Page 1

D D

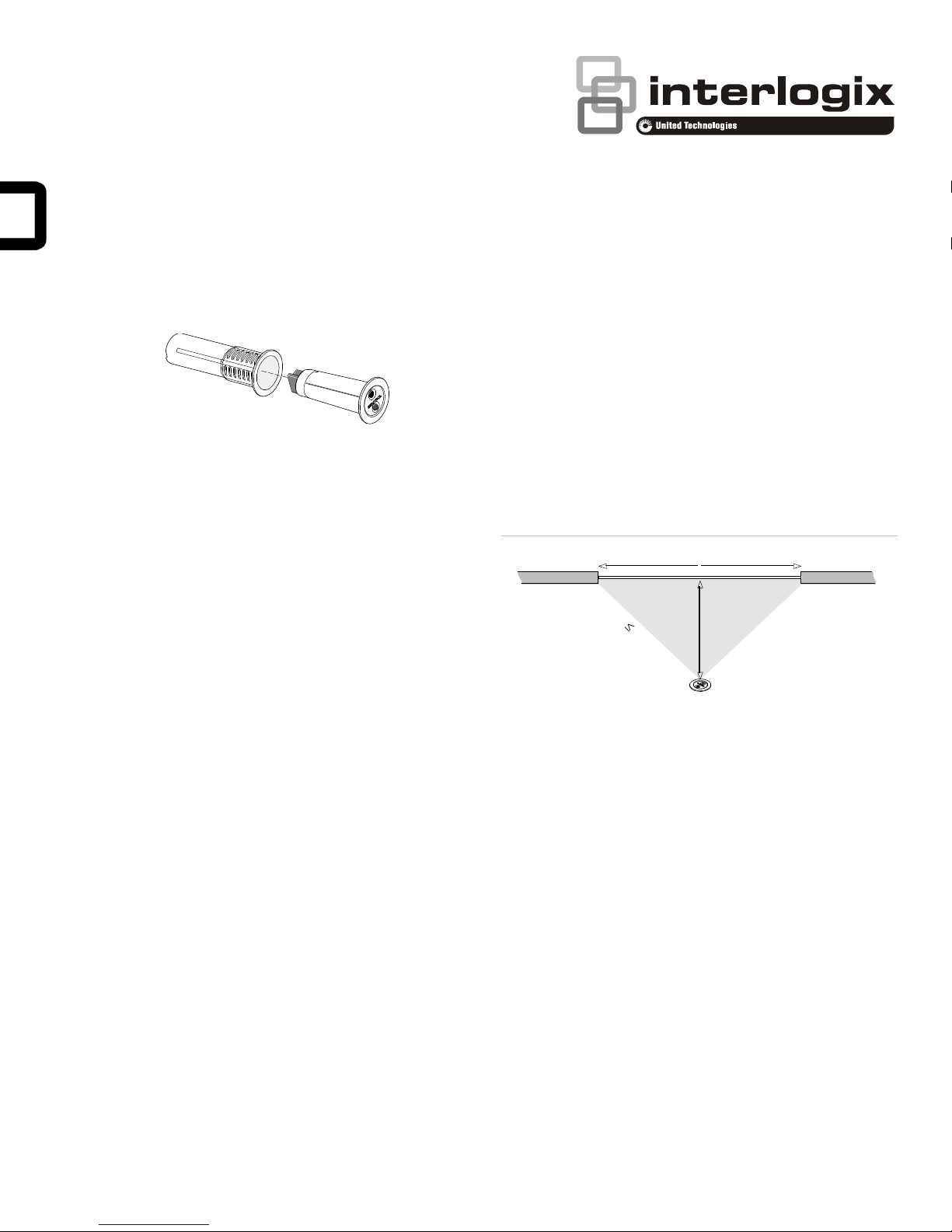

Optimum

detection

zone

D is distance from glass.

The optimum performance zone

is distance D in either direction

on the glass.

ShatterPro

D

2

5

f

t.

ShatterPro II Advanced Acoustic Sensor with

Pattern Recognition Technology Installation

Instructions

The mounting location can affect sensor detection ability. To

ensure optimum performance, the coverage zone width should

be no greater than two times the distance from the sensor to

the closest point of glass. For instance, if a sensor is mounted

SEE PAGE 4 FOR IMPORTANT WARNINGS, DISCLAIMERS,

AND PRODUCT/SAFETY INFORMATION.

10 ft. (3 m) from the glass, its optimum performance zone will

be 10 ft. (3 m) in either direction of the midpoint. You can

mount the sensors from 3.3 to 25 ft. (1 to 7.6 m) from the

farthest point of the glass. Figure 1 below shows the coverage

zone with D being the distance from the glass.

Introduction

This is the 5820A-W and 5825A-W ShatterPro II Advanced

Acoustic Sensor Installation Instructions. The ShatterPro II

sensor is designed to detect breaking glass from framed

windows in the perimeter of a building.

Install the sensors on a perimeter loop armed whenever the

door and window contacts are armed. To prevent false alarms,

avoid applications where glassbreak sensors are configured to

be active in all arming levels.

The sensor false alarm immunity technology functions best in

rooms with only moderate noise. Some sounds can duplicate

the points on the glassbreak pattern the sensors detect.

The sensors may not consistently detect cracks in glass or

bullets that break through the glass. Always complement

glassbreak sensors with interior protection.

Connect the sensors to a UL Listed control panel, or a power

supply that provides at least four hours of standby power.

Mounting location

You can mount the sensors on the ceiling or on a wall.

Wall mount

The best wall-mount location is on the wall opposite to the

glass to be protected, assuming this glass is within the sensor

range and line of sight. You can also use the adjoining wall.

Figure 1: Coverage zone

Use the following guidelines to determine the best mounting

location:

• Mount the sensors at least 3.3 ft. (1 m) from the windows

being protected and at least 4 ft. (1.2 m) from noise

sources such as TV’s, speakers, sinks and doors.

• Mount the sensors in the direct line of sight of the glass to

be protected.

• Avoid rooms smaller than 10 by 10 ft. (3 m by 3 m).

• Avoid locations where lined, insulating, or sound

deadening drapes or closed wooden shutters are used.

• Mount the sensors in a suitable environment: temperature

between 0 and 120°F (−18 and 50°C); and humidity

between 10 and 90% noncondensing. Do not install the

sensors in humid rooms. Excess moisture on the circuit

boards can eventually cause a short and a false alarm.

Ceiling mount

Mount the sensors in a location that is in direct line of sight of

the glass to be protected. However, since sound travels out

from a broken window, a position 8 ft. (2.4 m) into the room

provides better detection.

© 2017 UTC Fire & Security Americas Corporation, Inc. 1 / 6 P/N 466-2934 • REV A • ISS 26MAY17

• Mount the sensors on a stable surface up to 25 ft. (7.6 m)

from the farthest point on the glass surface.

Page 2

25 ft. (7.5 m)

2

5

f

t

.

(

7

.

5

m

)

Hold tester so that the speaker is

within 1 inch of sensor microphone.

In test mode the sensor LED will light

solid for about 4 seconds,

then blink for about a minute.

1 inch

• Avoid locations that expose the sensors to possible false

alarm sources such as:

- Glass airlocks and vestibule areas

- Kitchens

- Corner mountings

- Residential car garages

- Small utility rooms

- Stairwells

- Bathrooms

- Small acoustically live rooms

Coverage range

The sensors are omnidirectional, providing 360° coverage.

Coverage is measured from a sensor to the point on the glass

farthest from the sensor. The sensors can be mounted as

close as 3.3 ft. (1 m) from the glass. The maximum range

depends on the type of glass being protected:

Armor-coated glass

Mount the sensors no more than 12 ft. (3.65 m) from the glass.

Plate, tempered, laminated, and wired glass

When the sensors are mounted on the ceiling or the opposite

or adjoining wall, (Figure 2 below) maximum range is 25 ft.

(7.5 m).

Figure 2: Maximum coverage range

test mode, the LED will blink continuously. To extend test

time, activate the tester at least once a minute.

When the system is armed and the sensor trips to an alarm

condition, the LED will light solid for four seconds and then

revert back to a one minute test mode. At the end of one

minute, the LED will extinguish if it is in set up LED mode, or

the LED will light if it is in latching LED mode.

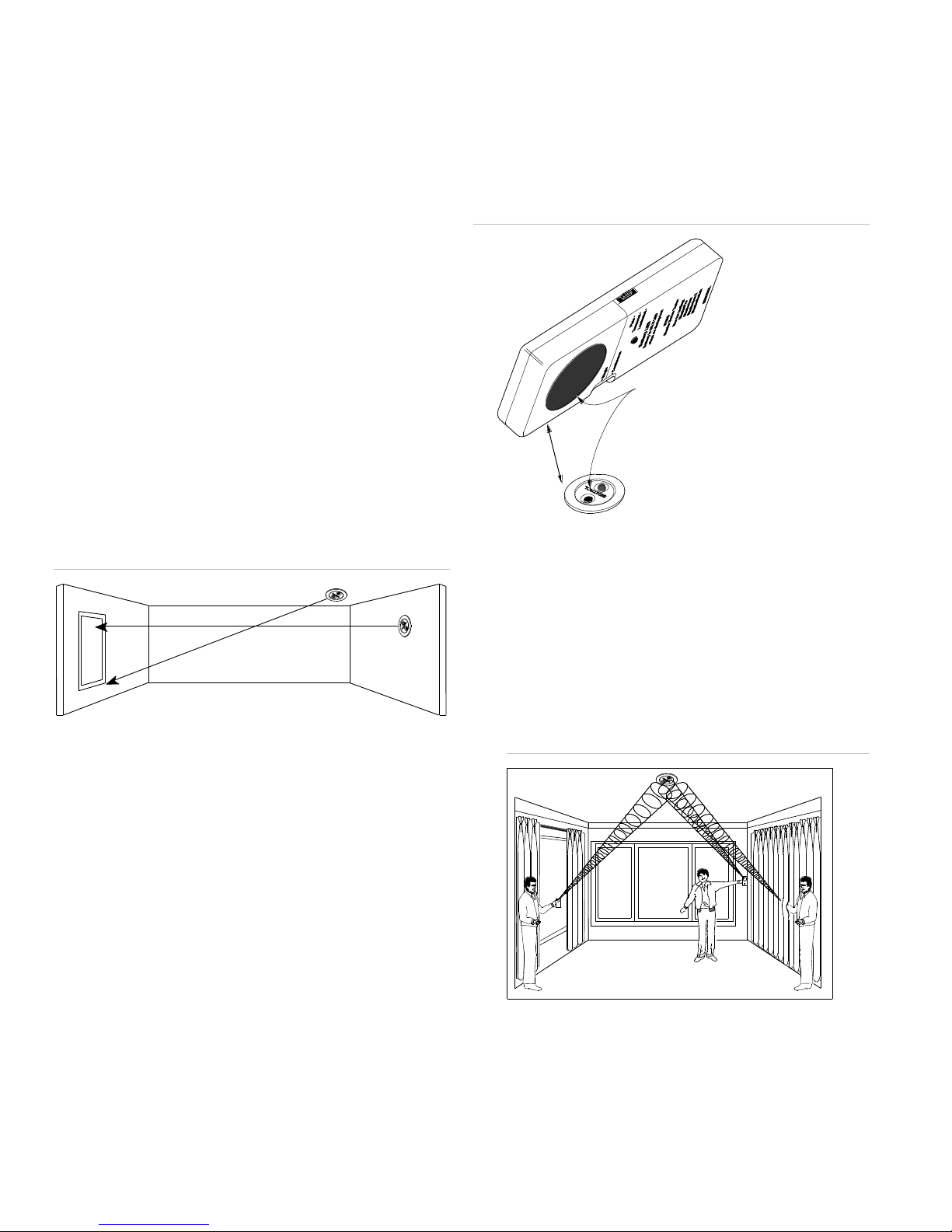

Figure 3: Activating test mode

Sensor test

Before you can test the sensors, they must be in test mode

(blinking). To test the sensors, do the following:

1. Choose the laminated setting on the tester.

Testing

Test the sensor upon installation and if the window glass-type

is changed.

The sensors are designed to detect the breaking of framed

glass mounted in an outside wall. Testing the sensors with

unframed glass, broken bottles, etc., may not trip the sensors.

The sensors typically do not trip to glass breaking in the middle

of the room. To verify sensor range and operation, you need to

use the UTC Fire & Security 5709C hand-held tester.

Test mode

To put the sensors in test mode, do the following:

1. Connect a 9-volt battery to the sensor for pretesting.

2. Temporarily mount sensor in the desired location.

3. Use the 5709C hand-held tester to put the sensor into test

mode. Set the tester to tempered glass and hold the tester

on top of the sensor (Figure 3 below). Activate the tester,

this will trip the sensor into test mode for one minute. In

2. Hold the tester near the surface of the glass to be

protected and aim the speaker at the sensor. Be sure the

tester is at the point on the glass farthest from the sensor.

If closed drapes or curtains are present, hold the tester

behind them (Figure 4 below).

Figure 4: Testing behind curtains

3. Press the test button on the tester. The LED on the sensor

should stay on for four seconds to indicate the glass is

within detection range of the sensor. If the LED does not

stay on for four seconds, move the sensor and retest.

For latching LED, provide a power reset by removing power

and resetting the LED.

2 / 6 P/N 466-2934 • REV A • ISS 26MAY17

Page 3

Voltage

9 to 16 VDC

Current:

Typical

Maximum

15 mA

25 mA

Relay output:

On resistance

Off resistance

Normally closed, open 4 seconds upon alarm

10 Ω −5 +10

> 1 MΩ

Maximum loop rating

16 VDC, 50 mA (relay)

Detection range

3.3 to 25 ft. (1 to 7.5 m) , 360°

Minimum glass size

12 by 24 in. (0.3 by 0.6 m)

Recommended glass

thickness:

Plate

Tempered

Wired

Laminated

3/32 to 1/4 in. (2.4 to 6.4 mm)

1/8 to 1/4 in. (3.2 to 6.4 mm)

1/4 in. (6.4 mm)

1/8 to 1/4 in. (3.2 to 6.4 mm)

Operating temperature

0 to 120°F (−18 to 50°C)

Relative humidity

10 to 90% noncondensing

Microphone

Omnidirectional electret

Color

White

Wiring terminals

14-22 AWG

Manufacturer

UTC Fire & Security Americas Corporation, Inc.

3211 Progress Drive, Lincolnton, NC, 28092, USA

AUTHORIZED EU REPRESENTATIVE:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert, Netherlands

FCC/IC

This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful

interference in a residential installation.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful

interference to radio communications. However, there

is no guarantee that interference will not occur in a

particular installation.

If this equipment does cause harmful interference to

radio or television reception, which can be determined

by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or

more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment

and receiver.

- Connect the equipment into an outlet on a circuit

5825A Single Gang Box

ShatterPro™ II

2.53 in. diameter (6.43 cm)

1 in. diameter hole (2.54 cm)

5829A Single Gang Box Plate

4.5 in.

(11.43 cm)

2.75 in.

(6.99 cm)

(Back box

not included)

Cut for

latching LED

Installation

All wiring must conform to the National Electric Code (NEC)

and/or local codes having jurisdiction.

Do not install sensors in rooms with ultrasonic sensors.

To mount the sensor on a wall or ceiling, do the following:

1. Drill a 1 in. (2.5 cm) hole. For hard woods, drill a 1 1/16 in.

(2.7 cm) hole. For a cleaner hole, use a spade bit rather

than a twist bit.

2. Run wires through the hole and the sleeve to the sensor.

3. Connect wires to the wire terminals as shown in “Wiring”

below.

4. Insert the sleeve into the mounting hole and insert the

sensor into the sleeve, matching the ribs on the sensor

with the grooves on the sleeve.

To mount the Single-gang Box ShatterPro II model (5825A-W)

in a single-gang box, see Figure 5 below and do the following:

1. Mount the adaptor bracket to the single-gang box (not

included) and mount the adaptor plate to the bracket.

2. Run wires through the wire entry hole and sleeve to the

sensor.

3. Connect wires to the wire terminals as shown in “Wiring”

below.

Maintenance

When installed and used properly, minimal maintenance is

required. You should test the sensors annually to ensure

proper operation.

Clean the covers with a damp (water) cloth as needed to keep

it free of dust and dirt. Always test the sensors after cleaning

them.

Specifications

4. Insert the sleeve into the adaptor plate and insert the

sensor into the sleeve, matching the ribs on the sensor

with the grooves in the sleeve.

Figure 5: Recessed mounting in a single gang box

Wiring

Strip back the outer jacket on your wiring cable. This allows

wires to flex in the case. Make sure the cable is slack in the

wall to avoid stressing the wires at their connections.

Figure 6 below shows the wiring terminals for ShatterPro II.

Figure 6: ShatterPro II wiring terminals

P/N 466-2934 • REV A • ISS 26MAY17 3 / 6

Regulatory information

Page 4

different from that to which the receiver is

connected.

- Consult the dealer or an experienced radio/TV

technician for help.

Changes or modifications not expressly approved by

UTC Fire and Security could void the user’s authority

to operate the equipment.

This device complies with Industry Canada licenseexempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause

interference, and (2) this device must accept any

interference, including interference that may cause

undesired operation of the device.

Cet appareil est conforme avec Industrie Canada

exempts de licence standard RSS (s). Son

fonctionnement est soumis aux deux conditions

suivantes: (1) cet appareil ne doit pas provoquer

d'interférences et (2) cet appareil doit accepter toute

interférence, y compris celles pouvant causer un

mauvais fonctionnement de l'appareil.

Copyright

Copyright © 2017 United Technologies Corporation.

All rights reserved.

Trademarks

Interlogix is a registered trademark of United

Technologies Corporation. Interlogix is part of UTC

Climate, Controls & Security, a unit of United

Technologies Corporation.

Product

warnings

THESE PRODUCTS ARE INTENDED FOR SALE TO

AND INSTALLATION BY AN EXPERIENCED

SECURITY PROFESSIONAL. UTC FIRE &

SECURITY AMERICAS CORPORATION, INC.

("INTERLOGIX") CANNOT PROVIDE ANY

ASSURANCE THAT ANY PERSON OR ENTITY

BUYING ITS PRODUCTS, INCLUDING ANY

“AUTHORIZED DEALER”, IS PROPERLY TRAINED

OR EXPERIENCED TO CORRECTLY INSTALL

SECURITY RELATED PRODUCTS.

A PROPERLY INSTALLED AND MAINTAINED

ALARM/SECURITY SYSTEM MAY ONLY REDUCE

THE RISK OF EVENTS SUCH AS BREAK-INS,

BURGLARY, ROBBERY OR FIRE; IT IS NOT

INSURANCE OR A GUARANTEE THAT SUCH

EVENTS WILL NOT OCCUR, THAT ADEQUATE

WARNING OR PROTECTION WILL BE PROVIDED,

OR THAT THERE WILL BE NO DEATH, PERSONAL

INJURY, AND/OR PROPERTY DAMAGE AS A

RESULT.

WHILE INTERLOGIX MAKES REASONABLE

EFFORTS TO REDUCE THE PROBABILITY THAT A

THIRD PARTY MAY HACK, COMPROMISE OR

CIRCUMVENT ITS SECURITY PRODUCTS,

RELATED SOFTWARE OR CLOUD SERVERS, ANY

SECURITY PRODUCT, SOFTWARE OR CLOUD

SERVER MANUFACTURED, SOLD AND/OR

LICENSED BY INTERLOGIX, MAY STILL BE

HACKED, COMPROMISED AND/OR

CIRCUMVENTED.

CERTAIN PRODUCTS OR SOFTWARE

MANUFACTURED, SOLD OR LICENSED BY

INTERLOGIX CONNECT TO THE INTERNET TO

SEND AND/OR RECEIVE DATA (“INTERNET OF

THINGS” OR “IOT” PRODUCTS). ANY CONTINUED

USE OF AN IOT PRODUCT AFTER INTERLOGIX

HAS CEASED SUPPORTING THAT IOT PRODUCT

(E.G., THROUGH NOTICE THAT INTERLOGIX NO

LONGER PROVIDES FIRMWARE UPDATES OR

BUG FIXES) MAY RESULT IN REDUCED

PERFORMANCE, MALFUNCTION, AND/OR

INCREASED VULNERABILITY TO HACKING,

COMPROMISE AND/OR CIRCUMVENTION.

INTERLOGIX DOES NOT ENCRYPT

COMMUNICATIONS BETWEEN ITS ALARM OR

SECURITY PANELS AND THEIR OUTPUTS/INPUTS

INCLUDING, BUT NOT LIMITED TO, SENSORS OR

DETECTORS UNLESS REQUIRED BY APPLICABLE

LAW. AS A RESULT THESE COMMUNICATIONS

MAY BE INTERCEPTED AND COULD BE USED TO

CIRCUMVENT YOUR ALARM/SECURITY SYSTEM.

THE ABILITY OF INTERLOGIX PRODUCTS AND

SOFTWARE TO WORK PROPERLY DEPENDS ON

A NUMBER OF PRODUCTS AND SERVICES MADE

AVAILABLE BY THIRD PARTIES OVER WHICH

INTERLOGIX HAS NO CONTROL INCLUDING, BUT

NOT LIMITED TO, INTERNET, CELLULAR AND

LANDLINE CONNECTIVITY; MOBILE DEVICE AND

OPERATING SYSTEM COMPATIBILITY; AND

PROPER INSTALLATION AND MAINTENANCE.

INTERLOGIX SHALL NOT BE LIABLE FOR ANY

DAMAGES CAUSED BY ACTIONS OR OMISSIONS

OF THIRD PARTIES.

BATTERY OPERATED SENSORS, DETECTORS,

KEYFOBS, PANIC DEVICES AND OTHER PANEL

ACCESSORIES HAVE A LIMITED BATTERY LIFE.

WHILE THESE PRODUCTS MAY BE DESIGNED TO

PROVIDE SOME WARNING OF IMMINENT

BATTERY DEPLETION, THE ABILITY TO DELIVER

SUCH WARNINGS IS LIMITED AND SUCH

WARNINGS MAY NOT BE PROVIDED IN ALL

CIRCUMSTANCES. PERIODIC TESTING OF THE

SYSTEM IN ACCORDANCE WITH PRODUCT

DOCUMENTATION IS THE ONLY WAY TO

DETERMINE IF ALL SENSORS, DETECTORS,

KEYFOBS, PANIC DEVICES AND OTHER PANEL

ACCESSORIES ARE FUNCTIONING PROPERLY.

CERTAIN SENSORS, PANIC DEVICES AND OTHER

PANEL ACCESSORIES MAY BE PROGRAMMED

INTO AN ALARM PANEL AS “SUPERVISORY” SO

THAT THE ALARM PANEL WILL INDICATE IF IT

DOES NOT RECEIVE A REGULAR SIGNAL FROM

THE DEVICE WITHIN A CERTAIN PERIOD OF TIME.

CERTAIN DEVICES CANNOT BE PROGRAMMED

AS SUPERVISORY. DEVICES CAPABLE OF BEING

PROGRAMMED AS SUPERVISORY MAY NOT BE

PROPERLY PROGRAMMED AT INSTALLATION,

RESULTING IN A FAILURE TO REPORT TROUBLE

WHICH COULD RESULT IN DEATH, SERIOUS

INJURY AND/OR PROPERTY DAMAGE.

SIRENS/SOUNDERS, INCLUDING INTERNAL

SIRENS/SOUNDERS IN PANELS, ARE DESIGNED

TO EMIT VERY LOUD SOUNDS. THESE SOUNDS

CAN CAUSE HEARING DAMAGE TO PERSONS

EITHER IN CLOSE PROXIMITY TO THE

SIREN/SOUNDER WHEN ACTIVATED OR

EXPOSED TO SUCH SOUNDS OVER LONGER

PERIODS OF TIME.

Warranty

disclaimers

and other

disclaimers

INTERLOGIX HEREBY DISCLAIMS ALL

WARRANTIES AND REPRESENTATIONS,

WHETHER EXPRESS, IMPLIED, STATUTORY OR

OTHERWISE INCLUDING (BUT NOT LIMITED TO)

ANY WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE WITH

RESPECT TO ITS SECURITY PRODUCTS AND

RELATED SOFTWARE. INTERLOGIX FURTHER

DISCLAIMS ANY OTHER IMPLIED WARRANTY

UNDER THE UNIFORM COMPUTER INFORMATION

4 / 6 P/N 466-2934 • REV A • ISS 26MAY17

Page 5

TRANSACTIONS ACT OR SIMILAR LAW AS

ENACTED BY ANY COUNTRY.

(USA ONLY) SOME STATES DO NOT ALLOW THE

EXCLUSION OF IMPLIED WARRANTIES, SO THE

ABOVE EXCLUSION MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS AND YOU MAY ALSO HAVE OTHER

LEGAL RIGHTS THAT VARY FROM STATE TO

STATE.

INTERLOGIX MAKES NO REPRESENTATION,

WARRANTY, COVENANT OR PROMISE THAT ITS

SECURITY PRODUCTS AND/OR RELATED

SOFTWARE (I) WILL NOT BE HACKED,

COMPROMISED AND/OR CIRCUMVENTED; (II)

WILL PREVENT, OR PROVIDE ADEQUATE

WARNING OR PROTECTION FROM, BREAK-INS,

BURGLARY, ROBBERY, FIRE; OR (III) WILL WORK

PROPERLY IN ALL ENVIRONMENTS AND

APPLICATIONS.

INTERLOGIX WILL NOT BE LIABLE FOR

UNAUTHORIZED ACCESS (I.E., HACKING) INTO

THE CLOUD SERVERS OR YOUR TRANSMISSION

FACILITIES, PREMISES OR EQUIPMENT, OR FOR

UNAUTHORIZED ACCESS TO DATA FILES,

PROGRAMS, PROCEDURES OR INFORMATION

THEREON, UNLESS AND ONLY TO THE EXTENT

THAT THIS DISCLAIMER IS PROHIBITED BY

APPLICABLE LAW.

SYSTEMS SHOULD BE CHECKED BY A QUALIFIED

TECHNICIAN AT LEAST EVERY 3 YEARS UNLESS

OTHERWISE INSTRUCTED IN THE PRODUCT

DOCUMENTATION AND, IF APPLICABLE, THE

BACKUP BATTERY REPLACED AS REQUIRED.

THE INFORMATION IN THIS DOCUMENT IS

SUBJECT TO CHANGE WITHOUT NOTICE.

UPDATED INFORMATION CAN BE FOUND AT

WWW.UTCFSSECURITYPRODUCTS.EU/PRODUCT

WARNING/. INTERLOGIX ASSUMES NO

RESPONSIBILITY FOR INACCURACIES OR

OMISSIONS AND SPECIFICALLY DISCLAIMS ANY

LIABILITIES, LOSSES, OR RISKS, PERSONAL OR

OTHERWISE, INCURRED AS A CONSEQUENCE,

DIRECTLY OR INDIRECTLY, OF THE USE OR

APPLICATION OF ANY OF THE CONTENTS OF

THIS DOCUMENT.

THIS PUBLICATION MAY CONTAIN EXAMPLES OF

SCREEN CAPTURES AND REPORTS USED IN

DAILY OPERATIONS. EXAMPLES MAY INCLUDE

FICTITIOUS NAMES OF INDIVIDUALS AND

COMPANIES. ANY SIMILARITY TO NAMES AND

ADDRESSES OF ACTUAL BUSINESSES OR

PERSONS IS ENTIRELY COINCIDENTAL.

REFER TO THE DATA SHEET AND USER

DOCUMENTATION FOR INFORMATION ON USE.

FOR THE LATEST PRODUCT INFORMATION,

CONTACT YOUR SUPPLIER OR VISIT

WWW.INTERLOGIX.COM.

2012/19/EU (WEEE directive): Products marked with

this symbol cannot be disposed of as unsorted

municipal waste in the European Union. For proper

recycling, return this product to your local supplier

upon the purchase of equivalent new equipment, or

dispose of it at designated collection points. For more

information see:

www.utcfssecurityproducts.eu/recycle/

Product

Description

5820A-W

Recessed ShatterPro II, latch or nonlatch LED

5825A-W

Single-gang Box ShatterPro II

Accessories

5709C-W

Glassbreak hand-held tester

P/N 466-2934 • REV A • ISS 26MAY17 5 / 6

Product ordering

Contact information

www.interlogix.com

For customer support, see www.interlogix.com/customer-

support

Page 6

6 / 6 P/N 466-2934 • REV A • ISS 26MAY17

Loading...

Loading...