International Comfort Products FEM4P1800A1, FSM4P1800A1, FSU4P1800A1, FEM4P1800AT1, FSM4P1800AT1 User Manual

...

TECHNICAL SUPPORT MANUAL

Fan Coils

FEM4P, FSM4P, FSU4P

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and

NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manuals that may

apply to the product.

DANGER − Immediate hazards which will result in

severe personal injury or death.

WARNING − Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION − Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE − Used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

!

The signal word CAUTION is used throughout this

manual in the following manner:

!

Signal Words on Product Labeling

Signal words are used in combination with colors

and/or pictures on product labels.

WARNING

CAUTION

TABLE OF CONTENTS

Model Number Identification 2.....................

FEM4P Wiring Diagram 3.........................

FSM4P, FSU4P Wiring Diagram 4..................

Airflow Tables 5 − 7...............................

Exploded Drawing 8 − 13..........................

FEM4P*A1 Parts List 14 − 15......................

FEM4P*AT1 Parts List 16 − 17.....................

FSM4P*A1 Parts List 18 − 19......................

FSM4P*AT1 Parts List 20 − 21.....................

FSU4P*A1 Parts List 22 − 23......................

FSU4P*AT1 Parts List 24 − 25.....................

MODELS

FEM4P1800A1 FSM4P1800A1 FSU4P1800A1

FEM4P1800AT1 FSM4P1800AT1 FSU4P1800AT1

FEM4P2400A1 FSM4P2400A1 FSU4P2400A1

FEM4P2400AT1 FSM4P2400AT1 FSU4P2400AT1

FEM4P3000A1 FSM4P3000A1 FSU4P3000A1

FEM4P3000AT1 FSM4P3000AT1 FSU4P3000AT1

FEM4P3600A1 FSM4P3600A1 FSU4P3600A1

FEM4P3600AT1 FSM4P3600AT1 FSU4P3600AT1

FEM4P4200A1 FSM4P4200A1 FSU4P4200A1

FEM4P4200AT1 FSM4P4200AT1 FSU4P4200AT1

FEM4P4800A1 FSM4P4800A1 FSU4P4800A1

FEM4P4800AT1 FSM4P4800AT1 FSU4P4800AT1

!

ELECTRICAL SHOCK HAZARD

Failure to turn off electric power could result in personal injury or death.

Before installing or servicing system, turn off main

power to the system. There may be more than one disconnect switch, including accessory heater(s).

WARNING

496 04 5500 01 Sept. 2010

TECHNICAL SUPPORT MANUAL Fan Coils: FEM4P, FSM4P, FSU4P

FAN COIL MODEL NUMBER IDENTIFICATION GUIDE

F E M 4 P 1800 A T

F = Fan Coil

S = Standard PSC

E = High efficiency ECM MOTOR TYPE

U = Upflow

M = Multiposition INSTALLATION TYPE

4 = Environmentally Sound R−410A REFRIGERANT

P = Piston Metering Device METERING DEVICE

1800 = 18,000 BTUH = 1½ tons

2400 = 24,000 BTUH = 2 tons

3000 = 30,000 BTUH = 2½ tons

3600 = 36,000 BTUH = 3 tons

4200 = 42,000 BTUH = 3½ tons

4800 = 48,000 BTUH = 4 tons

NOMINAL CAPACITY

A = Standard

AT = Tin coated copper tubes SALES CODE / FEATURES

ACCESSORIES PART NUMBER IDENTIFICATION GUIDE

EB AC 01 NCB A

EB = Evaporator Blower

AC = Accessory

01 = Product Identifier Number

NCB = Non−Combustible Base Kit

DFK = Down Flow Kit

PLG = Power Plug (no heat kit)

SPK = Single Point Wiring Kit

FKS = Filter Kit Small

FKM = Filter Kit Medium

FKL = Filter Kit Large

FKX = Filter Kit Extra Large

CTK = Condensate Trap Kit (PVC pipe)

Sales Code

ELECTRIC HEATER MODEL NUMBER IDENTIFICATION GUIDE

EHK 05 A K N 1

EHK = Electric Heater Kit

05 = 5 kW

07 = 7 kW

09 = 9 kW

10 = 10 kW

15 = 15 kW

18 = 18 kW

20 = 20 kW

25 = 25 kW

30 = 30 kW NOMINAL HEAT VALUE

Sales Code

K = 208 / 230 single−phase

H = 208 / 230, 3−phase

KC = 208 / 230, supplied as single phase, field convertible to 3−phase

HC = 208 / 230 supplied as 3−phase, field convertible to single phase VOLTAGE (60 Hz)

Product Identifier

Engineering Code

2 496 04 5500 01

TECHNICAL SUPPORT MANUAL Fan Coils: FEM4P, FSM4P, FSU4P

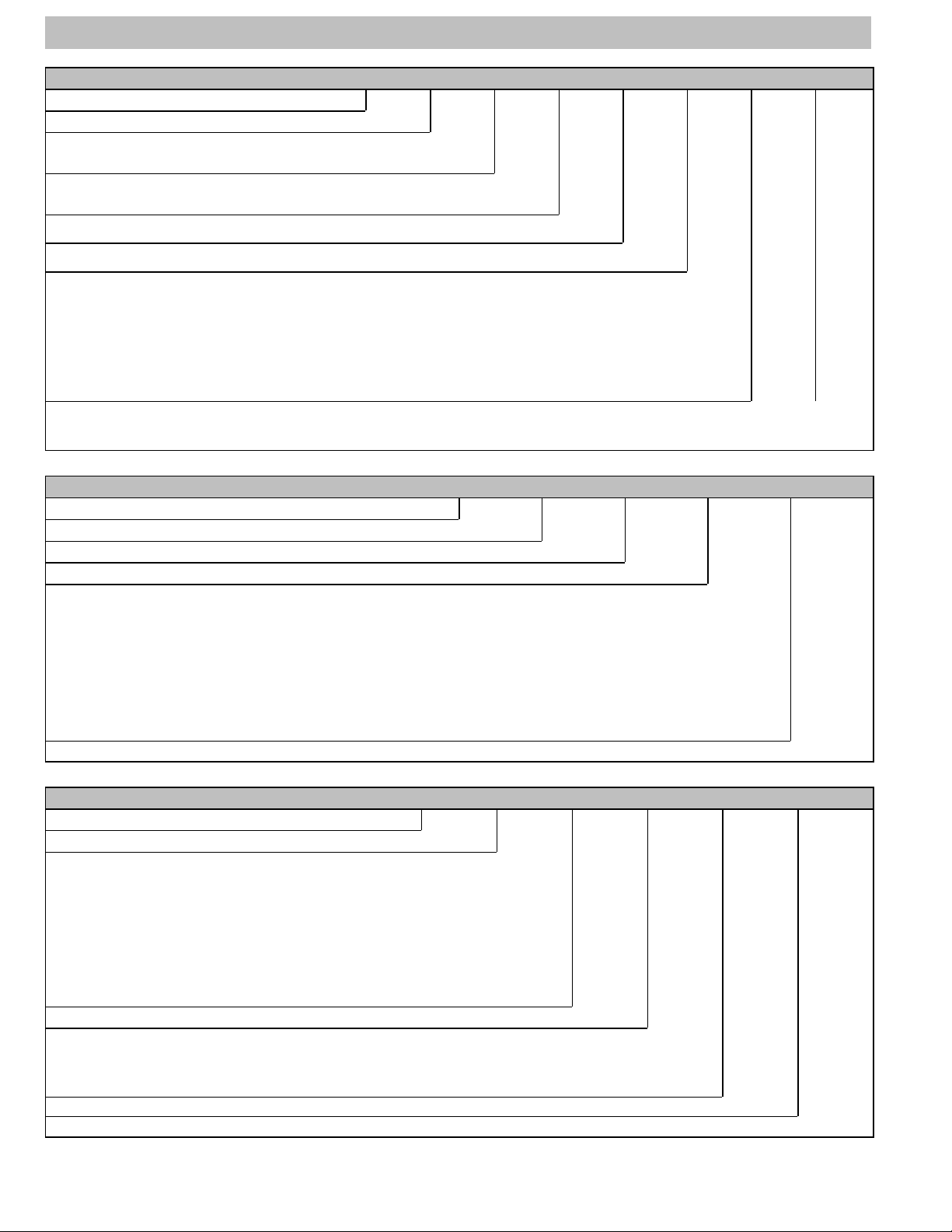

FEM4P

496 04 5500 01 3

TECHNICAL SUPPORT MANUAL Fan Coils: FEM4P, FSM4P, FSU4P

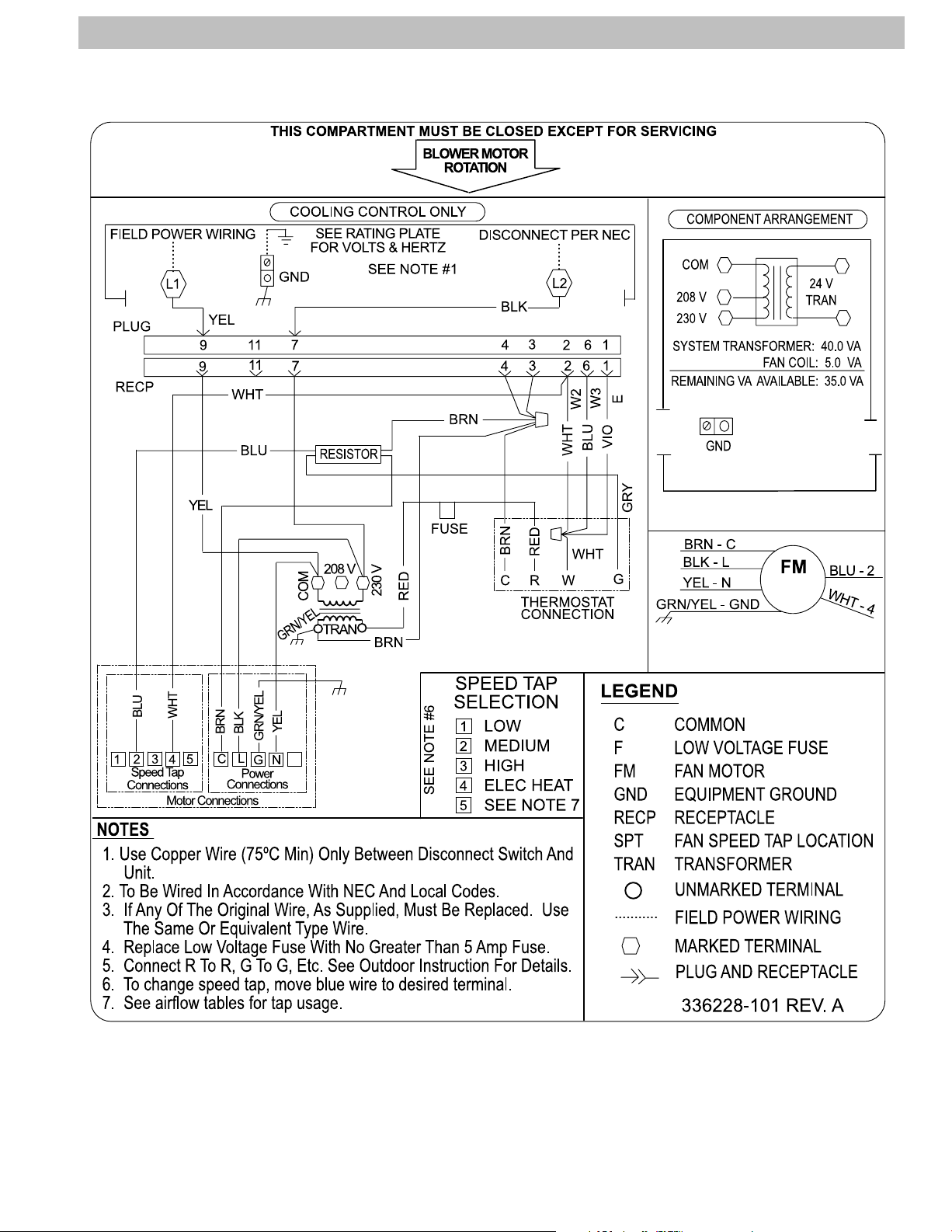

FSM4P & FSU4P

NOTES

1. Use Copper Wire (75ºC Min) Only

Between Disconnect Switch And Unit.

2. To Be Wired In Accordance With NEC

And Local Codes.

3. If Any Of The Original Wire, As

Supplied, Must Be Replaced, Use The

Same Or Equivalent Type Wire.

4. Replace Low Voltage Fuse With No

Greater Than 5 Amp Fuse.

5. (3) Speed Motor Shown Optional (2)

Speed Motor Uses HI (BLK) And LOW

(BLUE or RED).

6. Connect R To R, G To G, Etc. See

Outdoor Instruction For Details.

328964-101 REV. A

4 496 04 5500 01

TECHNICAL SUPPORT MANUAL Fan Coils: FEM4P, FSM4P, FSU4P

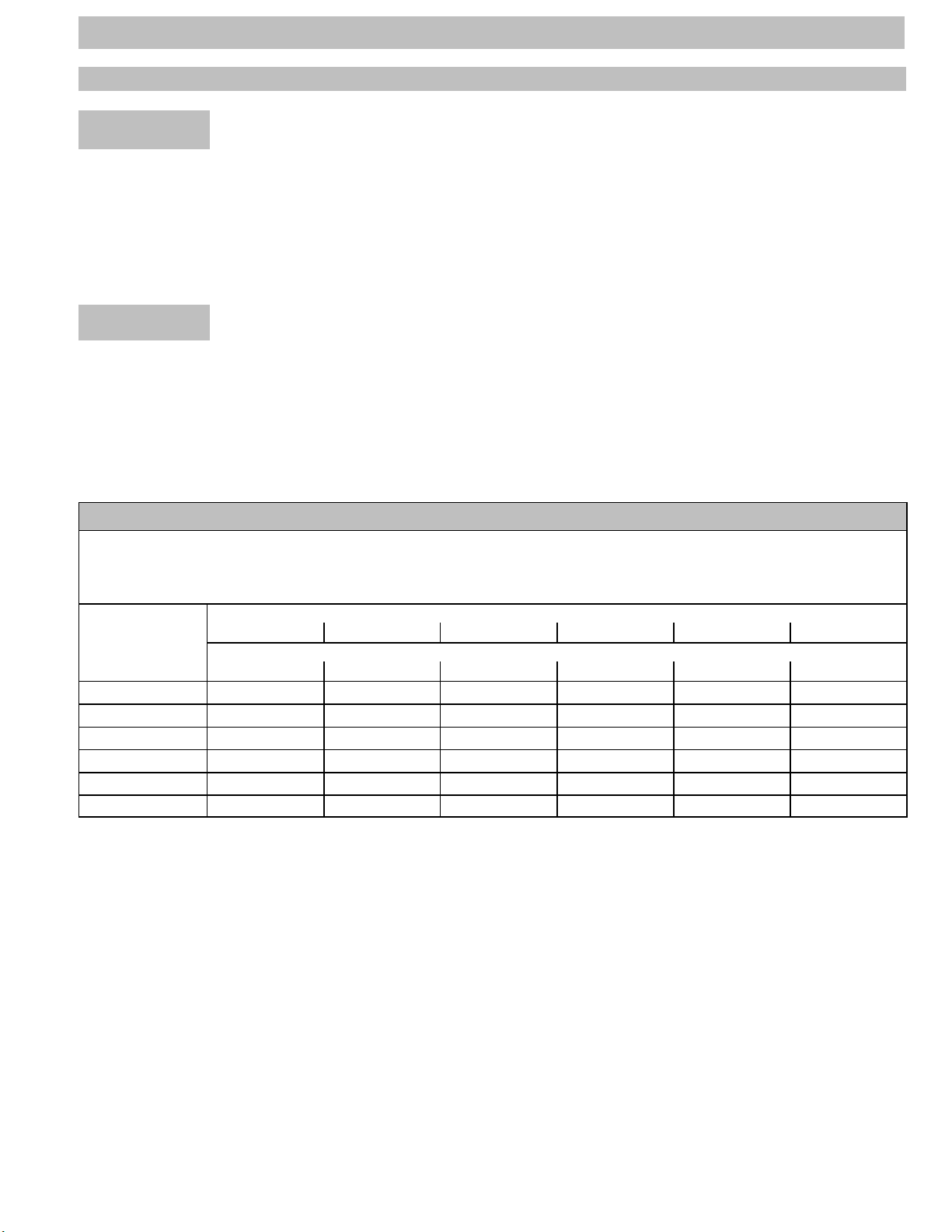

AIRFLOW PERFORMANCE − CFM at a given Speed and Static reading

Model Blower Speed

Tap 5 767 739 702 669 620 565

Tap 4 614 569 534 486 436 398

FEM4P1800

Tap 3 701 660 616 581 537 499

Tap 2 614 569 534 486 436 398

Tap 1 614 569 534 486 436 398

Tap 5 969 936 892 835 763 676

Tap 4 826 795 766 743 706 660

FEM4P2400

Tap 3 826 795 766 743 706 660

Tap 2 701 660 616 581 537 499

Tap 1 617 592 552 507 472 420

Tap 5 1108 1090 1065 1034 1009 974

Tap 4 1026 1000 969 938 899 865

FEM4P3000

Tap 3 1026 1000 969 938 899 865

Tap 2 909 873 842 799 762 724

Tap 1 825 795 757 722 674 634

Tap 5 1301 1276 1245 1218 1176 1121

Tap 4 1227 1191 1169 1143 1105 1074

FEM4P3600

Tap 3 1227 1191 1169 1143 1105 1074

Tap 2 1087 1062 1030 1001 966 930

Tap 1 1026 1000 969 938 899 865

Tap 5 1560 1544 1507 1464 1424 1358

Tap 4 1419 1397 1358 1320 1279 1239

FEM4P4200

Tap 3 1419 1397 1358 1320 1279 1239

Tap 2 1249 1220 1184 1142 1093 1052

Tap 1 1242 1205 1158 1110 1069 1026

Tap 5 1743 1712 1679 1642 1610 1574

Tap 4 1669 1634 1599 1564 1531 1499

FEM4P4800

Tap 3 1669 1634 1599 1564 1531 1499

Tap 2 1452 1413 1377 1339 1308 1271

Tap 1 1300 1256 1221 1182 1142 1101

0.10 0.20 0.30 0.40 0.50 0.60

Total Static (inches water column)

AIRFLOW PERFORMANCE − CFM at a given Speed and Static reading

Total Static (inches water column)

Model

Blower

Speed

0.10 0.20 0.30 0.40 0.50 0.60

208V 230V 208V 230V 208V 230V 208V 230V 208V 230V 208V 230V

FSM4P1800

FSU4P1800

FSM4P2400

FSU4P2400

FSM4P3000

FSU4P3000

FSM4P3600

FSU4P3600

FSM4P4200

FSU4P4200

FSM4P4800

FSU4P4800

- Airflow outside 450 cfm/ton.

NOTES:

1. Airflow based upon dry coil at 230v with factory−approved filter and electric heater (2 element heater sizes 1800 through 3600, 3 element

heater sizes 4200 through 4800). For FEM4P models, airflow at 208 volts is approximately the same as 230 volts because the ECM motor is

a constant torque motor. The torque doesn’t drop off at the speeds the motor operates.

2. To avoid potential for condensate blowing out of drain pan prior to making drain trap:

Return static pressure must be less than 0.40 in. wc.

Horizontal applications of 4200 − 4800 sizes must have supply static greater than 0.20 in. wc.

3. Airflow above 400 cfm/ton on 4800−4800 size could result in condensate blowing off coil or splashing out of drain pan.

High 742 825 707 768 642 714 568 648 466 526 403 434

Low 541 608 480 564 417 511 357 431 299 363 n/a 304

High 1041 1112 969 1030 888 936 774 791 573 654 341 438

Low 874 1014 838 953 781 868 684 740 506 573 341 418

High 1256 1327 1186 1242 1071 1132 952 1005 704 791 459 482

Low 965 1117 949 1074 916 1019 805 902 575 637 396 447

High 1306 1490 1264 1418 1207 1338 1135 1241 1043 1127 842 937

Low 1164 1335 1144 1290 1108 1226 1052 1148 970 1048 697 855

High 1723 1768 1639 1681 1544 1576 1435 1465 1309 1340 1144 1182

Low 1387 1543 1358 1488 1311 1410 1237 1315 1137 1200 997 1047

High 1902 1941 1803 1867 1706 1767 1593 1648 1472 1512 1303 1371

Low 1671 1777 1630 1711 1563 1630 1479 1528 1370 1412 1218 1266

496 04 5500 01 5

TECHNICAL SUPPORT MANUAL Fan Coils: FEM4P, FSM4P, FSU4P

PRESSURE DROP ACROSS FILTER (inches of water column)

Model

FEM4P

1800 0.02 0.044 0.075 — — — — — —

2400, 3000 — 0.022 0.048 0.072 0.100 — — — —

3600 4200, 4800 — — — 0.051 0.070 0.092 0.120 0.152 —

Models

FSM4P, FSU4P

1800, 2400 0.012 0.022 0.048 0.072 — — — — —

3000, 3600, 4200 — — 0.036 0.051 0.07 0.092 0.12 — —

4800 — — — — — 0.073 0.086 0.105 0.13

400 600 800 1000 1200 1400 1600 1800 2000

400 600 800 1000 1200 1400 1600 1800 2000

CFM

CFM

STATIC PRESSURE CORRECTION FROM DRY TO WET COIL (inches of water column)

Model

FEM4P

1800 0.034 0.049 0.063 — — — — — — — — — — — — —

2400 0.034 0.049 0.063 0.076 0.089 — — — — — — — — — — —

3000 — — — 0.049 0.059 0.070 0.080 — — — — — — — — —

3600 — — — — — 0.070 0.080 0.090 0.099 — — — — — — —

4200 — — — — — — — 0.049 0.056 0.063 0.070 — — — — —

4800 — — — — — — — — — 0.063 0.070 0.076 0.083 0.090 — —

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

CFM

Models

FSM4P,

FSU4P

1800 0.016 0.027 0.038 — — — — — — — — — — — — —

2400 0.016 0.027 0.038 0.049 0.059 — — — — — — — — — — —

3000 — — — 0.036 0.046 0.055 0.064 — — — — — — — — —

3600 — — — — — 0.055 0.064 0.073 0.081 — — — — — — —

4200 — — — — — — — 0.049 0.056 0.063 0.07 — — — — —

4800 — — — — — — — — — 0.038 0.043 0.049 0.054 0.059 — —

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

CFM

6 496 04 5500 01

TECHNICAL SUPPORT MANUAL Fan Coils: FEM4P, FSM4P, FSU4P

MINIMUM CFM WHEN USING ELECTRIC HEAT

Model

FEM4P

1800 525 525 525 — 600 — — — — —

2400 700 700 700 — 700 775 — — — —

3000 — 875 875 — 875 875 — 1060 — —

3600 — 1050 970 970 970 920 — 1040 — —

4200 — — 1225 1225 1225 1225 1225 1225 — —

4800 — — 1400 1400 1400 1400 1400 1400 1400 1400

Note: Speed Tap 4 (white wire) is used for electric heat only. White wire must remain on tap 4.

Models

FSM4P, FSU4P

1800 525 525 525 — 600 — — — — —

2400 700 700 700 — 700 775 — — — —

3000 — 875 875 — 875 875 — 1060 — —

3600 — 1050 970 970 970 920 — 1040 — —

4200 — — 1225 1225 1225 1225 1225 1225 — —

4800 — — 1400 1400 1400 1400 1400 1400 1400 1400

Note: Values indicate low or medium speed.

3 5 8 9 10 15 18 20 24 30

3 5 8 9 10 15 18 20 24 30

HEATER kW

HEATER kW

STATIC PRESSURE CORRECTION FOR ELECTRIC HEATERS (inches of water column)

Airflow performance chart was developed using fan coils with 10 kW electric heater (2 elements) in the 1800 − 3600 model

sizes, and 15 kW electric heaters (3 elements) in the 4200 − 4800 model sizes.

When using a different number of heater elements, adjust the static pressure numbers by adding or subtracting the values

in this table (for a given CFM, more electric heater elements create higher static pressure drop).

Heater kW

Model Size

1800 +0.02 +0.01 0 −0.02 −0.04 −

2400 +0.02 +0.01 0 −0.02 −0.04 −

3000 +0.02 +0.01 0 −0.02 −0.04 −

3600 +0.02 +0.01 0 −0.02 −0.04 −

4200 +0.04 − +0.02 0 −0.02 −0.10

4800 +0.04 − +0.02 0 −0.02 −0.10

No Heater 3 or 5 8 or 10 9 or 15 20 18, 24, or 30

Number of Heat Elements

0 1 2 3 4 6

496 04 5500 01 7

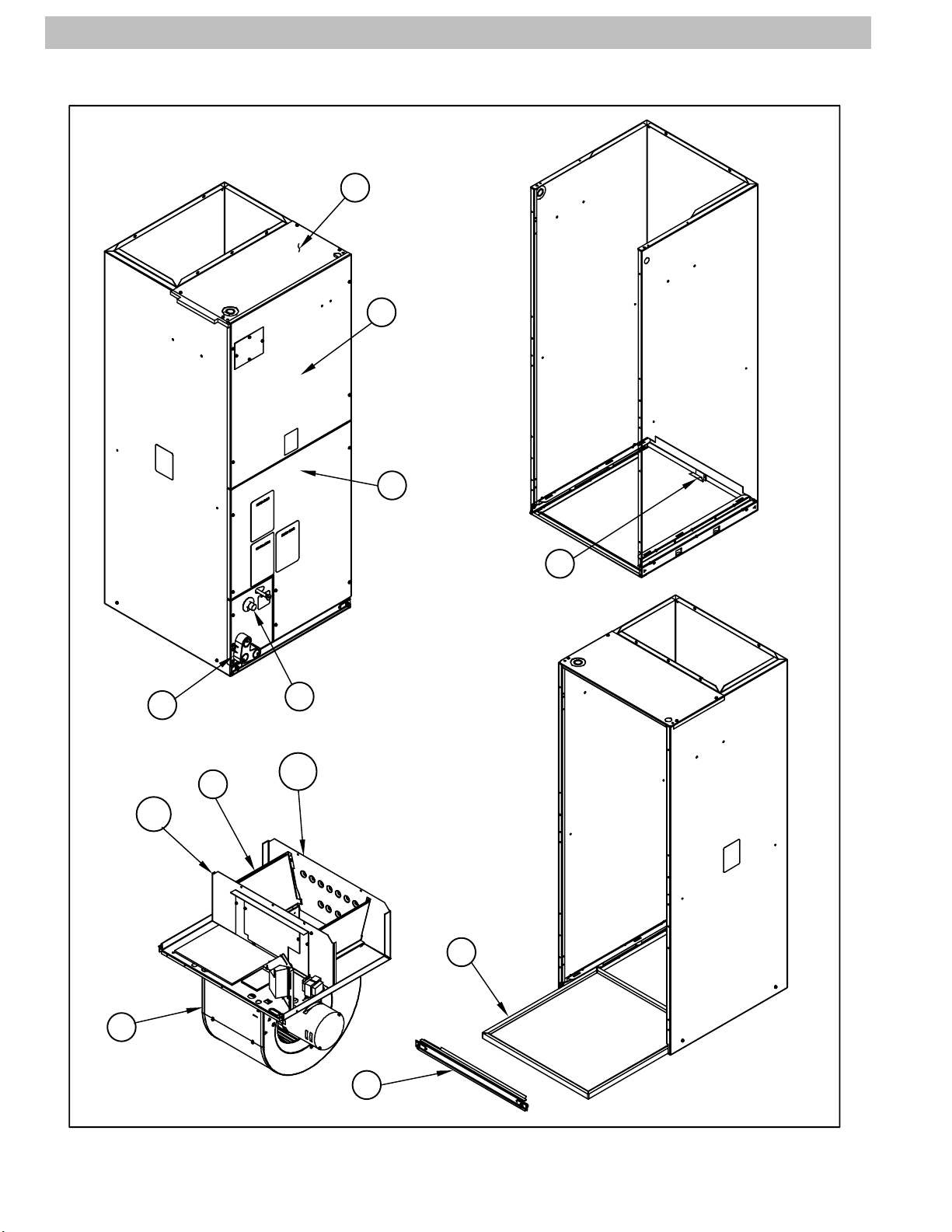

TECHNICAL SUPPORT MANUAL Fan Coils: FEM4P, FSM4P, FSU4P

FEM4P, FSM4P, FSU4P

NOTE: This illustration is for

reference only. Your unit may

differ in appearance or may not

include all components shown.

A

C

AA

B

H

D

K

BB

G

5

1

E

8 496 04 5500 01

Loading...

Loading...