DISHWASHER JACKSON

Place this chapter in the Small Equipment/

Miscellaneous section of the Equipment Manual.

MANUFACTURED

EXCLUSIVELY FOR

MCDONALD'S®

BY

JACKSON PRODUCTS CO.

P.O. BOX 140

LEXINGTON, TN 38351

PHONE: 1 (901) 968-5753

TOLL FREE: 1 (800) 736-8144

MODEL M-24BF

TABLE OF CONTENTS

PARTS IDENTIFICATION/FUNCTION ...........………………………………………………............................ Page 2

OPERATING INSTRUCTIONS ...............................................…………………………………………………. Page 9

EQUIPMENT SET -UP AND CLOSE PROCEDURES..............................…………………………………….. Page 9

TROUBLESHOOTING ...................................................………………………………………………… …..... Page 11

PARTS ORDERING/SERVICE INFORMATION..................................………………………………………… Page 13

NON-SCHEDULED MAINTENANCE......................................………………………………………………..... Page 14

WARRANTY

Jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship,

under normal use and operation for a period of (1) year from the date of purchase, but in no event to exceed 18

months from date of shipment from factory.

Jackson agrees under this warranty to repair or replace, at its discretion, any original part which proves to be

defective under normal use due to faulty material or workmanship, providing the machine has been unaltered,

and has been properly installed, maintained and operated in accordance with factory instruction manual. The

labor required to repair or replace such defective parts will be paid by Jackson, provided that the labor is

performed by a Jackson Authorized Service Agency.

There are no warranties, expressed or implied, including for fitness or merchantability, that are not set forth

herein, or that extend beyond the duration hereof. Under no circumstances will Jackson be liable for any loss or

damage, direct or consequential, or for damages in the nature of penalties, arising out of the use or inability to

any of its products.

This manual is for the exclusive use of licensees and employees of McDonald's Systems, Inc.

©1992 McDonald's Corporation Printed in July

All Rights Reserved EM MISC 36

PARTS IDENTIFICATION/FUNCTION

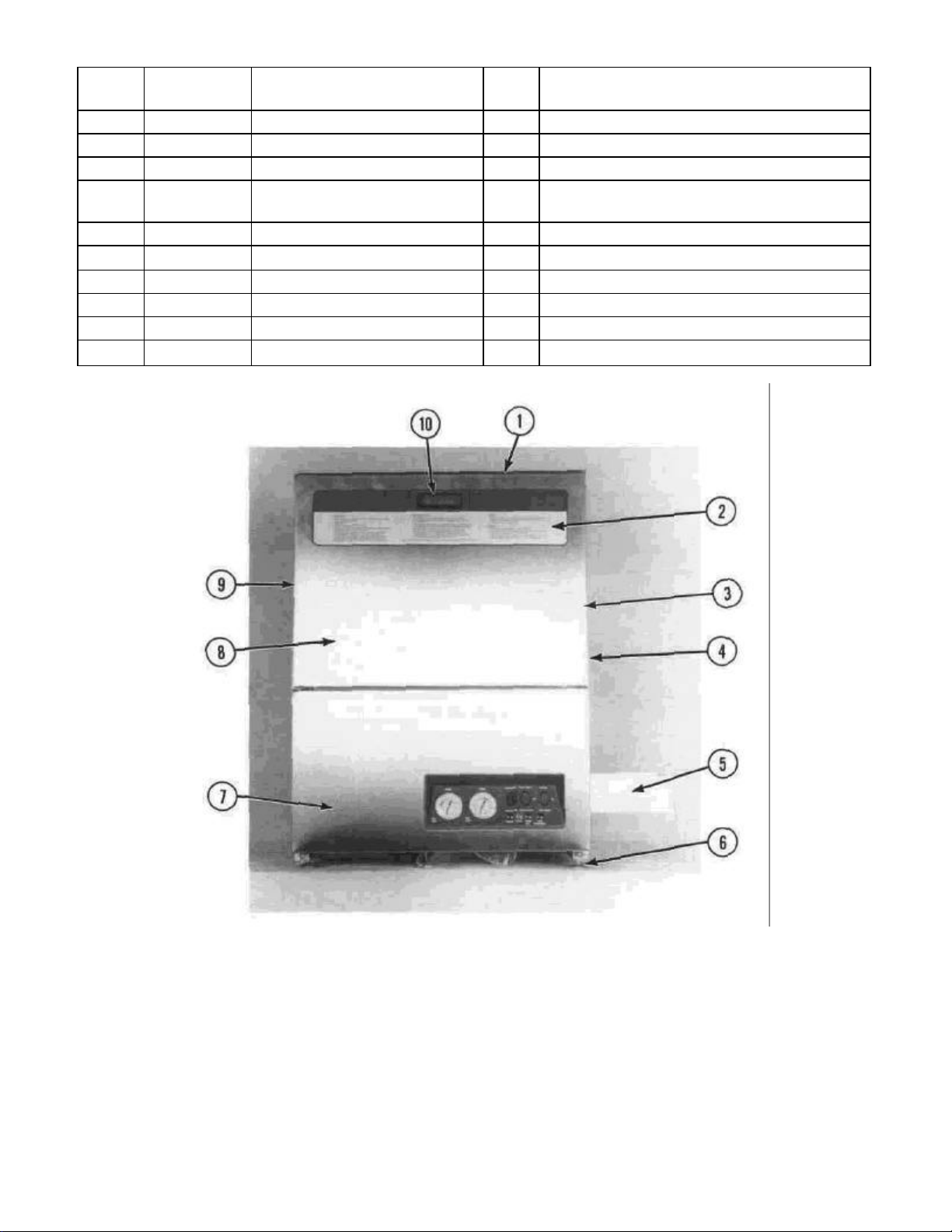

ITEM PART NO. DESCRIPTION QTY. FUNCTION

1 0413838 Top Panel 1 Covers top of dishwasher.

2 0313942 Operations Decal 1 Operating instructions.

3 0013808 Right Side Panel 1 Covers right side of unit.

4 0213941 Electrical Data Plate 1

5 0113928 Bottle Holder 1 Holds detergent bottle.

6 0114207 Leveling Feet 4 Adjusted to level machine.

7 0113944 Lower Kick Panel 1 Covers electrical components.

8 0013915 Door Assembly 1 Encloses washing cabinet.

9 0013837 Left Side Panel 1 Covers left side of unit.

10 0213918 Door Handle 1 Grasped to close door.

Shows machine electrical specifications and

machine serial number.

2

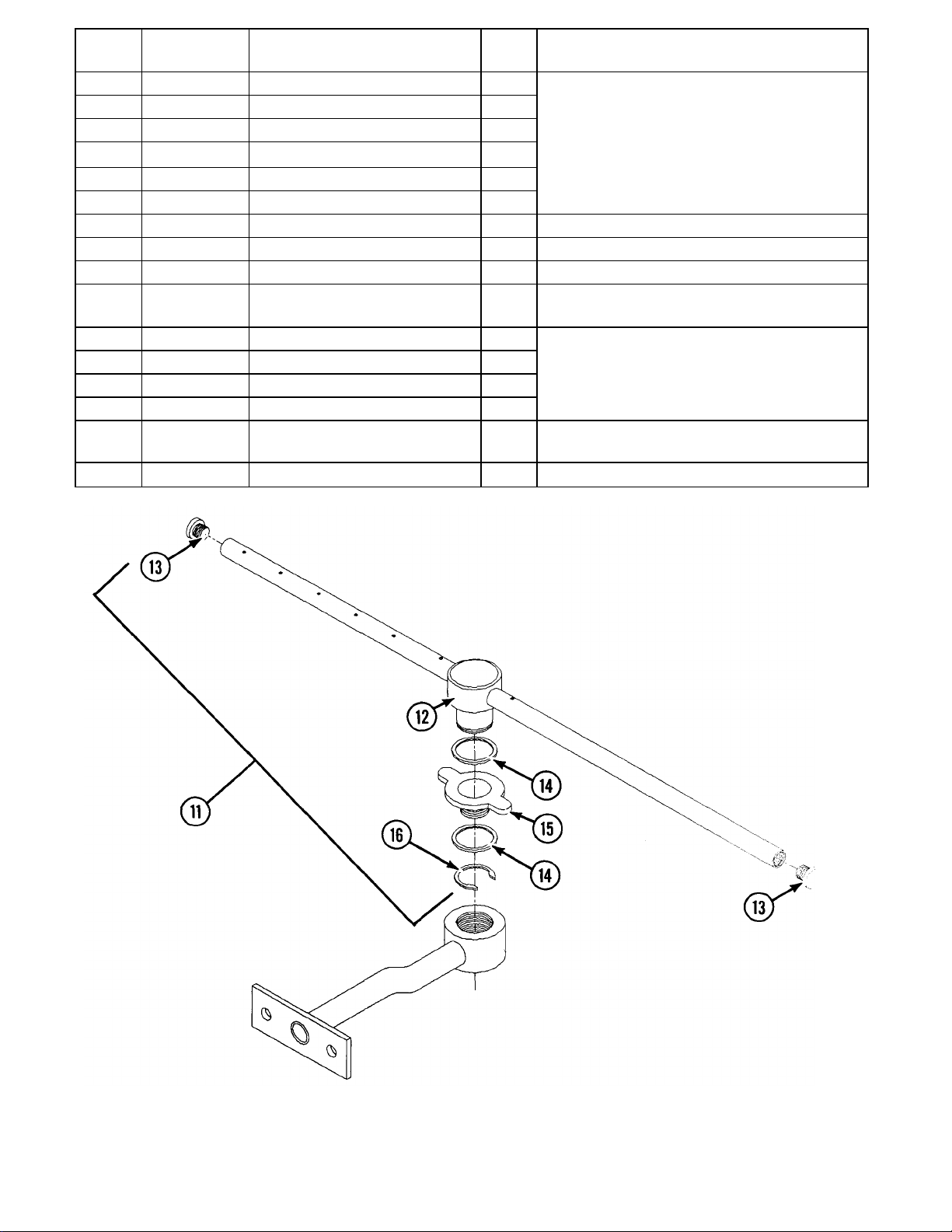

ITEM PART NO. DESCRIPTION QTY. FUNCTION

11 0313921 Upper Rinse Arm Assembly 2

12 0313850 Rinse Arm 1

13 6090400 End Plug 2

14 2001900 Plastic Washer 2

15 0213384 Bushing 1

16 1120111 Retaining Ring 1

17 3033800 Door Switch & Bracket 1 Starts dishwashing cycle.

18 0013815 Front Door Frame 1 Covers top & sides of door.

19 0313788 Right Side Rack Rail 1 Holds rack in washing area.

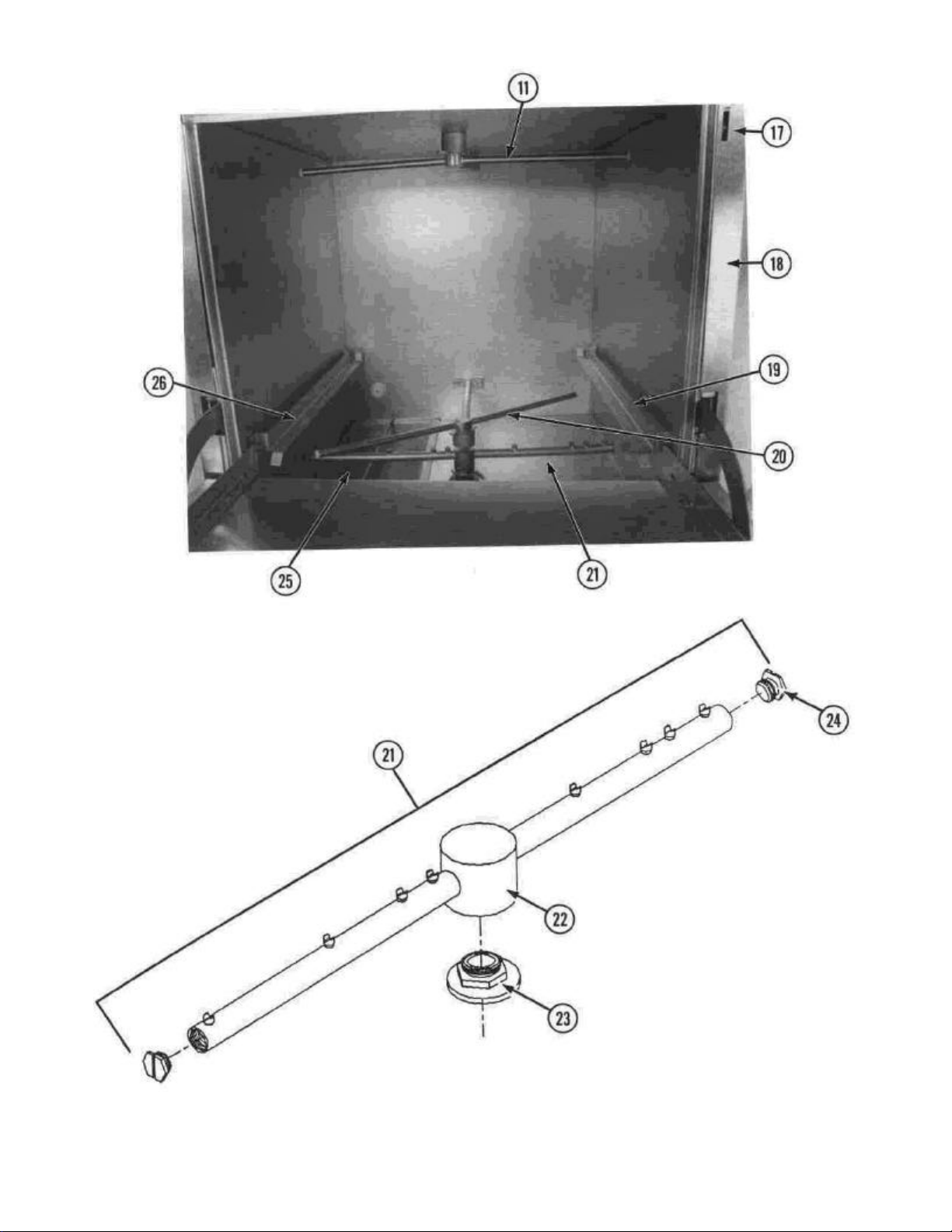

20 0313921 Lower Rinse Arm Assembly 1 Sprays hot water during rinse from the bottom.

21 0213923 Wash Arm Assembly 1

22 0213922 Wash Arm 1

23 0213597 Bearing Assembly 1

24 0113430 End Plug 2

25 0313538 Basket Strainer 1 Filters large food particles from pump system.

26 0313789 Left Side Rack Rail 1 Holds rack in washing area.

Sprays hot water during rinse from the top.

Sprays hot water to provide washing action to

fully clean ware/utensils.

3

4

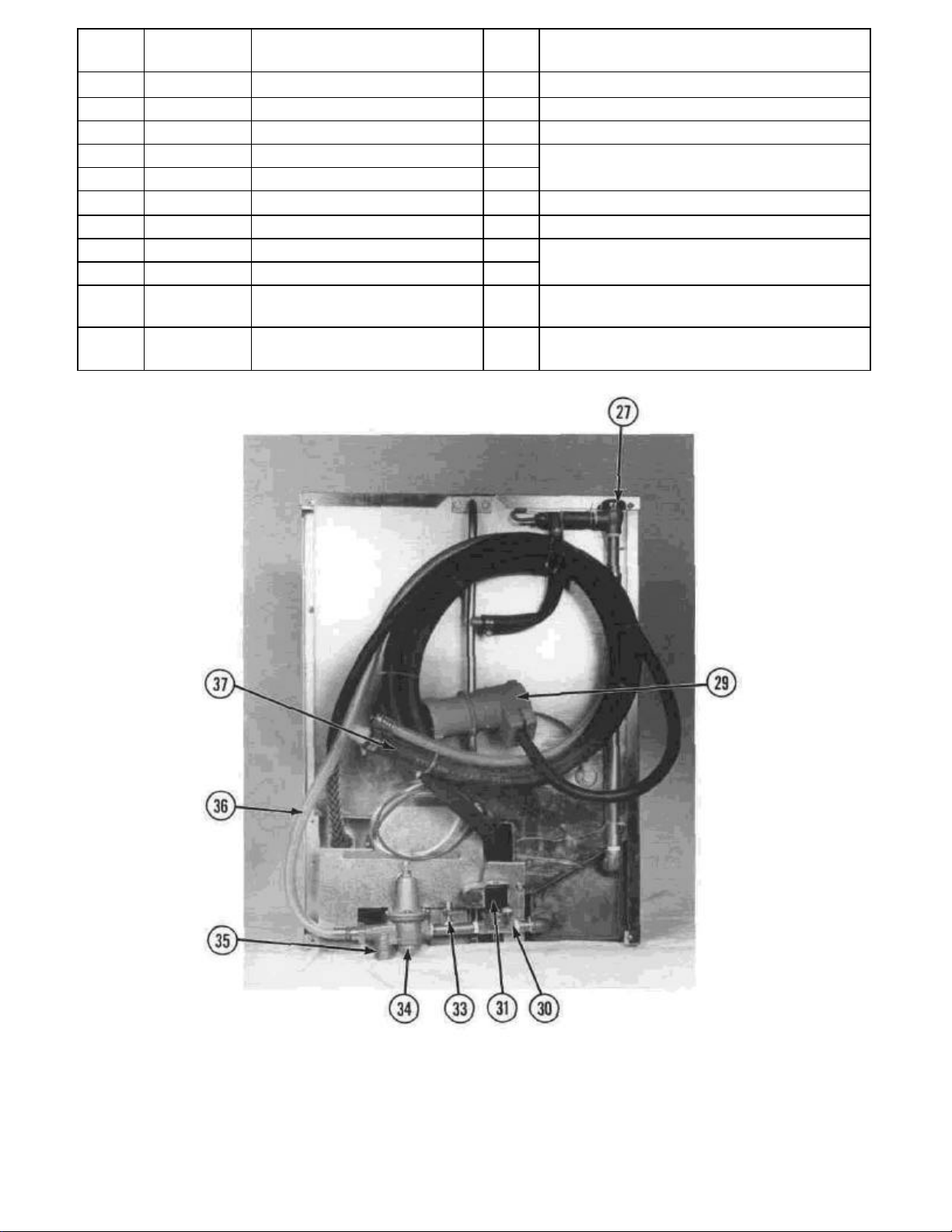

ITEM PART NO. DESCRIPTION QTY. FUNCTION

*Not Shown

27 0184101 Vacuum Breaker 1/2" 1 One-way water valve for fill.

*28 0184200 Repair Kit (Vacuum Breaker) 1

+29 0113960 Hubble Plug & Cord 1 Supplies power to machine.

30 1000918 Solenoid Valve 1/2" 1

31 0144000 Solenoid Coil 1

*32 0145000 Repair Kit (Solenoid Valve) 1

33 0114040 Pressure Gauge Valve 1 Mounting for pressure gauge.

34 1000406 Pressure Regulator 1

35

36 0113927 Fill Hose Assembly 1 Connects fresh water supply to dishwasher.

37 1113972 Drain Hose 1 Connects dishwasher to kitchen drain system.

+Optional

Line Strainer 1

Opens water supply line for fresh water fill and

rinse.

Reduces water supply pressure.

5

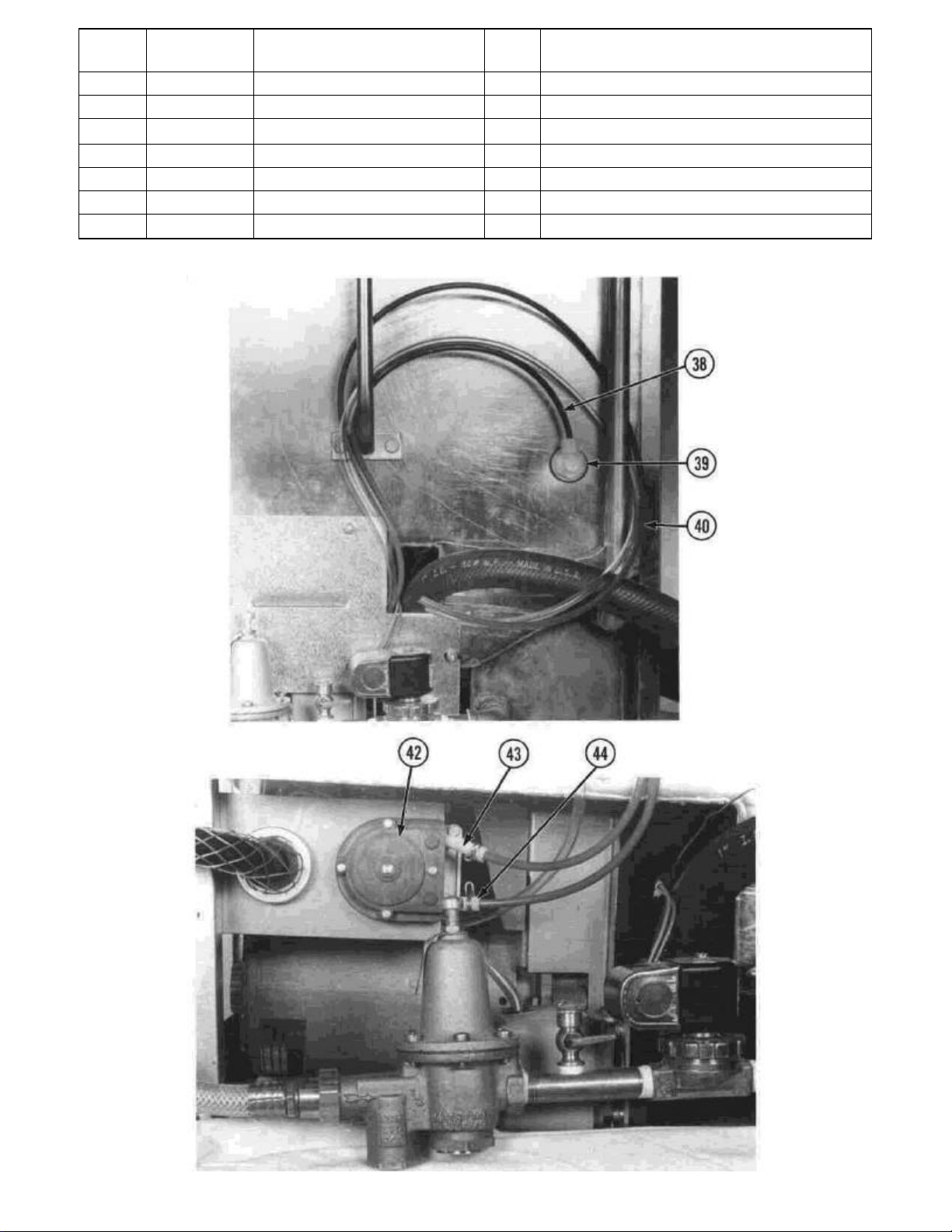

ITEM PART NO. DESCRIPTION QTY. FUNCTION

38 6011200 Feed Hose 1 Injects detergent in machine.

39 6090700 Injection Fitting 1 Holds feed hose in place.

40 0113980 Pickup Hose 1 Suctions detergent from bottle.

*41 1113952 Buzzer 1 Low detergent alarm.

42 1213710 Detergent Pump Assembly 1 Pumps detergent from bottle.

43 1010100 Squeeze Tube 1 Creates pumping action.

44 7191700 Hose Clamp 2 Holds hose inside tube.

* Not Shown

6

ITEM PART NO. DESCRIPTION QTY. FUNCTION

45 0414194 Control Panel 1 Mounts controls/gauges.

46 1113950 ON/Fill-OFF/Drain Switch 1 Used to select dishwashing functions.

47 1113951 Cycle Switch 1

48 1114037 Delime/Priming Switch 1

49 1114445 Red Light 1 Lights when detergent supply in bottle is low.

50 1113949 Green Light 1 Indicates dishwasher is filling or rinsing.

51 5040618 Amber Light 1 Indicates dishwasher is in a dishwashing cycle.

52 5040718 Red Light 1 Indicates power is ON.

53 1114039 Rinse Thermometer 1

54 1114038 Wash Thermometer 1 Gives temperature of wash water in wash tank.

Used to select Auto/Manual and Standby

functions.

Used to select deliming or detergent priming

functions.

Gives temperature reading of rinse water being

supplied from the booster.

7

ITEM PART NO. DESCRIPTION QTY. FUNCTION

55 0114424 Door Striker 1 Strikes door switch.

56 0114441 Door Latch Assembly 1 Holds door closed.

57 0114458 Door Spring 2 Lifts door.

58 3033800 Door Switch & Bracket 1 Starts dishwashing cycle.

EQUIPMENT SET -UP AND

CLOSE PROCEDURES

Set-Up — Complete the following:

1. Insure basket strainer has been cleaned

thoroughly of debris and is installed properly

into wash tank.

2. Check the wash spray arm and both upper and

lower rinse spray arms to insure they have the

end caps installed and that all are free and

clear of food debris and spin easily.

3. Close the door.

4. Depress the cycle switch to the AUTO position.

5. Depress the power switch to the ON/FILL

position — fill light will come ON.

6. When the rinse/fill light goes OUT the filling of

the dishwasher is complete.

7. Open and close the door and run (3) complete

dishwashing cycles to get the machine's

temperatures up to 150°F wash and 180°F

rinse.

NORMAL OPERATING PROCEDURE

Close the door and the machine will automatically

go through complete wash, drain and rinse cycles.

The amber cycle light will remain ON during the

complete dishwashing cycle and go OUT at the

completion of the cycle. The green light will come

ON only during the rinse portion of the cycle.

MANUAL WASH

Place cycle switch in the MANUAL wash position. In

this position, machine will wash indefinitely until

switch is placed in center OFF or AUTO cycle

position.

Close - Complete the following:

1. Remove rack from dishwasher.

2. Close the door and start a dishwashing cycle.

3. When the amber cycle light comes ON depress

the power switch to the OFF/Drain position.

Machine will complete the washing cycle and

drain but will not fill back up. The amber cycle

light will go OUT.

4. Open the door.

5. Remove the wash spray arm and both upper and

lower rinse spray arms by grasping the arm by

the hub and unscrewing counterclockwise to

remove. (See Figure 1)

STEP 5

DOOR SAFETY SWITCH OPERATION

If door is opened during a dishwashing cycle,

machine will stop the cycle until door is closed.

When door is closed, cycle will resume where it was

stopped.

CAUTION: If door is opened during cycle, open

it very slowly to allow sufficient time for

spraying action to stop.

STANDBY MODE OF OPERATION

Placing the cycle switch in the center OFF position

will allow the door to be opened and closed without

starting an automatic cycle. Machine will still

maintain proper temperatures in this position.

Figure 1

6. Remove the basket strainer.

7. Visually inspect the inside of the machine for a

lime build-up (yellowish-white powder). If

deliming is necessary, replace the basket

strainer, wash and rinse spray arms and delime

the interior of the machine. See Non-Scheduled

Maintenance Section procedures (4). Then

continue to Step 8.

9

8. Thoroughly clean these parts in a sink. Remove

end caps of spray arms with flat head

screwdriver and clean inside with tube brush if

needed. Inspect for seeds, bits of food, etc. that

may be clogging the holes or bearings. If spray

holes are clogged, clear the holes with a

straightened paper clip. Replace end caps

tighten securely in place.

9. Use a damp cloth and wipe down the inside and

outside of the machine.

NOTE: Do not use abrasive, sharp objects,

scouring pads, harsh or gritty cleansers on any part

of your dishwasher.

10

10. Install the basket strainer.

11. Install wash spray arm and both upper and

lower rinse spray arms by grasping the arm by

the hub and screwing clockwise to install.

12. Leave the door ajar to allow the interior to air

out and dry overnight.

NOTE: Do not turn OFF water valve supplying hot

water to dishwasher. If it has been turned OFF —

turn it back ON and leave it ON.

TROUBLESHOOTING GUIDE

WARNING: Inspection, testing and repair of

electrical equipment should be performed only

by qualified service personnel. Certain

procedures in this manual require electrical

tests or measurements while power is applied to

the dishwasher. Exercise extreme caution at all

times. If test points are not easily

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

No detergent being pumped into

dishwasher.

Improper amount of detergent. Call Jackson Service.

Lack of proper water pressure.

Line strainer clogged. Clean strainer. See page 17.

Temperature of water supply below 140°F.

Ware/utensils not

completely clean.

Dishwasher will not run

when door is closed.

Water leaking around

door.

Dishwasher fills

continuously.

Excessive sudsing.

Wash arm nozzles clogged or not

spinning.

Wash/Rinse arms missing end plugs. Replace end plugs. See page 15.

Basket strainer full of food debris. Clean basket.

Wrong type of detergent. Use McD dishwasher detergent.

Drain valve stuck open. Call Jackson Service.

Fill valve defective. Call Jackson Service.

Timer defective. Call Jackson Service.

Thermostat defective. Call Jackson Service.

Booster heater defective. Call Jackson Service.

No power to dishwasher. Check circuit breaker.

Cycle switch in center standby position.

Door switch needs to be adjusted. Adjust door switch. See page 14.

Reset of timer not completed.

ON/Fill-OFF/Drain switch defective. Call Jackson Service.

Cycle switch defective. Call Jackson Service.

Timer out of order. Call Jackson Service.

Pump motor defective. Call Jackson Service.

Dishwasher not level. Level unit. See page 19.

Excessive sudsing in wash tank. Use McD dishwashing detergent.

High water pressure to dishwasher.

Too much water in tank. Call Jackson Service.

Fill valve defective. Call Jackson Service.

Timer defective. Call Jackson Service.

Too much detergent. Call Jackson Service.

Wrong type of det ergent. Use McD dishwashing detergent.

accessible, disconnect power and attach test

equipment and reapply power to test. Disconnect the electrical power to the dishwasher at

the main circuit breaker box when servicing.

Place a tag on the circuit box indicating the

circuit is being repaired.

Detergent out — replace.

Check pressure to the machine. See page

16.

Check temperature of water supply. See

page 16.

Clean wash arms. Replace worn parts.

See page 15.

Depress cycle switch to AUTO position

and try.

Depress cycle to AUTO position, open

door, wait until cycle light goes OUT, close

door to start.

Check water pressure to unit. See page

16.

11

WARNING: Inspection, testing and repair of

electrical equipment should be performed only

accessible, disconnect power and attach test

by qualified service personnel. Certain

procedures in this manual require electrical

tests or measurements while power is applied to

the dishwasher. Exercise extreme caution at all

times. If test points are not easily

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Split hose at pump. Call Jackson Service.

Water under the

dishwasher.

Door does not close and

latch properly

Door drops hard and is

heavy to open.

Water remaining in

machine at end of

OFF/Drain cycle.

Dishwasher has musty

odor.

injected into the

dishwasher.

Detergent alert warning

light comes ON and the

buzzer sounds.

Pump seal defective. Call Jackson Service.

Split drain hose. Call Jackson Service.

Split rinse hose. Call Jackson Service.

Door latch defective. Replace door latch. See page 16.

Door spring broken. Replace door spring. See page 16.

Drain valve defective. Call Jackson Service.

Drain hose kinked. Straighten hose.

Timer inoperative. Call Jackson Service.

Dishwasher not cleaned properly or door

kept closed overnight.

Detergent pump runs too long. Call Jackson Service. Too much detergent being

Timer out of order. Call Jackson Service.

Detergent bottle empty.

Detergent lines not in detergent bottle. Put lines in and prime lines.

Air leak in line between detergent bottle

and pressure switch.

Pressure switch defective. Call Jackson Service.

Detergent bottle empty.

Detergent pump bad. Call Jackson Service.

equipment and reapply power to test. Disconnect the electrical power to the dishwasher at

the main circuit breaker box when servicing.

Place a tag on the circuit box indicating the

circuit is being repaired.

Review Equipment Set -Up and Close

Procedures.

Replace with full bottle and prime. See

page 14.

Replace line. See page 18.

Replace with full bottle and prime. See

page 14.

Not enough or no

detergent being injected

into the dishwasher.

Water leaking from rinse

arms when unit is OFF.

Dishwasher runs but

making humming sound

inside.

Vacuum breaker at back

of machine leaking.

Air leaks at fittings on detergent feed lines. Tighten fittings.

Detergent feed lines pinched or cracked. Replace feed lines. See page 18.

Timer not working. Call Jackson Service.

Detergent timer can not set properly. Call Jackson Service.

Fill valve defective. NOTE: A small amount

of water will leak from lower rinse arm as

water in booster tank expands during

heating.

No water in machine or not enough water. Complete Set -Up Procedures page 6.

Improper water pressure. Check pressure.

Pump motor defective. Call Jackson Service.

Internal parts defective. Install repair kit. See page 17.

12

Call Jackson Service.

WARNING: Inspection, testing and repair of

electrical equipment should be performed only

by qualified service personnel. Certain

procedures in this manual require electrical

tests or measurements while power is applied

to the dishwasher. Exercise extreme caution at

all times. If test points are not easily

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Wash temperature gauge

not reading any

temperature.

Rinse temperature gauge

not reading any

temperature.

Defective gauge. Call Jackson Service.

Defective gauge. Call Jackson Service.

accessible, disconnect power and attach test

equipment and reapply power to test. Disconnect the electrical power to the dishwasher at

the main circuit breaker box when servicing.

Place a tag on the circuit box indicating the

circuit is being repaired.

Wash arm not spinning or

very hard to spin.

Rinse arm not spinning or

very hard to spin.

Dish rac k hits rack rails

when pushed into

machine.

PARTS ORDERING/SERVCE INFORMATION

Parts orders must be placed directly with your local

Jackson Maintenance & Repair Center at this

telephone number:

The following information should be provided and

may be obtained from the dishwasher data plate

located on the right side of the machine.

Model Number: M-24BF

Serial Number:

Date Installed: ______________________________

Local Service Agency: _______________________

Telephone Number: _________________________

Address: _________________________________

Zip Code: _________________________________

(Fill in the above information for your records)

You should also have available the part number, its

description, and the quantity required. A list of

replacement parts is included in this manual and

should be used to assist in identifying and ordering

parts. Contact your local Jackson authorized

maintenance and repair center.

Internal parts worn or defective. Replace worn parts. See page 15.

Internal parts worn or defective. Replace worn parts. See page 15.

Rack rails need to be lowered. Adjust rack rails. See page 15.

Service assistance may be obtained by calling your

local Jackson authorized maintenance and repair

center.

When calling, the model number, serial number,

and electrical specifications should be available,

along with the nature of the problem, its symptoms

and any other informat ion that would be helpful in

solving the problem.

IMPORTANT SAFETY INSTRUCTIONS

Please read all instructions before using this

dishwasher. Safety precautions in this manual and

preceded by the words "DANGER", "WARNING",

"CAUTION" or "NOTE" and are very important.

DANGER is used to indicate the presence of a

hazard which will cause severe personal injury,

death or substantial property damage if the

statement is ignored. WARNING is used to indicate

the presence of a hazard which can cause severe

personal injury, death or substantial property

damage if the statement is ignored. CAUTION is

used to indicate the presence of a hazard which will

or can cause minor personal injury or property

damage if the statement is ignored. NOTE is used

to notify personnel of ins tallation, operations, or

maintenance information which is important, but not

hazard related.

13

NON-SCHEDULED MAINTENANCE

IMPORTANT SAFETY NOTICE:

The service information in this manual is

intended for use of individuals possessing

adequate backgrounds of electrical and

mechanical experience. Any attempt to repair

this dishwasher may result in personal injury

and property damage. The manufacturer or

seller cannot be responsible for the interpre tation of this information, nor can it assume any

liability in connection with its use.

When electrical wires are disconnected, they MUST

be marked in such a way to simplify replacement.

TO REPLACE EMPTY DETERGENT BOTTLE

Tools: None

Parts: Full bottle of detergent

1. Remove detergent pickup hose and lowdetergent alert hose from empty bottle of

detergent.

2. Insert both hoses in full bottle of detergent and

place bottle into holding bracket.

3. Follow "To Prime Detergent Feed Lines" to

prime detergent feed lines.

4. Machine is ready for use.

TO PRIME DETERGENT FEED LINES

Tools: None

Parts: None

1. Place the detergent hose in the bottle of

detergent and place bottle in rack.

2. Close and latch door.

3. Depress the cycle switch to the AUTO position

and depress the power switch to the ON/FILL

position. Machine will fill with water.

4. Depress and hold the prime switch for 20-30

seconds.

Figure 2

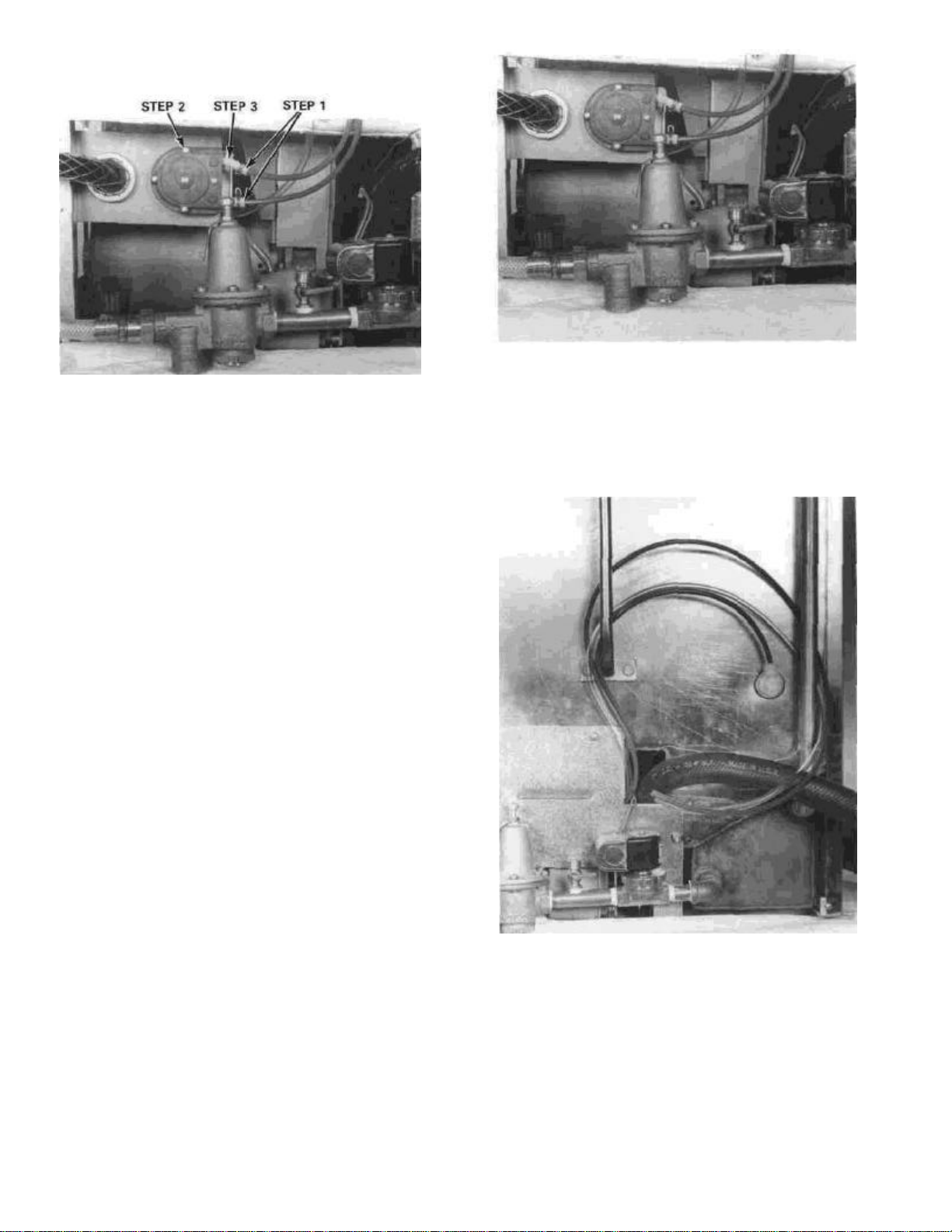

3. Loosen the door switch bracket which is

secured by 2 locknuts.

4. Close and latch door completely.

5. Slide door switch & bracket toward door striker

until lever of switch is depressed against striker

and a "click" is heard to indicate switch is

closed.

TO ADJUST THE DOOR SWITCH & BRACKET

Tools: #2 Phillips screwdriver, 7/16" nut

driver/socket

Parts: None

1. WARNING: Disconnect the electrical power

to the dishwasher at the main circuit box.

Place a tag on the circuit box indicating the

circuit is being worked on.

2. Remove front door flange which is secured by 4

screws and lay aside.

14

6. Tighten mounting nuts securely.

7. Reinstall front door flange.

8. Reconnect power.

TO REPLACE RINSE ARM WASHERS OR SNAP

RING

Tools: Flat blade screwdriver (1/4")

Parts: End Plug (Item #13 Washer (Item #14) Snap

Ring (Item #16)

1. Unscrew and remove rinse arm from feed pipe.

2. Remove snap ring from hub and disassemble.

3. Replace both nylatron (plastic) washers and snap

ring.

4. Reverse procedure to assembly arm.

5. Unscrew and replace plastic end caps if worn or

damaged.

6. Reinstall rinse arm into machine.

TO REPLACE WASH ARM BEARING OR END

CAPS

Tools: Adjustable wrench (10"), flat blade

screwdriver (1/4")

Parts: Bearing Assembly (Item #23), End Plug

(Item #24)

1. Unscrew and remove wash arm.

2. Unscrew and remove bearing assembly from

hub.

3. Install new bearing assembly into arm.

4. Replace end caps of arm if worn or damaged.

5. Reinstall arm assembly into machine. TO

4. Close and latch the door. The machine will begin

to run continuously. Allow the machine to run in

the deliming position for 10-15 minutes.

5. After deliming is completed, place the delime

switch to the center ON position and cycle

switch to the AUTO position and run a complete

cycle.

6. Run several normal cycles to completely flush

residual deliming solution from the machine.

7. Machine is ready for use.

NOTE: Never leave delimer solution in the machine

overnight or for long periods of time (over (1) hour).

TO ADJUST RACK RAILS INSIDE MACHINE

Tools: Nut driver or open end wrench (7/16")

Parts: None

1. Loosen rack rails which are secured by (2)

locknuts.

DELIME INTERIOR OF THE DISHWASHER

Tools: None

Parts: Packets of Delimer (HCS)

1. Follow Steps 1-3 of "Closing Procedure".

2. Depress power switch to ON/FILL position then

close and latch door. Allow machine to complete

a fill cycle (about 1 minute).

3. Open the door and pour in (2) packets delimer

into basket strainer. Place delime switch in the

deliming position and place cycle switch in

manual wash position.

2. Raise or lower to level of door and tighten

locknuts.

15

TO CHECK WATER SUPPLY PRESSURE

Tools: None

TO REPLACE THE DOOR SPRINGS

Parts: Teflon Tape, Pressure Gauge

1. Install a pressure gauge (1/4//) into the pet -cock

valve using teflon tape on the threads.

Tools: #2 Phillips screwdriver

Parts: Door Spring (Item #57)

1. WARNING: Disconnect the electrical power to

the dishwasher at the main circuit box. Place

a tag on the circuit box indicating the circuit

is being worked on.

2. Remove front door flange which is secured by 4

screws and lay aside.

3. Close and latch door completely.

4. Unhook defective spring from door and from lower

frame.

2. Turn petcock valve to open position.

3. Run a dishwashing cycle. During rinse portion of

cycle when green light comes on read pressure

of gauge, it must be between 15 and 25 psi.

4. Turn petcock valve to closed position.

CAUTION: Make certain that petcock valve is

closed before removing gauge.

TO CHECK WATER SUPPLY TEMPERATURE

Tools: None

Parts: Teflon Tape, Temperature Gauge

1. Install a temperature gauge (1/4") into the

petcock valve using teflon tape on the threads.

See "To Check Water Supply Pres sure", Step 1

for location.

2. Turn petcock valve to open position.

3. Run a dishwashing cycle. During rinse portion of

cycle when green light comes ON read

temperature of gauge, it must be at least 140°F.

4. Turn petcock valve to closed position.

CAUTION: Make certain that petcock valve is

closed before removing gauge.

5. Install new spring to lower frame hole and door

hinge.

6. Reinstall front door flange. Reconnect power.

Machine is ready for use.

TO REPLACE DOOR LATCH ASSEMBLY

Tools: #1 Phillips screwdriver

Parts: Latch Assembly (Item #56)

1. Remove latch by removing inner door rail which is

secured by screws.

2. Install new latch and reinstall inner door rail

securely.

16

TO CLEAN WATER LINE STRAINER

TO INSTALL VACUUM BREAKER REPAIR KIT

NOTE: Frequency of this task will vary depending on

local water quality.

Tools: Adjustable 10" wrench

Parts: None

Tools: Flat blade screwdriver (1/4")

Parts: Vacuum Breaker Repair Kit (Item #28)

1. WARNING: Disconnect the electrical power to

the dishwasher at the main circuit box. Place

a tag on the circuit box indicating the circuit

is being worked on.

2. Turn water supply OFF to dishwasher.

3. Remove cap from vacuum breaker which is

secured by (1) screw.

4. Unscrew top using screwdriver.

5. Install all repair kit parts.

1. Turn water supply OFF to dishwasher at service

connection.

2. Unscrew cap from pressure regulator valve.

NOTE: Some water will drain when cap is unscrewed.

3. Remove and clean line strainer completely.

4. Reinstall cap securely.

5. Turn water supply ON to dishwasher.

Figure 9

6. Reassemble in reverse order.

7. Turn water supply ON to dishwasher. Reconnect

power.

8. Dishwasher is ready for use.

TO REPLACE DETERGENT PUMP

SQUEEZE TUBE

Tools: Hose clamp pliers, adjustable wrench

(6"), Phillips screwdriver (#2)

Parts: Squeeze Tube (Item #43)

1. Remove pickup and feed hoses to squeeze tube

which are secured by hose clamps.

2. Remove pump face plate which is secured by (5)

screws.

17

3. Remove squeeze tube and replace with new

Figure

12

Machine is now ready to prime detergent lines.

tube.

Figure 10

4. Reassemble in reverse order.

5. Insert feed and pickup hoses into squeeze tube

and secure with clamps.

6. Insert pickup hose into detergent bottle.

7. Machine is now ready to prime detergent lines.

8. Follow "To Prime Detergent Feed Lines" for

priming detergent lines.

CAUTION: When using or working with the liquid

detergent use caution as it can irritate the skin.

2. Replace feed hose and install in reverse order of

above.

3. Remove detergent pickup hose from pump

squeeze which is secured by hose clamps.

Remove other end of hose from detergent bottle.

(See Figures 11 & 12)

Figure 11

TO REPLACE DETERGENT PUMP FEED AND

PICKUP HOSES

Tools: Hose clamp pliers, adjustable wrench (6"),

Phillips screwdriver

Parts: Detergent feed hose (Item #38), detergent

pickup hose (Item #40)

1. Remove detergent pump feed hose from the

pump squeeze tube which is secured by hose

clamps. Remove other end of hose from

injection fitting which is secured by a

compression nut at back of machine. (See

Figures 11 & 12)

4. Replace pickup hose and install in reverse order of

above.

5. Place pickup hose into detergent bottle.

6.

7. Follow "To Prime Detergent Feed Lines" for priming

detergent lines.

18

TO LEVEL DISHWASHER AND CHECK FOR

19

PROPER WATER LEVEL

Tools: Adjustable Wrench (8")

Parts: None

1. Depress the cycle switch to the AUTO position

and depress the power switch to the ON/FILL

position.

2. Install basket strainer squarely and completely in

wash tank.

3. Close and latch the door and allow dishwasher to

complete a cycle.

4. Open door. Adjust the leveling feet until the water

in the wash tank is touching the basket strainer

screen evenly from side to side and front to back.

Loading...

Loading...