Page 1

CREW® 66

Models

CREW® 66

*Product image shown with

optional Door Accent Panels

Standard Features

• 19-3/4” (502 mm) standard

clearance

• WISR™ Cleaning System

• Double-wall insulated cabinet

retains heat, keeping wash water

hot & generating less heat in the

dishroom

• Self-cleaning wash arms

• Fully automatic, including auto-fill

• Incoming water-pressure regulator

• Digital temperature readout

• Adjustable vent cowl collars

• 24V DC control circuit

• Exclusive EnergyGuard™ controls

• Self-draining stainless steel wash

pump

• Internally-operated drain lever

• PLC controls

Project

Item

Quantity

CSI Section 11400

Approval

Date

• Large front access for ease of

maintenance

• Conveyor drive motor comes

standard on the output end of

machine; must be specified at

time of order for input end

placement

• Inline heater for wash tank

(patent pending)

• Rainbow Rinse™ with arched

rinse arm (patent pending)

• Stainless steel strainer pans

• Splash shields

• Stainless steel frame and legs

• Exhaust vent fan control

• 18kW wash tank heater

• Front dress panel

• Adjustable bullet feet

CREW® 66

Mandatory Specs

Specify:

Electric

Steam

Specify Voltage______________

Specify Sanitizing Method:

High Temperature

Chemical Sanitizing

Specify Direction of Operation:

Left to Right

Right to Left

Options

Onboard Booster

40° F (4° C) Rise

70° F (21° C) Rise

Strike Plate Table Limit Switch

Flanged Feet

Door Accent Panels (must be specified at time of order)

Drain Quench System

Scaltrol

Water Hammer Arrestor

Prison Package

Specifications

Uses 0.32 gallons of water (1.44 liters) per rack

Cleans 218 racks per hour

18” (457 mm) wash section with a 14” (356 mm) separation

between wash and rinse

22” (559 mm) pre-wash sectiton has 3 upper and 1 lower

pre-wash arms

Stainless steel construction

Accessories

36-Compartment Rack

4-1/8” tall (104 mm)

5 - 5/8” tall (143 mm)

7” tall (178 mm)

Combination Rack

Peg Rack

Sheet Pan Rack

SHIP PING AD DRESS

6209 North U.S. Hi ghway 25E

Gray , KY 40 734

MAILING ADDR ESS

P.O. Box 106 0

Barbourville , KY 40906

Tel: 1-888-8 00-5672

Fax: 606-523 -1799

info@jackson msc.com

www.jacksonm sc.com

Page 2

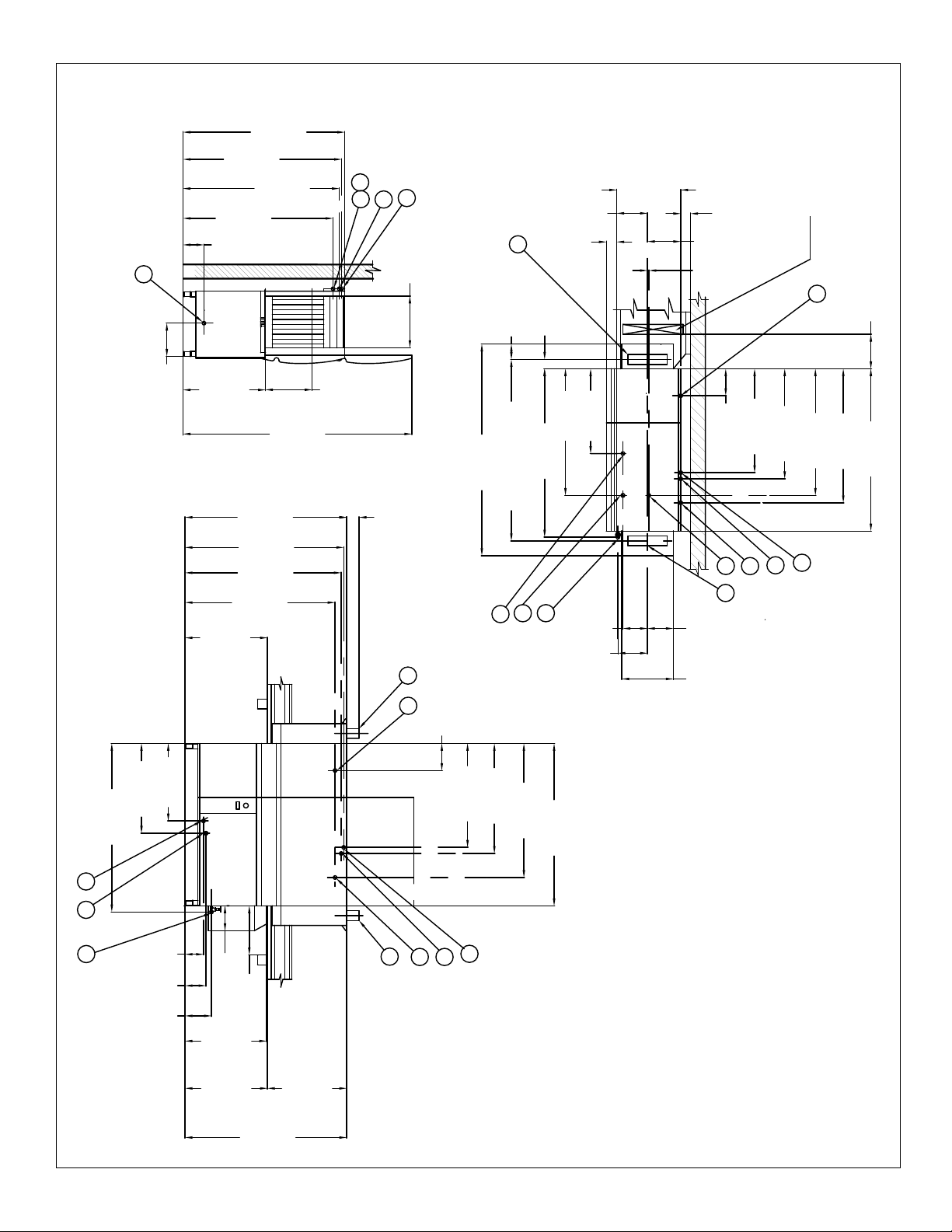

CREW® 66

Left to Right

3

(342.9 mm)

13 1/2"

(850.9 mm)

65 3/4"

(1670.0 mm)

64 1/2"

(1638.3 mm)

63 1/2"

(1612.9 mm)

61"

(1549.4 mm)

8 1/2"

(215.9 mm)

33 1/2"

(2362.2 mm)

TOP OF DOOR WHEN OPEN

93"

3

2

19 3/4"

(501.6 mm)

CLEARANCE

1

CLEARANCE

8

(533.4 mm)

21"

4 1/4"

5

(107.9 mm)

(158.8 mm)

(95.2 mm)

6 1/4"

3 3/4"

(1866.9 TO 1930.4 mm)

73 1/2" TO 76"

ADJUSTABLE FROM

(1739.9 mm)

(2184.4 mm)

86"

68 1/2"

12 1/2"

(317.5 mm)

(876.3 mm)

(876.3 mm)

51 1/2"

34 1/2"

26"

(660.4 mm)

4" MIN

(120.6 MM)

13 1/2"

(342.9 mm)

1/2"

(12.7 mm)

(279.4 mm)

11"

IN TABLE 4" (102 mm) WIDE

RECOMMENDED SCRAP SINK

X 16" (406 mm) X 4" (102 mm) DP

(355.6 mm)

3

(1073.2 mm)

(1136.6 mm)

42 1/4"

(1308.1 mm)

44 3/4"

(1384.3 mm)

51 1/2"

54 1/2"

(1676.4 mm)

14"

66"

(1181.1 mm)

7 4

6

(1308.1 mm)

36 1/2"

68 1/2"

7 1/2"

(190.5 mm)

8 1/2"

(215.9 mm)

10 3/4"

(273.1 mm)

(850.9 mm)

(876.3 mm)

31 1/2"

(850.9 mm)

(1549.4 mm)

33 1/2"

(254 mm)

10 1/8"

33 1/8"

65 3/4"

(1670.0 mm)

64 1/2"

(1638.3 mm)

63 1/2"

(1612.9 mm)

61"

(355.6 mm)

20"

5"

(127 mm)

5

5

3

(279.4 mm)

1

2

11"

(1073.2 mm)

42 1/4"

8

4

7

(1136.6 mm)

44 3/4"

(1384.3 mm)

54 1/2"

6

10"

(254.0 mm)

12"

(304.8 mm)

(1676.4 mm)

66"

4

5

10 1/2"

(266.7 mm)

21"

(533.4 mm)

6.

7.

8.

3/4” NPT STEAM CONNECTION

3/4” NPT CONDENSATE RETURN LINE

OPTIONAL TOP MOUNTED BOOSTER

HEATER ELECTRICAL CONNECTION

5.

VENT CONNECTION - INCLUDES

DAMPER. 2 PLACES:

4” I.D. X 16” I.D.

2

4.

1-1/2” NPT DRAIN CONNECTION (2 required)

8

1

1.

2.

3.

ELECTRICAL CONNECTION

1/2” NPT 180° F WATER INLET

FOR WASH AND FINAL RINSE

1/2” NPT 110° F MIN. WATER INLET

FOR PRE-WASH

65 3/4"

32 1/4"

(819.2 mm)

33 1/2"

(850.9 mm)

(1670.0 mm)

We reserve the right to change specifications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Page 3

4

10 3/4"

(273.1 mm)

65 3/4"

(1670.0 mm)

64 1/2"

(1638.3 mm)

63 1/2"

(1612.9 mm)

61"

(1594.4 mm)

6"

(152.4 mm)

33 1/2"

(850.9 mm)

(2362.2 mm)

TOP OF DOOR WHEN OPEN

65 3/4"

(1670.0 mm)

33 1/2"

(850.9 mm)

33 1/8"

(850.9 mm)

(355.6 mm)

20"

(254 mm)

10 1/8"

19 3/4"

(501.6 mm)

CLEARANCE

93"

32 1/4"

(819.2 mm)

3

1

2

(533.4 mm)

CLEARANCE

21"

6

CREW® 66

Right to Left

21"

(533.4 mm)

12"

8

7

(1866.9 mm TO 1930.4 mm)

73 1/2" TO 76"

(2184.4 mm)

86"

(187.75 mm)

5

(304.8 mm)

6

4

(254.0 mm)

ADJUSTABLE FROM

(63.5 mm)

68 1/2"

(800.1 mm)

31 1/2"

6 1/4"

12 1/2"

(317.5 mm)

10"

(95.2 mm)

3 3/4"

26"

(660.4 mm)

10 1/2"

(266.7 mm)

1/2"

(12.7 mm)

(279.4 mm)

4" MIN

(120.6 MM)

13 1/2"

(342.9 mm)

5

11"

(368.3 mm)

36 1/2"

8

1

2

(1676.4 mm)

(1384.3 mm)

54 3/4"

(1136.6 mm)

(1073.2 mm)

44 3/4"

42 1/2"

3

IN TABLE 4" (102 mm) WIDE

X 16" (406 mm) X 4" (102 mm) DP

66"

(355.6 mm)

14"

RECOMMENDED SCRAP SINK

4

7

(1739.9 mm)

68 1/2"

(368.3 mm)

36 1/2"

7 1/2"

(190.5 mm)

8 1/2"

(215.9 mm)

(800.1 mm)

31 1/2"

(850.9 mm)

33 1/2"

(1594.4 mm)

61"

63 1/2"

(1612.9 mm)

64 1/2"

(1638.3 mm)

65 3/4"

(1670.0 mm)

5

5

5"

(127 mm)

2

3

1

(1073.2 mm)

42 1/2"

(279.4 mm)

11"

8

1676.4 mm

(1384.3 mm)

54 3/4"

(1136.6 mm)

44 3/4"

66"

6.

7.

8.

3/4” NPT STEAM CONNECTION

3/4” NPT CONDENSATE RETURN LINE

OPTIONAL TOP MOUNTED BOOSTER

HEATER ELECTRICAL CONNECTION

5.

VENT CONNECTION - INCLUDES

DAMPER. 2 PLACES:

4” I.D. X 16” I.D.

4.

1-1/2” NPT DRAIN CONNECTION (2 required)

1.

2.

3.

ELECTRICAL CONNECTION

1/2” NPT 180° F WATER INLET

FOR WASH AND FINAL RINSE

1/2” NPT 110° F MIN. WATER INLET

FOR PRE-WASH

Visit us at www.jacksonmsc.com or call us at 1-888-800-5672

Page 4

CREW® 66

RECOMMENDED TABLE FABRICATION

TABLE CONNECTION

RACK RAIL

5/16" (8 mm)

1/4" (6 mm) TO

ABOVE DISHTABLE

RACK RAIL HEIGHT

TABLE

21.00" (533 mm)

MACHINE DIMENSIONS

MODEL NO.

CREW® 66

HEIGHT

65-3/4”

(1670 mm)

OPERATING CAPACITY

OPERATING TEMPERATURES

ELECTRICAL REQUIREMENTS

BOOSTER HEATER OPTIONS

208V/60HZ/3PH

208V/60HZ/1PH

230V/60HZ/3PH

230V/60HZ/1PH

460V/60HZ/3PH

HOW TO SPECIFY:

CREW® 66

3/4" (19 mm)

MAX TURNDOWN

ON TABLE

HEIGHT WITH

DOOR OPEN

93”

(2362 mm)

40° F (4° C) Minimum Rise 70° F (21° C) Minimum Rise

LENGTH

BETWEEN

DISHTABLES

66”

(1676 mm)

Approximate Total Load AMPS

66.5

108.5

61.1

102.1

28.4460V/60HZ/3PH

kW AMPS kW AMPS

12

12

12

DEPTH WEIGHT CLASS CUBE HEIGHT WIDTH DEPTH

30”

(762 mm)

Chemical SanitizingHigh-Temperature

Chemical SanitizingHigh-Temperature

110 -120° F (43 -49° C)110 - 140° F (43 - 60° C)Pre-Wash

120° F (49° C)160° F (71° C)Wash (minimum)

120° F (49° C) 180° F (82° C)Rinse (minimum)

SteamElectric Tank Heat

16.5208V/60HZ/3PH

22.0208V/60HZ/1PH

15.9230V/60HZ/3PH

21.2230V/60HZ/1PH

33.3 17.2 47.7

57.7 17.2 82.7

27.7 18 41.5

47.9 18 71.912

13.8 18 20.712

DRAIN

HEIGHT

6-1/2”

(165 mm)

218218Racks per Hour

5,4505,450Dishes per Hour

7,8487,848Glasses per Hour

8.0

DISHMACHINE TUB

USE SILICONE SEAL BETWEEN

TABLE & LIP OF DISHMACHINE

SHIPPING INFORMATION

1220 lbs

(553 kg)

92.5

204.83

cu. ft.

89”

(2261 mm)

WATER REQUIREMENTS

Inlet Temperature (minimum)

With 40° F (4° C) Rise Booster Heater

With 70° F (21° C) Rise Booster Heater

Gallons per Hour

Gallons per Rack

Waterline Size IPS (minimum)

Drainline Size IPS (minimum)

Flow Pressure (PSI)

Flow Rate GPM (minimum)

Wash Tank Capacity

WASH PUMPS

Pre-Wash Pump Motor

CONVEYOR

Conveyor Motor

VENTING REQUIREMENTS

Input End

STEAM COIL TANK HEAT (STEAM MODELS ONLY)

Steam Connection IPS

97”

(2464 mm)

270 GPM (1022 LPM)Wash Pump Capacity

6.07 FPM (1.85 MPM)Conveyor Speed (feet per minute)

(1041 mm)

140° F (60° C)

110° F (43° C)

69.8 gal (264 L)

0.32 gal (1.2 L)

1.16 (4.4 LPM)

35.6 gal (135 L)

2 hp

3 hpWash Pump Motor

220 GPM (833 LPM)Pre-Wash Pump Capacity

1/4 hp

200 CFM

200 CFMOutput End

400 CFMTotal CFM

3/4”

10-20Steam Flow Pressure (PSIG)

41”

1/2”

1-1/2”

15

60Consumption @ 15 PSIG (lbs/hr)

SHIP PING AD DRESS

6209 North U.S. Hi ghway 25E

Gray , KY 40 734

MAILING ADDR ESS

P.O. Box 106 0

Barbourville , KY 40906

Tel: 1-888-8 00-5672

Fax: 606-523 -1799

info@jackson msc.com

www.jacksonm sc.com

07610-003-82 -61 (10/06/11)

Loading...

Loading...