TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 1 -

IImmppoorrttaanntt

IInnffoorrmmaattiioon

n

(Please complete this information for your records

and for reference during any warranty claims.)

Motion Concepts

Serial Number:

(Serial Number is located on the

underside of the TRx seat frame)

Dealer: _______________________________

Address: _____________________________

Phone #: _____________________________

Purchase Date: _______________________

Power Base (Model): ___________________

MC#

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 2 -

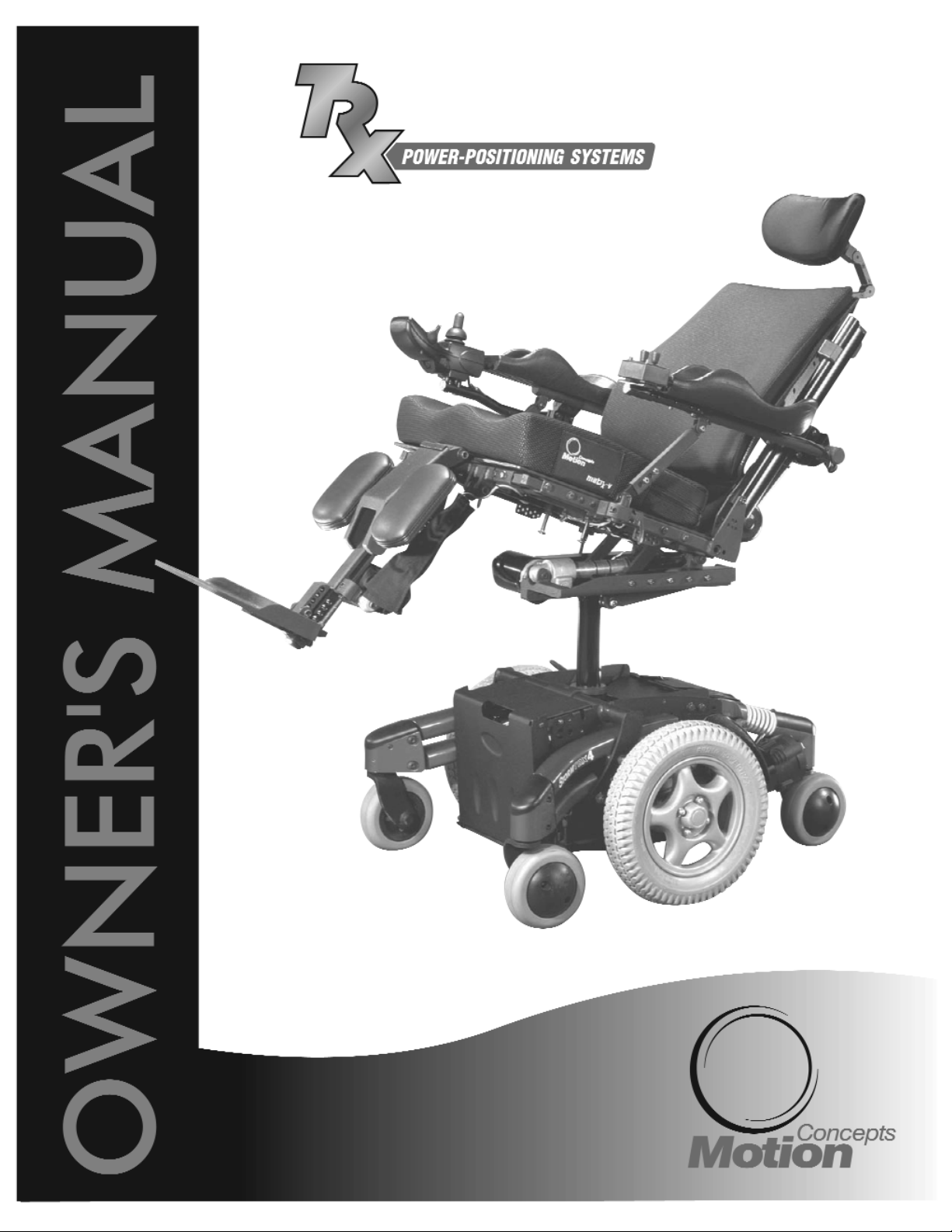

Congratulations on your decision to purchase a

Motion Concepts TRx system. Our goal at Motion

Concepts is to provide you with the best possible

power positioning system. Our close work with

many health care professionals has given us an

understanding of the challenges that you may confront, and has enabled us to design systems that

will help to meet your individual positioning needs.

We are confident that you will be delighted with

your new positioning system and as you grow or

your needs change, your new TRx system will be

able to grow and change with you.

If you have any questions or comments, please

contact us by calling Motion Concepts USAtoll free

at 1-888-433-6818 or Motion Concepts Canada at

1-866-748-7943. The more we are able to understand your needs, the better we will be able to meet

them.

*Important*

This owner’s manual applies specifically to your TRx Power Positioning System. It is

important that you read and understand its contents. It is also very important that you

read and understand the owner’s manual provided with your power base.

Safety Symbols:

Using your TRx Power Positioning System safely depends upon your diligence in following the warnings,

cautions and information provided in this Owner’s Manual. Setting up and operating the system safely

also depends on your own good judgement and common sense, as well as that of your provider, caregiver and/or health professional.

The symbols below are used throughout this manual to identify warnings, cautions and important notes.

It is very important for you to read and understand them completely.

!

i

CAUTION! Failure to heed the cautions in this Owner’s Manual may result in damage to your

TRx Power Positioning System.

WARNING! Failure to heed the warnings in this owner ’s manual may result in personal injury.

Important! Important information to remember when operating your TRx system

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 3 -

Table of Contents

--- Safety Symbols ..................................................................................... 2

1.0 Introduction ........................................................................................... 4

2.0 Important Information about your TRx System .................................. 5

Stability ............................................................................................................................. 5

Batteries ............................................................................................................................ 6

Weight Capacity .............................................................................................................. 6

Hardware .......................................................................................................................... 7

3.0 Safety Precautions ............................................................................... 8

4.0 Motor Vehicle Transportation .............................................................. 8

5.0 Power Positioning Functions .............................................................. 9

6.0 TRx Switches ........................................................................................ 10

Normal Mode vs. Auto-Reversing Mode ......................................................................... 10

TRx Switch Types ........................................................................................................... 11

7.0 Using the Power Base Joysticks: ........................................................ 12

7.1 Quickie Q-tronix Joystick ......................................................................................... 12

7.2 Pride Remote Plus Joystick ................................................................................... 13

7.3 Invacare MKIV AJoystick ...................................................................................... 14

7.4 Invacare MKV- DPJ Joystick .................................................................................. 15

7.5 Invacare MKV- MPJ Joystick ................................................................................. 16

8.0 Safety Lockout and Limit Switches ................................................... 17

9.0 General Maintenance & Safety ........................................................... 18

Maintenance Schedule ................................................................................................... 18

Safety Inspection Checklist ............................................................................................ 18

Lubrication ...................................................................................................................... 19

Battery Charging ............................................................................................................. 19

Battery Testing ................................................................................................................20

10.0 Troubleshooting Guide ........................................................................ 21

11.0 Electro-Magnetic Interference ............................................................ 22

12.0 Disclaimer and Warranty Information ................................................ 24

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 4 -

About Concepts

Motion Concepts is a Toronto based company that designs and manufactures the TRx line of Power

Positioning Systems. These systems were developed to provide effective positioning and pressure reduction for a wide range of disabilities. The modular design incorporates Center of Gravity T ilt, Power Recline,

Extended Shear Reduction, Power Elevating Seats, Power Legrests, Auxiliary Vent and Power Systems.

These systems have been designed to easily install on most types of power bases.

Our Mission at Concepts

At Motion Concepts we recognize the importance of independence and function. We are a dynamic team

dedicated to service, manufacturing, and design excellence. We understand unique seating and positioning needs and continuously strive to enhance our clients’ quality of life.

Contact Us

Do you have a question, comment, or suggestion? Please send us an e-mail or write to us. Whether it

pertains to information contained in this Owners Manual or if it relates to the safety and reliability of your

TRx Power Positioning System, we want your feedback!

Visit our website at www.motionconcepts.com and stay in tune with what’s new at Motion Concepts.

info@motionconcepts.com

techsupport@motionconcepts.com

Attn: Customer Service

84 Citation Drive

Concord, Ontario

Canada, L4K 3C1

Attn: Customer Service

700 Ensminger Rd. Suite 112

Tonowanda, New York

USA, 14150

1.0 Introduction

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 5 -

22..00 IImmppoorrttaanntt IInnffoorrmmaattiioonn aabboouutt yyoouurr TTRRxx SSyysstteemm

Important: Do not ignore unanswered questions. You have the right to understand

the product and all aspects of its operation. If necessary, please contact Motion

Concepts for information regarding any questions or concerns expressed.

Motion Concepts Power Positioning Systems are designed to accommodate a wide range of user

needs. Only the dealer and the health care professional can ensure that the system meets your

individual requirements. It is the dealer’s responsibility to ensure that the wheelchair and the

power positioning system are set up properly and safely for your specific needs.

ST

ST

ABILITY

ABILITY

By changing your seating position (tilting, reclining, or elevating), you are changing the stability characteristics of the wheelchair. It is very important that the system is set up so that it is stable in all seating

positions. When evaluating stability, remember the following:

Most TRx systems can be mounted onto the powerbase in various forward and aft positions. Make certain that the position selected provides you with maximum stability over the full range of seating positions.

Consider all personal gear and accessories (backpacks, vent systems, extra batteries, etc..) that will be

carried on the wheelchair. For example, a loaded backpack, attached to the back of the seating system,

can significantly reduce the rearward stability of your wheelchair.

Consider the backrest being used. For example, a recessed back can shift your center of gravity back and

significantly reduce the rearward stability of the wheelchair . Conversely, a thick back cushion will shift you

forward and reduce the wheelchairs forward stability.

If using a back other than Motion Concepts, check with manufacturer to ensure it is suitable for power

positioning system applications.

Consider the seat cushion being used. Athick seat cushion will raise your center of gravity and reduce the

wheelchairs stability in all directions.

All TRx systems are equipped with drive lockouts. Make sure this is set so as not to compromise your stability while driving.

All power-bases have programmable controllers which allow adjustment of the maximum acceleration and

deceleration of the wheelchair. Make sure that these are set to an appropriate level for the system and for

you, the user.

Ensure all medical conditions are considered when setting up your wheelchair. Involunt ary muscle movement such as spasms may affect the stability of the wheelchair, especially when the seating system is in

a tilted or reclined position.

When a system is fully tilted or reclined, the front wheels of the powerbase should never come off the

ground. If this occurs, please contact the Motion Concepts Technical Service Department immediately to

resolve the issue.

i

The most important link in the delivery chain is you, the end user. You must be satisfied with the product

in terms of function, safety and aesthetics. No sale is complete until you have received thorough training

in all aspects of the care and use of the system.

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 6 -

WEIGHT CAP

WEIGHT CAPAA

CITIES

CITIES

22..00 IImmppoorrttaanntt IInnffoorrmmaattiioonn aabboouutt yyoouurr TTRRxx SSyysstteemm

Several factors must be considered when determining the Total User Weight and the Wheelchair Weight

Capacity. To obtain the weight capacity data from the base manufacturer, please refer to your Powerbase

Owners Manual. Please refer to the Weight Capacity Calculator outlined below in order to calculate the

total user weight and the wheelchair weight capacity.

WARNING! The total user weight should never

exceed the wheelchair weight capacity or the

power positioning system (PPS) weight capacity.

ii) Power Positioning System (PPS) Weight Capacity

The weight capacity of the power positioning system can be obtained from Motion Concepts by contacting

our Customer Service department. Insert the specified PPS Weight Capacity into the Weight Capacity

Calculator (p.7) in order to verify that the Total User Weight does not exceed the PPS Weight Capacity.

i) Power Positioning System (PPS) Weight

The weight of a specific power positioning system can be obtained from Motion Concepts by contacting

our Customer Service department*. Insert the PPS Weight into the Weight Capacity Calculator (p.7) to

verify that the Total User Weight does not exceed the calculated Wheelchair Weight Capacity.

*Note: If a suitable weight scale is available at the Dealer facility, the PPS Weight can be readily determined by simply weighing the TRx Seating System prior to installation.

BBAATTERIES

TTERIES

DO NOT use the CHARGE LEVEL INDICATOR on a JOYSTICK DISPLAY to determine the existing battery

charge. The joystick display indicates SURFACE VOLTAGE only, and may not be the true charge.

(This can

be likened to charging a cell phone; if placed on its charger for a brief time, a cell phone display will often indicate that

the batteries are fully charged, however the cell phone quickly goes dead once it is used).

Heavily depleted batteries require more time to recharge. Insufficient charge time may result in the supply of LOW

VOLTAGE BATTERY OUTPUT to the electronics of the power positioning system. Low voltage output can pro-

duce LONGER DUTY -CYCLES and OVERHEATING, which will REDUCE THE LIFE-CYCLE of these electronics.

Important Infor mation on Batter y Char ging:

WARNING! For detailed information on the charging, handling and care of your powerbase batter-

ies, please be certain to read and carefully follow the instructions provided by the powerbase manufacturer and the battery charger manufacturer.

i

RECOMMENDED CHARGING PROCEDURES:

Normal Char ging: Allow eight (8) HOURS for normal charging.

(Note: to prolong the life of a battery

frequent charging is recommended, rather than only charging when necessary).

Heavily Depleted Batteries: Severly discharged batteries may require in excess of sixteen (16)

HOURS to be properly charged and equalized.

(Note: be certain to understand the charge status indicators on

the battery charger- refer to the charger manual).

Note: Smaller ON-BOARD CHARGERS are NOT SUFFICIENT to recharge rehab-style power products.

Batteries that require more frequent charging or take longer to charge than normal, may need to be replaced.

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 7 -

22..00 IImmppoorrttaanntt IInnffoorrmmaattiioonn aabboouutt yyoouurr TTRRxx SSyysstteemm

Important: If you have any concerns or questions regarding weight capacities, or if the total

User Weight is determined to be greater than the Wheelchair and/or PPS Weight Capacity,

please contact our Technical Service Department immediately

i

HARD

HARDWW

ARE

ARE

Should you require any replacement hardware for your TRx seating system, please contact our Customer

Service Department for assistance.

iii) Weight Capacity Calculator

Calculating Wheelchair Weight Capacity:

Weight capacity of base manufacturer’s wheelchair

(see Powerbase Owners Manual) ________

Weight of the original wheelchair seat that is being replaced + ________

(if the original wheelchair seat is being re-installed, enter zero)

Weight of the TRx Power Positioning System

(refer to p.6, i. PPS Weight) - ________

Weight of auxiliary equipment (cushions, headrest, vent, vent battery, etc) - ________

Wheelchair Weight Capacity = ________

PPS Weight Capacity:

(refer to p.6, ii. PPS Weight Capacity) = ________

Calculating User Weight:

Weight of user (incl. clothing, footwear, jacket, etc) ________

Maximum Weight of personal gear (knapsack and contents, books, etc) + ________

Total User Weight = ________

AA

AA

BB

BB

CC

CC

must be less than and must be less than

AA

AA

BB

BB

CC

CC

CC

CC

***(

)***

WARNING!: All hardware used by Motion Concepts in the manufacture of our TRx Power Positioning

Systems, as well as the hardware supplied to complete the installation of our seating systems, is high

strength. Do not substitute hardware. Use only the hardware supplied with the seating system.

WHEELCHAIR

POWERBASEPPS

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 8 -

WARNING!: Currently there are no standards approved for tie-down systems in a moving

vehicle of any type to transport a person while seated in a power wheelchair. Do not sit in

your wheelchair while it is in a moving vehicle. Although your chair may be equipped with a

positioning belt, this belt is not designed to provide proper restraint during motor vehicle

transport. Anyone travelling in a motor vehicle should be properly secured in the motor vehicle seat with safety belts securely fastened.

3.0 Safety Precautions

Important!- Motion Concepts disclaims all responsibility for any personal injury or damage

to property that occurs as a result of improper or unsafe use of the TRx system or the wheelchair on which the system is installed.

WARNING!: The following guidelines should be adhered to while operating your TRx

power positioning system to ensure safe operation:

Never transfer in or out of your wheelchair with the power on.

Always check your surroundings before operating your TRx system. Make sure that the way is

clear of obstructions through the full ranges of travel of the system before operating any function. Do not operate the system while it is underneath a table, desk, or other obstruction.

Never operate your TRx system while driving your wheelchair.

Never operate your TRx system while on an incline.

Never drive your wheelchair with the drive lockout system disabled or set beyond the maximum

20 degrees.

Never allow your TRx system to be used as a tie-down point in a vehicle.

Never allow your wheelchair to be lifted by any part of the TRx System.

If you have a system with anti-tipper lockouts, be aware of when these lockouts engage. Make

sure to drive very carefully when driving your wheelchair with the anti-tipper lockouts engaged.

For more information refer to Section 8.0- Safety Lockout and Limit Switches in this manual.

When tilted or reclined back, prevent your arms from extending back beyond the backrest. This

could shift your center of gravity enough to cause the wheelchair to become unstable. (Read

and follow the warnings/specifications in your powerbase manual on the subject of leaning).

i

4.0 Motor Vehicle Transportation

!

!

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 9 -

5.0 Power Positioning Functions

Tilt

The tilt function causes the whole seat, including the back and armrests, to rotate back around a fixed pivot.

CG (Centre of Gravity) Tilt

The CG tilt function compensates for weight shift by sliding the pivot axis and entire seat assembly forward

as the seat tilts back.

Recline

The recline function causes the position of your back to change by changing the angle of the backrest with

respect to the seat pan.

Precline

The precline function is similar to the recline function, but depending on the system may allow up to 30° of

forward recline (creating a lean-forward position). The range of recline is decreased approximately by the

number of degrees of precline.

Anterior Tilt

The anterior tilt function causes the whole seat, including the back and armrests, to tilt forward around a

front pivot. The degree of anterior tilt available, up to a maximum tilt of 30°, will depend on the system.

This function aids in forward standing transfers.

Extended Shear Reduction (ESR)

ESR works in conjunction with recline to reduce the shear movement between you and the backrest. This

is accomplished using a linkage that slides the backrest down on the backposts as the back reclines.

Power Sliding Back (PSB)

The switch operated PSB allows the back height to be adjusted to improve positioning and shift body

weight. The PSB may also be synchronized to operate in conjunction with the recline function.

Power Elevating Seat (PES)

This functions allows you to elevate your entire seating system by up to 8 inches.

Power Elevating Le gr ests

There are 3 configurations for power legrests:

i) Combined:

the legrest actuators are programmed to elevate in unison keeping your right and left

legs at the same height.

ii) Synchronized:

the legrests actuators are programmed to elevate in conjunction with the power

recline function (Note: legrests can also be synchronized with power tilt if specified). The legrests

elevate automatically as the seating system reclines (or tilts).

iii) Independent:

the legrest actuators are programmed to elevate separately to allow you to position

your right and left legs at different heights, independent from each other and the back position.

Pushrod Leg rests (Mechanical)

The pushrod legrests are synchronized with the power recline and operate via a mechanical linkage. A

pushrod elevates the legrests automatically as the seating system reclines. No additional actuators are

required.

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 10 -

6.0 TRx Switches

Nor

Nor

mal Mode vs

mal Mode vs..AA

uto-R

uto-Reevverer

sing Mode

sing Mode

TRx Push Buttons and Toggles can be set up to operate in “Normal” or “Auto-Reversing” mode.

i) Normal Mode: two switches are required for each function, one for each direction.

ii) Auto-Reversing Mode: only one switch is required for each function. In this mode, pressing

the switch once will activate the function; releasing the switch, waiting for two seconds and then

pressing it again, will cause the reverse direction of this function to occur

.

Tables A. and B. below show a comparison of Normal Mode vs. Auto-Reversing Mode when using a tog-

gle and/or a push button to control the tilt function of a power positioning system.

Table A. - Using a single toggle to control the tilt function:

Normal Mode

Pulling the toggle back will cause the seat to tilt

back. Pushing the toggle forward will cause the

seat to tilt forward.

Auto-Reversing

Mode

Pushing the toggle forward will cause the seat to tilt

back. Releasing the toggle to its rest position, waiting for two seconds, and pushing it forward again,

will cause the seat to tilt forward.

(This set-up allows

the rearward

(pulled back) toggle direction to be used for

a separate power positioning function (e.g. Recline)

Table B. - Using a dual push button to control the tilt function:

Normal Mode

Pushing the first button will cause the seat to tilt

back. Pushing the second button will cause the

seat to tilt forward.

Auto-Reversing

Mode

Pushing the first button will cause the seat to tilt

back. Releasing the button (rest position), waiting

for two seconds, and pushing the same button

again, will cause the seat to tilt forward.

(This set-up

allows the second push button to be used for a separate

power positioning function (e.g. Recline)

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 11 -

Push Button Switches

The push button switches come in singles, and

sets of two and four. To activate the function

simply hold the button down. The motion will

stop when the button is released. Two buttons

are required for each function in “Normal” mode,

and one button is required for each function in

“Auto-Reversing” mode.

Single Toggle

This type of switch is capable of operating one

function in “Normal” mode and two functions in

“Auto-Reversing” mode.

Dual Toggle

This type of switch is capable of operating two

functions in “Normal” mode and four functions in

“Auto-Reversing” mode.

Four-Way Toggle

This type of switch is capable of operating two

functions in “Normal” and four functions in

“Auto-Reversing” mode.

Eight-Way Tog gle

This type of switch is capable of operating four

functions in “Normal” and eight functions in

“Auto-Reversing” mode.

Heavy Duty Tog gle

This type of switch is capable of operating one

function in “Normal” mode.

Single Button

S-21

Dual Button

S-22

Four Button

S-24

TRx Switc

TRx Switch h TT

ypes

ypes

M-37

M-38

M-26

S-37

6.0 TRx Switches

S-18

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 12 -

7.1 Using the Quickie Q-TRONIX Remote Joystick

The remote joystick connects to the Q-Tronix Controller, which in turn controls the performance of the

power base. By pressing down and releasing the on/off mode select toggle switch, the controller is

placed in the standard drive selection mode. To place the controller in the power positioning

mode, the on/off mode select toggle switch must be pulled up twice. The power positioning options

are selected by using the left and right directions on the joystick. The power positioning function that

is selected will be highlighted on the actuator lights (see chart). To operate the selected power positioning function, the forward and reverse directions on the joystick are used. To return to the standard

drive selection mode, the on/off mode select toggle switch must be pulled up once again.

Note: Please refer to the Quickie Owners Manual for complete joystick set-up and operating instructions.

JOYSTICK

ON/OFF MODE SELECT

TOGGLE SWITCH

*Push forward on joystick to tilt and pull back on the joystick to recline

(i.e. operates in “auto-reversing mode”)

L2

L1

L3

L4

7.0 Using the Power Base Joysticks

ACTUATOR LIGHTS

Function Actuator Light

L1 L2 L3 L4

*Tilt/Recline + +

Right Legrest +

Left Legrest +

Both Legrests + +

Elevating Seat +

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 13 -

7.2 Using the (Pride) PG Remote Plus Joystick

The Remote Plus system operates via a joystick that is connected to a controller box on the power

base. The controller contains the primary electronics that operate the power base. By pressing once

on the on/off key, the controller is placed in the standard drive selection mode. To place the controller in power positioning mode, the mode key must be pressed down twice. The power positioning mode can now be selected by using the left and right directions on the joystick. The power positioning function that is selected will be highlighted on the LED Display (see chart). To operate the

selected power positioning function, the forward and reverse directions on the joystick are used. To

return to standard drive selection mode, the mode selection key must be pressed once more.

Note: Please refer to the Pride Owners Manual for complete joystick set-up and operating instructions.

L2

L4

L1

L3

MODE KEY

JOYSTICK

LED

ON/OFF KEY

Function LED

L1 L2 L3 L4

*Tilt/Recline + +

Right Legrest +

Left Legrest +

Both Legrests + +

Elevating Seat +

7.0 Using the Power Base Joysticks

*Push forward on joystick to tilt and pull back on the joystick to recline

(i.e. operates in “auto-reversing mode”)

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 14 -

7.3 Using the Invacare MKIV A Joystick

By pulling up and releasing the toggle switch, the controller will be placed in the standard drive

selection mode. The mode indicator light will remain on in drive selection mode. To place the con-

troller in the power positioning mode (ECU/Recline), the controller must sit inactive until the mode

indicator light begins to flash, then the joystick must be tapped to the left. (For complete instructions

on the set-up and operation of the power positioning system through the joystick, please refer to the

Invacare Owners Manual). The power positioning functions may be assigned to one or more drive

modes depending on the system set-up. To select the required drive mode, the toggle switch must be

pulled up again and released. This operation will be repeated until the required drive mode light

appears. To operate the power positioning functions*, the joystick can be moved in the forward,

reverse, left and right directions. The mode indicator light will remain OFF while in the power positioning mode. To return the controller to standard drive selection mode, the controller must remain

inactive until the mode indicator light begins to flash, then the joystick may be moved once in any

direction.

*Note: The power positioning functions may be assigned to the joystick depending on the type of seat-

ing system and the users preferred set-up (eg. forward= tilt, reverse= recline, etc...) An Invacare

Programmer is required in order to program/assign the specific motor functions to the MKIV-A

Joystick. Please refer to the Invacare Manual for complete programming instructions.

TOGGLE SWITCH

MODE INDICATOR LIGHT

JOYSTICK

LEVEL INDICTOR LIGHT

DRIVE POSITION MODE LIGHTS

7.0 Using the Power Base Joysticks

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 15 -

7.4 Using the Invacare MKV- DPJ Joystick

The MK5-DPJ joystick has two programmable drive selection modes: Drive 1 and Drive 2. To select

Drive 1 mode, the toggle switch must be placed in the UP position. To select Drive 2 mode, the tog-

gle switch is placed in the MIDDLE position. The mode switch LED indicator light will be OFF when

the wheelchair is placed in either drive mode. To put the controller in the power positioning mode*

(ECU/Recline), the mode switch must be pressed. The LED indicator light will be turned ON while

in the power positioning mode. To operate the power positioning functions, the joystick can be moved

in the forward, reverse, left and right directions. (Note: power positioning functions may be assigned

to the joystick directions depending on the seating system). To return to the drive selection mode, the

mode switch must be pressed again until the LED indicator light is OFF.

*Please Note: The DPJ Joystick is a basic model joystick and has limited programming capabilities

for power positioning. Please refer to the Invacare Manual for complete programming instructions.

7.0 Using the Power Base Joysticks

JOYSTICK

TOGGLE SWITCH

MODE SWITCH

BATTERY GAUGE DISPLAY

Drive 1, Drive 2. Off Switch

LED INDICATOR LIGHT

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 16 -

7.5 Using the Invacare MKV- MPJ Joystick

The MK5-MPJ joystick has four independent programmable drive selection modes: Drive 1, Drive

2, Drive 3, & Drive 4. The individual Drive modes can be selected by lifting and releasing the toggle

switch. The selected Drive mode appears in the LCD display on the joystick. Each time the toggle

switch is lifted and released it will cycle through to the next Drive mode. (i.e.; To select Drive 1 mode,

the toggle switch is lifted up once and released. To select Drive 2, the toggle switch is lifted again and

released, to select Drive 3... etc...) The controller will return back to Drive 1 after Drive 4. To operate

the power positioning system (ECU/Recline) through the joystick, a separate emergency stop

(reset) switch is typically installed. To access ECU1, tap the joystick to the left 2 times (left/left); if

ECU2 is required tap the joystick to the left 2 times and hold (left/left hold). (For complete instructions

on the set-up and operation of the power poistioning system through the joystick, please refer to the

Invacare Owners Manual). To operate the power positioning functions, the joystick can be moved in

the forward, reverse, left and right directions. The functions may be programmed* into the joystick

depending on the type of seating system and the users preferred set-up (eg. forward= tilt, reverse=

recline, etc...) The emergency reset switch must be opened in order to return to the drive selection

mode.

*Please Note: An Invacare Programmer is required in order to program/assign the specific motor

functions to the joystick. Please refer to the Invacare Manual for complete programming instructions.

7.0 Using the Power Base Joysticks

JOYSTICK

TOGGLE SWITCH

LCD Display

REMOTE On/Off PORT

Drive Select/ ON/ OFF Switch

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 17 -

Drive Lockout (DLO) Limit Switch

All TRx systems with tilt and/or recline functions are equipped with a drive lockout limit switch. This switch

prevents the drive motors from operating if the back is positioned beyond a pre-determined angle. The rec-

ommended drive lockout angle is 15° to 20° from the vertical. The limit switch should be set to the

angle that best meets the overall stability and individual needs of the user, but should not exceed the maximum 20° angle.

All TRx systems with power elevating seats are also equipped with a drive lockout limit switch. These systems typically use a microswitch to prevent the drive motors from operating once the seat begins to elevate. The microswitch should engage the Drive Lockout when the seat actuator has been elevated beyond

a recommended 1/2” limit [measured from the seat’s home (lowest) position].

Tilt Limit Switch

All TRx systems, except those using our basic single motor function relay box, can be equipped with a tilt

limit switch. The function of this switch is to prevent the back angle from extending beyond a pre-set angle.

Ultimately the angle should be set to meet the individual needs of the user. However, the recline angle

should never extend beyond a recommended 5° from the horizontal. The limit must also be checked

to ensure that with any combination of tilt and recline, there is absolutely no possibility of interference

between the back of the TRx system (or any accessories located on the back), and the wheelchair base.

CAUTION! When setting tilt limits remember to consider the size and location of any personal gear that

will be carried on the wheelchair, as it could cause interference with tilt or recline motor functions.

Elevating Seat Lockout Switch

All TRx power elevating seat systems, when combined with tilt and/or recline functions, are equipped with

an elevating seat lockout switch. This limit switch prevents the PES actuator from elevating or descending

when the system is in a tilted or reclined position. The recommended lockout limit should not exceed a

maximum of 8° from the seating system’s original pre-tilt (“home”) position, and it is recommended to be

set between 3° and 8°.

Anti-Tipper Latch Limit Switch

Certain powerbases come equipped with anti-tip devices that latch in order to ensure stability during tilt,

recline or elevating functions. For these powerbases, our TRx systems are engineered to control and

engage the anti-tipper latch through the use of a limit switch. The recommended limit switch settings are

determined by the type of power positioning system:

i) Tilt-Only: set switch to engage the anti-tippers when seat angle is at 10° (regardless of pre-tilt angle).

ii) Tilt/Recline & Recline-Only: set switch to engage the anti-tippers when the back reclines 10° (from upright)

iii) Power Elevating Seats (PES): set switch to engage the anti-tippers when seat actuator has elevated

beyond a recommended 1/2” limit.

In some instances, an anti-tipper latching system is added to the power base as part of the installation in

order to ensure the stability of the power positioning system is maintained.

8.0 Safety Lockout and Limit Switches

WARNING! The angle at which the limit switches are set is critical to the safe operation of

the power positioning system. Motion Concepts will not be liable for any injuries or damage

sustained when adjustments are made beyond the factory recommended range. These switches should only be adjusted and set by a trained Technician.

!

Important: Please refer to the Motion Concepts General TRx Set-up Manual for detailed

instructions on setting and adjusting Limit Switches

i

!

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 18 -

MAINTEN

MAINTEN

ANCE SCHEDULE

ANCE SCHEDULE

To ensure the optimal safety and reliability of your power positioning system, please adhere to the maintenance schedule/table below. In addition to the maintenance schedule, please note the following maintenance tasks that should be incorporated into your daily routine.

Daily

Check that the buttons or toggles that operate your TRx system function freely

Charge batteries (refer to the information provided in this chapter and to your powerbase Owners

Manual for details on battery charging & battery care)

To ensure your power positioning system is operating properly and safely, Motion Concepts recommends a complete Dealer inspection be performed on your power positioning system every 6 months.

*Please refer to the Powerbase Owners Manual for maintenance information specific to your powerbase*

9.0 General Maintenance & Safety

Item Ini tially Monthly 6 M ont hs Peri odically

load test batteries (individually) -see Battery Testing p.20 XX

ensure batteries are clean (free from corrosion/ moisture/

dirt)

XX

ensure connections are ti ght and clean XX

check for pinches or pulls in wiring (over full range of

seating system)

XX

inspect for w ear & tear damage to w ires XX

ensure connections are secure XX

ensure actuator rod ends are secure and pinned properly XX

ensure no inter ference/ sticking during system operati on

(over full range of seating system)

XX

inspect for excessive noise or grinding XX

ensure that the anti-tipper latch system functions properly

(if applicable)

XX

mounting hardw are (seating system to powerbase) XX

ensure all nuts and bolts are secure XX

inspect that all pivot points are operating smoothly & freely

and secured (do not overtighten)

XX

check all lim it sw itch settings XX

ensure DLO functions correctly XX

ensure channel is free from dirt/ dust/ grime XX

as needed, lightly lubricate slide channel using a nonlithium/ non-aerosol cleaner (eg. AGS- Si l Glyde Brake

Lubricant)

X

Limit Switches

Glide Blocks and Track M aintenance

Actuators (where applicable)

Tightening & Adjustment (hardware)

Batteries

El ectrical / Wiri n g Harnesses

SAFETY INSPECTION CHECKLIST

SAFETY INSPECTION CHECKLIST

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 19 -

9.0 General Maintenance & Safety

LLUBRICA

UBRICA

TION

TION

Important: To maintain the smooth operation of your TRx Power Positioning System, occassional

lubrication of the slide channels and/or the Power Elevating Seat (PES) actuator* is necessary. All Motion

Concepts Seating Systems are pre-lubricated at the factory using Sil-Glyde

®

Brake Lubricant . Testing has

proven this lubricant to be extremely effective in our system applications. Motion Concepts strongly discourages the use of any other grease or lubricants. Apacket of Sil-Glyde

®

Brake Lubricant (P/N- TRM0464)

is provided with each TRx Seating System (additional lubricant is available from Motion Concepts).

Slide Channel

i) Slide Channel Lubrication

Lubricate the left & right slide channels as needed

by applying a thin coat of Sil-Glyde®to the upper

and lower surface of each slide channel.

ii) PES Actuator Lubrication

Riser

Tube

Lubricate the power elevating seat

(PES) actuator as needed by

applying a thin coat of Sil-Glyde®to

the surface of the riser tube.

*Note- applies to part numbers:

TRC0198;TRC0199;TRC0200

Low-Pro CG Sub-System

BBAATTER

TTER

Y CHAR

Y CHAR

GING

GING

i

WARNING! For det ailed information on charging your powerbase batteries, please be certain to read and

carefully follow the instructions provided by the powerbase manufacturer and the battery charger manufacturer.

DO NOT use the CHARGE LEVEL INDICATOR on a JOYSTICK DISPLAY to determine the existing battery

charge. The joystick display indicates SURFACE VOLTAGE only, and may not be the true charge.

(This can

be likened to charging a cell phone; if placed on its charger for a brief time, a cell phone display will often indicate that

the batteries are fully charged, however the cell phone quickly goes dead once it is used).

Heavily depleted batteries require more time to recharge. Insufficient charge time may result in the supply of LOW

VOLTAGE BATTERY OUTPUT to the electronics of the power positioning system. Low voltage output can pro-

duce LONGER DUTY -CYCLES and OVERHEATING, which will REDUCE THE LIFE-CYCLE of these electronics.

Important Infor mation on Batter y Char ging:

NORMAL CHARGING:

Allow 8 hours for normal charging.

(Note: to prolong the life of a battery frequent charging is recommended,

rather than only charging when necessary).

HEAVILY DEPLETED BATTERIES:

Severly discharged batteries may require in excess of 16 hours to be properly charged and equalized.

(Note: be certain to understand the charge status indicators on the battery charger- refer to the charger manual).

Recommended Charging Procedures:

Note: Smaller ON-BOARD CHARGERS are NOT SUFFICIENT to recharge rehab-style power products.

Batteries that require more frequent charging or take longer to charge than normal, may need to be replaced.

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 20 -

9.0 General Maintenance & Safety

i) Battery Case Dr aw Test

1. Inspect battery for signs of corrosion, moisture and/or dirt that could

lead to unnecessary discharge of the battery.

2. Test with Voltmeter by placing one lead on the Positive (+) battery

terminal

3. Drag the other lead across the battery case (in different locations).

4. Voltmeter should read 0 (zero)

if the battery is not discharging

ii) No Load Voltage Testing

Test to determine the state of charge of the battery. Refer to the illustration below for testing instructions.

WARNING! Never attempt a voltage measurement with a test lead in the AMP (A) or MILLIAMP

(mA) input terminal. You may be injured or cause damage to the voltmeter.

MOTOR

CONTROLLER

Place lead on positive terminal

Drag second lead across

battery case

BBAATTER

TTERY Y

TESTING

TESTING

!

BLACK

RED

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 21 -

10.0 Troubleshooting Guide

TR

TR

OUBLESHOO

OUBLESHOO

TING GUIDE

TING GUIDE

Symptom Probable

Cause

Solutions

System tilted/ elev ated beyond the

Drive Lockout (DLO) angle

R eturn seating syst em t o neutral (home)

position.

Drive Motors not engaged

Engage Drive Motors

Lo w b at t eries C h eck/ Charge/ Replace Bat t eries

Lo ose/ Faulty electri cal conn ect ion

C h eck cable con nections/ Check cable

ties (too tight/ too loose)

B l own fuse Inspect/ R eplace fuse.

Lo ose/ Faulty electri cal conn ect ion

C h eck cable con nections/ Check cable

ties (too tight/ too loose)

Faulty Power H arness C h eck/ Replace Power Harness

Faulty Mercury Switch Ch eck/ Replace mercury swi t ch

Spongy Battery (fluctuating charge) Check/ Replace Battery

Relay box not programmed correctly

C h eck t he relay box con f iguration g uide

and verify dip switch/ jumper settings.

Mercury Switch is not set-up properly Adjust Mercury Switch.

Faulty Mercury Switch Ch eck/ Replace mercury swi t ch

Mercury Switch is not set-up properly Adjust Mercury Switch.

Incorrect switch settings in relay box

C h eck dip swit ch/ ju mper settin gs in rel ay

box (refer to the Configuration Guide)

In correct wirin g conn ect ions Check connections.

Lo ose/ faulty el ect rical con nection C h eck c onnections.

Faulty limit switch Check/ Replace limi t swi t ch

Limit switch is not set-up properly Adjust Limit Switch

Faulty limit switch Check/ Replace limi t swi t ch

Limit switch is not set-up properly Adjust Limit Switch.

Lo w Voltage/ Battery not charged

Test system po wer cab le usin g Volt met er/

C h arge batteri es ( Lazarus)

Joystick not plugged in Inspect cable connection

Joystick not turn ed on

Tu rn on p ower t o the Joystick via the

keypad

B l own base fuse In spect/ R eplace fuse

Pinched switch harness

A d just harness/ cabl e position to prevent

pinching

Stu ck swi t ch Inspect/ Repair / R eplace switch

Piv o t p o i n t(s) sticking

1st- oil pivot(s)

2nd- lightly grease pivot ( s) (AGS-Sil Glyde)

Sl i de chann el sticking l ightly grease channel s ( eg. AG S - S il Glyde)

Wheelchair po wer i s ON, bu t

system does not Drive

Seati ng System i s not

functioning

In t ermittent S eat ing Syst em

functions (day t o day , during tilt,

during recline… )

Drive Lockout (DLO) is not

functioning

System 'squ eaks' d uring

actuator functions

Joystick will not function

Ti lt/Recline actuat or keeps

running

DLO red indicator light does not

light up

DLO red indicator light is ON,

but no lockout

Limit switch not functioning

properly

System o nly op erat es in on e

direction

*Note: For further assistance on these or any other issues, contact our Technical Service Department at 888-433-6818.

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 22 -

11.0 Electro-MMagnetic Interference

Electromagnetic Interference (EMI) From Radio Wave Sources

Power positioning systems may be susceptible to electromagnetic interference (EMI), which is interfering

electromagnetic energy (EM) emitted from sources such as radio stations, TV stations, amateur radio

(HAM) transmitters, two way radios and cellular phones. The interference (from radio wave sources) can

cause the power positioning system to function by itself, or activate in unintended directions. It can also

permanently damage the control system.

The intensity of the interfering EM energy can be measured in volts per meter (V/m). Each power positioning system can resist EMI up to a certain intensity. This is called its "immunity level", the higher the

immunity level, the greater the protection. At this time, current technology is capable of achieving at least

a 20 V/m immunity level, which would provide useful protection from the more common sources of radiated EMI.

There are a number of sources of relatively intense electromagnetic fields in the everyday environment. Some

of these sources are obvious and easy to avoid. Others are not apparent and exposure is unavoidable.

The sources of radiated EMI can be broadly classified into three types:

1. Hand-held portable transceivers (transmitters-receivers with the antenna mounted directly on the trans-

mitting unit) - examples include: cellular telephones, citizen band (CB) radios,"walkie-talkies", security, fire

and police transceivers and other personal communication devices. NOTE: Some cellular telephones and

similar devices transmit signals while they are "ON", even when they are not being used.

2. Medium range mobile transceivers, such as those used in police cars, fire trucks, ambulances, and taxis.

These usually have the antennae mounted on the outside of the vehicle.

3. Long range transmitters and transceivers, such as commercial broadcast transmitters (radio and TV

broadcast antenna towers) and amateur (HAM) radios.

Note: Other types of hand held devices, such as cordless phones, laptop computers, AM/FM radios, TV

sets, CD players, cassette players, and small appliances such as electric shavers and hair dryers, so far

as we know, are not likely to cause EMI problems to your power wheelchair.

Electromagnetic Interference War ning

WARNING! It is very important that you read this information regarding the possible

effects of electromagnetic interference on your TRx power positioning system.

In addition, operation of power positioning systems can create electro-magnetic interference, the effect of which cannot be determined. Please make sure to read the associated

warnings in the owner's manual for your power base.

!

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 23 -

Electromagnetic Interference War ning ............................................. continued

Because EM energy rapidly becomes more intense as one moves closer to the transmitting antenna

(source) , the EM fields from hand-held radio wave sources (transceivers) are of special concern. It is possible to unintentionally bring high levels of EM energy very close to the control system while using these

devices.

WARNING!: The warnings listed below are recommended to prevent possible interference

with the control system of the power positioning system.

Do not turn on personal communications devices, such as cellular phones, or operate hand-

held transceivers (transmitters, receivers), such as citizens band (CB) radios, while the powered wheelchair is turned on.

Be aware of nearby transmitters, such as radio or TV stations, and try to avoid coming close

to them

If unintended movement occurs, turn the wheelchair off as soon as it is safe to do so.

Be aware that adding accessories or components, or modifying the power positioning sys-

tem may make it more susceptible to EMI. Note: There is no easy way to evaluate their effect

on the overall immunity of the powered wheelchair.

Report all incidents of unintended movement of the power positioning system to the manu-

facturer, and note whether there is a source of EMI nearby.

CAUTION! Modification of any kind to the electronics of the power positioning system as

manufactured by Motion Concepts may adversely affect the radio frequency interference

immunity (RFI) levels.

!

!

11.0 Electro-MMagnetic Interference

TRD0000, TRx Owner’s Manual- Rev. 5.0, January 20, 2005

- 24 -

Disclaimer

Motion concepts makes no claims as to the therapeutic effectiveness of the products. Our only claims

relate to the ability of the products to provide safe and reliable powered repositioning on the equipment onto

which they are installed.

Limited Warranty

All structural components manufactured by Motion Concepts are warranted to be free from defects in materials and workmanship for the lifetime of the original owner. Actuators and electronic components are warranted to be free from defects in material and workmanship for a period of two years. If during the warranty period, any component is determined, at the sole discretion of Motion Concepts, to be defective, such

component will be repaired or replaced at the option of Motion Concepts.

The sole obligation of Motion Concepts under this warranty shall be to repair or replace any component or

components which are found to be defective. For warranty service, contact the dealer from which the system was purchased. The purchaser of the product is responsible for returning the product to the dealer.

Any defective component, once replaced under warranty, shall become the property of Motion Concepts.

If further service is required, contact Motion Concepts USAat 1-888-433-6818 or Motion Concepts Canada

at 905-695-0134.

Limitations and Exclusions

The foregoing warranty shall apply only to the original purchase and shall not apply to product subjected

to neglect, abuse, improper operation, accidental damage or improper storage. The warranty shall not

apply to products which have been modified or fitted with improper parts or components without the written

consent of Motion Concepts. The warranty shall also not apply to a product which has been damaged as

a result of unauthorized repairs and/or by circumstances not under the control of Motion Concepts.

The foregoing is exclusive and in lieu of all other warranties, expressed or implied, including, without limitation, implied warranties of merchantability and fitness for a particular purpose. The warranty shall not be

extended beyond the duration of the expressed warranty provided herein. Motion Concepts shall not be

liable for any consequential or incidental damages whatsoever.

Some jurisdictions do not allow the exclusions or limitation of incidental or consequential damages, or limitation on the length of an implied warranty. Local laws should be reviewed to determine if the above exclusions and limitations apply.

12.0 Disclaimer and Warranty Information

DISCLAIMER &

DISCLAIMER & WW

ARRANTY INFORMA

ARRANTY INFORMA

TION

TION

Loading...

Loading...