Page 1

Intel® Server Platform

SR6850HW4

Technical Product Specification

Intel order number D23151-001

Enterprise Platforms and Services Division – Marketing

Intel Confidential

Revision 1.0

May, 2005

Page 2

Revision History Intel® Server Platform SR6850HW4 TPS

Revision History

Date Revision

Number

May 2005 1.0 Initial release.

Modifications

Disclaimers

Information in this document is provided in connection with Intel® products. No license, express

or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document. Except as provided in Intel's Terms and Conditions of Sale for such products, Intel

assumes no liability whatsoever, and Intel disclaims any express or implied warranty, relating to

sale and/or use of Intel products including liability or warranties relating to fitness for a particular

purpose, merchantability, or infringement of any patent, copyright or other intellectual property

right. Intel products are not intended for use in medical, life saving, or life sustaining

applications. Intel may make changes to specifications and product descriptions at any time,

without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked

“reserved” inches or “undefined” Intel reserves these for future definition and shall have no

responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

This document contains information on products in the design phase of development. Do not

finalize a design with this information. Revised information will be published when the product

is available. Verify with your local sales office that you have the latest datasheet before

finalizing a design.

The Intel® Server Platform SR6850HW4 may contain design defects or errors known as errata,

which may cause the product to deviate from published specifications. Current characterized

errata are available on request.

Intel Corporation server baseboards contain a number of high-density VLSI and power delivery

components that need adequate airflow to cool. Intel’s own chassis are designed and tested to

meet the intended thermal requirements of these components when the fully integrated system

is used together. It is the responsibility of the system integrator that chooses not to use Intel

developed server building blocks to consult vendor datasheets and operating parameters to

determine the amount of airflow required for their specific application and environmental

conditions. Intel Corporation cannot be held responsible if components fail or the server board

does not operate correctly when used outside any of their published operating or non-operating

limits.

Intel and Xeon are trademarks or registered trademarks of Intel Corporation.

*Other brands and names may be claimed as the property of others.

Copyright © Intel Corporation 2005.

Revision 1.0

ii

Intel order number D23151-001

Page 3

Intel® Server Platform SR6850HW4 TPS Table of Contents

Table of Contents

1. Product Overview.................................................................................................................1

2. System Overview..................................................................................................................3

2.1 System Feature Overview........................................................................................ 3

2.2 Introduction .............................................................................................................. 4

2.3 External Chassis Features - Front ........................................................................... 8

2.3.1 Front Control Panel.................................................................................................. 8

2.3.2 Hot-swap Hard Disk Drive and Peripheral Device Bays .......................................... 9

2.4 External Chassis Features - Rear.......................................................................... 10

2.5 Internal Chassis Features...................................................................................... 11

2.5.1 Server Board Set SE8500HW4 Mainboard............................................................ 11

2.5.2 Server Board Set SE8500HW4 Memory Board ..................................................... 12

2.5.3 Power Distribution Board ....................................................................................... 12

2.5.4 SCSI Backplane Board Board ...............................................................................12

2.5.5 Front Panel I/O Board............................................................................................ 13

2.5.6 Front Panel Control Board ..................................................................................... 13

2.5.7 SATA-to-IDE Converter Board............................................................................... 13

2.5.8 Intel® Management Module................................................................................... 13

2.5.9 Fibre Channel Module ...........................................................................................14

2.5.10 RAID On Motherboard (ROMB) ............................................................................. 14

2.5.11 Power Supply Module............................................................................................ 14

2.5.12 Cooling Subsystem................................................................................................ 16

2.6 New Platform Features .......................................................................................... 16

2.6.1 Advanced Memory Performance and Protection ................................................... 16

2.6.2 Rolling BIOS .......................................................................................................... 17

2.7 Server Management .............................................................................................. 17

2.7.1 Intel Management Module (IMM)........................................................................... 17

2.7.2 Hot Swap Controller............................................................................................... 19

2.8 Reliability, Availability, Serviceability, Usability, Manageability (RASUM) ............. 19

2.9 Expansion Support ................................................................................................20

2.10 Specifications......................................................................................................... 21

2.10.1 Environmental Specifications Summary ................................................................ 21

2.10.2 Physical Specifications .......................................................................................... 22

Revision 1.0

Intel order number D23151-001

iii

Page 4

Table of Contents Intel® Server Platform SR6850HW4 TPS

3. Server System Chassis and Assemblies .........................................................................23

3.1 Chassis, Rails and Top Cover ............................................................................... 23

3.1.1 Chassis .................................................................................................................. 23

3.1.2 Slide Rails.............................................................................................................. 25

3.1.3 Top Cover .............................................................................................................. 25

3.2 Power and Fans..................................................................................................... 25

3.3 Fan Subsystem...................................................................................................... 26

3.4 Mainboard Assembly ............................................................................................. 26

3.5 Peripheral Bay and Front Panel............................................................................. 27

3.5.1 Hot-Swap Hard Disk Drive Carrier......................................................................... 27

3.5.2 Optical Drive Carrier .............................................................................................. 28

3.5.3 Front Panel ............................................................................................................ 29

3.6 Front Bezel ............................................................................................................30

4. Cables and Connectors .....................................................................................................31

4.1 Cable and System Interconnect Descriptions........................................................ 33

4.2 User-accessible I/O Connectors ............................................................................ 35

4.2.1 Video Connectors .................................................................................................. 35

4.2.2 USB 2.0 Connectors .............................................................................................. 36

4.2.3 Etherent Connectors.............................................................................................. 37

4.2.4 External 68-pin Ultra320 SCSI VHDCI Connector................................................. 39

4.2.5 Internal 68-pin SCSI Connectors ........................................................................... 40

4.2.6 80-pin SCA2 Hard Disk Drive Connectors............................................................. 41

4.2.7 AC Power Input Connectors .................................................................................. 42

4.2.8 3-pin Chassis Intrusion Connector......................................................................... 42

4.2.9 12-pin Power Distribution Board Power Connector ............................................... 42

4.2.10 30-pin Power Distribution Board to Mainboard Connector .................................... 43

4.2.11 30-pin SCSI Backplane Board Board to Front Panel I/O Board Connector........... 43

4.2.12 100-pin Mainboard to SCSI Backplane Board Board Connector........................... 44

4.2.13 Peripheral Power Connector.................................................................................. 45

4.2.14 Fan Connectors ..................................................................................................... 46

4.2.15 50-pin Front Panel Control Module Connector ...................................................... 47

4.2.16 SATA-to-IDE Converter Board Connector ............................................................. 48

4.2.17 SATA-to-IDE Converter Board Power Connector .................................................. 48

4.2.18 SATA Connector.................................................................................................... 49

5. Power Supply......................................................................................................................51

Revision 1.0

iv

Intel order number D23151-001

Page 5

Intel® Server Platform SR6850HW4 TPS Table of Contents

5.1 Mechanical Outline ................................................................................................ 52

5.2 Power Supply Output Interface.............................................................................. 54

5.2.1 Blade Connector .................................................................................................... 54

5.3 AC Input Requirement ........................................................................................... 55

5.3.1 AC Input Voltage Specification .............................................................................. 55

5.3.2 Efficiency ...............................................................................................................55

5.3.3 Input Over-Current Protection................................................................................ 55

5.3.4 Inrush Current........................................................................................................ 55

5.3.5 Auto Restart........................................................................................................... 56

5.3.6 Power Factor Correction (PFC) ............................................................................. 56

5.3.7 AC Input Connector ............................................................................................... 56

5.4 DC Output Requirements ...................................................................................... 56

5.4.1 Hot Swap Functionality .......................................................................................... 57

5.4.2 Output Current Rating............................................................................................ 57

5.4.3 Over- and Under-Voltage Protection ..................................................................... 57

5.4.4 Over-current Protection .........................................................................................58

5.4.5 Short Circuit Protection.......................................................................................... 58

5.4.6 Reset After Shutdown............................................................................................ 58

5.4.7 Current Sharing .....................................................................................................59

5.4.8 I2C Devices ............................................................................................................ 59

5.4.9 Fan Speed Control................................................................................................. 61

5.4.10 Power Supply Module LED indicators ................................................................... 61

6. Power Distribution Board..................................................................................................63

6.1 Introduction ............................................................................................................ 63

6.2 Signal Descriptions and Pinouts ............................................................................ 65

6.2.1 Remote On/Off (-PS_ON)...................................................................................... 66

6.2.2 Power Good Signal (POK or P_GOOD) ................................................................66

6.2.3 VIN_GOOD............................................................................................................ 66

7. SCSI Backplane Board.......................................................................................................67

7.1 Introduction ............................................................................................................ 67

7.1.1 Block Diagram .......................................................................................................67

7.1.2 Architectural Overview........................................................................................... 68

7.1.3 Mechanical Specifcations ...................................................................................... 70

7.1.4 Component Location.............................................................................................. 71

7.2 Functional Architecture .......................................................................................... 73

Revision 1.0

Intel order number D23151-001

v

Page 6

Table of Contents Intel® Server Platform SR6850HW4 TPS

7.2.1 SCSI Buses ...........................................................................................................73

7.2.2 SCSI Drive Power Control .....................................................................................73

7.2.3 SCSI Enclosure Management ............................................................................... 75

7.2.4 Server Management Interface ............................................................................... 76

7.2.5 Resets.................................................................................................................... 77

7.2.6 Connector Interlocks.............................................................................................. 77

7.2.7 Clock Generation ................................................................................................... 77

7.2.8 Programmed Devices ............................................................................................ 78

7.3 Signal Descriptions ................................................................................................ 78

7.3.1 Power from the Power Distribution Board.............................................................. 79

7.3.2 Front Panel Power Connector ...............................................................................79

7.3.3 Front Panel I/O Board Ribbon Cable Connector ................................................... 79

7.3.4 LVD SCSI 68-pin Connector.................................................................................. 80

7.3.5 SCA2 80-pin Drive Connectors.............................................................................. 81

7.3.6 Fans....................................................................................................................... 82

7.3.7 Internal Logic Signals ............................................................................................82

7.4 Electrical, Environmental, and Mechanical Specifications..................................... 83

7.4.1 Electrical Specifications ......................................................................................... 83

8. Front Panel I/O and Control Boards .................................................................................85

8.1 Introduction ............................................................................................................ 85

8.1.1 Block Diagram .......................................................................................................85

8.1.2 Architectural Overview........................................................................................... 86

8.1.3 Component Location.............................................................................................. 87

8.2 Functional Architecture .......................................................................................... 88

8.2.1 VGA ....................................................................................................................... 88

8.2.2 USB .......................................................................................................................88

8.2.3 NMI Button............................................................................................................. 88

8.3 Signal Descriptions ................................................................................................ 89

8.3.1 USB Connector...................................................................................................... 89

8.3.2 Front Panel VGA Connector .................................................................................. 90

8.4 Electrical, Environmental, and Mechanical Specifications..................................... 90

8.4.1 Electrical Specifications ......................................................................................... 90

8.4.2 Connector Specifications ....................................................................................... 91

8.4.3 Cooling Requirements ........................................................................................... 91

8.5 Front Panel Control Module................................................................................... 92

Revision 1.0

vi

Intel order number D23151-001

Page 7

Intel® Server Platform SR6850HW4 TPS Table of Contents

8.5.1 Button Control Panel.............................................................................................. 92

8.5.2 Intel® Local Control Panel...................................................................................... 94

8.5.3 System ID Buttons and LEDs ................................................................................ 95

9. SATA-to-IDE Converter Board...........................................................................................97

9.1 Mechanical Outline ................................................................................................ 97

10. Regulatory Specifications .................................................................................................99

10.1 Important Safety Information ................................................................................. 99

10.2 Intended Application Uses ..................................................................................... 99

10.3 Product Safety ....................................................................................................... 99

10.4 Electromagnetic Compatibility (EMC) – Emissions and Immunity ......................... 99

10.5 Certifications / Registrations / Declarations ......................................................... 100

10.6 Regulatory Compliance Markings........................................................................ 101

10.7 Regional EMC Compliance Notices/Information.................................................. 102

Glossary...................................................................................................................................105

Reference Documents............................................................................................................107

Revision 1.0

Intel order number D23151-001

vii

Page 8

List of Figures Intel® Server Platform SR6850HW4 TPS

List of Figures

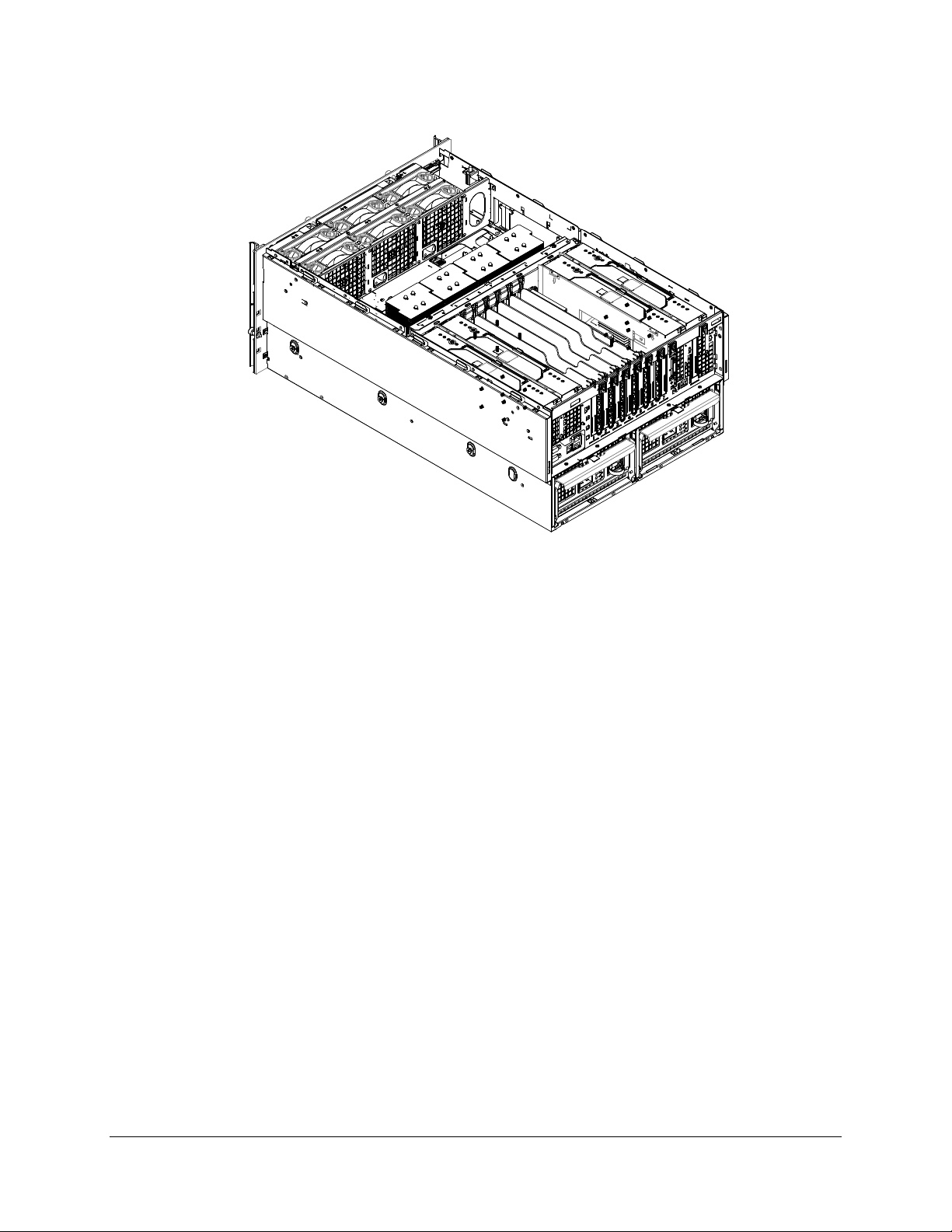

Figure 1. Intel

®

Server Platform SR6850HW4, Bezel Removed .................................................. 4

Figure 2. Server Platform SR6850HW4, Bezel and Pedestal Conversion Kit Installed ............... 5

Figure 3. Server Platform SR6850HW4, Rear View with Top Cover Removed........................... 6

Figure 4. Server Platform SR6850HW4 Chassis Block Diagram................................................ 7

Figure 5. Rear View of the Server Platform SR6850HW4 ........................................................10

Figure 6. Server Platform SR6850HW4 Rack and Pedestal Configurations ............................. 24

Figure 7. Server Platform SR6850HW4, Bezel and Top Cover Removed................................24

Figure 8. Rear of Server Platform SR6850HW4, Power Supplies Installed.............................. 25

Figure 9. System Fan................................................................................................................. 26

Figure 10. Mainboard and Sheet Metal Tray, Assembly............................................................ 27

Figure 11. Hot-Swap Hard Drive Carrier.................................................................................... 28

Figure 12. Optical Drive Carrier with SATA-to-IDE Converter Board.........................................28

Figure 13. Front Panel with Button Control Panel...................................................................... 29

Figure 14. Front Panel with Intel

®

Local Control Panel .............................................................. 29

Figure 15. Front Bezels (Rack and Pedestal) ............................................................................ 30

Figure 16. Server Platform SR6850HW4 Interconnect Diagram............................................... 32

Figure 17. Dual Stacked Ethernet Connector ............................................................................ 38

Figure 18. 68-Pin SCSI Connector Non-Shielded...................................................................... 40

Figure 19. SCA2 80-Pin SCSI Connector .................................................................................. 41

Figure 20. AC Power Input Connector ....................................................................................... 42

Figure 21. 1570W Power Supply ............................................................................................... 51

Figure 22. Power Supply Mechanical Specification ................................................................... 53

Figure 23. Power Supply Signal Sharing ................................................................................... 63

Figure 24. Power Distribution Board Layout .............................................................................. 64

Figure 25. Power Distribution Board to Power Supply Module Docking Connector Signals...... 65

Figure 26. Mainboard Connector Signals ..................................................................................66

Figure 27. Server Platform SR6850HW4 SCSI Backplane Board Board Block Diagram ......... 68

Figure 28. SCSI Backplane Board Board Component Placement (Primary Side) ..................... 70

Figure 29. SCSI Backplane Board Board Component Placement (Primary Side) ..................... 71

Figure 30. SCSI Backplane Board Board Component Placement (Secondary Side) ................ 72

Figure 31. Enclosure Management Signal Flow Diagram.......................................................... 75

Figure 32. Front Panel I/O Board Block Diagram ......................................................................86

Revision 1.0

viii

Intel order number D23151-001

Page 9

Intel® Server Platform SR6850HW4 TPS List of Figures

Figure 33. Front Panel I/O Board Placement Diagram .............................................................. 87

Figure 34. Front Panel I/O Board...............................................................................................88

Figure 35. Button Control Panel Features .................................................................................92

Figure 36. Local Control Panel Features ................................................................................... 95

Figure 37. SATA-to-IDE Converter Board Mechanical Outline .................................................. 97

Figure 38. SATA-to-IDE Converter Board.................................................................................. 97

Figure 39. SATA-to-IDE Converter Board with Attached Optical Drive...................................... 98

Figure 40. SATA-to-IDE Converter Board with Attached Optical Drive...................................... 98

Revision 1.0

Intel order number D23151-001

ix

Page 10

List of Tables Intel® Server Platform SR6850HW4 TPS

List of Tables

Table 1. Intel

Table 2. Front View of the Server Platform SR6850HW4, Bezel Removed................................. 8

Table 3. System Power Budget .................................................................................................15

Table 4. Expansion Support....................................................................................................... 20

Table 5. Environmental Specifications Summary ......................................................................21

Table 6. Physical Specifications ................................................................................................22

Table 7. Cable Descriptions.......................................................................................................33

Table 8. Connector Descriptions................................................................................................33

Table 9. Video Connector Pinout ............................................................................................... 35

Table 10. Dual USB Connector Pinout .....................................................................................36

Table 11. TaDual Ethernet Stacked Connector ......................................................................... 37

Table 12. Server Management Ethernet Connector .................................................................. 38

Table 13. Ultra320 SCSI VHDCI Connector Pinout ...................................................................39

Table 14. 68-Pin SCSI Connector Pinout ..................................................................................40

Table 15. SCA2 Drive Connector Pinout ...................................................................................41

Table 16. 3-pin Chassis Intrusion Connector.............................................................................42

®

Server Platform SR6850HW4 Feature List........................................................... 3

Table 17. Power Connector Pinout ............................................................................................ 42

Table 18. 30-pin Power Distribution Board to Mainboard Connector......................................... 43

Table 19. Front Panel I/O Board Connector Signal Description ................................................43

Table 20. 100-pin Connector Pinout (Unused and Ground) ......................................................44

Table 21. 100-pin Connector Pinout (Signals) ........................................................................... 44

Table 22. Peripheral Power Connector...................................................................................... 45

Table 23. 12-pin Fan Power and Control ................................................................................... 46

Table 24. 24-pin Fan Power and Control J6E1.......................................................................... 46

Table 25. Front Panel Control Module Connector Signal Description .......................................47

Table 26. SATA-to-IDE Converter Board Connector ................................................................. 48

Table 27. SATA-To-IDE Converter Board Power Connector..................................................... 48

Table 28. SATA Signal Connector ............................................................................................. 49

Table 29. PowerBlade Pin Assignment...................................................................................... 54

Table 30. AC Input Rating.......................................................................................................... 55

Table 31. DC Output Voltage Regulation Limits ........................................................................ 56

Table 32. 1570W Load Ratings .................................................................................................57

Revision 1.0

x

Intel order number D23151-001

Page 11

Intel® Server Platform SR6850HW4 TPS List of Tables

Table 33. Over- and Under-voltage Limits ................................................................................. 57

Table 34. Over-current Protection Limits ................................................................................... 58

Table 35. Output Current Sharing..............................................................................................59

Table 36. I/O Port Expander Signals .........................................................................................60

Table 37. I/O Port Expander Codes........................................................................................... 60

Table 38. Power Supply Fan Voltage ........................................................................................61

Table 39. Hot-swap SCSI Hard Disk Drive LED Details ............................................................74

Table 40. I

Table 41. Global I

Table 42. I

2

C Local Bus Addresses ...........................................................................................76

2

C Bus Addresses (IPMB Bus) ...................................................................... 77

2

C IO Bus Address .................................................................................................... 77

Table 43. Power Interface Signals ............................................................................................. 79

Table 44. Front Panel I/O Board Power Interface Signals ......................................................... 79

Table 45. Front Panel I/O Board Ribbon Connector Signal Description .................................... 79

Table 46. LVD SCSI Connector Signal Description ................................................................... 80

Table 47. .LVD SCSI Bus Signals.............................................................................................. 81

Table 48. Internal Logic Signals................................................................................................. 82

Table 49. Electrical Specifications ............................................................................................. 83

Table 50. Maximum Power Consumption .................................................................................. 83

Table 51. SCSI Backplane Board Board Power Limits per Drive .............................................. 84

Table 52. DC Voltage Regulation ..............................................................................................84

Table 53. USB Connector .......................................................................................................... 89

Table 54. VGA Connector Signal Description............................................................................ 90

Table 55. Electrical Specifications ............................................................................................. 90

Table 56. Maximum Power Consumption .................................................................................. 91

Table 57. DC Voltage Regulation ..............................................................................................91

Table 58. Server Platform SR6850HW4 Front Panel I/O Board Connector Specifications ......91

Table 59. Button Control Panel Details...................................................................................... 92

Table 60. System ID LED Details ..............................................................................................95

Table 61. Product Regulatory Compliance Markings............................................................... 101

Table 62. Regional EMC Compliance Information................................................................... 102

Revision 1.0

Intel order number D23151-001

xi

Page 12

List of Tables Intel® Server Platform SR6850HW4 TPS

< This page intentionally left blank. >

Revision 1.0

xii

Intel order number D23151-001

Page 13

Intel® Server Platform SR6850HW4 TPS Product Overview

1. Product Overview

This product specification details the features of the Intel® Server Platform SR6850HW4.

Reliability, low cost, time to market, modularity, high performance, and management features

are primary considerations in the design.

The Server Platform SR6850HW4 supports up to four 64-bit Intel

®

Xeon™ Processors MP with

up to 8MB L3 cache and incorporates features that clearly differentiate it as a high availability

server. Building on previous server platforms, the Server Platform SR6850HW4 introduces

redundant memory and networking in addition to the enterprise features of hot-swap power,

cooling, PCI slots, and hard disk drives. Advanced server management features are also

included to remotely monitor and manage the server. Finally, the server has two optional mass

storage expansion features.

This document is organized into ten chapters:

Chapter 1: Introduction

An overview of this document.

Chapter 2: System Overview

An overview of the system hardware.

Chapter 3: System Chassis and Sub-Assemblies

An overview of the chassis and major sub-assemblies.

Chapter 4: Cables and Connectors

Describes the cables and connectors specific to the Server Platform SR6850HW4.

Chapter 5: Power Supply

Describes the power supplies used in the Server Platform SR6850HW4.

Chapter 6: Power Distribution Board

Describes the Power Distribution Board used in the Server Platform SR6850HW4 and

®

Intel

Server Platform SR4850HW4.

Chapter 7: SCSI Backplane Board

Describes the SCSI Backplane Board used in the Server Platform SR6850HW4.

Chapter 8: Front Panel I/O and Control Boards

Describes the Front Panel I/O Board and Control Boards used in the Server Platform

SR6850HW4.

Chapter 9: SATA-to-IDE Converter Boards

Describes the SATA-to-IDE Converter Board used in the Server Platform SR4850HW4

and Server Platform SR6850HW4.

Chapter 10: Regulatory Specifications

Describes system compliance to regulatory specifications.

Revision 1.0

Intel order number D23151-001

1

Page 14

Product Overview Intel® Server Platform SR6850HW4 TPS

< This page intentionally left blank. >

Revision 1.0

2

Intel order number D23151-001

Page 15

Intel® Server Platform SR6850HW4 TPS System Overview

2. System Overview

This chapter describes the features of the Intel® Server Platform SR6850HW4.

2.1 System Feature Overview

Table 1 provides a list and brief description of the features of the Server Platform SR6850HW4,

which utilizes the Intel

®

Server Board Set SE8500HW4.

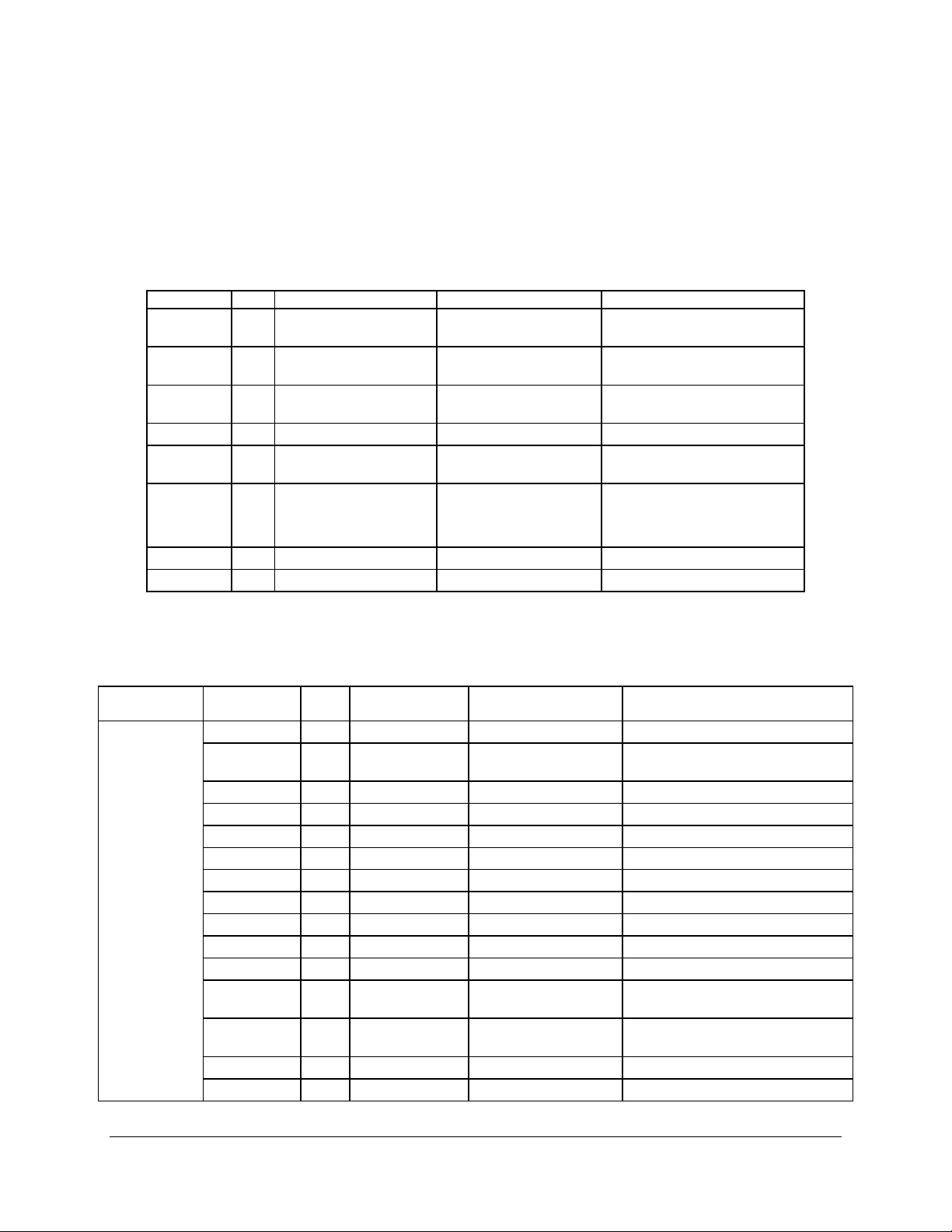

Table 1. Intel® Server Platform SR6850HW4 Feature List

Feature Description

Compact, high-density

system

Configuration flexibility One to four 64-bit Intel® Xeon™ processors MP with up to 8MB L3 cache

Serviceability Tool-less design features

Availability Two 1570W power supplies in a redundant (1+1) configuration with separate power cords

Manageability Remote management

Rack-mount server with a height of 6U (10.5 inches) and a depth of 28 inches (706mm)

Two Ultra320* SCSI ports

Two gigabit Ethernet ports

Ten 1-inch hot-swap Ultra320 SCSI hard disk drives

Seven PCI adapters (Four PCI Express* hot-plug, one PCI-X* 133MHz hot-plug, two PCI-X

100Mhz)

64GB Double Data Rate2 (DDR2) 400 MHz Synchronous Dynamic Random Access

Memory (SDRAM), ECC Registered

Customizable bezel

Optional system-specific 2Gbps Fibre Channel Module

Optional RAID On Motherboard (ROMB) with DDR2 DIMM for disk cache and optional

RAID Smart Battery (RSB) for cache battery backup

Either button or LCD front panel

Either Intel® Management Module (IMM) – Professional or Advanced

Front access to hot-swap hard disk drives

Top access to hot-plug PCI slots, cooling, and Hot-Swap Memory Boards

Rear access to hot-swap power supplies

Status and fault indicator LEDs

Front and rear viewable System ID switches and LEDs

Top viewable memory configuration and status LEDs

Processor failure LEDs

Detailed configuration label on top cover

Color-coded parts to identify hot-swap and non-hot-swap serviceable components

Four Hot-Plug Memory Boards

Intelligent Platform Management Interface (IPMI) 2.0 compliant

Wired For Management (WfM) 2.0 compliant

Emergency Management Port (EMP) – IPMI over serial or modem

Extensive system sensors and monitoring

Remote diagnostics support via serial and LAN ports

Web management console

With IMM Advanced:

Revision 1.0

Intel order number D23151-001

3

Page 16

System Overview Intel® Server Platform SR6850HW4 TPS

Feature Description

Dedicated Out-Of-Band management RJ45 port (telnet, embedded web server, DNS,

DHCP)

KVM console redirection and remote viewer

Full SNMP access

Front panel interface Switches: Power, Reset, NMI, System ID

Video connector, Three USB 2.0

Ports:

Power, System ID, System status,

LEDs:

LAN1 and LAN2 Activity, Hard drives status

Optional LCD

2.2 Introduction

The platform supports sockets for up to four 64-bit Intel Xeon processors MP, up to 64GB of

memory, ten hot-swap hard disk drives, seven PCI slots, two different server management

modules, two different front control panels, and two optional mass storage expansions. The

server can be configured for use as either a rack, as shipped, or pedestal, with an optional

accessory kit.

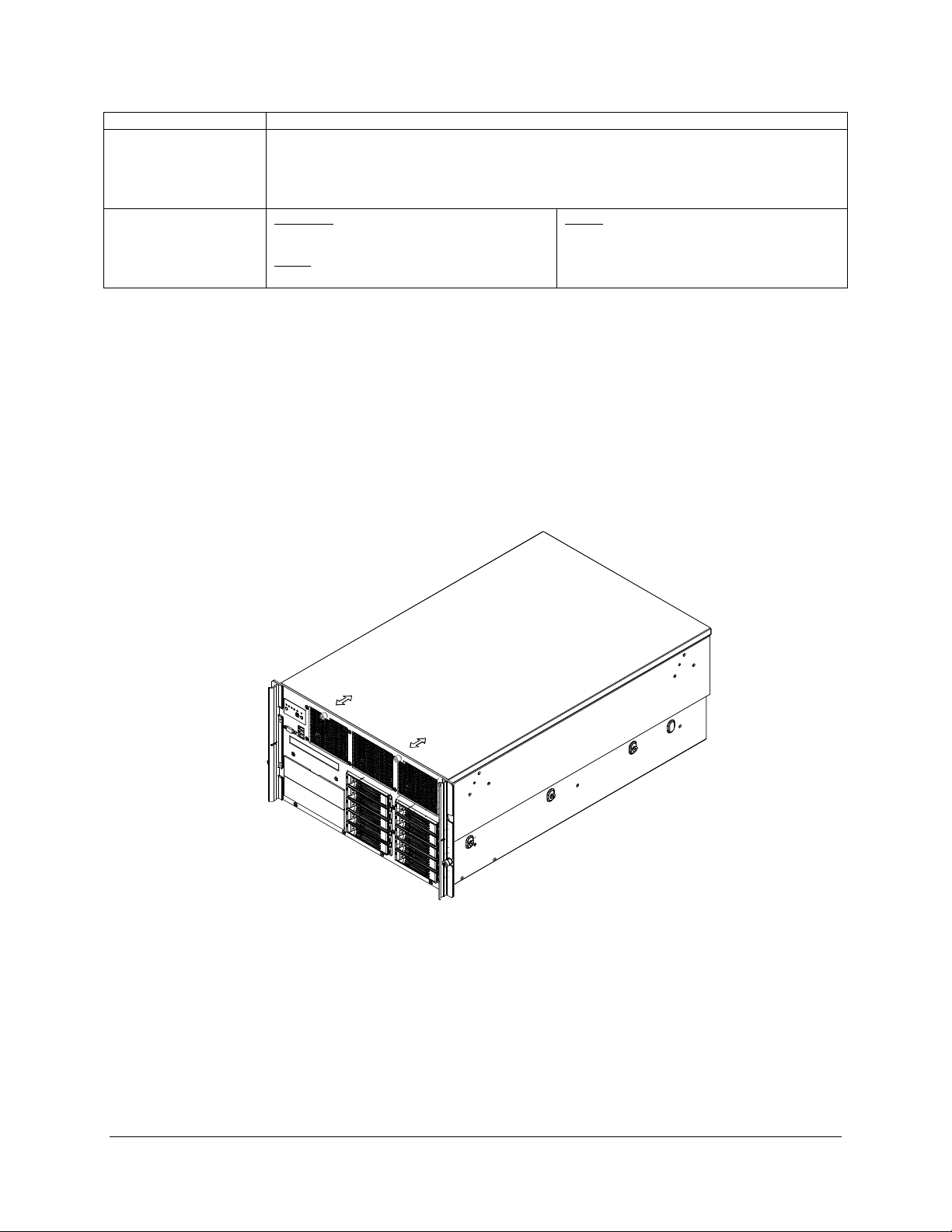

Figure 1, Figure 2 and Figure 3 show front and rear views of the platform.

Figure 1. Intel® Server Platform SR6850HW4, Bezel Removed

Revision 1.0

4

Intel order number D23151-001

Page 17

Intel® Server Platform SR6850HW4 TPS System Overview

1

2

TP01504

Figure 2. Server Platform SR6850HW4, Bezel and Pedestal Conversion Kit Installed

The Server Platform SR6850HW4 includes the Intel

®

Server Board Set SE8500HW4 with

the E8500 chipset. To provide structural support the Intel Server Board Set SE8500HW4

Mainboard is mounted on a sheet metal tray that is installed at the rear of the chassis,

above the power supplies.

Up to four Memory Boards can be installed into the Server Board Set SE8500HW4

Mainboard. The Memory Boards attach perpendicular to the Server Board Set SE8500HW4

Mainboard. These contain four DDR2 400HMz SDRAM DIMM slots each. With four Memory

Boards installed, the system supports up to 64GB of memory (using 4GB DIMMs).

The hard drive bay, located at the front of platform, provides a bay for ten hot-swap 1-inch

Ultra320* SCSI hard disk drives. SCSI hard disk drives plug into a vertical SCSI Backplane

Board at the rear of hard disk drive bay. One Slimline (½-inch high) optical drive bay and

one full-height 5¼-inch SCSI tape device bay are also located at the front of the platform.

The cooling subsystem requires six hot-swap system fan modules. Each fan module

contains a status LED that illuminates in the event of a fan failure. The fan modules are

accessible from the top of the system when the top cover is removed and connected into the

SCSI Backplane Board.

The front control panel provides video, USB, buttons, status LEDs, and an optional LCD,

that are used for monitoring and managing the platform. The front bezel is an optional

cosmetic accessory that is installed with snap-on features. The bezel can be customized to

meet integrator-specific industrial design requirements, including color and imprint.

Revision 1.0

Intel order number D23151-001

5

Page 18

System Overview Intel® Server Platform SR6850HW4 TPS

Figure 3. Server Platform SR6850HW4, Rear View with Top Cover Removed

The power supply modules are located at the rear of the system below the Server Board Set

SE8500HW4 Mainboard and plug directly into connectors on the horizontally oriented Power

Distribution Board. The system supports two hot-swap power supply modules in a 1+1

redundant configuration or one hot-swap power supply and a power bay fan module in a

non-redundant state.

Upon removal of the top cover, the user has access to the processors, Memory Boards, PCI

adapters, IMM Board and optional mass storage features.

Revision 1.0

6

Intel order number D23151-001

Page 19

Intel® Server Platform SR6850HW4 TPS System Overview

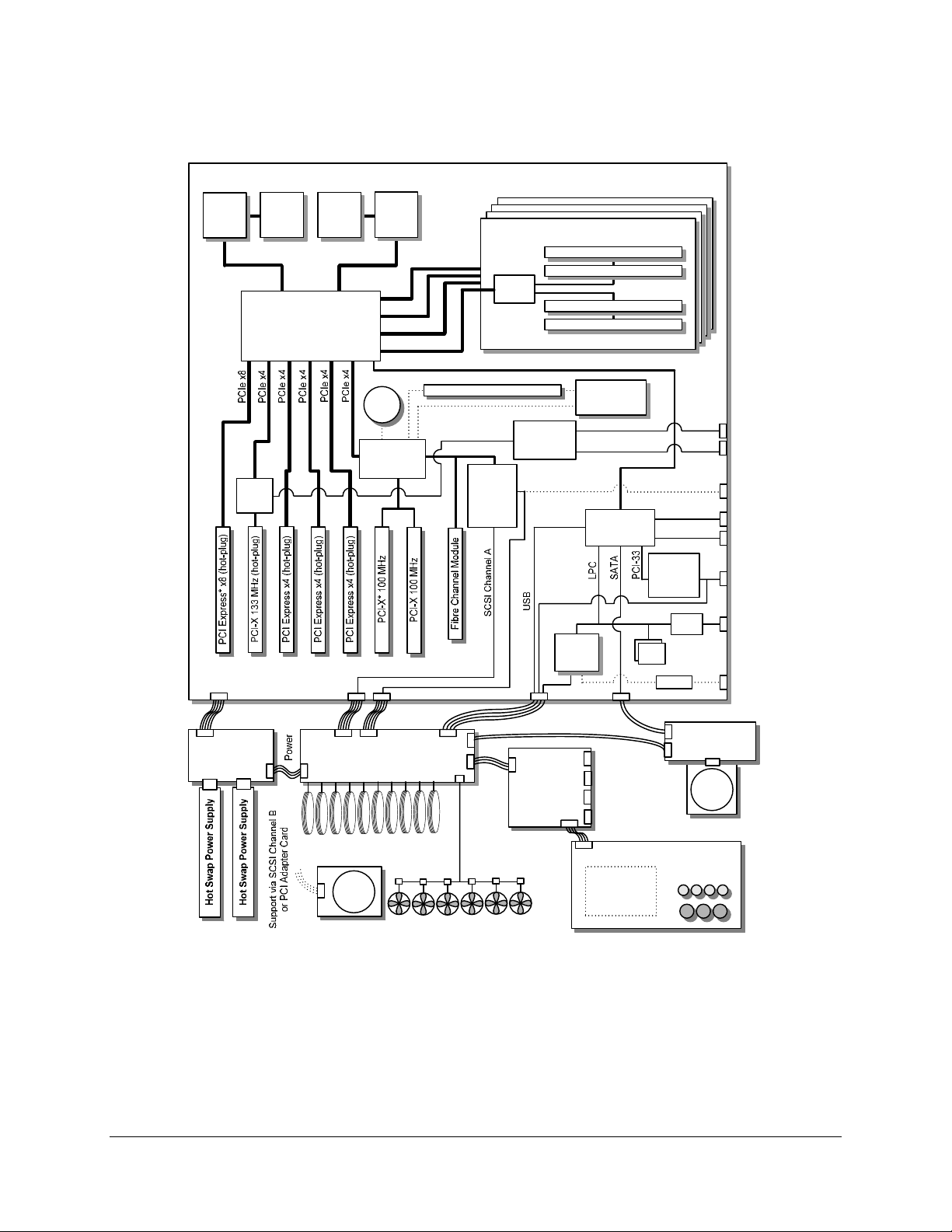

Intel® Server Board SE8500HW4 Main Board

CPU

1

FSB 1

6700

PXH

Power and

Signal

Power

Dist Board

CPU

CPU

2

E8500

North Bridge

(NB)

SCSI Cable

CPU

RAID

Act Key

3

IMI D

IMI C

IMI B

IMI A

4

FSB 0

IOP332

Processor

SCSI Cable

(optional)

SCSI

Backplane Board

XMB

XMB

XMB

XMB

DDR2 RAID DIMM

LSI*

53C1030

Ultra320*

SCSI

Controller

Memory Board

Memory Board

Memory Board

SE8500HW4 Memory Board

BRCM5704*

Ethernet

Controller

SCSI Channel B

DIMM

DIMM

DIMM

DIMM

DDR2 DIMM

DIMM

DIMM

DDR2 DIMM

DIMM

DIMM

DIMM

DIMM

DDR2 DIMM

DIMM

DIMM

DDR2 DIMM

RAID Smart

Battery

82801EB

ICH5

Radeon*

Controller

IMM

Power

Front

Panel I/O

Board

FWH

10/100

SATA Cable

Video Port

USB Port

USB Port

USB Port

ATI*

7000

Video

SIO

SATA-to-IDE

Converter Board

Optical

Drive

Ethernet Port

Ethernet Port

External SCSI

Connector

(optional)

USB Port

USB Port

Video Port

COM1/EMP

GCM

(optional)

Hot-swap SCSI Drives (10)

SCSI

Tape

Hot Swap Fans (6)

Figure 4. Server Platform SR6850HW4 Chassis Block Diagram

Revision 1.0

Intel order number D23151-001

Front Control Panel

Optional LCD

7

Page 20

System Overview Intel® Server Platform SR6850HW4 TPS

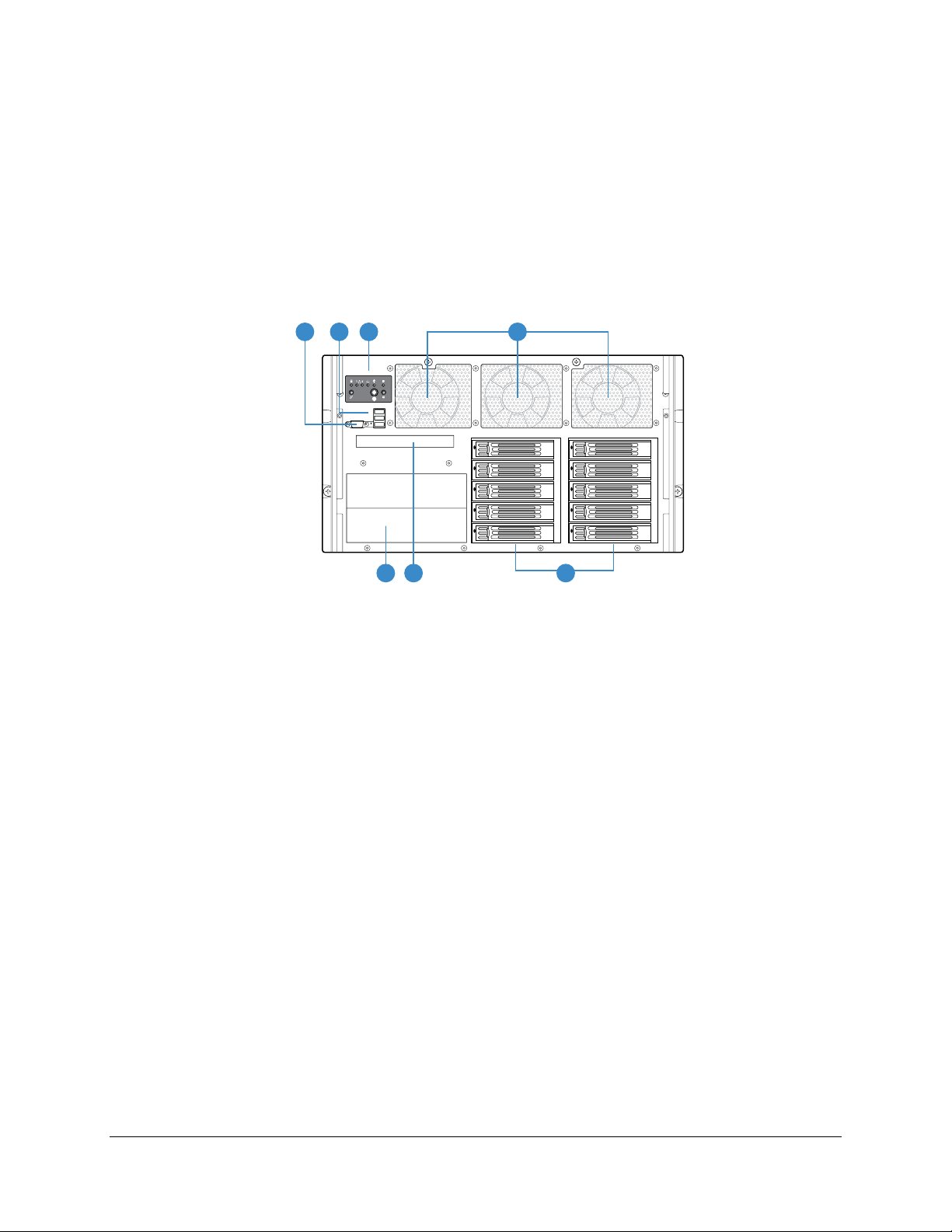

2.3 External Chassis Features - Front

Table 2 shows the front view of the Server Platform SR6850HW4 with the bezel removed.

The front provides access to the following components:

Buttons and LEDs (with optional LCD)

Video and USB connectors

Hard drive bay, optical drive, SCSI tape device

A

A Video connector

B USB 2.0 ports (three)

C Front control panel (button control panel shown)

D Hot-swap fans (six)

E 5 ¼ peripheral bay (full height)

F Optical drive bay

G Hot-swap SCSI hard disk drives (ten)

C

B

E

F

D

G

TP01508

Table 2. Front View of the Server Platform SR6850HW4, Bezel Removed

2.3.1 Front Control Panel

The front control panel contains system control buttons and LED status indicators. It also

contains one video connector, three USB 2.0 ports, NMI button, and the system speaker.

The front bezel must be removed to access the front control panel switches and connectors.

All LEDs are visible with the front bezel installed. See Chapter 8 or a description of the Front

Panel Boards.

Revision 1.0

8

Intel order number D23151-001

Page 21

Intel® Server Platform SR6850HW4 TPS System Overview

2.3.2 Hot-swap Hard Disk Drive and Peripheral Device Bays

The hard disk drive and peripheral device bays can accommodate the following devices:

Ten 1-inch hot-swap Ultra320 SCSI hard disk drives

One ½-inch optical drive (installed with base system)

Two half-height or one full-height 5¼-inch SCSI tape device

Note: Cooling and EMI constraints do not allow installation of an IDE hard disk drive in

the tape device bay.

The SCSI Backplane Board supports Low Voltage Differential (LVD) SCSI drives only.

Single-ended (SE) devices are supported off the secondary external SCSI channel on the

Server Board Set SE8500HW4 Mainboard. SE devices are not supported in the hot-swap

hard disk drive bays in the front of the system, or validated by Intel.

The optical drive and SCSI tape device(s) are not hot-swap devices. System power must be

turned off when installing or removing these drives.

Because hard disk drives have different cooling, power, and vibration characteristics, Intel

will validate specific hard disk drive types in the Server Platform SR6850HW4. See the Intel

Server Board Set SE8500HW4 Tested Hardware and Operating System List for the qualified

drives.

The hard disk drive carriers supplied with the system accommodate 3½-inch x 1-inch SCSI

hard disk drives. The hard disk drive is attached to the carrier with four Phillips*-head

screws. The carrier is retained in the chassis by a locking handle.

The SCSI Backplane Board contains a dual color LED for each hard drive to display status.

The LED signal is transmitted to the front of the system via a light pipe integrated in the hard

drive carrier.

Due to the required cable length and bus performance, the Server Board Set SE8500HW4

Mainboard contains a Serial ATA (SATA) connecter instead of a Parallel ATA (PATA)

connector. The optical drive connects to the SATA-to-IDE Converter Board, which converts

the SATA signal to an IDE signal for the 1/2-inch optical drive. The optical drive is installed

in a sheet metal bracket and then installed in the Server Platform SR6850HW4.

See Chapter 7 for a description of the SCSI Backplane Board. See Chapter 9 for

descriptions of the SATA-to-IDE Converter Board.

Revision 1.0

Intel order number D23151-001

9

Page 22

System Overview Intel® Server Platform SR6850HW4 TPS

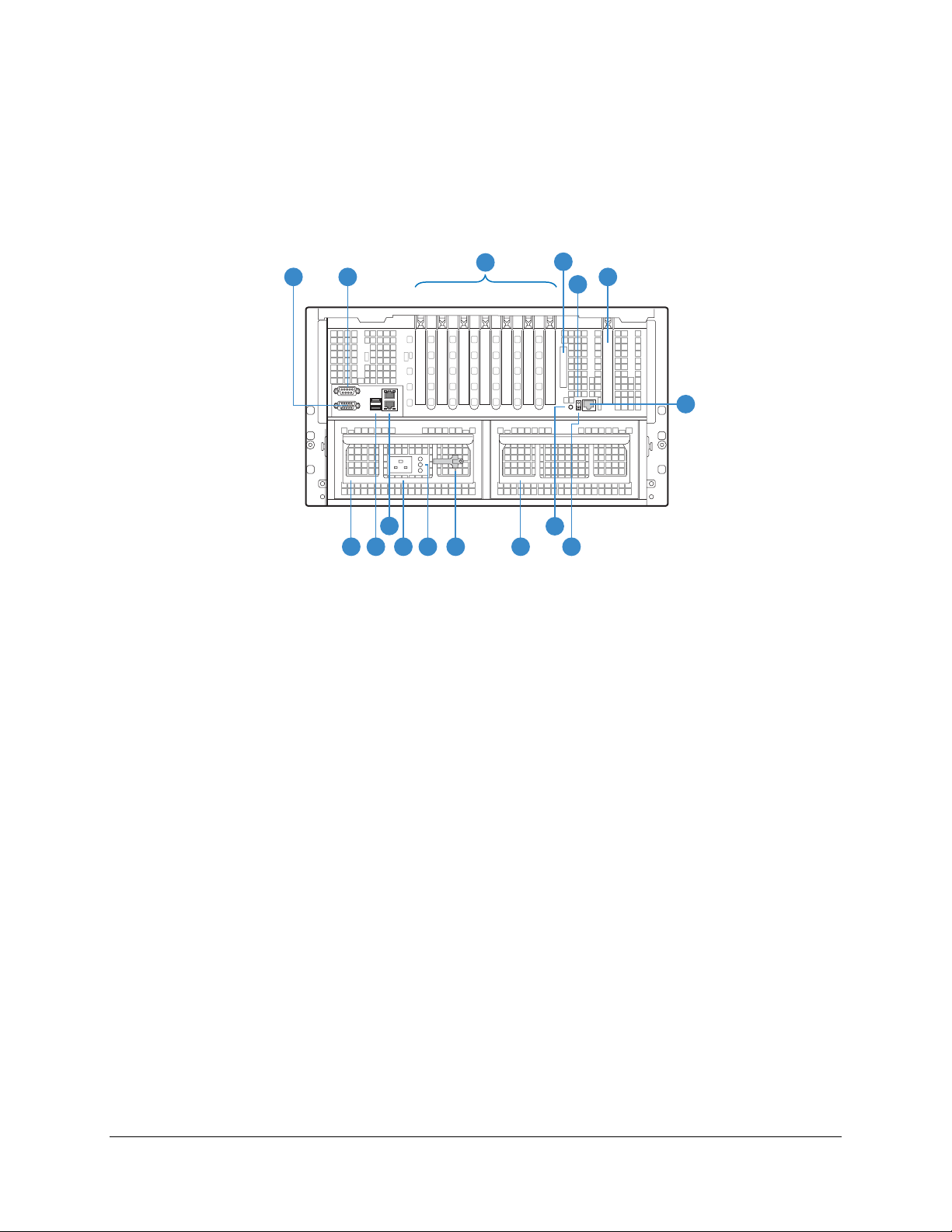

2.4 External Chassis Features - Rear

Figure 5 shows the rear view of the Server Platform SR6850HW4. The user-accessible

connectors, PCI slots, and power supply modules located at the rear of the system are described

in the following sections.

A

B

1743256

C

D

F

E

P

I

KJ

H

A Video connector

B Serial port connector

C PCI slots

Slot 1 PCI Express* x8 (hot-plug)

Slot 2 PCI-X* 133Mhz, 64-bit (hot-plug)

Slot 3 PCI Express x4 (hot-plug)

Slot 4 PCI Express x4 (hot-plug)

Slot 5 PCI Express x4 (hot-plug)

Slot 6 PCI-X 100Mhz, 64-bit (not hot-plug)

Slot 7 PCI-X 100Mhz, 64-bit (not hot-plug)

D External SCSI connector

E System ID LED (blue)

F Fibre Channel Module slot (optional accessory)

G Power supply unit

H USB 2.0 ports (two)

I LAN ports, RJ45 connector (LAN1 on top, LAN2 on bottom)

J AC input power connector

K Power supply unit status LEDs

L Power cord retention featurek

M Active fan power supply blank

N System ID button

O DC jack (not used)

P Dedicated server management port, RJ45 connector (used with the IMM Advanced)

LG M

N

O

TP01507

Figure 5. Rear View of the Server Platform SR6850HW4

Revision 1.0

10

Intel order number D23151-001

Page 23

Intel® Server Platform SR6850HW4 TPS System Overview

2.5 Internal Chassis Features

2.5.1 Server Board Set SE8500HW4 Mainboard

The Server Board Set SE8500HW4 Mainboard supports the following features:

Four sockets for 64-bit Intel Xeon processors MP with 1MB L2 cache or 64-bit Intel

Xeon processors with up to 8MB L3 cache

Four PCI Express* x16 Memory Board connectors

- Four independent memory interface buses

- Supports hot-remove and hot-add operations

Dual 667 MT/s Front Side Buses (FSB)

Intel E8500 chipset North Bridge (NB) with two shared 64-bit FSB interfaces

configured for symmetric multiprocessing (SMP)

Intel E8500 chipset eXtended Memory Bridge (XMB) for support of memory hot-plug

Intel

Intel

Intel

LSI Logic* 53C1030 Ultra320* SCSI Controller: provides two independent Ultra320

Broadcom* BRCM5704 NetXtreme* Gigabit Ethernet controller: provides two ports

ATI* Radeon* 7000 video controller

Advanced I/O slots including PCI Express and PCI-X and support circuits:

Buttons and LED indicators for PCI hot-plug slots

Low Pin Count (LPC) Super I/O* enables the serial port/EMP

USB 2.0 support

4MB Flash capacity to support rolling BIOS updates

Optional ROMB support: provides two channels of RAID 0, 1, 5, 10 or 50

Optional custom Fibre Channel Module: provides two optical connectors

Server management support via the Intel Management Module (IMM) connector

®

6700 PXH 64-bit Hub which acts as the bridge between the NB and PCI-X bus

®

82801EB I/O Controller Hub 5 (ICH5) which provides USB 2.0 and SATA

®

IOP332 storage I/O Processor for mass storage and PCI-X slots

SCSI interfaces

on the rear of the Mainboard

- 16MB embedded SDRAM

- Mirrored to both the rear and front I/O ports by default

- One hot-plug PCI Express x8 slot

- Three hot-plug PCI Express x4 slots

- One hot-plug 64-bit PCI-X 133MHz slot

- Two 64-bit PCI-X 100MHz slots (not hot-plug)

- Two ports at the rear of chassis

- Three ports on front of the chassis

See the Intel Server Board Set SE8500HW4 Technical Product Specification for a

description of this board.

Revision 1.0

Intel order number D23151-001

11

Page 24

System Overview Intel® Server Platform SR6850HW4 TPS

2.5.2 Server Board Set SE8500HW4 Memory Board

Each Memory Board supports the following features:

PCI Express x16 card edge connector that plugs into the Server Board Set

SE8500HW4 Mainboard

Intel E8500 chipset eXtended Memory Bridge (XMB)

Four DDR2 400HMz DIMM slots for registered ECC memory

Support for both single-rank and dual-rank DIMMs

Two DDR2 400MT/s busses

Independent Memory Interface (IMI), a high-speed differential bus

LED error indicators for each DIMM and an attention LED for hot-plug events

LED indicator for both memory mirroring and RAID configurations

Memory hot-plug at the card level, based on the PCI hot-plug model

Field Replaceable Unit (FRU) device

Two temperature sensors

Safety mechanism for instant power shut-down to the Memory Board when not

properly removed or inserted

See the Intel Server Board Set SE8500HW4 Technical Product Specification for

descriptions of this board.

2.5.3 Power Distribution Board

The Power Distribution Board is located horizontally, below the Server Board Set

SE8500HW4 Mainboard in the middle-rear of the chassis. It has two connectors for the hotswap power supply modules and provides 12V, standby power and server management

signals to the Server Board Set SE8500HW4 Mainboard and SCSI Backplane Board. The

power distribution circuitry reports quantity, quality, and location of the installed power

supplies through I

2

C server management. See Chapter 6 for a description of this board.

2.5.4 SCSI Backplane Board Board

The SCSI Backplane Board mounts vertically in the front of the system and contains ten

industry-standard hot-swap Single Connector Attach 2 (SCA-2) connectors (80-pin).

Ultra320 (or slower) Low Voltage Differential (LVD) SCSI hard disk drives can be installed in

the system. The backplane accepts 15,000-RPM (and slower) hard disk drives. SingleEnded (SE) SCSI devices are not supported in the hot-swap hard disk drive bay.

Revision 1.0

12

Intel order number D23151-001

Page 25

Intel® Server Platform SR6850HW4 TPS System Overview

The SCSI Backplane Board performs the tasks associated with hot-swapping of the hard

disk drives and enclosure (chassis) monitoring and management, as specified in the SCSI

Accessed Fault-Tolerant Enclosures (SAF-TE) Specification.

The SAF-TE-specified features

supported by the SCSI Backplane Board include, but are not limited to, the following:

Monitoring the SCSI bus for enclosure services messages, and acting on them

appropriately. Examples of such messages include: activate a drive fault indicator;

power down a drive that has failed; and report backplane temperature.

SAF-TE intelligent agent acts as proxy for "dumb" I

2

C devices (that have no bus

mastering capability) during intrachassis communications.

The SCSI Backplane Board connects to the Server Board Set SE8500HW4 Mainboard,

provides power, and signals to the front of the chassis. See Chapter 7 for a description of

this board.

2.5.5 Front Panel I/O Board

The Front Panel I/O Board mounts horizontally in the front left of the system and

communicates with the SCSI Backplane Board.

USB ports and an NMI button.

See Chapter 8 for a description of this board.

The board contains a video connector, three

2.5.6 Front Panel Control Board

Two different front panel Control Boards are supported, the standard control panel and the

Intel Local Control Panel (LCP). Both mount vertically into the chassis and connect to the

Front Panel I/O Board via a cable. Each module houses the system operating buttons, LEDs

and the Local Control Panel has an LCD. See Chapter 8 for a description of these boards.

2.5.7 SATA-to-IDE Converter Board

The SATA-to-IDE Converter Board attaches to the optical drive carrier, receives the SATA

signal from the Server Board Set SE8500HW4 Mainboard via a SATA cable, and converts it to

IDE signals routed to the optical drive. See Chapter 9 for a description of this board.

2.5.8 Intel® Management Module

The Intel Management Module (IMM) mounts onto the Server Board Set SE8500HW4

Mainboard and contains the Baseboard Management Controller (BMC) that provides server

management support.

The Advanced module adds more support for remote management. The Server Platform

SR6850HW4 will not boot without one of these modules installed.

Module Installation and User’s Guide or the Intel Management Module Technical Product

Specification for a description of this part.

There are two versions of the IMM, the Professional and Advanced.

See the Intel Management

Revision 1.0

Intel order number D23151-001

13

Page 26

System Overview Intel® Server Platform SR6850HW4 TPS

2.5.9 Fibre Channel Module

The Server Board Set SE8500HW4 Mainboard supports the Intel Fibre Channel Module as

a mass storage expansion option. The card is based on the Qlogic* ISP2322 FC PCI-X

controller and plugs into a reversed PCI Express x16 slot on the Server Board Set

SE8500HW4 Mainboard. See the Intel Fibre Channel Module Users Guide for descriptions

of this board.

2.5.10 RAID On Motherboard (ROMB)

The Server Board Set SE8500HW4 Mainboard supports a RAID On Motherboard (ROMB)

solution via the Intel IOP332 storage I/O Processor

in conjunction with the LSI Logic*

53C1030 SCSI controller. To enable this option the Intel RAID Activation Key and a DDR2

400MHz DIMM are required. The optional Intel RAID Smart Battery is also available to

maintain the contents of the DIMM in the event of power loss. See the Intel RAID Smart

Battery Technical Product Specification for a description of the ROMB solution.

2.5.11 Power Supply Module

Two hot-swap power supply modules are installed side by side at the rear of the chassis.

Each supply has its own AC input power connector and is rated at 1570W over an input

range of 100-240 VAC.

The power subsystem is configured as follows:

With two power supply modules installed, a fully configured system has (1+1) power

redundancy.

With one supply module installed, the system does not have redundant power but

will still run a fully configured system.

Note: When only one power supply module is installed, the active fan module is required in

the unpopulated power supply slot for proper system cooling.

One power supply module is capable of handling the maximum power requirements for a

fully configured Server Platform SR6850HW4, which includes four processors, 64 GB of

memory, seven PCI add-in cards, ten hot-swap hard disk drives, an optical drive, a Fibre

Channel Module, ROMB options installed, and a SCSI tape device.

When two power supply modules are installed, the user can replace a failed power supply

module without affecting the system functionality. Power supplies have three LEDs to

identify failure, power good and AC OK.

The power subsystem receives AC power through two power cords.

When two power supply

modules and two power cords are installed, the system has (1+1) power cord redundancy

and can be powered by two separate AC sources.

In this configuration, the system will

continue to function without interruption if one of the AC sources fails. See Chapter 5 for

more information.

Note: The total power requirement for the Server Platform SR6850HW4 exceeds the 240

VA energy hazard limits that define an operator accessible area. As a result, only

Revision 1.0

14

Intel order number D23151-001

Page 27

Intel® Server Platform SR6850HW4 TPS System Overview

qualified technical individuals should access the processor and non-hot-plug I/O

areas while the system is energized. Power cords should be removed from the

system before accessing non-hot-plug areas.

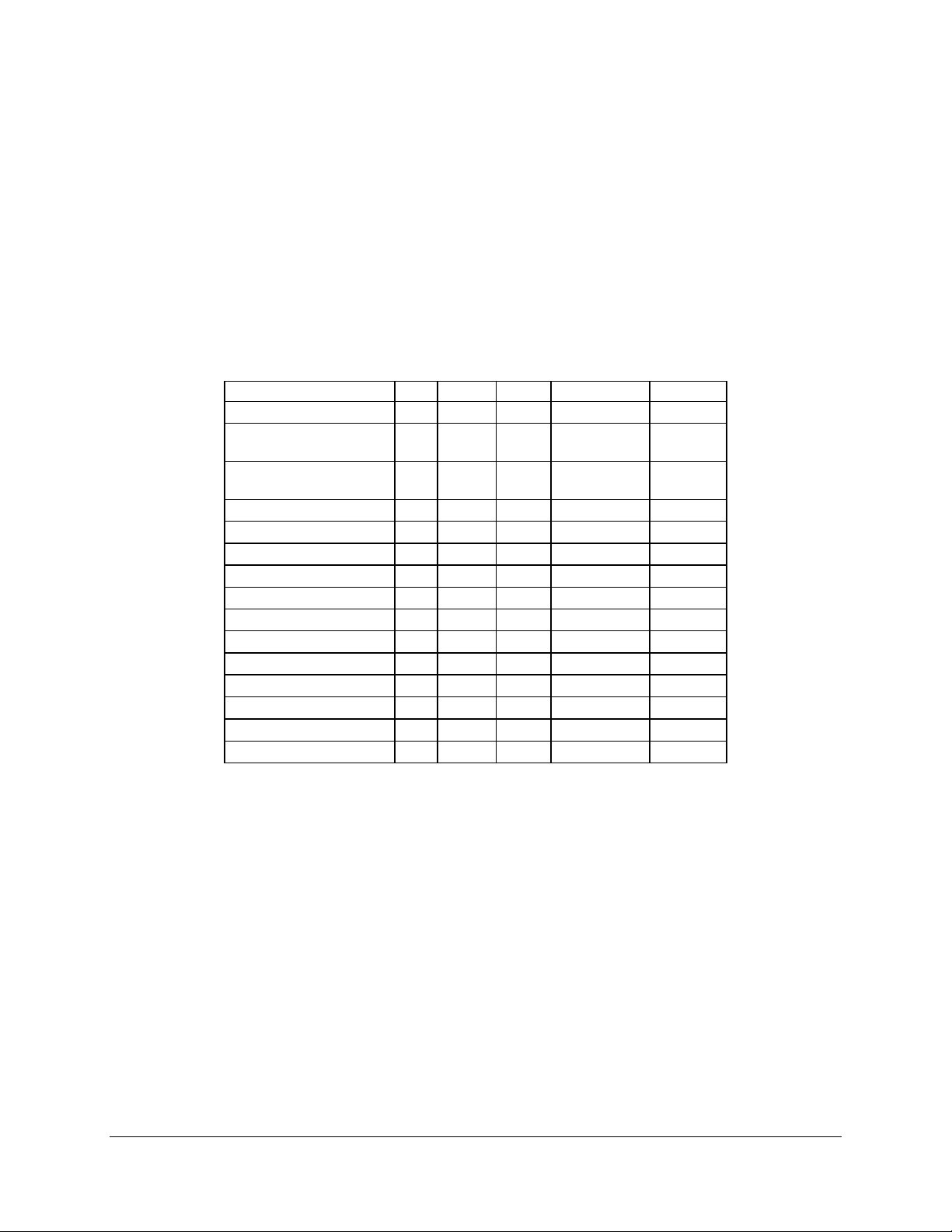

2.5.11.1 System Power Budget

Table 3 shows a summary of the system power budget.

voltage rail in columns and each major subsystem of the product in rows.

power per subsystem is listed for each voltage rail.

The power budget lists each major

The worst-case

The total power per voltage rail, the

power supply specification, and the margin available are shown at the bottom of the table.

Table 3. System Power Budget

Subsystem Qty +3.3V +5V +12V (Total) +3.3V

Mainboard 1 49W 27W 147W 15W

SCSI Backplane Board

Board

Front Panel I/O Board

and front panel

Processors 4 448W

Memory 16 4W 192W

Fans 6 173W

Hard disk drives 10 28W 84W

½inches optical drive 1 1W 6W

SCSI tape device 1 3W 7W

PCI-X* slots 3 45W

PCI Express* slots 4 80W

Fibre channel module 1 15W

System Total 1189.5W 15W

Power subsystem spec 1570W 16.5W

Margin 380.5W 1.5W

1 2.5W 2.5W

1ea 2W 2W

stby

Notes:

1. 3.3V and 5V are derived from the 12V single switched output of the power

supply modules.

2. 3.3V

Revision 1.0

is the standby output of the power supply modules.

stby

The 12V column includes the 3.3V and 5V power.

Intel order number D23151-001

15

Page 28

System Overview Intel® Server Platform SR6850HW4 TPS

2.5.12 Cooling Subsystem

Primary cooling is generated by six fans, located at the top front of the chassis. It connects

to the SCSI Backplane Board for power and server management. Air flows in through the

front and exhausts out the rear of the chassis. The chassis has several air baffles to duct the

air over critical parts, including processors, memory, and peripherals. Processor heat sinks

or processor heat sink blanks, and Memory Boards or Memory Board blanks must be

installed in each corresponding area to ensure proper airflow.

The system fans are sized to provide cooling for a fully configured system. The cooling

system is designed using a worst-case analysis and appropriate fan speeds were chosen to

meet acoustic and thermal requirements. Server management controls fan speed based on

ambient and component temperatures. To ensure proper cooling, failed fans should be

replaced within 1 minute.

2.6 New Platform Features

2.6.1 Advanced Memory Performance and Protection

The Server Board Set SE8500HW4 supports several new memory features that allow

flexibility in performance, redundancy and the ability to upgrade. The System BIOS can be

configured as follows:

Maximum performance, where memory is up to four-way interleaved

Maximum compatibility, where memory can be hot-added

Memory mirroring, where two or four boards are used to keep a copy of system

memory

Memory RAID, where four boards are used in a RAID4-like mode

Memory sparing, where a portion of each Memory Board is reserved for failover.

Hot-replace means the user can replace a Memory Board with another Memory Board of

identical total size. This operation is supported in maximum compatibility, memory RAID and

memory mirroring modes.

Hot-add means the user can add a Memory Board to a previously unoccupied slot. This

requires operating system support and is supported in memory compatibility and memory

mirroring modes.

Hot-removal means the user can remove a Memory Board. This operation is supported in

memory RAID and memory mirroring modes.

Hot upgrade means the user can replace an existing Memory Board with a Memory Board

that contains more memory capacity. A hot upgrade is not a unique operation, it is

implemented as a hot-remove followed by a hot-add. This requires operating system support

and is supported by the memory RAID mode only.

See the Intel Server Board Set SE8500HW4 Technical Product Specification for more

details on these new features.

Revision 1.0

16

Intel order number D23151-001

Page 29

Intel® Server Platform SR6850HW4 TPS System Overview

2.6.2 Rolling BIOS

The Server Board Set SE8500HW4 Mainboard supports two BIOS images to be stored in

Flash. This provides a mechanism for BIOS updates without a system reboot as well as

failover to an alternate image in the event of BIOS corruption. The system runs with the

current BIOS until a reboot, after which time the updated BIOS is used. See the Intel Server

Board Set SE8500HW4 Technical Product Specification for more details on this feature.

2.7 Server Management

The management subsystem conforms to the IPMI v2.0 Specification. The server

management features are implemented using two microcontrollers: the Intel Management

Module that plugs into the Server Board Set

controller on the SCSI Backplane Board. The functions of each component are summarized

in the following sections.

2.7.1 Intel Management Module (IMM)

The IMM has a Baseboard Management Controller (BMC) microcontroller and associated

circuitry. The IMM contains flash memory that holds the operation code and the BMC

configuration settings. The IMM monitors platform management events and logs their

occurrence on the onboard non-volatile System Event Log (SEL). This includes events such

as over-temperature and over-voltage conditions, fan failures, etc. The IMM also provides

the interface to this monitored information so system management software can poll and

retrieve the present status of the platform.

SE8500HW4 Mainboard, and the SCSI hot-swap

The IMM also provides the interface to the non-volatile Sensor Data Record (SDR)

repository. SDRs provide a set of information that system management software can use to

automatically configure itself for the number and type of IPMI sensors (e.g., temperature

sensors, voltage sensors, etc.) in the system.

The following is a list of the major functions for the IMM:

System power control

- ACPI power control

- ACPI sleep support

- Minimum power off time

System reset control

System initialization

- Processor temperature and voltage threshold setting

- Fault Resilient Booting (FRB)

Front panel user interface

- System status (green) LED control

- System status (amber) LED control

- System ID LED control

- Reset button control

- Power button control

- SDINT button control

Revision 1.0

Intel order number D23151-001

17

Page 30

System Overview Intel® Server Platform SR6850HW4 TPS

- System ID Button control

System fan management

System management watchdog timer

System Event Log (SEL) interface – up to 3,200 entries

Sensor Data Record (SDR) repository interface

SDR/SEL timestamp clock

FRU inventory device

Diagnostics and beep code generation

Event message generation and reception

Platform Event Paging and Platform Event Filtering (PEP and PEF)

Dial page alerting

Alert over LAN and serial/PPP

Serial over LAN (SOL)

Terminal Mode (TM)

Battery monitoring

Sensor monitoring

- Temperature

- Voltage

- Fan speed

- Processor status

- Power supplies

Processor Information ROM (PIROM) and Scratch Electrically Erasable

Programmable ROM (SEEPROM) access

IPMB communication interface

Emergency Management Port (EMP) interface - IPMI messaging over Serial/Modem.

This feature is also referred to as DPC (Direct Platform Control) over Serial/Modem

Inter-Chassis Management Bus (ICMB) interface - IPMI messaging between chassis

Additional features with IMM Advanced installed:

- Dedicated (Out-Of-Band) LAN interface through the Generic Communication

Module (GCM) on the rear of chassis (IMM Advanced)

- BMC-resident SNMP support for Out-Of-Band access using 3

rd

party applications

such as HP* Openview*

- Embedded web server to access system health, view the SEL and issue IPMI

commands

- Embedded Command Line Interface (using telnet server running on the BMC) to

allow direct access to the BMC

- Alerting via email

- Keyboard, Video, Mouse (KVM) console redirection and remote viewer

See the Management Module Technical Product Specification for more information.

Revision 1.0

18

Intel order number D23151-001

Page 31

Intel® Server Platform SR6850HW4 TPS System Overview

2.7.2 Hot Swap Controller

Two hot-swap controllers are on the SCSI Backplane Board. The primary function of each

hot-swap controller is as follows:

Implements the SAF-TE command set

Controls the SCSI hard disk drive power, activity and fault LEDs

Provides a path for management information via the SCSI bus

Retrieves hard disk drive fault status, SCSI Backplane Board temperature, and fan

failure information via IPMB

Queries the status of the Power Distribution Board by retrieving information from the

IMM via IPMB

Controls hard disk drive power-on and power-down, facilitating hot-swapping

2.8 Reliability, Availability, Serviceability, Usability, Manageability

(RASUM)

The Server Platform SR6850HW4 supports the following reliability, availability,

serviceability, usability and manageability (RASUM) features:

Reliability features

- Machine check architecture

- Error Checking Code (ECC) in main memory and processor caches

- ECC, parity, and protocol checking on the FSB

- Parity on the Hub Link (HL-1.5) interface

- Parity checking on PCI buses

- RAID On Motherboard (ROMB) with the Intel RAID Smart Battery which provides

battery back-up to the DDR2 400MHz DIMM for disk cache

- Voltage and temperature monitoring throughout the system

Availability features

- Hot-plug PCI Express and PCI-X

- Hot-Plug Memory Boards

- Redundant hot-swap power supplies

- Redundant power cords

- Redundant hot-swap system fans

- Hot-swap SCSI hard drives

- Teaming and failover Ethernet ports

Serviceability features

- Tool-less installation and removal of major sub-assemblies

- Color-coded parts to identify serviceable components

Green: Hot-swap or hot-plug components

Blue: Non-hot-swap components

- System ID buttons and LEDs

- LED indicators for system health, configured options, and activity

Revision 1.0

Intel order number D23151-001

19

Page 32

System Overview Intel® Server Platform SR6850HW4 TPS

Usability features

- Tool-less design features

- External access to hot-swap hard disk drives, power supplies, LEDs and switches

- Front and rear viewable System ID switches and LEDs

- Detailed configuration label on top cover

- Color-coded parts to identify hot-swap and non-hot-swap serviceable components

Manageability features

- Remote management via serial and LAN

- IPMI 2.0 and WfM 2.0 compliance

- Remote diagnostics via serial and LAN

- Remote management via KVM and dedicated LAN (IMM Advanced)

All boards are connected by a server management I

2

C bus to satisfy the system RASUM

requirements.

2.9 Expansion Support

Table 4 summarizes the expansion support provided by the platform.

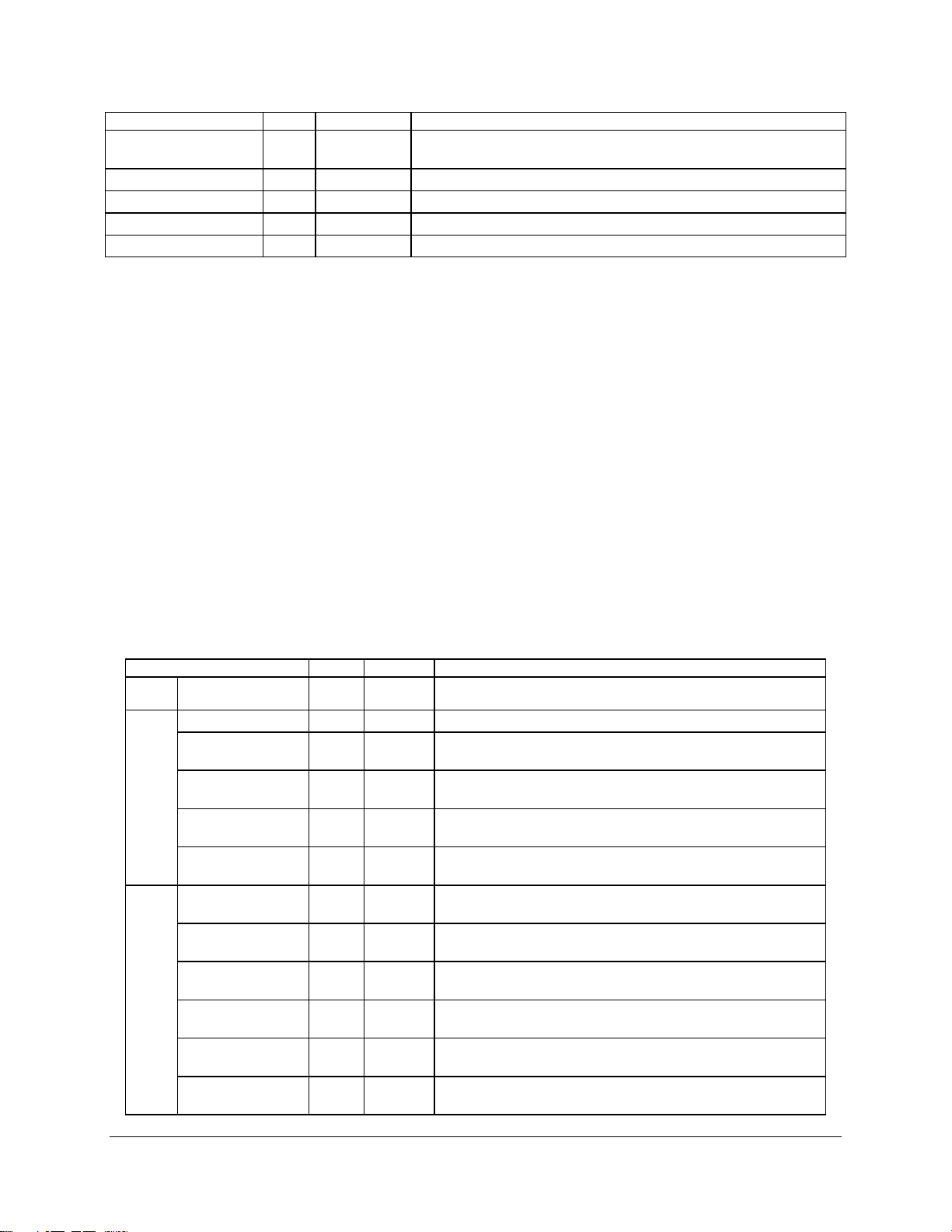

Table 4. Expansion Support

Quantity Type

4 64-bit Intel® Xeon™ processors MP

7 PCI expansion bus slots

10 Single connector attachment (SCA-2) Ultra320* SCSI hard disk drive bays

1 5 1/4-inch full-height drive bay

1 External SCSI connector

16 DDR2 400HMz SDRAM registered ECC DIMM module sockets (four per memory

module)

1 RAID On MotherBoard (ROMB) socket, DDR2 DIMM socket and battery connector

1 Fibre Channel module connector (with two FCAL 2GBps connectors)

Revision 1.0

20

Intel order number D23151-001

Page 33

Intel® Server Platform SR6850HW4 TPS System Overview

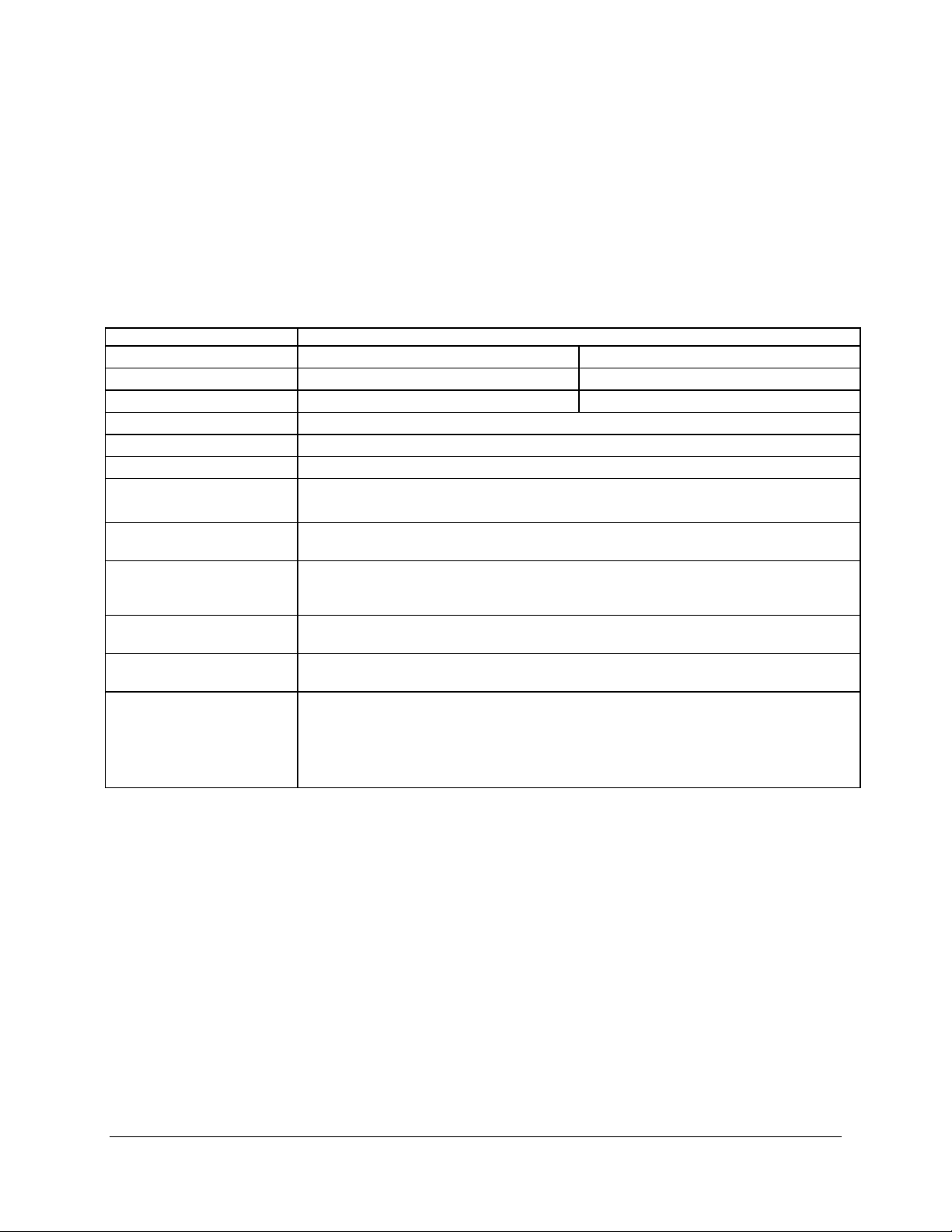

2.10 Specifications

2.10.1 Environmental Specifications Summary

The Server Platform SR6850HW4 will be tested to the environmental specifications as indicated

in Table 5.

Table 5. Environmental Specifications Summary

Environment Specification

Temperature operating 10°C to 35°C 50°F to 95°F

Temperature non-operating -40°C to 70°C -40°F to 158°F

Altitude -30 to 1,500 m -100 to 5,000 ft

Humidity non-operating 95%, non-condensing at temperatures of 25°C (77°F) to 30°C (86°F)

Vibration non-operating 2.2 Grms, 10 minutes per axis on each of the three axes

Shock operating Half-sine 2 G, 11 ms pulse, 100 pulses in each direction, on each of the three axes

Shock non-operating Trapezoidal, 25 G, two drops on each of six faces

∆V : 175 inches/sec on bottom face drop, 90 inches/sec on other 5 faces

Safety UL60 950, CSA60 950, AS/NZS 3562, GB4943-1995, EN60 950 and 73/23/EEC, IEC 60

950, EMKO-TSE (74-SEC) 207/94, GOST-R 50377-92

Emissions Certified to FCC Class A; tested to CISPR 22 Class A, EN 55022 Class A and

89/336/EEC, VCCI Class A, AS/NZS 3548 Class A, ICES-003 Class A, GB9254-1998,

MIC Notice 1997-42 Class A, GOST-R 29216-91 Class A, BSMI CNS13438

Immunity Verified to comply with EN55024, CISPR 24, GB9254-1998, MIC Notice 1997-41,

GOST-R 50628-95

Electrostatic discharge Tested to ESD levels up to 15 kilovolts (kV) air discharge and up to 8 kV contact

discharge without physical damage

Acoustic Sound pressure: < 55 dBA at ambient temperature < 23° C measured at bystander, floor

standing position

Sound power: < 7.0 BA at ambient temperature < 23° C measured using the Dome

Method

GOST MsanPiN 001-96

See Chapter 10 for more information on environmental specifications.

Revision 1.0

Intel order number D23151-001

21

Page 34

System Overview Intel® Server Platform SR6850HW4 TPS

2.10.2 Physical Specifications

Table 6 describes the physical specifications of the Server Platform SR6850HW4.

Table 6. Physical Specifications

Specification Value

Height – 6U 10.5inches 262 mm

Width 17.6inches 447 mm

Depth 27.8inches 706 mm

Front clearance 3inches 76 mm

Side clearance 1inches 25 mm

Rear clearance 6inches 152 mm

Weight (full config) 130 lbs 60 kg

Note: The system weight is an estimate for a fully configured system and will vary depending on number of

peripheral devices and add-in cards, and the number of processors and DIMMs installed in the system.

Revision 1.0

22

Intel order number D23151-001

Page 35

Intel® Server Platform SR6850HW4 TPS Server Sy stem Chassis and Assemblies

3. Server System Chassis and Assemblies

This chapter provides an overview of the chassis and assembly pieces that reside within the

platform. This chapter is divided into the following areas:

Section 3.1: Chassis, Rails and Top Cover

Section 3.2: Power and Fans

Section 3.3: Fan Subsystem

Section 3.4: Mainboard Assembly

Section 3.5: Peripherals Bay and Front Panel

Section 3.6: Front Bezel

3.1 Chassis, Rails and Top Cover

3.1.1 Chassis

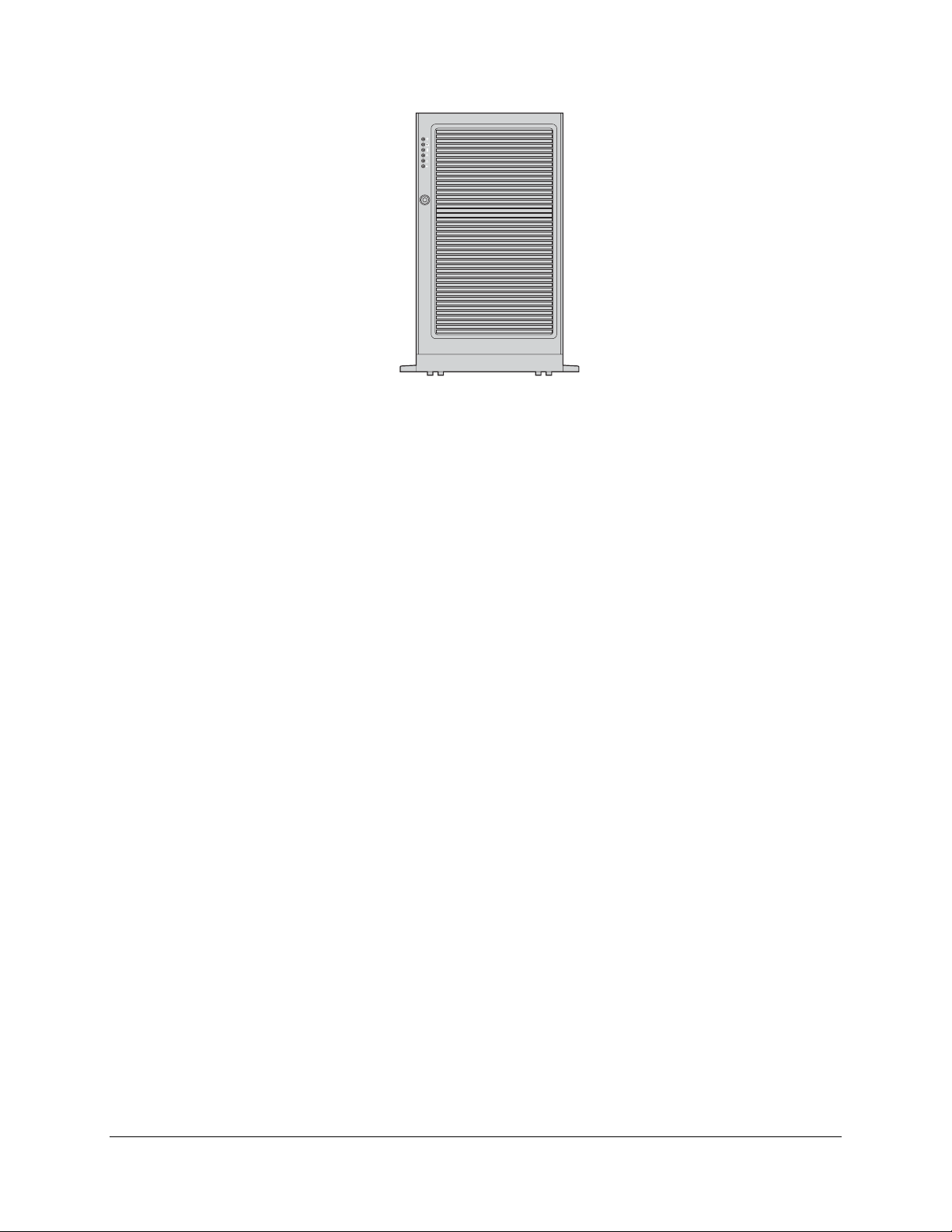

The Server Platform SR6850HW4 utilizes a standard 19-inch EIA chassis that is 6U high x 28

inches deep. The chassis can be rack-mounted or used as a pedestal system. Rack mounting

the platform requires a 6U x 19 inches x 34 inches deep space, with the extra six inches

required for cable management. When used in a rack, the chassis can be mounted with an

optional rail kit and cable management arm. Pedestal operation requires a pedestal conversion

kit that consists of a different bezel, floor supports/wheels and a cosmetic cover.