International Comfort Products FMU4X, FMU4P Installation Manual

INSTALLATION INSTRUCTIONS

UNCASED HORIZONT AL F AN COIL UNIT

FMU4X, FMU4P

NOTE: Read the entire instruction manual before starting

installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1.........................

INTRODUCTION 1....................................

INSTALLATION 2.....................................

Step 1 — Check Equipment 2.........................

Step 2 — Mount Fan Coil 2...........................

Step 3 — Supply--Air Connections 3....................

Step 4 — Condensate Drain 3.........................

Step 5 — Electrical Connections 3.....................

Step 6 — Select Proper Blower Speed 4................

Step7—TXV 4.....................................

START-- UP 4.........................................

SEQUENCE OF OPERATION 4.........................

CARE AND MAINTENANCE 5..........................

AIRFLOW PERFORMANCE TABLES 5..................

WIRING DIAGRAM 6..................................

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock, or other conditions which may cause death, personal

injury or property damage. Consult a qualified installer,

service agency, or your distributor or branch for information or

assistance. The qualified installer or agency must use

factory--authorized kits or accessories when modifying this

product. Refer to individual instructions packaged with kits or

accessories when installing.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use quenching cloth for brazing

operations. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warning or cautions

included in literature and attached to the unit. Consult local

building codes and the current editions of the National

Electrical Code (NEC) NFPA 70.

In Canada, refer to the current editions of Canadian Electrical

Code CSA C22.1.

Recognize safety information. This is the safety alert symbol

. When you see this symbol on the unit and in instructions

or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety alert

symbol. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or

death. CAUTION is used to identify unsafe practices, which

may result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

INTRODUCTION

FMU4P and FMU4X Fan Coils are designed for horizontal

orientation and are suitable for ceiling installations in

conditioned space. These units are available with

field--installed electric heat, and are used indoors as the fan

coil for split--system heat pumps or air conditioners. The

FMU4P models use a refrigerant piston metering device and

are available in 18,000 through 36,000 Btuh nominal cooling

capacities. The FMU4X models have a factory--installed TXV

and are available in 18,000 through 30,000 Btuh nominal

cooling capacities. All units utilize a 3--speed PSC motor.

Field--installed heaters are available in 5, 7.5, and 10 kW

sizes. The coil is equipped with sweat -- type connections and

is vapor-- charged with dry nitrogen.

Units are designed for horizontal applications only. Local

codes may limit this free--air--return type unit to installation in

single--level applications.

NOTE: Nuisance sweating may occur if the unit is installed in

a humid location with low airflow.

!

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in

personal injury or death.

Before installing or servicing unit, always turn off

all power to unit. There may be more than 1

disconnect switch. Turn off accessory heater

power if applicable. Lock out and tag switch with a

suitable warning label.

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs.

Use care and wear appropriate protective clothing

and gloves when handling parts.

WARNING

!

!

WARNING

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal

injury, and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures of air or gases containing

oxygen can lead to an explosion.

CAUTION

Specifications subject to change without notice.

496 01 8101 02 4/7/16

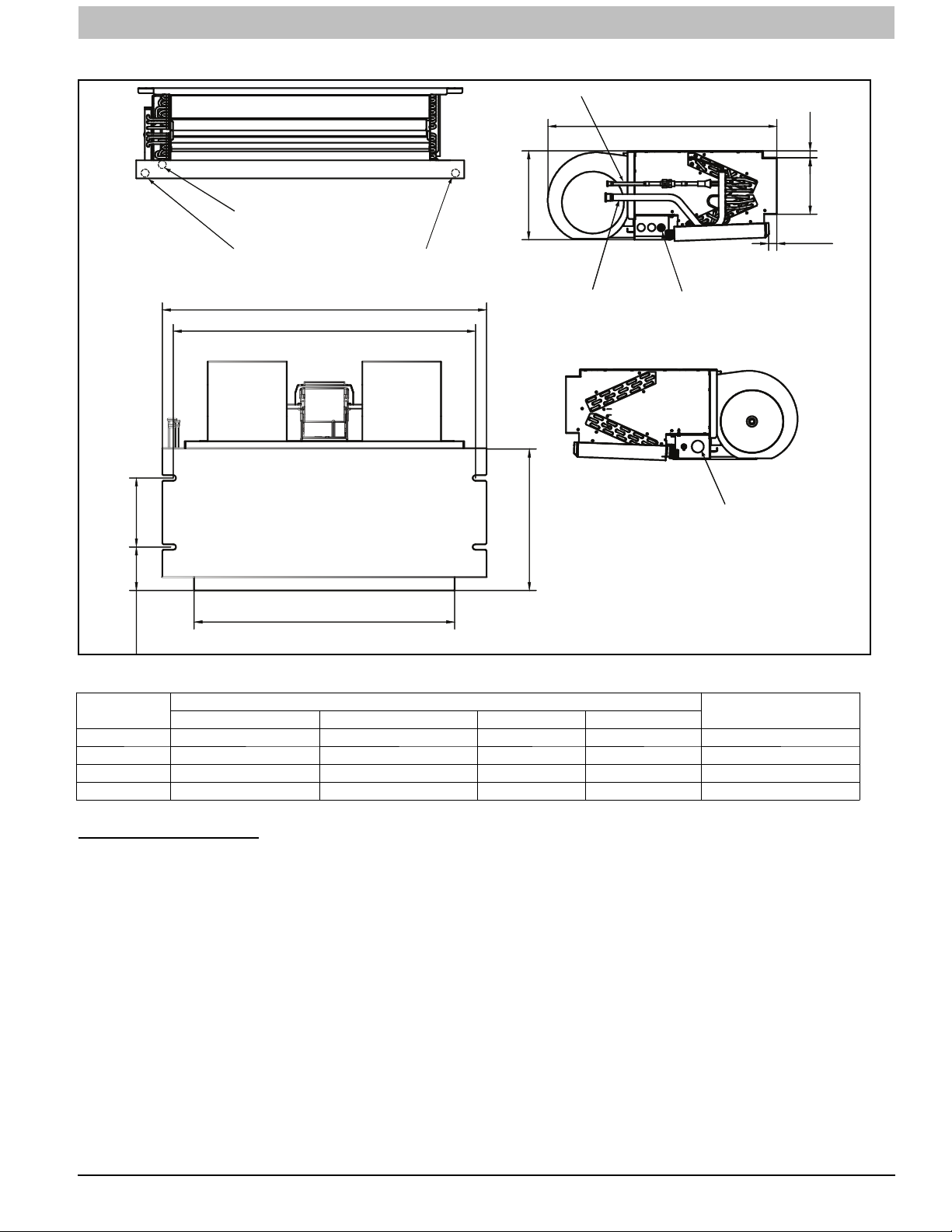

INSTALLA TION INSTRUCTIONS Fan Coil: FMU4X, FMU4P

A

B

C

D

26-3 /8 ”[67670 mm ]

10-1/4”

[

260 mm ]

7-7

/8

”

[

200

m

m ]

5

”

[

127

m

m

]

16-1 /4 ” [

412 m

m

]

1”[ 25 mm ]

Low voltagage

connection

V

aporliline comection

copper (sweat)

Liquid

line comection

copper (sweat)

High voltage connnnection

3/8” [35 mm] dia knock outs

Auxiliary drain c

onnection 3/4” ”

[20 mm]

male pipe thrhread(n(npt)

Primary

drain cononncetion 3/4” ”

[20mm]

male pipe thrhread(n(npt)

Figure 1 -- Dimensional Drawing

li

26-

onn

dr

20

7-

12

[20 mm]

[20mm]

26

10-1/4”

apo

41

16-

Lo

1-1-3/8” [35 mm]

Model Size

Table1–DimensionalData

Dimensions- inches [mm]

A B C D

Unit Operating Weight

lbs (kg)

A13183

18 37-1/4 [946] 34-11/16 [881] 30 [762] 6-1/2 [165] 75 (34)

24 37-1/4 [946] 34-11/16 [881] 30 [762] 6-1/2 [165] 75 (34)

30 49-1/4 [1251] 46-11/16 [1186] 42 [1067] 6-1/2 [165] 93 (42)

36 49-1/4 [1251] 46-11/16 [1186] 42 [1067] 6-1/2 [165] 93 (42)

INSTALLATION

Step 1 — Check Equipment

Unpack unit and move to final location. Remove from carton,

avoid lifting from blower wheels, taking care not to damage

unit. Inspect equipment for damage prior to installation. File

claim with shipping company if shipment is damaged or

incomplete. Locate rating plate on unit. It contains information

needed to properly install unit. Check rating plate to be sure

unit matches job specifications.

NOTE: Installation clearance from combustible materials is 0”

(0 mm) from unit and supply--air duct.

Step 2 — Mount Fan Coil

Fan Coil Mounting

Mounting slots on the top of the unit are provided for

attachment of the fan coil to supporting structure. The

supporting structure must be designed to safely support the

full weight of the fan coil. Field supplied washers and bolts

capable of supporting the fan coil load should be used to

secure the fan coil to the supporting structure at the mounting

slots.

2 496 01 8101 02

The fan coil must be mounted level to ensure proper drainage

of condensate. If the supporting structure is not level at the

points of fan coil attachment, then spacers must be used to

level the fan coil.

After mounting unit, install refrigerant tubing as follows:

1. Route tubing to connection points.

2. Remove plugs from liquid and vapor lines.

3. Wrap the TXV or piston body with a wet rag to prevent

overheating.

4. Braze connections using either silver bearing or

non--silver bearing brazing material. Do not use soft

solder (materials which melt below 800_F / 427_C).

Consult local code requirements. Always flow nitrogen

through the system refrigerant lines while brazing.

5. Pressurize system and leak--test. Repeat procedure

until leak--free.

NOTE: FMU4P fan coils are shipped with a piston metering

device designed for the most common outdoor unit matches.

The piston included with the fan coil is unique to this product

and cannot be replaced with the piston shipped with the

outdoor unit. Refer to AHRI ratings to check if your

combination can use the piston shipped with the unit or

requires an accessory TXV.

Specifications subject to change without notice.

Loading...

Loading...