International comfort products PGF3 Series Installation Instructions Manual

Printed in U.S.A.

462 01 1101 01 07−29−09

PACKAGED GAS / ELECTRIC UNITS

Installation Instructions

PGF3 Series

Code: PGF3

International Comfort Products, LLC

Lewisburg, TN. 37091

TABLE OF CONTENTS

UNIT DIMENSIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFE INSTALLATION REQUIREMENTS 3. . . . . . . . . . . . . . . . . . . . . . . . .

LOCATING THE UNIT 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEARANCES 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GROUND LEVEL INSTALLATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOISTING 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DOWNFLOW CONVERSION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HEATING VENT ASSEMBLY 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSATE DRAIN 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMBUSTION BLOWER PIPE INSTALLATION 5. . . . . . . . . . . . . . . . . . . .

PRE-EXISTING COMMON VENT CHECK 5. . . . . . . . . . . . . . . . . . . . . . . . .

GAS SUPPLY AND PIPING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORIFICES 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL WIRING 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DUCTWORK 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILTERS 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIRFLOW ADJUSTMENT 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START-UP PROCEDURES 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GAS PRESSURES 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HEATING START-UP PROCEDURES 13. . . . . . . . . . . . . . . . . . . . . .

OPERATION 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSPECTION AND CLEANING 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

RIGGING 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAMS 20 - 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOW

VOLTAGE

1/2`` CONDUIT

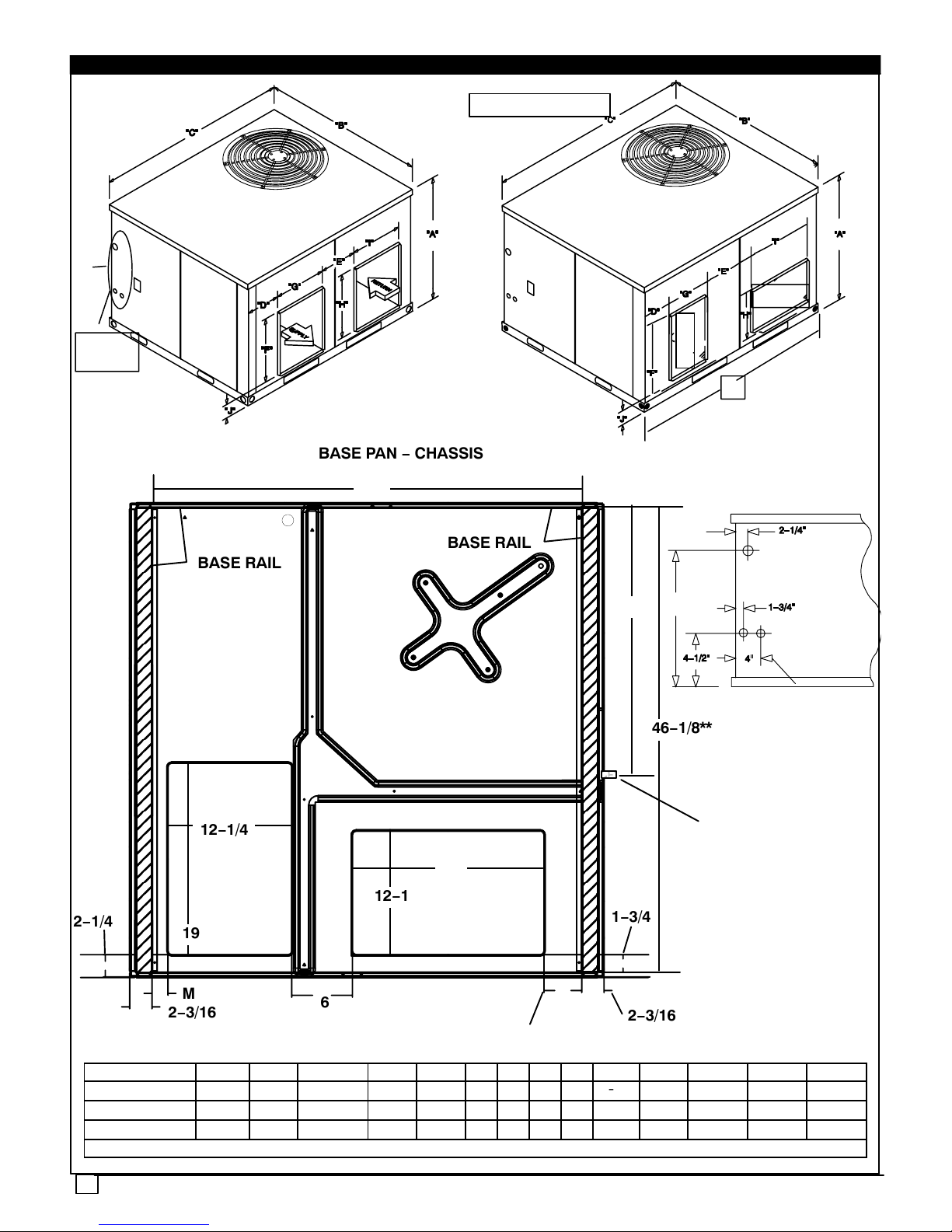

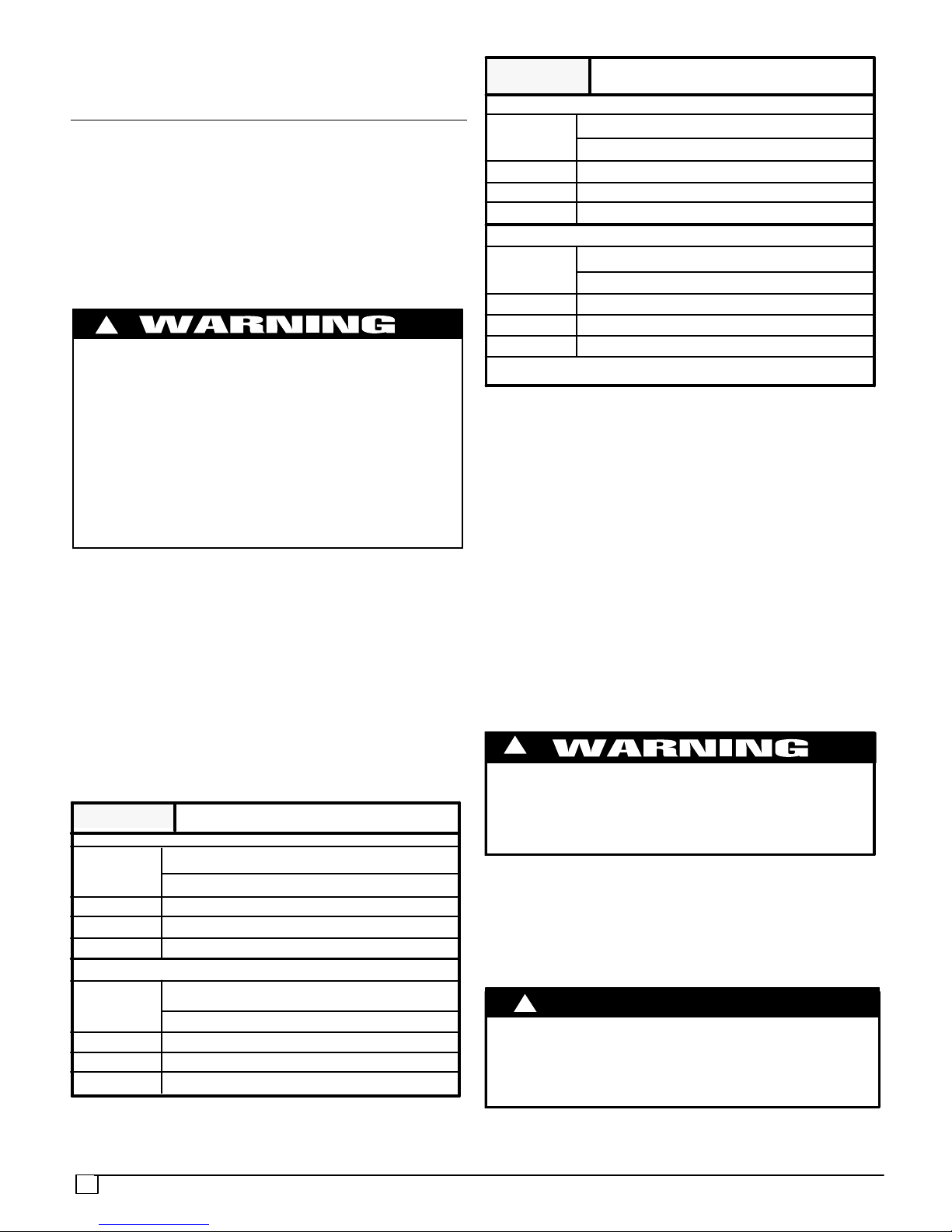

1. UNIT DIMENSIONS

ALL DIMENSIONS IN INCHES

GAS

CONNECTION

1/2`` PIPE

ELECTRICAL

POWER

CONDUIT

2 TON

2−1/2 TO 5 TON

K

See

Detail

Connections Detail

K

RETURN

SUPPLY

RETURN

SUPPLY

BASE PAN − CHASSIS

BASE RAIL

BASE RAIL

1−3/4

2−3/16

6

M

2−3/16

2−1/4

46−1/8**

12−1/4

19

12−1/4

19

L**

3−3/4

N

27

Condensate Drain

2

UNIT SIZE A B C D E F G H I J K L M N

2 Ton 29-1/2 47-1/2 47-1/2 3 9-1/2 12 14 12 14 4-1/2 16 42-3/4 1-9/16 46-1/2

2-1/2 TO 3-1/2 Ton 37-1/2 47-1/2 47-1/2 3-1/2 6-1/2 19 12 12 19 4-1/2 21-1/2 42-3/4 1-9/16 46-1/2

4 TO 5 Ton * 37-1/2 47-1/2 51 7-1/2 6-1/2 19 12 12 19 4-1/2 21-1/2 46-1/4 5-3/16 49-3/4

** Measured from inside to inside on base rails.

3

2. SAFE INSTALLATION REQUIREMENTS

Installation and servicing of air−conditioning equipment can

be hazardous due to system pressure and electrical

components. Only trained and qualified personnel should

install, repair, or service air−conditioning equipment.

Untrained personnel can perform basic maintenance

functions of cleaning coils and filters. All other operations

should be performed by trained service personnel. When

working on air−conditioning equipment, observe

precautions in the literature, tags, and labels attached to the

unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations.

Have fire extinguisher available for all brazing operations.

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISON HAZARD

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide

poisoning, fire, or an explosion which can result in

personal injury or unit damage. Consult a qualified

installer, service agency, or gas supplier for information

or assistance. The qualified installer or agency must use

only factory−authorized kits or accessories when

modifying this product.

!

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISON HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Before performing service or maintenance operations

on unit, turn off gas supply to unit. Then turn off unit main

power switch and install lockout tag. Electrical shock or

explosion could cause serious injury or death.

!

Recognize safety information. This is the safety−alert

symbol . When you see this symbol in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety−alert symbol. DANGER identifies the most serious

hazards which will result in serious injury or death.

WARNING signifies a hazard which could result in serious

injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation,

reliability, or operation.

These instructions cover minimum requirements and

conform to existing national standards and safety codes. In

some instances, these instructions exceed certain local

codes and ordinances, especially those that may not have

kept up with changing residential construction practices.

We require these instructions as a minimum for a safe

installation.

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND CARBON

MONOXIDE POISON HAZARD

!

Failure to carefully read and follow all instructions in this

manual could result in furnace malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes or, in the absence of

local codes, with the National Fuel Gas Code NFPA

54−2005/ANSI Z223.1−2005 and the National Electrical

Code NFPA70−2005 or in Canada the National Standard

CAN/CGA B149−1 and CSA C.22.1 − Canadian Electrical

Code Part 1.

The information contained in this manual is intended for

use by a qualified service technician familiar with safety

procedures and equipped with the proper tools and test

instruments.

SAFETY CONSIDERATIONS

• Use only with type of gas approved for this unit. Refer to

unit rating plate.

• Install this unit only in a location and position as specified

in section 3 of this manual.

• Never test for gas leaks with an open flame. Use a commercially available soap solution made specifically for the

detection of leaks to check all connections, as specified in

section 5.

• Always install unit to operate within the unit’s intended

temperature−rise range with a duct system, which has an

external static pressure within the allowable range, as

specified in section 9. Refer to unit rating plate for the allowable external static pressures.

• All connecting ductwork to the unit (supply and return)

must be sealed to the unit casing as specified in section 7.

• Do NOT use this furnace as a construction heater.

• Check to see that filters are installed correctly and are the

proper type an size.

NOTE: It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

UNIT SAFETY

CAUTION

!

Failure to follow this caution may reduce unit reliability.

It is recommended that a qualified service technician

check the heat exchanger integrity every two (2) years,

after the first four (4) years of operation.

INTRODUCTION

The PGF3 unit is a fully self−contained, combination

Category I gas heating/electric cooling unit designed for

outdoor installation (See pages 2 for unit dimensions). All

unit sizes have return and discharge openings for both

horizontal and downflow configurations, and are

factory−shipped with all downflow duct openings covered.

Units may be installed either on a rooftop, cement slab, or

directly on the ground if local codes permit.

Models with a ”1” in the twelfth position of the model number

are dedicated Low NOx units designed for California

installations. The emissions of these models do not exceed

40 nanograms of nitrogen oxide emissions per joule of heat

output as shipped from the factory, and must be installed in

California Air Quality Management Districts or any other

regions in North America where a Low NOx rule exists.

!

4

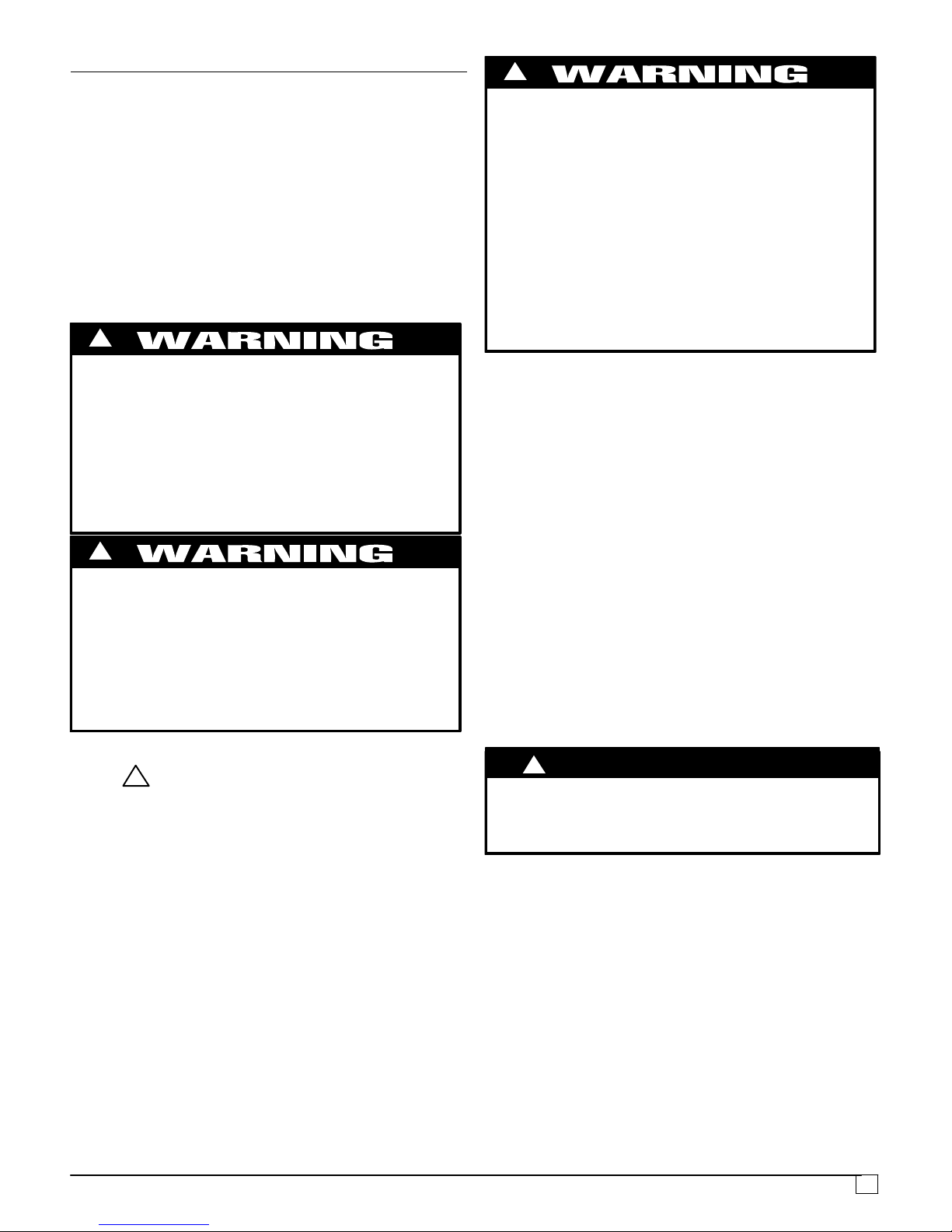

3. LOCATING THE UNIT

ACCESS PANELS

See FIGURE 1 for a general view of unit and location of

access panels.

CARBON MONOXIDE POISONING HAZARD.

!

Failure to follow this warning could result in personal

injury and/or death.

Keep blower door closed.

CLEARANCES

The location MUST allow for minimum clearances and

should not be adjacent to a patio or other area where the

unit’s operating sound level might be objectionable. The

combustion air inlet openings MUST not be obstructed (see

FIGURE 1). In addition, local codes MUST be observed.

NOTE: Units with available filter racks need a 26″ minimum

clearance at side of unit for removal of filters. See chart

below if unit is going to be placed near combustible

construction or materials.

While minimum clearances are acceptable for safety

reasons, they may not allow adequate air circulation around

the unit for proper operation in the cooling mode. Whenever

possible, it is desirable to allow additional clearance,

especially around the condenser inlet and discharge

openings.

Do NOT install the unit in a location that will permit

discharged air from the condenser to recirculate to the

condenser inlet.

Do NOT operate unit in a corrosive atmosphere

containing chlorine, fluorine, or any other corrosive

chemicals.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in shorten life

of unit components.

Minimum Clearances to Combustible Construction

Furnace Plenum 2″ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Duct Side 2″. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condenser Inlet 30″ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Service (Side) 30″ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Service Side

(Front Combustion Air Inlet) 30″ . . . . . . . . . . . . .

Clearance between 3 Ft. Overhang

and Top of Unit 30″ . . . . . . . . . . . . . . . . . . . . . . . .

Combustible Base

(Wood or Class A, B or C

roof covering material) 0″. . . . . . . . . . . . . . . . . . . .

FIGURE 1

Minimum Clearances

30”

36”

Return

Air Duct

Supply

Air Duct

2”

30”

30”

30”

2”

Internal Filter

Access Panel (Filter Field Supplied)

Burner Compartment

Panel

INSTALLATION

NOTICE

Unit will NOT operate properly unless it is installed level front to rear and side to side. The slope MUST NOT be

greater than

1

/8″ per foot (10mm per meter). For side to

side leveling, the drain side MUST always be lower.

Ground Level Installation

Ground level platform requirements:

− The unit MUST be situated to provide safe access for

servicing.

− Platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to

support unit weight.

− Position platform separate from building foundation.

− Install in well−drained area, with top surface of platform

above grade level.

− Platform must be high enough to allow for proper

condensate trap installation and drainage. See

FIGURE 4 and associated text for more information

about condensate drainage.

Rooftop Installation

Rooftop platform requirements:

− The unit MUST be situated to provide safe access for

servicing.

− The existing roof structure MUST be adequate to

support the weight of the unit or the roof MUST be

reinforced.

Check the weight of the unit in relation to the roof

structure and local building codes or ordinances and

reinforce roof structure if necessary. See the last page

of this manual for unit weights.

− Support for the unit MUST be level and strong enough

to carry unit weight. The support may consist of a

platform or a combination of platform and roof beams or

curb.

− See Hoisting section for hoisting instructions.

5

HOISTING

NOTE: All access panels MUST be secured in place before

hoisting.

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail.

Two spreader bars MUST be placed on top of the unit to

protect the unit from damage from the pressure exerted by

the slings. Make sure that all equipment is adequate to

handle the weight of the unit and that the slings will not allow

the unit to shift.

Refer to FIGURE 19 on the back cover of this manual for

illustrated rigging instructions and weight chart.

DOWNFLOW CONVERSION

NOTE: In downflow applications with roof curbs or jack

stands, the center rail under the unit must be removed. The

center rail is attached to the base rail with screws.

These units are adaptable to downflow use. To convert to

downflow use, follow these steps:

1. Remove the blockoff plates found in the return air

compartment and the supply air compartment.

NOTE: Blockoff plate in the supply air compartment only

contains one screw. If reinstalling plate, back part of plate

MUST fit into mating dimples on flange. To reinstall, slant

plate into dimples, then put plate into position and fasten

with screw.

2. Install the removed plates on the horizontal return and

supply air openings.

3. Install roof curb on the building. Be sure to follow all

directions included with curb and all applicable building

codes in your installation.

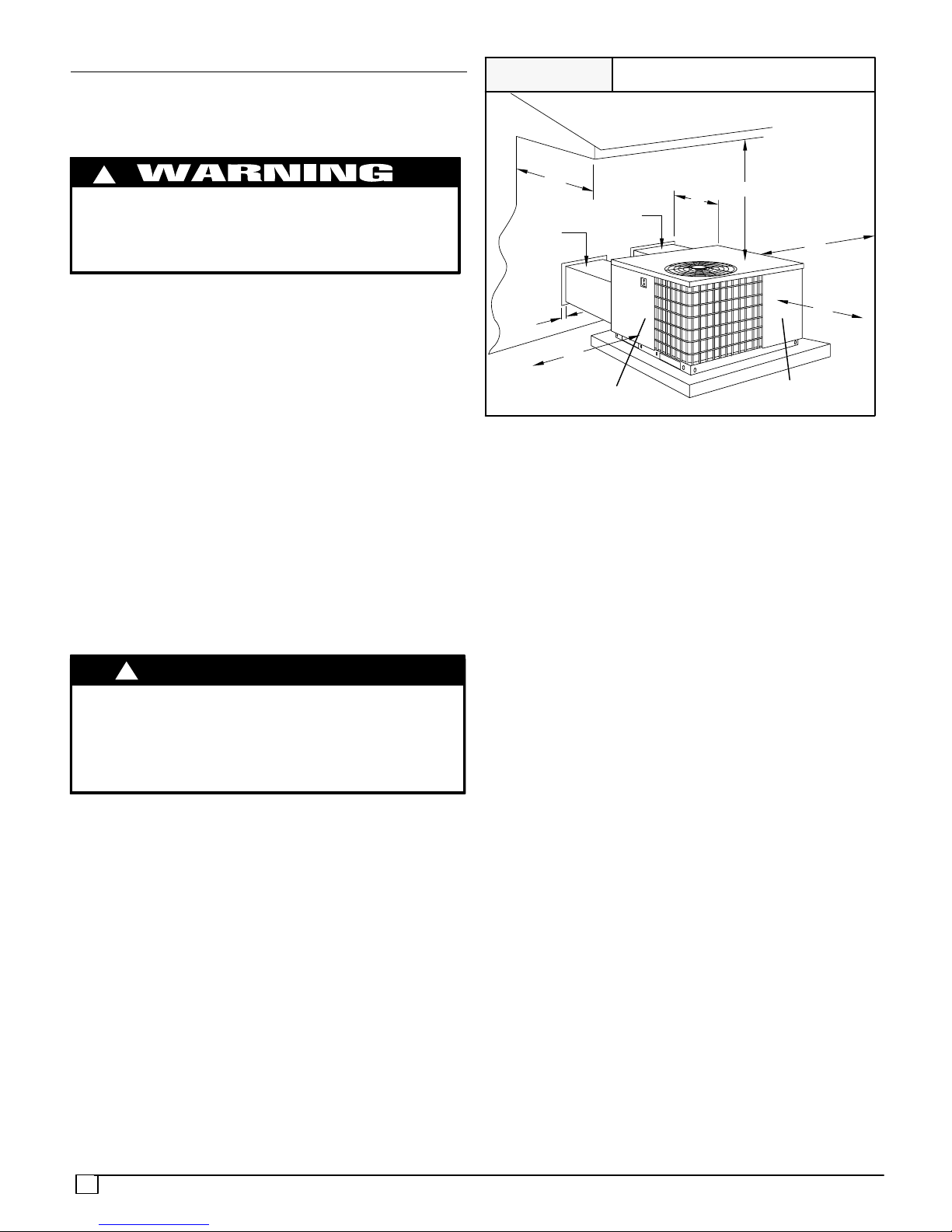

Combustion Blower Pipe Installation

Remove the combustion blower pipe from the right corner of

the burner compartment and position the end of the pipe

with the screw hole over the opening of the combustion

blower. The other end of the pipe should now be aligned

through the opening in the side panel of the unit. The pipe

should slightly protrude through the opening in the side

panel. See Figure 2.

Remove (1) chisel pointed #10 screw (self−drilling) taped to

the vent cap. Position the screw to the hole in the pipe and

drill through the combustion blower outlet securing the pipe

to the combustion blower.

FIGURE 2 Combustion Pipe Installation

Combustion

Pipe

Heating Vent Assembly

Refer to FIGURE 3 and assemble as shown.

FIGURE 3

Heating Vent Assembly

Flue PipeAttach with 2 screws

Heating

Vent

UNIT DAMAGE

CAUTION

!

Do not operate the unit without the vent assembly

installed.

Failure to follow this caution may result in unit

damage.

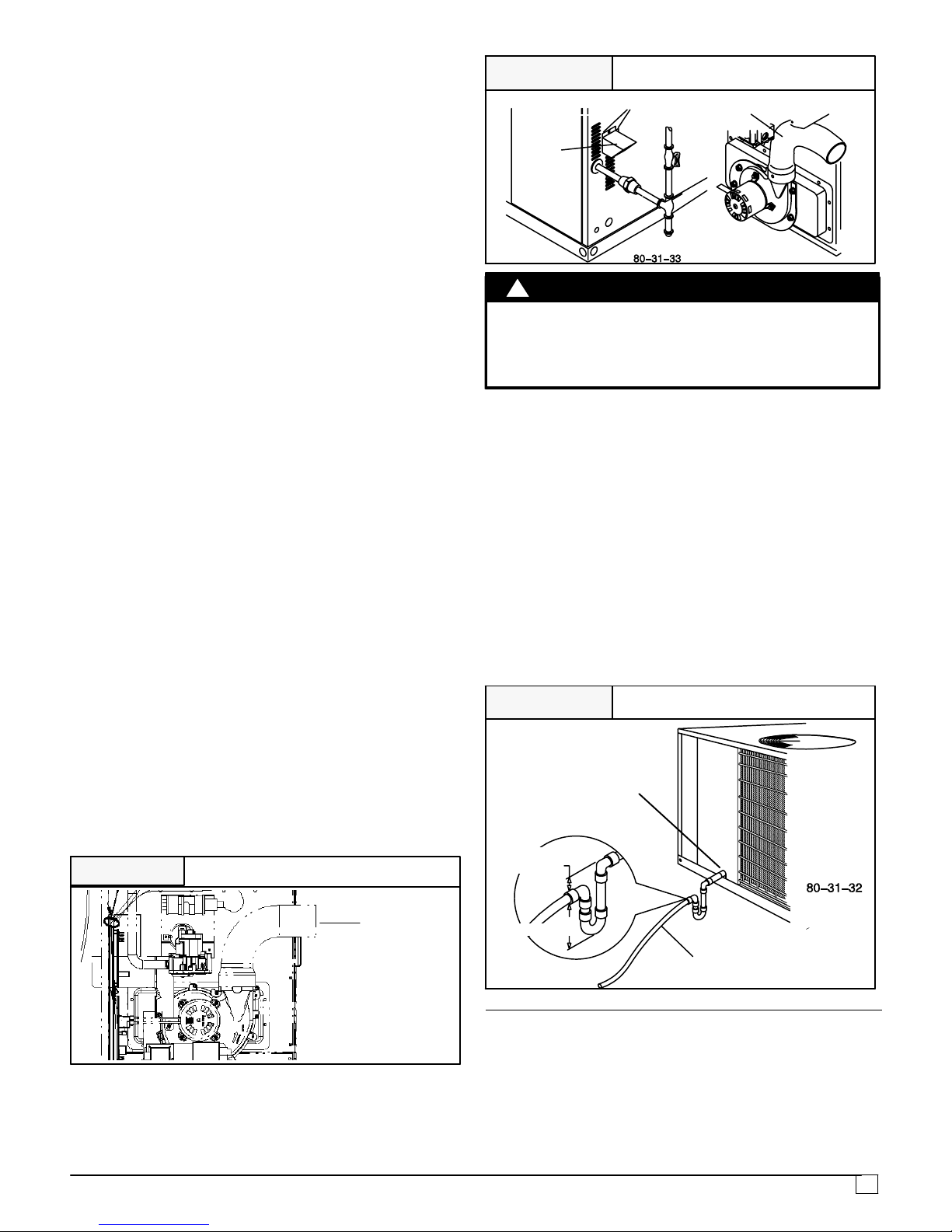

Condensate Drain

The condensate drain outlet is a

3

/4″ (19.1mm) female PVC

connection located at the bottom on the left hand side (see

FIGURE 4).

The circulating blower creates a negative pressure on the

condensate drain line that can prevent the condensate from

draining properly. To combat this negative pressure, a field

supplied condensate trap that will allow a standing column

of water of at least 2″ (50.8mm) MUST be installed . Top of

outlet from trap MUST be at least 1″ (25.4mm) below top of

outlet from unit. Install the trap as near to the unit as

possible for proper drainage.

A

3

/4″ (19.1mm) drain line MUST be installed if required by

local codes or if location of unit requires it. Run the drain line

to an open drain or other suitable disposal point.

FIGURE 4

Condensate Drain Information*

* Condensate trap MUST be installed.

3

/4″ (19.1mm)

Drain Line

1″

(25.4mm)

2″ (50.8mm)

3

/4″ (19.1mm)

Female PVC

Fitting

4. PRE−EXISTING COMMON VENT CHECK

If the installation of this new combination gas heat/electric

cool unit involves removing an existing gas−fired furnace

from a common vent system with other gas−fired

appliances (gas−fired hot water heater, etc.), the existing

vent system must be checked and inspected by a qualified

technician. The qualified technician can determine if the

existing vent system will properly vent the flue products of

the remaining gas−fired appliances. In many cases, the

6

existing vent system may be oversized for the remaining

appliances.

5. GAS SUPPLY AND PIPING

NOTE: Because there are many types of liquified petroleum

(LP) gases, the term LP as used in this manual refers to

propane gas. If you intend to use any type of LP gas, proper

precautions MUST be used in the handling, piping, and use

of such gas. NOTE: In Canada, installations MUST be

performed by licensed LP installers.

The UL rating plate located on the side panel on the unit

contains the model number, type of gas, gas input rating,

and other important information.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Make certain the unit is equipped to operate on the type of

gas available. Models designated as natural gas are to be

used with natural gas only. Models designated for use

with liquefied petroleum (LP) gas are shipped with

orifices sized for commercially pure propane gas. They

MUST not be used with butane or a mixture of butane and

propane unless properly sized orifices are installed by a

licensed LP installer.

!

GAS PIPING

The gas supply line MUST be of adequate size to handle the

Btu/hr requirements and length of the run for the unit being

installed. Determine the minimum pipe size for natural gas

from the table in FIGURE 5 or FIGURE 6. Base the length

of the run from the gas meter or source to the unit.

Gas Pipe Size

Btu ratings of all other gas appliances MUST be considered

for sizing of main gas line. Check gas line to installation for

compliance with local codes or, in the absence of local

codes, with the National Fuel Gas Code NFPA

54−2005/ANSI Z223.1−2005 or in Canada the National

Standard CAN/CGA B149−1 or current editions.

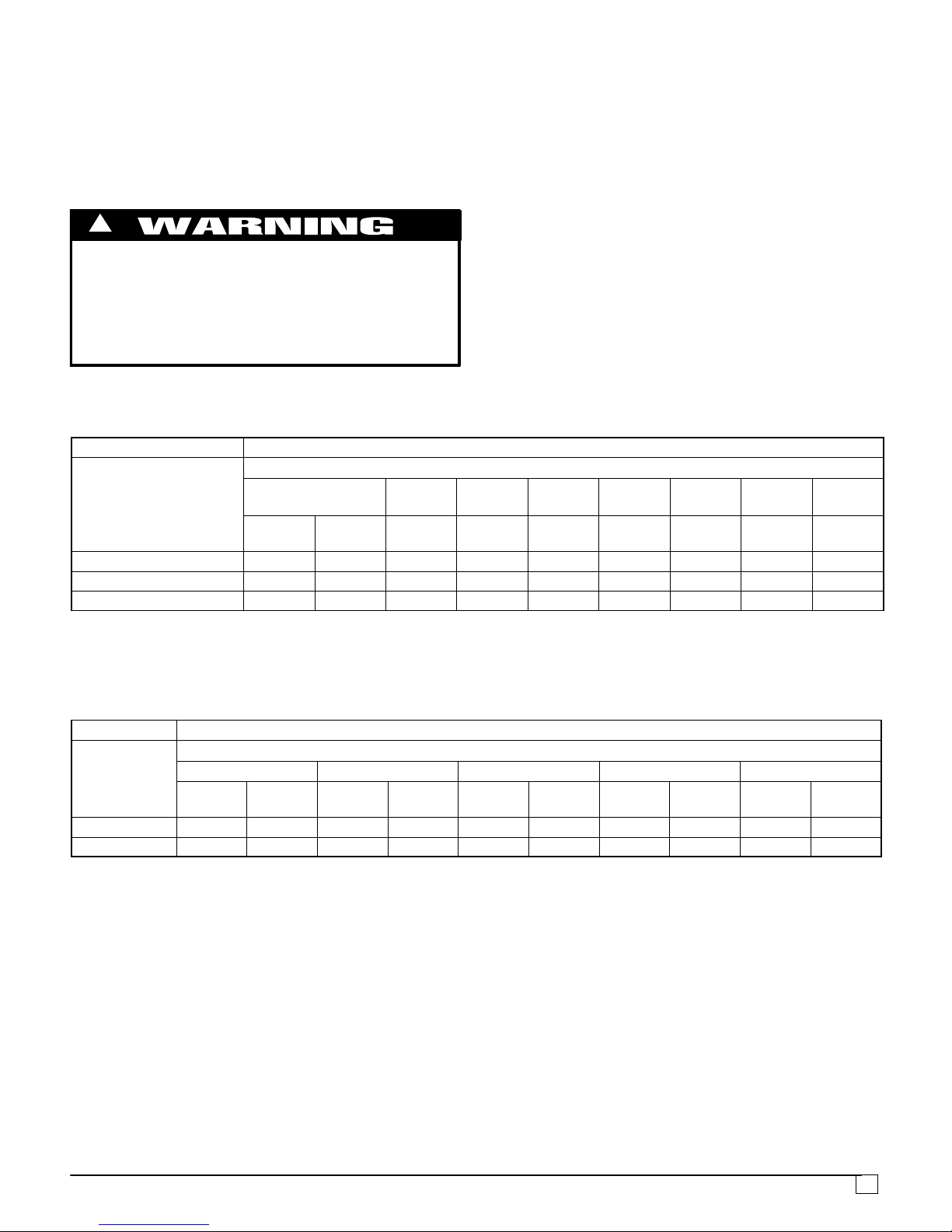

Gas Pipe Size, Length and Btu/hr Capacity

for Schedule 40 Iron Pipe (English)

20′ 190 350 730 1,100 2,100

40′ 130 245 500 760 1,450

60′ 105 195 400 610 1,150

FIGURE 5

Btu/hr (in thousands)

LP GAS

NATURAL GAS

Pipe Length

(Includes

Fittings)

3

/4″ 1″ 11/4″ 11/2″ 2″

20′ 189 393 732 1,496 2,299

40′ 129 267 504 1,039 1,559

60′ 103 217 409 834 1,275

Btu/hr (in thousands)

Pipe Length

(Includes

Fittings)

1

/2″

3

/4″ 1″ 11/4″ 11/2″

Pipe Length

(Includes

Fittings)

6.1m 56 103 214 322 615

12.2m 38 72 147 223 425

18.3m 31 57 117 179 337

FIGURE 6

kW**

LP GAS

NATURAL GAS

Pipe Length

(Includes

Fittings)

3

/4″ 1″ 11/4″ 11/2″ 2″

6.1m 55 115 215 438 674

12.2m 38 78 148 305 457

18.3m 30 64 120 244 374

kW**

1

/2″

3

/4″ 1″ 11/4″ 11/2″

**kW (Kilowatts) is the metric equivalent of Btu/hr.

Gas Pipe Size, Length and Btu/hr Capacity

for Schedule 40 Iron Pipe (English)

PIPING AT UNIT

Connections

NOTE: The rules listed apply to natural and LP gas pipe

installations.

1. If installation is for LP gas, have LP gas installer use

TWO−STAGE REGULATION and make all

connections from storage tank to unit.

2. Use black iron or steel pipe and fittings or other pipe

approved by local code.

3. If copper tubing is used, it MUST comply with limitation

set in Fuel Gas Code.

NOTE: If a flexible gas connector is used, it MUST be

acceptable to local authority. Connector MUST NOT be

used inside the furnace or be secured or supported by the

furnace or ductwork. Do not use a connector which has

previously serviced another gas appliance. Always use a

new listed connector.

FIRE OR EXPLOSION HAZARD

!

Failure to do so could result in personal injury, death

and/or property damage.

Gas connector MUST be properly installed and can NOT

be used inside the furnace.

4. Use pipe joint compound on external (male) threads

ONLY. Joint compound MUST be resistant to any

chemical action of LP gases. Do NOT put pipe

compound on last 2 threads of pipe.

5. Use ground joint unions and install a drip leg no less

than 3 inches (76 mm) long to trap dirt and moisture

before it can enter gas valve.

Overtightening assembly may cause damage to the gas

valve and/or wiring and may misalign the burners.

CAUTION

!

UNIT OPERATION AND COMPONENT DAMAGE HAZARD

Failure to follow this caution may result in misaligned

burners, flame rollout and or unit damage.

6. Use a wrench on gas valve when making connections

to prevent gas valve from turning. Do NOT use a pipe

wrench on the gas valve body.

7

7. Provide a 1/8 inch (3mm) National Pipe Thread (NPT)

plug for test gauge connection immediately upstream of

the gas supply connection to the furnace if none is

supplied with the gas valve of unit.

8. Install a manual shutoff valve and tighten all joints

securely.

LEAK CHECK /PRESSURE TESTING OF GAS SUPPLY

PIPING

FIRE OR EXPLOSION HAZARD

!

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of leaks

to check all connections. A fire or explosion may result causing

property damage, personal injury or loss of life.

The unit and its equipment shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of .5 psi (3.5kPa).

The unit must be isolated from the gas supply piping system

by closing the equipment shut off valve during any pressure

testing of the gas supply piping system at test pressures

equal to or less than .5 psi (3.5 kPa).

ORIFICES

Orifice Sizes

Orifice sizes MUST be matched to the heating value of the

gas (see TABLE 1 & 2). Check with your gas supplier and

the National Fuel Gas Code ANSI Z223.1.

NOTE: An LP Conversion Kit MUST be used for conversion

to LP gas.

NOTE: For elevations above 2000 feet (610 meters), the

Btu input rating MUST be reduced by 4% for each 1000 feet

(305 meters) above sea level, unless the gas supplier’s

Btu/ft

3

content has already been adjusted for altitude.

Check Table 1 & 2 for the proper orifice sizes.

TABLE 1 & 2: Equivalent Orifice Sizes at High Altitudes

Table 1 NATURAL GAS ORIFICE SIZING

Nominal Heating Size

MEAN ELEVATION FEET ABOVE SEA LEVEL

0 to 2000 2001 to

4000

4001 to

5000

5001 to

6000

6001 to

7000

7001 to

8000

8001 to

9000

9001 to

10000

Orifice

Drill #

Kit

Number

Orifice

Drill #

Orifice

Drill #

Orifice

Drill #

Orifice

Drill #

Orifice

Drill #

Orifice

Drill #

Orifice

Drill #

040, 060, 080 44 1173863 45 46 47 47 48 48 49

100 41 1173865 43 43 43 44 44 45 46

120, 140 42 1173865 43 43 44 44 45 46 47

NOTE: The orifice sizes in the chart above derate the input rate at 4% per 1000 feet above sea level for altitudes exceeding 2000 feet

above sea level. If converting from LP gas to Natural Gas at altitudes exceeding 2000 feet above sea level, use part number

330732−401, plus the required orifice size # shown in Table 1. Natural Gas data is based on 0.60 specific gravity, a heating value of 1030

Btu/Cu.Ft., and 3.5” W.C. manifold pressure. For fuels with different specific gravity, consult the National Fuel Gas Code NFPA

54−2005/ANSI Z223.1−2005 or National Standard of Canada, Natural Gas and Propane Installation Code CSA B149.1−05.

Table 2

LP GAS ORIFICE SIZING

Nominal Heating

Size

MEAN ELEVATION FEET ABOVE SEA LEVEL

0 to 2000 2001 to 4000 4001 to 7000 7001 to 9000 9001 to 10,000

Orifice

Drill #

Kit

Number

Orifice

Drill #

Kit

Number

Orifice

Drill #

Kit

Number

Orifice

Drill #

Kit

Number

Orifice

Drill #

Kit

Number

040, 060, 080 55 1173857 55 1173857 56 1173859 56 1173859 57 1173861

100, 120, 140 54 1173855 55 1173857 55 1173857 56 1173859 56 1173859

NOTE: The orifice sizes in the chart above derate the input rate at 4% per 1000 feet above sea level for altitudes exceeding 2000 feet

above sea level. LP Gas data is based on 1.52 specific gravity, a heating value of 2500 Btu/Cu.Ft., and 10.0” W.C. manifold pressure. For

fuels with different specific gravity, consult the National Fuel Gas Code NFPA 54−2005/ANSI Z223.1−2005 or National Standard of

Canada, Natural Gas and Propane Installation Code CSA B149.1−05.

Loading...

Loading...