Isuzu RODEO General Description Manual

RODEO

Brake Control System 5A–1. . . . . . . . . . . . . . . . . . . .

Anti–lock Brake System 5B–1. . . . . . . . . . . . . . . . . .

Power–assisted Brake System 5C–1. . . . . . . . . . . .

Parking Brakes (4x4 Model) 5D1–1. . . . . . . . . . . . . .

Parking Brakes (4x2 Model) 5D2–1. . . . . . . . . . . . . .

Brake Control System

BRAKES

CONTENTS

CONTENTS

BRAKE CONTROL SYSTEM

5A–1

Service Precaution 5A–2. . . . . . . . . . . . . . . . . . . . . .

General Description 5A–3. . . . . . . . . . . . . . . . . . . . .

Functional Description 5A–4. . . . . . . . . . . . . . . . .

System Components 5A–10. . . . . . . . . . . . . . . . . . .

Electronic Hydraulic Control Unit (EHCU) 5A–10.

ABS Warning Light 5A–10. . . . . . . . . . . . . . . . . . . .

Wheel Speed Sensor 5A–10. . . . . . . . . . . . . . . . . .

G-Sensor 5A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal and Anti-lock Braking 5A–10. . . . . . . . . . .

Brake Pedal Travel 5A–10. . . . . . . . . . . . . . . . . . . .

Acronyms and Abbreviations 5A–10. . . . . . . . . . . .

General Diagnosis 5A–11. . . . . . . . . . . . . . . . . . . . . . .

General Information 5A–11. . . . . . . . . . . . . . . . . . . .

ABS Service Precautions 5A–11. . . . . . . . . . . . . . .

Computer System Service Precautions 5A–11. . .

General Service Precautions 5A–11. . . . . . . . . . . .

Note on Intermittents 5A–11. . . . . . . . . . . . . . . . . . .

Test Driving ABS Complaint Vehicles 5A–12. . . . .

“ABS” Warning Light 5A–12. . . . . . . . . . . . . . . . . . .

Normal Operation 5A–12. . . . . . . . . . . . . . . . . . . . .

Tech 2 Scan Tool 5A–13. . . . . . . . . . . . . . . . . . . . . .

DATA LIST 5A–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

ACTUATOR TEST 5A–17. . . . . . . . . . . . . . . . . . . . .

Tech 2 Service Bleed 5A–21. . . . . . . . . . . . . . . . . .

Basic Diagnostic Flow Chart 5A–22. . . . . . . . . . . .

Basic Inspection Procedure 5A–23. . . . . . . . . . . . .

EHCU Connector Pin-out Checks 5A–24. . . . . . . . .

Circuit Diagram 5A–25. . . . . . . . . . . . . . . . . . . . . . .

Connector List 5A–28. . . . . . . . . . . . . . . . . . . . . . . .

Part Location 5A–29. . . . . . . . . . . . . . . . . . . . . . . . .

Symptom Diagnosis 5A–30. . . . . . . . . . . . . . . . . . . . .

Chart A-1 ABS Works Frequently But

Vehicle Does Not Decelerate 5A–30. . . . . . . . . . .

Chart T A-1 ABS Works Frequently But

Vehicle Does Not Decelerate

(Use TECH 2) 5A–31. . . . . . . . . . . . . . . . . . . . . . . .

Chart A-2 Uneven Braking Occurs While

ABS Works 5A–31. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart T A-2 Uneven Braking Occurs While

ABS Works (Use TECH 2) 5A–31. . . . . . . . . . . . .

Chart A-3, TA-3 The Wheels Are Locked 5A–32.

Chart A-4 Brake Pedal Feed Is Abnormal 5A–33.

Chart A-5, TA-5 Braking Sound

(From EHCU) Is Heard While Not Braking 5A–34

Diagnostic Trouble Codes 5A–35. . . . . . . . . . . . . . . .

Diagnosis By “ABS” Warning Light

Illumination Pattern 5A–37. . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Codes (DTCs) 5A–38. . . . . . .

Chart B-1 With the key in the ON position

(Before starting the engine). Warning

light (W/L) is not activated. 5A–40. . . . . . . . . . . . .

Chart B-2 CPU Error (DTC 14 (Flash out) /

C0271, C0272, C0273, C0284 (Serial

communications)) 5A–41. . . . . . . . . . . . . . . . . . . . .

Chart B-3 Low or High Ignition Voltage

(DTC 15 (Flash out) / C0277, 0278

(Serial communications)) 5A–41. . . . . . . . . . . . . . .

Chart B-4 Excessive Dump Time

(DTC 17 (Flash out) / C0269

(Serial communications)) 5A–41. . . . . . . . . . . . . . .

Chart B-5 Excessive Isolation Time

(DTC 18 (Flash out) / C0274

(Serial communications)) 5A–42. . . . . . . . . . . . . . .

Chart B-6 G-Sensor Output Failure

(DTC 21 (Flash out) / C0276

(Serial communications)) 5A–42. . . . . . . . . . . . . . .

Chart B-7 Brake Switch Failure

(DTC 22 (Flash out) / C0281

(Serial communications)) 5A–42. . . . . . . . . . . . . . .

Chart B-8 2WD Controller in 4WD Vehicle

Controller (DTC 13 (Flash out) / C0285

(Serial communications)), 4WD State Input

Signal Failure (DTC 24 (Flash out) / C0282

(Serial communications)) 5A–43. . . . . . . . . . . . . . .

Chart B-9 Pump Motor Failure (DTC 32

(Flash out) / C0267, C0268

(Serial communications)) 5A–43. . . . . . . . . . . . . . .

Chart B-10 EHCU Valve Relay Failure

(DTC 35 (Flash out) / C0265, C0266

(Serial communications)) 5A–44. . . . . . . . . . . . . . .

Chart B-11 FL Isolation Solenoid Coil Failure

(DTC 41 (Flash out) / C0245, C0247

(Serial communications)) 5A–44. . . . . . . . . . . . . . .

Chart B-12 FL Dump Solenoid Coil Failure

(DTC 42 (Flash out) / C0246, C0248

(Serial communications)) 5A–44. . . . . . . . . . . . . . .

5A–2

BRAKE CONTROL SYSTEM

Chart B-13 FR Isolation Solenoid Coil Failure

(DTC 43 (Flash out) / C0241, C0243

(Serial communications)) 5A–45. . . . . . . . . . . . . . .

Chart B-14 FR Dump Solenoid Coil Failure

(DTC 44(Flash out) / C0242, C0244

(Serial communications)) 5A–45. . . . . . . . . . . . . . .

Chart B-15 Rear Isolation Solenoid Coil

Failure (DTC 45 (Flash out) / C0251,

C0253 (Serial communications)) 5A–45. . . . . . . .

Chart B-16 Rear Dump Solenoid Coil

Failure (DTC 46 (Flash out) / C0252,

C0254 (Serial communications)) 5A–46. . . . . . . .

Chart B-17 FL Speed Sensor Open or

Shorted (DTC 51 (Flash out) / C0225

(Serial communications)) 5A–46. . . . . . . . . . . . . . .

Chart B-18 FR Speed Sensor Open or

Shorted (DTC 52 (Flash out) / C0221

(Serial communications)) 5A–47. . . . . . . . . . . . . . .

Chart B-19 Rear Speed Sensor Open or

Shorted (DTC 53 (Flash out) / C0235

(Serial communications)) 5A–48. . . . . . . . . . . . . . .

Chart B-20 FL Speed Sensor Missing

(DTC 61 (Flash out) / C0226, C0227

(Serial communications)) 5A–49. . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

Chart B-21 FR Speed Sensor Missing

(DTC 62 (Flash out) / C0222, C0223

(Serial communications)) 5A–50. . . . . . . . . . . . . . .

Chart B-22 Rear Speed Sensor Missing

(DTC 63 (Flash out) / C0236, C0237

(Serial communications)) 5A–51. . . . . . . . . . . . . . .

Chart B-23 Simultaneous Drop-out of

Front Speed Sensor Signal (DTC 64 (Flash

out) / C0229 (Serial communications)) 5A–52. . .

Chart B-24 Wheel Speed Input Abnormality

(DTC 65 (Flash out) / C0238 (Serial

communications)) 5A–53. . . . . . . . . . . . . . . . . . . . .

Unit Inspection Procedure 5A–54. . . . . . . . . . . . . . . .

Chart C-1-1 FL Sensor Output Inspection

Procedure 5A–54. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart C-1-2 FR Sensor Output Inspection

Procedure 5A–55. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart C-1-3 Rear Sensor Output Inspection

Procedure 5A–55. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart TC-1 Sensor Output Inspection

Procedure 5A–56. . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 5A–57. . . . . . . . . . . . . . . . . . . . . . . . . . .

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The Anti-lock Brake System (ABS) works on all four

wheels. A combination of wheel speed sensor and

Electronic Hydraulic Control Unit (EHCU) can determine

when a wheel is about to stop turning and adjust brake

pressure to maintain best braking.

BRAKE CONTROL SYSTEM

This system helps the driver maintain greater control of

the vehicle under heavy braking conditions.

NOTE: The Electronic Hydraulic Control Unit (EHCU)

comprises the Hydraulic Unit (H/U) and the coil Integrated

Module.

5A–3

Legend

(1) Electronic

(2) Hydraulic

(3) Hydraulic Unit (H/U)

C05RW004

(4) Coil Integrated Module

(5) Front Wheel Speed Sensor

(6) Rear Wheel Speed Sensor

(7) Proportioning and Bypass (P&B) Valve

5A–4

BRAKE CONTROL SYSTEM

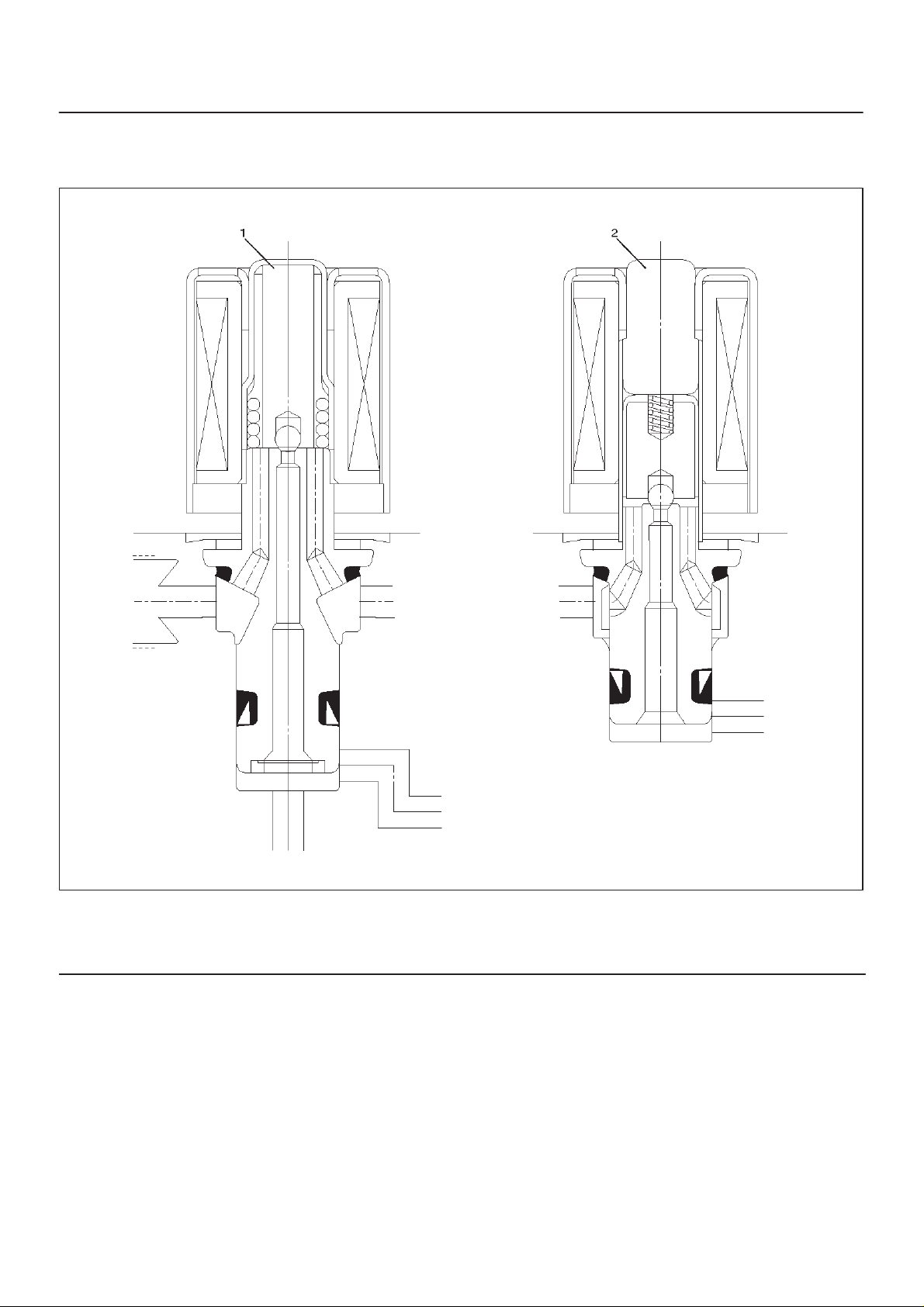

Functional Description

Hydraulic Unit (H/U)

Solenoid Valve

Legend

(1) Isolation Valve

(2) Dump valve

C05RW012

BRAKE CONTROL SYSTEM

5A–5

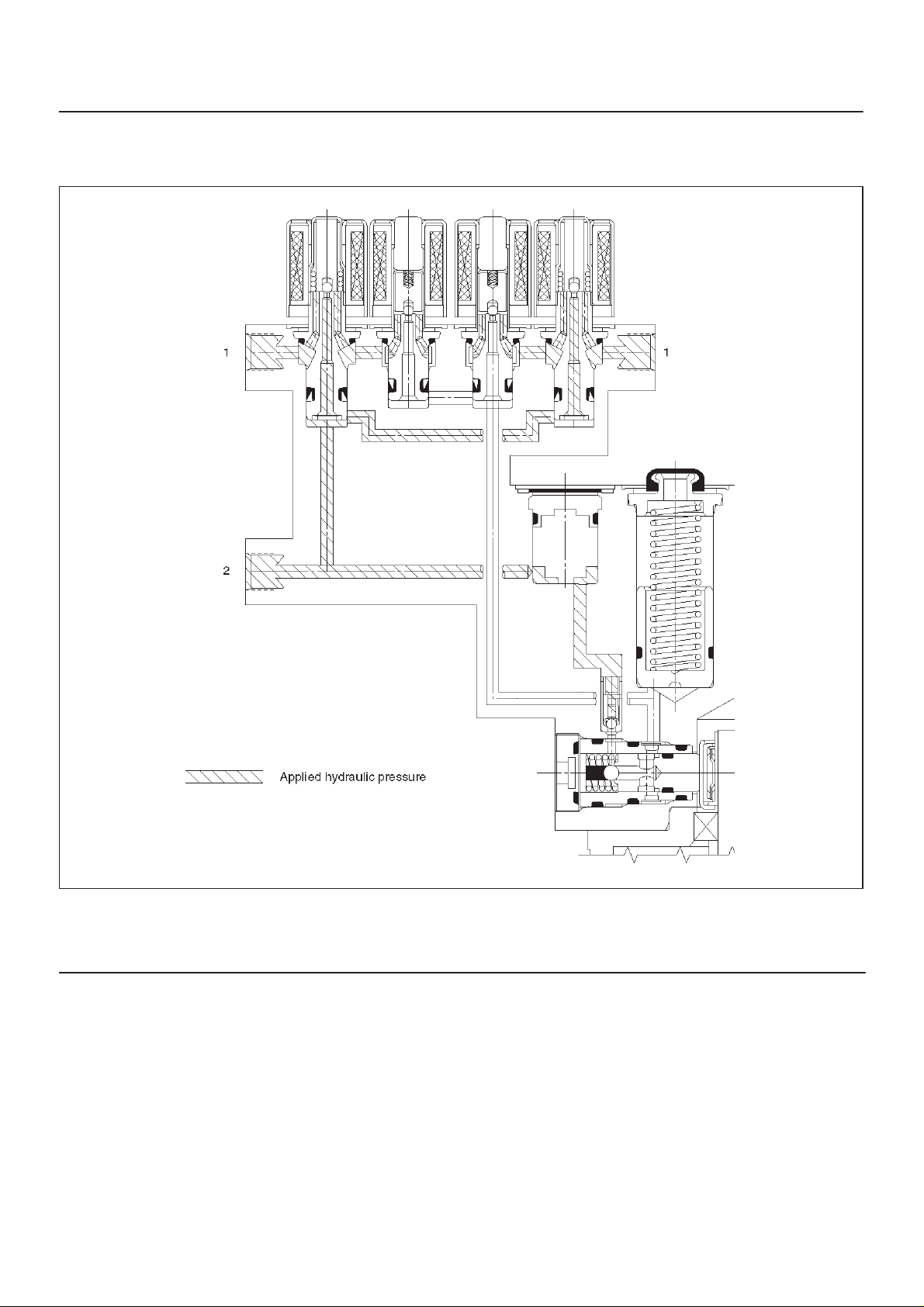

Normal Braking

During normal (non anti-lock) braking, the solenoid valves

are without current and closed due to spring force.

Brake fluid travels through the centre of the normally open

isolation valve around the normally closed dump valve

and on to the brake pistons.

Legend

(1) Brake

(2) Master Cylinder

C05RW010

5A–6

BRAKE CONTROL SYSTEM

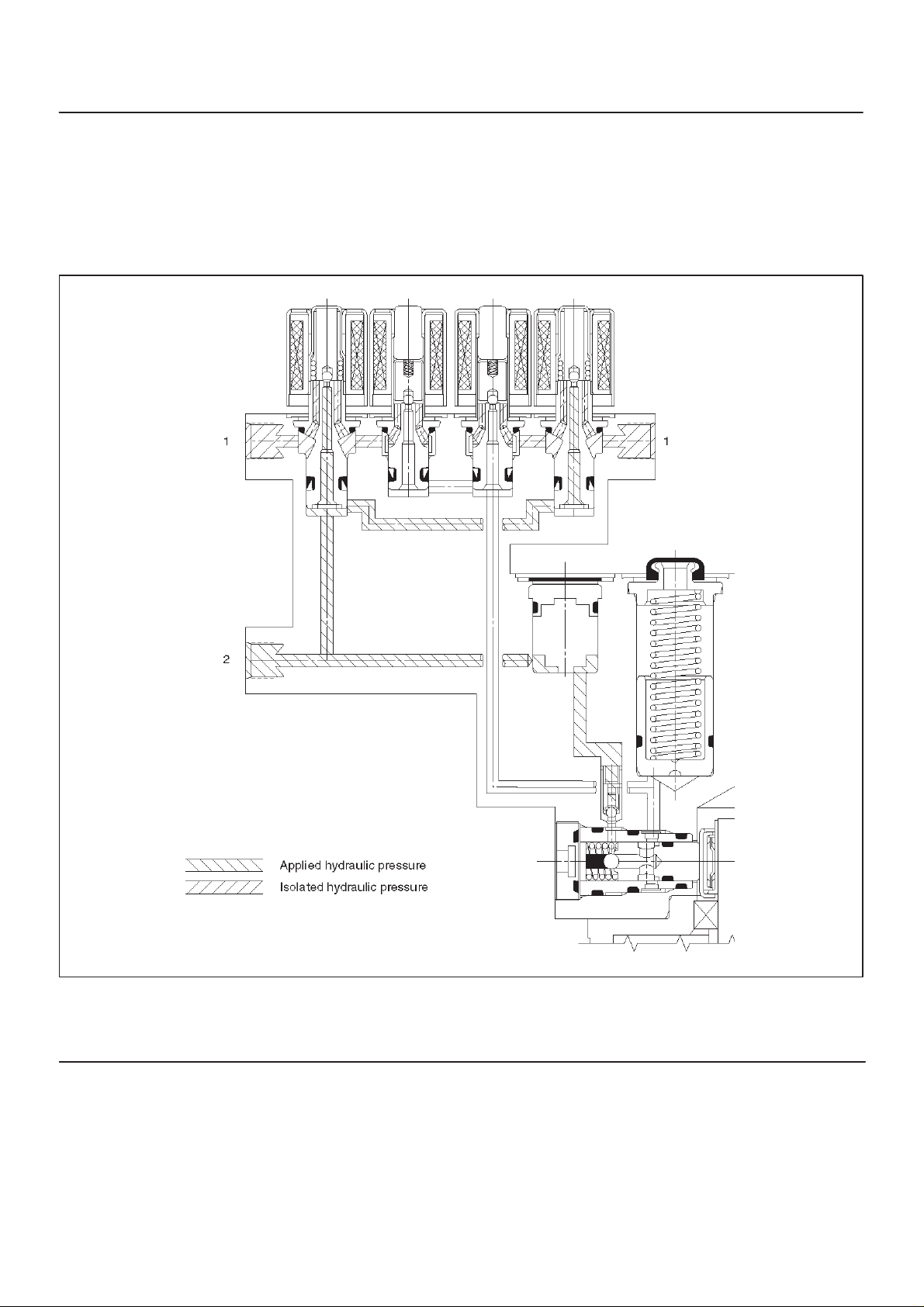

Pressure Isolation (Pressure Maintain)

The electro-hydraulic control unit is activated when the

brakes are applied which sends a signal to the coil

integrated module to prepare for a possible anti-lock stop.

If the information from the wheel speed sensors indicates

excessive wheel deceleration (imminent lockup), the first

step in the anti-lock sequence is to isolate the brake

pressure being applied by the brake pedal.

The microprocessor in the coil integrated module sends a

voltage to the coil to energize and close the isolation

valve. This prevents any additional fluid pressure applied

by the brake pedal from reaching the wheel. With the

isolation valves closed, further unnecessary increase in

the brake pressure is therefore prevented.

Legend

(1) Brake

(2) Master Cylinder

C05RW011

BRAKE CONTROL SYSTEM

5A–7

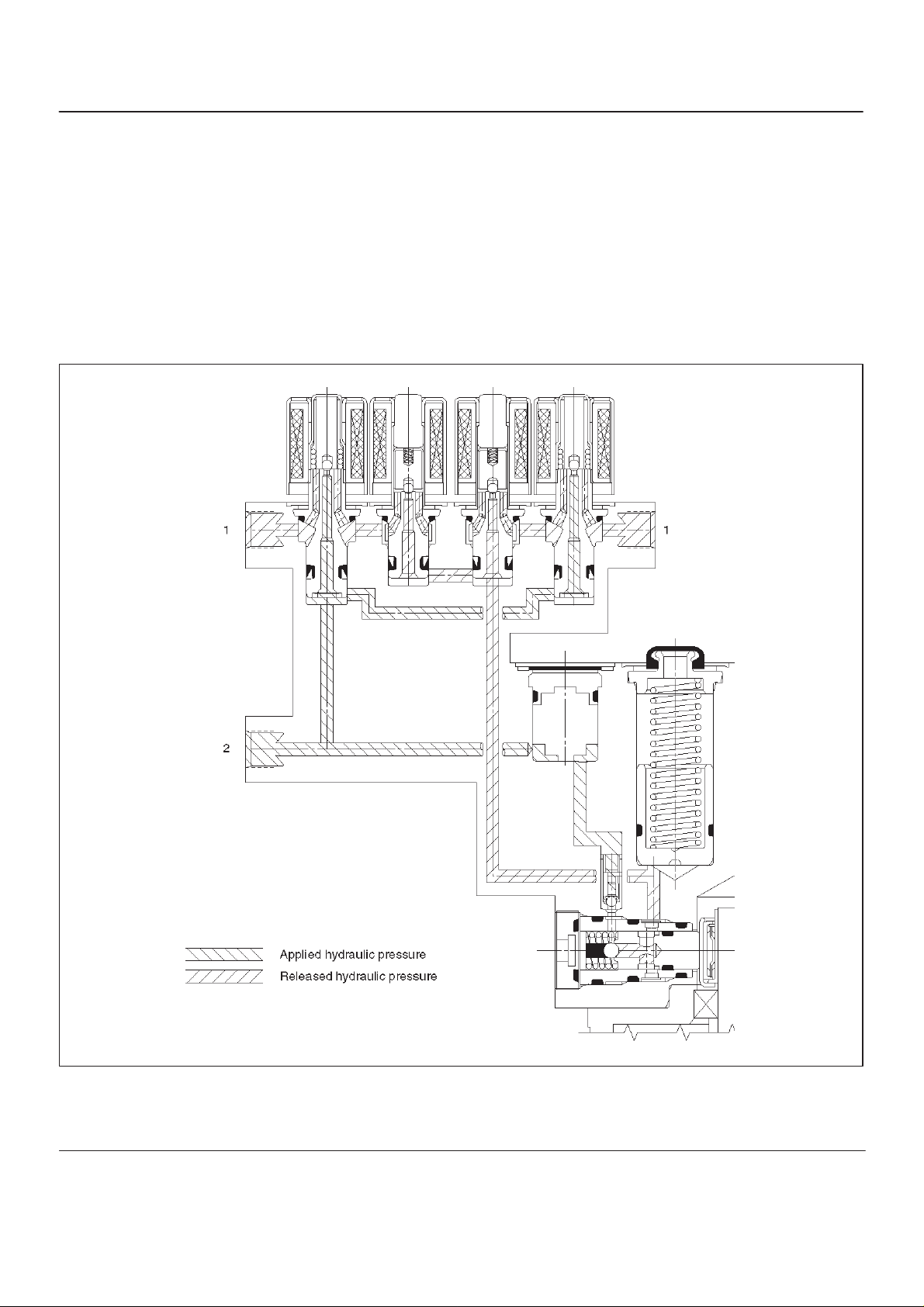

Pressure Reduction

Once the brake pressure is isolated, it must be reduced to

allow the wheels to unlock. This is accomplished by

dumping a portion of the brake fluid pressure into a low

pressure accumulator.

The microprocessor activates the normally closed dump

valve to open, allowing fluid from the wheels to be

dumped into the accumulator. This is done with very short

activation pulses opening and closing the dump valve

passageway . Brake pressure is reduced at the wheel and

allows the wheel to begin rotating again. The fluid from the

brake piston is stored in the accumulator against spring

pressure and a portion of this fluid also primes the pump.

The dump valves are operated independently to control

the deceleration of the wheel. At this point, the brake

pedal is isolated from the base brake system, the

hydraulic control unit pumps are primed and the

attenuators are ready to pump fluid.

Legend

(1) Brake

(2) Master Cylinder

C05RW009

5A–8

BRAKE CONTROL SYSTEM

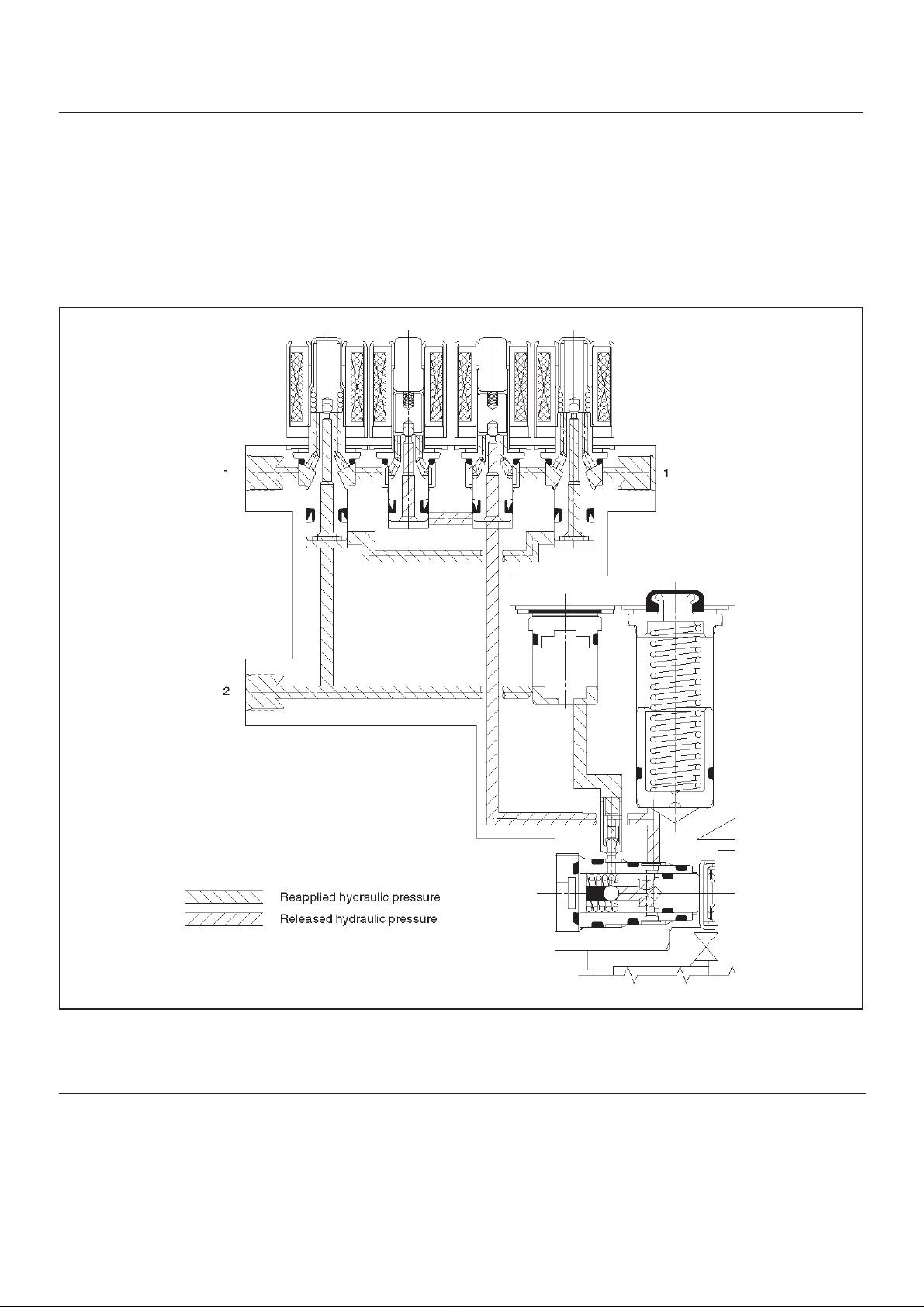

Pressure Increase (Re-apply)

The re-apply sequence is initiated to achieve optimum

braking. The isolation valve is momentarily opened to

allow master cylinder and pump pressure to reach the

brakes. This controlled pressure rise continues until the

wheel is at optimum brake output or until the brake

pressure is brought up to the master cylinder output

pressure.

If more pressure is required, more fluid is drawn from the

master cylinder and applied to the brakes. The driver may

feel slight pedal pulsations, or pedal drop, this is normal

and expected.

As fluid is re-applied to the brakes, the wheel speed will

reduce. If the wheels approach imminent lockup again,

the module will isolate, dump and re-apply again. This

cycle occurs in millisecond intervals, allowing several

cycles to occur each second. It is a much faster and more

controlled way of “pumping the pedal”.

Legend

(1) Brake

(2) Master Cylinder

C05RW014

BRAKE CONTROL SYSTEM

5A–9

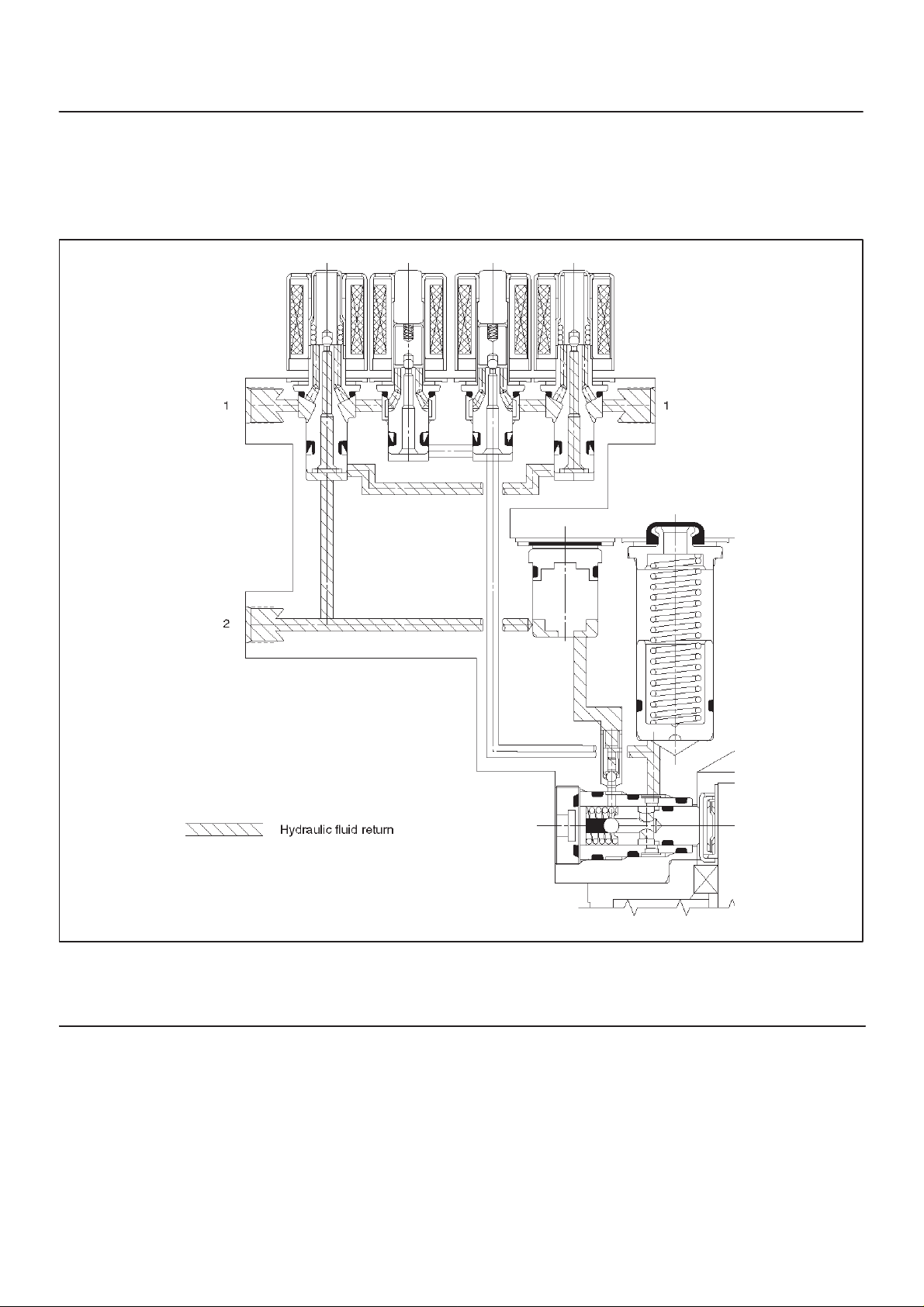

Brake Release

At the end of the anti-lock stop, when the brake pedal is

released, the pump will remain running for a short time to

help drain any fluid from the accumulators. As this fluid

returns into the system, the spring forces the piston back

to its original position.

The isolation valve opens and fluid may return to the

master cylinder. Conventional braking is then resumed.

Legend

(1) Brake

(2) Master Cylinder

C05RW013

5A–10

BRAKE CONTROL SYSTEM

System Components

Electronic Hydraulic Control Unit (EHCU), three Wheel

Speed Sensors, Warning Light, and G-sensor.

Electronic Hydraulic Control Unit (EHCU)

The EHCU consists of ABS control circuits, fault detector,

and a fail-safe. It drives the hydraulic unit according to the

signal from each sensor, cancelling ABS to return to

normal braking when a malfunction has occurred in the

ABS.

The EHCU has a self-diagnosing function which can

indicate faulty circuits during diagnosis.

The EHCU is mounted on the engine compartment rear

right side. It consists of a Motor, Plunger Pump, Solenoid

V alves.

Solenoid Valves: Reduces or holds the caliper fluid

pressure for each front disc brake or both rear disc brakes

according to the signal sent from the EHCU.

Reservoir: Temporarily holds the brake fluid that returns

from the front and rear disc brake caliper so that pressure

of front disc brake caliper can be reduced smoothly.

Plunger Pump: Feeds the brake fluid held in the reservoir

to the master cylinder.

Motor: Drives the pump according to the signal from

EHCU.

Check Valve: Controls the brake fluid flow.

ABS Warning Light

Wheel Speed Sensor

It consists of a sensor and a rotor. The sensor is attached

to the knuckle on the front wheels and to the rear axle

case on the rear differential.

The rotor is press-fit in the axle shaft.

The flux generated from electrodes magnetized by a

magnet in the sensor varies due to rotation of the rotor,

and the electromagnetic induction generates alternating

voltage in the coil. This voltage draws a “sine curve” with

the frequency proportional to rotor speed and it allows

detection of wheel speed.

G-Sensor

The G-sensor installed inside the EHCU detects the

vehicle deceleration speed and sends a signal to the

EHCU. In 4WD operation, all four wheels may be

decelerated in almost the same phase, since all wheels

are connected mechanically.

This tendency is noticeable particularly on roads with low

friction coefficient, and the ABS control is adversely

affected.

The G-sensor judges whether the friction coefficient of

road surface is low or high, and changes the EHCU’s

operating system to ensure ABS control.

Normal and Anti-lock Braking

Under normal driving conditions, the Anti-lock Brake

System functions the same as a standard power assisted

brake system. However, with the detection of wheel

lock-up, a slight bump or kick-back will be felt in the brake

pedal. This pedal “bump” will be followed by a series of

short pedal pulsations which occurs in rapid succession.

The brake pedal pulsation will continue until there is no

longer a need for the anti-lock function or until the vehicle

is stopped. A slight ticking or popping noise may be heard

during brake applications when the Anti-lock features is

being used.

When the Anti-lock feature is being used, the brake pedal

may rise even as the brakes are being applied. This is

also normal. Maintaining a constant force on the pedal

will provide the shortest stopping distance.

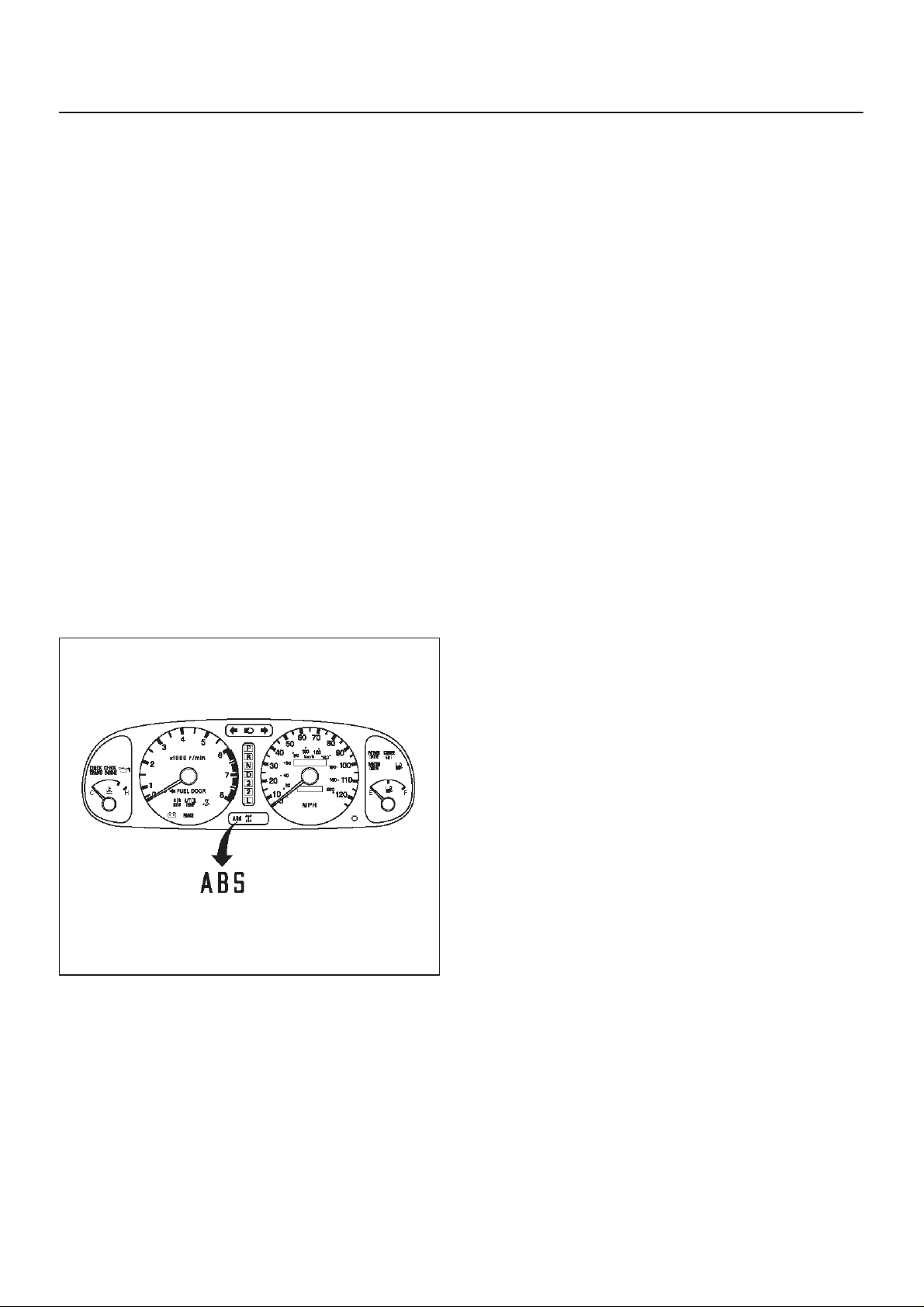

Vehicles equipped with the Anti-lock Brake System have

821RW093

an amber “ABS” warning light in the instrument panel.

The “ABS” warning light will illuminate if a malfunction in

the Anti-lock Brake System is detected by the Electronic

Hydraulic Control Unit (EHCU). In case of an electronic

malfunction, the EHCU will turn “ON” the “ABS” warning

light and disable the Anti-lock braking function.

The “ABS” light will turn “ON” for approximately three

seconds after the ignition switch is to the “ON” position.

If the “ABS” light stays “ON” after the ignition switch is the

“ON” position, or comes “ON” and stays “ON” while

driving, the Anti-lock Brake System should be inspected

for a malfunction according to the diagnosis procedure.

Brake Pedal Travel

Vehicles equipped with the Anti-lock Brake System may

be stopped by applying normal force to the brake pedal.

Although there is no need to push the pedal beyond the

point where it stops or holds the vehicle, by applying more

force the pedal will continue to travel toward the floor.

This extra brake pedal travel is normal.

Acronyms and Abbreviations

Several acronyms and abbreviations are commonly used

throughout this section:

ABS

Anti-lock Brake System

CIM

Coil Integrated Module

CKT

Circuit

BRAKE CONTROL SYSTEM

5A–11

DLC

Data Link Connector

EHCU

Electronic Hydraulic Control Unit

FL

Front Left

FR

Front Right

GEN

Generator

H/U

Hydraulic Unit

MV

Millivolts

RR

Rear

RPS

Revolution per Second

VDC

DC Volts

VAC

AC Volts

W/L

Warning Light

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS troubles can be classified into two types, those

which can be detected by the ABS warning light and those

which can be detected as a vehicle abnormality by the

driver.

In either case, locate the fault in accordance with the

“BASIC DIAGNOSTIC FLOWCHART” and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

Powertrain Control Module. These modules are designed

to withstand normal current draws associated with

vehicle operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for opens

or shorts, do not ground or apply voltage to any of the

circuits unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be

tested with a high impedance multimeter (J-39200) or

special tools as described in this section. Power should

never be removed or applied to any control module with

the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure to

observe these precautions may result in Anti-lock Brake

System damage.

D If welding work is to be performed on the vehicle using

an electric arc welder, the EHCU and valve block

connectors should be disconnected before the

welding operation begins.

D The EHCU and valve block connectors should never

be connected or disconnected with the ignition “ON” .

D If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS” warning light will

illuminate. But actually no trouble exists. After

inspection stop the engine once and re-start it, then

make sure that the “ABS” warning light does not

illuminate.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS)

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS to a

non-operative state by removing the fuse for the ABS

(60A). After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning light does not light.

ABS Service Precautions

Required Tools and Items:

D Box Wrench

D Brake Fluid

D Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

J-39200 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.

Computer System Service Precautions

The Anti-lock Brake System interfaces directly with the

Electronic Hydraulic Control Unit (EHCU) which is a

control computer that is similar in some regards to the

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may be

helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be useful

in isolating the failure. Most intermittent problems are

caused by faulty electrical connections or wiring. When

an intermittent failure is encountered, check suspect

circuits for:

D Suspected harness damage.

D Poor mating of connector halves or terminals not fully

seated in the connector body (backed out).

D Improperly formed or damaged terminals.

5A–12

BRAKE CONTROL SYSTEM

Test Driving ABS Complaint Vehicles

In case that there has been an abnormality in the lighting

pattern of “ABS” warning light, the fault can be located in

accordance with the “DIAGNOSIS BY “ABS” WARNING

LIGHT ILLUMINATION PATTERN” . In case of such

trouble as can be detected by the driver as a vehicle

symptom, however, it is necessary to give a test drive

following the test procedure mentioned below, thereby

reproducing the symptom for trouble diagnosis on a

symptom basis:

1.Start the engine and make sure that the “ABS” W/L

goes OFF. If the W/L remains ON, it means that the

Diagnostic Trouble Code (DTC) is stored. Therefore,

read the code and locate the fault.

NOTE: The DTC cannot be cleared if the vehicle speed

does not exceed 12 km/h (8 mph) at DTC, even though

the repair operation is completed.

2.Start the vehicle and accelerate to about 30 km/h (19

mph) or more.

3.Slowly brake and stop the vehicle completely.

4.Then restart the vehicle and accelerate to about 40

km/h (25 mph) or more.

5.Brake at a time so as to actuate the ABS and stop the

vehicle.

6.Be cautious of abnormality during the test. If the W/L

is actuated while driving, read the DTC and locate the

fault.

7.If the abnormality is not reproduced by the test, make

best efforts to reproduce the situation reported by the

customer.

8.If the abnormality has been detected, repair in

accordance with the “SYMPTOM DIAGNOSIS” .

NOTE:

D Be sure to give a test drive on a wide, even road with a

small traffic.

D If an abnormality is detected, be sure to suspend the

test and start trouble diagnosis at once.

Normal Operation

“ABS” Warning Light

When the ignition is first moved from “OFF” to “RUN” , the

amber “ABS” warning light will turn “ON” . The “ABS”

warning light will turn “ON” during engine starting and will

usually stay “ON” for approximately three seconds after

the ignition switch is returned to the “ON” position. The

warning light should remain “OFF” at all other times.

“ABS” Warning Light

When ABS trouble occurs to actuate “ABS” warning light,

the trouble code corresponding to the trouble is stored in

the EHCU. Only ordinary brake is available with ABS

being unactuated. Even when “ABS” warning light is

actuated, if the starter switch is set ON after setting it OFF

once, the EHCU checks up on the entire system and, if

there is no abnormality , judges ABS to work currently and

the warning light is lit normally even though the trouble

code is stored.

NOTE: Illumination of the “ABS” warning light indicates

that anti-lock braking is no longer available. Power

assisted braking without anti-lock control is still available.

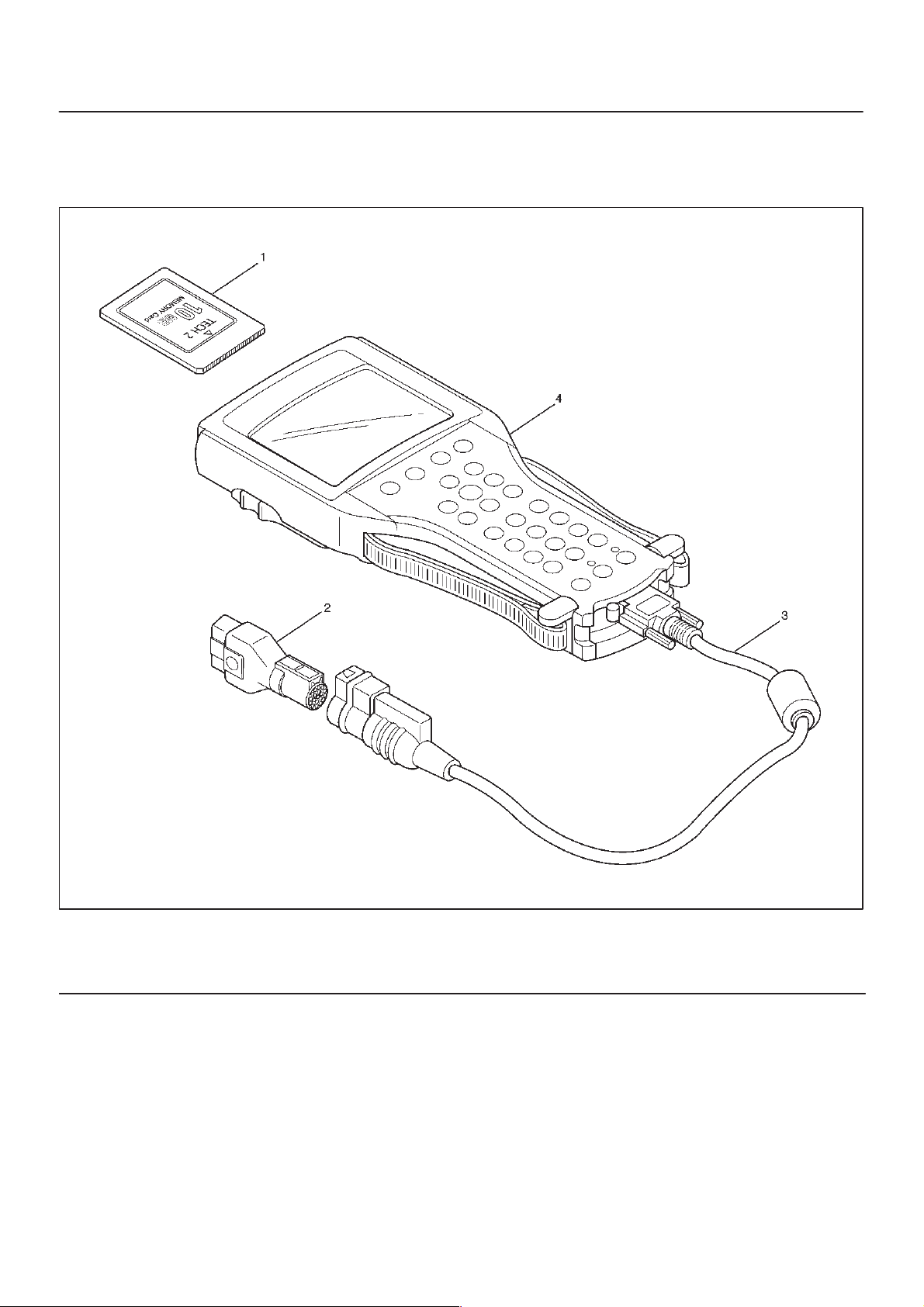

Tech 2 Scan Tool

From 98 MY, Isuzu dealer service departments are

recommended to use T ech 2. Please refer to Tech 2 scan

tool user guide.

BRAKE CONTROL SYSTEM

5A–13

Legend

(1) PCMCIA Card

(2) SAE 16/19 Adaptor

901RW257

(3) DLC Cable

(4) Tech–2

5A–14

BRAKE CONTROL SYSTEM

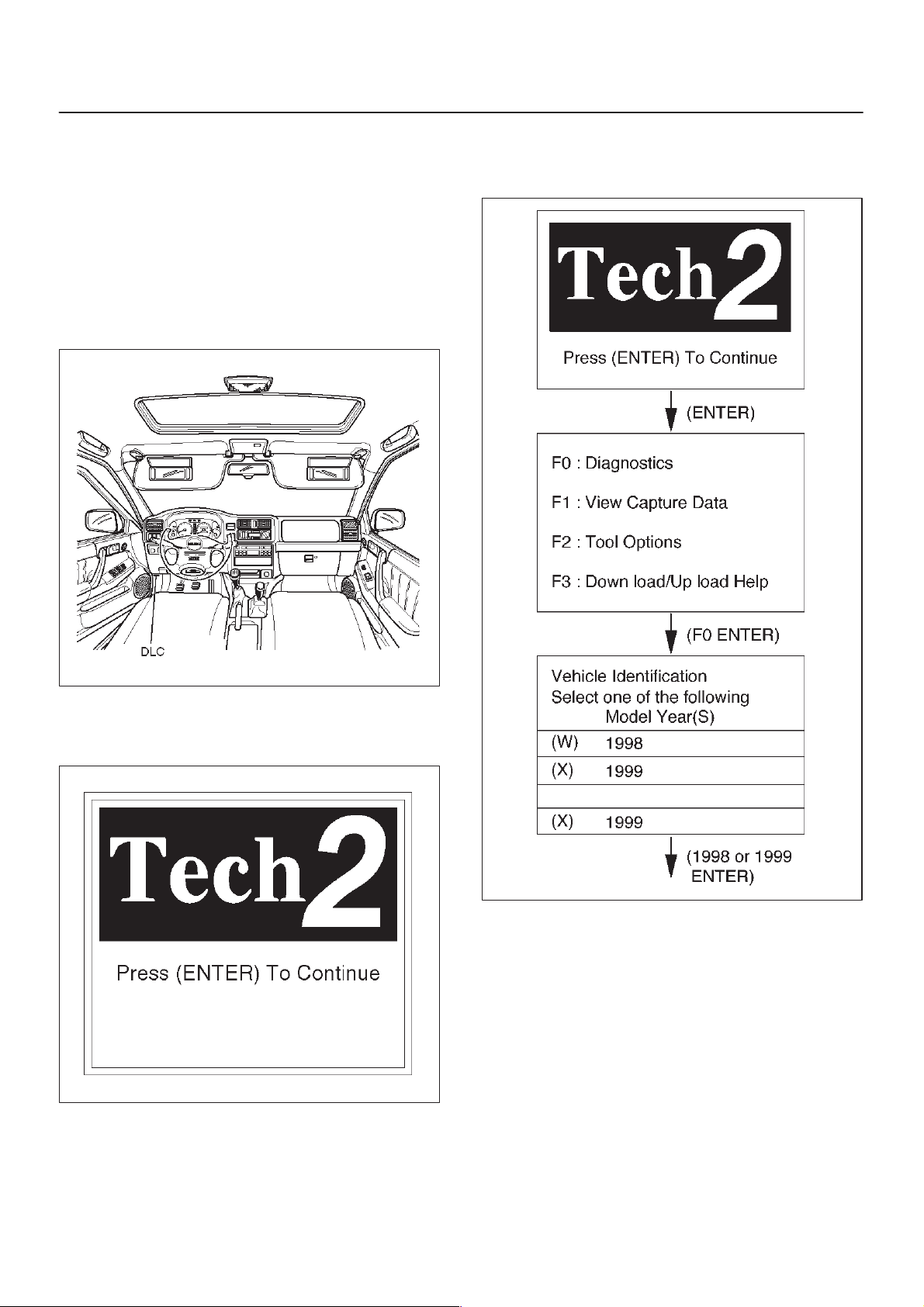

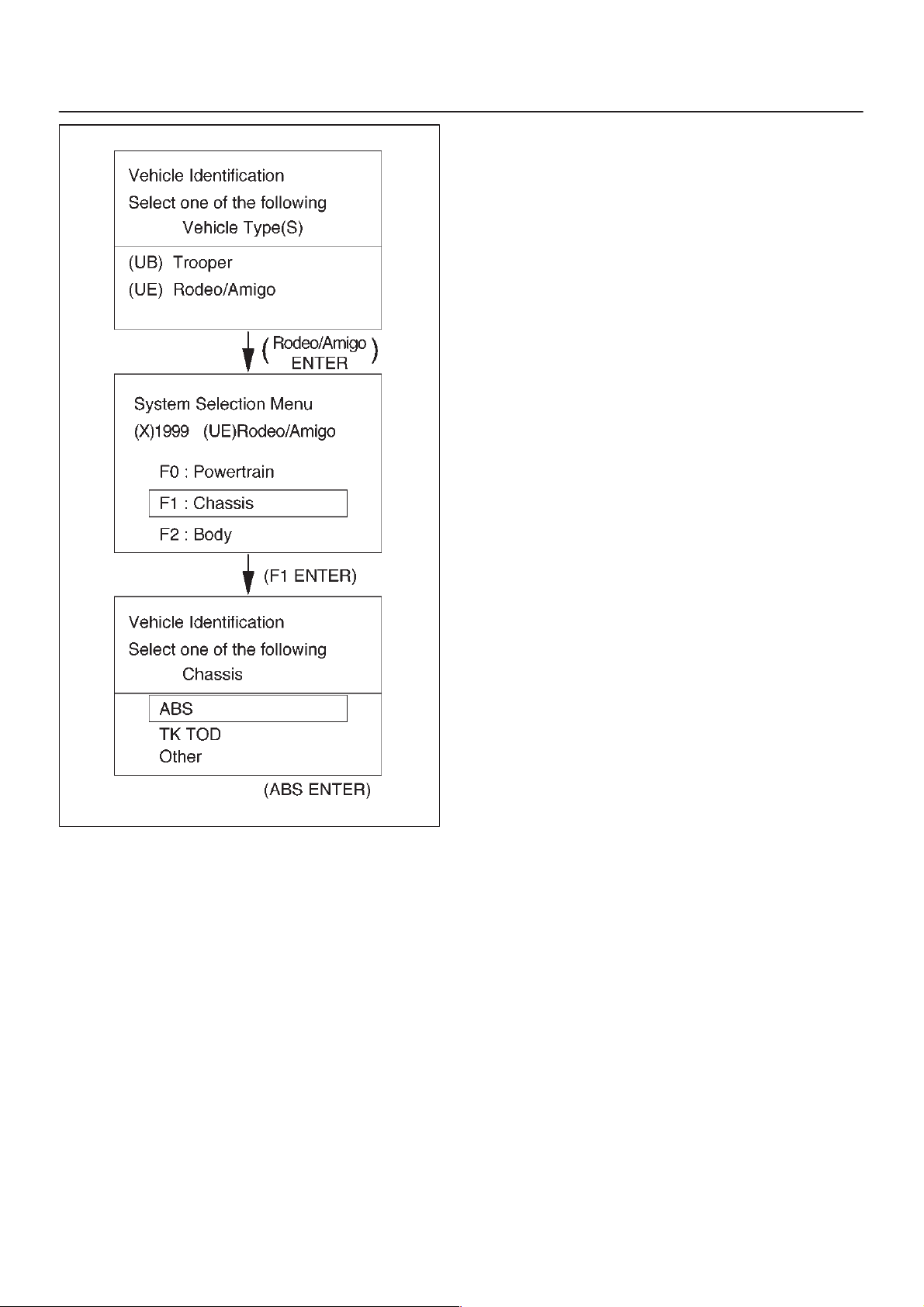

Getting Started

D Before operating the Isuzu PCMCIA card with the

Tech 2, the following steps must be performed:

1.The Isuzu 98 System PCMCIA card (1) inserts into

the Tech 2 (4).

2.Connect the SAE 16/19 adapter (2) to the DLC cable

(3).

3.Connect the DLC cable to the Tech 2 (4).

4.Make sure the vehicle ignition is off.

5.Connect the Tech 2 SAE 16/19 adapter to the vehicle

DLC.

Operating Procedure

The power up screen is displayed when you power up the

tester with the Isuzu systems PCMCIA card. Follow the

operating procedure below.

6.The vehicle ignition turns on.

7.Power up the Tech 2.

8.Verify the Tech 2 power up display.

740RW060

060RX065

060RW009

BRAKE CONTROL SYSTEM

5A–15

060RX063

5A–16

BRAKE CONTROL SYSTEM

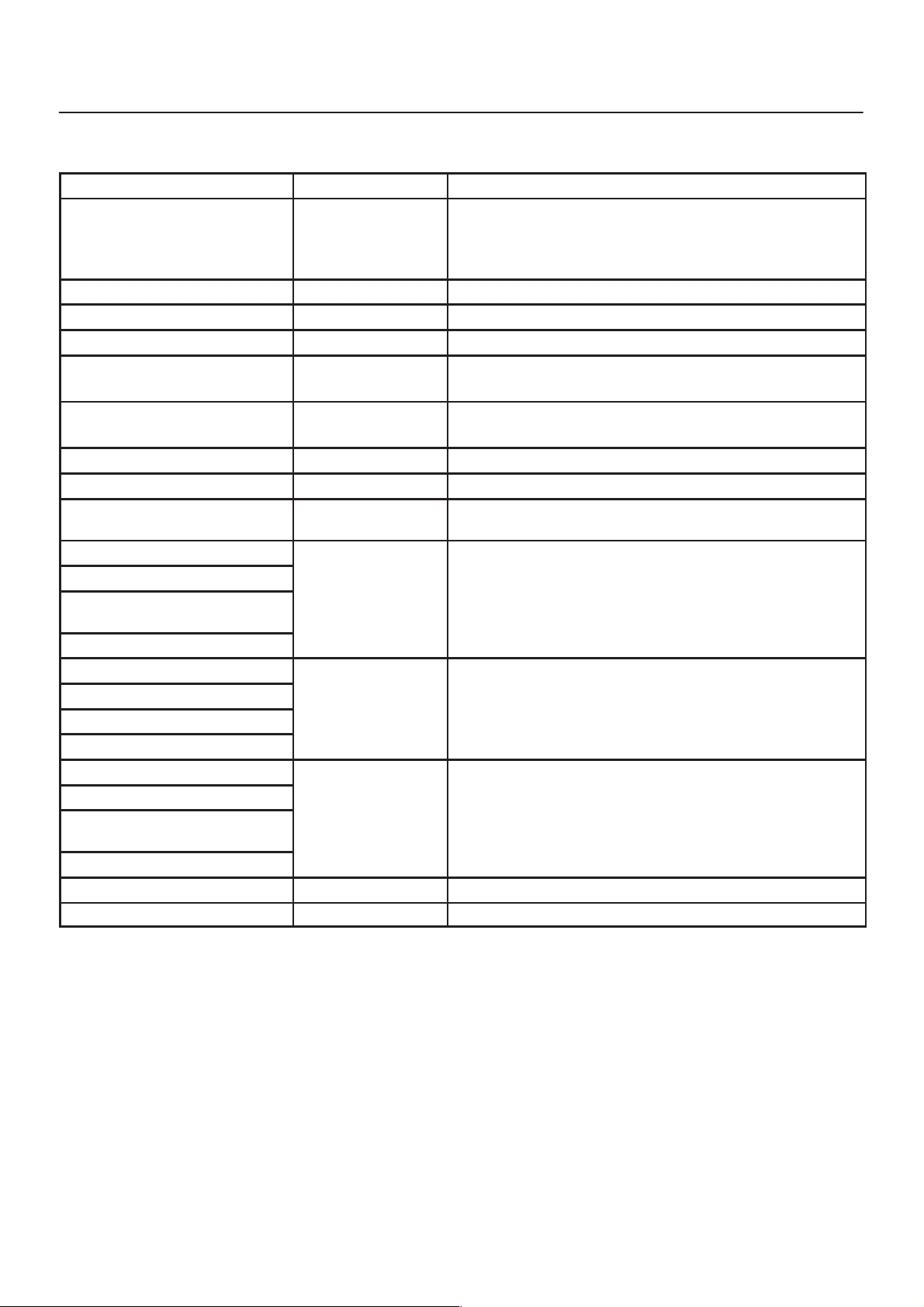

DATA LIST

The data displayed by DAT A LIST are as follows:

Display

Front Left Wheel Speed

Front Right Wheel Speed

Rear Wheel Speeds

Warning Lamp ON/OFF D T o be OFF usually

ABS State ON/OFF D T o be OFF usually

ABS Relay Active/Inactive D To be Active usually

4 Wheel Drive Active/Inactive D 2WD: Inactive

Brake Switch Active/Inactive D Inactive (Released)

Brake Fluid Level Normal or not D To be Normal usually

Return Pump Active/Inactive D To be Inactive usually

DRP (Dynamic Rear Propor-

tioning)

Rear Dump Valve Commanded

Rear Dump Valve Feedback

Rear Isolation Valve Comman-

ded

Rear Isolation Valve Feedback

FL Dump Valve Commanded

FL Dump Valve Feedback

FL Isolation Valve Commanded

FL Isolation Valve Feedback

FR Dump Valve Commanded

FR Dump Valve Feedback

FR Isolation Valve Comman-

ded

FR Isolation Valve Feedback

G–Sensor Voltage D 0.00V when vehicle is stopped

Battery Voltage V oltage D Between 10–16.9V

Content OK/NG Criteria for Data

km/h (MPH) D Start the vehicle and make sure of linear change in

each wheel speed.

D Turn each wheel by hand and make sure that each

speed data change.

D 4WD: Active

D Active (Pressed)

Active/Inactive D To be Inactive usually

Active/Inactive D To be Inactive usually

Active/Inactive D To be Inactive usually

Active/Inactive D To be Inactive usually

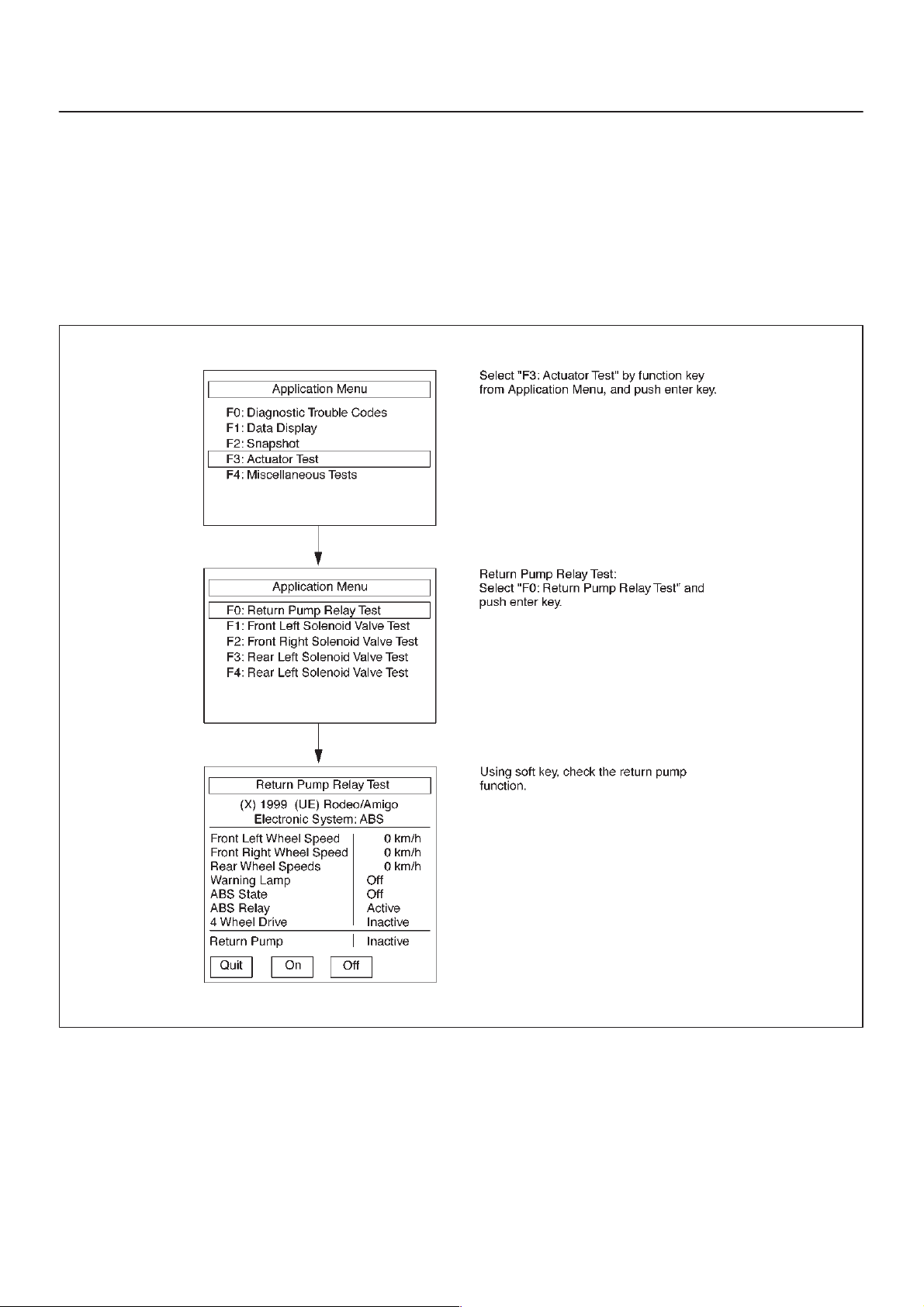

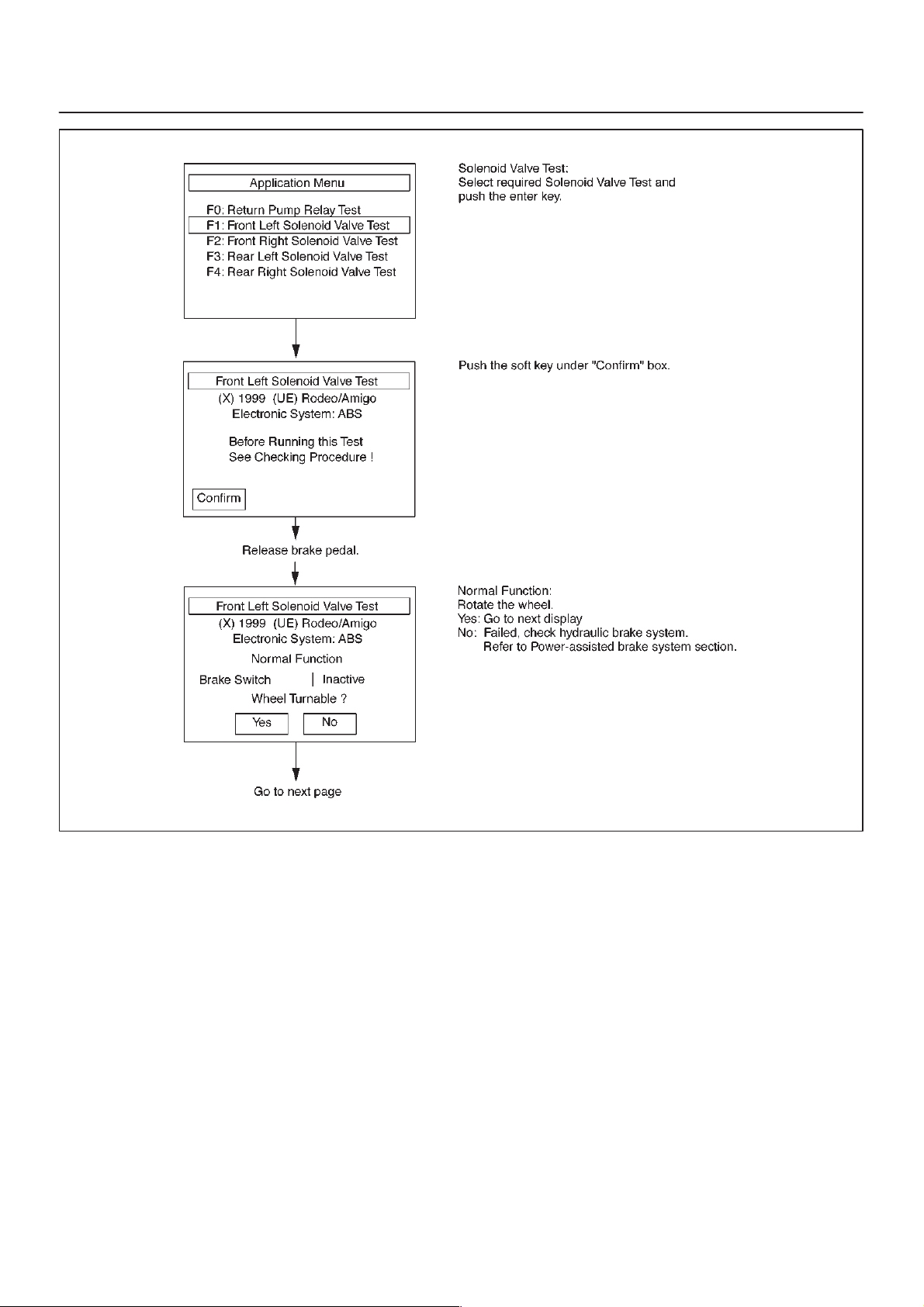

ACTUATOR TEST

This mode is used to exercise the ABS actuators and

make sure they operate normally. Prior to the test, pay

attention to the cautions below. (When checking the

solenoid valve system, be sure to jack up the vehicle.)

CAUTION:

D Before testing, be sure that the brakes work normally .

D Make sure that the battery is fully charged.Conduct

the test by two persons (A TECH 2 operator and a

vehicle checker).

BRAKE CONTROL SYSTEM

5A–17

D Be sure to start ACTUATOR TEST with the engine

stopped.

D Before testing, make sure that electrical trouble, if

any , has been completely repaired. Conducting tests

of ABS solenoid with electrical circuit problem

remaining uncorrected could damage the control unit.

F05RX001

5A–18

BRAKE CONTROL SYSTEM

F05RX002

Loading...

Loading...