Page 1

iTerra Elite

Quick Start Guide

iSys-The Imaging Systems Group Inc.

iTerra Elite Quick Start Guide © iSys-The Imaging Systems Group Inc. Rev1.2-030708

Page 2

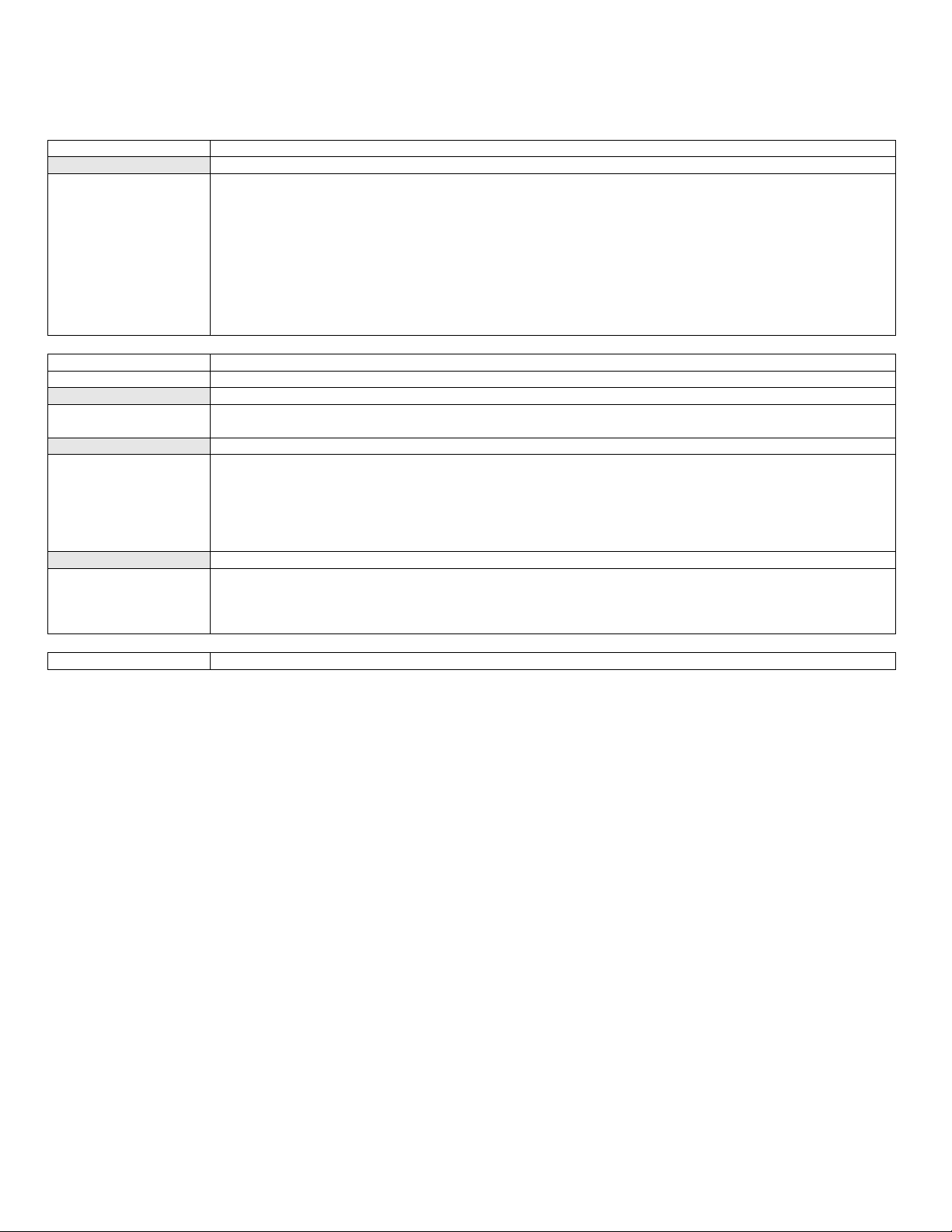

TABLE OF CONTENTS

1. INSTALLATION

I. INSTALLING CONSUMABLES AND PRINT MEDIA ................................................... 4

II. INSTALLING ACCESSORIES ................................................................................... 11

III. CONNECT TO POWER ........................................................................................... 16

IV. LOADING CONTINUOUS FORM FEED PRINT MEDIA ......................................... 17

V. PRINT MEDIA PROPERTIES ................................................................................... 21

2. ORDERING CONSUMABLE SUPPLIES

I. HOW TO ORDER QUALIFIED MEDIA AND CONSUMABLES ................................. 22

3. INTERFACE SETUP AND INSTALLATION

I. INTERFACES ............................................................................................................. 23

II. LOCAL INSTALLATION ............................................................................................ 24

III. NETWORK INSTALLATION ..................................................................................... 25

IV. PRINT DRIVER INSTALLATION ............................................................................. 26

V. NETWORK CARD IP ADDRESS-CHECKING AND SETTING ................................ 37

VI. WEB BROWSER TO PRINTER (Advanced Users and Administrators) ................. 38

VII. WINDOWS 2000 & XP PRINT DRIVER PROPERTIES ......................................... 39

VIII. GENERAL TAB ...................................................................................................... 39

VIX. SHARING TAB ....................................................................................................... 40

X. PORTS TAB .............................................................................................................. 40

XI. ADVANCED TAB ..................................................................................................... 41

XII. COLOR MANAGEMENT TAB ................................................................................. 41

XIII. SECURITY TAB ..................................................................................................... 42

XIV. DEVICE OPTION TAB ........................................................................................... 42

4. OPERATION – CONTINUOUS PAPER MODE

I. PRINTER CONTROL PANEL OVERVIEW ................................................................ 43

II. FEEDER OPERATING INSTRUCTIONS .................................................................. 45

_________________________________________________________________________________________________________________________

PAGE 2 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 3

III. EXIT SPEEDS AND PRINT CONTROLS ................................................................. 47

IV. OUTPUT VIA BACK ................................................................................................. 50

V. OUTPUT VIA TOP (Using optional top stacker) ....................................................... 51

VI. OUTPUT PROBLEMS .............................................................................................. 53

5. PRINT DRIVER PREFERENCES

I. CHANGING THE iSys CLP825 PRINTING PREFERENCES .................................... 56

II. THE SET UP TAB ...................................................................................................... 57

III. THE JOB OPTIONS TAB ......................................................................................... 65

IV. COLOR TAB ............................................................................................................. 80

V. COLOUR MATCHING ............................................................................................... 82

6. TROUBLESHOOTING

I. ERROR CODES ......................................................................................................... 86

II. CONTROL PANEL MESSAGES ............................................................................... 94

III. PAPER JAMS ........................................................................................................... 97

7. FAQs AND SOLUTIONS FOR COMMON PROBLEMS

I. PAPER FEED PROBLEMS ...................................................................................... 103

II. PROBLEMS PRINTING FROM WINDOWS ............................................................ 104

III. PROBLEMS WITH POOR QUALITY PRINTING ................................................... 108

8. QAN MANAGEMENT

QAN MANAGEMENT PROGRAM .............................................................................. 116

9. JOB MANAGEMENT

JOB MANAGEMENT ................................................................................................... 118

10. SERVICE AND SUPPORT

SERVICE AND SUPPORT .......................................................................................... 119

_________________________________________________________________________________________________________________________

PAGE 3 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 4

1. INSTALLATION

Follow the steps below to properly install the printer consumables and accessories.

I. INSTALLING CONSUMABLES AND PRINT MEDIA

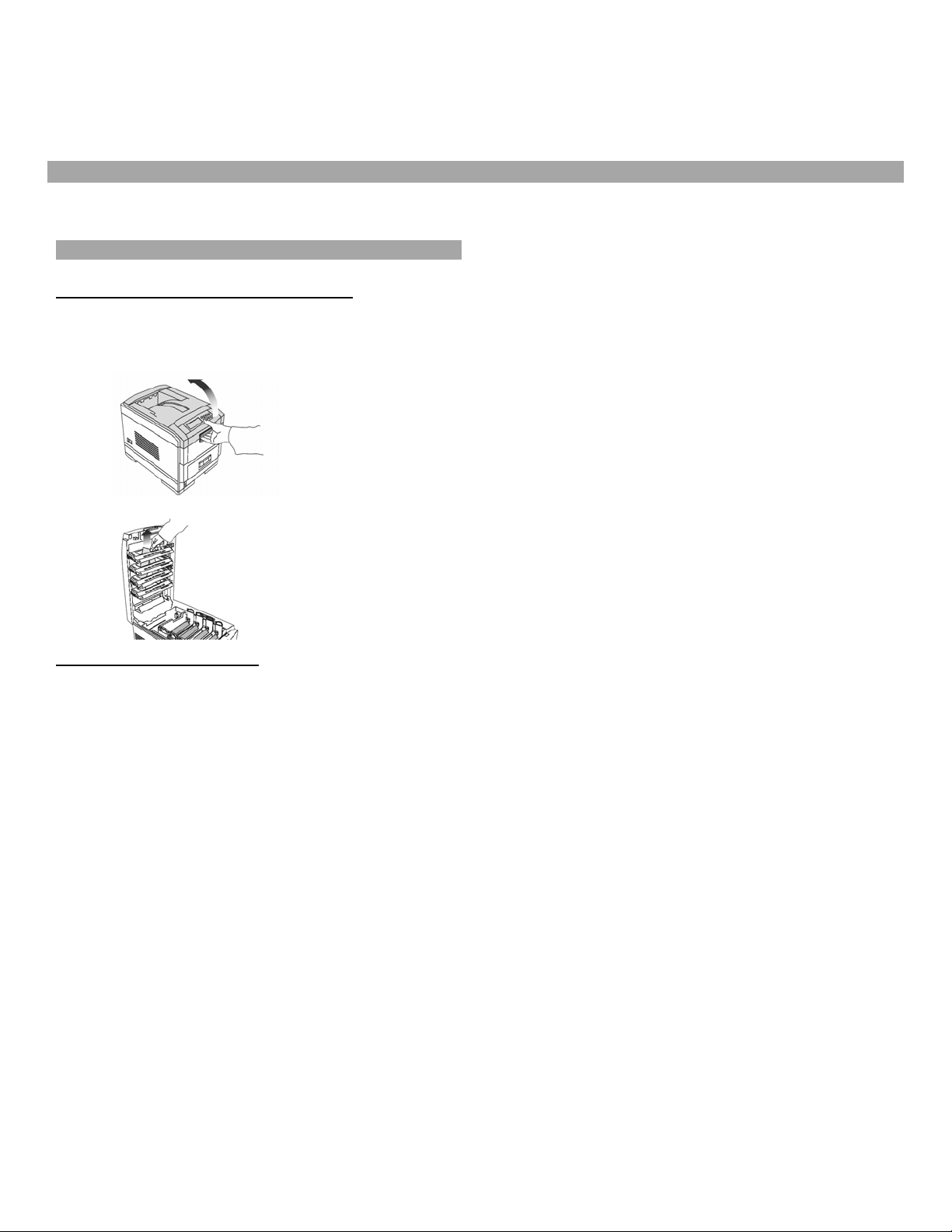

Removing Protective Shipping Materials

1) Remove the two strips of shipping tape from the rear door paper exit.

2) Pull up the release latch and open the cover.

3) Remove the cardboard v-shaped shipping restraint from behind the LED heads.

Preparing the Image Drums

_________________________________________________________________________________________________________________________

PAGE 4 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 5

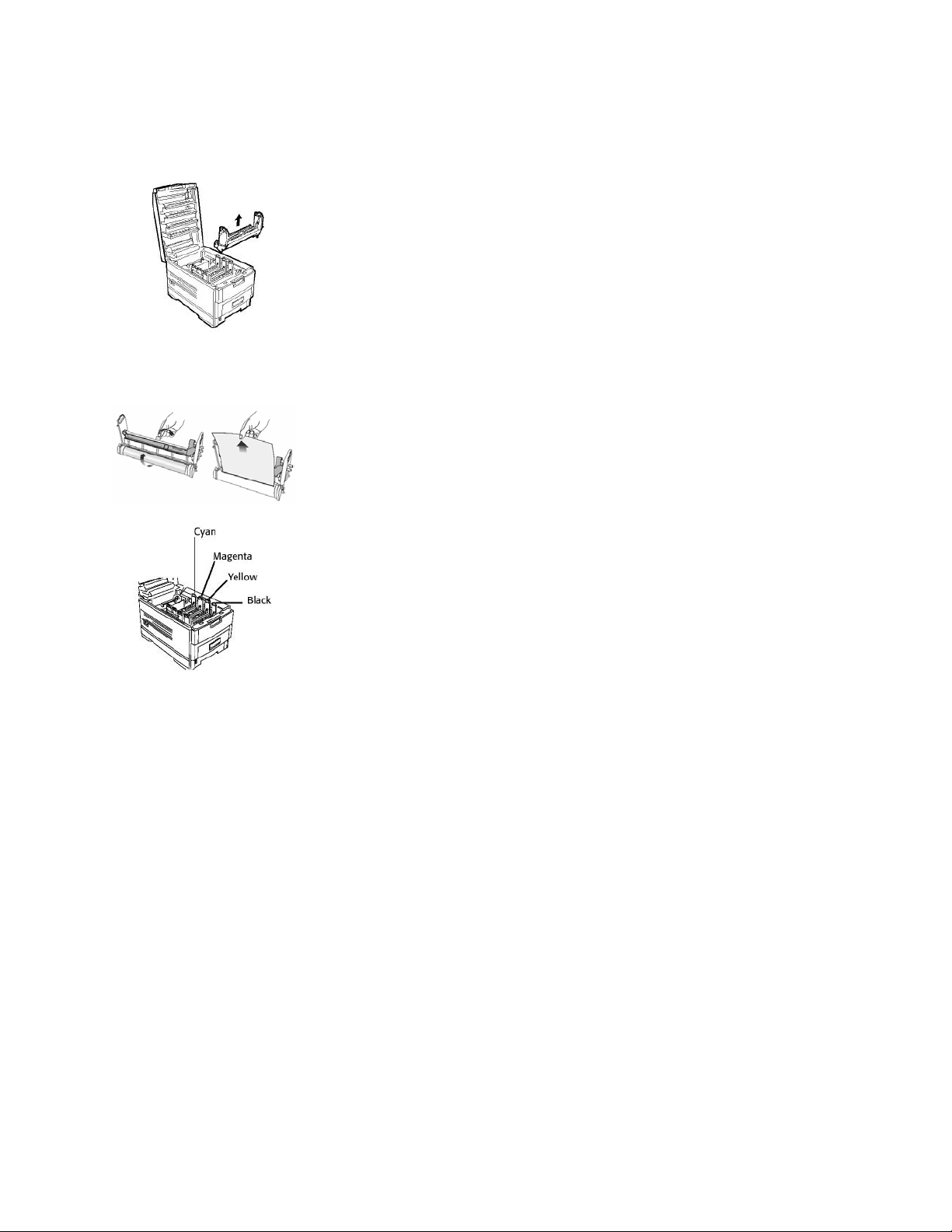

1) Lift out the four image drums and place them on a flat surface.

2) Remove the protective sheet. Push the tab in the direction of the arrow and remove the orange blanking plate

from each drum.

3) Place the drums back into the printer.

_________________________________________________________________________________________________________________________

PAGE 5 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 6

4) If it is ever necessary to remove the entire drum tray, simply do so by holding the blue handles on either side of

the tray and pull upwards.

CAUTION:

Ensure the drums are in their correct color position.

_________________________________________________________________________________________________________________________

PAGE 6 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 7

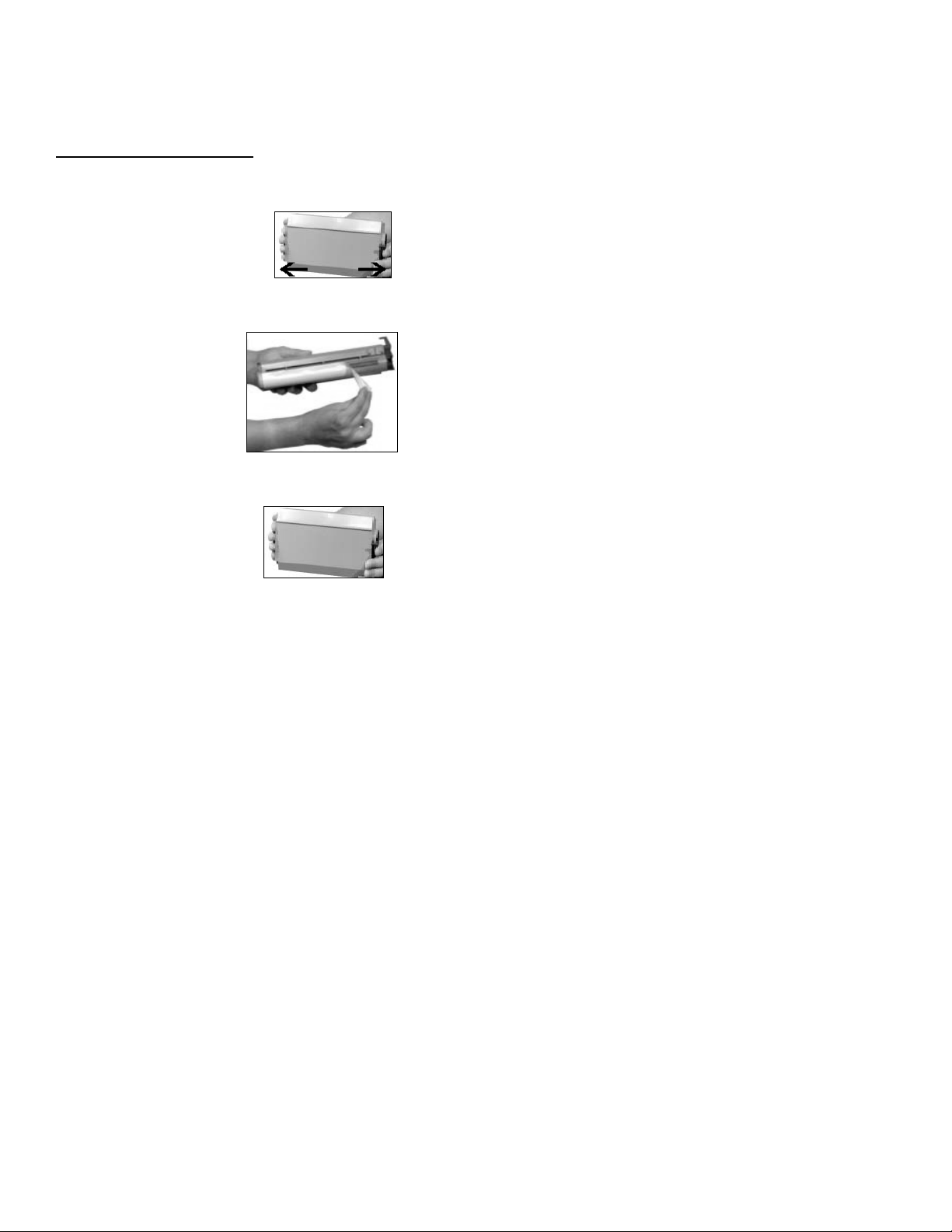

Installing Toner Cartridges

1) Remove plastic bag from black toner cartridge and lightly shake it back and forth to loosen settled toner.

2) Hold the cartridge in a horizontal position and remove protective tape.

3) Hold the cartridge in the vertical position, with the port on the left and the blue lock lever on the right.

4) Lower the left end of the cartridge into the image drum, closest to the front of the printer and matched to the black

drum, so that the tube on the drum slides into the port on the toner cartridge.

_________________________________________________________________________________________________________________________

PAGE 7 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 8

5) Press the cartridge toward the left slightly, and then lower the right end, aligning the white tab with the groove in

the drum.

6) Push the lock lever toward the back of the printer until it stops.

NOTE:

After installing a new toner cartridge, the message TONER LOW or CHANGE TONER may appear on the

display after the printer is turned on. If this message does not disappear after a few pages have been

printed, reinstall the appropriate toner cartridge.

_________________________________________________________________________________________________________________________

PAGE 8 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 9

CAUTION:

Repeat the process for each toner cartridge, being careful to match the toner color to the drum.

7) Close the cover.

_________________________________________________________________________________________________________________________

PAGE 9 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 10

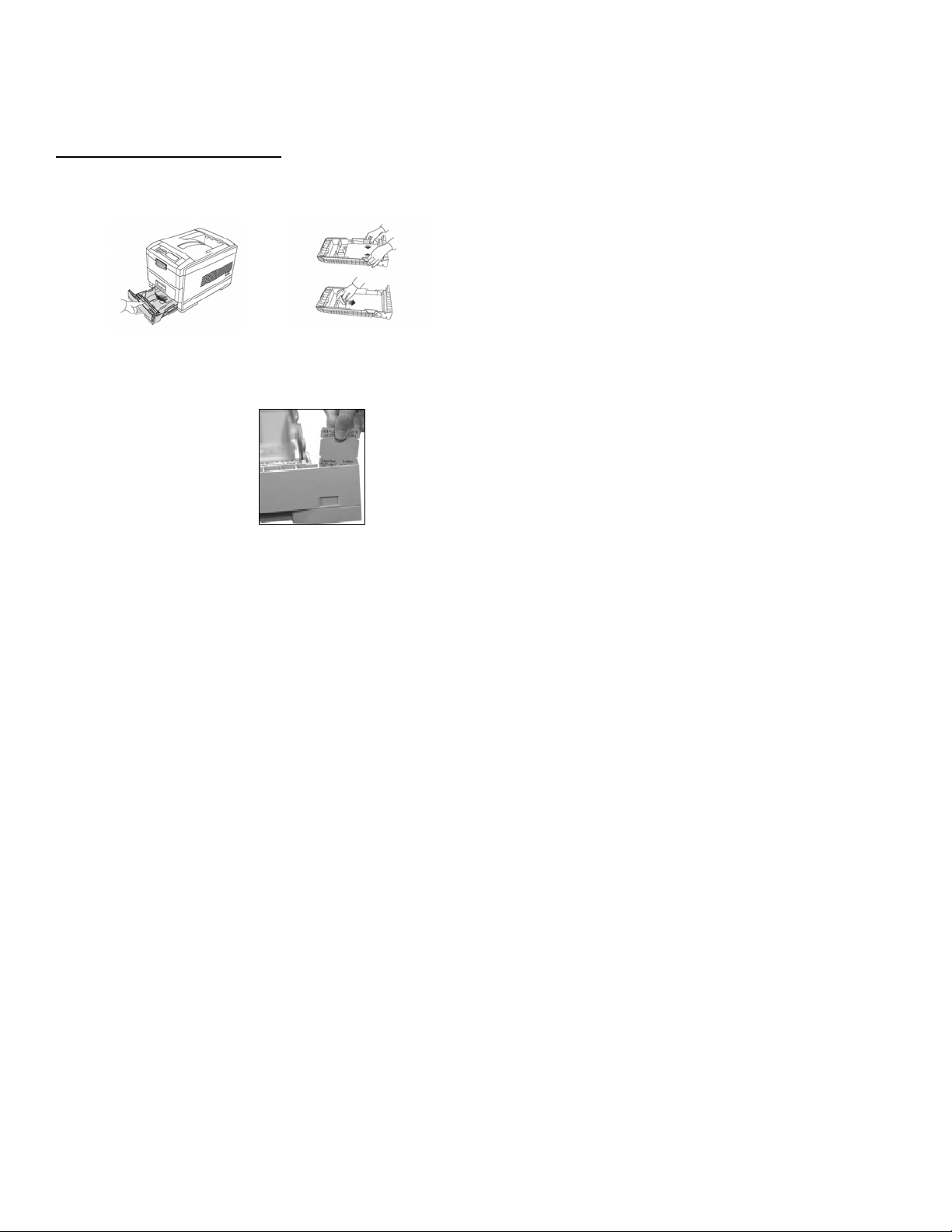

Loading Cut Sheet Print Media

1) Pull the paper tray out of the printer and adjust the paper guides and rear paper stopper for the paper size you are

using (see iTerra Elite Print Media Specifications).

2) Fan the paper (max. 530 sheets 20-lb. paper) and load it. Keep it below the “MAX” mark.

3) If necessary, lift out the paper media indicator and reinsert it with the proper paper size showing.

4) Push the tray back in. The paper gauge indicates the amount of paper inserted or remaining in the tray.

_________________________________________________________________________________________________________________________

PAGE 10 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 11

II. INSTALLING ACCESSORIES

The items you will need to install your accessories are as follows: feeder, feeder-to-printer cable, media input tray, and top

media stacker (optional).

WARNING:

The iTerra Elite printer is very heavy and requires two people when lifting or moving.

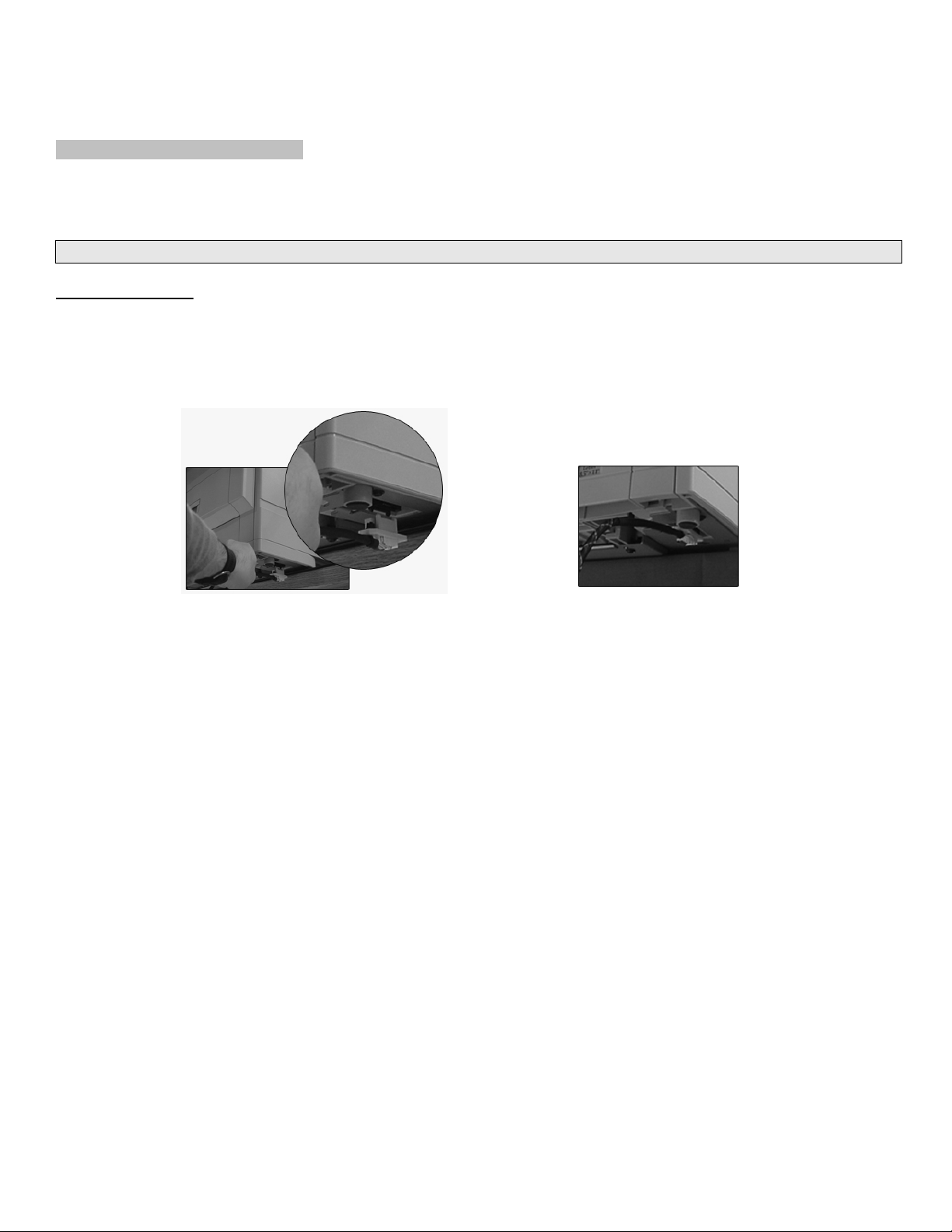

Feeder Installation

1) Remove feeder cable from plastic bag and set power cord aside.

2) Using two people, place iTerra Elite printer on the table’s edge, just slightly, so that the feeder-to-printer cable can

be plugged into its appropriate socket (underneath printer).

3) Return printer to its original position with all four feet in a secure position.

4) Remove feeder from protective packaging.

_________________________________________________________________________________________________________________________

PAGE 11 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 12

5) Insert left and right feeder hooks into corresponding feeder slots on the front opening of the printer.

6) Carefully let feeder down - its weight will secure it to the printer

7) Attach feeder-to-printer cable via connector and secure thumbscrews to the feeder.

_________________________________________________________________________________________________________________________

PAGE 12 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 13

Media Input Tray Installation

1) Remove media input tray from protective packaging.

2) Slide the input tray into the white support brackets of the feeder until the left and right tray locks attach to the

support bracket.

Support Brackets

_________________________________________________________________________________________________________________________

PAGE 13 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 14

3) To release the tray, push up on the locks and pull tray towards you.

Tray Locks

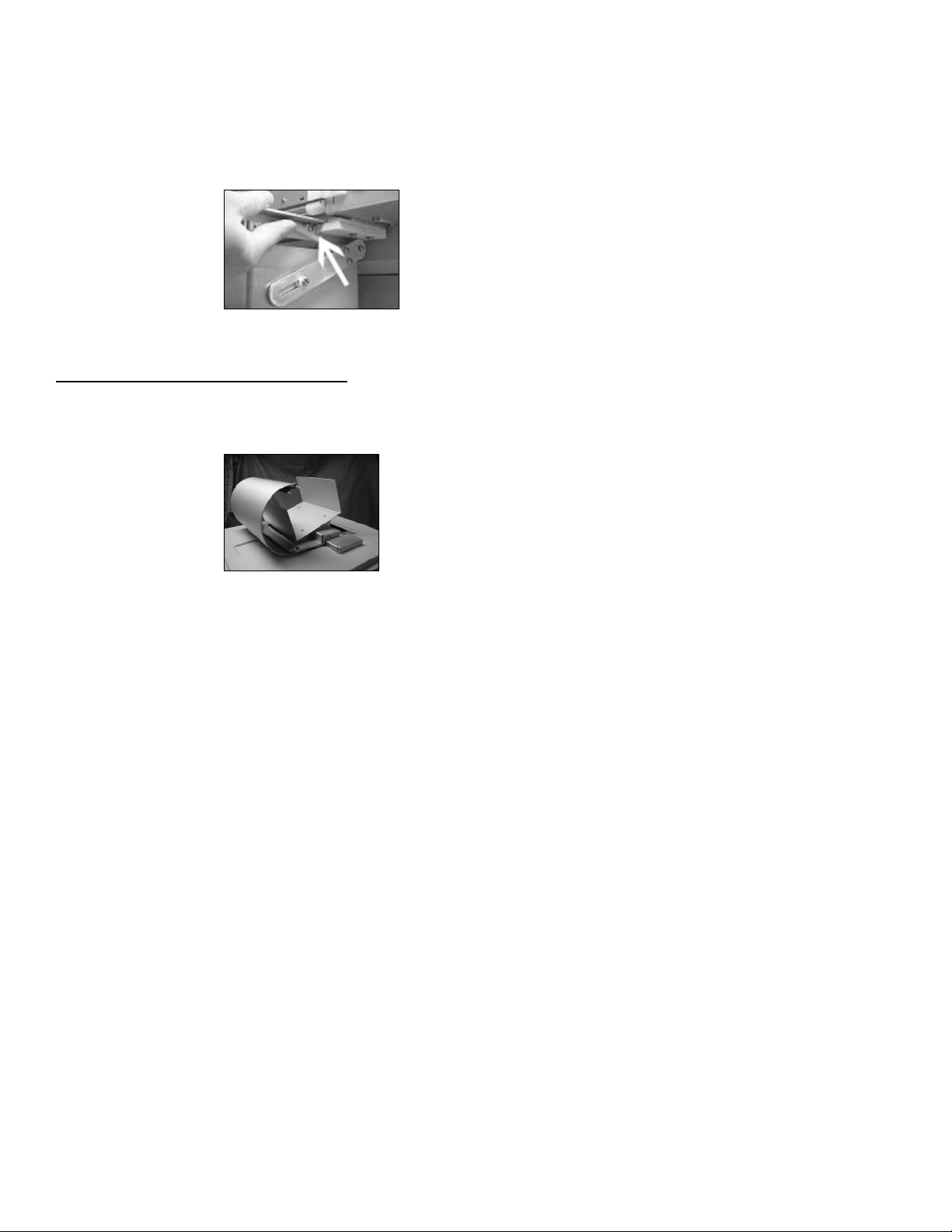

Optional Top Media Stacker Installation

1) Slide the media catcher into the opening on top of the printer. The large radius should be towards the front of the

printer.

_________________________________________________________________________________________________________________________

PAGE 14 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 15

2) The top media stacker must be parallel with the top of the rear jam sensor box, with a 1mm (1/32”) space

between the top media stacker and the jam sensor box.

_________________________________________________________________________________________________________________________

PAGE 15 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 16

III. CONNECT TO POWER

Note: When cycling the printer power (on-off-on), leave the printer power switch in the off position for at least

10 seconds to allow the printer to fully power down before turning it back on again.

1) Attach the power cord to the back of the printer.

2) Connect to grounded power socket.

3) Turn the printer on and wait for it to warm up. The printer will go through its initialization and warm up sequence.

When the printer is ready, the READY indicator comes on and stays on (green) and the LCD indicates ONLINE.

_________________________________________________________________________________________________________________________

PAGE 16 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 17

IV. LOADING CONTINUOUS FORM FEED PRINT MEDIA

1) Push right and left snap latches inward to open the tray door and pull it down.

2) Insert continuous fanfold paper so that the black I-Mark (TOF) is positioned towards the back and to the right side

of the tray (See “Print Media Specifications” for paper size).

Tension Bar

_________________________________________________________________________________________________________________________

PAGE 17 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 18

3) Feed leading edge of the paper behind the tension rod.

Tension Bar

4) Load the leading edge of the paper under the pinch roller in a straight and level manner with even margins at the

left and right of the drive roller collars. Manually hold and push the paper in until the leading edge is secure under

the cutter bar.

Cutter

_________________________________________________________________________________________________________________________

PAGE 18 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 19

5) Close the tray door firmly until latched.

6) Push the right and left white media-limit slides inward. These ensure constant reading of the I-Mark (TOF) by

sensor.

_________________________________________________________________________________________________________________________

PAGE 19 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 20

7) Press and hold the ADVANCE button on the feeder to load paper. (Hold until green LED stops flashing.) Make

sure the paper has tension.

8) If loading paper from a box of more than 800 fanfold sheets, place box directly in front of printer on the floor. Do

not insert paper into tray but simply feed paper through print media slot on bottom of paper tray. Carry on with

steps (2-7).

9) You are now ready to plot.

NOTE:

Step 7 must be repeated any time the green light is flashing. Cycling the printer on and off, as well as

removing paper from the feeder after a jam or other unintended operation, will cause this light to flash.

_________________________________________________________________________________________________________________________

PAGE 20 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 21

V. PRINT MEDIA PROPERTIES

Standard Paper

WARNING:

Custom:

• Continuous Fan Fold (8.5” wide)

Single Sheet Only:

• Letter, Executive

• Legal-14, legal 13.5, Legal 13

• A4, A5, A6, B4, B5

Using certified iSys Media is critical to your day-to-day operation of this printer. Using non-qualified media

will result in print job failures, poor output quality, lost time and down time. Call iSys Media or your Sales

Representative to learn more about this.

Feed Paths:

• Tray 1

• Paper Tray

Exit Paths:

• Top

• Rear

Weight:

• 16-54 lb. US Bond

_________________________________________________________________________________________________________________________

PAGE 21 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 22

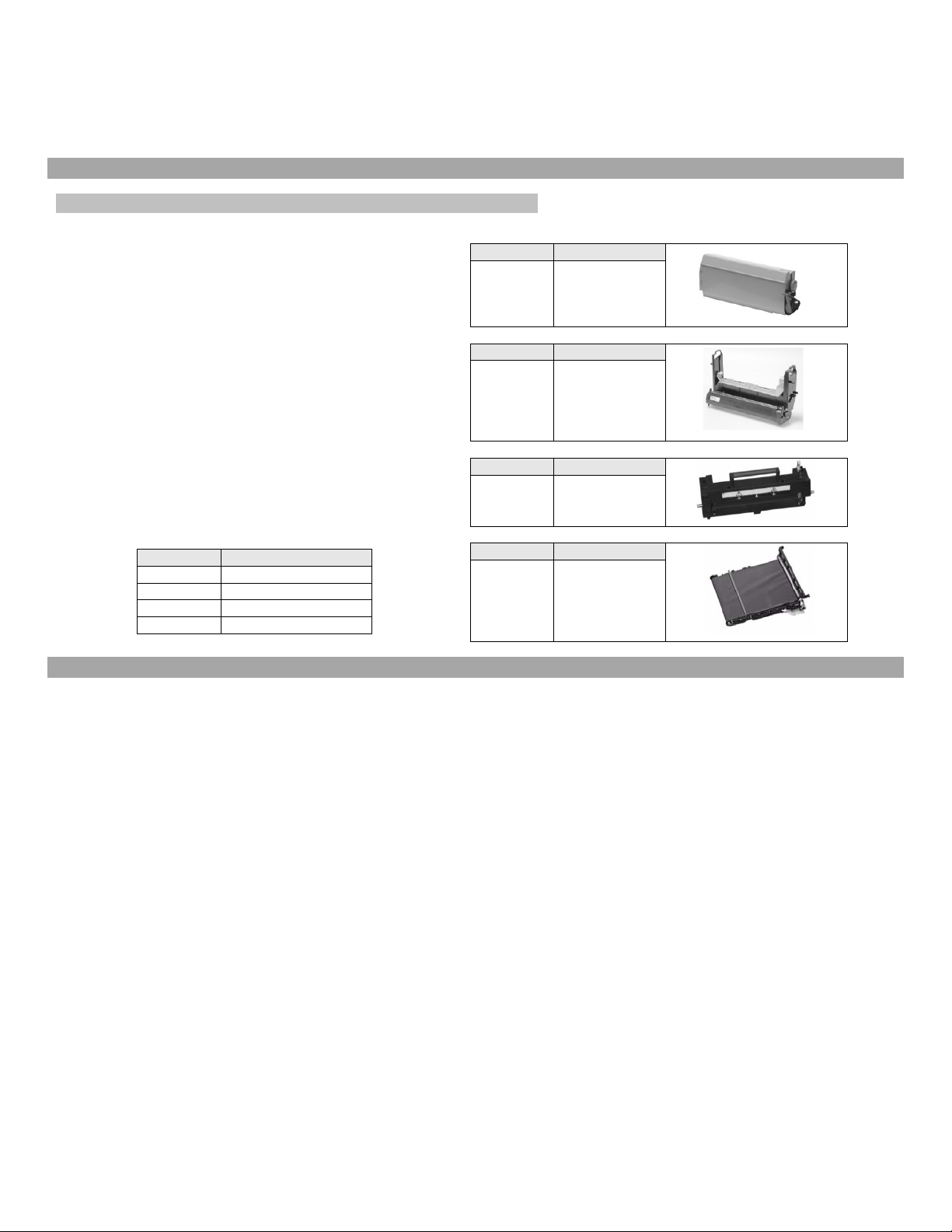

2. ORDERING CONSUMABLE SUPPLIES

I. HOW TO ORDER QUALIFIED MEDIA AND CONSUMABLES

Using non-Qualified iTerra media and

consumables will void the printers’ warranty.

Toll-free by phone at 1-866-415-4797 within North

America or 1-403-204 5200 globally.

By fax at 1-403-204-1971 using an iSys Elite

Media order form.

All prices in US dollars. Credit Card accepted.

Sales tax, Shipping & Handling are added where

applicable.

You can use a purchase order to purchase

products directly from iSys if the order value is over

$500, excluding freight and taxes and if you have

been approved for credit.

Paper

Media iSys Part No.

1000 sht CL85FF1000

3800 sht CL85FF3800

5500 sht CL85FF5500

6000 sht CL85FF6000

Toner Cartridges

Color iSys Part No.

Black

Cyan

Magenta

Yellow

CL2-BKT

CL2-CYT

CL2-MGT

CL2-YWT

Image Drums

Color iSys Part No.

Black

Cyan

Magenta

Yellow

CL2-BKD

CL2-CYD

CL2-MGD

CL2-YWD

Fusers

Voltage iSys Part No.

120 Volts

230 Volts

CL3-Fuser120

CL3-Fuser230

Transfer Belt

Item iSys Part No.

Transfer

CL3-Belt

Belt

3. INTERFACE SETUP AND INSTALLATION

_________________________________________________________________________________________________________________________

PAGE 22 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 23

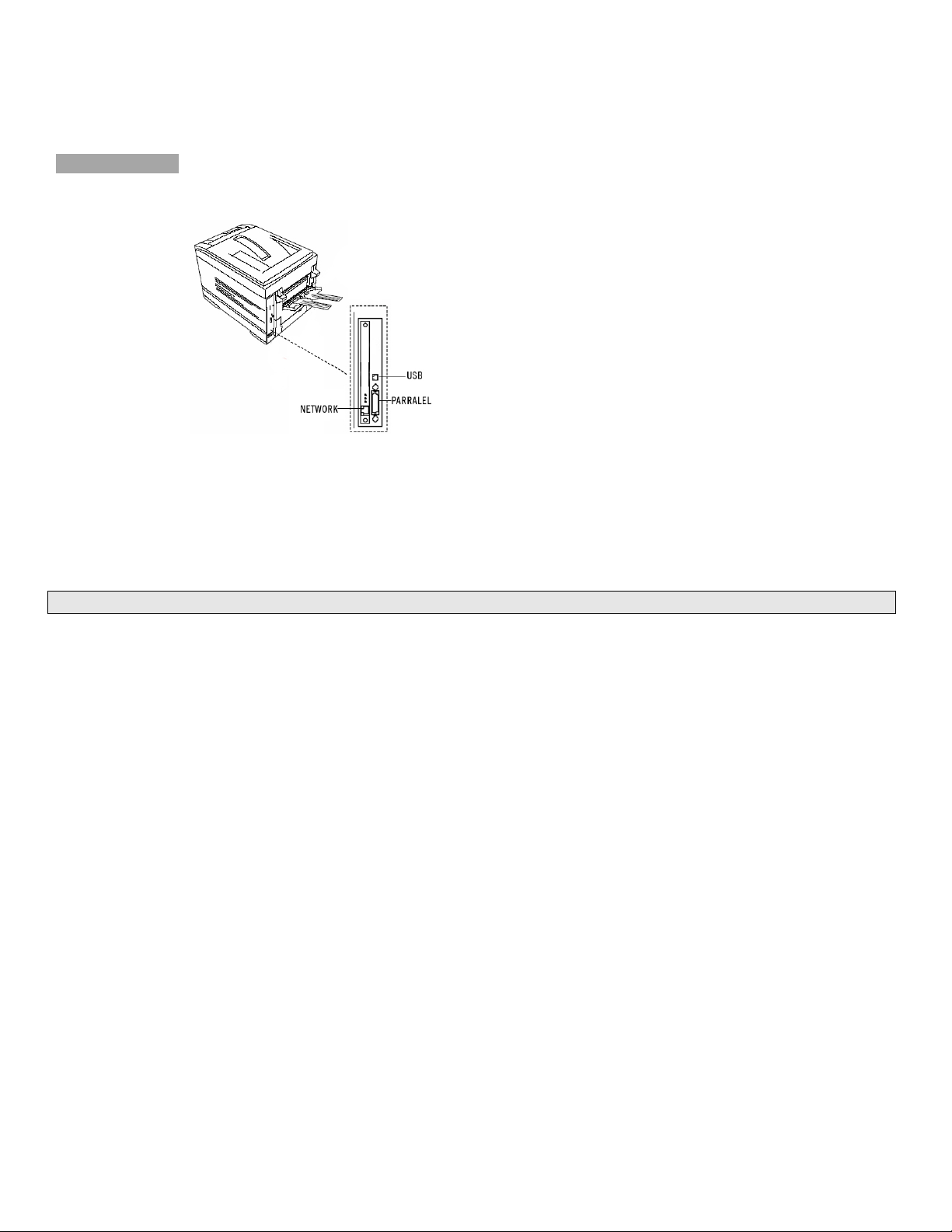

I. INTERFACES

Your printer is equipped with a selection of data interfaces. See rear of Printer:

1. Parallel – For direct connection to a PC. This requires a bi-directional parallel port with a (IEEE 1284 compliant)

parallel cable.

2. USB – For connection to a PC running Windows XP or Windows 2000. This port requires a cable conforming to

USB version 1.1 or above.

The operation of a printer is not assured if a USB compatible device is connected concurrently with other USBcompatible devices (USB A Male to USB B Male cable).

3. Ethernet – For network cable connection. Optional Network card is required.

NOTE:

Administrator’s authority may be required when installing a network connection.

_________________________________________________________________________________________________________________________

PAGE 23 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 24

II. LOCAL INSTALLATION

A. Parallel Port Connection

1. Turn off both the computer and the printer.

2. Attach a standard IEEE-1284 parallel cable (not supplied) to the parallel port on the printer, securing it

with the spring clips.

3. Attach the other end to the parallel port on the computer and secure it in place with the screws.

B. USB Port Connection

NOTE:

CAUTION:

NOTE:

No USB interface cable is supplied with the printer. Use a USB cable that is compatible with USB

specification 1.1).

Install Windows Driver before powering up printer with USB interface connected to eliminate incorrect

driver being auto installed.

1. Turn off both the computer and the printer.

2. Connect the USB cable to the USB port on the computer.

3. Connect the other end of the cable to the USB port on the printer.

A USB interface will only operate using Windows 2000, Windows XP, Windows Me and

Windows 98). It will not operate using MS-DOS, Windows 95, 3.1, or NT 4.0.

Printer operation is not assured if another USB compatible device is connected

concurrently with it.

If a USB hub is used it must be connected directly to the computer.

_________________________________________________________________________________________________________________________

PAGE 24 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 25

III. NETWORK INSTALLATION

C. Network Port Connection

NOTE:

Ethernet® cable is not supplied with the printer. Use an Ethernet cable with two twisted wire pairs and an

RJ45 plug.

1) Turn the printer off.

2) Connect your Ethernet cable to the network port on the printer (1).

3) Connect the other end of the Ethernet cable to the network port, Hub or host system (2).

4) Turn the printer on and wait for the print server status light (3) to stop blinking.

If you are unaware of what the network IP set value is for the printer, follow the instructions below to determine that value.

You will need to know the printer IP before you can load the printer driver.

If a network configuration card is not already installed refer to Trouble Shooting Chapter and/or Accessory installation (if

network card is purchased later than printer).

_________________________________________________________________________________________________________________________

PAGE 25 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 26

IV. PRINT DRIVER INSTALLATION

Overview Windows 2000 & Windows XP

The iTerra Elite (CLP825) Continuous Printer Driver for Windows 2000 & XP allows users to print directly from Windows

applications to the iTerra Elite printer. These instructions describe installation of drivers from a driver installation CD ROM

or from driver files on your hard disk to the Windows 2000 host system.

Printing can be done through the parallel port, USB port or a network. The printer can be set up as a shared device so

that other Windows host systems on the network can access it although drivers will need to be loaded on each of the host

systems.

Preparation

The following items will be necessary to complete this installation procedure:

1) Be sure that the IP address of the printer has been properly assigned and set. The IP address of the printer is

required in the driver installation. See the next section entitled ‘Network Card IP Address checking and setting’ to

check, change and set the printer’s IP.

2) Ensure that the driver can be accessed on the host system. You may have a CD ROM that was supplied with the

purchase of the printer or you may have downloaded a driver zip file from the www.isys-group.com website. If

you did download a zip file you will have to unpack the files and make note of the location to where you have

unpacked it.

3) It is a good idea to have the Windows 2000 distribution CD available at the time of the driver installation.

_________________________________________________________________________________________________________________________

PAGE 26 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 27

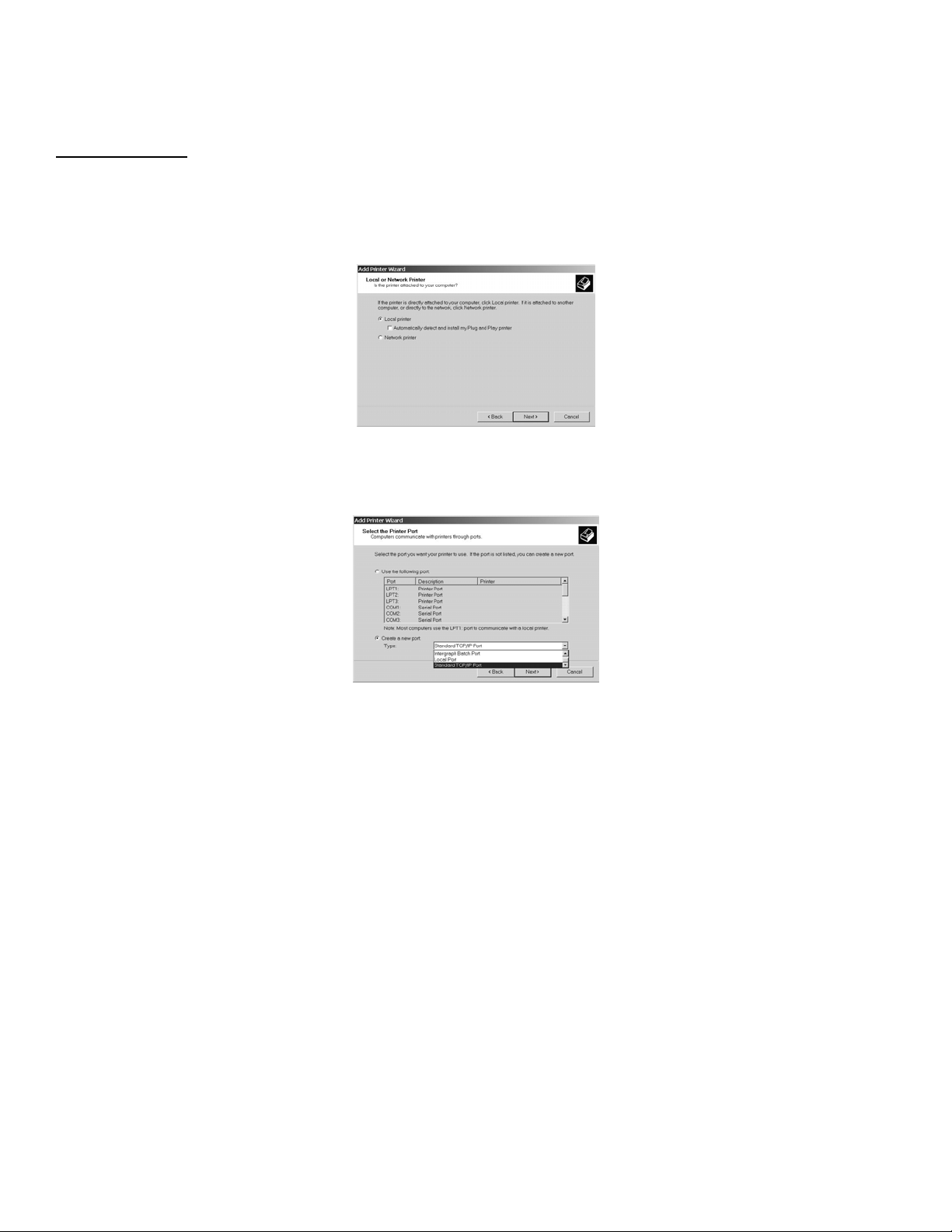

Driver Installation

1) Start the Windows 2000 host system.

2) Click Start-Settings-Printers, and then double-click on the Add Printer icon.

3) This will start the Add Printer Wizard, Click NEXT to continue to the next diagram.

4) Be sure to click LOCAL PRINTER and be sure the AUTOMATICALLY DETECT…box is unchecked as shown.

Click NEXT to continue to the next diagram:

_________________________________________________________________________________________________________________________

PAGE 27 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 28

5) As shown above, select the type of port to which the printer has been connected. If the port selected is not a

network port such as LPT1 or a USB port continue on to section 10). If you are connected on a network, click on

CREATE A NEW PORT, and then select STANDARD TCP/IP PORT. Then click NEXT to continue to the Add

Standard TCP/IP Port Wizard. Click NEXT to continue to the next diagram:

6) In the screen shown above, type the IP address of the printer in the top box (not the same as shown above). A

unique port name will be automatically created in the lower box. This name can be kept (recommended) or it can

be changed to any other name. Click NEXT to continue.

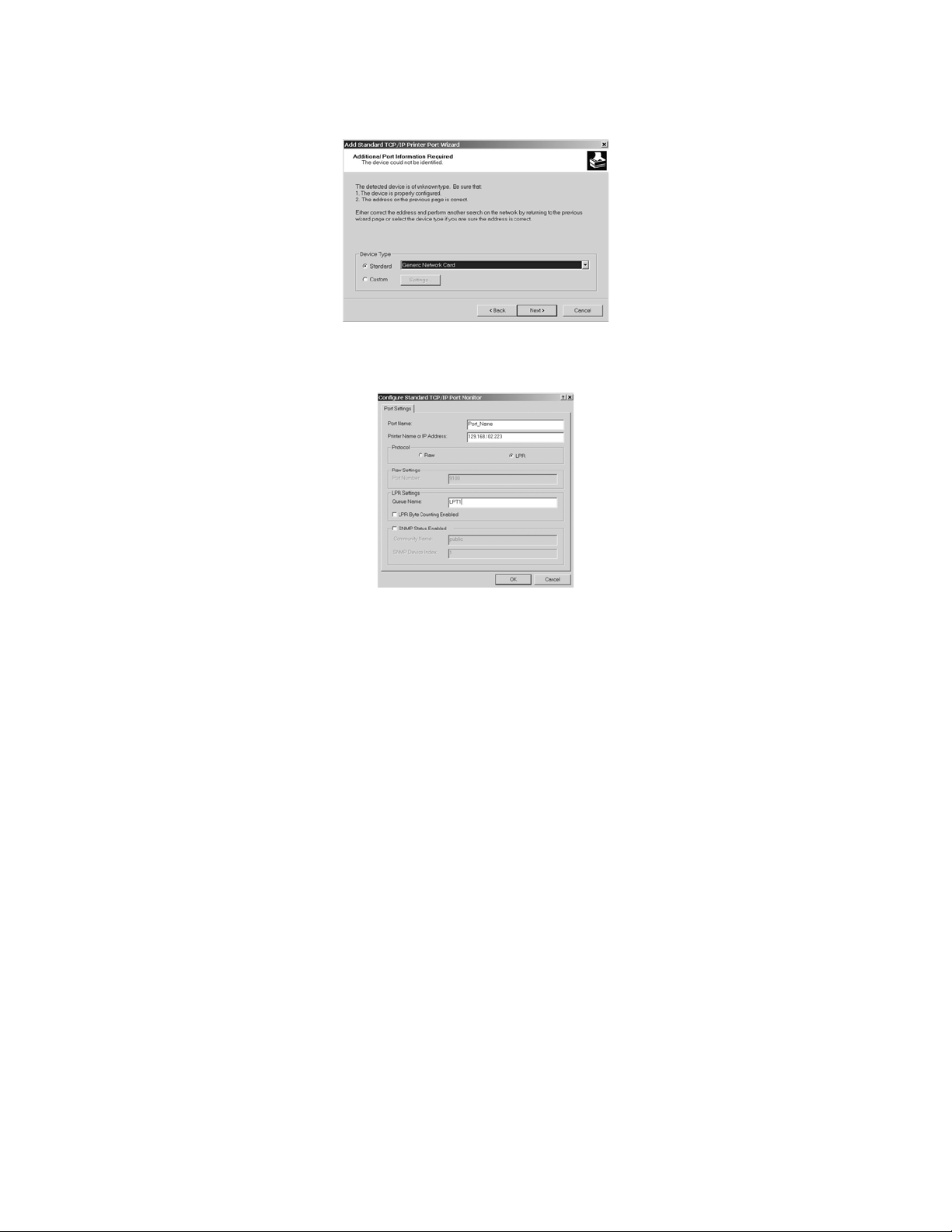

7) Windows will now try to locate and identify the printer on the network. This may take 20-30 seconds. If there is

an error check network connections and IP addresses. If all network connections are correct and Windows

locates the printer, the screen will be displayed, as shown in the next diagram.

_________________________________________________________________________________________________________________________

PAGE 28 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 29

8) This screen indicates that Windows located the printer but does not recognize it. This is not a problem. Click on

CUSTOM and then click on SETTINGS. The next diagram will be displayed:

9) As shown above, click the LPR button in the Protocol box. Then, in the LPR Settings box type in “LPT1” (no

quotes) for the Queue Name. Click OK. This will return you to the previous screen. Click NEXT and on the

following screen click FINISH to complete setting up the LPR port.

_________________________________________________________________________________________________________________________

PAGE 29 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 30

10) The next diagram, should now be displayed.

_________________________________________________________________________________________________________________________

PAGE 30 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 31

In the above screen click HAVE DISK and then on the following screen click BROWSE. A browser screen like the one in

the next diagram will be displayed.

11) In the example shown above, the driver files were found on a floppy disk in drive A. Depending on the situation

these may also be found on a CD drive, on the hard drive of the host system, or at the networked drive location.

In any case, when file Ok71121e.inf is found, click OPEN and on the next screen click OK.

12) The screen below should be displayed indicating that the iSys CLP825 drivers were found. Click NEXT.

_________________________________________________________________________________________________________________________

PAGE 31 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 32

13) On the next three screens you will be given the option to enter a name for the printer, to share it over a network

and to print a test page. Make the appropriate entries and click NEXT each time.

NOTE:

Printing a test page is recommended, as it will test the LPR connection. However since printing

parameters have not set been set, the print may be less then ideal.

14) On the last screen of the Add Printer Wizard click FINISH. Depending on the system settings a warning screen

may be displayed about the “digital signature” of the drivers. This can be ignored by clicking YES.

NOTE:

It is possible that the system could be set to block unsigned drivers. In that case, change the setting

at Start-Settings-Control Panel. Or contact your system administrator.

_________________________________________________________________________________________________________________________

PAGE 32 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 33

15) At this point the system will need to copy additional driver files and may need to copy system files for the LPR

service. A prompt like the one shown in the next diagram will be displayed.

The exact prompts will depend on settings at the host system. The prompt will generally ask for the Windows

2000 CD, but that is not always necessary.

16) When the entire printer installation process has completed successfully, a new printer icon will be added to the

Printers folder.

_________________________________________________________________________________________________________________________

PAGE 33 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 34

Setting Default Properties

The default properties for the printer just installed can be set as follows:

1) Click START button, then select SETTINGS-PRINTERS to open the Printers folder.

2) Right click on the icon for the Horizon printer. In the drop-down box select PRINTING PREFERENCES.

NOTE:

Another choice in the drop-down box is RENAME. This could be used to change the name of the printer.

Also, SET AS DEFAULT can be used to designate this as the Windows default printer.

3) Click on the Layout tab and then click on the ADVANCED button to access and select default media type and

size, as well as many other settings.

Changing the Printer IP Address

After a printer has been installed on a Windows 2000 host system, its IP address can be changed if that becomes

necessary.

1) Click START-SETTINGS-PRINTERS, then click on the icon for the printer to be changed, select PROPERTIES

and then click on the PORTS tab. The screen should look as shown in the next diagram:

_________________________________________________________________________________________________________________________

PAGE 34 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 35

2) Be sure the port with the iSys printer is selected then click CONFIGURE PORT. The Configure Port Screen will

look as displayed in the next diagram:

3) On the Configure Port screen change the IP address to the new setting.

NOTE:

The Port Name cannot be changed by this procedure. If the Port Name was unacceptable, e.g. if it

includes the old IP address, to change it use Delete Port. The printer and port will have to be fully installed

again.

4) Click on the General tab and make a Windows test print or close the Properties box altogether and send a test

print from a Windows application.

Making a Printer a Shared Device

_________________________________________________________________________________________________________________________

PAGE 35 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 36

If a printer was installed as an unshared device and it is later desired to share it, its status can be changed as follows:

1) Click START-SETTINGS-PRINTERS then right click on the icon for the printer to be changed, select

PROPERTIES and then click on the SHARING tab. The screen should look as shown below.

2) Click the SHARED AS button, which will enable the text box. Type the Share name in the box. Do not click on

ADDITIONAL DRIVERS. Drivers will have to be installed on the client systems that want to share this printer.

Click OK. The printer will appear as a shared resource in Network Neighborhood.

_________________________________________________________________________________________________________________________

PAGE 36 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 37

V. NETWORK CARD IP ADDRESS-CHECKING AND SETTING

The following section enables you to determine the printer’s IP Address as well as how to set it to the desired value. The

following actions will only create results if a network card is presently installed in the printer.

From the front operating panel of the printer, follow the instructions below.

Set IP Address

Set Subnet Mask Address

Set Default Gateway Address

_________________________________________________________________________________________________________________________

PAGE 37 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Press Button 0

1.

Display will read “NETWORK MENU”

Press Button 1

2.

Display will read “IP ADDRESS 000.000.000.000”

Press Button 1 or 5

3.

Press Button 2 or 6

4.

Press Button 3

5.

Press Button 4

6.

Press Button 0

1.

Display will read “NETWORK MENU”

Press Button 1

2.

Display will read “SUBNET MASK 255.000.000.000”

Press Button 1 or 5

3.

Press Button 2 or 6

4.

Press Button 3

5.

Press Button 4

6.

9 times

once

to select address group to change

to set the desired value

to save changes

to put printer back ONLINE

9 times

5 times

to select address group to change

to set the desired value

to save changes

to put printer back ONLINE

Press Button 0

1.

Display will read “NETWORK MENU”

9 times

Page 38

Press Button 1

2.

Display will read “SUBNET MASK 000.000.000.000”

Press Button 1 or 5

3.

Press Button 2 or 6

4.

Press Button 3

5.

Press Button 4

6.

9 times

to select address group to change

to set the desired value

to save changes

to put printer back ONLINE

VI. WEB BROWSER TO PRINTER (Advanced Users and Administrators)

A Network iTerra Elite printer can also be accessed via a web browser, where default settings can be modified to suit your

User Environment. You will need to know the IP setting (for your web browser URL address input) and the printer name.

The printer name is displayed on the Network Information sheet that is printable as part of the Menu Map (see Printing the

Menu Map section). This name can be found under the Auto Discovery section of the Network Information sheet. The

Username is ‘root’ and the Password is the last six (6) characters of the Printer Name. For example: Printer Name

displayed on the Menu Map printout is ETHERA485C5, therefore the password is A485C5).

NOTE:

Password is case sensitive while the username is not.

_________________________________________________________________________________________________________________________

PAGE 38 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 39

VII. WINDOWS 2000 & XP PRINT DRIVER PROPERTIES

Open the printing properties page, through the Printers folder (START Æ SETTINGSÆ PRINTERS) then right click on the

printer name, and selecting the PROPERTIES box.

This will open a window

to the following Æ

VIII. GENERAL TAB

This window tab displays general information such as the printer name

(iSys CLP825), allows the user to view and set the ‘PRINTING

PREFERENCES’ (see the Printing Preferences doc) and lets you print a

windows test page from the ‘PRINT TEST PAGE’ button.

_________________________________________________________________________________________________________________________

PAGE 39 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 40

VIX. SHARING TAB

From this windows screen the user can enable printer sharing on their host

computer.

X. PORTS TAB

Allows the user to select or change the connectivity from the host computer

to the iSys printer (see the driver installation doc for more information on

setting up a TCP/IP port).

_________________________________________________________________________________________________________________________

PAGE 40 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 41

XI. ADVANCED TAB

This window allows the user to change the printers’ availability, which

will spool up the jobs until the appropriate available time; spooler

options and you can have the spooler create a separator page between

jobs if required.

XII. COLOR MANAGEMENT TAB

You can add a color profile if color matching is important. (See Printer

Preferences for more information).

_________________________________________________________________________________________________________________________

PAGE 41 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 42

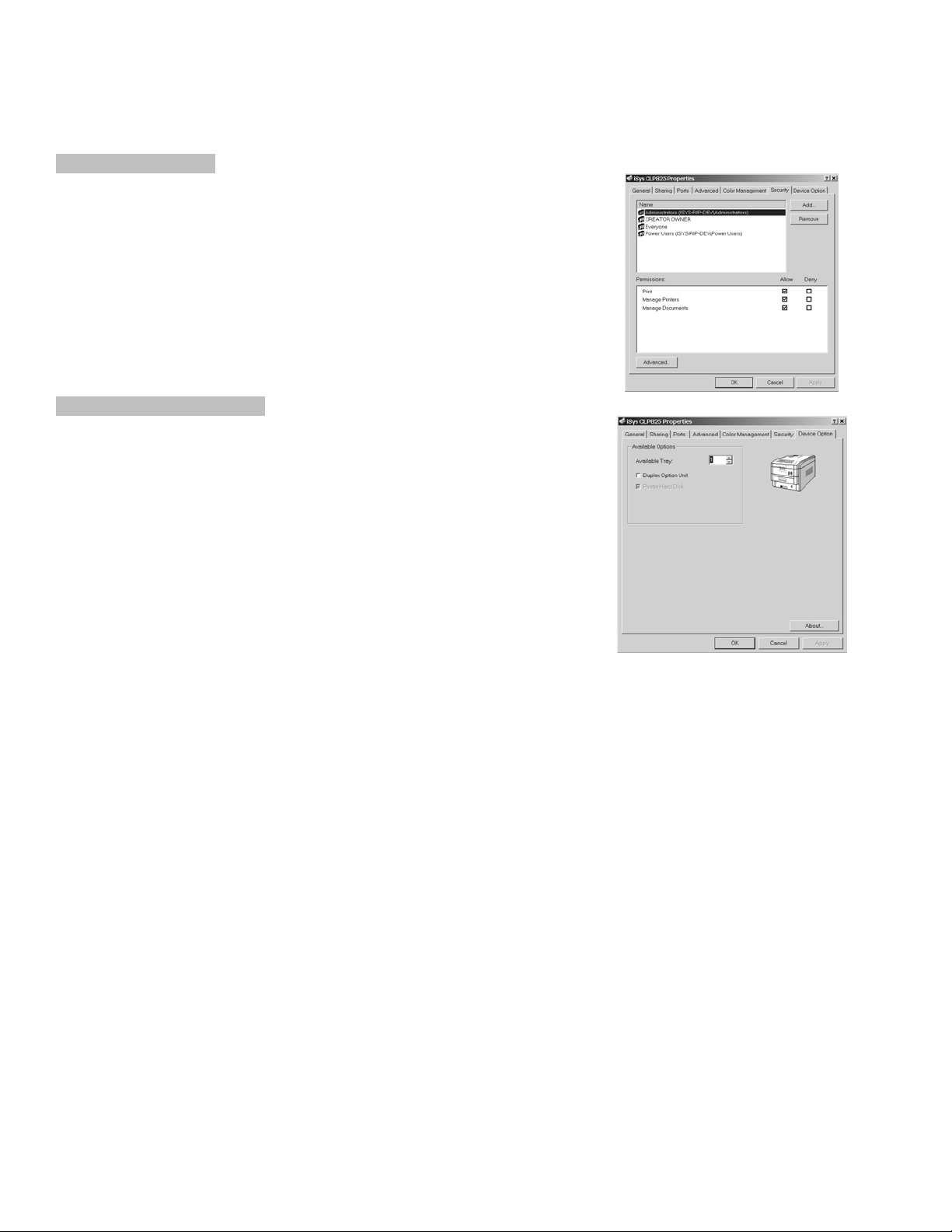

XIII. SECURITY TAB

You can allow specific users access to the printer on the host computer.

This is usually only changed if the printer is being shared on a network.

XIV. DEVICE OPTION TAB

This window is typically not changed unless a duplexer has been added

and is not used if running continuous media.

_________________________________________________________________________________________________________________________

PAGE 42 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 43

4. OPERATION – CONTINUOUS PAPER MODE

I. PRINTER CONTROL PANEL OVERVIEW

• Attention indicator (red). ON indicates that attention is required, but printing will continue. FLASHING indicates

that attention is required, but printing will stop.

• Ready indicator (green). ON - ready to receive data. FLASHING indicates processing data or error.

• Liquid crystal display (LCD) panel. Two rows of up to 24 alphanumeric characters displaying print status, menu

items in menu mode, and error messages.

_________________________________________________________________________________________________________________________

PAGE 43 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 44

Menu button

Press briefly to enter the MENU mode. Press briefly again to select the

next menu. Press for more than 2 seconds to scroll through the

different menus.

Item (+)

Press briefly to scroll forward to the next menu item.

button

Value (+)

button

Select button

Online button

Press briefly to scroll forward to the next value setting for each menu

item.

Press briefly to select the menu, item or value indicated on the LCD.

Switches between online and offline status

When pressed in MENU mode, it returns the printer to on line

status.

When pressed with DATA PRESENT displayed, it forces the

printer to print out the remaining data in the printer.

When there is an error message indicating wrong paper size,

pressing the ONLINE button forces the printer to print.

Item (–)

Press briefly to scroll backward to the previous menu item.

button

Value (–)

button

Cancel

Press briefly to scroll backward to the previous value setting for each

menu item.

Press to cancel a print job.

button

_________________________________________________________________________________________________________________________

PAGE 44 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 45

II. FEEDER OPERATING INSTRUCTIONS

Loading Continuous Media

1) Manually load media

2) Turn on printer

3) The switch panel lights will illuminate in sequence during the feeder boot up.

4) Once the green light begins flashing on the feeder switch panel (media pre-load required), push and hold the

ADVANCE button until green light stops flashing and remains on (ready for printing)

NOTE:

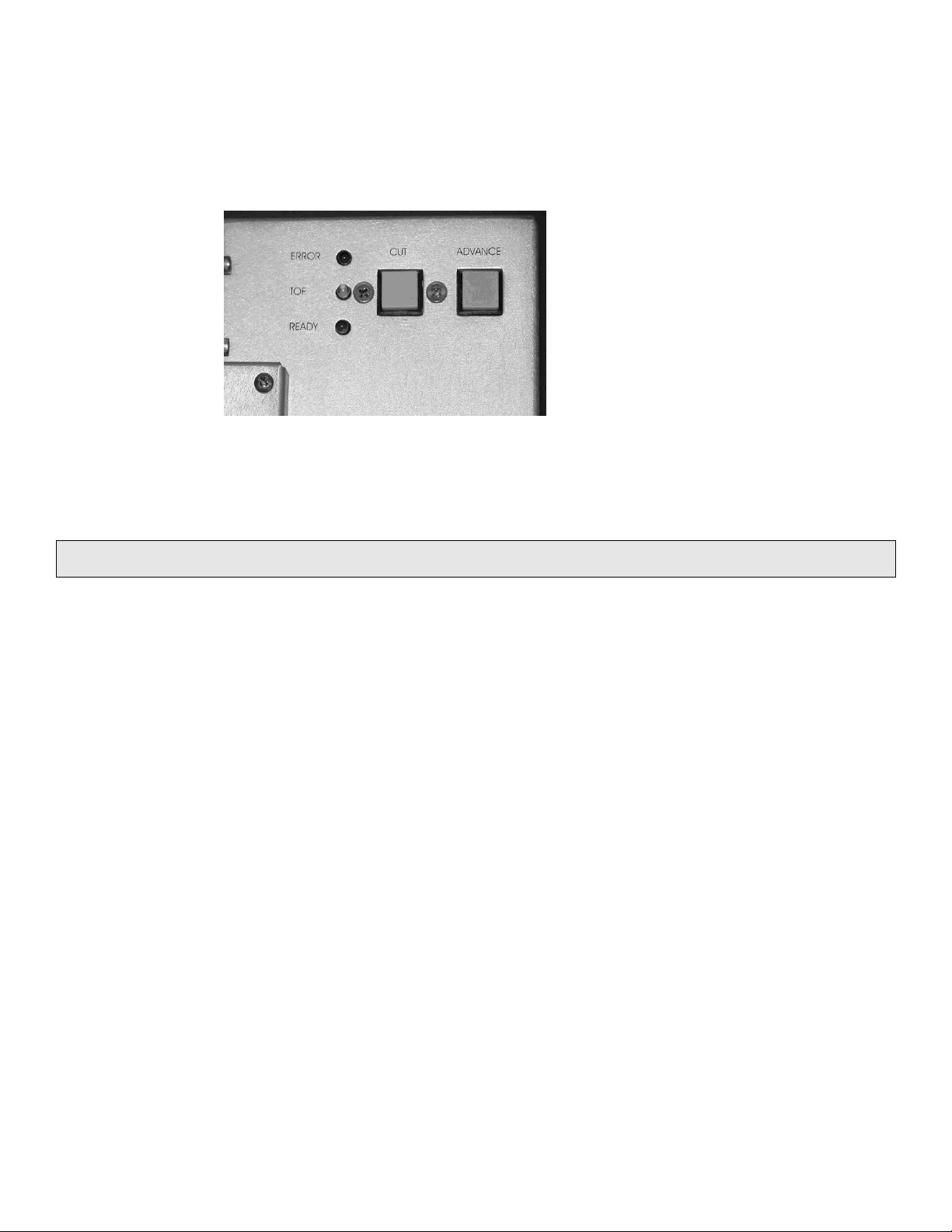

Feeder Switch Panel Functions

Feeder Switch Panel Indicators

The paper feeder will not automatically load the paper into the printer until Step 4 is completed. Step 4 must be

repeated any time the green light is flashing. This condition will exist if the printer is cycled off and on or if paper is

cleared from the feeder after a paper jam.

Cut Button

Pressing this button for 2 seconds will actuate a paper cut operation.

Cut paper must be cleared out from paper feeder.

Advance

Button

Pressing and holding this button will activate the paper pre-load

sequence. This button becomes locked out (inactive) during printing or

if the green light is on steady.

_________________________________________________________________________________________________________________________

PAGE 45 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 46

Red

Flashing means an error condition was encountered. Please call iSys

service at 1-866-415-4797. See chapter 6, Troubleshooting, for more

information.

Yellow

ON means TOF sensor sees the black I-Mark. OFF means a TOF

sensor sees white paper.

Green

Flashing means that a paper pre-load is required. Steady means that

the printer is ready for printing.

_________________________________________________________________________________________________________________________

PAGE 46 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 47

III. EXIT SPEEDS AND PRINT CONTROLS

To select exit location (Back or Top) or to adjust print quality from the front panel of the printer the following steps must be

performed:

1) Push button 4 (online button 1x). Printer must be OFFLINE before working in the extended menu. This will

ensure that a print job does not print while modifying the settings.

2) Push Buttons 6 and 7 together and hold for a few seconds and release. Fan Fold print control.

3) Push Button 1 (item button 1x). This will display the current paper exit location. (Example: Exit: Top

Status: Good)

4) Using Button 2 or 6 (value button + or -) allows the user to scroll through the menu options. There are

currently six options available under Fan Fold Print Control.

5) To change the current setting scroll through the menu options using buttons 2 and 6 until the desired option

is displayed on the screen.

6) Push button 3 (select button 1x). Option saved.

7) Cycle Print Power. Check print quality. Display on printer will remain blank for up to 45 seconds before

returning Online, this is normal.

(If you continue to experience print quality difficulty, please contact iSys Technical Support at 1-866-415-5797).

Printer Front Panel

How to print test plot on disk:

Press Button 0

_________________________________________________________________________________________________________________________

PAGE 47 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Option 1: Exit: Back Status: Stall

Option 2: Exit: Back Status: Smear

Option 3: Exit: Back Status: Good

Option 4: Exit: Top Status: Stall

Option 5: Exit: Top Status: Smear

Option 6: Exit: Top Status: Good

once

Page 48

Display will read “PRINT JOBS MENU”

Press Button 3

Display will read “ENTER PASSWORD ****”

Press Button 2

Display will read

Press Button 1

Display will read

Repeat previous

2 steps 3 times

until Display

reads

Press Button 3

Display will read “SELECT JOB

Press Button 2

Press Button 3

Display will read

Press Button 3

once

twice

“ENTER PASSWORD 1***”

once

“ENTER PASSWORD 1***”

“ENTER PASSWORD 1111”

once

ALL JOBS”

until the Display reads

“iTerraElite_Demo”

once

“Set Collating Amount”

1

to plot test file selected. Printer will go

back ONLINE.

How to print a Menu Map (Printer Configuration):

Press Button 0

Display will read “INFORMATION MENU”

Press Button 3

Display will read “PRINT MENU MAP EXECUTE”

Press Button 3

_________________________________________________________________________________________________________________________

PAGE 48 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

2 times

once

once more to print the menu map. Printer

Page 49

will go back ONLINE.

How to change number of copies:

Press Button 0

Display will read “PRINT MENU”

Press Button 3

Display will read “COPIES 1*”

Press Button 2

Press Button 6

Press Button 3

Press Button 4

4 times

once

to increase # of copies desired

to decrease # of copies

to save change

to put printer back ONLINE

_________________________________________________________________________________________________________________________

PAGE 49 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 50

IV. OUTPUT VIA BACK

Press Buttons 6 & 7

Display should read

Press Button 1

Display should read “Fanfold Print Control

Smearing

Press Button 2

Display should read

Press Button 3

Display should read

Press Button 4

Display should read

Cycle the printer’s power

Run Test Plot to check quality of plot

Repeat these steps until image quality is

acceptable

NOTE:

Ensure you are only changing the Status for where your media is exiting the printer.

once

“Fanfold Print Control

Exit: Back Status:

Smear ”

once to save change

“Fanfold Print Control

Exit: Back Status:

Smear *”

once to put printer back

ONLINE

“Cycle Printer Power

Check Print Quality”

at same time

“Fanfold Print Control”

once

Exit: Back Status: Good *”

(Default)

Jamming

Press Button 2

Display should read “Fanfold Print Control

Press Button 3

Display should read “Fanfold Print Control

Press Button 4

Display should read “Cycle Printer Power

Cycle the printer’s power

Run Test Plot to check quality of plot

Repeat these steps until JAMMING in front of fuser

stops

twice

Exit: Back Status:

Stall”

once to save change

Exit: Back Status: Stall

*”

once to put printer back

ONLINE

Check Print Quality”

_________________________________________________________________________________________________________________________

PAGE 50 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 51

V. OUTPUT VIA TOP (Using optional top stacker)

Press Buttons 6 & 7

Display should read

Press Button 1

Display should read

Press Button 6

Display should read

at same time

“Fanfold Print Control”

once

“Fanfold Print Control

Exit: Back Status: Good *” (Default)

3 times to select Exit out the Top of the printer.

“Fanfold Print Control

Exit: Top Status: Good ”

_________________________________________________________________________________________________________________________

PAGE 51 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 52

Smearing

Press Button 2

Display should read

Press Button 3

Display should read “Fanfold Print Control

Press Button 4

Display should read “Cycle Printer Power

Cycle the printer’s power

Run Test Plot to check quality of plot

Repeat these steps until image quality is acceptable

once

“Fanfold Print Control

Exit: Top Status: Smear

”

once to save change

Exit: Top Status: Smear

*”

once to put printer back

ONLINE

Check Print Quality”

NOTE:

Ensure you are only changing the Status for where your media is exiting the printer.

Jamming

Press Button 2

Display should read

Press Button 3

Display should read

Press Button 4

Display should read “Cycle Printer Power

Cycle the printer’s power

Run Test Plot to check quality of plot

Repeat these steps until image quality is acceptable

twice

“Fanfold print Control

Exit: Top Status:

Stall

once to save change

“Fanfold Print Control

Exit: Top Status: Stall

*”

once to put printer back

ONLINE

Check Print Quality”

_________________________________________________________________________________________________________________________

PAGE 52 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 53

VI. OUTPUT PROBLEMS

Jamming

For Continuous Plotting Fanfold a JAM could occur in 4 places.

1) Feeder green LED is flashing.

• Media is not loaded-press and hold ADVANCE button until green LED stops flashing.

2) Front of the printer while Feeder is loading.

• Check leading edge of media for damage.

• Check the pinch roller.

• Check to see if media is loaded correctly through the input tray.

• Load motor might need calibration.

3) Front of the Fuser

• Leading edge of paper is damaged (curls or bends).

• EXIT Speed is too slow.

4) Behind the Fuser or past the EXIT of the printer.

TOP

• Paper may not be folding properly in the Top Stacker tray.

• Check to see if the Top Stacker is installed correctly. Check the distance to the JAM box.

BACK

• Check to see if the cable is installed on the Rear Jam block.

• Make sure paper is free to fall to the floor.

_________________________________________________________________________________________________________________________

PAGE 53 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 54

Smearing:

• Consumables not installed correctly or non-iSys brand.

• Paper moisture content is too high. Check for pock

marking.

• Paper width not within specification.

• Paper not tracking properly through the feeder

• Exit Speed too slow.

Creasing or Wrinkling:

• Consumables not installed correctly or non-iSys brand.

• Paper moisture content is too high. Check for pock

marking.

• Paper width not within specification.

• Paper not loading square to the front feed roller in the

printer.

_________________________________________________________________________________________________________________________

PAGE 54 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 55

5. PRINT DRIVER PREFERENCES

This chapter explains how to set up color printing and how to use the printer’s features from within the driver preferences.

Most of these features are designed for sheet operation via Tray 1, yet many also apply to continuous ‘super long page’

operation via modified multi purpose tray.

NOTE:

Most applications allow the printer properties to be accessed from within the document print dialog box.

_________________________________________________________________________________________________________________________

PAGE 55 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 56

I. CHANGING THE iSys CLP825 PRINTING PREFERENCES

There are few ways a user can open the printing preferences page:

through the Printers folder

START Æ SETTINGSÆ PRINTERS

then right click on the printer name

or when using an applications

FILE Æ PRINT OPTIONS and

selecting the PROPERTIES box

or from the iSys CLP825

PROPERTIES page

_________________________________________________________________________________________________________________________

PAGE 56 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 57

II. THE SET UP TAB

There are 4 subsections under the SETUP tab:

A. Media

B. Finishing Mode

C. 2-Sided Printing

D. Driver Settings

_________________________________________________________________________________________________________________________

PAGE 57 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 58

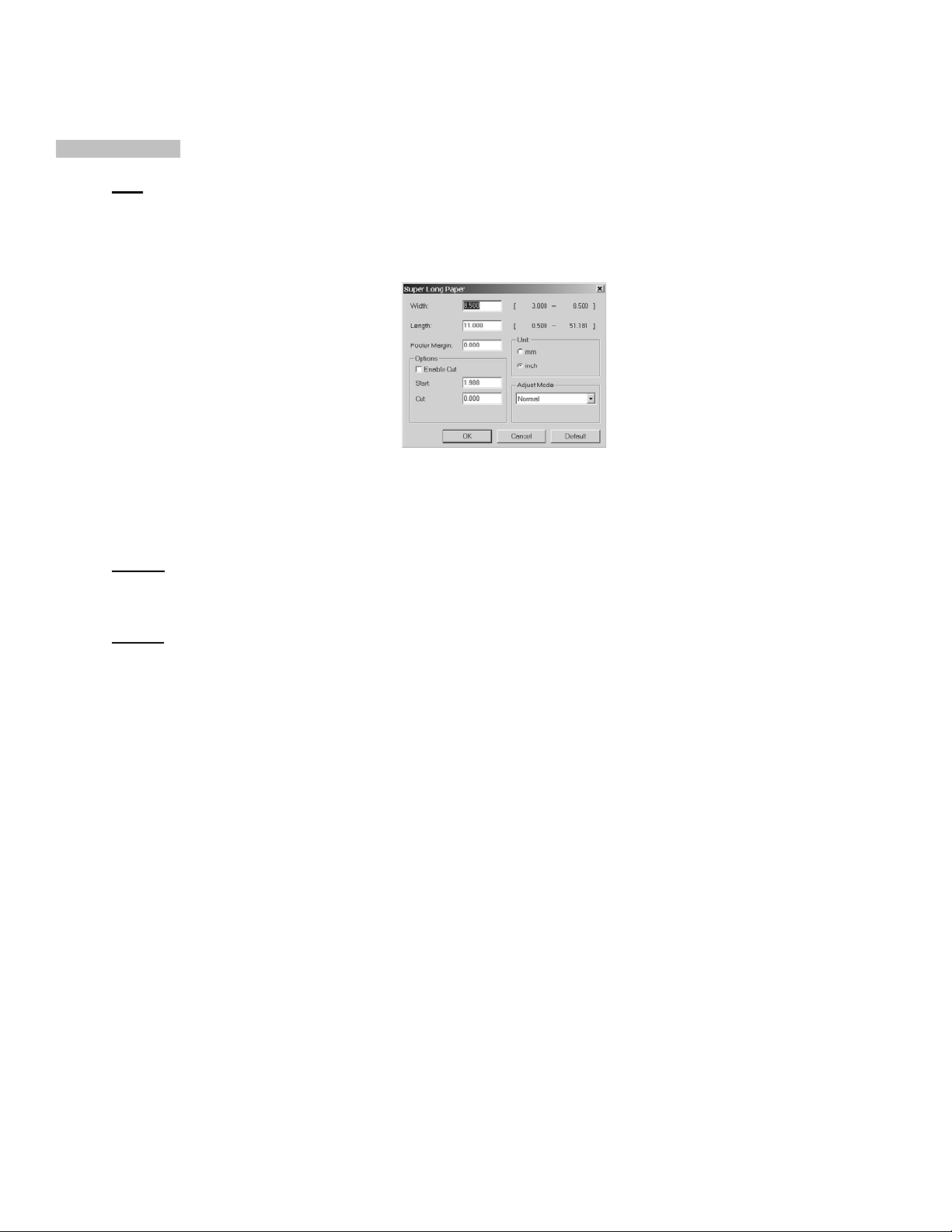

A. Media Section

Size

Drop down list of various standard sheet paper sizes and default ‘Super Long Paper’. Select ‘Super Long

Paper’ for continuous printing operation. Default Super Long Paper specification is for 20-24lb paper with a width

of 8.5” and support to 400’ in length. For a complete Super Long Paper specification sheet, notify your sales

Representative. This will open a window as follows:

From here you can toggle the ‘Enable Cut’ option if the user requires a cut between multi-copy jobs. You can

also adjust the ‘START’ field, which changes the distance where the image is placed. You might use this if you

would like to adjust the distance from the leading edge of paper or the initial tear-perforation using continuous

media. This ‘CUT’ field adjusts where the cut occurs.

Source

Allows the user to change the printer paper tray to be used. For continuous plotting the only tray that can be used

is the ‘Multi Purpose Tray’, the remaining standard sheet tray is labeled ‘Tray1’.

Weight

You can change the media weight (media type and thickness). For continuous plotting the default should be

‘Printer Setting’.

_________________________________________________________________________________________________________________________

PAGE 58 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 59

The ‘Paper Feed Options’

The user should not have to change anything on this menu other than for generating a user defined ‘Custom

Super Long Paper’ size or Custom Size. The default settings have been optimized for continuous printing.

Fit to Page

For sheet printing functions, this toggle will resize the image to fit the source paper size.

Cover Printing

For sheet printing, this allows the user to select another source for the first page of the print job. With only one

sheet tray in the printer, this is likely an unused function.

Paper Feed Options

“Auto Tray Change” toggle is likely not used due to only one paper tray available, would allow the printer to

automatically select a second source for same size paper. “Media Check” toggle will let the printer sense the

paper before printing, checking for thickness and adjusting the print properties automatically.

Multi Purpose Tray Settings

Toggle to make the Manual Paper Tray slot to be manual feed with human interaction required. Not for use with

Continuous Media printing, or when an automated feeder is attached.

Custom Size or Custom Super Long Paper Sizes

These two types are virtually the same, with Custom Super Long Paper having the additional functions to activate

or modify the start, cut positions, etc. Custom page sizes can only be printed via the multi purpose tray. The paper

(media) size for the multi purpose tray must be manually set in the driver to the custom paper size before use.

Custom page sizes range:

• Width: 3½ to 8½ inches [89 to 216 mm], • Length: 5 to 14 inches [127 to 356 mm]

NOTE:

Up to 32 custom page sizes can be defined in the driver.

1.) Open the file in your application. Select FILE Æ PRINT.

_________________________________________________________________________________________________________________________

PAGE 59 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 60

2.) In the Print dialog box, on the GENERAL tab, click the appropriate driver. Click the SETUP tab.

3.) Under MEDIA, in the SIZE drop-down list, select USER DEFINED SIZE. The Set Free Size dialog box

appears.

4.) Select the unit. Enter the width and length measurements. Custom page sizes can be defined provided they

fall within the following ranges:

• Width: 3.0 to 8.5 inches [76.2 to 215.9 mm]

• Length: 0.5 to 51.181 inches [12.7 to 1300.0 mm]

1. Click OK.

2. Make sure that USER DEFINED

now appears in the SIZE list on the SETUP tab.

Default

This button will reset the driver ‘Paper Feed’ preferences to the original or default values.

_________________________________________________________________________________________________________________________

PAGE 60 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 61

B. Finishing Mode Section

If ‘Super Long Paper’ is selected this field is deactivated. If a standard sheet type media is selected for output

the following applies and is available. Use the dropdown style and make a selection or press the ‘Options’ button

to call up the Standard / N –up dialogue box.

Standard / N-up

This allows you to print multiple pages on one sheet, with each page image reduced in size.

Pages per Sheet:

This function reduces the image size of each page so that the desired number of pages will fit on a single

page. With each selection, the preview area will change. Please confirm the page layout in the preview

area.

1: Prints one page on one sheet of paper (default)

2: Prints 2 pages on one sheet of paper

4: Prints 4 pages on one sheet of paper

6: Prints 6 pages on one sheet of paper

8: Prints 8 pages on one sheet of paper

9: Prints 9 pages on one sheet of paper

16: Prints 16 pages on one sheet of paper

_________________________________________________________________________________________________________________________

PAGE 61 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 62

NOTE:

Data is not laid out centered on the page. The reduced image for the first page will be pasted to the

upper left corner of the actual page. Fit to Page and Scale factor options, if used, will affect the position

of the pages on the printed sheet. Fit to Page is applied first, then N-up, and finally Scale. Use the

Preview area to check the effects of your changes.

Border

For N-up selections other than 1, you may select a page border to surround each individual page image that will

be printed on the single sheet of paper.

Page layout

You can set the page order, if multiple images per page are selected.

Bind Margin

Reduces the size of the image to be printed and ads a margin for binding the document.

Poster Print

When Poster Print is selected one-page print data is enlarged into multiple pages.

Enlarge

2: One page is enlarged into 2 pages.

4: One page is enlarged into 4 pages.

9: One page is enlarged into 9 pages.

Custom: A user can select a number of pages. 1x1 ~ 4x4.

Custom

When Custom is selected the Settings button is enabled. Clicking the Settings button will open the Custom

setting dialog window.

Add Registration Marks

_________________________________________________________________________________________________________________________

PAGE 62 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 63

When checked, crop marks are added.

Specify the color of crop marks, if click Color button.

Add Overlap

When checked, overlap is added.

Sets the amount of pile part.(0.01~0.79 inch , 0.1~20.0 mm)

C. 2-Sided (Duplex) Printing Section

This will always be disabled unless a duplexer is installed. This option can never be used with continuous printing

job. If outfitted with a Duplexing unit, three options are available: None, Long Edge and Short Edge.

None

The printer does not print on both sides of the paper.

Long Edge

Pages are bound on the long-edge (length). For portrait orientation, the backside of the page is printed in the

same direction as the front side. This will give a printed result that is easy-to-read when the document is bound

on the left side or the right side. For landscape orientation, the backside of the page is printed in the opposite

direction to the front side. This will give an easy-to-read print result when the document is bound at the top or the

bottom.

Short Edge

Pages are bound on the short-edge (width). For portrait orientation, the backside of pages is printed in the

opposite direction to the front side. This will give an easy-to-read print result when the document is bound at the

_________________________________________________________________________________________________________________________

PAGE 63 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 64

top or the bottom. For landscape orientation, the backside of pages is printed in the same direction as the front

side. This will give an easy-to-read print result when the document is bound on the left side or the right side.

NOTE:

This function is not available unless a Duplex Option Unit is installed. Once the Duplex Option Unit is

installed in your printer, open the Paper tab in Printer Properties and press the Device Options button.

Place a check by the Duplex Option Unit to activate it.

D. Driver Settings

This function will SAVE the user defined settings in the driver to a user-controlled filename.

Set Names: Sets the settings selected on the list under the saved set name.

Add: Displays the dialog to enter the set name and saves the driver settings under the set name.

Remove: Removes the selected Set Names from the list.

Whether or not to include saving of the settings in Paper Group can be selected on the dialog to

enter Set Names.

_________________________________________________________________________________________________________________________

PAGE 64 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 65

III. THE JOB OPTIONS TAB

There are 4 subsections and 5 subsection buttons under

the Job Options tab:

A. Quality

B. Orientation

C. Job Type

D. Scale

E. Watermark

F. Overlay

G. Font

H. Advanced

I. Default

A. Quality

Used to select the desired resolution. The ‘Toner Saving’ check box is used for limiting the amount of toner used during

printing, this will affect the quality of the output and is equivalent to a ‘Draft’ copy.

B. Orientation

Standard printing options are Portrait or Landscape printing. The 180º option is for rotating each page 180 degrees. This

does not flip the entire job, but each individual page. When ‘Super Long Page’ is the paper size, this option is restrictive.

C. Job Type

Select the desired job type. Default values of ‘Normal’ with no ‘PIN’ are recommended for regular use.

_________________________________________________________________________________________________________________________

PAGE 65 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Normal

Page 66

Specify this for normal printing.

Proof and Print

When printing multiple copies of a document, Proof and Print allows you to verify (Proof) the first copy

before printing the remaining copies. The first copy is printed normally. The remaining copies can be

printed (or deleted) upon entering your PIN and selecting the document at the printer's control panel, via

the ‘Print Jobs Menu’. At the Printers Control Panel, Press the MENU button on the control panel. The

PRINT JOBS menu is displayed. Press the SELECT button. A password is requested for access to print

jobs (enter value of 1111). Then press the VALUE+ button until the job that you want to print is displayed

in the PRINT JOBS menu. Press the SELECT button and you will be prompted to provide the PIN ID that

you gave the print job. Enter the PIN and press SELECT, the proof document will begin printing.

Secure Print

The Secure Print selection provides a mechanism for controlling when a confidential or important

document will be printed. Printing will not begin until you enter the security Printer Identification Number

(PIN) that you defined as a part of the print job at the control panel of the printer. Press the MENU button

on the control panel. The PRINT JOBS menu is displayed. Press the SELECT button. A password is

requested for access to print jobs (enter value of 1111). Then press the VALUE+ button until the job that

you want to print is displayed in the PRINT JOBS menu. Press the SELECT button and you will be

prompted to provide the PIN ID that you gave the print job. Enter the PIN and press SELECT, the secure

document will begin printing.

NOTE:

The first entry in the list is "ALL JOBS”, so ensure that you have selected the correct job.

_________________________________________________________________________________________________________________________

PAGE 66 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 67

Store to HDD

This command sends and stores the print job on printer hard disk. Job is then printed via the printer control

panel by accessing the ‘Print Jobs Menu’. At the Printers Control Panel, Press the MENU button on the

control panel. The PRINT JOBS menu is displayed. Press the SELECT button. A password is requested for

access to print jobs (enter value of 1111). Then press the VALUE+ button until the job that you want to print is

displayed in the PRINT JOBS menu. Press the SELECT button and you will be prompted to provide the PIN

ID that you gave the print job. Enter the PIN and press SELECT, the stored document will begin printing.

• For the Proof and Print, Secure Print and Store to HDD functions, an internal printer hard disk must be

installed.

• When you install a printer hard disk, check Printer Hard Disk in Device Option tab. In addition, a PIN is

required.

• If the hard disk memory is insufficient for the spooled data, DISK FULL is displayed and expectant output

maybe compromised.

• If the software application being used has a collate print option, it must be turned OFF for proof and print

to operate correctly. Proof and print may not be available in some software applications.

• Jobs can be deleted off of the printers disk drive by the following procedure:

Press the MENU button to access the PRINT JOBS MENU a press the SELECT button.

1. Enter PASSWORD number using the buttons on the printer control panel. (Password is 1111).

2. Press the VALUE button until ALL JOBS or the required job name is displayed.

3. Press the CANCEL button to delete the job.

4. When the deletion confirmation message appears, confirm by pressing the SELECT button.

Copies

Enter the number of copies you wish to have printed.

Collate

Prints the document with the pages in ascending numerical order for multiple-copy printing.

D. Scale

_________________________________________________________________________________________________________________________

PAGE 67 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 68

This allows you to set a rate to enlarge or reduce your printed image. The image size may be adjusted over a range of

25%-400%.

When "Disabled" item is checked, it notifies that the driver does not have a scaling function capability. If ‘Super Long

Paper’ is the media size selection, this option is unavailable. Some software applications may not be able to utilize this

function.

E. Watermarks

In the Watermark dialog, you set watermark print related items. A watermark is a graphic or text that is layered over an

existing image. If you use the Watermark function, you can print the characters on top of the data you have created in an

application program. Select a watermark from the list. The selected watermark can be edited. When (None) is selected,

no watermark will be printed. Watermarks can be added, edited and removed from the list. If you wish for the watermark

to appear ONLY on the first page, activate the First Page Only box.

Create a New watermark by pressing the ‘New’ button. Entering the text string that you wish, modify the Font or Color by

activating the buttons and working through the sub-layer dialogue boxes. Modify the Position and the Angle of orientation.

The Trim function allows for different border around the text. Press OK to complete the Create New dialogue.

_________________________________________________________________________________________________________________________

PAGE 68 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 69

Edit a watermark follows a similar dialogue as New Watermark. (see diagrams to follow).

Remove

a watermark from the list. Select watermark on list and then press ‘Remove’.

Default will return this Tab and the modified values back to the original set values.

_________________________________________________________________________________________________________________________

PAGE 69 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 70

F. Overlay

The Overlay tab allows you to apply additional information to your printed documents.

An Overlay is a single page document, or pieces of a document that have been stored on the printer's hard disk or flash

memory. Examples of overlays include company logos, purchase order forms, or commonly used items within your

documents. The result is similar to the Watermark feature, but with the ability to be much more elaborate.

As an example, Overlays can be used to create a corporate letterhead that is applied to your business letters. The logo

and address that make up the letterhead reside in the printer. This insures that the letterhead appears consistent when

applied by multiple uses, and reduces the amount of data being sent to the printer.

_________________________________________________________________________________________________________________________

PAGE 70 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 71

Basic Steps for Using Overlays:

1. Create the overlay. Many Windows applications can be used to design forms and overlays. After proofing

your overlay, use the 'print to file' feature to create a PRN file representing the overlay.

2. Store the Overlay in the printer's hard disk drive (HDD) or flash memory. The Storage Device Manager utility

can be used to download the PRN file to the printer's hard disk or flash memory. Record the ID values

assigned to each overlay stored in the printer. Notify your sales representative to get your free copy of

Storage Device Manger utility.

3. Select the Overlay tab in Printer Properties, then press the Define Overlays button to add information about

the overlays stored in your printer. You can indicate specific pages for applying the overlay and combine

multiple overlay ID values into a single user-defined Overlay name.

4. Add one or more of the Defined Overlays to the list of Active Overlays by selecting the Overlay Names, then

pressing the Add button. Enable Print Using Active Overlays to apply the overlay(s) to the next printed

document. While this is enabled, all future print jobs will use this overlay until the Print Using Active Overlays

function is disabled. This setting can also be enabled from an application for a particular document. After the

document prints, the Print Using Active Overlays option automatically reverts to a disabled state when the

application is closed.

5. To modify an existing Overlay, follow the steps shown below:

a. Select an item to be changed from the Defined Overlays list.

b. Enter an Overlay name to be added to Overlay Name.

c. Enter up to 3 Overlay ID numbers, separated by commas in the ID value(s) edit box.

d. Select the pages that are to be printed using the Overlay from the Print on Pages list.

e. If you selected Custom in Step (4), enter the page numbers or range of pages to be printed,

separated by commas in the Custom Pages edit box.

_________________________________________________________________________________________________________________________

PAGE 71 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 72

f. Press the Apply button to save the changes to an existing Defined Overlay, or press the Add button

if you have created a new Defined Overlay.

g. Press the Close button when you are finished creating or editing Defined Overlays.

6. If you have made changes to the Active Overlays dialog, press either the Apply button or OK button to

preserve these changes. Press the Cancel button to close the dialog without saving your changes.

When you check ‘Print using active overlays’, the active overlay feature is turned on.

Active Overlays

Displays the list of one or more overlays that may be applied to a document. The initial settings will display an

empty ‘Active Overlays’ window.

To add to the list of Active Overlays, select one or more of the Defined Overlays and press the Add button. You

may add up to 4 Overlays to the list at one time. Use the Remove button to delete an overlay from the list of

Active Overlays.

_________________________________________________________________________________________________________________________

PAGE 72 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 73

Defined Overlays

Displays the list of user-defined overlays. Defined Overlays can be made Active Overlays by selecting the

desired item(s) and pressing the Add button. Up to 4 Defined Overlays can be added to the Active Overlay list at

one time. Initially this list will be blank.

Edit this list by pressing the Define Overlay button, then provide information about the overlay stored in your

printer. When the information is complete, press the Add button. This adds the current overlay information to the

Defined Overlay list.

The Defined Overlay list may contain up to 32 overlays.

_________________________________________________________________________________________________________________________

PAGE 73 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 74

ID Value

Enter the ID of the overlay stored in your printer. This ID represents the PCL macro ID value assigned when

using Storage Device Manager. The range of valid ID numbers is from 0 to 32767.

Up to 3 ID values can be specified to create a single overlay from three different PCL macros. Separate the ID

numbers with commas. (Example: 32, 7, 125). Macros will be executed in the order that they are entered.

Specifies the pages that will be printed using the overlay. Select from the list of pre-defined pages shown below,

or select Custom to define specific pages.

Print On Pages

All pages

First page

Even pages

Odd pages

Custom: Overlay is printed on the pages entered in Custom Pages.

Custom Pages

Allows you to define a range of pages or specific pages to be printed with the overlay when Custom is selected

from the Print on pages list.

Enter a range of pages and/or specific page numbers, separated by commas. (Example: 1,3,6, 4-8).

You can specify pages in the range from 1 to 999.

Follow these instructions to transfer your .prn overlay to the Elite printers hard drive.

_________________________________________________________________________________________________________________________

PAGE 74 --- iTerra Elite Quick Start Guide © 2008 iSys-The Imaging Systems Group Inc.

Page 75

NOTE:

Connectivity Type

1) Parallel Connect Instructions

• Open a DOS command Prompt window and CD (change directory) to the appropriate host directory

• Type the following to send overlay .prn to printer ‘copy/b filename lpt1:’ and hit return or enter.

2) Network Connect Instructions

• Open a DOS Command Prompt window and CD (change directory) to the appropriate host directory

• Use lpr command to send overlay .prn file to the printer, as follows from command prompt window.

3) USB Connect Instructions

• to print via USB connection, you will need to install ‘Free Raw Print’ utility. This is a freeware utility

• Use Free Raw Print application to print overlay .prn file. Ensure that printer highlighted is the iTerra

• The printer windows driver should be installed first and configured.

• The printer should be powered on and connection type configured.

• Use this method if you do not have the Storage Manager Utility.

where the overlay file is loaded.