Page 1

SERVICE MANUAL

1060

JMSC

-

Warranty Policy

-

Installation Requirements

CONSERVER I

LOW TEMPERATURE CHEMICAL SANTIZING DOOR

TYPE DISHWASHER

INCLUDES:

-Operating Instructions

-Description of Components

-Troubleshooting Guide

-Illustrated Parts List

-Basic Functions of Dishwasher

-Maintenance and Care

-Wiring Diagrams

WORLD HEADQUARTERS & MANUFACTURING OPERATIONS

Highway 25E, P.O. Box

Barbourville, KY 40906

888/800-

Fax: 606/523-9196

May 30,1997 P/N 7610-100-09-00 Rev A

Page 2

INDEX

SPECIFICATIONS 3

GENERAL INSTRUCTIONS(Installation) 4-5

GENERAL INSTRUCTIONS(Operation) 6-7

GENERAL INSTRUCTIONS (Preventive Maintenance) 8

WASH/RINSE HEAD ASSEMBLY 9

TIMER ADJUSTMENTS 10

TIMER ASSEMBLY, SPANNER WRENCH

TIMERMICROSWITCH,SIDE VIEW OFCAM 11

FUNCTION OF SWITCHES CIRCUIT BREAKER,

INDICATOR LIGHTS AND CYCLE COUNTER 12

REPLACEMENTOFSW1TCHES IN CONTROL PANEL 13

PERISTALTIC PUMPSANITIZING DISPENSING SYSTEM 14

SANITIZING AGENT INJECTOR 15

WASH/RINSE PUMP ASSEMBLY 16

REPLACING SEAL & CERAMIC ON WASH\RINSE PUMP 17

CORNER DRAIN ASSEMBLY 16

SERVICEINSTRUCTIONS (lncoming Water Solenoid Valve) 19

APPLYING NYLATRON STRIP TO CONSERVER DOOR 20

INSTRUCTIONS FOR ADJUSTING TENSION OF CANTILEVER 21

TROUBLE SHOOTING GUIDE 23

PICTORIALS:

FRONT VIEW CORNER MODEL 25

BACK SIDE VIEWSTRA1GHTTHROUGH MODEL 26

RIGHT SIDE VIEW STRAIGHT THROUGH MODEL 27

LEFTSIDE VIEWSTRA1GHTTHROUGH MODEL 28

INCOMING PLUMBING VACUUM BREAKER, MERCURY RELAY 29

ELECTRICAL DRAWINGS 30

PARTS LIST 32

PARTS DISTRIBUTORS Inside Back Cover

Page 3

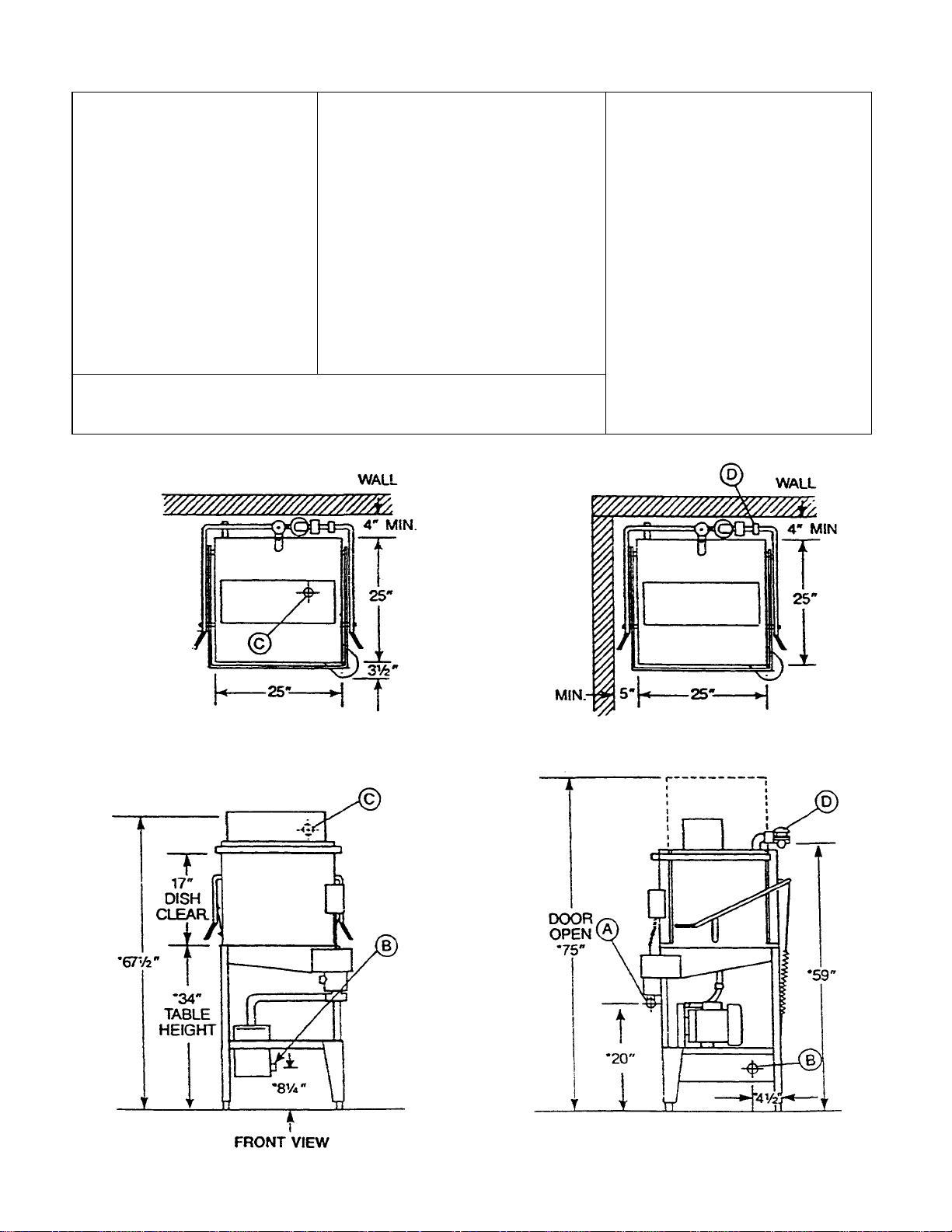

SPECIFICATIONS

Combination Optional

115

TOP VIEW

TOP V

IEW

A-

Drain connection withou

t

accumulator. Either side

optional wast accumulator

¾”

Operating Capacity Thermometers Wash Pump Motor

Racks per Hour 38 Wash - °F 140 Horsepower 1

(NSF Rated)

Dishes per Hour 950

Rinse - °F 140

Glasses per Hour 950 Water Requirements Depth 25"

Operating Cycle

(NSF Rated)

Inlet Temperature - °F

140 Height 52 ¾"

Total Cycle — Sec. 90 Gallons per Hour 114 Standard Table Height 34"

Wash Tank Capacity

Gallons

Wash Pump Capacity

Gallons per Minute

25

55

Flow Pressure PSI

Flow GPM

Inlet IPS

20

105

¾”

Drain IPS ¾" Racks

Dimensions

Width 25"

Maximum Clearance

for Dishes 17"

Dish, 19 ¾ x 19 ¾ Optional

Electrical Rating

Volts

Cylcle Phase Total Load

60 1 (3 Wire) 13

RACK GUIDES IN

STRAIGHT-THRU

CONFIGURATION

Amps Shipping Weight

Approx. Basic Model 300

optional waste

of “Tee”- 2”.

B- Drain connection with

– 2”.

C- Electrical connection-

condiut.

RACK GUIDES IN

CORNER CONFIGURATION

•All dimensions from floor are adjustable ±1/2" due to bullet feet.

3

RIGHT SIDE

Page 4

GENERAL INSTRUCTIONS

(INSTALLATION)

Note: Read the following instructions carefully, proper installation of your Conserver Dishwasher

will ensure proper machine operation.

1. Cut straps holding machine to base of crate, ease machine on to floor and move into place of

installation.

2. Connect drain line to bottom of machine (2 IPS female fitting on front of machine) to conform with

local and/or national codes. Drain is a gravity feed system from the machine.

a. The Conserver is designed to accommodate an external scrap trap if one is shipped with the

unit. The scrap trap should be placed beneath the unit with the top opening to the right of the

pump and motor mounting shelf so that the top hole of the scrap trap is in line with the drain

opening from the machine.

b. Direct the drain line from the dishwasher to the top of the trap and plumb accordingly with 2"

pipe of the necessary length. Connect a 2" fitting to the back of the scrap trap and plumb to the

drain line. The drain line is a gravity feed system from the dishwasher to the scrap trap and also

from the scrap trap to the drain line. Scrap trap aids sluggish drains by containing machine

water as it drains and letting it drain off slower.

3. Connect incoming ¾" water line with capacity to supply 10.5 gallons per minute with a flow pressure

of 20 PSI at a temperature of 140 degrees fahrenheit. This connection is just before the Y-strainer.

Connect to conform with local and/or national codes (standards). a. It is recommended that in areas

where there is fluctuating water pressure a restrictor valve allowing 8 gallons of water per minute be

installed. This will help to provide a steady fill rate. The restrictor should be located down the line

from the Y-strainer.

4. Install the proper circuit breaker, wire and conduit size to conform with local and/or national codes.

Refer to data plate for electrical rating.

5. Electrical connections are made to the circuit breaker located in the dispenser/control box on top of

the machine. The circuit breaker is located on the side of the box with a grounding lug next to it.

Three wires L1, N and a ground wire should be passed through the hole in the back of the box and

pulled over to the top two terminals of the circuit breaker. Wires L1 and N are connected to the top

two terminals of the circuit breaker and the ground wire connected to the grounding lug next to the

circuit breaker.

6. Do not apply power until step # 9.

7. Turn on water supply to machine; check for any leaks in plumbing and connections.

8. Place the open end of the red tube into a container of detergent, white, into a container of sanitizer

and blue, into a container of rinse additive.

9. To energize electrically, proceed as follows:

a. Turn on customer's circuit breaker controlling the machine.

b. Check voltage at incoming terminals L1 and N, it should match data plate voltage. Voltage at

L1 should be checked to ground to ensure that a high (or wild) leg is NOT connected.

(Voltage exceeding 150V to ground would indicate a high leg).

c. If voltages are in required range, turn on circuit breaker on the side of the dispenser/ control

box.

10. To fill the unit with water:

a. Located on the right side of the control box are two rocker type momentary switches. To fill this

unit initially with water, push and hold the fill switch to the top of the unit until the water

reaches the overflow hole the side of the drain stopper. Release the switch and it will return to

the center position.

b. After the unit is full of water, check for leaks and see if the solenoid valve opens and closes as

the fill switch is turned on and off.

c. After checking the plumbing lines for leaks, run the unit through a complete cycle to determine

the proper water level. The proper level for the water is the overflow hole in the side of the

drain stopper if this level is either not reached or is exceeded, please turn to the timer section

of this manual to determine the proper adjustment of the timer that has to be made.

4

Page 5

d. Above each peristaltic pump is a priming switch. After making sure that the feeder tubes to the pumps are in

2. 0012000

CUSTOMER ELECTRICAL

7. 0154300

START SWITCH

SERVICE CONNECTION

8.

FILL LEVEL

4. 0046500

RINSE ADDITIVE DISPENSER PUMP

10. 0156300

DELIME/PURGE SWITCH

DISPENSER PUMP

their proper containers, as marked on the pumps, press the switch and hold it until there is a discharge of the

fluid into the machine. This is to be done to each pump before the initial operation of the machine. Water must

be in wash-rinse tub to prevent discoloration or deterioration of the stainless tub by chemicals.

e. The dishwasher is now ready to proceed with the washing of dishes in accordance with operating instructions

in this manual.

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1.

INCOMING WATER CONNECTION(3/4") 6. 0154300 PRIMING SWITCHES

3. 0046500 DETERGENT DISPENSER PUMP 9.

5. 0046500 SANITIZING SOLUTION 11. 0204101 WASTE ACCUMULATOR (OPTIONAL)

DRAIN OUTLET (2" GRAVITY FEED)

5

Page 6

GENERAL INSTRUCTIONS

(OPERATION)

Note: Read the following instructions carefully, proper operation of your Conserver Dishwasher

will ensure clean and sanitized glasses and dishes at optimum efficiency.

Dish Preparation:

1. Scrape dishes thoroughly.

2. Pre-wash by soaking or spraying with a pre-rinse hose.

3. Place dishes and cups in dish rack; cups, upside down.

4. Place glasses and silverware in combination glass silverware rack; glasses, upside down. Scatter

silverware loosely on bottom. Do not put glasses on top of silverware.

Note: Silverware should be washed upright in a special compartment silverware rack for best

results. These silverware compartment racks are available through your dealer or service

agency.

Machine Operation:

1. Insert strainer.

2. Be sure the drain stopper is in place.

3. Insert a rack of dishes and close all doors.

4. Check the levels of the soap detergent, rinse additive and sanitizing agent containers. Fill

them if necessary.

5. To put the unit into operation at the beginning of the day or a meal period, make sure the

circuit breaker on the left side of the dispenser/control box on top of the machine is on.

6. For the initial fill, push the fill switch on the right side of the dispenser/control box to the top.

Hold the switch in this position until the water level reaches the top of the cut out for the

drain opening.

7. When the unit Is full of water, insert a rack of soiled dishes then push the start switch on

either the right or left side to the top and count to three. This activates the time cycle and

the cycle light will come on.

8. When the light goes out, open the doors and slide out the rack of clean dishes. Slide in a

rack of soiled dishes and repeat steps #7 and #8.

9. At the end of the mealtime, shut off the circuit breaker on the dispenser/control box and

drain the unit by pulling on the drain stopper. Clean any food debris out of the basket

strainer.

Note: If the unit is not operated for extended periods of time, the water will drain out or

go down in level. Be sure to check the water level before operating and if the level

is down, see step #6.

6

Page 7

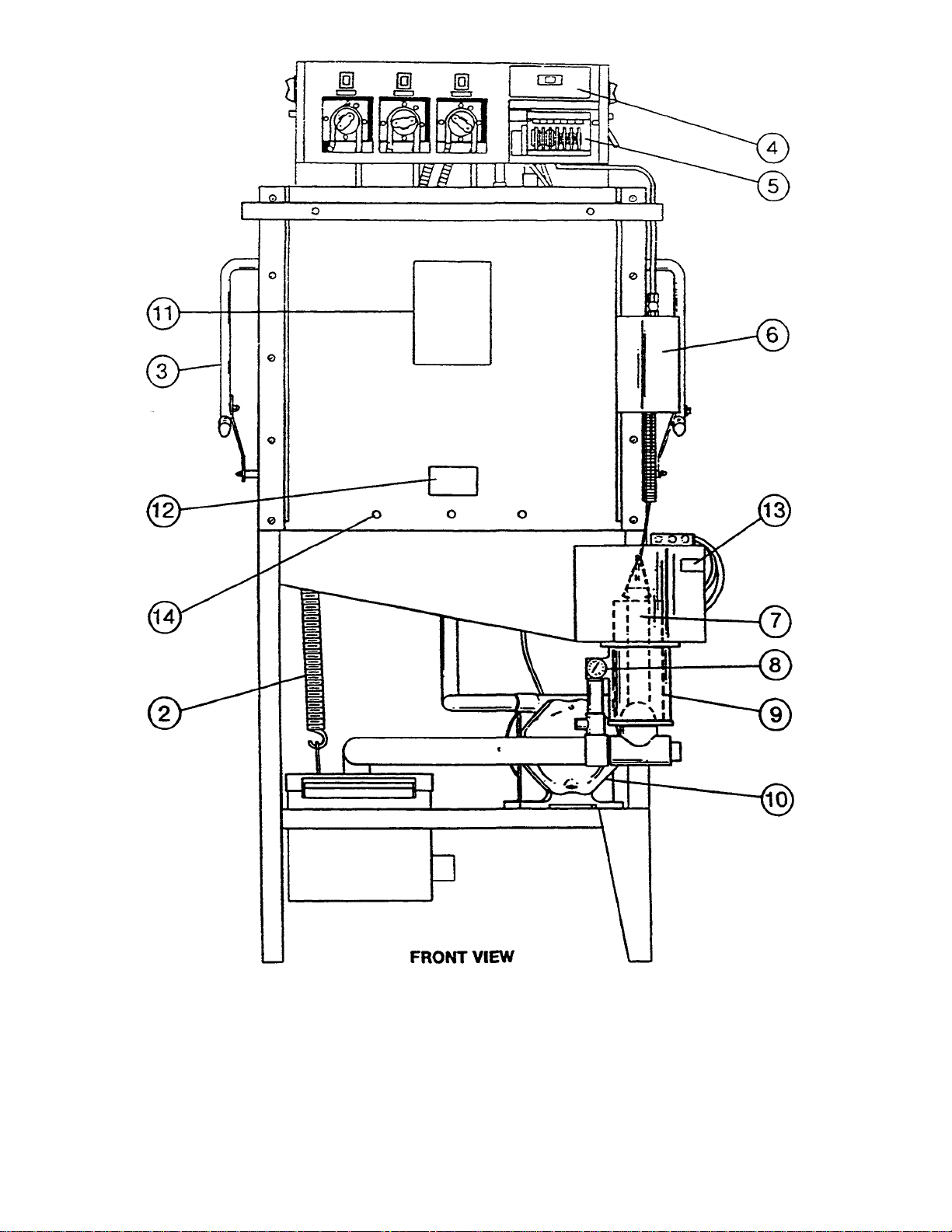

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1. 0143400 RINSE/FILL SOLENOID VALVE 9. 0152100 PUMP INTAKE STRAINER

2. 0009000 CANTILEVER DOOR SPRING 10. 0087000 PUMP AND MOTOR ASSEMBLY

3. 0008500 CANTILEVER 11. 0001210 OPERATIONS DECAL

4. 0001207 DELIME SWITCH DECAL 12. 0001204 DOOR CAUTION DECAL

5. 0171100 TIMER 13. 0001203 CLEAN STRAINER DECAL

6. 0054106 DRAIN SOLENOID "T" STYLE 14. 0051900 DOOR, HOLE PLUGS, BLACK RUBBER

7. 0053813 DRAIN STOPPER

8. 0169000 WASH-RINSE WATER THERMOMETER

7

Page 8

GENERAL INSTRUCTIONS

(PREVENTIVE MAINTENANCE)

THE FOLLOWING IS TO BE PERFORMED AS NEEDED.

Note: Read the following instructions carefully. Proper maintenance of your Conserver

Dishwasher will assure optimum service with a minimum of down time.

Before removing the cover to the Dispenser/Control Box, turn off the circuit breaker on

the side of the box.

1. Removal of Lime and Corrosion Deposits (Weekly or as needed.)

a. Fill machine with wash water as would ordinarily be done for washing.

b. Unlock the Electrical Control Box with the key provided and locate the "Normal/Purge/Delime"

switch. Push the switch to the "Purge" mode. Run the machine for 3 cycles without any dishes in it

c. Push the switch to the "Delime" mode.

d. Open door and place one cup or less of deliming compound into water. (Be sure to follow the

amount and directions given on the package or bottle of the compound used.) The compound is

available from your detergent supplier.

e. Close door and push start switch. The machine will continuously run in the delime mode. Run

the machine for 5 minutes and then turn off.

f. Open door and examine the interior. All lime should be removed and parts should be shiny. If

not, scrub stubborn deposits with brush and repeat operation. (Protect hands with waterproof

gloves.)

g. After the interior is clean, empty wash water by removing the drain stopper. Remove basket

strainer and flush away all debris and build-up.

h. Push the switch to the "Purge" mode and run the machine for 3 cycles.

i. Physically inspect the interior of the machine. By now the interior should be clean. If not, repeat

steps 4 and 5.

j. Push the switch back to "Normal" position. Now the machine is ready for normal operation.

2. Clean the strainer basket to provide for the maximum amount of water return to the pump as

possible. (Daily or as needed.)

a. Remove basket from drain opening and brush away any debris or force it out of the strainer

openings with water.

3. Clean Y-strainer on incoming water line. (Yearly or as needed)

a. Water to machine must be turned "off* for this operation.

b. Remove plug and clean strainer. As water is trapped near strainer, and 120 degrees to 140 degrees

fahrenheit, use care in removing plug and have container to catch water.

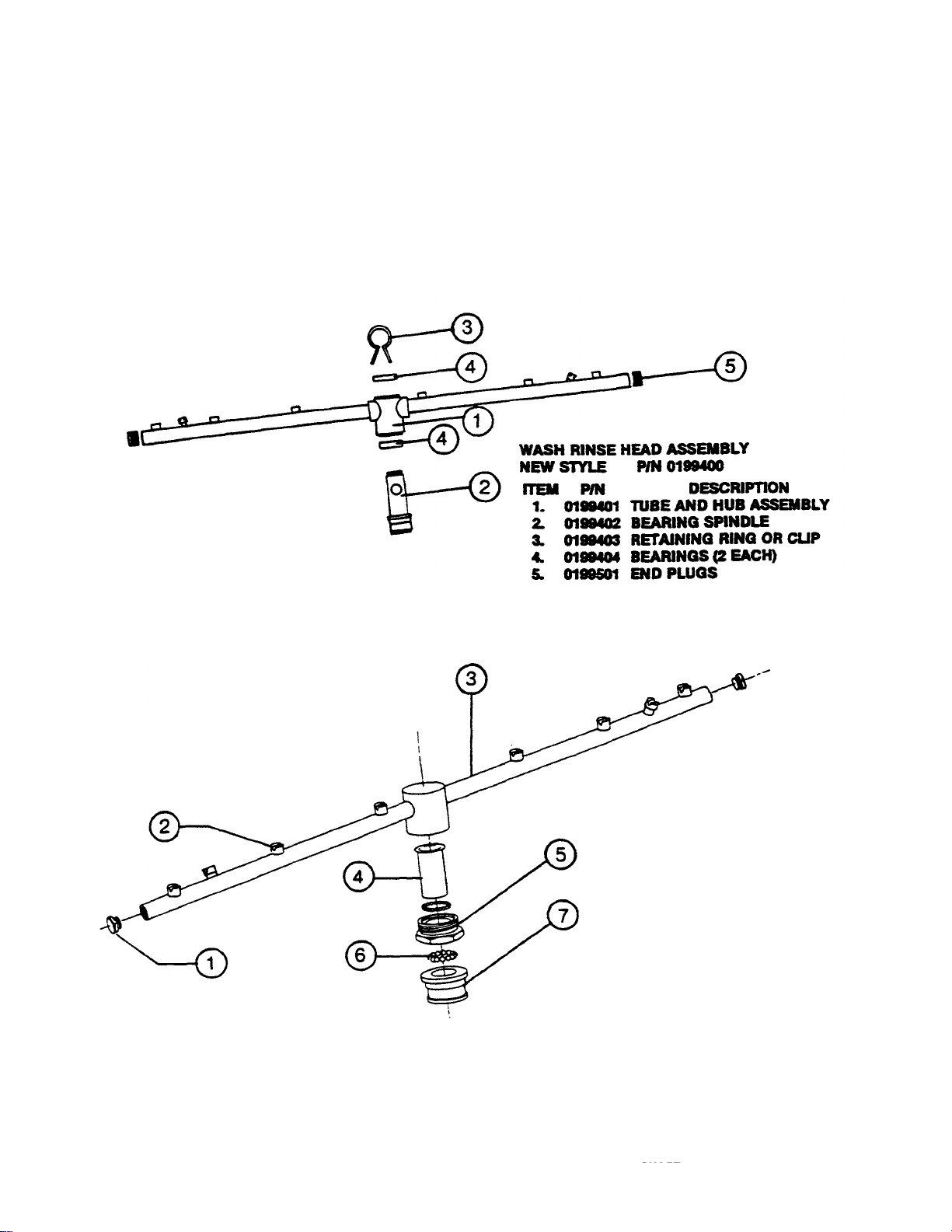

4. Clean wash/rinse tubes. (Weekly or as needed.) (See Drawing Next Page)

a. Turn the circuit breaker to “off” position.

b. Open door and drain machine by lifting drain stopper.

c. When empty, replace drain stopper.

d. Loosen the two thumb screws opposite each other on the top and bottom assemblies.

e. Pull the assembly out of the base.

f. Remove the hub assembly by loosening the nut with a wrench.

g. After hub is off, remove the end plugs and either flush with clean water or a brush.

(A straightened paper clip makes an excellent tool for cleaning the nozzles.)

h. Clean the hub by either soaking or brushing with a deliming solution. (A toothbrush makes

an excellent tool.)

i. The bearings cannot be replaced separately, the whole hub must be replaced if it is

needed.

j. Reassemble the wash/rinse assembly by reversing steps d, e, f, and g.

5. Clean any deposits which may have built up on exterior moving parts (Only as needed.)

a. Remove with clean cloth. (A stainless polish or oil may be used to loosen deposits.)

b. Deposits around fill switch can be removed with a dry toothbrush.

8

Page 9

6. If an external scrap trap is supplied with the unit, flush the drain line and the scrap trap

(Weekly or as needed.)

a. Remove the 2" pipe nipple on the end of the fitting underneath the drain outlet.

b. Insert a hose into the line and flush the line out with a steady stream of water.

c. Remove the scrap tray from the scrap trap and empty the food debris into a disposable

container.

d. Before reinstalling the scrap tray, flush the line from the machine to the trap, then from

the trap to the drain line.

e. Reinstall the scrap tray and replace the lid.

7. Never allow the main pump to be operated without water in the machine.

8. Inspect the peristaltic pumps on a weekly schedule for cracks in the tubes. On the right side of the

dispenser/control box there is a counter to register each time the unit completes a full cycle. Anticipate

about every 30,000 cycles having to replace the tubes in the peristaltic pumps. The tubes and

instructions are available from your area parts distributor listed in the back of this manual.

WASH RINSE HEAD ASSEMBLY

NEW STYLE P/N 0199400

Item

1.

2.

3.

4.

5.

P/N Description

0199401 Tube and Hub Assembly

0199402 Bearing Spindle

0199403 Retaining Ring or Cup

0199404 Bearings (2 Each)

0199501 End Plugs

WASH RINSE HEAD ASSEMBLY P/N 0199500

4 PER MACHINE

ITEM P/N DESCRIPTION

ITEM P/N DESCRIPTION

1. 0199501 END PLUGS (4)

1. 0199501 END PLUGS (4)

2. VEE JETS (16)

2. VEE JETS(16)

3. 0199503 TUBE (4)

3. 0199503 TUBE (4)

4. 0199504 INTERNAL SHAFT

4. 0199504 INTERNAL SHAFT

5. 0199504 HEX BUSHING COMPLETE UNIT

5. 0199504 HEX BUSHING

6. 0199504 BEARINGS 4 EACH

6. 0199504 BEARINGS

7. 0199504 EXTERNAL SHAFT

7. 0199504

EXTERNAL

COMPLETE UNIT

4 EACH

9

Page 10

TIMER ADJUSTMENTS

The timer is a self-contained (frame-mounted) timer of the repeating cycle type. It is mounted in the

control box on the top of the machine to control the automatic functions of the machine. The timer motor

operates on 110 VAC, 60 cycles, taking 90 seconds to complete one full revolution. There are six micro

switches which are controlled by rotating cams driven by the timer motor. Two of the cams are fixed and

cannot be adjusted. The remaining four cams are adjustable and can be adjusted to either lengthen or

shorten the desired operation.

Remove the power to the machine when making all timer adjustments.

Included and taped in each control panel is a spanner wrench (as shown in the drawing). This wrench is

needed to adjust the cams on the timer. The cams are preset at the factory but may have to be

readjusted for different conditions of the country and for the different brands of detergent, rinse additive

and sanitizing solutions. On both sides of the four adjustable cams, there are holes into which the

spanner wrench is placed to apply leverage to make the desired change. The left side of the cam will

always start an operation and the right side will end it The cam on the right side is the one that will be

adjusted more often since this one determines the length of the operation.

When making adjustments to the timer cams be sure that the first cam next to the timer motor is in its

stop position in the notch. Place one hand over the timer motor with your thumb lodged next to or on the

first cam so that it will not move when the other cams are being adjusted. To make the adjustment, place

the wrench in the holes on the right side of the cam. If a longer operating time is desired, increase the

gap between the left and right side of the cam. If a shorter operating time is desired, decrease the gap

between the left and right side of the cam. At the extreme end from the timer motor, there is a cam

marked in five-degree increments. Every four degrees equals one second of the timer's revolution.

Function of each micro switch starting from the timer motor and going left to right:

Timer Motor Micro Switch: controlled by a fixed cam that controls the total length of the cycle. It is

activated by engaging the fill/start switch in the start position.

Detergent Micro Switch: controlled by an adjustable cam. It operates the peristaltic pump that

dispenses the detergent. By adjusting the right side of the cam, you can either increase or decrease your

amount of detergents.

Drain Solenoid Micro Switch: controlled by a fixed cam. It opens the solenoid valve during the cycle

that drains the wash water out of the unit.

Fresh Water Solenoid Valve Micro Switch: controlled by adjustable cam. It is important that the unit

have two-and-a-half gallons of water in it during the wash and rinse cycles. The proper level indicator is

the height of the cut-out leading into the drain strainer and stopper. By adjusting the right side of the

cam, you can either increase or decrease your water supply to meet this required level. Fill water is

turned on before drain cycle ends to insure machine is flushed before filling.

Rinse Agent Micro Switch: controlled by an adjustable cam. It operates the peristaltic pump that

dispenses the rinse agent. By adjusting the right side of the cam, you can either increase or decrease

your amount of rinse additive. It should activate during the fill cycle.

Sanitizing Agent Micro Switch: controlled by an adjustable cam. It operates the peristaltic pump that

dispenses the sanitizer solution. By adjusting the right side of the cam, you can either increase or

decrease your amount of sanitizer solution. It should activate during the fill cycle. When the timer is

preset at the factory, it is set to dispense 15 milliliters of detergent 11 milliliters of rinse additive and 9.5

milliliters (50 parts per million) sanitizing agent based on an 8.4% solution of Sodium Hypochlorite.

10

Page 11

11

Page 12

FUNCTION OF SWITCHES, CIRCUIT

BREAKER, INDICATOR LIGHT AND

CYCLE COUNTER

Circuit Breaker — The circuit breaker is rated at 15 amps and is utilized for the customer's incoming

electrical service connection and as a protection device for the unit. (P/N 120)

Fill/Start Switch, Straight through Model (before S/N 1163) — The Fill/Start switch is a three position

Spring loaded momentary toggle switch which is utilized for two basic functions of the machine. When the

switch is held to the forward position it allows water to enter the machine to the desired level. When the

switch is held to the back for a count of three the automatic timer is started. The center position is off.

(P/N 1626)

Fill Switch, Straight through Model (after S/N 1163) — The Fill switch is a spring loaded momentary

rocker switch and must be held in the up position until the water has reached the desired level.

(P/N 1543)

Start Switch, Straight through Model (after S/N 1163) — The Start switch is a spring loaded

momentary rocker switch and must be held in the up position for a count of three to start the automatic

timer. (P/N 1543)

Fill/Start Switch, Corner Model (after S/N 1163) — The Fill/Start switch is a spring loaded three

position momentary rocker switch with the center position being off. To fill the machine push the switch

up and hold until the water reaches the proper level. To start the unit push the switch down and hold for a

count of three. (P/N 1627)

Drain Switch, Corner Models (all Inside sump) — The drain switch is a spring loaded momentary

rocker switch utilized to activate the drain solenoid when it is necessary to drain the machine at times

other than during the normal operation of washing and rinsing. (P/N 1543)

Primer Switches — The primer switches are a spring loaded momentary rocker switch located over

each peristaltic dispensing pump. The switches are utilized to operate the pumps when it is necessary to

refill the intake tubes or pumps after they have been emptied. The pump is activated by pushing up on

the switch and holding it for the desired length of time. (P/N 1543)

Cycle or Machine Light — This light comes on only when the automatic cycle is in progress and

extinguishes when the cycle is complete. (P/N 835)

Cycle Counter — The counter totals each single cycle that the unit goes through and is activated by the rinse

additive micro switch on the timer. This counter can not be reset. (P/N 340)

Power On Light — This light is lit all the time the circuit breaker is on. (P/N 835)

Delime/Purge Switch — The Delime/Purge Switch is a three position switch. It allows normal operation, a

purge operation and a delime operation.

12

Page 13

REPLACEMENT of SWITCH

in CONTROL PANEL

There is one type of manually operated switch utilized on the Conserver dishwasher. It is the rocker

switch.

Before working on the machine, it is important that the power be turned off at the customer's circuit

breaker to prevent the possibility of electrical shock, trip the breaker to the "OFF" position. Then turn the

machine circuit breaker "OFF" located on the side of the control box.

The Rocker switch is mounted in a rectangular hole held in position by a bracket. These switches are

designed to be released from the inside and pushed outward. The spring sides must be depressed to

release the switch and bracket from the hole- To remove the bracket from the switch wedge a

screwdriver in between them then lift up and move off.

If the switch is found to be defective mount a new one into the bracket and insert it into the hole in the

control box. Make sure that the tab on the switch is in the proper notch on the bracket for easy operation

of the switch. Replace the wires from the used switch terminal by terminal on to the new switch.

Power can now be applied to the dishwasher and run through cycles checking all operations.

ROCKER SWITCH

1. CONNECTION TERMINALS

2. BRACKET SPRING SIDES

3. PANEL PLATE

4. BRACKET FRONT

5. ROCKER BUTTON

13

Page 14

PERISTALIC PUMP SANITIZING

DISPENSING SYSTEM

The peristaltic pumps are mounted in the Control/Dispenser Box which is attached to the top of the unit.

The pumps receive their electrical signals from two sources.

The first source is the primer switch which is used to prime the pump when it is first put into operation

and then every time the agent is changed and/or the tubes are clear of any solution.

The second source is the timer which activates the pumps during the cycle at the proper time to

dispense the correct agent when needed.

If control box is locked and access to prime switches is not available just run dishwasher through

several cycles to move liquid from storage bottles to pumps.

Checkout of Sanitizing Injector

The pump can be deemed operational if the following items are observed:

1. If the cam roller assembly rotates during each cycle.

2. If the solution is observed passing through the tube.

Note: Both of these operations must be observed to determine if the sanitizing agent is being

dispensed.

If it is determined that the unit is not operating correctly, the following procedures will aid in correcting

the problem:

1. Make certain that the tube is in the bottle of solution.

2. Make certain that there are no cracks in the tubing and particularly in the pump hose.

3. Check all wire connections on the pump, the timer cam, and the primer switch.

4. Check to see that there is no debris in the tubes.

5. Make sure that the tubing is inserted into the pump hose so that air is not drawn into the system.

14

Page 15

SANITIZING AGENT INJECTOR

P/N 465 COMPLETE PUMP ASSEMBLY, 60 CYCLE

ITEM P/N

1. 0046501

2. 0046502

3. 0046503

4. 0046504

5. 0046505

6. 0046506

7. 0046507

DESCRIPTION

PUMP MOTOR, 60 CYCLE 8. 0046506 FACEPLATE

PUMP HOUSING 9. 0046509 PLATE MOUNTING

HOUSING MOUNTING BOLTS

(3) 10/32 FILLSTER HEAD 10. 0046510 INTAKE OR SUCTION

CAM ROLLER ASSEMBLY

CAM ROLLER SET SCREW 11. 0046510 OUTPUT OR

PUMP HOSE

HOSE CLAMPS

ITEM P/N DESCRIPTION

SCREWS (4) 8/32

HOSE

INJECTOR HOSE

15

Page 16

It is important to obtain the name of the correct type of pump/motor assembly before ordering these replacement parts,

GOULDS:

PRICE PUMP/CENTURY MOTOR ASSEMBLY:

Impeller

as needed. Both assemblies can be identified by the data plates, which will indicate either the GOULDS or CENTURY

Motor.

PLEASE REFER TO THE ILLUSTRATION WITH PARTS BREAKDOWN LIST OF BOTH ASSEMBLIES

Note: The Goulds Pump/Motor Assembly may be used in place of the Price Pump/Century Motor. However, new mounting holes MUST

be drilled for proper placement.

WASH/RINSE PUMP ASSEMBLY

P/N 0087000

PRICE PUMP/CENTURY MOTOR ASSEMBLY

P/N 0087400

GOULDS ASSEMBLY:

ITEM P/N DESCRIPTION

1. 0087001 MOTOR, 110V, 1 HP,3450 RPM

2. 0087002 MOTOR SHAFT DEFLECTOR

3. 0087003 HOUSING TO FLANGE CAP

SCREW

4. 0087004 HOUSING TO MOTOR CAP

SCREW

5. 0087005 HOUSING

6. 0087006 CERAMIC FACE FOR SEAL

7. 0087006 MECHANICAL SEAL

8. 0087008 IMPELLER

9. 0087009 IMPELLER NUT

10. 0087010 FLANGE GASKET

11. 0087911 FLANGE

12. 0087912 FLANGE PETCOCK

16

1. 0087401 • Motor-Century

6. & 7. 0087403 • Mech. Seal & Ceramic Face

8. 0087404 -

10. 0087402 • Gasket

Page 17

REPLACING SEAL and CERAMIC on

WASH/RINSE PUMP ASSEMBLY

Function:

The pump is part of the total motor-pump system and utilizes one shaft seal and ceramic to prevent the

pump from leaking around the impeller and shaft. One gasket is used to prevent leakage between the

pump housing and the pump flange.

Replacement of Seal and/or Ceramic

1. Remove the power source to the machine by turning the circuit breaker to its "OFF"

position on the side of the control/dispenser box.

2. Drain the system by raising the plunger and leaving it at an angle to allow all of the

water to drain out of the unit. Open the petcock on the pump and drain the water from

the pump into a catch basin.

3. Remove the four bolts that are holding the pump unit to the base of the machine.

4. Remove the eight bolts that hold the pump housing to the pump flange. This will eliminate having to

remove the plumbing going into and coming out of the pump flange.

5. Pull the motor and the remaining pump parts away from the pump flange and

plumbing. If unable to work on the pump at its present location, disconnect the wires and move it to a

stable location.

6. To remove the impeller jam nut insert a screwdriver into one of the passages of the impeller and back

off the jam nut with a 5/8" socket and wrench.

7. Remove the impeller by inserting a screwdriver in the end of the motor shaft to prevent

it from turning and unscrew the impeller in a counter clockwise direction from the shaft.

8. To remove the mechanical seal from the shaft, place two screwdrivers opposite each

other with their flat edges under the seal with the shank of the screwdrivers against the housing. Push

on the screwdrivers with equal force and this will pry the seal off of the shaft.

9. After removing the four bolts that hold the housing to the motor take off the housing and place it on a

flat surface. Push out the ceramic seat and rubber cup being careful not to touch the housing.

10. Clean thoroughly the flange and housing gaskets of any scale or dirt build up. Clean the counterbore

where the ceramic seat is located and the shoulder of the motor shaft that fits next to the impeller.

11. To enable the ceramic face and rubber cap to be installed in the housing squarely and evenly the

counterbore in the housing and the rubber cup should be coated with a thin film of oil. Press the

ceramic face and rubber cup into the counterbore of the housing using your thumbs. Apply even

pressure all the way around to insure a good tight fit, but be careful not to damage the top of the

ceramic face.

12. Replace the housing on the motor being very careful not to damage or move the ceramic when

passing the shaft through the ceramic. Tighten the four bolts tightly.

13. Apply a thin film of oil to the new mechanical seal and press it into place by placing a piece of tubing

over the shaft and pushing it toward the ceramic face. The face of the seal has to fit snugly against the

surface of the ceramic face. Be very careful not to allow the ceramic face to come out of the rubber

cup while installing the seal.

14. Reassemble the pump and motor by reversing the procedure in steps 1-9. Close petcock on pump.

Caution: Do not operate unit until pump is filled with water.

17

Page 18

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1. 0054101 BOLT, CHAIN TO STOPPER 7. 0054107 ADJUSTING LEVER

2. 0054102 CHAIN TO STOPPER 8. 0054108 MOUNTING PLATE

3. 0054103 LINK SPRING 9. 0054109 COTTER PINS (2)

4. 0054104 BOLTS (4) SOLENOID TO PLATE 10. 0054110 LINK

5. 0054105 SOLENOID COIL STRAPS 11. 0054111 LINK WASHERS (2)

6. 0054106 SOLENOID COIL, 115V 12. STOPPER HEIGHT ADJUSTMENT

13. 0053812 STOPPER

14. 0053813 STOPPER BALL

18

Page 19

SERVICE INSTRUCTIONS

(INCOMING WATER SOLENOID VALVE)

SOLENOID VALVE

P/N 0143400, 115V

2 PER UNIT

P/N 0143000, 220V

To Take The Valve Apart:

Disassembly—These valves may be taken apart by

unscrewing the bonnet and the enclosing tube assembly from

the valve body assembly. See Fig. 3. After unscrewing,

carefully lift off the bonnet and enclosing tube assembly. Don't

drop the plunger. The "O" ring seal and diaphragm cartridge

can now be lifted out.

Be careful not to damage the machined faces while the valve

is apart.

To Reassemble—Place the diaphragm cartridge in the body

with the pilot port extension UP. Hold the plunger with the

synthetic seat against the pilot port. Make sure the "O" ring is

in place, then lower the bonnet and enclosing tube assembly

over the plunger. Screw bonnet assembly snugly down on the

body assembly.

DIAPHRAGM CARTRIDGE

F

I

G

.

3

FIG. 3

Possible Problems:

Pilot Port extension #1 clogged.

Hole #2 clogged.

Remedy:

Pass heated straight pin through hole #2 or

clean hole #1.

19

Page 20

APPLYING NYLATRON STRIP

Fig.

1 - PUT A STREAM OF SILASTIC

to CONSERVER DOOR

It's important when removing the old door guides that the surface be cleaned thoroughly. This can be done

with a solvent that will dissolve the remaining glue and/or the use of a fine sandpaper to scratch the surface

where the door guide would make contact with the stainless steel door.

After this is accomplished and you are quite convinced that the surface is cleaned of all oil, glue, dirt,

detergent, etc., then the door guide should be placed on a flat surface and a bed of a silicone adhesive or

any good non-hardening glue should be laid on the inside of the door guide's surface (top to bottom, making

sure that none of the exposed surface to the outside has any glue on it).

Take the door guide and snap it over the door's edge as described in the attached sketch. Let this door

set for at least one hour before use so that the glue or adhesive has a chance to set somewhat.

If these instructions are followed, the door guides should adhere to the door.

OR NON-HARDENING ADHESIVE IN

INSIDE CORNER OF STRIP.

Fig. 2 - SIDE VIEW OF

NYLATRON STRIP.

Fig. 3 - SNAP STRIP ON DOOR

LIP.

NOTE: DO NOT SLIDE STRIP

FROM END ALWAYS SNAP ON.

Fig. 4 - PRESS DOWN WITH THUMB

AND INWARD WITH FINGERS.

Fig. 5 - FINISHED

APPLICATION -

END VIEW.

20

Page 21

INSTRUCTIONS for ADJUSTING

TENSION of CANTILEVER

Problem: Doors raise hard, but lower easily.

Solution:

1. Back off (loosen) upper adjusting nuts (F) on both eyebolts (E) about two or three complete turns.

2. Tighten lower adjusting nuts (G) on both eyebolts (E) a complete turn.

3. Check door for easy operation. Adjust further, if necessary.

4. When adjustment is completed, tighten upper adjusting nuts (F) down against angle to lock in position. Check

both eyebolts.

Problem: Doors raise easily, but lower hard.

Solution:

1. Back off lower adjusting nuts (G) carefully, making sure there is still some thread on eyebolt available (both

eyebolts).

2. Check door for easy operation. Adjust further, if necessary.

3. When adjustment is complete, tighten upper adjusting nuts (F) down against angle to lock in position. Check

both eyebolts.

Problem: Doors sticking, or are hard to move up and down.

Solution:

1. Raise doors.

2. Clean inside door channels on machine with a good cleaning compound. It may be necessary to

remove doors to completely clean channel. If so, remove only one door at a time. Make sure

cantilever has stop to prevent pulling other door up and out of channel. If it does not have stop,

secure cantilever arm to machine with doors in the closed position.

3. Build-up should be completely removed so it may be necessary to use an abrasive pad (nonmetallic) to clean.

4. While you have the door out of channel, make sure it is not dented or crooked. If channel is

crooked or dented, use 1/2" wide block to spread to proper opening.

5. Clean nylatron runners on the doors or replace nylatron, if excessively worn. See instructions on

door runners.

6. Check door channels on machine for evenness and burrs.

7. After replacing doors, check for proper operation by raising and lowering with cantilever.

Problem: One side of door higher than other and does not close completely.

Solution:

1. Straighten cantilever arm.

2. This can sometimes be accomplished while arm is on machine by forcing down on the arm connected to the

high door while the other side of the cantilever is pulled up.

3. If step two cannot be accomplished on machine, cantilever will have to be removed and straightened.

21

Page 22

22

Page 23

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Nothing on machine operates. 1. No voltage to dishwasher

a. Customer's fuse a. Replace or reset.

blown or circuit

breaker tripped

2- Machine circuit 2. Turn on or reset

breaker tripped or

turned off.

3. Voltage to machine 3. Contact your electrician

low or circuit to machine and/or power company

broken. for repair.

Wilt not fill with 1. Water hand valve off. 1. Turn hand valve on.

electrical power 2- Fill switch faulty 2. Replace switch or wire

applied even though other or loose wire connection. terminal.

components work. 3. Solenoid valve does not 3. Contact your service agent,

operate. electrician or power

company for repair.

Water runs continuously 1. Fill switch sluggish 1. Replace.

with power on- or faulty.

2. Solenoid valve dirty 2. Contact your service ag<im,

or faulty. plumber or local repair mar1..

Water runs with no electrical 1- Water pressure excessive. | 1. Check, using pressure

power applied to solenoid. gauge during the flow

Master switch off.) period (solenoid valve open;,

should read 20 PSS; if in

excess, installation of a

Pressure Reducer can

reduce pressure.

Vacuum breaker leaks. 1. Limed up. 1. Disassemble:

a. Remove top using flat

jaw wrench or

channel locks.

b. Remove poppet.

c. Clean poppet and V.B. top

and body

d. Replace parts removed.

2. Faulty. 2. Replace needed parts or

whole V.B.

Wash arms spray water, 1. Race ways, where ball 1. See instructions for

but do not rotate. bearings rotate, rough or full preventative maintenance.

of food particles.

Wash water only sprays up 1. Pump drain strainer 1. Remove pump drain strainer

and out of tubes a couple clogged. and clean thoroughly.

of inches. 2. Pump impeller worn or 2. Contact your service agent.

broken (only after many

years of use).

3. Obstruction in pump chute 3. Contact your service agent.

or wash manifold.

4. Wash arms clogged. 4. Clean arm.

Wash motor does not operate. 1. Faulty. 1. Contact your service agent.

Indicator light does not glow 1. Lights faulty or poor 1. Replace or correct

at any time. connection. connection.

Page 24

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

None of the automatic 1. Start switch faulty. 1. Check both start switches.

functions work (wash, rinse) Replace if necessary. See

instructions page concerning

replacement of switches in

control panel.

2- Wire connections poor. 2. Correct connection.

3. Time rinse or wash micro 3. Contact your service agent.

switch faulty.

Level of agents in bottle 1. Defective agent pump 1. Replace.

does not change. (peristaltic)

2. Suction hose (intake tube) 2. Return to bottle.

out of supple bottle.

3. Tubes in peristaltic 3. Replace tubes.

pumps worn.

Machine will not drain. 1. Timer micro switch 1. Replace

defective.

2. Drain solenoid defective. 2. Replace or contact local

service agent

3. Chain to stopper broken. 3. Repair with wire and/or

replace.

4. Debris clogged around 4. Clean out

stopper.

Page 25

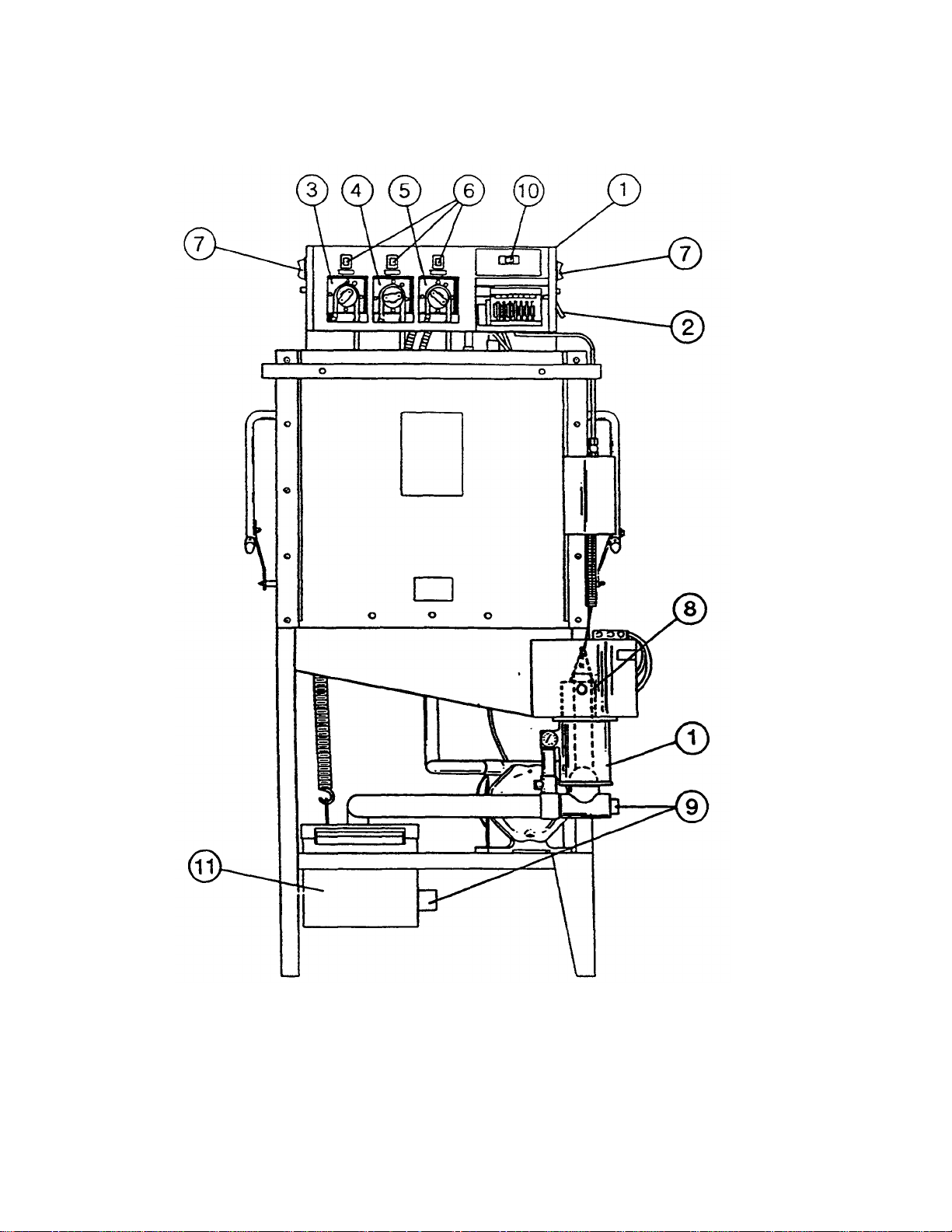

ITEM

1. 0087000 PUMP & MOTOR ASSEMBLY 10. 0053813 STOPPER TUBE AND BALL

2. 0011501 CANTILEVER DOOR COUPLER 11. 0054120 DRAIN SOLENOID COVER

3. 0008503 CANTILEVER ARM W/YOKES 12. 0169000 THERMOMETER

4. 0046514 DISPENSER, DROP TUBE 13.

5. 0012000 CIRCUIT BREAKER/CUSTOMER 14 0087301 PLUMBING FROM SUMP TO PUMP N/S

6. 0154300 START SWITCH 16. 0001210 TIMER DECAL AND DET, SAN RIN

7. 0047501 CORNER FRONT DOOR

8. 0049900 CORNER DOOR WRAPAROUND 17. 0048901 DOOR WRAPAROUND SPACER

9. 0008502 CANTILEVER ARM, HANDLE 18. 0204101 WASTE ACCUMULATOR (OPTIONAL)

P/N DESCRIPTION ITEM P/N DESCRIPTION

ELECTRICAL SERVICE CONNECTION 15. 0087302 PLUMBING FROM PUMP TO MANIFOLD

CONNECTOR

25

CUSTOMER DRAIN CONNECTION 2"

DECALS

W/HDW FOR FRONT

Page 26

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1. 0009400 CANTILEVER, EYE BOLTS 10. 0154300 START SWITCH

2. 0087000 PUMP & MOTOR ASSEMBLY 11. 0084301 VACUUM BREAKER

3. 0009000 CANTILEVER SPRINGS 12. 0046510 DISPENSER INTAKE TUBING/WHITE

4. 0008703 CANTILEVER SPRING RODS

5. 0011500 CANTILEVER DOOR COUPLER

6. 0008500 CANTILEVER ARM 13.

7. 0008200 CANTILEVER MOUNTING BRACKET 14. 0143400 SOLENOID VALVE

8. 0009100 CANTILEVER YOKE ASSEMBLY 15.

9. 0020600 CONTROL & DISPENSER BOX 16. 0001201 110V POWER SUPPLY DECAL

0046604 DISPENSER INTAKE TUBING/REF

0046605 DISPENSER INTAKE TUBING/BLL

CUSTOMER DRAIN CONNECTION

INCOMING WATER CONNECTION 3/4'

26

Page 27

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

2.

CUSTOMER DRAIN CONNECTION

2"

ELECTRICAL SERVICE CONNECTION

7. 0034000

COUNTER, CYCLE

15. 0087306

PLUMBING FROM SUMP TO PUMP

1. See p. 16 PUMP & MOTOR ASSEMBLY 10. 0012000 CIRCUIT BREAKER/CUSTOMER

3. 0054203 DRAIN TEE-SUMP 11. 0184301 VACUUM BREAKER

4. 0054200 DRAIN HOUSING 12. 0143400 SOLENOID VALVE

5. 0054102 DRAIN, STOPPER CHAIN 13.

6. See p. 18 DRAIN, LINK & SPRING 14. 0046512 DISPENSING TUBE STIFFENERS

8. 0154300 START SWITCH 16. 0087303 PLUMBING FROM PUMP TO MANIFOLD

8A. 0083500 CYCLE LIGHT 17. 0001200 FILL & START SWITCH DECAL

9. 0154300 FILL SWITCH 18. 0001202 WARNING DECAL

9A. 0083500 POWER ON LIGHT 19. 0001204 DOOR CAUTION DECAL

27

INCOMING WATER CONNECTION 3/4"

Page 28

LEFT SIDE VIEW

STRAIGHT THROUGH MODEL

ITEM

10. 0001209 LH START SWITCH DECAL 20. 002970

11. 0054120 DRAIN SOLENOID COVER 21. 004900

P/N

1. 0046512 DISPENSING TUBE STIFFENERS

2. 0009400 CANTILEVER EYE BOLTS 13. 001150

3. 0143400 SOLENOID VALVE 14. 005420

4. 0009000 CANTILEVER SPRINGS 15. 005420

5. 0048000 DOOR, SIDE 16. 016900

6. 0008703 CANTILEVER SPRING ROD 17.

7. 0008500 CANTILEVER ARM 18. 008700

8. 0009100 CANTILEVER YOKE ASSEMBLY 19. 002980

9. 0184301 VACUUM BREAKER

DESCRIPTION ITEM

12.

22. 000120

P/N

000840

DESCRIPTION

CANTILEVER HANDLE GRIPS

CANTILEVER DOOR COUPLER

DRAIN HOUSING

DRAIN TEE-SUMP

WASH/RINSE THERMOMETER

CUSTOMER DRAIN CONNECTION 2"

PUMP & MOTOR ASSEMBLY

CONTROL & DISPENSER BOX LOCK

ONLY W/KEY

CNTRL BOX COVER ONLY W/OUT LOCK

DOOR SPACER, SEID W/HDW

DOOR CAUTION DECAL

26

Page 29

MERCURY RELAY P/N

0122600,

110V

MERCURY RELAY P/N 0122700, 220V

VACUUM BREAKER P/N 0184301

ITEM P/N DESCRIPTION

1. 0153700 Y-STRAINER

2. REMOVABLE FILTER

3. 0143400 SOLENOID VALVE 3/4", 110V

0143000 SOLENOID VALVE 33/4", 220V

4. PIPE UNION

29

Page 30

ANTI-FOAM VALVE 3/4"

ASSEMBLY P/N 0185500

DIAPHRAGM KIT 0185501

30

Page 31

"SANALERT" JUMPER

CONNECTOR PLUG

POWER SUPPLY

USE MINIMUM 12 GAUGE WIRE. DO NOT CONNECT TO A CIRCUIT PROTECTED BY A BREAKER LARGER THAN 20 AMPS.

SUPPLY CONN:

HOOK UP WITH CONDUIT ONLY.

032183-1

31

CONSERVER I 110V/60 CY/ 1 PH

WITH SANALERT CONNECTION

Page 32

POWER SUPPLY

USE MINIMUM OF 12 GAUGE WIRE. DO NOT CONNECT TO A CIRCUIT PROTECTED BY A BREAKER LARGER THAN 20 AMPS.

SUPPLY CONN:

HOOK UP WITH CONDUIT ONLY.

2E-032183-1

32

9905-100-66-00

• = TIMER MOTOR

ARE PUMPS AT 50 RPM

CONSERVER I 110V/60 CY/ 1 PH

WITHOUT SANALERT CONNECTION

Page 33

CONSERVER PARTS LIST

Part Number Description Number Used

0001201 110V Power Supply Decal

0001202 Warning Decal

0001203 Clean Strainer Decal

0001204 Door Caution Decal

0001208 Full & Start Switch Decal

0001209 LH Start Switch Decal

0001210 Operations Decal

0001211 Timer Decal

0008200 Cantilever Mounting Brackets 2

0008400 Cantilever Handle Grips 2

0008600 Cantilever Arm ONLY 1

0008700 Cantilever Spring Rods 2

0009000 Cantilever Springs 2

0009100 Cantilever Yoke Assembly 2

0009400 Cantilever Eye Bolts 2

0009600 Cantilever Nuts, for Eye Bolts 2

0010000 Cantilever Sleeve 2

0010300 Cantilever Bolt for Sleeve ¼”x 1 3/8” 2

0010600 Cantilever Washer Flat. for Sleeve Bolt ¼” 2

0010900 Cantilever Acorn Nut, for Sleeve Bolt ¼” 2

0011200 Cantilever Lock Washer, for Sleeve Bolt ¼” 2

0011500 Cantilever Door Coupler, to Cantilever 2

0011600 Cantilever Block, to Door 2

0012000 Circuit Breaker, 15 AMP 1

0020800 Control/Dispenser Box, Completely wired 1

0029700 Control Dispenser Box Cover, w/out lock 1

0029800 Control/Dispenser Box Lock Only. w/key 1

0034000 Counter, Cycle 1

0046000 Dispenser, Peristaltic Pump Complete, 230V, 50 Cycle

0046100 Dispenser, Peristaltic Pump Motor, 230V, 50 CYCLE

0046500 Dispenser, Peristaltic Pump Complete 3

0046501 Dispenser, Peristaltic Pump Motor 3

0046502 Dispenser, Peristaltic Pump Housing 3

0046503 Dispenser, Peristaltic Pump Housing Mounting Bolts. 10/32'' Fillster Head (3) 12

0046504 Dispenser, Peristaltic Pump Cam Roller Assembly 3

0046505 Dispenser, Peristaltic Pump Cam Roller Set Screw 3

0046506 Dispenser, Peristaltic Pump Hose 3

0046507 Dispenser, Peristaltic Pump Hose Clamp (2) 6

0046508 Dispenser, Peristaltic Pump Face Place 3

0046509 Dispenser, Peristaltic Pump Face Plate Mounting Screws. 8/32" (4) 12

0046510 Dispenser, Peristaltic Pump Intake or Outlet Tubing per foot (specify color) 3

0046512 Dispenser, Intake Tubing Stiffeners 3

0048001 Door, Side 2

0049000 Door Spacer, Side

0049500 Door Screw, for Spacer ¼” 20 x 1 3/8"

0049600 Door Stop w/nut and Bolt N/S

0051000 Door, Handle for Lid 1

0051800 Door, Nylatron Guides 4

0052200 Door Strip s/s Glue. Tube

0053810 Drain Ball 2

0053811 Drain Stem 2

0053812 Drain Stopper Seat Plate 2

0053813 Drain Stopper Ball & Stem 2

0054100 Drain, Assembly Complete 2

0054101 Drain, Bolt, Chain to Stopper 2

0054102 Drain, Stopper Chain 2

0054103 Drain, Link Spring 2

0054104 Drain. Bolts, Solenoid to Plate (4) 8

0054105 Drain, Solenoid Coil Straps 8

0054106 Drain, Solenoid Coil, 115V 2

0054107 Drain, Adjusting Lever 2

0054108 Drain, Mounting Plate 2

0054109 Drain, Cotter Pins (2) 4

0054110 Drain, Link 2

0054111 Drain, Link Slotted Washers (2) 4

33

Page 34

CONSERVER PARTS LIST

Part Number Description Number Used

0054114 Drain, Solenoid Cover 1

0054116 Drain. Solenoid Coil, 220V

0054212

Drain, Housing L/H

2

0054218 Drain, Housing R/H

0054201 Drain. Housing Gasket Upper 2

0054202 Drain, Housing Gasket, Lower 2

0054203 Drain. Tee-Sump 2

0054204 Drain Housing. Single Drain N/S Special Units

0054205 Drain Housing. Gasket, Upper, Single Drain N/S

0083500 Light, Indicator 2

0086900 Pump Motor, 1 HP, 2850 RPM, 220V, 1 phase, 50 cycle

0087000 Pump & Motor Assembly Complete 1 HP. 3450 RPM. 115V, 1 phase, 60 cycle 2

0087001 Pump, Motor. 115V, 1 HP, 3450 RPM 2

0087002 Pump, Motor Shaft Deflector 2

0087003 Pump, Housing to Flange Cap Screw (8) 16

0087004 Pump, Housing to Motor Cap Screw (4) 8

0087005 Pump, Housing 2

0087006 Pump, Ceramic Face for Seal 2

0087007 Pump, Mechanical Seal 2

0087008 Pump, Impeller 2

0087009 Pump, Impeller Nut 2

0087010 Pump, Flange Gasket 2

0087012 Pump, Flange Petcock 2

0087100 Pump & Motor Mounting Plate 2

0122600 Relay, Mercury 2

0122700 Relay, Mercury, 220V

0143000 Solenoid Valve, 3/4", 220V, J E

0143400 Solenoid Valve, J E, 3/4",110V 2

0143500 Solenoid Valve Coil, J E, 110V 2

0145500 Solenoid Valve Diaphragm Cartridge and 'O' Ring, 3/4" J E 2

0148000 Solenoid Valve 'O' Ring, 3/4" J E

0148500 Solenoid Valve Plunger Assembly, for 1/2" and 3/4" J E

0150000 Solenoid Valve Strainer Screen, 3/4" J E

0150100 Solenoid Valve Gasket 3/4" J E

0152100 Strainer, Pump/Drain Line 2

0152300 Strainer, Pump/Drain Line, Single Drain, N/S

0153700 Strainer, Y 3/4" 1

0154300 Switch, Primer, Drain, Rocker Type 5

0165500 Terminal Board, 3 Pole, Complete

0169000 Thermometer, Rigid Stem 1

0171100 Timer, 110V w/wires, Adjustable, 6 Cams 1

0173100 Timer Motor, 110V Single Cycle 1

0173200 Timer, w/wires Single Cycle, 220V, 50 Cycle

0177600 Timer Micro Switch 6

0179500 Track Assembly Complete 1

0184301 Vacuum Breaker, 3/4" Con braco 1

0184400 Vacuum Breaker, 3/4" Conbraco Repair Kit 1

0185000 Valve, 1/4" for Health Inspectors Gauge

0185500 Valve, Anti-Foam, 3/4"

0185501 Valve Anti-Foam Diaphragm Kit

0199400 Wash/Rinse Head Assembly N/S

0199401 Wash/Rinse Head Tube & Hub Assembly

0199402 Wash/Rinse Head Bearing Spindle N/S

0199403 Wash/Rinse Head Retaining Ring S/S

0199404 Wash/Rinse Head Bearing N/S 2

0199500 Wash/Rinse Head Assembly Comp 4

0199501 Wash/Rinse Head End Plugs 8

0199502 Wash/Rinse Head Vee Jets 32

0199503 Wash/Rinse Head Tube 8

0199504 Wash/Rinse Head Bearing & Shaft Assembly 4

0199505 Wash/Rinse Head Thumb Screws 8

0199506 Wash/Rinse Head Adaptor Riser 2

0199600 Wash/ Rinse Head Manifold 2

0199601 Wash/Rinse Head Manifold Gasket 2

0199612 Wash/Rinse Head Manifold; Left 1

0199613 Wash/Rinse Head Manifold; Right 1

34

Page 35

Part Number Description Used on

541H Drain, Mounting Plate X

541I Drain, Cotter Pins (2) X

541K Drain, Link Slotted Washers (2) X

541R Drain. Link X

541Q Drain, Bolt.w/Locknut X

541T Drain, Solenoid Cover S

542 Drain, Housing X

542A Drain, Housing Gasket Upper X

542B Drain, Housing Gasket Lower X

542C Drain, Tee-Sump X

542F Drain, Solenoid Housing

542H Drain, Solenoid Wire Conduit

835 Light, Indicator X

870 Pump & Motor Assembly Complete, 1 HP, 3450 RPM, 115V. 1 phase, 60cycle X

870A Pump, Motor 1 15V, 1 HP, 3450 RPM X

870B Pump, Motor Shaft Deflector X

870C Pump. Housing to Flange Cap Screw (8) X

870D Pump, Housing to Motor Cap Screw (4) X

870E Pump. Housing X

870F Pump, Ceramic Face for Seal X

870G Pump. Mechanical Seal X

870H Pump, Impeller X

870I Pump, Impelier Nut X

870J Pump, Plange Gasket X

870K Pump, Flange X

870L Pump, Flange Petcock X

871 Pump & Motor Mounting Rate X

873A Plumbing from Sump to Pump C

873B Plumbing from Pump to Manifold C

873C Plumbing from Pump to Manifold S

873F Plumbing from Sump to Pump S

1226 Relay, Mercury X

1434 Solenoid Valve, J E, 3/4" 110V X

1436 Solenoid Valve Coil, JE, 110V X

1455 Solenoid Valve Diaphragm CartridgeJ E, 3/4" X

1486 Solenoid Valve Plunger Assembly, JE, 3/4" X

1521 Strainer, Pump/Drain Line S

1522 Strainer, Pump/Drain Line C

1537

1543 Switch, Primer, Drain, Start, Fill, Rocker Type X

1563 Delime Rocker Switch X

1690 Thermometer, Rigid Stem X

1711 Timer, 110V w/wires. Adjustable, 6 Cams X

1731 Timer Motor, 110 V SingleCycle X

1776 Timer Micro Switch X

1791 Track Assembly Corner Straight Thru Convertible X

1843A Vacuum Breaker, 3/4" Conbraco X

1844 Vacuum Breaker, 3/4" Conbraco Repair Kit X

1995 Wash/Rinse Head Assembly Comp X

1995A Wash/Rinse Head End Plugs X

1195B

1995C Wash/Rinse Head Tube X

1995D Wash/Rinse Head Bearing & Shaft Assembly X

1995E Wash/Rinse Head Thumb Screws X

1996 Wash/Rinse Head Manifold X

1996A Wash/Rinse Head Manifold Gasket X

2041A Waste Accumulator X

Strainer, 'Y' 3/4

Wash/Rinse Head Vee Jets (8)

CONSERVER PARTS LIST

• S = Straight Through Model C = Corner Model X = Both Models

35

X

X

Loading...

Loading...