Operating manual VK 30.03

Material selections switch

VK 30.03

Ident.-No.: 109 8756 12/2018

Operating manual VK 30.03

Contents

1 Miscellaneous ............................................................................. 1

1.1 Information about this manual ........................................... 1

1.2 Explanation of the symbols ................................................ 1

1.3 Liability and Warranty ........................................................ 1

1.4 Copyright ........................................................................... 2

2 Safety .......................................................................................... 2

2.1 Intendend use .................................................................... 2

2.2 User’s responsibility ........................................................... 3

2.3 Safety requirements .......................................................... 3

2.4 Radio interference suppression / EMV .............................. 3

2.5 Quality Management Certification ...................................... 3

2.6 Environmental Management .............................................. 3

3 General ........................................................................................ 4

4 Connection ................................................................................. 4

4.1 Connection plan ................................................................ 4

4.2 Current output 4 – 20 mA .................................................. 4

4.3 Parameterization VK 30.03 ................................................ 6

5 Parameterization pyrometer PA ................................................ 7

5.1 Configuration I/O (configuration layer: C010) ............... 7

5.2 Display of internal measured values .................................. 7

6 Shipping, Packaging and Disposal ........................................... 8

6.1 Inspecting your shipment ................................................... 8

6.2 Packaging .......................................................................... 8

6.3 Disposal of used apparatus ................................ ............... 8

810-het

VK30.03_en.doc

18.12.2018

Operating manual VK 30.03

1

1 Miscellaneous

1.1 Information about this manual

The Operating Manual shall enable the user to install the material selection switch and those accessories, which are necessary.

Before starting installation, be sure to read and understand this entire

manual, in particular the chapter on safety! The instructions contained in

this manual, especially those concerning safety, as well as site-specific

regulations for accident prevention must be complied with at all times!

1.2 Explanation of the symbols

Important safety-related references in this manual are marked with a

symbol. It is imperative that you observe the safety precautions or instructions indicated by these symbols. Failure to do so might result in

accidents involving physical injury and/or material damage

CAUTION!

This symbol indicates important information which, if neglected, might

result in material selection switch damage, malfunction or breakdown.

PLEASE NOTE!

This symbol points out guidelines which should be heeded for efficient

and trouble-free operation.

1.3 Liability and Warranty

All information compiled in this manual is in accordance with applicable

regulations. The statements made are based on state-of-the-art technology and reflect our extensive knowledge and many years of experience.

PEASE NOTE!

Always carefully read this Operating Manual before beginning any

work on or with the instrument, especially prior to installation and

initial setup! The Manufacturer shall not be held liable for any

damages or malfunctions arising from a disregard of the warnings

and instructions contained herein.

This Operating Manual must be retained for future use. Please ensure

that all persons who wish to operate the instrument have access to this

manual.

Operating manual VK 30.03

2

1.4 Copyright

This Operating Manual should be treated as confidential. It is solely intended for use by persons involved with the instrument. This manual

may not be made available to a third party without prior Manufacturer’s

consent. Please contact the Manufacturer if the need should arise.

PLEASE NOTE!

The data, texts, charts, drawings, images or other representations contained in this manual are copyright-protected and furthermore, subject to

intellectual property rights. Violators will be prosecuted. Unauthorised

use and copyright infringement will be subject to penalty by law.

Reproductions of any kind, in whole or in part, as well as the exploitation

or disclosure of this manual’s content without the explicit written approval

of the Manufacturer are expressly prohibited by law. Violations shall be

subject to compensation claims by the Manufacturer. The right to claim

additional indemnities remains reserved.

2 Safety

This chapter outlines all important safety aspects to be considered for

optimum employee protection and to ensure safe and reliable operations.

2.1 Intendend use

The pyrometer is solely intended for non-contact measurement of temperatures as described in this manual. Any other use is not intended.

Operational safety can only be ensured when the instrument is used for

its intended purpose

CAUTION!

It is prohibited to use the pyrometer for any other purpose beyond what

is specified in this manual. Using the instrument in any other manner will

be considered as improper.

The Manufacturer/Authorised Agent shall not be held liable for any damages or loss resulting from such unintended or improper use; in this case

the risk is solely borne by the user.

Operating manual VK 30.03

3

2.2 User’s responsibility

The material selection switch may only be used when it is in perfect

working condition.

2.3 Safety requirements

The instrument works with an operating voltage of 24 VDC. The voltage required for operation must be supplied by a separate power supply. This

power supply unit must conform to directive IEC 61010.

2.4 Radio interference suppression / EMV

The instrument complies with the requirements of EC Directive

89/336/EEC changed by 91/263/EEC; 92/31/EEC; 93/68/EEC relating to

radio interference suppression and electromagnetic compatibility.

European certification: EN 61000 - 6 - 4

EN 61000 - 6 - 2

EN 55011

When connecting a power supply unit, make sure that is also conforms

to these standards. Radio interference may arise if the pyrometer is interconnected with such peripheral devices which have not been properly

interference-suppressed. This may necessitate additional interference

suppression measures.

2.5 Quality Management Certification

The KELLER HCW Quality Management System meets the DIN EN ISO

9001 standards for design, production, repairs and service for noncontact infrared temperature measuring equipment.

2.6 Environmental Management

Sustainable economic management is more important than ever.

KELLER HCW’s corporate environmental management system complies

with DIN EN 14001/50001 standards.

Operating manual VK 30.03

4

3 General

The material selections switch allows the external correction of the emissivity or emissivity ratio of the PA pyrometer.

4 Connection

4.1 Connection plan

The material selections switch works with an operating voltage of 24 V

DC. The voltage required for operation must be supplied by a separate

power supply. This power supply unit must conform to directive DIN IEC

61010.

3

GND current output

4

0/4 … 20 mA

12

Power supply + 24 DC

13

Power supply GND

4.2 Current output 4 – 20 mA

The material selections switch VK 30.03 has an active linear current output. For the connection to the PA pyrometer a 500 Ω resistor (not included in the delivery) must be installed between the analogue input of the

PA pyrometer and ground.

Operating manual VK 30.03

5

Pyrometer PA

PIN 3

GN (green)

Analogue output 2 /analogue input

PIN 8

RD (red)

L- (GND)

VK 30.03

Clamp 4

Current output

Clamp 3

L – (GND)

Operating manual VK 30.03

6

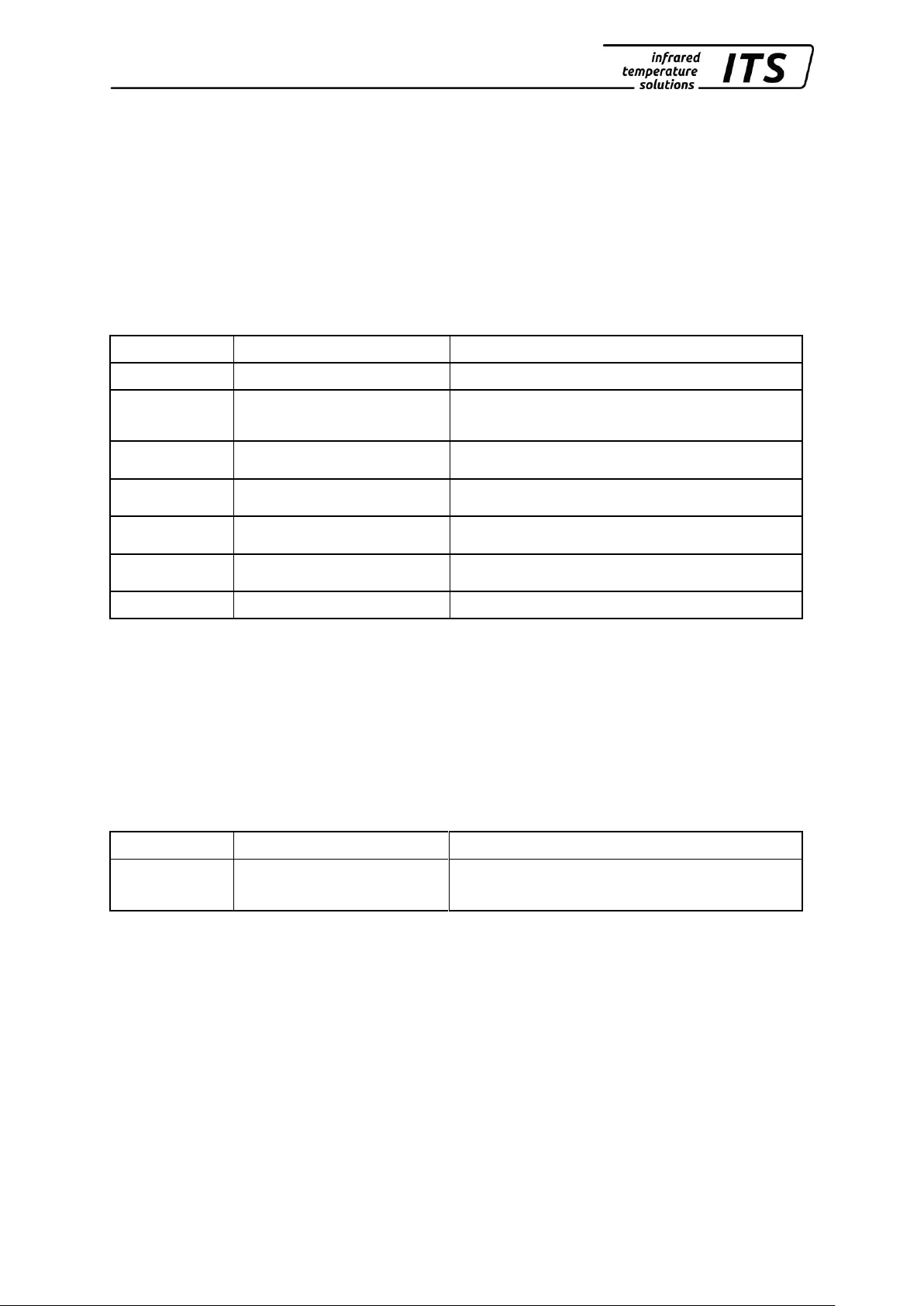

4.3 Parameterization VK 30.03

In the following example, the material selector switch for external emissivity

ratio adjustment is configured with a value range from 100.0 to 110.0.

Key

Display

Description

to be operated for

2 s

Current set point value.

To change the values, use the arrow keys

and

Configuration of the analogue output

Use the keys and to select

4 – 20 mA.

Set point for power on

rEStor= set

Point value remains valid in case of power

failure

Selection with the keys and

Number of decimal digits

Use the keys and and 0.

Start value for the display range of the set

point value.

Use the keys and to select

100.0.

End value for the display range of the set

point value.

Use the keys and to select

110.0.

Press the key until the current set point value

is shown.

Operating manual VK 30.03

7

5 Parameterization pyrometer PA

The current output 2 of the pyrometer is deactivated by default. In order

to use the VK 30.03, you must parameterize the analogue output 2 as

voltage input and assign it to the emissivity or emissivity ratio.

In the following configuration example, the voltage input is used for the

external adjustment of the emissivity ratio.

5.1 Configuration I/O (configuration layer: C010)

Parameter

Function

Explanation

AO2.

Analogue output 2

OFF off

AI.FN

Analogue input

function

EPS.Q emissivity ratio

AI.U1

Ain Scaling

Define lower limit of voltage for input voltage

(2 V)

AI.U2

Ain Scaling

Define upper limit of voltage for input voltage

(10 V)

AI.V1

Ain Scaling

Input of lower voltage value

(example 100% emissivity ratio)

AI.V2

Ain Scaling

Input of upper voltage value

(example 110% emissivity ratio)

SAVE

Save

Save changes / exit menu

5.2 Display of internal measured values

According to standard the current temperature is shown in the display of

the pyrometer. Should the current value at the voltage input is to be

shown in the display, change to code page C020 and select parameter

AIN.

Configuration layer: C020

Parameter

Function

Explanation

AIN

Initial value at analogue input

Current value of analogue input

Operating manual VK 30.03

8

6 Shipping, Packaging and Disposal

6.1 Inspecting your shipment

Unpack and inspect the entire shipment immediately upon receipt to

make sure it is complete and undamaged.

If the container/package shows visible signs of damage, please refuse

the shipment. If this is not possible, accept the shipment on the condition

that the freight carrier’s delivery record is noted with the extent of the

damage in order to file a claim.

Should you discover a concealed loss or damage, report it to KELLER

HCW and to the freight carrier immediately. If the period for filing claims

has expired, you will no longer be able to make any claims for compensation of damage or loss.

6.2 Packaging

The packages used by KELLER HCW are made of carefully selected,

environmentally compatible materials and are thus recyclable. We suggest you retain the packaging for possible future use; otherwise please

ensure that they are disposed of in an ecologically sound manner.

6.3 Disposal of used apparatus

Used electrical and electronic equipment often contain valuable components. The owner/user may either return such an instrument to the manufacturer for disposal, or he must dispose of it himself in a professional

and nonpolluting manner.

KELLER HCW will not be held accountable for any inappropriate disposal carried out by the user/owner of KELLER HCW instruments.

Operating manual VK 30.03

9

Loading...

Loading...