Page 1

IRIS MODEL S550 APPLICATION MANUAL

FLAME MONITORING SYSTEM

MODEL S550, S552, S556 VIEWING HEAD

APPLI CATION MANUAL

PAGE 1

Page 2

IRIS MODEL S550 APPLICATION MANUAL

TABLE OF CONTENTS

S550 GEN ERAL DE SCRIP TION............................2

S552 GEN ERAL DE SCRIP TION............................2

S556 GEN ERAL DE SCRIP TION............................2

COM PARI SON WITH OTHER MODEL 500 VH’s ...2

TECH NOL OGY USED IN THE S550......................3

CA BLE PREPA RA TION DWG ................................4

FI NAL AS SEM BLY (CA BLE) DWG .........................4

WIR ING OF VIEW ING HEAD .................................5

SIGHT ING OF VIEW ING HEAD .............................6

IR DE TEC TOR ........................................................6

UV DE TEC TOR .......................................................7

ORI FIC ING ..............................................................7

DE FAULT SET TINGS FOR THE S550 ...................8

BEF ORE MAK ING AD JUST MENTS.......................10

NEW P520/P522 FRONT PANEL...........................10

CALI BRAT ING THE S550.......................................10

EX AM IN ING RE SULTS GAIN SET TINGS CALIB ...10

CHECKING OR CHANG ING UV GAIN...................11

CHECKING OR CHANG ING IR FIL TER.................11

CHECKING OR CHANG ING IR GAIN ....................11

MAN UAL SETUP OF THE S550 .............................12

RE TURN TO DE FAULT SET TINGS ........................12

AN GLE OF VIEW ....................................................13

GEN ERAL COM MENTS .........................................13

TECH NI CAL HELP..................................................13

FIGURE 1 FRONT PANEL DRAW ING ....................14

WHERE S550 SET TINGS ARE STORED ..............8

AS SIGN ING DIFF S550 SET TINGS TO A&B .........9

US ING TWO VIEW ING HEADS PER AM PLI FIER .9

FIGURE 2 VH OUT LINE DRAW ING .......................14

FIG 3 FLOW CHART OF S550 PROGRAMMING ...15

FIG 4 FLOWCHART OF S552 PROGRAMMING ...16

FIG 5 FLOW CHART OF S556 PROGRAMMING ...17

PAGE 2

Page 3

IRIS MODEL S550 APPLICATION MANUAL

S550 GENERAL DESCRIPTION

The IRIS Model S550 is a state- of- the-art flame

monitor viewing head utilizing two types of

detectors, an IR (infrared) solid state and UV

(ultra violet) tube.

The S550’s work with the latest version of the

P520/P522 signal processors. Like other viewing

heads in the S500 family, the S550’s produce

output pulse rates propor tional to the flame signal

strength; the pulse rates are displayed at the front

panel of the signal processors. But, unlike the

other members of the S500 family, certain

parameters in the S550 viewing head can be

selected or adjusted remotely from the front panel

of the P520/P522 signal processors. The

parameters are:

a) UV gain 0-99

b) Fil ter Se lec tion 1-8

c) IR gain 0-699

Once adjusted, the new parameters are stored in

EEPROM in the signal processor. If power is

removed from the signal processor which powers

the viewing head and then reapplied, the signal

processor then automati cally re-sends the stored

parameters out to the S550 viewing head. In

addition, at the front panel of the signal processors

the operator may also select “CAL”, a semiau to matic mode which will help to speed up the S550

setup. This is explained in detail in the section

called CALIBRATING THE S550 on page 10. Also

notice the FLOWCHART OF S550 PROGRAMMING ,

Fig ure 3 on page 15. Thus the S550 is a dual sensor viewing head where the gain and filter

selec tions are adjusted remotely and stored in the

P520/P522 signal processors.

S552 GENERAL DESCRIPTION

The S552 is for IR sensing only. It is basically an

S550 without a UV capability. The P520 or P522

will be aware of which viewing head of the S550

family is connected to it so that only those adjust ments which are appro priate to the S552 will be

made available to the operator. These adjust ments

apply to the S552:

When it comes to features like CAL, which will be

described later, the operator is only given those

choices which are appro priate. For example, he

does not have to choose between calibrating with

the UV sensor or the IR sensor; in CAL he is only

offered the choice of calibrating with the IR sensor

or not. This is shown in the FLOWCHART OF S552

PROGRAMMING

, Fig ure 4 on page 16.

To keep the manual straightforward only the

operation of an S550 is described. If one has an

S552 one should simply disregard references to

those features of the S550 which are UV-related.

S556 GENERAL DESCRIPTION

The S556 is for UV sensing only. It is basically an

S550 without an IR capability. The P520 or P522

will be aware of which viewing head of the S550

family is connected to it so that only the

adjustment which is appro priate to the S556 will

be made available to the operator:

a) UV gain 0-99

When it comes to features like CAL, which will be

described later, the operator is only given those

choices which are appro priate. For example, he

does not have to choose between calibrating with

the UV sensor or the IR sensor; in CAL he is only

offered the choice of calibrating with the UV

sensor or not. This is shown in the FLOWCHART

OF S556 PROGRAMMING

, Fig ure 5 on page 17.

To keep the manual straightforward only the

operation of an S550 is described. If one has an

S556 one should simply disregard references to

those features of the S550 which are IR-related.

COM PARI SON WITH OTHER MODEL 500

SE RIES VIEW ING HEADS

The S550 uses a Germanium sensor for IR

detection like an S511 and uses a high- voltage

vacuum tube sensor for UV detection like the

S506’s, but both sensors are in the same housing

in the S550. The pulses from the UV and IR

sensors are summed inter nally into a single pulse

stream out to the signal processor.

a) Filter Selection 1-8

b) IR gain 0-699

PAGE 3

A dual-LED indicator is used to indicate the pulse

rate out of the S550. It is visible at the rear of the

Page 4

IRIS MODEL S550 APPLICATION MANUAL

viewing head housing. (See Fig. 2). For every 128

pulses from the UV sensor it emits one green

pulse; for every 128 pulses from the IR sensor it

emits one red pulse. With a count rate of 1200

displayed at the signal processor the LED will

flash 9 or 10 times per second. This is very useful

for aiming and sighting the viewing head. One can

readily distin guish differ ences in pulse rates at the

LED and use this indicator to adjust the sighting to

obtain a maximum pulse rate at the LED and

therefore a maximum reading at the signal

processor.

The S550 differs from older models in that the

gain for each sensor and the selection of the filter

for IR may be set remotely through the front panel

of the P520/P522 signal processors.

Also the earlier IR sensitive family members had

only 4 high pass filters to choose from; the S550

has 8:

S511 & S512 S550

LL 36 Hz 1 16 Hz

L 71 Hz 2 24 Hz

M 105 Hz 3 33 Hz

H 186 Hz 4 52 Hz

5 75 Hz

6 100 Hz

7 155 Hz

8 215 Hz

TECH NOL OGY USED IN THE S550

The UV and IR sensors in the S550 share a

common optical axis efficiently by using a unique

dichroic beamsplitting mirror. Over 80% of the

ultra violet light is reflected off the surface of the

45 de gree mirror and yet over 80% of the infrared

radiation is trans mitted through the beamsplitting

mirror.

The electronics in the S550 is designed using

highly reliable surface mount technology.

The high pass frequency responses of eight

different filters in the S550 and S552 are imple mented compu ta tionally in a high- performance,

CMOS micro con troller inside the viewing heads.

This approach reduces the parts count and

PAGE 4

Page 5

IRIS MODEL S550 APPLICATION MANUAL

PAGE 5

Page 6

IRIS MODEL S550 APPLICATION MANUAL

increases the reliability of the S550 compared to

earlier approaches that used discrete analog

compo nents to implement four active filters. The

micro con troller also handles commu ni ca tions

with the P520/P522 signal processors.

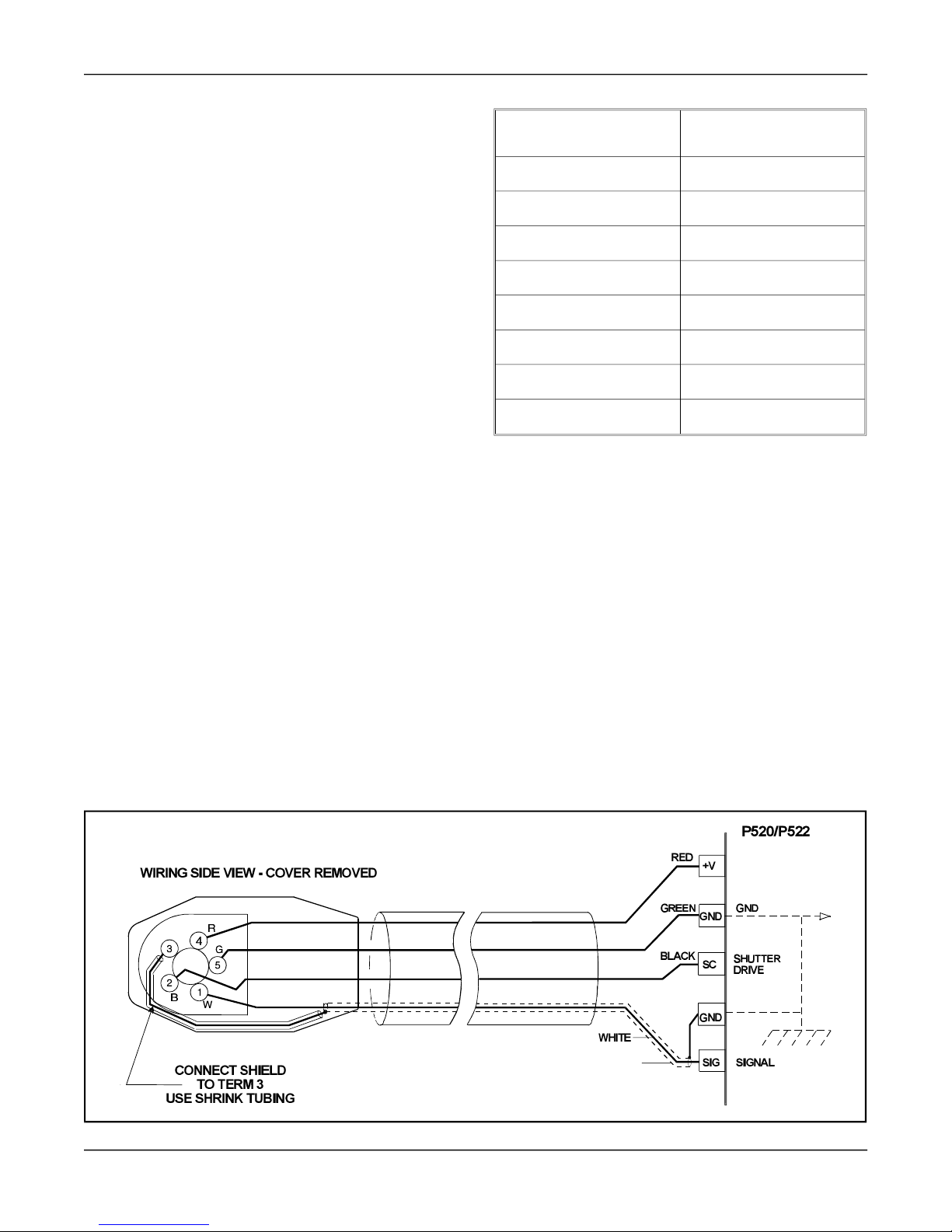

WIRING OF VIEWING HEAD

Wiring of the viewing head is made to the

terminals on the rear backplane PC board (or

output module) on the P520 signal processor and

is made to the terminals on the lower right side of

the P522. These terminals are listed functionally

as follows:

TERM DE SCRIP TION

GND

+V

SC

SIG

Power Ground

+24 VDC power to view ing head

Shut ter Drive Sig nal to V.H.

Flame Sig nal from V.H.

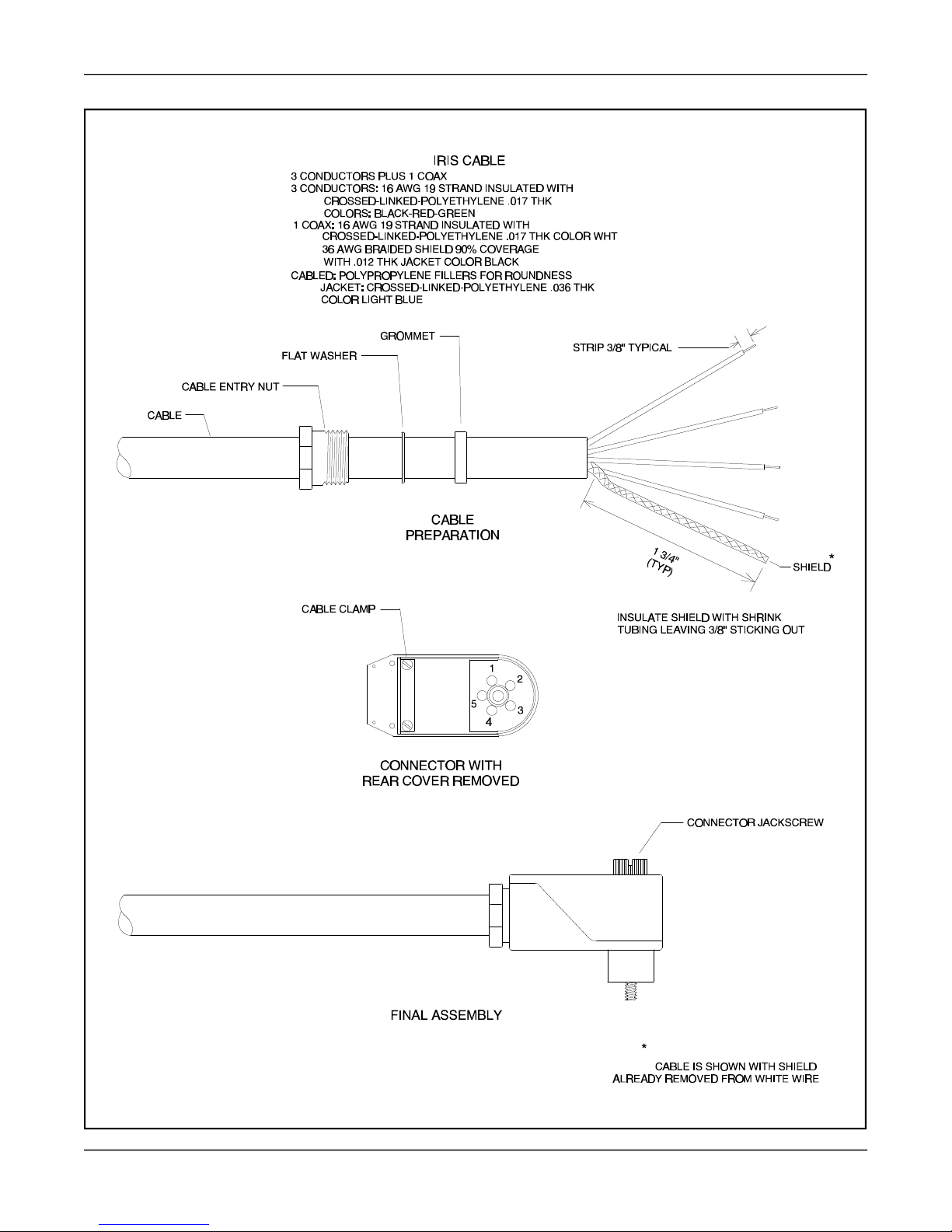

1. Strip 2 inches of the cable outer cover from the

cable removing any cello phane wrap or filler

material and strip the insulation from the

shielded wire (if insulated over shield) a full 2

inches to expose shield.

2. Slide the shield back until a bulge develops

close to where the wire exits the cable outer

covering.

3. Carefully spread a few strands of the shield at

the bulge (making sure not to break any

strands) to cre ate an opening and slip wire out

of shield through opening.

4. Carefully return shield to original shape and

length by pulling gently, then cover with

plastic shrink tubing to prevent shorts.

5. Slide nut (with threads toward the cable end),

the washer and the grommet onto cable

approxi mately 6 inches.

SIG GND

Sig nal Ground

The figures on the previous pages show a four

conductor cable to the viewing head. Note that the

flame signal wire going to terminal SIG is

shielded and the shield is termi nated at both ends

of the cable(SIG GND).

The standard IRIS Model 500 cable is desig nated

as part number C328. It is specified as a four

conductor cable with one wire shielded. The

shield is used as the signal ground wire which

goes to terminal SIG GND on the P520/P522 and

to pin 3 on the viewing head plug. The shield is a

braided type for this appli cation (a foil type shield

should not be used) so that a solid signal ground is

maintained. This signal ground shield is also the

self- checking or shutter drive circuit return path. It

is recom mended that the IRIS cable be used for all

appli ca tions. Ref er to the diagrams on pages 3 and

4 for wiring details.

Connec tions of the IRIS cable to the viewing head

plug should be done as follows:

Remove the plug from its packaging and layout

the components.

6. Slip the cable through the bottom opening of

the connector making sure that the cable outer

jacket is secure under the cable clamp and

tighten the two screws on the cable clamp.

7. Reassemble the grommet, flat washer, and

cable entry nut and tighten.

8. Bef ore wiring to connector, strip each wire

3/8" as shown in assembly drawing on pre vious page.

9. Proceed to wire the connector as follows: (Ref er to drawings on page 3 for terminal

locations.)

Connect viewing head signal wire (the shielded

wire) WHT to terminal No. 1 by inserting into

opening and then tight ening the retaining screw.

Connect the self- checking signal wire BLK to

terminal No. 2. Connect the signal ground shield

from WHT wire with shrink tubing to terminal

No. 3. Connect + 24 VDC power wire RED to

terminal No. 4. Connect the power ground wire

GRN to terminal No. 5. Assemble the back of the

plug and insert jackscrew through plug assembly.

PAGE 6

Page 7

IRIS MODEL S550 APPLICATION MANUAL

The cable wiring on the other end going to the

signal processor is easier to do. The cable should

be prepared in a similar way to the plug end

particu larly the shield from the WHT wire. Make

sure the shield doesn't touch the other terminals.

SIGHT ING OF VIEW ING HEAD

The sighting of the viewing head should be

parallel to the cen terline of the burner in the

direction of the flame. The sight pipe should be

mounted as close to the cen terline as possible; the

idea is to sight along the flame rather than across

the flame. This will help prevent drop outs of the

flame under changing load condi tions.

Utilizing a sighting or the sight pipe aimed at the

root of the flame (where the turbulent combustion

air mixes with the flame) is a good starting point

for optimizing the sighting. Using a swivel mount

to “zero-in” on the highest signal will assure

maximum performance. Make sure the diameter

of this sight pipe is large enough to allow a

reasonable field of view. The S550’s has two

angles of view, one for the IR detector, which is

1.0° and one for the UV detector which is about

3.0°; this trans lates into a circle of view that

varies with the viewing distance as shown in the

following table.

Dis tance Dis tance

ft inches inches inches

2 24 .64 1.3

3 36 .73 1.9

6 72 1.45 3.8

12 144 2.90 7.6

18 216 4.35 11.4

Di ame ter of

IR view

Di ame ter of

UV view

Detecting flame in a sulfur recovery unit can

present problems for flicker type flame monitors

such as the IR detector in the S550 viewing head.

The IR detector will detect natural gas used for the

warm-up of the reactor. Usually the combustion

air is turbulent enough to cause a good flicker

signal. When the sour gas is intro duced and the

natural gas shut down the flame signal may drop

off or drop out entirely. The reason for this is that

there is a complete change in the flicker content

for the existing viewing head sighting. If this is the

case, then one should try and optimize the flame

signal for the sour gas by “zeroing-in” on this

flame, not the warm-up burner.

After optimizing the sighting for the sour gas one

may find that the signal level is too low on the

natural gas. One should then try the UV detector

for this appli cation. It may be necessary to use two

sets of set points for flame ON and flame OFF, one

set for proving and detecting the natural gas flame

and the other for proving and detecting the sour

gas flame. The switch-over from Channel A to

Channel B should be done when removing the

natural gas burner. This can be imple mented from

the burner control system. This switch-over and

the use of Channels A and B with their

independent settings is explained in the section

ASSIGNING DIFFERENT S550 SETTINGS TO

CHANNEL A and B on page 9.

IR DETECTOR

The IR detector responds to the flicker content in

the flame. Flame flicker is caused by the

combustion, or forced air injected into the flame.

This combustion air can be mixed with the fuel

(pulverized coal) or can be intro duced separately.

In either case, forced air at high velocity is intro duced in such a way as to aid the combustion

process. This air is usually made turbulent by

causing it to swirl with spin vanes located in the

burner barrel.

Flame flicker is created when this turbulent air

mixes with the flame. It is composed of random

frequencies from zero Hz to over 2,000 Hz. The

amount of high frequency flicker (above 200 Hz)

is dependent on the fuel and burner. The amplitude

of the flicker frequencies always follows an

exponential curve with zero frequency having the

highest amplitude and the higher frequencies the

lowest. The amplitude level of the higher

frequencies is usually 40dB down (factor of 100)

from zero Hz or DC.

PAGE 7

Page 8

IRIS MODEL S550 APPLICATION MANUAL

The S550 and S552 respond to flicker frequencies

16 Hz and above. They ignore the lower

frequencies so it is important to sight the viewing

head on the highly turbulent portion of the flame

that contains these higher frequencies. One can

predict where these higher frequencies will be by

examining the burner with regard to where the

flame envelope begins and where the turbulent air

enters this flame. This spot can be chosen by

examining the drawings of the burner but it is

better to do this empiri cally by using a swivel

mount on the viewing head.

UV DETECTOR

The S550 viewing head with its dichroic mirror

and UV tube have a combined spectral response of

190-215 nm. The UV tube is inher ently a pulsing

device, that is, the power supply has been

designed so that the tube emits pulses when UV

radiation is present. Its output is pulse stream of

randomly spaced pulses whose average rate is

propor tional to the UV radiation present.

The very narrow spectral response of the S550

viewhead makes it ideal for discrimi nating

between flame and glowing refractory and other

burners. How ever, because the tube responds to

only the very short wavelengths, problems can

occur because this radiation is easily absorbed and

masked, for example with pulverized coal, by

unburned fuel or other impurities in the fuel. Sour

gas (H2S) will readily absorb these short 200nm

wavelengths as well as other waste fuels resulting

in a dropout of the flame signal. Even standard

glass will absorb this wavelength, hence, the

necessity of using a quartz lens with this viewing

head.

In general, the UV viewing head will work well on

natural gas flames. It will respond to oil flames but

with a lower signal level. The sighting for both oil

and gas flames should be parallel to the axis of the

burner and aimed at the root of the flame, as with

the IR detector. (See pre vious section IR

DETECTOR.

) Photo graphs of gas and oil flames

using visual and UV-sensitive film show clearly

that the UV zone is much smaller than the visible

zone, and the highest UV intensity occurs near the

flame root. In addition, the zone of higher UV

intensity does not overlap the same zones of

adjacent or opposing burners so that, with proper

sighting, discrimi nation is predictable.

As a general rule, the sighting of the S550 when

using the UV detector, will be more likely a “line of- sight” than the IR flicker detector which will

read flame signals bouncing off the side of the

sight pipe and other “reflectors”. Sometimes the

reading with the IR detectors can be greater with a

reflected signal than the direct line of sight. The

UV detector on the other hand, will have to be

aimed at the part of flame that has the highest

concen tration of UV, which usually is at the root

of the flame (at the throat of the burner) and in a

very narrow region. The angle of view of the S550

UV is somewhat wider than the S550 IR but this

does not offset the fact that the UV radiation

present is from a very small region.

This small region emitting UV is not the case

how ever, for low NOX gas burners. The UV

radiation is usually much less in intensity and

spread out with this type of burner, such that one

gets relatively high readings from all over the

furnace when many burners are on. This is

particu larly true when flue gas recir cu lation is

used. There will be, how ever, a relatively stronger

signal near the “root” of the flame and this more

intense spot should be located during the aiming

or sighting process. This “root” or intense spot

may be further out than with the standard gas

burner so it is imperative that one use a swivel

mount when making these sighting adjust ments.

Also, another factor one must con sid er when

aiming the viewing head is the load condition of

the boiler. The flames from a burner can be

radically different at different loads. This is one of

the reasons for trying to pick a sighting initially

that will minimize this changing flame at different

loads. If the flame moves further out at higher

loads then the parallel to the burner axis sighting

will be the best. Using a large diameter sight pipe

with a swivel mount is recom mended for all

instal la tions on large multi burner boilers.

ORIFICING

There are many appli ca tions where the burner

flames can be so bright they will saturate the S550

sensors. With these condi tions orificing the

PAGE 8

Page 9

IRIS MODEL S550 APPLICATION MANUAL

viewing head sight path will greatly improve the

performance, particu larly with regard to discrimi nation between flames. Although saturation is less

likely with the Ge (germanium) IR photo de tector

used for the S550 as compared to prior model

viewing heads using the PbS (lead sulfide) type

photo de tector, the possi bility should not be

ignored. Saturation is more prob able with large

power utility boilers where the burners are very

large and relatively close to one another. If one

cannot look at the flame with the naked eye

without it hurting, then orificing should be used.

This eye test works for incan descent type flames

such as oil and coal but will not be valid for

natural gas flames.

Orificing may help improve the discrimi nation

charac ter istics for the UV detector as well as the

IR. The UV tube in the S550 is not likely to

saturate; how ever, orificing will usually improve

the discrimi nation ratio for large size burners.

An orificing disc is simply a metal disc with a

circular hole in the cen ter which is placed directly

in front of the lens. Four orificing discs are

available with cen ter hole diameters of 3/8, 1/4,

3/16 and 1/8 inch. These discs are installed with

retaining rings in the flange at the edge of the 1/2

inch NPT female pipe thread for the purge air. An

internal type retaining ring is first installed by

positioning a ring in the machined groove inside

flange opening from the housing side. The

orificing disc is then inserted. Use a second

retaining ring to hold it in place so that it is

sandwiched tightly between the two retaining

rings.

Usually an orificing disc with a larger diameter

hole is tried first. There will be a reduction in the

signal level so if the associated S550 and signal

processor has been previ ously calibrated it will be

necessary to calibrate the processor again so that

the gain settings will be correct. If the discrimi nation is still not satis factory then try an orificing

disc with a smaller diameter hole.

Generally speaking, orificing should always be

considered when the burner(s) are large (50K lbs

of steam and up), particu larly when the IR

detector is used which would be the case for oil or

pulverized coal.

The following table shows the signal reducing

charac ter istics of the different orificing discs:

Ap er ture

Hole

1" 2 1

3/8" 5.3 1/8

1/4" 8 1/16

3/16" 10.7 1/32

1/8" 16 1/64

Fn

(f Stop)

Rela tive light

pass ing power

DEFAULT SETTINGS FOR THE S550

A new P520 / P522 will send the S550’s default

“Gains” as follow:

UV Gain = 32 (out of 0-99 range)

Fil ter = Fil ter 3 (high pass above 33Hz)

IR Gain = 451 (out of 0- 699 range)

These are nominal settings that should allow for

initial sightings and adjust ments. Both UV and

IR sensors are active in the default mode. They

are the same settings that will be active in an S550

when used with an older version of the P520/P522

or with an M502 signal processor. If the settings

for the S550 have been changed from the default

settings the operator may reset the “Gain” to the

factory default from the P520 / P522 control

panel. (See Return to Default Settings on Page 12.)

WHERE S550 SETTINGS ARE STORED

Settings for the S550s are stored in EEPROM in

the particular P520/P522 which made the adjust -

ments. On subse quent power-up cycles the

P520/P522 will send out the settings again to the

S550 viewing head. In fact, if one S550 is

exchanged with another one, the P520/P522

cannot tell one S550 from another and will send

out the same settings. This simplifies field

replace ments; all S550’s are made to very close

PAGE 9

Page 10

IRIS MODEL S550 APPLICATION MANUAL

tolerences, so any other S550 will work virtually

the same as the one it replaces.

NOTE: the S550 is designed to work only with

newer P520/P522 signal processors. How ever,

besides working with newer signal processors,

S552’s and S556’s are designed to work also with

older P520/P522 and M502 signal processors;

with these they will operate at their default gain

settings.

AS SIGN ING DIF FER ENT S550 SET TINGS

TO CHAN NEL A AND B

With the P520/P522 an operator may assign one

group of S550 settings to Channel A and another

group of S550 settings to Channel B, just as he

would assign different Flame ON and Flame OFF

set points to Channels A and B. How one may

store settings for each channel in the P520/P522

will be briefly reviewed.

If the CHAN SEL input to the P520/P522 is open

or de-energized, then the Channel A lighted push button on the front panel will be continu ously ON.

If a voltage of 7.5V to 30V is applied across the

two CHAN SEL inputs, then Channel B will be

selected and the Channel B lighted push button

will be continu ously ON. When Channel A is

selected, any P520/P522 parameters changed (this

includes Flame ON and Flame OFF set points and

the analog gain of the P520/P522 as well as the

gain and filter selection for the S550) will be

stored for use when Channel A is selected.

Similarly, when Channel B is selected any

P520/P522 changes are stored for use when

Channel B is selected. When the CHAN SEL

input is changed, the P520/P522 changes the set

points in use accord ingly and sends the appro priate gain and filter selec tions to the S550

viewing head.

In the P520/P522 there is a way to observe and

change settings for the channel which is not

selected: simply press the other channel push

button - it will blink indicating that the selection is

temporary - and then proceed as if the CHAN SEL

input had changed. This method is available for

examining or changing Flame ON and Flame OFF

set points and other settings in the P520/P522. The

same pro ce dure applies to manually changing

S550 settings when the desired channel is not

selected: press the push- button for the desired

channel and then proceed. During the process of

examining or changing the S550 settings, with the

Channel A and B (NO and YES) push buttons, the

red LED for the channel which the changes apply,

will be blinking.

One should visually check which channel push

button is lighted when the S550 settings are being

reviewed or changed. It is easy to get into the S550

CAL modes with the wrong channel selected. For

example, if the Channel A LED is on or blinking

and one intends to press both buttons at the same

time to enter the CAL mode for Channel A, but,

instead, one presses the Channel B push button

well bef ore the Channel A push button, the

P520/P522 will think that the operator has

selected Channel B then subse quently pressed

both push buttons. Then, in the CAL modes, the

red LED for Channel B will be blinking, which is

not what was intended. If this happens, one should

get out of the CAL mode, select the desired

channel, and press both push buttons again to

reenter the CAL mode, but this time pressing both

push buttons at approxi mately the same time.

USING TWO VIEWING HEADS PER

AMPLIFIER

Two viewing heads can easily be hooked up to the

same amplifier using the V.H. A and V.H. B

inputs. To permit this to work properly the P520

or P522 should be wired so that a 24VDC channel

select signal will be applied simul ta ne ously to the

coil of the VH select relay and to the channel

select input. Then, when the channel selection is

changed, the alternate set of data inputs from

viewing head B will be switched into the signal

processor by the VH select relay and the processor

will apply a different group of set points and gains

in response to the A/B Channel switch.

There is no restriction on how viewing heads may

be mixed between the two channels. One can

have an S550 on one channel and an S511 on

another, or an S552 on one channel and an S556

on another, or any combination. Of course, the

earlier 500 series viewing heads - Models S506,

S511 and S512 - are not adjustable remotely as the

S550 family of viewing heads are. The P520 or

PAGE 10

Page 11

IRIS MODEL S550 APPLICATION MANUAL

P522 signal processors will continue to work as

they have in the past with an earlier 500 series

viewing head when the channel with that viewing

head is selected.

BEFORE MAKING ADJUSTMENTS

Bef ore making any adjust ments to the S550 one

should optimize the flame signal strength by

aiming the viewing head at the most intense part

of the flame as explained in the two pre vious

sections IR DETECTOR and UV DETECTOR. This

operation should be done with the default settings.

NEW P520/P522 FRONT PANEL

Please ref er to Fig. 1 at the end of this manual

which shows the current front panel for the

P520/P522. The words NO , CAL and YES are

shown here in black but are actually red. This

latest version of the P520/P522 signal processors

may be used to commu nicate with the S550

viewing heads as described below.

CALIBRATING THE S550

The S550 calibrate feature is designed to aid with

the setup of the S550. It is basically an auto mat ic

gain adjustment for the selected sensor; the gain

for the sensor not selected is set to zero. CAL tries

to bring the displayed count to about 1200. It also

automati cally sets the Flame ON set point at 800

and Flame OFF set point at 600, which control the

Flame Relay. The filter selection remains

unchanged.

3) Bring the firing rate of the burner to a low fire

condition.

4) If the flame relay has not pulled in, adjust the

flame on & off set points so it does pull in.

5) Decide whether to calibrate using the UV or

IR sensor. See earlier sections on IR

DETECTOR and UV DETECTOR.

At the front panel of the P520/P522 press both

A and B push buttons simul ta ne ously. The

display will respond with “CAL?”. Press YES.

The display will then show “CALu”. Press

YES to calibrate the UV response or press NO.

If NO is pressed the display will show

“CALr”. Press YES to calibrate the IR

response. (Pressing NO will return the

P520/P522 to normal operation, exiting the

S550 CAL mode.) The P520/P522 will

automati cally adjust the gain for the selected

sensor; this takes a few seconds. If this

adjustment is successful the display will show

“----”, and the P520/P522 will return to

normal operation, displaying a reading of 1100

to 1300. But if the signal input is too low the

P520/P522 will display “2-Lo”. Press the

RESET button to return to the pre vious

settings. If the signal level is too high, the

display will show “OriF”. (See section on

ORIFICING.) Press RESET to return to the pre -

vious settings.

Calibration Pro ce dure:

1) Make a quick initial adjustment of the sighting

of the viewing head, trying to obtain a high

pulse rate. Red pulses from the LED indicate

that the IR sensor is producing output pulses;

green pulses indicate that the UV sensor is

producing output pulses.

2) Be sure that the external input for CHAN SEL

is properly set for the channel about to be

calibrated and that the channel LED is on

continu ously. When Using the calibrate

feature one does not have the option of

working with the channel that is not selected

by the external input.

PAGE 11

6) If step 5 was successful, re-aim the S550 for a

final adjustment using the LED to adjust the

viewing angle for a maximum pulse rate. Then

redo the CAL sequence as in step 5). The

Flame Relay will remain pulled-in. The

display should show a reading between 1100

and 1300.

7) Review the settings for F.F.R.T. And TIME

DELAY ON and adjust if necessary.

EXAMINING THE RE SULTS OF GAIN

SET TINGS FROM CALIBRATION

The gain settings deter mined automati cally by the

forgoing calibration pro ce dure may be viewed by

following the steps below for checking or

changing the UV and IR gain. Changes to these

Page 12

IRIS MODEL S550 APPLICATION MANUAL

settings, of course, may be made. The auto mat ic

calibration process is not sacred; it only finds gain

values. The user may change these, if he wishes,

to suit his needs. For example, one may wish to

increase the gain so the nominal displayed value is

1500 instead of 1200.

Note that the calibration pro ce dure sets the gain of

the sensor not being used to zero, but one can

adjust the gain of the unused sensor so the S550

responds to both sensors. The S550 sums the

sensor outputs.

CHECKING OR CHANGING UV GAIN

At the front panel of the P520/P522 press both A

and B push buttons simul ta ne ously. The current

numerical data on the 4 digit display will be

replaced with “CAL?” meaning, “Do you wish to

Calibrate?” If you press YES you will enter the

Calibration mode described in the pre vious

section. Press NO to enter the Adjust mode. The

display will show “AdJ?” meaning, “Do you wish

to make manual adjust ments?” If you do, press the

button near YES, which is the B push button. The

display will show “AuNN” where NN is the

current UV gain with the range 00 - 99. A gain of

00 turns off the sensor. To change the UV gain use

the up or down push buttons. If you then press

YES the new value will be stored; if you press NO

(Channel A push- button) the new value will be

ignored.

CHECKING OR CHANGING IR FILTER

You next have an oppor tunity to change the IR

filter. The display will show “ArFN” where N is

the current filter selected ranging from 1 to 8. Use

the up and down push- buttons to change the filter

if you wish. See COMPARISON WITH OTHER

MODEL 500 SERIES VIEWING HEADS for a listing

of the high-pass frequencies for these filters. Press

YES to accept a new filter value or NO to ignore

any changes you may have made.

For further infor mation please call the factory or

contact IRIS Systems Inc. See page 13 for contact

infor mation.

CHECKING OR CHANGING IR GAIN

You now have an oppor tunity to make a final

adjustment of the IR gain. After the filter

selection, the display will show “ANNN” where

NNN, the IR gain, ranges from 000 to 699. The up

and down push- buttons can be used to change the

IR gain. Changed values can be accepted by

pressing YES or ignored by pressing NO. If the

S550 settings are changed, the display will show

“----” indicating that the values are stored in

EEPROM bef ore continuing with the normal

numerical display.

If you do change the IR gain you may be surprised

to see the displayed gain values “jump” as you

scroll through them. As you increase the gain from

zero you will see this sequence:

000 - 099

150 - 199

250 - 299

350 - 399

450 - 499

550 - 599

650 - 699

The two least significant digits are linear gain

multi pliers; e.g., from 150 to 199 is a 99/50

increase in gain. But the most significant digit is

nonlinear; with each step change in the most

significant digit, the gain doubles. For example, a

setting of 250 has twice the gain as a setting of

150. Now it is possible to see why, as the gain is

increased from 150 to 199 the next step is to 250;

an increase from 150 to 199 is an increase of

99/50, which is a gain increase of almost 2, but the

next step to 250 is to a gain increase, theore ti cally,

to exactly 2. This relationship is true of all the

gains to 699.

It is recom mended that the #3 default filter (33Hz

cutoff) be used for all of the initial setup proce dures described in this manual. Further infor mation on how these filters can affect the discrimi nation ratio is found in the P520 APPLI CATION

MANUAL and in the P522 APPLI CATION MANUAL

in the section MULTI BURNER REQUIRE MENTS.

The two least significant digits can be used below

050 down to 000; 000, of course, selects a gain of

zero (which turns OFF the sensor). When the

display is ramped down from 699 the following

sequence will be seen:

PAGE 12

Page 13

IRIS MODEL S550 APPLICATION MANUAL

673 - 637

573 - 537

473 - 437

373 - 337

273 - 237

173 - 137

073 - 000

This approach makes a wide range available for

gain multi plier changes using the two least

significant digits. For example, over a range of

137 to 199 the gain is changed by a ratio of 99/37.

It is advan ta geous for moderate changes in gain to

change only the gain multi plier digits because the

response to these changes is very linear. When

changes are made in the most significant gain

digit, the gain change is not always exactly an

ideal 2:1 step change.

MAN UAL SETUP OF THE S550

The steps below for manual setup should result in

the P520 or P522 displaying a reading close to

1200 with flame on. This pro ce dure should pro vide similar gain settings for each selected sensor

as in the CALIBRATION pro ce dure described

earlier.

1) Bring the firing rate of the burner to a low fire

condition.

stays the same or actually increases, the S550

is saturated. Continue reducing the gain in

steps of 100 until the displayed reading is

reduced. Then set the gain so the reading is in

the 1000 to 1400 range. If the IR sensor was

not saturated one can skip para graph 5) below.

5) If the S550 was saturating one should check

the aiming of the S550 again using the LED

on the back of the housing to adjust the

viewing angle of the head for a maximum

pulse rate. If the LED pulse rate is then too

high (the LED is ON almost continu ously)

change the gain once more by using the Adjust

Mode pro ce dure to get a reading in the 1000 to

1400 range. Then maximize the pulse rate by

re-aiming the S550 viewing head. This pro ce dure of optimizing the sighting and adjusting

the gain may have to be done more than one

time to be assured that the S550 is properly

setup.

6) If the UV sensor has been chosen adjust the

gain (00-99) using the Adjust Mode so the

displayed reading is close to 1200. The UV

sensor is not likely to saturate but if the flame

signal readings are very high on low gain

settings then one should orifice the sighting.

See section ORIFICING.

2) Be sure that the external input for CHAN SEL

is properly set for the channel calibration (A or

B) that is currently being set and the channel

LED is ON continu ously.

3) Decide whether to setup the S550 using the

UV or IR sensor bef ore aiming the viewing

head. In some flames the best UV reading of

the flame envelope may be found at a different

location from the best IR reading. See earlier

sections IR DETECTOR and UV DETECTOR .

Use the Adjust Mode (“AdJ?”) pro ce dure for

the S550 described above and set the gain for

the sensor not being used to zero.

4) If the IR sensor is being used, bef ore final

aiming but with a typical reading on the

display, verify that the S550 is not saturated by

reducing the IR gain by 100. The displayed

reading should be reduced by roughly 1/2. If it

PAGE 13

7) Set or at least check the Flame ON and Flame

OFF set points. If they are still at the factory

default values (Flame ON at 800 and Flame

OFF at 600) they may be satis factory as they

are. If the Flame ON reading is less than 1200

the Flame OFF setting should be propor tion ately less.

8) Review the settings for F.F.R.T. and TIME

DELAY ON and adjust if necessary.

RE TURN TO DE FAULT SET TINGS

There are three major branches on the decision

tree after one gets into the S550 setup by pressing

the A and B push buttons. Ref er to Fig. 3 at the

end of this manual. That is, if one says NO to

“CAL?”, one is asked if one wishes to do adjust. If

one says NO to “AdJ?”, one is asked if one wishes

to go back to the default settings. If one says NO

to “dEF?”, then the P520/P522 and S550 continue

Page 14

with normal operation. If one says YES to

defaults, then the original default settings are

stored for the selected channel overwriting the

pre vious S550 settings for that channel.

ANGLE OF VIEW

The angle of view for S550 viewing head utilizing

the IR detector will be the same as the S511

because the Ge photo de tector element is 1mm in

diameter which results in an angle of 1.0°. When

using the UV detector the angle of view will be the

same as the S506 which is about 3.0 °. See section

SIGHTING OF VIEWING HEAD for details.

GENERAL COMMENTS

It will be obvious to the user of this new

innovative product that this is the ultimate state of- the-art flame monitor. The way it works has

been described only in a general sense and

obviously the algorithms imple mented by the

embedded controller software are proprietary and

will not be made pub li c. Any existing P520 or

P522 signal processor can be upgraded to an S550

compatible processor by changing the controller

chip and the front panel.

IRIS MODEL S550 APPLICATION MANUAL

TECH NI CAL HELP

For technical help in applying this product please

contact:

Factory and Repairs:

IRIS Systems Inc.

(JB Systems, Inc.)

4944 - 113th Avenue North

Largo, FL 33760

Tel: 727 545-3900

Fax: 727 547-9589

Sales and Appli ca tions Support:

IRIS Systems Inc.

7583 Vantage Placey

Delta, BC V4G 1A5

Tel: 604 584-4747

604 538-5972

Fax: 604 581-9790

1-800-667-IRIS

PAGE 14

Page 15

IRIS MODEL S550 APPLICATION MANUAL

Figure 1

PAGE 15

Figure 2

Page 16

IRIS MODEL S550 APPLICATION MANUAL

PAGE 16

Fig ure 3

Page 17

IRIS MODEL S550 APPLICATION MANUAL

PAGE 17

Fig ure 4

Page 18

IRIS MODEL S550 APPLICATION MANUAL

Fig ure 5

PAGE 18

Page 19

IRIS MODEL S550 APPLICATION MANUAL

PAGE 19

5 June 1997

Loading...

Loading...