Page 1

DELTA 5

CHEMICAL SANITIZING DISHMACHINE

SERVICE MANUALSERVICE MANUAL

Visit Jackson on the Internet at:

www.jacksonmsc.com

October 22, 2001 P/N 7610-002-50-40 (REVSION A)

Page 2

TABLE OF CONTENTS

SECTION TITLE/DESCRIPTION PAGE

I. Specifications of the Delta 5 1

II. Installation Instructions 2

III. Operation Instructions 3

IV. Programming Instructions 6

V. Programming Chart for the Delta 5 7

VI. Troubleshooting Guide 8

VII. Dimensions 9

VIII. Parts Section

Control Box Assembly 10

Chemical Feeder Pump Assembly 12

Electrical Connection Box Assembly 13

Frame Weldment/Hood Assembly 14

Tub Components 15

Spillway Weldment Assembly/Pump Suction Hose 16

Wash Arm Assembly 17

Upper Halo Assembly 18

Drain Solenoid Assembly 19

Booster Tank Assembly 20

Incoming Plumbing Assembly 21

Solenoid Valve Repair Parts 22

Pump and Motor Assembly 23

Booster Tank Dishcarge Hose/Fill Tube Weldment Assembly 24

Strainers 25

Door Components 26

Front Panel Assembly 27

IX. 8 - Pin Harness Diagram 30

X. Electrical Diagram (115V, 60 Hz, 1 Phase) 31

i

Page 3

SPECIFICATIONS OF THE DELTA 5

OPERATING CAPACITY

RACKS PER HOUR 40

DISHES PER HOUR 1000

GLASSES PER HOUR 1000

OPERATING CYCLES (SECONDS)

NORMAL CYCLE:

WASH TIME 45

RINSE TIME 25

TOTAL CYCLE TIME 90

HEAVY CYCLE:

PREWASH TIME 20

WASH TIME 45

RINSE TIME 25

TOTAL CYCLE TIME 130

WASH TANK CAPACITY (GALLONS) 1.2

WASH PUMP CAPACITY (GALLONS PER MINUTE) 61

OPERATING TEMPERATURES (FAHRENHEIT):

WASH (MINIMUM) 120

WASH (RECOMMENDED) 140

RINSE (MINIMUM) 120

RINSE (RECOMMENDED) 140

ELECTRICAL REQUIREMENTS:

WASH PUMP MOTOR HORSEPOWER 1/2

RINSE BOOSTER TANK HEATER ELEMENT 2 KW

VOLTS FREQUENCY PHASE TOTAL AMP LOAD

115 60 HZ 1 24.1

WATER REQUIREMENTS:

WATER LINE SIZE (I.P.S.) 1/2”

DRAIN LINE SIZE (I.P.S.) 2”

FLOW PRESSURE (OPTIMUM) 20 PSI

MINIMUM CHLORINE REQUIRED 50 PPM

FRAME DIMENSIONS:

WIDTH 24.25”

DEPTH 25.25”

DEPTH, WITH FRONT DOOR OPEN 38”

HEIGHT 41”

MAXIMUM WASH CHAMBER CLEARANCE 11.5”

1

Page 4

INSTALLATION INSTRUCTIONS

VISUAL INSPECTION: Before installing the unit, check the container and the machine for any damage. A damaged container

could be an indication of damage to the unit. If there is damage to

both the container and the unit, DONOT throw away the container. The dishmachine has been inspected and packed at the factory with the expectation that it will arrive to you in new, undamaged

condition. However, rough handling by carriers or others may

damage the unit while in transit. If this situation does occur, do not

return the unit to Jackson; instead contact the carrier and ask

them to inspect the damage to the unit and to complete an inspection report. You must contact the carrier within 48 hours of receiving the machine. Also, contact the dealer you purchased the

machine through.

UNPACKING THE DISHMACHINE: Remove the machine from

the container and inspect for any missing parts. If an item appears

to be missing, contact Jackson immediately to report it.

LEVEL THE DISHMACHINE: The dishmachine(s) covered in this

manual are designed to operate on a level surface. Ensure that

the machine is level from side to side and from front to back;

adjust the unit’s bullet feet as required. Failure to level the dishmachine may cause decreased washing performance.

PLUMBING THE DISHMACHINE: All plumbing connections must

comply with all applicable local, state and national plumbing

codes. The plumber is responsible for flushing the incoming water

line prior to connecting it to remove all foreign debris that may get

trapped in the valves or cause an obstruction. Any valves that are

fouled by matter left in the water line and the expenses resulting

are not the responsibility of the manufacturer.

ELECTRICAL POWER CONNECTION: Electrical and grounding

connections must comply with all applicable portions of the

National Electric Code (ANSI/NFPA 70) and/or other electrical

codes that may apply.

Disconnect the electrical power supply and place a safety tag at

the disconnect switch to indicate that you are working on the circuit.

The dishmachine data plate is located on the left front corner of

the machine. Refer to this data plate for information concerning

the unit’s specific electrical requirements.

To install the incoming power lines, open the connection box by

removing the connection box lid. Install 1/2” coduit into the prepunched holes in the back of the connection box. Route the power

wires and connect to the power block and grounding lug. Install

the service wires (L1 and N) to the appropriate terminals as they

are marked on the terminal block. Install the grounding wire into

the lug provided. Wires should be firmly secured in place.

It is recommended that “De-Ox” or another similar anti-oxidation

agent be used on all voltage connections.

VOLTAGE CHECK: Ensure that the machine is off and apply

power to the machine. Check the incoming power at the terminal

block and ensure it corresponds to the voltage on the machine

data plate. Do not run the dishmachine if the voltage is too high or

too low. Shut off the service breaker and mark it as being for the

dishmachine. Advise all personnel of the location of the service

breaker. Replace all covers and tighten the screws.

CONNECTING THE DRAIN LINE: The DELTA 5 drain requires a

minimum 2” IPS piping that is pitched at least 1/4” per foot. There

must also be an air gap between the machine drain line and the

floor sink or drain. If a grease trap is required by code, it should

have a flow capacity of 5 gallons per minute.

WATER SUPPLY CONNECTION: Install the water supply line

(1/2” IPS minimum) to the dishmachine line strainer using copper

pipe. It is recommended that a water shut-off valve be installed

between the main supply and the machine to allow for service.

The water supply line must be capable of 20 PSI “flow” pressure

at the recommended temperature as indicated on the data plate.

In areas where the water pressure fluctuates or is greater than the

recommended pressure, it is suggested that a water pressure regulator be installed. The DELTA 5 does not come with a water pressure regulator as standard equipment.

It is also recommended that a shock absorber (not supplied with

the DELTA 5) be installed in the incoming water line. This prevents

line hammer (hydraulic shock), induced by the solenoid valve,

which can cause damage to the equipment.

PLUMBING CHECK: Slowly turn on the water supply to the

machine after connecting the incoming fill line and drain line.

Check for leaks and repair as required. Leaks must be repaired

prior to placing the machine in operation.

2

Page 5

OPERATION INSTRUCTIONS

OPERATIONAL START-UP AND CHECK: Before proceeding

with the start-up, verify the following:

1. Open the door and verify that the sump stariner is correctly

installed in the sump.

2. Verify that the drain stopper is in position.

3. Check that the plugs are securely screwed into the ends of the

wash arm.

4. Check that the wash arm is securely screwed into the stationary base and that it rotates freely.

5. Check the levels in all chemical containers and replace if necessary.

INSTALLATION/INITIAL START-UP PROCEDURE:

1. Turn on dishmachine

a) Turn on the incoming power to the machine at the cir-

cuit disconnect box. The display will indicate OFF.

b) Turn on the dishmachine by pressing the ON/OFF but-

ton. The display will indicate HEATER DISABLED.

2. Fill rinse booster heater with water

a) Before the heater element can be energized, the rinse

booster heater must be initially filled with water. Damage to the

heater element will occur if the element is not submerged in water.

To initially fill the booster heater with water:

i) Press and hold the PROGRAM button.

ii) The display will indicate ENTER CODE.

Press CYCLES, DELIME, ENTER and CYCLES.

iii) The display will indicate PROG DRAIN/FILL.

Repeatedly press the PROGRAM button until ENGINEERING is

displayed. Press ENTER to enter the engineering mode.

iv) Repeatedly press the PROGRAM button

until PRESS ENTER TO OPEN FILL is displayed.

v) Press and hold the ENTER button to turn on

the incoming water solenoid valve. Continue holding the button

until you hear water entering the wash chamber through the airgap, then release the button. The rinse booster heater is now filled

with water.

vi) Repeatedly press the PROGRAM button

until PRESS ENTER TO EXIT is displayed. Press the ENTER button to exit the ENGINEERING mode.

3. Enable heater element

a) For the initial start-up only, the heater element must be

enabled. The machine is shipped from the factory with the heater

element disabled. This is done to ensure that the heater element

is not damaged by energizing the element without the element

being submerged in water. To enable the heater element:

Note: After completing step 2.v., you will still be in the pro gramming mode. However, if you do not press any keys for

45 seconds, the controller will automatically log out of the

programming mode. Follow steps 2.i. and 2.ii. above to reenter the programming mode.

i) Repeatedly press the PROGRAM button until

SYSTEM is displayed. Press ENTER to enter the SYSTEM programming mode.

ii) Repeatedly press the ENTER button until

HEATER ELEMENT IS DISABLED is displayed.

iii) Press the NORMAL button to change the

display to HEATER ELEMENT IS ENABLED.

iv) Press the PROGRAM key to exit the SYSTEM programming mode. You should hear the heater contactor

close.

v) Repeatedly press the PROGRAM button until

EXIT is displayed. Press the ENTER button to exit the programming mode.

vi) The display will indicate HEATING WATER.

4. Adjust dishmachine fill level

a) Once the temperature in the rinse booster heater has

reached its preset value, the incoming water solenoid valve will

open to fill the wash tank with water (FILLING and the time

remaining for the will be displayed during the fill sequence).

b) The display will then indicate OPEN DOOR.

c) Open the door and observe the water level in the wash

tank sump. The water level should be between the two score lines

on the drain stopper.

d) If the water level is not satisfactory, drain the sump by

lifting the drain stopper. Close the door. Enter the programming

mode and adjust the fill time as necessary (PROG DRAIN/FILL

menu). Press the AUTO FILL button to refill the wash tank. Open

the door and observe the water level. Repeat these steps until the

proper water level is obtained.

5. Adjust dishmachine drain time

a) At the very end of the drain cycle, open the doors to

interrupt the cycle. Observe the sump area. All water from the

wash cycle should be drained from the wash tank sump.

b) In the programming section, adjust the DRAIN time

(PROG DRAIN/FILL menu) as necessary. Allow enough time for

the machine to completely drain before the rinse begins. Avoid

making the drain time too long, which will unnecessarily lengthen

the total cycle time.

3

Page 6

OPERATION INSTRUCTIONS (CONTINUED)

6. Adjust dishmachine flush time

a) The FLUSH will use fresh water to rinse out the deter-

gent residue and soils in the wash tank before the rinse begins.

The FLUSH time is the time that the drain valve will remain open

at the beginning of the FILL cycle. Avoid making the flush time too

long, which will increase the water usage per machine cycle.

b) In the programming section, increase or decrease the

FLUSH time (PROG DRAIN/FILL menu) as necessary.

7. Measure and adjust chemical concentrations.

8. Check all water and drain fittings for leaks.

9. Instruct machine operators on proper cleaning and operating

procedures.

GENERAL OPERATION SEQUENCE:

CAUTION: Water must be in the wash tank sump while the

wash pump is running in order to avoid damage to the pump

seal.

Close the machine's door. Turn on the machine by pressing the

PUSH ON/OFF button on the front panel. The display will indicate

HEATING WATER while the rinse water is heated in the booster

heater. This heating may take several minutes, depending on how

long the machine has set idle.

When the water in the booster heater reaches the specified temperature, the machine will automatically fill the wash sump with

water (FILLING and the time remaining for filling will be indicated

on the display). The minimum water level should be between the

two score lines on the drain stopper. To adjust the water level, see

programming instructions. During this initial fill, the detergent dispensing pump will run to dispense into the wash tank sump.

The display will indicate OPEN DOOR. Open the door and insert

a rack of soiled dishes. The display will indicate CLOSE DOOR.

Close the door. The display will indicate PRESS START TO

START CYCLE. At any time between cycles, the operator can

press select the NORMAL or HEAVY cycles by pressing the

appropriate button on the keypad. The default cycle is the normal

cycle. When either of these cycle keys is pressed, the display will

momentarily display the selection. The cycle will begin when the

PUSH TO START button on the front panel is pressed.

At the start of the cycle, a PREWASH sequence is initiated and

the wash pump is turned on. The length of this PREWASH

sequence is 20 seconds. PREWASH and the time remaining will

be displayed on the first line of the display. The TEMPERATURE

of the wash water will be displayed on the second line of the display.

At the end of the prewash sequence, if the wash tank water temperature is less than 120°F, or if the HEAVY cycle has been

selected, the machine will drain the wash water, and refill the

sump with fresh, heated water from the booster tank. The display

will indicate DRAINING, FLUSH and FILLING and will countdown

the time remaining for each during these steps. Detergent will be

dispensed during the filling sequence.

If the detergent dispensingtime is longer than the fill time, the

incoming water solenoid valve will be opened for one second at

the completion of the detergent dispensing, in order to flush out

any remaining detergent from the air gap. No rinse aid or sanitizer are dispensed. At the end of the prewash sequence, if the temperature of the wash water is greater than 120°F and the NOR MAL cycles was selected, these steps are skipped and control

goes directly to the washing sequence.

During the washing sequence, the wash pump is turned on.

WASHING and the time remaining will be displayed on the first

line of the display. The TEMPERATURE of the wash water will be

displayed on the second line of the display. If the length of the

DETERGENT WASH is longer than the length of DETERGENT

PREWASH, the detergent dispenser pump will run for the difference in these time values, dispensing additional detergent into the

wash tank sump. The length of the wash cycle is 45 seconds.

At the end of the wash cycle, if the temperature in the rinse booster tank has not reached 120°F (regardless of the rinse tank temperature setting), the wash time will be extended until the 120 ° is

reached, or three minutes, whichever is shorter. The display will

indicate EXTENDED WASH.

At the completion of the wash cycle, the machine will drain the

wash water, and refill the sump with fresh, heated water from the

booster tank. The display will indicate DRAINING, FLUSH and

FILLING and will countdown the time remaining for each during

these steps. During the FILLING sequence, rinse aid and sanitizer are dispensed.

The rinsing sequence now begins. RINSING and the time remaining will be displayed on the first line of the display. The TEMPERATURE of the rinse water will be displayed on the second line of

the display.

The completion of the rinse sequence is the end of the cycle, and

the display will indicate OPEN DOOR. Detergent is now dispensed into the wash tank sump for the next wash cycle. Open the

door, remove the clean dishes, load a rack of soiled dishes, close

the door and press the start button to start the next cycle. If the

next cycle is started before the completion of the detergent dispensing, the display will indicate DETERGENT DISPENSE, and

countdown the time remaining until the cycle will automatically

begin.

If the door is opened at any time during a cycle, CLOSE DOOR

will be displayed. The cycle will restart at the beginning of the prewash sequence when the door is closed again.

The cycle counter will only increment when cycles are fully completed. To display the number of cycles completed, between

cycles, press the CYCLES button on the keypad. Then number of

NORMAL cycles completed will be displayed. Press the CYCLES

button again to display the number of completed HEAVY cycles.

DETERGENT PREWASH - The run time of the detergent dispensing pump before the prewash sequence which controls the

amount of detergent dispensed.

4

Page 7

OPERATION INSTRUCTIONS (CONTINUED)

DETERGENT WASH - The run time of the detergent dispensing

pump before the wash sequence which controls the amount of

detergent dispensed.SANITIZER - The run time of the sanitizer

dispensing pump before the rinse sequence which controls the

amount of sanitizer dispensed.

RINSE TANK TEMPERATURE - When the water in the rinse

water booster heater reaches this temperature value, the heating

element will be turned off.

SHUTDOWN AND CLEANING: To turn off the machine, press the

ON/OFF button. The machine will automatically drain (TURNING

OFF will be displayed) and then will turn off (OFF will be displayed).

Remove, clean and install the lower wash arm.

Remove, clean and install the four upper spray nozzles.

Remove, clean and install the accumulator strainer.

PRIMING THE CHEMICAL DISPENSING PUMPS: To prime the

chemical feeder pumps that dispense the detergent, rinse aid and

sanitizer chemicals, press and hold the corresponding prime but ton on the keypad. The machine must be idle (between cycles) for

these prime buttons to be active.

DELIMING OPERATIONS: The DELTA 5 machine has a pre-programmed delime sequence which will lead the operator through

the steps required to properly delime the machine.

To begin, the machine must be OFF. Press and hold the DELIME

button on the keypad. The machine will automatically fill with fresh

water (FILLING will be indicated on the display). The display will

then indicate to OPEN DOOR - ADD LIME-A-WAY (deliming

chemical agent). Open the doors and add the delime chemical

agent. The display will indicate CLOSE DOORS TO START

DELIME. When the doors are closed, the wash pump will turn on

to circulate the delime agent throughout the machine. At any time,

the doors can be opened in order to inspect the inside of the

machine. The wash pump will restart when the doors are closed.

The display will indicate PRESS DELIME TO STOP CYCLE.

When the DELIME button on the keypad

5

Page 8

PROGRAMMING INSTRUCTIONS

To access the programming mode, the machine must be ON, and

idle (between cycles). Press and hold the PROGRAM button on

the keypad. The display will prompt to ENTER CODE. At this

prompt, enter the keys corresponding to the access code. Once in

the programming mode, the PROGRAM button is used to scroll

between the programming catagories, the ENTER button is used

to select a program section or parameter. To change the value of

the parameter, use the HEAVY button to decrease the value of the

parameter, and the NORMAL button to increase the value. To confirm a change to a programmable vale, press the ENTER button.

To abort or escape out of a change, press the PROGRAM button.

Once in the programming mode, if there have been no keypad

inputs for approximately 45 seconds, the system will automatically exit out of the programming mode.

All time adjustments are in minutes and seconds (minutes:seconds).

The following parameters can be adjusted in the programming

mode:

1. In the PROG(RAM) DRAIN/FILL section:

a) FILL TIME - Length of fill cycles. The minimum water

level should be between the score lines of the drain stopper.

b) FLUSH TIME - Time of overlap between the drain and

fill times.

c) DRAIN TIME - Time that the drain is open after the

wash cycle.

2. In the PROG(RAM) CHEMICAL section:

4. The ENGINEERING section is used when trouble-shooting

problems with the machine. In the ENGINEERING section:

a) TOTAL WASH CYCLES - This counter accumulates

the total number of cycles which the machine has been run. It is a

total of all wash cycles and it cannot be reset.

b) PRESS ENTER TO:

i) RUN PUMP - Press and hold the ENTER button to run the wash pump motor. Release the ENTER button to

make it stop.

ii) OPEN DRAIN - Press and hold the ENTER

button to energize (open) the drain solenoid. Release the ENTER

button to de-energize the solenoid.

iii) OPEN FILL - Press and hold the ENTER button to energize (open) the fill water valve solenoid. Release the

ENTER button to de-energize the solenoid.

iv) EXIT - Press the ENTER button to exit the

ENGINEERING section.

5. RESET CYCLES - The system will prompt CLEAR COUNT(S)?

E(YES) or P(NO) to confirm the that the cycle counter is to be

reset. Press the ENTER button on the keypad to reset the counter

or press the PROGRAM button to exit without resetting the

counter.

6. EXIT - Press the ENTER button on the keypad to exit the programming mode.

a) DETERGENT PREWASH - The run time of the detergetn dispensing pump before the prewash sequence which controls the amount of detergent dispensed.

b) DETERGENT WASH - The run time of the detergent

dispensing pump before the wash sequence which controls the

amount of detergent dispensed.

c) RINSE AID - The run time of the rinse aid dispensing

pump before the rinse sequence which controls the amount of

rinse aid dispensed.

d) SANITIZER - The run time of the sanitizer dispensing

pump before the rinse sequence which controls the amount fo

sanitizer dispensed.

3. In the SYSTEM section:

a) ENABLE/DISABLE HEATER ELEMENT - Selects

whether or not the rinse water booster element can be energized.

The selection options are ENABLE or DISABLE.

b) RINSE TANK TEMPERATURE - When the water in

the rinse water booster heater reaches this temperature value, the

heating element shall be turned off.

c) DISPLAY IN FAHRENHEIT OR CELSIUS - Selects the

unit of measure for water temperature display.

6

Page 9

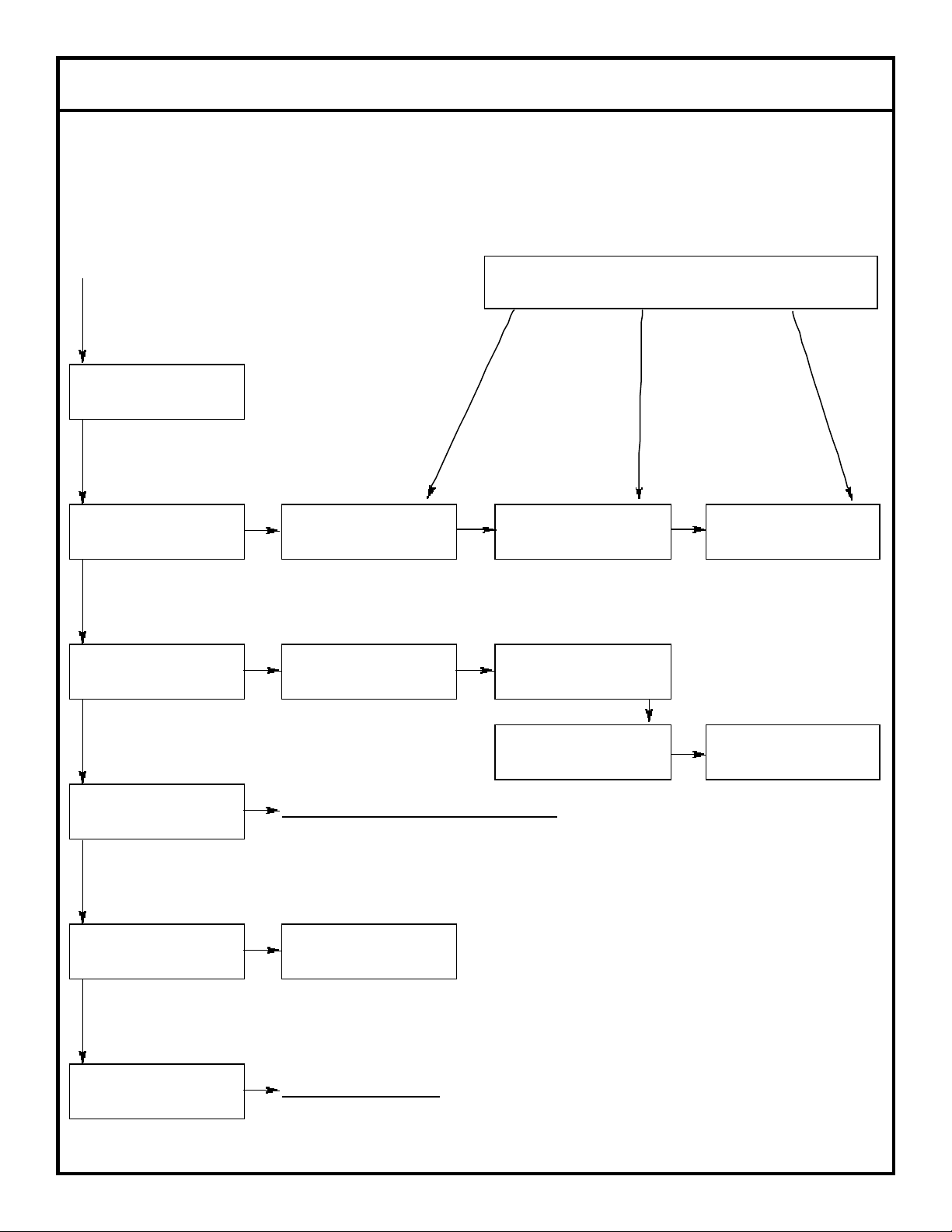

PROGRAMMING CHART FOR THE DELTA 5

Short Version

Press and hold PROGRAM (P) for 2 seconds.

Press CYCLES, DELIME, ENTER, CYCLES

CODE

****

Press ENTER Press ENTER Press ENTER

PROG DRAIN/FILL FILL TIME 0:07 FLUSH TIME 0:03 DRAIN TIME 0:06

Press PROGRAM Press ENTER Press ENTER

PROG CHEMICAL

DETERGENT 0:05

PREWASH

Press UP ARROW (NORMAL) to increase time settings

Press DOWN ARROW (HEAVY) to decrease time

DETERGENT 0:05

WASH

Press ENTER

Press ENTER

Press PROGRAM

SYSTEM

Press PROGRAM

RESET COUNTS CLEAR COUNTS?

Press PROGRAM

EXIT

Refer to IO manual for system programming

Press ENTER Press ENTER to clear counter back to zero

Press ENTER

Back to regular operation

RINSE AID 0:05 SANITIZER 0:05

7

Page 10

TROUBLESHOOTING GUIDE

The DELTA 5 dishmachine uses a microprocessor-based electronic controller to control function of the machine. The microprocessor

is pre-programmed at the factory to run a machine that is installed in a typical application. A LCD display is used to indicate the status

of the machine.

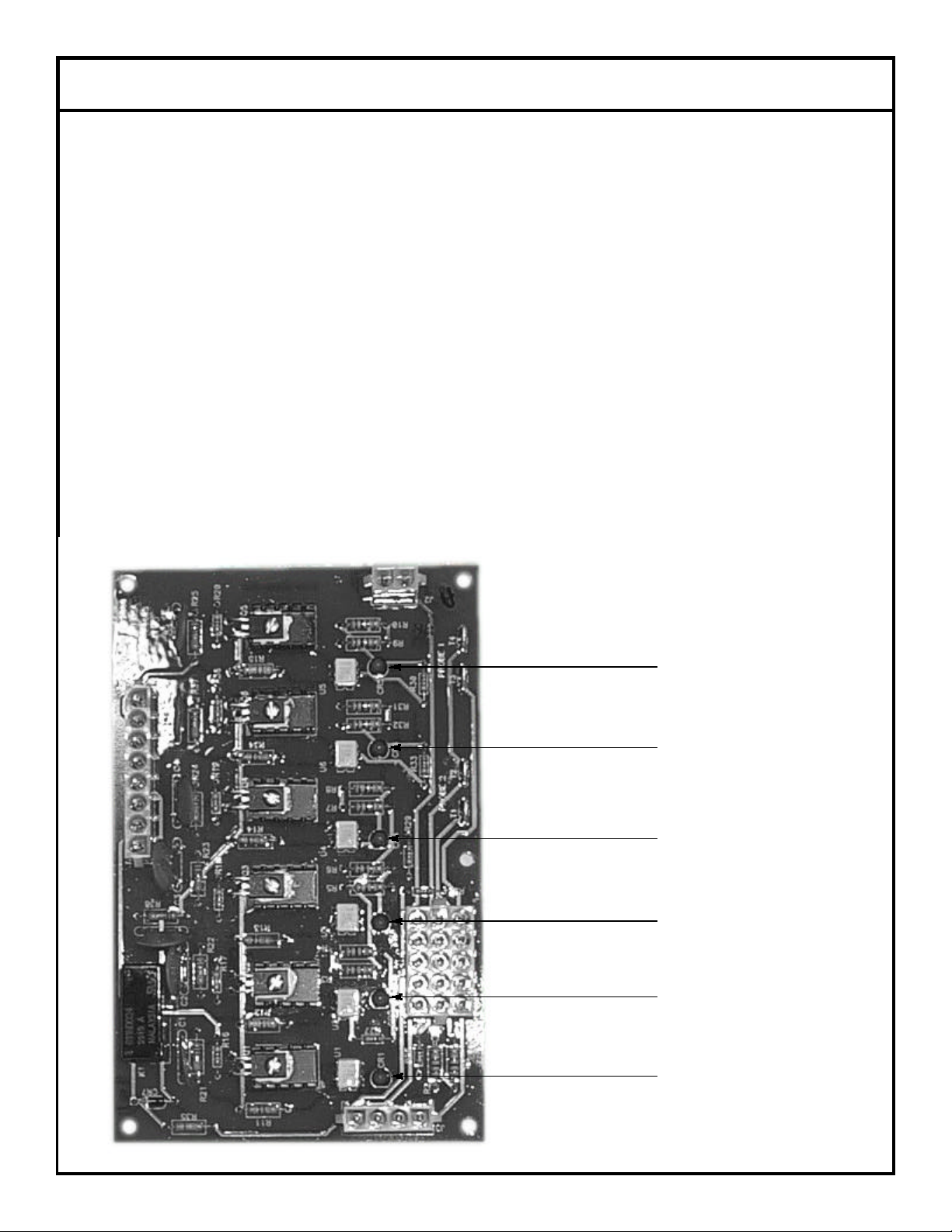

The electronic controller board with LCD display controls all timing functions. The controller board is connected to the interface board.

It sends signals to the interface board to turn components on and off. The remaining electrical control components in the machine are

connected to the interface board.

To aid in troubleshooting, the interface board contains six red LED (light emitting diodes). These diodes are illuminated whenever the

output signal to the corresponding control item is ON. The following example will illustrate the troubleshooting sequence that should be

used for all electrical control components. The wash pump runs at the first sequence of every cycle. The LED corresponding to the

wash pump motor contactor will be ON when the pump is to be On. If the LED is ON, and the pump motor is not running, measure the

voltage at the pump motor contactor soil (when the LED is on, meaning voltage should be applied to the coil from the interface board).

If there is no voltage, then replace the interface board. If there is voltage, then there is a problem in the pump motor and pump motor

contactor. If the display indicates that the machine is in a wash cycle, and both the pump motor is not running and the LED is not ON,

check the continuity of the cable that connects the controller board to the interface board. If continuity exists, replace the controller

board. If the controller board has been replaced and the problem still exists, replace the interface board.

The interface board contains six triacs, which are essentially electronic relays. Use a multimeter to verify that the interface board out put is supplying voltage to a control item (solenoid valve, peristaltic pump, motor contactor, etc.). During any troubleshooting, it is crit ical to remember that a 120 volt signal will always be measured at the outputs of the interface board (pins 1 through 8 on connector

J4) if the corresponding load (solenoid valve, peristaltic pump, motor contactor, etc.) is not connected to the output. To avoid false readings, the control item that is being tested must be connected to the interface board output.

Drain LED

Pump LED

Fill LED

Sanitizer LED

Rinse Aid LED

Detergent Fill LED

8

Page 11

DIMENSIONS

9

Page 12

CONTROL BOX ASSEMBLY

DELTA 5 Control Box Base

1 per machine

Mfg. No.: 5700-002-40-03

12

3 4

101112

Associated Hardware:

Locknut, 6-32 S/S Hex w/Nylon Insert 5310-373-03-00

Locknut, 10-24 S/S Hex w/Nylon Insert 5310-373-01-00

Locknut, 1/4”-20 S/S Hex w/Nylon Insert 5310-374-01-00

Screw, 6-32 x 3/8” Phillip Round Head 5305-171-02-00

10

789

56

Page 13

CONTROL BOX ASSEMBLY (CONTINUED)

2

1

Noise Filter, Corcom

5910-002-20-37

3

1

Interface Board

6680-002-16-81

5

1

Inner Control Panel

5700-002-21-71

6

1

Terminal Board

5700-021-70-70

8

1

6 Pole Fuse Holder

5920-002-42-13

6

Fuse, 1.5 AMP Fastblow 3AG

5920-002-44-12

10

1

Motor Contactor

5945-109-05-69

11

1

Relay

5945-002-45-20

2

2

Motor, Chemical Feeder Pump, 36 RPM

4320-111-35-14

3

1

Motor, Chemical Feeder Pump, 14 RPM

4320-111-35-13

5

1

Chemical Feeder Pump Kit

4320-121-37-10

6

1

Tubing, 1/4" OD x 120" Long, White

5700-011-37-13

8

1

Tubing, 1/4" OD x 120" Long, Blue

5700-011-37-17

1

Tubing, 1/4" OD x 5" Long, Red

5700-002-52-32

10

1

Tubing, 1/4" OD x 5" Long, White

5700-002-52-33

11

1

Tubing, 1/4" OD x 5" Long, Blue

5700-002-52-34

ITEM QTY DESCRIPTION MFG NO.

1 1 Control Box Weldment 5700-002-45-72

4 4 Circuit Board Holder 5940-002-21-87

7 1 Bracket, Fuse Strip Assembly 5700-002-42-60

9

12 1 Transformer 115V to 24V 5950-002-16-78

11

7

9

6

10

* Represents an item not shown.

8

5

5

5

2 2 3

1

4

ITEM QTY DESCRIPTION MFG NO.

1 1 Control Box Assembly Cover 5700-002-40-00

4 1 Drip Channel 5700-002-40-65

7 1 Tubing, 1/4" OD x 120" Long, Red 5700-011-37-15

9

*12 1 Stiffener 17 3/8" 5700-011-35-23

11

Page 14

CHEMICAL FEEDER PUMP ASSEMBLY

2

2

Screw, 8-32 x 3/8" Long, Phillipshead

5305-011-37-07

3

2

Screw, 8-32 x 1/2" Long Phillipshead

5305-011-37-06

5

1

Housing, Front

4320-111-37-08

6

4

Screw, 6-32 x 3/4" Long Phillips Panhead

5305-011-37-05

1

Chemical Feeder Pump Squeeze Tube - Detergent

5700-111-35-29

1

Chemical Feeder Pump Squeeze Tube - Rinse Aid

5700-111-35-29

1

Chemical Feeder Pump Motor (14 RPM) - Sanitizer

4320-111-35-13

2

1

5

3

4

ITEM QTY DESCRIPTION MFG NO.

1 1 Housing, Rear 4320-111-37-09

4 1 Roller, Anko 4320-111-36-70

6

1 Chemical Feeder Pump Squeeze Tube - Sanitizer 5700-011-76-41

1 Chemical Feeder Pump Motor (36 RPM) - Detergent 4320-111-35-14

1 Chemical Feeder Pump Motor (36 RPM) - Rinse Aid 4320-111-35-14

12

Page 15

ELECTRICAL CONNECTION BOX ASSEMBLY

2

1

Terminal Block

5940-500-09-61

3

1

Terminal Block Spacer

5700-011-40-05

1

Nut, 1" NPT Locking Heyco

5975-002-35-55

5

1

Locknut, 10-24 with Nylon Insert

5310-373-01-00

7

1

Electrical Connection Box Weldment

5700-002-45-69

1

Decal, Power Connection

9905-011-47-64

8

1

Electrical Connection Box Cover

5700-002-45-70

1

Decal, Warning to Disconnect Power

9905-100-75-93

8

1

2

3

4

7

ITEM QTY DESCRIPTION MFG NO.

1 1 Locknut, 6-32 with Nylon Insert 5310-373-03-00

5

6

4 1 Fitting, Straight Through, Liquidtite (1.375) 5975-002-30-67

6 1 Lug, Ground 5940-200-76-00

1 Decal, Copper Conductors Only 9905-011-47-35

1 Screw, 10-32 x 3/8" Long, Phillips Trusshead 5305-173-12-00

13

Page 16

FRAME WELDMENT/HOOD ASSEMBLY

2

1

Plate, Door Pivot (Right Side)

5700-002-55-95

3

1

Door Weldment

5700-002-45-65

5

1

Plate, Shock Mounting

5700-002-45-64

6

1

Fill Tube Weldment

5700-002-45-61

8

1

Door Dampener

5340-002-42-63

Delta 5 Frame Weldment

1 per machine

Ecolab No.: 96039748

Mfg. No.: 5700-002-4235

To order the Bullet Feet

4 per Frame Weldment

Ecolab No.: 96552666

Mfg. No.: 5340-108-01-03

Associated Hardware:

Locknut, 1/4”-20 S/S Hex Low Profile w/Nylon Insert 5310-374-02-00

Locknut, 1/4”-20 S/S Hex w/Nylon Insert 5310-374-01-00

Washer, S/S 1/4”-20 ID 5310-174-01-00

Bolt, 1/4”-20 x 1/2” Long 5305-274-02-00

Bolt, 1/4”-20 x 3/4” Long 5305-274-04-00

1

9

6

7

8

5

ITEM QTY DESCRIPTION MFG NO.

1 1 Hood Weldment 5700-002-44-36

2

3

4

4 2 Rack Rail Weldment 5700-002-45-67

7 1 Airgap Weldment 5700-002-45-60

9 1 Plate, Door Pivot (Left Side) 5700-002-45-62

14

Page 17

Stand Pipe Weldment

Mfg. No.: 5700-021-33-29

The entire Stand Pipe

Assembly may be

ordered using Mfg. No.:

5700-031-35-55.

TUB COMPONENTS

1 per machine

DELTA 5 Tub Weldment

1 per machine

Mfg. No.: 5700-002-45-50

Stand Pipe Stopper

1 per machine

Mfg. No.: 5700-021-35-54

Lower Manifold Weldment

1 per machine

Mfg. No.: 5700-002-45-51

Associated Hardware:

Bolt, Hex 3/8-16 x 1 1/4” 5305-276-10-00

Lockwasher, 3/8” 5311-276-01-00

Nut, Hex 3/8-16 S/S 5310-276-01-00

To order the O-ring or gasket, please refer to the items associated with the Modified Casting on the page entitled ‘Wash Arm

Assembly”.

15

Page 18

SPILLWAY WELDMENT ASSEMBLY/PUMP SUCTION HOSE

DELTA 5 Spillway Weldment

1 per machine

Mfg. No.: 5700-031-37-86

Associated Hardware:

Locknut, Hex w/Nylon Insert 5310-373-01-00

DELTA 5 Drain Seat Insert

1 per machine

Mfg. No.: 5700-021-34-38

DELTA 5 Spillway Gasket

2 per machine

Mfg. No.: 5700-111-34-52

DELTA 5 Pump Suction Hose

1 per machine

Mfg. No.: 5700-002-40-82

*To order the hose clamps for the Pump Suction Hose:

Mfg. No.: 4730-719-01-37

16

Page 19

WASH ARM ASSEMBLY

Order items 1 & 2 together using Mfg. No. 5700-021-39-23.

1

2

3

ITEM QTY DESCRIPTION MFG NO.

1 1 Wash Arm Weldment with End Plugs 5700-021-46-58

2 1 Wash Arm Bearing Assembly 5700-021-35-97

3 1 Modified Casting Wedge 5700-002-45-06

4 1 Manifold Gasket 5700-111-35-03

5 1 Manifold O-Ring 5330-111-35-15

17

4

5

Page 20

UPPER HALO ASSEMBLY

Upper Wash Halo Nozzle

3 per machine

Mfg. No.: 4730-002-45-22

DELTA 5 Upper Wash Halo Weldment

1 per machine

Mfg. No.: 5700-002-45-66

DELTA 5 Manifold Tube

1 per machine

Mfg. No.: 5700-002-40-71

DELTA 5 Upper Wash Halo Nozzle Receptical

3 per machine

Mfg. No.: 4730-002-45-21

Manifold O-Ring

1 per assembly

Mfg. No.: 5330-111-35-15

18

Page 21

DRAIN SOLENOID ASSEMBLY

DELTA 5 Solenoid Box

Mfg. No.: 5700-002-40-69

Order the following associated components with these numbers:

Fitting, Liquid Tight (.231 I.D. to .394 O.D.)

Mfg. No.: 5975-011-49-03

Fitting, Liquid Tight (.25 I.D. to .546 O.D.)

Mfg. No.: 5975-011-65-51

1 per machine

DELTA 5 Solenoid Box Cover

1 per machine

Mfg. No.: 5700-002-40-70

Order the following associated parts with these part numbers:

Locknut, 10-24 with Nylon Insert Mfg. No.: 5310-373-01-00

Decal, Warning Mfg. No.: 9905-100-75-93

Drain Link Assembly

Cotter Pin (Not Shown)

1 per assembly

Mfg. No.: 5315-011-60-09

Drain Link

1 per assembly

Mfg. No.: 5700-002-40-83

Order the entire Drain Link Assembly using MFG. No.:

5700-002-45-52

Drain Link Connector

1 per assembly

Mfg. No.: 5700-002-38-10

Nut, Hex, 5-16”-18

1 per assembly

Mfg. No.: 5310-275-01-00

The DELTA 5 drain solenoid and related hardware may be ordered using the following part numbers:

Drain Solenoid (115 Volt) Mfg. No.: 4810-200-11-00

Locknut, 10-24 w/Nylon Insert Mfg. No.: 5310-373-01-00

19

Page 22

BOOSTER TANK ASSEMBLY

1

1

Booster Tank Weldment

5700-002-45-56

3

1

Heater, 120V, 2000 Watts

4540-002-45-13

4

4

3/8" Lockwasher

5311-276-01-00

5

4

Nut, Hex, 5/16"-18 S/S

5310-275-01-00

1

4

2

Booster Tank Cover

1 per machine

Mfg. No.: 5700-002-39-07

Secured with Screw 10-32 x 3/8” Long Phillip Truss Head

Mfg. No.: 5305-173-12-00

Decal, Warning to Disconnect Power

Mfg. No.: 9905-100-75-93

3

ITEM QTY DESCRIPTION MFG NO.

5

2 1 Plug, 1/4" NPT 4730-209-01-00

20

Page 23

INCOMING PLUMBING ASSEMBLY

2

1

Nipple, Close, 1/2" NPT, Brass

4730-207-15-00

3

1

Valve, Solenoids, 1/2" NPT, 115V

4810-100-12-18

5

2

Tube, Copper, 1/2" x 1.25" Long

5700-001-08-28

6

1

Union, 1/2", Copper to Copper

4730-412-05-01

8

1

Tube, Copper, 1/2" x 4.25" Long

5700-001-01-60

1

3

2

4

5

6

5

7

8

ITEM QTY DESCRIPTION MFG NO.

1 1 Y-Strainer 4730-217-01-10

9

4 1 Adapter, 1/2" (CU to MSPS) 4730-401-03-01

7 1 Elbow, 607, 1/2" Copper to Copper 4730-406-01-01

9 1 Elbow, 1/2" x 90 Degree (CU to MSPS) 4730-406-32-01

21

Page 24

Data Plate

1

1

Solenoid Valve Coil

4810-200-02-18

3

1

Plunger

4810-200-04-18

4

1

O-Ring

4810-100-10-18

5

1

Diaphragm

4810-100-10-18

Valve Bonnet

Diaphragm

Retainer

SOLENOID VALVE REPAIR PARTS

Screw

1

2

3

Spring position is moved for clarity.

Goes below Item 3.

4

Screen Retainer

Valve Body

Order the entire solenoid valve using manufacturer part number 4810-100-12-18.

5

Mesh Screen

ITEM QTY DESCRIPTION MFG NO.

2 1 Spring 4810-200-04-18

22

Page 25

PUMP AND MOTOR ASSEMBLY

2

1

Discharge Tube Connector

5700-011-70-34

3

1

Wash Pump & Motor

6105-002-50-10

1

Motor Mounting Bracket (Not Shown)

5700-002-40-86

1

2

3

ITEM QTY DESCRIPTION MFG NO.

1 1 Pump Suction Hose 5700-002-40-82

23

Page 26

BOOSTER TANK DISCHARGE HOSE/FILL TUBE WELDMENT ASSEMBLY

Order the entire Booster Tank Discharge Hose Assembly with

MFG. No.: 5700-002-45-48.

Hose, 1/2” x 19” Long

1 per assembly

Mfg. No.: 5700-002-45-59

Fitting, 1/2” Pushlock, Female, Brass

2 per assembly

Mfg. No.: 4730-011-93-99

Connects to the Incoming Plumbing Assembly

with a 1/2” NPT Brass Close Nipple:

Mfg. No.: 4730-207-15-00

Chemical Tube Grommet

3 per assembly

Mfg. No.: 5325-002-42-65

FILL TUBE WELDMENT ASSEMBLY

DELTA 5 Fill Tube Weldment

1 per machine

Mfg. No.: 5700-002-45-61

24

Page 27

STRAINERS

Accumulator Strainer Weldment

1 per machine

Mfg. No.: 5700-002-45-54

Associated hardware:

Screw, 1/4”-20 x 1-1/2” Hex Head Mfg. No.: 5305-274-23-00

Washer, 1/4”, Flat Mfg. No.: 5311-174-01-00

Locknut, 1/4”-20 w/Nylon Insert Mfg. No.: 5310-374-01-00

Pump Intake Strainer

1 per machine

Mfg. No.: 5700-021-37-87

Accumulator Shell Weldment

1 per machine

Mfg. No.: 5700-002-45-53

25

Page 28

Door Pivot Plate Weldment

1 per assembly

Mfg. No.: 5700-002-45-63

DOOR COMPONENTS

Door Pivot Plate Assembly

Door Pivot Plate Bearing

1 per assembly

Mfg. No.: 5700-002-45-09

Order the entire assembly using Mfg. No.:

5700-002-45-62

Door Dampener

1 per machine

Mfg. No.: 5340-002-42-63

Shock Mounting Plate Weldment

1 per machine

Mfg. No.: 5700-002-45-64

Door Weldment

1 per machine

Mfg. No.: 5700-002-45-65

26

Page 29

FRONT PANEL ASSEMBLY

2

2

Switch, Apem

5930-002-20-39

2

1

3

2

ITEM QTY DESCRIPTION MFG NO.

1 1 Light, Red Indicator 5945-002-45-86

3 1 Light, Yellow Indicator 5945-002-45-87

27

Page 30

FRONT PANEL ASSEMBLY (CONTINUED)

1

2

11

5

6

7

8

4

3

10

9

12

28

Page 31

FRONT PANEL ASSEMBLY (CONTINUED)/MAGNET SWITCHES

2

4

Wingnut, 1/4"-20, Nylon

5310-994-01-00

3

1

Decal, DELTA 5 Keypad

9905-002-45-85

5

1

Decal Panel

5700-002-37-53

6

4

Nylon Spacer

5940-002-21-73

8

1

Control Board

5945-002-45-84

3

Rubber Strip, 1/2" x 7.875" Long

5700-002-50-05

10

1

Rubber Strip, 11.25" Long

5700-002-37-74

11

1

Electrical Panel Back

5700-002-39-98

ITEM QTY DESCRIPTION MFG NO.

1 1 Front Panel Weldment 5700-002-45-83

4 1 Keypad 5945-002-16-79

7 4 Nut, 6-32, Keps, Stainless Steel 5310-002-24-29

9

12 1 Fitting, Liquid Tight, .231 ID x .394 OD 5975-011-49-03

Magnet Switch Bracket

Mfg. No.: 5700-002-40-80

Locknut, 1/4”-20 Low Profile Hex w/Nylon Insert

2 per Switch Bracket

Mfg. No.: 5310-374-02-00

Washer, S/S, 1/4”-20 I.D.

2 per Switch Bracket

Mfg. No.: 5311-174-01-00

1 per machine

Reed Switch

1 per machine

Mfg. No.: 5930-111-51-22

Locknut, 6-32 Hex w/Nylon Insert

2 per Reed Switch

Mfg. No.: 5310-373-03-00

29

Page 32

8 - PIN HARNESS

30

Page 33

DELTA 5

ELECTRICAL DIAGRAM

115 volt - 50/60 Hertz - Single Phase

31

Loading...

Loading...