Page 1

Vacuum Breaker

07610-003-04-97 B

January 18, 2006

Dishmachine Component

Maintenance Instructions

Repair Kits

Page 2

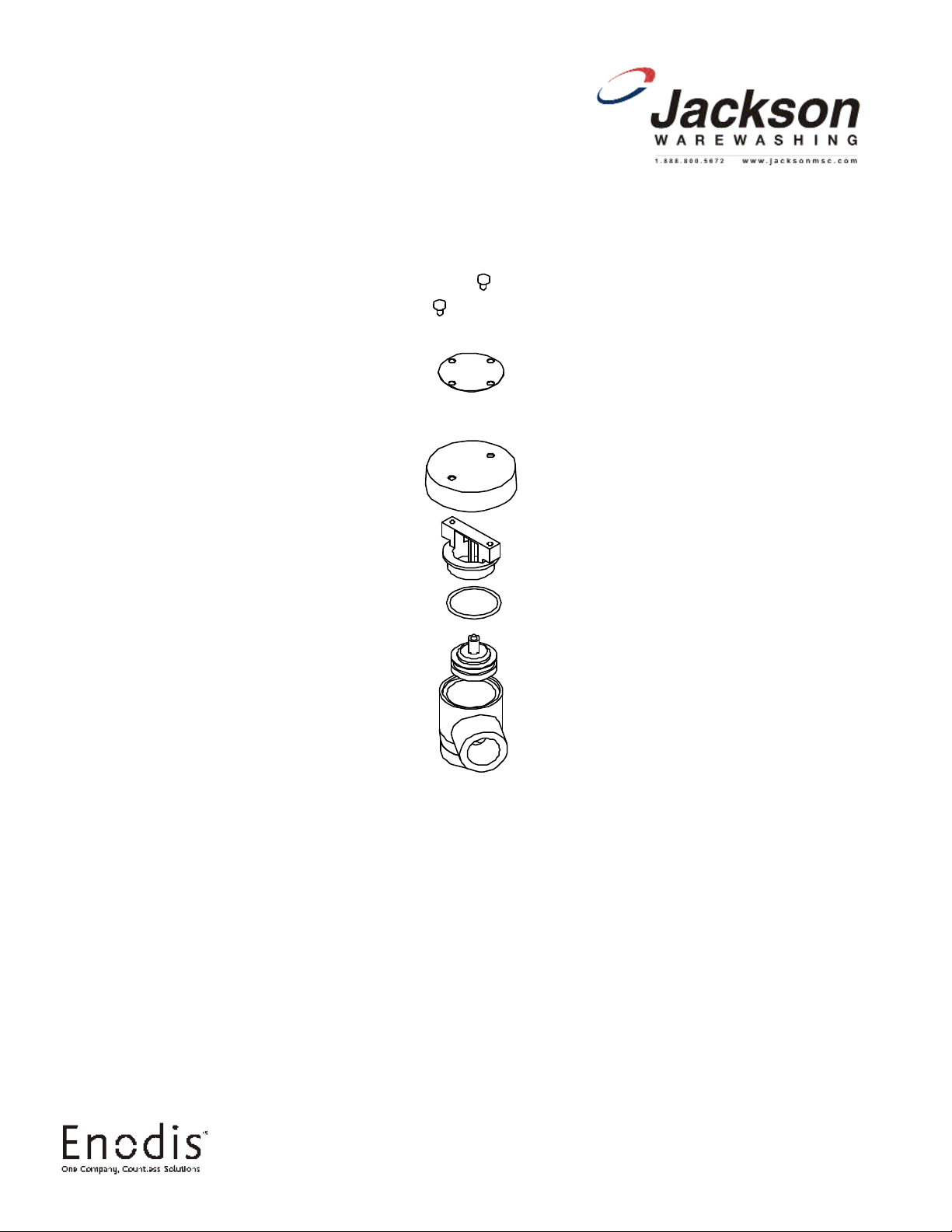

These instructions only apply to vacuum breakers (1/2”

NPT and 3/4” NPT) as pictured below. The repair kits indicated in

-

-

-

uum breaker that has been removed from the plumbing assembly,

these maintenance steps could be performed with it installed so

long as the requirements in the section entitled “PREPARATION”

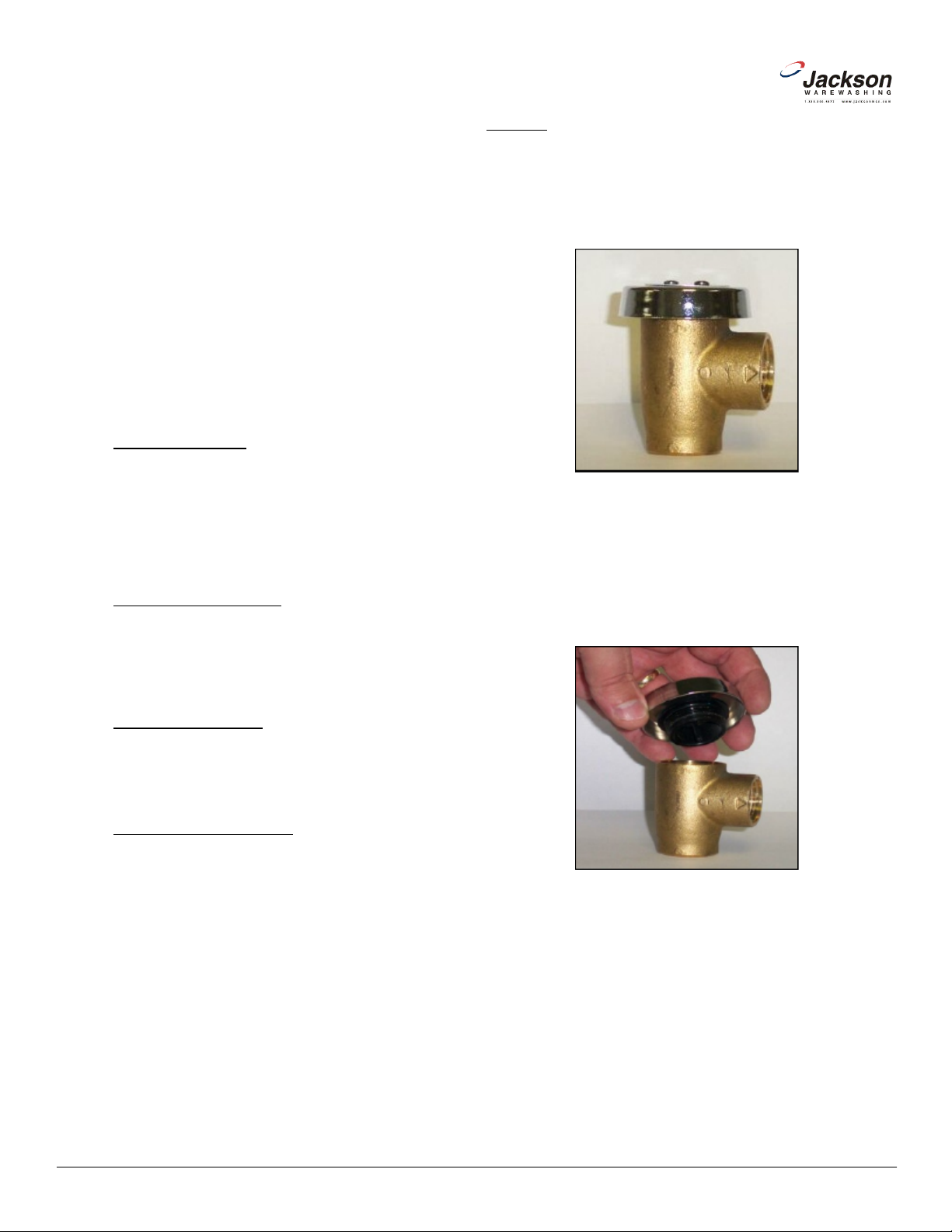

3. Remove the top cap by gripping firmly and turning to the left. The

5. Using the needle nose pliers, gently lift out the plunger and set

breaker. The plunger is required to sit flat on this surface so it must

be free of defects, imperfections and the like. If there is debris,

remove it. If it is chipped or cracked then the vacuum breaker must

be replaced. Failure to do so may result in the vacuum breaker not

working according to its design and could result in damage to the

www.jacksonmsc.com

Many Jackson dishmachines are equipped with vacuum

breakers to serve as back-flow prevention devices. ASSE requirements specify what type of back-flow prevention is necessary on

dishmachines. Vacuum breakers, unlike air gaps, have certain

parts that have specific tolerances and design aspects that must

be met in order to function properly.

Jackson offers repair kits for replacing some of the wear

items associated with vacuum breakers which will allow you to

save money in that replacement of these parts can take place with-

out removing the vacuum breaker from the plumbing assembly.

The instructions provided here are for maintenance personnel only. Unauthorized persons should not attempt any of the

steps contained in these instructions.

Warning: many of the instructions and steps within

this document require the use of tools. Only authotized per sonnel should ever perform any maintenance procedure on

the dishmachine!

PREPARATION

1. Power must be secured to the unit at the service breaker. Tag or lock out the service breaker to prevent accidental or

unauthorized energizing of the machine.

2. Ensure that incoming water to the machine is secured

either by use of a shut-off valve or disconnecting the incoming

water line.

TOOLS REQUIRED

STEPS

1. Note:

these instructions will only work on those style of back-flow preven

ters. If you have a machine with a different style of vacuum break

er, contact Jackson service about replacement components.

Vacuum breaker

2. Note: Even though the photos in these instructions show a vac

have been met.

The following tools will be needed to perform this mainte-

nance evolution:

1. Small flathead screwdriver

2. Needle nose pliers

TIME REQUIRED

It is estimated that it will take (1) person twenty minutes to

perform this task, not including all of the items indicated in the section entitled “PREPARATION”.

IMPORTANT NOTES

1. Read these instructions thoroughly before attempting

this maintenance evolution. Become familiar with the parts and

what actions need to be taken. This will save time in the long run!

cap should come off after a few turns.

Removing the cap

4. Set the cap to the side.

to the side. Examine the brass seating surface inside the vacuum

dishmachine.

2

Vacuum Breaker Repair Kits Instructions

Revision B (01/18/2006)

Page 3

7. If any of these conditions are present, replace the old plunger

with the new one from your kit. Verify that the new plunger is also

free from defects. If it is not, contact Jackson Technical Service

8. The plunger should drop into the vacuum breaker and seat.

Ensure it is not flipped upside down (the orange seal ring should

9. Pick up the cap and examine it. With a soft towel, remove any

grit, grime or debris that may have gotten caught in the threads of

both the cap retainer or the vacuum breaker body. There is an O-

ring that should be present on the cap retainer as well. Regardless

of the condition of the plunger, this O-ring should be replaced once

the cap is removed. Using a small flathead screwdriver, remove the

-

1. Reconnect the incoming water (if disconnected) and

turn on. Then restore power to the unit. Run the unit for at least 10

minutes to ensure there are no leaks. If any problems arise you

-

-

ning this or any other maintenance evolution on a unit under war

-

ranty, you should contact a certified Jackson technician or Jackson

Technical Service. You can find a list of qualified service agencies

www.jacksonmsc.com

immediately.

be up towards the top of the vacuum breaker).

Removing the plunger

6. Your repair kit comes with a new plunger. Examine the old one

and ensure that the mating surface is not damaged or cut. Also

inspect the rubber seal on the top of the plunger to ensure it is in

good condition and not torn.

Examining the seal ring on the plunger

old O-ring.

Replacing the O-ring

10. With the new O-ring in place, screw the cap back on the vacu

um breaker body. The cap needs to only be hand tight (snug).

AFTER MAINTENANCE ACTIONS

Examining the plunger seating surface

Vacuum Breaker Repair Kits Instructions

Revision B (01/18/2006)

can contact Jackson Technical Service.

SPECIAL NOTES

1. Work performed on Jackson dishmachines by unautho

rized or unqualified personnel may void the warranty. Before begin

in the back of you unit’s installation manual.

SPECIAL PARTS

Vaccum breaker repair kit:

For 1/2” NPT order 06401-003-06-23

For 3/4” NPT order 06401-003-06-24

3

Page 4

www.jacksonmsc.com

CONTACT INFORMATION

Jackson MSC Inc. provides technical support for all of the

dishmachines detailed in this manual. We strongly recommend that

you refer to this manual before making a call to our technical sup port staff. Please have this manual with you when you call so that

our staff can refer you, if necessary, to the proper page. Technical

support is available from 8:00 a.m. to 5:00 p.m. (EST), Monday

through Friday. Technical support is not available on holidays.

Contact technical support toll free at 1-888-800-5672. Please

remember that technical support is available for service personnel

only.

4

Vacuum Breaker Repair Kits Instructions

Revision B (01/18/2006)

Loading...

Loading...