Page 1

Intel® Server System R1000RP Family

Quick Installation User's Guide

Thank you for buying an Intel® Server System. The following information will help you

assemble your Intel® Server System and install components.

If you are not familiar with ESD [ElectroStatic Discharge] procedures used during

system integration, see the complete ESD procedures described in your Service Guide.

This guide and other supporting documents are located on the web at:

http://www.intel.com/p/en_US/support/.

2.5" hard drive bay system as shown

*

G85599-002

Page 2

(This page is intentionally left blank.)

Page 3

Table of Contents

System Overview .............................................................................................................................. 1

General Installation Process ........................................................................................................ 2

Preparing the System ...................................................................................................... 2

Remove the Top Cover .................................................................................................... 2

Remove the Air Duct ........................................................................................................ 2

Remove Processor Heatsink ........................................................................................ 2

Install the Processor ........................................................................................................ 3

Install Processor Heatsink ............................................................................................. 4

Install Memory Modules .................................................................................................. 4

Install Hard Drives .............................................................................................................. 5

Install Optical Drive ............................................................................................................ 7

Install the Air Duct ............................................................................................................. 8

Remove Add-in Card Riser Assembly ...................................................................... 8

Install Add-in Card .............................................................................................................. 8

Install Add-in Card Riser Assembly ........................................................................... 8

Install Rack Handles .......................................................................................................... 8

Install Intel® I/O Expansion Module (optional) ..................................................... 9

Install Intel® ESRT2 RAID AXXRAKSW5 Upgrade Key (optional) ................ 9

Install Intel® Remote Management Module 4 (optional) ................................ 9

Install Intel® RAID Smart Battery (optional) ........................................................ 10

Replace Fixed Power Supply Module (optional) ............................................... 10

Replace Redundant Power Supply Module (optional) .................................. 10

Install Bezel (optional) .................................................................................................... 11

Install the Top Cover ........................................................................................................ 11

Finishing Up ......................................................................................................................... 11

Software ............................................................................................................................... 11

Reference ............................................................................................................................................ 12

i

Page 4

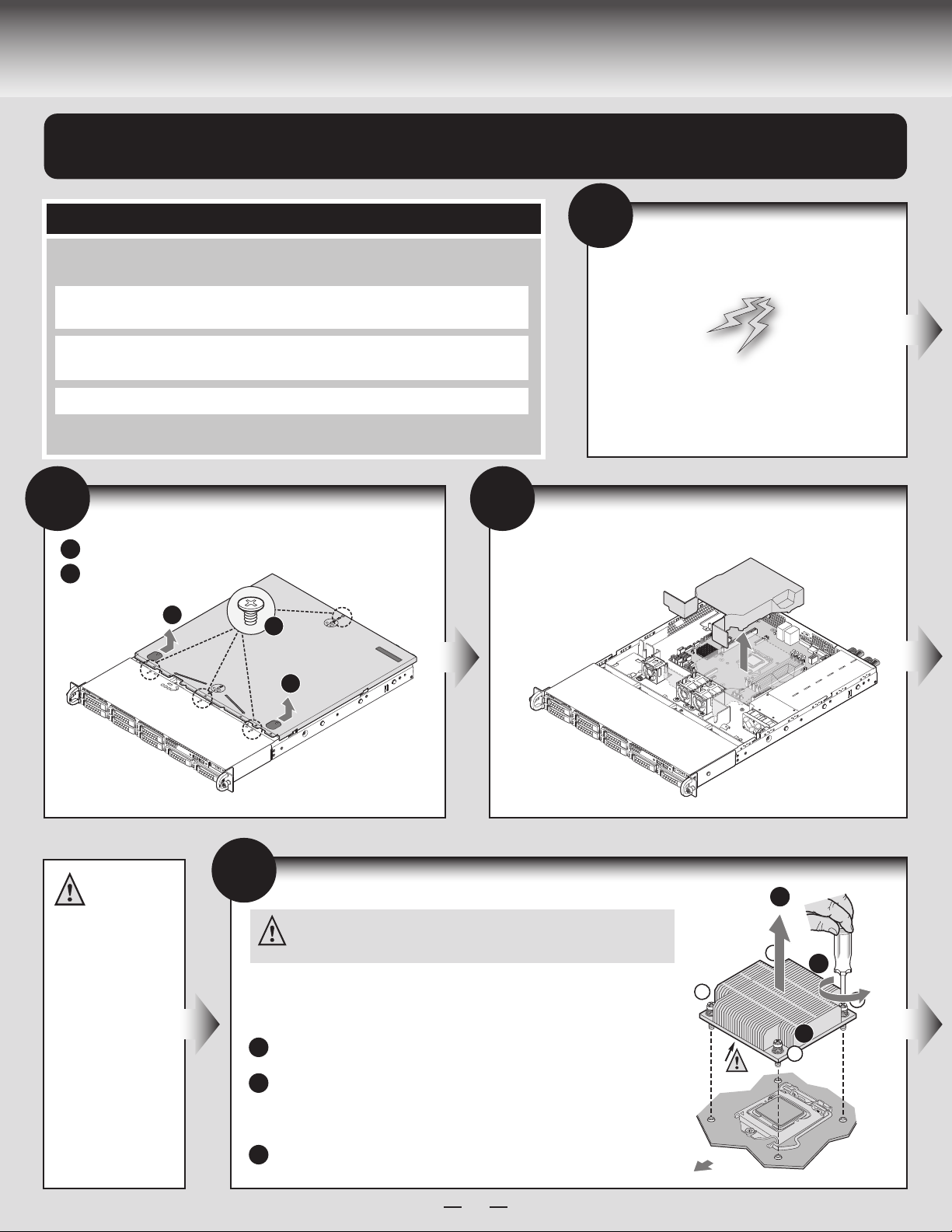

Warning

Warning Caution

Tools Required

Read all caution and safety

statements in this document

before performing any of the

instructions. Also see the Intel®

Server Board and Server Chassis

Safety Information document at:

http://www.intel.com/support/

Installation and service

of this product is to be

performed only by

qualified service personnel

to avoid risk of injury from

electrical shock or energy

hazard.

motherboards/server/sb/cs-010770

.htm for complete safety information.

Intel® is a registered trademark of Intel Corporation or its subsidiaries in the United States and other countries. *Other names and brands may be claimed as the

property of others. Copyright © 2013, Intel Corporation. All rights reserved.

Observe normal ESD

[Electrostatic Discharge]

procedures during system

integration to avoid possible

damage to server board and/or

other components.

Phillips*

screwdriver

Anti-static

wrist strap

Thermal Operation and Configuration Requirements

To keep the system operating within supported maximum thermal limits, the system must meet the following operating and configuration

guidelines:

• Ambient in-let temperature cannot exceed 35 ºC and should not remain at this maximum level for long periods of time.

Doing so may affect long term reliability of the system.

st

• DIMM Population on CPU: Install DIMMs the in order; Channels A, and B. Start with 1

DIMM slot (blue) on each channel.

• All hard drive bays must be populated. Hard drive carriers either can be populated with a hard drive or supplied drive blank.

• The air duct must be installed at all times.

• The system top-cover must be installed at all times.

ii

Page 5

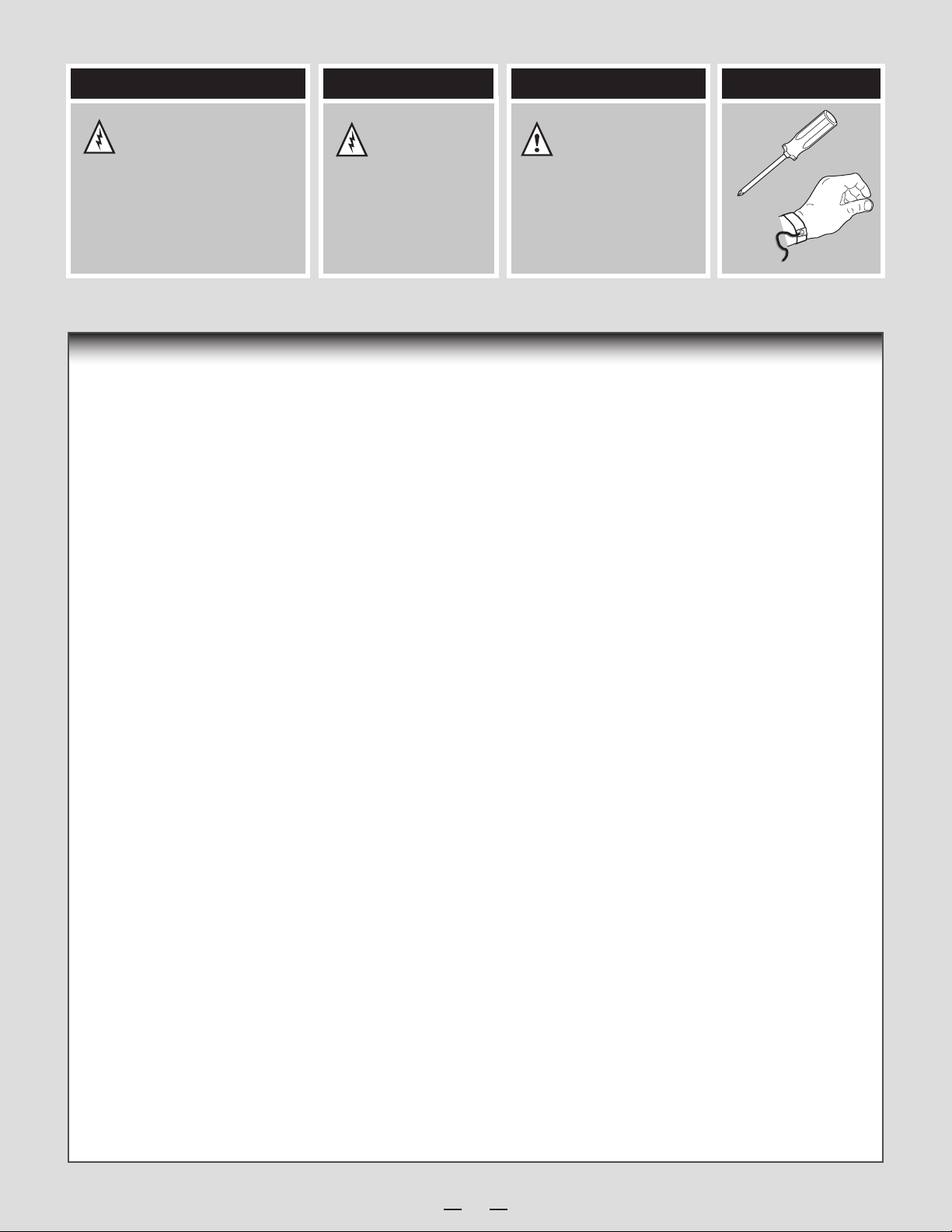

System Overview

Intel® Server System R1000RP Family

System Features and Components

System Fans

Hard Drive Bays

Front Control Panel

* 2.5" Hard Drive Bay system as shown

Server Board

PCI Slots

CPU

Power Supply

Memory Slots

Air Duct

1

Page 6

General Installation Process

The installation instructions in this section are for common components of Intel® Server System

R1000RP family.

Minimum Hardware Requirements

To avoid integration difficulties and possible board damage, your system must meet

the following minimum requirements:

®

B

®

Xeon

processor E3-1200 V3 product family or the 4

A

• Processor: Intel

Generation Intel® Core™ i3 processor series.

• Memory Type:

Minimum of one 1GB DDR3L 1333/1600 MHz ECC UDIMM

• Hard Disk Drives: SATA

For a complete list of compatible processors, heatsinks, and memory, see

http://www.intel.com/p/en_US/support/ (post-production only)

2

Remove the Top Cover

Remove the four screws.

A

Slide cover back

B

and lift upward.

1

th

3

Remove the Air Duct

Remove the air duct by

lifting straight up.

Preparing the System

Observe normal ESD (Electrostatic Discharge)

procedures.

Place your Intel® Server System on a flat anti-static

surface to perform the following integration procedures.

Observe ESD procedures before reaching inside to make

server board connections or install components.

IMPORTANT!

Before proceeding

further, check your

®

Intel

Server System

for disconnected or

loose cables and

components that

may have occurred

during shipping.

B

4

Remove Processor Heatsink

CAUTION: The heatsink has thermal interface material (TIM) on the underside

of it. Use caution so that you do not damage the thermal interface material.

Use gloves to avoid sharp edges.

The heatsink is attached to the server board / processor socket with captive fasteners.

Using a #2 Phillips* screwdriver, loosen the four screws located on the

heatsink corners in a diagonal manner using the following procedure:

Using a #2 Phillips* screwdriver, start with screw 1 and loosen it by

A

giving it two rotations and stop. (IMPORTANT: Do not fully loosen.)

Proceed to screw 2 and loosen it by giving it two rotations and stop.

B

Similarly, loosen screws 3 and 4.

Repeat steps A and B by giving each screw two rotations each time

until all screws are loosened.

Lift the heatsink straight up.

C

2

TIM

Chassis Front

C

3

A

1

B

4

2

Page 7

General Installation Process

5

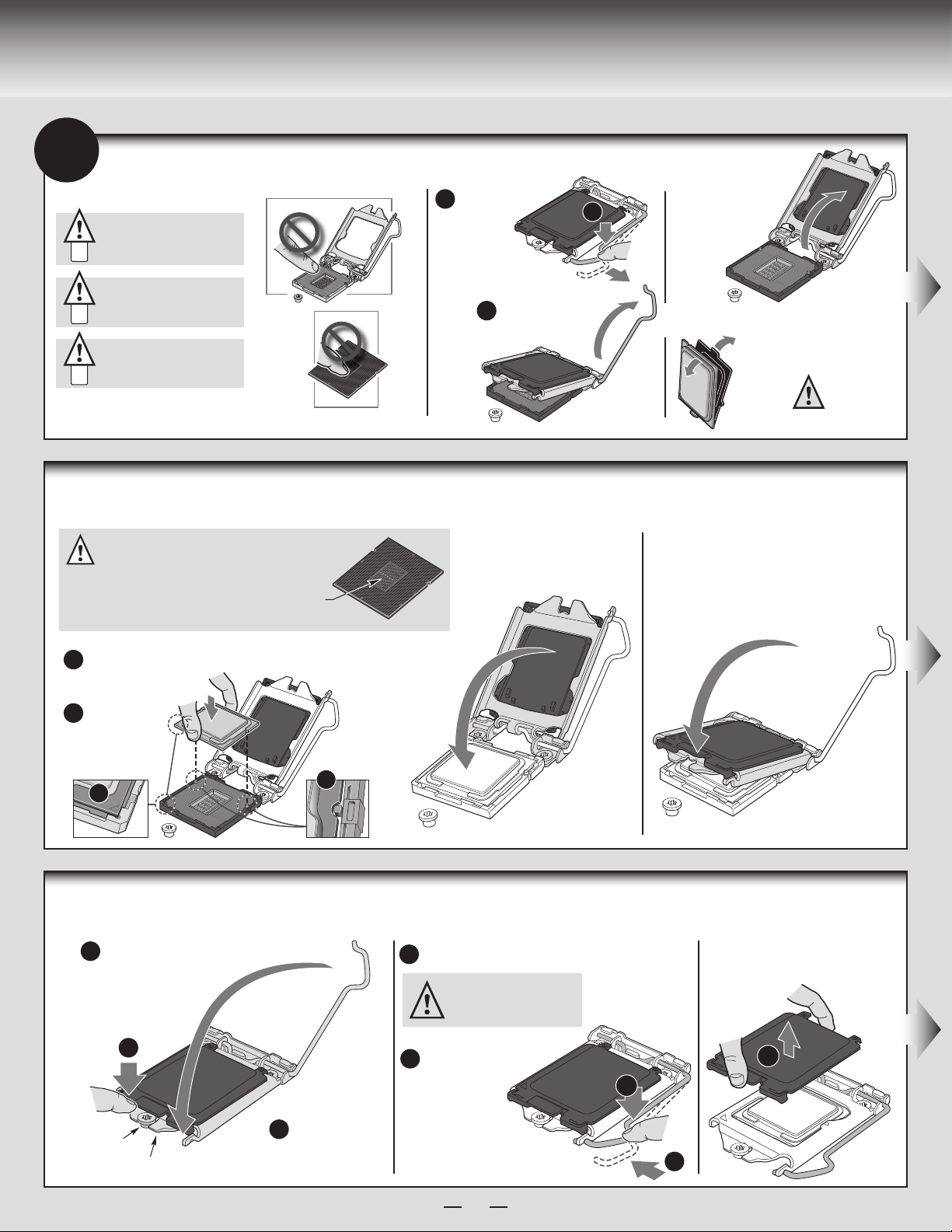

Install the Processor

Cautions:

When removing the protective

cover, DO NOT TOUCH the

gold socket pins.

A

To avoid damage, DO NOT

DROP the cover onto the

socket pins or components.

B

When unpacking a processor,

hold by the edges only to avoid

touching the gold contact pins.

C

Install the Processor ... continued

D.

Install the Processor

CAUTION: The underside of the processor has components

that may damage the socket wires if installed improperly.

Processor must align correctly with the socket opening

before installation.

DO NOT DROP processor into socket!

Components

A. Open the Socket Lever

Push the lever

A

handle

down

and away

from the socket

to release it.

Rotate the lever

B

open all the way.

Carefully lower the load plate

over the processor.

A

B. Open the

Load Plate

Open the load

plate as shown.

C. Unpack the Processor

Carefully remove

protective cover

as shown.

Save the

protective

cover.

E. Close the Load Plate

Carefully lower the load plate

over the processor.

Orient the processor with the socket so that the processor

A

cutouts match the two

socket pins.

Note location

B

of gold key at

corner of

processor.

A

B

Install the Processor ... continued

F. Engage the Load Plate

Make sure the front edge of the load plate

A

slides under the shoulder

screw as the lever is

lowered.

A

Close the load

Shoulder

Screw

Load Plate

Front Edge

B

plate locking

lever.

G. Latch the Locking Lever

Push down on the locking lever.

A

CAUTION: DO NOT damage the

server board with the tip of the

locking lever.

Slide the tip

B

of the lever

under the

notch in the

load plate.

Make sure

the lever is securely latched.

H.

Remove the Cover

Carefully lift the cover

straight up as shown.

Save the

protective

cover.

A

A

A

B

3

Page 8

General Installation Process

6

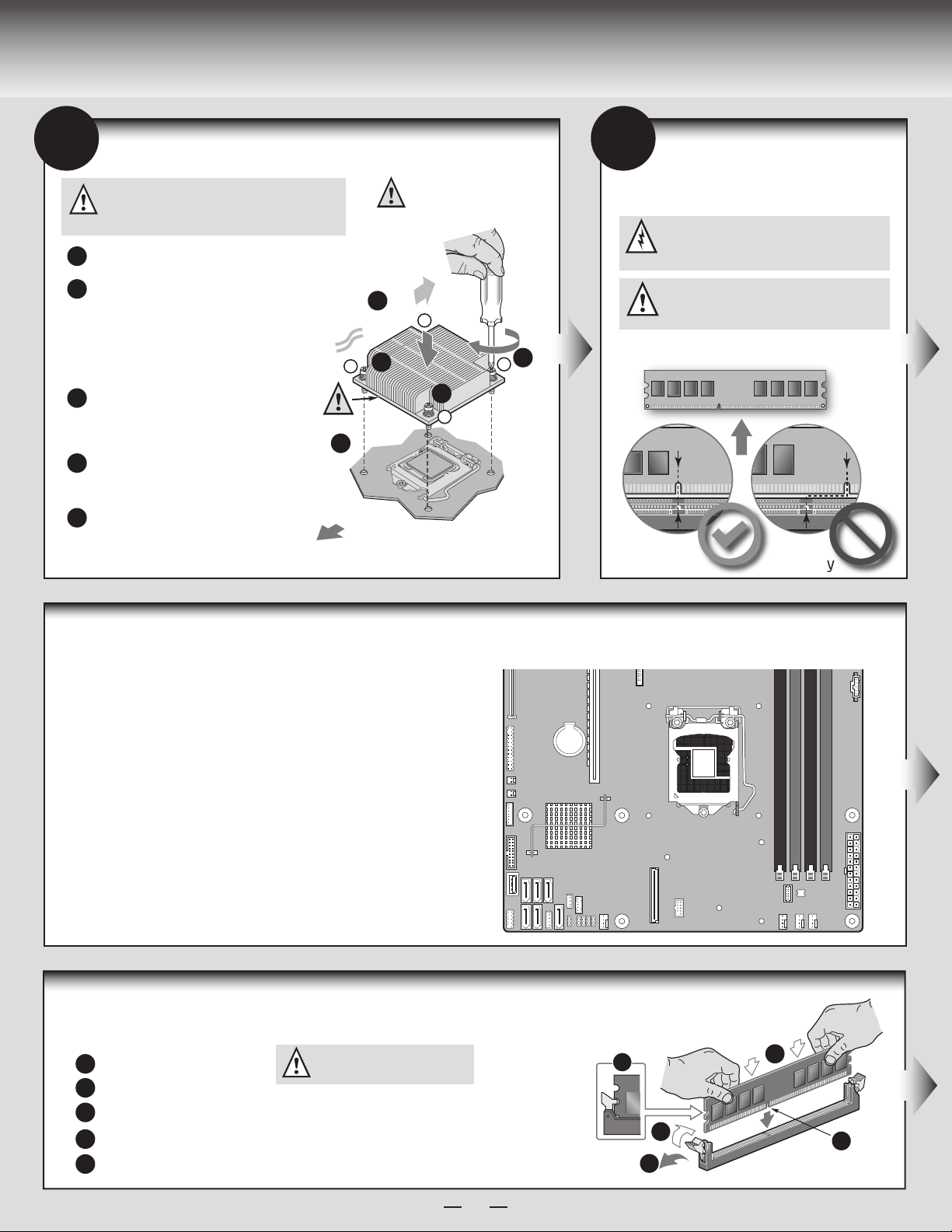

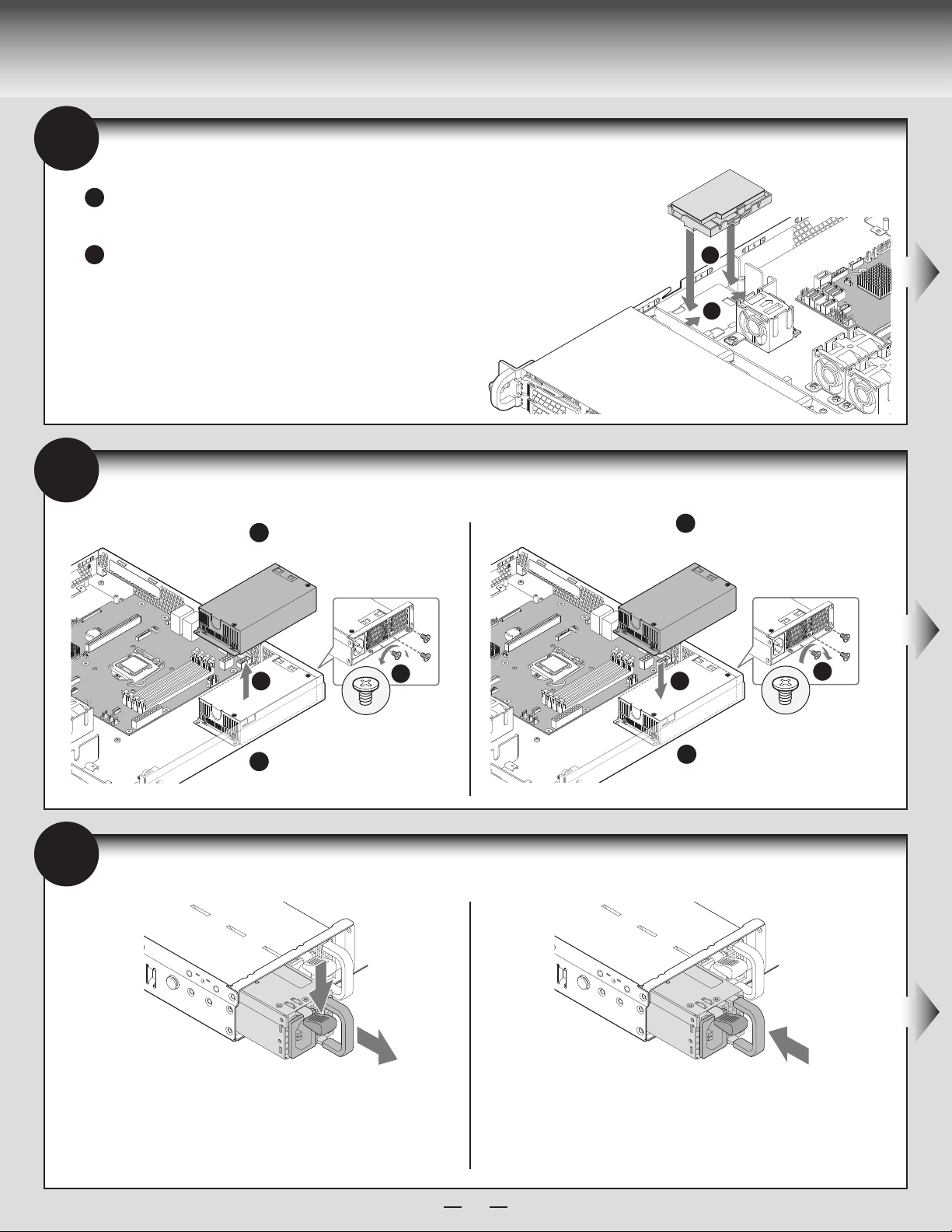

Install Processor Heatsink

CAUTION: The heatsink has thermal interface

material (TIM) on the underside of it. Use caution so

that you do not damage the thermal interface material.

Use gloves to avoid sharp edges.

Remove the protective film on the TIM if present.

A

Align heatsink fins to the front and back of

B

the chassis for correct airflow.

Airflow goes from front-to-back of chassis.

Each heatsink has four captive fasteners and

should be tightened in a diagonal manner using

the following procedure:

Using a #2 Phillips* screwdriver,

C

start with screw 1 and engage screw

threads by giving it two rotations

and stop. (Do not fully tighten.)

Proceed to screw 2 and engage screw

D

threads by giving it two rotations and

stop. Similarly, engage screws 3 and 4.

Repeat steps C and D by giving each

E

screw two rotations each time until

each screw is lightly tightened up to

a maximum of 8 inch-lbs torque.

B

AIRFLOW

D

2

TIM

A

Chassis Front

CAUTION:

Do not

over-tighten

fasteners.

3

C

1

E

4

Note: Heatsink styles may vary.

7

Install Memory Modules

DDR3L DIMM Memory Identification:

CAUTION: Observe normal ESD (ElectroStatic

Discharge) procedures to avoid possible damage to

system components.

This server board supports up to 6 DDR3L 1333/1600

ECC UDIMM. Non-ECC memory is NOT supported by

this server board.

DIMM notch and socket bump must align as shown below.

DDR3

Other

Memory

Install Memory Modules ...continued

Memory Configurations and Population Order:

For the best performance, a minimum of three DIMMs per CPU is recommended,

populated in the blue slot of each memory channel.

Note: For additional memory configurations, see the Service Guide on the

®

Server Deployment & Management DVD that accompanied

Intel

®

your Intel

http://www.intel.com/p/en_US/support/ (post-production)

Memory sizing and configuration is supported only for qualified DIMMs approved by

Intel

http://serverconfigurator.intel.com/sct_app.aspx (post-production)

Server System, or go to:

®

. For a list of supported memory, go to:

Install DIMM Memory Modules ... Continued

To Install DIMMs:

Open both DIMM socket levers.

A

B

Note location of alignment notch.

C

Insert DIMM making sure the connector edge of the DIMM aligns correctly with the slot.

D

Push down firmly on the DIMM until it snaps into place and both levers close.

E

IMPORTANT! Visually check that each latch is fully closed and correctly engaged with each DIMM edge slot.

CAUTION: Avoid touching contacts

when handling or installing DIMMs.

Intel® Server Board S1200V3RPM

DIMM_A2

DIMM_A1

CPU Socket

E

C

D

A

DIMM_B2

DIMM_B1

B

4

Page 9

General Installation Process

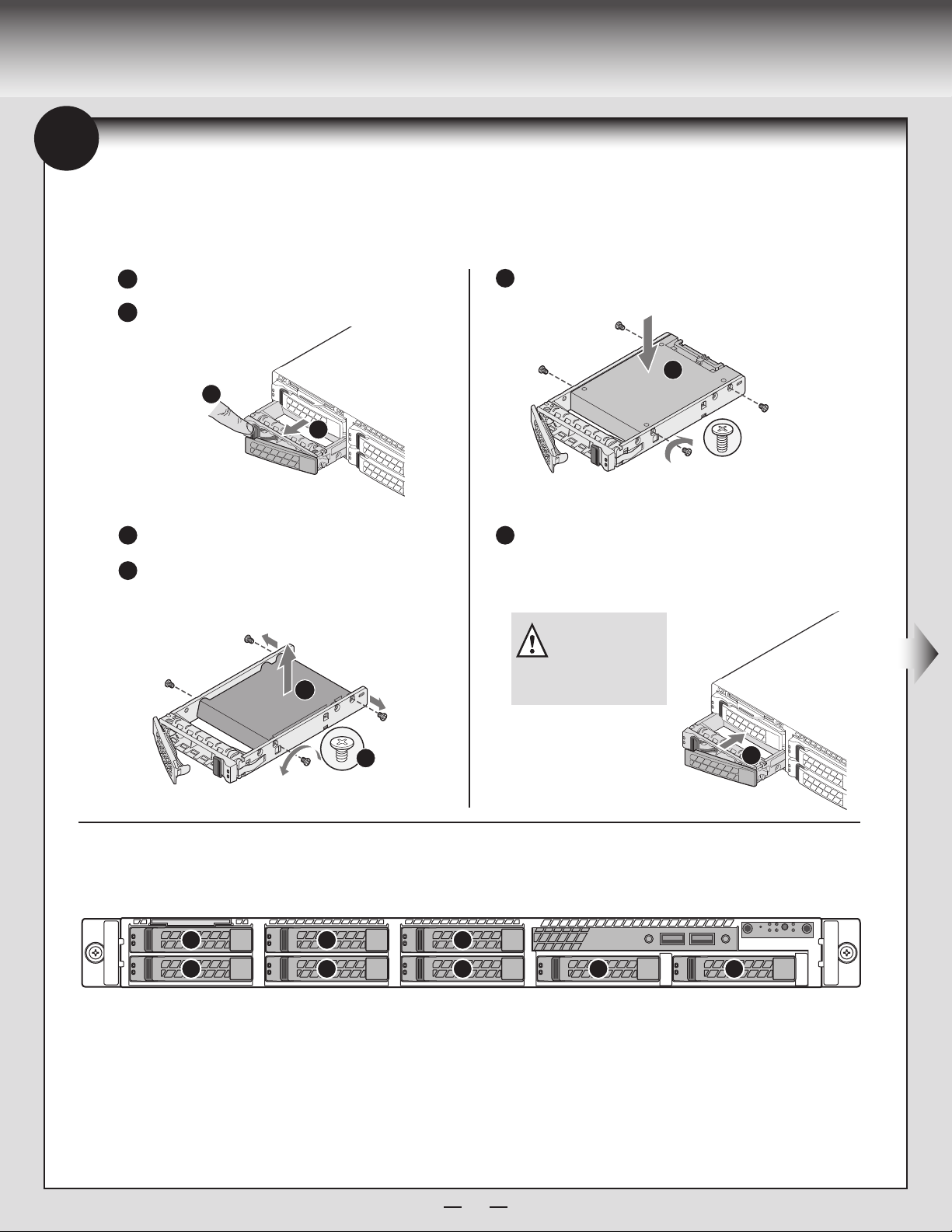

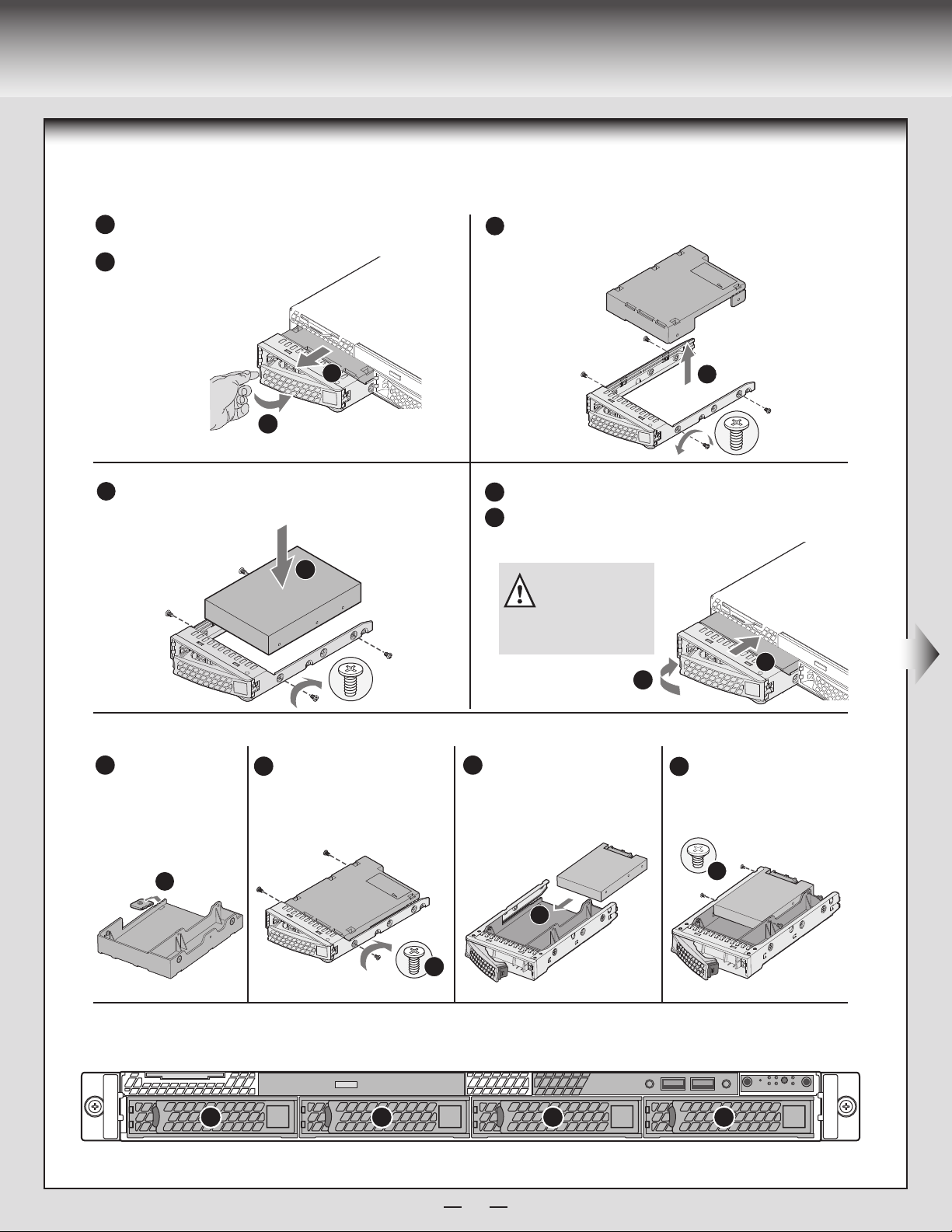

2.5" HDD

8

Install

Hard Drives

2.5" Hard Drive Carrier (For system with 2.5" hard drive bay only)

Remove the drive carrier by pressing the

A

to unlock.

B

Pull out the black lever and slide the carrier out.

green

A

B

Remove the four screws securing the plastic drive blank

C

from the 2.5” HDD carrier.

Disengage the plastic drive blank from the HDD carrier.

D

Remove the plastic drive blank from the 2.5” HDD carrier.

latch

Install the hard disk drive using the four screws as shown. Make Sure

E

that the connector end of the drive matches the backplane connector.

E

With the lever open, insert the hard disk drive assembly into the chassis,

F

then push in the lever to lock it into place.

1

0

Drive 0 Primary

CAUTION: If you do not

install all drives, empty drive

bays must be occupied by

carriers with plastic drive

blank provided to maintain

D

C

proper system cooling.

F

Hard Drive Numbering Diagram

3

2

5

4

6

7

8 x 2.5" hard drive bay as shown

5

Page 10

General Installation Process

2.5" HDD

TOP

BREAK OFF TAB

BEFORE MOUTING

2.5´´ HARD DRIVE

Install

A

B

D

Hard Drives ...continued

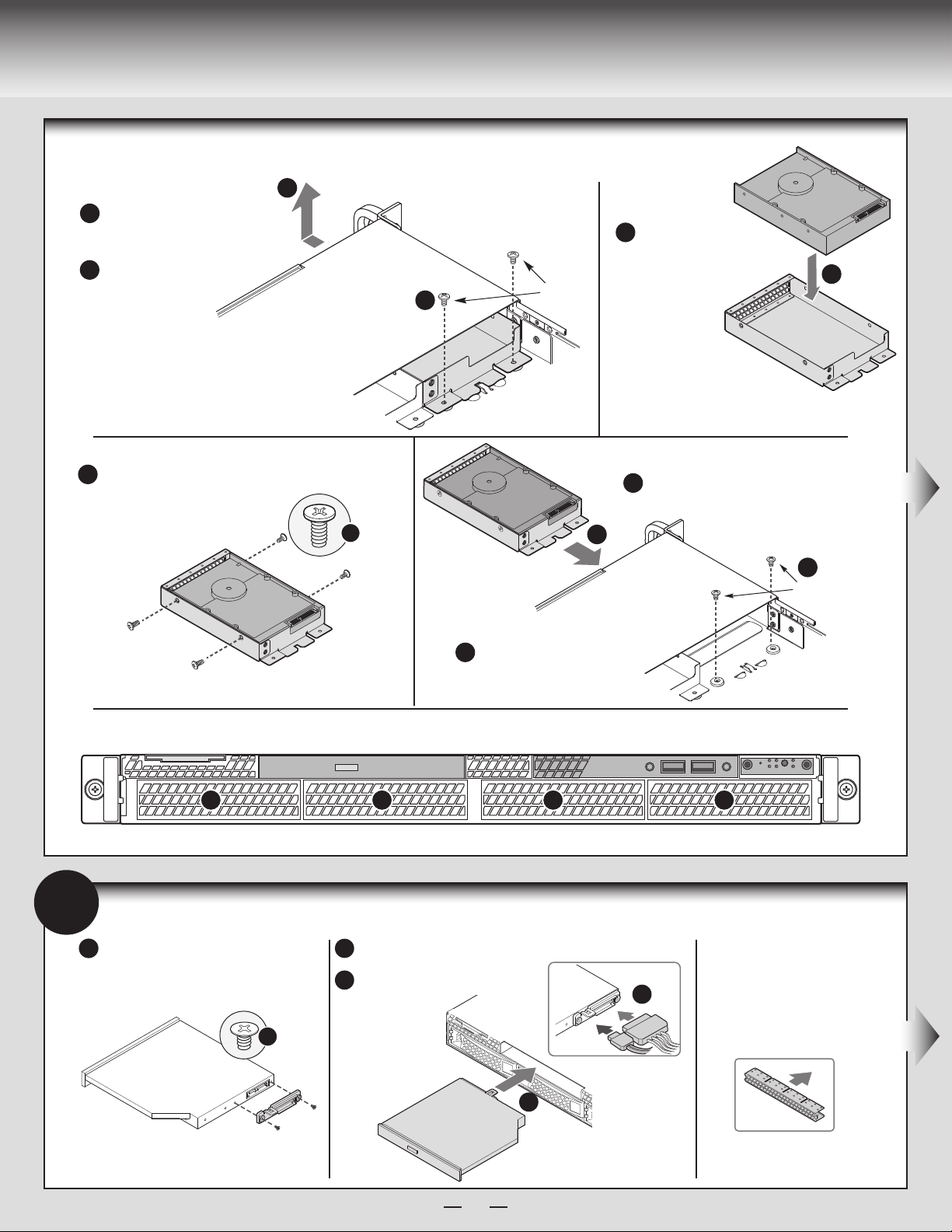

3.5" Hard Drive Carrier (For system with 3.5" Hot Swap hard drive bay only)

Remove the drive carrier by pressing the green button and opening

the lever.

Slide the carrier out.

B

A

Install the hard disk drive using the same four screws as shown. Make

sure the connector end of the drive matches the backplane connector.

D

3.5´´ HDD

Remove the four screws securing the HDD interface bracket and remove

C

the HDD interface bracket.

BREAK OFF TAB

BEFORE MOUTING

2.5´´ HARD DRIVE

TOP

C

With the lever open, insert the hard disk drive assembly into the chassis.

E

F

Push in the lever to lock it into place.

CAUTION: If you do not

install all drives, empty drive

bays must be occupied by

carriers with plastic drive

blank provided to maintain

proper system cooling.

E

F

Install 2.5” Hard Drive as option:

d1

Break off the tab on the

HDD interface bracket.

d2

d1

Bottom

View

0 1 2 3

Drive 0 Primary

Install the HDD interface bracket

from top. Secure the bracket with

three screws as shown.

BREAK OFF TAB

BEFORE MOUTING

2.5´´ HARD DRIVE

TOP

d2

Hard Drive Numbering Diagram

Slide the 2.5” HDD into the

d3

bracket to align the screw holes

with the right and the left rail.

2.5" HDD

d3

6

Secure the hard disk drive using

d4

the four screws for 2.5” HDD.

d4

4 x 3.5” hard drive bay as shown

Page 11

General Installation Process

Install

Hard Drives ...continued

Remove the screws securing

A

the drive carrier to

the chassis.

Slide the carrier away

B

from the chassis.

Attach the hard drive to the carrier with

D

four screws as shown.

B

Note: Hard

drive 0 location

is shown

above.

3.5" Fixed Hard Drive

Insert hard drive into

C

the carrier with

the bottom-side

A

Screw

D

of the drive facing up.

E

E

Re-install the hard drive/carrier assembly

into the chassis.

C

F

Screw

Drive 0 Primary

9

Install Optical Drive

Install the plastic guide onto the back

A

of the drive and attach with two screws

as shown.

Secure the hard

F

drive/carrier assembly

with the screws.

Hard Drive Numbering Diagram

0 1 2 3

3.5” Fixed hard drive as shown

Rear View

of Optical

Drive

Insert the optical drive into chassis opening

B

and push all the way until it stops.

Connect the cables as shown.

C

A

Optical

Device

Assembly

B

Optical

Drive

C

Data

Power

IMPORTANT NOTE: If you do not

install a device at this location,

install the optical device bay filler

panel shown below.

This is required to maintain

proper system cooling.

7

Page 12

General Installation Process

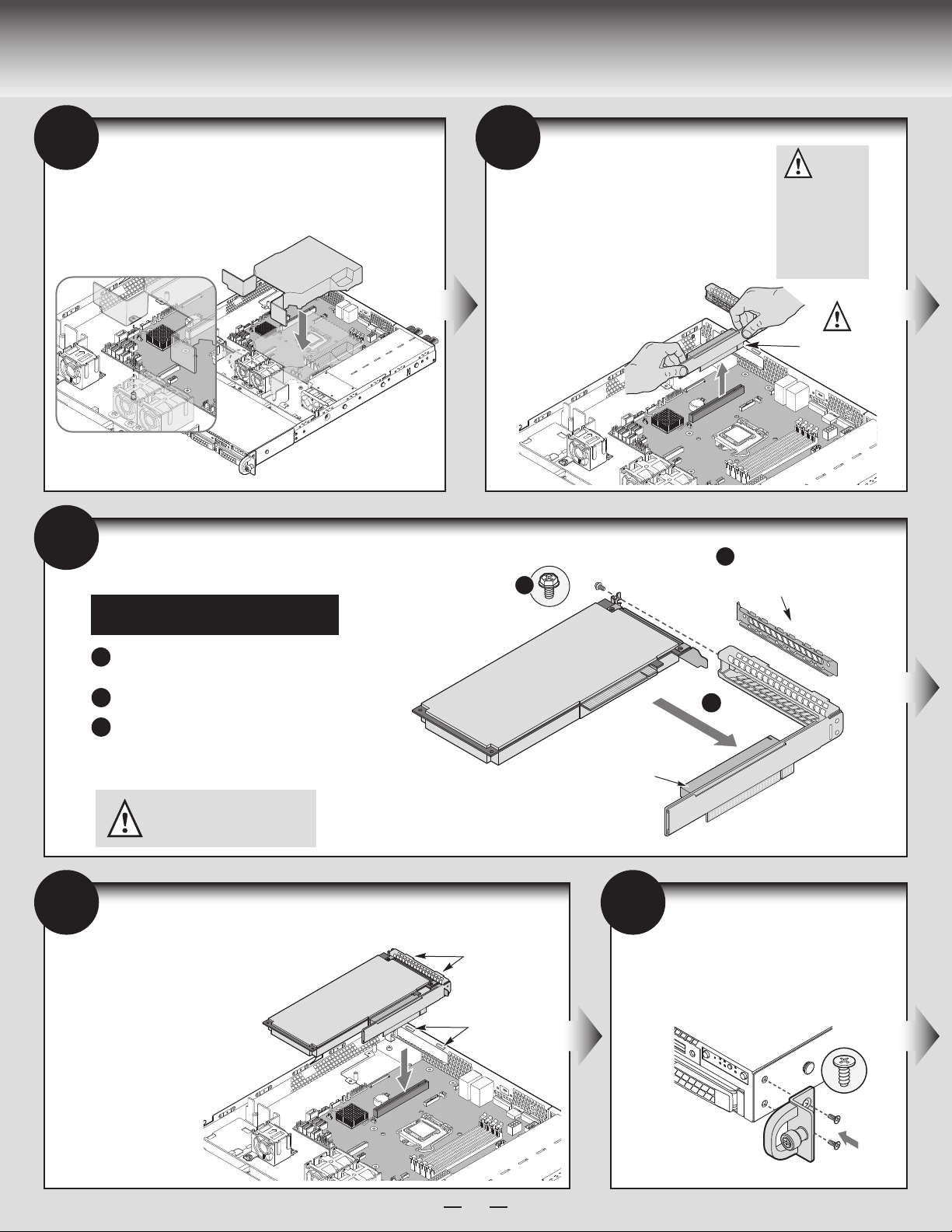

Add-in Card

10

12

Install the Air Duct

Align the two holes on the air duct with the alignment

pins on the chassis and install the air duct into place.

Use care to avoid pinching system cables.

Install Add-in Card

• Full-height PCIe Card Shown

Note: Add-in card install sequence for low-profile add-in

cards is the same.

11

C

Remove Add-in Card

Riser Assembly

Grasp the riser assembly with

both hands and pull up to

remove from system.

CAUTION:

Place the riser

assembly

upside down to

avoid damage

to the riser card

connector.

Riser Card

Connector

A

REMOVE Filler Panel

Remove the filler panel from the add-in card slot and

A

remove the screw as shown.

Insert add-in card until it sits in the riser connector.

B

Secure add-in card with screw as shown.

C

Note: Make sure that all empty add-in card slots have

filler panels installed.

13

Install Add-in Card Riser Assembly

Position the riser card edge

connector over the server

board riser socket and align

the hook of the riser with the

slot at the back of the chassis,

then press straight down into

riser socket.

CAUTION:

Observe normal ESD precautions

when installing add-in cards.

Hooks

Slots

Add-in Card

Riser Connector

14

B

Install Rack Handles

Note: Rack handles are required to install

the bezel. For detailed instructions, see the

Service Guide.

8

Page 13

General Installation Process

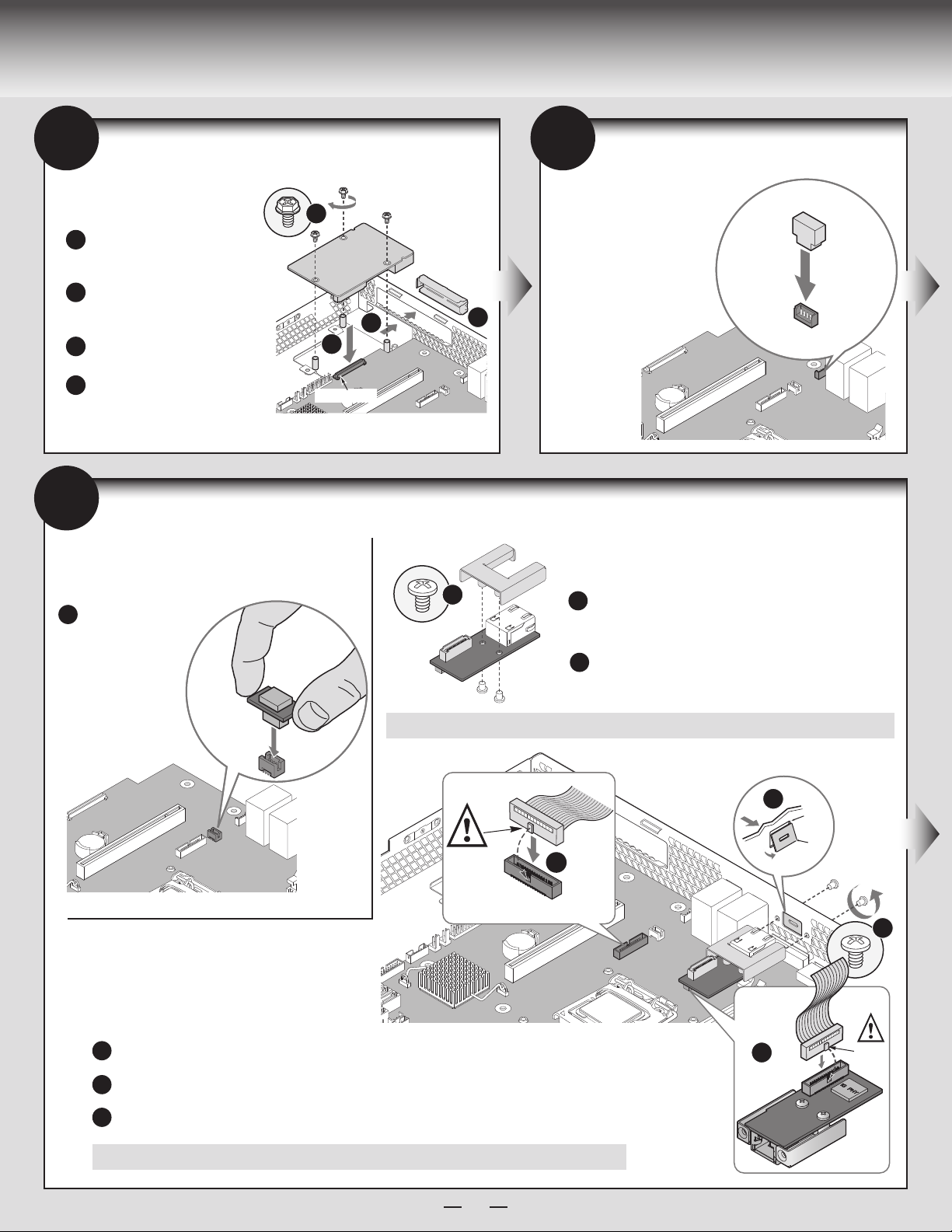

I/O Connector

SATA_KEY

RMM4 Lite

Connector

15

Install Intel® I/O Expansion Module

(optional)

Squeeze the sides of the filler panel to

A

disengage it from the server system

back panel and remove it.

Position the module over the server

B

board, fit the front of the module into

the back panel slot.

Attach the module to the server

C

board connector.

Secure the module with the three

D

screws as shown.

Note: If included, remember to install the EMI shield.

17

A

Install Intel® Remote Management Module 4 (optional)

Installing the Intel® RMM4 Lite Installing the Intel® RMM4 NIC

Locate the RMM4 Lite

connector close to the

Riser Slot.

Carefully pick up the

®

RMM4 Lite

Intel

module, match the

alignment pin of the

module and the

connector on server

board. Press to install.

D

I/O Module

C

16

Install Intel® ESRT2 RAID

AXXRAKSW5

Upgrade Key

(optional)

Locate the white 4-pin key,

carefully pick up the Intel

B

A

A

Caution: Carefully remove the knock out with screwdriver, directly removing it with finger has potential risk.

C600 Upgrade Key. Match the

key and connector orientation

and press down to install.

Attach the metal fastening bracket to Intel® Dedicated

A

Server Management NIC module and secure the bracket

with two screws.

Remove the alternate RMM4 knock out by pressing the

B

knock out from inside the chassis.

®

RAID

Latch

RMM4 NIC

Connector

Connect the cable to the RMM4 NIC connector to the RMM4 NIC connector on your server board.

C

Mount the NIC module to the rear panel of the chassis and secure the bracket with two screws.

D

Connect the cable to the cable connector on the Intel® Dedicated Server Management NIC module.

E

Caution: Care should be used when attaching or removing this cable. Mishandling the cable could cause damage.

9

E

B

C

Bottom View

Chassis

Back

Opening

Filler

D

Latch

Page 14

General Installation Process

A

18

19

Install Intel® RAID Smart Battery (optional)

Locate the BBU bracket inside the chassis. Align the tabs on the plastic battery holder

A

with mounting holes on the BBU bracket.

Slide the plastic battery holder toward the rear of the system until the tabs engage with

B

the mounting holes in the BBU bracket.

Replace Fixed Power Supply Module (optional)

Unsecure the three screws from the

A

module as shown.

A

B

Insert the power supply module into

A

the chassis.

20

B

Remove the power supply module.

B

Replace Redundant Power Supply Module (optional)

Power Supply Removal

Using the handle, pull the module from the

chassis while pressing the green latch in the

direction shown.

Power Supply Installation

Insert the power supply module into the power

supply cage and push all the way until it clicks

into place.

A

Secure the module with the three screws

B

as shown.

B

10

Page 15

General Installation Process

21

A

B

Install Bezel (optional)

Note: Before installing the bezel, you must install the rack handles.

Lock the right end of the front bezel to the rack handle.

Rotate the front bezel clockwise till the left end clicks into place.

Lock the bezel if needed.

B

A

23

Finishing Up

Before installing your operating system, you

must finish your system installation, make I/O

connections, and plug in power cord(s).

1. Verify the system top cover is installed.

2. Install the server into the rack using the instructions

provided with the rack mounting kit.

3.

Connect your USB keyboard/mouse, video and other

I/O cables/devices as shown.

Then connect the power cord(s).

CAUTION: This system must be operated with the

TOP COVER installed to ensure proper cooling.

22

A

B

For system with S1200V3RP Server Board

2nd Power

Supply

Module

Install the Top Cover

Place the top cover on system and slide towards the front of the chassis until the

recessed front edge is fully engaged.

Recessed

Edge

Install the three screws at

the front and torque to 7-9in-lbs.

Then install the screw at the back

and torque to 7-9in-lbs.

Intel ® RMM4

NIC Port

(optional)

1st Power

Supply

Module

Serial

Port A

Display Port

(S1200V3RPM only)

A

NIC 1

Video

Network

NIC 2

USB

Ports

B

A

Add-in Card Slot

Intel ® I/O

Module

(optional)

24

Software

A. Update the System Software:

1. Boot from the Intel

2. Use the Wizard to access the latest versions on the Internet and update the BIOS, firmware, FRUSDRs, and Intel® RMM4. Note: You may also download files on a USB key.

Note: The FRUSDR utility must be run for full platform management functionality.

B. Configure your RAID Controller:

If using a RAID card, use the instructions provided with the RAID controller. If using on-board RAID, you must activate RAID in the BIOS setup. See the Intel

R1000RP Service Guide for more information.

C. Install your Operating System:

Use the instructions provided with the RAID controller and with the operating system.

D. Install Operating System Drivers:

With the operating system running, insert the Intel® Server Deployment & Management DVD. If using a Microsoft Windows* operating system, the Express Installer will

autorun and allow you to select the appropriate drivers to install. On other operating systems, browse the CD folders to locate and install the driver files.

E. Install Intel® System Management Software (optional):

Download the latest version of the Intel® System Management Software from

http://www.intel.com/content/www/us/en/server-management/intel-server-management.html and use the instructions provided at that link to install the software.

* Other brands and names may be claimed as the property of others.

• BIOS, Drivers, and Operating System Installation

®

Server Deployment & Management DVD.

11

®

Server System

Page 16

Reference

Front Panel Controls and Indicators

Your system may include one of two front control panel types.

The features of each are as follows:

A. ID Button with integrated LED

B. NMI Button

C. LAN-1 Activity LED

D. System Cold Reset Button

E. System Status LED

F. Power Button with integrated LED

G. LAN-2 Activity LED

H. HDD Activity LED

Intel® Server Board S1200V3RP Component Layout

Status LED ID LED

NIC2

NIC1

USB3

USB1

USB4

SATA Key

Diagnostic

LED

RMM4 LITE

USB2

Standard Control Panel

HG

A B C D E F

S1200RPM only

VGA

SYS FAN_4

Display

Port

CPU Power

Serial A

Serial_B

IO Module

Front Panel

Chassis

Intrusion

HDD LED

LCP

USB 5/6

USB 7

SATA 1

USB 8/9

RMM4 NIC

Slot 6 ( PCI e_x16 )

Battery

C224 For S1200RPO

C226 For S1200RPM

SATA 3

SATA 0 IPMB CPU FAN

SATA 2 SATA 4

SATA 5

HSBP_I2C

SATA_SGPIO

SYS FAN_1

CPU Socket

SAS Module

eUSB SSD

TPM

DIMM_A2

DIMM_A1

Main Power

SYS FAN_3

SYS FAN_2

PS AUX

DIMM_B2

DIMM_B1

See your Intel® Server System R1000RP Service Guide for expanded component and connection information.

12

Page 17

Reference

System Fan Connection

FAN 4

DIMM_A2

DIMM_A1

DIMM_B2

DIMM_B1

Fixed System Fans

FAN 1

1

FAN 2 FAN 3

Ai r F l ow

2

3

A complete list of accessories and spares can be found at: http://www.intel.com/p/en_US/support/ (post-production only).

13

Page 18

Reference

Optical Drive

System Cabling Diagram

For system with 4 x 3.5” fixed hard drive bay:

Intel® Integrated

RAID Module

CPU Power

Front Panel

SATA 4

SATA 3

SATA 1

Front Panel USB

SATA 2

SATA 0

BBU

7 Pin

SATA

SAS Module

SYS FAN_1

SYS FAN_2

FAN 1 FAN 2 FAN 3

1x5 Pin

SATA

Pwr

7 Pin

SATA

1x5 Pin

SATA

Pwr

7 Pin

SATA

1x5 Pin

SATA

Pwr

7 Pin

SATA

1x5 Pin

SATA

Pwr

Main Power

SYS FAN_3

PS AUX

350W

Power

Supply

3.5”

SATA

HDD

3.5”

SATA

HDD

3.5”

SATA

HDD

3.5”

SATA

HDD

14

Page 19

Reference

Optical Drive

System Cabling Diagram

For system with 4 x 3.5” hot swap hard drive bay:

Intel® Integrated

RAID Module

CPU Power

Front Panel

SATA 4

SATA 3

SATA 1

Front Panel USB

SATA 2

SATA 0

HDD O

BBU

HSBP_I2C

SYS FAN_1

I2C

SAS Module

SYS FAN_2

FAN 1 FAN 2 FAN 3

SATA SGPIO

4 x 3.5" HSBP

HDD 1 HDD 2

PS AUX

350W

Power

Supply

Main Power

SYS FAN_3

HDD 3

15

Page 20

Reference

Optical Drive

System Cabling Diagram

For system with 8 x 2.5” hot swap hard drive bay:

Intel® Integrated

RAID Module

CPU Power

Front Panel

Front Panel USB

SATA 0

I2C

BBU

HSBP_I2C

SAS Module

SYS FAN_1

SYS FAN_2

FAN 1 FAN 2 FAN 3

8 x 2.5" HSBP

PS AUX

450W

Power

Supply

PDB

Main Power

SYS FAN_3

16

Page 21

Page 22

G85599-002

Page 23

Intel® Server System R1000RP Family

Quick Installation User's Guide

Thank you for buying an Intel® Server System. The following information will help you

assemble your Intel® Server System and install components.

If you are not familiar with ESD [ElectroStatic Discharge] procedures used during

system integration, see the complete ESD procedures described in your Service Guide.

This guide and other supporting documents are located on the web at:

http://www.intel.com/p/en_US/support/.

2.5" hard drive bay system as shown

*

G85599-002

Page 24

(This page is intentionally left blank.)

Page 25

Table of Contents

System Overview .............................................................................................................................. 1

General Installation Process ........................................................................................................ 2

Preparing the System ...................................................................................................... 2

Remove the Top Cover .................................................................................................... 2

Remove the Air Duct ........................................................................................................ 2

Remove Processor Heatsink ........................................................................................ 2

Install the Processor ........................................................................................................ 3

Install Processor Heatsink ............................................................................................. 4

Install Memory Modules .................................................................................................. 4

Install Hard Drives .............................................................................................................. 5

Install Optical Drive ............................................................................................................ 7

Install the Air Duct ............................................................................................................. 8

Remove Add-in Card Riser Assembly ...................................................................... 8

Install Add-in Card .............................................................................................................. 8

Install Add-in Card Riser Assembly ........................................................................... 8

Install Rack Handles .......................................................................................................... 8

Install Intel® I/O Expansion Module (optional) ..................................................... 9

Install Intel® ESRT2 RAID AXXRAKSW5 Upgrade Key (optional) ................ 9

Install Intel® Remote Management Module 4 (optional) ................................ 9

Install Intel® RAID Smart Battery (optional) ........................................................ 10

Replace Fixed Power Supply Module (optional) ............................................... 10

Replace Redundant Power Supply Module (optional) .................................. 10

Install Bezel (optional) .................................................................................................... 11

Install the Top Cover ........................................................................................................ 11

Finishing Up ......................................................................................................................... 11

Software ............................................................................................................................... 11

Reference ............................................................................................................................................ 12

i

Page 26

Warning

Warning Caution

Tools Required

Read all caution and safety

statements in this document

before performing any of the

instructions. Also see the Intel®

Server Board and Server Chassis

Safety Information document at:

http://www.intel.com/support/

Installation and service

of this product is to be

performed only by

qualified service personnel

to avoid risk of injury from

electrical shock or energy

hazard.

motherboards/server/sb/cs-010770

.htm for complete safety information.

Intel® is a registered trademark of Intel Corporation or its subsidiaries in the United States and other countries. *Other names and brands may be claimed as the

property of others. Copyright © 2013, Intel Corporation. All rights reserved.

Observe normal ESD

[Electrostatic Discharge]

procedures during system

integration to avoid possible

damage to server board and/or

other components.

Phillips*

screwdriver

Anti-static

wrist strap

Thermal Operation and Configuration Requirements

To keep the system operating within supported maximum thermal limits, the system must meet the following operating and configuration

guidelines:

• Ambient in-let temperature cannot exceed 35 ºC and should not remain at this maximum level for long periods of time.

Doing so may affect long term reliability of the system.

st

• DIMM Population on CPU: Install DIMMs the in order; Channels A, and B. Start with 1

DIMM slot (blue) on each channel.

• All hard drive bays must be populated. Hard drive carriers either can be populated with a hard drive or supplied drive blank.

• The air duct must be installed at all times.

• The system top-cover must be installed at all times.

ii

Page 27

System Overview

Intel® Server System R1000RP Family

System Features and Components

System Fans

Hard Drive Bays

Front Control Panel

* 2.5" Hard Drive Bay system as shown

Server Board

PCI Slots

CPU

Power Supply

Memory Slots

Air Duct

1

Page 28

General Installation Process

The installation instructions in this section are for common components of Intel® Server System

R1000RP family.

Minimum Hardware Requirements

To avoid integration difficulties and possible board damage, your system must meet

the following minimum requirements:

®

B

®

Xeon

processor E3-1200 V3 product family or the 4

A

• Processor: Intel

Generation Intel® Core™ i3 processor series.

• Memory Type:

Minimum of one 1GB DDR3L 1333/1600 MHz ECC UDIMM

• Hard Disk Drives: SATA

For a complete list of compatible processors, heatsinks, and memory, see

http://www.intel.com/p/en_US/support/ (post-production only)

2

Remove the Top Cover

Remove the four screws.

A

Slide cover back

B

and lift upward.

1

th

3

Remove the Air Duct

Remove the air duct by

lifting straight up.

Preparing the System

Observe normal ESD (Electrostatic Discharge)

procedures.

Place your Intel® Server System on a flat anti-static

surface to perform the following integration procedures.

Observe ESD procedures before reaching inside to make

server board connections or install components.

IMPORTANT!

Before proceeding

further, check your

®

Intel

Server System

for disconnected or

loose cables and

components that

may have occurred

during shipping.

B

4

Remove Processor Heatsink

CAUTION: The heatsink has thermal interface material (TIM) on the underside

of it. Use caution so that you do not damage the thermal interface material.

Use gloves to avoid sharp edges.

The heatsink is attached to the server board / processor socket with captive fasteners.

Using a #2 Phillips* screwdriver, loosen the four screws located on the

heatsink corners in a diagonal manner using the following procedure:

Using a #2 Phillips* screwdriver, start with screw 1 and loosen it by

A

giving it two rotations and stop. (IMPORTANT: Do not fully loosen.)

Proceed to screw 2 and loosen it by giving it two rotations and stop.

B

Similarly, loosen screws 3 and 4.

Repeat steps A and B by giving each screw two rotations each time

until all screws are loosened.

Lift the heatsink straight up.

C

2

TIM

Chassis Front

C

3

A

1

B

4

2

Page 29

General Installation Process

5

Install the Processor

Cautions:

When removing the protective

cover, DO NOT TOUCH the

gold socket pins.

A

To avoid damage, DO NOT

DROP the cover onto the

socket pins or components.

B

When unpacking a processor,

hold by the edges only to avoid

touching the gold contact pins.

C

Install the Processor ... continued

D.

Install the Processor

CAUTION: The underside of the processor has components

that may damage the socket wires if installed improperly.

Processor must align correctly with the socket opening

before installation.

DO NOT DROP processor into socket!

Components

A. Open the Socket Lever

Push the lever

A

handle

down

and away

from the socket

to release it.

Rotate the lever

B

open all the way.

Carefully lower the load plate

over the processor.

A

B. Open the

Load Plate

Open the load

plate as shown.

C. Unpack the Processor

Carefully remove

protective cover

as shown.

Save the

protective

cover.

E. Close the Load Plate

Carefully lower the load plate

over the processor.

Orient the processor with the socket so that the processor

A

cutouts match the two

socket pins.

Note location

B

of gold key at

corner of

processor.

A

B

Install the Processor ... continued

F. Engage the Load Plate

Make sure the front edge of the load plate

A

slides under the shoulder

screw as the lever is

lowered.

A

Close the load

Shoulder

Screw

Load Plate

Front Edge

B

plate locking

lever.

G. Latch the Locking Lever

Push down on the locking lever.

A

CAUTION: DO NOT damage the

server board with the tip of the

locking lever.

Slide the tip

B

of the lever

under the

notch in the

load plate.

Make sure

the lever is securely latched.

H.

Remove the Cover

Carefully lift the cover

straight up as shown.

Save the

protective

cover.

A

A

A

B

3

Page 30

General Installation Process

6

Install Processor Heatsink

CAUTION: The heatsink has thermal interface

material (TIM) on the underside of it. Use caution so

that you do not damage the thermal interface material.

Use gloves to avoid sharp edges.

Remove the protective film on the TIM if present.

A

Align heatsink fins to the front and back of

B

the chassis for correct airflow.

Airflow goes from front-to-back of chassis.

Each heatsink has four captive fasteners and

should be tightened in a diagonal manner using

the following procedure:

Using a #2 Phillips* screwdriver,

C

start with screw 1 and engage screw

threads by giving it two rotations

and stop. (Do not fully tighten.)

Proceed to screw 2 and engage screw

D

threads by giving it two rotations and

stop. Similarly, engage screws 3 and 4.

Repeat steps C and D by giving each

E

screw two rotations each time until

each screw is lightly tightened up to

a maximum of 8 inch-lbs torque.

B

AIRFLOW

D

2

TIM

A

Chassis Front

CAUTION:

Do not

over-tighten

fasteners.

3

C

1

E

4

Note: Heatsink styles may vary.

7

Install Memory Modules

DDR3L DIMM Memory Identification:

CAUTION: Observe normal ESD (ElectroStatic

Discharge) procedures to avoid possible damage to

system components.

This server board supports up to 6 DDR3L 1333/1600

ECC UDIMM. Non-ECC memory is NOT supported by

this server board.

DIMM notch and socket bump must align as shown below.

DDR3

Other

Memory

Install Memory Modules ...continued

Memory Configurations and Population Order:

For the best performance, a minimum of three DIMMs per CPU is recommended,

populated in the blue slot of each memory channel.

Note: For additional memory configurations, see the Service Guide on the

®

Server Deployment & Management DVD that accompanied

Intel

®

your Intel

http://www.intel.com/p/en_US/support/ (post-production)

Memory sizing and configuration is supported only for qualified DIMMs approved by

Intel

http://serverconfigurator.intel.com/sct_app.aspx (post-production)

Server System, or go to:

®

. For a list of supported memory, go to:

Install DIMM Memory Modules ... Continued

To Install DIMMs:

Open both DIMM socket levers.

A

B

Note location of alignment notch.

C

Insert DIMM making sure the connector edge of the DIMM aligns correctly with the slot.

D

Push down firmly on the DIMM until it snaps into place and both levers close.

E

IMPORTANT! Visually check that each latch is fully closed and correctly engaged with each DIMM edge slot.

CAUTION: Avoid touching contacts

when handling or installing DIMMs.

Intel® Server Board S1200V3RPM

DIMM_A2

DIMM_A1

CPU Socket

E

C

D

A

DIMM_B2

DIMM_B1

B

4

Page 31

General Installation Process

2.5" HDD

8

Install

Hard Drives

2.5" Hard Drive Carrier (For system with 2.5" hard drive bay only)

Remove the drive carrier by pressing the

A

to unlock.

B

Pull out the black lever and slide the carrier out.

green

A

B

Remove the four screws securing the plastic drive blank

C

from the 2.5” HDD carrier.

Disengage the plastic drive blank from the HDD carrier.

D

Remove the plastic drive blank from the 2.5” HDD carrier.

latch

Install the hard disk drive using the four screws as shown. Make Sure

E

that the connector end of the drive matches the backplane connector.

E

With the lever open, insert the hard disk drive assembly into the chassis,

F

then push in the lever to lock it into place.

1

0

Drive 0 Primary

CAUTION: If you do not

install all drives, empty drive

bays must be occupied by

carriers with plastic drive

blank provided to maintain

D

C

proper system cooling.

F

Hard Drive Numbering Diagram

3

2

5

4

6

7

8 x 2.5" hard drive bay as shown

5

Page 32

General Installation Process

2.5" HDD

TOP

BREAK OFF TAB

BEFORE MOUTING

2.5´´ HARD DRIVE

Install

A

B

D

Hard Drives ...continued

3.5" Hard Drive Carrier (For system with 3.5" Hot Swap hard drive bay only)

Remove the drive carrier by pressing the green button and opening

the lever.

Slide the carrier out.

B

A

Install the hard disk drive using the same four screws as shown. Make

sure the connector end of the drive matches the backplane connector.

D

3.5´´ HDD

Remove the four screws securing the HDD interface bracket and remove

C

the HDD interface bracket.

BREAK OFF TAB

BEFORE MOUTING

2.5´´ HARD DRIVE

TOP

C

With the lever open, insert the hard disk drive assembly into the chassis.

E

F

Push in the lever to lock it into place.

CAUTION: If you do not

install all drives, empty drive

bays must be occupied by

carriers with plastic drive

blank provided to maintain

proper system cooling.

E

F

Install 2.5” Hard Drive as option:

d1

Break off the tab on the

HDD interface bracket.

d2

d1

Bottom

View

0 1 2 3

Drive 0 Primary

Install the HDD interface bracket

from top. Secure the bracket with

three screws as shown.

BREAK OFF TAB

BEFORE MOUTING

2.5´´ HARD DRIVE

TOP

d2

Hard Drive Numbering Diagram

Slide the 2.5” HDD into the

d3

bracket to align the screw holes

with the right and the left rail.

2.5" HDD

d3

6

Secure the hard disk drive using

d4

the four screws for 2.5” HDD.

d4

4 x 3.5” hard drive bay as shown

Page 33

General Installation Process

Install

Hard Drives ...continued

Remove the screws securing

A

the drive carrier to

the chassis.

Slide the carrier away

B

from the chassis.

Attach the hard drive to the carrier with

D

four screws as shown.

B

Note: Hard

drive 0 location

is shown

above.

3.5" Fixed Hard Drive

Insert hard drive into

C

the carrier with

the bottom-side

A

Screw

D

of the drive facing up.

E

E

Re-install the hard drive/carrier assembly

into the chassis.

C

F

Screw

Drive 0 Primary

9

Install Optical Drive

Install the plastic guide onto the back

A

of the drive and attach with two screws

as shown.

Secure the hard

F

drive/carrier assembly

with the screws.

Hard Drive Numbering Diagram

0 1 2 3

3.5” Fixed hard drive as shown

Rear View

of Optical

Drive

Insert the optical drive into chassis opening

B

and push all the way until it stops.

Connect the cables as shown.

C

A

Optical

Device

Assembly

B

Optical

Drive

C

Data

Power

IMPORTANT NOTE: If you do not

install a device at this location,

install the optical device bay filler

panel shown below.

This is required to maintain

proper system cooling.

7

Page 34

General Installation Process

Add-in Card

10

12

Install the Air Duct

Align the two holes on the air duct with the alignment

pins on the chassis and install the air duct into place.

Use care to avoid pinching system cables.

Install Add-in Card

• Full-height PCIe Card Shown

Note: Add-in card install sequence for low-profile add-in

cards is the same.

11

C

Remove Add-in Card

Riser Assembly

Grasp the riser assembly with

both hands and pull up to

remove from system.

CAUTION:

Place the riser

assembly

upside down to

avoid damage

to the riser card

connector.

Riser Card

Connector

A

REMOVE Filler Panel

Remove the filler panel from the add-in card slot and

A

remove the screw as shown.

Insert add-in card until it sits in the riser connector.

B

Secure add-in card with screw as shown.

C

Note: Make sure that all empty add-in card slots have

filler panels installed.

13

Install Add-in Card Riser Assembly

Position the riser card edge

connector over the server

board riser socket and align

the hook of the riser with the

slot at the back of the chassis,

then press straight down into

riser socket.

CAUTION:

Observe normal ESD precautions

when installing add-in cards.

Hooks

Slots

Add-in Card

Riser Connector

14

B

Install Rack Handles

Note: Rack handles are required to install

the bezel. For detailed instructions, see the

Service Guide.

8

Page 35

General Installation Process

I/O Connector

SATA_KEY

RMM4 Lite

Connector

15

Install Intel® I/O Expansion Module

(optional)

Squeeze the sides of the filler panel to

A

disengage it from the server system

back panel and remove it.

Position the module over the server

B

board, fit the front of the module into

the back panel slot.

Attach the module to the server

C

board connector.

Secure the module with the three

D

screws as shown.

Note: If included, remember to install the EMI shield.

17

A

Install Intel® Remote Management Module 4 (optional)

Installing the Intel® RMM4 Lite Installing the Intel® RMM4 NIC

Locate the RMM4 Lite

connector close to the

Riser Slot.

Carefully pick up the

®

RMM4 Lite

Intel

module, match the

alignment pin of the

module and the

connector on server

board. Press to install.

D

I/O Module

C

16

Install Intel® ESRT2 RAID

AXXRAKSW5

Upgrade Key

(optional)

Locate the white 4-pin key,

carefully pick up the Intel

B

A

A

Caution: Carefully remove the knock out with screwdriver, directly removing it with finger has potential risk.

C600 Upgrade Key. Match the

key and connector orientation

and press down to install.

Attach the metal fastening bracket to Intel® Dedicated

A

Server Management NIC module and secure the bracket

with two screws.

Remove the alternate RMM4 knock out by pressing the

B

knock out from inside the chassis.

®

RAID

Latch

RMM4 NIC

Connector

Connect the cable to the RMM4 NIC connector to the RMM4 NIC connector on your server board.

C

Mount the NIC module to the rear panel of the chassis and secure the bracket with two screws.

D

Connect the cable to the cable connector on the Intel® Dedicated Server Management NIC module.

E

Caution: Care should be used when attaching or removing this cable. Mishandling the cable could cause damage.

9

E

B

C

Bottom View

Chassis

Back

Opening

Filler

D

Latch

Page 36

General Installation Process

A

18

19

Install Intel® RAID Smart Battery (optional)

Locate the BBU bracket inside the chassis. Align the tabs on the plastic battery holder

A

with mounting holes on the BBU bracket.

Slide the plastic battery holder toward the rear of the system until the tabs engage with

B

the mounting holes in the BBU bracket.

Replace Fixed Power Supply Module (optional)

Unsecure the three screws from the

A

module as shown.

A

B

Insert the power supply module into

A

the chassis.

20

B

Remove the power supply module.

B

Replace Redundant Power Supply Module (optional)

Power Supply Removal

Using the handle, pull the module from the

chassis while pressing the green latch in the

direction shown.

Power Supply Installation

Insert the power supply module into the power

supply cage and push all the way until it clicks

into place.

A

Secure the module with the three screws

B

as shown.

B

10

Page 37

General Installation Process

21

A

B

Install Bezel (optional)

Note: Before installing the bezel, you must install the rack handles.

Lock the right end of the front bezel to the rack handle.

Rotate the front bezel clockwise till the left end clicks into place.

Lock the bezel if needed.

B

A

23

Finishing Up

Before installing your operating system, you

must finish your system installation, make I/O

connections, and plug in power cord(s).

1. Verify the system top cover is installed.

2. Install the server into the rack using the instructions

provided with the rack mounting kit.

3.

Connect your USB keyboard/mouse, video and other

I/O cables/devices as shown.

Then connect the power cord(s).

CAUTION: This system must be operated with the

TOP COVER installed to ensure proper cooling.

22

A

B

For system with S1200V3RP Server Board

2nd Power

Supply

Module

Install the Top Cover

Place the top cover on system and slide towards the front of the chassis until the

recessed front edge is fully engaged.

Recessed

Edge

Install the three screws at

the front and torque to 7-9in-lbs.

Then install the screw at the back

and torque to 7-9in-lbs.

Intel ® RMM4

NIC Port

(optional)

1st Power

Supply

Module

Serial

Port A

Display Port

(S1200V3RPM only)

A

NIC 1

Video

Network

NIC 2

USB

Ports

B

A

Add-in Card Slot

Intel ® I/O

Module

(optional)

24

Software

A. Update the System Software:

1. Boot from the Intel

2. Use the Wizard to access the latest versions on the Internet and update the BIOS, firmware, FRUSDRs, and Intel® RMM4. Note: You may also download files on a USB key.

Note: The FRUSDR utility must be run for full platform management functionality.

B. Configure your RAID Controller:

If using a RAID card, use the instructions provided with the RAID controller. If using on-board RAID, you must activate RAID in the BIOS setup. See the Intel

R1000RP Service Guide for more information.

C. Install your Operating System:

Use the instructions provided with the RAID controller and with the operating system.

D. Install Operating System Drivers:

With the operating system running, insert the Intel® Server Deployment & Management DVD. If using a Microsoft Windows* operating system, the Express Installer will

autorun and allow you to select the appropriate drivers to install. On other operating systems, browse the CD folders to locate and install the driver files.

E. Install Intel® System Management Software (optional):

Download the latest version of the Intel® System Management Software from

http://www.intel.com/content/www/us/en/server-management/intel-server-management.html and use the instructions provided at that link to install the software.

* Other brands and names may be claimed as the property of others.

• BIOS, Drivers, and Operating System Installation

®

Server Deployment & Management DVD.

11

®

Server System

Page 38

Reference

Front Panel Controls and Indicators

Your system may include one of two front control panel types.

The features of each are as follows:

A. ID Button with integrated LED

B. NMI Button

C. LAN-1 Activity LED

D. System Cold Reset Button

E. System Status LED

F. Power Button with integrated LED

G. LAN-2 Activity LED

H. HDD Activity LED

Intel® Server Board S1200V3RP Component Layout

Status LED ID LED

NIC2

NIC1

USB3

USB1

USB4

SATA Key

Diagnostic

LED

RMM4 LITE

USB2

Standard Control Panel

HG

A B C D E F

S1200RPM only

VGA

SYS FAN_4

Display

Port

CPU Power

Serial A

Serial_B

IO Module

Front Panel

Chassis

Intrusion

HDD LED

LCP

USB 5/6

USB 7

SATA 1

USB 8/9

RMM4 NIC

Slot 6 ( PCI e_x16 )

Battery

C224 For S1200RPO

C226 For S1200RPM

SATA 3

SATA 0 IPMB CPU FAN

SATA 2 SATA 4

SATA 5

HSBP_I2C

SATA_SGPIO

SYS FAN_1

CPU Socket

SAS Module

eUSB SSD

TPM

DIMM_A2

DIMM_A1

Main Power

SYS FAN_3

SYS FAN_2

PS AUX

DIMM_B2

DIMM_B1

See your Intel® Server System R1000RP Service Guide for expanded component and connection information.

12

Page 39

Reference

System Fan Connection

FAN 4

DIMM_A2

DIMM_A1

DIMM_B2

DIMM_B1

Fixed System Fans

FAN 1

1

FAN 2 FAN 3

Ai r F l ow

2

3

A complete list of accessories and spares can be found at: http://www.intel.com/p/en_US/support/ (post-production only).

13

Page 40

Reference

Optical Drive

System Cabling Diagram

For system with 4 x 3.5” fixed hard drive bay:

Intel® Integrated

RAID Module

CPU Power

Front Panel

SATA 4

SATA 3

SATA 1

Front Panel USB

SATA 2

SATA 0

BBU

7 Pin

SATA

SAS Module

SYS FAN_1

SYS FAN_2

FAN 1 FAN 2 FAN 3

1x5 Pin

SATA

Pwr

7 Pin

SATA

1x5 Pin

SATA

Pwr

7 Pin

SATA

1x5 Pin

SATA

Pwr

7 Pin

SATA

1x5 Pin

SATA

Pwr

Main Power

SYS FAN_3

PS AUX

350W

Power

Supply

3.5”

SATA

HDD

3.5”

SATA

HDD

3.5”

SATA

HDD

3.5”

SATA

HDD

14

Page 41

Reference

Optical Drive

System Cabling Diagram

For system with 4 x 3.5” hot swap hard drive bay:

Intel® Integrated

RAID Module

CPU Power

Front Panel

SATA 4

SATA 3

SATA 1

Front Panel USB

SATA 2

SATA 0

HDD O

BBU

HSBP_I2C

SYS FAN_1

I2C

SAS Module

SYS FAN_2

FAN 1 FAN 2 FAN 3

SATA SGPIO

4 x 3.5" HSBP

HDD 1 HDD 2

PS AUX

350W

Power

Supply

Main Power

SYS FAN_3

HDD 3

15

Page 42

Reference

Optical Drive

System Cabling Diagram

For system with 8 x 2.5” hot swap hard drive bay:

Intel® Integrated

RAID Module

CPU Power

Front Panel

Front Panel USB

SATA 0

I2C

BBU

HSBP_I2C

SAS Module

SYS FAN_1

SYS FAN_2

FAN 1 FAN 2 FAN 3

8 x 2.5" HSBP

PS AUX

450W

Power

Supply

PDB

Main Power

SYS FAN_3

16

Page 43

Page 44

G85599-002

Loading...

Loading...