Page 1

WORKSHOP MANUAL

TF SERIES

MANUAL TRANSMISSION

(MSG MODELS)

SECTION 7B

Page 2

Page 3

MSG MODEL 7B-1

SECTION 7B

MANUAL TRANSMISSION

(MSG MODELS)

TABLE OF CONTENTS

PAGE

Main Data and Specifications .................................................................................... 7B - 2

General Description.................................................................................................... 7B - 3

Torque Specification .................................................................................................. 7B - 4

Repair Kit .................................................................................................................... 7B - 6

Removal and Installation ........................................................................................... 7B - 7

Disassembly ............................................................................................................... 7B - 15

Inspection and Repair ............................................................................................... 7B - 25

Reassembly ................................................................................................................ 7B - 29

Special Service Tool .................................................................................................. 7B - 42

Page 4

7B-2 MSG MODEL

MAIN DATA AND SPECIFICATIONS

Transmission type Fully synchronized 5-forward gears with a constant

mesh type reverse gear.

Transmission Control Direct control with the gear shift lever on the floor.

Gear ratio MSG5K

1st : 4.122

2nd : 2.493

3rd : 1.504

4th : 1.000

5th : 0.855

Rev : 3.720

Oil capacity lit. (US gal.) 1.55(0.41)

Weight ; approx. kg(lbs) 33.3(73.8)

Page 5

GENERAL DESCRIPTION

MSG MODEL 7B-3

The MSG type transmission is fully synchronized 5-speed unit with blocking ring type synchronizers and a constant

mesh type reverse gear.

The unit consists principally of a case with an integral clutch housing, intermediate plate, rear cover and gears.

The top of the rear cover is a quadrant box containing the transmission control mechanism.

The case and rear cover are cast aluminum alloy to reduce weight.

Page 6

7B-4 MSG MODEL

TORQUE SPECIFICATION

STANDDARD BOLTS

The torque values given in the following table should be applied where a particular torque is not specified.

N×m (kgf×m/lb×ft)

Strength 4.8/4T 7T 8.8 9.8/9T

Class Refined Non-Refined

Bolt Identifi-

Bolt

M6 ´ 1.0 6 (0.6 / 52 lb.in) 7 (0.7 / 61 lb.in) 8 (0.8 / 69 lb.in) -

Standard Hex.

M8 ´ 1.25 13 (1.3 / 113 lb.in) 17 (1.7 / 12) 20 (2.0 / 14) 24 (2.4 / 17)

Head Bolt

M10 ´ 1.25 27 (2.8 / 20) 37 (3.8 / 27) 42 (4.3 / 31) 50 (5.1 / 37)

M12 ´ 1.25 61 (6.3 / 45) 76 (7.8 / 56) 87 (8.9 / 64) 95 (9.7 / 70)

M14 ´1.5 96 (9.8 / 71) 116 (11.8 / 85) 133 (13.6 / 98) 142 (14.5 / 105)

M16 ´ 1.5 130 (13.3 / 96) 170 (17.3 / 125) 193 (19.7 / 143) 200 (20.4 / 148)

M18 ´ 1.5 188 (19.2 / 139) 244 (24.9 / 180) 278 (28.3 / 205) 287 (29.3 / 212)

M20 ´ 1.5 258 (26.3 / 190) 337 (34.4 / 249) 385 (39.3 / 284) 396 (40.4 / 292)

M22 ´ 1.5 332 (33.9 / 245) 453 (46.3 / 335) 517 (52.7 / 381) 530 (54.1 / 391)

M24 ´ 2.0 449 (45.8 / 331) 570 (58.2 / 421) 651 (66.3 / 480) 692 (70.6 / 511)

* M10 ´ 1.5 26 (2.7 / 20) 36 (3.7 / 27) 41 (4.2 / 30) 48 (4.9 / 35)

* M12 ´ 1.75 57 (5.8 / 42) 71 (7.2 / 52) 80 (8.2 / 59) 89 (9.1 / 66)

* M14 ´ 2.0 89 (9.1 / 66) 110 (11.2 / 81) 125 (12.7 / 92) 133 (13.6 / 98)

* M16 ´ 2.0 124 (12.7 / 92) 162 (16.5 / 119) 185 (18.9 / 137) 191 (19.5 / 141)

Flange Bolt M6 ´ 1.0 7 (0.7 / 61 lb.in) 8 (0.8 / 69 lb.in) 9 (0.9 / 78 lb.in) -

M8 ´ 1.25 15 (1.5 / 11) 19 (1.9 / 14) 22 (2.2 / 16) 26 (2.7 / 20)

M10 ´ 1.25 31 (3.2 / 23) 41 (4.2 / 30) 47 (4.8 / 35) 56 (5.7 / 41)

M12

M14 ´ 1.5 104 (10.6 / 77) 126 (12.8 / 93) 144 (14.6 / 106) 154 (15.7 / 114)

M16 ´ 1.5 145 (14.8 / 127) 188 (19.2 / 139) 214 (21.8 / 158) 221 (22.5 / 163)

M18

M20 ´ 1.5 - - - -

M22 ´ 1.5 - - - -

M24

* M10 ´ 1.5 30 (3.1 / 22) 40 (4.1 / 30) 46 (4.7 / 34) 54 (5.5 / 40)

* M12 ´ 1.75 64 (6.5 / 47) 78 (8.0 / 58) 89 (9.1 / 66) 99 (10.1 / 73)

* M14

* M16 ´ 2.0 137 (14.0 / 101) 178 (18.2 / 132) 203 (20.7 / 132) 210 (21.5 / 155)

Diameter´´´´

Pitch (mm)

´

´

´

´

The asterisk * indicates that the bolts are used for female-threaded parts that are made of soft materials such as

casting, etc.

cation

No mark

1.25 69 (7.0 / 51) 85 (8.7 / 63) 97 (9.9 / 72) 106 (10.8 / 78)

1.5 - - - -

2.0 - - - -

2.0 97 (9.9 / 72) 119 (12.1 / 88) 135 (13.8 / 99.7) 144 (14.7 / 107)

-

FLARE NUTS

Pipe diameter mm (in) Torque N××××m (kgf××××m/lb××××ft) Pipe diameter mm (in) Torque N××××m (kgf××××m/lb××××ft)

4.76 (0.187) 16 (1.6 / 12) 10.00 (0.394) 54 (5.5 / 40)

6.35 (0.250) 26 (2.7 / 20) 12.00 (0.472) 88 (9.0 / 65)

8.00 (0.315) 44 (4.5 / 33) 15.00 (0.591) 106 (10.8 / 78)

Page 7

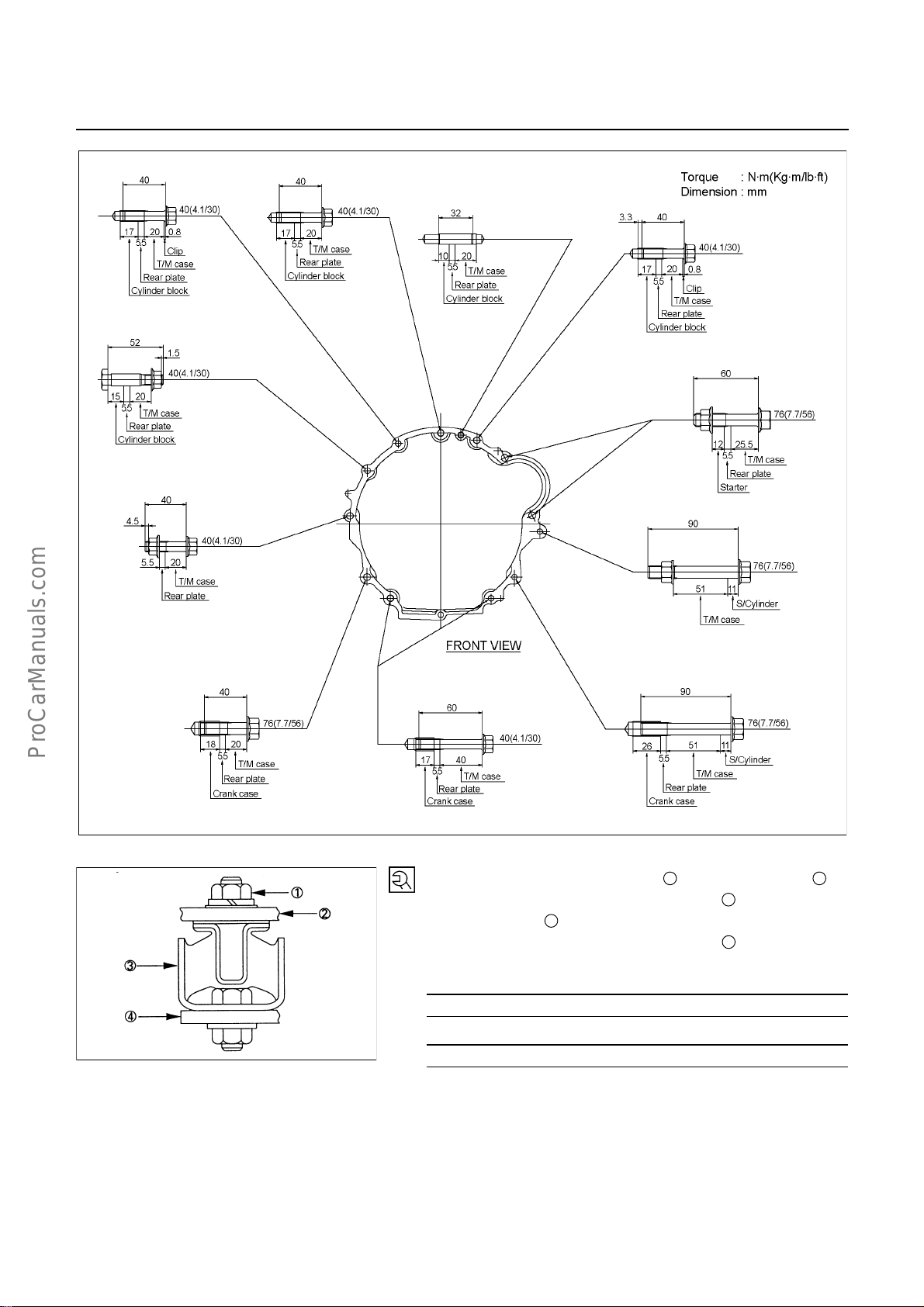

MSG MODEL 7B-5

SPECIAL PARTS FIXING NUTS AND BOLTS

N×m (kgf×m/lb×ft)

RTW47BXF000101

Page 8

7B-6 MSG MODEL

REPAIR KIT

1. Case to front cover gasket

2. Control box gasket

3. Plate gasket

4. Filler plug O-ring

5. Drain plug O-ring

RTW47BLF000201

Page 9

MSG MODEL 7B-7

REMOVAL AND INSTALLATION

Read this Section carefully before performing any removal and installation procedure. This Section gives you

important points as well as the order of operation. Be sure that you understand everything in this Section before

you begin.

Important Operations - Removal

Battery Cable

Disconnect the negative (-) cable from the battery terminal.

Engine Hood

Apply setting marks to the engine hood and the engine hood

hinges before removing the engine hood.

Gear Shift Lever

1. Place the gear shift lever in the neutral position.

2. Remove the gear shift lever knob.

3. Remove the front console assembly.

4. Remove the gear shift lever grommet and dust cover.

5. Remove the gear shift lever cover bolts.

6. Remove the gear shift lever.

Note:

Cover the shift lever hole to prevent the entry of foreign

material into the transmission.

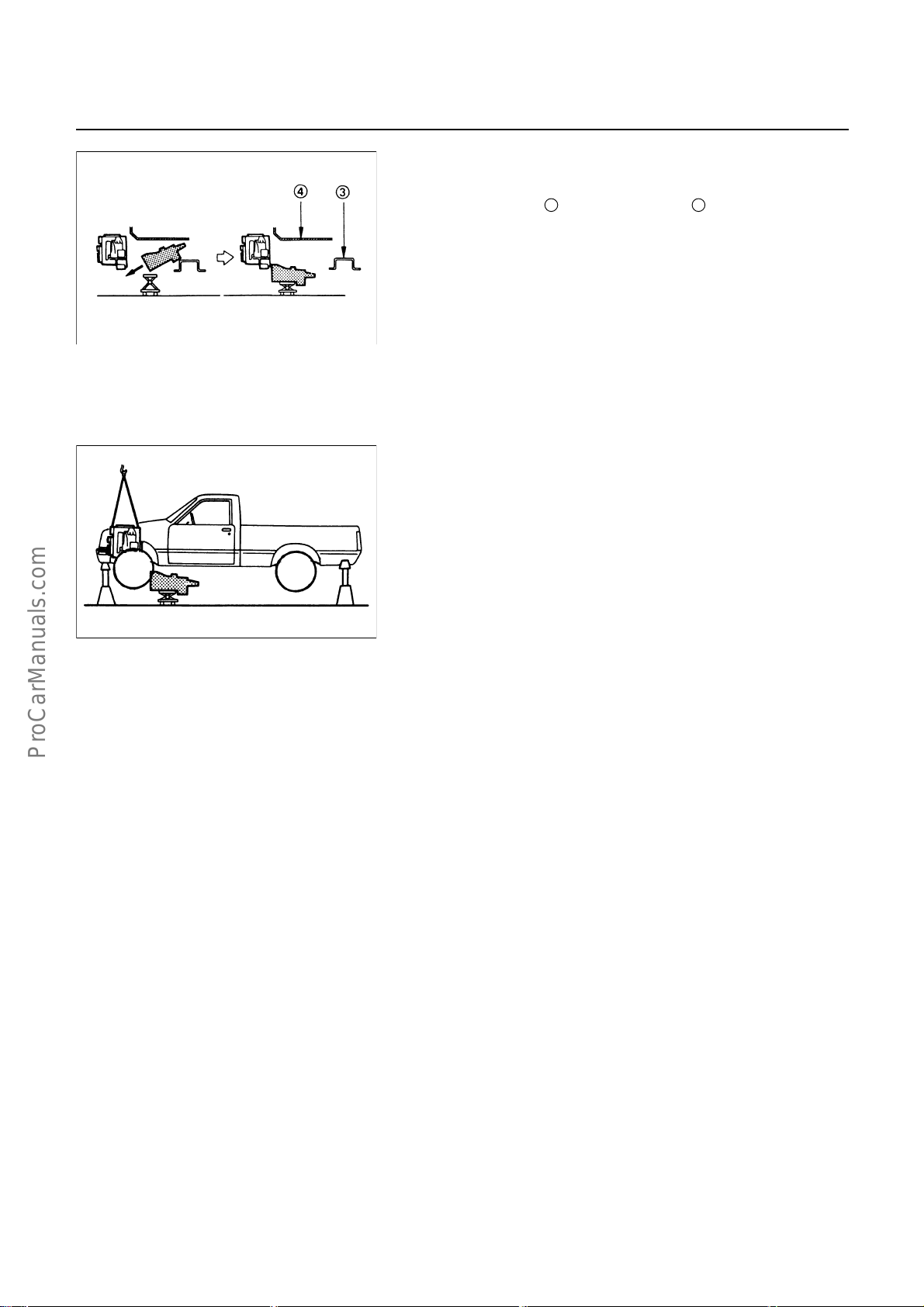

Lifting the Vehicle

1. Jack up the vehicle.

2. Place chassis stands at the front and the rear of the

vehicle.

Transmission Oil Draining

1. Remove the transmission oil drain plug.

2. Replace the drain plug after draining the oil.

Page 10

7B-8 MSG MODEL

Exhaust Pipe

1. Remove the exhaust pipe bracket from the transmission

case.

2. Remove the exhaust pipe.

Rear Propeller Shaft (Single Shaft Type)

1. Remove the propeller shaft flange yoke at the drive pinion

1

.

side

2. Remove the propeller shaft from the transmission main

2

shaft spline

Rear Propeller Shaft (Dual Shaft Type)

1. Apply setting marks to the 2nd propeller shaft flange yoke.

This will prevent mispositioning during the installation

procedure.

2. Remove the 2nd propeller shaft flange yoke bolts at the

drive pinion side

3. Remove the center bearing retainer bolts

4. Remove the 1st propeller shaft with the center bearing and

the 2nd propeller shaft.

Pull the 1st propeller shaft toward the rear of the vehicle

until the spline yoke is free of the transmission main shaft.

Harness Connector

Disconnect the back up light switch connector and the

speedometer sensor connector.

Slave Cylinder

Remove the slave cylinder from the transmission case.

.

1

.

2

.

Page 11

MSG MODEL 7B-9

A

Engine Lifting Hanger

1. Attach the engine lifting hanger to the front portion of the

engine.

2.

ttach the lifting wire to both ends of the engine lifting

hanger.

Starter Motor

Remove the starter motor motor from the engine rear plate.

Transmission

1. Support the transmission with a transmission jack.

2. Remove the engine rear mounting bracket bolts and nuts

from the transmission 2.

3. Remove the bracket from No.3 crossmember.

4. Loosen the nuts for the rear mounting rubber.

3

5. Remove the rear mounting rubber

4

.

6. Remove the gear control box from the transmission.

7. Remove the transmission from the engine.

The removal of the transmission will require the cooperative

efforts of two mechanics.

1) Remove the transmission nuts and bolts

engine rear plate.

2) Place a transmission jack

Do not raise the transmission jack.

2

from the transmission

1

from the

beneath the transmission .

1

Page 12

7B-10 MSG MODEL

3) Manually move the transmission as far as possible toward

the rear of the vehicle (into the space between the No.3

crossmember

4) Lower the clutch housing end of the transmission toward the

transmission jack.

The rear of the transmission is supported by the No.3

crossmember at this time.

5) Firmly grasp the transmission rear cover (1st mechanic).

Raise the transmission jack toward the transmission (2nd

mechanic).

Carefully lower the transmission onto the transmission jack.

The transmission must be centered on the transmission

jack.

8. Carefully pull the transmission jack with the transmission

from beneath the vehicle.

3

and the floor panel 4 .

Page 13

MSG MODEL 7B-11

Important Operations - Installation

Follow the removal procedure in the reverse order to perform

the installation procedure.

Pay careful attention to the important points during the

installation procedure.

Transmission

1. Apply a thin coat of molybdenum disulfide grease to the top

gear shaft spline.

2. Place the transmission on a transmission jack.

3. Carefully move the transmission jack and transmission into

position behind the engine.

4. Slowly operate the transmission jack to raise the

transmission until the rear of the transmission is at the

1

same level as the No.3 crossmember

5. Manually support the transmission rear cover.

Move the transmission into position between the No.3

crossmember and the floor panel

.

2

.

6. Slowly raise the transmission jack until the front of the

transmission is aligned with the rear of the engine.

The slope of the engine and the transmission must be the

same.

7. Install the gear control box the transmission.

8. Align the top gear shaft spline with the clutch drive plate

spline.

9. Install the transmission to the engine.

Tighten the transmission nuts and bolts as shown in the

figure.

Page 14

7B-12 MSG MODEL

RTW37BLF000901

10. Install the rear mounting rubber 3 to the transmission 2.

3

Install the rear mounting rubber

4

crossmember

.

11. Tighten the rear mounting rubber nuts

to the No.3

1

to the specified

forque.

Rear Mounting Rubber Nut Torque N×m (kgf×m/lb×ft)

41 (4.2 / 30)

Mounting Bolt Torgue N×m (kgf×m/lb×ft)

41 (4.2 / 30)

Page 15

MSG MODEL 7B-13

)

Starter Motor

1. Install the starter motor to the engine rear plate.

2. Tighten the starter motor bolts to the specified torque.

Starter Motor Torque N×m (kgf×m/lb×ft)

78 (8.0 / 58)

Slave Cylinder

Install the slave cylinder to the transmission case.

Slave Cylinder Bolt Torque N×m (kgf×m/lb×ft

78 (8.0 / 58)

Harness Connector

Connect the back up light switch connector and speedometer

sensor connector.

Rear Propeller Shaft (Single Shaft Type)

1. Insert the splined yoke 1 with the propeller shaft into the

2

transmission main shaft spline

2. Install the propeller shaft flange yoke

side.

3. Tighten the propeller shaft flange yoke bolt to the specified

torque.

Propeller Shaft Flange Yoke Bolt Torque N×m (kgf×m/lb×ft)

M8 : 35.3 (3.6 / 26)

M10 : 62.7 (6.4 / 46.3)

.

3

to the drive pinion

Rear Propeller Shaft (Dual Shaft Type)

1. Place the center bearing and retainer 1 together with the

2

1st propeller shaft

crossmember

2. Insert the splined yoke

5

spline

3. Tighten the center bearing retainer bolts

torque.

Center Bearing Retainer Bolt Torque N×m (kgf×m/lb×ft)

4. Connect the 2nd propeller shaft

Be sure to align the setting marks applied at disassembly.

5. Tighten the coupling bolts to the specified torque.

Propeller Shaft Flange Yoke Bolt

Torque N×m (kgf×m/lb×ft)

.

and 2nd propeller shaft

3

.

4

into the transmission main shaft

60.8 (6.2 / 44.8)

7

M8 : 35.3 (3.6 / 26)

M10 : 62.7 (6.4 / 46.3)

and drive pinion side 8.

7

6

to the specified

on the No.4

Page 16

7B-14 MSG MODEL

Exhaust Pipe

1. Install the exhaust pipe to the exhaust manifold and the

2nd exhaust pipe.

2. Install the exhaust pipe bracket to the transmission case.

Gear Shift Lever

1. Replenish the transmission case with the specified engine

oil.

Transmission Case Oil lit(US gal.)

1.55 (0.41)

2. Install the gear shift lever to the gear control box.

3. Tighten the gear shift lever cover bolts to the specified

torque.

Shift Lever Cover Bolt Torque N×m(kgf×m/lb×ft)

19.6 (2.0 / 14.5)

4. Install the dust cover and the grommet.

5. Install the front console assembly.

6. Install the gear shift lever knob.

Lowering the Vehicle

1. Place a jack beneath the vehicle.

2. Raise the jack to remove the chassis stands.

3. Lower the vehicle to the ground.

Engine Hood

Align the setting marks(applied at removal)on the engine hood

and the engine hood hinges to install the engine hood.

Battery Cable

Connect the negative (-) cable to the battery terminal.

Page 17

MSG MODEL 7B-15

DISASSEMBLY

MAJOR COMPONENTS

Disassembly Steps

1. Clutch shift block and release bearing

2. Clutch shift fork

3. Speedometer sensor

4. Speedometer driven gear assembly

5. Gear control box assembly

I

6. Front cover with oil seal

I

7. Counter gear snap ring

I

8. Bearing snap ring

9. Rear cover with oil seal

10. Transmission case

11. Intermediate plate with gear assembly

RTW47BLF000301

Page 18

7B-16 MSG MODEL

Important Operations

6. Front Cover with Oil Seal

Remove the front cover with oil seal from the transmission

case.

7. Counter Gear Snap Ring

8. Bearing Snap Ring

Use pair of snap ring pliers to remove the snap ring.

Page 19

INTERNAL PARTS

MSG MODEL 7B-17

MAJOR COMPONENT

Disassembly steps

1. Detent assembly

2. Shift fork assembly & interlock pin

3. Rev. and 5th gear assembly

4. Counter gear shaft assembly

5. Top & main gear shaft assembly

Page 20

7B-18 MSG MODEL

MINOR COMPONENTS

DETENT, SHIFT ARM ASSEMBLY AND INTERLOCK PIN

Disassembly Steps

1. Detent spring plate and gasket

2. Detent spring

I

3. Detent ball

4. Rev. - 5th shaft rod

5. Rev. - 5th shaft arm

6. 1st - 2nd shift rod

I

7. 3rd - 4th shift rod

I

8. 3rd - 4th shift arm

I

9. 1st - 2nd shift arm

10. Interlock pin

11. Intermediate plate and gear assembly

Page 21

MSG MODEL 7B-19

Important Operations

3. Detent Ball

7. 3rd - 4th Shift Rod

8. 3rd - 4th Shift Arm

9. 1st - 2nd Shift Arm

1) Hold a round bar against the shift arm end.

This will prevent damage to other components.

2) Use a spring pin remover to remove the shift arm spring pin

from the shift arm and the shift rod.

Spring Pin Remover : 9-8529-2201-0

Discard the used spring pin.

3) Move the 3rd - 4th shift rod forward.

Take care not to lose the interlock pins.

Page 22

7B-20 MSG MODEL

REVERSE GEAR AND 5TH GEAR

Disassembly Steps

1. Bearing snap ring

2. Speedometer drive gear and lock ball

3. Bearing spacer

4. Mainshaft end ball bearing

5. Thrust ring snap ring

6. Thrust washer thrust ring

7. Thrust washer and lock ball

8. Counter reverse gear nut and washer

I

9. Counter end ball bearing

I

10. Counter 5th gear

11. Counter reverse gear

12. 5th gear

13. 5th block ring

14. Needle bearing

I

15. Mainshaft lock nut and washer

I

16. Rev. - 5th synchronizer assembly

17. Reverse gear

18. Needle bearing

19. Needle bearing collar

20. Thrust washer

21. Counter reverse gear lock nut

22. Thrust washer

23. Reverse idler gear

24. Thrust washer

25. Reverse idler shaft

I

26. Bearing snap ring

I

27. Bearing snap ring

I

28. Intermediate plate

Page 23

MSG MODEL 7B-21

r

Important Operations

9. Counter End Ball Bearing

10. Counter 5th Gear

Use the gear remover to remove the counter 5th gear with the

ball bearing.

Gear Remover : 5-8840-0013-0 (J-22888)

15. Mainshaft Lock Nut and Washer

1) Engage the 3rd - 4th synchronizer with the 3rd gear.

2) Engage the 1st - 2nd synchronizer with the 1st gear.

3) Attach the holding fixture to the mainshaft and the

countergear.

Holding Fixture : 5-8840-2001-0 (J-29768)

4) Use the lock nut wrench to remove the lock nut.

Lock Nut Wrench: 5-8840-0353-0 (J-36629)

16. Rev. - 5th Synchronizer Assembly

1) Remove the synchronizer assembly as a set.

2) Disassemble the synchronizer assembly.

1

Springs

2

Sleeve

3

Clutch Hub

4

Inserts

26. Bearing Snap Ring

1) Insert the snap ring pliers

snap ring hole

2

.

1

into the counter gear bearing

The snap ring hole is in the intermediate plate

3

.

2) Use the snap ring pliers to force open the counter gea

bearing snap ring.

Tap on the front of the intermediate plate.

The ball bearing snap ring will come free.

Page 24

7B-22 MSG MODEL

27. Bearing Snap Ring

28. Intermediate Plate

1) Insert the snap ring pliers into the mainshaft bearing snap

ring hole.

1

The snap ring hole is in the intermediate plate

2

2) Use the snap ring pliers

bearing snap ring

3

.

to force open the mainshaft

.

Hold the snap ring open with the pliers.

3) Push the intermediate plate toward the rear of the

transmission to remove it.

The ball bearing snap ring will come free.

Page 25

MSG MODEL 7B-23

TOP GEAR SHAFT, MAINSHAFT GEAR AND COUNTER GEAR

Disassembly Steps

I

1. Top shaft snap ring

I

2. Top gear shaft

I

3. Ball bearing

4. Needle bearing

5. 4th block ring

6. Mainshaft snap ring

I

7. 3rd - 4th synchronizer assembly

8. 3rd block ring

9. 3rd gear

10. Needle bearing

I

11. Mainshaft ball bearing

12. 1st gear thrust washer

13. 1st gear

14. Needle bearing collar

15. Needle bearing

16. 1st block ring

I

17. 1st - 2nd synchronizer assembly

18. 2nd block ring

19. 2nd gear

20. Needle bearing

21. Mainshaft

I

22. Rear ball bearing

23. Bearing snap ring

I

24. Front ball bearing

25. Counter gear

Page 26

7B-24 MSG MODEL

Important Operations

1. Top Gear Shaft Snap Ring

2. Top Gear Shaft

3. Ball Bearing

1) Use a pair of snap ring pliers to remove the snap ring.

2) Use a bench press and the bearing remover to remove the

ball bearing.

Bearing Remover : 5-8840-0015-0 (J-22912-01)

7. 3rd - 4th Synchronizer Assembly

1) Remove the synchronizer assembly as a set.

2) Disassembly the synchronizer assembly.

1

Springs

2

Sleeve

3

Clutch Hub

4

Inserts

11. Mainshaft B all Bearing

Use a bench press and the bearing remover to remove the ball

bearing.

Bearing Remover : 5-8840-0015-0 (J-22912-01)

17. 1st - 2nd Synchronizer Assembly

1) Remove the synchronizer assembly as a set.

2) Disassembly the synchronizer assembly.

1

Springs

2

Sleeve

3

Clutch Hub

4

Inserts

22. Rear Ball Bearing

24. Front Ball Bearing

Use a bench press and the bearing remover to remove the ball

bearing.

Bearing Removar : 5-8840-0015-0 (J-22912-01)

Page 27

MSG MODEL 7B-25

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

SHIFT ARM THICKNESS

Use a micrometer to measure the shift arm thickness.

If the measured value is less than the specified limit, the shift

arm must be replaced.

Shift Arm Thickness mm(in)

Standard Limit

1st-2nd 9.6-9.8 (0.378-0.386) 9.0 (0.354)

3rd-4th 6.95-7.2 (0.273-0.283) 6.5 (0.256)

Rev.-5th 6.8-6.9 (0.268-0.272) 6.3 (0.248)

DETENT SPRING FREE LENGTH

Use a venier caliper to measure the detent spring free length.

If the measured value is less than the specified limit, the

detent spring must be replaced.

Detent Spring Free Length mm(in)

Standard Limit

25.6 (1.01) 23.6 (0.93)

DETENT SPRING TENSION

Use a spring tester to measure the valve spring tension.

If the measured value is less than the specified limit, the valve

spring must be replaced.

Valve Spring Tension N(kg/lb)

Compressed

Height mm(in)

22.1 (0.870)

Standard Limit

61.8-65.7

(6.3-6.7/13.9-14.8)

(5.7/12.6)

55.9

BLOCK RING AND DOG TEETH

CLEARANCE

Use a thickness gauge to measure the clearance between the

block ring and the dog teeth.

If the measured value exceeds the specified limit, the block

ring must be replaced.

Block Ring and Dog Teeth Clearance mm(in)

Standard Limit

1st,2nd 2.0 (0.078) 1.3 (0.051)

3rd, 4th, 5th 1.5 (0.059) 0.8 (0.032)

Page 28

7B-26 MSG MODEL

BLOCK RING AND INSERT CLEARANCE

Use a thickness gauge to measure the clearance between the

block ring and the insert.

If the measured value exceeds the specified limit, the block

ring and the insert must be replaced.

Block Ring and Insert Clearance mm(in)

Standard Limit

1st,2nd 3.46-3.74 (0.136-0.147)

3rd, 4th, 5th 3.51-3.79 (0.138-0.149)

4.0 (0.157)

CLUTCH HUB AND INSERT CLEARANCE

Use a thickness gauge to measure the clearance between the

clutch hub and the insert.

If the measured value exceeds the specified limit, the clutch

hub and the insert must be replaced.

Clutch Hub and Insert Clearance mm(in)

Standard Limit

0.01 - 0.19 (0.0004 - 0.0075) 0.3 (0.012)

MAINSHAFT RUN - OUT

1. Install the mainshaft to a grinding machine.

2. Use a dial indicator to measure the mainshaft central

portion run-out.

If the measured mainshaft run-out exceeds the specified

limit, the mainshaft must be replaced.

Mainshaft Run - Out mm(in)

Limit

Less than 0.03 (0.0012)

GEAR INSIDE DIAMETER

Use an inside dial indicator to measure the gear inside

diameter.

If the measured value is less than the specified limit, the gear

must be replaced.

Gear Inside Diameter mm(in)

Standard Limit

1st

Rev.

2nd

3rd

5th

45.00-45.01

(1.7717-1.7720)

41.00-41.01

(1.6142-1.6146)

34.03-34.04

(1.3398-1.3402)

45.10 (1.7756)

41.10 (1.6181)

34.10 (1.3425)

Page 29

MSG MODEL 7B-27

r

r

)

REVERSE IDLER GEAR AND IDLER

GEAR SHAFT CLEARANCE

1. Use a micrometer to measure the idler gear shaft diameter.

2. Use an inside dial indicator to measure the idler gear inside

diameter.

3. Calculate the idler gear and idler gear shaft clearance.

Idler gear inside diameter - idler gear shaft diameter = idle

gear and idler gear shaft clearance.

If the measured value exceeds the specified limit, the idle

gear and/or the idler gear shaft must be replaced.

Idler Gear and Idler Gear Shaft Clearance mm(in)

Standard Limit

0.041 - 0.074 (0.0016 - 0.0029) 0.150 (0.0059)

CLUTCH HUB SPLINE PLAY

1. Set a dial indicator to the clutch hub to be measured.

2. Move the clutch hub as far as possible to both the right and

the left.

Note the dial indicator reading.

It the measured value exceeds the specified limit, the

clutch hub must be replaced.

Clutch Hub Spline Play mm(in

Standard Limit

0.019 (0 - 0.075) 0.20 (0.0079)

Page 30

7B-28 MSG MODEL

r

BALL BEARING PLAY

Use a dial indicator to measure the ball bearing play.

Ball Bearing Play mm(in)

Limit

0.2 (0.0079)

FRONT COVER OIL SEAL

Oil Seal Replacement

Oil Seal Removal

Use a screwdriver to pry the oil seal from the front cover.

Oil Seal Installation

1. Use the oil seal installer to install the oil seal to the front

cover.

Oil Seal Installer : 5-8840-0026-0 (J-26540)

2. Apply engine oil to the oil seal lip.

REAR COVER OIL SEAL

Oil Seal Replacement

Oil Seal Removal

Use a screwdriver to pry the oil seal from the rear cover.

Oil Seal Installation

1. Use the oil seal installer to install the oil seal to the rea

cover.

Oil Seal Installer : 5-8522-0050-0 (J-29769)

2. Apply engine oil to the oil seal lip.

Page 31

INTERNAL PARTS

MSG MODEL 7B-29

REASSEMBLY

MAJOR COMPONENT

Reassembly steps

1. Top & main gear shaft assembly

2. Counter gear shaft assembly

3. Rev. and 5th gear assembly

4. Shift fork assembly & interlock pin

5. Detent assembly

Page 32

7B-30 MSG MODEL

MINOR COMPONENTS

TOP GEAR SHAFT, MAINSHAFT GEAR AND COUNTER GEAR

Reassembly Steps

1. Mainshaft

I

2. Needle bearing

I

3. 2nd gear

4. 2nd block ring

I

5. 1st-2nd synchronizer assembly

6. 1st block ring

I

7. Needle bearing collar

I

8. Needle bearing

I

9. 1st gear

I

10. 1st gear thrust washer

I

11. Mainshaft ball bearing

I

12. Needle bearing

I

13. 3rd gear

14. 3rd block ring

I

15. 3rd-4th synchronizer assembly

I

16. Mainshaft snap ring

17. Needle bearing

18. 4th block ring

I

19. Top gear shaft

I

20. Ball bearing

21. Top gear shaft snap ring

22. Counter gear

23. Front ball bearing

24. Bearing snap ring

I

25. Rear ball bearing

Page 33

MSG MODEL 7B-31

A

Important Operations

2. Needle Bearing

3. 2nd Gear

1) Apply the engine oil to the 2nd needle bearing and the 2nd

gear.

2) Install the needle bearing and the 2nd gear to the

mainshaft.

The dog teeth of the 2nd gear must be facing the rear side

of the transmission.

5. 1st-2nd Synchronizer Assembly

1) Apply the engine oil to the clutch hub spline.

2) Install the synchronizer assembly to the mainshaft.

The outside sleeve heavy chamfering must be facing the

rear of the transmission.

1

Chamfer Angle = 30°

2

Chamfer Angle = 45°

7. Needle Bearing Collar

Use a bench press and the collar installer to install the needle

bearing collar.

Collar Installer : 5-8840-0178-0 (J-33851)

8. Needle Bearing

9. 1st Gear

gear.

pply the engine oil to the 1st needle bearing and the 1st

1)

2) Install the needle bearing and the gear to the mainshaft.

The dog teeth of the 1st gear must be facing the front side

of the transmission.

10. 1st Gear Thrust Washer

Install the thrust washer to the mainshaft.

The thrust washer oil groove must be facing the 1st gear side.

Page 34

7B-32 MSG MODEL

f

A

A

11. Mainshaft B all Bearing

1) Apply the engine oil to the ball bearing inside

circumference.

2) Use a bench press and the bearing installer to install the

bearing.

The bearing snap ring groove must be facing the front o

the transmission.

Bearing Installer : 5-8840-0015-0 (J-22912-01)

12. Needle Bearing

13. 3rd Gear

1)

pply the engine oil to the 3rd needle bearing and the 3rd

gear.

2) Install the needle bearing and the gear to the mainshaft.

The dog teeth of the 3rd gear must, be facing the front side

of the transmission.

15. 3rd-4th Synchronizer Assembly

1)

pply the recommended lubricating oil to the clutch hub

spline.

2) Install the synchronizer assembly to the mainshaft.

1

The sleeve light chamfering

2

boss

must be facing the rear of the transmission.

and the clutch hub heavy

16. Mainshaft Snap Ring

1) Select the snap ring which will provide the minimum

clearance between the mainshaft and the snap ring.

There are four snap ring sizes available.

The snap rings are numbered to indicate their thickness.

Mainshaft and Snap Ring Clearance mm(in)

Standard

0 - 0.05 (0.002)

Snap Ring Availability mm(in)

Thickness Identification Number

1.50 (0.059) 1

1.55 (0.061) 2

1.60 (0.063) 3

1.65 (0.065) 4

2) Use a pair of snap ring pliers to install the snap ring to the

mainshaft.

Page 35

MSG MODEL 7B-33

19. Top G ear Shaft

20. Ball Bearing

Use a bench press and the installer to install the ball bearing

to the top gear shaft.

The snap ring groove must be facing the front of the

transmission.

Bearing Installer : 5-8840-0015-0 (J-22912-01)

25. Rear Ball Bearing

Use a bench press and the bearing installer to install the

bearing to the counter gear.

Bearing Installer : 5-8840-0015-0 (J-22912-01)

Page 36

7B-34 MSG MODEL

REVERSE GEAR AND 5TH GEAR

Reassembly Steps

I

1. Intermediate plate

I

2. Reverse idler shaft

3. Bearing snap ring

4. Bearing snap ring

5. Thrust washer

I

6. Reverse idler gear

7. Thrust washer

I

8. Counter reverse gear lock nut

I

9. Thrust washer

10. Needle bearing collar

11. Needle bearing

12. Reverse gear

I

13. Rev.-5th synchronizer assembly

I

14. Mainshaft lock nut and washer

15. Needle bearing

16. 5th block ring

17. 5th gear

I

18. Thrust washer and lock ball

19. Counter reverse gear

20. Counter 5th gear

21. Counter end ball bearing

I

22. Counter reverse gear nut and washer

I

23. Thrust washer thrust ring

I

24. Thrust ring snap ring

25. Mainshaft end ball bearing

26. Bearing spacer

27. Speedometer drive gear and lock ball

28. Bearing snap ring

Page 37

r

MSG MODEL 7B-35

Important Operations

1. Intermediate Plate

2. Reverse Idler Shaft

1) Install the reverse idler shaft to the intermediate plate.

2) Tighten the reverse idler shaft bolt to the specified torque.

Idler Shaft Bolt Torque N×m(kgf×m/lb×ft)

18.6 (1.9 / 13.7)

3) Set the mainshaft with gear assembly

2

gear assembly

to the holding fixture

Holding Fixture : 5-8840-2001-0 (J-29768)

4) Place the holding fixture (with the mainshaft and the

counter shaft) in a vise.

5) Mesh the 3rd-4th synchronizer to the 3rd gear.

Mesh the 1st-2nd synchronizer to the 1st gear.

6) Install the intermediate plate to the mainshaft and the

counter gear ball bearings.

6. Reverse Idler Gear

8. Counter Reverse Gear Lock Nut

1) Apply the engine oil to the idler shaft and the reverse gea

inside circumference.

2) Install the reverse gear to the idler shaft.

3) Install a new counter reverse gear lock nut.

Never reinstall the old lock nut.

4) Tighten the reverse gear lock nut to the specified torque.

Lock Nut Torque N×m (kgf×m/lb×ft)

107.8 (11 / 79.6)

9. Thrust Washer

1) Apply the engine oil to both sides of the thrust washer.

2) Install the thrust washer to the mainshaft.

The thrust washer oil groove must be facing the reverse

gear side.

1

and the counter

3

.

Page 38

7B-36 MSG MODEL

w

13. Rev.-5th Synchronizer Assembly

1) Apply the engine oil to the clutch hub spline.

2) Install the synchronizer assembly to the mainshaft.

The sleeve heavy chamfer

1

and the insert short side

2

must be facing to the rear side of the transmission.

14. Mainshaft Lock Nut and Washer

1) Install a new lock nut and washer to the mainshaft.

Never reinstall the used lock nut and washer.

2) Use the lock nut wrench to tighten the lock nut to the

specified torque.

Lock Nut Wrench : 5-8840-0353-0 (J-36629)

Lock Nut Torque N×m(kgf×m/lb×ft)

107.8 (11 / 79.6)

22. Counter Reverse Gear Nut and Washer

Tighten the counter gear lock nut to the specified torque.

Reverse Gear Nut Torque N×m(kgf×m/lb×ft)

107.8 (11 / 79.6)

18. Thrust Washer and Lock Ball

23. Thrust Washer Thrust Ring

24. Thrust Ring Snap ring

1) Install the thrust washer with lock ball together with the

thrust ring to the mainshaft.

2) Use a pair of snap ring pliers to install the snap ring.

3) Use a thickness gauge to measure the clearance between

the 5th gear and the thrust washer.

5th Gear and Thrust Washer Clearance mm(in)

Standard

0.1 - 0.3 (0.004 - 0.012)

If required, replace the existing thrust washer with a ne

thrust washer to bring the clearance to specification.

Page 39

MSG MODEL 7B-37

There are six thrust washer sizes available.

Thrust Washer Availability mm(in)

7.8 (0.307) 7.9 (0.311) 8.0 (0.315)

8.1 (0.319) 8.2 (0.323) 8.3 (0.327)

4) Position the thrust ring snap ring gap

2

gap

so that they are separated at a 90° angle.

1

and the thrust ring

Page 40

7B-38 MSG MODEL

DETENT AND SHIFT ARM ASSEMBLY

Reassembly Steps

1. Intermediate plate and gear assembly

I

2. 1st-2nd shift arm

I

3. 3rd-4th shift arm

4. Interlock pin

5. 3rd-4th shift rod

6. 1st-2nd shift rod

I

7. Rev.-5th shift arm

8. Rev.-5th shift rod

9. Detent ball

10. Detent spring

I

11. Detent spring plate and gasket

Page 41

MSG MODEL 7B-39

Important Operations

2. 1st-2nd Shift Arm

3. 3rd-4th Shift Arm

7. Rev.-5th Shift Arm

1) Hold a round bar against the shift rod end lower face to

protect it against damage.

2) Use a spring pin installer to install the spring pin to the shift

arm and the shift rod.

Never reinstall the used spring pins.

11. Detent spring Plate and Gasket.

1) Install the new detent plete and new gasket onto the

transmission case into the correct direction.

2) Tighten the detent spring plate bolts to the specified torque.

Detent Spring Plate Bolt Torque N×m(kgf×m/lb×ft)

18.6 (1.9 / 13.7)

Page 42

7B-40 MSG MODEL

MAJOR COMPONENTS

Reassembly steps

1. Intermediate plate with gear assembly

I

2. Rear cover with oil seal

I

3. Transmission case

I

4. Bearing snap ring

5. Counter gear snap ring

I

6. Front cover with oil seal

7. Speedometer driven gear

8. Gear control box assembly

9. Speedpmeter sensor

10. Clutch shift fork

11. Clutch shift block and release bearing

RTW47BLF000401

Page 43

MSG MODEL 7B-41

A

A

A

RTW47BSH000201

RTW47BSH000301

Important Operations

2. Rear Cover with Oil Seal

1)

lign the pins at the lower side of the rear cover with the

holes in the lower side of the intermediate plate.

2)

pply recommended liquid gasket or its equivalent to the

rear cover fitting surfaces.

3) Install the rear cover to the intermediate plate.

4) Tighten the rear cover bolts to the specified torque.

Rear Cover Bolt Torque N×m(kgf×m/lb×ft)

37.2 (3.8 / 27.5)

Note:

Take care not to twist or puncture the oil seal during the

installation procedure.

3. Transmission Case

4. Bearing Snap Ring

1) Apply the engine oil to the transmission case top gear shaft

ball bearing fitting faces.

pply recommended liquid gasket or its equivalent to the

2)

transmission case fitting surfaces.

3) Install the transmission case to the intermediate plate.

4) Pull the top gear shaft from the transmission case until the

ball bearing snap ring grove protrudes from the

transmission case front cover fitting faces.

5) Use a pair of snap ring pliers to install the snap ring to the

ball bearing.

6. Front Cover with Oil Seal

1) Clean and apply recommended liquid gasket or its

equivalent to the through bolt threads.

2) Install the new gasket and tighten the new cover bolt to the

specified torgue.

Front Cover Bolt Torgue N×m(kgf×m/lb.ft)

24.5 (2.5 / 18.1)

10. Shift Fork

Apply molybdenum disulfide type grease to the areas as

shown in the figure and install shift fork (Diesel engine).

RTW47BSH000101

Page 44

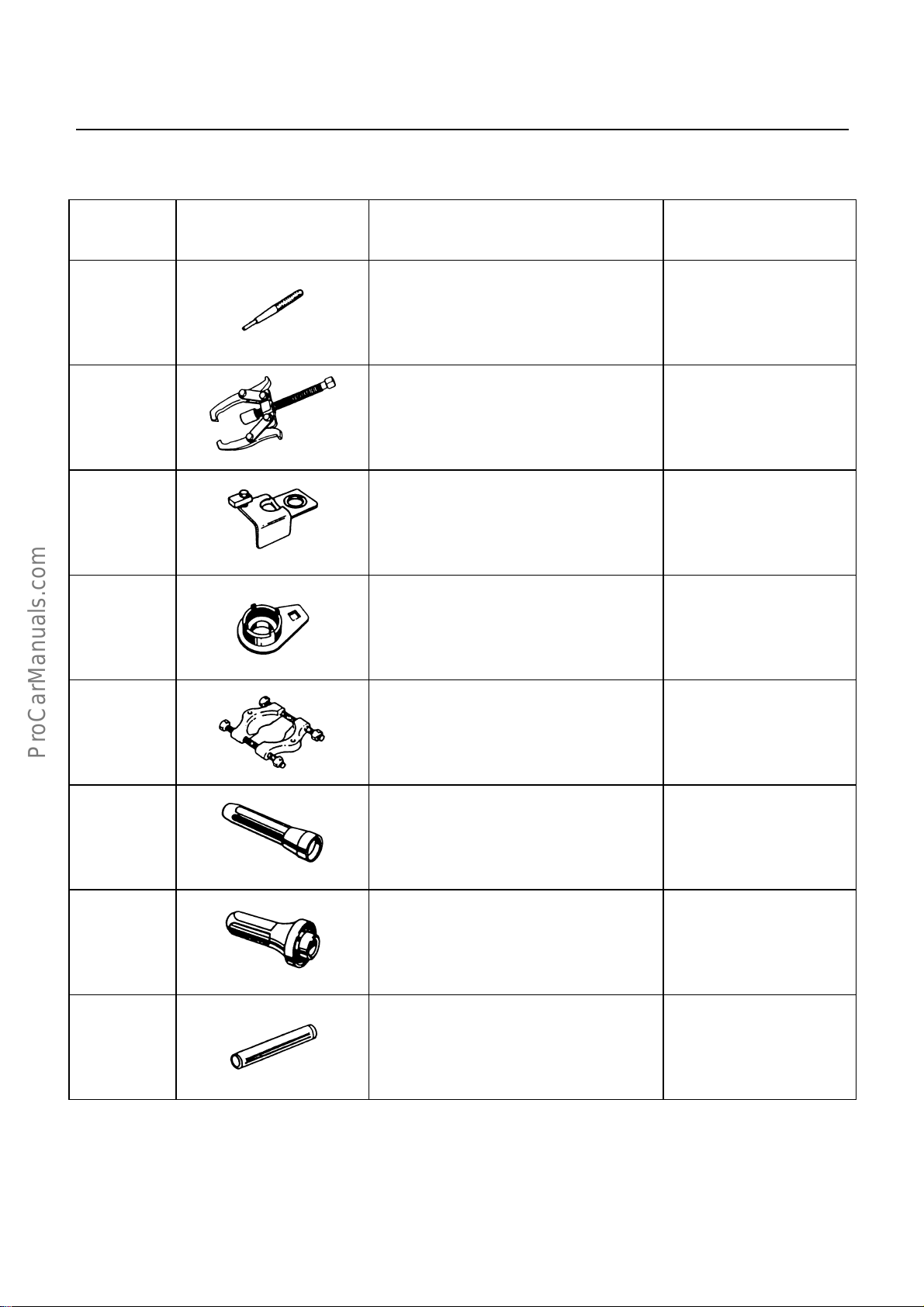

7B-42 MSG MODEL

SPECIAL SERVICE TOOL

ITEM NO. ILLUSTRATION PART NO. PART NAME

MTL-42

MTL-1

MTL-9

MTL-35

MTL-3

9-8529-2201-0

5-8840-0013-0

5-8840-2001-0

5-8840-0353-0

5-8840-0015-0

(J-22888)

(J-29768)

(J-36629)

(J-22912-01)

Spring pin remover

Gear remover

Holding fixture

Mainshaft nut wrench

Bearing remover/installer

MTL-13

MTL-14

MTL-21

5-8840-0026-0

5-8522-0050-0

5-8840-0178-0

(J-26540)

(J-29769)

(J-33851)

Front cover oil seal

installer

Rear cover oil seal

installer

Mainshaft collar installer

Page 45

Page 46

No. TFMSG-WE-0431

Loading...

Loading...