Page 1

Intel® Server System R1000BB Family

Service Guide

A Guide for Technically Qualified Assemblers of Intel® identified Subassemblies/Products

Order Number: G65886-001

Page 2

Disclaimer

Disclaimer

®

Information in this document is provi ded in connection with Intel

products. No license, express or i m plied, by

estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in

Intel®’s Terms and Conditions of Sale for such pr oducts, Intel assumes no liability whatsoever, and Intel

disclaims any express or implied warranty, relating to sale and/or use of I ntel products including liability or

warranties relating to fitness for a particular purpose, merchantabil ity, or infringement of any patent, copyright

or other intellectual property right. Intel products are not designed, intended or authorized for use in any

medical, life saving, or life sustai ning applications or for any other application in which the failure of the Intel

product could create a situation where personal injury or death may occur. Intel may make changes to

specifications and product descriptions at any time, without notice.

®

Intel

server boards contain a number of hi gh-density VLSI and power delivery components that need

adequate airflow for cooling. Intel’s own chassis are design ed and tested to meet the intended thermal

requirements of these components when the fully integrated system is used t ogether. It is the responsibility of

the system integrator that chooses not to use Intel developed server building blocks to consult vendor

datasheets and operating parameters to determine the amount of airflow required for their specific application

and environmental conditions. Intel Corporation can not be held respo nsible if components fail or the ser v er

board does not operate correctly when used outside any of their published operating or non-operating limits.

Intel, Intel Pentium, and Intel Xeon are trademarks or registered trademar ks of Intel Corporation or its

subsidiaries in the United States and other countries.

* Other names and brands may be claimed a s the property of others.

Copyright © 2012 Intel Corporation. All Rights Reserved.

ii Intel® Server System R1000BB Service Guide

Page 3

Safety Information

重要安全指导

Safety Information

Important Safety Instructions

Read all caution and safety statements in t his document before performing any of the instructions.

See also Intel

Deployment Toolkit 3.0 CD and/or at

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm

Wichtige Sicherheitshinweise

Lesen Sie zunächst sämtliche Warnund Sicherheitshinweise in diesem Dokument, bevor Sie eine

der Anweisungen ausführen. Beachten Sie hierzu auch die Sicherheitshinweise zu Intel

Serverplatinen und Servergehäusen auf der Intel

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm

Consignes de sécurité

Lisez attention toutes les consign es de sécurité et les mises en garde indiquées dans ce document

avant de suivre toute instruction. Con sultez Intel Server Boards and Server Chassis Safety

Information sur le Intel

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm

®

Server Boards and Server Chassis Safety Information on the Intel

.

®

Server Deployment Toolkit 3.0 CD oder unter

.

®

Server Deployment Toolkit 3.0 CD ou bien rendez-vous sur le site

.

®

Server

®

-

Instrucciones de seguridad importantes

Lea todas las declaraciones de seguridad y precaución de este documento antes de realizar

cualquiera de las instrucciones. Vea Intel

®

el Intel

Server Deployment Toolkit 3.0 CD y/o en

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm

在执行任何指令之前,请阅读本文档中的所有注意事项及安全声明。和/或

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm

and Server Chassis Safety Information(《Intel

®

Server Boards and Server Chassis Safety Information en

.

®

服务器主板与服务器机箱安全信息》)。

上的 Intel

®

Server Boards

Intel® Server System R1000BB Service Guide iii

Page 4

Warnings

Warnings

Heed safety instructions: Before working with your server product, whether

you are using this guide or any other resource as a reference, pay close

attention to the safety instructions. You must adhere to the assembly

instructions in this guide to ensure and maintain compliance with existing

product certifications and approvals. Use only the described, regulated

components specified in this guide. Use of other products/components will

void the UL listing and other regulatory approvals of the product and will

most likely result in noncompliance with product regulations in the region(s)

in which the product is sold.

System power on/off: The power button DOES NOT turn off the system AC

power. To remove power from the system, you must unplug the AC power

cord from the wall outlet. Make sure the AC power cord is unplugged before

you open the chassis, add, or remove any components.

Hazardous conditions, devices and cables: Hazardous electrical conditions

may be present on power, telephone, and communication cables. Turn off the

server and disconnect the power cord, t eleco mmuni cat i on s sy stems, n etwo rk s,

and modems attached to the server before opening it. Otherwise, personal

injury or equipment damage can result.

Electrostatic discharge (ESD) and ESD pro t ect ion: ESD can damage disk

drives, boards, and other parts. We recommend that you perform all

procedures in this chapter only at an ESD workstation. If one is not available,

provide some ESD protection by wearing an antistatic wrist strap attached to

chassis groundany unpainted metal surfaceon your server when

handling parts.

ESD and handling boards: Always handle boards carefully. They can be

extremely sensitive to ESD. Hold boards only by their edges. After removing

a board from its protective wrapper or from the server, place the board

component side up on a grounded, static free surface. Use a conductive foam

pad if available but not the board wrapper. Do not slide board over any

surface.

Installing or removing jumpers: A jumper is a small plastic encased

conductor that slips over two jumper pins. Some jumpers have a small tab on

top that you can grip with your fingertips or with a pair of fine needle nosed

pliers. If your jumpers do not have such a tab, take care when using needle

nosed pliers to remove or install a jumper; grip the narrow sides of the

jumper with the pliers, never the wide sides. Gripping the wide sides can

damage the contacts inside the jumper, causing intermittent problems with

the function controlled by that jumper. Take care to grip with, but not

squeeze, the pliers or other tool you use to remove a jumper, or you may

bend or break the pins on the board.

iv Intel® Server System R1000BB Service Guide

Page 5

Preface

For in-depth technical information about this product.

Intel® Server System R1000BB Product Family Technic al Product

For a quick guide of how to assemble the server system

Intel® Server System R1000BB Product Family Quick Integration

For product list and supported Intel spares and accessories

Spares and Accessories List and Configuration Guide

Intel® Server Configurator tool

For system power budget guidance

Power Budget Tool

For system firmware updates and onboard device drivers

Product Safety and Regulatory document

Intel Server Products - Product Safety and Regulatory Compliance

Preface

About this Manual

This manual is written for system technicians who are responsible for troubleshooting, upgrading,

and repairing this server system. This document provides a brief overview of the features of the

server board/chassis, a list of accessories or other components you may need, troubleshooting

information, and instructions on how to add and replace components on the Intel

R1000BB family products. For the latest revision of this manual, go to

http://www.intel.com/support

.

Manual Organization

Chapter 1 provides a brief overview of the Intel® Server System R1000BB family. In this chapter,

you will find a list of the server system features, and figures of the system and components to help

you identify your system components and their locations.

Chapter 2 provides instructions on adding and replacing components. Use this chapter for step-bystep instructions and diagrams for installing or replacing components such as the fan, power supply,

and front panel board, among other components.

®

Server System

Chapter 3 provides instructions on using the utilities that are shipped with the board or that may be

required to update the system. This includes information for navigating through the BIOS Setup

screens, performing a BIOS update, and resetting the password or BIOS defaults.

The back of this manual provides technical specifications, regulatory information, LED Decoder,

"getting help" information, and Intel

®

Server Issue Report Form.

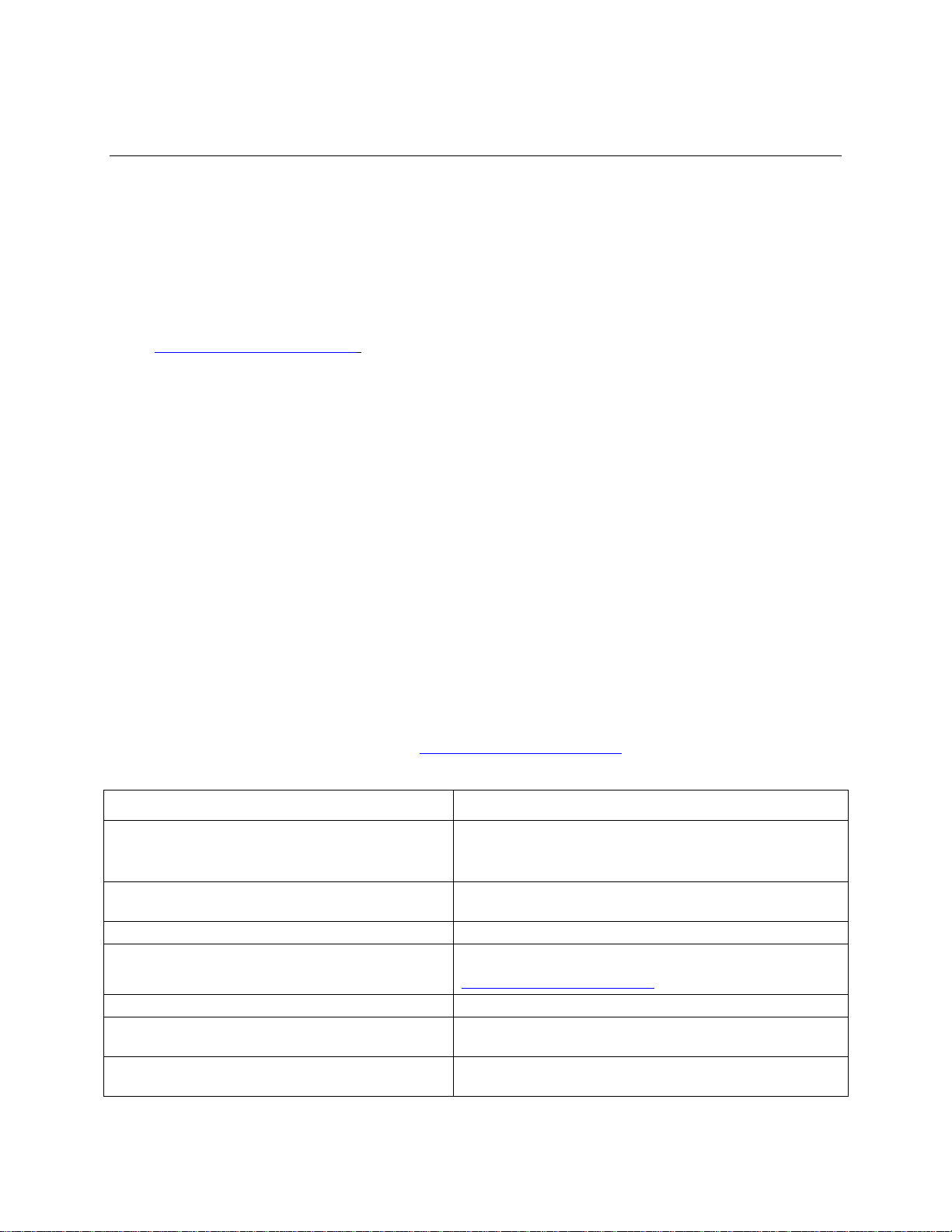

Additional Information and Software

For additional information about this family of products or any of their supported accessories, refer

to the following resources available at http://www.intel.com/support

Table 1. Server System References

For this information or software Use this Document or Software

Specification

Intel® Server Board S2400BB Technical Product Specification

and install components

For server configuration guidance and compatibility

Guide

http://serverconfigurator.intel.com

.

and software to manage your Intel® Server System.

Intel® Server System R1000BB Service Guide v

Intel® Server Deployment & Management DVD

Document

Page 6

Table of Contents

Table of Contents

Safety Information ................................................................................................ iii

Preface ....................................................................................................................v

1 Server System Features ......................................................................................1

Server System Feature Overview ................................................................................................ 1

Server System Components ........................................................................................................ 4

Hot Swap Hard Drive Bay and Front Panel Options ...................................................................... 4

Front Panel ............................................................................................................................... 5

Back Panel ................................................................................................................................ 5

Server Board Components .......................................................................................................... 6

®

Intel

Light-Guided Diagnostics ................................................................................................. 7

System Recovery Jumpers .......................................................................................................... 9

Peripheral Devices ................................................................................................................... 10

2 Hardware Installations and Upgrades ............................................................. 13

Before You Begin .................................................................................................................... 13

Tools and Supplies Needed .............................................................................................. 13

System Reference ........................................................................................................... 13

Cable Routing ......................................................................................................................... 14

For system with 4 x 3.5” hard drive bay: ........................................................................... 15

For system with 8 x 2.5” hard drive bay: ........................................................................... 16

Fan Connections ...................................................................................................................... 17

Removing and Installing the Front Bezel ................................................................................... 17

Removing the Front Bezel ............................................................................................... 17

Installing the Front Bezel ................................................................................................. 18

Removing and Installing the System Cover ................................................................................ 18

Removing the System Cover ............................................................................................ 18

Installing the System Cover ............................................................................................. 19

Removing and Installing the Air Duct ........................................................................................ 20

Removing the Air Duct ................................................................................................... 20

Installing the Air Duct ..................................................................................................... 20

Removing and Installing Processor ............................................................................................ 21

Removing Processor Heatsink(s) ...................................................................................... 21

Installing the Processor .................................................................................................... 21

Installing Processor Heatsink(s) ....................................................................................... 23

Removing the Processor .................................................................................................. 24

Installing and Removing Memory ............................................................................................. 24

Installing Memory .......................................................................................................... 24

Removing Memory ......................................................................................................... 25

Installing and Removing Hot-swap Hard Drive........................................................................... 25

Installing a Hard Disk Drive into 3.5” Hard Dr ive Carrier ................................................... 25

Installing a Hard Disk Drive into 2.5” Hard Dr ive Carrier ................................................... 27

Removing and Installing the PCI Riser Assembly ....................................................................... 28

Removing the PCI Riser Assembly ................................................................................... 28

Installing the PCI Riser Assembly .................................................................................... 29

Installing and Removing a PCI Add-in Card ............................................................................... 29

vi Intel® Server System R1000BB Service Guide

Page 7

Table of Contents

Installing a PCI Add-in Card ............................................................................................ 29

Removing a PCI Add-in Card .......................................................................................... 30

Replacing a PCI Riser Card ...................................................................................................... 30

Removing a PCI Riser Card ............................................................................................. 31

Installing a PCI Riser Card .............................................................................................. 31

Installing and Removing a Slimline Optical Drive ...................................................................... 31

Installing a Slimline Optical Drive .................................................................................... 32

Removing a Slimline Optical Drive .................................................................................. 32

Installing and Removing Intel

®

Installing Intel

Removing Intel

I/O Expansion Module ............................................................................. 33

®

I/O Expansion Module ............................................................................ 34

Installing and Removing the Intel

Installing the Intel

Removing the Intel

Installing and Removing the Intel

Installing the Intel

Install the Intel

®

RMM4 NIC ........................................................................................... 35

Removing the Intel

Removing the Intel

Installing and Removing the Intel

Installing the Intel

Removing the Intel

®

I/O Expansion Module ................................................................ 33

®

®

RAID C600 Upgrade Key ................................................................... 34

®

RAID C600 Upgrade Key ................................................................. 35

®

RMM4 Lite ....................................................................................... 35

®

RMM4 Lite ...................................................................................... 36

®

RMM4 NIC ..................................................................................... 36

®

RAID Smart Battery ........................................................................... 36

®

RAID Smart Battery ......................................................................... 37

RAID C600 Upgrade Key...................................................... 34

®

Remote Management Module 4.............................................. 35

®

RAID Smart Battery ............................................................. 36

Replacing the Power Supply ..................................................................................................... 37

Installing and Removing the Server Board ................................................................................. 39

Removing the Server Board ............................................................................................. 39

Installing the Server Board .............................................................................................. 40

Replacing the Backup Battery ................................................................................................... 41

Replacing a System Fan ........................................................................................................... 43

Replacing the Backplane .......................................................................................................... 43

Removing the Backplane ................................................................................................. 43

Installing the Backplane .................................................................................................. 44

Installing and Removing the Rack Handles ................................................................................ 45

Installing the Rack Handles ............................................................................................. 45

Removing the Rack Handles ............................................................................................ 45

3 Server Utilities ................................................................................................ 46

Using the BIOS Setup Utility .................................................................................................... 46

Entering BIOS Setup ....................................................................................................... 46

If You Cannot Access Setup ............................................................................................ 46

Setup Menus .................................................................................................................. 46

Upgrading the BIOS........................................................................................................ 48

Clearing the Password ..................................................................................................... 48

Restoring the BIOS Defaults ............................................................................................ 48

Appendix A: Technical Reference ........................................................................ 49

Power Supply Input Voltages ........................................................................................... 49

Power Supply Output Voltages ........................................................................................ 49

System Environmental Specifications ............................................................................... 49

Intel® Server System R1000BB Service Guide vii

Page 8

Table of Contents

Appendix B: Regulatory and Com pl ianc e Inf orm at i on ......................................... 51

Appendix C: Getting Help .................................................................................... 52

Warranty Information ...................................................................................................... 52

Appendix D: Intel® Server Issue Report Form ...................................................... 53

viii Intel® Server System R1000BB Service Guide

Page 9

List of Figures

List of Figures

Figure 1. Intel® Server System R1000BB ..................................................................................... 1

Figure 2. Intel

®

Server System R1000BB Components ................................................................ 4

Figure 3. 3.5" Hard Drive Bay - 4 Drive Configuration .................................................................. 4

Figure 4. 2.5" Hard Drive Bay - 8 Drive Configuration .................................................................. 4

Figure 5. Front Panel Options ....................................................................................................... 5

Figure 6. Back Panel Feature Identification .................................................................................. 5

Figure 7. Server Board Connector and Component Locations ..................................................... 6

Figure 9. Configuration Jumpers ................................................................................................. 10

Figure 10. Optional Peripherals (8x2.5-inch hard drive bays as shown)..................................... 10

Figure 11. Front view of Front Bezel ........................................................................................... 11

Figure 12. 4 x 3.5-inch Hard Drive Backplane Components (Front View) .................................. 11

Figure 13. 4 x 3.5-inch Hard Drive Backplane Components (Rear View) ................................... 12

Figure 14. 8 x 2.5-inch Hard Drive Backplane Components (Front View) .................................. 12

Figure 15. 8 x 2.5-inch Hard Drive Backplane Components (Rear View) ................................... 12

Figure 16. Cable Routing – 4 x 3.5” HDD ................................................................................... 15

Figure 17. Cable Routing – 8 x 2.5” HDD ................................................................................... 16

Figure 18. System Fan Order ..................................................................................................... 17

Figure 19. Connecting the Fan Power Cables to the Mother Board ........................................... 17

Figure 20. Removing the Front Bezel ......................................................................................... 18

Figure 21. Installing the Front Bezel ........................................................................................... 18

Figure 22. Removing the System Cover ..................................................................................... 19

Figure 23. Installing the System Cover ....................................................................................... 19

Figure 24. Removing the Air Duct ............................................................................................... 20

Figure 25. Installing the Air Duct ................................................................................................. 20

Figure 26. Removing Processor Heatsink .................................................................................. 21

Figure 27. Installing Processor – Open the Socket Lever ........................................................... 22

Figure 28. Installing Processor – Open the Load Plate .............................................................. 22

Figure 29. Installing Processor – Install the Processor ............................................................... 22

Figure 30. Installing Processor – Remove the Cover ................................................................. 23

Figure 32. Installing Processor – Latch the Locking Lever ......................................................... 23

Figure 33. Installing Processor Heatsink .................................................................................... 24

Figure 34. Installing Memory ....................................................................................................... 25

Figure 35. Installing Hard Disk Drive – Removing 3.5” HDD carrier ........................................... 25

Figure 36. Installing Hard Disk Drive – Removing 3.5” HDD interface bracket ........................... 26

Figure 37. Installing Hard Disk Drive – Installing 3.5” HDD ........................................................ 26

Figure 38. Installing Hard Disk Drive – Installing 2.5” HDD ........................................................ 26

Figure 39. Installing Hard Disk Drive – Inserting 3.5” HDD assembly......................................... 27

Figure 40. Installing Hard Disk Drive – Removing 2.5” HDD carrier ........................................... 27

Figure 41. Installing Hard Disk Drive – Removing plastic drive blank ......................................... 27

Figure 42. Installing Hard Disk Drive – Installing 2.5” HDD ........................................................ 28

Figure 43. Installing Hard Disk Drive – Inserting 2.5” HDD assembly......................................... 28

Figure 44. Removing PCI Riser Assembly .................................................................................. 28

Figure 45. Installing PCI Riser Assembly .................................................................................... 29

Figure 46. Installing a PCI Add-In Card ...................................................................................... 30

Figure 47. Removing a PCI Add-In Card .................................................................................... 30

Figure 48. Removing the PCI Riser Card ................................................................................... 31

Figure 49. Installing the PCI Riser Card ..................................................................................... 31

Intel® Server System R1000BB Service Guide ix

Page 10

List of Figures

Figure 50. Installing the Plastic Guide to the Optical Drive ......................................................... 32

Figure 51. Installing an Optical Drive .......................................................................................... 32

Figure 52. Removing the Slimline Optical Drive ......................................................................... 33

®

Figure 53. Installing Intel

Figure 54. Removing an I/O Expansion Module ......................................................................... 34

Figure 55. Installing the Intel

Figure 56. Installing the Intel

Figure 57. Installing the Intel

Figure 58. Removing the Intel

Figure 59. Installing the Intel

Figure 60. Removing the Intel

I/O Expansion Module ........................................................................ 33

®

RAID C600 Upgrade Key ............................................................ 34

®

RMM4 Lite ................................................................................... 35

®

RMM4 NIC .................................................................................. 35

®

RMM4 NIC ................................................................................ 36

®

RAID Smart Battery ..................................................................... 37

®

RAID Smart Battery ................................................................... 37

Figure 61. Removing the filler panel ........................................................................................... 38

Figure 62. Removing the power supply module .......................................................................... 38

Figure 63. Installing the power supply module ............................................................................ 38

Figure 64. Installing the filler panel ............................................................................................. 39

Figure 65. Removing the Air Duct ............................................................................................... 39

Figure 66. Removing the Server Board ...................................................................................... 40

Figure 67. Installing the Server Board ........................................................................................ 41

Figure 69. Replacing the Backup Battery ................................................................................... 42

Figure 70. Replacing a system fan ............................................................................................. 43

Figure 71. Removing the backplane ........................................................................................... 44

Figure 72. Installing the backplane ............................................................................................. 44

Figure 73. Installing the Rack Handle ......................................................................................... 45

Figure 74. Removing the Rack Handle ....................................................................................... 45

x Intel® Server System R1000BB Service Guide

Page 11

List of Tables

List of Tables

Table 1. Server System References ............................................................................................. v

Table 2. Intel

®

Server System R1000BB Feature Summary ......................................................... 1

Table 3. Hard Disk Drive Options ............................................................................................... 10

Table 4. BIOS Setup: Keyboard Command Bar ......................................................................... 47

Table 5. Power Supply Output Capability ................................................................................... 49

Table 6. System Environmental Limits Summary ....................................................................... 49

Intel® Server System R1000BB Service Guide xi

Page 12

Page 13

Server System Features

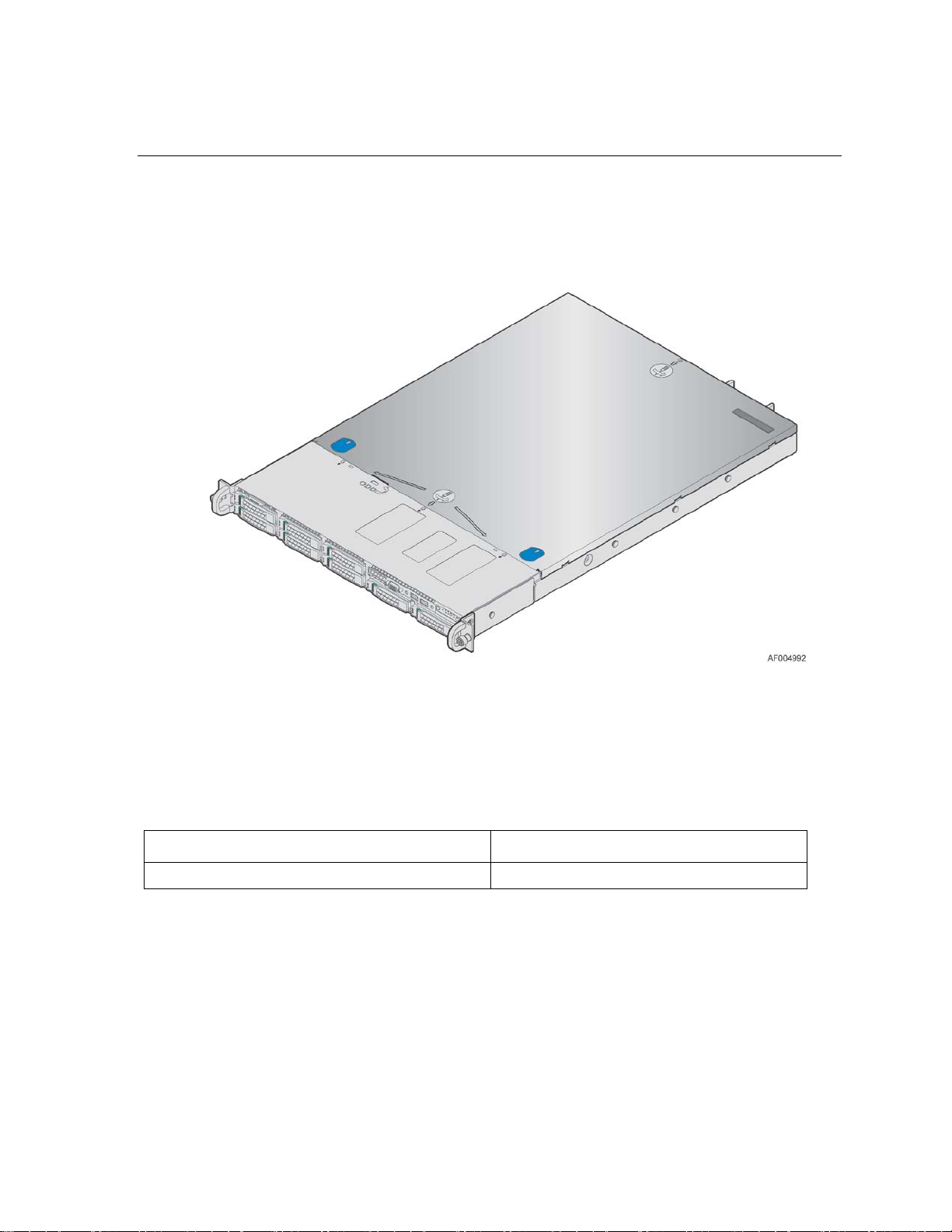

1 Server System Features

This chapter briefly describes the main f eatures of the Intel® Server System R1000BB family.

This includes illustrations of the products, a list of the server system features, and diagrams

showing the location of important components and connections on the server systems.

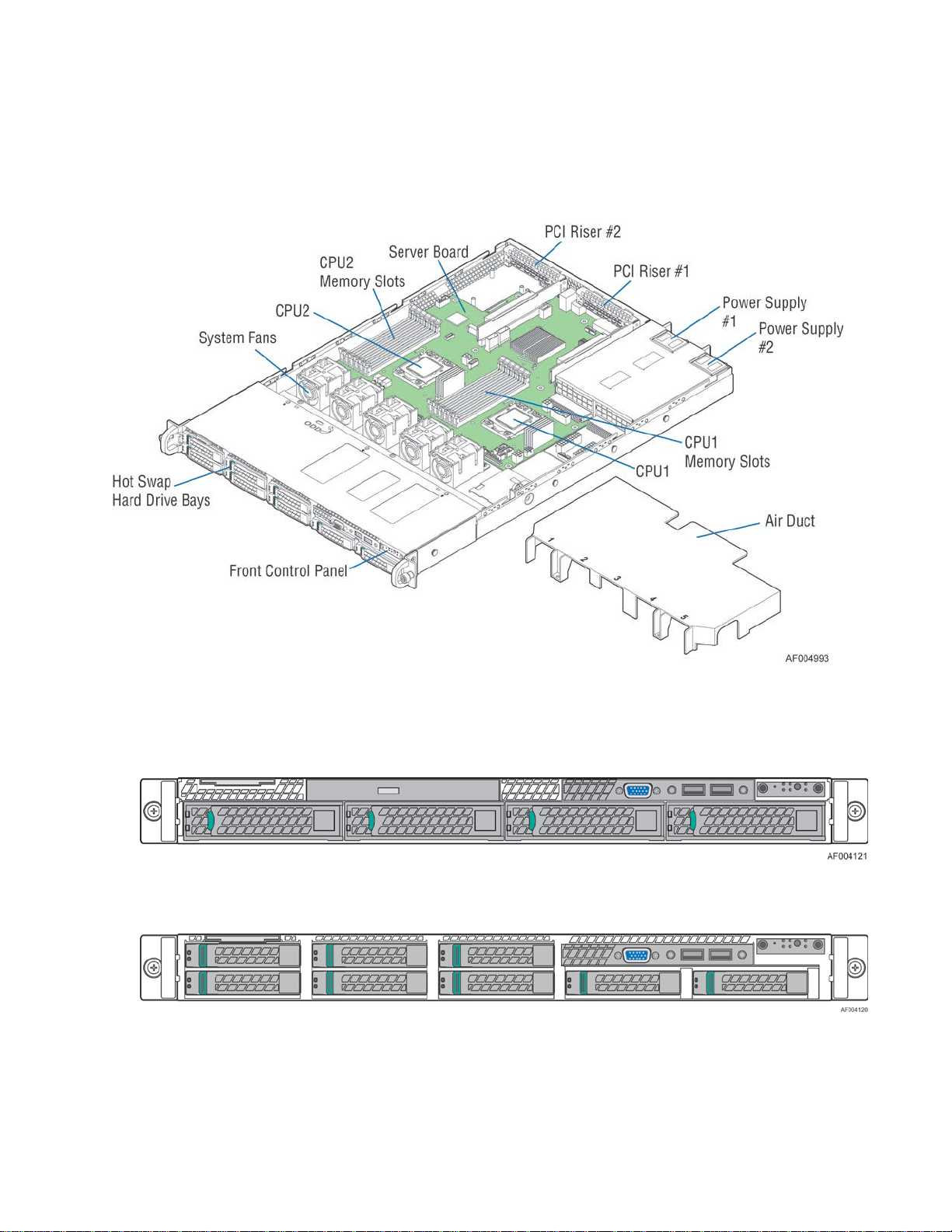

Figure 1. Intel® Server System R1000BB

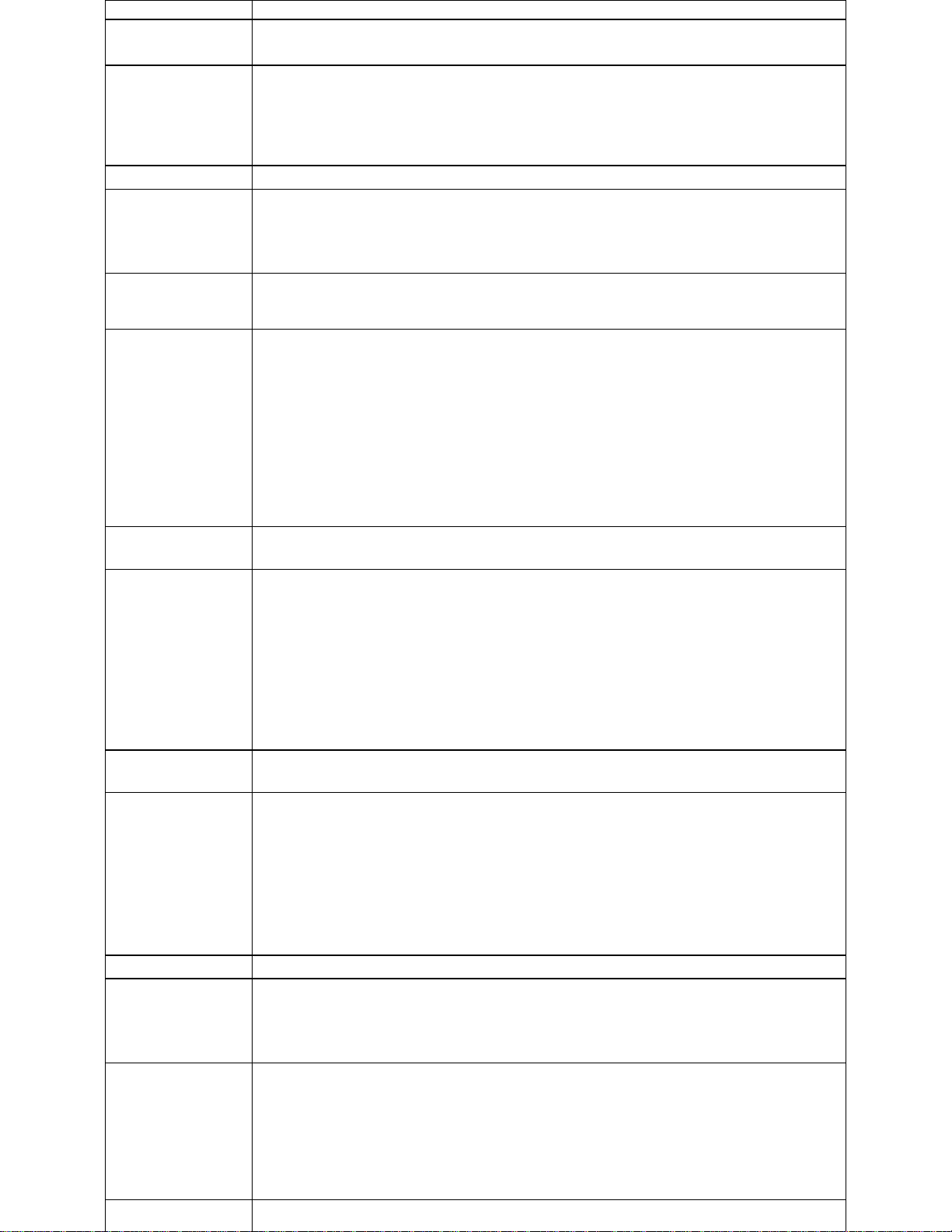

Server System Feature Overview

Table below sumarizes the features of the the server systems.

Table 2. Intel® Server System R1000BB Feature Summary

Server System Integrated Server Board

Intel® Server System R1000BB product family Intel® Server Board S2400BB

Intel® Server System R1000BB Service Guide 1

Page 14

Feature

Description

Support for one or two Intel® Xeon® processors E5-2400 product family with a Therm al

12 DIMM slots – 2 DIMMs / Channel – 3 memory channels per processor

Video (back and front video c onnectors)

One Type-A USB 2.0 connect or

Five dual rotor managed system fans

Integrated 2D Video Controller

One eUSB 2x5 pin connector to support 2mm low-profile eUSB solid state devices

Integrated Baseboard Man agement Controller, IPMI 2.0 compliant

The server system can have up to two power supply modules installed, providing support

o

4x – 3.5” SATA/SAS Hot Swap Hard Drive Bays + Optical Drive support

Server System Features

Processor Support

Design Power (TDP) of up to 95 Watts.

Memory

Chipset Intel® C602 chipset with support for optional Intel® RAID C600 Upgrade keys

External I/O

connections

Internal I/O

connectors /

headers

I/O Module

Accessory Options

Unbuffered DDR3 (UDIMM), registered DDR3 (RDIMM), and Load Reduced DDR3

(LRDIMM)

Memory DDR3 data transfer r ates of 800, 1066, 1333, and 1600 MT/s

DDR3 standard I/O voltage of 1.5V and DDR3 Low Voltage of 1.35V

RJ-45 Serial- A Port

Four RJ-45 Network Interfac e Connectors supporting 10/100/1000Mb

USB 2.0 connectors - 3 on back panel + 2 on front panel

One DH-10 Serial-B port connector

The following I/O modules utilize a single proprietary on-board connector. An installed I/O

module can be supported in addition to s tandard on-board features and any add-in

expansion cards.

Quad port 1 GbE based on Intel® Ethernet Controller I350 – RMS25CB0080

Dual port 10GBase-T Ethernet module based on Intel

®

Ethernet Controller I350 –

AXX10GBTWLIOM

Dual SFP+ port 10GbE module based on Intel® 82500 10 GbE controller –

AXX10GBNIAIOM

Single Port FDR speed InfiniBand module with QSFP connector – AXX1FDRIBIOM

Intel® Quick Assist Accelerator Card - AXXQAAIOMOD

System Fans

One power supply fan for eac h i ns talled power supply module

Support for two PCIe riser cards. Riser cards for Riser #1 and Riser #2 are not the same.

• Riser Slot #1 (PCIe x16): Single add-in card slot – PCIe x16 lanes, x16 slot

• Riser Slot #2 (PCIe x24): Suppor ted riser cards for this slot include:

o Single add-in card slot – PCIe x8 lanes, x 16 slot

Riser Cards

o Single add-in card slot – PCIe x16 lanes, x16 slot (dual CPU configurations

only)

o Butterfly Riser Card (Accessory Option) -: Two add-in card slots: one PCIe

x16 lanes, x16 slot and one PCIe x8 lanes, x8 slot. Note: The PCIe x8 addin card slot is designed specifically for an Intel® Integrated RAID Modul e.

Video

16 MB DDR3 Memory

One mSATA SSD connector

One 7-pin single port AHCI SATA connectors capable of supporting up t o 6 Gb/sec

On-board storage

controllers and

options

Two SCU 4-port mini-SAS connectors capable of supporting up to 3 Gb/sec SAS/SATA

o SCU 0 Port (Enabled standard)

o SCU 1 Port (Requires Intel RAID C600 Upgrade Key)

®

RAID C600 Upgrade Key support prov iding optional expanded SATA / S AS RAID

Intel

capabilities

Security Intel® Trusted Platform Module (TPM) - AXXTPME5 (Accessory Option)

Support for Intel® Server Management Software

Server Management

Power Supply

Options

2 Intel® Server System R1000BB Service Guide

Storage Bay

Intel® Remote Management Module 4 Lite – Accessory option

®

Remote Management Module 4 Management NIC – Accessory option

Intel

for the following power configurations: 1+0, 1+1 Redundant Power, and 2+0 Combined

Power

Three power supply optio ns :

o AC 460W Gold

o AC 750W Platinum

DC 750W

Page 15

Server System Features

Intel® Server System R1000BB Service Guide 3

Page 16

Server System Features

Server System Components

This section helps you identify th e components of your server system. If you are near the system, you can

also use the Quick Reference Label provided on the inside of the chassis co ver to assist in identifying

components.

®

Figure 2. Intel

Server System R1000BB Components

Hot Swap Hard Drive Bay and Front Panel Options

Figure 3. 3.5" Hard Drive Bay - 4 Drive Configuration

Figure 4. 2.5" Hard Drive Bay - 8 Drive Configuration

4 Intel® Server System R1000BB Service Guide

Page 17

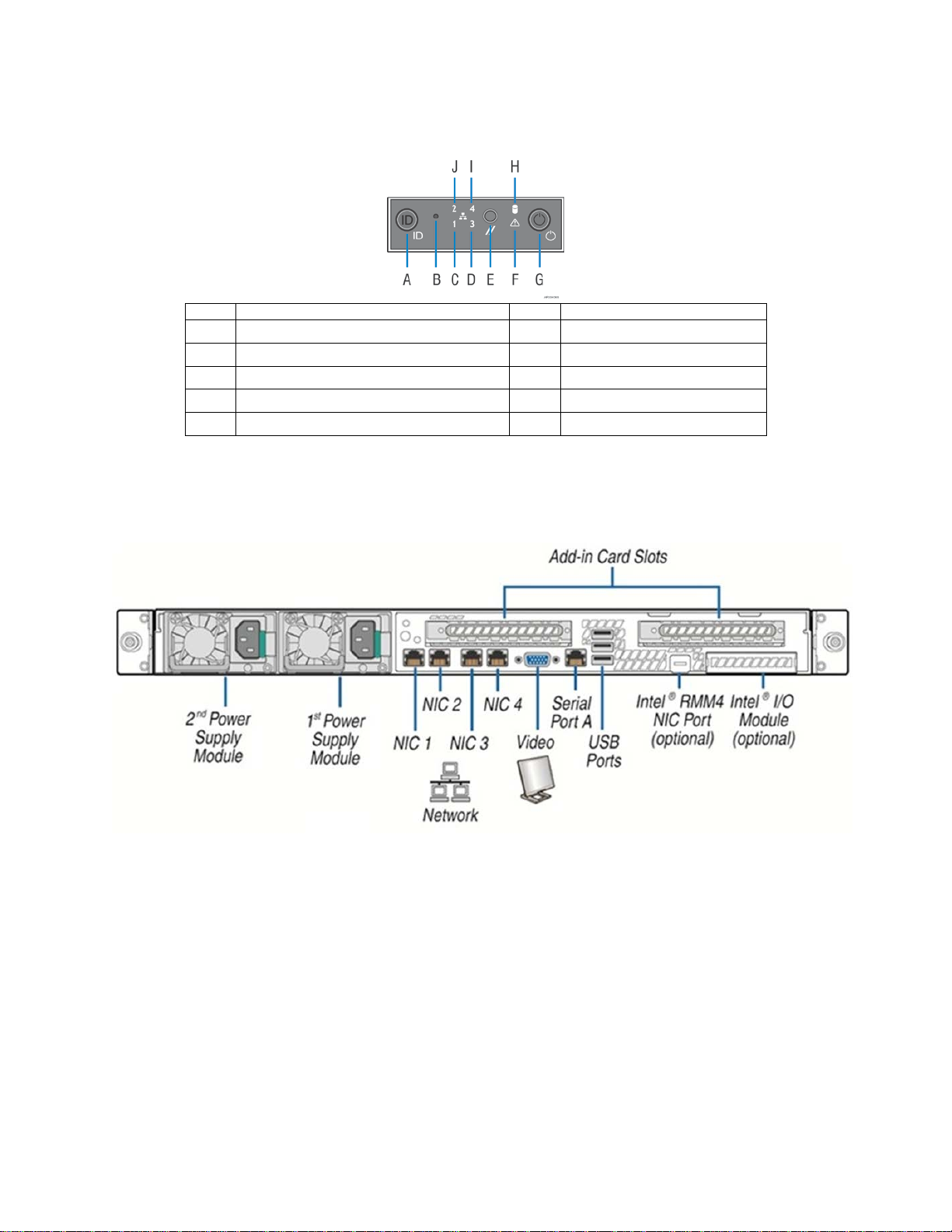

Front Panel

Label

Description

Label

Description

A System ID Button w/Integrated LED F System Status LED

B NMI Button (recessed, tool required for use) G Power Button w/Integrated LED

C NIC-1 Activity LED H Hard Drive Activity LED

D NIC-3 Activity LED I NIC-4 Activity LED

E System Cold Reset Button J NIC-2 Activity LED

Server System Features

Figure 5. Front Panel Options

Back Panel

Figure 6. Back Panel Feature Identification

Intel® Server System R1000BB Service Guide 5

Page 18

Server System Features

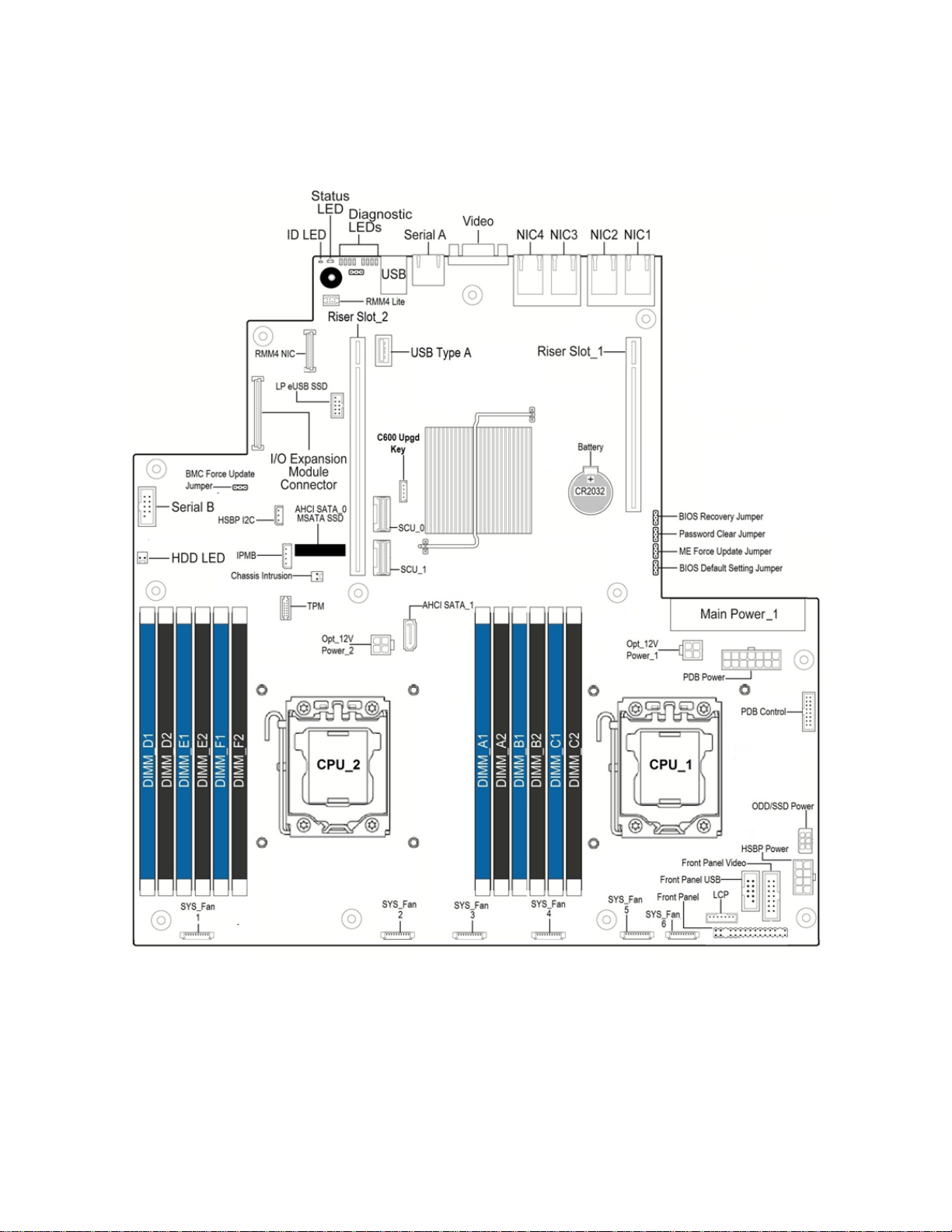

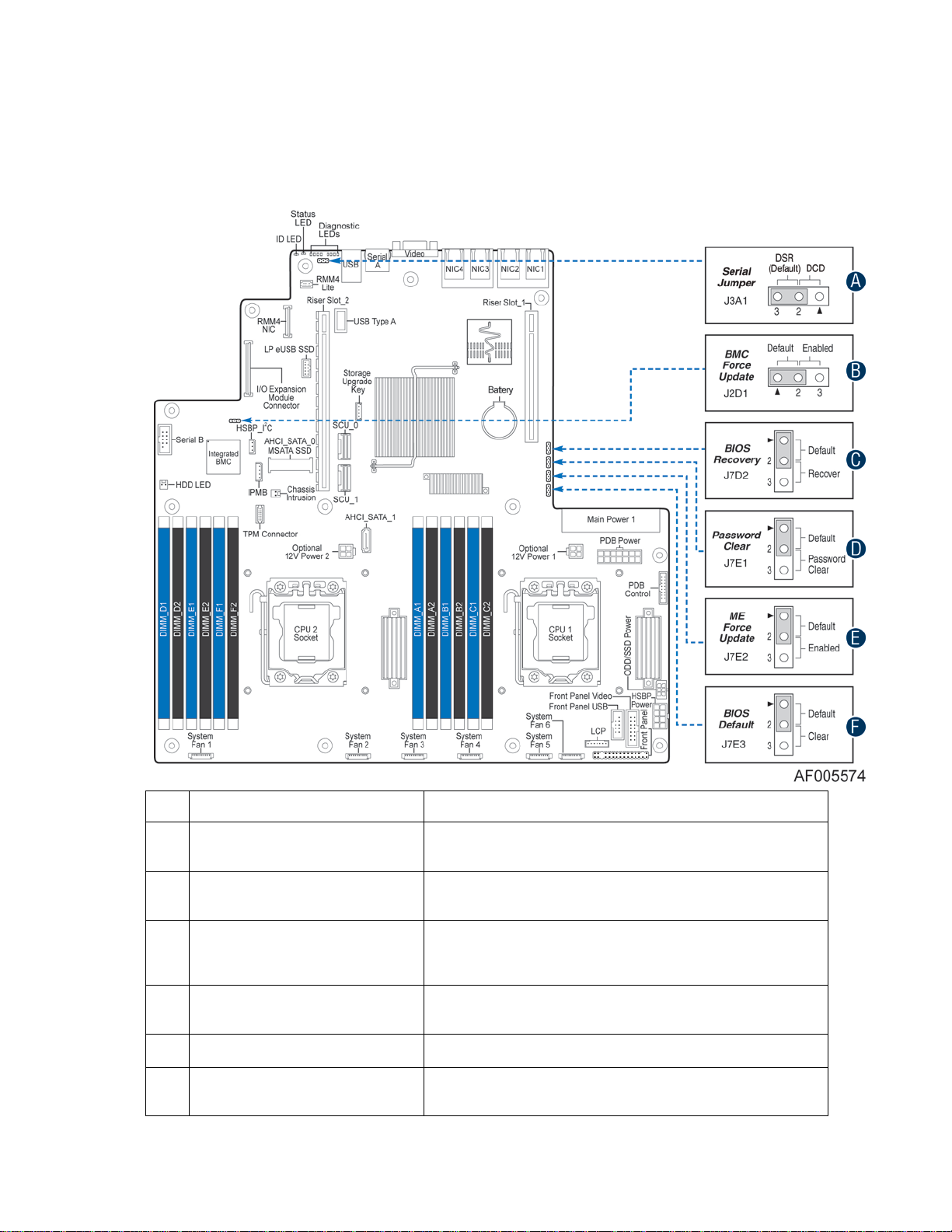

Server Board Components

This section helps you identify the components and connectors on the server board.

Figure 7. Server Board Connector and Component Locations

6 Intel® Server System R1000BB Service Guide

Page 19

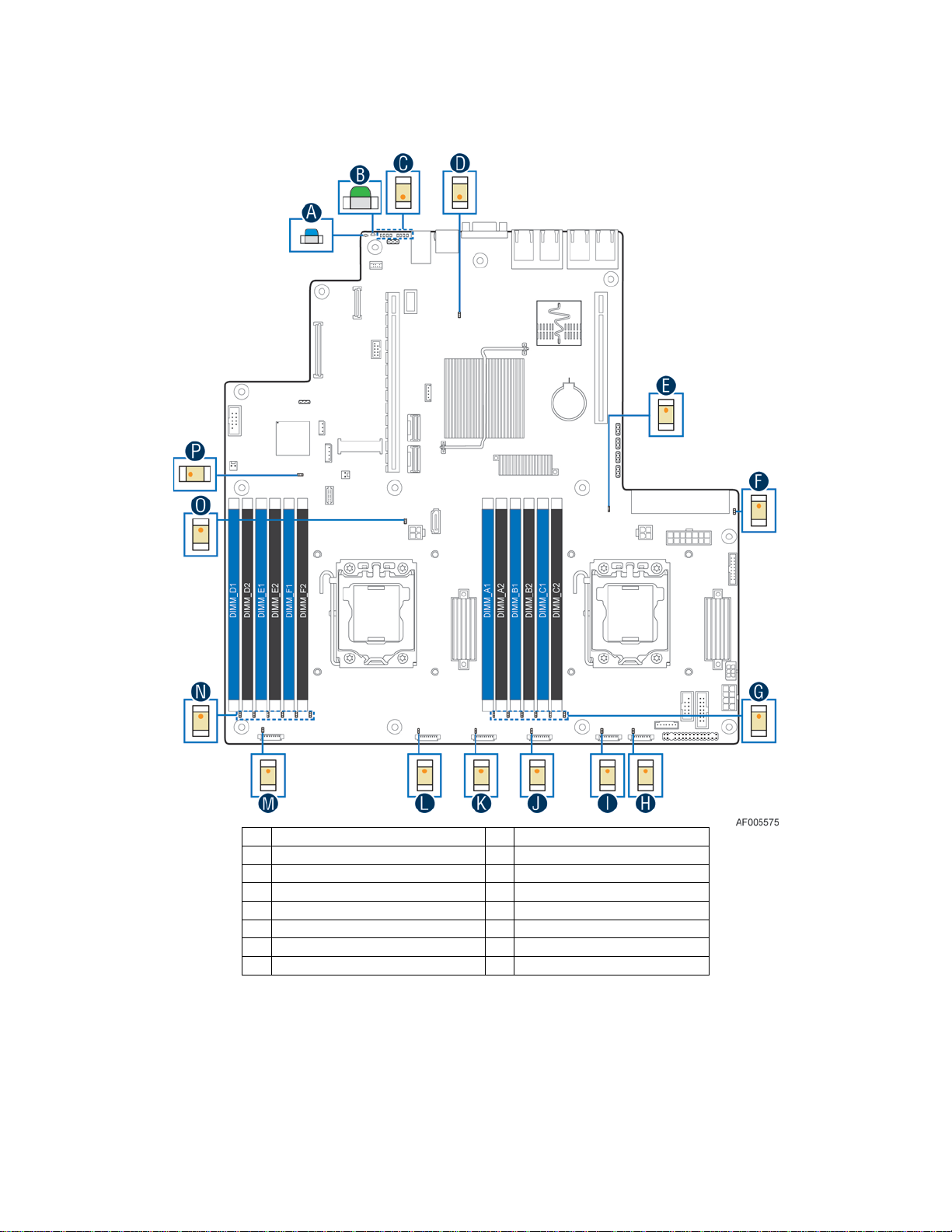

Intel® Light-Guided Diagnostics

A

System ID LED

I

System Fan – 5 Fault LED

B

System Status LED

J

System Fan – 4 Fault LED

C

POST Code Diagnostic LEDs

K

System Fan – 3 Fault LED

D

System Power Good LED

L

System Fan – 2 Fault LED

E

CPU-1 Fault LED

M

System Fan – 1 Fault LED

F

12V Standby LED

N

DIMM Fault LEDs

G

DIMM Fault LEDs

O

CPU-2 Fault LED

H

System Fan – 6 Fault LED

P

CATERR LED

Server System Features

The server system contains the following diagnostic LEDs, each providing the following functions:

A - The System Identification LED on the front and back panel helps identify the server from among

several servers. The ID LED is off by default, and blue when activated by button or software.

Intel® Server System R1000BB Service Guide 7

Figure 8. Intel® Light-Guided Diagnostic LEDs - Server Board

Page 20

Server System Features

B - The System Status LED on the front and back panels shows the overall health of the system (green,

blinking green, blinking amber, amber, off).

C - POST Code Diagnostic LEDs on the server board change color or state (off, green, red, and amber)

according to the POST sequence.

D – System power good LED on the server board is illuminated when system power is good.

P – CPU CATERR LED is illuminated when CPU CATERR error occurred.

F - The 12V-STBY LED on the server board is illuminated (green) when power is applied.

M, L, K, J, I and H - Fan Fault LEDs help identify failed and failing fans. The fan fault LEDs turn on

(amber) if there is a fan fault.

E and O - CPU fault LEDs help identify the failure of CPU. The CPU fault LEDs turn on (amber) if there

is a CPU fault.

N and G - DIMM Fault LEDs on the server boar d help identify failed and failing DIMM slots. The

DIMM fault LEDs turn on (amber) if there is a DIMM fault.

8 Intel® Server System R1000BB Service Guide

Page 21

System Recovery Jumpers

If pins 1-2 are selected, the serial-A configuration is in Data Carrier

normal system operation.

If pins 2-3 are selected, the Integrated BMC Force Update Mode is

operation.

If pins 2-3 are selected, the system can only boot from EFI-bootable

ecovery BIOS image. The main system

system operation.

If pins 2-3 are selected, administrator and user passwords are cleared

should be selected on 1-2 for normal system operation.

If pins 2-3 are selected, the ME Force Update Mode is enabled.

These pins should be selected on 1-2 for normal system operation.

If pins 2-3 are selected, the BIOS settings are cleared on the next

2 for normal system

operation.

Server System Features

A Serial Jumper (J3A1)

B BMC Force Update (J2D1)

C BIOS Recover (J7D2)

D Password Clear (J7E1)

E ME Force Update (J7E2)

F BIOS Default (J7E3)

Intel® Server System R1000BB Service Guide 9

Jumper Name Jumper Purpose

Detect (DCD) mode. These pins should be selected on 2-3 for

enabled. These pins should be selected on 1-2 for normal system

recovery media with the r

BIOS will not boot. These pins should be selected on 1-2 for normal

within five to ten seconds after the system is powered on. These pins

reset. These pins should be selected on 1-

Page 22

Server System Features

Figure 9. Configuration Jumpers

Peripheral Devices

The Intel® Server System R1000BB provides locations and hardware for installing hard drives, CDROM drive, or DVD-ROM drive. The following figure shows the available options.

A System Label Pull-out

B Slimline Optical Drive Bay

C Video Port

D USB Ports

E Front Control Panel

F Hard Disk Drive Bays

Figure 10. Optional Peripherals (8x2.5-inch hard drive bays as shown)

Hard Disk Drive Carriers

The Intel® Server System R1000BB ships with either 3.5-inch or 2.5 inch hard disk dirve carrier,

and with different maximun number of hard disk drives, see Table 4 for details :

Table 3. Hard Disk Drive Options

Intel® Server System Supported Hard Drive Type Maximun Hard Drive Number

R1304BB 3.5-inch or 2.5-inch 4

R1208BB 2.5-inch 8

®

Note: SAS drives are only supported when proper Intel

RAID Module is installed.

For instructions on installing hard drives, see “Installing a Hot-swap Hard Disk Drive”.

Note: Drives can consume up to 17 watts of power each. Drives must be specified to run at a maximum

ambient temperature of 45

Note: The Intel

®

Server System R1000BB does not support all SAS or Serial ATA (SATA) hard drives. For

°C.

a web link to a list of supported hard drives, see “Additional Information and Software”.

RAID C600 Upgrade Key or Intel® Integrated

10 Intel® Server System R1000BB Service Guide

Page 23

Server System Features

A

SAS/SATA Hot-swap Connectors

Slimline Optical Drive Support

The system has support for a single opt ical drive. The optical drive is NOT hot-swappable. The

system power must be turned off to insert or remove the slimline optical drive. For instructions on

installing an optical drive, see “Installing or Removing a Slimline Optical Drive”.

®

makes the following optical drive accessory kits available for this server system:

Intel

• Slimline DVD-ROM Drive: AXXSATADVDROM

• Slimline DVD-RW Drive: AXXSATADVDRWROM

Note: For a complete list of supported peripherals, go to http://serverconfigurator.intel.com

Bezel

The front bezel is available as optio nal accessory for the server system:

.

Figure 11. Front view of Front Bezel

Hot-Swap SAS/SATA Bac kplane

The Hot-Swap SAS/SATA backplane serves as an interface between the mother board and the

system drives. The following diagrams show the location for each connector found on the

backplane.

4 x 3.5-inch Hard Drive Backplane

Figure 12. 4 x 3.5-inch Hard Drive Backplane Components (Front View)

Intel® Server System R1000BB Service Guide 11

Page 24

Server System Features

A

Power Connector

B

SGPIO Connector

C

I2C Connector

D

SATA Connectors

A

SAS/SATA Hot-swap Connectors

A

Power Connectors

B

Mini-SAS Connectors

C

I2C Connector

Figure 13. 4 x 3.5-inch Hard Drive Backplane Comp on ents (Rear View)

8 x 2.5-inch Hard Drive Backplane

Figure 14. 8 x 2.5-inch Hard Drive Backplane Components (Front View)

Figure 15. 8 x 2.5-inch Hard Drive Backplane Compone nt s ( Rear View)

Advanced Management Options

Intel® Remote Management Module 4

The Intel® Remote Management Module 4 plugs into a dedicated connector on the server board

and provides additional server management functionality to the server board. This module

provides a dedicated web server for viewing server information and remote control of the system.

It also provides Remote KVM Redirection and USB Media Redirection allowing USB devices

attached to the remote system to be used on the managed server. For instructions on installing the

®

Remote Management Module 4, see “Installing and Removing the Intel® Remote

Intel

Management Module 4”.

12 Intel® Server System R1000BB Service Guide

Page 25

Hardware Installations and Upgrades

2 Hardware Insta l l a tions and Upgrades

Before You Begin

Before working with your server product, pay close attention to the “Safety Information” at the

beginning of this manual.

Note: Whenever you service the system, you must first power down the server and unpl ug all peripheral

devices and the power cord.

Tools and Supplies Needed

Phillips* (cross head) screwdriver (#2 bit)

Needle nosed pliers

Anti-static wrist strap and conductive foam pad (recommended)

System Reference

All references to left, right, front, top, and bottom assume the reader is facing the front of the

chassis as it would be positioned for normal operation.

®

Note: The Intel

product family are identical.

Server System R1208BB is shown for illlustration purposes. Server components with the

®®

Intel

Server Chassis P4000S Service Guide 13

Page 26

Hardware Installations and Upgrades

Cable Routing

When you add or remove components from your server system, make sure your cables are routed

correctly before reinstalling the server system cover. Use caution to make sure no cables o r wires

are pinched and that the airflow from the fans is not blocked. Use the figures below to determine

the correct cable routing.

Note: Red lines are for power connection, dot lines are for optional device connection.

14 Intel

®®

Server System R1000BB Service Guide

Page 27

For system with 4 x 3.5” hard drive bay:

Hardware Installations and Upgrades

Figure 16. Cable Routing – 4 x 3.5” HDD

®

Intel

Server System R1000BB Service Guide 15

Page 28

Hardware Installations and Upgrades

For system with 8 x 2.5” hard drive bay:

Note: To activate the port SCU1 (4-7) on the server board, a proper Intel® RAID C600 Upgrade

Key must be installed. For instructions, see Intel

®

RAID C600 Upgrade Key Installation Guide.

Note: An optical drive can be installed to replace the Front Panel I/O.

Figure 17. Cable Routing – 8 x 2.5” HDD

16 Intel

®®

Server System R1000BB Service Guide

Page 29

Fan Connections

Use the figures below to determine the proper fan connections.

Hardware Installations and Upgrades

Figure 18. System Fan Order

Figure 19. Connecting the Fan Power Cables to the Mother Board

Removing and Installing the Front Bezel

Removing the Front Bezel

If your system includes a front bezel, follow these steps to remove the front bezel:

1. Unlock the bezel if it is locked.

2. Remove the left end of front bezel from rack handle (see letter “A”).

3. Rotate the front bezel anticlockwise to release the latches on the right end from the rack

handle (see letter “B”).

®

Intel

Server System R1000BB Service Guide 17

Page 30

Hardware Installations and Upgrades

Figure 20. Removing the Front Bezel

Installing the Front Bezel

Note: Before installing the bezel, you must install the rack handles.

1. Lock the right end of the front bezel to the r ack handle (see letter “A”).

2. Push in the left side of the bezel until it clicks into place (see letter “B”).

3. Lock the bezel if needed.

Figure 21. Installing the Front Bezel

Removing and Installing the System Cover

Removing the System Cover

The server system must be operated with the system cover in place to ensure proper cooling. You will

need to remove the top cover to add or replace components inside of the server. Before removing t he

18 Intel

®®

Server System R1000BB Service Guide

Page 31

Hardware Installations and Upgrades

top cover, power down the server and unplug all peripheral devices and the power cable(s).

Note: A non-skid surface or a stop behind the server system may be needed to prevent the server

system from slding on your work surface.

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the power cord.

4. Remove the four screws (see letter "A").

5. Slide cover back and lift upward (see letter "B").

6.

Figure 22. Removing th e System Cover

Installing the System Cover

1. Place th e top cover on system and slide towards the front of chassis until the recessed front

edge is fully engaged. (see letter “A”).

2. Install the three screws at the front and torque to 7-9in-lbs, then install the screw at the

back and torque to 7-9in-lbs. (see letter “B”).

3.

Figure 23. Installing the System Cover

®

Intel

Server System R1000BB Service Guide 19

Page 32

Hardware Installations and Upgrades

Removing and Installing the Air Duct

Always operate your server system with the air duct in place. The air duct is required for proper airflow

within the server system.

Removing the Air Duct

Remove the air duct by lifting straight up.

Figure 24. Removing the Air Duct

Installing the Air Duct

Align the two holes on the air duct with the alignment pins on the chassis and install the air duct

into place.

Figure 25. Installing the Air Duct

20 Intel

®®

Server System R1000BB Service Guide

Page 33

Hardware Installations and Upgrades

Removing and Installing Processor

The heatsink has thermal interface mate r ial (TIM) on the underside of it. Use caution so that you do

not damage the thermal interface material. Use gloves to avoid sharp edges.

Removing Processor Heatsink(s)

The heatsink is attached to the server board/processor socket with captive fasteners. Using a #2

Phillips* screwdriver, loosen the four scr ews located on the heatsink corners in a diag onal manner

using the following procedure:

1. Using a #2 Phillips* screwdriver, start with screw 1 and loosen it by giving it two rotations

and stop (see letter “A”). (IMPORTANT: Do not fully loosen.)

2. Proceed to screw 2 and loosen it by giving it two rotations and stop (see letter “B”).

Similarly, loosen screws 3 and 4. Repeat steps A and B by giving each screw two rotations

each time until all screws are loosened .

3. Lift the heatsink straight up (see letter “C”).

Figure 26. Removing Processor Heatsink

Installing the Processor

Caution: Processor must be appropriate: You may damage the server board if you install a

processor that is inappropriate f or your server. For a web link to t he list of compatible processo r( s) ,

see “Additional Information and Software” on page 4.

Caution: ESD and handling processors: Reduce the risk of electrostatic discharge (ESD) damag e

to the processor by doing the following: (1) Touch the metal chassis before touching the processor

or server board. Keep part of your body in contact with the metal chassis to dissipate the static

charge while handling the processor. (2) Avoid moving around unnecessarily.

Caution: Protective socket cover needs to be removed for proper cooling of the processor; fail ure

to remove the cover could result in da mage to the system.

®

Intel

Server System R1000BB Service Guide 21

Page 34

Hardware Installations and Upgrades

1. Open the Socket Lever. Push the level handle down and away from the socket to release it (see

letter “A”). Rotate the lever open all t he way (see letter “B”).

Figure 27. Installing Processor – Open the Socket Lever

2. Open the Load Plate. Press the locking lever slightly to raise the load plate (see letter “A”).

Open the load plate all the way (see letter “B”).

Figure 28. Installing Processor – Open the Load Plate

3. Install the Processor. Take the processor out of the box and remove the protective shipping

cover. Orient the processor with the sock et so that the orientation notches on the processor

align with the two orientation posts on the socket (see letter “A”).

Figure 29. Installing Processor – Install the Processor

Note: The underside of the processor has co mponents that may damage the socket pins if installed

improperly. Processor must align correctly with the socket opening before installation. DO NOT

DROP processor into socket!

4. Press the protective cover to remove it fr om the load plate. Close the Load Plate and Socket

Lever.

22 Intel

®®

Server System R1000BB Service Guide

Page 35

Figure 30. Installing Processor – Remove the Cover

5. Close the load plate all the way as shown.

Hardware Installations and Upgrades

Figure 31. Installing Processor – Close the Load Plate

6. With your finger, push down on the load plate lever as shown. Close the socket lever and

ensure that the load plate tab engages under the socket lever when fully closed.

Figure 32. Installing Processor – Latch the Locking Lever

(see letter “B”).

Installing Processor Heatsink(s)

1. Remove the protective film on the TIM if p r esent (see letter “A”).

2. Align heatsink fins to the front and back of the chassis for correct airflow. Airflow goes from

front-to-back of chassis (see letter “B”).

Each heatsink has four captive fasteners and should be tightened in a diagonal manner using the

following procedure:

3. Using a #2 Phillips* screwdriver, start with screw 1 and engage screw threads by giving it two

rotations and stop (see letter “C”). (Do not fully tighten.)

4. Proceed to screw 2 and engage screw threads by giving it two rotations and stop (see letter “D”).

Similarly, engage screws 3 and 4.

®

Intel

Server System R1000BB Service Guide 23

Page 36

Hardware Installations and Upgrades

5. Repeat steps C and D by giving each screw two rotations each time until each screw is lightly

tightened up to a maximum of 8 inch-lbs torque (see letter “E”).

6.

Figure 33. Installing Processor Heatsink

Removing the Processor

1. Remove the processor heatsink, see Figure 26.

2. Open the socket lever, see Figure 27.

3. Open the load plate, see Figure 28.

4. Remove the processor.

Installing and Removing Memory

Installing Memory

1. Locate the DIMM sockets. Make sure the cli ps at either end of the DIMM socket(s) are pu shed

outward to the open position (see letter “A”).

2. Holding the DIMM by the edges, remove it from its anti-static package. Position the DIMM

above the socket. Align the notch on the bottom edge of the DIMM with the key in the DIMM

socket (see letter “B”).

3. Insert the bottom edge of the DIMM into the socket (see letter “C”). When the DIMM is

inserted, push down on the top edge of the DIMM until the retaining clips snap into place (see

letter “D”). Make sure the clips are firmly in place (see letter “E”).

24 Intel

®®

Server System R1000BB Service Guide

Page 37

Hardware Installations and Upgrades

Figure 34. Installing Memory

Removing Memory

1. Locate the DIMM sockets. Gently spr ead the retaining clips at each end of the socket. The

DIMM lifts from the socket.

2. Holding the DIMM by the edges, lift it from the socket, and store it in an anti-static package.

Installing and Removing Hot-swap Hard Drive

Caution: If you don't install all drives, empty drive bays must be occupied by carriers with plast ic

drive blank provided to maintain proper system cooling.

Installing a Hard Disk Drive into 3.5” Hard Drive Carrier

1. Remove the drive carrier by pressing the green button and opening the lever (see letter “A”).

Slide the carrier out (see letter “B”).

Figure 35. Installing Hard Disk Drive – Removing 3.5” HDD carrier

2. Remove the four screws securing th e HDD in terface bracket and remove the HDD interface

bracket (see letter “C”).

®

Intel

Server System R1000BB Service Guide 25

Page 38

Hardware Installations and Upgrades

Figure 36. Installing Hard Disk Drive – Removing 3.5” HDD interface bracket

3. Install the hard disk drive using the same four screws as shown. Make sure the connector end of

the drive matches the backplane connector (see letter “D”).

Figure 37. Installing Hard Disk Drive – Installing 3.5” HDD

For installing 2.5” Hard Disk Drive as option:

Break off the tab on the HDD interface bracket (see letter “d1”).Install the HDD interface

bracket from top. Secure the bracket with three screws as shown (see letter “d2”). Slide the 2.5"

HDD into the bracket to align the screw holes with the right and left rail (see letter “d3”). Secure

the hard disk drive using the four screws fo r 2.5" HDD (see letter “d4”).

Figure 38. Installing Hard Disk Drive – Installing 2.5” HDD

4. With the lever open, insert the hard disk drive assembly into the chassis (see letter “E”). Push in

the lever to lock it into place (see letter “F”) .

26 Intel

®®

Server System R1000BB Service Guide

Page 39

Hardware Installations and Upgrades

Figure 39. Installing Hard Disk Drive – Inserting 3.5” HDD assembly

Installing a Hard Disk Drive into 2.5” Hard Drive Carrier

1. Remove the drive carrier by pressing the green latch to unlock (see letter “A”). Pull out the

black lever and slide the carrier out (see letter “B”).

Figure 40. Installing Hard Disk Drive – Removing 2.5” HDD carrier

2. Remove the four screws securing the plastic drive blank from the 2.5" HDD carrier (see letter

“C”). Disengage the plastic drive blank from the HDD carrier. Remove the plastic drive blank

from the 2.5" HDD carrier (see letter “D”).

Figure 41. Installing Hard Disk Drive – Removing plastic drive blank

3. Install the hard disk drive using the four screws as shown. Make sure the connector end of the

drive matches the backplane connector (see letter “E”).

®

Intel

Server System R1000BB Service Guide 27

Page 40

Hardware Installations and Upgrades

Figure 42. Installing Hard Disk Drive – Installing 2.5” HDD

4. With the lever open, insert the hard disk drive assembly into the chassis, then push in the lever

to lock it into place (see letter “F”).

Figure 43. Installing Hard Disk Drive – Inserting 2.5” HDD assembly

Removing and Installing the PCI Riser Assembly

Removing the PCI Riser Assembly

Disconnect any cables attached to any add-in cards. Grasp the riser assembly with both hands

and pull up to remove from system.

Figure 44. Removing PCI Riser Assembly

Do one of the following:

28 Intel

®®

Server System R1000BB Service Guide

Page 41

Hardware Installations and Upgrades

— If you need to add or replace a PCI add-in card, see “Installing and Removing a PCI Add-in

Card”.

— If you need to add or replace a PCI riser card, see “Replacing a PCI Riser Card”.

— If you removed the PCI riser assembly for another procedure, continue with that procedure.

Installing the PCI Riser Assembly

1. Position the riser card edge connector over the server board riser socket and align the two

hooks on the back edge of the riser assembly with the slots on the back of the chassis, th en

press straight down into riser socket.

Figure 45. Installing PCI Riser Assembly

2. Connect any cables to add-in cards that requ ire them. See your add-in card documentation for

information and add-in card requirements.

Installing and Removing a PCI Add-in Card

Installing a PCI Add-in Card

1. Remove the PCI riser assembly. For instructions, see “Removing the PCI Riser Assembly”.

2. Remove the filler panel from the add-in card slot and remove the screw as shown (see letter

“A”).

3. Insert add-in card until it seats in the riser connector (see letter “B”).

4. Secure add-in card with screw as shown (see l etter “C”).

®

Intel

Server System R1000BB Service Guide 29

Page 42

Hardware Installations and Upgrades

Figure 46. Installing a PCI Add-In Card

Removing a PCI Add-in Card

1. Remove the PCI riser assembly. For instructions, see “Removing the PCI Riser Assembly”.

2. Remove the screw as shown (see letter “A”).

3. Remove the PCI add-in cad from the riser card connector (see letter “B”).

Figure 47. Removing a PCI Add-In Card

Note: Make sure that all empty add-in card slots have filler panels installed.

Replacing a PCI Riser Card

Caution: PCI riser cards are NOT hot-swappable. Before removing or replacing the riser card,

you must first take the server out of service, turn of f all peripheral devices connected to the system,

30 Intel

®®

Server System R1000BB Service Guide

Page 43

Hardware Installations and Upgrades

turn off the system by pressing the power b utton, and unplug the power cord from the system or

wall outlet.

Note: To eliminate the possibility of installing the replacement connector on the wrong side of the

PCI riser assembly, replace one connector at a time.

Removing a PCI Riser Card

1. Disconnect any cables attached to any add-in cards.

2. Remove the PCI riser assembly. For instructions, see “Removing the PCI Riser Assembly”.

3. Remove any add-in cards from the PCI riser card. For instructions, see “Removing a PCI Add-

in Card”.

4. Remove the two screws securing the PCI Riser Card (see letter “A”).

5. Remove from the riser card from riser assembly (see letter “B”).

Figure 48. Removing the PCI Riser Card

Installing a PCI Riser Card

1. Place the riser card onto the riser assembly (see letter “A”).

2. Secure the riser card using the two screws (see letter “B”).

Figure 49. Installing the PCI Riser Card

Installing and Removing a Slimline Optical Drive

Caution: The slimline optical drive is NOT hot-swappable. Before removing or replacing the drive,

you must first take the server out of service, turn off all peripheral devices connected to the system,

turn off the system by pressing the power button, and unplug the power cord from the system or

wall outlet.

®

Intel

Server System R1000BB Service Guide 31

Page 44

Hardware Installations and Upgrades

To maintain proper system cooling, a filler panel must be installed if you do not install a device at

this location.

Installing a Slimline Optical Drive

1. Install the plastic guide onto the back of the drive and attach with two screws as shown (see

letter “A”).

Figure 50. Installing the Plastic Guide to the Optical Drive

2. Insert the optical drive into chassis opening and push all the way until it stops (see letter “B”).

3. Connect the cables as shown (see letter “C”).

Figure 51. Installing an Optical Drive

Removing a Slimline Optical Drive

1. Remove the cables (see letter “A”).

2. Lift up the blue tab to release the optical drive (see letter “B”).

3. Slide the optical drive out (see letter “C”).

32 Intel

®®

Server System R1000BB Service Guide

Page 45

Hardware Installations and Upgrades

Figure 52. Removing the Slimline Optical Drive

4. If no device will be installed in this location, install a filler panel in this location.

Installing and Removing Intel® I/O Expansion Module

Installing Intel® I/O Expansion Module

1. Squeeze the sides of the filler panel to disengage it from the server system back panel and

remove it (see letter “A”).

2. Position the module over the server board, fit the front of the module into the back panel slot

(see letter “B”).

3. Attach the module to the server board connector (see letter “C”).

4. Secure the module with the three screws as shown (see letter “D”).

5.

Figure 53. Installing Intel® I/O Expansion Module

®

Intel

Server System R1000BB Service Guide 33

Page 46

Hardware Installations and Upgrades

Removing Intel® I/O Expansion Module

1. Remove the three screws as shown (see lett er “A”).

2. Remove the module out of the server system (see letter “B”).

3.

Figure 54. Removing an I/O Expansion Module

4. Install the I/O expansion module filler panel into the system back panel.

Installing and Removing the Intel® RAID C600 Upgrade Key

Installing the Intel® RAID C600 Upgrade Key

Locate the white 4-pin key header next to the SCU_0 and SCU-1 miniSAS connectors. Carefully

pickup the Intel

down to install.

®

RAID C600 Upgrade Key. Match the Key and connector orientation and press

Figure 55. Installing the I n tel® RAID C600 Upgrade Key

34 Intel

®®

Server System R1000BB Service Guide

Page 47

Hardware Installations and Upgrades

Removing the Intel® RAID C600 Upgrade Key

Pull up the key to remove it from the mother board.

Installing and Removing the Intel® Remote Management Module 4

Installing the Intel® RMM4 Lite

Locate the RMM4 Lite connector next to the POST diagnostic LEDs, carefully pickup the Intel®

RMM4 Lite module, match the alignment pin of the module and the connector on server board,

then press to install.

Figure 56. Installing the Intel® RMM4 Lite

Install the Intel® RMM4 NIC

1. Push out and remove the metal cover on the chassis where the NIC RJ-45 receptacle will align

(see letter “A”).

2. Position the module over the server board, fit the front of the module into the back panel slot,

then attach the module to the server board connector (see letter “B”).

3. Secure the module with the two screws as shown (see letter “C”).

4.

Figure 57. Installing the Intel® RMM4 NIC

®

Intel

Server System R1000BB Service Guide 35

Page 48

Hardware Installations and Upgrades

Removing the Intel® RMM4 Lite

Pull up the RMM4 Lite module to remove it from the mother board.

Removing the Intel® RMM4 NIC

1. Remove the two screws as shown (see lett er “A”).

2. Remove the module out of the server system (see letter “B”).

3.

Figure 58. Removing the Intel® RMM4 NIC

Installing and Removing the Intel® RAID Smart Battery

Installing the Intel® RAID Smart Battery

1. Connect the cable between the BBU and the RAID card. For details, see Intel® RAID Smart

Battery User’s Guide.

2. Locate the BBU bracket inside the chassi s. Align the tabs on the plastic battery holder with

mounting holes on the BBU bracket (see letter “A”).

3. Slide the plastic battery holder toward the rear of the system until the tabs engage with the

mounting holes in the BBU bracket (see letter “B”).

36 Intel

®®

Server System R1000BB Service Guide

Page 49

Hardware Installations and Upgrades

4.

Figure 59. Installing the Intel® RAID Smart Battery

Removing the Intel® RAID Smart Battery

1. Slide the plastic battery holder toward the front of the system to disengage it from the BBU

bracket (see letter “A”).

2. Lift the battery up to remove it from the server chassis (see letter “B”).

3.

Figure 60. Removing the Intel® RAID Smart Battery

Replacing the Power Supply

Caution: The power supply is only hot-swappable if you have a redundant system with two power

supplies installed. If you only have one power supply installed, before removing or replacing the

power supply, you must first take the server out of service, turn off all periph eral devices connected to

the system, turn off the system by pressing the power button, and unplug the AC power cord from t he

system or wall outlet.

The power supply can be replaced if it fails. To replace the power supply, follow these steps:

1. Do one of the following:

®

Intel

Server System R1000BB Service Guide 37

Page 50

Hardware Installations and Upgrades

- If a filler panel is installed, use the 'finger hole' to remove the filler panel (see letter “A”).

-

Figure 61. Removing the filler panel

- If a power supply is installed, push the green latch in the direction shown while pulling out

of the system by the handle.

-

Figure 62. Removing the power supply module

2. Do one of the following:

- Insert the power supply module into the power supply cage and push all the way until it

clicks into place (see letter “B”).

-

Figure 63. Installing the power supply module

- If no power supply is to be installed, install the filler panel into the power supply cage.

38 Intel

®®

Server System R1000BB Service Guide

Page 51

Hardware Installations and Upgrades

Figure 64. Installing the filler panel

Installing and Removing the Server Board

Removing the Server Board

1. Lift the air duct straight up to remove from the server board

2. Disconnect all cables from the server bo ar d.

Figure 65. Removing the Air Duct

3. Remove the nine screws from the server board. (see letter “A”).

4. Lift the server board from the server system. (see letter “B”).

®

Intel

Server System R1000BB Service Guide 39

Page 52

Hardware Installations and Upgrades

Figure 66. Removing th e Server Board

Installing the Server Board

1. Place the server board into the server system (see letter “A”).

2. Secure the server board with nine screws (see letter “B”).

40 Intel

®®

Server System R1000BB Service Guide

Page 53

Hardware Installations and Upgrades

3.

Figure 67. Installing t he Server Board

4. Install air duct onto the server board.

Figure 68. Installing the Air Duct

5. Connect all power cables to the server b oard.

Replacing the Backup Battery

The lithium battery on the server board powers the RTC for up to 10 years in the absence of power.

When the battery starts to weaken, it loses voltage, and the server settings stored in CM OS RAM in

®

Intel

Server System R1000BB Service Guide 41

Page 54

Hardware Installations and Upgrades

the RTC (for example, the date and time) may be wrong. Contact your customer service

representative or dealer for a list of appro ved devices.

Warning: Danger of explosion if battery is incorrectly replaced. Replace only with the same or

equivalent type recommended by the equipment manufacturer. Discard used batteries according to

manufacturer's instructions.

Advarsel: Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering. Udskiftning må kun ske med

batteri af samme fabrikat og type. Levér det brugte batteri tilbage til leverandøren.

Advarsel: Lithiumbatteri - Eksplosjonsfare. Ved utskifting benyttes kun batteri som anbefalt av

apparatfabrikanten. Brukt batteri retur neres apparatleverandøren.

Varning: Explosionsfara vid felaktigt batteribyte. Använd samma batterityp eller en ekvivalent typ

som rekommenderas av apparattillverkar en. Kassera använt batteri enligt fabrikan tens instruktion.

Varoitus: Paristo voi räjähtää, jos se on virheellisesti asennettu. Vaihda paristo ainoastaan

laitevalmistajan suosittelemaan tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

1. Locate the battery on the server board.

2. Gently press the metal clip as shown to release the battery (see letter “A”).

3. Remove the battery from the plastic socket (see letter “B”).

4.

Figure 69. Replacing the Backup Battery

5. Dispose of the battery according to local ordinance.

6. Remove the new lithium battery from its package, and, being careful to observe the correct

polarity, insert it in the battery socket.

42 Intel

®®

Server System R1000BB Service Guide

Page 55

Hardware Installations and Upgrades

Note: You will need to run the BIOS Setup to restore the configuration settings to the RTC.

Replacing a System Fan

Note: The system fans cannot be hot swapped. System power must be removed when replacing

a system fan.

1. Disconnect the fan cable (see letter “A”).

2. Pull system fan straight up to remove it from the fan holder.

Figure 70. Replacing a system fan

3. Replace the system fan.

Replacing the Backplane

Removing the Backplane

1. Remove all hot-swap drive carriers, regardless of whether or not a drive i s installed in the

carrier.

2. Disconnect all cables from the backpl ane.

3. Remove the screw (see letter “A”).

4. Pull up the backplane (see letter “B”).

5. Remove the backplane from the server chassis (see letter “C”).

®

Intel

Server System R1000BB Service Guide 43

Page 56

Hardware Installations and Upgrades

Figure 71. Removing the backplane

Installing the Backplane

1. Remove all hot-swap drive carriers, regardless of whether or not a drive i s installed in the

carrier.

2. Hold the backplane only by the edges. Do not push or pull on any components on the backplane.

Position the backplane in place at the front of the server system (see letter “A”).

3. Slide the backplane into the server system gui des (see letter “B”).

4. Secure the backplane with the screw as shown (see letter “C”).

Figure 72. Installing the backplane

5. Connect cables to backplane, please refer to “Cable Routing”

44 Intel

®®

Server System R1000BB Service Guide

Page 57

Hardware Installations and Upgrades

Installing and Removing the Rack Handles

Installing the Rack Handles

Align the rack handle with the two hol es on the side of the server system and attach the rack handle

to the server system with two screws as shown.

Figure 73. Installing the Rack Handle

Removing the Rack Handles

Remove the two screws holding the rack handle in place, and remove the rack handle from the

server system as shown.

Figure 74. Removing the Rack Handle

®

Intel

Server System R1000BB Service Guide 45

Page 58

Server Utilities

3 Server Utili ties

Using the BIOS Setup Utility

This section describes the BIOS Setup utility options, which is used to change server configuration

defaults. You can run the BIOS Setup with or without an operating system being present. For information

about specific BIOS setup screens, see the Intel

For a web link to this document, see “Additional Information and Software”.

Entering BIOS Setup

To enter the BIOS Setup using a keyboard (or emulated keyboard), press the <F2> function key

during boot time when the OEM or Intel Logo Screen or the POST Diagnostic Screen is displayed.

The following instructional message is displayed on the Diagnostic Screen or under the Quiet Boot

Logo Screen:

®