Page 1

WORKSHOP MANUAL

NHR • NKR • NPR

ENGINE

4J SERIES

SECTION 6

Page 2

MEMO

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

.......................................................................................................................................................................................

Page 3

NOTICE

Before using this Workshop Manual to assist you in performing

vehicle service and maintenance operations, it is reco mmended

that you carefully read and thoroughly understand the

information contained in Section 0A under the headings

“GENERAL REPAIR INSTRUCTIONS” and “HOW TO USE THIS

MANUAL”.

All material contained in this Manual is based on the latest

product information available at the time of publication.

All rights are reserved to make changes at any time without prior

notice.

Applicable Model : NHR55. NKR55. NPR55. NPR69

This manual is applicable to 1994 year model and later vehicles

.

Page 4

THIS MANUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION NO. CONTENTS

00 Service Information

6A Engine Mechanical

6A1 4JB1/4JB1T/4JB1-TC/4JG2 Engine

6B Engine Cooling

6C Fuel System

6D Engine Electrical

6E Exhaust Gas Reci rculation (EGR) System

6F Exhaust

6G Turbocharger

Page 5

SERVICE INFORMATION 00 – 1

HOME

SECTION 00

SERVICE INFORMATION

CONTENTS

PAGE

Troubleshooting .............................................................................................................. 00 -2

Main Data and Specifications......................................................................................... 00 -30

Service Standard ............................................................................................................. 00 -34

Servicing........................................................................................................................... 00 -38

Fixing Torque...................................................................................................................00 -51

Special Tools.................................................................................................................... 00 -60

Page 6

00 – 2 SERVICE INFORMATION

TROUBLESHOOTING

CONTENTS

PAGE

Hard Starting.................................................................................................................... 00 - 3

Starter Inoperative....................................................................................................... 00 - 3

Starter Motor Operates but Engine Does Not Turn Over......................................... 00 - 3

Engine Turns Over but Does Not Start...................................................................... 00 - 4

Quick-on Start System................................................................................................ 00 - 5

Unstable Idling.................................................................................................................00 - 6

Insufficient Power............................................................................................................ 00 - 7

Excessive Fuel Consumption......................................................................................... 00 - 9

Excessive Oil Consumption............................................................................................ 00 - 9

Overheating...................................................................................................................... 00 - 10

White Exhaust Smoke..................................................................................................... 00 - 10

Dark Exhaust Smoke....................................................................................................... 00 -11

Oil Pressure Does Not Rise............................................................................................ 00 - 11

Abnormal Engine Noise .................................................................................................. 00 -12

Engine Knocking......................................................................................................... 00 - 12

Gas Leakage Noise...................................................................................................... 00 -12

Continuous Noise........................................................................................................ 00 - 12

Slapping Noise............................................................................................................. 00 -13

Engine Cooling Trouble .................................................................................................. 00 -14

Engine Electrical Part Trouble........................................................................................ 00 - 15

Turbocharger ................................................................................................................... 00 -20

Lubrication Chart............................................................................................................. 00 - 29

Page 7

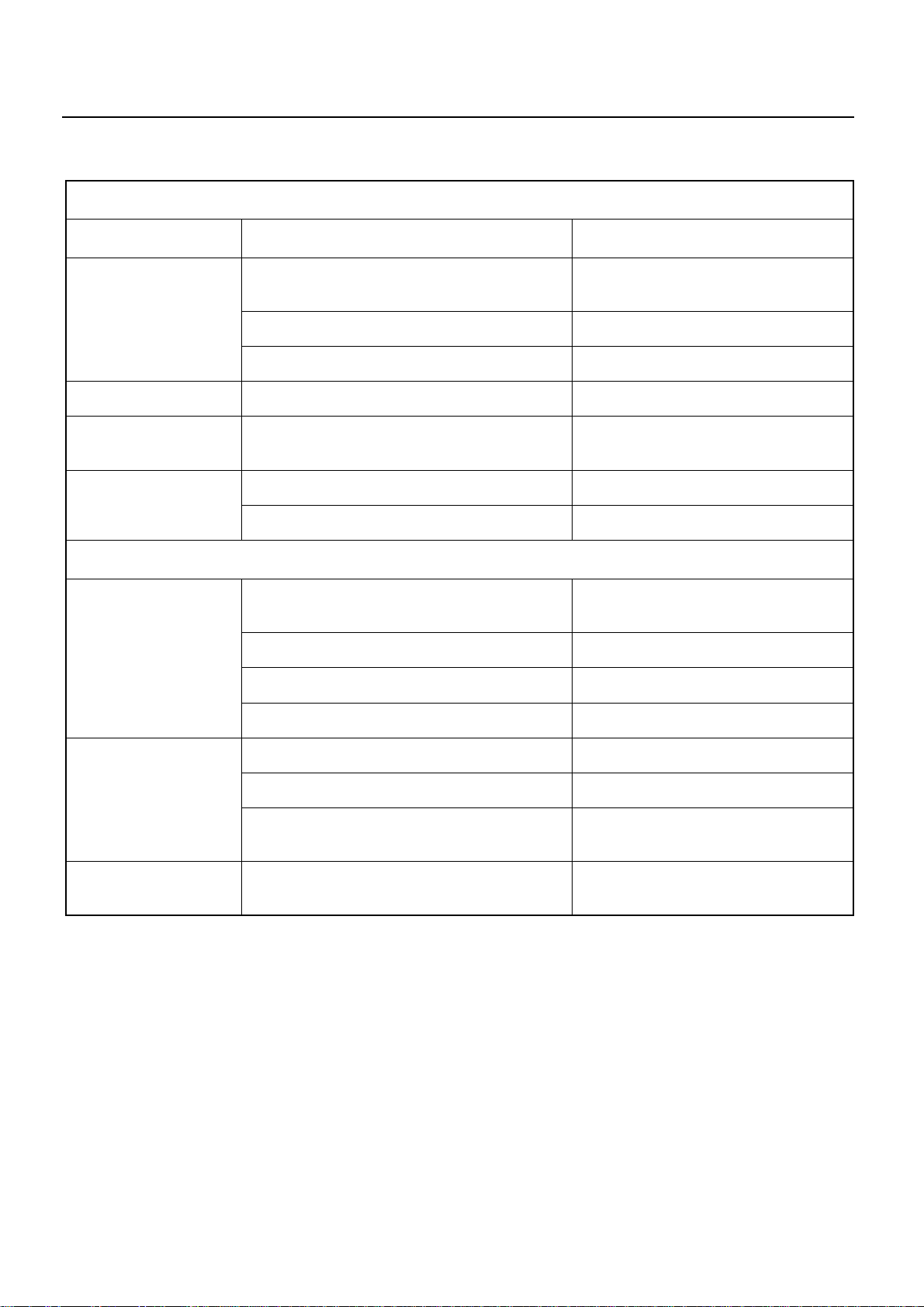

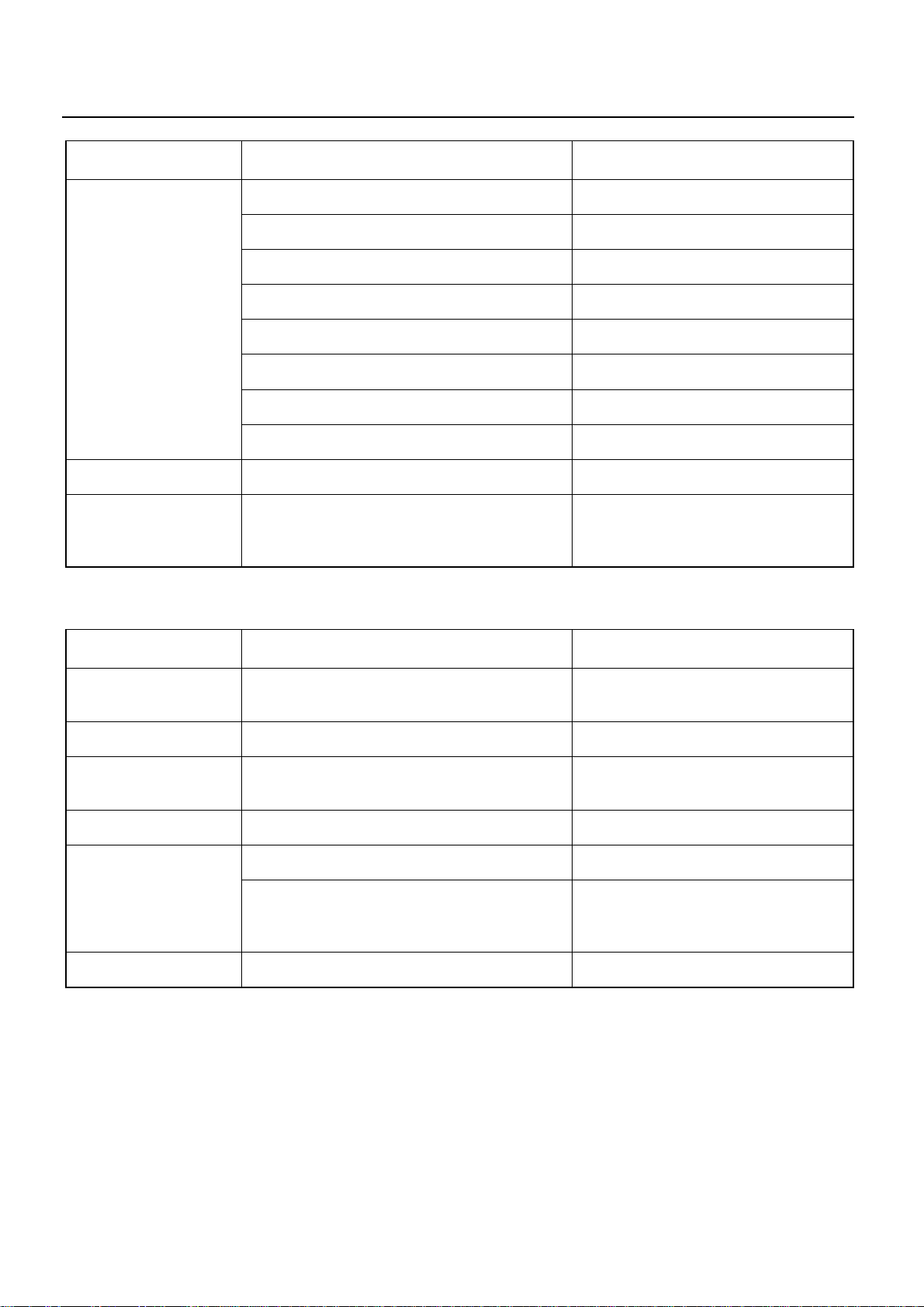

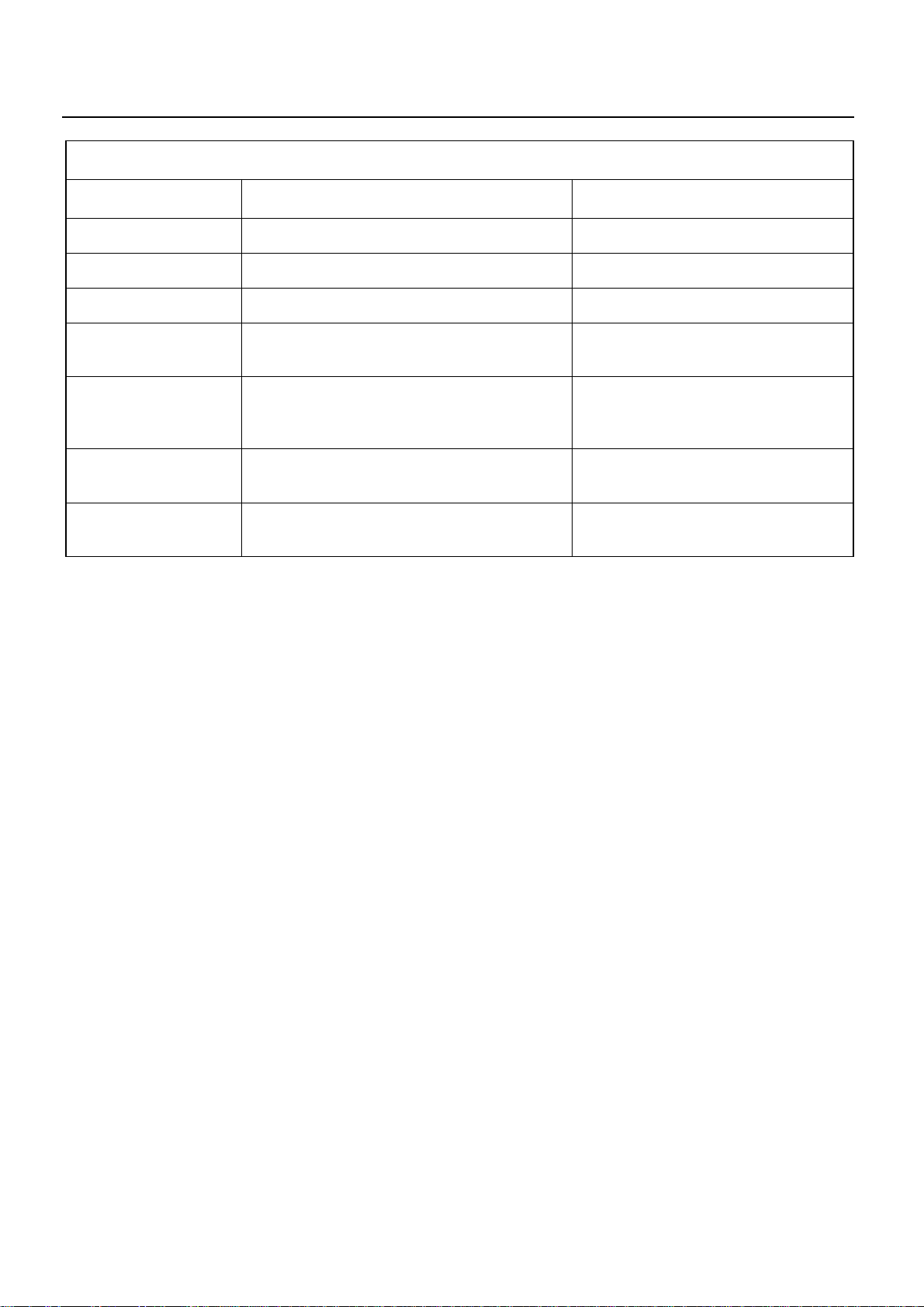

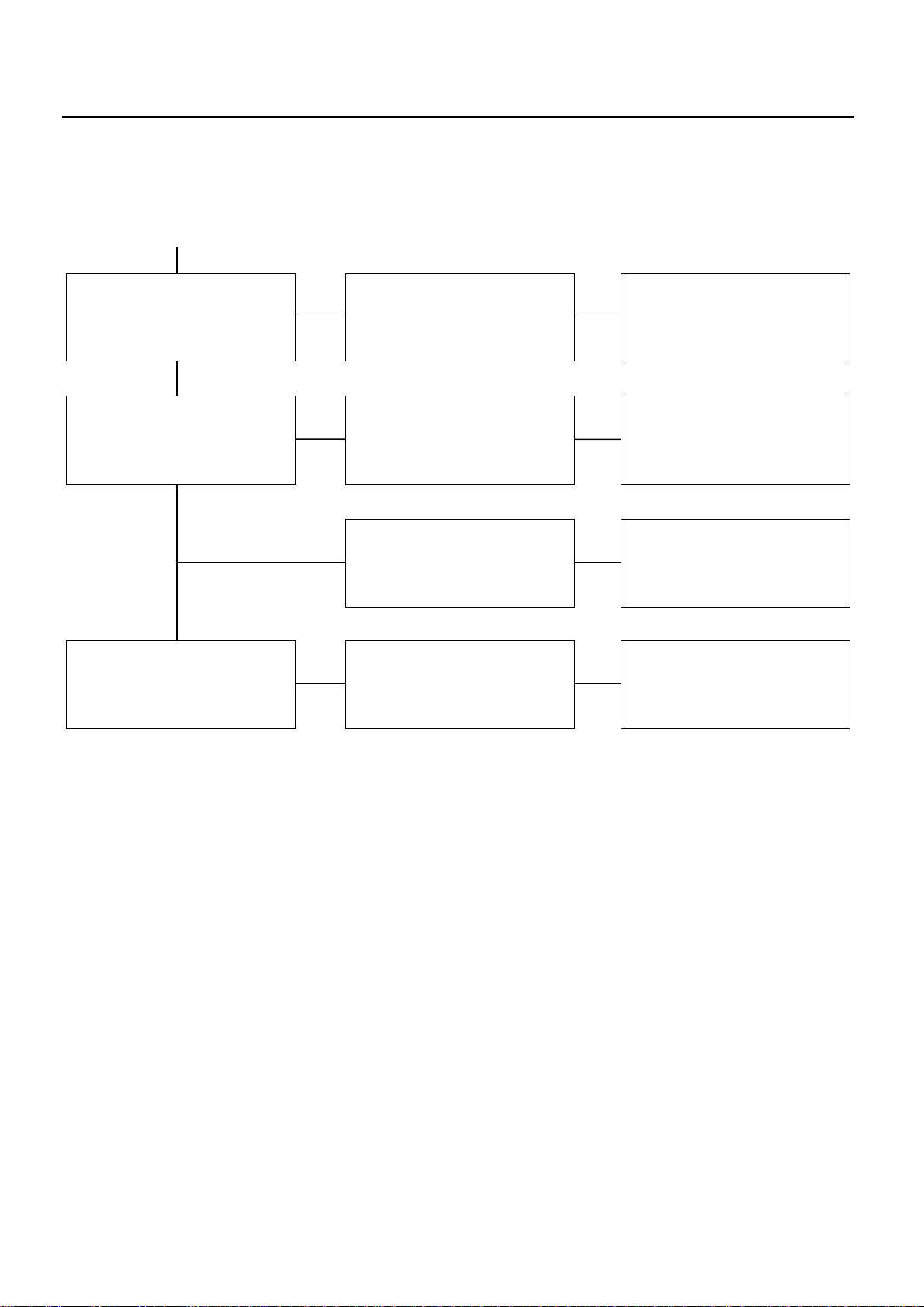

SERVICE INFORMATION 00 – 3

1.HARD STARTING

1. STARTER INOPERATIVE

Checkpoint Possible cause Correction

Battery

Fusible link Fusible link shorted Replace the fusible link

Starter switch Defective starter switch or starter relay Replace the starter switch or the

Loose battery cable terminal poor

connections due to rusting

Battery discharged or weak Recharge or replace the battery

Fan belt loose or broken Adjust or replace the fan belt

Defective magnetic switch or starter relay Repair or replace the magnetic switchStarter motor

Defective starter motor Repair or replace the starter motor

Clean and/or retighten the battery

cable terminal

Starter relay

2. STARTER MOTOR OPERATES BUT ENGINE DOES NOT TURN OVER

Battery

Loose battery cable terminal Clean and/or retighten the battery

cable terminal

Poor connections due to rusting Recharge or replace the battery

Battery discharged or weak Recharge or replace the battery

Fan belt loose or broken Adjust or replace the fan belt

Starter

Engine Piston, crank bearing seizure, or other

Defective pinion gear Replace the pinion gear

Defective magnetic switch Repair or replace the magnetic switch

Brush wear, Weak brush spring Replace the brush and/or the brush

damage

spring

Repair or replace the related parts

Page 8

00 – 4 SERVICE INFORMATION

3. ENGINE TURNS OVER BUT DOES NOT START

Checkpoint Possible cause Correction

Engine stop

mechanism

Defective fuel cut solenoid valve Replace the fuel cut solenoid valve

FUEL IS NOT BEING DELIVERED TO THE INJECTION PUMP

Fuel Fuel tank is empty Fill the fuel tank

Fuel piping Clogged or damaged fuel lines. Loose fuel

line connection

Fuel filter

Fuel system Air in the fuel system Bleed the air from the fuel system

Fuel feed pump Defective feed pump Repair or replace the feed pump

Fuel filter overflow valve does not close Repair or replace the fuel filter

Clogged fuel filter element Replace the fuel filter element or the

Repair or replace the fuel lines

Retighten the fuel line connection

overflow valve

filter cartridge

FUEL IS BEING DELIVERED TO THE INJECTION PUMP

Fuel

Use of the wrong fuel Use the correct fuel

Water particles in the fuel Change the fuel

Fuel system

Injection pump

Air in the injection pump Bleed the air from the fuel system

Injection nozzle stickingInjection nozzle

Injection nozzle injection starting pressure

too low

Improper spray condition

Defective fuel injection nozzle resulting in the

fuel drippage after fuel injection

Defective injection pump control rack

operation

Injection pump plunger worn or stuck Replace the injection pump plunger

Injection pump drive shaft seizure or other

damage

Injection pump governor spring seizure Replace the injection pump governor

Adjust or replace the injection nozzle

Replace the delivery valve

Repair or replace the injection pump

control rack

assembly

Replace the injection drive shaft

spring

Page 9

SERVICE INFORMATION 00 – 5

4. QUICK-ON START SYSTEM

PREPARATION

1 Disconnect the thermoswitch connector.

2. Determine whether or not the glow plugs are receiving power.

a) Make sure that the starter switch is “OFF”.

b) Connect a voltmeter between one of the glow plugs and the cylinder wall.

c) Move the starter switch to the “ON” position.

The voltmeter needle will show the souse voltage (12V) if the glow plugs are receiving power.

If the voltmeter needle does not move, the glow plugs are not receiving power.

3. Perform the troubleshooting procedure.

GLOW PLUGS ARE RECEIVING POWER

Checkpoint Possible cause Correction

Glow plug indicator

light does not turn on

Quick-on start timer Defective quick-on start timer Replace the quick-on start timer

Glow plug indicator

light turns on the 0.3

seconds

Glow plug indicator

light turns on for 3.5

seconds

Thermoswitch Defective thermoswitch Replace the thermoswitch

Glow plug continuity No glow plug continuity Replace the glow plugs

Defective indicator light bulb Replace the indicator light bulb

Defective quick-on start timer Replace the quick-on start timer

Return the starter switch to the “ON” position

from the “START” position after the engine

starts if the glow plug relay remains on less

than 14 seconds, the quick-on start timer is

defective

Move the starter switch from the “OFF”

position to the “ON” position if the glow plug

relay remains on less than 14 seconds, the

quick-on start timer is defective

Replace the quick-on start timer

Replace the quick-on start timer

GLOW PLUGS ARE NOT RECEIVING POWER

Glow plug indicator

light does not turn on

Quick-on start timer Defective quick-on start timer Replace the quick-on start timer

Broken indicator light fuse Replace the fuse

Page 10

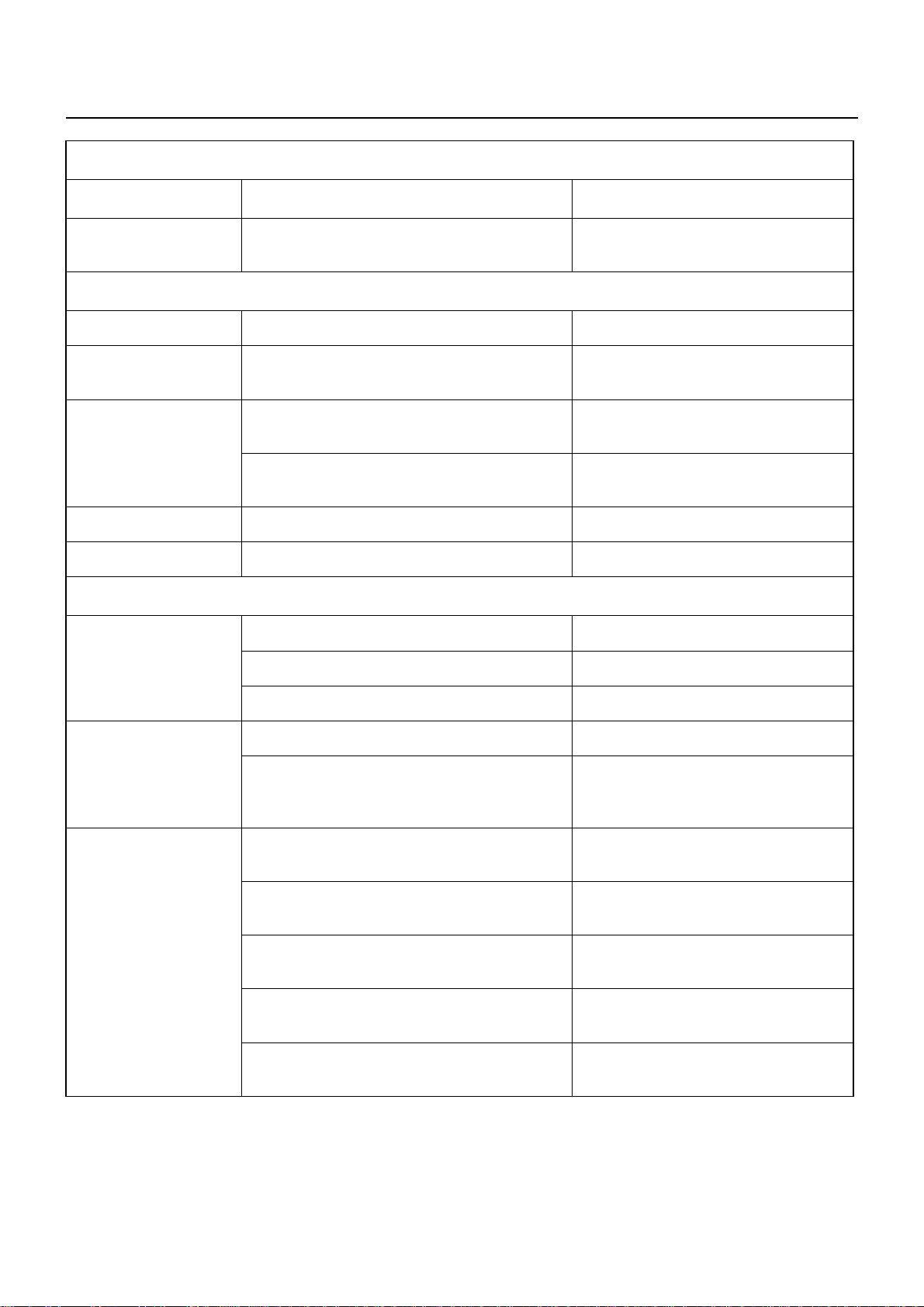

00 – 6 SERVICE INFORMATION

GLOW PLUGS ARE NOT RECEIVING POWER (Cont’d)

Checkpoint Possible cause Correction

Glow plug indicator

light turns on for 3.5

seconds

Defective glow plug relay

The glow plug relay does not turn on after the

starter switch is moved from the “OFF”

position to the “ON” position

Defective quick-on start timer Replace the quick-on start timer

Defective glow plug relay wiring harness Repair or replace the wiring harness

Defective fusible link or wiring harness

The glow plug relay turns on when the starter

switch is moved from the “OFF” position to

the “ON” position

Replace the glow plug relay

Replace the fusible link or the wiring

harness

2. UNSTABLE IDLING

Checkpoint Possible cause Correction

Idling system Idling improperly adjusted Adjust the idling

Fast idling speed Defective fast idling speed control device Repair or replace the fast idling speed

control device

Accelerator control

system

Accelerator control system improperly

adjusted

Adjust the accelerator control system

Fuel system

Fuel filter Clogged fuel filter element Replace the fuel filter element or the

Fuel feed pump Defective fuel feed pump Repair or replace the fuel feed pump

Injection pump Defective delivery valve resulting in fuel

Fuel system leakage or blockage Repair or replace the fuel system

Air in the fuel system Bleed the air from the fuel system

Water particles in the fuel system Change the fuel

fuel filter cartridge

Injection nozzle sticking Replace the injection nozzleInjection nozzle

Injection nozzle injection starting pressure

too low

Improper spray condition

drippage after fuel injection

Adjust or replace the injection nozzle

Replace the delivery valve

Page 11

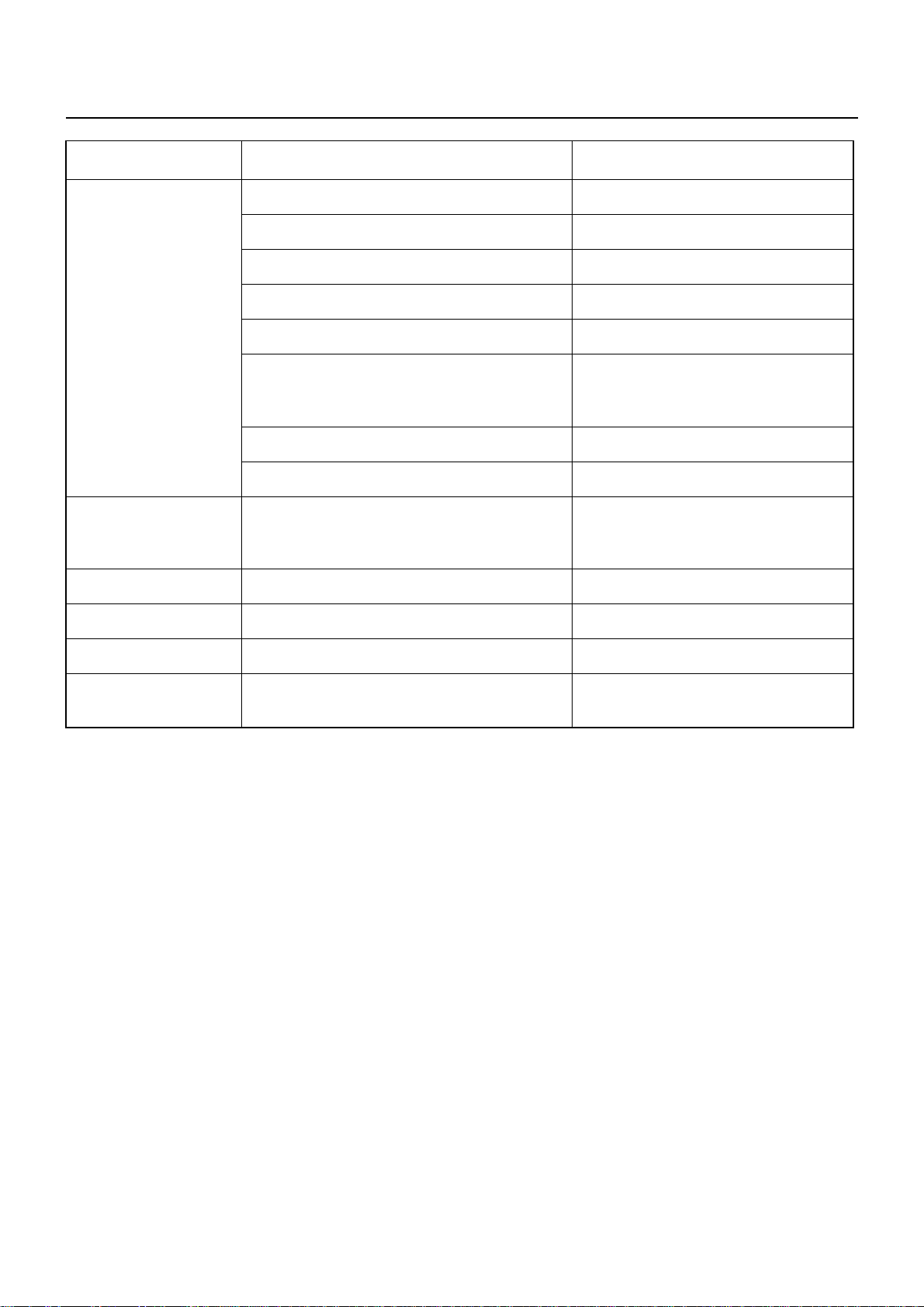

SERVICE INFORMATION 00 – 7

Checkpoint Possible cause Correction

Injection pump

(Cont’d)

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Compression pressure Blown out cylinder head gasket. Worn

Injection timing improperly adjusted Adjust the injection timing

Insufficient injection volume Adjust the injection volume

Defective idle spring Replace the idle spring

Defective governor lever operation Repair or replace the governor lever

Regulator valve improperly adjustment Adjust or replace the regulator valve

Broken plunger spring Replace the plunger spring

Worn plunger Replace the plunger assembly

Worn cam disc Replace the cam disc

Replace the related parts

cylinder liner.

Piston ring sticking

3. INSUFFICIENT POWER

Checkpoint Possible cause Correction

Air cleaner Clogged air cleaner element Clean or replace the air cleaner

element

Fuel Water particle in the fuel Replace fuel

Fuel filter Clogged fuel filter element Replace the fuel filter element or the

fuel filter cartridge

Fuel feed pump Defective fuel feed pump Repair or replace the fuel feed pump

Injection nozzle sticking Replace the injection nozzleInjection nozzle

Injection nozzle injection starting pressure

too low

Improper spray condition

Fuel injection pipes Fuel injection pipes damaged or obstructed Replace the fuel injection pipes

Adjust or replace the injection nozzle

Page 12

00 – 8 SERVICE INFORMATION

Checkpoint Possible cause Correction

Injection pump

Compression pressure Blown out cylinder head gasket. Worn

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Valve spring Valve spring weak or broken Replace the valve spring

Defective regulating valve Repair or replace the regulating valve

Defective delivery valve Replace the delivery valve

Defective timer Repair or replace the timer

Worn cam disc Replace the cam disc

Improper control lever operation Adjust or replace the control lever

Defective injection timing Adjust the injection timing

Repair or replace the injection pump

timer

Weak governor spring Replace the governor spring

Worn plunger Replace the plunger assembly

Replace the related parts

cylinder liner.

Piston ring sticking

Exhaust system Exhaust pipe clogged Clean the exhaust pipe

Full load adjusting

screw seal

Open and improperly set adjusting screw

seal

Adjust and reseal the adjusting screw

Page 13

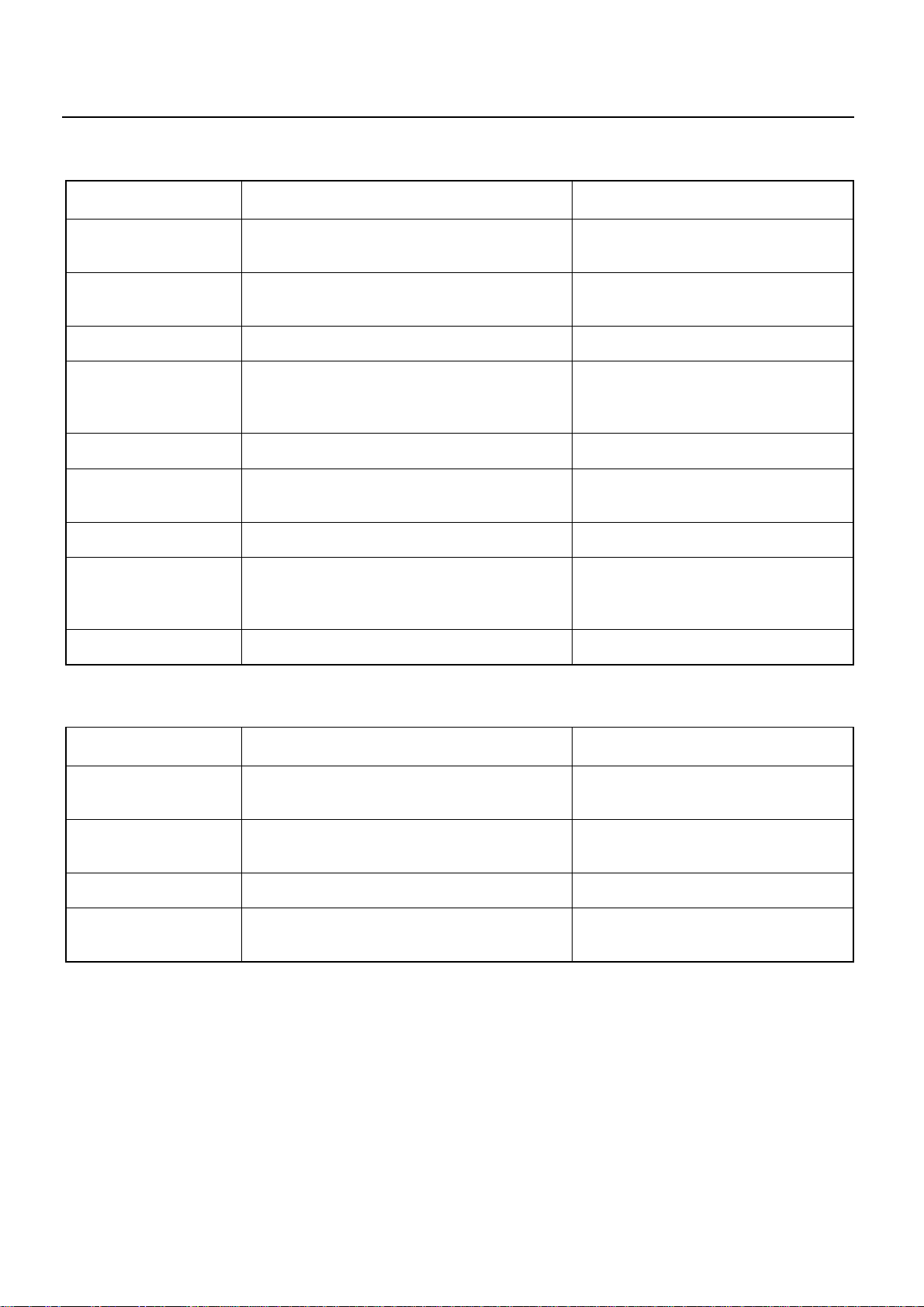

SERVICE INFORMATION 00 – 9

4. EXCESSIVE FUEL CONSUMPTION

Checkpoint Possible cause Correction

Fuel system Fuel leakage Repair or replace the fuel system

related parts

Air cleaner Clogged air cleaner element Clean or replace the air cleaner

element

Idling speed Poorly adjusted idling speed Adjust the idling speed

Injection nozzle Injection nozzle injection starting pressure

too low

Improper spray condition

Fuel injection timing Fuel injection timing improperly Adjust the fuel injection timing

Injection pump Defective Delivery valve resulting is fuel

drippage after fuel injection

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Compression pressure Blown out cylinder head gasket. Worn

cylinder liner.

Piston ring sticking

Valve spring Valve spring weak or broken Replace the valve spring

Adjust or replace the injection nozzle

Replace the delivery valve

Replace the related parts

5. EXCESSIVE OIL CONSUMPTION

Checkpoint Possible cause Correction

Engine oil Engine oil unsuitable

Too much engine oil

Replace the engine oil

Correct the engine oil level

Oil seal and gasket Oil leakage from the oil seal and/or the

gasket

Air breather Clogged air breather Clean the air breather

Intake and exhaust

valve

Worn valve stems and valve guides Replace the intake and exhaust

Replace the oil seal and/or the gasket

valves and the valve guides

Page 14

00 – 10 SERVICE INFORMATION

6. OVERHEATING

Checkpoint Possible cause Correction

Cooling water Insufficient cooling water Replenish the cooling water

Fan clutch Oil leakage from the fan clutch Replace the fan clutch

Fan belt Fan belt loose or cracked causing slippage Replace the fan belt

Radiator Defective radiator cap or clogged radiator

core

Water pump Defective water pump Repair or replace the water pump

Cylinder head and

cylinder body sealing

cap

Thermostat Defective thermostat Replace the thermostat

Cooling system Cooling system clogged by foreign material Clean the foreign material from the

Fuel injection timing Fuel injection timing improperly adjusted Adjust the fuel injection timing

Defective sealing cap resulting in water

leakage

Replace the radiator cap or clean the

radiator core

Replace the sealing cap

cooling system

7. WHITE EXHAUST SMOKE

Checkpoint Possible cause Correction

Cooling water Insufficient cooling water Replace the cooling water

Fuel Water particles in the fuel Replace the fuel

Fuel injection timing Delayed fuel injection timing Adjust the fuel injection timing

Compression pressure Blown out cylinder head gasket. Worn

cylinder liner.

Piston ring sticking

Inlet and exhaust valve

Valves seals

Defective valve seals.

Worn valves stems and valve guides

Replace the related parts

Replace the valve seals, the valves,

and the valve guides

Page 15

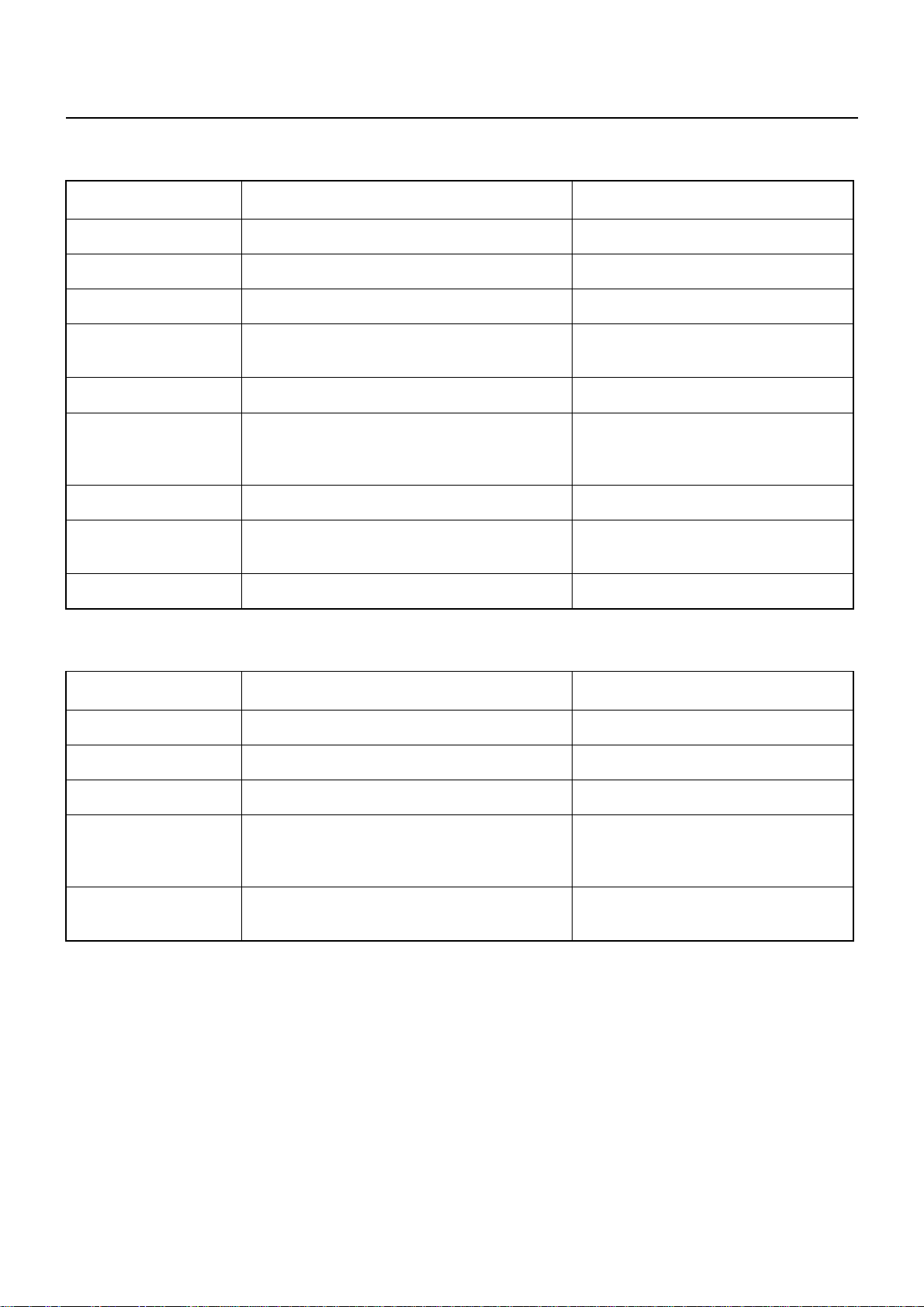

SERVICE INFORMATION 00 – 11

8. DARK EXHAUST SMOKE

Checkpoint Possible cause Correction

Air cleaner Clogged air cleaner element Clean or replace the air cleaner

element

Injection nozzle Injection nozzle injection starting pressure

too low

Improper spray condition

Fuel injection timing Fuel injection timing improperly adjusted Adjust the fuel injection timing

Defective delivery valve resulting in fuel

drippage after fuel injection

Excessive injection volume Adjust the injection volume

Adjust or replace the injection nozzle

Replace the delivery valveInjection pump

9. OIL PRESSURE DOES NOT RISE

Checkpoint Possible cause Correction

Engine oil Improper viscosity engine oil.

Insufficient engine oil

Oil pressure gauge or

unit

Oil pressure indicator

light

Oil filter Clogged oil filter element Replace the oil filter element or the oil

Defective oil pressure gauge or unit

Defective indicator light

Replace the engine oil

Correct the engine oil volume

Repair or replace the oil pressure

gauge or unit

Replace the indicator light

filter cartridge

Relief valve and bypass valve

Rocker arm shaft Worn rocker arm bushing Replace the rocker arm bushing

Camshaft Worn camshaft and camshaft bearing Replace the camshaft and the

Crankshaft and

bearings

Relief valve sticking and/or weak by-pass

valve spring

Clogged oil pump strainer Clean the oil pump strainerOil pump

Worn oil pump related parts Replace the oil pump related parts

Worn crankshaft and bearings Replace the crankshaft and/or the

Replace the relief valve and/or the by-

pass valve spring

camshaft bearing

bearings

Page 16

00 – 12 SERVICE INFORMATION

10. ABNORMAL ENGINE NOISE

1. ENGINE KNOCKING

Check to see that the engine has been thoroughly warmed up before beginning the troubleshooting procedure.

Checkpoint Possible cause Correction

Fuel Fuel unsuitable Replace the fuel

Fuel injection timing Fuel injection timing improperly adjusted Adjust the fuel injection timing

Injection nozzle Improper injection nozzle starting pressure

and spray condition

Compression pressure Blown out head gasket

Broken piston ring

Adjust or replace the injection nozzle

Replace the head gasket or the piston

ring

2. GAS LEAKAGE NOISE

Exhaust pipes Loosely connected exhaust pipes. Broken

exhaust pipes

Injection nozzles

and/or glow plugs

Exhaust manifold Loosely connected exhaust manifold and/or

Cylinder head gasket Damaged cylinder head gasket Replace the cylinder head gasket

Loose injection nozzles and/or glow plugs Replace the washers

glow plugs

Tighten the exhaust pipe connections

Replace the exhaust pipes

Tighten the injection nozzles and/or

the glow plugs

Tighten the exhaust manifold

connections

3. CONTINUOUS NOISE

Fan belt Loose fan belt Readjust the fan belt tension

Cooling fan Loose cooling fan Retighten the cooling fan

Water pump bearing Worn or damaged water pump bearing Replace the water pump bearing

Generator or vacuum

pump

Valve clearance Clearance improperly adjust Adjust the valve clearances

Defective generator or vacuum pump Repair or replace the generator or the

vacuum pump

Page 17

SERVICE INFORMATION 00 – 13

4. SLAPPING NOISE

Checkpoint Possible cause Correction

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Rocker arm Damaged rocker arm Replace the rocker arm

Flywheel Loose flywheel bolts Retighten the flywheel bolts

Crankshaft and thrust

bearings

Crankshaft and

connecting rod

bearings

Connecting rod

bushing and piston pin

Piston and cylinder

liner

Worn or damaged crankshaft and/or thrust

bearings

Worn or damaged crankshaft and/or

connecting rod bearings

Worn or damaged connecting rod bushing

and piston pin

Worn or damaged piston and cylinder liner. Replace the piston and the cylinder

Replace the crankshaft and/or the

thrust bearings

Replace the crankshaft and/or the

connecting rod bearings

Replace the connecting rod bushing

and/or the piston pin

liner.

Page 18

00 – 14 SERVICE INFORMATION

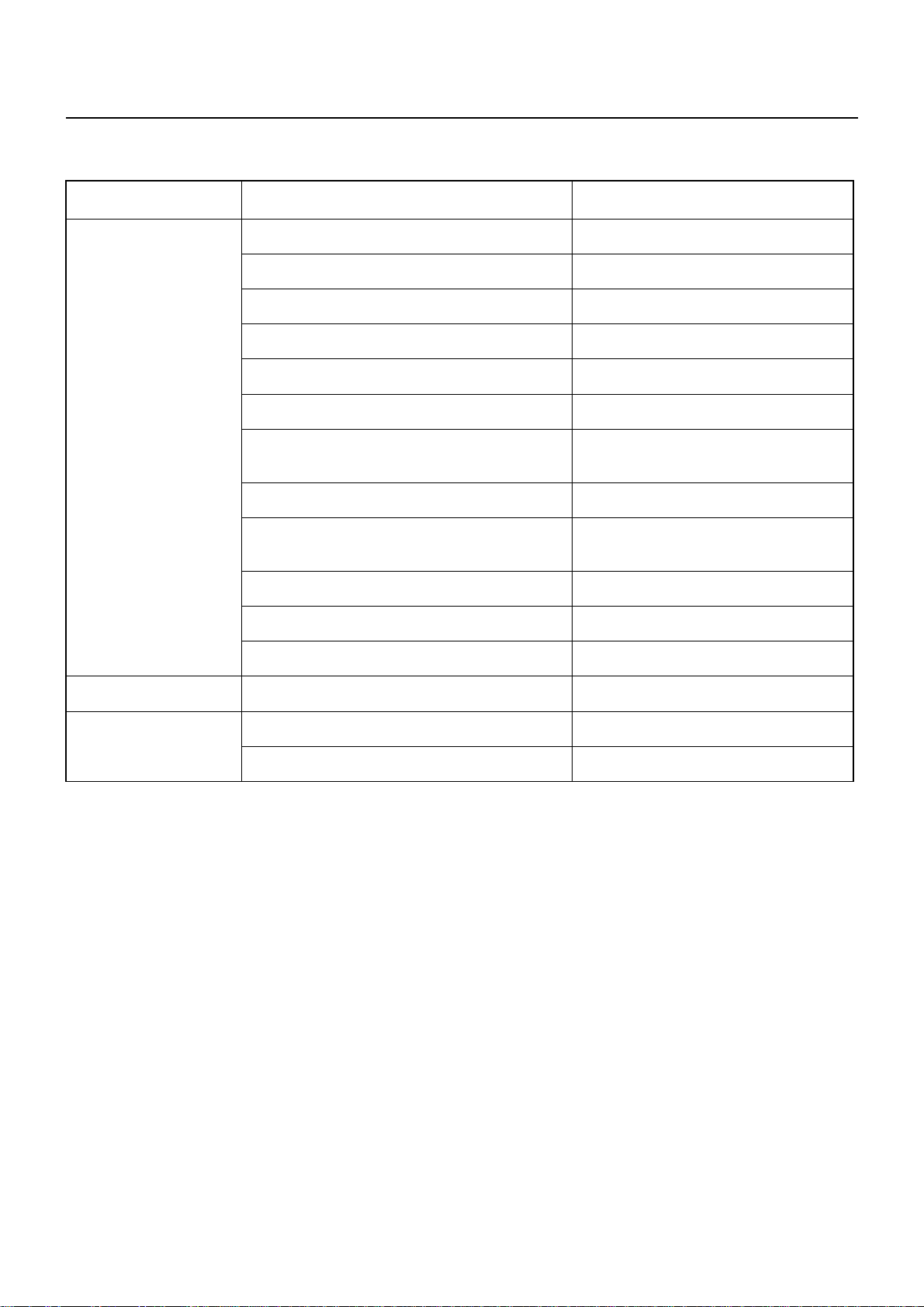

11. ENGINE COOLING TROUBLE

Checkpoint Possible cause Correction

Engine overheating

Low coolant level Replenish

Thermo unit faulty Replace

Faulty thermostat Replace

Faulty coolant unit Repair or replace

Clogged radiator Clean or replace

Faulty radiator cap Replace

Low engine oil level or use of improper

engine oil

Damaged cylinder head gasket Replace

Clogged exhaust system Clean exhaust system or replace

Loose fan belt Adjust

Excessive fuel injected Adjust

Improper injection timing Adjust

Replenish or change oil

Replenish

faulty parts

Engine overcooling Faulty thermostat Replace

Faulty thermostat ReplaceToo long engine

warm-up time

Thermo unit faulty Replace

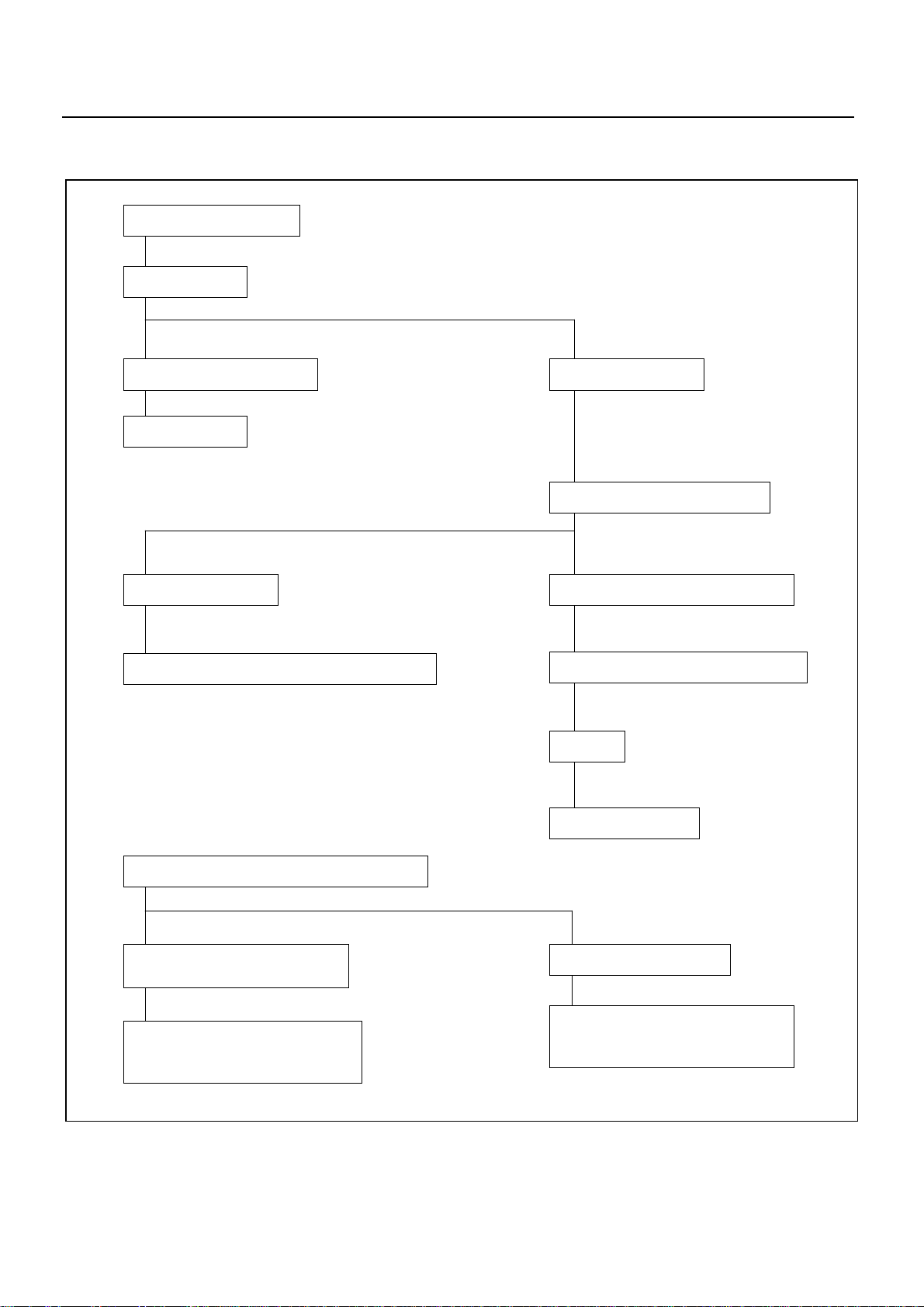

Page 19

12. ENGINE ELECTRICAL PART TROUBLE

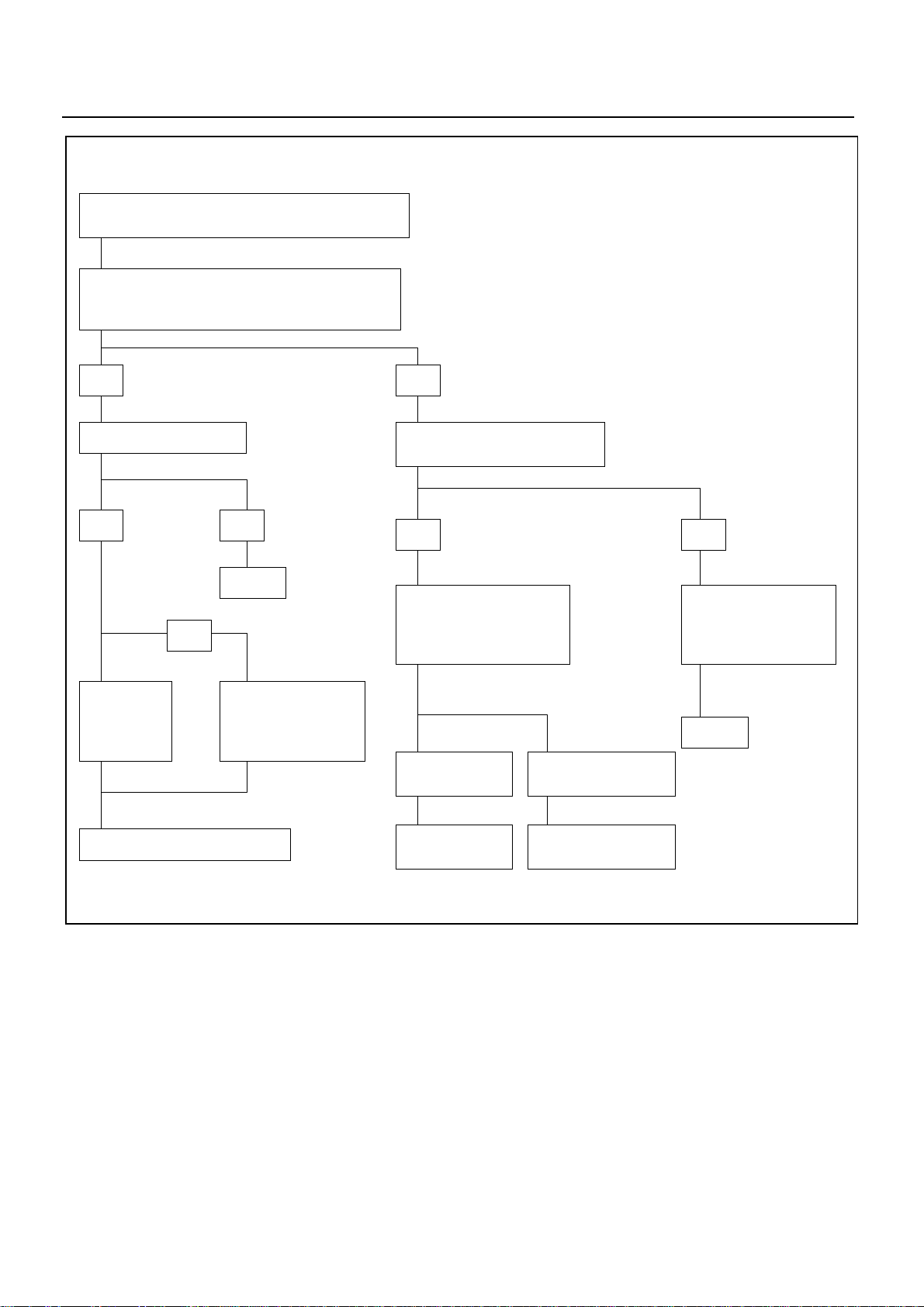

STARTER DOES NOT RUN

CHECK BATTERY

SERVICE INFORMATION 00 – 15

CHARGING FAILURE OR LIFE

CHECK BATTERY

CONNECTION FAILURE

CLEAN BATTERY TERMINALS, AND RECONNECT

BATTERY IS NORMAL

CHECK TERMINAL CONNECTION

TERMINAL CONNECTION IS NORMAL

CHECK STARTER OR STARTER SWITCH

FAILURE

REPAIR OR REPLACE

TURN ON HEAD LAMP AND STARTER SWITCH

HEAD LAMP DOES NOT COME ON

OR IT IS EXTREMELY DARK

a) LACK OF BATTERY CHARGING

b) SHORT-CIRCUIT IN STARTER OIL

c) FAULTY STARTER PARTS

HEAD LAMP ILLUMINATES

a) DISCONNECT STARTER CIRCUIT

b) DISCONNECT STARTER COIL

c) FAULTY STARTER SWITCH

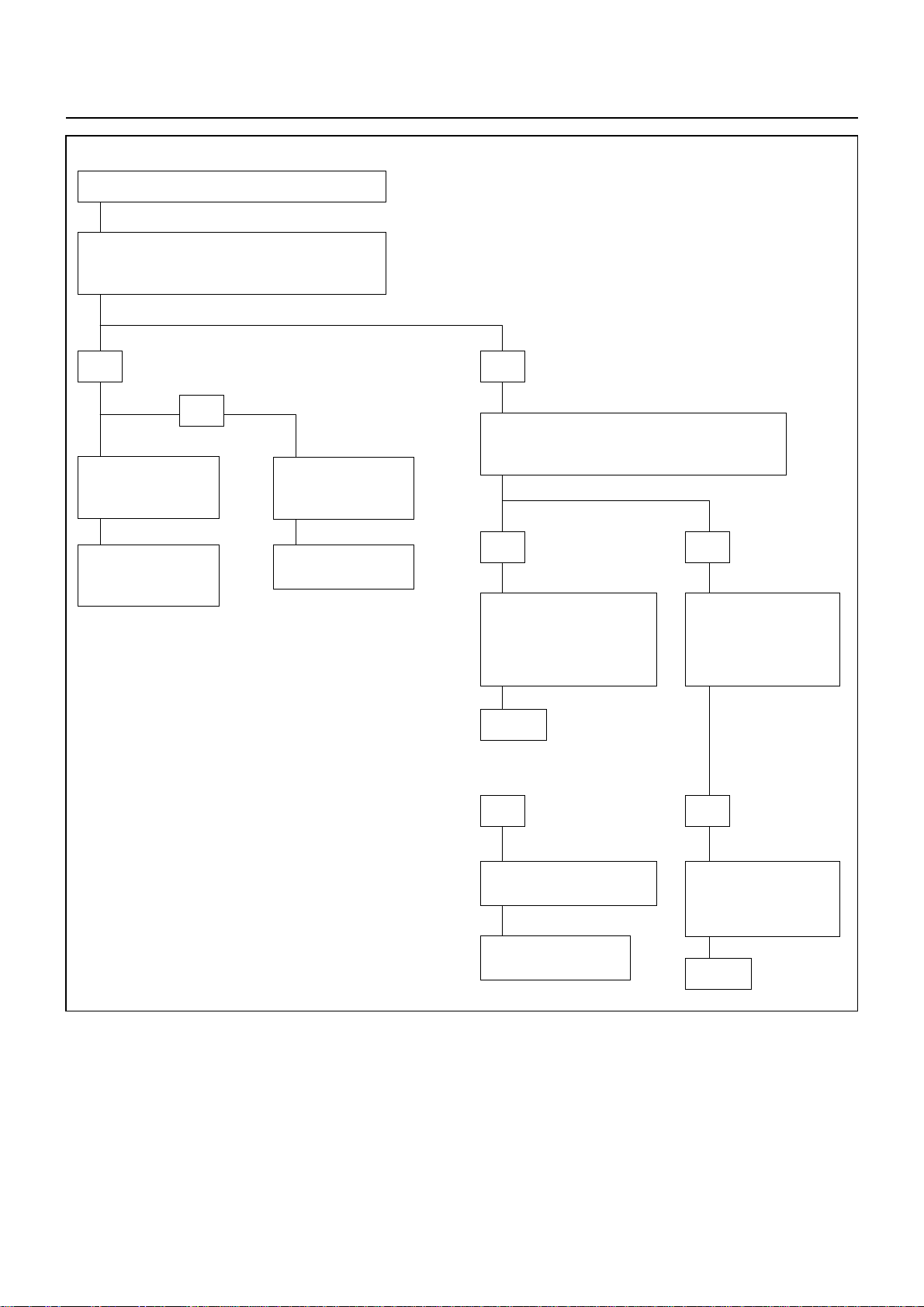

Page 20

00 – 16 SERVICE INFORMATION

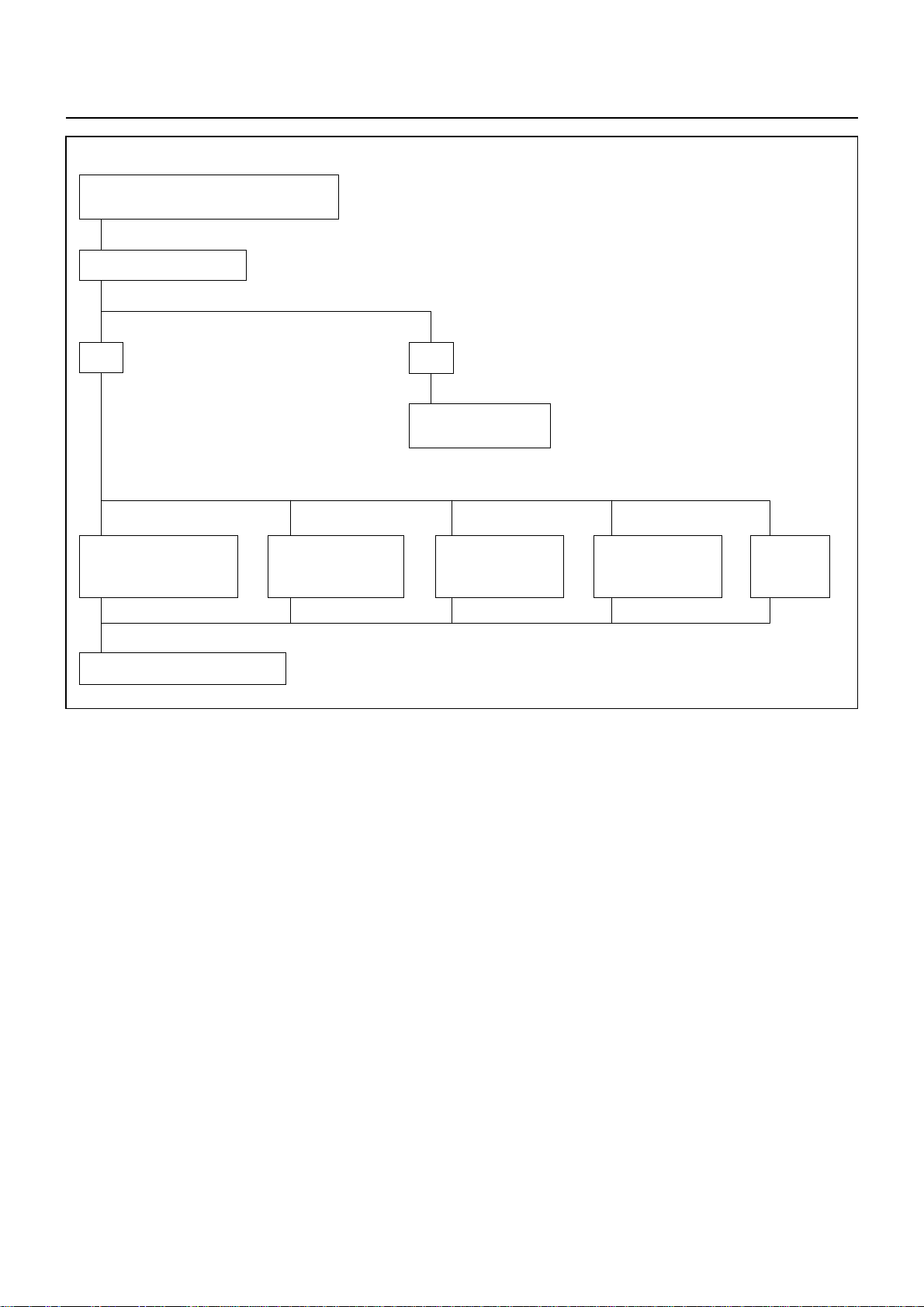

FAULTY MESHING OF PINION AND RING GEAR

CHECK IF BATTERY VOLTAGE IS PRESENT AT

MAGNETIC SWITCH TERMINAL “S” WHEN

STARTER SWITCH IS TURNED TO “START (ST)”

YES

OR

EXTREME WEAR OF

PINION AND RING

GEAR

REPAIR OR REPLACE

STARTER, REPLACE

RING GEAR

STARTER SLIDING

RESISTANCE IS

LARGE

REPAIR OR REPLACE

STARTER

NO

UNDER THIS CONDITION, CHECK IF VOLTAGE

OF CONNECTOR 3BW ON MAGNETIC SWITCH

OF RESTART RELAY IS NORMAL

YES NO

DISCONNECTION OR

FAULTY CONNECTION

BETWEEN STARTER

SWITCH AND MAGNETIC

SWITCH

REPAIR

YES NO

CHECK IF VOLTAGE IS

PRESENT AT WIRING

CONNECTOR 3BW ON

STARTER SWITCH OF

RESTART RELAY

FAULTY CONNECTION OF

STARTER SWITCH

REPLACE STARTER

SWITCH

DISCONNECTION OR

FAULTY CONNECTION

BETWEEN STARTER

SWITCH AND BATTERY

REPAIR

Page 21

MAGNETIC SWITCH DOES NOT OPERATE THOUGH

STARTER SWITCH IS TURNED TO “START (ST)”

CHECK IF VOLTAGE IS PRESENT AT MAGNETIC

SWITCH TERMINAL “S” WHEN STARTER SWITCH IS

TURNED TO “START (ST)”

SERVICE INFORMATION 00 – 17

YES

YES

YES

CHECK GROUND CABLE

YES NO

REPAIR

OR

PINION

SLIDING

PART DOES

NOT MOVE

MAGNETIC SWITCH

OR COIL IS

DISCONNECTED OR

BURNED OUT

NO

CHECK IF INDICATOR LAMP ON

METER COMES ON NORMALLY

YES NO

CHECK CONTINUITY

STARTER SWITCH AND

MAGNETIC SWITCH

TERMINAL “S”

CHECK STARTER

RELAY

FAULTY CONNECTION

OR STARTER SWITCH

DISCONNECTION OR

FAULTY CONNECTION

BETWEEN BATTERY

AND STARTER SWITCH

REPAIR

REPAIR OR REPLACE STARTER

CHECK CLUTCH

START

REPLACE STARTER

SWITCH

Page 22

00 – 18 SERVICE INFORMATION

PINION MESHES WITH RING GEAR BUT

ENGINE DOES NOT RUN

CHECK GROUND CABLE

YES

FAULTY CONNECTION

OF BRUSH AND

COMMUTATOR

REPAIR OR REPLACE STARTER

BURNED-OUT

MAGNETIC

STARTER SWITCH

NO

REPAIR OR REPLACE

GROUND CABLE

DISCONNECTION

OR DAMAGE OF

FIELD COIL

DISCONNECTION

OR DAMAGED OF

ARMATURE COIL

SLIP OF

PINION

CLUTCH

Page 23

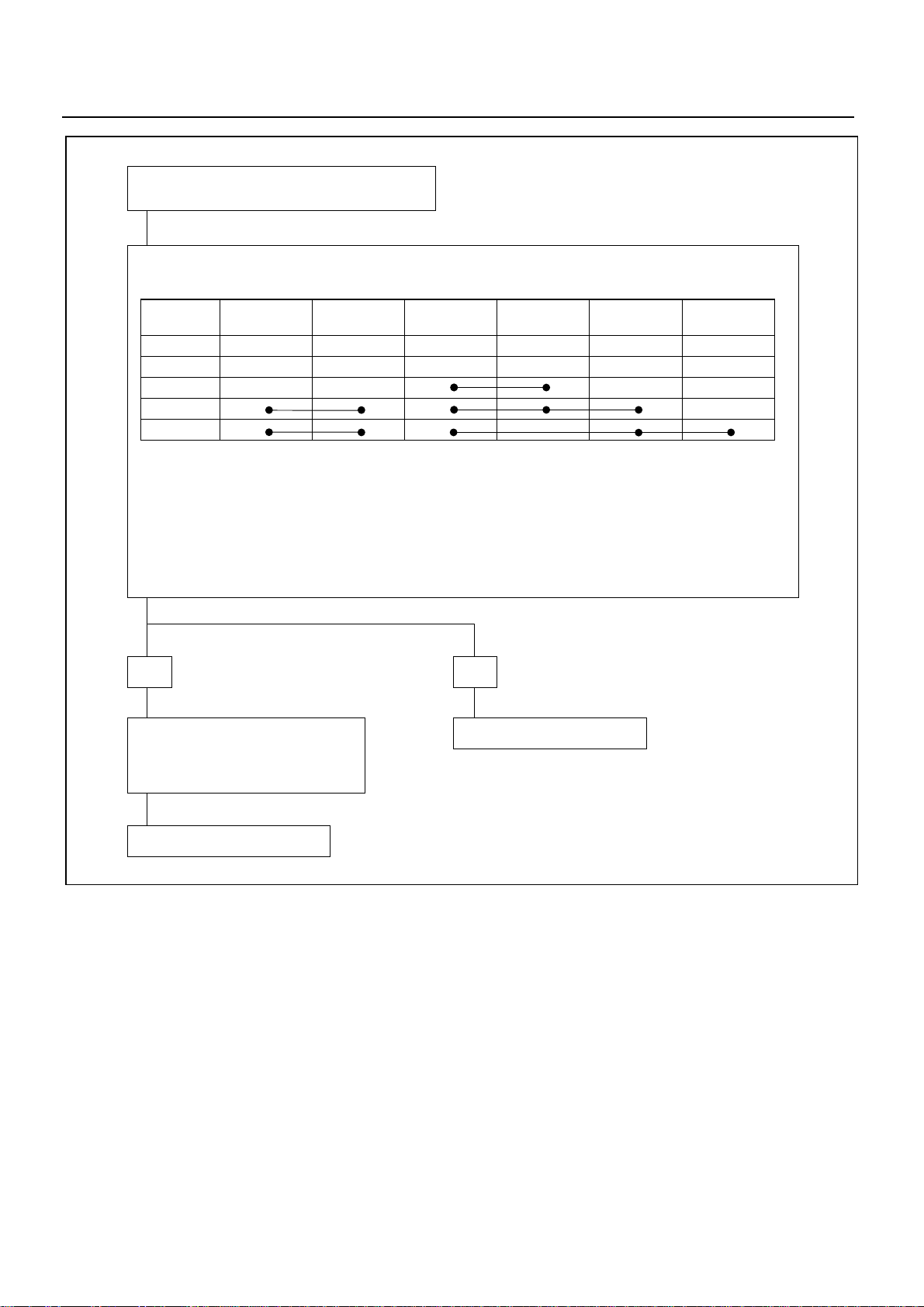

SERVICE INFORMATION 00 – 19

STARTER DOES NOT STOP THOUGH STARTER

SWITCH IS RETURNED TO “ON” FROM “START”

DISCONNECTED STARTER SWITCH WIRING CONNECTOR, AND CHECK STARTER SWITCH OPERATION.

KEY

POSITION

LOCK

OFF

ACC

ON

START

THERE MUST BE NO CONTINUITY EXCEPT ABOVE LINES.

YES

MAGNETIC SWITCH CONTACTS ARE

FUSED AND NOT MOVED, OR A

RETURN SPRING IS BROKEN OR

DETERIORATED

BATTERY

B1

IGNITION

IG1

BATTERYB2ACCESSORIES

ACC

IGNITION

NO

REPLACE STARTER SWITCH

IG2

STARTER

ST

REPLACE MAGNETIC SWITCH

Page 24

00 – 20 SERVICE INFORMATION

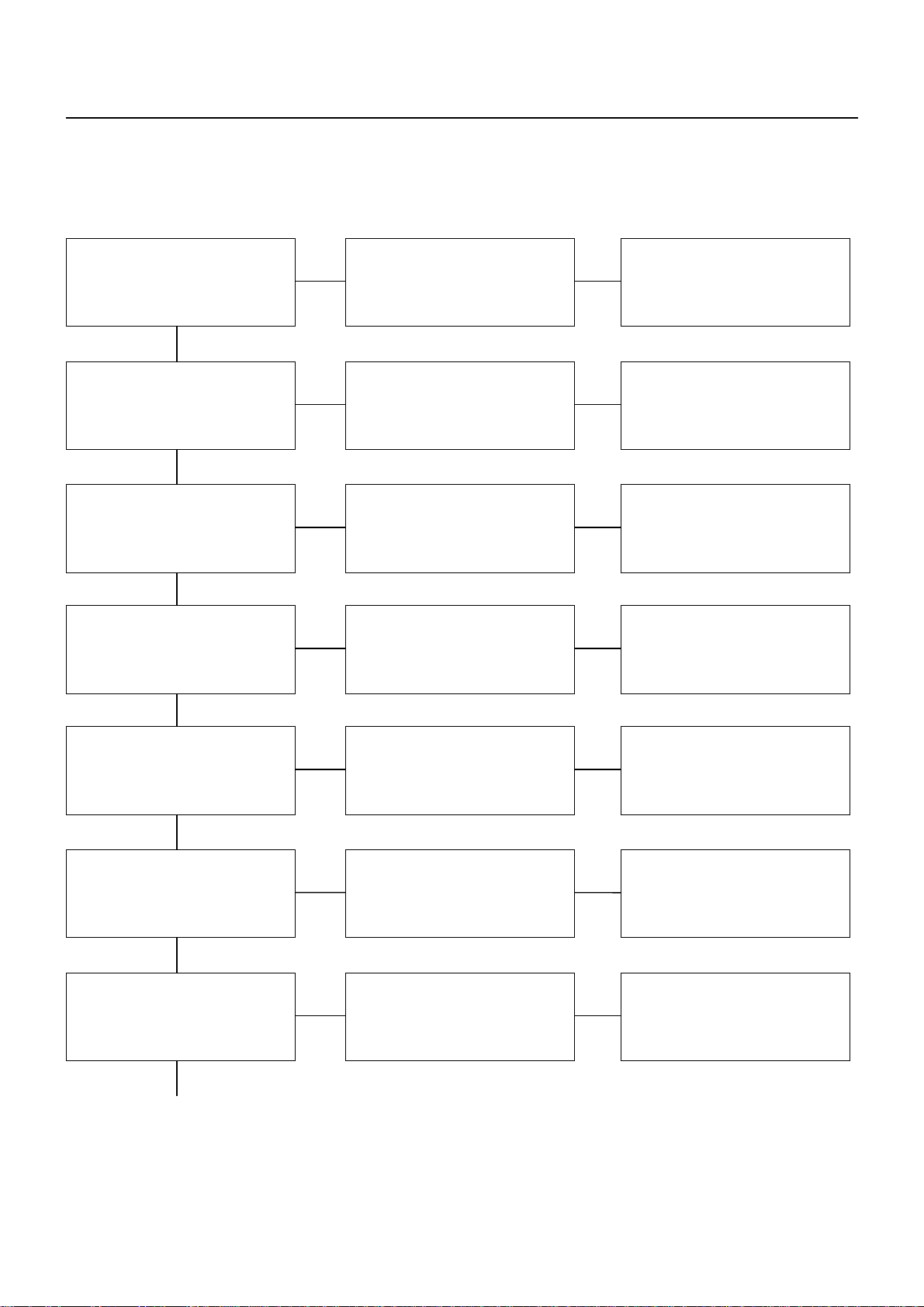

1) ENGINE HAS LESS THAN NORMAL POWER

Checkpoint Trouble Cause Countermeasure

13. TURBOCHARGER

Air cleaner Restricted Clean or replace

OKOK

Intake pipe and hose Restricted Clean or replace

OK

Compressor/Intake manifold Loose (Leaking) Repair

OK

Exhaust manifold/turbine inlet Loose (Leaking) Repair

OK

NG

NG

NG

NG

NG

Exhaust piping and silencers Restricted Clean or replace

OK

Air breather Restricted Clean or replace

OK

Boost compensator

(Injection pump)

Continued on the next page

NG

NG

Defective Repair or replace

Page 25

Checkpoint Trouble Cause Countermeasure

Continued from the previous page

OK

SERVICE INFORMATION 00 – 21

Compressor wheel Impact damage Replace

OKOK

Turbine wheel Impact damage Replace

OK

Rotating assembly Dragging or seized Replace

NG

NG

NG

Carbon build-up Replace

NG

Page 26

00 – 22 SERVICE INFORMATION

Checkpoint Trouble Cause Countermeasure

2) BLUE OR BLACK SMOKE

Air cleaner or intercooler Restricted Clean, repair, or replace

OKOK

Turbocharger oil seal Leakage Replace

OK

Turbocharger oil drain pipe Restricted Repair or replace

OK

Air breather Restricted Clean

OK

NG

NG

NG

NG

Boost compensator

(Injection pump)

OK

Compressor wheel Impact damage Replace

OK

Turbine wheel Impact damage Replace

Continued on the next page

NG

Defective Repair or replace

NG

NG

Page 27

Checkpoint Trouble Cause Countermeasure

Continued from the previous page

OK

SERVICE INFORMATION 00 – 23

Center housing oil drain passage Restricted Clean or replace

NG

Page 28

00 – 24 SERVICE INFORMATION

Checkpoint Trouble Cause Countermeasure

3) EXCESSIVE OIL CONSUMPTION

Air breather Restricted Clean

OKOK

Boost compensator

(Injection pump)

OK

Turbocharger oil seal Leakage Replace

OK

Turbocharger oil drain pipe Restricted Clean or replace

OK

NG

NG

Defective Repair or replace

NG

NG

NG

Turbine wheel Impact damage Replace

OK

Compressor wheel Impact damage Replace

OK

Oil pressure Excessive Repair

Continued on the next page

NG

NG

Page 29

Checkpoint Trouble Cause Countermeasure

Continued from the previous page

OK

SERVICE INFORMATION 00 – 25

Center housing oil drain passage

NG

Restricted Clean or replace

Page 30

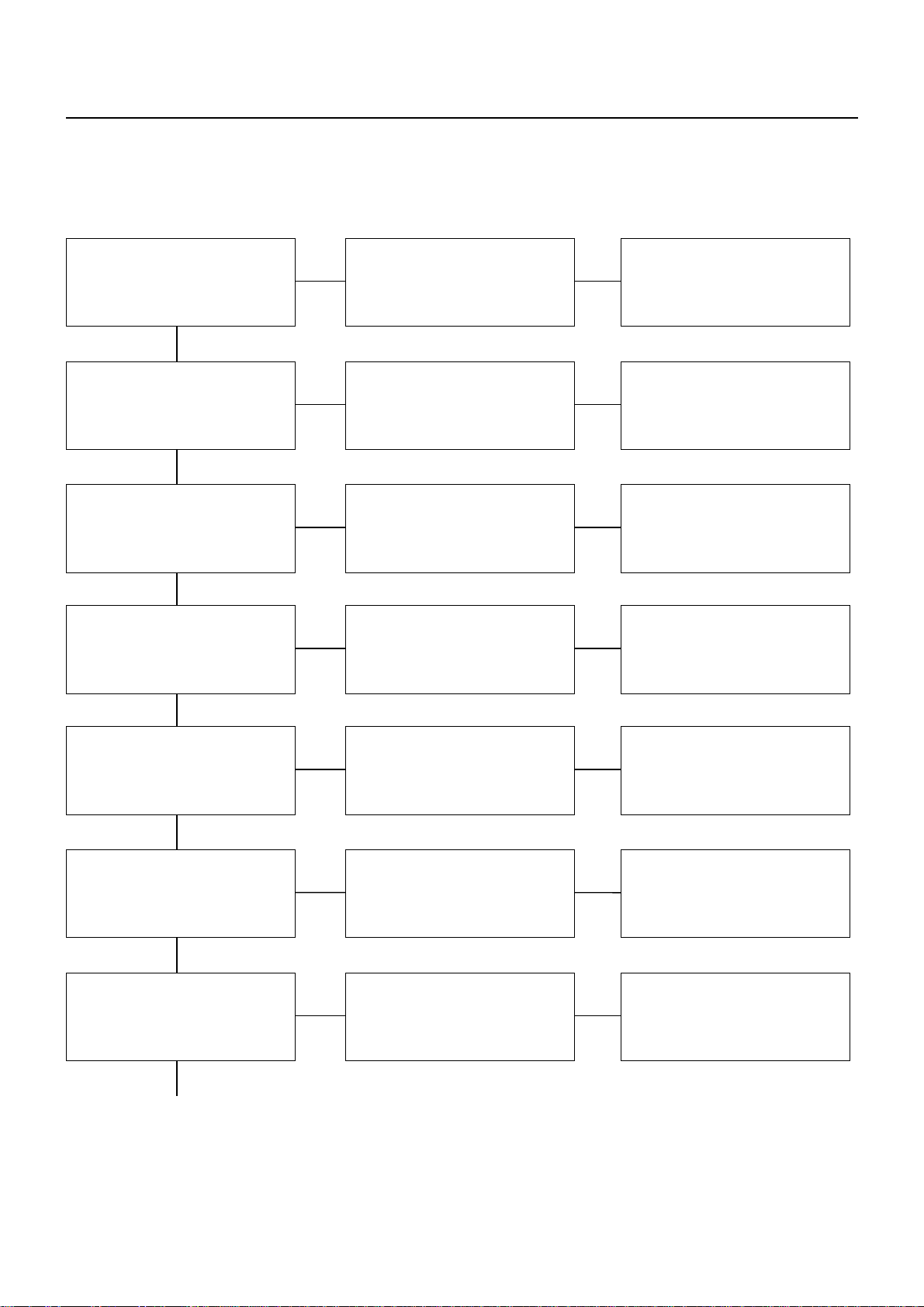

00 – 26 SERVICE INFORMATION

4) EXCESSIVE TURBOCHARGER NOISE

Checkpoint Trouble Cause Countermeasure

Intake and exhaust

system joints

OKOK

Intake and exhaust system

gaskets

OK

Turbocharger rotating parts Rough rotation Replace

Compressor wheel

NG

NG

NG

NG

Restricted Repair

Damaged Replace

Rubbing against housing Repair or replace

OK

Turbine wheel

Continued on the next page

NG

NG

NG

NG

Damaged Replace

Rubbing against housing Repair or replace

Damaged Replace

Carbon deposits Clean or replace

Page 31

Checkpoint Trouble Cause Countermeasure

Continued from the previous page

OK

SERVICE INFORMATION 00 – 27

Oil level Too low Correct

OK

Turbocharger oil feed pipe Restricted Repair or replace

OK

Turbine housing Carbon deposits Clean

OK

NG

NG

Contaminated Replace oil

NG

NG

NG

Compressor housing Dirty Clean

OK

Turbine shaft bearings Worn Replace

NG

Page 32

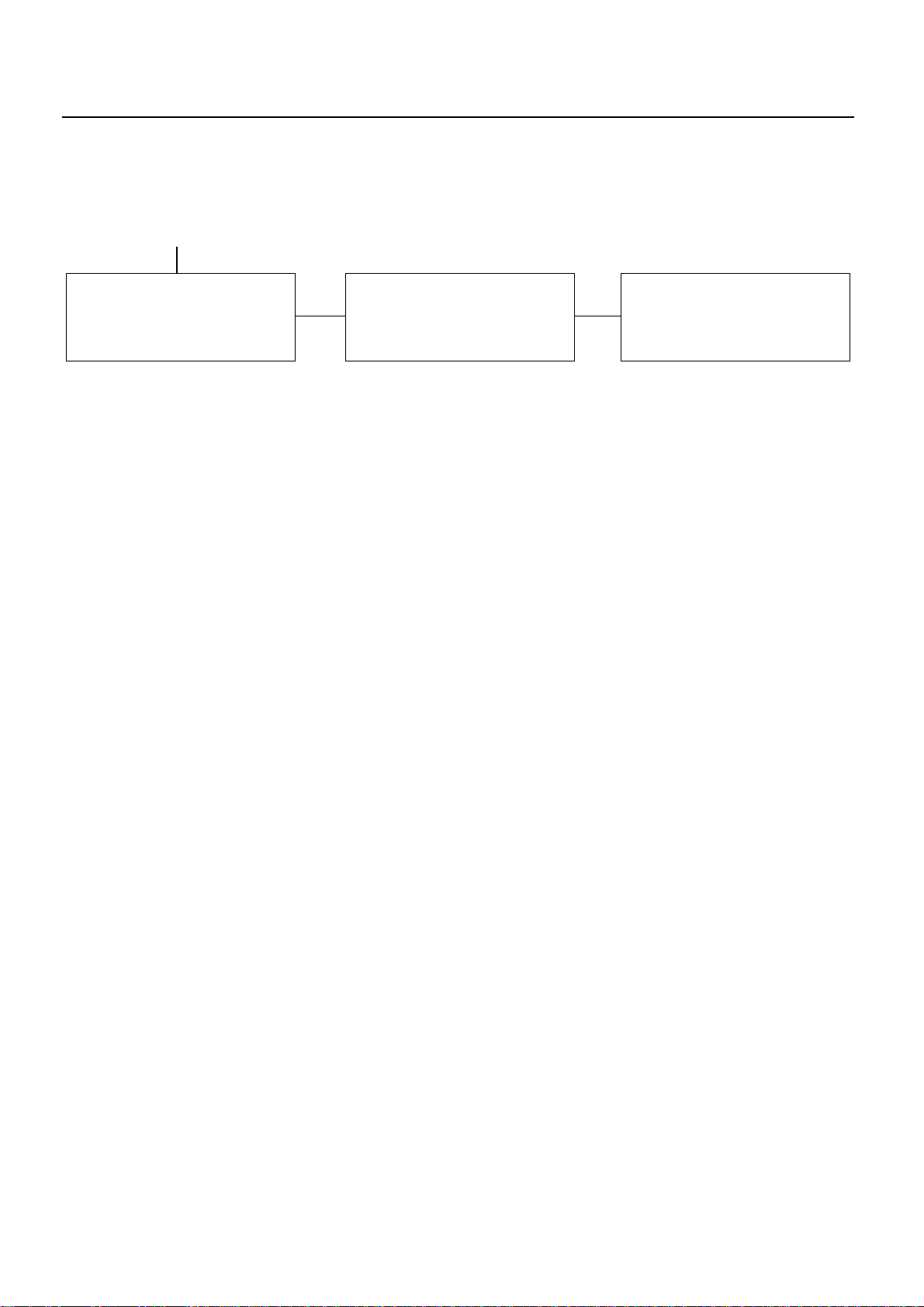

00 – 28 SERVICE INFORMATION

5) EXCESSIVE ROTATING PART WEAR

Checkpoint Trouble Cause Countermeasure

Engine oil Contaminated Change

OK

Turbocharger oil feed pipe Restricted Clean or replace

OK

Turbocharger oil seal Defective Replace

OK

NG

NG

Wrong grade or type Change

NG

NG

Center housing oil

drain passage

OK

Turbine shaft Oil sludge and coking Replace

OK

Engine lubrication system Inadequate oil supply Correct

NG

Restricted Clean or replace

NG

NG

Page 33

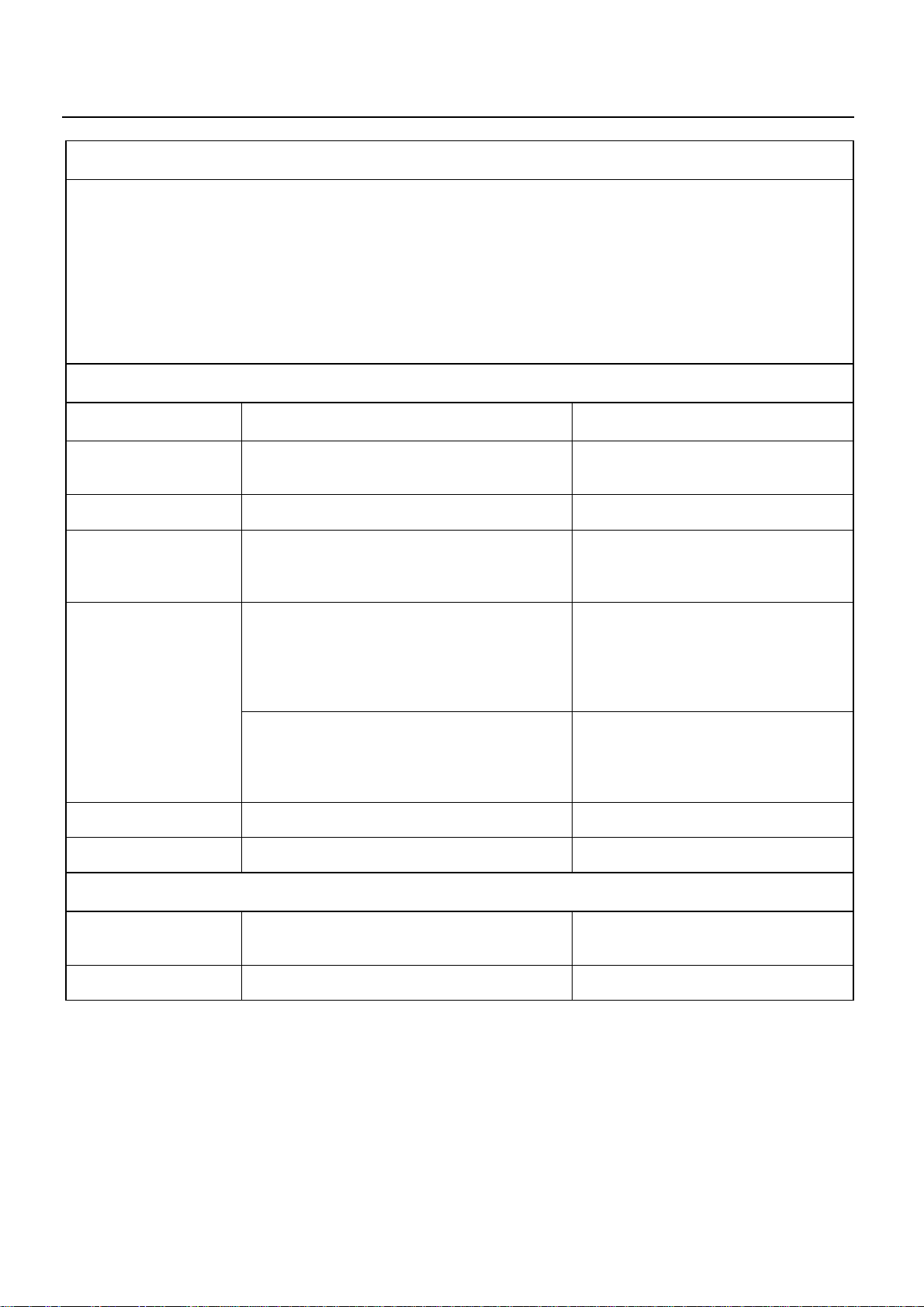

LUBRICATION CHART

4JB1, 4JB1TC, 4JG2, Oil Filter & Oil Cooler

SERVICE INFORMATION 00 – 29

kPa (Kg/cm2/psi)

!

Oil filter relief valve opening pressure : 559 - 0618 (5.7 - 6.3/81 - 90)

"

Oil cooler safety valve opening pressure : 314 - 373 (3.2 - 3.8/46 - 54)

#

Oil filter safety valve opening pressure : 78 - 118 (0.8 - 1.2/11 - 19)

$

Oil pressure switch opening pressure : 29.4 - 49.0 (0.3 - 0.5/4.3 - 7.1)

Lubu Chart 5J.tif

The 4J Series engine lubricating system is a full flow type.

Lubricating oil is pumped from the oil pump to the cylinder body oil gallery through the oil cooler and the oil filter

(replaceable type oil filters have on oil cooler). It is then delivered to the vital parts of the engine from the cylinder

body oil gallery.

Page 34

00 – 30 SERVICE INFORMATION

MAIN DATA AND SPECIFICATIONS

MAIN DATA AND SPECIFICATIONS

Item

Engine type Four-cycle, overhead valve, water cooled

Combustion chamber type Direct injection In direct injection

Cylinder liner type Dry type, chrome plated, stainless steel tube

Timing train system Gear drive Gear and Belt Drive

No. of cylinders - Bore x stroke mm (in) 4 - 93 x 102

No. of piston rings Compression rings: 2 / Oil ring: 1

Total piston displacement cm3 (in3) 2,771 (169.0) 3,059 (186.6)

Compression ratio (to 1) 18.2 (4JB1)

Compression pressure kPa (kg/cm2/psi) 3,038 (31 / 441) 3,334 (34 / 483.8)

Engine weight (Dry) N (kg/lb) Approximately

Fuel injection order 1 - 3 - 4 - 2

Engine Model

4JB1 / 4JB1T / 4JB1TC 4JG2 (G. EXP & EC)

4 - 95.4 x 107

(3.66 x 4.02)

18.1 (4JB1T/4JB1TC)

(For EC 2,363 (24.1 / 531))

2,245 (229 / 505) (4JB1)

2,511 (256 / 564)

(4JB1T/4JB1TC)

(3.76 x 4.21)

20.1

Approximately

2,403 (245 / 540)

Fuel injection timing deg BTDC 14 (4JB1)

BTDC 12 (’91/542A) (4JB1)

BTDC 11 (4JB1T)

BTDC 4 (4JB1TC)

Specified fuel type SAE No. 2 diesel fuel

Idling speed rpm 750 - 790 700 – 740

Valve clearances (At cold): Intake mm(in) 0.40 (0.016)

Exhaust mm(in) 0.40 (0.016)

Valve clearances (At hot): Intake mm(in) 0.45 (0.018)

Exhaust mm(in) 0.45 (0.018)

Intake valves Open at (BTDC) deg 24.5

Close at (ATDC) deg 55.5

Exhaust valves Open at (BTDC) deg 54

Close at (ATDC) deg 26

NOTE: G.EXP : General Export Model

EC : European Countries

Emission Gas Control Standard

’91/542A : Euro 1

’91/542B : Euro 2

ATDC 1 (Belt ’91/542A)

TDC 0° (Belt ’91/542B)

ATDC 2 (Gear ’91/542A)

Page 35

SERVICE INFORMATION 00 – 31

Item

Lubricating system

Lubrication method Pressurized circulation

Specified engine oil (API grade) CC (4JB1)

Oil pump type Gear

Oil filter type Disposable cartridge (Spin-on) Paper element

Oil capacity (Including oil filter)

Oil cooler type Water cooled

Fuel system

Injection pump type Bosch distributor

Governor type Mechanical (Partially variable speed) (For EC Variable speed)

Injection nozzle type Hole Pinttle

Injection nozzle kPa (kg/cm2/psi)

opening pressure

Engine Model

lit (US/UK gal) 6.6 - 7.1 (1.74 - 1.87/2.62 - 2.82)

4JB1 / 4JB1T / 4JB1TC 4JG2 (G. EXP & EC)

CC

CD (4JB1T/4JB1TC)

(For EC 6.2 - 8.2 (2.17 - 1.64 / 1.36 - 1.80))

18,142 (185 / 2,631)

(4JB1/4JB1T)

14,710 (150/2,133)

1st: 19,500 (199 / 2,830)

2nd: 26,500 (270 / 3,840)

(4JB1TC)

Main fuel filter type Cartridge paper element and water separator

Air cleaner type Dry paper element

Generator capacity V-A (W) 12 - 40 (480) and 12 - 50 (600) 12 - 50 (600)

(For EC 12 - 60 (720))

Starter motor output V-kW 12 - 2.0 and 12 - 2.2 12 - 2.2

(For EC 12 - 2.0)

Turbocharger IHI RHB5 (4JB1T)

IHI RHF4 (4JB1TC)

Page 36

00 – 32 SERVICE INFORMATION

Engine Cooling

Cooling system

Radiator

Heat radiation capacity kcal/h

Heat radiation area m

Front area m

2

(ft2)

2

(ft2)

Dry weight N (Kg/lb)

Radiator cap

Valve opening pressure kPa (Kg/cm

2

/psi)

Coolant capacity lit (Imp.qt./US qt.)

88.2 - 116.7 (0.899 - 1.199/12.78 - 17.05)

Coolant forced circulation

(2 tube in row) Tube type Corrugated

71400

11.78 (126.8)

0.216 (2.325)

105 (10.7/23.6)

3.1 (2.73/3.28)

(For EC 5.8 (5.1/6.13))

Coolant pump

Pulley type

Pulley ratio

Thermostat type

Centrifugal impeller type

1.2

wax pellet with jiggle valve.

Without jiggle valve (Thailand only)

Valve opening °C (°F)

Valve full open °C (°F)

82 (180)

95 (203)

Coolant total capacity Iit (Imp.qt./US qt.) 10 (8.80/10.57) (For EC 7.3 (6.42/7.71))

Starting System

Manufacturer DENSO

Engine Model 4JB1 / 4JB1T / 4JB1TC 4JG2 (G.EXP & EC)

Rating

Voltage V 12

Output kW 2.0 2.2

Time Sec 30

Number of tooth of pinion 9

Rotating direction (as viewed from pinion) Clockwise

Weight (approx.) kg 4.6 5.4

No-load characteristics

Voltage/current V/A

Speed rpm

11.5/100 or less

3700 or more

Load characteristics

Voltage/current V/A

Torque N•m(Kg•m/lb•ft)

7.5/500 or less

13.7 (1.4/10.1)

Speed rpm 1200 or more 1400 or more

Locking characteristics

Voltage/current V/A

Torque N•m(Kg•m/lb•ft)

2.4/800 or less

18 (1.8/13) or more

2.0/850 or less

16 (1.6/12) or more

Page 37

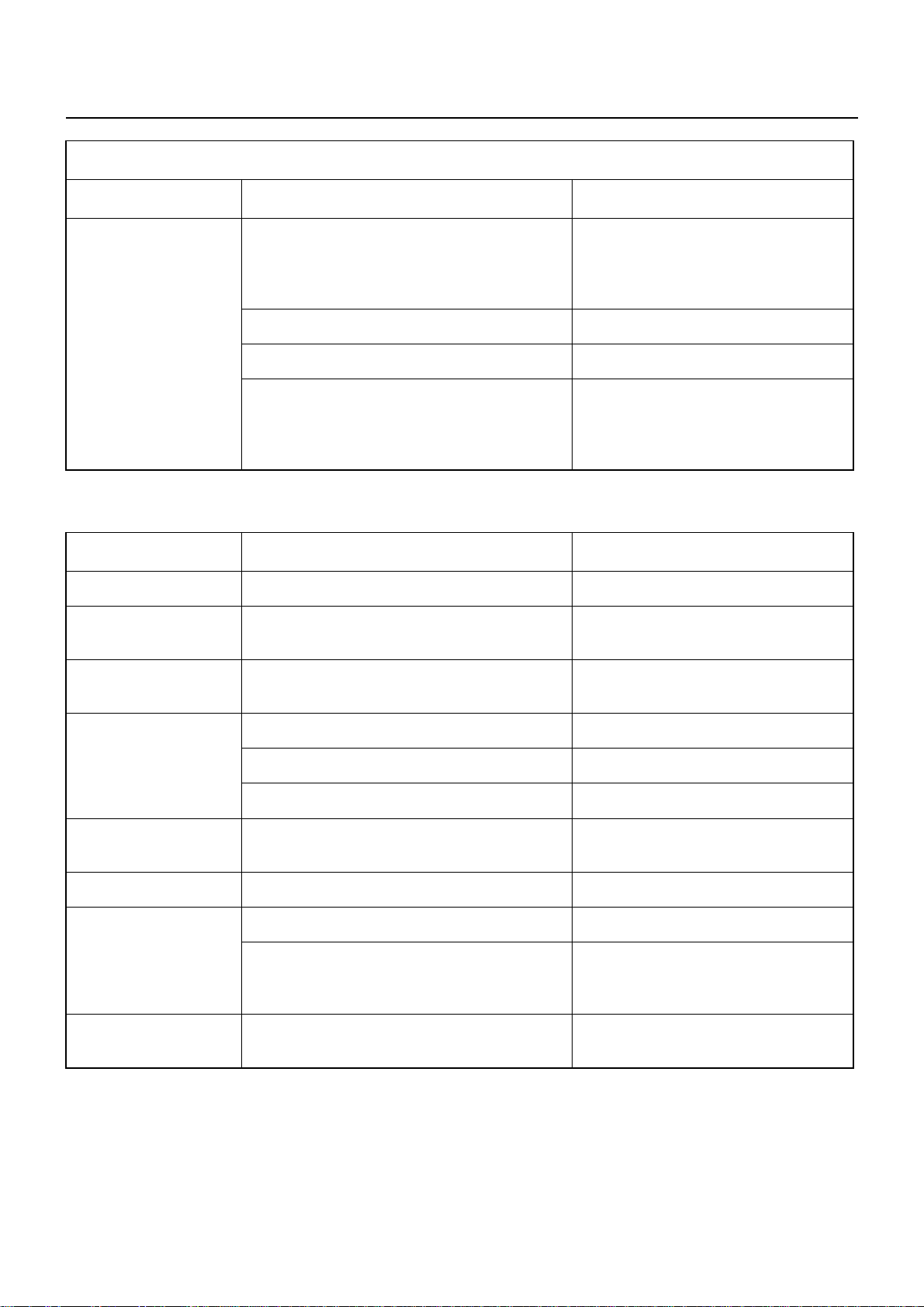

SERVICE INFORMATION 00 – 33

Charging System

Manufacturer HITACHI LR150-449B DENSO

Rated voltage V 12 12

Rated output A 50 40

Rotating direction

(As viewed from pulley)

Pulley effective diameter mm (in) 80 (3.15) 82 (3.23)

Weight (with pump) kg (lb) 6.0 (13.27)

Clockwise Clockwise

6.7 (14.77)

4JB1TC for G.E

4JB1TC for EC

4JB1TC for Thailand

Page 38

00 – 34 SERVICE INFORMATION

SERVICE STANDARD

Engine Mechanical

Parts Items

Cylinder

Head

Valve

Spring

Cylinder head deck, and

exhaust manifold mating

surface for flatness

Cylinder head height 92.0 (3.622) 91.55 (3.6043)

Cylinder Head Lower Face

Warpage.

Manifold Warpage.

Hot plug sinking

Hot plug exert pressure

Free height

Squareness

Service standard Service limit

4JG2

0.05 (0.002) or less 0.2 (0.0079)

0.05 (0.002)or less

0.05 (0.002) or less

4,500 – 5,500 kg

(9922.5 - 12127.5 lbs)

48.0 (1.891)

4JB1 / 4JB1T /

4JB1TC

-

-

4JG2

0.20 (0.008)

0.20 (0.008)

0.02 (0.0008)

-

47.10 (1.856)

1.7 (0.067)

4JB1 / 4JB1T /

4JB1TC

mm (in)

Remarks

Cannot be

Reground

Valve

and

Valve

Guide

Spring tension N (kg/lb)

Diameter Valve Stem

IN

EX

Valve and valve guide

clearance IN

EX

Valve guide upper end

height (Measured from the

Cylinder head upper face)

Valve guide margin

Valve thickness IN

EX

Valve seat contact surface

angle

296 (30.2/66.4)

7.946 - 7.961

(0.3128 - 0.3134)

7.921 - 7.936

(0.3118 - 0.3124)

0.039 - 0.069

(0.0015 - 0.0027)

0.064 - 0.096

(0.0025 - 0.0038)

13.0 (0.512)

1.1 (0.0433)

1.41 (0.0556)

1.39 (0.0547)

1.79 (0.0705)

1.83 (0.0720)

45°

257.9 (26.3/57.9) At installed

7.880 (0.3102)

7.850 (0.3090)

0.200 (0.0079)

0.250 (0.0098)

-

1.6 (0.0630)

1.1 (0.0433)

1.1 (0.0433)

1.5 (0.06)

1.5 (0.06)

height

38.9 (1.531)

Valve seat contact width

IN

EX

1.7 (0.0669)

2.0 (0.0787)

2.2 (0.0866)

2.5 (0.0984)

Page 39

SERVICE INFORMATION 00 – 35

Service standard Service limit

Parts Items

4JG2

Push rod Curvature - 0.4 (0.0157) or less

4JB1 / 4JB1T /

4JB1TC

4JG2

4JB1 / 4JB1T /

4JB1TC

mm (in)

Remarks

Camshaft End play

Cam lobe height

Journal diameter

Runout

Camshaft bearing inside

diameter

Camshaft oil clearance

Tappet Outside diameter

Oil clearance

(Between tappet and

cylinder body)

Rocker

arm

Assembly

Rocker shaft outside

diameter

Rocker arm inside

diameter

Oil clearance

(Between rocker arm and

rocker shaft)

0.08 (0.0031)

42.02 (1.6543)

49.945 - 49.975(1.9663-1.9675)

0.02 (0.0008) or less

50.000 - 50.030

(1.9685 - 1.9697)

0.025 - 0.085

(0.0098 - 0.00334)

12.97 - 12.99 (0.5106 - 0.5114)

0.03 (0.0118)

18.98 - 19.00

(0.7472 - 0.7480)

19.036 - 19.060

(0.7494 - 0.7504)

0.06 - 0.08

(0.00235 - 0.00315)

0.2 (0.0079)

41.65 (1.6397)

49.60 (1.9527)

0.10 (0.0039)

50.08(1.9716)

0.12 (0.0047)

12.95 (0.5098)

0.10 (0.0039)

18.90 (0.7440)

19.10 (0.7520)

0.10 (0.004)

Rocker shaft runout

Oil clearance

Body and gear

Body cover and gear 0.06 (0.0024) 0.02 - 0.07

Crankshaft Thrust clearance 0.10 (0.0039) 0.30 (0.018)

Main bearing clearance

(Between main bearing

and Crankshaft)

Crankshaft runout

Main journal diameter

Crankshaft pin diameter

Crankshaft Journal and

Crank Pin uneven wear

Crank Pin and Bearing

Clearance.

0.14 (0.0055) 0.13 - 0.14

0.031-0.063

(0.0012-0.0025)

0.05 (0.00197) or less

69.917 - 69.932 (2.7526 - 2.7532)

52.915 - 52.930 (2.0833 - 2.0839)

0.05 (0.002) or less

0.029 - 0.066 (0.0011 - 0.0026)

-

(0.0051-0.0055)

(0.0008-0.0028)

0.035-0.080

(0.0014-0.0032)

0.2 (0.0079) or less

0.20 (0.0079) 0.15 (0.0059)Oil pump

0.15 (0.0059)

0.11

(0.0043)

0.08 (0.0031)

69.91 (2.7524)

52.90 (2.0827)

0.08 (0.003)

0.100 (0.0039)

Page 40

00 – 36 SERVICE INFORMATION

Parts Items

Service standard Service limit

4JG2

4JB1 / 4JB1T /

4JB1TC

4JG2

4JB1 / 4JB1T /

4JB1TC

mm (in)

Remarks

Piston

pin,

Piston

ring and

Connecting rod

Piston diameter 95.365 - 95.404

(3.7545-3.9039)

Piston Clearance

(Between piston and

Cylinder liner)

Piston ring gap 1st

Piston ring clearance 1st

0.047 - 0.065

(0.0019-0.0026)

(0.0079 –

2nd

(0.0146 -

Oil

(0.0079 -

(0.0035 -

2nd

(0.002 -

0.20 - 0.35

0.0138)

0.37 - 0.52

0.0205)

0.20 - 0.40

0.00157)

0.09 - 0.13

0.0051)

0.05 - 0.09

0.0035)

92.985 - 93.024

(3.6600-3.6623)

0.025 - 0.045

(0.0010-0.0018)

0.20 - 0.40

(0.0079 –

0.0157)

0.20 - 0.40

(0.0079 -

0.00157)

0.10 - 0.30

(0.0039 -

0.0118)

0.090 - 0.125

(0.0035 -

0.0049)

0.050 - 0.075

(0.0020 -

0.0030)

-Piston,

-

1.5 (0.0591)

1.5 (0.0591)

1.5 (0.0591)

0.15 (0.0059)

Oil 0.03 - 0.07

(0.0012 - 0.0028)

Piston pin diameter 33.995 - 34.000

(1.3384-1.3386)

Fitting interference

(Between connecting

rod and piston pin)

Fitting interference

(Between piston and

piston pin)

Connecting rod

alignment Bend

Twist

Piston pin and Connecting

Rod Bushing Clearance

Connecting rod thrust

clearance

Oil clearance

(Between crank pin and

Connecting rod) 0.0033) 0.0026)

0.029 -0.083 0.029 - 0.066 0.100 (0.0039)

(0.0014 - (0.0011 -

0.008 - 0.020

(0.0003 - 0.0008)

0.002 - 0.015

(0.0001 - 0.0006)

0.08 (0.0031) or less

0.05 (0.0020) or less

0.008 - 0.020

(0.0003 - 0.0008)

0.230 (0.0091)

30.995 - 31.000

(1.2202-1.2204)

0.15 (0.0059)

33.970

(1.3374)

0.05 (0.0020)

0.04 (0.0016)

0.20 (0.0079)

0.15 (0.0059)

0.050 (0.0020)

0.35 (0.0138)

30.970

(1.2190)

Per 100

(3.94)

Per 100

(3.94)

Page 41

Parts Items

SERVICE INFORMATION 00 – 37

Service standard Service limit

4JG2

4JB1 / 4JB1T /

4JB1TC

4JG2

4JB1 / 4JB1T /

4JB1TC

mm (in)

Remarks

Cylinder

Block

Warpage

(Upper surface of the

cylinder block)

Cylinder bore diameter 97.000 - 97.040 95.011 - 95.040

(3.8189 - (3.7406 -

3.8205) 3.7417)

Cylinder liner projection 0.0-0.1

Cylinder liner inside 95.420 - 95.460 93.020 - 93.060

diameter (3.7567 - (3.6622 -

3.7583) 3.6638)

Cylinder liner outside 97.011-97.050 95.011 - 95.050

diameter (3.8193 - (3.7405 -

3.8209) 3.7421)

- 0.20 (0.0079)

(0.00-0.0039)

Page 42

00 – 38 SERVICE INFORMATION

SERVICING

Servicing refers to general maintenance procedures to be

performed by qualified service personnel.

MODEL IDENTIFICATION

Engine Serial Number

The engine number is stamped on the front left hand side

of the cylinder body.

0038-1.tif

AIR CLEANER

Dry Type Paper Element

Element cleaning procedures will vary according to the

condition of the element.

0038-2.tif

Dust fouled Element

Rotate the element with your hand while applying

compressed air to the inside of the element. This will

blow the dust free.

Compressed air pressure kPa (kg/cm

392 - 490 (4 - 5/57 - 71)

CAUTION

Do not bang the element against another object in an

attempt to clean it. Damage to the element will result.

Carbon and Dust Fouled Element

1. Prepare a cleaning solution of Isuzu Genuine Element

Cleaner (Donaldson D1400) diluted with water.

2. Submerge the element in the solution for twenty

minutes.

2

/Psi)

0038-3.tif

Page 43

0039-1.tif

SERVICE INFORMATION 00 – 39

3. Remove the element from the solution and rinse it

well with running water.

Water pressure must not exceed 274 kPa (2.8 kg/cm

/40Psi)

4. Dry the element in a well ventilated area.

An electric fan will hasten drying.

NOTE:

Do not use compressed air or an open flame to dry

the element quickly. Damage to the element will

result. It will usually take two or three days for the

element to dry completely. Therefore, it is a good idea

to have a spare on hand to use in the interim.

2

0039-2.tif

050LX001.tif

LUBRICATING SYSTEM

Main Oil Filter (Cartridge Type Paper Element)

Replacement Procedure

1. Loosen the used oil filter by turning it

counterclockwise with the filter wrench.

2. Clean the oil filter fitting face.

This will allow the new oil filter to seat properly.

3. Apply a light coat of engine oil to the O-ring.

4. Turn in the new oil filter until the filter O-ring is fitted

against the sealing face.

5. Use the filter wrench to turn in the filter an additional 1

and 1/4 turns.

Filter Wrench : 5-8840-0200-0 (89mm/3.5in)

5-8840 0202-0 (106mm/4.2in)

5-8840-2209-0 (100.6mm/4.0in)

6. Check the engine oil level and replenish to the

specified level if required.

Replenishment Engine Oil lit (Imp qt/US qt)

0.7 (0.62/0.74)

0039-4.tif

7. Start the engine and check for oil leakage from the

main oil filter.

Page 44

00 – 40 SERVICE INFORMATION

FUEL SYSTEM

Fuel Filter

Replacement Procedure

1. Loosen the used fuel filter by turning it

counterclockwise with the filter wrench.

Filter Wrench: 5-8840-0253-0 (J-22700)

0040-1.tif

2. Clean the filter cover fitting faces.

This will allow the new fuel filter to seat properly.

0040-2.tif

0040-3.tif

0040-4.tif

3. Turn in the fuel filter until the sealing face comes in

contact.

4. Turn in the fuel filter an additional 2/3 of a turn with a

filter wrench.

Filter Wrench: 5-8840-0253-0 (J-22700)

5. Loosen the bleeder plug on the injection pump

overflow valve.

6. Operate the priming pump until fuel begins to flow

from the fuel filter.

7. Retighten the bleeder plug.

8. Operate the priming pump several times and check

for fuel leakage.

NOTE:

The use of an ISUZU genuine fuel filter is strongly

recommended.

0041-1.tif

Fuel Filter Water Draining Procedure

The indicator light will come on when the water level in

the water separator exceeds the specified level.

Drain the water and foreign material from the water

separator with the following procedure.

Page 45

0041-2.tif

SERVICE INFORMATION 00 – 41

1. Find a safe place to park the vehicle.

2. Open the engine hood and place a container

(Approximately 0.2 liter capacity) at the end of the

vinyl hose beneath the drain plug on the separator.

3. Loosen the drain plug by turning it counterclockwise

(Approximately 5 turns) and operate the priming pump

up and down about 10 times until water is drained

approximately 0.1 liter.

4. After draining, securely tighten the drain plug by

turning it clockwise and operate the priming pump

manually up and down several times.

5. After starting the engine, check to see that there is no

fuel leak from the drain plug. Also check to see that

the fuel filter water indicator light has turned off.

If water separator requires frequent draining, have the

fuel tank drained for removal of water at your Isuzu

Dealer.

Air Bleeding

1. Loosen the bleeder screw on the injection pump

overflow valve.

2. Operate the priming pump until fuel mixed with foam

flows from the bleeder screw.

3. Tighten the bleeder screw.

4. Operate the priming pump several times and check

for fuel leakage.

0041-3.tif

0041-4.tif

0042-1.tif

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator reserve

tank as necessary.

If the coolant level falls below the “MIN” line, carefully

check the cooling system for leakage. Then add enough

coolant to bring the level up to the “MAX” line.

Engine coolant change procedure

1. To change engine coolant, make sure that the engine

is cool.

WARNING:

When the coolant is heated to a high

temperature, be sure not to loosen or remove

the radiator cap. Otherwi se you might get

scalded by hot vapor or boiling water. To open

the radiator cap, put a piece of thick cloth on the

cap and loosen the cap slowly to reduce the

pressure when the coolant has become cooler.

2 Open radiator cap and drain the cooling system by

loosening the drain valve on the radiator and on the

cylinder body.

Page 46

00 – 42 SERVICE INFORMATION

NOTE:

For best result it is suggested that the engi ne

cooling system be flushed at least once a year.

it is advisable to flush the interior of the cooling

system including the radiator before using antifreeze (ethylene-glycol based).

Replace damaged rubber hoses as the engine

anti-freeze coolant is liabl e t o l eak out even

minor cracks. Isuzu recommends to use lsuzu

genuine anti-freeze (ethylene-glycol based) or

equivalent, for the cooling system and not add

any inhibitors or additives.

CAUTION:

A failure to correctly fill the engine cooling

system in changing or topping up coolant may

sometimes cause the coolant to overflow f r om

the filler neck even before the engine and

radiator are completely full. If the engine runs

under this condition, shortage of coolant may

possibly result in engine overheating. To avoid

such trouble, the following precautions should

be taken in filling the system.

3 To refill engine coolant, pour coolant up to filler neck

using a filling hose which is smaller in outside

diameter of the filler neck.

Othewise air between the filler neck and the filling

hose will block entry, preventing the system from

completely filling up.

4 Keep a filling rate of 9 liter/min. or less. Filling over

this maximum rate may force air inside the engine

and radiator. And also, the coolant overflow will

increase, making it difficult to determine, whether or

not the system is completely full.

5 After filling the system to the full, pull out the filling

hose and check to see if air trapped in the system is

dislodged and the coolant level goes down. Should

the coolant level go down, repeat topping-up until

there is no more drop in the coolant level.

6 After directly filling the radiator, fill the reservoir to the

maximum level.

7 Install and tighten radiator cap and start the engine.

After idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.

WARNING:

When the coolant is heated to a high

temperature, be sure not to loosen or remove

the radiator cap. Otherwi se you might get

scalded by hot vapor or boiling water. To open

the radiator cap, put a piece of thick cloth on the

cap and loosen the cap slowly to reduce the

pressure when the coolant has become cooler.

8 After tightening radiator cap, warm up the engine at

about 2,000 rpm. Set heater adjustment to the

highest temperature position, and let the coolant

circulate also into heater water system.

9 Check to see the thermostat has opened through the

Page 47

0042-2.tif

0042-3.tif

SERVICE INFORMATION 00 – 43

needle position of water thermomete, conduct a

5 minutes idling again and stop the engine.

10 When the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant is found, Check the

coolant system and reservoir tank hose for leakage.

11 Fill the coolant into the reservoir tank up to “MAX”

line.

Cooling System Inspection

Install a radiator filler cap tester to the radiator. Apply testing

pressure to the cooling system to check for leakage.

The testing pressure must not exceed the specified pressure.

Testing Pressure kPa (Kg/cm2/psi)

147 (1.5/21)

Radiator Cap Inspection

The radiator filler cap is designed to maintain coolant

pressure in the cooling system at 1.05 kg/cm

kPa). Check the radiator filler cap with a radiator filler cap

tester. The radiator filler cap must be replaced if it fails to

hold the specified pressure during the test procedure.

Radiator Filler Cap Pressure

Pressure Valve kPa (Kg/cm

Negative Valve (Reference) kPa (Kg/cm2/psi)

88 - 118 (0.9 - 1.2/12.8 - 17.1)

1.0 - 13.9 (0.01 - 0.04/0.14 - 0.57)

2

(15 psi / 103

2

/psi)

0042-4.tif

Thermostat Operating Test

1. Completely submerge the thermostat in water.

2. Heat the water.

Stir the water constantly by suitable wood bar (2) to

avoid direct heat being applied use wood plate (3) to

the thermostat.

3. Check the thermostat initial opening temperature.

Thermostat Initial

Opening Temperature °C (°F)

4. Check the thermostat full opening temperature.

Thermostat Full

Opening Temperature °C (°F)

Valve Lift at Fully Open Position mm (in)

82 (180)

95 (203)

10 (0.39)

Page 48

00 – 44 SERVICE INFORMATION

0043-1.tif

Drive Belt Adjustment

Depress the drive belt mid portion with a 98N (10 kg/22

lb) force.

Drive Belt Deflection mm (in)

10 (0.39)

Check the drive belt for cracking and other damage.

1. Crankshaft damper pulley

2. Generator pulley

3. Cooling fan pulley

4. Oil pump pulley or idler pulley

5. Compressor pulley or idle pulley

Cooling Fan Pulley Drive Belt

Fan belt tension is adjusted by moving the generator.

Depress the drive belt mid portion with a 98N (10 kg/22

lb) force.

1. Crankshaft damper pulley

2. Generator pulley

3. Cooling fan pulley

0043-2.tif

0043-3.tif

0043-4.tif

Compressor Pulley Drive Belt

Move the idler pulley as required to adjust the compressor

drive belt tension.

If the vehicle is equipped with power steering, move the

oil pump as required.

Depress the drive belt mid portion with a 98N (10 kg/22

lb) force.

Belt Deflection mm (in)

14 - 17 (0.55 - 0.67)

1. Crankshaft damper pulley

2. Oil pump pulley or idler pulley

Power Steering Oil Pump Pulley Drive Belt

Move the oil pump as required to adjust the oil pump drive

belt tension.

On air conditioner equipped models, both drive belts

pulley must always be replaced as a set.

Depress the drive belt mid portion with a 98N (10 kg/22

lb) force.

Belt Deflection mm (in)

1. Crankshaft damper pulley

2. Oil pump pulley

3. Compressor pulley or idler pulley

14 - 17 (0.55 - 0.67)

Page 49

SERVICE INFORMATION 00 – 45

ENGINE CONTROL

Idling Speed Inspection

1. Set the vehicle parking brake and choke the drive

wheels.

2. Place the transmission in neutral.

3. Start the engine and allow it to warm up.

4. Disconnect the engine control cable from the control

lever.

5. Set a tachometer to the engine.

6. Check the engine idling speed.

If the engine idling speed is outside the specified

range, it must be adjusted.

Engine Idling Speed rpm

4JB1 / 4JB1T / 4JB1TC 750 - 790

4JG2 700 - 740

Idling Speed Adjustment

0044-1.tif

1. Loosen the idling set bolt lock nut on the injection

pump idling set bolt.

2. Adjust the idling speed to the specified range by

turning the idling set bolt.

3. Lock the idling set bolt with the idling set bolt lock nut.

4. Check that the idling control cable is tight (free of

slack).

If required, remove the slack from the cable.

Accelerator Control Cable Adjustment

1. Loosen the accelerator cable clamp bolt.

2. Check that the idling control knob on the instrument

panel is in the engine idling position.

3. Hold the accelerator lever in the fully closed position

and stretch the control cable in the direction indicated

by the arrow to remove any slack.

Accelerator Pedal Adjustment

1. Loosen the lock nut.

2. Adjust bolt height from floor.

Adjust Bolt Height A mm (in)

18 - 28 (0.71 - 1.1)

0044-2.tif

Page 50

00 – 46 SERVICE INFORMATION

0045-1.tif

1. Hold the accelerator pedal pad securely by hand, and

give it a full stroke.

2. Adjust the stopper bolt so that the clearance between

the pad stopper bolt and the rear side of the pad

becomes the specified length.

0 - 2 (0 - 0.079)

mm (in)

3. Check to see if the accelerator pedal play is in the

range of 5 to 10mm above the pedal pad.

4. Press down on the accelerator pedal fully and check

to see if the engine rotates at its maximum speed with

each of the linkage in the smooth operation.

5. In the operating range of accelerator pedal and the

injection pump lever returns to their respective original

positions without fail.

VALVE CLEARANCE ADJUSTMENT

1. Bring the piston in either the No. 1 cylinder or the No.

4 cylinder to TDC on the compression stroke by

turning the crankshaft until the crankshaft damper

pulley TDC line is aligned with the timing pointer.

0045-2.tif

0045-3.tif

0045-4.tif

2. Check the rocker arm shaft bracket nuts for

looseness.

Tighten any loose rocker arm shaft bracket nuts

before adjusting the valve clearance.

Rocker Arm Shaft

Bracket Nut Torque N∙m (kg∙m/lb∙ft)

54 (5.5/40)

3. Check for play in the No. 1 intake and exhaust valve

push rods.

If the No. 1 cylinder intake and exhaust valve push

rods have play, the No. 1 piston is at TDC on the

compression stroke.

If the No. 1 cylinder intake and exhaust valve push

rods are depressed, the No. 4 piston is at TDC on the

compression stroke.

Page 51

0046-1.tif

SERVICE INFORMATION 00 – 47

Adjust the No. 1 or the No. 4 cylinder valve clearance

while their respective cylinders are at TDC on the

compression stroke.

Valve Clearance (At Cold) mm (in)

0.4 (0.016)

4. Loosen each valve clearance adjusting screw as

shown in the illustration.

5. Insert a feeler gauge of the appropriate thickness

between the rocker arm and the valve stem end.

6. Turn the valve clearance adjusting screw until a slight

drag can be felt on the feeler gauge.

7. Tighten the lock nut securely.

8. Rotate the crankshaft 360°.

9. Realign the crankshaft damper pulley TDC notched

line with the timing pointer.

10. Adjust the clearance for the remaining valves as

shown in the illustration.

0046-2.tif

0046-3.tif

0046-4.tif

INJECTION TIMING ADJUSTMENT

1. Check that the notched line on the injection pump

flange is aligned with the front plate or the timing gear

case notched line.

2. Bring the piston in the No. ! cylinder to TDC 1 on the

compression stroke by turning the crankshaft until the

crankshaft pulley TDC line is aligned with the timing

"

mark

Note:

Check for play in the No. 1 intake and exhaust valve

push rods.

If the No. 1 cylinder intake and exhaust valve push

rods have play, the No. 1 piston is at TDC on the

compression stroke.

.

0046-5.tif

3. Disconnect the injection pipe from the injection pump.

4. Remove one bolt from the distributor head.

5. Insert a screwdriver into a hole in the fast idle lever

and turn the lever to release the W-C.S.D. function. (If

so equipped)

6. Install the static timing gauge

#

.

The probe of the gauge should be depressed inward

approximately 2 mm (0.079 in).

Static Timing Gauge : 5-8840-0145-0 (J-28827)

Page 52

00 – 48 SERVICE INFORMATION

0047-1.tif

0047-2.tif

7. Rotate the crankshaft to bring the piston in the No. 1

cylinder to a point 30 - 40° BTDC.

8. Set the timing gauge needle to zero.

9. Move the crankshaft pulley slightly in both directions

to check that the gauge indication is stable.

10. Turn the crankshaft clockwise and read the gauge

indication when the crankshaft pulley timing mark is

aligned with the pointer.

mm (in)

4JB1 BTDC 14°

4JB1T BTDC 11°

4JB1TC BTDC 4°

4JG2 ATDC 2°

Standard Reading mm (in)

0.5 (0.02)

0047-3.tif

If the injection timing is outside the specified range,

continue with the following steps.

11. Loosen the injection pump fixing nuts and bracket

bolts.

12. Adjust the injection pump setting angle.

When large than

standard value

When smaller than

standard value

Gear drive A B

A : Move the injection pump toward the engine.

B : Move the injection pump away from the engine.

Tighten the pump fixing nut, adjust bolt and pump

distributor head plug to the specified torque.

Pump Fixing Bolt N∙m (kg∙m/lb∙ft)

Adjust Bolt N∙m (kg∙m/lb∙ft)

24 (2.4/17)

19 (1.9/14)

Injection Pump

Distributor Head Plug N∙m (kg∙m/lb∙ft)

17 (1.7/12)

CAUTION

• When installing the distributor head/plug, be sure

to use new copper washer.

Page 53

0048-1.tif

SERVICE INFORMATION 00 – 49

COMPRESSION PRESSURE MEASUREMENT

1. Start the engine and allow it to idle until the coolant

temperature reaches 70 - 80°C (158 - 176°F).

2. Remove the following parts.

* Glow plugs

* Fuel cut solenoid connector

* QOS (Quick-On Start System) fusible link wire at

the connector.

3. Set the adapter and compression gauge to the No. 1

cylinder glow plug hole.

Compression Gauge

(with Adapter): 5-8840-2008-0 (J-29762)

Adapter: 5-8531-7001-0

4. Turn the engine over with the starter motor and take

the compression gauge reading.

Compression Pressure at 200 rpm kPa (Kg/cm

Standard Limit

2

/psi)

0048-2.tif

0048-3.tif

4JB1 3,038 (31/441) 2,157 (22/313)

4JG2 3,334 (34/484) 2,452 (25/356)

5. Repeat the procedure (Steps 3 and 4) for the

remaining cylinders.

If the measured value is less than the specified limit,

refer to “Troubleshooting” in this Manual.

QUICK-ON START II SYSTEM

(4JB1 / 4JB1T / 4JB1TC only)

Quick-On Start System Inspection Procedure

1. Disconnect the thermo-sensor connection on the

thermostat outlet pipe.

2. Turn the starter switch to the “ON” position.

If the Quick-On Start II System is operating properly,

the glow relay will make a clicking sound within 15

seconds after the starter switch is turned on.

3. Measure the glow plug terminal voltage with a circuit

tester immediately after turning the starter switch to

the “ON” position.

Glow Plug Terminal Voltage V

Approx. 11

0048-4.tif

Page 54

00 – 50 SERVICE INFORMATION

0049-1.tif

0049-2.tif

QUICK-ON START III SYSTEM

(4JG2 only)

Quick-On Start System Inspection Procedure

1. Disconnect the thermo-sensor connection on the

thermostat outlet pipe.

2. Turn the starter switch to the “ON” position.

If the Quick-On Start III System is operating properly,

the glow relay will make a clicking sound within seven

seconds after the starter switch is turned on.

3. Measure the glow plug terminal voltage with a circuit

tester immediately after turning the starter switch to

the “ON” position.

Glow Plug Terminal Voltage V

NOTE:

Electrical power to the quick-on start system will be

cut after the starter has remained in the “ON”

position for twenty seconds.

Turn the starter switch to the “OFF” position and

back to the “ON” position.

This will reset the Quick-On Start III System.

8 – 9

Page 55

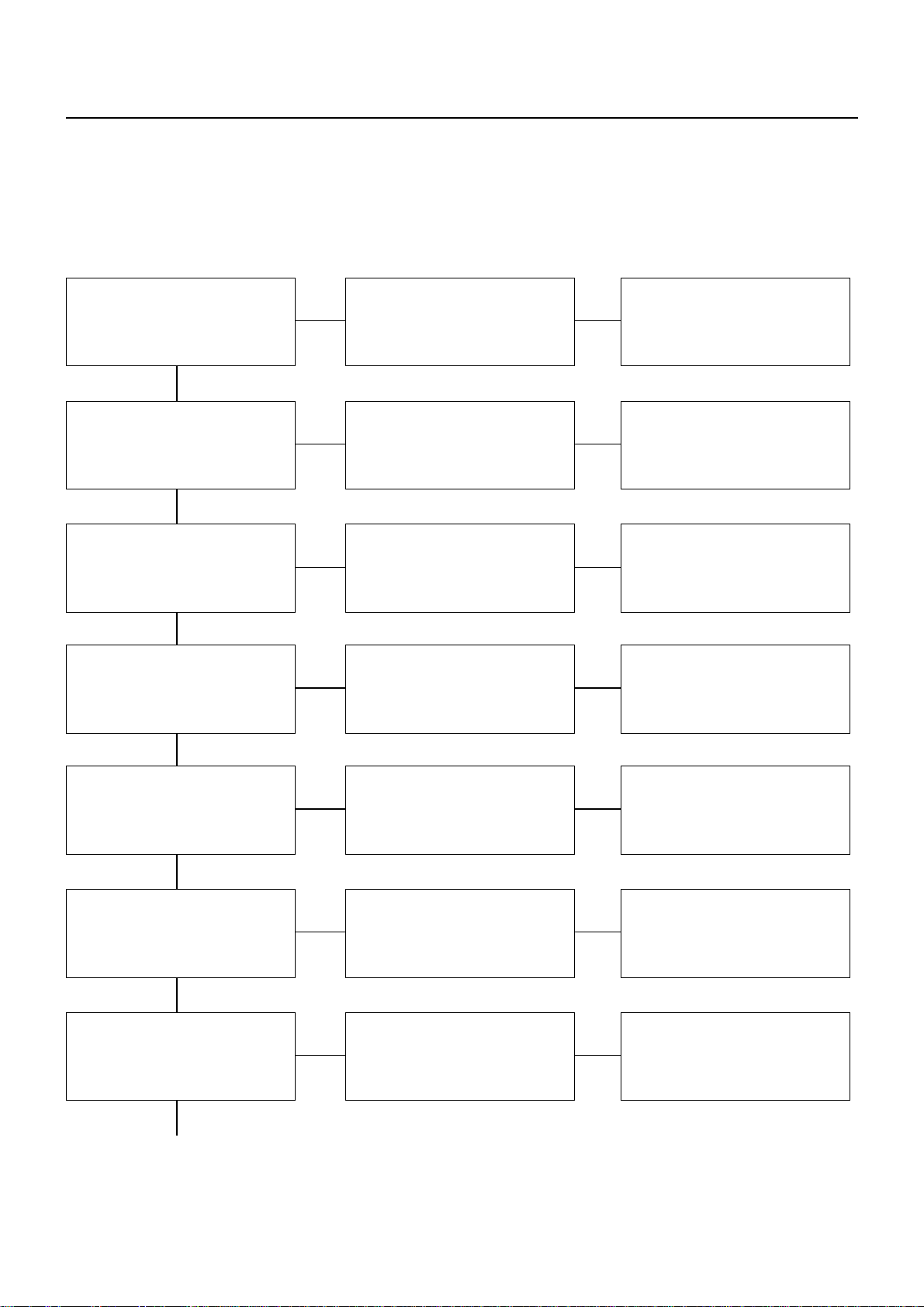

FIXING TORQUE

CYLINDER HEAD COVER, CYLINDER HEAD ROCKER,

SHAFT BRAKER

SERVICE INFORMATION 00 – 51

N∙m (kg∙m/lb∙ft)

011LX002.tif

Page 56

00 – 52 SERVICE INFORMATION

Crankshaft, Bearing Cap, Connecting Rod Bearing Cap, Crankshaft Damper

Pulley, Flywheel, Oil Pan

N∙m (kg∙m/lb∙ft)

0051-1.tif

Page 57

Timing Pulley Housing, Timing Pulley, Timing Gear,

Camshaft Oil Seal Retainer

SERVICE INFORMATION 00 – 53

N∙m (kg∙m/lb∙ft)

014LX001.tif

Page 58

00 – 54 SERVICE INFORMATION

Cooling System and Lubrication System

N∙m (kg∙m/lb∙ft)

Page 59

SERVICE INFORMATION 00 – 55

Intake Manifold, Exhaust Manifold, Exhaust Pipe

N∙m (kg∙m/lb∙ft)

150LX004.tif

Page 60

00 – 56 SERVICE INFORMATION

N∙m (kg∙m/lb∙ft)

036LX003.tif

Page 61

SERVICE INFORMATION 00 – 57

Engine Electricals

N∙m (kg∙m/lb∙ft)

0056-1.tif

Page 62

00 – 58 SERVICE INFORMATION

Engine Fuel

N∙m (kg∙m/lb∙ft)

0057-1.tif

Page 63

SERVICE INFORMATION 00 – 59

Engine Mounting Bracket

N∙m (kg∙m/lb∙ft)

0058-1.tif

Page 64

00 – 60 SERVICE INFORMATION

SPECIAL TOOLS

ILLUSTRATION TOOL NO. TOOL NAME

5-8840-2035-0 Crank Timing Pulley (4JG2 Belt Drive only)

5-8840-0200-0 Oil Filter Wrench (89.0 mm/3.5 in)

5-8840-0202-0 Oil Filter Wrench (106.0 mm/4.2 in)

5-8840-2209-0 Oil Filter Wrench (100.6 mm/4.0 in)

9-8523-1423-0 (J-29760) Valve Spring Compressor

5-8840-2033-0 Oil Seal Installer

5-8840-9018-0 Piston Ring Compressor

5-8840-2093-0 Tacho Meter

9-8523-1212-0 Valve Guide Replacer

5-8840-0086-0

Camshaft Timing Pulley Remover

(4JG2 Belt Drive only)

5-8840-0199-0 Rubber Hardness Tester

Page 65

SERVICE INFORMATION 00 – 61

SPECIAL TOOLS (CONT.1)

ILLUSTRATION TOOL NO. TOOL NAME

5-8840-2675-0 Compression gauge

5-8531-7001-0 Gauge Adapter

5-8531-7002-0 Gauge Adapter

5-8840-0145-0 Measuring Device

5-8522-0024-0

5-8840-0266-0 Angle Gauge

5-8840-9016-0 Injection Nozzle Tester

5-8840-2034-0 Nozzle Holder Remover (4JB1 only)

5-8840-2038-0 Camshaft Bearing Replacer

5-8840-2036-0

Crankshaft Timing Pulley Installer

(4JG2 Belt Drive only)

Front Oil Seal Installer

(4JB1, 4JG2, Gear Drive only)

Page 66

00 – 62 SERVICE INFORMATION

SPECIAL TOOLS (CONT.2)

LLUSTRATION TOOL NO. TOOL NAME

5-8840-0259-0 Nozzle Holder Wrench (4JG2 only)

5-8840-0253-0 (J-22700) Fuel Filter Wrench

5-8840-2362-0 Front Oil Seal Remover (4JG2, Belt Drive only)

5-8840-2361-0 Front Oil Seal Installer (4JG2, Belt Drive only)

5-8840-2360-0 Rear Oil Seal Remover

5-8840-2359-0 Rear Oil Seal Installer

5-8840-2040-0 Cylinder Liner Installer (4JB1 only)

5-8840-2313-0 Cylinder Liner Installer (4JG2 only)

5-8840-2039-0 Cylinder Liner Remover (4JB1 only)

5-8840-2304-0 Cylinder Liner Remover Ankle (4JG2 only)

5-8840-2000-0 Pilot Bearing Remover

5-8840-0019-0 Sliding Hammer

5-8522-0024-0 Pilot Bearing Installer

Page 67

SERVICE INFORMATION 00 – 63

MEMO

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................

.....................................................................................................................................................................................