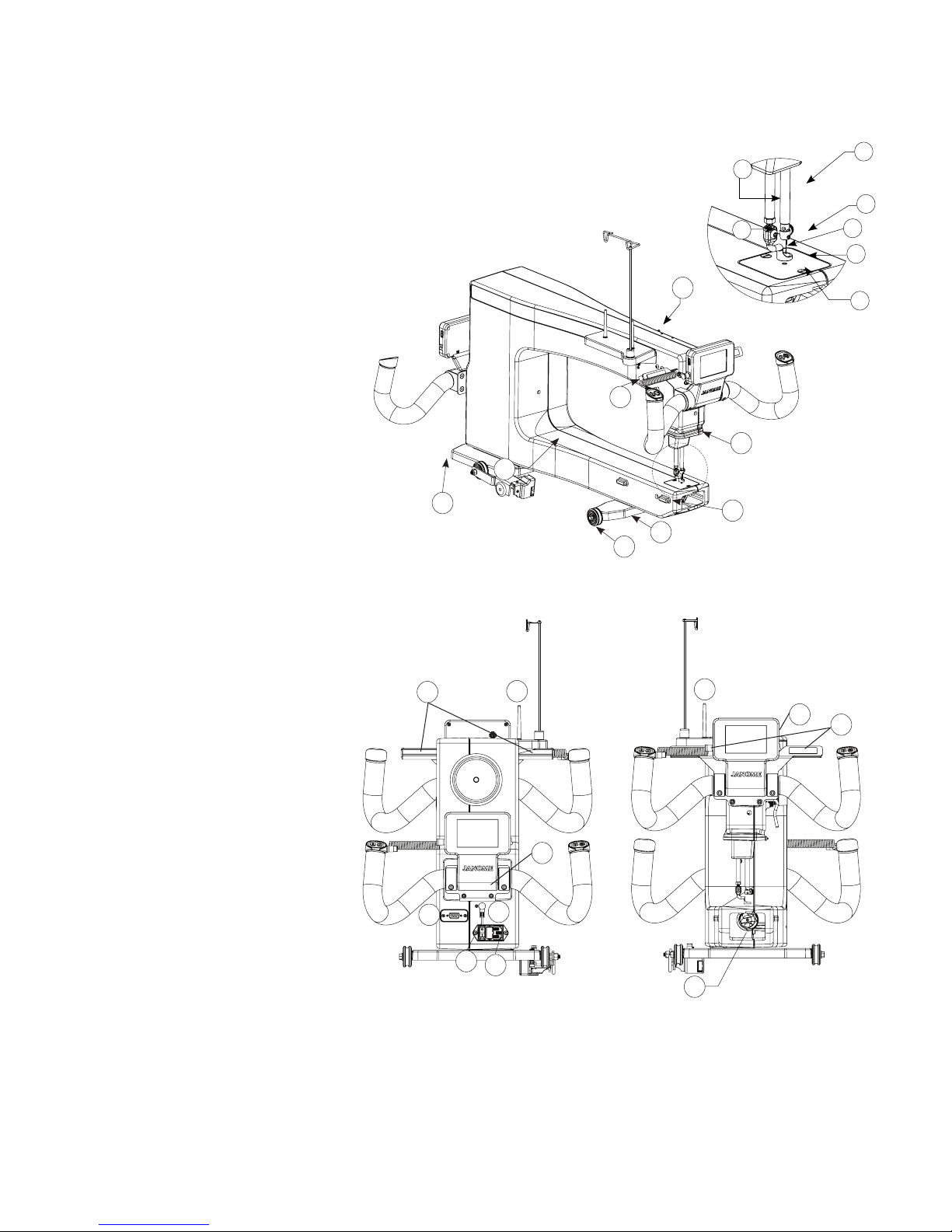

Page 8

Janome Quilt Maker Pro 18 Components

Back Side View

14. Ruler Foot

15. Needle

16. Needle Bar Thread Guide

17. Needle Bar

18. Presser Bar

19. Feet Mount

20. Needle Plate

21. LED Light Ring

22. Front Handlebar Connector

23. Ruler Base Position Guides

24. Front Wheel Base

25. Wheels (4)

26. Back Casing/Frame

27. Rear Wheel Base

28. Horizontal Spool Pin Hole*

27

26

22

25

Figure 2

24

28

17

18

16

19

21

23

15

14

20

Rear and Front Views

29. Spool Pin 1

30. Magnets

31. Serial Port for Stitch Regulator

32. Rear Handle Bar Serial Port

33. Rear Threaded Handles

34. LED Modules

35. Power Cord Connector

36. On/Off Switches

37. Spool Pin 2

38. Bobbin Assembly

Rear

34

31

36

32

35

37

33

Front

Figure 2.1

38

29

35

30

* Horizontal Spool Pin is an optional accessory. Please contact your local Janome dealer to purchase.

Page 8

Quilt Maker Pro 18 User Manual

201704

Page 9

Installation (Quilt Maker Frame)

1. Place the carriage, wheels down, on the table rails,

ensuring that the Carriage Encoder Assembly (small

black box) is positioned on the opposite side from the

frame poles. Be sure to place the carriage on the frame

correctly (see Figure 3).

2. Place the machine on the carriage with the back of

the machine on the same end as the Carriage Encoder

Assembly. Be sure that the silver rails on the carriage

are inserted into the groove in the machine wheels.

3. On the rear of the machine there is a ribbon cable

attached and folded up. Unfold the ribbon cable and

plug the unattached end of the ribbon cable from the

machine into the Carriage Encoder Assembly. The

connector is keyed to assure correct alignment. Make

sure the keyed portion of the cable connector aligns

with the keyed portion of the encoder connector. Do

not force.

5. REMEMBER that if the machine is to be removed

from the carriage, the cable must be disconnected

from the Carriage Encoder Assembly. The other

two connectors on the cable should remain in place.

Failure to unplug the cable when removing the

machine from the carriage could result in damage to

the cable, encoders, and carriage.

Figure 3

Installing Front Handlebars

Caution: Unplug the Janome Quilt Maker Pro 18 from

the electrical outlet. All power to the machine must be

turned off when installing the front handles. Failure to do

so can result in damage to the machine.

Locate the handlebar with lights and magnets attached—

this is the front handlebar. On the front of the machine

locate the 4 threaded holes in a square pattern. (See

Figure 4) Use the 4 bolts found in the machine accessory

box in the small bag with the black spiral serial cables

to attach the front handlebar mounting plate using the

included 4mm hex wrench.

Find the serial connection point on the left side of the

front display and the serial connection point on the

left side of the front of the machine. Connect the front

display to the machine using one of the black spiral serial

cords. (See Figure 4.1) Be careful to align the pins in the

cord with the pins in the serial connection points. Insert

carefully.

Handlebars can rotate to desired position by loosening

the bolts and rotating the handlebars being sure to not

pull them out.

Figure 4

Note: There are magnets on the reverse of the lighting

for convenient storage.

janome.com

Figure 4.1

Page 9

Page 10

Installing Rear Handlebars

Installing the Power Cord

Check that the Janome Quilt Maker Pro 18 is unplugged

from the electrical outlet. All power to the machine must

be turned off when installing the back handlebar. Failure

to do so can result in damage to the machine.

Locate the handlebar without lights and magnets

attached –that is the rear handlebar. On the back of the

machine locate the 4 threaded holes in a square pattern.

(See Figure 4.2) Use the 4 bolts found in the machine

accessory box in the small bag with the black spiral serial

cables to attach the rear handlebar mounting plate using

the included 4mm hex wrench. The mounting plate has

4 access holes for the hex wrench to tighten the bolts.

(See Figure 4.2)

Find the serial connection point on the left side of the

rear display and the serial connection point on the rear

of the machine. Connect the rear display to the machine

using one of the black spiral serial cords. (See Figure

4.3) Be careful to align the pins in the cord with the pins

in the serial connection points. Insert carefully.

Note: After the handles have been completely installed

and plugged in, test them by turning the Janome Quilt

Maker Pro 18 on/off switch to “on”. You will not be

able to turn on the machine until the front handlebars

are installed. If nothing is displayed, check that the

handlebar cable on the side of the machine is plugged

in securely, that your machine is turned on, and that

the power cord is plugged into the machine as well as a

power source.

Insert the cord into power connector on the rear of the

machine. Plug the three-prong end into a power source

(see Figure 5).

Figure 5

Turning on the Janome Quilt Maker Pro 18

Figure 4.2

Figure 4.3

Page 10

Figure 6

There are two power switches for your machine. The

main power switch is at the rear of the machine and

a white power switch is on the right side of the front

screen for your added convenience.

(Figure 6)

The machine is turned on when both switches are turned

on. The machine is turned off when both switches are

off. However, you may turn off the machine functions by

turning off only the front switch if you will be returning

to quilt within a day.

Turn on the back switch first by toggling the switch from

the 0 position to the 1 position. Then turn on the front

switch by toggling it as well. The front switch will not

turn on the machine unless the back switch is already on.

IMP O RTAN T: If you will not be using the machine for

more than a day, we recommend you turn off both

switches and unplug the power cord from the power

source.

IMP O RTAN T: Refer to the safety instructions.

Quilt Maker Pro 18 User Manual

201704

Page 11

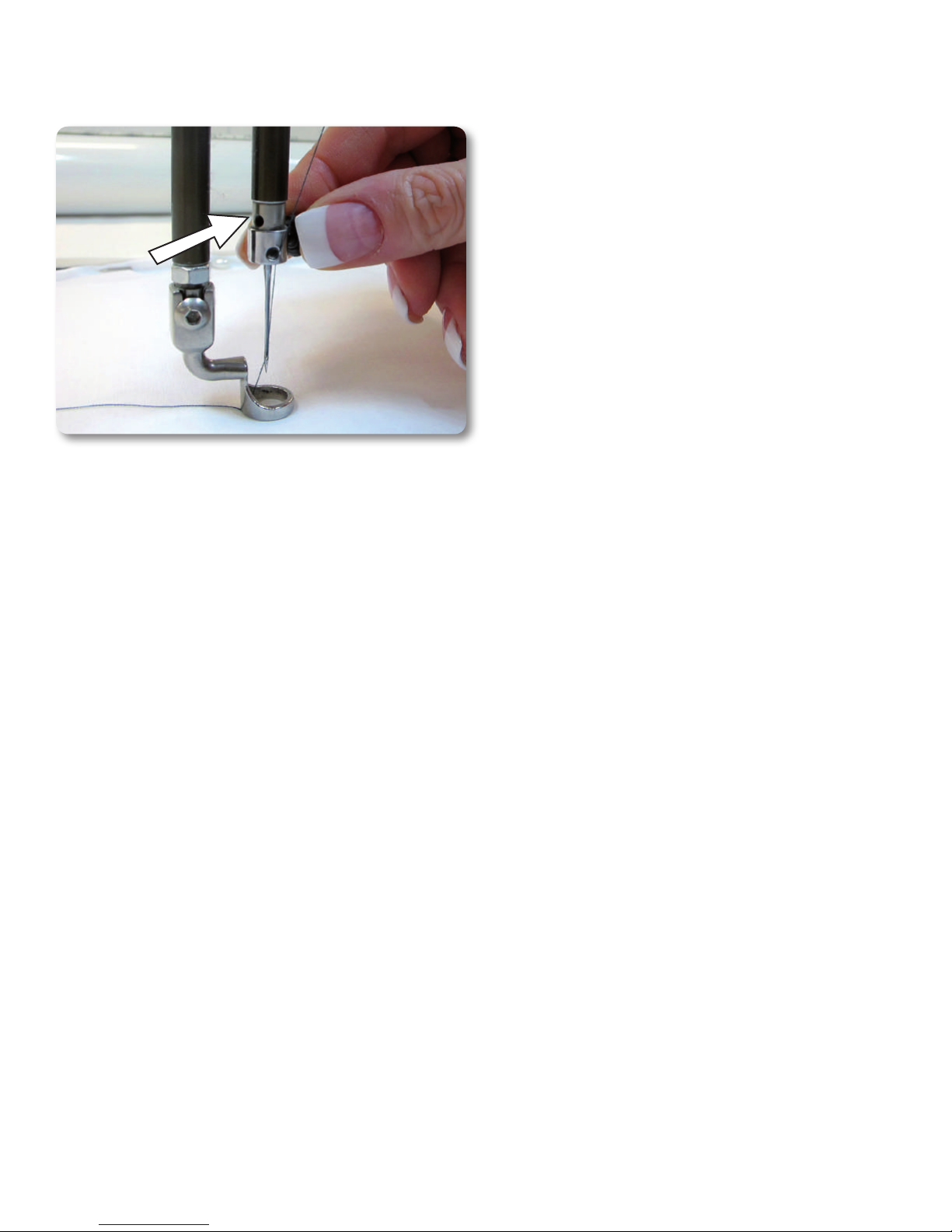

Inserting (or changing) the Needle

SIGHT

HOLE

Figure 7

1. Check that all power is turned off.

2. Move the needle bar to the highest position by turning

the hand wheel or by pressing the needle up/down

control on the handles (prior to turning the power

off).

3. Loosen the needle-bar clamp thumb screw (Figure 7).

4. With the scarf (small ground out section/dip on the

back side of the needle just above the needle eye)

facing the rear hand wheel side of the machine, and

the long groove down the front of the needle facing

the bobbin case side (see Figure 7), push the needle

all the way up into the needle bar – until it can go no

farther. Look into the sight hole to verify that the butt

of the needle reaches the top of the sight hole.

5. Carefully tighten the needle bar clamp screw. Over

tightening the needle clamp screw will result in

damaged threads stripping the hole. Stripped holes

are not covered under warranty. Another side effect

of damaged threads from over-tightening that the

needle may be very tight when inserted up into the

needle bar. To avoid over-tightening the screw, finger

tighten only.

NOTE: Changing the needle is recommended for each

new quilt loaded on the machine or any time the needle

becomes bent, dull or burred.

IMP O RTAN T: Check the needle to confirm that it is fully

inserted. The needle bar has a stop/sight hole above

the needle bar clamp screw – make sure the needle is

touching the top of the stop/sight hole (Figure 7). If

it is not, the machine timing will be off and it may be

possible for the needle to collide with internal parts

causing damage not covered by warranty.

CAUTION: Your Janome machine stitches at a much

faster speed than your home sewing machine.

Therefore it is essential that the needle is firmly

seated in the needle bar and fully tightened (but not

over tightened). Check often that the needle has not

become loose. If the needle comes loose, it could

break in the machine causing damage, throw off the

machine’s timing, or worse, cause bodily harm.

janome.com

Page 11

Page 12

Changing the Feet

Your machine came with two Feet: a ruler foot and an

open-toe foot. Use the ruler foot for ruler work and

everyday quilting, and the open-toe foot when you need

greater stitch visibility (such as micro quilting). Other

Feet are available, such as the Couching Foot Kit.

1. Remove the foot that is on the mount by using the

2.5mm hex wrench to loosen the mounting screw far

enough that you can slide the foot off of the mount.

2. Slide the desired foot onto the mount (figure 8). Note

that the opening on the side of the foot is lined up

with the screw hole. Push the Foot up as far as it will

go.

3. Ensure the foot is centered with the needle when the

foot is fully tightened with the 2.5mm hex wrench. If

it isn’t properly centered, loosen the lock nut; center

the foot with the needle; hold the foot in position; and

firmly tighten the lock nut (Figure 9).

Figure 9

Figure 8

Page 12

Quilt Maker Pro 18 User Manual

201704

Page 13

Laser Stylus Safety and Use Guidelines

The laser stylus projects a straight laser beam visible as

a dot on surfaces it hits. The laser dot is used as a guide

or stylus, allowing you to stitch the same pattern onto a

quilt that is being traced with the laser dot.

Laser Operation and Use

There is not a separate on/off switch for the laser. Power

is supplied to the laser when it is plugged into the

Janome Quilt Maker Pro 18. Be sure the laser is attached

to the Janome Quilt Maker Pro 18 and pointed downward

toward the table before connecting it to the port. Never

point it in a direction that would project the beam into

someone’s eyes. If the laser should cease to operate,

check to ensure the plug is firmly seated into the Janome

Quilt Maker Pro 18 laser port.

CAUTION: Use of controls or adjustments or

performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Figure 10

Laser Focus/Laser Image Size

This high quality laser is focusable. The laser is focused

by simply grasping the threaded housing surrounding

the lens and turning clockwise or counter-clockwise (see

Figure 10). The laser image can be adjusted bigger or

smaller. The direction of rotation needed is determined

by the distance of the laser from the intended focal

plane. Experiment by turning the threaded end to

achieve your desired focal size.

Clamp Adjustment

The laser attaches to a mounting post. The post may be

vertical or horizontal. The clamp is designed to articulate

in any direction by rotating the clamp on the post and

pivoting the laser up or down. To make an adjustment,

simply loosen the black thumbscrews, position, and

retighten.

Location of Laser Labels

The label is attached to the case of the laser and

contains an arrow which indicates the direction the laser

light will shine when energized. The label must remain

in place on the laser. Removal of the label will void the

laser’s warranty.

janome.com

Page 13

Page 14

Installing the Laser Stylus

Figure 11

To attach the laser stylus to the machine:

1. Locate the threaded hole on side of the machine

near the handwheel (see Figure 1, #12, page 7). The

laser stylus guide post comes with the washer and

nut on it. Remove the nut and washer, replace the

nut onto the post and then place the washer under

the nut and onto the machine painted surface. The

washer protects the painted surface when the nut

is tightened. Tighten the post clockwise until it is

securely in place. Use the nut to secure the post to the

machine.

2. Be sure the laser stylus is inserted into the laser

clamp.

3. Slide the laser clamp over the post to the desired

height.

4. Plug the laser power cord into the port on the rear

side of the machine. (see Figure 1, #13, page 7).

Installing the Thread Mast

Figure 12

1. Find the two threaded holes located towards the front

of the upper machine arm. Attach the plastic thread

stand by placing two screws through the holes on the

side of the thread stand and attaching those screws

into the two threaded holes on the side of the upper

machine arm.

2. Remove the screw from the bottom of the thread mast

and place it in the thread stand socket on the front

corner of the thread stand. Secure the thread mast

by placing the removed screw through the underside

of the thread stand and into the bottom of the thread

mast.

Page 14

Quilt Maker Pro 18 User Manual

201704

Page 15

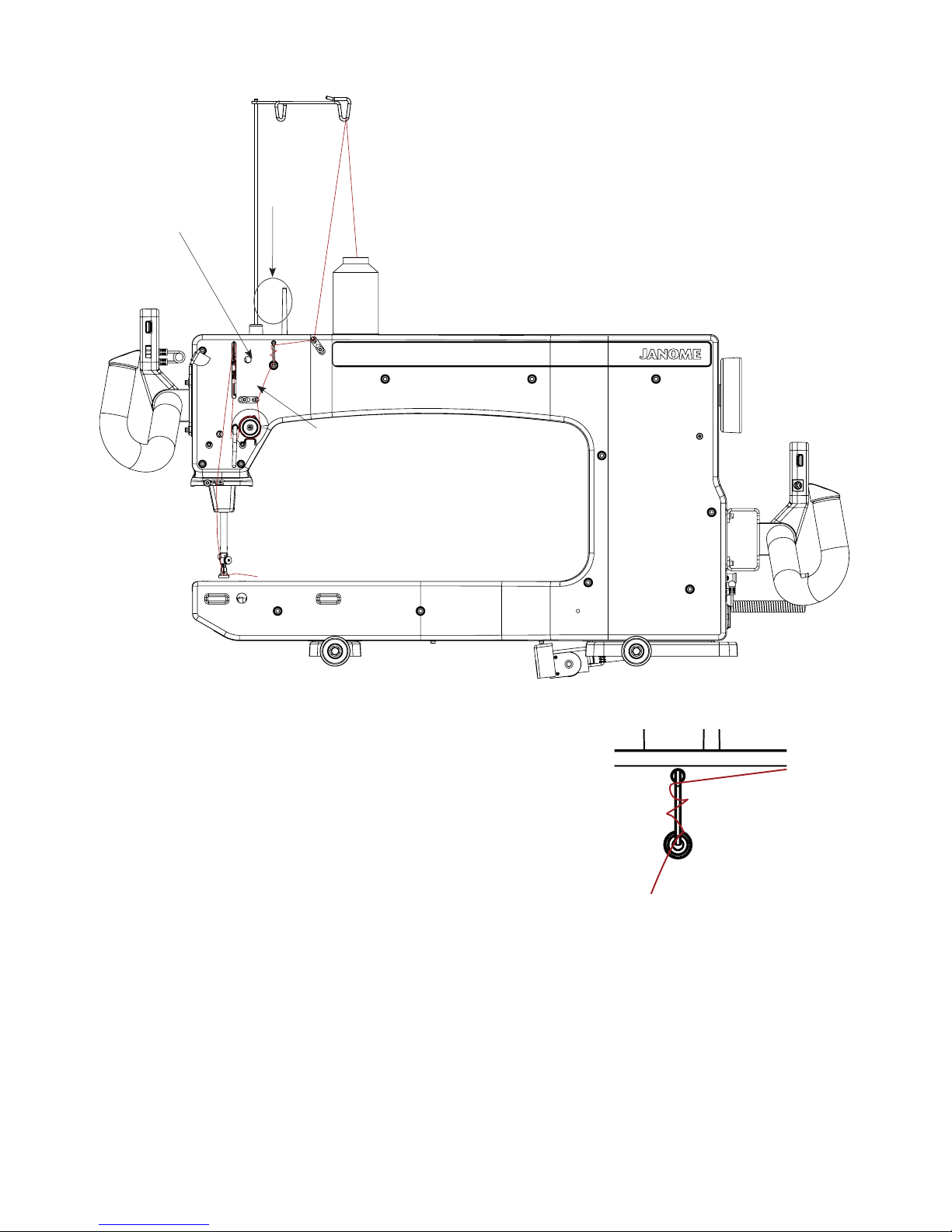

Threading the Machine

Guide

Take Up Spring

B

Tension Assembly

Figure 13

1. Place a cone or spool of thread on the spool pin. Pass

the thread through the thread-mast eyelet from back

to front, continuing to thread guide A. (Figure 13)

2. Continue to the three-hole thread guide B. Wrap all

three holes from back to front, hand wheel side to

needle side. (Figure 14).

Note: The purpose of the three-hole thread guide B is

to prevent loops of thread coming off the thread cone

from going into the top tension as a knot causing thread

breakage and bad tension. For most threads on a cone,

it is important to thread all three holes for consistent

results and to make adjustments at the top tension

assembly. An exception to this rule is when working with

very delicate threads, such as holographic or threads

that are prone to breakage, in which case you may try

skipping one or two holes on thread guide B.

Figure 14

janome.com

Page 15

Page 16

E

3. Thread continues through thread guide C, and then

down to the tension assembly (see Figure 15).

NOTE: It is important that the thread is “flossed” up

between the two tension discs. If the thread is not firmly

in place between the two tension discs, the thread rests

on the outside of the tension discs (without tension) and

looping on fabric or thread nests may occur.

4. Once the thread is in place, be sure that the thread

C

catches on the take-up spring and then pull it down

under the stirrup (thread guide D).

5. Bring the thread back up through the take-up lever

from back to front, and then down through thread

guide E. Pull the thread at the take up lever to ensure

that it is properly flossed between the tension disks.

D

If it is properly flossed in the tension disks you should

feel some resistance as you pull the thread. If it is not,

then the thread will pull freely.

6. Pull the thread down to the needle thread guide and

thread through the hole (thread guide F).

7. Make sure the thread is following the groove down the

front of the needle and threads from front to back.

Be careful that the thread does not twist around the

needle.

F

Figure 15

Page 16

Important notes: The Janome

Quilt Maker Pro 18

quilting machine does not have a presser foot lever or

top tension release like a home sewing machine. On

a home sewing machine the top tension is released

when the presser foot is raised, allowing the thread to

come freely out of the machine. When a home machine

is threaded, the presser foot is raised and the tension

discs are released and open for the thread to easily fall

between the tension discs. This is not the case with the

Janome

Quilt Maker Pro 18 quilting machine where the

top tension is always tight and the tension discs are

never open. Therefore, the thread must be pulled up

or “flossed” between the tension discs or it will stay

outside the discs and float without tension, causing

serious tension problems and/or thread nests. It is also

possible to bend the needle while it is threaded if care

is not taken while moving the machine around the quilt

because the top tension is never released.

Quilt Maker Pro 18 User Manual

201704

Page 17

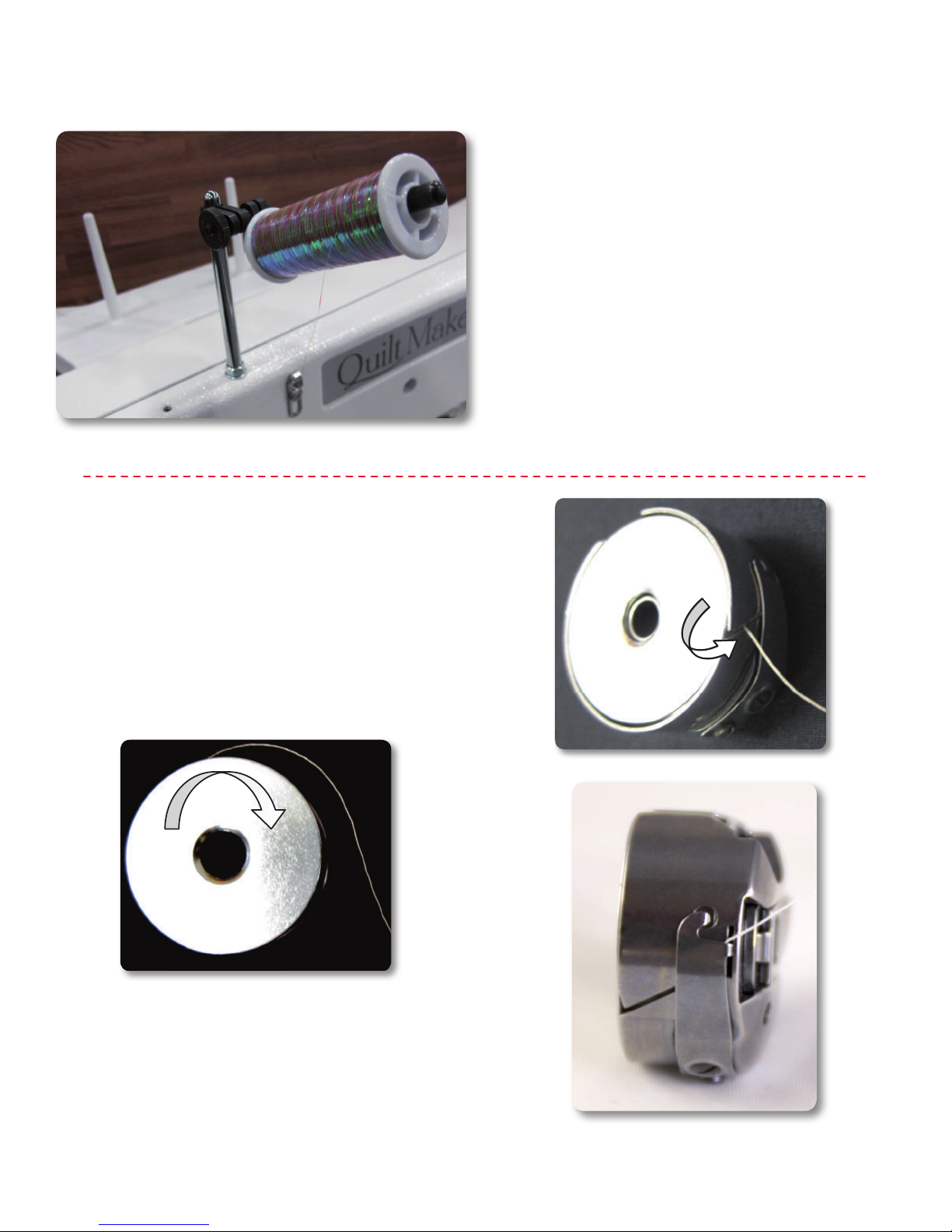

Optional Horizontal Spool Pin

Figure 16

Bobbin and Thread Tension

1. An optional horizontal spool pin is available for

metallic and specialty threads wound on a spool (not

a cone).

2. The horizontal spool pin mounts on the laser stylus

guide post on the top of the machine

(see Figure 16).

3. When using threads on the Horizontal Spool Holder,

skip thread guide A. Thread the top hole only of the

three-hole thread guide B, back to front.

4. Continue threading the machine as described in steps

3 through 7 on page 16.

Adjustments

Inserting the Bobbin

Note: Turn off the power switch while inserting the

bobbin case or anytime your hands are near the needle

area.

1. Place the bobbin in the bobbin case so that the

thread pulls off clockwise when viewing the open side

(Figure 17).

Figure 17

Figure 18

2. Slide the thread through the slot (Figure 18) and

under the tension spring leaving 5 to 6 inches of

thread hanging loose (Figure 19).

janome.com

TENSION

SPRING

Figure 19

Page 17

Page 18

Bobbin and Thread Tension Adjustments...cnt’d

3. Turn off the power switch while inserting the bobbin

case or anytime the hands are near the needle area.

4. Do not lift the lever on bobbin case. When placing the

machine fit the bobbin case onto the hook spindle in

the machine. Rotate the casing until the open throat

keys into the alignment notch in the middle of the

hook. Push the casing in until it stops in place. Push

inward until it clicks (see Figure 20).

Note: It is not suggested that the lever on the bobbin

case be used for this installation. The latch lever should

be used only for removal of the bobbin case.

Bobbin Tension

The bobbin tension is the foundation tension for the

entire machine. To test that bobbin tension is correct,

hold the bobbin case in the palm of your hand with the

open end facing up. Wrap the thread around your index

finger and while pulling up on the thread and gently

wiggling the finger front to back (not up and down

which is not consistent), the bobbin case should lift up

on its side, but NOT lift out of your hand. If it will not

lift up onto its side, it is too loose and if it lifts out of

your hand, it is too tight. The small screw in the center

of the tension spring is where the adjustment is made

(see Figure 21). Turn clockwise to tighten and counterclockwise to loosen the bobbin case tension. Check your

bobbin tension every time a new bobbin is inserted.

Note: Bobbin tension adjustment is a minute turn of the

screw like the ticking of a clock.

Figure 20

Drawing the Bobbin Thread to the Top of

the Quilt

1. After the machine is threaded, locate needle up/down

button on the left handle.

2. While firmly holding the tail of the needle thread

with the left hand, press the needle up/down button

with right hand, bringing the needle back to the up

position.

3. Pull the machine three to four inches away while

holding the needle thread.

4. Bobbin thread will pull up and through to the top,

allowing you to grasp the loop and pull it to the

desired length.

Figure 21

Page 18

Quilt Maker Pro 18 User Manual

201704

Page 19

Easy-Set Tension™ Adjustment

IMPORTANT: Top tension should be adjusted only after

the bobbin case foundation tension adjustment is made.

Puckering, gathers and thread breakage occur when the

top tension is too tight. Loops and thread nests occur

on the back when the top thread tension is too loose.

Tension may need to be adjusted depending on the

fabric, thread or batting you are using on each project.

It is easy to set the top tension with the Janome Quilt

Maker Pro 18 Easy-Set Tension. To adjust the top tension

tighter, turn the tension knob clockwise. To loosen the

tension, turn the tension knob counterclockwise. Unlike

the bobbin-case adjustment, which requires minute

adjustments (like the tick of a clock), the top tension

knob might need to be turned anywhere from 1/4 of a

turn to two to four turns to achieve balanced tension.

Maintenance

Cleaning and Lubricating the Machine

Only use light sewing machine oil in the Janome Quilt

Maker Pro 18. Internal oiling is not necessary on the

Janome Quilt Maker Pro 18 except when the machine is

taken to a service technician for routine maintenance

and cleaning. The hook assembly, however, needs

regular lubricating. Failure to keep the hook assembly

lubricated can cause severe damage to the machine.

As you adjust the tension, a tension value appears on

the Main Screen (when the machine is turned on). make

a note of this value to easily set the tension again in the

future for the same type of thread.

Note: Before adjusting the top tension, remember to

floss or pull the top thread up into the tension discs or

it will float outside the discs providing little or no top

tension. This could cause significant tension or nesting

problems on the bottom side of the quilt.

To lubricate, turn off the machine. Remove bobbin and

case before oiling. Clean around the hook assembly

with a soft brush to remove lint. Put a very small drop of

oil on the hook in the region where the bobbin basket

assembly and the rotating hook meet (see Figure 22).

The bobbin basket is the portion of the hook that the

bobbin case snaps into. The bobbin basket remains

stationary while the hook rotates around the basket. The

oil lubricates the region where these two components

interlock. A drop of oil in the region indicated will work

its way back into the interlocking area of the hook and

bobbin basket.

The frequency of lubrication depends upon the usage

of the machine. Lubricating is recommended before

running the machine if it has not been used regularly,

or every other bobbin change if used frequently. After

oiling, always sew a scrap piece as oil may cling to

thread. Over oiling can cause excess dripping from the

bobbin assembly. Lack of lubricant may be noticed by a

change in the sound of the machine and will affect stitch

quality.

Figure 22

Cleaning the Touchscreen

Never use any chemicals to clean your display as this

may adversely affect the touch screen response. Use a

soft rag dampened with isopropyl alcohol and gently

wipe the display to remove any marks.

janome.com

Page 19

Page 20

Using the Touch Screen Displays on the Handlebars

Machine and Handlebar Menus

The Janome Quilt Maker Pro 18 has touch-screen

displays on the front and rear handlebars. Settings may

be changed at either of these locations.

Main Screen

Manual Mode Screen

Button Functions:

Pressing the “Regulated” button while in the Manual

Mode Screen will toggle to the Regulated Mode Screen.

The current stitching mode is highlighted in blue when

activated. Different options are available depending

upon which mode the system is in. (Figure 23)

Needle Stop

Figure 23

The Needle Stop setting enables you to specify whether

you want the needle to end in the up or down position

when you stop quilting (Figure 24). If you select Down,

when you press the stop button on the right handlebar,

the needle ends in the down position. If you select Up,

the needle ends in the up position when you press the

stop button on the right handlebar. Switch between

the up and down position by pressing the Needle Stop

button.

Figure 24

Figure 25

Easy-Set Tension

The tension box (Figure 25) on the Main Screen shows

the current tension setting as a numeric value. As you

turn the tension dial clockwise to tighten the top tension,

the number increases in increments of five. As you turn

the tension dial counterclockwise to loosen the top

tension, the number decreases in increments of five. The

faster you turn the dial, the faster the numbers increase

or decrease.

After setting the bobbin tension, test the top tension

by stitching on a fabric scrap on the edge of the quilt

batting and backing. Increase or decrease as needed

until you have achieved balanced tension. Make a note

of the type of thread (weight, brand, color) you’re using

and the tension value. You will be able to quickly and

easily set the tension when you use this same thread

again in the future.

Page 20

Quilt Maker Pro 18 User Manual

201704

Page 21

Figure 26

Figure 27

Figure 28

Bobbin Thread Indicator

If you use the Low-Bobbin Estimator feature, The Bobbin

Thread Indicator box (Figure 26) shows how much

bobbin thread remains on the bobbin. The value counts

down until it gets to zero, at which time the low-bobbin

alarm alerts you that it is time to put in a new bobbin if

the alarm is enabled. While the machine is recording how

much thread is on a bobbin, REC appears on the screen

to remind you that it is estimating the bobbin capacity.

Speed

Pressing the Limit “+” will increase the manual mode

motor speed and pressing the Limit “–” button will

decrease the manual mode motor speed. This has the

same effect as pressing the “+” and “-” buttons on the

actual handles. The speed range is between 5% and

100%, or between 90 and 2,200 stitches per minute

(SPM). The percent speed is displayed in the white box

at the top of the screen. (Figure 27)

Manual Presets

Save up to three manual-mode preset speeds to quickly

switch between speed preferences. For example, you

may prefer a slower speed when using rulers and a faster

speed when doing all-over meandering quilting. Use the

“+” and “-” buttons to adjust the speed percentage and

then press one of the record buttons next to the preset

value to store that speed as a preset. When you want to

use one of the preset speeds, simply press the speed.

(Figure 27)

On/Off Indicator

The circle in the center of the top bar turns green when

you press the “Start” button on the handles to indicate

the needle is in motion. When you press “Stop,” the

circle will turn red. (Figure 28)

Figure 29

janome.com

Regulated Mode Screen Button Functions

Stitches Per Inch (SPI)

Pressing the “+” or “-” buttons near the top right portion

of the screen will increase or decrease the stitches per

inch (SPI) setting. The setting is reflected in the white

indicator box at the top right portion of the screen. This

value can be adjusted between 4 and 18 stitches per

inch. (Figure 29)

Page 21

Page 22

Basting Stitches

There are four basting stitch settings controlled by

the stitches per inch function. After the SPI reaches its

lowest stitch setting of 4 stitches per inch, pressing the

“-” button will activate the basting settings:

• 0.5-inch (one stitch every half-inch movement of

the machine)

• 1-inch (one stitch every one inch movement of the

machine)

• 2-inch (one stitch every two inches of movement of

the machine)

• 4-inch (one stitch every four inches of movement

of the machine)

Figure 30

Figure 31

After selecting the basting stitch setting, begin quilting

by pressing the Start button. As you move the machine

across the quilt, it will perform a stitch (needle down and

then needle up) every half inch, one inch, two inches, or

four inches according to your choice. The basting stitch

options are available in stitch regulation mode: Cruise

and Precision. (Figure 30)

Stitch Regulation Style (SR)

The “SR Style” box in the lower right-hand corner of the

screen indicates whether the machine is in “Precision”

regulation mode or in “Cruise” regulation mode. (Figure

30)

Precision

If “Precision” mode is selected, the Janome

Quilt Maker

Pro 18 will not start stitching until you begin pushing the

machine. (Figure 31)

Page 22

Quilt Maker Pro 18 User Manual

201704

Page 23

Cruise

If “Cruise” mode is selected, when you press “Start” on

the handles the machine will immediately begin stitching

at the percent speed indicated below the “Cruise”

button. The “Cruise” speed is the minimum speed the

machine will stitch, regardless of how slow you are

pushing the machine. This means that when you slow

down to a stop, the needle will continue stitching at the

set cruise speed until you begin moving the machine

faster than what the cruise speed is set to or you press

the “Stop” button on the handles. The “Cruise” speed

can be adjusted using the “+” and “-” buttons that

appear below the “Cruise” button when “Cruise” mode

is selected. “Cruise” speed can be adjusted between 3%

and 50%. (Figure 32)

Figure 32

Figure 33

The start indicator box (Figure 33), which is the box at

the top center of the screen, will change from red to

green as soon as you press the “Start” button on the

handles. If you are in “Precision” mode, the needle will

not start moving until you start moving the machine, so

this green indicator shows that the “Start” command was

accepted and the machine is ready to begin stitching.

In “Cruise” mode, the red box will turn to green and

the needle will begin stitching immediately at the set

“Cruise” speed.

On/Off Indicator

If the machine does not sense that it has been moved

in any direction after it has been started, it will

automatically stop regulation mode and the start

indicator box will turn red. When in “Precision” mode,

this happens when no movement of the machine has

been detected for two minutes. A system message will

appear on the screen to warn the user the machine

has stopped. This box is cleared by pressing the “OK”

button. In “Cruise” mode, the machine will stop stitching

after about three seconds if no movement has occurred.

Tools Menu

The Tools screen provides access to other functions

available on the Janome Quilt Maker Pro 18 (Figure 34).

Figure 34

janome.com

Page 23

Page 24

Low Bobbin

The Janome Quilt Maker Pro 18 includes a low bobbin

capability so you can estimate how soon your bobbin

thread will run out. This Low Bobbin Capacity is based

on an estimate of how much of a particular thread can fit

on a bobbin, in combination with other quilting factors

such as tension, stitches per inch, and how much bobbin

thread you pull up when beginning and ending your

quilting (Figure 35 and 36).

To estimate how much thread is on a bobbin, place a full

bobbin in the machine and under the heading Bobbin

Thread Capacity, press the Record button (Figure 36),

quilt as usual.

Figure 35

Figure 36

When the bobbin runs out, press the square Stop

Recording button and note the number that is indicated

under the Bobbin Thread Capacity (Figure 36), perhaps

210. Since you want a warning as to when the bobbin

is getting low, use the “-” button to specify a lower

number, such as 195. Save that as one of the Bobbin

Thread Capacity Presets. You might want to make a note

as to which type of thread the preset represents. Put a

new bobbin with the same thread into the machine and

press the New Bobbin button. Then press the Alarm

button. As you quilt, the remaining bobbin thread value

will estimate how much thread remains on the current

bobbin, and when you reach the capacity value, an alarm

will sound warning you that your bobbin is nearly out of

thread (Figure 37).

When operating in Manual mode, the low bobbin

function assumes you will stitch at approximately the

last SPI setting you had on the regulated screen. If the

SPI setting was below 8 stitches per inch, the function

will assume you will quilt at 10 stitches per inch. It is

advisable therefore to set the stitches per inch that

you will be quilting on the regulated screen before you

change to manual mode.

Figure 37

Page 24

You can store three Bobbin Thread Capacity preset

values – one for each of three different types of thread.

Simply go through the record process with a full bobbin

of that type of thread and then store the capacity as a

preset. When you switch to using that type of thread,

press appropriate preset button. Insert a full bobbin with

that type of thread, press New Bobbin, then press the

Alarm button and all of the settings will be based on that

type of thread.

Quilt Maker Pro 18 User Manual

201704

Page 25

Figure 38

Timers

There are two useful timers. The first (top) timer is a

reminder timer. It enables you to set an alarm to go off

after a specific period of time, similar to a kitchen timer.

Use the “+” and “-” buttons to set the time duration.

Then press the “play” button to activate the timer. When

the time duration has elapsed, an alarm will sound and a

message appears on the display (Figure 38).

The second (bottom) timer enables you to track how

much time you spend on a quilt project. When you begin

a new project, press the Reset button. Then press the

“play” button to begin recording your quilting time. The

timer records when the machine is quilting. The time is

saved even when the machine is turned off. When you

begin another quilting session, quilting time is added to

the timer. Only press Reset when you want to zero-out

the timer and begin a new timing session.

Sound Screen

The “Volume” portion of this screen has two buttons and

a sliding control. Pressing on the “Mute” button turns the

alarm volume off. Pressing the “Max” button turns the

volume to its loudest level. Pressing the sliding control in

any position sets the volume to the level indicated in that

control. Pressing and moving back and forth across the

sliding control will change the volume up as it is moved

left to right and down as it is moved from right to the

left. The Over-Speed Alarm box allows the user to turn

the alarm on and off. (Figure 39)

Figure 39

Figure 40

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to

the “More” menu screen.

Calculator

A basic calculator is provided. (Figure 40)

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to

the “More” menu screen.

janome.com

Page 25

Page 26

Figure 41

Lights

The Janome Quilt Maker Pro 18 comes equipped with a

light ring around the needle bar, two high intensity LED

modules on each side of the display. These lights are

directed towards the quilting area. (Figure 41)

Turn lights on or off by touching the light bulb icons. Use

the slider to adjust the light brightness from low to high.

(Figure 42)

Figure 42

Page 26

Quilt Maker Pro 18 User Manual

201704

Page 27

System Information

Information contained in the white ovals identify the

electronics board revision numbers as well as the

firmware revision numbers of the Janome Quilt Maker

Pro 18 and its handlebars. The Lifetime and Trip (or

project) stitch counters count the number of stitches

the machine has performed. The Lifetime count is the

total number of stitches made since the machine was

built. The Trip Counter can be reset to keep track of the

number of stitches made during a given project. To reset

this counter, press the blue “Reset” button just to the left

of the “Trip” box. The Lifetime counter cannot be reset

and should be used as an indicator to determine when

general machine maintenance should be performed by

an authorized Janome Representative. (Figure 43)

Figure 43

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to

the “More” menu screen.

Set Language

The Janome

Quilt Maker Pro 18 screens can appear

in English, French, German, or Spanish. On the More

Screen, press the lower-left button to cycle between

English, Français, Deutsch, and Español. After selecting

your preferred language, press Main to return to the

Main Screen.

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to

the “More” menu screen.

Diagnostics Screen

Seven different diagnostics tests can be performed on

the machine. These functions test the motion encoders,

the motor control functions, the key switches and the

internal position sensors. (Figure 44)

Figure 4 4

janome.com

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to

the “More” menu screen.

Page 27

Page 28

Figure 45

Diagnostics Tests

Motor Sensor Test

The “Motor” Sensor test can help you determine whether

there may be a problem with the Janome Quilt Maker

Pro 18 motor. Slowly rotating the handwheel should

result in a pulsing audible “beep.” If you get a constant

solid “beep” or no “beep” at all, this indicates a failed

test and the machine should be inspected by a qualified

Janome repair technician. (Figure 45)

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to

the “More” menu screen.

Needle Sensor Test

The Needle Sensor test will indicate whether the needle

position sensor is functioning properly. Rotating the

handwheel should result in a “beep” for half of a stitch

cycle followed by no “beep” for the other half. (Figure 46)

If you hear a constant beep or no beep at all for a full

360° rotation of the handwheel, this indicates a failed

test and the machine should be inspected by a qualified

Janome repair technician.

Figure 46

Figure 47

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to

the “More” menu screen.

X Motion Sensor Test

Use the X Motion Sensor test to verify functionality of

the “X” stitch regulator encoder (the encoder mounted

at the rear of the carriage). As you slowly move the

carriage left and right you should hear a pulsing “beep”

that pulses faster as you move faster. A solid beep, no

beep, or periods of irregular beeping (with constant

motion) indicate a problem with the “X” encoder. The

most likely cause of a problem is a stitch regulator wheel

that is not making consistent contact with the track.

Check the spring tension on the sensor assembly on the

carriage to assure that it will easily return to the fully

extended position after being compressed. Also assure

that the track is straight with no dips or indentations and

that it is clean and free of contamination. Other causes

are an unplugged or damaged cable or possibly an issue

with the main control board. (Figure 47)

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to

the “More” menu screen.

Page 28

Quilt Maker Pro 18 User Manual

201704

Page 29

Motor Speed Sensor Test

The “Speed” Sensor test can help you determine whether

or not there is a problem with the Janome Quilt Maker Pro

18 speed sensor. Before performing this test, remove the

bobbin case and the top thread. Press the “Start” button

and the machine will begin slowly rotating. The white box

will show a number that should stabilize at 100 if the sensor

is functioning properly. Pressing “Start” again will stop the

machine. (Figure 48)

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to the

“More” menu screen.

Figure 48

Figure 49

Y Motion Sensor Test

Use the Y Motion Sensor test to verify functionality of the

“Y” stitch regulator encoder (the encoder mounted to the

rear power pod side machine wheel). As you slowly move

the carriage toward and away from you, you should hear

a pulsing “beep” that pulses faster as you move faster. A

solid beep, no beep, or periods of irregular beeping (with

constant motion) indicate a problem with the “Y” encoder.

The most likely cause of a problem is a stitch regulator

wheel that is not making consistent contact with the track.

Check the spring tension on the sensor assembly on the

machine to assure that it will easily return to the fully

extended (down) position after being compressed. Also

assure that the track is straight with no dips or indentations

and that it is clean and free of contamination. Other causes

are an unplugged or damaged cable or possibly an issue

with the main control board. (Figure 49)

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to the

“More” menu screen.

Figure 50

janome.com

Keyp a d Tes t

The Keypad test allows the user to press any of the

four keys on the front or back handles to verify that the

Janome

18

Quilt Maker Pro 18 is reading the buttons as they

are pressed. When a key is pressed the name of the key

that is pressed will appear in the white box. When it is

released, the name will disappear. Perform this test on the

rear display for the rear keys, and the front display for the

front keys. (Figure 50)

Press the “Main” button to return to the “Regulated” or

“Manual” menu screen or the “Back” button to return to the

“More” menu screen.

Page 29

Page 30

Figure 51

Calibrate Tension

The Tension button enables you to calibrate the tension

device (Figure 51). You should only calibrate the tension

device under the direction of Janome technical support.

While calibrating the tension, you will be asked to do the

following:

1. Remove the tension knob.

2. Gently press the spring against the tension discs while

not compressing the spring.

3. While holding the spring in place, press Reset.

4. When calibration is complete, replace the tension

knob.

Page 30

Quilt Maker Pro 18 User Manual

201704

Page 31

Janome STITCH REGULATOR OPERATION

Choose from Two Types of Stitch Regulation: Cruise or Precision

In regulation mode the status box at the top left of the

screen should say “Regulated”. If it says “Manual”, simply

press the “Regulated” button on the touch screen to

switch from “Manual” mode to “Regulated” mode.

IMPORTANT NOTES ABOUT TURNING STITCHREGULATION ON OR OFF

You can stop the machine at any time by pushing either

the “Start/Stop” or the “Needle Up/Down” key on the

handles. In Cruise Regulation mode, if you don’t move

the machine after 3 or 4 seconds, the machine will stop

and position the needle. In Precision Regulation mode,

the needle pauses when you stop moving the machine

and will begin stitching again when you start moving the

machine. Press the “Start/Stop” (or “Needle Up/Down”)

key in Precision Regulation mode to stop the needle

completely and cause the needle to position itself in the

Needle Up or Down position.

Cruise Regulation Mode

When in Cruise Regulation mode, the start indicator box

in the top center of the “Regulated” screen is red. When

you press the “Start/Stop” key to start the machine,

the indicator will turn green AND the needle will begin

moving up and down.

Precision Regulation Mode

When in Precision Regulation mode, the start indicator

box in the top center of the “Regulated” screen is

red. When you press the “Start/Stop” key to start the

machine, the indicator will turn green. As you start

moving the machine, it will begin stitching. When you

stop moving the machine, the needle pauses (sometimes

in mid-stroke.)

When you press the “Start/Stop” (or “Needle Up/Down”)

key to stop the machine, the indicator will turn red,

showing that the needle will not move when you move

the machine.

Always make sure the indicator is RED when you are in

Precision Regulation mode prior to working with your

hands near the needle (changing the needle, replacing

the bobbin, etc.) to avoid unwanted stitching in your

quilt or your hands!

If you leave the Janome Quilt Maker Pro 18 in Precision

Regulation mode with the start indicator box green and

do not move the machine for two minutes, the system

will “time-out” and a message box will appear. This

indicates that the system has stopped and you will need

to press the “Start” button again to resume quilting.

The minimum speed of the needle is dependent upon

the setting you choose (from 3% to 50%). Janome

recommends beginning with a setting of 3%.

When to Use Cruise Regulation Mode

The constant minimum stitching speed featured in the

Cruise Regulation mode is used for precise placement

of stitching when backtracking (such as along the tops

of feathers) or when creating sharp points (such as the

point of a star or the bottom of a heart).

When to Use Precision Regulation Mode

Precision Regulation mode is especially useful for ruler

work. Stitch along the length of the ruler for the span

of your hand and stop. When you stop moving the

machine, the needle pauses. Do not turn off the machine.

Move the ruler and commence quilting. The Precision

Regulation helps you avoid “bobbles” and uneven

stitches.

Quilting Speed While in Stitch-Regulation Mode

It is important not to move the machine too fast, since

this will result in an OVERSPEED CONDITION, during

which, the machine cannot maintain stitch regulation

until you slow your motions to an appropriate speed.

The Overspeed Alarm will alert you to this condition,

giving you the signal to slow down. Stitch regulation is

not a license to move the machine as fast as you can. Its

purpose is to maintain even stitches while quilting at an

appropriate speed.

You can return to manual mode by pushing the “Manual”

button below the “Regulated” button on the touch

screen display.

janome.com

Page 31

Page 32

Getting Started Quilting

Thread Requirements

Threads have a tendency to dry rot over a period

of time. Be sure to choose high quality threads for

your valuable heirloom quilts. Most machine quilting

threads on the market today are acceptable.

Needle Requirements

For general quilting, a size 16/100 needle will

accommodate most threads and fabrics.

Heavier threads, such as top stitch and some

decorative threads, require a larger needle such as

18/110 or 20/120. Lofty batts and heavier fabrics such

as denim, canvas or densely woven fabric may also

require a larger needle.

To Prepare for Quilting

With any quilting machine, it is important to

understand the basics of free motion quilting. The

Janome Quilt Maker Pro 18 does not have feed dogs

like domestic machines; therefore, the fabric does

not automatically feed under the hopping foot. The

operator should synchronize the speed as well as the

movement of the machine to get an even, consistent

stitch.

pressing the “Start/Stop” key on the front or rear handle

bars to begin quilting make certain to begin moving

the machine immediately. If the needle stitches in one

place too long, the stitches build up on top of each

other causing a build-up of thread or thread breakage.

When bringing the machine to a complete stop press

the “Start/Stop” key at the same moment the machine

stops moving. If the machine is still moving when the

“Start/Stop” key is pressed, it can cause deflection in the

needle, possibly causing it to bend or break.

In PRECISION REGULATION mode, the needle will not

begin moving when you press the “Start/Stop” key until

you begin moving the machine.

When quilting, relax your hands and maintain a light

touch on the handlebars. Gripping the handlebars too

tightly may cause body tension resulting in poor quilting

quality. The Janome

the Quilt Maker Pro 18 Frame system will give you a

smooth even glide.

18

Quilt Maker Pro 18, combined with

In order to become comfortable with the free motion

of the Janome Quilt Maker Pro 18, users can begin

with a few “beginner” techniques.

In Manual Mode: Set the machine at a medium speed

and begin moving it until you become accustomed

to the resistance. By moving the machine faster,

the stitches begin to elongate. The stitch speed can

either be increased or the machine can be moved

slower to get the stitches back to the desired

length. By moving the machine slower, the stitches

get shorter and can build up on top of each other,

breaking the thread or making it extremely difficult

to unpick. The stitch speed can be decreased, while

maintaining a constant motion with the machine to

bring the stitches back to the desired length.

In Stitch Regulator Mode: Set the machine to desired

stitch length. Begin moving the machine to become

accustomed to the resistance. The machine motor

will slow down or speed up to maintain a consistent

stitch length according to how quickly or slowly you

move the machine. Moving the machine too fast or

in radical or jerky movements will defeat the stitch

regulator function.

In MANUAL or CRUISE REGULATION mode, when

Page 32

Quilt Maker Pro 18 User Manual

201704

Page 33

Troubleshooting

You can correct many problems on your own. If you need additional help, contact your local, authorized Janome

retailer. You can also contact Janome Monday through Friday 8:30AM - 5:00PM EST, 1-800-631-0183 option 3 .

First check the following:

The AC power cord is properly connected and the power switch is turned on.

Confirm that all cables are properly seated into their connections.

Turn off the machine completely. Wait for at least ten seconds and then turn it back on.

If the above checks did not solve the problem, refer to the information below.

Skipped Stitches Corrective Measure(s)

The needle is damaged, dull, bent,

or installed improperly

• Replace the needle regularly, at least once per quilt. Use only the

recommended needle system.

• Always change the needle if the needle has struck any hard object such

as a straight pin, etc. The tip of the needle can become damaged or

burred, resulting in fabric damage as well as skipped stitches, thread

breakage, or shredding.

• Always change the needle if it has been hit, bumped or pulled off center

while maneuvering the machine about the quilt. A slightly bent needle

can be a major cause of skipped stitches.

Incorrect needle size • Use the proper size of needle for the work and thread being used.

Some battings and fabrics used in quilting may constrict or impede the

thread passing through the front groove of the needle. This diminishes

the loop lift required for stitch formation. Typically, a larger needle

will solve the problem. However, using certain smaller sizes of needles

and ball pointed needles solve some specific problems. You will need

to experiment to determine which work best with your combination of

fabric, thread, and batting.

Fabric is too tight on the frame • Loosen the pole tension on the frame. Fabric that is rolled too tightly

causes the fibers to separate and the fabric to bounce while quilting.

This reduces the needle friction on the thread, resulting in a smaller

thread loop or skipped stitches.

Thread tension too tight • Check bobbin case tension and then check top thread tension. (For

more information about adjusting tension, see Bobbin and Bobbin

Tension and Top Thread Tension in the Using Your Machine section of

this manual.)

janome.com

Page 33

Page 34

Troubleshooting

The needle is not positioned

properly

Improper threading • Ensure that the machine is threaded correctly.

The Needle Breaks Corrective Measure(s)

The needle is bent or not installed

properly

• Position the needle properly to the needle bar. Inspect the position of

the needle to make sure the needle is at the 6 o’clock position. When

you stand directly in front of the needle (facing the bobbin case side

of the machine), you will see the entire needle eye directly facing you.

This is 6 o’clock position.

• Make sure (a) the needle is installed all the way into the needle bar to

the needle-stop hole in the needle bar, (b) the long groove in the needle

is toward the front (bobbin case side), and (c) the scarf (scooped out

part of the back of the needle) is toward the back of the machine.

• The needle can sometimes be rotated to 5 o’clock (slightly right) or 7

o’clock (slightly left) to adjust for a more positive thread loop pickup by

the hook point.

• Replace the needle. Make sure that the needle is pushed into the needle

bar clamp until it can go no farther. Visually check that it is up to the

top of the stop/sight hole above the needle bar clamp screw. If the

needle isn’t installed properly, it can cause damage in the bobbin area

and needle plate.

The needle hits the needle plate • Correctly position the needle, needle plate, or hopping foot. Replace

with a new needle.

Stitches are Puckered Corrective Measure(s)

The tension is not balanced.

Top and bottom tension are both

too tight.

Needle too large for quilting fabric • Replace the needle with a size better suited for the fabric.

Poor Stitch Quality Corrective Measure(s)

The tension is not balanced • Balance the tension of the needle thread after ensuring the bobbin

Bobbin case is damaged,

corroded, dirty, etc.

Loose Display Housing Corrective Measure(s)

Loose display housing Loosen handle bar clamp bolts, rotate handlebars to desired position and

• Balance the tension of the needle thread after ensuring the bobbin

tension is adjusted correctly. (For more information about adjusting

tension, see Bobbin and Bobbin Tension and Top Thread Tension in the

Using Your Machine section of this manual.)

tension is adjusted correctly. (For more information about adjusting

tension, see Bobbin and Bobbin Tension and Top Thread Tension in the

Using Your Machine section of this manual.)

• Since thread slides over the surface of the bobbin case at a high speed,

make sure the case is free of any lint or foreign matter that could

impede thread passage through the machine.

push together, tighten clamp bolts.

Page 34

Quilt Maker Pro 18 User Manual

201704

Page 35

Troubleshooting

Moving the machine too fast

for needle speed selected

(Manual mode)

Tension is Poor Corrective Measure(s)

Lint caught under the tension

spring in the bobbin

Hand Wheel Won’t Rotate Corrective Measure(s)

Thread is entangled and caught in

the hook

Thread Nests Under Quilt Corrective Measure(s)

Not enough tension on

top thread

• Synchronize machine movement and needle speed to get roughly 8 to

10 stitches per inch. Elongated stitches are an indication of moving the

machine too fast for the current speed.

• If using short staple threads, inexpensive, or industrial threads, or

coated threads, lint and other material will build up under the tension

spring and begin to lift the spring, reducing the spring’s ability to

compress against the thread. Insert a needle or business card under the

spring and clear out the lint. The bobbin tension will return fairly close

to its preset tension. Test the tension before quilting.

• Turn off the machine and unplug the machine from the electrical outlet.

Lubricate the hook, strongly turn the hand wheel clockwise and if

necessary counterclockwise several times, and then remove the thread

caught in the hook.

• Check that the machine is threaded correctly. Make certain that the

thread is flossed snugly in place between the two tension discs. If

the machine is threaded correctly, tighten top tension by rotating the

tension knob clockwise. (For more information about adjusting tension,

see Bobbin and Bobbin Tension and Top Thread Tension in the Using

Your Machine section of this manual.)

Improper threading

Hard to Guide Machine Corrective Measure(s)

Carriage wheels not centered

on track

Thread caught in wheels • Remove all thread or debris in wheels. Check that the tracks are free of

Motor Fails to Run Corrective Measure(s)

On/Off switch turned off

Machine not receiving power • Check that the power connector is securely plugged into the back of

* If the troubleshooting above does not eliminate the problem, please consult an authorized Janome Quilt Maker

Pro 18 representative.

• Refer to threading diagram and threading instructions.

• Center the carriage wheels on top of the continuous track. Check that

the machine carriage has not jumped the track.