Page 1

Model TTI-7-R

Precision Digital Thermometer

Operators Handbook

Isotech North America

158 Brentwood Drive, Unit 4

Colchester, VT 05446

Phone: (802)-863-8050

Fax: (802)-863-8125

www.isotechna.com

sales@isotechna.com

Page 2

ENGLISH

IMPORTANT SAFETY INFORMATION

22/1/97

GENERAL

This instrument has been designed and tested to comply with the Electromagnetic Compatibility Directive 89/336/EEC

and Low Voltage Directive 93/68EEC in accordance with EN 61010 -1 :1995 relating to the safety requirements for

electrical equipment for measurement, control and laboratory use.

Before connecting the instrument to the main supply please ensure the following safety precautions have been read and

understood.

SAFETY SYMBOLS

The following symbols are used to describe important safety aspects of th is instrument, these symbols appear on the

instrument and in the operation instructions.

Attention Symbol:

Indicates a potentially hazardous condition exists and that it is

necessary for the operator to refer to the instruction manual to ensure the safe operation

of thi s instrument.

Hot Surface Warning:

Indicates a hot surface that may be at a temperature capable of

causing burns, refer to the instruction manual for further safety information.

Caution Risk of Electric Shock:

Indicates hazardous voltages may be present,

refer to the instruction manual for further safety information.

Protective Conductor Terminal:

For protection against electrical shock during a fault

condition. This symbol is used to indicate terminals that must be connected to electrical

ground before operating equipment.

SUMMARY OF SAFETY PRECAUTIONS

The following general safety precautions must be observed while operating or servicing thi s instrument. Failure to

comply with these precautions may result in personnel i njur y or death.

INSTRUMENT ELECTRICAL EARTH

This instrument is designed as a Class 1 electrical safety ins ulat ion device. To ensure continued protection from

electric shock the instrument chassis must be connected to an electrical ground. The instrument is supplied with an AC

power cable with an earth connection.

LIVE CIRCUITS DANGER

Do not connect the power supply to or operate thi s instrument with the protective covers removed. Component

replacement and internal adjustments must be made by qua li fied service personnel. Do not replace components with the

power cable connected. Under certain conditions, dangerous voltages may exist with the power cable removed. To avoid

inj ur ie s always disconnect power and discharge circuits before touching them.

DO NOT MODIFY THIS INSTRUMENT OR SUBSTITUTE PARTS

Because of the danger of introducing additional hazards; do not perform any unauthorized modification or i nst a l l

substitute parts to the instrument. Only fuses with the rated current, voltage and specified type should be used,

fai lu re to do so may cause an electric shock or f ir e hazard. Return the instrument to Automatic Systems Laboratories

for service and repair to ensure the safety features are maintained.

DO NOT OPERATE IN EITHER DAMP OR EXPLOSIVE ENVIRONMENTS

This instrument is not designed to operate w h ile wet, in an environment of condensing humidity or in the presence of

flammable gases or vapors. The operation of thi s instrument in such an environment constitutes a safety hazard.

HOT SURFACES DANGER

Equipment marked with a Hot Surface warning symbol should be regarded as operating at temperatures capable of

causing burns. Do not touch, handle or transport hot components or l iqu id s un t il they are at safe temperatures. Care

should be taken not to spill or splash water or volatile fluids on or into hot surfaces or liquids.

CERTIFICATION

Automatic Systems Laboratories certifies that th is product met it s published specifications at the time of shipment

from our factory. A ll calibration measurements performed in the manufacture of t his instrument are traceable to the

National Physical Laboratory (London).

ASSISTANCE

For after sales support and product service assistance please contact Automatic Systems Laboratories Customer

Support Group. Contact information is provided in the operation instruction manual.

Page 3

Contents

Table of Contents

1. INTRODUCTION.................................................................................................................1-1

1.1 Overview ...................................................................................................................1-1

1.2 Definitions and Terminology.......................................................................................1-3

1.3 Principles of measurement........................................................................................1-4

1.3.1 PRT measurement...........................................................................................1-4

1.3.2 Thermocouple measurement............................................................................1-5

1.3.3 Thermocouple reference junction compensation...............................................1-6

2. SETTING UP THE TTI-7-R ............................................................................................... 2-1

2.1 Safety information......................................................................................................2-1

2.2 Unpacking the instrument..........................................................................................2-1

2.3 Voltage selection and fuse rating...............................................................................2-2

2.3.1 Setting the Voltage and Fuse Rating.................................................................2-2

3. ABOUT THE TTI-7-R ........................................................................................................ 3-1

3.1 The Front Panel ........................................................................................................3-1

3.2 On/Off switch and internal battery.............................................................................. 3-1

3.3 The Function Keypad ................................................................................................3-2

3.4 About the TTI-7-R Display ......................................................................................... 3-4

3.5 Thermometer inputs..................................................................................................3-8

3.6 Rear panel .................................................................................................................3-9

3.6.1 AC Power Input Socket..................................................................................3-10

3.6.2 Rating plate ....................................................................................................3-10

3.6.3 Input channel expansion card .........................................................................3-10

3.6.4 RS232/IEEE 488.2 Communication interface card ..........................................3-10

3.6.5 Analogue output .............................................................................................3-10

3.6.6 Name plate.....................................................................................................3-10

4. MEASURING TEMPERATURE...........................................................................................4-1

4.1 Measurement uncertainty and traceability .................................................................4-1

4.2 International temperature scale .................................................................................4-1

4.3 Thermocouple measurement introduction ..................................................................4-3

4.3.1 Connecting thermocouples ................................................................................4-4

4.4 PRT measurement .................................................................................................... 4-4

4.4.1 PRT linearization functions ...............................................................................4-6

5. OPERATING THE TTI-7-R ................................................................................................. 5-1

5.1 About the display screen ...........................................................................................5-1

5.2 About function keys ..................................................................................................5-3

5.3 Power-up sequence .................................................................................................. 5-4

5.3.1 Self-Test ..........................................................................................................5-4

5.3.2 System Configuration....................................................................................... 5-5

5.4 Setting up Measurement Options ..............................................................................5-6

Contents - 1

Page 4

Contents

5.4.1 Selecting thermometer input channel. .............................................................. 5-6

5.4.2 Selecting differential input measurement .......................................................... 5-6

5.4.3 Setting up a PRT measurement....................................................................... 5-7

5.4.4 Setting up a PRT measurement with user defined probe memories.................. 5-9

5.4.5 Setting up a PRT measurement: checking/editing probe memory co-eff. values..

...................................................................................................................... 5-10

5.4.6 Selecting thermocouple type.......................................................................... 5-11

5.4.7 Selecting the reference junction compensation method.................................. 5-12

5.4.8 Selecting ext. ref. junction PRT linearization whose temperature is measured by

a PRT connected to the same channel. ........................................................................... 5-13

5.5 Selecting Screen Display Options........................................................................... 5-14

5.5.1 Selecting measurement units ........................................................................ 5-14

5.5.2 Selecting display resolution modes................................................................ 5-14

5.5.3 Selecting relative temperature measurement .................................................5-14

5.5.4 Using the measurement trigger function [Run/Hold] .......................................5-15

5.5.5 Selecting PRT measurement sense current................................................... 5-15

5.6 Data Logger ............................................................................................................ 5-17

5.6.1 Data logger functions ..................................................................................... 5-17

5.6.2 Setting up the data logger ..............................................................................5-17

5.6.3 Configuring the Scanner ................................................................................ 5-18

5.6.4 Configuring the Timer. .................................................................................... 5-19

5.6.5 Configuring the data log memory ................................................................... 5-21

5.6.6 Starting the data log.......................................................................................5-22

5.6.7 Reviewing log results ..................................................................................... 5-23

5.6.8 Reviewing log statistics .................................................................................. 5-24

5.7 Setting up the basic controls .................................................................................. 5-25

5.7.1 Review system configuration.......................................................................... 5-25

5.7.2 Setting up the TTI-7-R ................................................................................... 5-26

5.7.3 Configuring the communications interface. ..................................................... 5-28

5.7.4 Setting up Trigger Mode................................................................................. 5-30

5.7.5 Displaying the firmware version ...................................................................... 5-31

5.7.6 Adjusting the display contrast........................................................................ 5-31

6. CALIBRATING THE TTI-7-R .............................................................................................6-1

6.1 TTI-7-R Instrument calibration ................................................................................... 6-1

7. COMMUNICATIONS INTERFACE .....................................................................................7-1

7.1 Introduction............................................................................................................... 7-1

7.2 Fitting the Interface................................................................................................... 7-2

7.3 Overview of the RS-232 Serial Interface .................................................................... 7-3

7.3.1 The RS-232 Connector. .................................................................................... 7-4

7.3.2 Pin Connections............................................................................................... 7-4

7.3.3 RS-232 Settings............................................................................................... 7-5

7.3.4 RS-232 Operating Modes ................................................................................. 7-5

7.3.5 RS-232 Interface Commands ........................................................................... 7-6

Contents - 2

Page 5

Contents

7.4 Programming the Interface ........................................................................................7-6

7.4.1 Introduction ......................................................................................................7-6

7.4.2 Command Tree.................................................................................................7-7

7.4.3 Command Directives ........................................................................................7-7

7.4.4 Command Syntax .............................................................................................7-8

7.5 IEEE-488.2 Common Command Group ....................................................................7-10

7.5.1 IEEE-488.2 Common Command Summary.....................................................7-10

7.5.2 IEEE-488.2 Common Commands ..................................................................7-10

7.6 Measurement Command Group ..............................................................................7-14

7.6.1 Measurement command summary...................................................................7-14

7.6.2 CONFigure Commands...................................................................................7-14

7.6.3 MEASure Command .......................................................................................7-18

7.7 SENSe Command Group........................................................................................7-20

7.7.1 Sense command summary.............................................................................7-20

7.7.2 Sense Commands .........................................................................................7-20

7.8 Mathematical Operation Commands........................................................................7-22

7.8.1 CALCulate:AVERage command summary ......................................................7-22

7.8.2 CALCulate:AVERage commands ....................................................................7-22

7.9 Route Command Group ...........................................................................................7-23

7.9.1 Route command summary. .............................................................................7-23

7.9.2 Route commands ...........................................................................................7-23

7.10 Trigger Command Group.....................................................................................7-25

7.10.1 Trigger command summary ............................................................................7-25

7.10.2 Trigger commands..........................................................................................7-25

7.11 System Related Commands ...............................................................................7-29

7.11.1 System command summary...........................................................................7-29

7.11.2 System commands .........................................................................................7-29

7.12 DATAIogger Command Group..............................................................................7-31

7.12.1 Datalogger command summary.......................................................................7-31

7.12.2 Datalogger commands ...................................................................................7-31

7.13 Status Reporting Structure AND Commands ......................................................7-34

7.13.1 The Status Reporting System is summarised in the following diagram.............7-35

7.14 Command Summary...........................................................................................7-39

7.15 Analogue Output.................................................................................................7-42

7.15.1 Specification...................................................................................................7-42

7.75.1 Default Settings..............................................................................................7-42

7.15.1 Analogue Output Connection..........................................................................7-42

8. OPTIONS AND ACCESSORIES ........................................................................................8-1

8.1 Accessories ..............................................................................................................8-1

8.2 High = PRTs ..............................................................................................................8-1

8.3 Low = PRTs .............................................................................................................. 8-2

9. SPECIFICATIONS .............................................................................................................9-1

9.1 Pt100 resistance thermometer measurement............................................................ 9-1

Contents - 3

Page 6

Contents

9.2 Thermocouple measurement............................................................................................ 9-1

9.3 Internal battery operation ................................................................................................. 9-2

9.4 Supply ...................................................................................................................... 9-2

9.5 Environmental........................................................................................................... 9-2

9.6 Data communication interface options ...................................................................... 9-2

9.7 Analogue output option............................................................................................. 9-3

9.8 Display...................................................................................................................... 9-3

9.9 Physical....................................................................................................................9-3

9.10 Pt100 System accuracy ....................................................................................... 9-3

10. CLEANING AND MAINTENANCE................................................................................... 10-1

10.1 Cleaning............................................................................................................. 10-1

10.2 Preventive Maintenance...................................................................................... 10-1

10.3 General Safety Warning .....................................................................................10-1

11. SERVICE AND WARRANTY........................................................................................... 11-1

11.1 Technical Support .............................................................................................. 11-1

11.2 Returned Instruments ......................................................................................... 11-1

Contents - 4

Page 7

1.1 Overview

The TTI-7-R Precision Thermometer is a high accuracy instrument

designed for laboratory and industrial temperature measurement and

calibration applications.

Features include:

• unique dual capability for both thermocouple and resistance

thermometer measurements;

• number of input channel can be expanded from two to ten

channels;

• large graphic LCD display for temperature measurement values

as well as configuration settings and statistical results;

• advanced functions include differential measurement, four

programmable scanning routines, programmable timer, data

logging to none volatile memory, statistical reporting;

• analogue output, IEEE 488 and RS232 communication

interfaces available for automated monitoring and calibration

applications;

• internal battery provides up to 20 hours mains free operation for

remote measurement and data logging applications.

The TTI-7-R will operate with any Pt25 (25 Ohm) and all 2, 3 and 4-wire

Pt100 (100 Ohm) platinum resistance thermometers as well as most

standard international thermocouple types. Temperature measurement

units are selectable by single front panel key operation; °C, °F,K Base

measurement units mV, are also displayed.

Resistance accuracy is better than ±4m for Pt100 400 Ohm range

and ±1.5m for Pt25 100 Ohm range (over full range of –200 to 100°C

at +20°C ±2°C). This is equivalent to temperature measurement

precision of ±15mK for Pt25 thermometers and ±10mK for Pt100

thermometers. Total system measurement uncertainties as low as

±20mK are possible when the TTI-7-R is used with a calibrated

reference thermometer.

1. Introduction

Page 1-1

Page 8

Introduction

Overall system accuracy depends on the PRT quality and calibration. See Section

9 for details of the system measurement accuracy specification.

Standard miniature and 4mm instrument sockets allow convenient connection for

thermocouple inputs. Connection sockets incorporate integral temperature

compensation sensors making high accuracy thermocouple measurement

possible without the use of an external reference junction.

Standard features of the TTI-7-R Precision Thermometer include:

• direct temperature measurement display in °C, °F,K;

• 2 x Pt 25 or Pt100 channel inputs on front panel using 4mm gold plated

spade lug connectors or wire/banana plugs;

• 2, 3 and 4 wire PRT probe measurement;

• Thermocouples B,C,D,E,J,K,N,R,S,T,U,W

• 1 to 20 probe coefficients for ITS90 or CVD entered and stored from

programming PRT calibrations;

• High Accuracy to 0.01 deg.C over –200 to 660 deg.C

• High Resolution 0.001 deg.C for 25/100 Ohm PRT’s and 0.01 deg.C for TC’s;

• Measuring Range –200 to 1100 deg.C for PRT’s and 0 to 2315 deg.C TC’s;

• PRT self-heating and measurement current polarity selection;

• illuminated display;

• compact rugged case;

• 2 to 10 channel expansion with rear panel SPRT, RTD, and TC modules;

• Automatic Cold Junction compensation for TC’s;

• Switched DC (current reversal) option to eliminate thermal e.m.f.s on PRT’s;

• Internal data logging and storage of 4000 measurements;

• Statistical data internally (Min, Max, Peak/Peak, Average, Std. Deviation) ;

• Differential (Difference between any 2 channels connected) ;

• PC interface (RS232) included;

• Portable 20 hour use using internal battery + charger fitted or mains supply;

Page 1-2

Page 9

Introduction

1.2 Definitions and Terminology

i. 0°C = 273.15K

ii. 1 mK (milli-Kelvin) = 0.001 °C (one milli-degree Celsius)

iii. 1 milli-degree C = 0.001 °C = 1m°C = 1mK= 1.8m°F

iv. 1 milli-degree F = 0.001 °F = 1 m°F = 0.56mK = 0.56m°C

v. Alpha, or , is the temperature coefficient, or temperature

sensitivity, of the platinum wire used in PRTs. In general, the

greater the alpha value, the better the PRT thermometer

measurement reproducibility, stability and performance.

vi. Abbreviations for platinum resistance thermometers include: PRT

(Platinum Resistance Thermometer)

Pt100 (PRT with nominally 100 resistance at 0°C) RTD (Resistance

Temperature Device) vii. Thermocouples are referred to as a TC

element or TC sensor.

viii. The TTI-7-R 's thermocouple connection sockets are often referred

to as a temperature compensated reference junction. See Section

1.3 for more details.

ix. System accuracy refers to the overall, combined accuracy of the

TTI-7-R and thermometer.

Key functions and menu options are described as [Function] in the

text or the actual keytop is shown.

General warning symbol. This indicates that a

hazardous condition or general danger may exist.

You must read the relevant sections in the

Operator's Handbook before operating the

instrument.

Page 1-3

Page 10

Introduction

1.3 Principles of measurement

1.3.1 PRT measurement

The TTI-7-R measures the voltage (Vt) developed across the unknown

sensor resistance (Rt) and the voltage (Vs) across a stable internal

reference resistance (Rs) connected in series and passing the same

current. The voltages are in proportion to the resistances so the

thermometer resistance is derived from: Rt = Rs x Vt / V

s

This technique achieves immunity from slow moving time and

temperature drift in the electronics as it is not affected by voltage

measurement gain variations or current source fluctuations.

In the same way that AC resistance measurement eliminates thermal

EMFs, switched DC achieves a similar advantage. Switched DC

works by reversing the current flow on alternate measurement cycles

and taking the average value, thereby cancelling any thermal EMF

offsets from the measurement.

For PRTs, the relationship between resistance and temperature varies

slightly from one PRT to another. Therefore, no matter how accurately

the TTI-7-R measures the PRT resistance, if the relationship between

resistance and temperature for a particular PRT is not known,

accurate temperature measurement is not possible.

The TTI-7-R uses PRT calibration data to overcome this problem and

calculates temperature from temperature conversion functions stored

in internal memory. This method enables the TTI-7-R accurately to

convert resistance to temperature, uniquely for each PRT used. It is

very important therefore that a PRT is used on the correct and

properly configured input channel.

The system accuracy is a combination of the TTI-7-R accuracy in

measuring PRT resistance and the calibration uncertainty placed on

the PRTs by the calibrating laboratory. Using the TTI-7-R with PRT

type 935-14-61, this is ±0.020°C for temperatures from -80°C to

+350°C. See section 9.1 for PRT measurement performance details.

Page 1-4

Page 11

Introduction

1.3.2 Thermocouple measurement

As well as the PRT resistance measurement facility the TTI-7-R also

functions as a precision milli-voltmeter. Designed for high accuracy

measurement over the EMF voltage range of all standard base and

precious metal thermocouples, the TTI-7-R achieves a basic voltage

accuracy of better than 3µV

(at +20 °C ±2 °C) over the full measurement range and significantly

better over smaller ranges. See Section 9.2 for thermocouple

measurement performance details. Thermocouple EMFs are

converted to temperature using the NIST monograph 175

linearization functions. Special types C and D use the linearizations

specified by ASTM E988.

The voltage input connection is specially designed to minimise the

thermal gradient between the terminals. This is particularly important

when the internal reference junction compensation is used, as any

temperature difference at the connection junction will influence the

measurement result. The connection junction is introduced in

Section 1.3.3 below.

Page 1-5

Page 12

Introduction

1.3.3 Thermocouple reference junction compensation

The electrical connection between the thermocouple element and the

TTI-7-R input connector is often referred to as the internal reference

junction. All standard thermocouple reference functions are defined

relative to 0°C. To eliminate the physical need to reproduce this

temperature inside the TTI-7-R , the actual connection temperature

is accurately measured with an internal PRT. This temperature is

converted to an equivalent EMF and added to the actual

thermocouple voltage measurement, thereby correcting for the

connection temperature.

For high precision thermocouple measurement applications, i.e.

calibration, an external reference junction may be used. Using an

external reference junction eliminates the uncertainties associated

with reference junction compensation.

Page 1-6

Page 13

2.1 Safety information

Please read and follow these important safety instructions:

• Read the safety information sheet at the beginning of this

handbook before operating the TTI-7-R ;

• Make the necessary electrical safety and connection checks. In

particular, select the correct line voltage and make sure that the

correct AC power fuse is installed. Incorrect voltage or fuse

selection present both an electrical safety and a fire hazard.

2.2 Unpacking the instrument

When you unpack the TTI-7-R thermometer, check that the following

items are present before starting to use the unit:

• 1x TTI-7-R thermometer

• 1 x AC power cord

• 1x Operator's handbook

• 1x Calibration certificate

Please contact the ISOTECH NA Technical Services Group

immediately if any of these items are missing or damaged.

2. Setting up the TTI-7-R

Page 2-1

Page 14

Setting up the TTI-7-R

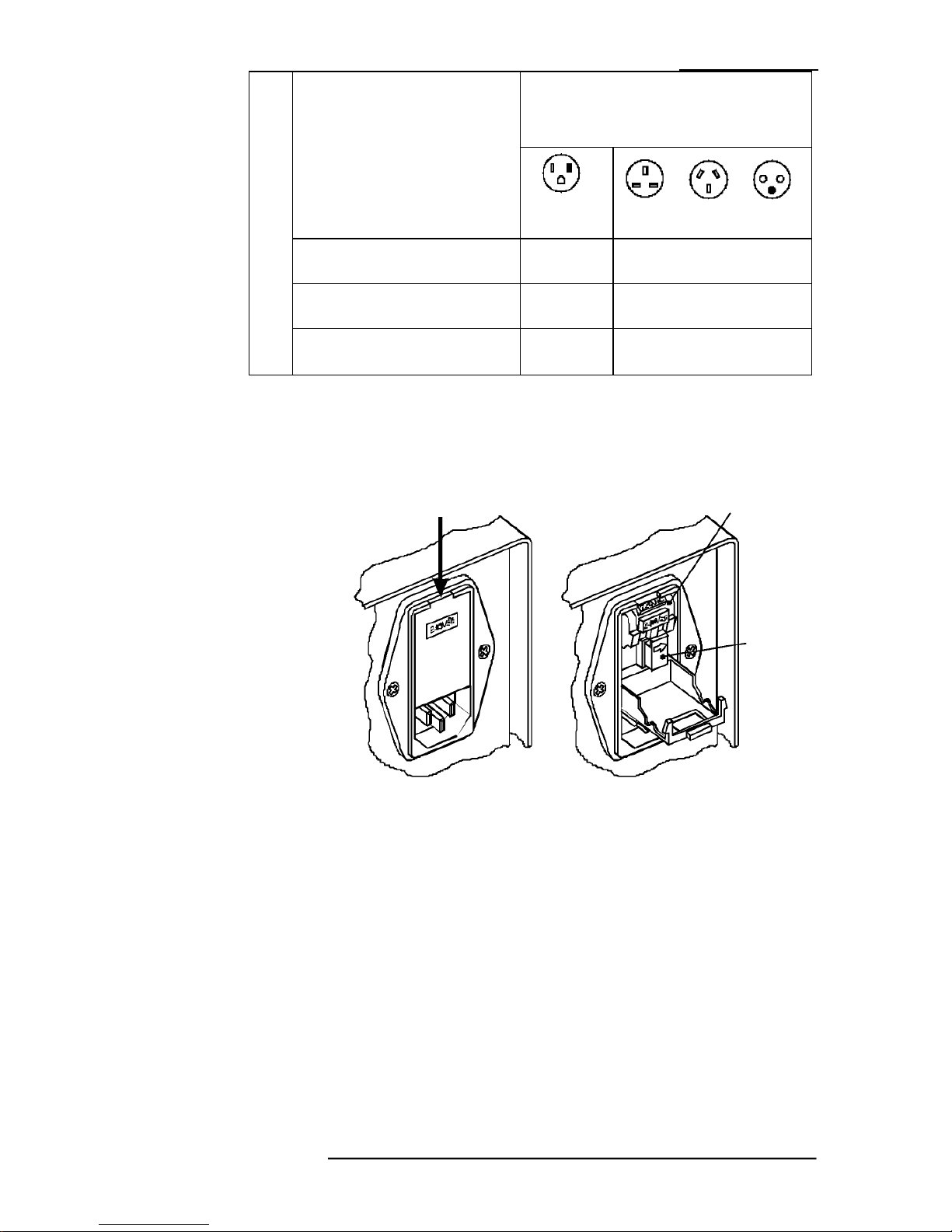

2.3 Voltage selection and fuse rating

The AC Power Input Unit incorporates a voltage selector and fuse

holder, to enable the TTI-7-R operating voltage and fuse rating to be

selected for the local AC electricity supply. The table below describes

the correct voltage selection range and fuse to use.

Voltage Selection

Voltage Range

Fuse Type

100V 90-110V T630mA (250V AC)

120V 108- 132V T630mA (250V AC)

220V 198-244V T315mA (250V AC)

240V 216-264V T315mA (250V AC)

WARNING: DO NOT CONNECT THE POWER

CABLE UNTIL THE VOLTAGE AND FUSE RATING

OF THE INSTRUMENT HAVE BEEN CHECKED

AND CHANGED IF NECESSARY.

2.3.1 Setting the Voltage and Fuse Rating

Lever open the Power Input Unit from the top with a flat bladed

screwdriver. Inside is a plastic cam: remove this and replace it so that

the voltage to be set is displayed through the window as detailed in

Figure 2.1.

Where fused plugs are connected to the AC power cord, the correct

fuse rating is 3 Amps. The AC power cord provided with the TTI-7-R is

colour coded in accordance with national standards to match the plug

type fitted, as follows:

Page 2-2

Page 15

Setting up the TTI-7-R

Earth (protective conductor) Green Green/Yellow

Live Black Brown

Neutral White Blue

Figure 2.1 - Fused Power Input Unit and Voltage Selector

INSERT SCREWDRIVER

TO LEVER DOOR OPEN

VOLTAGE SELECT

PLASTIC CAM

FUSE

HOLDER

Page 2-3

Page 16

Setting up the TTI-7-R

This page has been left blank intentionally

Page 2-4

Page 17

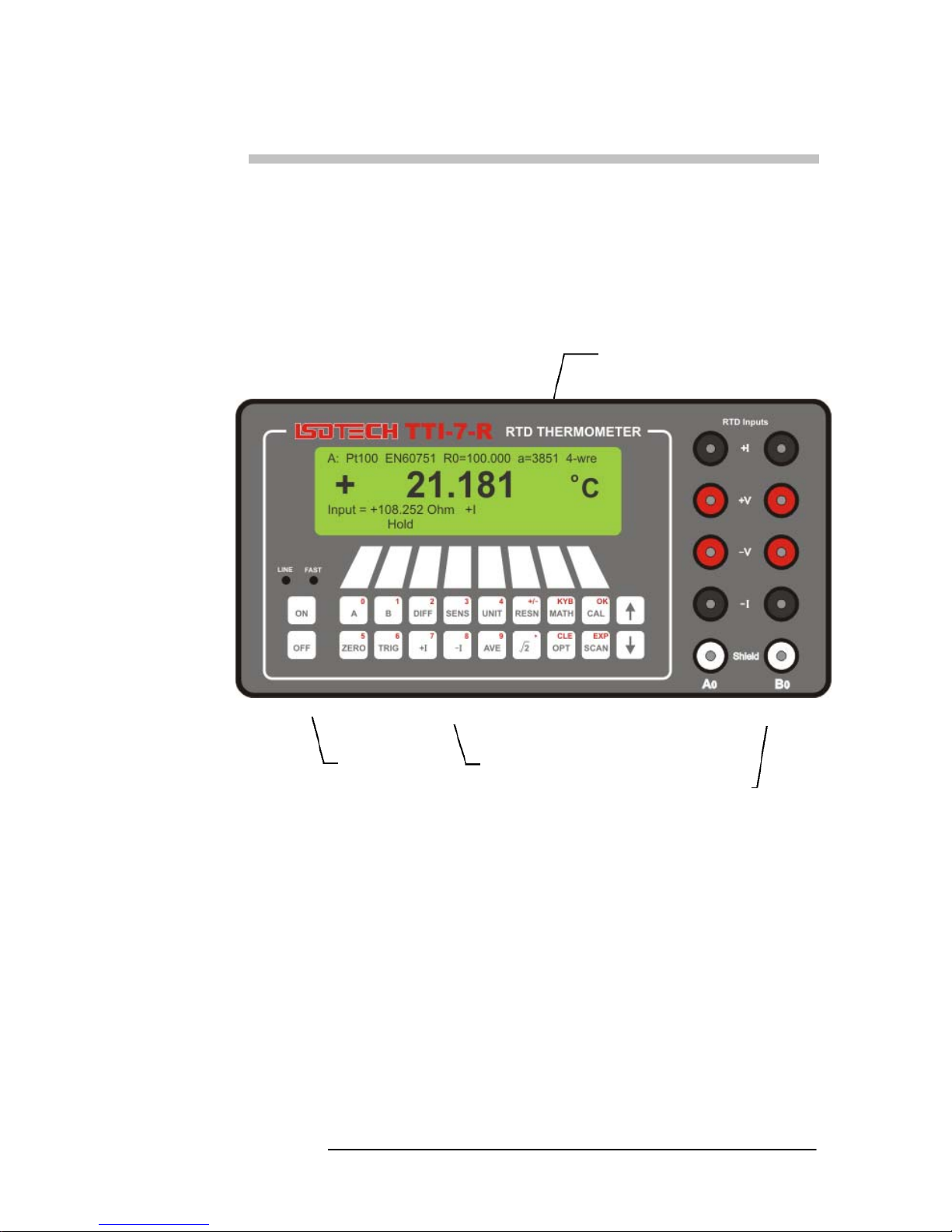

3. About the TTI-7-R

This section introduces you to the features and functions of the TTI-7-

R Precision Thermometer.

3.1 The Front Panel

Figure 3.1- Front Panel

On/Off

switches

Function keys

Display

Thermometer

inputs

3.2 On/Off switch and internal battery

The ON / OFF keys switch the TTI-7-R on and off. During power

on all TTI-7-R measurement functions are reset to their default state.

It is important to note that THE POWER OFF FUNCTION DOES

NOT DISCONNECT THE TTI-7-R FROM THE ELECTRICITY

SUPPLY. The power supply remains connected to the mains supply.

Page 3-1

Page 18

About the TTI-7-R

Battery charging operation is unaffected by the ON / OFF

key operation.

The TTI-7-R 0 may be operated from the AC electricity supply or the

internal battery. Fully charged batteries provide approximately 8 hours

continuous operation. The internal battery charger operates

whenever the electricity supply is connected. Front panel LEDs

indicate connection to the AC electricity supply and when the battery

is charging.

The batteries are a sealed lead acid type and require no routine

maintenance. Continuous charging causes no harm to the batteries.

Operate the TTI-7-R from the mains when possible to ensure the

batteries are always fully charged.

<LOW BATTERY> indication is displayed when the batteries have

approximately 10% charge or 50 minutes operating time remaining.

To extend the battery operation time, switch the display backlight off.

See Section 5.6.1.

If the batteries are left discharged for a long time, they become

difficult to charge on the first re-charging cycle. During this first re-

charge, it may not be possible to turn on the TTI-7-R . Leave the TTI-

7-R connected to the AC electricity supply for at least 12 hours to

allow the batteries to fully re-charge before using the TTI-7-R again.

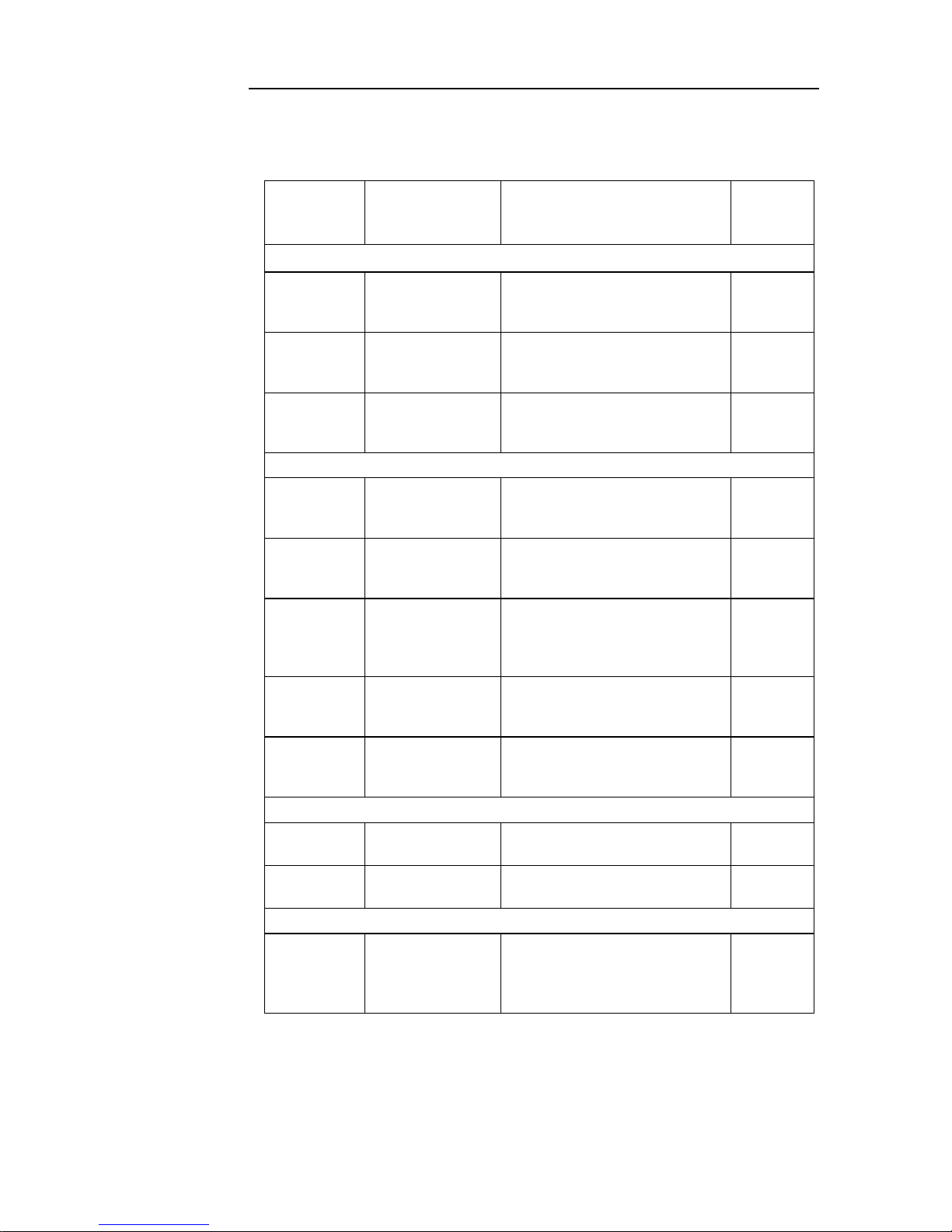

3.3 The Function Keypad

All TTI-7-R measurement and programming facilities are accessed

through the function keypad. A brief description of key functions is

given in the table below. For a detailed description of how to use the

keys to configure and operate the TTI-7-R , refer to Section 5.

Page 3-2

Page 19

About the TTI-7-R

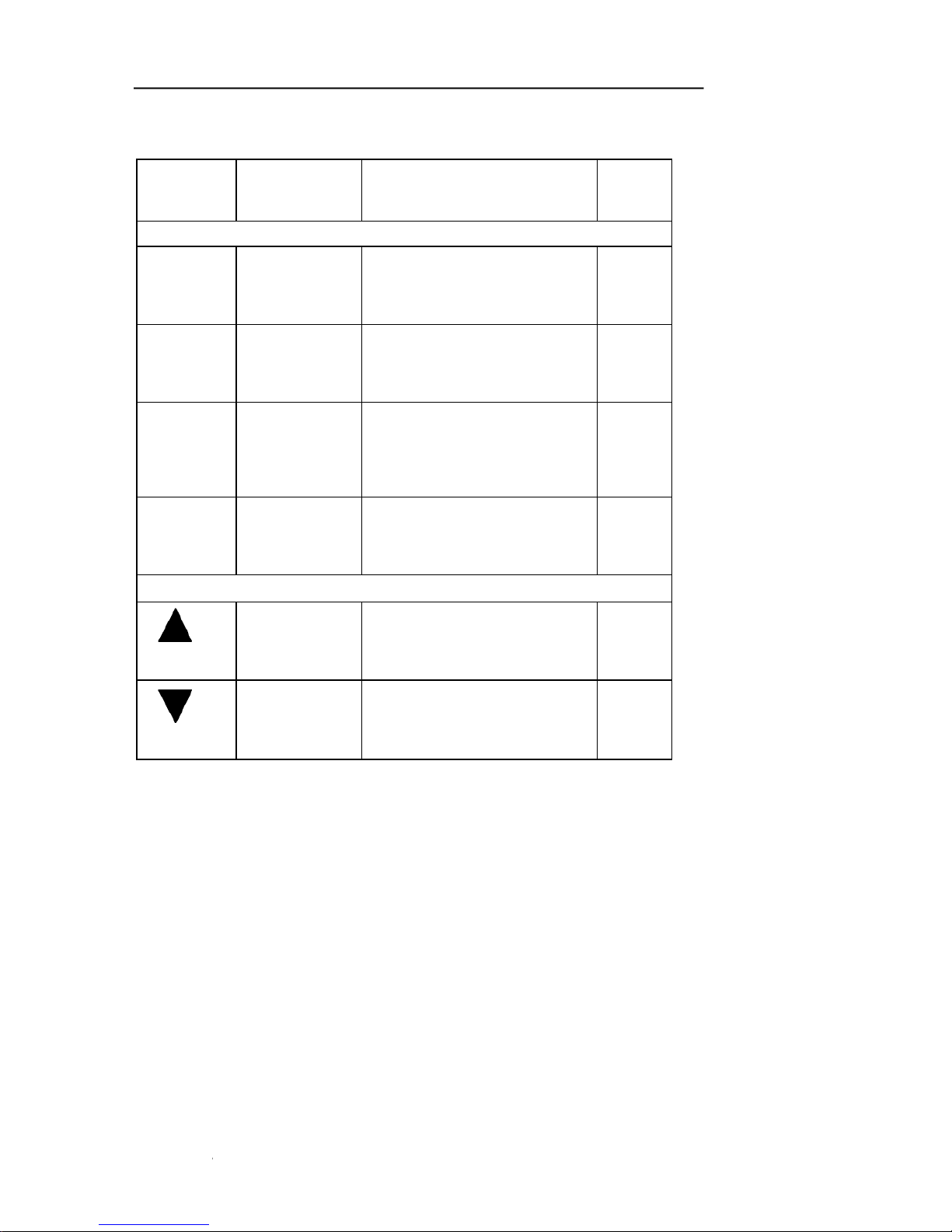

Table 3.1 Summary of basic key functions

Page 3-3

Key symbol Description Function

Direct

function

or Menu

Setting up Input Channels

A

Select input

channel A0 to A4

Selects and displays

measurement channel A0 to A4

Direct

from

keypad

B

Select input

channel BO to B4

Selects and displays

measurement channel BO to B4

Direct

from

keypad

Diff

Select differential

measurement Ch1 Ch2

Relative measurement function

which displays the difference

between the Ch1 and Ch2 inputs

Direct

from

keypad

Setting up Measurement Options

SENS

Temperature

sensor type

Selects sensor type and

measurement configuration for the

selected channel

Menu

UNIT

Measurement

units

Selects measurement display

units: °C, °F, K

Direct

from

keypad

RES

Measurement

display resolution

Selects measurement display

resolution: Thermocouple: 0.1,

0.01 PRT:0.01, 0.001

Direct

from

keypad

ZERO

Measurement

display zero

function

Nulls the display at the current

reading and displays measured

values relative to the nulled value.

Direct

from

keypad

TRIG

Measurement run/

hold/single step

Display hold function, triggers

single or continuous

measurement.

Direct

from

keypad

Logging Data and Statistical Displays

MATH

Math display

functions

Selects the math menu statistical

display and function

Menu

CAL

Calibration menu

functions

Selects the instrument calibration

menu functions

Menu

Options and configuration

OPT

Setup options and

functions

Selects the instrument

configuration options menu and

communication interface

functions

Menu

Page 20

About the TTI-7-R

(Table 3.1 continued:)

SCAN

Scanner, timer

and data logger

functions

Scanner, timer and data logger

menu.

Menu

PRT measurement current

+ l

PRT

measurement

positive current

mode

Positive PRT measurement

current polarity selection

Direct

from

keypad

-I

PRT

measurement

negative current

mode

Negative PRT measurement

current polarity selection

Direct

from

keypad

AVE

PRT

measurement

current reversal

mode

Measures average sensor

resistance with successive

positive and negative current

polarity Default PRT

measurement state

Direct

from

keypad

2

PRT

measurement 2

current selection

2 measurement current division,

reduces measurement current to

allow PRT self heating effect to be

calculated

Direct

from

keypad

Scroll and contrast control

Up command

key; Display

contrast, page

scroll

Controls the display contrast and

page scroll functions

Direct

from

keypad

Down command

key; Display

contrast, page

scroll

Controls the display contrast and

page scroll functions

Direct

from

keypad

3.4 About the TTI-7-R Display

The liquid crystal graphic display clearly indicates the measured

temperature and measurement status as well as displaying available

menu options and measurement analysis when selected. Whilst in

Temperature Mode (see Section 5.1), there are three possible

display layouts:

Page 3-4

Page 21

About the TTI-7-R

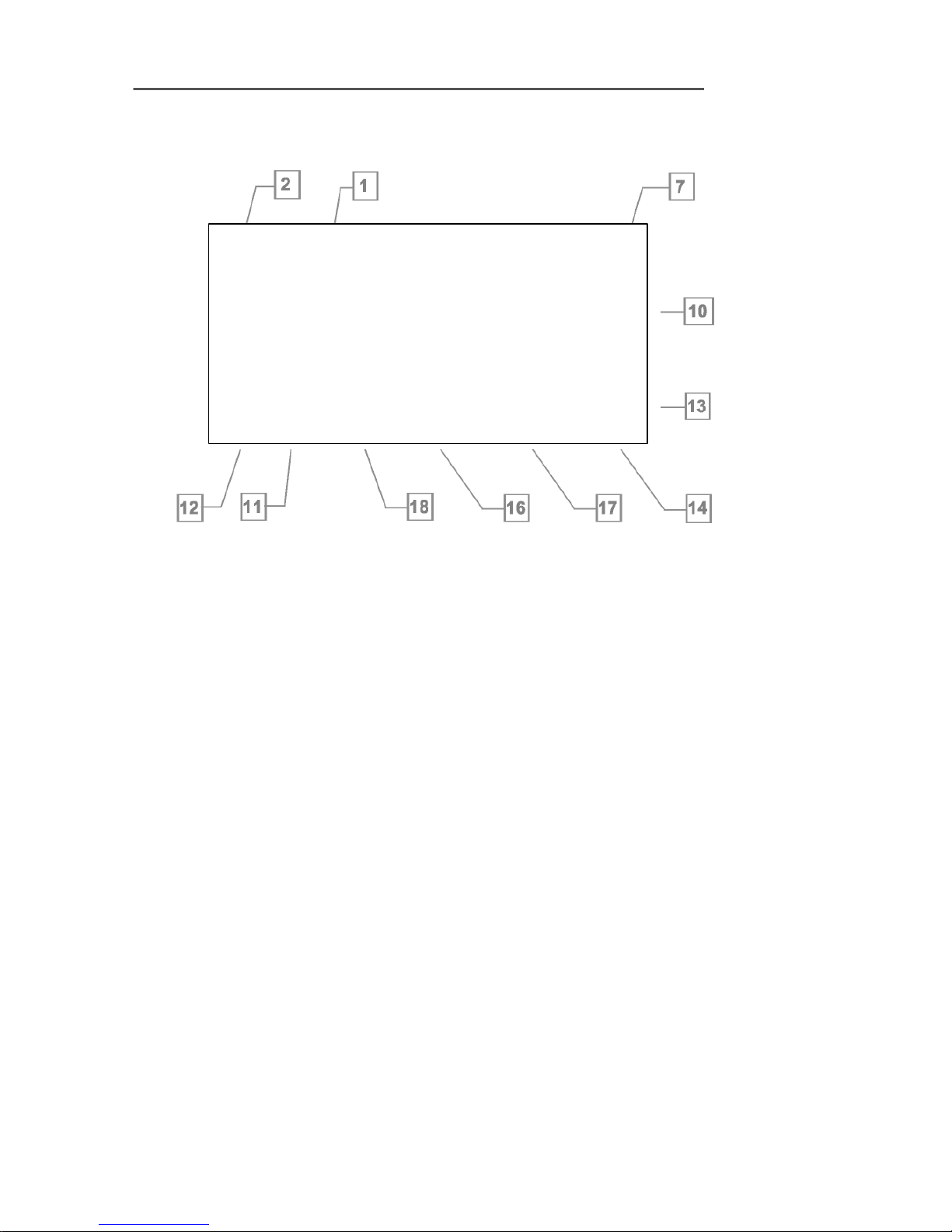

Figure 3.2 - Main display layout (PRT measurement)

A1 Pt100 IEC751 / R0 = 100.000 a=3850 4-wre

+ 18.90 °C

Input = +106.591 Ohm Ave

XXXX/YYYY

Figure 3.3 - Main display layout (Thermocouple measurement)

A1 TC Type

N

RJ Mode= Internal

+ 18.90 °C

Input = -0.170 mV RJ = +24.62 deg C

Mem Adr Rem

Page 3-5

Busy

LOBAT

Run Mem Adr

Zero

Rem

SLX

Busy

LOBA

T

Run

X

XXX/YYYY

Zero SL

X

Page 22

About the TTI-7-R

Figure 3.4 -Main display layout (Relative A1-B1 measurement)

A1-B1

- 0 . 1

°C

Busy

LOBAT

Adr

XXXX/YYYY

The table below describes the location of information as it appears in the

various display layouts:

Page 3-6

Run

Re

Mem

Zero SL

X

Page 23

About the TTI-7-R

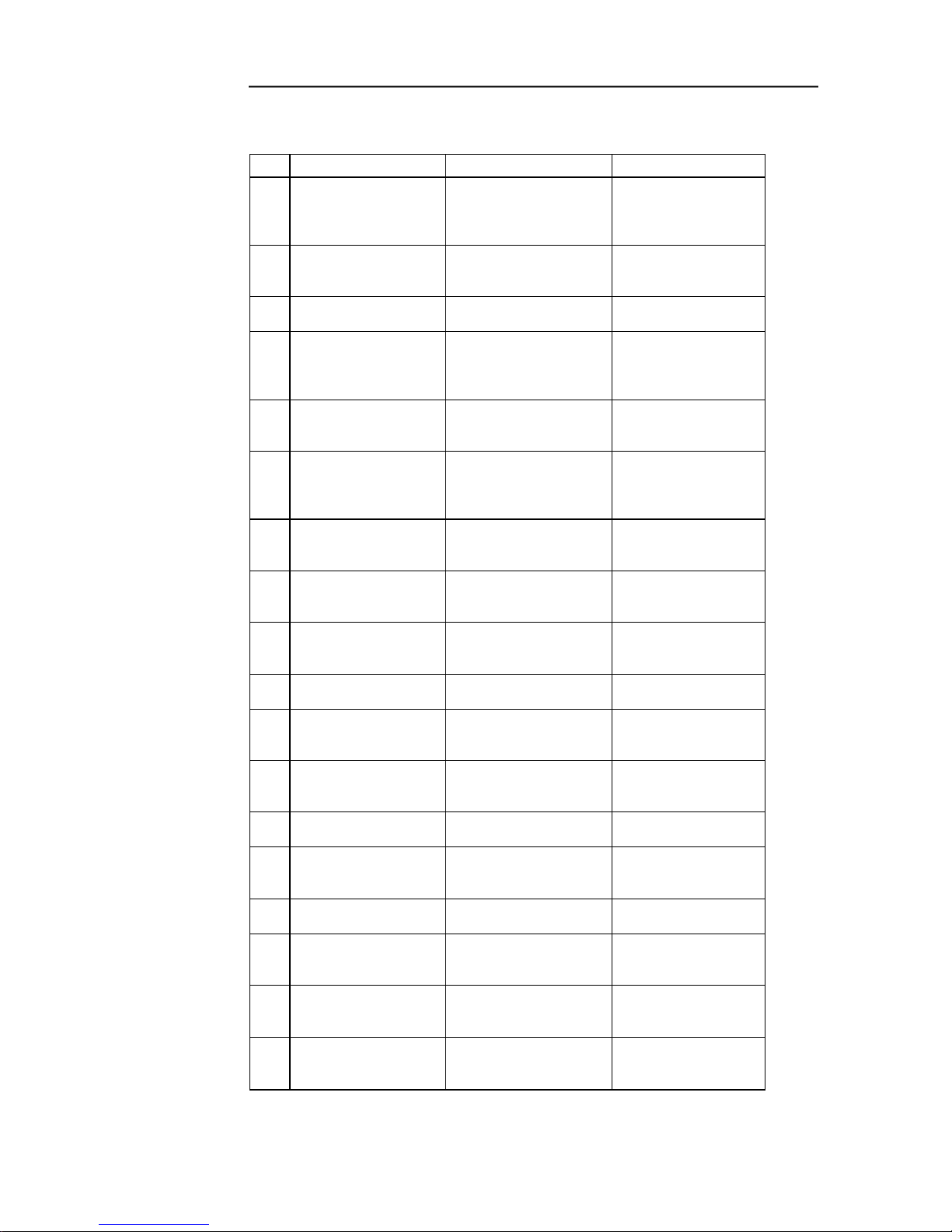

Table 3.2 - Measurement mode display features

PRT measurement Thermocouple Relative Ch1 - Ch2

1

Selected channel

temperature

Selected channel

temperature

Temperature

difference between

CM and Ch2

2

Input channel

selected

Input channel selected CM - Ch2

3

Pt100 TC Not used

4

PRT linearization

standard

Thermocouple type

selected, letter

designation

Not used

5

PRT alpha value

Reference junction

mode

Not used

6

3, 4 wire

measurement

configuration

Not used Not used

7

Temperature display

units

Temperature display

units

Temperature display

units

8

Measured input value

in Ohms

Measured input value

in mV

Not used

9

Measurement current

polarity

Reference Junction

temperature if selected

Not used

10

Measurement status Measurement status Measurement status

11

Trigger run/ hold,

single condition

Trigger run/ hold,

single condition

Trigger run/ hold,

single condition

12

Measurement zeroed

indication

Measurement zeroed

indication

Measurement zeroed

indication

13

Low Battery indication Low Battery indication Low Battery indication

14

Re mote/Addressed

remote operation

Remote/Addressed

remote operation

Re mote/Addressed

remote operation

15

R0 value in ohms Not used Not used

16

X samples taken of Y

number of samples

X samples taken of Y

number of samples

X samples taken of Y

number of samples

17

Logging data to none

volatile memory

Logging data to none

volatile memory

Logging data to none

volatile memory

18

Scanning mode ON

SLx scan list

Scanning mode ON

SLx scan list

Scanning mode ON

SLx scan list

Page 3-7

Page 24

About the TTI-7-R

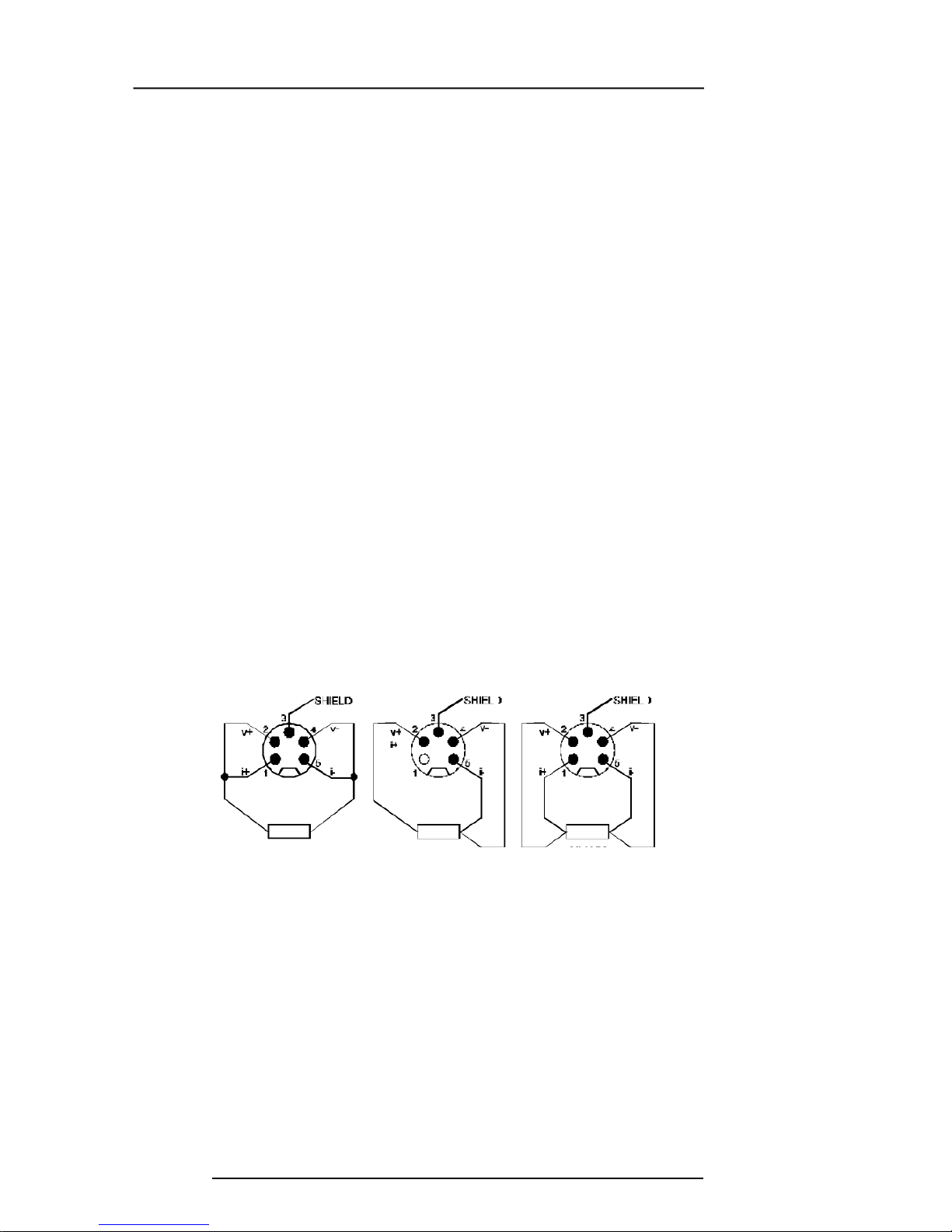

3.5 Thermometer inputs

The TTI-7-R has two main thermometer input channels, the input

sockets are located on the instruments front panel.

The two input channels can be independently configured for

measurement of PRT sensors or thermocouples.

Separate connection is provided for PRTs and thermocouples,

enabling easy direct connection of most thermometer types.

PRTs are connected via the 5 pin DIN sockets. You may connect 2, 3,

or 4 wire PRTs as shown in Figure 3.5. See Section 5.3.3 on PRT

selection. Un-terminated platinum resistance thermometers may be

connected through an optional adapter box which is available as an

accessory, (Part Number FA-ADAP-250). Refer to the Accessory

section at the end of this handbook.

Figure 3.5 - PRT input connection configuration

PRT CONNECTION - 2 WlRE PRT CONNECTION - 3 WIRE PRT CONNECTION - 4 WIRE

(5-pin DIN connector) (5-pin DIN connector) (5-pin DIN connector)

Pt100

R100

R100

View towards front panel connector

Thermocouples may be directly connected to the TTI-7-R either at the

standard miniature sockets or the two 4mm instrument sockets as

shown in Figure 3.6. Special adapter connectors are available for

connecting bare wire thermocouples to the TTI-7-R . These sockets

are within a temperature compensated isothermal block which

eliminates the need for an external ice point reference junction.

However, the TTI-7-R may also be used with an external ice point

reference for high precision measurement and calibration work.

Page 3-8

Page 25

About the TTI-7-R

Figure 3.6 - Thermocouple input connection

THERMOCOUPLE

CONNECTION

LOW THERMAL EMF

COPPER BANANA (4mm)

PLUGS

3.6 Rear panel

Figure 3.7 - Rear Panel layout, showing all options

PRT expansion

module ( op t ional)

Thermocouple

expansion module

(optional)

RS232or I EE E

Communications

Interface (optional)

Analogue output

(optional)

Voltage selector

and fuse cover

Name plate

IE C power

connector

Rating plate

Page 3-9

Page 26

About the TTI-7-R

3.6.1 AC Power Input Socket

Accepts an IEC type power connector.

The AC power input unit incorporates a voltage selection tumbler, to

enable the user to match the TTI-7-R to the local AC voltage

supply, and a power line fuse holder.

3.6.2 Rating plate

Instrument rating plate, contains the AC voltage selection and line

fuse rating, operating supply frequency range, the instrument

maximum power consumption and instrument serial number.

3.6.3 Input channel expansion card

Optional input channel expansion card slots. Blanking plates are

fitted if there is no input channel expansion cards.

3.6.4 RS232/IEEE 488.2 Communication interface card

Optional RS232/IEEE 488.2 communication interface card slot. A

blanking plate is fitted if there is no communication interface card.

3.6.5 Analogue output

Optional analogue output BNC socket. A blanking plug is fitted if

there is no analogue output.

3.6.6 Name plate

Instrument name plate, contains the manufacture name and

address details.

Page 3-10

Page 27

4.1 Measurement uncertainty and traceability

Measurement is usually made on the assumption that there is a true

value. Whenever a measurement is performed it is unlikely that the

measured value will equal the true value. The difference between the

two values is the measurement error which will lie within the specified

limits of uncertainty. Uncertainty is defined as an estimate

characterising the range of values within which the true value lies.

By taking a statistically significant number of measurement samples, a

distribution of results will emerge. Confidence in the distribution

increases as more measurements are made. Using statistical

methods, the distribution may be described in terms of mean, variance

and standard deviation. The uncertainty or precision limit of a particular

measurement is characterised by this distribution.

Traceability is defined as the property of a measurement that may be

related to appropriate reference standards through an unbroken chain

of comparisons. Through traceability it is possible to demonstrate the

accuracy of a measurement in terms of SI units.

4.2 International temperature scale

The purpose of the International Temperature Scale is to define

procedures by which certain specified practical thermometers

including PRTs and thermocouples of the required quality can be

calibrated. The values of temperature obtained from them can be

precise and reproducible, matching at the same time the

corresponding thermodynamic values as closely as current technology

permits.

4. Measuring Temperature

Page 4-1

Page 28

Since 1968 when the International Practical Temperature Scale of

1968 (IPTS68) was adopted, there have been significant advances in

the techniques employed in establishing temperature standards and

in the measurement of thermodynamic temperature. The

International Temperature Scale of 1990 (ITS-90) gives practical

effect to these improvements. Particular features are:

• ITS-90 specifies the use of the PRT up to the freezing point of

silver, 961.78 °C. The platinum 10% rhodium/platinum

thermocouple is no longer specified for use in the scale, though

it and other noble metal thermocouples will continue to be used

as secondary standards.

• New, more precise, fixed points have been introduced and

mathematical procedures for calculating resistance temperature

equivalents have been revised so as to reduce the 'non-

uniqueness' of the scale: that is, to reduce the differences which

occur between different, identically calibrated PRTs. In particular,

the calibration of a PRT can no longer be extrapolated beyond

the freezing point of zinc, 419.527 °C, but requires a

measurement at the freezing point of aluminium, 660.323 °C.

• Alternative definitions are permitted in certain sub-ranges, the

calibration of a PRT can be terminated at almost any fixed point.

This allows primary calibrations to be carried out with suitable

PRTs over reduced ranges, and will be of special importance to

metrology standards departments which need to make precise

measurements at ambient temperatures.

• The part of the ITS-90 scale which may be measured by PRTs

extends from 83.8058 K (-189.3442 °C) to 961.78 °C. The TTI-7-

R

is specified to measure temperature over the range

-200 °C to +962 °C. The actual range of temperatures which may

be measured depends on the type and range of the PRT.

Measuring Temperature

Page 4-2

Page 29

Measuring Temperature

The ITS-90 scale has much improved continuity, precision and

reproducibility compared with IPTS68. The implementation of the

ITS-90 scale according to its definition calls for changes in

equipment and procedure compared with IPTS68, but lower

uncertainties of calibration are achievable in all parts of the range.

However, the instruments and equipment needed to implement the

ITS-90 scale in calibration laboratories will be substantially the

same.

4.3 Thermocouple measurement introduction

Very broadly the thermoelectric effect occurs when an electrical

circuit consisting of dissimilar metal conductors is subjected to a

temperature gradient. An electric potential or voltage is developed

along the conductors. This voltage potential varies proportionally with

temperature and provides a means by which to measure

temperature.

There are two categories of thermocouple:

• Rare metal, Platinum based types

• Base metal, Nickel based

Rare metal, platinum types are mostly used for high temperature

precision thermometry. Maximum temperatures of 1700 °C and

measurement uncertainties of up to 0.3 °C are possible. The

sensitivity of platinum based thermocouples is usually in the region of

10µV/ °C, which means that high accuracy, high resolution

measurements require sensitive instruments such as the TTI-7-R .

Base metal thermocouples easily account for the bulk of temperature

sensors used today, and offer the advantages of being easy to

package into a variety of sensor configurations and relatively low

cost. Base metal thermocouples operate over a wide temperature

range with high temperature types designed for use up to 1600 °C.

Temperatures above 2300°C are possible with new high temperature

tungsten rhenium types. Typical sensitivity figures of

Page 4-3

Page 30

Measuring Temperature

>30µV/ °C characterise most of the base metal thermocouple

family.

Base metal thermocouples are easily affected by contamination

effects which results in decalibration and drift. This is especially

pronounced at high temperatures where drift figures of the order of

10 °C are possible. It is important to be aware of the particular

contamination effects and to select the correct thermocouple for the

measurement environment. The N type thermocouple offers the best

performance in terms of reproducibility and measurement

uncertainty, operating up to 1250 °C. It is the best choice for most

general measurement applications, calling for accuracy with low

time and temperature drift.

4.3.1 Connecting thermocouples

Thermocouples measure temperature difference. As all practical

thermocouples consist of at least 2 junctions, it is important when

performing absolute temperature measurement that one of the

junctions is referenced to a known temperature.

The reference junction and voltage measurement precision

significantly influence the overall temperature measurement

accuracy. Intermediate connection junctions such as connectors and

extension cables between the measurement thermocouple and the

TTI-7-R also influence the measurement result.

4.4 PRT measurement

The TTI-7-R will operate with either 25 Ohm SPRT’s/PRT’s or a

range of 2, 3 and 4-wire 100 Ohm PRTs. The best performance will

be achieved only where good quality PRTs are used from reputable,

proven sources. As with any measured parameter, the performance

of a measurement system depends upon its stability and

repeatability. Low quality PRTs are likely to reduce system

performance.

The relationship between temperature and resistance depends on

several factors, including the alpha value and the PRT calibration.

Page 4-4

Page 31

Consequently more than one equation is required for resistance to

temperature conversion. Calibration data for the PRTs takes the

form of Callendar van Dusen coefficients.

ISOTECH NA Inc. provides a range of proven PRTs especially for

use with the TTI-7-R , as well as offering a service to provide

customised PRTs to meet individual customers' requirements.

High "alpha" PRTs: The best possible system accuracy is

achieved using high "alpha" (Ω) PRTs, or more correctly, PRTs

using high Ω (high purity) platinum wire.

Low "alpha" PRTs: Low Ω PRTs contain a higher level of impurities

in the platinum resistance wire used. This affects the resistance

value at a given temperature (the temperature coefficient). As

impurities already exist in the platinum resistance wire, additional

contamination has a reduced effect and hence low Ω PRTs are more

immune to contamination and are therefore better for industrial

applications. To ensure a robust PRT, the detector within the PRT is

contained within materials, which can themselves be the source of

contamination at elevated temperatures. The PRTs supplied by

ISOTECH NA Inc. have been optimized for the temperature ranges

for which they are specified and, when calibrated, are temperature

cycled to enhance stability in use.

PRTs which are used outside their design and/or calibration

temperature range, especially at higher temperatures, risk

irreversible alteration to their calibration either by induced thermal

stresses or by contamination.

Measuring Temperature

Page 4-5

Page 32

Measuring Temperature

4.4.1 PRT linearization functions

The TTI-7-R provides 3 standard and 20 user definable algorithms

for converting resistance to temperature. The choice will depend on

the type of PRT and its calibration. See also Section 9, which gives

PRT sensor information.

IEC751 (1983):- used for un-calibrated industrial PRTs with

0.003850 "alpha" value, to provide a conversion of resistance to

temperature in accordance with the IEC751 (IPTS 68) standard.

• EN60751 (1992):- used for un-calibrated industrial PRTs with

0.003851 "alpha" value, to provide a conversion of resistance to

temperature in accordance with the

BS EN60751 (ITS 90) standard.

• US/JIS:- used for un-calibrated industrial PRTs with 0.003916

"alpha" value, to provide a conversion of resistance to

temperature in accordance with the JEMIMA standard.

Un-calibrated PRTs conforming to IEC751/DIN43760/BS1904 have

traditionally used the IEC751 pre-programmed standard, which

provides a conversion in accordance with published DIN43760 or

BS1904 tables. These tables were created using temperatures

defined by the superseded International Practical Temperature Scale

of 1968 (IPTS68) and have inaccuracies compared with the

International Temperature Scale of 1990 (ITS-90). ISOTECH NA Inc.

has included the values for standard coefficients from IEC751 and

the more recent

EN60751 standards. The use of EN60751 is now recommended for

use with uncalibrated industrial PRTs.

Page 4-6

Page 33

Measuring Temperature

IEC751

Selecting IEC751 from the standard menu selects the standard

coefficients from IEC751 (DIN43760/ BS1904 -based on IPTS68).

The coefficients for IEC751 are as follows:

Ro A B C

IEC751 100 Ohms 3.90802 x 10

-3

-5.802 x 10-7 - 4.2735 x 10

-12

EN751

Selecting EN751 from the standard menu selects the standard

coefficients from BS EN60751 based on ITS90. The advantage of this

is that it removes the temperature conversion errors associated with

the old IEC751 standard which is based on the earlier and

superseded IPTS68. The coefficients for EN60751 are as follows:

Ro A B C

EN60751 100 Ohms 3.9083 x 10

-3

-5.775 x 10-7 -4.183 x 10

-12

US/JIS

Selecting US/JIS from the standard menu selects the standard

coefficients from JEMIMA for high alpha PRT reference

thermometers. The coefficients for US/JIS are as follows:

Ro A B C

JIS/US 100 Ohms 3.97478 x 10

-3

-5.8775 x 10-7 -3.4813 x 10

-12

Usr

Selecting Usr from the standard menu allows the coefficients

provided with calibrated PRTs to be used in converting resistance to

temperature.

Either 25 or 100 Ohm SPRT’s/RTD’s may be used and coefficients for

ITS90 or Callendar Van Dusen entered. The instrument recognises from

data entered under Ro if a 25 or 100 Ohm probe is being used and

automatically adjusts the measuring range and measuring current.

Page 4-7

Page 34

Measuring Temperature

This page has been left blank intentionally

Page 4-8

Page 35

5. Operating the TTI-7-R

5.1 About the display screen

The TTI-7-R display screen is your direct link to the instrument,

presenting you with information or menus that prompt you on what to

do next.

It has two modes:

• the Temperature Measurement Mode which displays status

information and a sequence of temperature readings;

• the Configuration Mode which lets you set up and configure

the equipment.

Figure 5.1 shows an example of the Temperature Measurement

Mode display. The top line of the screen gives status information: in

this example, an N type thermocouple is connected to input socket

A1 and the internal reference junction method has been selected.

The temperature reading is displayed in degrees Celsius.

Figure 5.1 - Example of Temperature Measurement Mode

A1 TC Type N RJ Mode= Internal

+

18.3

°C

Input = -0.170 mV RJ = +24.62 deg C Busy

Run

The keypad below the display screen controls the TTI-7-R . Some keys

perform a function directly. For example, pressing changes the

temperature units. Other keys switch the display to configuration

mode which allows you to select options through a series of menus.

The option menus all follow the same format. The configuration mode

is indicated on the screen by a dashed line displayed directly

Page 5-1

Page 36

Operating the TTI-7-R

below the main reading. An instruction prompt under the dashed line

indicates the current menu. The available menu options are displayed

on the bottom row of the display as shown in Figure 5.2. Press the

corresponding function key to select an option.

Figure 5.2 - Example of Configuration Mode screen

A1 TC Type

N

RJ Mode= Internal

Sensor Type?

T/C PRT Quit

Indicates

current menu

Indicates menu

options

A white guideline printed on the front panel helps you to link the

menu option printed on the screen with the correct key on the

keypad.

White guideline

indicating which key

to press

Page 5-2

Page 37

Operating the TTI-7-R

5.2 About function keys

You only use the top row of function keys to select menu options. The

lower row of function keys are enabled only when entering numerical

data; these instances are covered later in this section. Both rows of

function keys are shown in Figure 5.3.

Figure 5.3 - Function keys

The [Quit] and [OK] menu options consistently use the QUIT/MATH

and OK/MEM keys. Use the [Quit] key to leave a menu or return to the

Temperature Measurement Mode screen. Use the [OK] key to confirm

a particular choice and continue to the next set of menu options.

Not all function keys are used to access the Configuration Mode. Some

just invoke the function which is printed on the key. For

example, pressing

4/UNIT

cycles you through a sequence of

Celsius, Fahrenheit and Kelvin temperature units. If you miss the

option you want, just continue until it is displayed again.

The rest of this section describes how to set up the equipment, log

data and review the results. It also describes how to modify some of

the settings, such as date and time. Some of these are reset to

default values every time the machine is switched on.

Page 5-3

Page 38

Operating the TTI-7-R

5.3 Power-up sequence

The instruments power on/off is controlled from the

ON / OFF keys located on the TTI-7-R front panel.

On power-up, the TTI-7-R performs a memory self-test routine

followed by a system configuration check.

5.3.1 Self-Test

On power-up the TTI-7-R performs a memory self-test routine

Figure 5.4 - Memory Self-Test Display

Performing Self-Test.......

On successfully completing the memory self-test the TTI-7-R will

report PASSED and proceed with a system configuration check.

If the memory self-test fails the TTI-7-R reports the message FAILED

Press OK to restore defaults.

Figure 5.5 - Memory Self-Test Fail Display

Performing Self-Test......

Failed

Press OK to restore defaults

Press the [OK] key to restore the instrument variables to the factory

default values.

Page 5-4

Page 39

5.3.2 System Configuration

On power-up the TTI-7-R performs a system configuration

check searching for input channel expansion cards or

communication card. The screen displays:

Checking system configuration

The following information is read from each card on detection and

displayed by the system configuration display for 2 seconds.

Communication card

RS-232, Baud rate, Character bits, Parity, Start bit, Stop bit.

IEEE488.2, Address.

Input channel expansion card

Card ID, Serial Number, Card type, Channel numbers.

Figure 5.6 - Example System Configuration Display

System configuration

RS-232 9600,8,0,1,2

Card A1 Sn12345 4Ch TC Ch A1 to A4

Card B1 Sn30123 4Ch PRT Ch B1 to B4

The system configuration can also be reviewed from the options

menu.

After the power-up sequence, the instrument begins its normal

operation.

Operating the TTI

-7-

R

Page 5-5

Page 40

Operating the TTI-7-R

5.4 Setting up Measurement Options

This section describes how to set up the TTI-7-R for your

specific measurement requirements.

You need to select an input channel before configuring a probe.

5.4.1 Selecting thermometer input channel

To select an input channel with no input channel expansion cards

fitted, press ′/A to select input channel AD or 1/B to select input

channel BO.

To select an input channel with an input channel expansion card

fitted, press ′/A to select channels [A0 to A4], press 1/B to select

channel [B0 to B4]. The screen displays:

Enter channel number: (A or B)

Quit

Enter the channel number from the TTI-7-R function keypad at the

A or B prompt. Select [Quit] to return to the main display.

The selected channel number is displayed in the top left hand corner

of the display screen.

If a channel is selected that is not available the TTI-7-R will

display an error message channel not available and prompt for

a new channel number.

5.4.2 Selecting differential input measurement

Press 2/DIFF 1 to select differential measurement with no input

channel expansion cards fitted.

To select differential measurement with an input channel expansion

card fitted press 2/DIFF. The screen displays:

Enter channel number: (Ch1-Ch2):

Quit

Enter the channel numbers from the TTI-7-R function keypad, each

channel number consists of a letter A or B followed by a single

digit number, A and B are entered from the and function

Page 5-6

Page 41

Operating the TTI-7-R

keys. A differential measurement can be taken from any two

available channels. Select [Quit] to return to the main display.

If a channel is selected that is not available the TTI-7-R will

display an error message channel not available and prompt for

new channel numbers.

The selected channels are displayed in the top left-hand corner of the

display screen.

The TTI-7-R will displays the difference between the input channels

[Ch1-Ch2].

5.4.3 Setting up a PRT measurement

Three standard PRT linearization functions are available. In addition,

20 user-definable memories are available for coefficients provided

with calibrated probes. These memories allow calibration coefficients

to be stored in the Callendar van Dusen form for high precision

temperature measurement.

2. For input channels [A0] and [B0], the Sensor type? menu will be

displayed. Select [PRT] option, the standard? menu will be

displayed.

Sensor type?T/C PRT

Quit

For PRT input channel expansion cards the Standard? menu will be

displayed:

Standard?

IEC US/ EN-

Rev 751 Jis 751 Usr Quit OK

3. Next select a linearization standard from the list displayed on the

screen. Note that you cannot start measuring temperature until you

have made this selection.

Page 5-7

1.To configure a selected channel press 3/SENS .

Page 42

The TTI-7-R is pre-programmed with three standard linearization

standards (see Section 4.4.1) as follows:

i. [IEC751] IEC751 (1983)

ii. [EN751] BS EN60751 (1992)

iII. [US/JIS]

JEMIMA

To choose one of these linearization standards, press the

appropriate function key and then [OK] if you want to go on to

configure 3 wire or 4 wire measurement or configure another

channel. Otherwise press [Quit]. The previous 3 wire or 4 wire

settings will remain unchanged.

4. If you press [OK], the screen displays:

Connection?3W 4W

Quit OK

5. Select the connection option you want, select 4 wire measurement

when using 2 wire PRTs.

6. Se lect [Quit] to return to Temperature Measurement Mode.

7. To configure all the channels of an expansion card to the same set

up, select one of the channels on the card and follow steps 1 to 5

above. At the Connection? menu select [OK], the screen displays:

Select channel?

Ch- Ch+ All Quit OK

8. Select [All] to configure all the channels of the expansion card to the

same set-up.

9. [Ch-] and [Ch+] can be used to select a channel without returning to

the Temperature Measurement Mode.

10. On completion of configuring all the input channels select [Quit] to

return to Temperature Measurement Mode.

5.4.4 Setting up a PRT measurement with user defined probe

memories

Operating the TT

I

-7-

R

Page 5-8

Page 43

Operating the TTI-7-R -R

Standard?

IEC US/ EN-

Rev 751 JIS 751 Usr Quit OK

2. Select the [Usr] option. The screen displays:

Enter Probe #(1-20):

Quit OK

3. Enter a number between 1 and 20 using the numbers on the keypad

and then [OK]. The number you have entered is shown on the top

line on the display. If you make an error, press

USER/OPTN

and re-

enter number. The TTI-7-R will only accept values in the range 1-20

and will signal an error if your entry is outside this range.

Page 5-9

1. Press 3/SENS and then the [PRT] function key. The screen displays:

Page 44

Operating the TTI-7-R

5.4.5 Setting up a PRT measurement: checking/editing probe

memory co-eff. values

This allows you to assign coefficient values to probe memories or

check the values already assigned.

1. Press 3/SENS and if PRT and TC inputs used, the screen

requests [PRT] or [TC]. When only a PRT channel is

available (NO channel expansion modules fitted) the screen

shows:

Standard?

IEC US/ EN-

Rev 751 JIS 751 Usr Quit OK

2. Select the [Rev] option. If you have already selected one of

the three standard linearizations, the four pre-programmed

standard coefficients are displayed at the top of the screen.

These cannot be altered.

3. If you want to enter a new set of coefficients, press

User in ‘Standard’ screen above. The screen requests

a probe coefficient set 1 to 20. Enter an empty

memory box number, e.g. 11. The screen displays:

User 11 empty

Enter Quit

4. Select enter. The screen shows:

IPRT SPRTCVD ITS90

5. Select required probe coefficient type, e.g. SPRT, ITS90

and the screen shows:

Ro Ap Bp Cp >> Quit Ok

.

6. Select and enter each coefficient in turn. (If no coefficient

exists, do not enter any value). To enter the coefficient,

e.g. –3.98e-2. first put in a – sign, then the number 3.98

from the front panel keys. For the exponential form, press

the exponential key on the front panel (on the lower right

Page 5-10

Page 45

side) and then the number 2.

7. Go to the next page >> to enter the other coefficients. Dp,

An, Bn, and Wt as in 6, above. Note: The coefficients

entered can be viewed at the top of the screen.

8. Select Ok:

Save new coefficients Yes No

Select Yes.

9. If you are entering CVD coefficients, select CVD in item 4

above. Then proceed as in items 5, 6 and 7 to enter the Ro,

A, B and C terms.

Note: The 20 probe memories are already calibrated with the BS

EN60751 standard when the unit is shipped. This lets you obtain

sensible results from the onset; you can go back and edit the probe

coefficients at a later date, not necessarily at the time you select

them.

5.4.6 Selecting thermocouple type

1. Press and then the [TC] menu key. The screen displays:

Thermocouple type?

B C D E J » Quit OK

2. Select one of the ten thermocouple standards supported; B, C, D,

E, J are displayed on the first screen: K, N, R, S, T on the second.

Switch between the screens with the [»] key. Type the appropriate

key and then [Quit]. Measurement will start as soon as you have

selected the standard you want. The thermocouple type is displayed

in the top left-hand corner of the screen.

Page 5-11

Page 46

Operating the TTI-7-R

5.4.7 Selecting the reference junction compensation method

1.

You can select the reference junction compensation method after

selecting the thermocouple type by pressing [OK] instead of [Quit].

The screen displays:

RJ mode?

Off Int Ext Quit OK

The menu options list the three reference junction methods

supported:

Menu option

Description When used

[Int]

Internal reference junction

compensation using the

TTI-7-R 's internal

temperature compensated

copper isothermal junction.

This is the default mode.

For direct temperature

connection with no

external reference

junction. High accuracy

measurement, requiring

no additional connection

reference junctions.

[Ext]

External reference

junction compensation

using PRT measurement

of reference junction. No

measurement channels

are lost as the reference

channel PRT uses the

corresponding input

channel.

For temperature

controlled or ovenised

reference junctions.

[Off]

No reference junction

compensation applied to

the measurement. All

measurements are made

with respect to 0 °C.

Used with an external ice

point reference junction.

Suitable for highest

precision measurement.

Select the reference junction method with the appropriate function key.

If you have selected [Off] or [Int], you can now press [Quit] to start

measurement.

Page 5-12

Page 47

5.4.8 Selecting ext. ref. junction PRT linearization whose

temperature is measured by a PRT connected to the same channel.

1. The [Ext] menu option allows you to set up an external reference

junction whose temperature is measured by a PRT connected to the

same channel. When you select [Ext] you are prompted to choose

the PRT linearization for this PRT, the screen displays:

Standard?

IEC US/ EN751 JIS 751 Usr Quit OK

2. This lets you choose one of three standard linearizations which can

be used with uncalibrated probes. A fourth option, [Usr], gives you

access to the 20 probe memories for Callendar van Dusen

coefficients provided with calibrated probes.

3. If you want to select one of the standard linearization options,

[IEC751], [US/JIS] or [EN751], press the appropriate function key

and then [Quit]. Reference junction information is displayed at the

top right hand corner of the screen, e.g.

RJ Mode= Ext US/JIS

4. If you want to access one of the probe calibrations already in

memory, press [Usr]. The screen displays:

Enter Probe #(1-20):

Quit OK

Use the keypad to enter the probe number and then press [Quit].

Section 5.3.5 describes how to enter user coefficients.

Operating the TTI-7-R

Page 5-13

Page 48

Operating the TTI-7-R

5.5 Selecting Screen Display Options

This section describes how to modify information displayed by the TTI-

7-R . It covers:

5.5.1 Selecting measurement units

Press 4/UNIT to sequence between the three measurement units

available. These are Celsius (°C), Fahrenheit (°F) and Kelvin (K). The

measurement unit selected is applied to all temperature displays,

including logged data.

5.5.2 Selecting display resolution modes

Press +-/RES to toggle between the two display resolution modes

available. The table below gives the display resolutions for

thermocouple and PRT inputs. The TTI-7-R defaults to low resolution

mode when first switched on.

High

Low

Thermocouple 0.01

0.1

PRT 0.001 0.01

5.5.3 Selecting relative temperature measurement

In Zero mode, the TTI-7-R displays temperature relative to a fixed

reference point. Press 5/ZERO to store the current display value; this

will be subtracted from all subsequent readings. To cancel Zero

mode, either press 5/ZERO again, change the input channel, change

the sensor type or turn off the power.

When Zero mode is enabled, a Zero message is displayed in the

bottom left hand corner of the screen.

Page 5-14

Page 49

Operating the TTI-7-R

5.5.4 Using the measurement trigger function [Run/Hold]

The TTI-7-R default trigger mode is Run/Hold. It can also be

configured

to operate in single shot mode. Press the key to alternate

between continuous measurement (Run), and measurement hold

(Hold). Measurement hold mode stops all measurement operations,

freezing the current display value. It also halts all scanning and data

logging operations. When measurement hold is enabled, a Hold

message is displayed on the bottom line.

Press 3/TRIG again to resume measurement, scanning or data

logging operations. A Run message is displayed on the bottom line

and the message Busy flashes on every time a new temperature

measurement is taken.

Setting the trigger mode to single shot mode is described in Section

5.6.3. In single shot mode, the TTI-7-R remains in the hold state until

you press the 3/TRIG key; it then captures a single

measurement reading.

If you have scanning enabled this allows you to single step through the

scanning routine.

If the data logger is enabled all the spot readings will be stored in the

data log memory.

5.5.5 Selecting PRT measurement sense current