Page 1

07610-003-05-39 A

April 15, 2005

Dishmachine Component

Maintenance Instructions

Parker-Style

Solenoid Valve

Repair Kits

Page 2

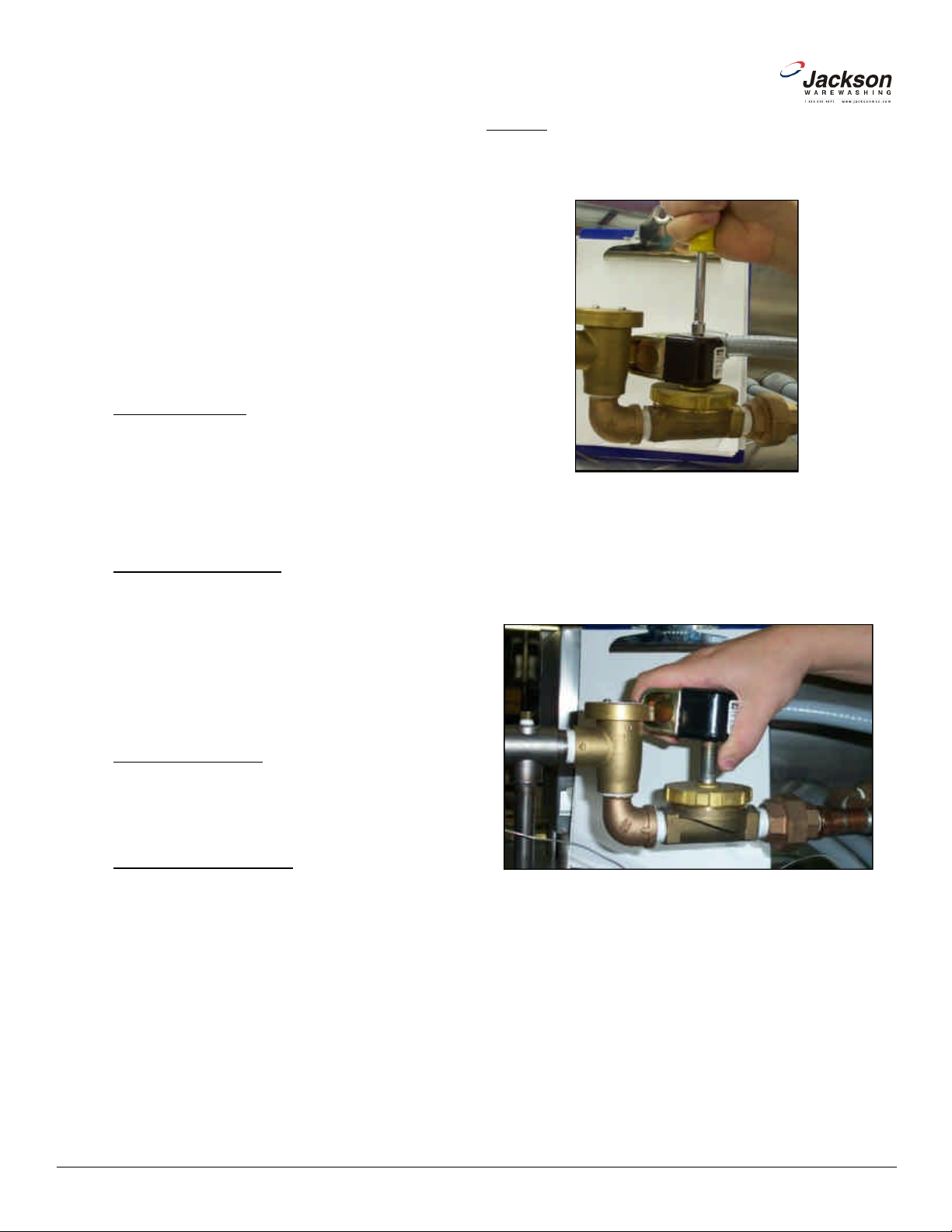

1. Remove the top screw with the 5/16” nutdriver. Remove the

2. With the top screw and data plate removed, grasp the solenoid

coil and gently pull up. The coil should slide up, allowing you to

remove it from the valve bonnet. If you are wanting to replace the

coil, continue on with Step 3. If you are wanting to replace some of

Replacing the solenoid coil requires working with the

wiring of your machine. It is important that all wiring maintenance

be performed by qualified personnel. Always verify the wiring steps

presented in this instruction with the schematic that shipped with

the unit. A current schematic can also be found in the unit’s instal

-

lation manual. Before beginning any step that involves working

with wiring, ensure that the steps located in the section entitled

“Preparation” have been performed. Power must be secured to the

machine at the service breaker. Failure to do so could result in

www.jacksonmsc.com

Many Jackson dishmachines are equipped with electrical

solenoid valves to allow for automatic fill and rinse. These valves

are designed to specific tolerances and design aspects that must

be met in order to function properly.

Jackson offers repair kits for replacing some of the wear

items associated with solenoid valves which will allow you to save

money in that replacement of these parts can take place without

removing the solenoid valve from the plumbing assembly.

The instructions provided here are for maintenance personnel only. Unauthorized persons should not attempt any of the

steps contained in these instructions.

Warning: many of the instructions and steps within

this document require the use of tools. Only authorized per sonnel should ever perform any maintenance procedure on

the dishmachine!

PREPARATION

1. Power must be secured to the unit at the service breaker. Tag or lock out the service breaker to prevent accidental or

unauthorized energizing of the machine.

2. Ensure that incoming water to the machine is secured

either by use of a shut-off valve or disconnecting the incoming

water line.

TOOLS REQUIRED

STEPS

screw and the data plate and set to the side.

Removing the top screw

The following tools will be needed to perform this mainte-

nance evolution:

1. Small flathead screwdriver

2. Medium flathead screwdriver

2. Needle nose pliers

3. 5/16” nutdriver

4. Channel locks

5. 12” pipe wrench

TIME REQUIRED

It is estimated that it will take (1) person twenty minutes to

perform this task, not including all of the items indicated in the section entitled “PREPARATION”.

IMPORTANT NOTES

1. Read these instructions thoroughly before attempting

this maintenance evolution. Become familiar with the parts and

what actions need to be taken. This will save time in the long run!

2. The procedures demonstrated in this manual are

shown being performed on an AJ-44 rack conveyor dishmachine.

The actual maintenance steps, however, apply to any Parker style

solenoid valve found on a Jackson dishmachine.

the internal components of the valve, proceed to step 12.

Removing the coil

3. NOTE:

severe injury to maintenance personnel.

2

Parker Style Solenoid Valve Repair Kit Instructions

Revision A (04/15/2005)

Page 3

-

ing ring for the conduit nut. Once it is loosened, use your fingers to

8. Pull the conduit away and discard the bad coil. Take the new coil

and attach the conduit, reinstall & tighten the conduit nut, and pullg

the wires through so that you will be able to wire the valve back up.

-

noid as they had been connected previously. Ensure that the wire

10. Slide the coil wire cover back on, taking care not to damage the

11. If you are done performing maintenance on the valve, continue

12. To remove the valve bonnet, grasp it with the jaws of the pipe

on some models you may have

www.jacksonmsc.com

Prying open the coil wire cover

4. When replacing the coil, ensure that when removing the coil wire

cover that care is taken not to damage the wires inside. Using the

medium flathead screwdriver, gently use it to open the cover

enough to where it could be pulled off.

Straightening the wires

5. Once the coil wire cover has been removed and set to the side,

take the internal wires and pull them out straight.

Loosening the conduit nut

7. Using a pair of channel locks, gently loosen the conduit retain

unscrew and remove it.

9. Reconnect the wires from the conduit to the wires from the sole

nuts are on tight.

wires.

on to step 23. Otherwise, please go on to step 12.

Removing the wire nuts

6. Remove the wire nuts from the wires and separate them.

Parker Style Solenoid Valve Repair Kit Instructions

Revision A (04/15/2005)

Loosening the valve bonnet

wrench and turn to the left. Note:

3

Page 4

17. Remove the diaphragm retainer and then the diaphragm itself.

Many problems associated with a solenoid valve can be traced to

18. As indicated in the photo above, the extension hole can

become clogged. If it is difficult to clean out, you can use a heated

straight pin to push through the hole. The center hole, the pilot port,

must also be clear. If the diaphragm is torn or bent in any way, it

www.jacksonmsc.com

to remove the valve in order to perform this and any further steps.

Be careful not to damage the plumbing assembly. Only use the

pipe wrench enough to where you can spin the valve bonnet off

with your hand.

Removing the valve bonnet

Removing the diaphragm

13. Slowly remove the valve bonnet. Note: The spring for the

plunger is located directly under the bonnet and may come free if

you are not careful. Remove the plunger, spring and valve bonnet

and place to the side.

Removing the O-ring

14. Remove the O-ring and inspect it. If it has any tears or cuts or

excessive flat spaces, it should be replaced.

15. Examine the threads for the valve bonnet. Check them for scoring or signs of damage. Take a cloth and clean them out to remove

any foreign particles that might get lodged in the threads and cause

a leak. Severely damage threads should not be repaired; instead it

is recommended that the entire valve should be replaced. These

instructions do not provide information on replacing the solenoid

valve.

a clogged pilot port in the diaphragm.

Pointing out the extension hole

must be replaced.

1

2

16. Note: Even though an O-ring may not appear damaged, it is a

good idea to go ahead and replace it if you have a new one. This

will help ensure that your valve remains leak-free in the future!

Diaphragm showing (1) pilot port and (2) extension hole

4

Parker Style Solenoid Valve Repair Kit Instructions

Revision A (04/15/2005)

Page 5

22. With the mesh screen removed, look down into the valve and

verify it is not clogged. Remove any foreign objects from the valve

23. Reassemble the valve, reversing the steps needed to take it

ordered kits. Ensure that components are sufficiently tightened to

Reconnect the incoming water (if disconnected) and turn

-

utes to ensure there are no leaks. If any problems arise you can

-

-

ning this or any other maintenance evolution on a unit under war

-

ranty, you should contact a certified Jackson technician or Jackson

Technical Service. You can find a list of qualified service agencies

Jackson MSC Inc. provides technical support for all of the

dishmachines detailed in this manual. We strongly recommend that

-

port staff. Please have this manual with you when you call so that

our staff can refer you, if necessary, to the proper page. Technical

support is available from 8:00 a.m. to 5:00 p.m. (EST), Monday

through Friday. Technical support is not available on holidays.

Contact technical support toll free at 1-888-800-5672. Please

remember that technical support is available for service personnel

Removing the screen retainer

20. Using the small flathead screwdriver, lift out the screen retain er. Verify that the holes in it are free of clogs and debris.

www.jacksonmsc.com

body that would obstruct flow.

apart. Replace defective replacement parts with new parts from

prevent leakage.

AFTER MAINTENANCE ACTIONS

on. Then restore power to the unit. Run the unit for at least 10 min

contact Jackson Technical Service.

SPECIAL NOTES

Work performed on Jackson dishmachines by unautho

rized or unqualified personnel may void the warranty. Before begin

in the back of you unit’s installation manual.

Removing the mesh strainer screen

21. Again using the small flathead screwdriver, carfully remove the

mesh screen from inside the valve body. The screen should be

taken and rinsed out to remove any debris fouling it.

SPECIAL PARTS

Solenoid Valve Plunger Kit

Includes plunger and spring

Part number 04810-200-09-18

Solenoid Valve Diaphragm Kit

Includes diaphragm and o-ring

Part number 04810-200-03-18 (1/2” NPT)

Part number 04810-100-10-18 (3/4” NPT)

Solenoid Valve 110 Volt Coil and Housing

Part number 04810-200-01-18

Solenoid Valve 230 Volt Coil and Housing

Part number 04810-200-02-18

Complete Solenoid Valve

Part number 04810-100-12-18 (1/2”, 110 Volt)

Part number 04810-100-09-18 (1/2”, 230 Volt)

Part number 04810-100-53-00 (3/4”, 110 Volt)

Part number 04810-100-03-18 (3/4”, 230 Volt)

CONTACT INFORMATION

you refer to this manual before making a call to our technical sup

View inside the solenoid valve body

Parker Style Solenoid Valve Repair Kit Instructions

Revision A (04/15/2005)

only.

5

Loading...

Loading...