Page 1

TECHNICAL MANUAL

Jackson MSC Inc.

P.O. Box 1060

Barbourville, KY. 40906

(606) 523-9795

Fax: (606) 523-9196

Company

HOT WATER SANITIZING UNDERCOUNTER DISHMACHINE

FOR JACKSON MODEL:

JPX-300NSU

August 16, 2005

P/N 7610-002-75-96 (Revision E)

An

www.jacksonmsc.com

Page 2

MANUFACTURERS WARRANTY ONE YEAR LIMITED PARTS & LABOR WARRANTY

DEFECTS IN MATERIAL OR WORKMANSHIP, UNDER NORMAL USE AND OPERATION FOR A PERIOD OF (1) ONE

YEAR FROM THE DATE OF PURCHASE, BUT IN NO EVENT TO EXCEED (18) EIGHTEEN MONTHS FROM THE DATE

Jackson MSC agrees under this warranty to repair or replace , at its discretion, any original part which fails under normal use due to faulty

-

tained and operated in accordance with the applicable factory instruction manual furnished with the machine and the failure is reported to

the authorized service agency within the warranty period. This includes the use of factory specified genuine replacement parts, purchased

-

The labor to repair or replace such failed part will be paid by Jackson MSC, within the continental United States, Hawaii and Canada, during

the warranty period provided a Jackson MSC authorized service agency, or those having prior authorization from the factory, performs the

service. Any repair work by persons other than a Jackson MSC authorized service agency is the sole responsibility of the customer. Labor

-

es, pressure regulators, pre rinse units, etc. that are shipped with the unit and installed at the site are included. Labor to repair or replace

-

thorized persons, improper installation, if serial number has been removed or altered, or if unit is used for purpose other than it was origi

-

Jackson MSC limits warranty travel time to (2) two hours and mileage to (100) one hundred miles. Jackson MSC will not pay for travel time

Jackson replacement parts are warranted for a period of 90 days from the date of installation or 180 days from the date of shipment from the

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING FOR FITNESS OR MERCHANTABILITY, THAT ARE NOT SET

LIABLE FOR ANY LOSS OR DAMAGE, DIRECT OR CONSEQUENTIAL, OR FOR THE DAMAGES IN THE NATURE OF PENALTIES,

-

ers at anytime. Nor does it cover adjustments such as, but not limited to timer cams, thermostats or doors, beyond 30 days from the date

of installation. In addition, the warranty will only cover the replacement of wear items such as curtains, drain balls, door guides or gaskets

during the first 30 days after installation. Also, not covered are conditions caused by the use of incorrect (non-Commercial) grade detergents,

ALL NEW JACKSON DISHWASHERS ARE WARRANTED TO THE ORIGINAL PURCHASER TO BE FREE FROM

OF SHIPMENT FROM THE FACTORY.

material or workmanship during the warranty period, providing the equipment has been unaltered, and has been properly installed, main

directly from a Jackson authorized parts distributor or service agency. Use of generic replacement parts may create a hazard and void war

ranty certification.

coverage is limited to regular hourly rates, overtime premiums and emergency service charges will not be paid by Jackson MSC.

Accessory components not installed by the factory carry a (1) one year parts warranty only. Accessory components such as table limit switch

these components is not covered by Jackson MSC.

This warranty is void if failure is a direct result from shipping, handling, fire, water, accident, misuse, acts of god, attempted repair by unau

nally intended.

TRAVEL LIMITATIONS

and mileage that exceeds this, or any fees such as those for air or boat travel without prior authorization.

WARRANTY REGISTRATION CARD

The warranty registration card supplied with the machine must be returned to Jackson MSC within 30 days to validate the warranty.

REPLACEMENT PARTS WARRANTY

factory, which ever occurs first.

PRODUCT CHANGES AND UPDATES

Jackson MSC reserves the right to make changes in design and specification of any equipment as engineering or necessity requires.

THIS IS THE ENTIRE AND ONLY WARRANTY OF JACKSON MSC. JACKSON’S LIABILITY ON ANY CLAIM OF ANY KIND, INCLUDING

NEGLIGENCE, WITH RESPECT TO THE GOODS OR SERVICES COVERED HEREUNDER, SHALL IN NO CASE EXCEED THE PRICE

OF THE GOODS OR SERVICES OR PART THEREOF WHICH GIVES RISE TO THE CLAIM.

FORTH HEREIN, OR THAT EXTEND BEYOND THE DURATION HEREOF. UNDER NO CIRCUMSTANCES WILL JACKSON MSC BE

ARISING OUT OF THE USE OR INABILITY TO USE ANY OF ITS PRODUCTS.

ITEMS NOT COVERED

This warranty does not cover cleaning or deliming of the unit or any component such as, but not limited to, wash arms, rinse arms or strain

incorrect water temperature or pressure, or hard water conditions.

AJ Series Installation/Operation Manual

7610-001-76-21 Rev. E (02/15/2005)

Page 3

REVISION

A 03-27-03 MAW 6698 Release to production

B 11-17-03 MAW N/A Updated part numbers.

C 04-29-04 MAW N/A Added 2nd Enodis logo to cover.

D 04-18-05 MAW N/A Removed title “ Installation Manual for Export Units” from cover.

E 08-16-05 MAW

REVISION

DATE

MADEBYAPPLICABLE

ECN

6964, 6988

7006, 7383

DETAILS

Changed thermostat from 5930-121-71-36 to 5930-011-49-43.

Added 4-3/4” Din Rail 5700-002-90-18 to Control Box Assembly.

Changed thermostat bracket from 5700-011-73-72 to 5700-01181-64. Changed vacuum breaker from 4820-300-07-00 to 4820003-06-13. Added service procedure pages.

i

Page 4

NOMENCLATURE FOR THE MODEL COVERED IN THIS MANUAL

JPX-300NSU

JPX-300NSU - Hot water sanitizing, electrically-heated dishmachine,

Model:

Serial No.:

Installation Date:

Service Rep. Name:

Phone No.:

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

ii

Page 5

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

I. SPECIFICATION INFORMATION

Specifications 2

Dimensions 3

II. INSTALLATION & OPERATION INSTRUCTIONS

Installation Instructions 5

Electrical Installation Instructions 6

Deck Mounting of Dishmachine 7

Detergent Control 8

Operation Instructions 9

III. PREVENTATIVE MAINTENANCE 11

IV. TROUBLESHOOTING 13

V. SERVICE PROCEDURES

Rinse Solenoid Valve Repair Parts Kit 16

Vacuum Breaker Repair Parts Kit 20

VI. PARTS SECTION

Electric Panel Assembly 23

Switch Panel Assembly 24

Switch Panel Assembly (Stainless Steel Switches) 25

Kick Panel Assembly 26

Incoming Plumbing Assembly 27

Solenoid Valve Repair Kit / Vacuum Breaker Repair Kit 30

Drain Valve Assembly 31

Drain Plumbing Assembly 32

Wash Motor to Wash Tub Assembly 33

Rinse Tank & Components 34

Door Assembly 35

Rinse Arm & Wash Arm Assemblies 36

Miscellaneous Parts 37

Frame & Panel Components 38

VII. ELECTRICAL SCHEMATICS

460 V, 60 HZ, three phase 40

460 V, 60 HZ, three phase (with Stainless Steel Switches) 41

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

iii

Page 6

THIS PAGE IS INTENTIONALLY LEFT BLANK

iv

Page 7

SECTION 1:

SPECIFICATION INFORMATION

1

Page 8

SECTION 1: SPECIFICATION INFORMATION

PERFORMANCE/CAPABILITIES

SPECIFICATIONS

ELECTRICAL REQUIREMENTS

WASH PUMP MOTOR HORSEPOWER 3/4

OPERATING CAPACITY (RACKS/HOUR)

RACKS PER HOUR 30

DISHES PER HOUR 600

GLASSES PER HOUR 600

OPERATING CYCLE (SECONDS)

WASH TIME 82

DRAIN TIME 28

RINSE TIME 10

TOTAL CYCLE TIME (MINUTES) 2

5 MINUTE TIMER OPERATING CYCLE (SECONDS)

WASH TIME 262

DRAIN TIME 28

RINSE TIME 10

TOTAL CYCLE TIME (MINUTES) 5

TANK CAPACITY (GALLONS)

WASH TANK 5.65

RINSE TANK 3

RINSE TYPICAL

HEATER TOTAL ELECTRICAL

VOLTS PH HZ RATINGS AMPS CIRCUIT

460 3 60 8.2KW @ 460V 11 A 15 AMP

460 3 60 10KW @ 460V 14 A 20 AMP

WATER REQUIREMENTS

INLET TEMPERATURE (40° BOOSTER) 140

INLET TEMPERATURE (70° BOOSTER) 110

GALLONS PER HOUR 52.3

WATER LINE SIZE NPT (MINIMUM) 1/2”

DRAIN LINE SIZE NPT (MINIMUM) 1 1/2”

FLOW PRESSURE P.S.I. 20 A5

FLOW, GALLONS PER MINUTE 7.1

FRAME DIMENSIONS

HEIGHT, MINIMUM 33 1/4”

HEIGHT, MAXIMUM 34 1/4”

WIDTH 24 1/4”

DEPTH 22 5/8”

MAXIMUM INSIDE CLEARANCE HEIGHT 14 1/2”

MAXIMUM INSIDE CLEARANCE WIDTH 20 1/4”

°F

°F

WASH PUMP CAPACITY

GALLONS PER MINUTE 60

TEMPERATURES

WASH---°F (MINIMUM) 150

RINSE---°F 180-195

MAXIMUM INSIDE CLEARANCE DEPTH 21 1/4”

DOOR OPEN DEPTH 39 1/2”

CLEARANCE, WALL TO MACHINE 2 1/2”

NOTE: Always refer to the machine data plate for specific

electrical and water requirements. The material provided

on this page is for reference only and may be subject to

change without notice.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

2

Page 9

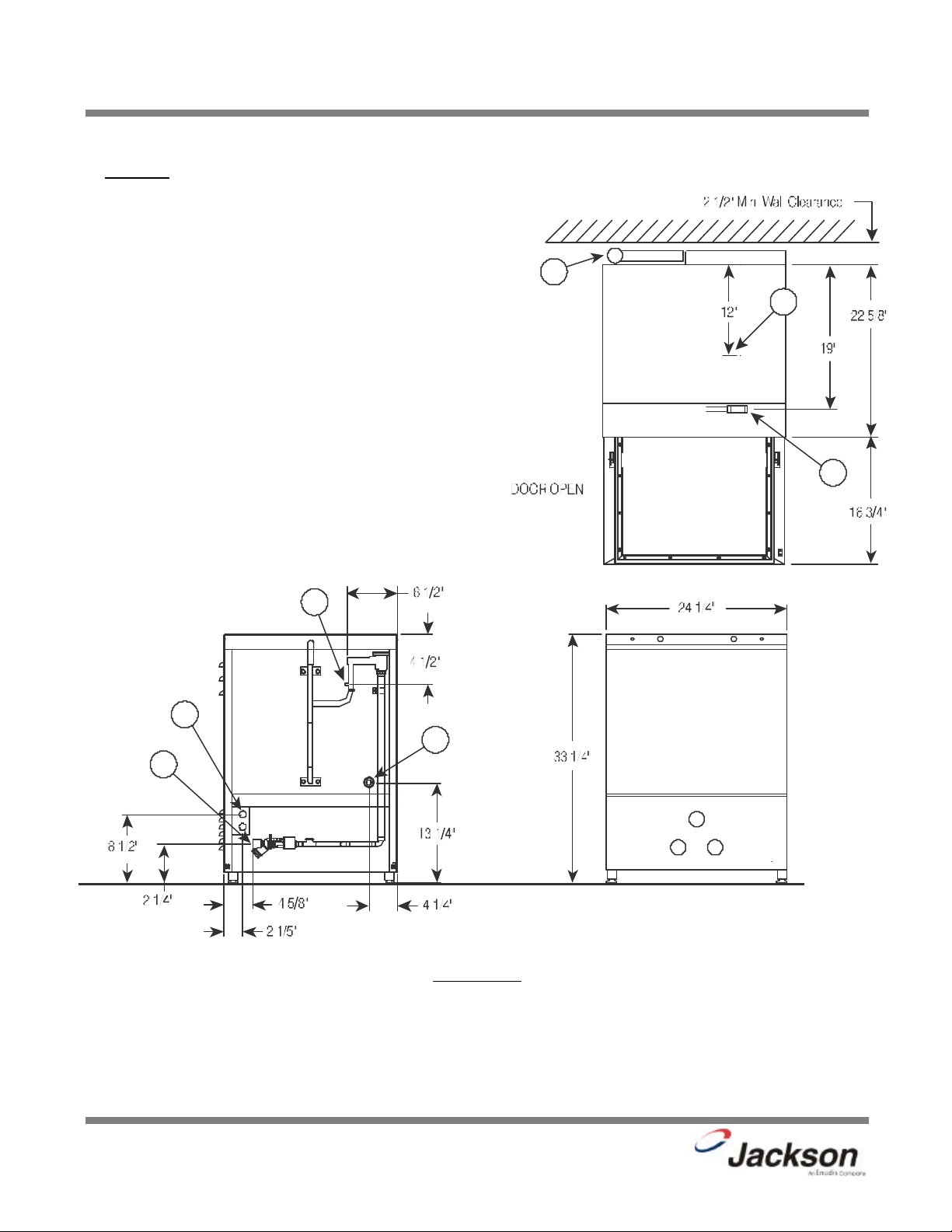

DIMENSIONS

Undercounters

CBA

C

LEGEND

A - Water Inlet 1/2” ID Female Pipe Thread, 2 1/2”

B - Chemical Feeder Connection

C - Electrical Connection.

B - Rinse Additive Connection

SECTION 1: SPECIFICATION INFORMATION

D

B

A

DIMENSIONS

Height (minimum): 33 1/4” Inside Clearance Height: 14 1/2”

Height (maximum): 34 1/4” Inside Clearance Width: 20 1/4”

Width: 24 1/4” Inside Clearance Depth: 21 1/4”

Depth: 22 5/8” Door Open Depth: 39 1/2”

Wall Clearance (minimum): 2 1/2”

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

3

Page 10

SECTION 2:

INSTALLATION/OPERATION

INSTRUCTIONS

4

Page 11

SECTION 2: INSTALLATION & OPERATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

Jackson MSC Inc. provides technical support for all of the dishmachines detailed in this manual. We strongly recommend that

you refer to this manual before making a call to our technical support staff. Please have this manual with you when you call so

that our staff can refer you, if necessary, to the proper page. Technical support is available from 8:00 a.m. to 5:00 p.m. (EST),

Monday through Friday. Technical support is not available on holidays. Contact technical support toll free at 1-888-800-5672.

Please remember that technical support is available for service personnel only.

This equipment is not recommend for use with deionized water or other aggressive fluids. Use of deionized water or

other aggressive fluids will result in corrosion and failure of materials and components. Use of deionized water or

other aggressive fluids will void the manufacturer's warranty.

VISUAL INSPECTION: Before installing the unit, check the container and machine for damage. A damaged container is an indi-

cator that there may be some damage to the machine. If there is damage to both the container and machine, do not throw away

the container. The dishmachine has been inspected and packed at the factory and is expected to arrive to you in new, undamaged condition. However, rough handling by carriers or others may result in there being damage to the unit while in transit. If

such a situation occurs, do not return the unit to Jackson; instead, contact the carrier and ask them to send a representative to

the site to inspect the damage to the unit and to complete an inspection report. You must contact the carrier within 48 hours of

receiving the machine. Also, contact the dealer through which you purchased the unit.

UNPACKING THE DISHMACHINE: Once the machine has been removed from the container, ensure that there are no missing parts from the machine. This may not be obvious at first. If it is discovered that an item is missing, contact Jackson immediately to have the missing item shipped to you.

LEVEL THE DISHMACHINE: The dishmachine is designed to operate while being level. This is important to prevent any damage to the machine during operation and to ensure the best results when washing ware. The unit comes with adjustable bullet

feet, which can be turned using a pair of channel locks or by hand if the unit can be raised safely. Ensure that the unit is level

from side to side and from front to back before making any connections.

PLUMBING THE DISHMACHINE: All plumbing connections must comply with all applicable local, state, and national plumbing codes. The plumber is responsible for ensuring that the incoming water line is thoroughly flushed prior to connecting it to

any component of the dishmachine. It is necessary to remove all foreign debris from the water line that may potentially get

trapped in the valves or cause an obstruction. Any valves that are fouled as a result of foreign matter left in the water line, and

any expenses resulting from this fouling, are not the responsibility of the manufacturer.

CONNECTING THE DRAIN LINE: The JPX-300NSU machine is a pumped (pressure) drain capable of pumping waste water

to a height of 24 inches from the floor to the kitchen’s drain system. The dishmachine is supplied with a 10 foot long hose that

extends from the rear side of the machine. There must also be an air gap between the machine drain line and the floor sink or

drain. If a grease trap is required by code, it should have a flow capacity of 12 gallons per minute.

WATER SUPPLY CONNECTION: Ensure that you have read the section entitled “PLUMBING THE DISHMACHINE” above

before proceeding. Install the water supply line (1/2” ID pipe size minimum)

to the dishmachine line strainer using copper pipe. It is recommended that a water shut-off valve be installed in the water line

between the main supply and the machine to allow access for service. The water supply line is to be capable of 20 A5 PSI

“flow” pressure at the recommended temperature indicated on the data plate.

Do to areas where the water pressure fluctuates or is greater than the recommended pressure, it is recommended installing

supplied water pressure regulator. Do not confuse static pressure with flow pressure. Static pressure is the line pressure in a

“no flow” condition (all valves and services are closed). Flow pressure is the pressure in the fill line when the fill valve is opened

during the cycle.

It is also recommended that a shock absorber (not supplied) be installed in the incoming water line. This prevents line hammer

(hydraulic shock), induced by the solenoid valve as it operates, from causing damage to the equipment.

PLUMBING CHECK: Slowly turn on the water supply to the machine after the incoming fill line and the drain line have been

installed. Check for any leaks and repair as required. All leaks must be repaired prior to placing the machine in operation.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

5

Page 12

SECTION 2: INSTALLATION & OPERATION INSTRUCTIONS

ELECTRICAL INSTALLATION INSTRUCTIONS

ELECTRICAL POWER CONNECTION: Electrical and grounding connections must comply with the applicable portions of the

National Electrical Code ANSI/NFPA 70 (latest edition) and/or other electrical codes.

Disconnect electrical power supply and place a tag at the disconnect switch to indicate that you are working on the circuit.

The dishmachine data plate is located on the front of the machine. Refer to the data plate for machine operating requirements,

machine voltage, total amperage load and serial number.

To install the incoming power lines, remove the kick panel. This will require taking a phillips head screwdriver and removing the

two (2) 1/4 turn screws at the bottom of the kickplate; open the door slightly while carefully lifting the kickplate up and out of

the way. Install 3/4” conduit into the pre-punched holes in the back of the control box. Route power wires and connect to power

block and grounding lug. Install the service wires (L1, L2 and L3) to the appropriate terminals as they are marked on the terminal block. Install the grounding wire into the lug provided. It is recommended that “DE-OX” or another similar anti-oxidation

agent be used on all power connections.

VOLTAGE CHECK: Ensure that the power switch is in the OFF position and apply power to the dishmachine. Check the incoming power at the terminal block and ensure it corresponds to the voltage listed on the data plate. If not, contact a qualified service agency to examine the problem. Do not run the dishmachine if the voltage is too high or too low. Shut off the service breaker and mark it as being for the dishmachine. Advise all proper personnel of any problems and of the location of the service

breaker. Replace the control box cover and tighten down the screws.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

6

Page 13

7

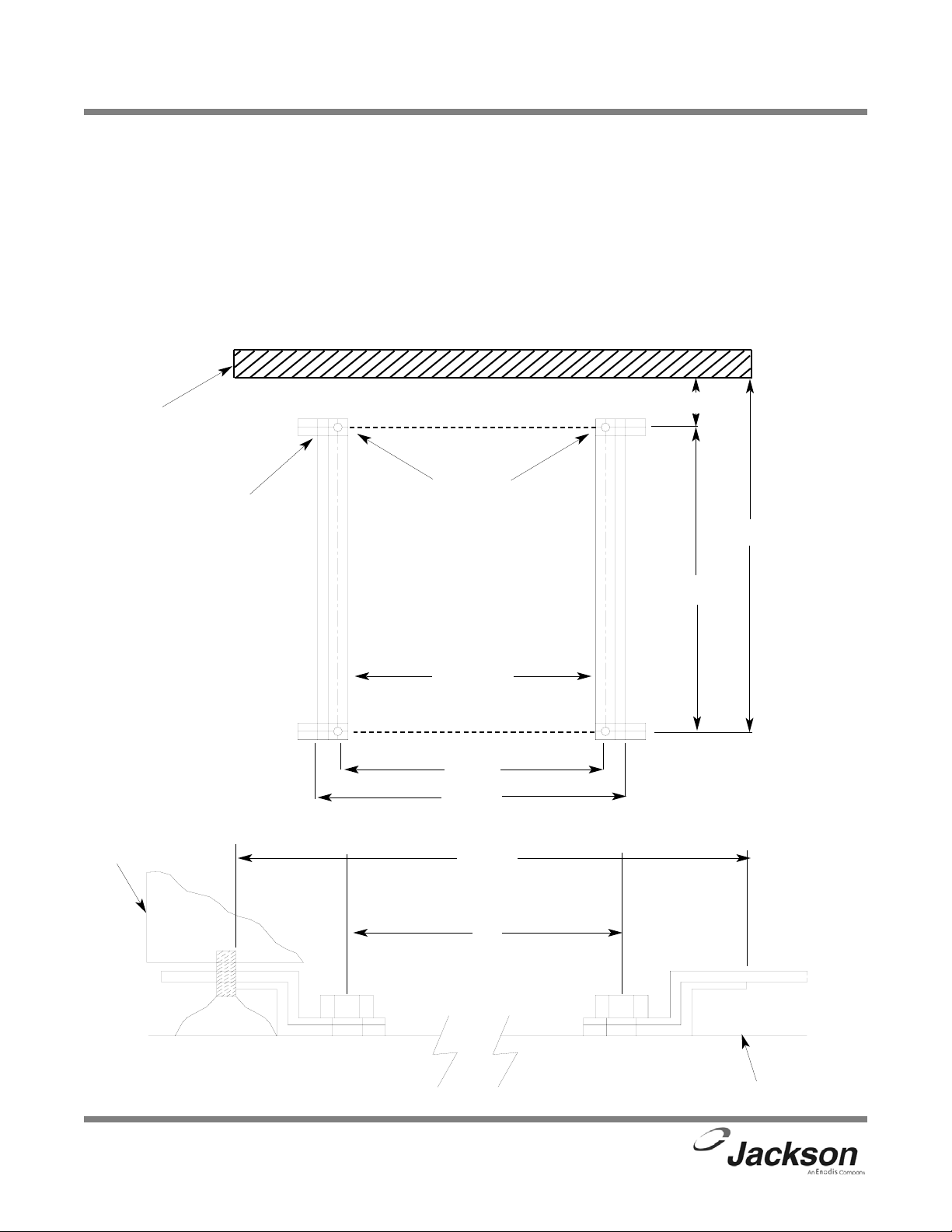

SECTION 2: INSTALLATION & OPERATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS (CONTINUED)

DECK MOUNTING OF THE DISHMACHINE: The dishmachine must be secured in place using the deck mounting tracks and

caps provided with machine. Install the (4) adjustable feet provided into screw holes where shipping bolts were removed earlier. Adjust the level of the dishmachine by screwing the adjustable feet in or out. The front of the machine should be adjusted

1/4” to 1/2” higher than the back. Install the deck mounting hardware as shown in the drawing below, at the location where the

dishmachine will be permanently positioned. Install 3/8” stainless steel lug bolts to secure tracks and caps to the deck. Drill

holes into deck as shown below and insure rear holes are located 2-1/4” from the wall. The racks and rear end caps may be

tightened at this time. Slide dishmachine onto tracks and into position at rear end caps. Install front end caps into place and

adjust if necessary to remove any movement of machine; if possible, tack weld tracks to deck.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

TYPICAL

LOCATION

OF FOOT

LEVELER

EXISTING WALL

19”

21 7/8”

21 1/4”

23 1/2”

2 1/4”

TOP VIEW

REAR

END CAPS

FRONT VIEW

19”

TYPICAL

LOCATION

OF FOOT

LEVELER

FRONT PANEL

OF DISHWASHER

21 7/8”

FLOOR

Page 14

SECTION 2: INSTALLATION & OPERATION INSTRUCTIONS

DETERGENT CONTROL

Detergent usage and water hardness are two factors that contribute greatly to how efficiently your dishmachine will operate.

Using detergent in the proper amount can become, in time, a source of substantial savings. A qualified water treatment specialist can tell you what is needed for maximum efficiency from your detergent, but you should still know some basics so you’ll

understand what they are talking about.

First, you must understand that hard water greatly effects the performance of the dishmachine. Water hardness is the amount

of dissolved calcium and magnesium in the water supply. The more dissolved solids in the water, the greater the water hardness. Hard water works against detergent, thereby causing the amount of detergent required for washing to increase. As you

use more detergent, your costs for operating the dishmachine will increase and the results will decrease. The solids in hard

water also may build-up as a scale on wash and rinse heaters, decreasing their ability to heat water. Water temperature is

important in removing soil and sanitizing dishes. If the water cannot get hot enough, your results may not be satisfactory. This

is why Jackson recommends that if you have installed the machine in an area with hard water, that you also install some type

of water treatment equipment to help remove the dissolved solids from the water before it gets to the dishmachine.

Second, hard water may have you adding drying agents to your operating cycle to prevent spotting, when the real problem is

deposited solids on your ware. As the water evaporates off of the ware, the solids will be left behind to form the spotting and

no amount of drying agent will prevent this. Again, using treated water will undoubtedly reduce the occurrences of this problem.

Third, treated water may not be suitable for use in other areas of your operation. For instance, coffee made with soft water may

have an acid or bitter flavor. It may only be feasible to install a small treatment unit for the water going into the dishmachine

itself. Discuss this option with your qualified water treatment specialist.

Even after the water hardness problems have been solved, there still must be proper training of dishmachine operators in how

much detergent is to be used per cycle. Talk with your water treatment specialist and detergent vendor and come up with a

complete training program for operators. Using too much detergent has as detrimental effects as using too little. The proper

amount of detergent must be used for job. It is important to remember that certain menu items may require extra detergent by

their nature and personnel need to be made aware of this. Experience in using the dishmachine under a variety of conditions,

along with good training in the operation of the machine, can go a long way in ensuring your dishmachine operates as effi ciently as possible.

Certain dishmachine models require that chemicals be provided for proper operation and sanitization. Some models even

require the installation of third-party chemical feeders to introduce those chemicals to the machine. Jackson does not recommend or endorse any brand name of chemicals or chemical dispensing equipment. Contact your local chemical distributor for

questions concerning these subjects.

Some dishmachines come equipped with integral solid detergent dispensers. These dispensers are designed to accommodate

detergents in a certain sized container. If you have such a unit, remember to explain this to your chemical distributor upon first

contacting them.

As explained before, water temperature is an important factor in ensuring that your dishmachine functions properly. The data

plate located on each unit details what the minimum temperatures must be for either the incoming water supply, the wash tank

and the rinse tank, depending on what model of dishmachine you have installed. These temperatures may also be followed by

temperatures that Jackson recommends to ensure the highest performance from you dishmachine. However, if the minimum

requirements are not met, the chances are your dishes will not be clean or sanitized. Remember, a dish can look clean, but it

may not be sanitized. Instruct your dishmachine operators to observe the required temperatures and to report when they fall

below the minimum allowed. A loss of temperature can indicate a much larger problem such as a failed heater or it could also

indicate that the hot water heater for your operation is not up to capacity and a larger one may need to be installed.

There are several factors to consider when installing your dishmachine to ensure that you get the best possible results from it

and that it operates at peak efficiency for many years. Discuss your concerns with your local chemical distributor and water

treatment specialist before there is a problem.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

8

Page 15

SECTION 2: INSTALLATION & OPERATION INSTRUCTIONS

OPERATION INSTRUCTIONS

PREPARATION: Before proceeding with the start-up of the unit, verify the following:

1. The strainer is in place and is clean.

2. That the wash and rinse arms are screwed securely into place and that their endcaps are tight. The wash and rinse arms should

rotate freely.

3. Verify all chemical levels for machine chemical feeder pumps are correct.

POWER UP: To energize the unit, turn on the power at the service breaker. The voltage should have been previously verified as being

correct. If not, the voltage will have to be verified.

FILLING THE WASH TUB: For the initial fill, close the door and ensure that the MANUAL switch light is not on. Depress and hold the

START CYCLE switch until the auto light comes on and releases. For the initial fill, run the machine through 3 cycles to fill the tub

sump. The machine will run a partial cycle and fill to the bottom of the pan strainer. Open the door and verify that the water level is correct.

NOTE: Ensure the orange/white wires at the heater contactor are connected properly. They have been purposely disconnected at the factory to avoid damage to the heater element when there is no water in the booster heater.

Hereafter, the water level is controlled by the timer that has been preset at the factory. Verify that there are no other leaks on the unit

before proceeding any further. The wash sump must be completely filled before operating the wash pump to prevent damage to the

component. Once the wash tub is filled, the unit is ready for operation.

The machine runs a complete cycle to drain and fill. If the machine is not allowed to drain, the water will build up inside the tub. After

the initial fill, the rinse water for the current cycle will become the wash water for the next cycle.

WARE PREPARATION:Proper preparation of ware will help ensure good results and less re-washes. If not done properly, ware may

not come out clean and the efficiency of the dishmachine will be reduced. It is important to remember that a dishmachine is not a

garbage disposal and that simply throwing unscraped dishes into the machine simply defeats the purpose altogether of washing the

ware. Scraps should be removed from ware prior to being loaded into a rack. Pre-rinsing and pre-soaking are good ideas, especially

for silverware and casserole dishes. Place cups and glasses upside down in racks so that they do not hold water during the cycle. The

dishmachine is meant not only to clean, but to sanitize as well, to destroy all of the bacteria that could be harmful to human beings. In

order to do this, ware must be properly prepared prior to being placed in the machine.

DAILY MACHINE PREPARATION: Refer to the section entitled “PREPARATION” at the top of this page and follow the instructions

there. Afterwards, check that all of the chemical levels are correct and/or that there is plenty of detergent available for the expected

workload.

WARM-UP CYCLES: For a typical daily start-up, it is recommended to run the machine through 3 cycles to ensure that all of the cold

water is out of the system and to verify that the unit is operating correctly. To cycle the machine, ensure that the power is on and that

the tub has filled to the correct level.

Press the START CYCLE button and hold until the green auto light is on and releases, the unit will start, run through the cycle, and

shut off automatically. Repeat this two more times. The unit should now be ready to proceed with the washing of ware.

WASHING A RACK OF WARE: To wash a rack, open the door completely and slide the rack into the unit. Close the door, press the

START CYCLE button and hold until the green auto light is on and releases, the unit will start. Once the cycle is completed, open the

door and remove the rack of clean ware. Replace with a rack of soiled ware and close the door. The process will then repeat itself.

OPERATIONAL INSPECTION: Based upon usage, the pan strainer may become clogged with soil and debris as the workday progresses. Operators should regularly inspect the pan strainer to ensure it has not become clogged. If the strainer does, it will reduce

the washing capability of the machine. Instruct operators to clean out the pan strainer at regular intervals or as required by work load.

SHUTDOWN AND CLEANING: At the end of the workday, close the door. Start a cycle. Wait approximately five seconds and then

push the POWER OFF switch. This will put the machine in shutdown mode which will let the machine drain completely prior to shutting off. Once the wash tub is drained and power light is off, remove he pan strainer. Remove soil and debris from the strainer and set

to the side. Unscrew the wash and rinse arms from their manifolds. Remove the endcaps and flush the arms with water. Use a brush

to clean out the inside of the arms. If the nozzles appear to be clogged, use a toothpick to remove the obstruction. Wipe the inside of

the unit out, removing all soil and scraps. Reassemble the wash and rinse arms and replace them in the unit. The arms only need to

be hand tight, do not use tools to tighten them down. Reinstall the strainer and close the door.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

9

Page 16

SECTION 3:

PREVENTATIVE MAINTENANCE

10

Page 17

SECTION 3: PREVENTATIVE MAINTENANCE

PREVENTATIVE MAINTENANCE

The dishmachines covered in this manual are designed to operate with a minimum of interaction with the operator. However,

this does not mean that some items will not wear out in time.

There are many things that operators can do to prevent catastrophic damage to the dishmachine. One of the major causes of

component failure has to do with prescrapping procedures. A dishmachine is not a garbage disposal; any large pieces of material that are put into the machine shall remain in the machine until they are either broken up (after spreading out on your ware!)

or physically removed. Strainers are installed to help catch debris, but they do no good of they are clogged. Have operators

regularly inspect the pan strainers to ensure (1) that they are free of soil and debris and (2) they are laying flat in the tub.

When cleaning out strainers, do NOT beat them on waste cans. The strainers are made of metal and can be forgiving; but once

severe damage is done, it is next to impossible for the strainer to work in the way it was designed to. Wipe out strainers with

a rag and rinse under a faucet if necessary. For stubborn debris, a toothpick should be able to dislodge any obstructions from

the perforations. Always ensure that strainers are placed back in the machine before operation and that they lay flat in the tub.

You may wish to contact Jackson in order to learn more about how your water hardness will effect the performance of your

machine. Hard water makes dishmachines work harder and decreases efficiency.

Again, it is important to remind operators that trying to perform corrective maintenance on the dishmachine could lead to larger problems or even cause harm to the operator. If a problem is discovered; secure the dishmachine using proper shut down

procedures as listed in this manual and contact Jackson.

Some problems, however, may having nothing to do with the machine itself and no amount of preventative maintanence is

going to help. A common problem has to do with temperatures being too low. Verify that the water temperatures coming to your

dishmachine match the requirements listed on the machine data plate. There can be a variety of reasons why your water temperature could be too low and you should discuss it with Jackson to determine what can be done.

By following the operating and cleaning instructions in this manual, you should get the most efficient results from your machine.

As a reminder, here are some steps to take to ensure that you are using the dishmachine the way it was designed to work:

1. Ensure that the water temperatures match those listed on the machine data plate.

2. Ensure that all strainers are in place before operating the machine.

3. Ensure that all wash and/or rinse arms are secure in the machine before operating.

4. Ensure that drains are closed/sealed before operating.

5. Remove as much soil from dishes by hand as possible before loading into racks.

6. Do not overfill racks.

7. Ensure that glasses are placed upside down in the rack.

8. Ensure that all chemicals being injected to machine have been verified as being at the correct concentrations.

9. Clean out the machine at the end of every workday as per the instructions in the manual.

10. Always contact your Ecolab representative whenever a serious problem arises.

11. Follow all safety procedures, whether listed in this manual or put forth by local, state or national codes/regulations.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

11

Page 18

SECTION 4:

TROUBLESHOOTING

12

Page 19

SECTION 4: TROUBLESHOOTING SECTION

COMMON PROBLEMS

WARNING: Inspection, testing and repair of electrical equipment should be performed only by qualified service personnel.

Certain procedures in this section require electrical tests or measurements while power is applied to the machine. Exercise

extreme caution at all times. If test points are not easily accessible, disconnect power, attach test equipment and reapply

power to test. When replacing electrical parts, disconnect power at source circuit breaker.

Problem: Water overflow from bottom of door.

1. Clogged drain. Remove obstruction.

2. Machine not level. Level machine, or increase height to the front.

3. Excessive inlet pressure. Install pressure reducing valve, or adjust if one is present. Ensure flow is 20A5 PSI.

4. Detergent foaming. Reduce detergent quantity.

Problem: Wash motor doesn’t operate on manual wash.

1. Loose or broken wires. Reconnect or replace wires in motor.

2. Defective manual wash switch. Replace.

3. Defective motor starting relay. Replace.

Problem: Motor operates on manual wash but not on automatic.

1. Defective timer. Replace timer.

2. Defective circuit in manual wash switch. Replace switch.

Problem: No water comes through the rinse arms when the “START CYCLE” switch is depressed.

1. Water not turned on. Turn water on.

2. Defective solenoid valve. Replace solenoid valve.

3. Probes are dirty or coated. Clean probes.

4. Defective water level control. Replace.

Problem: Little or no water coming through the rinse assemblies.

1. Limed up rinse heads or piping. Delime rinse heads.

2. Low water pressure. Increase pipe size to machine. Adjust pressure regulator.

Problem: Rinse water runs continuously with breaker turned off.

1. Defective plunger in solenoid valve. Replace.

2. Defective diaphragm in solenoid valve. Replace diaphragm.

Problem: Rinse doesn’t operate on automatic during timed cycle (but does operate in auto/fill operation).

1. Timer defective. Replace timer.

Problem: Rinse water runs continuously with power applied to machine, but when circuit breaker to machine is turned

off, water stops.

1. Defective water level control. Replace.

2. Probes are dirty or coated. Clean probes.

Problem: Wash temperature not at required reading on thermometer.

1. Defective thermometer. Replace.

2. Defective thermostat. Adjust thermostat. Replace thermostat.

3. Rinse heater defective. Replace heater element.

4. Water level protection control device. Replace.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

13

Page 20

SECTION 4: TROUBLESHOOTING SECTION

Problem: Rinse water not at required temperature range.

1. Thermometer is defective. Replace.

2. Thermostat is defective. Adjust the thermostat. Replace if necessary.

Problem: Machine doesn’t drain when “POWER OFF” switch is pressed.

1. Drain solenoid clogged. Remove obstruction.

2. Defective “POWER OFF” switch. Replace.

3. Defective motor or motor start relay. Replace.

4. Defective drain solenoid. Replace.

5. Defective timer. Replace.

Problem: No indication of pressure.

1. Water turned off. Turn water on.

2. 1/4” test cock ball valve is closed. Open the ball valve.

COMMON PROBLEMS

14

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

Page 21

SECTION 5:

SERVICE PROCEDURES

15

Page 22

SECTION 5: SERVICE PROCEDURES

RINSE SOLENOID VALVE REPAIR PARTS KIT

These dishmachines are equipped with electrical

solenoid valves to allow for automatic fill and rinse. These

valves are designed to specific tolerances and design aspects

that must be met in order to function properly.

Jackson offers repair kits for replacing some of the

wear items associated with solenoid valves which will allow

you to save money in that replacement of these parts can take

place without removing the solenoid valve from the plumbing

assembly.

The instructions provided here are for maintenance

personnel only. Unauthorized persons should not attempt any

of the steps contained in these instructions.

Warning: many of the instructions and steps

within this document require the use of tools. Only autho rized personnel should ever perform any maintenance

procedure on the dishmachine!

PREPARATION

1. Power must be secured to the unit at the service

breaker. Tag or lock out the service breaker to prevent accidental or unauthorized energizing of the machine.

2. Ensure that incoming water to the machine is

secured either by use of a shut-off valve or disconnecting the

incoming water line.

TOOLS REQUIRED

The following tools will be needed to perform this

maintenance evolution:

1. Small flathead screwdriver

2. Medium flathead screwdriver

2. Needle nose pliers

3. 5/16” nutdriver

4. Channel locks

5. 12” pipe wrench

STEPS

1. Remove the top screw with the 5/16” nutdriver. Remove the

screw and the data plate and set to the side.

Removing the top screw

2. With the top screw and data plate removed, grasp the sole noid coil and gently pull up. The coil should slide up, allowing

you to remove it from the valve bonnet. If you are wanting to

replace the coil, continue on with Step 3. If you are wanting to

replace some of the internal components of the valve, proceed

to step 12.

TIME REQUIRED

It is estimated that it will take (1) person twenty min utes to perform this task, not including all of the items indicated in the section entitled “PREPARATION”.

IMPORTANT NOTES

1. Read these instructions thoroughly before attempt ing this maintenance evolution. Become familiar with the parts

and what actions need to be taken. This will save time in the

long run!

2. The procedures demonstrated in this manual are

shown being performed on an AJ-44C rack conveyor dishmachine. The actual maintenance steps, however, apply to any

Parker style solenoid valve found on a Jackson dishmachine.

Removing the coil

3. NOTE: Replacing the solenoid coil requires working with

the wiring of your machine. It is important that all wiring main tenance be performed by qualified personnel. Always verify

the wiring steps presented in this instruction with the schemat ic that shipped with the unit. A current schematic can also be

found in the unit’s installation manual. Before beginning any

step that involves working with wiring, ensure that the steps

located in the section entitled “Preparation” have been performed. Power must be secured to the machine at the service

breaker. Failure to do so could result in severe injury to main tenance personnel.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

16

Page 23

RINSE SOLENOID VALVE REPAIR PARTS KIT (CONTINUED)

SECTION 5: SERVICE PROCEDURES

Prying open the coil wire cover

4. When replacing the coil, ensure that when removing the coil

wire cover that care is taken not to damage the wires inside.

Using the medium flathead screwdriver, gently use it to open

the cover enough to where it could be pulled off.

Straightening the wires

5. Once the coil wire cover has been removed and set to the

side, take the internal wires and pull them out straight.

Loosening the conduit nut

7. Using a pair of channel locks, gently loosen the conduit

retaining ring for the conduit nut. Once it is loosened, use your

fingers to unscrew and remove it.

8. Pull the conduit away and discard the bad coil. Take the

new coil and attach the conduit, reinstall & tighten the conduit

nut, and pull the wires through so that you will be able to wire

the valve back up.

9. Reconnect the wires from the conduit to the wires from the

solenoid as they had been connected previously. Ensure that

the wire nuts are on tight.

10. Slide the coil wire cover back on, taking care not to damage the wires.

11. If you are done performing maintenance on the valve, continue on to step 23. Otherwise, please go on to step 12.L

Removing the wire nuts

6. Remove the wire nuts from the wires and separate them.

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

Loosening the valve bonnet

12. To remove the valve bonnet, grasp it with the jaws of the

pipe wrench and turn to the left. Note: on some models you

may have to remove the valve in order to perform this and any

further steps. Be careful not to damage the plumbing assembly. Only use the pipe wrench enough to where you can spin

the valve bonnet off with your hand.

17

Page 24

SECTION 5: SERVICE PROCEDURES

Removing the valve bonnet

13. Slowly remove the valve bonnet. Note: The spring for the

plunger is located directly under the bonnet and may come

free if you are not careful. Remove the plunger, spring and

valve bonnet and place to the side.

RINSE SOLENOID VALVE REPAIR PARTS KIT (CONTINUED)

Removing the diaphragm

17. Remove the diaphragm retainer and then the diaphragm

itself. Many problems associated with a solenoid valve can be

traced to a clogged pilot port in the diaphragm.

Removing the O-ring

14. Remove the O-ring and inspect it. If it has any tears or cuts

or excessive flat spaces, it should be replaced.

15. Examine the threads for the valve bonnet. Check them for

scoring or signs of damage. Take a cloth and clean them out

to remove any foreign particles that might get lodged in the

threads and cause a leak. Severely damage threads should

not be repaired; instead it is recommended that the entire

valve should be replaced. These instructions do not provide

information on replacing the solenoid valve.

16. Note: Even though an O-ring may not appear damaged, it

is a good idea to go ahead and replace it if you have a new

one. This will help ensure that your valve remains leak-free in

the future!

Pointing out the extension hole

18. As indicated in the photo above, the extension hole can

become clogged. If it is difficult to clean out, you can use a

heated straight pin to push through the hole. The center hole,

the pilot port, must also be clear. If the diaphragm is torn or

bent in any way, it must be replaced.

1

2

Diaphragm showing (1) pilot port and (2) extension hole

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

18

Page 25

RINSE SOLENOID VALVE REPAIR PARTS KIT (CONTINUED)

Removing the screen retainer

19. Using the small flathead screwdriver, lift out the screen

retainer. Verify that the holes in it are free of clogs and debris.

SECTION 5: SERVICE PROCEDURES

21. With the mesh screen removed, look down into the valve

and verify it is not clogged. Remove any foreign objects from

the valve body that would obstruct flow.

22. Reassemble the valve, reversing the steps needed to take

it apart. Replace defective replacement parts with new parts

from ordered kits. Ensure that components are sufficiently

tightened to prevent leakage.

AFTER MAINTENANCE ACTIONS

Reconnect the incoming water (if disconnected) and

turn on. Then restore power to the unit. Run the unit for at

least 10 minutes to ensure there are no leaks. If any problems

arise please contact Jackson.

SPECIAL PARTS

Solenoid Valve Plunger Kit

Includes plunger and spring

Part number 6401-003-07-40

Removing the mesh strainer screen

20. Again using the small flathead screwdriver, carefully

remove the mesh screen from inside the valve body. The

screen should be taken and rinsed out to remove any debris

fouling it.

Solenoid Valve Diaphragm Kit

Includes diaphragm and o-ring

Part number 6401-003-07-41 (1/2” NPT)

Solenoid Valve 110 Volt Coil and Housing Kit

Part number 6401-003-07-43

Complete Solenoid Valve

Part number 04810-100-12-18 (1/2”, 110 Volt)

View inside the solenoid valve body

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

19

Page 26

SECTION 5: SERVICE PROCEDURES

VACUUM BREAKER REPAIR PARTS KIT

These dishmachines are equipped with vacuum

breakers to serve as back-flow prevention devices. ASSE

requirements specify what type of back-flow prevention is necessary on dishmachines. Vacuum breakers, unlike air gaps,

have certain parts that have specific tolerances and design

aspects that must be met in order to function properly.

Jackson offers repair kits for replacing some of the

wear items associated with vacuum breakers which will allow

you to save money in that replacement of these parts can take

place without removing the vacuum breaker from the plumbing assembly.

The instructions provided here are for maintenance

personnel only. Unauthorized persons should not attempt any

of the steps contained in these instructions.

Warning: many of the instructions and steps

within this document require the use of tools. Only autho rized personnel should ever perform any maintenance

procedure on the dishmachine!

PREPARATION

1. Power must be secured to the unit at the service

breaker. Tag or lock out the service breaker to prevent accidental or unauthorized energizing of the machine.

2. Ensure that incoming water to the machine is

secured either by use of a shut-off valve or disconnecting the

incoming water line.

TOOLS REQUIRED

STEPS

1. Note: These instructions only apply to vacuum breakers

(1/2” NPT and 3/4” NPT) as pictured below. The repair kits

indicated in these instructions will only work on those style of

back-flow preventers. If you have a machine with a different

style of vacuum breaker, contact your Ecolab representative

about replacement components.

Vacuum breaker

2. Note: Even though the photos in these instructions show a

vacuum breaker that has been removed from the plumbing

assembly, these maintenance steps could be performed with it

installed so long as the requirements in the section entitled

“PREPARATION” have been met.

3. Remove the top cap by gripping firmly and turning to the

left. The cap should come off after a few turns.

The following tools will be needed to perform this

maintenance evolution:

1. Small flathead screwdriver

2. Needle nose pliers

TIME REQUIRED

It is estimated that it will take (1) person twenty min utes to perform this task, not including all of the items indicated in the section entitled “PREPARATION”.

IMPORTANT NOTES

1. Read these instructions thoroughly before attempt ing this maintenance evolution. Become familiar with the parts

and what actions need to be taken. This will save time in the

long run!

Removing the cap

4. Set the cap to the side.

5. Using the needle nose pliers, gently lift out the plunger and

set to the side. Examine the brass seating surface inside the

vacuum breaker. The plunger is required to sit flat on this surface so it must be free of defects, imperfections and the like. If

there is debris, remove it. If it is chipped or cracked then the

vacuum breaker must be replaced. Failure to do so may result

in the vacuum breaker not working according to its design and

could result in damage to the dishmachine.

20

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

Page 27

VACUUM BREAKER REPAIR PARTS KIT (CONTINUED)

Removing the plunger

6. Your repair kit comes with a new plunger. Examine the old

one and ensure that the mating surface is not damaged or cut.

Also inspect the rubber seal on the top of the plunger to

ensure it is in good condition and not torn.

SECTION 5: SERVICE PROCEDURES

7. If any of these conditions are present, replace the old

plunger with the new one from your kit. Verify that the new

plunger is also free from defects. If it is not, contact your

Ecolab representative immediately.

8. The plunger should drop into the vacuum breaker and seat.

Ensure it is not flipped upside down (the orange seal ring

should be up towards the top of the vacuum breaker).

9. Pick up the cap and examine it. With a soft towel, remove

any grit, grime or debris that may have gotten caught in the

threads of both the cap retainer or the vacuum breaker body.

There is an O-ring that should be present on the cap retainer

as well. Regardless of the condition of the plunger, this O-ring

should be replaced once the cap is removed. Using a small

flathead screwdriver, remove the old O-ring.

Examining the seal ring on the plunger

Examining the plunger seating surface

Replacing the O-ring

10. With the new O-ring in place, screw the cap back on the

vacuum breaker body. The cap needs to only be hand tight

(snug).

AFTER MAINTENANCE ACTIONS

1. Reconnect the incoming water (if disconnected)

and turn on. Then restore power to the unit. Run the unit for

at least 10 minutes to ensure there are no leaks. If any prob lems arise please contact Jackson.

SPECIAL PARTS

To order the kit with components and instructions:

Components of 1/2” Repair Kit

6401-003-06-23

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

21

Page 28

SECTION 6:

PARTS SECTION

22

Page 29

ELECTRICAL PANEL ASSEMBLY

SECTION 6: PARTS SECTION

21

22

1

2 3 34 5 6

7, 8

9

10

11, 12,

5

14, 5

15, 1613

17 18, 19, 16

ITEM QTY DESCRIPTION Mfg. No.

1 1 Bushing, Snap 5975-210-03-00

2 1 Track, Terminal 6 7/8" 5700-021-62-91

3 2 End Clamp 5940-111-60-30

4 2 Contactor,Mini 5945-111-60-07

5 9 Screw, 10-32 x 3/8 Phillips Truss Round Head 5305-173-12-00

6 1 Track, Terminal 4 3/4" 5700-002-75-74

7 1 Decal, L1, L2, L3 9905-101-12-66

8 3 Block, Snap-in Terminal 5940-500-02-19

9 1 Electrical Control Panel Weldment 5700-031-62-94

10 1 Grommet, 1 1/8" Heyco 5975-210-08-00

11 1 Wire Lug 5940-200-76-00

12 1 Ground Decal 9905-011-41-82

13 1 Overload, Contactor 5945-111-60-08

14 1 ACME Transformer, 480 to 120 Volt 5950-011-50-70

15 1 Terminal Board, 1/4 QC 5940-021-94-85

16 2 Screw, 6-32 x 3/8” Sems with External Tooth Lockwasher 5305-002-25-91

17 1 Locknut, 10-24 S/S Hex with Nylon Insert 5310-373-01-00

18 1 Timer, 6 Cam 5945-121-44-69

19 1 Decal, Timer 9905-011-40-70

20 4 Locknut, 1/4-20 S/S Hex with Nylon Insert (not shown) 5310-374-01-00

21 1 Fuse Holder 5920-011-72-89

22 1 Fuse, 1/4 Amp 5920-002-75-95

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

23

Page 30

SECTION 6: PARTS SECTION

SWITCH PANEL ASSEMBLY

2

1

8

3

5

6

9

77

9

48

ITEM QTY DESCRIPTION Mfg. No.

1 1 Switch Panel Weldment 5700-002-71-11

2 1 Decal, Control Panel 5700-002-75-75

3 1 Switch, Yellow Reed 5930-011-47-50

4 1 Decal, High Limit 9905-002-75-98

5 1 Switch, Prime 5930-002-68-27

6 1 Light, Amber 5945-504-06-18

7 2 Switch, Button DPDT 5930-002-43-44

8 2 Light, Red 5945-504-07-18

9 2 Light, Green 5945-504-08-18

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

24

Page 31

SWITCH PANEL ASSEMBLY (WITH STAINLESS STEEL SWITCHES)

SECTION 6: PARTS SECTION

3

1

8

2

5

6

9

77

9

48

ITEM QTY DESCRIPTION Mfg. No.

1 1 Switch Panel Weldment 5700-003-02-65

2 1 Decal, Control Panel 5700-002-75-75

3 1 Switch, Yellow Reed 5930-011-47-50

4 1 Decal, High Limit 9905-002-75-98

5 1 Switch, Prime 5930-003-05-30

6 1 Light, Amber 5945-504-06-18

7 2 Switch, ON/OFF 5930-003-05-29

8 2 Light, Red 5945-504-07-18

9 2 Light, Green 5945-504-08-18

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

25

Page 32

SECTION 6: PARTS SECTION

Gauge, Pressure 0-100 PSI

6680-011-86-42

Thermometer, Rinse 120”

6685-111-68-49

KICK PANEL ASSEMBLY

Thermometer, Wash 48”

6685-111-68-48

Decal, Wash

9905-002-68-95

Decal, Rinse

9905-002-68-96

Kick Panel Weldment

5700-002-71-19

Pressure Hose Assembly

5700-002-72-17

Nylon Loop

4320-002-71-22

Locknut, 6-32 Hex S/S with Nylon Insert

5310-373-03-00

Fitting, 1/4”

4730-011-95-42

Hose, 5/16” x 12” Long

5700-011-86-45

Fitting, 1/4”

4730-011-95-41

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

26

Page 33

PLUMBING ASSEMBLY

Adapter, 1/2" Ftg. x Male

4730-011-59-53

SECTION 6: PARTS SECTION

Copper Tube, 1/2" x 1 1/4"

5700-000-38-78

Union, 1/2" C to C

4730-412-05-01

Nipple, 1/2" Close

4730-207-15-00

Tee, 1/2 x 1/2 x 1/4

4730-411-25-01

Adapter, 1/2" Ftg. x Male

4730-401-03-01

Valve, Solenoid 1/2" 220 volt

4810-100-09-18

Y-Strainer, 1/2"

4730-217-01-10

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

27

Page 34

SECTION 6: PARTS SECTION

Fitting, Outlet Elbow

4820-111-51-18

Nut, P/P for 1/8” Tubing

4730-011-59-45

Valve, Check

4820-111-51-14

Plug, 1/4” Brass

2 per machine

4730-209-01-00

PLUMBING ASSEMBLY (CONTINUED)

Injector Weldment

5700-031-41-83

Vacuum Breaker

4820-300-07-00

Adapter, 1/2" Ftg. x Male

4730-401-03-01

Pipe, Clamp

5700-011-38-62

Copper Tube, 1/2” x 20 1/4”

5700-031-41-83

Adapter, 1/2" Ftg. x Male

4730-401-03-01

Nipple, 1/2” Close Brass

4730-207-15-00

Secure with:

Locknut, 1/4”-20 S/S Hex with Nylon Insert

5310-374-01-00

Elbow, 1/2” NPT 90B Brass

4730-011-42-96

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

28

Page 35

PLUMBING ASSEMBLY (CONTINUED)

SECTION 6: PARTS SECTION

Clamp, Hose

4730-719-06-09

Locknut, 1/4”-20 S/S Hex with Nylon Insert

5310-374-01-00

Gasket, Rinse

330-111-42-81

Hose, 3/4” x 8 1/2”

5700-011-38-83

Gasket, Manifold

5330-002-34-77

Rinse Stiffener Weldment

5700-002-59-79

Locknut, 1/4”-20 S/S Hex with Nylon Insert

5310-374-01-00

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

Rinse Hub Weldment

5700-021-38-31

29

Page 36

SECTION 6: PARTS SECTION

1/2” SOLENOID VALVE & 1/2” NPT VACUUM BREAKER REPAIR PARTS KITS

Screw

Data Plate

Valve Bonnet

Diaphragm

Retainer

Screen

Retainer

Coil & Housing

Spring & Plunger Kit

6401-003-07-40

Diaphragm & O-ring Kit

6401-003-07-41

Mesh Screen

Data Plate

Cap Retainer

Components of Repair Kit

6401-003-06-23

Cap Screw

Cap

O-Ring

Plunger

Body

Valve Body

Complete 110 Volt Solenoid Valve Assembly

4810-100-09-18

Coil & Housing only

6401-003-07-44

Complete Vacuum Breaker Assembly

4820-003-06-13

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

30

Page 37

DRAIN VALVE ASSEMBLY

SECTION 6: PARTS SECTION

17

16

1213

6 7

8

11

5

10

4

2

1

9

1415

3

ITEM QTY DESCRIPTION Mfg. No.

1 1 Valve, With Brackets 5700-002-23-28

2 1 Hosebarb, 1” x 3/4” NPT Polypropylene 4730-011-65-86

3 1 Hosebarb, 90B 1” x 3/4” NPT 4730-011-65-87

4 1 Plate, Motor Mounting Weldment 5700-031-96-02

5 4 Tricnut, 10-32 AK Fastener, S/S 5340-111-58-10

6 1 Lockwasher, #10 External Tooth 5311-273-02-00

7 1 Grommet, Heyco 5975-210-03-00

8 1 Cam Weldment 5700-011-65-78

9 1 Plate, Dielectric 5700-011-65-80

10 1 Switch, Micro 5930-011-65-81

11 2 Screw, 4-40 x 5/8" 5305-011-49-70

12 1 Motor, Chemical Feeder Pump 14 RPM 4320-011-79-34

13 1 Terminal, Ground Spade 5940-011-75-70

14 4 Locknut, 10-32 S/S Hex with Nylon Insert 5310-373-02-00

15 1 Valve, Cover 5700-031-65-70

16 4 Screw, 10-32 x 3/8” Truss Head 5305-173-12-00

17 1 Decal, Warning-Disconnect Power 9905-100-75-93

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

31

Page 38

SECTION 6: PARTS SECTION

DRAIN PLUMBING ASSEMBLY

1

7

2

8

1

9

3, 10

4

5

6

6

ITEM QTY DESCRIPTION Mfg. No.

1 3 Clamp, 3/16” to 1 1/2” 4730-719-06-09

2 1 Hose, Formed Drain 4720-121-40-36

3 2 Bolt, 10-32 x 1/2” Slotted Truss Head 5305-173-04-00

4 1 Diverter Valve Assembly 5700-002-23-21

5 1 Clamp, 11/16” to 1 1/4” 4730-002-18-40

6 1 Hose, 1” I.D. x 10 Feet Long 5700-011-39-72

7 2 Locknut, 1/4”-20 S/S Hex with Nylon Insert 5310-374-01-00

8 2 Bolt, 1/4”-20 x 1/2” Long 5305-274-02-00

9 1 Bracket, Valve Mounting with Tricnuts 5700-021-66-37

10 2 Washer, #10 External Tooth Star 5311-273-02-00

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

32

Page 39

WASH MOTOR TO WASH TUB ASSEMBLY

3

5

6

SECTION 6: PARTS SECTION

1

2

4

8

9

10

12

11 - NOT SHOWN

4

7

4

11 - NOT SHOWN

ITEM QTY DESCRIPTION Mfg. No.

1 1 Hub, Discharge Machined 5700-021-37-90

2 1 Gasket, 2” O.D. x 1 1/2” I.D. x 1/16” 5330-200-23-00

3 1 Nut, Jam 1 1/2”-12 NPT 5700-000-86-23

4 4 Hose Clamp, 1 5/16" - 2 1/4" # 28 4730-719-01-37

5 1 Hose,1 1/4” x 2 1/4” Reinforced 5700-011-44-48

6 1 Motor, Wash, 460V, 3/4 HP 6105-121-60-06

7 1 Hose, Bottom Manifold Pump 5700-001-22-92

8 1 Gasket, Suction Adapter 5330-021-40-87

9 1 Casting, Suction Adapter 9515-031-39-86

10 4 Washer, S/S 1/4”-20 I.D. 5311-174-01-00

11 6 Locknut, 1/4”-20 S/S 5310-374-01-00

12 4 Washer, 1/4” I.D. x 3/4” O.D. S/S 5311-011-76-30

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

33

Page 40

SECTION 6: PARTS SECTION

Rinse Tank Weldment

5700-002-71-00

Secured with: Locknut, 1/4”-20 S/S Hex with Nylon Insert

5310-374-01-00

Fitting, 1/4” Imperial Brass

5310-924-02-05

Gasket, Heater

5330-011-47-79

RINSE TANK & COMPONENTS

Dielectric Cover

5700-011-40-50

Nut, 5/16”-18 S/S Hex

5310-275-01-00

Lockwasher, 5/16” Split

5311-275-01-00

The JPX-300NSU comes supplied with various heaters, depending on the characteristics of the machine. To ensure that you

order the correct heater for the model you are servicing, please refer to the following table:

40

°F Rise

70

°F Rise

Volts Hz Phase Rinse Heater (8.2 KW) Rinse Heater (10 KW)

460 60 3 4540-111-51-46 4540-002-29-82

Thermostat, Rinse Tank

5930-121-71-29

Decal, Thermostat Regulating

9905-011-84-31

Thermostat, High Limit

5930-011-49-43

Screw, 6-32 x 3/8” Sems w/External Tooth Washer

Thermostat Mounting Bracket

5700-*011-81-64

The thermostat attaches with 2:

5305-002-25-91

Decal, High Limit

9905-011-84-32

34

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

Page 41

DOOR ASSEMBLY

14

SECTION 6: PARTS SECTION

Order this entire assembly using 5700-002-59-46

1

12, 13

11

14

3

4

5

2

9, 10

8

7 6

ITEM QTY DESCRIPTION Mfg. No.

1 1 Door Weldment 5700-002-59-37

2 1 Inner Door Weldment 5700-002-71-80

3 2 Bearing, Nyliner Standard Flanged 3120-002-71-66

4 2 Lockwasher, 3/8” S/S 5311-276-01-00

5 2 Locknut, 3/8”-16 S/S Hex with Nylon Insert 5310-011-72-55

6 2 Spring, Door 5340-011-44-58

7 2 Door Lever Weldment 5700-002-72-97

8 1 Lever, Door, Left Hand 5700-002-71-64

9 2 Magnet, Reed Switch 5930-002-68-53

10 6 Nut, 8-32 Hex Locking 5310-272-02-00

11 8 Screw, Cross Recessed Flat Countersunk Tapping 5305-002-71-12

12 2 Bolt, 1/4”-20 x 1/2" Long 5305-274-02-00

13 2 Washer, 1/4” I.D. S/S 5311-174-01-00

14 1 Lever, Door, Right Hand 5700-002-72-96

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

35

Page 42

SECTION 6: PARTS SECTION

Bearing, Rinse Head

3120-002-72-24

Bushing, Rinse Head

5700-021-33-84

Ring, Retaining

5340-112-01-11

Plug, Rinse Arm

4730-609-04-00

RINSE ARM & WASH ARM ASSEMBLIES

Rinse Arm Assembly

5700-031-39-21

Rinse Arm

5700-031-38-30

Washer, Rinse Arm

5330-011-42-10

Wash Arm Assembly

5700-021-39-23

Wash Arm Weldment

5700-021-46-58

Bearing Assembly

5700-021-35-97

O-ring (Not Shown)

5330-002-60-69

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

36

Page 43

MISCELLANEOUS PARTS

SECTION 6: PARTS SECTION

Back Panel

5700-031-44-33

Right Hinge Plate Weldment

5700-002-59-40

Rail, Right Rack

5700-002-59-94

Rail, Left Rack

5700-002-59-93

Left Hinge Plate Weldment

5700-002-59-39

Strainer Spacer

5700-002-70-60

Attaches with:

Nut, Nylon Wing, 1/4”-20

5310-994-01-00

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

Strainer Weldment

5700-031-35-81

37

Page 44

SECTION 6: PARTS SECTION

FRAME, & PANEL COMPONENTS

Right Frame Weldment

5700-002-59-36

The swivel feet used on the unit may be ordered using 5340-002-71-71

Left Frame Weldment

5700-002-59-35

The Panels are secured with

10-32 x 1/2” Truss Head Screws

5305-011-39-36

Top Panel

5700-002-71-10

Left Dress Panel

5700-002-71-03

Right Dress Panel

5700-002-71-07

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

38

Page 45

SECTION 7:

ELECTRICAL DIAGRAMS

39

Page 46

JPX-300NSU 460 VOLT, 60 HERTZ, THREE PHASE

SECTION 7: ELECTRICAL DIAGRAMS

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005))

40

Page 47

SECTION 7: ELECTRICAL DIAGRAMS

JPX-300NSU 460 VOLT, 60 HERTZ, THREE PHASE (WITH STAINLESS STEEL SWITCHES)

41

JPX-300NSU Technical Manual

7610-002-75-96 Rev. E (08/16/2005)

Loading...

Loading...