Page 1

9000 XDT TALL FORK/STEM CONVERSION KIT

Assembly, Installation and Operating Instructions

Kit Nos. 1070843 and 1075042

NOTE: This instruction sheet pertains to the following Kits:

1070843 (chrome), for wheelchairs built before 10/97, and

Kit No. 1075042 (chrome), for wheelchairs built after 10/97.

NOTE: Check all parts for shipping damage. If damage is

found, DO NOT use. Contact Carrier/Invacare for further

instructions.

SAFETY SUMMARY

The following recommendations are made for the

safe and proper installation and use of the 9000

XDT T all Fork/Stem Conversion Kit:

GENERAL WARNING

DO NOT assemble or use this equipment

without first reading and understanding this instruction sheet. If you are unable to understand the Warnings, Cautions or Instructions, contact a healthcare

professional, dealer or technical personnel if applicable before attempting to install this equipment otherwise, injury or damage may occur.

INSTALLATION WARNING

After ANY adjustments, repair or service and BEFORE use, make sure that all attaching hardware is

tightened securely.

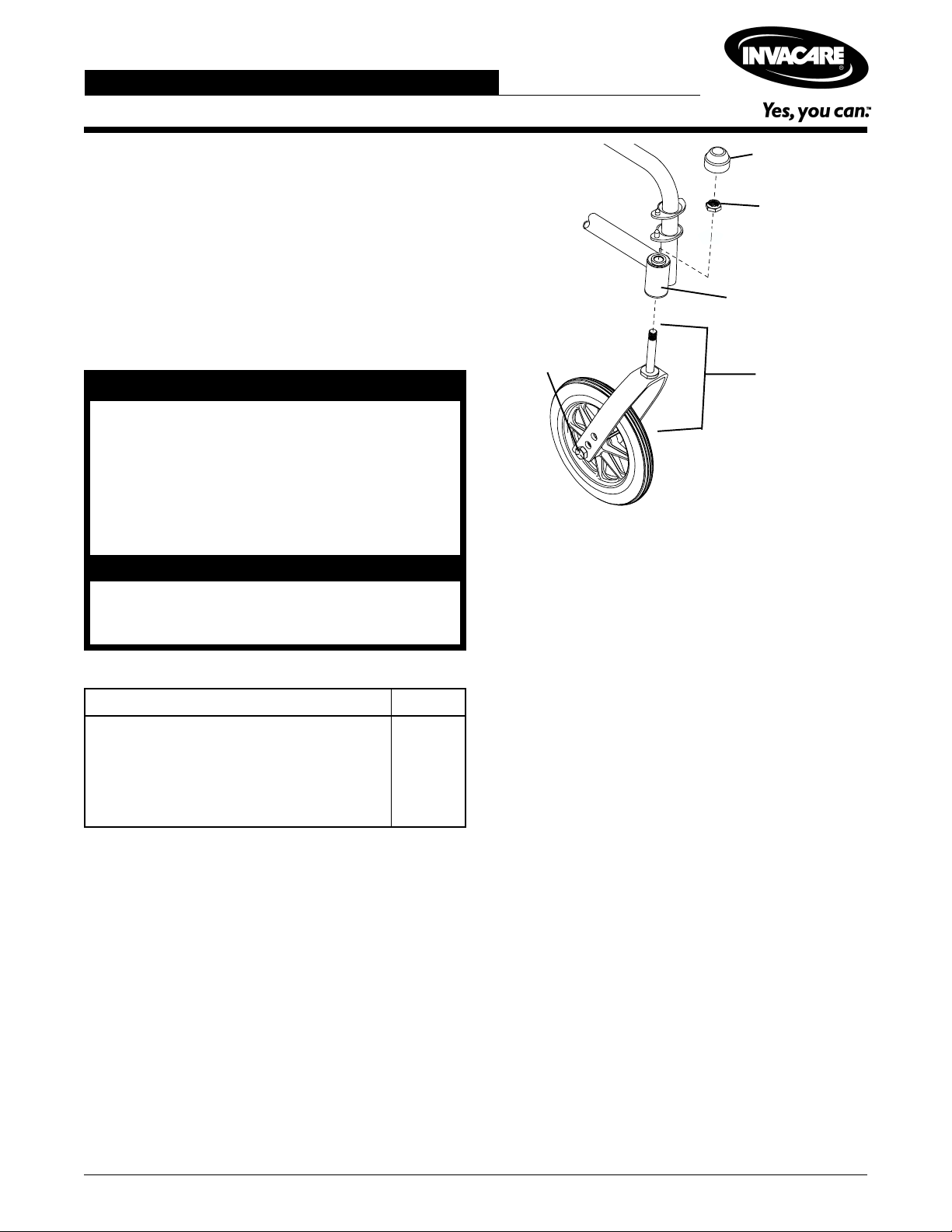

Dust Cover

Locknut

Caster Headtube

Hex Screw,

Washers and

Locknut

Front Caster

and Fork

FIGURE 1 - DISASSEMBLING THE EXISTING

FORK/STEM ASSEMBLY

DISASSEMBLING THE EXISTING

CASTER HEADTUBE ASSEMBLY

(FIGURE 2)

All Kits Include the Following:

Description Quantity

Flanged Bearing 2

Dust Cover 2

Locknut 2

Fork Assembly 2

Bottom Sleeve With Bearing 2

DISASSEMBLING THE EXISTING

FORK/STEM ASSEMBLY (FIGURE 1)

1. Remove and discard the dust cover.

2. Remove and discard the locknut that secures the fork

to the caster headtube.

3. Drop the front caster and fork out of the caster

headtube.

4. Remove the hex screw, washers and locknut that secures the front caster to the fork. Discard the fork.

NOTE: Front casters will be assembled to NEW fork.

5. Disassemble the existing caster headtube assembly.

Refer to DISASSEMBLING THE EXISTING CASTER

HEADTUBE ASSEMBL Y in this instruction sheet.

NOTE: There are two (2) different bottom bearing assemblies. Refer to FIGURE 2 to determine the proper bearing.

1. Place a punch through the opening in the

BOTTOM flanged bearing or assembly housing of

the caster headtube and position it against the side of

the TOP flanged bearing.

2. Using a rubber mallet, gently tap the punch while moving it from side-to-side until the TOP flanged bearing

is free from the caster headtube. Discard the TOP

flanged bearing.

3. Place a punch through the opening in the caster head

tube and and position it against the side of the BOTTOM flanged bearing or assembly housing.

4. Using a rubber mallet, gently tap the punch while moving t from side-to-side until the BOTTOM flanged bearing or assembly housing is free from the caster

headtube.

5. Repeat STEPS 1 through 4 for the opposite caster

headtube bearings.

6. Assemble the tall fork/stem assembly. Refer to AS-

SEMBLING THE T ALL FORK/STEM ASSEMBLY

in this instruction sheet.

1

Page 2

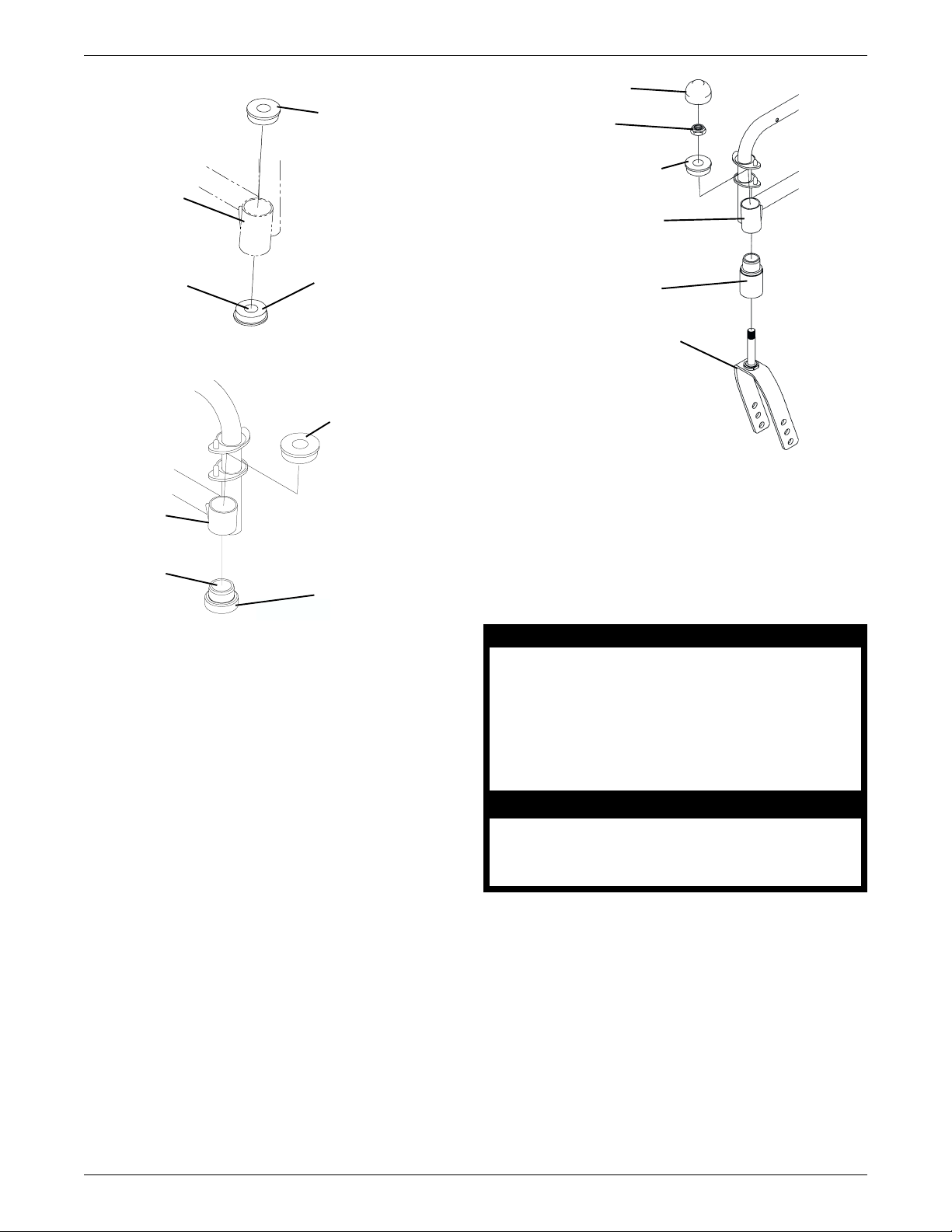

WHEELCHAIRS BUILT BEFORE 10/97

NEW Dust Cover

TOP Flanged

Bearing

Caster

Headtube

Opening

BOTTOM Flanged

WHEELCHAIRS BUILT AFTER 10/97

TOP Flanged

Bearing

Caster

Headtube

Opening

Assembly Housing

NEW Locknut

NEW Flanged Bearing

Caster Headtube

NEW Sleeve

Bottom With Bearing

Bearing

NEW Tall Fork/Stem Assembly

FIGURE 3 - REASSEMBLING THE TALL FORK/

STEM ASSEMBLY

REINSTALLING FRONT CASTERS

(FIGURE 4)

NOTE: Refer to the INSTALLATION WARNING in the

SAFETY SUMMARY section of this instruction sheet.

FIGURE 2 - DISASSEMBLING THE EXISTING

CASTER HEADTUBE ASSEMBLY

ASSEMBLING THE TALL FORK/

STEM ASSEMBLY (FIGURE 3)

NOTE: Refer to the INSTALLATION WARNING in the

SAFETY SUMMARY section of this instruction sheet.

1. Using a rubber mallet, gently tap the NEW flanged

bearing into the TOP of the caster headtube.

2. Using a rubber mallet, gently tap the NEW sleeve bottom with bearing into the BOTTOM of caster headtube.

3. Insert the NEW tall fork/stem assembly through the

bearings in the caster headtube.

4. Secure with the NEW locknut.

5. Repeat STEPS 1-4 for the opposite fork/stem

assembly.

NOTE: DO NOT install the NEW dust covers at this time,

as adjustments to the locknuts may be required later.

6. Install the casters onto the NEW tall fork/stem assemblies. Refer to REINST ALLING FRONT CASTERS

in this instruction sheet.

WARNINGS

Replacement of front caster tire or tube MUST be

performed by an authorized Invacare dealer or

qualified technician.

Make sure both front casters are positioned in the

same mounting hole BEFORE using the wheelchair

- otherwise, injury or damage may occur.

CAUTION

As with any vehicle, the wheels and tires should be

checked periodically for cracks and wear, and

should be replaced.

1. Position the front caster on the fork to the determined

mounting hole. Refer to CHANGING SEAT-TO-FLOOR

HEIGHT in 9000 Series Service Manual Part No.

1076155 to determine the proper front caster mounting

holes for caster size and seat-to-floor height.

2. Install the existing washers, hex screw and locknut.

Tighten securely.

3. Repeat STEPS 1-2 for the opposite front caster.

4. Reposition the rear wheels. Refer to REPOSITION-

ING THE REAR WHEELS in this instruction sheet.

2

Page 3

Fork

Locknut

C. Let the casters drop to the bottom of the arc

(the wheels should swing once to one-side, then

immediately rest in a straight downward position).

Hex Screw

Washer

Washer

Front Caster

FIGURE 4 - REINSTALLING FRONT CASTERS

REPOSITIONING THE REAR

WHEELS (FIGURE 5)

NOTE: When the 9000 XDT Tall Fork/Stem is installed

and a Tall Seat-to-Floor is desired, the rear wheel MUST

be repositioned in the BOTTOM Mounting Hole to avoid

excessive rear seat dump.

BOTTOM Mounting Hole

D. Adjust the locknuts according to the freedom of

the caster swing.

2. Test the wheelchair for maneuverability.

3. Readjust the locknuts if necessary, and repeat STEPS

1-2 until correct.

4. Snap the dust covers over the locknut and stem.

5. Install the wheel lock shoe extensions if necessary.

Refer to INSTALLING WHEEL LOCK SHOE EX-

TENSIONS in this instruction sheet.

INSTALLING WHEEL LOCK SHOE

EXTENSIONS (FIGURE 6)

NOTE: Refer to the INSTALLATION WARNING in the

SAFETY SUMMARY section of this instruction sheet.

NOTE: The wheel lock shoe extensions are to ensure that

the wheel lock engages properly and holds the wheelchair

in place. They are needed for chairs with U2222 rear wheels

in the tall configurartion. If this chair already has wheel

lock shoe extensions installed, do NOT replace. Refer to

Parts Book Form No. 95-137 for proper wheel lock shoe

extensions part numbers.

1. Place the wheel lock in the unlocked position.

FIGURE 5 - REPOSITIONING THE REAR WHEELS

1. Reposition rear wheels if necessary. Refer to REAR

WHEEL in 9000 Series Owner's Manual Part No.

1056953 and CHANGING SEAT-TO-FLOOR

HEIGHT in 9000 Series Service Manual Part No.

1076155.

2. After the rear wheel has been repositioned, perform

WHEELCHAIR MANEUVERABILITY. Refer to

WHEELCHAIR MANEUVERABILITY in this instruc-

tion sheet.

WHEELCHAIR MANEUVERABILITY

1. Properly tighten the caster journal system and guard

against flutter by performing the following check:

A. Tip the back of the wheelchair to the floor.

2. Loosen the two (2) set screws in the wheel lock shoe

extension.

3. Position the wheel lock shoe extension over the existing wheel lock shoe.

NOTE: Ensure the wedge end of the wheel lock shoe

extension is facing the rear wheel.

4. Securely tighten set screws.

5. Repeat STEPS 1-4 for the opposite wheel lock.

6. Adjust the wheel locks. Refer to ADJUSTING THE

PATIENT OPERA TED WHEEL LOCKS in this instruction sheet.

Wheel

Lock

Wheel

Lock Shoe

Set Screws

Wheel Lock

Shoe Extension

Wedge

End

B. Pivot both the forks and casters to the top of their

arc simultaneously.

FIGURE 6 - INSTALLING WHEEL LOCK SHOE SPACERS

3

Page 4

ADJUSTING THE PATIENT

OPERATED WHEEL LOCK (FIGURE 7)

NOTE: Refer to the INSTALLATION WARNING in the

SAFETY SUMMARY section of this instruction sheet.

NOTE: If wheels are pneumatic, before adjusting or replacing the wheel lock assemblies, ensure that the tires

are inflated to the recommended p.s.i. The recommended

tire pressure is located on the side wall of the tire.

1. Loosen the bolt and locknut that secure the wheel

lock assembly to the wheelchair frame.

Mounting

Positions

Bolt and Locknut

Wheel Lock

Handle

Wheelchair

Frame

Wheel

Lock

Shoe/

Shoe

Extension

2. Adjust the position of wheel lock until the measurement between the rear wheel and the wheel lock shoe

or shoe extension is between 5/32 and 5/16-inches.

NOTE: If a measurement between 5/32 and 5/16-inches

cannot be achieved, remove the bolt and locknut that

secure the wheel lock to the wheelchair and mount the

wheel lock in one (1) of two (2) mounting positions.

3. Securely tighten the bolt and locknut.

4. Engage the wheel lock and push it against the wheelchair to determine if the wheel lock engages the wheel

lock shoe enough to hold the wheelchair.

5. Repeat STEPS 1-4 until the wheel lock holds the

wheelchair.

6. Repeat STEPS 1-5 for the opposite wheel lock.

Wheel

Lock

5/32 and

5/16-inches

Rear

Wheel

FIGURE 7 - ADJUSTING THE PATIENT

OPERATED WHEEL LOCK

Invacare Corporation www.invacare.com

USA Canada

One Invacare Way 5970 Chedworth Way Invacare and "Yes, you can" are trademarks of Invacare

Elyria, Ohio USA Mississauga, Ontario Corporation.

44036-2125 L5R 3T9, Canada © 2000 Invacare Corporation

800-333-6900 905-890-8838 Form No. 97-196 Part No. 1075041 Rev A (1) 4/00

Loading...

Loading...