Janome JSR4400N SCARASeries, JS4400N SCARA Series, JSG GANTRY Series, JR2000N Series Operation Manual

JANOME SCARA/GANTRY ROBOT

JS/JSR4400N/JSG Series

JANOME DESKTOP ROBOT

JR2000N Series

Operation Manual

Features II

(Variables/Commands/Functions)

Thank you for purchasing a Janome Robot.

z Read this manual thoroughly in order to ensure proper use of this robot. Be

sure to read “For Your Safety” before you use the robot. The information will

help you protect yourself and others from possible dangers during operation.

z After having read this manual, keep it in a handy place so that you or the

operator can refer to it whenever necessary.

z This manual is written according to IEC 62079.

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

xxiii

CONTENTS

Features II

FOR YOUR SAFETY ______________________________________________________________ i

PREFACE ____________________________________________________________________ xxi

CONTENTS __________________________________________________________________ xxiii

EXPRESSION STRUCTURE_______________________________________________________ 1

COMMAND LIST ________________________________________________________________ 3

VARIABLE LIST _________________________________________________________________ 8

FUNCTION LIST _______________________________________________________________ 11

SYSTEM FLAG LIST ____________________________________________________________ 14

VARIABLES ___________________________________________________________________ 18

Free Variables: #mv, #mkv, #nv, #nkv, #sv, #skv _____________________________________ 18

Input Variables: #sysIn1..., #genIn1..., #handIn1... ____________________________________ 19

Output Variables: #sysOut1..., #genOut1..., #handOut1... ________________________________ 20

Down Timer: #downTimer1 – #downTimer10 ________________________________________ 21

Point Job Start Height: #jobStartHight______________________________________________ 22

Pallet: #palletFlag (1 – 100), #palletCount (1 – 100) ___________________________________ 23

Workpiece Adjustment: #workAdj_X, #workAdj_Y, #workAdj_Z, #workAdj_R, #workAdj_Rotation _

__________________________________________________________________________

25

Point Coordinates: #point_X,#point_Y,#point_Z, #point_R,#point_TagCode ________________ 27

Designated Point Coordinates: #P_X, #P_Y, #P_Z, #P_R, #P_TagCode __________________ 28

Designated Point Coordinates in Designated Programs: #prog_P_X, #prog_P_Y, #prog_P_Z,

#prog_P_R, #prog_P_TagCode__________________________________________________

29

FUNCTIONS __________________________________________________________________ 30

Robot System Functions________________________________________________________ 30

Arithmetic System Functions ____________________________________________________ 33

String System Functions________________________________________________________ 34

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

xxiv

ON/OFF OUTPUT CONTROL _____________________________________________________ 36

Output to I/O: set, reset, pulse, invPulse____________________________________________ 36

Output after X Seconds: delaySet, delayReset _______________________________________ 39

Sound a Buzzer: onoffBZ _______________________________________________________ 40

Blink the LED (Green): onoffGLED________________________________________________ 41

Blink the LED (Red): onoffRLED__________________________________________________ 42

Output Values from I/O: dataOut, dataOutBCD ______________________________________ 43

Motor Power ON, Servo Motor ON and OFF: motorPowerON, servoON, servoOFF __________ 44

IF BRANCH, WAIT CONDITION ___________________________________________________ 45

if Branch: if, then, else, endIf_____________________________________________________ 45

Wait Condition: waitCond, waitCondTime, timeUp, endWait ____________________________ 47

CONDITION ___________________________________________________________________ 49

Condition Settings: ld, ldi, and, ani, or, ori, anb, orb ___________________________________ 49

DELAY, DATA IN, WAIT START ___________________________________________________ 52

Time Delay: delay_____________________________________________________________ 52

Waiting for a Start Signal: waitStart, waitStartBZ _____________________________________ 54

Input from I/O: dataIn, dataInBCD_________________________________________________ 56

PALLET CONTROL _____________________________________________________________ 57

Pallet Command: loopPallet, resPallet, incPallet _____________________________________ 57

EXECUTION FLOW CONTROL ___________________________________________________ 60

Subroutine Call for Jobs according to Point Types: callBase ____________________________ 60

Subroutine Call for Point Job Data: callJob__________________________________________ 62

End the Point Job: returnJob ____________________________________________________ 64

Subroutine Call for a Program: callProg ____________________________________________ 65

Subroutine Call for a Point String: callPoints_________________________________________ 69

End a Program: endProg _______________________________________________________ 70

Assigning the Returned Value of a Function: returnFunc _______________________________ 71

Jump to the Specified Point: goPoint, goRPoint, goCRPoint ____________________________ 72

Jumping to a Specified Command Line: jump, Label __________________________________ 74

FOR, DO-LOOP ________________________________________________________________ 75

for, do-loop: for, next, exitFor, do, loop, exitDo _______________________________________ 75

MOVE________________________________________________________________________ 77

Move the Z-Axis Alone: upZ, downZ, movetoZ_______________________________________ 77

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

xxv

Linear Movement in CP Drive by Point Job: lineMove, lineMoveStopIf_____________________ 79

Mechanical Initialization by Point Job: initMec _______________________________________ 81

Position Error Detection: checkPos________________________________________________ 82

LCD, 7SLED___________________________________________________________________ 83

Display the Specified Strings on the Teaching Pendant: clrLCD, clrLineLCD, outLCD, eoutLCD _ 83

Display the Desired Number on the 7SLED: sys7SLED, out7SLED_______________________ 84

COM INPUT/OUTPUT ___________________________________________________________ 85

COM Input/Output: outCOM, eoutCOM, inCOM, setWTCOM, cmpCOM, ecmpCOM, clrCOM,

shiftCOM____________________________________________________________________

85

PC Communication: stopPC, startPC ______________________________________________ 89

VARIABLE, COMMENT, SYSTEM CONTROL ________________________________________ 90

Variable Declaration and Assignment: declare, let ____________________________________ 90

Comment Insertion: rem, crem ___________________________________________________ 92

Change a Program Number by Point Job: setProgNum________________________________ 93

Change a Sequencer Number by Point Job: setSeqNum_______________________________ 94

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

1

EXPRESSION STRUCTURE

Expression

An expression is fixed numbers (string type and numeric type), variables, functions, and operators

combined.

Fixed Number

There are two types of fixed numbers, numeric type (e.g. 125, 2.0, 2e15) and string type (e.g. "ABC").

Numeric type fixed numbers are handled as 8-byte real type (double type), and string type fixed

numbers are handled as 255-byte.

For string type fixed numbers, characters can be specified in hexadecimal code using the % symbol.

e.g. eoutCOM port2,"%0D%0A" : Output CR・LF code.

If there is any character other than 0 – 9, A – F, and a second % symbol after the first %, the second %

is treated as a character.

e.g. eoutCOM port2,"%G01" : Output %G01.

If there is any character from 0 – 9 and A – F, enter %% to output %.

e.g. eoutCOM port2,"%%300" : Output %300.

Variable

A variable is a container into which numeric and string values are placed.

You can use the built-in variables (which are built into the robot as a function) and the user-defined

variables (which can be freely defined by the user).

User-defined variables other than local variables (variables effective only in defined point job data

which are defined by the declare command) are defined in the Customizing mode. (See the operation

manual Features IV for details of the Customizing mode.)

Boolean type (boo): 1-bit variable which holds only 1 (true) or 0 (false)

Numeric type (num): 8-byte real type (double type) variable

String type (str): 255-byte variable

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

2

Function

A function returns a converted value if values or strings are given.

You can use the built-in functions (which are built into the robot as a function) and the user-defined

functions (which can be freely defined by the user).

The user-defined functions are defined in the Customizing mode. (See the operation manual Features

IV for details of the Customizing mode.)

Operator

Operator Description

Value

+

Adds the left and right values.

num

-

Deducts the right value from the left value.

num

*

Multiplies the left and right values.

num

/

Divides the left value by the right value.

num

&

Combines the left and right values. e.g. "A" & "B" Æ "AB"

str

=

Assigns the right value to a left value.

num,str

>

Returns 1 if the left value is larger than the right value.

Returns 0 if the left value is smaller than or the same as the right value.

num,str

<

Returns 1 if the left value is smaller than the right value.

Returns 0 if the left value is larger than or the same as the right value.

num,str

>=, =>

Returns 1 if the left value is larger than or the same as the right value.

Returns 0 if the left value is smaller than the right value.

num,str

<=, =<

Returns 1 if the left value is smaller than or the same as the right value.

Returns 0 if the left value is larger than the right value..

num,str

<>, ><

Returns 1 if the left value is not equal to the right value.

Returns 0 if they are equal.

num,str

==

Returns 1 if the left value is equal to the right value.

Returns 0 if they are not equal.

num,str

The priority of operators is as follows:

1. Expressions in brackets

2. Functions and variables

3. “Independent” + and -

4. * and /

5. +, -, and &

6. >, >=, =>, =<, <=, <, <>, and >< (Relational operator)

7. = (Assignment operator)

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

3

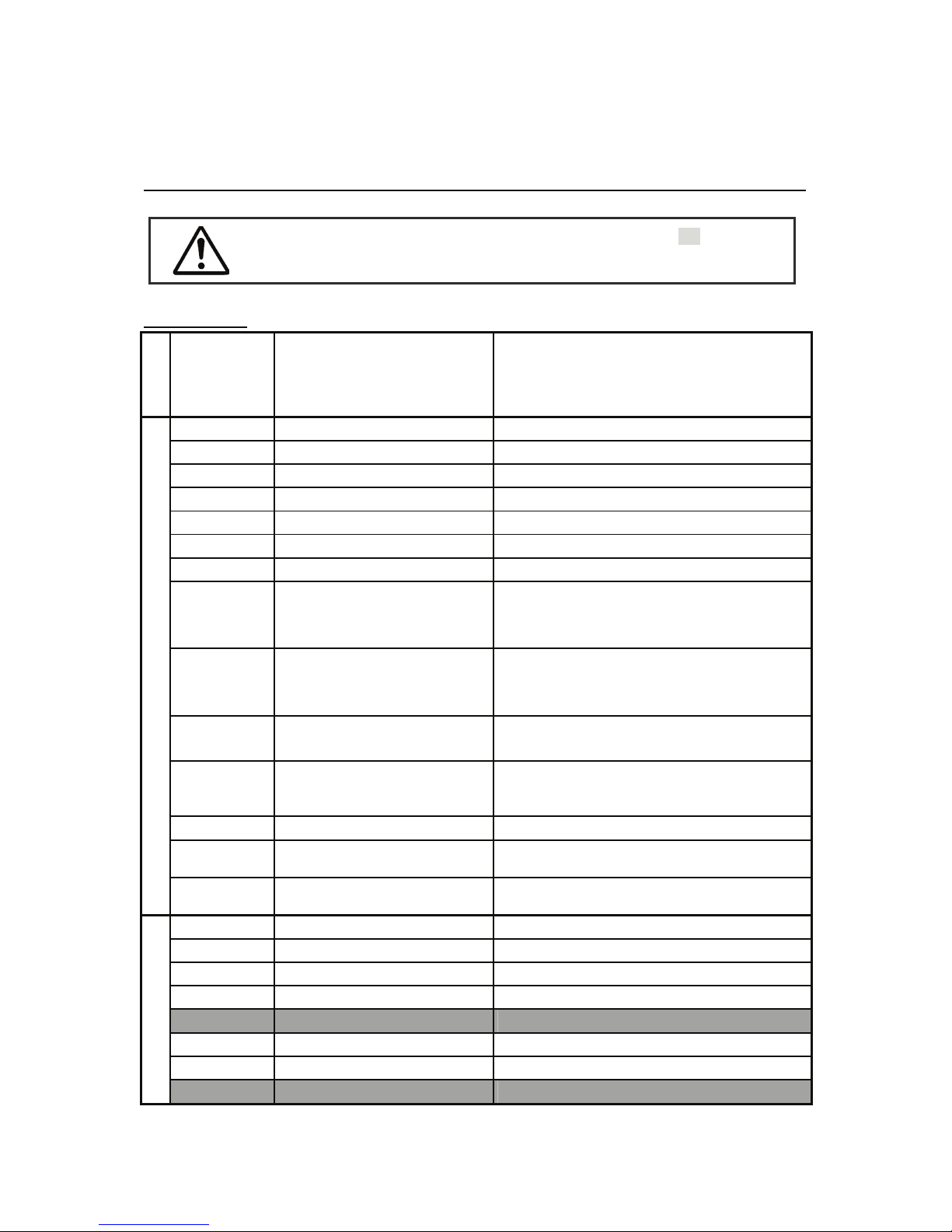

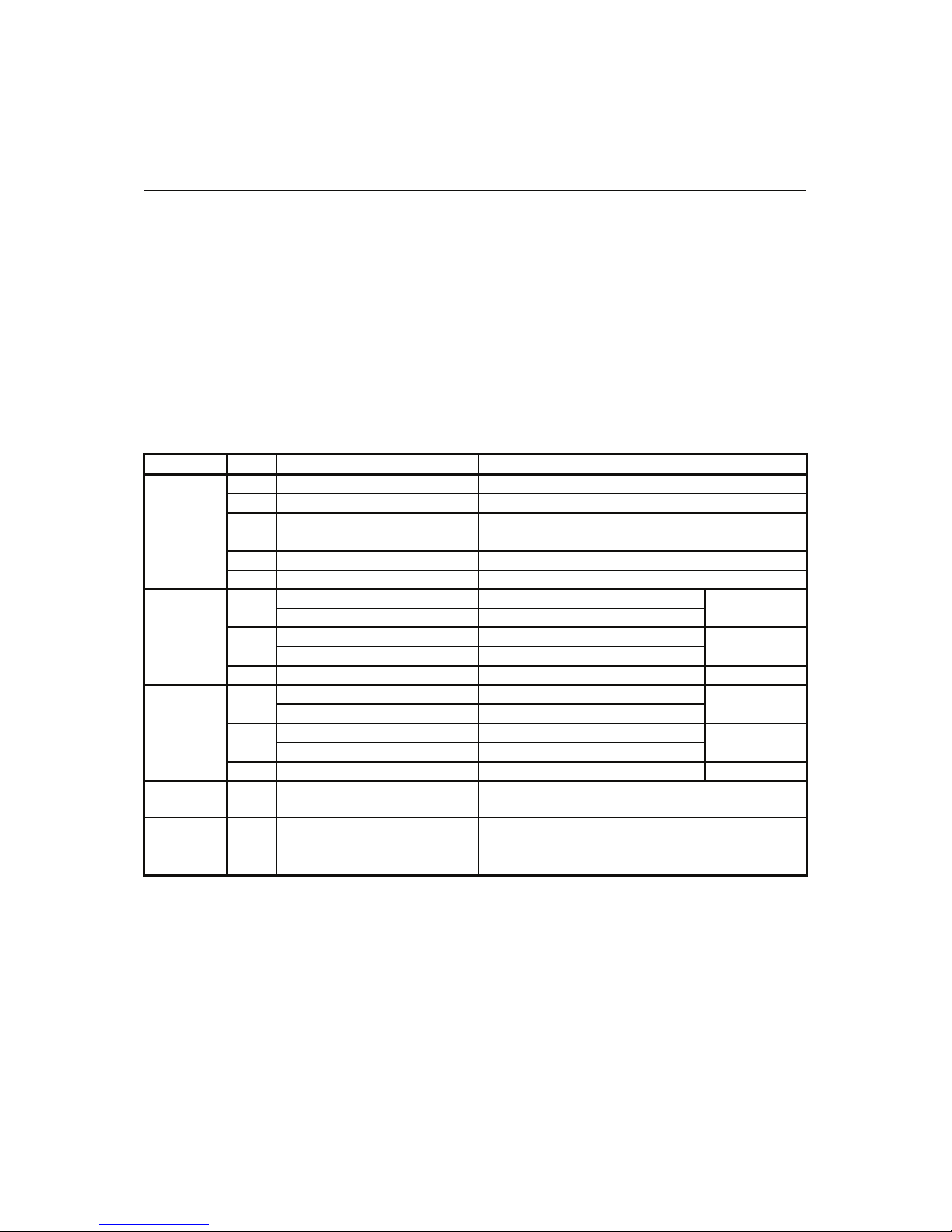

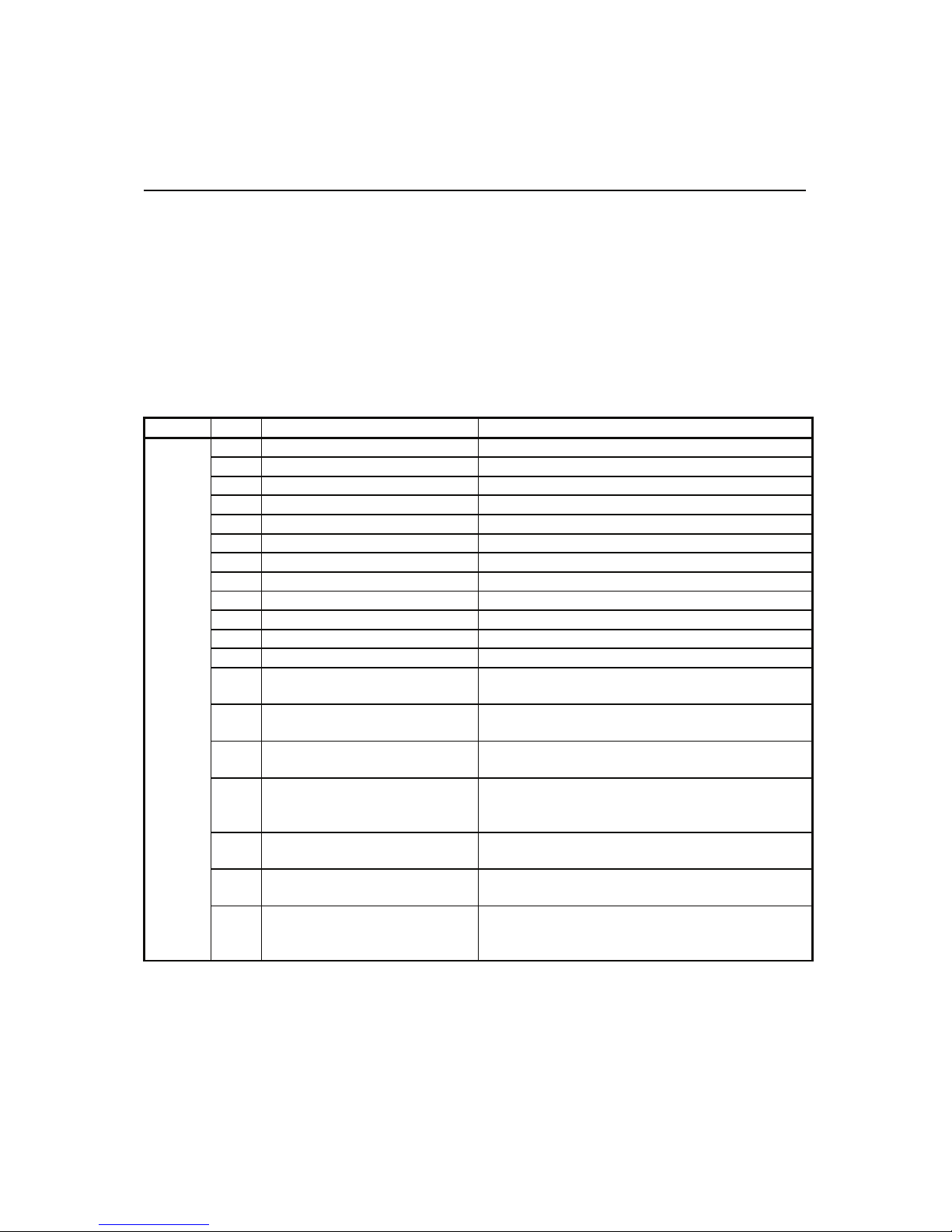

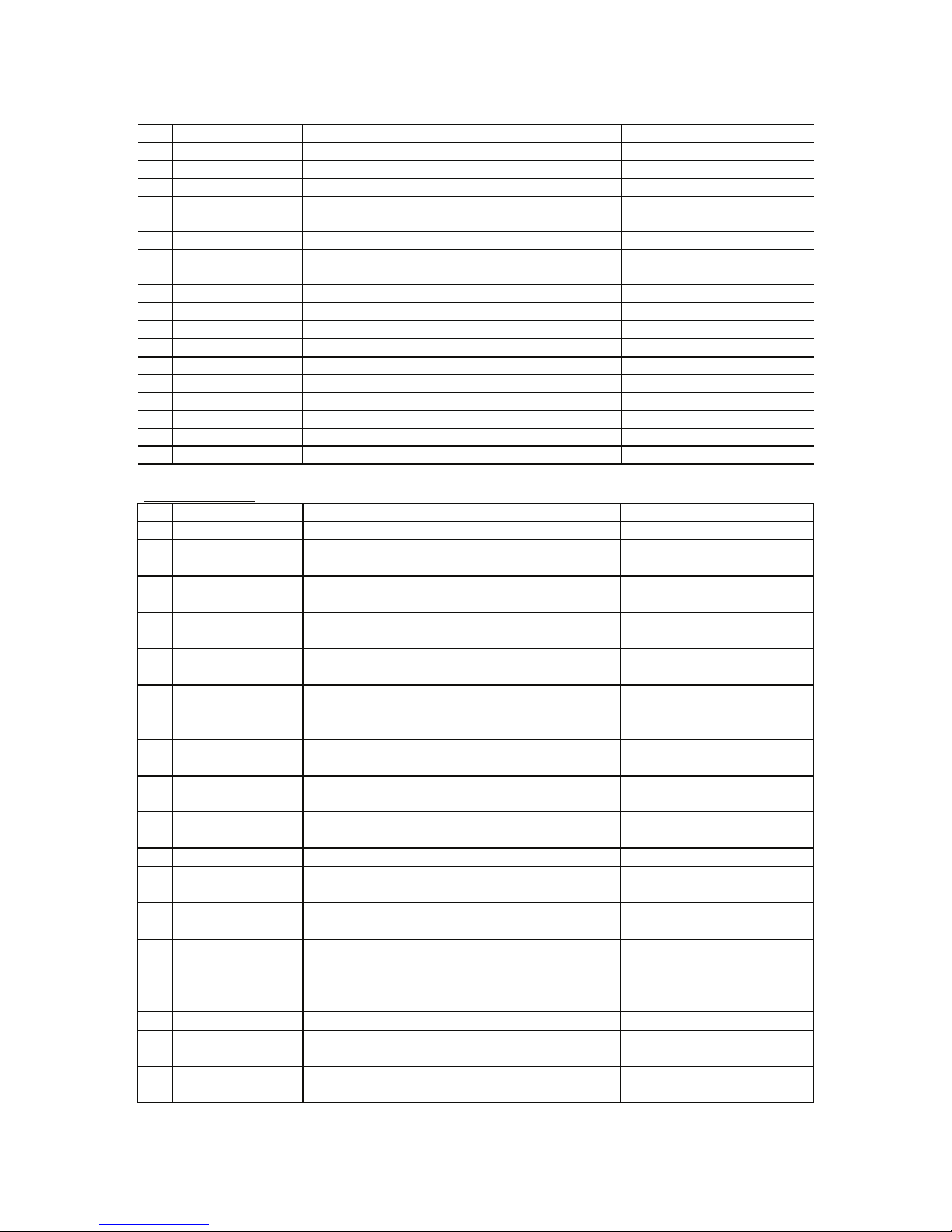

COMMAND LIST

Point Job Data

Category

Command Necessary Parameter Description

set Output Destination Output ON.

reset Output Destination Output OFF.

pulse Output Destination, Pulse Width Output ON pulses of predetermined length.

invPulse Output Destination, Pulse Width Output OFF pulses of predetermined length.

delaySet Output Destination, Delay Time Output ON after the predetermined delay time.

delayReset Output Destination, Delay Time Output OFF after the predetermined delay time.

onoffBZ ON Time, OFF Time Sound the buzzer on and off.

onoffGLED ON Time, OFF Time

Flash the green LED on the front of the

JR2000N Series robot (or on the operation box

for the JSR4400N robot).

onoffRLED ON Time, OFF Time

Flash the red LED on the front of the JR2000N

Series robot (or on the operation box for the

JSR4400N robot).

dataOut

Output Data, Output Bit

Number, Output Destination

Output numeric data or a tag code assigned to

a point to the I/O.

dataOutBCD

Output Value, Output Bit

Number, Output Destination

Output numeric data or a tag code assigned to

a point to the I/O in BCD (binary-coded

decimal).

motorPowerON –

servoON Axis

Turn on the designated Axis servomotor.

(Available only for the JS and JSG Series)

ON/OFF Output Control

servoOFF Axis

Turn off the designated Axis servomotor.

(Available only for the JS and JSG Series)

if – Conditional branching

then

–

Perform if true.

else

–

Perform if false.

endIf

–

End of conditional branching

waitCondTime Wait Time Wait for conditions for a designated period.

timeUp

–

Perform when time is up.

endWait

–

End of wait condition

if Branch, Wait Condition

waitCond

–

Wait for conditions.

If you assign point job data that includes any of the highlighted ( ) commands

to a CP passing point, the commands will be ignored.

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

4

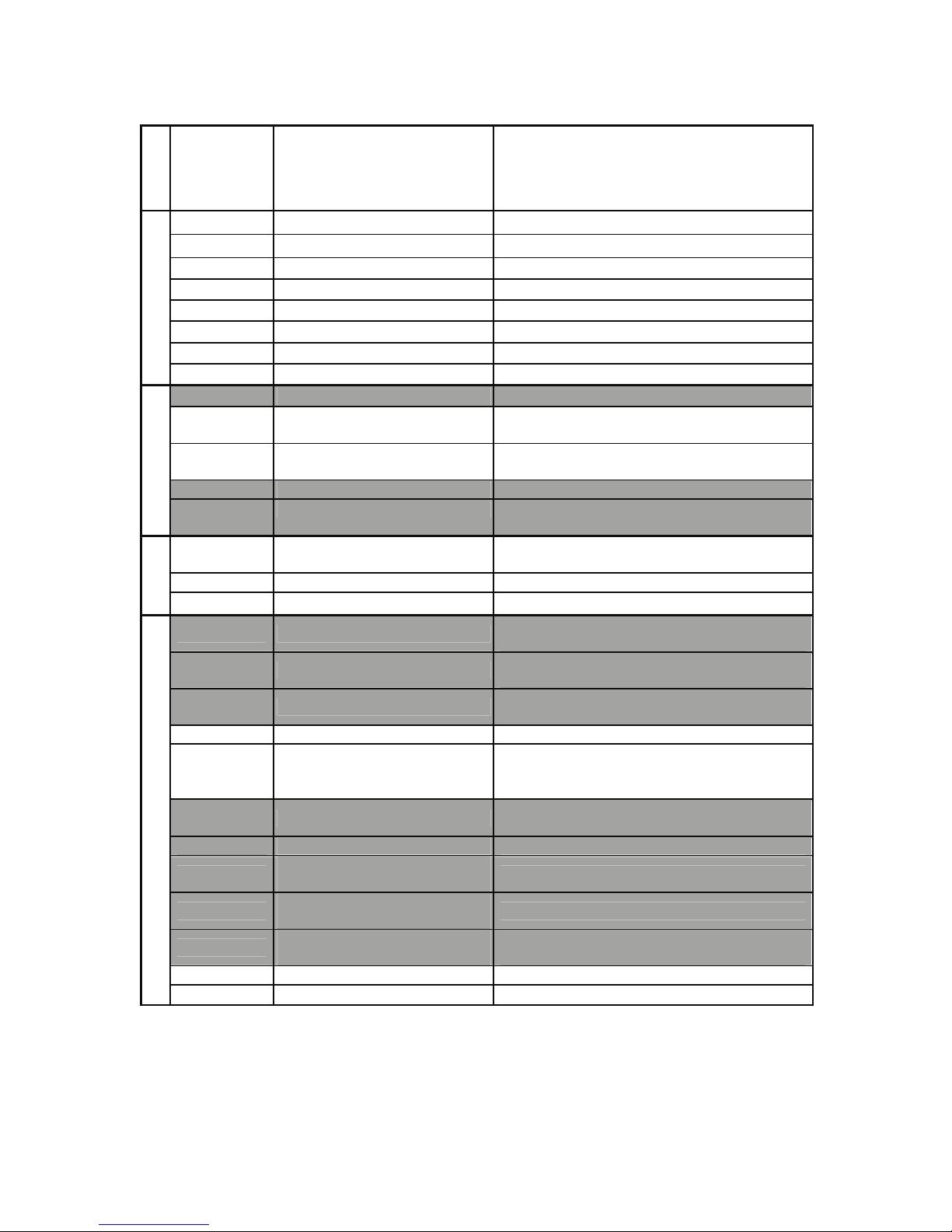

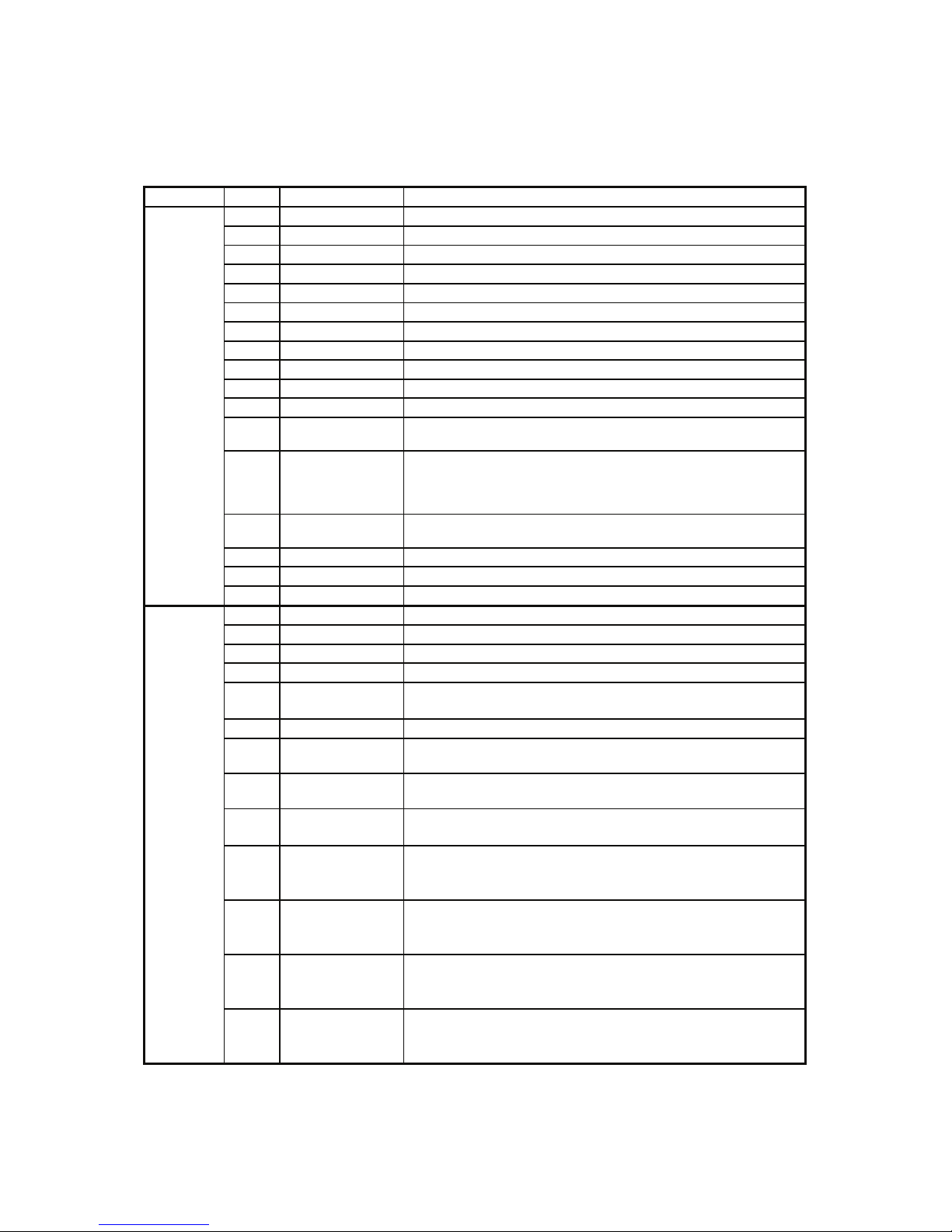

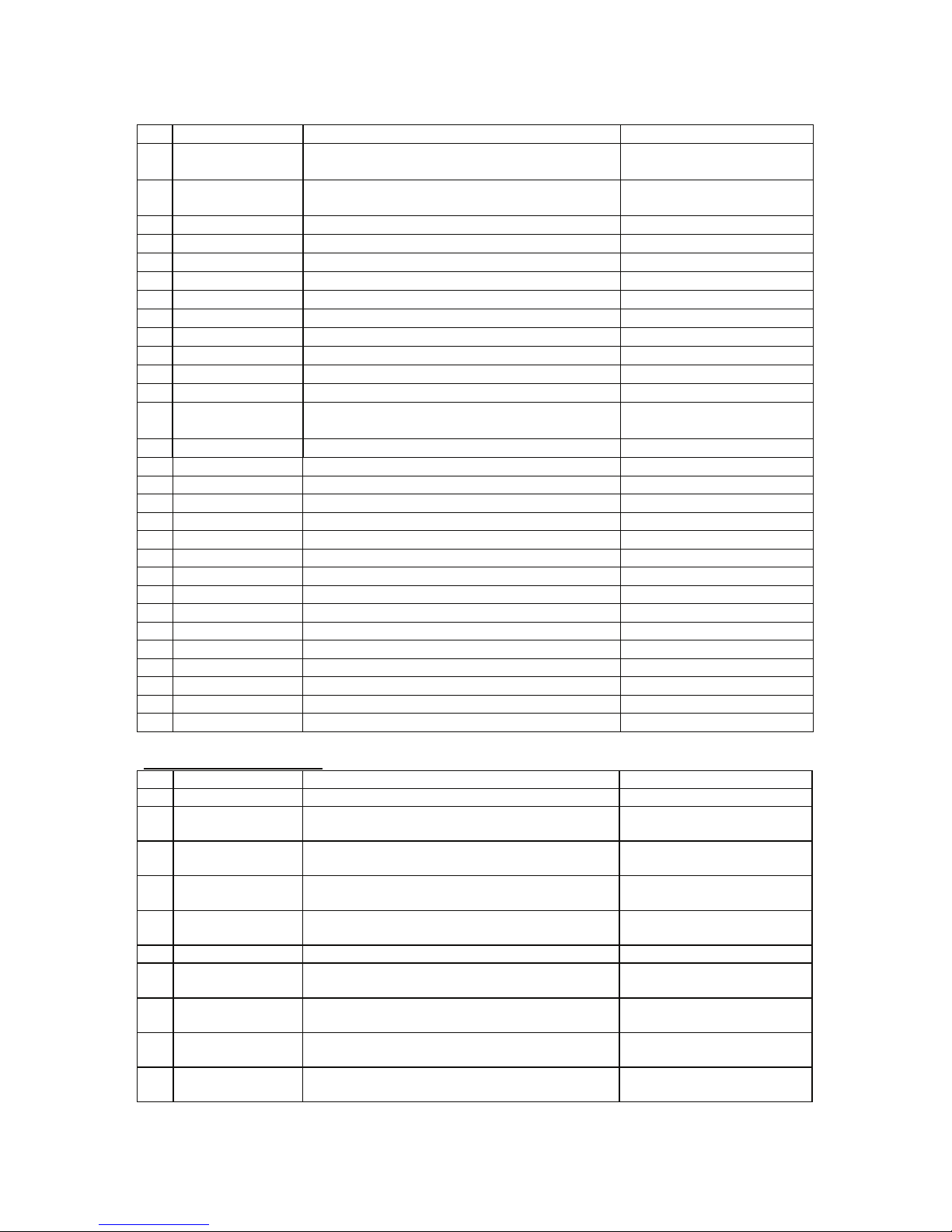

Category

Command Necessary Parameter Description

ld Boolean variable or Expression

Input ON.

ldi Boolean variable or Expression

Input OFF.

and Boolean variable or Expression

Input serial ON.

ani Boolean variable or Expression

Input serial OFF.

or Boolean variable or Expression

Input parallel ON.

ori Boolean variable or Expression

Input parallel OFF.

anb –

Serial connection of blocks

Condition

orb –

Parallel connection of blocks

delay

Delay Time Stop for a specified time.

dataIn

Numeric Variable Name, Input

Bit Number, Input Source

Read out numeric data from the I/O.

dataInBCD

Numeric Variable Name, Input

Bit Number, Input Source

Read numeric data in BCD from the I/O.

waitStart –

Wait for a start signal.

Delay

waitStartBZ

–

Wait for a start signal while acknowledging an

error with an alarm buzzer.

loopPallet

Pallet Routine Number, go Point

Number

Pallet loop

resPallet Pallet Routine Number

Reset the pallet counter.

Pallet

incPallet Pallet Routine Number

Increase the pallet counter number. (+1)

callBase

–

Call a user-defined point job from a point to

which a point job number is set.

callJob

Point Job Number

Call a point job data subroutine specified by

number.

callPoints

Variable Name (Identifier)

Perform a specified point string (defined in the

Customizing mode).

returnJob

– End of point job

returnFunc

Return Value (Expression)

Terminate the function by assigning the value

of the specified expression as a return value.

(This command is valid in functions only.)

callProg

Program Number

Call a program subroutine specified by

number.

endProg

– End of program

goPoint

PTP Condition Number, go Point

Number

Jump to a specified point.

goRPoint

PTP Condition Number, Relative

go Point Number

Jump to a relatively-specified point.

goCRPoint

PTP Condition Number, Relative

go Point Number

Jump to a selected destination point while

running in the CP drive.

jump

Label Number Jump to a specified label.

Execute Flow Control

Label

Label Number Label

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

5

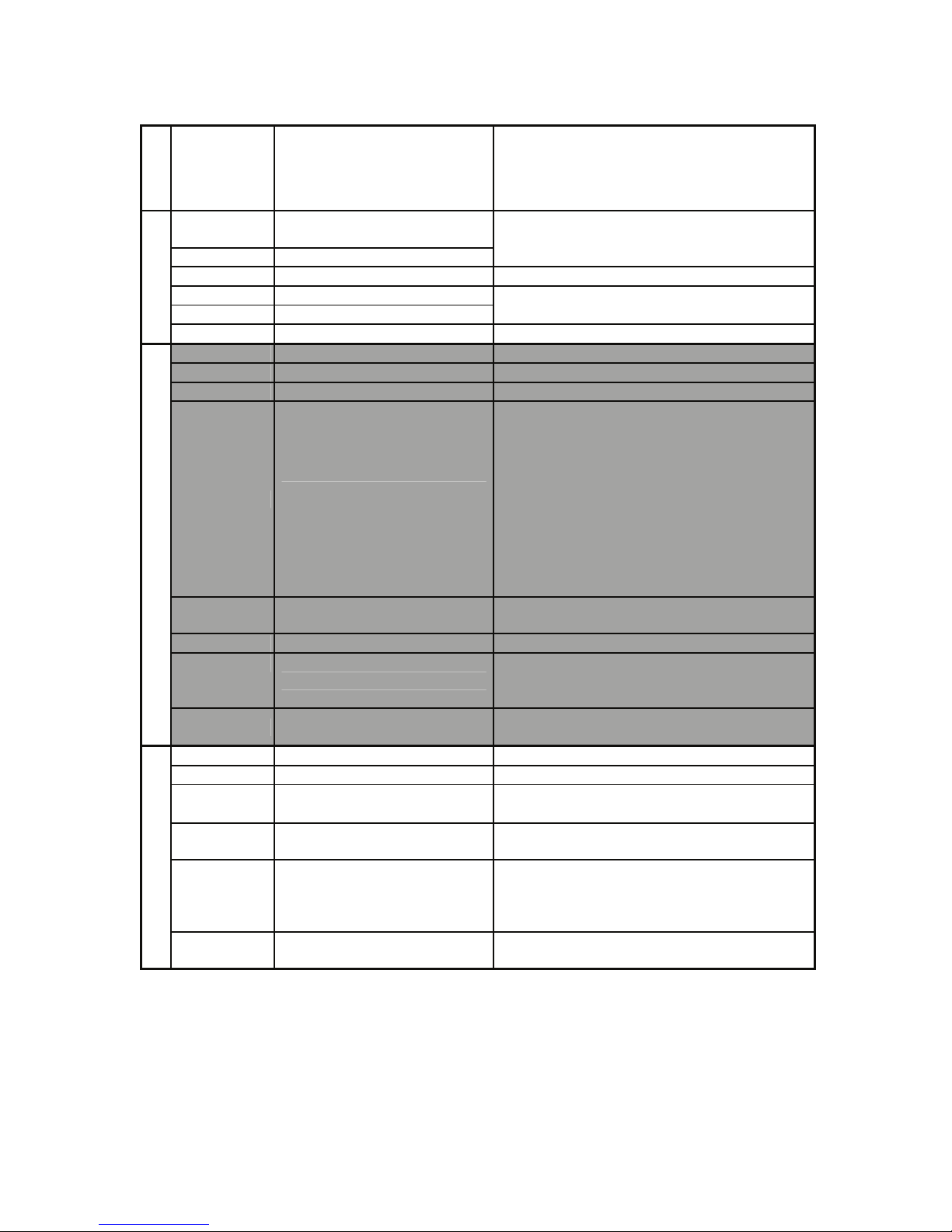

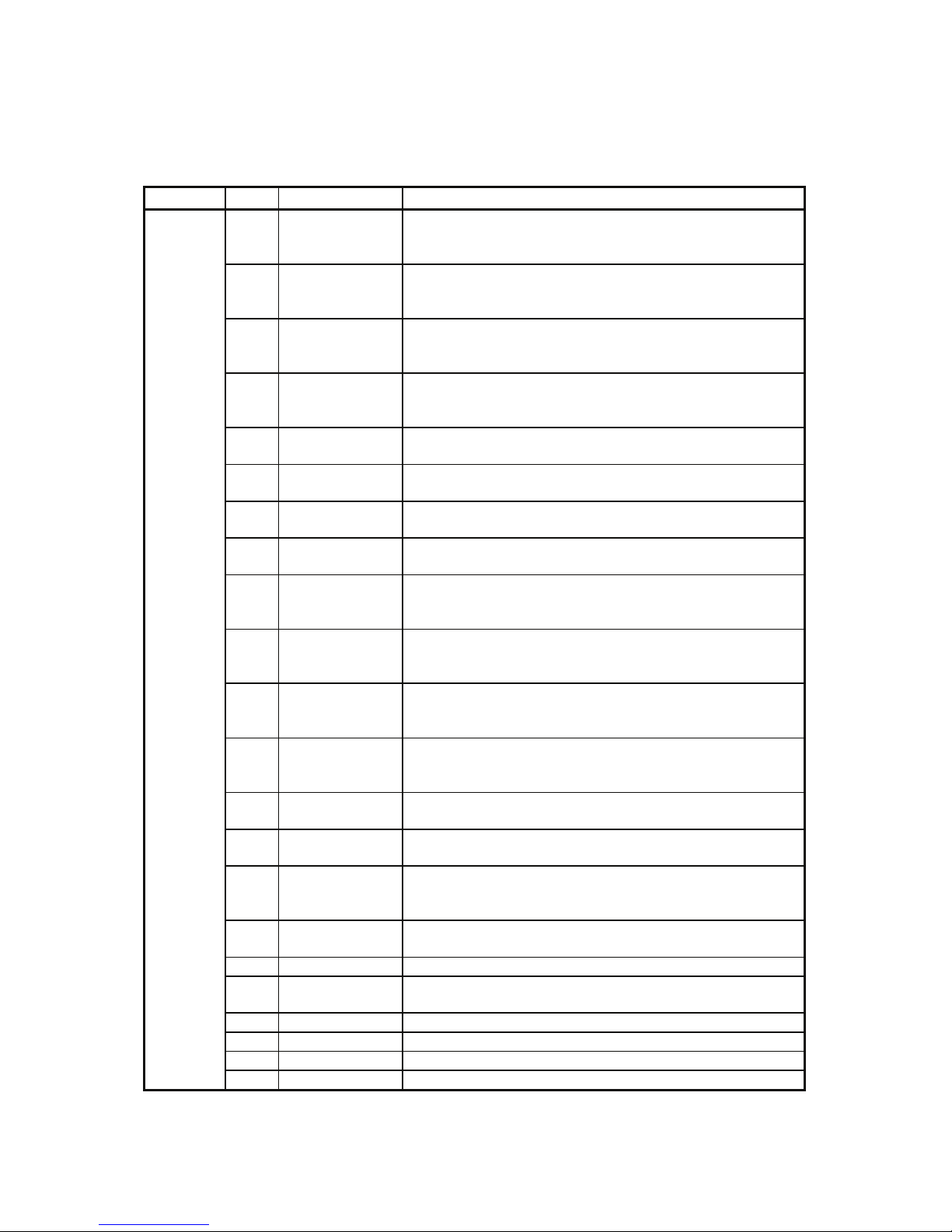

Category

Command Necessary Parameter Description

for

Variable Name, Initial Value,

End Value, Step Value

next –

Repeat commands between for and next until

the specified variable changes from the initial

value to the end value.

exitFor –

Break from for loop.

do –

loop –

Repeat commands between do and loop.

For, do-loop

exitDo –

Break from do loop.

upZ Speed, Distance Z Up

downZ Speed, Distance Z Down

movetoZ Speed, Distance Z Move

lineMove

Line Speed, (X, Y, Z) Distance,

R Rotate Angle

Make an Axis move a specified distance

(relative distance) at a specified speed in the

CP line drive. (Relative move command)

Entering this command will display the

specified shifting speed and distance of each

Axis as follows:

e.g. lineMoveSpeed 20

lineMoveX 10

lineMoveY 20

lineMoveZ 0

lineMoveR 0

lineMoveStopIf

– Terminate the movement of an Axis made by

lineMove if the conditions are met.

endLineMove – End of lineMoveStopIf condition statements.

initMec

Axis

Return the specified Axis to its initial position.

(Perform mechanical initialization.) (Available

only for the JR2000N and JSR4400N Series)

Move

checkPos

– Detect a position error. (Available only for the

JR2000N Series)

clrLCD

– Clear the LCD display.

clrLineLCD

Clear Line (1 – 13) Clear a specified line on the LCD display.

outLCD

Display Line (1 – 13), Display

Column (1 – 40), Display Data

Display strings on the LCD display.

eoutLCD

Display Line (1 – 13), Display

Column (1 – 40), Display Data

Display the result of the string expression on

the LCD display.

sys7SLED –

Returns the 7 segment LED display changed

by out7SLED to the previous program number.

(Available only for the JR2000N Series and

JSR4400N Series)

LCD Control

out7SLED Type, Output Value

Output 7 segment LED. (Available only for the

JR2000N Series and JSR4400N Series)

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

6

Category

Command Necessary Parameter Description

outCOM Input/Output, Output Data Output the string from the COM.

eoutCOM Input/Output, Output Data

Output the result of the string expression from

the COM.

setWTCOM Input/Output, Wait Time

Set [Wait Time] (time-out period) for receiving

data from the COM.

inCOM

Variable Name, Input/Output,

Character Length

Assign the receive data from the COM to the

specified variable.

cmpCOM Input/Output, Compare Data

Compare the receive data and string. The result

is entered into the system flags (sysFlag(1) –

sysFlag(20)).

ecmpCOM Input/Output, Compare Data

Compare the receive data and string expression.

The result is entered into the system flags

(sysFlag(1) – sysFlag(20)).

clrCOM Input/Output Clear the COM receive buffer.

shiftCOM Input/Output, Shift Number

Shift data received from the COM. Delete data

from the top by the specified [Shift Number].

stopPC – Stop the PC communication of the COM1.

COM Input/Output

startPC – Start the PC communication of the COM1.

declare Variable Type, Variable Name

Local variable declaration

let Expression

Assign the l-value to the r-value.

The symbols +, -, *, /, =, (, ), & can be used.

rem Output Data

One line comment

crem Output Data

Comment at the end of a command line

setProgNum Program Number

Change the program number.

z Do not carry out this command while the

robot is running. Use the command

callProgram if you change the program to

be run while the robot is running.

Variable, Comment, System Control

setSeqNum Sequencer Number

Change the sequencer number in the system

data.

cameraWadj Work Adjustment Number

Take an image with a camera and calculate the

offset from the data gained according to the

[Workpiece Adjustment] setting.

wCameraWadj

Work Adjustment Number,

Shot Number

Use this command when calculating offset using

two camera images according to the [Workpiece

Adjustment].

ca m er a Too l Tool Nu mbe r

Take an image with a camera and calculate

[TCP-X] and [TCP-Y] from the data gained

according to the [Point Tool Data Settings].

cameraPallet Pallet Routine Number

Take an image with a camera and set the

number of gained marks and the coordinates as

the number and the coordinates of the [Pallet

Routine] to be performed.

Camera, Z Adjustment

takeZWadj Work Adjustment Number

Calculate the Z offset from the data gained by

the distance or touch-sensitive sensor according

to the [Workpiece Adjustment] settings.

z For the [Camera, Z Adjustment] command category, refer to the Camera & Sensor Functions

operation manual.

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

7

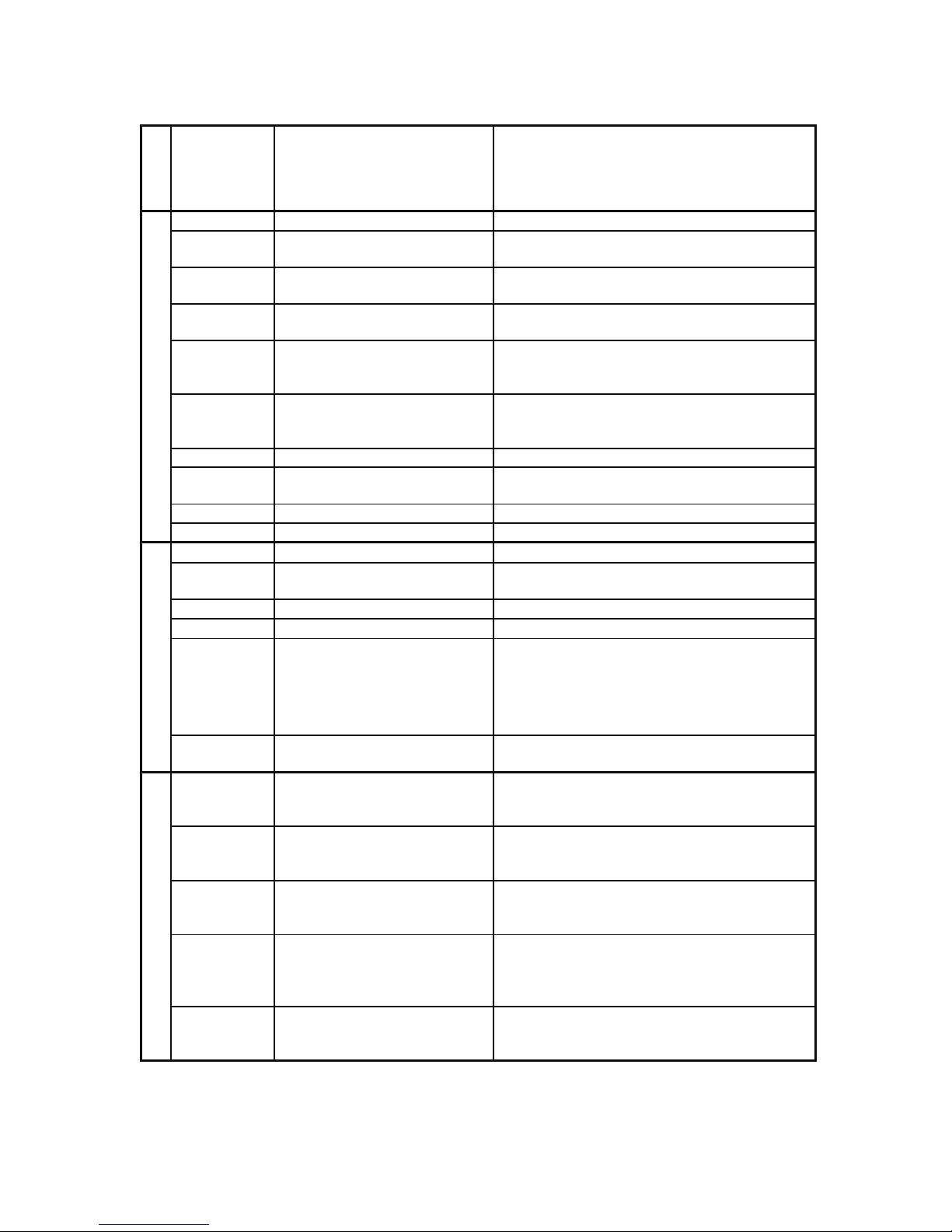

Execute Condition

Category

Command Necessary Parameter Description

ld Boolean variable or expression Input ON.

ldi Boolean variable or expression Input OFF.

and Boolean variable or expression Input serial ON.

ani Boolean variable or expression Input serial OFF.

or Boolean variable or expression Input parallel ON.

ori Boolean variable or expression Input parallel OFF.

anb – Serial connection of blocks

Condition

orb – Parallel connection of blocks

Sequencer

Category

Command Necessary Parameter Description

ld Boolean variable Input ON.

ldi Boolean variable Input OFF.

and Boolean variable Input serial ON.

ani Boolean variable Input serial OFF.

or Boolean variable Input parallel ON.

Calculate

ori Boolean variable Input parallel OFF.

out Output Destination Coil drive

set Output Destination

Set the coil drive hold command.

reset Output Destination

Reset the coil drive hold command.

pls Output Destination

Output the rising edge of pulse.

Coil

plf Output Destination

Output the falling edge of pulse.

anb –

Parallel connection of serial circuit block

orb –

Serial connection of parallel circuit block

mps –

Store data in process of calculation.

mrd –

Read out data in process of calculation.

Connection

mpp –

Read out and reset data in process of

calculation.

Others

nop – No operation

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

8

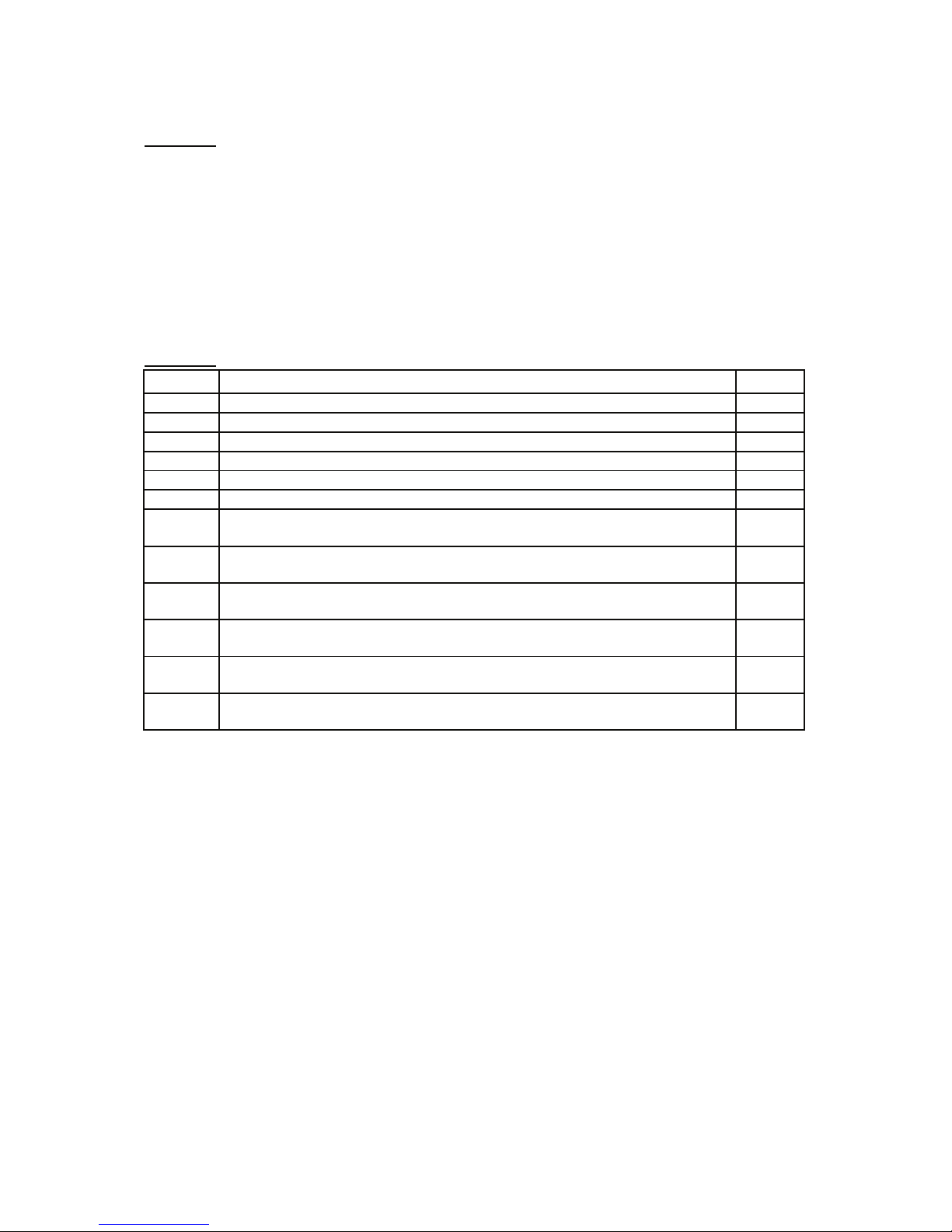

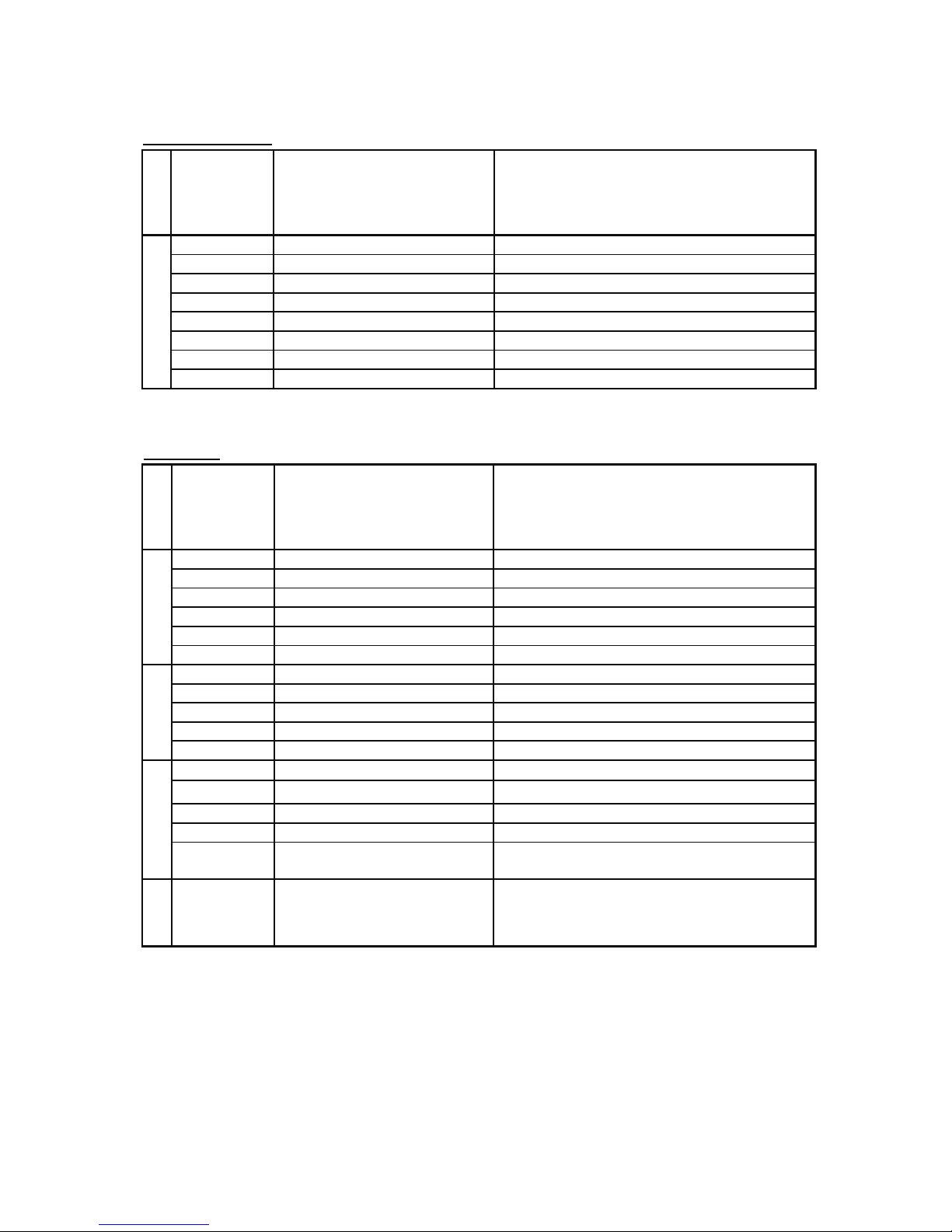

VARIABLE LIST

You can use the built-in variables (which are built into the robot as a function), and the user-defined

variables (which can be freely defined by the user).

User-defined variables other than local variables (variables effective only in defined point job data

which are defined by the declare command) are defined in the Customizing mode. (See the operation

manual Features IV for details of the Customizing mode.)

Boolean type (boo): 1-bit variable which holds only 1 (true) or 0 (false)

Numeric type (num): 8-byte real type (double type) variable

String type (str): 255-byte variable

Category Type Identifier Description

boo #mv (1 – 99) Boolean variable

boo #mkv (1 – 99) Boolean variable (Keeping variable)*

num #nv (1 – 99) Numerical variable

num #nkv (1 – 99) Numerical variable (Keeping variable)*

str #sv (1 – 99) String variable

Free

Vari able

str #skv (1 – 99) String variable (Keeping variable)*

#sysIn1 – 15 (JS and JSG Series)

boo

#sysIn1 – 16 (JR2000N and JR4400N Series)

I/O-SYS

#genIn1 – 18 (JS and JSG Series)

boo

#genIn1 – 8 (JR2000N and JR4400N Series)

I/O-1

Input

Vari able

boo #handIn1 – 4 (Available only for JS Series) I/O-H

#sysOut1 – 14 (JS and JSG Series)

boo

#sysOut1 – 16 (JR2000N and JR4400N Series)

I/O-SYS

#genOut1 – 22 (JS and JSG Series)

boo

#genOut1 – 8 (JR2000N and JR4400N Series)

I/O-1

Output

Vari able

boo #handOut1 – 4

(Available only for JS Series) I/O-H

System

Flag

boo #sysFlag(1) – #sysFlag(999) Refer to “SYSTEM FLAG LIST” on Page 14.

set #FBZ : Sound the buzzer.

reset #FBZ : Stop the buzzer.

Buzzer boo #FBZ

(onoffBZ : Turn the buzzer on and off.)

*: Variables which hold their values even if the robot is turned off are collectively referred to as

keeping variables in the operation manuals.

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

9

Variables

Category Type Identifier Description

num #downTimer1 – 10

The assigned value will be decreased

automatically (by msec).

num #jobStartHight

Start a point job from a position above the Zcoordinate determined by the assigned value.

(Invalid in the CP drive)

num #jobStartX

Start a point job from a position at a distance

from the X-coordinate determined by the

assigned value.

(Invalid in the CP drive)

num #jobStartY

Start a point job from a position at a distance

from the Y-coordinate determined by the

assigned value.

(Invalid in the CP drive)

Special

Vari able

num #jobStartR

Start a point job from a position at a distance

from the R-coordinate determined by the

assigned value.

(Invalid in the CP drive)

boo #palletFlag (1 – 100)

Pallet flag

(Corresponds to Pallet Routine Nos. 1 – 100.)

Pallet

Routine

num #palletCount (1 – 100)

Pallet counter

(Corresponds to Pallet Routine Nos. 1 – 100.)

Workpiece

Adjustment

num

#workAdj_X (1 – 100)

#workAdj_Y (1 – 100)

#workAdj_Z (1 – 100)

#workAdj_R (1 – 100)

#workAdj_Rotation (1 – 100)

Adjustment value of each Axis in [Workpiece

Adjustment] settings

(Corresponds to Work Adjustment Nos. 1 –

100.)

Tool Data num

#tool_X (1 – 100)

#tool_Y (1 – 100)

#tool_Z (1 – 100)

#tool_R (1 – 100)

TCP value of each Axis in [Point Tool Data

Settings] settings.

(Corresponds to Tool Nos. 1 – 100.)

PTP

Condition

num #priorityPTPCondNum

PTP condition number

The PTP condition number set by using this

variable has

priority over other PTP condition

numbers in the PTP drive (even at the points

to which the additional function data [PTP

Condition] is set).

boo #seqT (1 – 99)

Add 1 when #seqTCount reaches the

specified value or greater.

num

#seqTCount (1 – 50):

Integrating timer

#seqTCoun (51 – 99):

Unintegrating timer

One counter can count 0.001 – 2,147,483,647

seconds (by 0.001 second).

boo #seqC (1 – 99)

Add 1 when #seqCCount reaches the

specified value or greater.

Sequencer

num #seqCCount (1 – 99) One counter can count 1 – 2,147,483,647.

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

10

Variables

Category Type Identifier Description

num #point_X

X-coordinate value of the point currently

performed

num #point_Y

Y-coordinate value of the point currently

performed

num #point_Z

Z-coordinate value of the point currently

performed

num #point_R

R-coordinate value of the point currently

performed

Current

Point

Coordinates

num #point_TagCode

Tag code value of the point currently

performed

num #P_X (1 – last point number) X-coordinate value of the specified point

num #P_Y (1 – last point number) Y-coordinate value of the specified point

num #P_Z (1 – last point number) Z-coordinate value of the specified point

num #P_R (1 – last point number) R-coordinate value of the specified point

Specified

Point

Coordinates

num

#P_TagCode (1 – last point

number)

Tag code value of the specified point

num

#prog_P_X (1 – 255, 1 – last

point number)

X-coordinate value of the specified point in the

specified program

num

#prog_P_Y (1 – 255, 1 – last

point number)

Y-coordinate value of the specified point in the

specified program

num

#prog_P_Z (1 – 255, 1 – last

point number)

Z-coordinate value of the specified point in the

specified program

num

#prog_P_R (1 – 255, 1 – last

point number)

R-coordinate value of the specified point in the

specified program

Specified

Program,

Specified

Point

Coordinates

num

#prog_P_TagCode (1 – 255,

1 – last point number)

Tag code value of the specified point in the

specified program

num #point_CondNum

Condition setting variable number set to the

point currently performed

num

#P_CondNum (1 – last point

number)

Condition setting variable number set to the

specified point

Condition

Number

num

#prog_P_CondNum (1 –

255, 1 – last point number)

Condition setting variable number set to the

specified point in the specified program

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

11

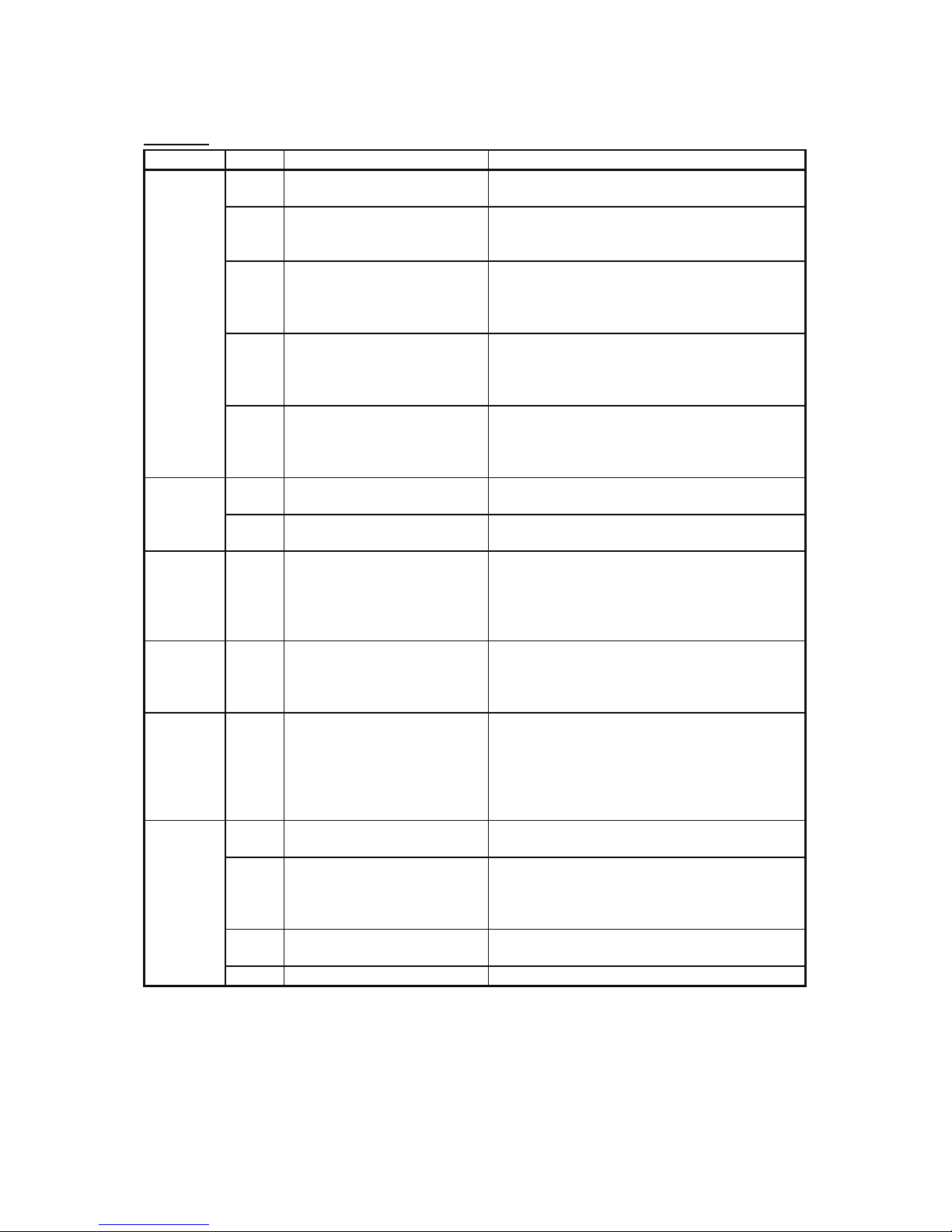

FUNCTION LIST

You can use the built-in functions (which are built into the robot as a function) and the user-defined

functions (which can be freely defined by the user).

The user-defined functions are defined in the Customizing mode. (See the operation manual Features

IV for details of the Customizing mode.)

x, y: Numerical value or numerical variable

n, m: Numeric value becomes larger than a certain value through rounding or truncation

a, b: String or string variable

Category Type Identifier Description

num currentMainProgNumber () Currently performed main program number

num currentSubProgNumber () Currently performed sub program number

num currentPointNumber () Currently performed point number

num currentArmX () Current X-coordinate [mm]

num currentArmY () Current Y-coordinate [mm]

num currentArmZ () Current Z-coordinate [mm]

num currentArmR () Current R-coordinate [deg]

num currentCmdArmX () Current command X-coordinate [mm]

num currentCmdArmY () Current command Y-coordinate [mm]

num currentCmdArmZ () Current command Z-coordinate [mm]

num currentCmdArmR () Current command R-coordinate [deg]

num numCOM (COM port number) Data byte count of COM receiving port

num isConditionData (n)

Display whether the specified condition data

number is available (1) or not (0).

str strCenterLCD (a)

Adjust the strings on the teaching pendant LCD

(centering).

str strRightLCD (a)

Adjust the strings on the teaching pendant LCD

(right justification).

str strPlusRLCD (a,b)

Teaching pendant LCD: Right priority; Items on

the right are displayed in full if there is an

overlap.

str strPlusLLCD (a,b)

Teaching pendant LCD: Left priority; Items on the

left are displayed in full if there is an overlap.

num getSystemPTPmoveTime ()

Valid only for [Job while Moving].

Time required for the current PTP drive [sec]

Robot

System

num getSystemPTPrestTime ()

Valid only for [Job while Moving].

Time left before the current PTP drive ends

(reaching the destination) [sec]

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

12

x, y: Numerical value or numerical variable

n, m: Numeric value becomes larger than a certain value through rounding or truncation

a, b: String or string variable

Category Type Identifier Description

num abs (x)

Absolute value

num max (x,y) Maximum value

num min (x,y) Minimum value

num degrade (x) Conversion from degree to radian (x*π/180)

num raddeg (x) Conversion from radian to degree (x*180/π)

num sqrt (x) Square root

num sin (x) Sine

num cos (x) Cosine

num tan (x) Tangent

num atan (x) Arctangent

num atan2 (x,y) Arctangent

num int (x)

Maximum integer that does not exceed x.

e.g. int (1.3) Æ 1, int (-1.3) Æ -2

num ip (x)

Integer part of x: sgn (x)*int (abs(x))

(If x is a negative number, sgn (x) becomes -1. If x is a

positive number, sgn (x) becomes +1.)

e.g. ip (1.3) Æ 1, ip (-1.3) Æ -1

num fp (x)

Decimal part of x: x-ip (x)

e.g. fp (1.3) Æ 0.3, fp (-1.3) Æ -0.3

num mod (x,y) Value of x modulo y: x-y*int (x/y)

num remainder (x,y) Remainder of dividing x by y: x-y*ip (x/y)

Arithmetic

System

num pow (x,y) x to the power of y

str chr (x)

Return a string (1 character) with the given character code.

num ord (a) Return the top character code. Other codes are ignored.

num len (a) Return the string length (non-multibyte).

num strPos (a,b) Return the first part string position in a matching b.

str strMid (a,n,m)

Return the strings n – m counted from the top of the given

string a.

str str (x) Convert a numeric value to a decimal digit string.

str strBin (n,m)

Convert a numeric value to a binary string.

m: Number of binary string digits

str strHex (n,m)

Convert a numeric value to a hexadecimal string.

m: Number of hexadecimal string digits

str str1SI (x)

Round a numeric value to a 1-byte signed integer to convert

it to a 1-byte string. (1-byte Signed Integer)

str str2SIBE (x)

Round a numeric value to a 2-byte signed integer to convert

it to a 2-byte string using the Big Endian byte order. (2-byte

Signed Integer Big Endian)

str str2SILE (x)

Round a numeric value to a 2-byte signed integer to convert

it to a 2-byte string using the Little Endian byte order.

(2-byte Signed Integer Little Endian)

str str4SIBE (x)

Round a numeric value to a 4-byte signed integer to convert

it to a 4-byte string using the Big Endian byte order. (4-byte

Signed Integer Big Endian)

String

System

str str4SILE (x)

Round a numeric value to a 4-byte signed integer to convert

it to a 4-byte string using the Little Endian byte order.

(4-byte Signed Integer Little Endian)

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

13

x, y: Numerical value or numerical variable

n, m: Numeric value becomes larger than a certain value through rounding or truncation

a, b: String or string variable

Category Type Identifier Description

str str4FBE (x)

Regard a numeric value as a float to convert it to a 4-byte

string using the Big Endian byte order. (4-byte Signed Float

Big Endian)

str str4FLE (x)

Regard a numeric value as a float to convert it to a 4-byte

string using the Little Endian byte order. (4-byte Signed

Float Big Endian)

str str8DBE (x)

Regard a numeric value as a float to convert it to an 8-byte

string using the Big Endian byte order. (8-byte Signed Float

Big Endian)

str str8DLE (x)

Regard a numeric value as a float to convert it to an 8-byte

string using the Little Endian byte order. (8-byte Signed

Float Little Endian)

num val (a)

Regard a string as a decimal digit string to convert it to a

numeric value.

num valBin (a)

Regard a string as a binary string (sequence of “0”, “1”) to

convert it to a numeric value.

num valHex (a)

Regard a string as a hexadecimal string (sequence of “0” –

“1”, “A” – “F”, or “a” – “f”) to convert it to a numeric value.

num val1SI (a)

Convert the top character to a 1-byte signed integer. (1-byte

Signed Integer)

num val2SIBE (a)

Convert the top 2 characters to a 2-byte signed integer

using the Big Endian byte order. (2-byte Signed Integer

Big Endian)

num val2SILE (a)

Convert the top 2 characters to a 2-byte signed integer

using the Little Endian byte order. (2-byte Signed Integer

Little Endian)

num val4SIBE (a)

Convert the top 4 characters to a 4-byte signed integer

using the Big Endian byte order. (4-byte Signed Integer Big

Endian)

num val4SILE (a)

Convert the top 4 characters to a 4-byte signed integer

using the Little Endian byte order. (4-byte Signed Integer

Little Endian)

num val4FBE (a)

Convert the top 4 characters to a float using the Big Endian

byte order. (4-byte Float Big Endian)

num val4FLE (a)

Convert the top 4 characters to a float using the Little

Endian byte order. (4-byte Float Little Endian)

num val8DBE (a)

Convert the top 8 characters to a double-precision float

using the Big Endian byte order. (8-byte Double Big

Endian)

num val8DLE (a)

Convert the top 8 characters to a double-precision float

using the Little Endian byte order. (8-byte Little Big Endian)

num valSum (a) Return the sum of a string code from top to bottom.

num valCRC (a)

Remainder of dividing a string (bit string) by a generator

polynomial X

16+X12+X5

+1

str bitNot (a) Bit invert

str bitAnd (a,b) Bit logical conjunction

str bitOr (a,b) Bit logical add

String

System

str bitXor (a,b) Bit exclusive disjunction

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

14

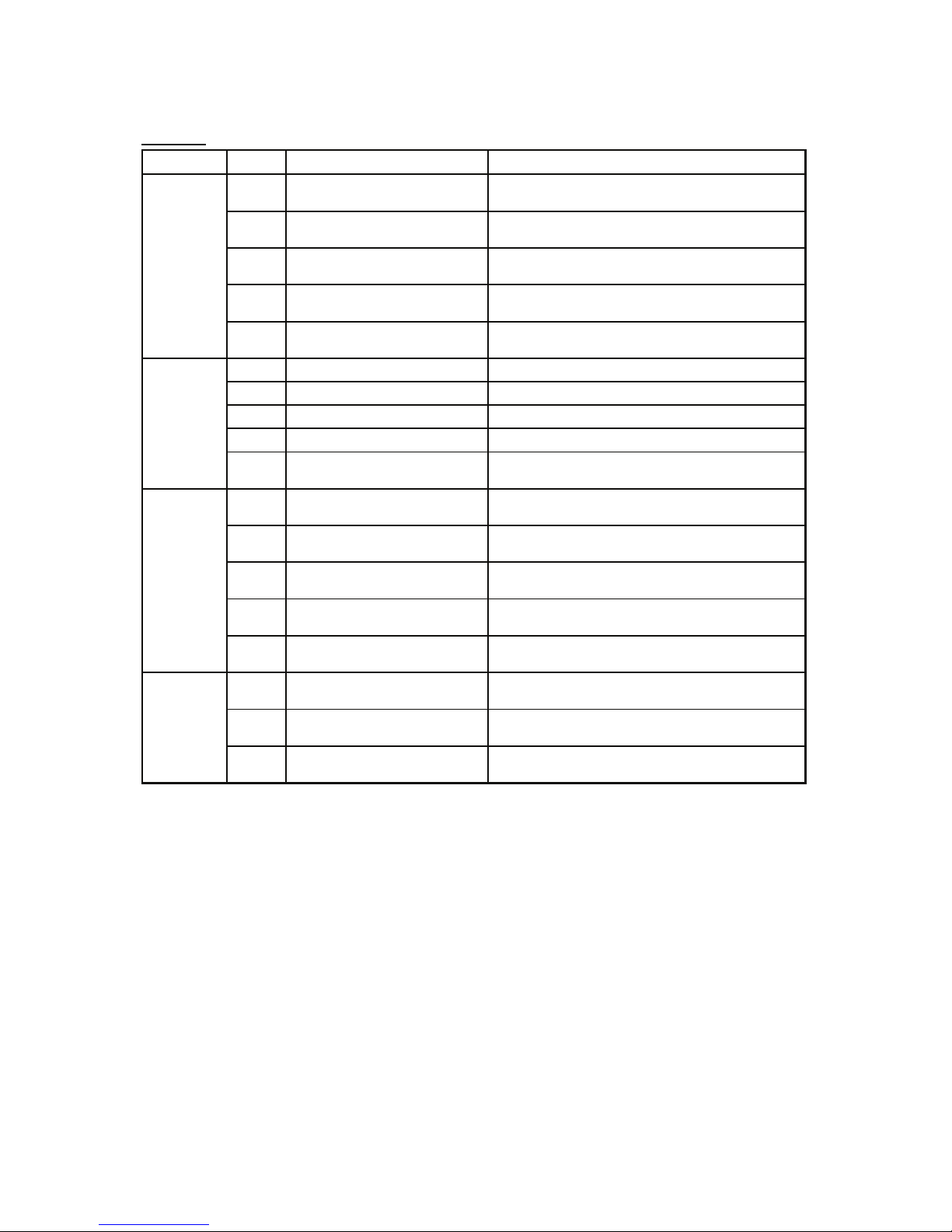

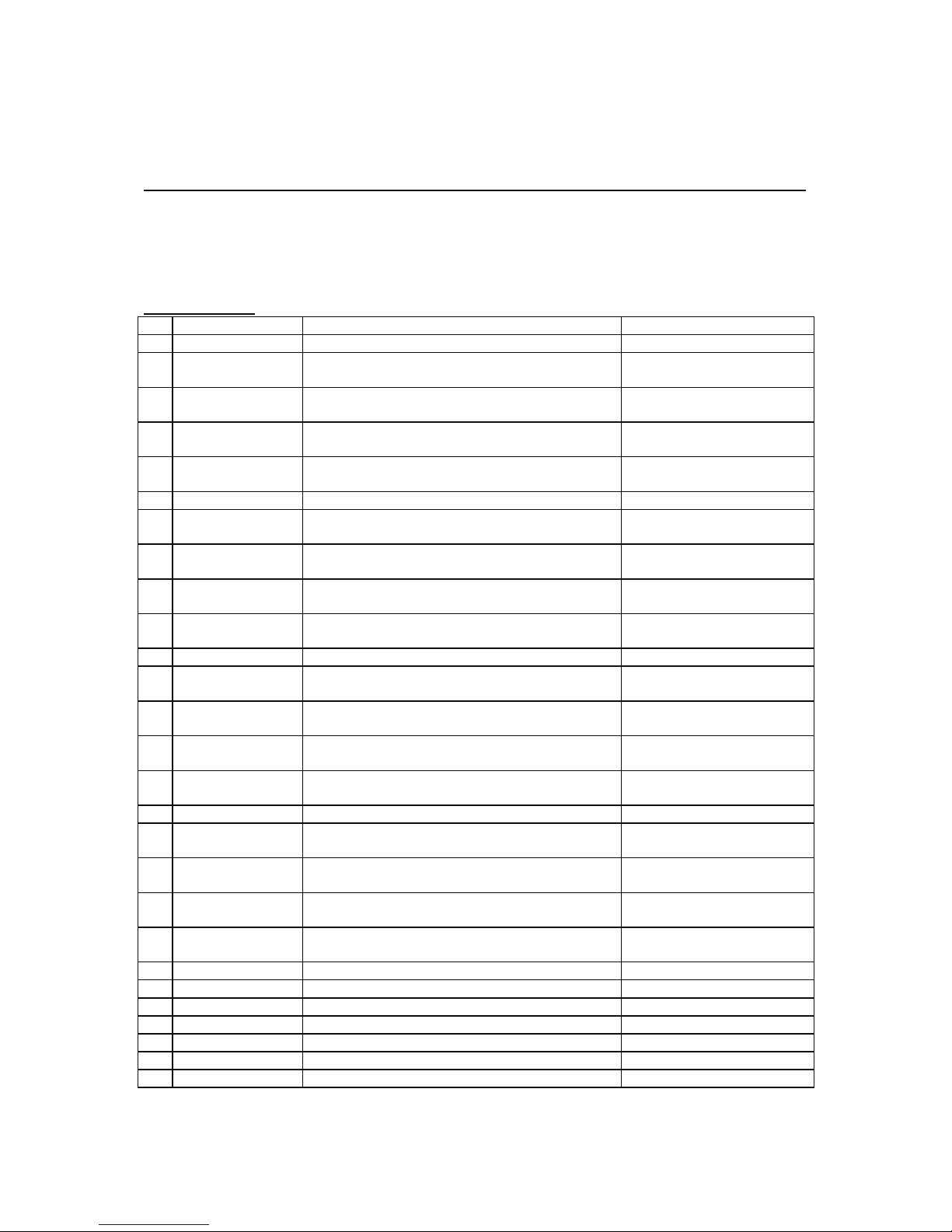

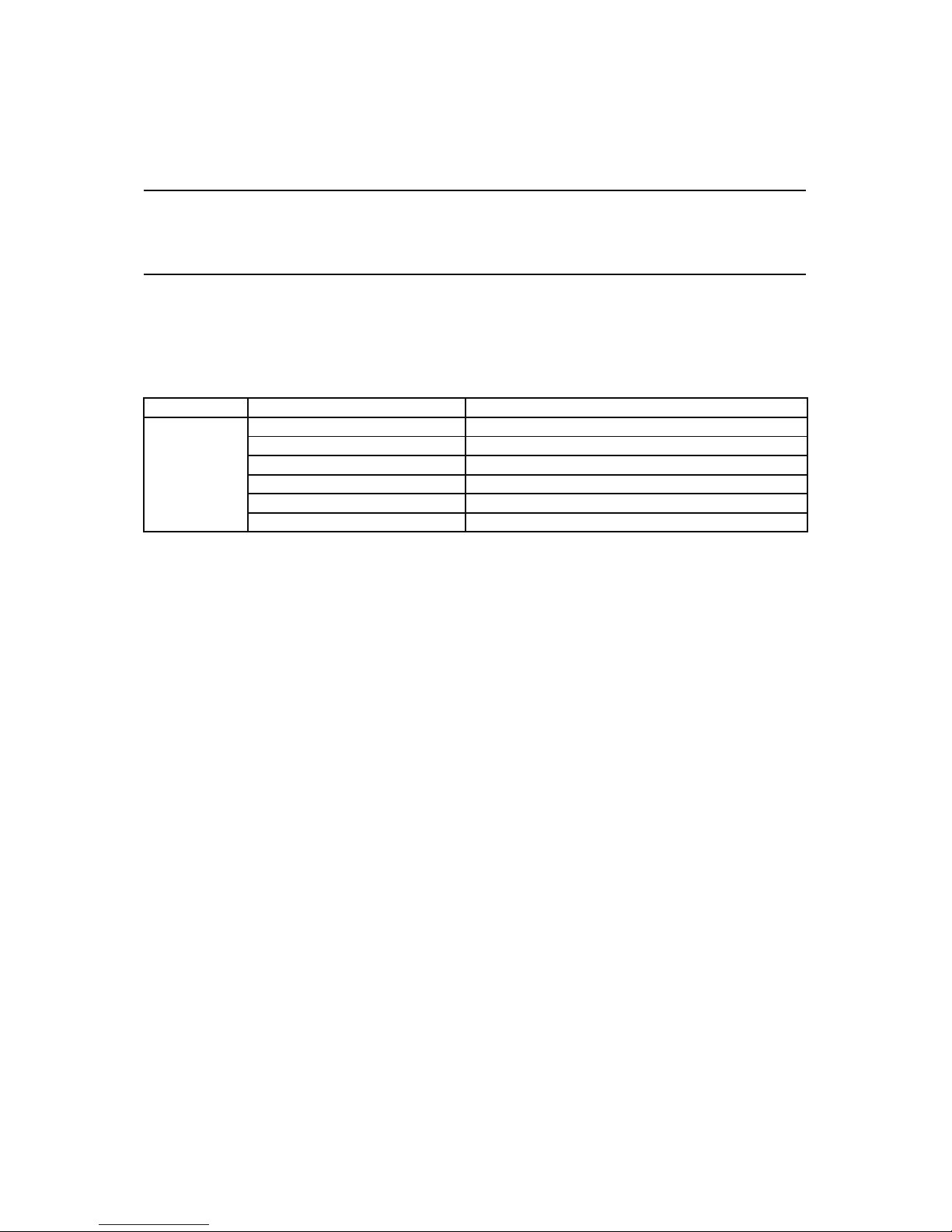

SYSTEM FLAG LIST

You can use the system flags as Boolean valuables. If conditions are met, “1” (true) is automatically

assigned to a system flag. If conditions are not met, “0” (false) is assigned. You can refer to the

assigned values whenever necessary.

JR2000N Series

No. Identifier Description Condition “1” (True)

01 #FisCOM1 COM1 receive data existence Exists

02 #FltCOM1

Result of COM1 receive data compare command

(cmpCOM)

Constant > Receive data

03 #FeqCOM1

Result of COM1 receive data compare command

(cmpCOM)

Constant = Receive data

04 #FgtCOM1

Result of COM1 receive data compare command

(cmpCOM)

Constant < Receive data

05 #FtimeOutCOM1

COM1 receive data compare command

(cmpCOM) timeout

Timeout

06 #FisCOM2 COM2 receive data existence Exists

07 #FltCOM2

Result of COM2 receive data compare command

(cmpCOM)

Constant > Receive data

08 #FeqCOM2

Result of COM2 receive data compare command

(cmpCOM)

Constant = Receive data

09 #FgtCOM2

Result of COM2 receive data compare command

(cmpCOM)

Constant < Receive data

10 #FtimeOutCOM2

COM2 receive data compare command

(cmpCOM) timeout

Timeout

11 #FisCOM3 COM3 receive data existence Exists

12 #FltCOM3

Result of COM3 receive data compare command

(cmpCOM)

Constant > Receive data

13 #FeqCOM3

Result of COM3 receive data compare command

(cmpCOM)

Constant = Receive data

14 #FgtCOM3

Result of COM3 receive data compare command

(cmpCOM)

Constant < Receive data

15 #FtimeOutCOM3

COM3 receive data compare command

(cmpCOM) timeout

Timeout

16 #FisCOM4 COM4 receive data existence Exists

17 #FltCOM4

Result of COM4 receive data compare command

(cmpCOM)

Constant > Receive data

18 #FeqCOM4

Result of COM4 receive data compare command

(cmpCOM)

Constant = Receive data

19 #FgtCOM4

Result of COM4 receive data compare command

(cmpCOM)

Constant < Receive data

20 #FtimeOutCOM4

COM4 receive data compare command

(cmpCOM) timeout

Timeout

30 #FinitMecError State of mechanical initialization command error Mechanical initialization error

31 #FcameraError State of camera data error Error

32 #FtakeZError State of Z height data (takeZWadj) error Error

33 #FlMoveOutRange Relative move command range Out of range

34 #FlMoveStop Condition stop state of relative move command Stopped by the stop condition

35 #FcheckPosError Result of the position error detect command Position error

36 #FdataInBCDError State of dataInBCD command error Error

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

15

No. Identifier Description Condition “1” (True)

60 #FstartSW Start switch ON (Pressed)

61 #FincSW Program number selection key (+) ON (Pressed)

62 #FdecSW Program number selection key (–) ON (Pressed)

63 #FemgSW EMG direct input

ON (The emergency stop

switch is pressed.)

64 #Fios I/O-S direct input Circuit open (Disconnected)

71 #Fsensor1 Initial X position sensor ON

72 #Fsensor2 Initial Y position sensor ON

73 #Fsensor3 Initial Z position sensor ON

74 #Fsensor4 Initial R position sensor ON

76 #Fdrvoz1 X driver 0-phase Close

77 #Fdrvoz2 Y driver 0-phase Close

78 #Fdrvoz3 Z driver 0-phase Close

79 #Fdrvoz4 R driver 0-phase Close

91 #FenableSW Enable switch ON (Pressed)

92 #FspmodeSW Special mode switch ON

93 #FspareSW Spare switch ON

94 #FmotorPower State of the power to the motor ON

JR4400N Series

No. Identifier Description Condition “1” (True)

01 #FisCOM1 COM1 receive data existence Exists

02 #FltCOM1

Result of COM1 receive data compare command

(cmpCOM)

Constant > Receive data

03 #FeqCOM1

Result of COM1 receive data compare command

(cmpCOM)

Constant = Receive data

04 #FgtCOM1

Result of COM1 receive data compare command

(cmpCOM)

Constant < Receive data

05 #FtimeOutCOM1

COM1 receive data compare command

(cmpCOM) timeout

Timeout

06 #FisCOM2 COM2 receive data existence Exists

07 #FltCOM2

Result of COM2 receive data compare command

(cmpCOM)

Constant > Receive data

08 #FeqCOM2

Result of COM2 receive data compare command

(cmpCOM)

Constant = Receive data

09 #FgtCOM2

Result of COM2 receive data compare command

(cmpCOM)

Constant < Receive data

10 #FtimeOutCOM2

COM2 receive data compare command

(cmpCOM) timeout

Timeout

11 #FisCOM3 COM3 receive data existence Exists

12 #FltCOM3

Result of COM3 receive data compare command

(cmpCOM)

Constant > Receive data

13 #FeqCOM3

Result of COM3 receive data compare command

(cmpCOM)

Constant = Receive data

14 #FgtCOM3

Result of COM3 receive data compare command

(cmpCOM)

Constant < Receive data

15 #FtimeOutCOM3

COM3 receive data compare command

(cmpCOM) timeout

Timeout

16 #FisCOM4 COM4 receive data existence Exists

17 #FltCOM4

Result of COM4 receive data compare command

(cmpCOM)

Constant > Receive data

18 #FeqCOM4

Result of COM4 receive data compare command

(cmpCOM)

Constant = Receive data

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

16

No. Identifier

Description Condition “1” (True)

19 #FgtCOM4

Result of COM4 receive data compare command

(cmpCOM)

Constant < Receive data

20 #FtimeOutCOM4

COM4 receive data compare command

(cmpCOM) timeout

Timeout

30 #FinitMecError State of mechanical initialization command error Mechanical initialization error

31 #FcameraError State of camera data error Error

32 #FtakeZError State of Z height data (takeZWadj) error Error

33 #FlMoveOutRange Relative move command range Out of range

34 #FlMoveStop Condition stop state of relative move command Stopped by the stop condition

35 #FcheckPosError Result of the position error detect command Position error

36 #FdataInBCDError State of dataInBCD command error Error

60 #FstartSW Start switch ON (Pressed)

61 #FincSW Program number selection key (+) ON (Pressed)

62 #FdecSW Program number selection key (–) ON (Pressed)

63 #FemgSW EMG direct input

ON (The emergency stop

switch is pressed.)

64 #Fios I/O-S direct input Circuit open (Disconnected)

66 #FmponSW Power ON switch ON (Pressed)

68 #FmdSW1 Select key switch 1 ON

69 #FmdSW2 Select key switch 2 ON

71 #Fsensor1 Initial X position sensor ON

72 #Fsensor2 Initial Y position sensor ON

73 #Fsensor3 Initial Z position sensor ON

74 #Fsensor4 Initial R position sensor ON

76 #Fdrvoz1 X driver 0-phase Close

77 #Fdrvoz2 Y driver 0-phase Close

78 #Fdrvoz3 Z driver 0-phase Close

79 #Fdrvoz4 R driver 0-phase Close

91 #FenableSW Enable switch ON (Pressed)

92 #FspmodeSW Special mode switch ON

93 #FspareSW Spare switch ON

94 #FmotorPower State of the power to the motor ON

JS Series and JSG Series

No. Identifier Description Condition “1” (True)

01 #FisCOM1 COM1 receive data existence Exists

02 #FltCOM1

Result of COM1 receive data compare command

(cmpCOM)

Constant > Receive data

03 #FeqCOM1

Result of COM1 receive data compare command

(cmpCOM)

Constant = Receive data

04 #FgtCOM1

Result of COM1 receive data compare command

(cmpCOM)

Constant < Receive data

05 #FtimeOutCOM1

COM1 receive data compare command

(cmpCOM) timeout

Timeout

06 #FisCOM2 COM2 receive data existence Exists

07 #FltCOM2

Result of COM2 receive data compare command

(cmpCOM)

Constant > Receive data

08 #FeqCOM2

Result of COM2 receive data compare command

(cmpCOM)

Constant = Receive data

09 #FgtCOM2

Result of COM2 receive data compare command

(cmpCOM)

Constant < Receive data

10 #FtimeOutCOM2

COM2 receive data compare command

(cmpCOM) timeout

Timeout

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

17

No. Identifier Description Condition “1” (True)

11 #FisCOM3 COM3 receive data existence Exists

12 #FltCOM3

Result of COM3 receive data compare command

(cmpCOM)

Constant > Receive data

13 #FeqCOM3

Result of COM3 receive data compare command

(cmpCOM)

Constant = Receive data

14 #FgtCOM3

Result of COM3 receive data compare command

(cmpCOM)

Constant < Receive data

15 #FtimeOutCOM3

COM3 receive data compare command

(cmpCOM) timeout

Timeout

16 #FisCOM4 COM4 receive data existence Exists

17 #FltCOM4

Result of COM4 receive data compare command

(cmpCOM)

Constant > Receive data

18 #FeqCOM4

Result of COM4 receive data compare command

(cmpCOM)

Constant = Receive data

19 #FgtCOM4

Result of COM4 receive data compare command

(cmpCOM)

Constant < Receive data

20 #FtimeOutCOM4

COM4 receive data compare command

(cmpCOM) timeout

Timeout

30 #FinitMecError State of mechanical initialization command error Mechanical initialization error

31 #FcameraError State of camera data error Error

32 #FtakeZError State of Z height data (takeZWadj) error Error

33 #FlMoveOutRange Relative move command range Out of range

34 #FlMoveStop Condition stop state of relative move command Stopped by the stop condition

35 #FcheckPosError Result of the position error detect command Position error

36 #FdataInBCDError State of dataInBCD command error Error

63 #FemgSW EMG direct input ON (Pressed)

64 #Fios IOS direct input Circuit open (Disconnected)

66 #FmponSW Power ON switch ON (Pressed)

68 #FmdSW1 Select key switch 1 ON

69 #FmdSW2 Select key switch 2 ON

91 #FenableSW Enable switch ON (Pressed)

92 #FspmodeSW Special mode switch ON

93 #FspareSW Spare switch ON

94 #FmotorPower Motor power state ON

121 #FsvReady1 J1/X servo ready Ready

122 #FsvReady2 J2/Y servo ready Ready

123 #FsvReady3 J3/Z servo ready Ready

124 #FsvReady4 J4/R servo ready Ready

126 #FsvAlarm1 J1/X servo alarm Servodriver error

127 #FsvAlarm2 J2/Y servo alarm Servodriver error

128 #FsvAlarm3 J3/Z servo alarm Servodriver error

129 #FsvAlarm4 J4/R servo alarm Servodriver error

131 #FsvPos1 J1/X servo finish positioning Positioning finished

132 #FsvPos2 J2/Y servo finish positioning Positioning finished

133 #FsvPos3 J3/Z servo finish positioning Positioning finished

134 #FsvPos4 J4/R servo finish positioning Positioning finished

136 #FencOz1 J1/X encoder zero phase

Close

137 #FencOz2 J2/Y encoder zero phase

Close

138 #FencOz3 J3/Z encoder zero phase

Close

139 #FencOz4 J4/R encoder zero phase

Close

141 #FencBattery1 J1/X battery warning Battery run out

142 #FencBattery2 J2/Y battery warning Battery run out

143 #FencBattery3 J3/Z battery warning Battery run out

144 #FencBattery4 J4/R battery warning Battery run out

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

18

VARIABLES

Free Variables: #mv, #mkv, #nv, #nkv, #sv, #skv

A variable is a container into which numeric and strings values are placed.

You can use the built-in variables listed below freely. Variable declaration is unnecessary when using

these variables.

Identifier Description

#mv (1 – 99) Boolean variable

#mkv (1 – 99) Boolean variable (Keeping variable)*

#nv (1 – 99) Numerical variable

#nkv (1 – 99) Numerical variable (Keeping variable)*

#sv (1 – 99) String variable

Free Variable

#skv (1 – 99) String variable (Keeping variable)*

*: Variables which hold their values even if the robot is turned off are collectively referred to as

keeping variables in the operation manuals.

#mv (1 – 99) and #mkv (1 – 99): Boolean variable

A Boolean variable is a variable that can hold a value of 1-bit 0 or 1. It can be used as a condition

operation expression (ld, ldi) or assignment expression (let) parameter.

z Boolean type free variables, #mv (1 – 99) and #mv (1 – 99), can also be used in sequencer

programs

#nv (1 – 99) and #nkv (1 – 99): Numeric variable

These are double type numeric variables that can be used as assignment expression (let) parameters.

#sv (1 – 99) and #skv (1 – 99): String variable

These can hold up to 255 bytes. When used as assignment expression (let) parameters, assignment

by = and connection by & are possible.

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

19

Input Variables: #sysIn1..., #genIn1..., #handIn1...

An input variable is a Boolean variable that can only be referred to. You cannot enter a value into it.

It corresponds to the I/O-SYS, I/O-1, and I/O-H input pins. When an ON signal comes, the input

variable becomes “1” (true).

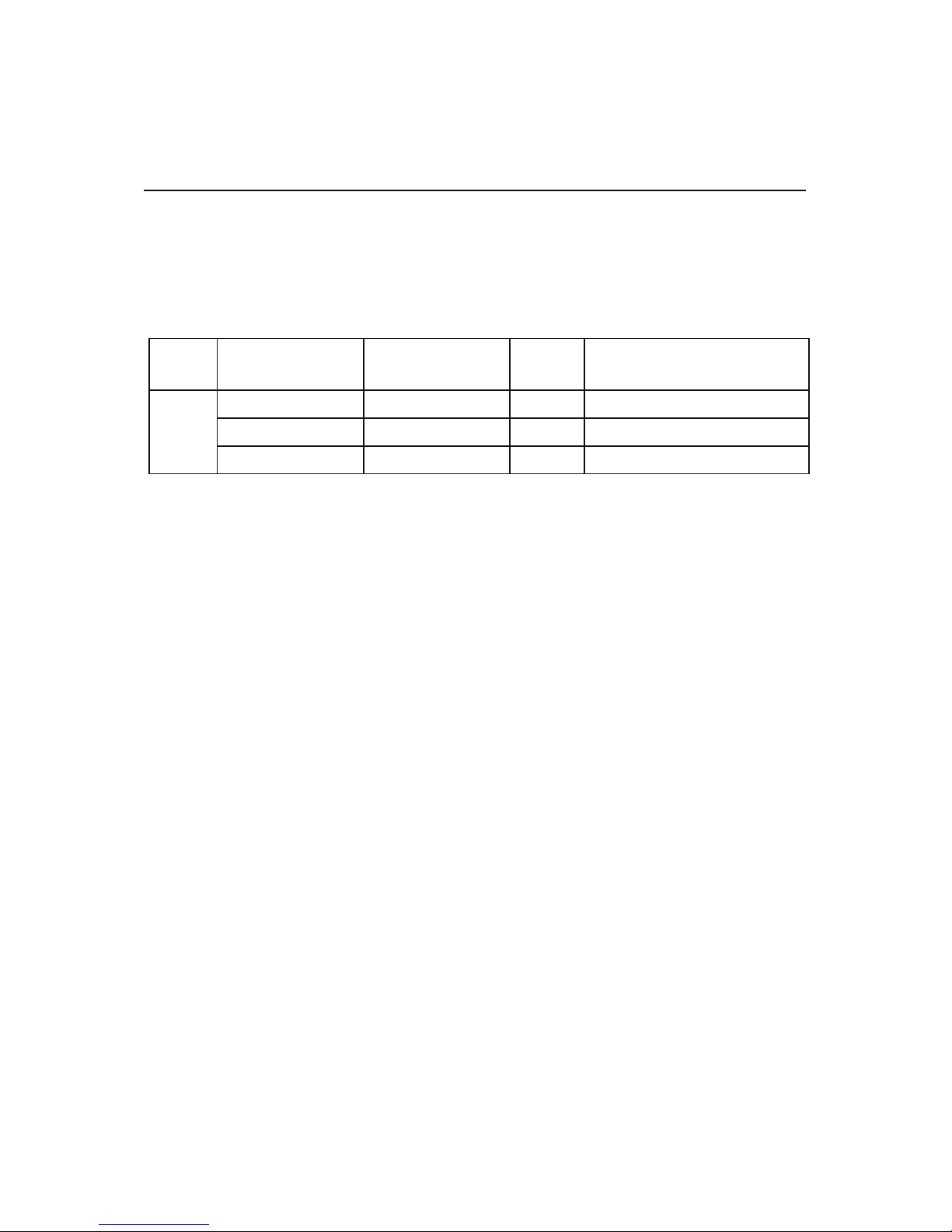

Category

Identifier

(JS and JSG Series)

Identifier

(JR2000N and

JSR4400N Series)

Connector Description

#sysIn1 – #sysIn15 #sysIn1 – #sysIn16 I/O-SYS Boolean variable for reference only

#genIn1 – #genIn18 #genIn1 – #genIn8 I/O-1 Boolean variable for reference only

Input

Variable

#handIn1 – #handIn4

-

I/O-H Boolean variable for reference only

Some of the #sysIn1 – #sysIn15, and 16 (I/O-SYS) pins have pre-assigned functions.

e.g. #sysIn1: Start (When this signal is turned on, the robot starts operation.)

If you wish to use

the #sysIn1 – #sysIn15, and 16 (I/O-SYS) pins for functions other than the

pre-assigned ones, switch the function to [Free] in the [IO-SYS Function Assignment] settings ([Run

Mode Parameter] menu).

z The JSG, JR2000N, and JSR4400N Series are not equipped with I/O-H. Identifiers #handIn1 –

#handIn4 are activated for the JS Series only. Note that if you are using I/O-U (option) for the JS

Series, any commands from the robot to I/O-H are deactivated.

z For details of the I/O-SYS pre-assigned functions, see the External Control I (I/O-SYS) operation

manual.

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

20

Output Variables: #sysOut1..., #genOut1..., #handOut1...

An output variable is a Boolean variable.

Output variables correspond to the I/O-SYS, I/O-1, and I/O-H output pins. When an ON signal is

output, the output variables become “1” (true).

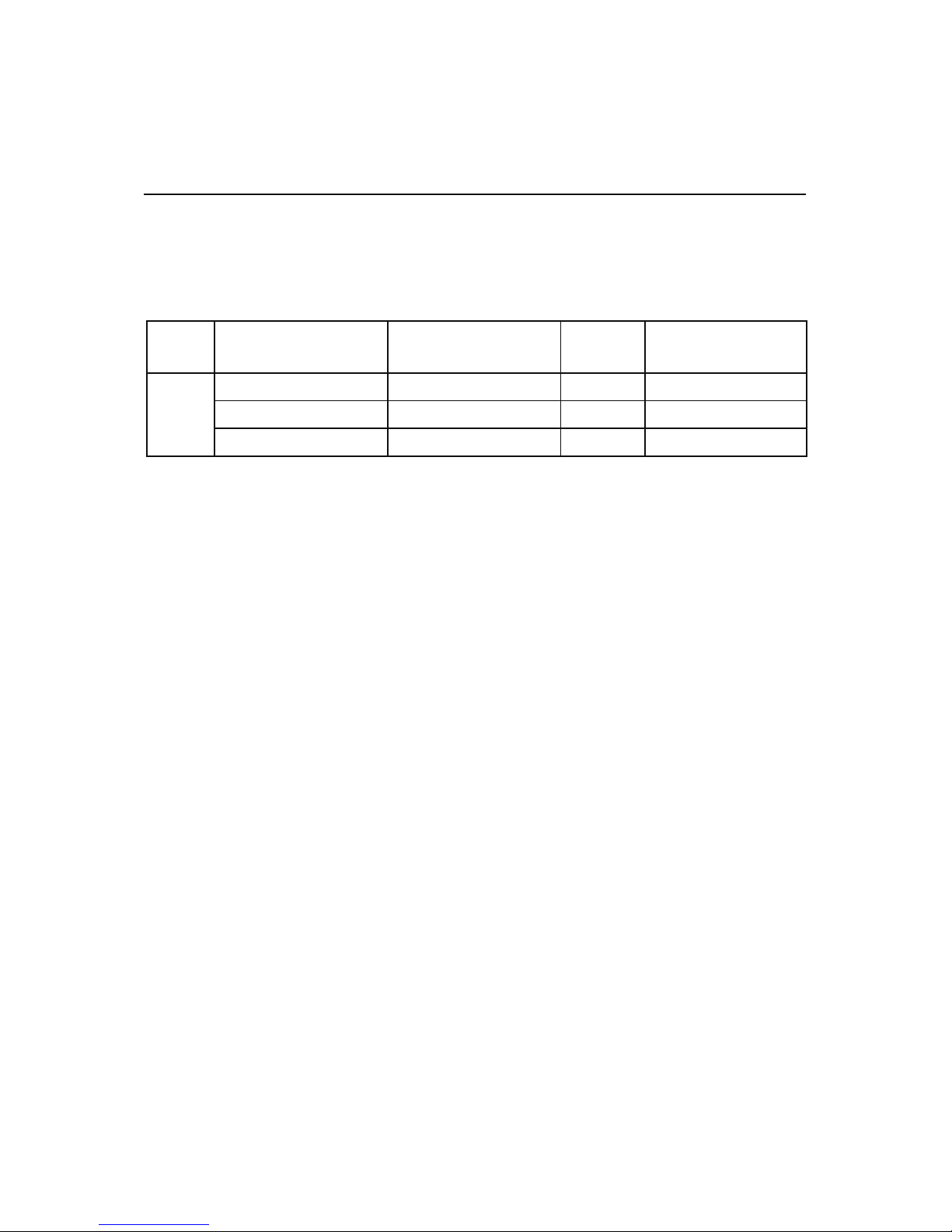

Category

Identifier

(JS and JSG Series)

Identifier

(JR2000N and

JSR4400N Series)

Connector Description

#sysOut1 – #sysOut14 #sysOut1 – #sysOut16 I/O-SYS Boolean variable

#genOut1 – #genOut18 #genOut1 – #genOut8 I/O-1 Boolean variable

Output

Variable

#handOut1 – #handOut4

-

I/O-H Boolean variable

Some of the #sysOut1 – #sysOut14, 15 and 16 (I/O-SYS) pins have pre-assigned functions.

e.g. #sysIn1: Ready for Start (When this signal is turned on, the robot can start operation.)

If you wish to use

the #sysOut1 – #sysOut14, 15 and 16 (I/O-SYS) pins for functions other than the

pre-assigned ones, switch the function to [Free] in [IO-SYS Function Assignment] settings ([Run Mode

Parameter] menu).

z The JSG, JR2000N, and JSR4400N Series are not equipped with I/O-H. Identifiers #handOut1 –

#handOut4 are activated for the JS Series only. Note that if you are using I/O-U (option) for the JS

Series, any commands from the robot to I/O-H are deactivated.

z For details of the I/O-SYS pre-assigned functions, see the External Control I (I/O-SYS) operation

manual.

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

21

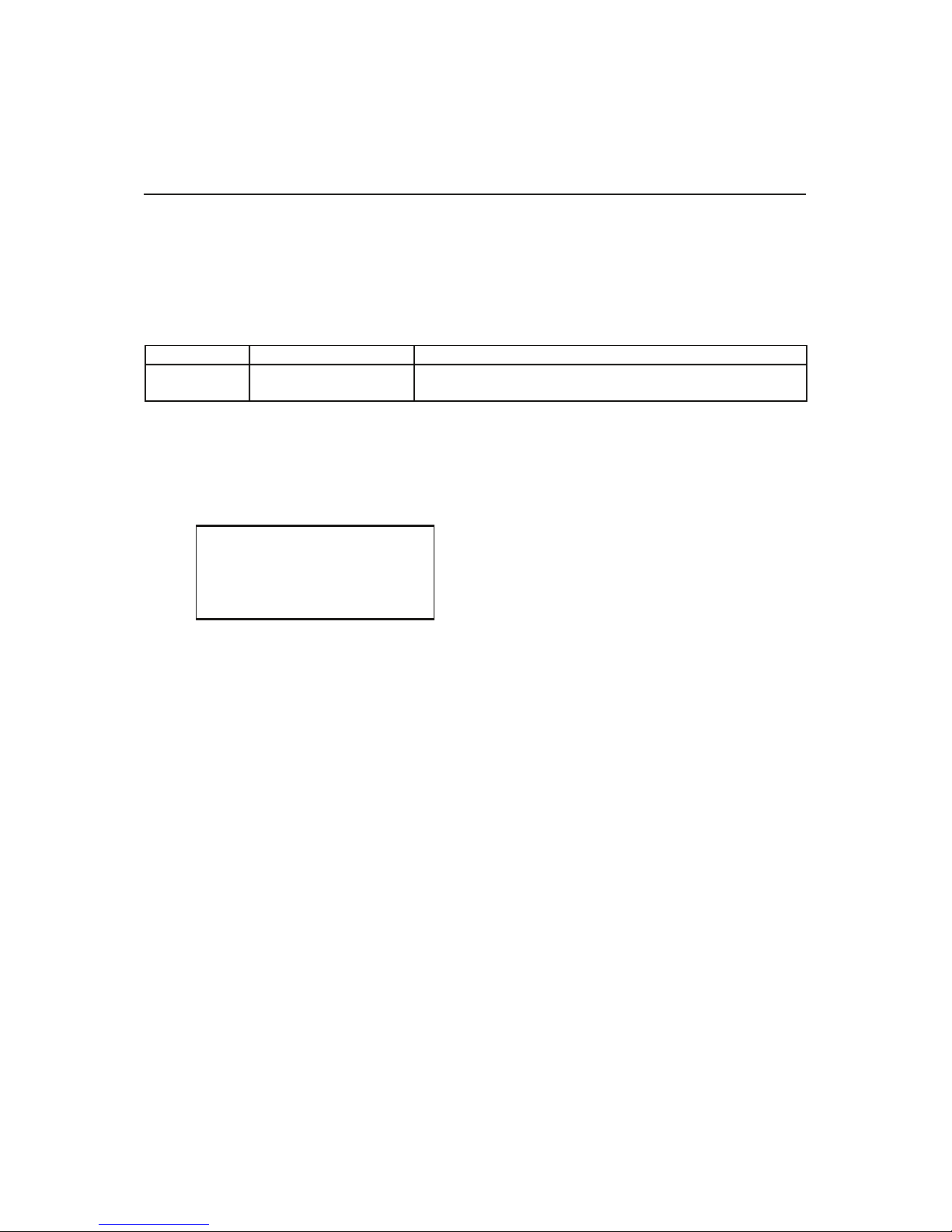

Down Timer: #downTimer1 – #downTimer10

A numeric variable: The assigned value (using a let command) is decreased automatically (by msec).

You can assign another value during the countdown.

The maximum value that can be assigned is 2,147,483,647 (msec).

Category Identifier Description

Special

Vari able

#downTimer1 –

#downTimer 10

The assigned value is decreased automatically (by msec).

For example, create the following point job data and set it to a point as [Job while CP Moving]. The

hexadecimal CR code is output to COM2 every 0.5 seconds while it moves in the CP drive.

if

ld #downTimer1 == 0

then

eoutCOM port2,"%0D"

#downTimer1 = 500

If

#downTimer1=0

Then

Output a hexadecimal code CR from COM2 and

assign 500 (0.5sec) to #downTimer1.

z In this case, you need to assign a value to #downTimer1 in advance (e.g. during a point job).

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

22

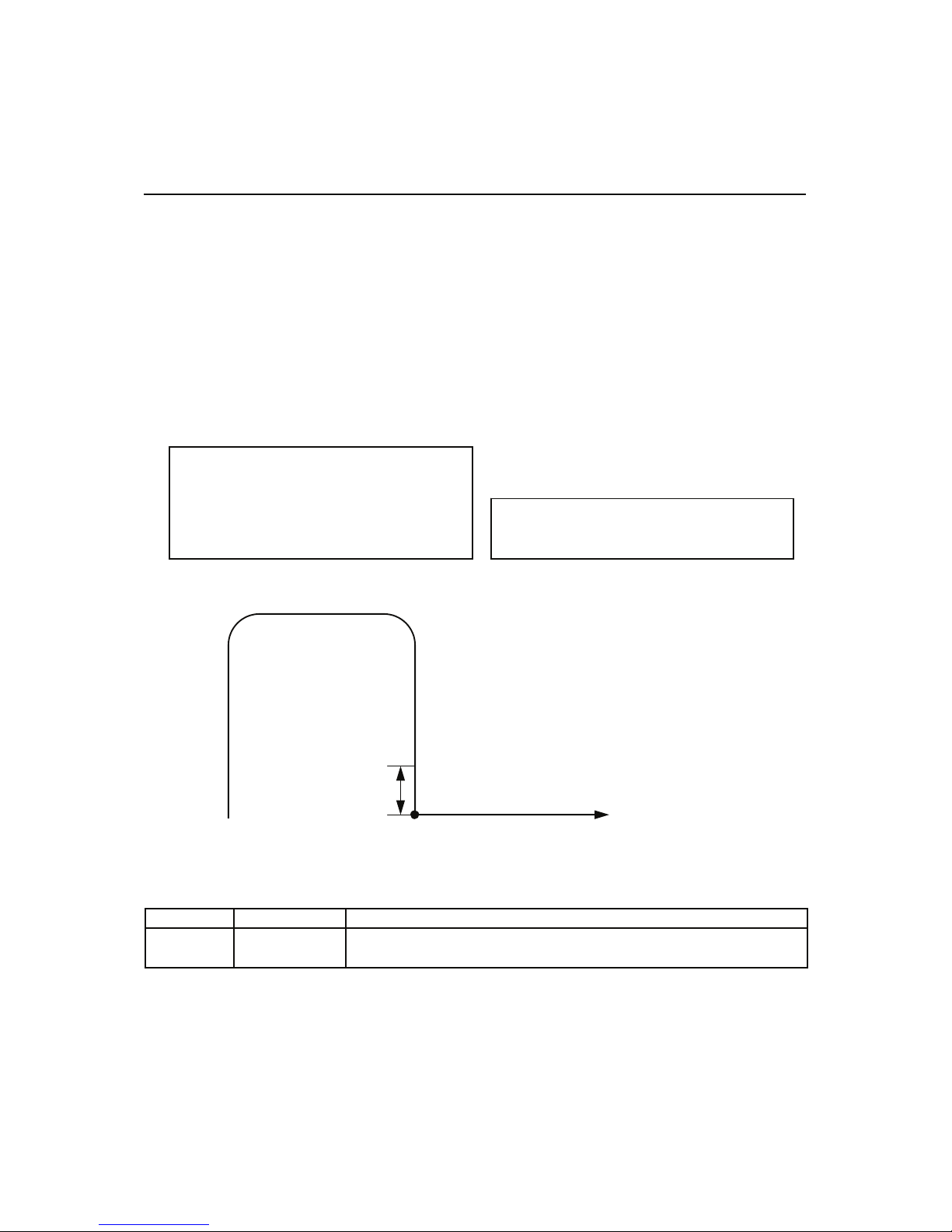

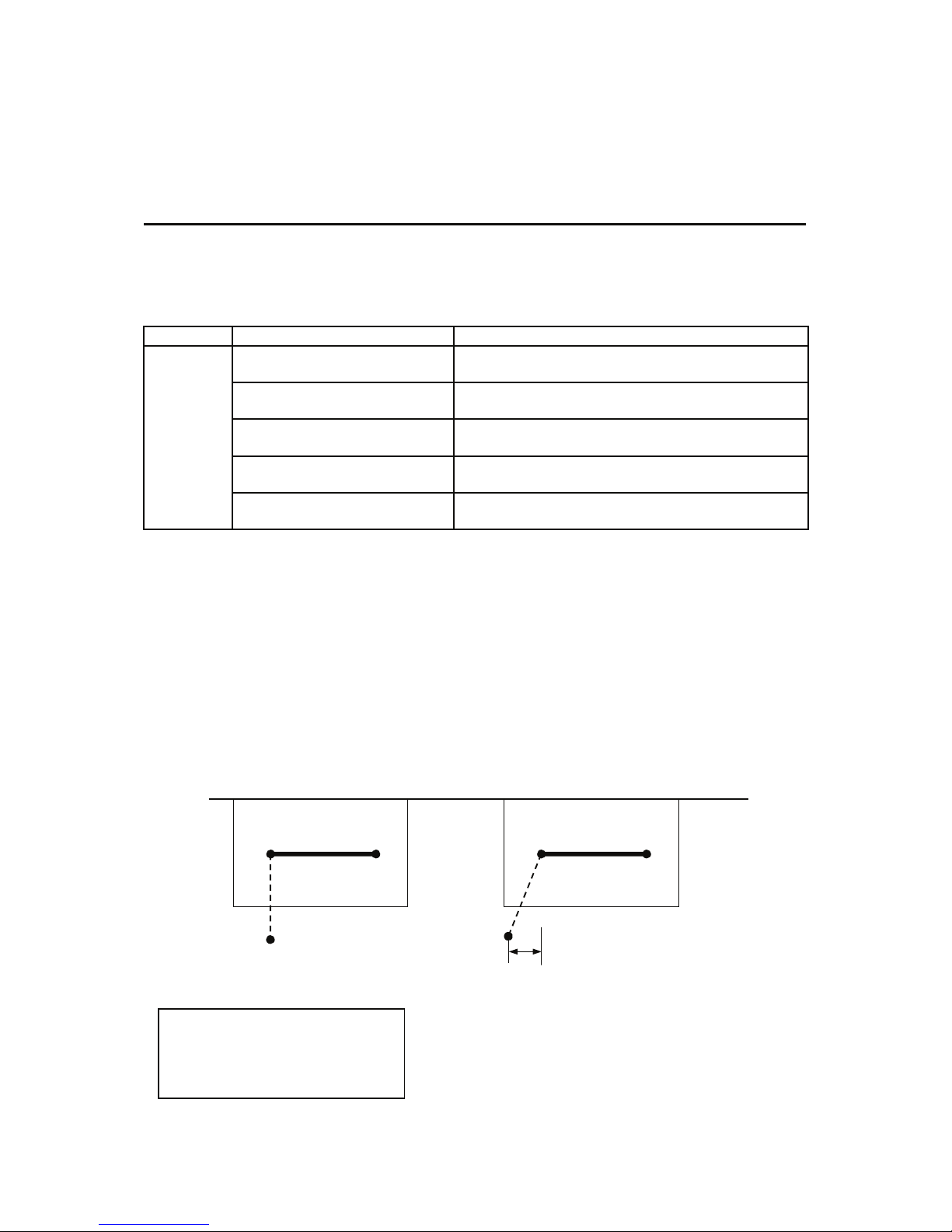

Point Job Start Height: #jobStartHight

When a value is assigned to the variable “#jobStartHight” (using a let command) and the variable is

set as [Job before Moving] or [Job while Moving], the point job starts from a position that is higher than

the set Z-coordinate by the assigned value.

Do not set point job data that includes #jobStartHight as the [Point Job] because the robot Axis or Arm

has already reached the point job start position. Also, since this variable acts only on the set point, the

point job start position of the next point does not change.

e.g.

Category Identifier Description

Special

Vari able

#jobStartHight

The point job is started from a position that is higher than the set Z

coordinate by the assigned value. (Deactivated during the CP drive)

[Point Job] (Point Job Data 12) is started from a

position 2.5mm higher than the preset height.

2.5mm

P1

P01

Type: CP Start Point

Job before Moving: Point Job Data 3

Point Job: Point Job Data 12

#jobStartHight 25

Point Job Data 3

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

23

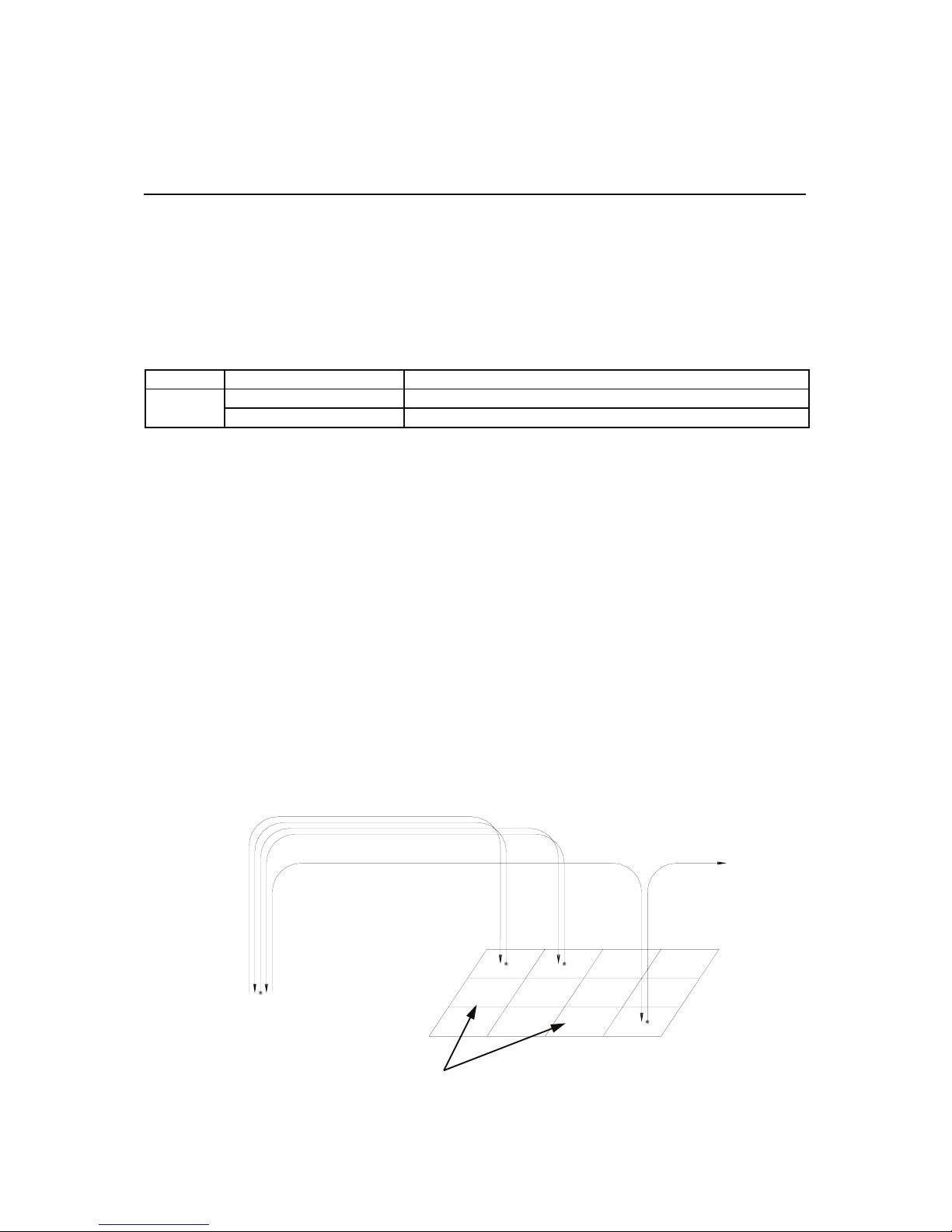

Pallet: #palletFlag (1 – 100), #palletCount (1 – 100)

#palletCount (1 – 100) is a numeric variable and #palletFlag (1 – 100) is a Boolean variable.

Each variable retains the value of the corresponding pallet counter and pallet flag (1 (true) when the

pallet counter is full) in additional function data [Pallet Routine].

By using these variables, you can move to the next point during a pallet job or skip the designated

pallet.

Category Identifier Description

#palletFlag (1 – 100) Pallet flag (Corresponds to Pallet 1 – 100.)

Pallet

#palletCount (1 – 100) Pallet counter (Corresponds to Pallet 1 – 100.)

z #palletFlag (1 – 100) does not become “1” (true) even if a value which fills the counter is assigned

to #palletCount (1 – 100).

For example, you can skip a designated pallet during a pallet job.

The robot picks up a workpiece at P1, places it on a pallet (set at P2) and moves to the next point (P3) when

the pallet becomes full. However, there are two points (P2-5 and P2-11) on the pallet where a workpiece is

not placed.

In this example, the [Pallet Routine Number] is [3] and the tool unit is connected according to the

following settings:

Picking up a workpiece: #handOut1 is ON.

Placing a workpiece: #handOut1 is OFF.

Points where a workpiece is not placed

P2-1(P0) P2-2

P1

To P 3

P2-12

●

●

P2-5

P2-11

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

24

Point job data set to P1

set #handOut1

Pick up workpiece.

Point job data set to P2

if

ld #palletCount(3) == 5

or #palletCount(3) == 11

else

reset #handOut1

endIf

loopPallet 3,1

If

#palletCount (3) is

other than 5 (P2-5) and 11 (P2-11),

Place (release) a workpiece.

Add 1 to the counter of Pallet 3.

If the counter reaches maximum, go to the next

command. (In this example, the point job is over

because there are no more commands.)

If not, shift to Point 01 (P1).

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

25

Workpiece Adjustment: #workAdj_X, #workAdj_Y,

#workAdj_Z, #workAdj_R, #workAdj_Rotation

These numeric variables hold the adjustment amount and rotation adjustment amount of each Axis in

additional function data [Workpiece Adjustment].

Category Identifier Description

#workAdj_X (1 – 100)

Workpiece adjustment amount in the X direction

(Corresponds to Workpiece Adjustment 1 – 100.)

#workAdj_Y (1 – 100)

Workpiece adjustment amount in the Y direction

(Corresponds to Workpiece Adjustment 1 – 100.)

#workAdj_Z (1 – 100)

Workpiece adjustment amount in the Z direction

(Corresponds to Workpiece Adjustment 1 – 100.)

#workAdj_R (1 – 100)

Workpiece adjustment amount in the R direction

(Corresponds to Workpiece Adjustment 1 – 100.)

Workpiece

Adjustment

#workAdj_Rotation (1 – 100)

Workpiece adjustment amount by the rotating angle

(Corresponds to Workpiece Adjustment 1 – 100.)

For example, you can perform a line dispensing between P2 – P3.

At P1, the workpiece adjustment amount (workpiece offset value) is received from the sensor connected to

COM.

In this example, the [Workpiece Adjustment] is [6] and the tool unit is connected according to the

following settings:

Starting dispensing: #handOut1 is ON.

Stopping dispensing: #handOut1 is OFF.

Point job data set to P1

declare str hosei

inCom hosei,port1,10

#workAdj_X(6) = hosei

Declaration of a string type local variable hosei

Receive a work adjustment amount from COM1 to hosei.

Assign the value in hosei to #workAdj_X(6).

(#workAdj_X(6) is the X direction adjustment amount of

Workpiece Adjustment 6)

CP Start Point

P3

CP End Point

P1

CP Start Point

P3

CP End Point

P1

Workpiece adjustment amount

Features II JS/JSR4400N SCARA Robot

JSG GANTRY Robot

JR2000N Desktop Robot

26

Point job data set in P2 ([Workpiece Adjustment] is set to this point.)

set #handOut1

Start dispensing.

Point job data set in P3

reset #handOut1

Stop dispensing.

z The [Workpiece Adjustment] set to a [CP Start Point] point is activated until the tool unit reaches a

[CP End Point] point.

Loading...

Loading...