Page 1

Refer to Installation manual for full instructions.

On-Premise

TMB795C

TM795C

Laundry

Planning

Handbook

50 and 75 Pound Tumblers

Through Serial No. 0904002963

4-08-44R3

June 2011

Page 2

Table of

Contents

Tumblers – 50 and 75 ......................................................................... 2

Introduction...................................................................................... 2

Model Identification .................................................................. 2

Specifications and Dimensions ........................................................ 4

Cabinet Dimensions................................................................... 5

Exhaust Outlet Locations........................................................... 6

Gas Connection Locations......................................................... 7

Electrical Connection Locations................................................ 8

Steam Connection Locations ..................................................... 9

Installation........................................................................................ 10

Pre-Installation Inspection ......................................................... 10

Tumbler Enclosure..................................................................... 11

Exhaust Requirements ..................................................................... 12

Layout ........................................................................................ 12

Make-Up Air.............................................................................. 12

Venting ...................................................................................... 12

Individual Venting..................................................................... 13

Manifold Venting....................................................................... 15

50 Pound Gas and Steam Models .................................................... 18

75 Pound Gas and Steam Models .................................................... 19

50 and 75 Pound Electric Models .................................................... 20

© Published by permission of the copyright owner.

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 3

Introduction

TMB795C

Tumblers – 50 and 75

TMB795C

Model Identification

Gas Steam/Thermal Oil Electric

50 Pound IPD50G2-IT050L IPD50G2-IT050N IPD50S2-IT050S IPD50S2-IT050T IPD50E2-IT050E

75 Pound IPD75G2-IT075L IPD75G2-IT075N IPD75S2-IT075S IPD75S2-IT075T IPD75E2-IT075E

Includes models with the following control suffixes:

3V – DX4 vended QT – dual digital timer SD – single drop

3X – DX4 prep for coin RD – reversing DMP OPL SX – single drop, prep for coin

DO – DMP OPL RQ – reversing dual digital timer

4-08-44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

2

Page 4

Tumblers – 50 and 75

TMB803N

1

0

2

0

40

30

50

60

0

1

0

5

PUSH

TO

STA

RT

HEAT

C

OO

L

DO

WN

HIGH

TEMPER

ATURE

LOW

15

0

1

1

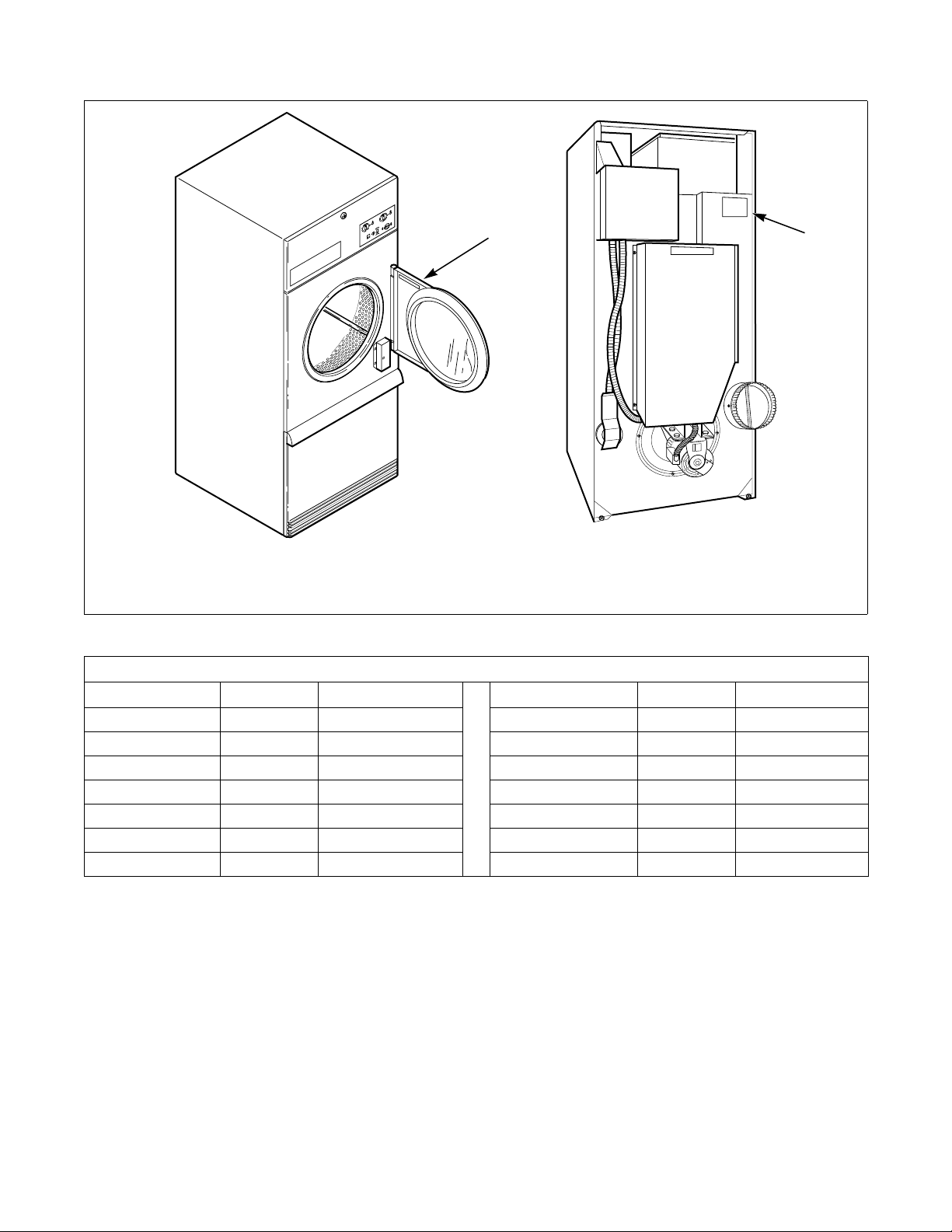

1 Serial Plate

Conversion Table

Multiply By To Obtain Multiply By To Obtain

Btu 0.252 kCal Pounds/sq. inch 0.06895 Bars

Btu 1055 Joules Pounds/sq. inch 0.070 kg/sq. cm

Inch 25.4 Millimeters Pounds (lbs.) 0.454 Kilograms

Inches W.C. 0.036 Pounds/sq. inch Boiler Horsepower 33,479 Btu/hr.

Inches W.C. 0.249 kPa Boiler Horsepower 34.5 lbs. steam/hr.

2

lb/inch

ft

(psi) 6.895 kPa CFM 0.471 liters/second

3

28.32 Liters kW 3414 Btu/hr.

TMB803N

3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 5

Specifications and Dimensions

Specifications 50 Pound 75 Pound

Noise level measured during operation at

operator position of 3.3 feet (1 meter) in front

of machine and 5.2 feet (1.6 meters) from

floor.

Net Weight (approximate):

Pounds (kg)

Cylinder Size:

Inches (mm)

Cylinder Capacity (dry weight):

Pounds (kg)

Air Outlet Diameter:

Inches (mm)

Maximum Static Back Pressure:

W.C.I. (mbar)

Maximum Airflow:

C.F.M. (L/sec.)

Tumblers – 50 and 75

63 dBA 69 dBA

545

(247)

37 x 30

(940 x 762)

50

(22.7)

8

(203)

0.5

(1.3)

750

(354)

Gas/Steam 60 Hz 920 (434)

Gas/Steam 50 Hz 750 (354)

Electric 750 (354)

(279)

37 x 36

(940 x 914)

(34)

(203)

(1.3)

615

75

8

0.5

Motor Horsepower:

Nonreversing

Reversing

Fan

Cylinder

Gas Connection

Gas Burner Rating:

Btu/hr0 (Mj/hr.)

Heating Element Rating:

Kilowatts (kW)

Steam Connection

Steam Coil Rating at 100 psig:

Boiler Horsepower (Btu/hr.)

(recommended operating pressure

80-100 psig)

1/2

1/3

1/3

Gas Models

1/2 in. NPT 1/2 in. NPT

120,000

(126.6)

Electric Models

21 kW (240 V/50 Hz)

30 kW (other voltages)

Steam Models

3/4 in. NPT 3/4 in. NPT

5.1

(177,500)

3/4

1/3

1/3

165,000

(174.1)

30 kW

6.1

(210,300)

4-08-44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4

Page 6

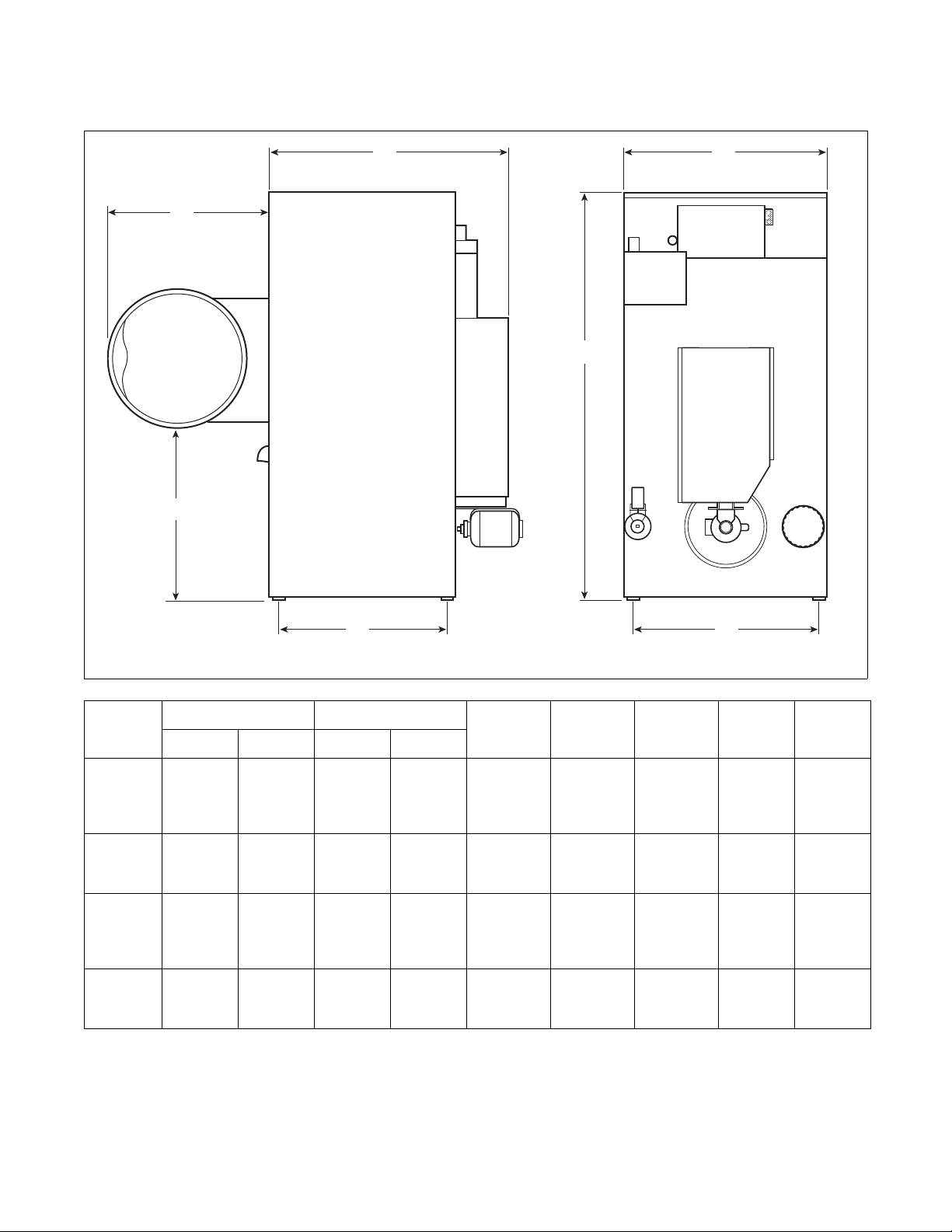

Tumblers – 50 and 75

C

B

E

D

A

G

F

Cabinet Dimensions

Models

CDEFG

******

50

AB

Pound

Gas and

30.75 in.

(781 mm)

28.75 in.

(730 mm)

28.25 in.

(717 mm)

33.87 in.

(860 mm)

47 in.

(1194 mm)

(1946 mm)

Electric

50

Pound

Steam

30.75 in.

(781 mm)

28.75 in.

(730 mm)

28.25 in.

(717 mm)

33.87 in.

(860 mm)

47 in.

(1194 mm)

(2032 mm)

75

Pound

Gas and

30.75 in.

(781 mm)

28.75 in.

(730 mm)

28.25 in.

(717 mm)

33.87 in.

(860 mm)

53 in.

(1346 mm)

(1946 mm)

Electric

75

Pound

Steam

30.75 in.

(781 mm)

28.75 in.

(730 mm)

28.25 in.

(717 mm)

33.87 in.

(860 mm)

53 in.

(1346 mm)

(2032 mm)

* A, H, S and U models prior to Serial No. 0308001307 and all other models.

** A, H, N, S and U models after Serial No. 0308001307.

76.625 in.

80 in.

76.625 in.

80 in.

38.625 in.

(981 mm)

38.625 in.

(981 mm)

38.625 in.

(981 mm)

38.625 in.

(981 mm)

33 in.

(838 mm)

33 in.

(838 mm)

33 in.

(838 mm)

33 in.

(838 mm)

TMB2210N

29.5 in.

(749 mm)

29.5 in.

(749 mm)

35.5 in.

(902 mm)

35.5 in.

(902 mm)

5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 7

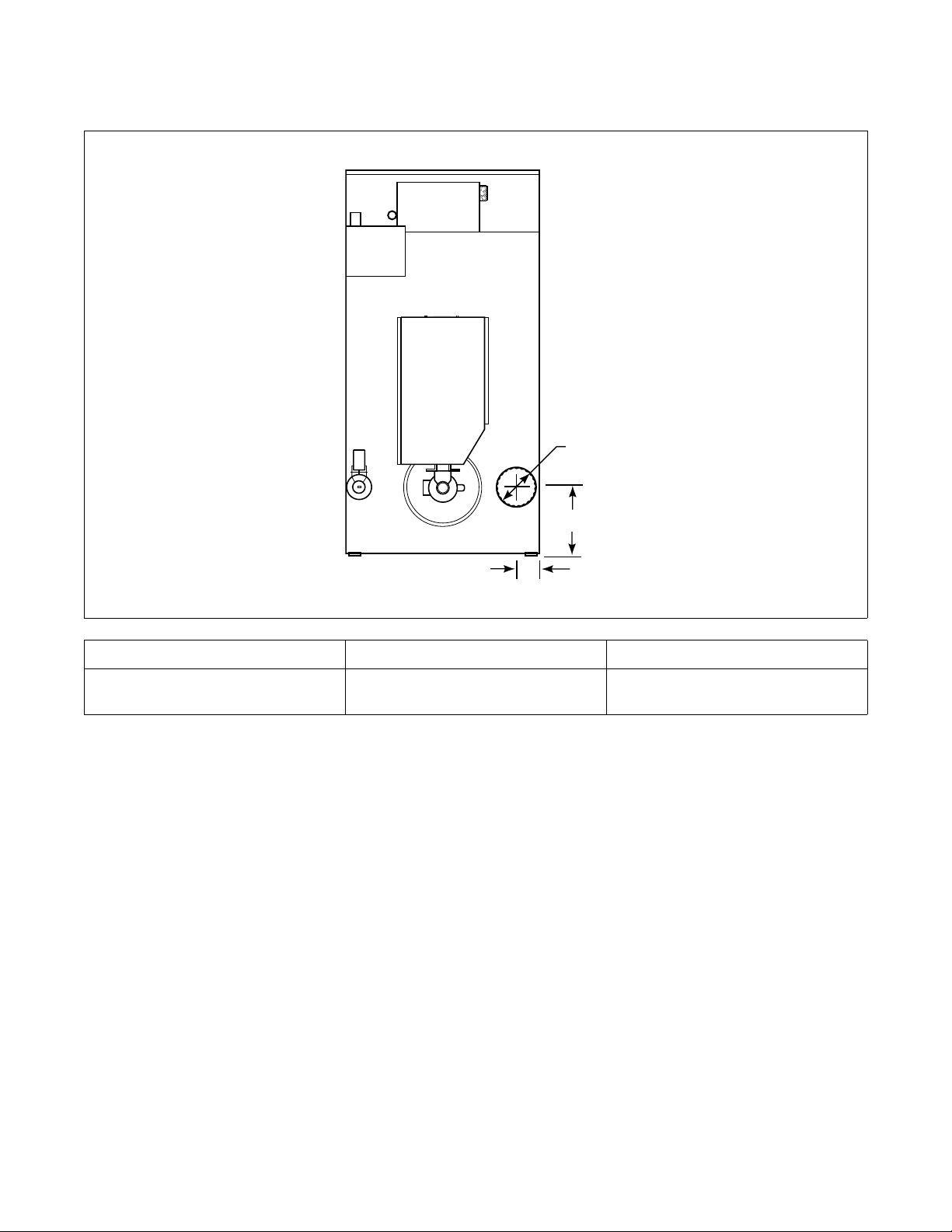

Exhaust Outlet Locations

A

B

C

Tumblers – 50 and 75

TMB811N

ABC

5.375 in.

(137 mm)

8 in.

(203 mm)

13.375 in.

(340 mm)

4-08-44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

6

Page 8

Tumblers – 50 and 75

A

B

Gas Connection Locations

Models Diameter A B

50 Pound

75 Pound

1/2 in. NPT 15.5 in.

(394 mm)

1/2 in. NPT 15.75 in.

(400 mm)

65.75 in.

(1670 mm)

65.75 in.

(1670 mm)

TMB812N

7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 9

Electrical Connection Locations

TMB813N

GAS AND STEAM ELECTRIC

A

B

B

A

Tumblers – 50 and 75

Models A B

Gas and Steam

Electric

(241 mm)

(483 mm)

NOTE: These figures are approximate dimensions only.

9.5 in.

19 in.

TMB813N

63.5 in.

(1613 mm)

64 in.

(1626 mm)

4-08-44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

8

Page 10

Tumblers – 50 and 75

C

A

B

D

Steam Connection Locations

TMB814N

DiameterABCD

3/4 in. NPT

15.25 in.

(387 mm)

72.75 in.

(1848 mm)

7.5 in.

(190 mm)

64.75 in.

(1645 mm)

9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 11

Installation

Pre-Installation Inspection

Upon delivery, visually inspect the crate, carton and

parts for any visible shipping damage. If the crate,

carton, or cover is damaged or signs of possible

damage are evident, have the carrier note the condition

on the shipping papers before the shipping receipt is

signed, or advise the carrier of the condition as soon as

it is discovered.

Remove the crate and protective cover as soon as

possible and check the items listed on the packing list.

Advise the carrier of any damaged or missing articles

as soon as possible. A written claim should be filed

with the carrier immediately if articles are damaged or

missing.

IMPORTANT: Warranty is void unless tumbler is

installed according to instructions in this manual.

Installation should comply with minimum

specifications and requirements detailed herein,

and with applicable local gas fitting regulations,

municipal building codes, water supply regulations,

electrical wiring regulations, and any other

relevant statutory regulations. Due to varied

requirements, applicable local codes should be

thoroughly understood and all pre-installation

work arranged for accordingly.

Tumblers – 50 and 75

4-08-44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

10

Page 12

Tumblers – 50 and 75

TMB2131N

3

1

4

5

6

7

2

WARNING

To reduce the risk of severe injury, clearance of tumbler cabinet from combustible

construction must conform to the minimum clearances.

W056

8

Tumbler Enclosure

NOTE: Shaded areas indicate adjacent structure.

1 0.5 in. (13 mm) recommended between machines for removal or installation

2 Allow 2-4 in. (51-102 mm) opening at top of machine to aid in removal or installation. A removable trim piece

may be used to conceal the opening; zero clearance allowed for trim.

3 4 in. (102 mm) maximum header thickness

4 12 in. (305 mm) minimum clearance permitted for remainder

5 Guard

6 Provision for make-up air

7 24 in. (610 mm) minimum, 36 in. (914 mm) recommended for maintenance purposes

8 0.25 in. (6 mm) recommended for removal or installation purposes, zero clearance allowed

Figure 1

TMB2131N

11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 13

Tumblers – 50 and 75

A drying tumbler produces combustible

lint. To reduce the risk of fire, the tumbler

must be exhausted to the outdoors.

W057

To reduce the risk of fire and accumulation

of combustible gases, DO NOT exhaust

tumbler air into a window well, gas vent,

chimney or enclosed, unventilated area

such as an attic wall, ceiling, crawl space

under a building, or concealed space of a

building.

W059

WARNING

WARNING

To reduce the risk of fire due to increased

static pressure, we do not recommend

installation of in-line secondary lint filters

or lint collectors. If secondary systems

are mandated, frequently clean the

system to assure safe operation.

W749

Improperly sized or assembled ductwork

causes excess back pressure which

results in slow drying, lint collecting in the

duct, lint blowing back into the room, and

increased fire hazard.

W355

WARNING

Exhaust Requirements

Layout

Whenever possible, install tumblers along an outside

wall where duct length can be kept to a minimum, and

make-up air can be easily accessed. Elbows and long

vents tend to increase drying time. Construction must

not block the airflow at the rear of the tumbler. Doing

so would prevent adequate air supply to the tumbler’s

combustion chamber.

Make-Up Air

A tumbler is forced air exhausted and requires

provisions for make-up air to replace the air exhausted

by the tumbler.

IMPORTANT: Do not obstruct the flow of

combustion and ventilation air.

Make-up air openings should be as close to the

tumbler(s) as possible.

The required make-up air opening to the outside for

tumbler is:

each

Required Make-Up Air Opening

(to the outside) for Each Tumbler

Model Opening

2

144 in

50 Pound

75 Pound

195 in

(928 cm2)

2

(1258 cm2)

Make-up air openings for a room containing

tumbler(s) and/or gas fired hot water heater or other

gravity vented appliances must be increased

sufficiently to prevent downdrafts in any of the vents

when all tumblers are in operation. Do not locate

gravity vented appliances between tumbler(s) and

make-up air openings. If it is necessary to duct makeup air to the tumbler(s), increase the area of the

ductwork by 25% to compensate for any restriction in

air movement.

Venting

IMPORTANT: Installing in-line filters or lint

collectors will cause increased static pressure.

Failure to maintain the secondary lint system will

decrease tumbler efficiency and may void machine

warranty.

For maximum efficiency and minimum lint

accumulation, tumbler air must be exhausted to the

outdoors by the shortest possible route.

Proper sized exhaust ducts are essential for proper

operation. All elbows should be sweep type. Exhaust

ducts must be assembled so the interior surfaces are

smooth, so the joints do not permit the accumulation

of lint. DO NOT use plastic or thin foil flexible ducts –

rigid metal ducts are recommended. Use exhaust ducts

made of sheet metal or other noncombustible material.

DO NOT use sheet metal screws or fasteners on

exhaust pipe joints which extend into the duct and

catch lint. Use of duct tape or pop-rivets on all seams

and joints is recommended, if allowed by local code.

Verify that old ducts are thoroughly cleaned out before

installing new tumbler(s).

Make-up air openings with louvers will restrict

airflow. The opening must be increased to compensate

for area taken up by louvers.

4-08-44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

12

Page 14

Tumblers – 50 and 75

NOTE: Exhaust ducts must be constructed of sheet

metal or other noncombustible material. Such

ducts must be equivalent in strength and corrosion

resistance to ducts made of galvanized sheet steel

not less than 0.0195 inches (0.495 mm) thick. Local

codes may require additional thickness.

Where the exhaust duct pierces a combustible wall or

ceiling the opening must be sized per local codes. The

space around the duct may be sealed with

noncombustible material. Refer to Figure 2.

IMPORTANT: For best performance provide an

individual exhaust duct for each tumbler. Do not

install a hot water heater in a room containing

tumblers. It is better to have the water heater in a

separate room with a separate air inlet.

Individual Venting

For maximum efficiency and performance, it is

preferred to exhaust tumbler(s) individually to the

outdoors.

IMPORTANT: At no point may the cross sectional

area of installed venting be less than the cross

sectional area of the exhaust outlet of the tumbler.

The exhaust duct must be designed so the static back

pressure measured 12 inches (305 mm) from the

exhaust outlet does not exceed the maximum

allowable pressure specified on the installation sticker

on the rear of the tumbler.

Duct

Diameter

6 in. (152 mm)

8 in. (203 mm)

10 in. (254 mm)

12 in. (305 mm)

14 in. (356 mm)

16 in. (406 mm)

18 in. (457 mm)

Equivalent Length (feet) = 1.17 x Duct Diameter (inches)

Equivalent Length of Rigid

Straight Duct

One 90° elbow = 7 ft. (2.1 m)

One 90° elbow = 9.3 ft. (2.83 m)

One 90° elbow = 11.6 ft. (3.5 m)

One 90° elbow = 14 ft. (4.3 m)

One 90° elbow = 16 ft. (4.9 m)

One 90° elbow = 18.7 ft. (5.7 m)

One 90° elbow = 21 ft. (6.4 m)

Table 1

Example: A 12 inch (305 mm) diameter duct’s

equivalent length of 14 feet (4.3 m) of duct and two

90° elbows is:

Equivalent Length = 14 feet + (2) 90° elbows

= 14 feet + 14 feet + 14 feet

= 42 feet (12.8 meters)

With the tumbler in operation, airflow at any point

in the duct should be at least 1200 feet per minute

(366 meters per minute) to ensure that lint remains

airborne. If 1200 feet per minute cannot be

maintained, schedule monthly inspections and

cleaning of the ductwork.

NOTE: Static back pressure must be measured

with the tumbler running.

The maximum allowable length venting of the same

diameter as the exhaust thimble is 14 feet (4.3 m) and

two 90° elbows or equivalent. If the equivalent length

of a duct required for an installation exceeds the

maximum allowable equivalent length, the diameter of

a round duct must be increased by 10% for each

additional 20 feet (6.1 m). Cross section area of a

rectangular duct must be increased by 20% for each

additional 20 feet (6.1 m). Refer to Table 1 to

determine equivalent venting.

NOTE: The maximum length of a flexible metal

duct must not exceed 7.87 ft. (2.4 m) as required to

meet UL2158, claus 7.3.2A.

13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 15

Tumblers – 50 and 75

TMB2103N

1

2

3

4

5

1 Removable strip of panel in framing wall to permit removal of tumbler from framing wall

2 Partition or bulkhead

3 Minimum distance between exhaust opening and roof, ground or other obstruction: 36 in. (914 mm)

4 2 in. (51 mm) minimum clearance on both sides of duct

5 Exhaust airflow – maximum length of duct: 14 ft. (4.3 m)

NOTE: Do not install wire mesh or screen in

exhaust duct opening to avoid lint build-up or

impacting proper discharge of air from tumblers.

NOTE: Where exhaust duct pierces a combustible

wall or ceiling, the opening must be sized per local

Figure 2

NOTE: Inside of duct must be smooth. Do not use

sheet metal screws to join sections.

Consult your local building code for regulations which

may also apply.

codes.

TMB2103N

4-08-44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

14

Page 16

Tumblers – 50 and 75

Manifold Venting

While it is preferable to exhaust tumblers individually

to the outdoors, a main collector duct may be used if it

is sized according to Figure 4 and Figure 5. This

illustration indicates minimum diameters, which

should be increased if the collector length exceeds 14

feet (4.3 meters) and two 90° elbows. The diameter of

a round duct must be increased by 10% for each

additional 20 feet (6.1 meters). Cross sectional area of

a rectangular or square duct must be increased 20% for

each additional 20 feet (6.1 meters). Refer to Table 2

and Table 3 to determine equivalent ducting sizing.

The collector duct may be rectangular or square in

cross section, as long as the area is not reduced.

Provisions MUST be made for lint removal and

cleaning of the collector duct.

The vent collector system must be designed so the

static back pressure measured 12 inches (305 mm)

from the exhaust outlet does not exceed the maximum

allowable pressure specified on the installation sticker

on the rear of tumbler. Static back pressure must be

measured with all tumblers vented into the collector

operating.

NOTE: Never connect a tumbler duct at a 90°

angle to the collector duct. Refer to Figure 3. Doing

so will cause excessive back pressure, resulting in

poor performance. Never connect two tumbler

exhaust ducts directly across from each other at the

point of entry to the collector duct.

With the tumbler in operation, airflow at any point in

the duct should be at least 1200 feet per minute (366

meters per minute) to ensure that lint remains airborne.

If 1200 feet per minute cannot be maintained, schedule

monthly inspections and cleaning of the ductwork.

T438I

Figure 3

15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 17

1 NOTE: Where the exhaust duct pierces a

LKJ I HG F

E

DCB A

3

1

2

ONE MANIFOLD ASSEMBLY

combustible wall or ceiling, the opening

MUST be sized per local codes.

Tumblers – 50 and 75

TMB2019N

2 Outlet duct diameter

3 45° typical

Figure 4

Duct Station 8 in. (203 mm) Duct

A

B

C

D

E

F

G

H

I

J

K

L

8 in. (203 mm)

12 in. (305 mm)

15 in. (381 mm)

17 in. (432 mm)

19 in. (483 mm)

21 in. (533 mm)

23 in. (584 mm)

25 in. (635 mm)

26 in. (660 mm)

27 in. (686 mm)

29 in. (737 mm)

30 in. (762 mm)

Table 2

4-08-44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

16

Page 18

Tumblers – 50 and 75

1

2

3

LKJ I

L

K

J

I

CONTINUE

TO A

CONTINUE

TO A

TWO MANIFOLD ASSEMBLIES

1 NOTE: Where the exhaust duct pierces a

combustible wall or ceiling, the opening

MUST be sized per local codes.

Duct Station 8 in. (203 mm) Duct

A

B

C

D

E

F

G

H

I

J

K

L

Figure 5

2 Outlet duct diameter

3 45° typical

13 in. (330 mm)

17 in. (432 mm)

18 in. (457 mm)

24 in. (610 mm)

27 in. (686 mm)

30 in. (762 mm)

33 in. (838 mm)

34 in. (864 mm)

37 in. (940 mm)

39 in. (991 mm)

40 in. (1016 mm)

42 in. (1067 mm)

TMB2018N

Table 3

17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 19

Tumblers – 50 and 75

50 Pound Gas and Steam Models

Refer to Table 4.

NOTE: Wire sizes were obtained from the

Canadian Electrical Code for 75 C. wire and are

intended for use as a guideline only. Electrical

connections should be made by a qualified

electrical contractor in accordance with all

applicable local and national requirements.

Terminal Block

Serial Plate Rating

120V/60Hz/1ph

200-208V/60Hz/1ph

200-208-240V/60Hz/1ph

230-240V/50Hz/1ph

200-208V/60Hz/3ph

200V/50Hz/3ph

240V/60Hz/3ph

230-240V/50Hz/3ph

380V/50 or 60Hz/3ph

400-415V/50Hz/3ph

440V/60Hz/3ph

460-480V/60Hz/3ph

N/A = Not Applicable

Connections

Required

L1, Neutral and ground 9.3 N/A 15A – 1 pole 14 (2.08)

L1, Neutral and ground 5.1 N/A 10A – 1 pole 14 (2.08)

L1, L2 and ground 5.1 N/A 10A – 2 pole 14 (2.08)

L1, Neutral and ground 6.3 6.9 15A – 1 pole 14 (2.08)

L1, L2, L3 and ground 2.8 4.0 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 3.3 4.2 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 2.8 4.0 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 3.1 4.3 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 1.6 2.0 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 1.6 2.0 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 1.4 1.9 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 1.4 1.9 10A – 3 pole 14 (2.08)

NOTE: Electrical specifications below are subject

to change without notice. Always refer to product

serial plate for most current specifications of

product being installed.

NOTE: Use copper conductors only.

NOTE: Connect to individual branch circuit.

NOTE: 3 Phase Only – Each tumbler must be

connected to its own individual branch circuit

breaker, not fuses, to avoid the possibility of “single

phasing” and causing premature failure of the

motor(s).

7

Serial Plate Amps Recommended Circuit

Nonreversing Reversing Breaker Rating

Wire Size

AWG (m m

2

)

4-08-44

Table 4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

18

Page 20

Tumblers – 50 and 75

75 Pound Gas and Steam Models

Refer to Table 5.

NOTE: Wire size and breaker ratings were

obtained from the Canadian Electrical Code for

75 C. wire and are intended for use as a guideline

only. Electrical connections should be made by a

qualified electrical contractor in accordance with

all applicable local and national requirements.

NOTE: Electrical specifications below are subject

to change without notice. Always refer to product

serial plate for most current specifications of

product being installed.

Terminal Block

Serial Plate Rating

120V/60Hz/1ph

200-208V/60Hz/1ph

200-208-240V/60Hz/1ph

230-240V/50Hz/1ph

200-208V/60Hz/3ph

200V/50Hz/3ph

240V/60Hz/3ph

230-240V/50Hz/3ph

380V/50 or 60Hz/3ph

400-415V/50Hz/3ph

440V/60Hz/3ph

460-480V/60Hz/3ph

N/A = Not Applicable

Connections

Required

L1, Neutral and ground 13.8 N/A 20A – 1 pole 12 (3.31)

L1, Neutral and ground 7.6 N/A 15A – 1 pole 14 (2.08)

L1, L2 and ground 7.6 N/A 15A – 2 pole 14 (2.08)

L1, Neutral and ground 6.7 7.0 15A – 1 pole 14 (2.08)

L1, L2, L3 and ground 3.8 4.3 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 3.5 4.5 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 3.8 4.3 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 3.5 4.9 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 1.8 2.1 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 1.8 2.1 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 1.9 2.1 10A – 3 pole 14 (2.08)

L1, L2, L3 and ground 1.9 2.1 10A – 3 pole 14 (2.08)

NOTE: Use copper conductors only.

NOTE: Connect to individual branch circuit.

NOTE: 3 Phase Only – Each tumbler must be

connected to its own individual branch circuit

breaker, not fuses, to avoid the possibility of “single

phasing” and causing premature failure of the

motor(s).

Serial Plate Amps Recommended Circuit

Nonreversing Reversing

Breaker

Rating

Wire Size

AWG (m m

2

)

19

Table 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4-08-44

Page 21

Tumblers – 50 and 75

50 and 75 Pound Electric Models

Refer to Table 6.

NOTE: Wire size and breaker ratings were

obtained from the Canadian Electrical Code for

75 C. wire and are intended for use as a guideline

only. Electrical connections should be made by a

qualified electrical contractor in accordance with

all applicable local and national requirements.

NOTE: Electrical specifications below are subject

to change without notice. Always refer to product

serial plate for most current specifications of

product being installed.

Terminal Block

Serial Plate Rating

240V/50Hz/1ph

(50 Pound only)

200-208V/60Hz/3ph

200V/50Hz/3ph

230V/50Hz/3ph

240V/50Hz/3ph

240V/60Hz/3ph

380V/50 or 60Hz/3ph

400-415V/50Hz/3ph

440V/60Hz/3ph

480V/60Hz/3ph

Connections

Required

L1, Neutral and Ground 93 95 125A – 1 pole 1 (42.4)

L1, L2, L3 and ground 89 88 125A – 3 pole 1 (42.4)

L1, L2, L3 and ground 84 85 125A – 3 pole 1 (42.4)

L1, L2, L3 and ground 73 75 100A – 3 pole 3 (26.7)

L1, L2, L3 and ground 79 78 100A – 3 pole 3 (26.7)

L1, L2, L3 and ground 79 78 100A – 3 pole 3 (26.7)

L1, L2, L3 and ground 47 48 60A – 3 pole 6 (13.3)

L1, L2, L3 and ground 43 44 60A – 3 pole 6 (13.3)

L1, L2, L3 and ground 41 41 51A – 3 pole 6 (13.3)

L1, L2, L3 and ground 38 38 50A – 3 pole 6 (13.3)

Nonreversing Reversing

NOTE: Use copper conductors only.

NOTE: Connect to individual branch circuit.

NOTE: 3 Phase Only – Each tumbler must be

connected to its own individual branch circuit

breaker, not fuses, to avoid the possibility of “single

phasing” and causing premature failure of the

motor(s).

Serial Plate Amps Recommended Circuit

Breaker

Rating

Wire Size

AWG (m m

2

)

4-08-44

Table 6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

20

Loading...

Loading...