International Comfort Products FCM4X24 Installation Manual

INSTALLATION INSTRUCTIONS

Fan Coils

FCM4X24--60

These instructions must be read and understood completely before attempting installation.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and

NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manuals that may

apply to the product.

DANGER -- Immediate hazards which will result in

severe personal injury or death.

WARNING -- Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION -- Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE -- Used to highlight suggestions which will

result in enhanced installation, reliability , or

operation.

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

WARNING

!

The signal word CAUTION is used throughout this

manual in the following manner:

!

Signal Words on Product Labeling

Signal words are used in combination with colors

and/or pictures on product labels.

WARNING

CAUTION

TABLE OF CONTENTS

Introduction 2.......................................

INSTALLATION 2...................................

Check Equipment 2..............................

Mount Fan Coil 2................................

Air Ducts 6.....................................

Electrical Connections 7..........................

Refrigerant Tubing Connection & Evacuation 9......

Condensate Drain 9.............................

Unit Start--Up 10................................

Accessory Installation 10.........................

Start--Up and Troubleshooting 1 1..................

FCM4X Fan Coil Sequence of Operation 15.........

CARE AND MAINTENANCE 15.......................

R--410A Quick Reference Guide 17....................

!

PERSONAL INJURY, AND/OR PROPERTY DAMAGE

HAZARD

Failure to carefully read and followthis warning could

result in equipment malfunction, property damage,

personal injury and/or death.

Installation or repairs made by unqualified persons

could result in equipment malfunction, property d amage, personal injury and/or death.

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper

tools and test instruments.

Installation must conform with local building codes

and with the National Electrical Code NFPA70 current

edition.

WARNING

496 01 4201 03 Mar/2016

INSTALLA TION INSTRUCTIONS Fan Coils: FCM4X

INTRODUCTION

Model FCM4X fan coils are designed to be installed with

the Observert Communicating Wall Control. The FCM4X

fan coils will provide airflow at a rate commanded by the

Wall Control. The nominal airflow/ton rate is 350 CFM/ton.

The Wall Control will modify the commanded airflow under

certain operating modes. Refer to the Wall Control

literature for further system control details. This fan coil will

not respond to commands from a common thermostat

except under certain emergency situations explained in

this document. The instructions contained herein provide

guidance to successfully install this fan coil.

Model FCM4X fan coil units are designed for flexibility and

can be used for upflow, horizontal, or downflow

applications. These units are designed specifically for

R--410A refrigerant and must be used only with R--410A

refrigerant air conditioners and heat pumps as shipped.

INSTALLATION

Procedure 1. — Check Equipment

Unpack unit and move to final location. Remove carton

taking care not to damage unit.

Inspect equipment for damage prior to installation. File

claim with shipping company if shipment is damaged or

incomplete. Locate unit rating plate which contains proper

installation information. Check rating plate to be sure unit

matches job specifications.

Procedure 2. — Mount Fan Coil

FCM4X unit can stand or lie on floor, or hang from ceiling

or wall. Allow space for wiring, piping, proper trapping and

servicing unit.

IMPORTANT: When unit is installed over a finished ceiling

and/or living area, building codes may require and it is

recommended by the factory, a field--supplied secondary

condensate pan to be installed under the entire unit. Some

localities may allow the alterative of running a separate,

secondary condensate line. Consult local codes for

additional restrictions or precautions.

FCM4X fan coils can be installed for upflow and

horizontal--left applications as factory shipped. (See

Figures 1, 2 and 3.) FCM4X units can be installed for

horizontal--right applications with field modifications.

FCM4X units may be converted for downflow applications

using factory--authorized accessory kits.

NOTE: To ensure proper drainage for horizontal

installations, unit must be installed so it is within 1/8” / 3.18

mm level of the length and width of unit.

A. Modular Units

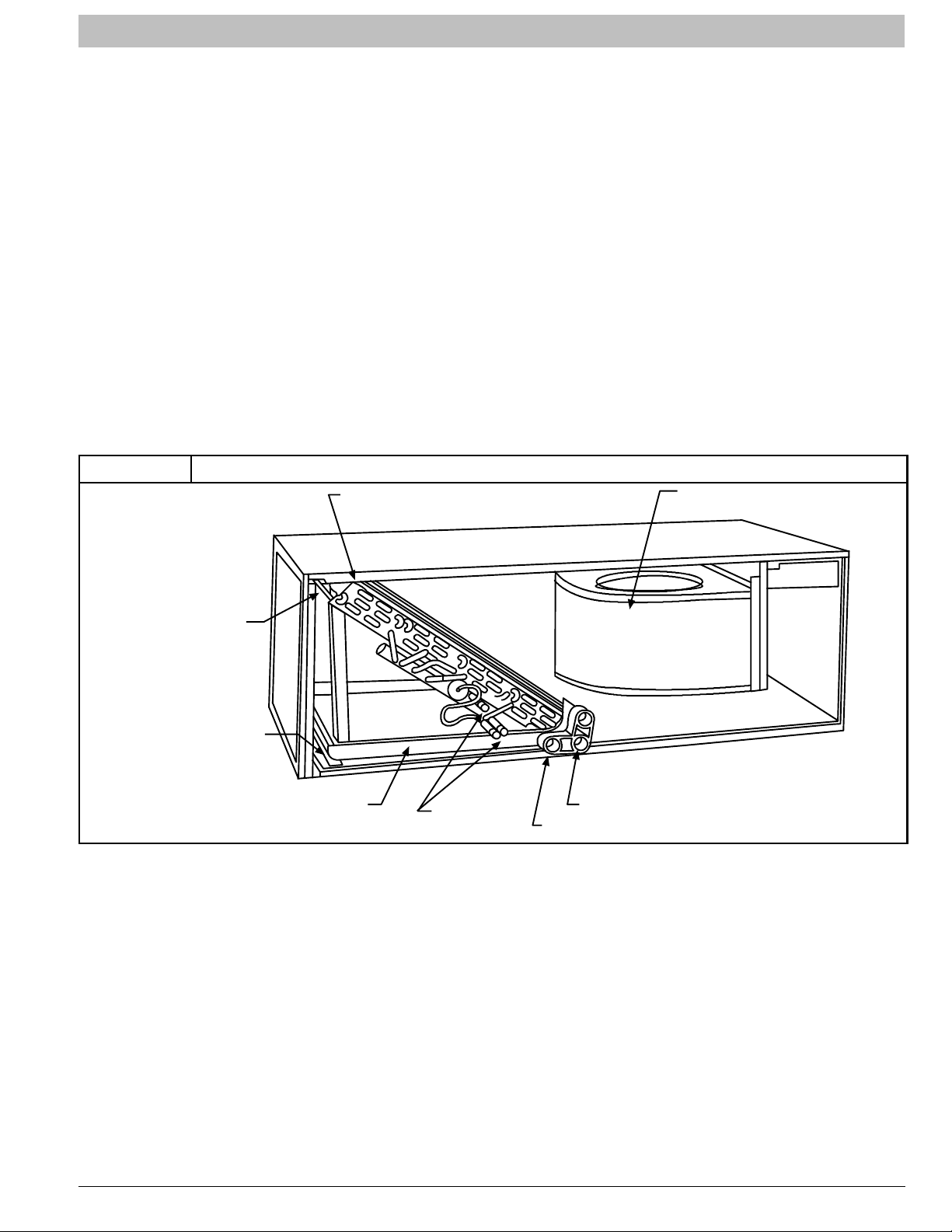

The FCM4X60 Fan Coil are 2--piece modular units.

Modular construction allows installer to disassemble unit

into 2 components, coil box and blower box, for ease of

installation.

These units are designed to meet low air leak

requirements currently in effect. Because of this, units

need special attention in the condensate pan and drain

connection area and when brazing tubing.

These units are available for application in systems of

24,000 through 60,000 Btuh nominal cooling capacities.

Factory--authorized, field--installed electric heater

packages are available in 5 through 30 kW. See

Specifications for available accessory kits.

If the unit is located in an area of high humidity, nuisance

sweating of the casing may occur. On these installations a

wrap of 2 (51 mm) fiberglass insulation with a vapor

barrier is recommended.

To disassemble unit, remove rear corner brackets by

removing 2 screws which secure brackets. Remove either

2 screws in each front corner of coil box, or 2 screws in

blower box. (See Fig. 4.) Do not remove all 4 screws in

each corner. Sections may now be separated by lifting top

section from lower section.

To reassemble, reverse above procedure. Be certain to

reinstall all fasteners when reassembling.

B. Upflow Installation

If return air is to be ducted through a floor, set unit on floor

over opening and use 1/8” / 3.18 mm to 1/4” / 6.35 mm

thick fireproof resilient gasket between duct, unit, and

floor.

Side return is a field option on slope coil models. Cut

opening per dimensions. (See Fig. 1.) A field--supplied

bottom closure is required.

All return--air must pass through the coil.

C. Horizontal Installations

Units must not be installed with access panels facing up or

down.

Be sure installation complies with all applicable building

codes that may require installation of a secondary

condensate pan.

1. Arrange support for unit by setting it in or above

secondary condensate pan.

2. When suspending unit from ceiling dimples in casing

indicate proper location of screws for mounting metal

support straps. (See Fig. 2.)

2 496 01 4201 03

INSTALLA TION INSTRUCTIONS Fan Coils: FCM4X

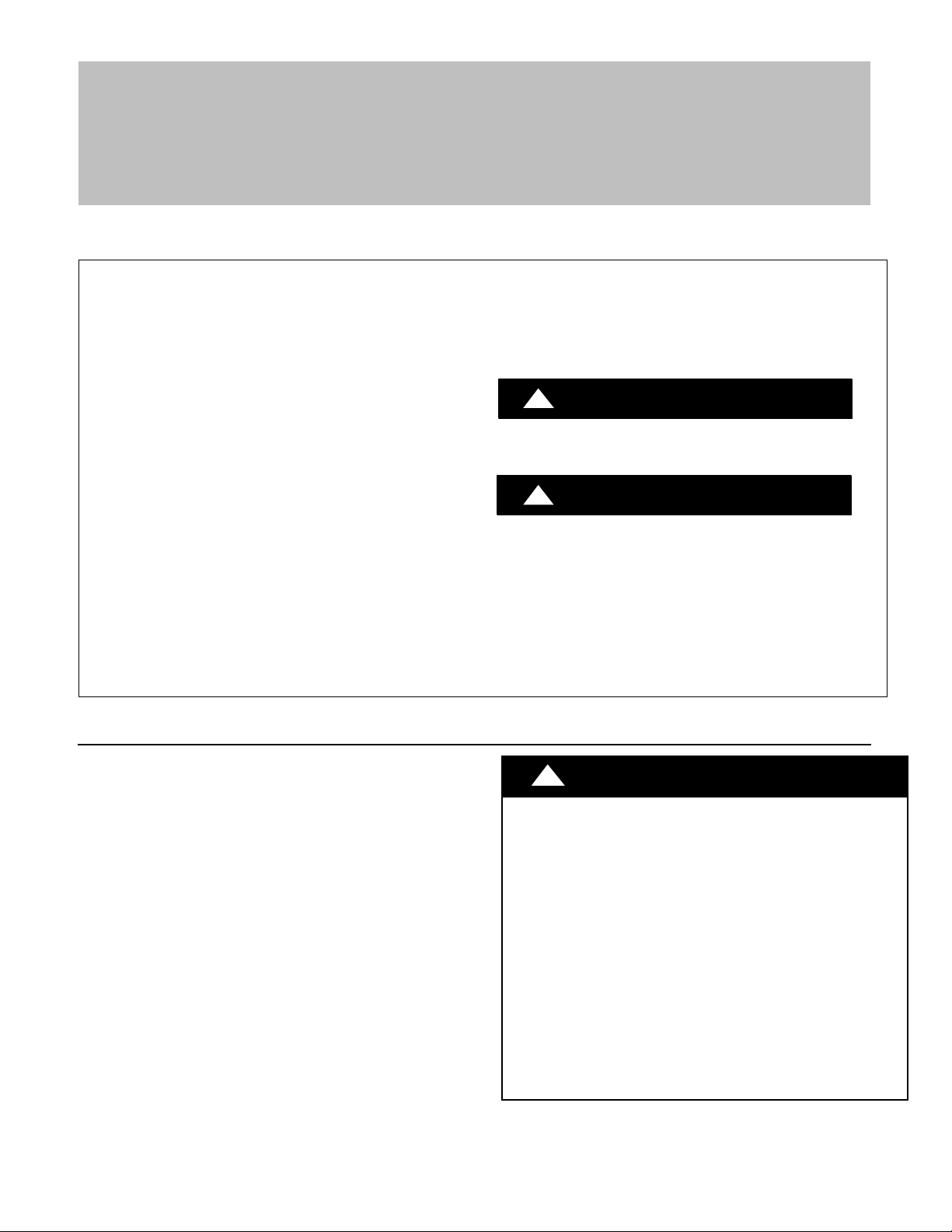

Figure 1 Slope Coil Unit in Upflow Application

POWER ENTRY OPTIONS

24 -- 17.5” (444.5 mm)

36, 48 -- 21” (533.4 mm)

60 -- 24” (609.6 mm)

FRONT SERVICE

CLEARANCE

ACOIL

UNITS

UPFLOW/DOWNFLOW

SECONDARY DRAIN

FIELD SUPPLIED SUPPLY DUCT

LOW VOLT ENTRY OPTIONS

38.1 mm)

1--1/2”

UPFLOW/DOWNFLOW

PRIMARY DRAIN

19”

(482.6 mm)

FIELD MODIFIED

SIDE RETURN

19”

2--1/2”

(63.5 mm)

(482.6 mm)

LOCATION FOR

36 UNITS ONLY

UPFLOW/DOWNFLOW

SECONDARY DRAIN

UPFLOW/DOWNFLOW

PRIMARY DRAIN

FIELD SUPPLIED

RETURN PLENUM

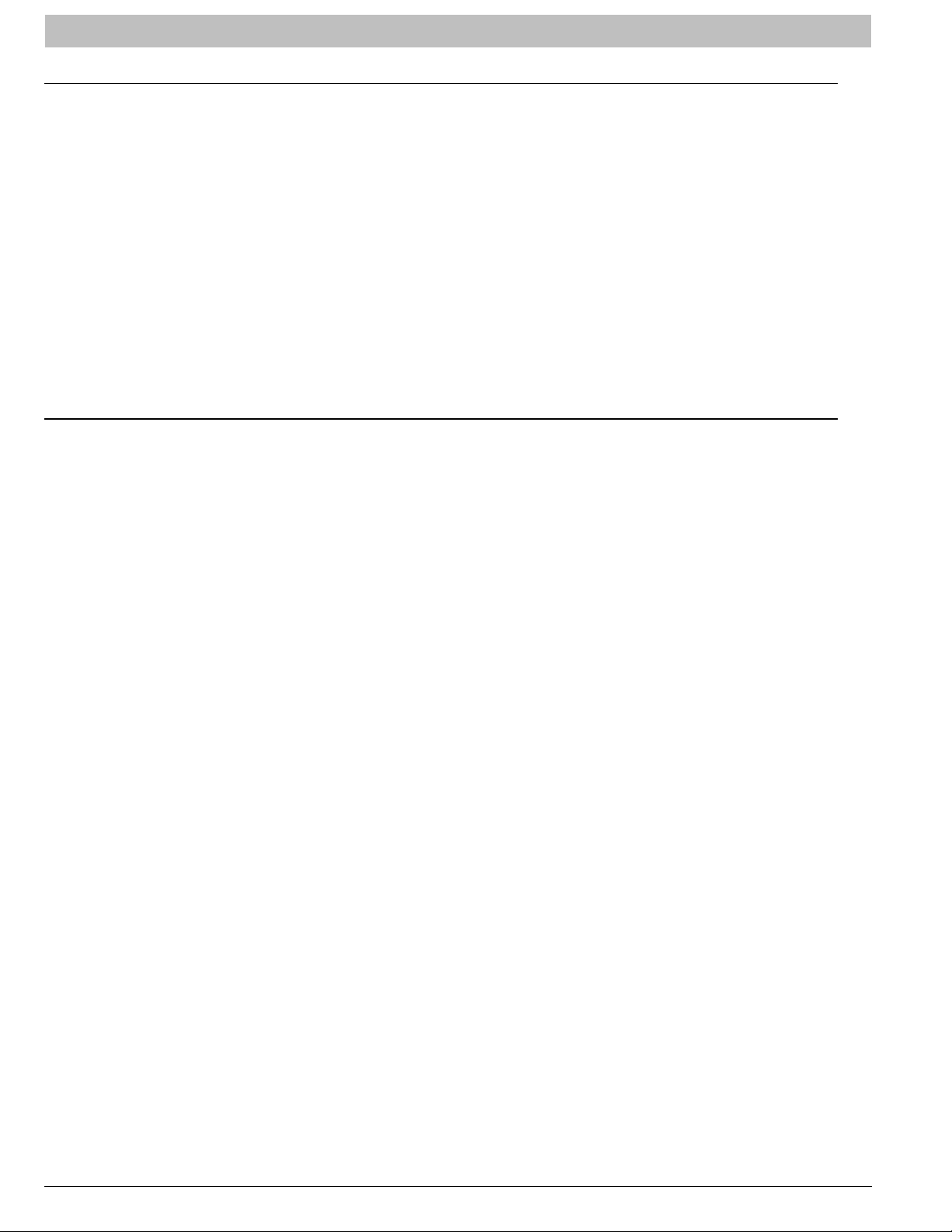

Figure 2 Slope Coil in Horizontal--Left Application (Factory Ready unit only)

A-- COIL

HORIZONTAL LEFT

FIELD

SUPPLIED

HANGING

STRAPS

UNIT

SECONDARY

DRAIN

24 36, 48 21” (533.4 mm)

60 24” (609.6 mm)

FRONT SERVICE

CLEARANCE

(FULL FACE

OF UNIT)

DRAIN

YPRIMAR

A07139

LOW VOLT

ENTRY

OPTIONS

/4” (44.45 mm)

3

1

FILTER ACCESS

CLEARANCE

PRIMARY

DRAIN

A07140

POWER

ENTRY OPTIONS

SECONDARY

DRAIN

496 01 4201 03 3

INSTALLA TION INSTRUCTIONS Fan Coils: FCM4X

Figure 3 A Coil in Horizontal--Left Application

A

FACTORY SHIPPED

HORIZONTAL LEFT

APPLICATION

B

C

HORIZONTAL

DRAIN PAN

Figure 4 Modular Unit Assembly

BLOWER BOX

2 SCREWS

2 SCREWS

REAR CORNER

BRACKET

2 SCREWS

COIL BOX

COIL

BRACKET

COIL

SUPPORT

RAIL

DRAIN PAN

SUPPORT

BRACKET

COIL

BRACKET

PRIMARY DRAIN

AIR SEAL

ASSEMBL

Y

REFRIGERANT

CONNECTIONS

D. Horizontal--Right Conversion of Units with Slope

HORIZONTAL LEFT

SECONDARY DRAIN

HORIZONTAL LEFT

A00072

Coils

NOTE

: Gasket kit number EBAC01GSK is required for

horizontal slope coil conversion to maintain low air

leak/low sweat performance.

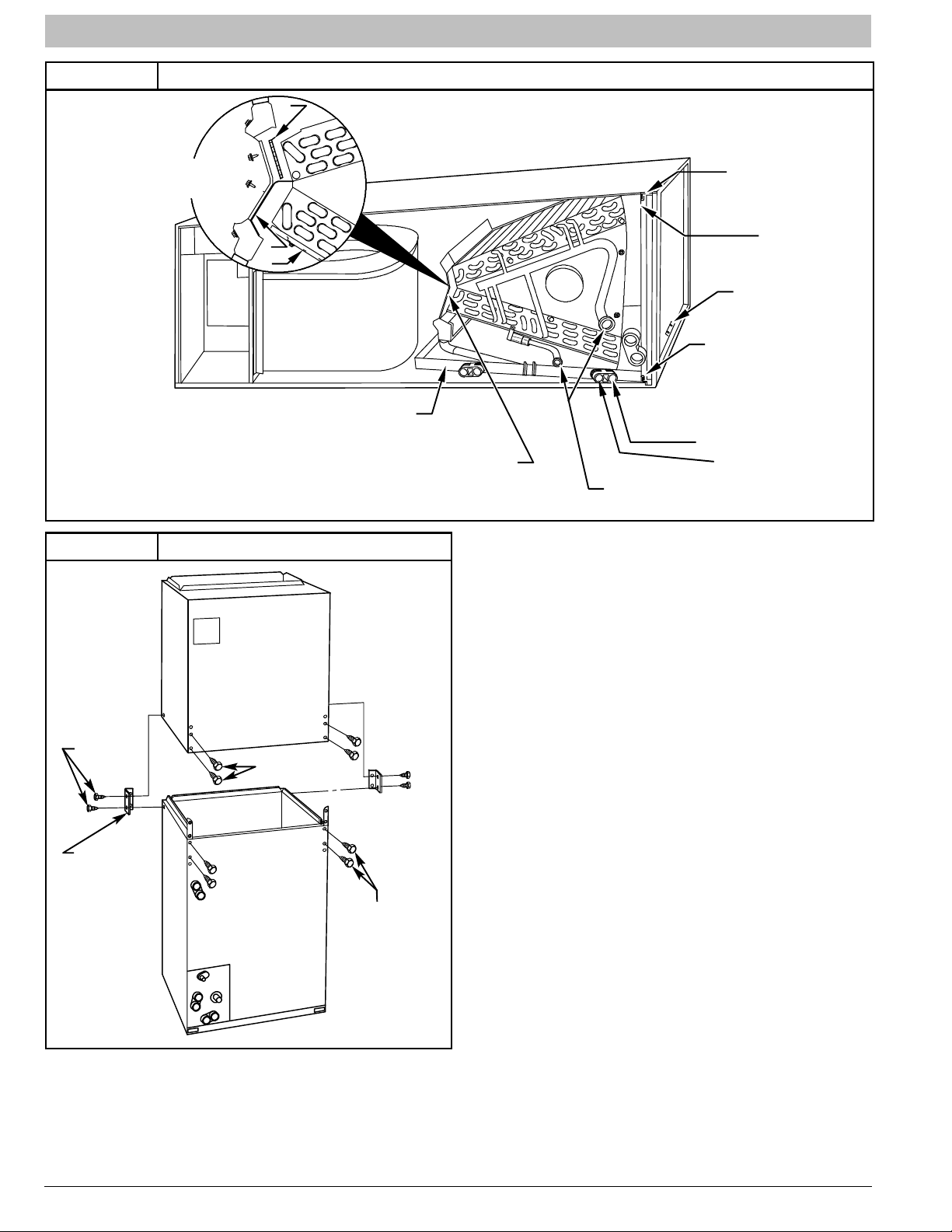

1. Remove blower and coil access panels and fitting

panel. (See Fig. 5.)

2. Remove screw securing coil assembly to right side

casing flange.

3. Remove coil assembly.

4. Lay fan coil on its right side and reinstall coil assembly

with condensate pan down.

5. Attach coil to casing flange using previously removed

coil mounting screw.

6. Make sure pan cap in fitting door is properly seated on

fitting door to retain low air leak rating of the unit.

7. Add gaskets included in kit per kit instructions.

8. Reinstall access panels and fitting panel, aligning

holes with tubing connections and condensate pan

connections.

Make sure liquid and suction tube grommets are in place

to prevent air leaks and cabinet sweating. Install grommets

after brazing.

E. Horizontal Right Conversion of Units With A--Coil

To convert units for horizontal right installations:

1. Remove blower and coil access panels. (See Fig. 6.)

2. Remove metal clip securing fitting panel to

condensate pan. Remove fitting panel.

3. Remove 2 snap--in clips securing A--coil in unit.

4. Slide coil and pan assembly out of unit.

5. Remove horizontal drain pan support bracket from coil

support rail on left side of unit and reinstall on coil

support rail on right side of unit.

4 496 01 4201 03

INSTALLA TION INSTRUCTIONS Fan Coils: FCM4X

6. Convert air seal assembly for horizontal right.

a. Remove air seal assembly from coil by removing 4

screws.

b. Remove air splitter (B) from coil seal assembly by

removing 3 screws. (See Fig. 6 inset)

c. Remove filler plate (A) and install air splitter (B) in

place of filler plate.

d. Install filler plate (A) as shown in horizontal right

application.

e. Remove condensate troughs (C) and install on

opposite tube sheets.

f. Install hose onto plastic spout.

7. Install hose onto plastic spout.

8. Slide coil assembly into casing. Be sure coil bracket on

each corner of vertical pan engages coil support rails.

9. Reinstall 2 snap--in clips to correctly position and

secure coil assembly in unit. Be sure clip with large

offset is used on right side of unit to secure horizontal

pan.

Figure 5

Slope Coil in Horizontal Right Application

COIL MOUNTING

SCREW

10. Remove two oval fitting caps from left side of the coil,

access panel, and fitting panel.

1 1. Remove insulation knockouts on right side of coil

access panel.

12. Remove 2 oval coil access panel plugs and reinstall

into holes on left side of coil access panel and fitting

panel.

13. Install condensate pan fitting caps (from Step 10) in

right side of coil door making sure that cap snaps and

seats cleanly on back side of the coil door. Make sure

no insulation interferes with seating of cap.

14. Reinstall access and fitting panels, aligning holes with

tubing connections and condensate pan connections.

Be sure to reinstall metal clip between fitting panel and

vertical condensate pan.

Make sure liquid and suction tube grommets are in place

to prevent air leaks and cabinet sweating.

BLOWER

ASSEMBLY

COIL

SUPPORT

RAIL

SLOPE COIL

SKI

DRAINPAN

REFRIGERANT

CONNECTIONS

PRIMARY DRAIN

SECONDARY DRAIN

A03001

496 01 4201 03 5

Loading...

Loading...