Page 1

Intel® Core™ i7-900 Desktop

Processor Extreme Edition Series

®

and Intel

Core™ i7-900 Desktop

Processor Series on 32-nm Process

Datasheet, Volume 1

June 2011

Document # 323252-003

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED,

BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS

PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER,

AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING T O SALE AND/OR USE OF INTEL PRODUCT S INCLUDING

LIABILITY OR WARRANTIES RELA TING T O FITNES S FOR A PARTICULAR PURPOSE, MERCHANT ABILITY, OR INFRINGEMENT OF ANY

PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. INTEL PRODUCTS ARE NOT INTENDED FOR USE IN MEDICAL,

LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel

reserves these for future definition and shall have no responsibility whatsoev er for conflicts or incompatibilities arising from future

changes to them.

®

The Intel

as errata which may cause the product to deviate from published specifications.

Intel processor numbers are not a measure of performance. Processor numbers differentiate features within each processor

family, not across different processor families. See http://www.intel.com/products/processor_number for details. Over time

processor numbers will increment based on changes in clock, speed, cache, FSB, or other features, and increments are not

intended to represent proportional or quantitative increases in any particular feature. Current roadmap processor number

progression is not necessarily representative of future roadmaps. See www.intel.com/products/processor_number for details.

Core™ i7-900 desktop processor Extreme Edition series on 32-nm process ma y co ntain design defects or errors known

Hyper-Threading Technology requires a computer system with a processor supporting HT Technology and an HT Technologyenabled chipset, BIOS and operating system. Performance will va ry de pe ndi ng on the specific hardware and software y ou use. For

more information including details on which processors support HT Technology, see

http://www.intel.com/products/ht/hyperthreading_more.htm

®

64 requires a computer system with a processor, chipset, BIOS, operating system, device drivers and applications enabled

Intel

®

for Intel

depending on your hardware and software configuration s. See www .intel.com/info/em64t for more information in cluding details on

which processors support Intel

± Intel

for some uses, certain platform software, enabled for it. Functionality, performance or other benefit will vary depending on

64. Processor will not operate (including 32-bit operation) without an Intel 64-enabled BIOS. Performance will vary

®

®

Virtualization T echnology requires a compute r system with a processor, chipset, BIOS, virtual machine monitor (VMM) and

64 or consult with your system vendor for more information.

hardware and software configurations. Intel Virtualization Technology-enabled VMM applications are currently in development.

Enabling Execute Disable Bit functionality requires a PC with a processor with Execute Disable Bit capability and a supporting

operating system. Check with your PC manufacturer on whether your system delivers Execute Disable Bit functionality.

Enhanced Intel® SpeedStep Technology. See the Processor Spec Finder

or contact your Intel representative for more information.

Intel® Turbo Boost Technology requires a PC with a processor with Intel Turbo Boost Technology capability. Intel Turbo Boost

Technology performance varies depending on hardware, software and overall system configuration. Check with your PC

manufacturer on whether your system delivers Intel Turbo Boost Technology. For more information, see www.intel.com

.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Intel, Intel SpeedStep, Intel Core, and the Intel logo are trademarks or registered trademarks of Intel Corporation or its

subsidiaries in the United States and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2010–2011 Intel Corporation.

2 Datasheet, Volume 1

Page 3

Contents

1Introduction..............................................................................................................9

1.1 Terminology .....................................................................................................10

1.2 References.......................................................................................................11

2 Electrical Specifications...........................................................................................13

2.1 Intel

2.2 Power and Ground Lands....................................................................................13

2.3 Decoupling Guidelines ........................................................................................13

2.4 Processor Clocking (BCLK_DP, BCLK_DN).............................................................14

2.5 Voltage Identification (VID) . ...............................................................................15

2.6 Reserved or Unused Signals................................................................................18

2.7 Signal Groups................................................. .. .. ......................... .. .. .................19

2.8 Test Access Port (TAP) Connection.......................................................................20

2.9 Platform Environmental Control Interface (PECI) DC Specifications...........................21

2.10 Absolute Maximum and Minimum Ratings................................ .............................22

2.11 Processor DC Specifications................................................................................23

2.12 Intel® QuickPath Interconnect (Intel® QPI) Specifications.......................................32

3 Package Mechanical Specifications ..........................................................................35

3.1 Package Mechanical Drawing...................... .........................................................35

3.2 Processor Component Keep-Out Zones............................. ............................ .. .. ....38

3.3 Package Loading Specifications ....................................... ... ........................... .. ....38

3.4 Package Handling Guidelines............................. .. .. .. ........................... ... ..............38

3.5 Package Insertion Specifications................................................... .. .. .. ... ..............38

3.6 Processor Mass Specification...............................................................................39

3.7 Processor Materials............................................................................................39

3.8 Processor Markings............................................................................................39

3.9 Processor Land Coordinates................................................................................40

4Land Listing.............................................................................................................41

5 Signal Descriptions..................................................................................................71

6 Thermal Specifications ............................................................................................75

6.1 Package Thermal Specifications......................... .. .. ........................... .. .................75

6.2 Processor Thermal Features................................................................................81

®

QuickPath Interconnect (Intel® QPI) Differential Signaling.............................13

, V

, V

, V

2.3.1 V

CC

TTA

TTD

Decoupling.............................................................14

DDQ

2.4.1 PLL Power Supply...................................................................................14

2.9.1 DC Characteristics..................................................................................21

2.9.2 Input Device Hysteresis ..........................................................................22

2.11.1 DC Voltage and Current Specification.................................................... .. ..24

2.11.2 V

Overshoot Specification............................. .. .. ... ........................... .. .. ..31

CC

2.11.3 Die Voltage Validation............................................................... .. ............31

6.1.1 Thermal Specifications............................................................................75

6.1.1.1 Specification for Operation Where Digital Thermal Sensor

Exceeds T

CONTROL

.....................................................................79

6.1.2 Thermal Metrology .................................................................................80

6.2.1 Processor Temperature ...........................................................................81

6.2.2 Adaptive Thermal Monitor........................................................................81

6.2.2.1 Frequency/VID Control................................... .. .. .......................82

6.2.2.2 Clock Modulation ......................................................................83

6.2.2.3 Immediate Transiton to combined TM1 and TM2 ...........................83

6.2.2.4 Critical Temperature Flag ...........................................................83

6.2.2.5 PROCHOT# Signal.....................................................................83

6.2.3 THERMTRIP# Signal ...............................................................................84

Datasheet, Volume 1 3

Page 4

6.3 Platform Environment Control Interface (PECI)......................................................84

6.3.1 Introduction...........................................................................................84

6.3.1.1 Fan Speed Control with Digital Thermal Sensor .............................85

6.3.1.2 Processor Thermal Data Sample Rate and Filtering.........................85

6.3.2 PECI Specifications .................................................................................86

6.3.2.1 PECI Device Addres s................................................... ... ............86

6.3.2.2 PECI Command Support.............................................. ... .. ..........86

6.3.2.3 PECI Fault Handling Requirements...............................................86

6.3.2.4 PECI GetTemp0() Error Code Suppo rt ..........................................86

6.4 Storage Conditions Specifications.........................................................................87

7Features..................................................................................................................89

7.1 Power-On Configuration (POC).............................................................................89

7.2 Clock Control and Low Power States........................... .. .. ............................ ..........89

7.2.1 Thread and Core Power State Descriptions .................................................90

7.2.1.1 C0 State ........................... .. .......................... ......................... ..90

7.2.1.2 C1/C1E State............................................................................90

7.2.1.3 C3 State ........................... .. .......................... ......................... ..91

7.2.1.4 C6 State ........................... .. .......................... ......................... ..91

7.2.2 Package Power State Descriptions.............................................................91

7.2.2.1 Package C0 State........................................... .. .........................91

7.2.2.2 Package C1/C1E State ............................. ..................................91

7.2.2.3 Package C3 State........................................... .. .........................91

7.2.2.4 Package C6 State........................................... .. .........................92

7.3 Sleep States .....................................................................................................92

7.4 ACPI P-States (Intel

®

Turbo Boost Technology) ................................................... ..92

7.5 Enhanced Intel SpeedStep® Technology ...............................................................93

8 Boxed Processor Specifications................................................................................95

8.1 Introduction......................................................................................................95

8.2 Mechanical Specifications....................................................................................96

8.2.1 Boxed Processor Cooling Solution Dimensions.............................................96

8.2.2 Boxed Processor Fan Heatsink Weight .......................................................98

8.2.3 Boxed Processor Retention Mechanism and Heatsink Attach Clip Assembly .....98

8.3 Electrical Requirements ......................................................................................98

8.3.1 Fan Heatsink Power Supply........................ .. .. .. ............................ ............98

8.4 Thermal Specifications........................... ........................... ..................................99

8.4.1 Boxed Processor Cooling Requirements......................................................99

8.4.2 Variable Speed Fan.................. .. .. ......................... ... .. ......................... ..101

4 Datasheet, Volume 1

Page 5

Figures

1-1 High-Level View of Processor Interfaces .................................................................9

2-1 Active ODT for a Differential Link Example............................................................13

2-2 Input Device Hysteresis .....................................................................................22

2-3 V

2-4 V

2-5 V

3-1 Processor Package Assembly Sketch ....................................................................35

3-2 Processor Package Drawing (Sheet 1 of 2)............................................................36

3-3 Processor Package Drawing (Sheet 2 of 2)............................................................37

3-4 Processor Top-side Markings...............................................................................39

3-5 Processor Land Coordinates and Quadrants, Top View............................................40

6-1 Intel

6-2 Intel

6-3 Thermal Test Vehicle (TTV) Case Temperature (T

6-4 Frequency and Voltage Ordering..........................................................................82

7-1 Power State......................................................................................................90

8-1 Mechanical Representation of the Boxed Processor.................................................95

8-2 Space Requirements for the Boxed Processor (side view) ........................................96

8-3 Space Requirements for the Boxed Processor (top view).........................................97

8-4 Space Requirements for the Boxed Processor (overall view)....................................97

8-5 Boxed Processor Fan Heatsink Power Cable Connector Description ...........................98

8-6 Baseboard Power Header Placement Relative to Processor Socket ............................99

8-7 Boxed Processor Fan Heatsink Airspace Keepout Requirements (top view) ..... ......... 100

8-8 Boxed Processor Fan Heatsink Airspace Keepout Requirements (side view) ............. 100

8-9 Boxed Processor Fan Heatsink Set Points............................................................ 101

Static and Transient Tolerance Load Lines.......................................................26

CC

Static and Transient Tolerance Load Line ........................................................28

TT

Overshoot Example Waveform ......................................................................31

CC

®

Core™ i7-900 Desktop Processor Extreme Edition Series Thermal Profile......... 77

®

Core™ i7-900 Desktop Processor Series Thermal Profile................................78

) Measurement Location ........... 80

CASE

Datasheet, Volume 1 5

Page 6

Tables

1-1 References........................................................................................................11

2-1 Voltage Identification Definition ...........................................................................16

2-2 Market Segment Selection Truth Table for MS_ID[2:0] ...........................................18

2-3 Signal Groups ...................................................................................................19

2-4 Signals with ODT...............................................................................................20

2-5 PECI DC Electrical Limits.....................................................................................21

2-6 Processor Absolute Minimum and Maximum Ratings ...............................................23

2-7 Voltage and Current Specifications.......................................................................24

2-8 V

2-9 V

2-10 V

2-11 DDR3 Signal Group DC Specifications...................................................................28

2-12 RESET# Signal DC Specifications .........................................................................29

2-13 TAP Signal Group DC Specifications......................................................................29

2-14 PWRGOOD Signal Group DC Specifications ............................................................30

2-15 Control Sideband Signal Group DC Specifications ...................................................30

2-16 VCC Overshoot Specifications..............................................................................31

2-17 Intel

2-18 Parameter Values for Intel

3-1 Processor Loading Specifications..........................................................................38

3-2 Package Handling Guidelines...............................................................................38

3-3 Processor Materials............................................................................................39

4-1 Land Listing by Land Name .................................................................................41

4-2 Land Listing by Land Number ..............................................................................56

5-1 Signal Definitions...............................................................................................71

6-1 Processor Thermal Specifications ........................................................................76

6-2 Intel

6-3 Intel

6-4 Thermal Solution Performance above T

6-5 Supported PECI Command Functions and Codes ....................................................86

6-6 GetTemp0() Error Codes.....................................................................................86

6-7 Storage Condition Ratings...................................................................................87

7-1 Power On Configuration Signal Options .................................................................89

7-2 Coordination of Thread Power States at the Core Level ...........................................90

7-3 Processor S-States.............................................................................................92

8-1 Fan Heatsink Power and Signal Specifications ........................................................99

8-2 Fan Heatsink Power and Signal Specifications ......................................................101

Static and Transient Tolerance.......................................................................25

CC

Voltage Identification (VID) Definition.............................................................26

TT

Static and Transient Tolerance ......................................................................27

TT

®

QuickPath Interconnect (Intel QPI) Specifications .........................................32

®

Core™ i7-900 Desktop Processor Extreme Edition Series Thermal Profile .........77

®

Core™ i7-900 Desktop Processor Series Thermal Profile ................................78

®

QuickPath Interconnect (Intel QPI) Channel at 6.4 GT/s..33

CONTROL

......................................................79

6 Datasheet, Volume 1

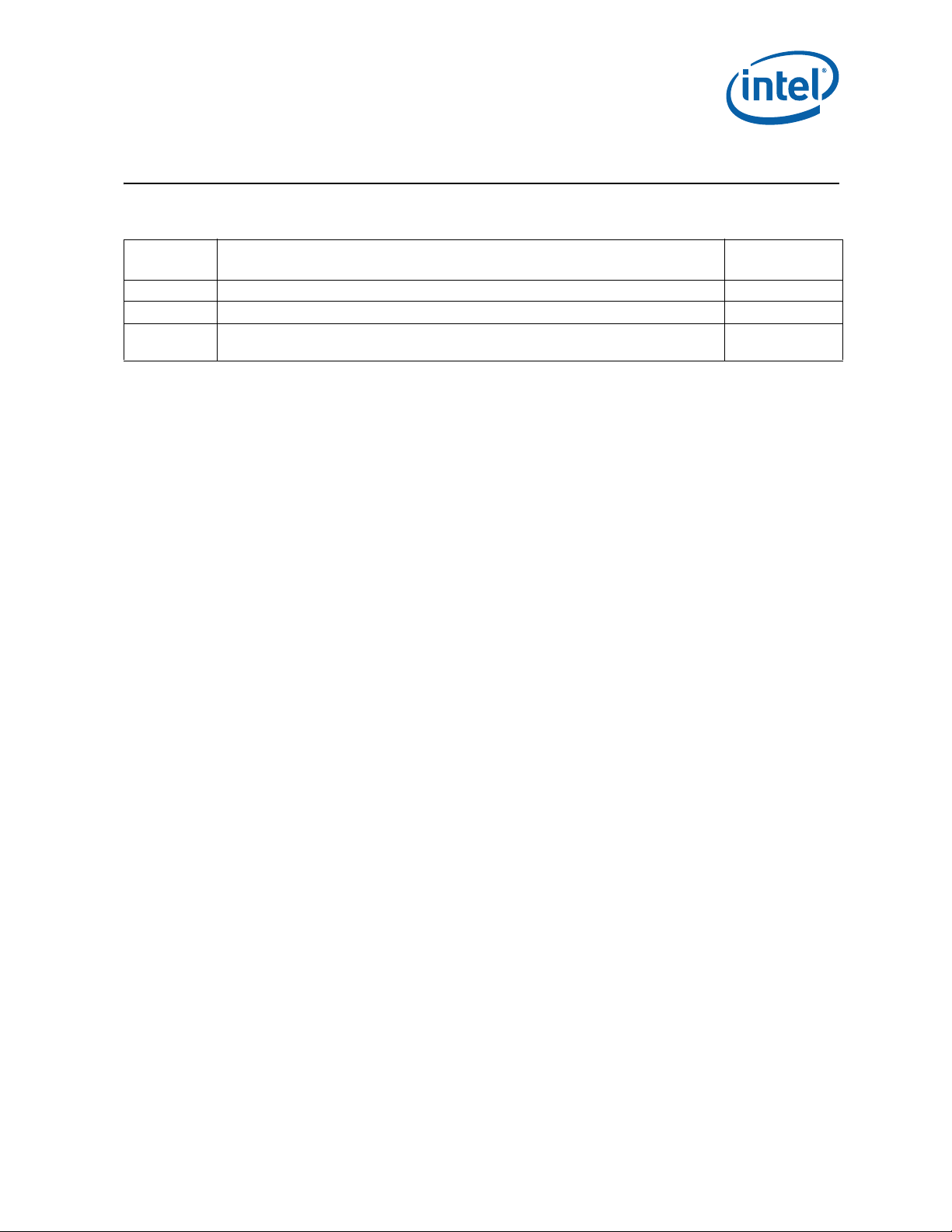

Page 7

Revision History

Revision

Number

001 • Initial release March 2010

002 • Added Intel

003

• Added Intel

• Added Intel

®

Core™ i7-970 desktop processor series July 2010

®

Core™ i7-990X desktop processor Extreme Edition

®

Core™ i7-980 desktop processor

Description Date

June 2011

§

Datasheet, Volume 1 7

Page 8

8 Datasheet, Volume 1

Page 9

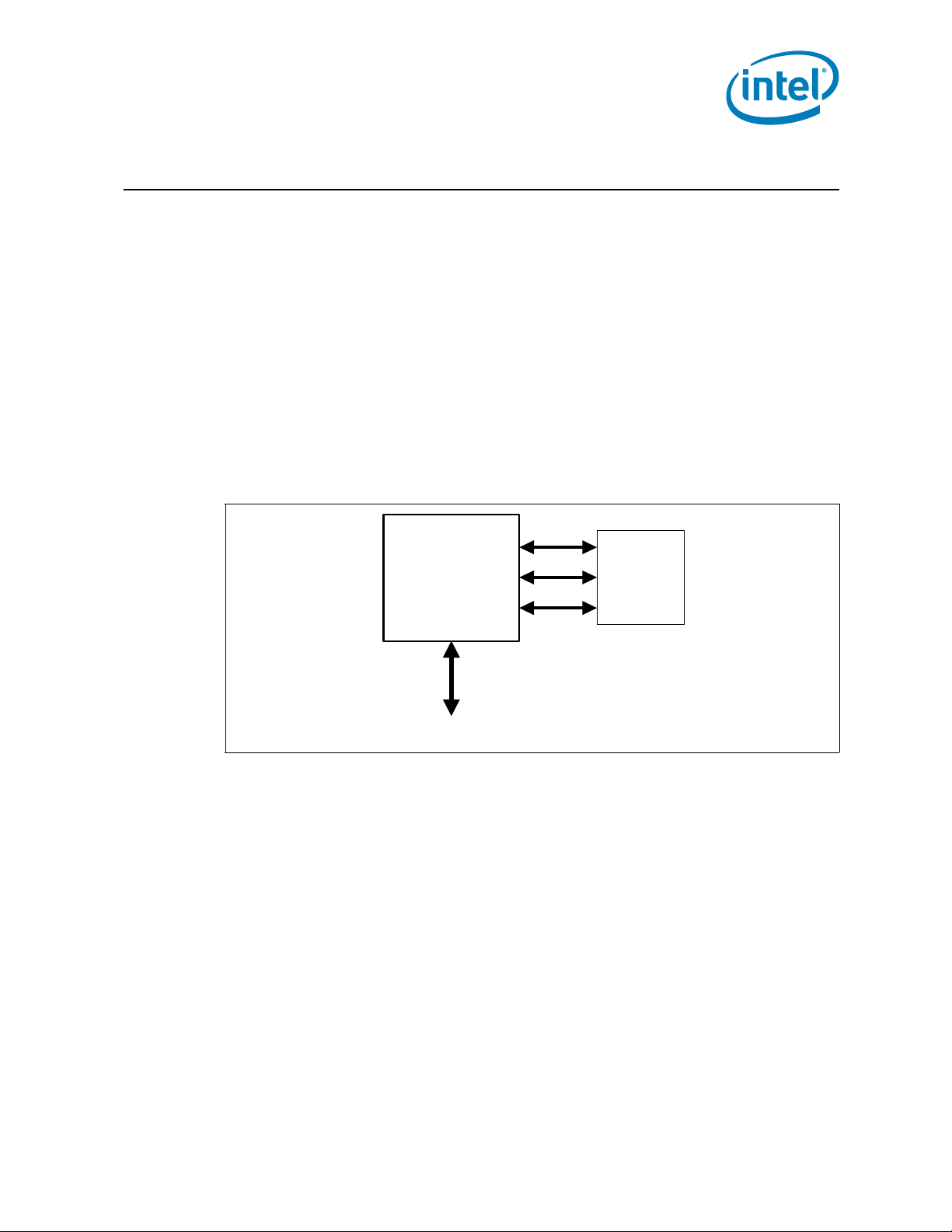

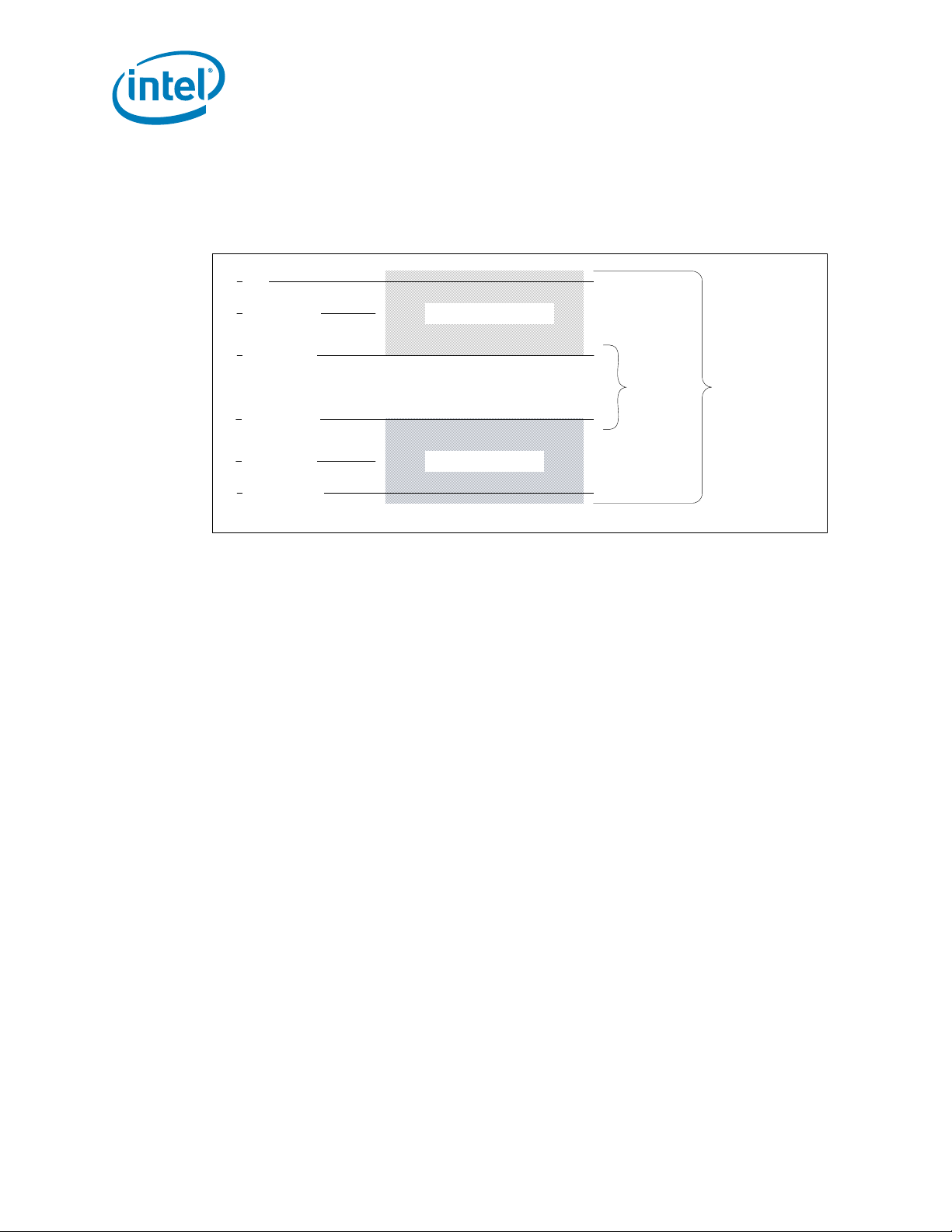

Introduction

Processor

Intel®QuickPath

Interconnect (Intel

®

QPI)

CH 0

CH 1

CH 2

System

Memory

(DDR3)

1 Introduction

The Intel® Core™ i7-900 desktop processor Extreme Edition series and Intel® Core™

i7-900 desktop processor series on 32-nm process processor is intended for high

performance, high-end desktop systems. Several architectural and microarchitectural

enhancements have been added to this processor including six processor cores in the

processor package and increased shared cache.

®

The Intel

Core™ i7-970 desktop processor series on 32-nm process is a desktop multi-core

processor with these key technologies:

• Integrated memory control ler

• Point-to-point link interface based on Intel QuickPath Interconnect (Intel QPI)

Figure 1-1 shows the interfaces used with these new technologies.

Figure 1-1. High-Level View of Processor Interfaces

Core™ i7-900 desktop processor Extreme Edition series and and Intel®

Note: In this document the Intel® Core™ i7-900 desktop processor Extreme Edition series on

32-nm process will be referred to as “the processor.”

®

Note: The Intel

refers to the Intel

Note: The Intel

Intel

Core™ i7-900 desktop processor Extreme Edition series on 32-nm process

®

Core™ i7-900 desktop processor series on 32-nm process refers to the

®

Core™ i7-980 and i7-970 desktop processors.

®

Core™ i7-980X and i7-990X desktop processor Extreme Edition.

The processor is optimized for performance with the power efficiency of a low-power

microarchitecture.

This document provides DC electrical specifications, differential signaling specifications,

pinout and signal definitions, package mechanical specifications and thermal

requirements, and additional features pertinent to the implementation and operation of

the processor.

Datasheet, Volume 1 9

The processor is a multi-core processor built on the 32-nm process technology, that

uses up to 130 W thermal design power (TDP). The processor features an Intel QPI

point-to-point link capable of up to 6.4 GT/s, 12 MB Level 3 cache, and an integrated

memory controller.

Page 10

The processor supports all the existing Streaming SIMD Extensions 2 (SSE2),

Streaming SIMD Extensions 3 (SSE3) and Streaming SIMD Extensions 4 (SSE4). The

processor supports several Advanced Technologies: Intel

Enhanced Intel SpeedStep® Technology, Intel® Virtualization Technology (Intel® VT),

Turbo Boost Technology, and Hyper-Threading Technology.

1.1 Terminology

A ‘#’ symbol after a signal name refers to an active low signal, indicating a signal is in

the active state when driven to a low level. For example, when RESET# is low, a reset

has been requested. Conversely, when VTTPWRGOOD is high, the VTT power rail is

stable.

‘_N’ and ‘_P’ after a signal name refers to a differential pair.

Commonly used terms are explained here for clarification:

®

• Intel

Core™ i7-900 desktop processor series on 32-nm process — The entire

product, including processor substrate and integrated heat spreader (IHS).

• 1366-land LGA package — The processor is available in a Flip-Chip Land Grid

Array (FC-LGA) package, consisting of the processor mounted on a land grid array

substrate with an integrated heat spreader (IHS).

• LGA1366 Socket — The processor (in the LGA 1366 package) mates with the

system board through this surface mount, 1366-contact socket.

• DDR3 — Double Data Rate 3 Synchronous Dynamic Random Access Memory

(SDRAM) is the name of the new DDR memory standard that is being developed as

the successor to DDR2 SRDRAM.

• Intel

point-to-point link-based electrical interconnect specification for Intel processors

and chipsets.

• Intel® QuickPath Technology Memor y Controller — A memory controller that

is integrated into the processor die.

• Integrated Heat Spreader (IHS) — A component of the processor package used

to enhance the thermal performance of the package. Component thermal solutions

interface with the processor at the IHS surface.

• Functional Operation — Refers to the normal operating conditions in which all

processor specifications, including DC, AC, signal quality, mechanical, and thermal,

are satisfied.

• Enhanced Intel SpeedStep

Technology allows the operating system to reduce power consumption when

performance is not needed.

• Execute Disable Bit — Execute Disable allows memory to be marked as

executable or non-executable when combined with a supporting operating system.

If code attempts to run in non-executable memory , the processor raises an error to

the operating system. This feature can prevent some classes of viruses or worms

that exploit buffer overrun vulnerabilities and can thus help improve the overall

security of the system. See the Intel

for more detailed information. Refer to http://developer.intel.com/ for future

reference on up to date nomenclatures.

• Intel

allowing the processor to execute operating systems and applications written to

Core™ i7-900 desktop processor Extreme Edition series and Intel®

®

QuickPath Interconnect (Intel® QPI)— Intel QPI is a cache-coherent,

®

64 Architecture — An enhancement to the Intel IA-32 architecture,

®

64 Technology (Intel® 64),

®

Technology — Enhanced Intel SpeedStep

®

Architecture Software Developer's Manual

Introduction

10 Datasheet, Volume 1

Page 11

Introduction

take advantage of Intel 64. Further details on the Intel 64 architecture and

programming model can be found at

http://developer.intel.com/technology/intel64/.

• Intel® Virtualization Technology (Intel® VT) — A set of hardware

enhancements to Intel server and client platforms that can improve virtualization

solutions. Intel

®

VT provides a foundation for widely-deployed virtualization

solutions and enables a more robust hardware assisted virtualization solution. More

information can be found at: http://www.intel.com/technology/virtualization/

• Unit Interval (UI) — Signaling convention that is binary and unidirectional. In

this binary signaling, one bit is sent for every edge of the forwarded clock, whether

it is a rising edge or a falling edge. If a number of edges are collected at instances

, t2, tn,...., tk then the UI at instance “n” is defined as:

t

1

• Jitter — Any timing variation of a transition edge or edges from the defined Unit

Interval.

• Storage Conditions — Refers to a non-operational state. The processor may be

installed in a platform, in a tray , or loose. Processors may be sealed in packaging or

exposed to free air. Under these conditions, processor lands should not be

connected to any supply voltages, have any I/Os biased, or receive any clocks.

• OEM — Original Equipment Manufacturer.

1.2 References

Material and concepts available in the following documents may be beneficial when

reading this document.

Table 1-1. References

®

Core™ i7-900 Desktop Processor Extreme Edition Series and

Intel

®

Intel

Core™ i7-900 Desktop Processor Series on 32-nm Process

Specification Update

®

Intel

Core™ i7-900 Desktop Processor Extreme Edition Series on

32-nm Process Datasheet, Volume 2

®

Core™ i7-900 Desktop Processor Extreme Edition Series and

Intel

®

Core™ i7-900 Desktop Processor Series and LGA1366 Socket

Intel

Thermal and Mechanical Design Guide

Intel X58 Express Chipset Datasheet http://www.intel.com/Assets/PDF/dat

AP-485, Intel

IA-32 Intel

• Volume 1: Basic Architecture

• Volume 2A: Instruction Set Reference, A-M

• Volume 2B: Instruction Set Reference, N-Z

• Volume 3A: System Programming Guide, Part 1

• Volume 3B: Systems Programming Guide, Part 2

®

Processor Identification and the CPUID Instruction http://www.intel.com/design/processo

®

Architecture Software Developer's Manual

UI n = t n – t

Document Location

n – 1

http://www.intel.com/Assets/PDF/spe

http://download.intel.com/design/pro

http://download.intel.com/design/pro

http://www.intel.com/products/proces

cupdate/323254.pdf

cessor/datashts/323253.pdf

cessor/designex/320837.pdf

asheet/320838.pdf

r/applnots/241618.htm

sor/manuals/

Notes:

1. Contact your Intel representative to receive the latest revisions of these documents.

2. Document is available publicly at http://developer.intel.com.

3. Document not available at time of printing.

4. The LGA1366 Socket and Heatsink Keepout Zones – Mechanical Models will be made available

electronically.

Datasheet, Volume 1 11

Page 12

Introduction

§

12 Datasheet, Volume 1

Page 13

Electrical Specifications

T

X

R

X

R

TT

R

TT

R

TT

R

TT

Signal

Signal

2 Electrical Specifications

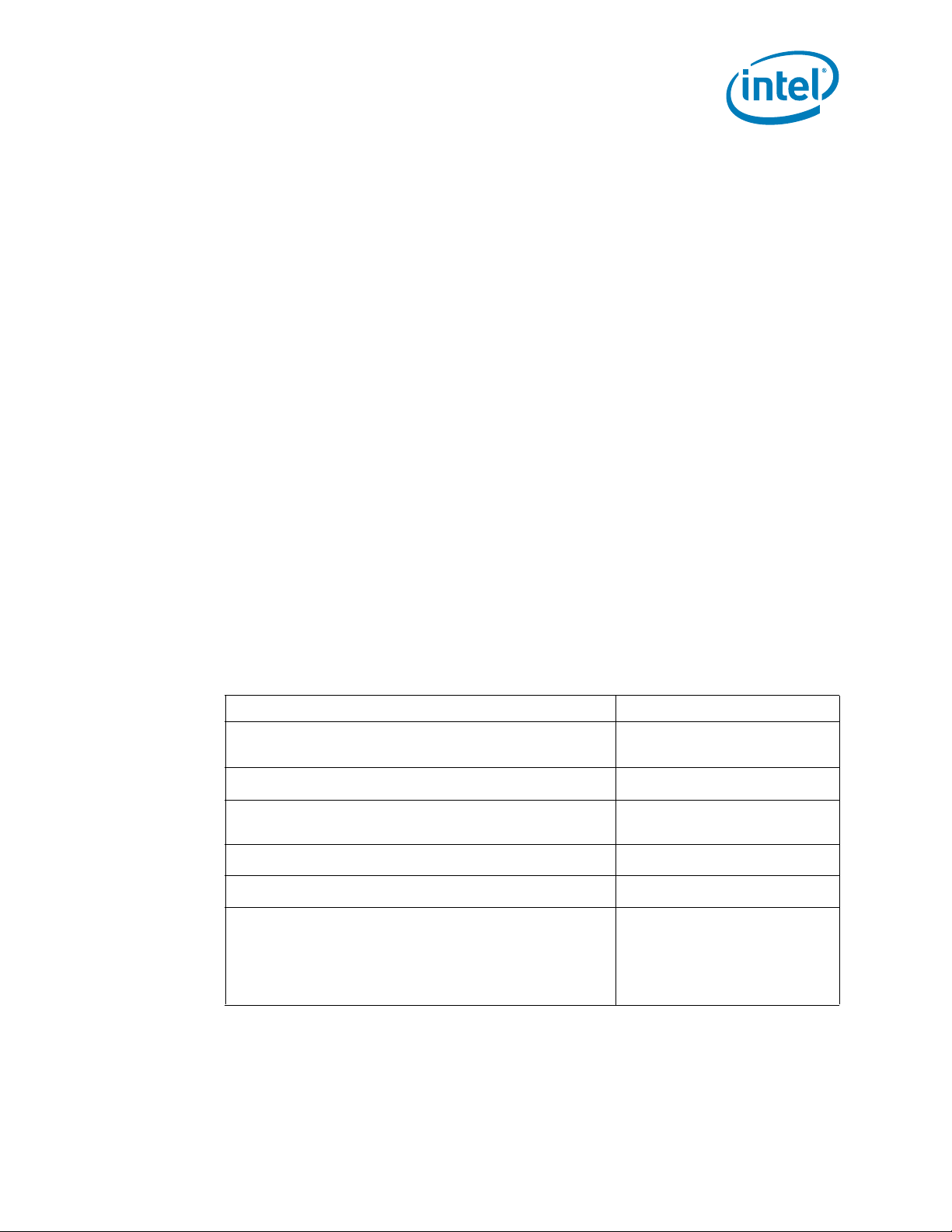

2.1 Intel® QuickPath Interconnect (Intel® QPI) Differential Signaling

The processor provides an Intel QPI port for high speed serial transfer between other

Intel QPI-enabled components. The Intel QPI port consists of two unidirectional links

(for transmit and receive). Intel QPI uses a differential signalling scheme where pairs of

opposite-polarity (D_P, D_N) signals are used.

On-die termination (ODT) provided on the processor silicon and termination is to V

Intel chipsets also provide ODT; thus, eliminating the need to terminate the Intel QPI

links on the system board.

Intel strongly recommends performing analog simulations of the Intel QPI interface.

Figure 2-1 illustrates the active ODT. Signal listings are included in Table 2-3 and

Table 2-4. See Chapter 5 for the pin signal definitions. All Intel QPI signals are in the

differential signal group.

Figure 2-1. Active ODT for a Differential Link Example

2.2 Power and Ground Lands

For clean on-chip processor core power distribution, the processor has 210 VCC pads

and 119 VSS pads associated with VCC; 8 VTTA pads and 5 VSS pads associated with

; 28 VTTD pads and 17 VSS pads associated with V

V

TTA

pads associated with V

VCCPLL lands must be connected to their respective processor power planes, while all

VSS lands must be connected to the system ground plane. The processor VCC lands

must be supplied with the voltage determined by the processor Voltage IDentification

(VID) signals. Table 2-1 specifies the voltage level for the various VIDs.

; and 3 VCCPLL pads. All VCCP, VTTA, VTTD, VDDQ, and

DDQ

, 28 VDDQ pads and 17 VSS

TTD

SS

.

2.3 Decoupling Guidelines

Due to its large number of transistors and high internal clock speeds, the processor is

capable of generating large current swings between low and full power states. This may

cause voltages on power planes to sag below their minimum values if bulk decoupling is

not adequate. Larger bulk storage (C

current during longer lasting changes in current demand; such as, coming out of an idle

condition. Similarly, capacitors act as a storage well for current when entering an idle

Datasheet, Volume 1 13

), such as electrolytic capacitors, supply

BULK

Page 14

Electrical Specifications

condition from a running condition. Care must be taken in the baseboard design to

ensure that the voltage provided to the processor remains within the specifications

listed in Table 2-7. Failure to do so can result in timing violations or reduced lifetime of

the processor.

2.3.1 VCC, V

Voltage regulator solutions need to provide bulk capacitance and the base b oard

designer must assure a low interconnect resistance from the regulator to the LGA1366

socket. Bulk decoupling must be provided on the baseboard to handle large current

swings. The power delivery solution must insure the voltage and current specifications

are met (as defined in Table 2-7).

TTA

, V

TTD

, V

Decoupling

DDQ

2.4 Processor Clocking (BCLK_DP, BCLK_DN)

The processor core, Intel QPI, and integrated memory controller frequencies are

generated from BCLK_DP and BCLK_DN. Unlike previous processors based on front side

bus architecture, there is no direct link between core frequency and Intel QPI link

frequency (such as, no core frequency to Intel QPI multiplier). The processor maximum

core frequency, Intel QPI link frequency and integrated memory controller frequency,

are set during manufacturing. It is possible to override the processor core frequency

setting using software. This permits operation at lower core frequencies than the

factory set maximum core frequency.

The processor’s maximum non-turbo core frequency is configured during power-on

reset by using values stored internally during manufacturing. The stored value sets the

highest core multiplier at which the particular processor can operate. If lower maximum

non-turbo speeds are desired, the appropriate ratio can be configured using the

CLOCK_FLEX_MAX MSR.

The processor uses differential clocks (B CLK_DP, BCLK_DN). Clock multiplying within

the processor is provided by the internal phase locked loop (PLL) that requires a

constant frequency BCLK_DP, BCLK_DN input, with exceptions for spread spectrum

clocking. The processor core frequency is determined by multiplying the ratio by

133 MHz.

2.4.1 PLL Power Supply

An on-die PLL filter solution is implemented on the processor. Refer to Table 2-7 for DC

specifications.

14 Datasheet, Volume 1

Page 15

Electrical Specifications

2.5 Voltage Identification (VID)

The Voltage Identification (VID) specification for the processor is defined by the Voltage

Regulator Down (VRD) 11.1 Design Guidelines. The voltage set by the VID signals is

the reference voltage regulator output voltage to be delivered to the processor VCC

pins. VID signals are CMOS push/pull drivers. Refer to Table 2-15 for the DC

specifications for these signals. The VID codes will change due to temperature and/or

current load changes in order to minimize the power of the part. A voltage range is

provided in Table 2-7. The specifications have been set such that one voltage regulator

can operate with all supported frequencies.

Individual processor VID values may be set during manufacturing such that two devices

at the same core frequency may have different default VID settings. This is reflected by

the VID range values provided in Table 2-1.

The processor

uses eight voltage identification signals, VID[7:0], to support automatic

selection of voltages. Table 2-1 specifies the voltage level corresponding to the state of

VID[7:0]. A ‘1’ in this table refers to a high voltage level and a ‘0’ refers to a low

voltage level. If the processor socket is empty (VID[7:0] = 11111111), or the voltage

regulation circuit cannot supply the voltage that is requested, the voltage regulator

must disable itself. See the Voltage Regulator Down (VRD) 11.1 Design Guidelines for

further details.

The processor

provides the ability to operate while transitioning to an adjacent VID and

its associated processor core voltage (VCC). This will represent a DC shift in the

loadline. It should be noted that a low-to-high or high-to-low voltage state change will

result in as many VID transitions as necessary to reach the target core voltage.

T ransitions above the maximum specified VID are not permitted. Table 2-8 includes VID

step sizes and DC shift ranges. Minimum and maximum voltages must be maintained

as shown in Table 2-8.

The VR used must be capable of regulating its output to the value defined by the new

VID. DC specifications for dynamic VID transitions are included in Table 2-7 and

Table 2-8. Refer to the Voltage Regulator Down (VRD) 11.1 Design Guidelines for

further details.

Datasheet, Volume 1 15

Page 16

Electrical Specifications

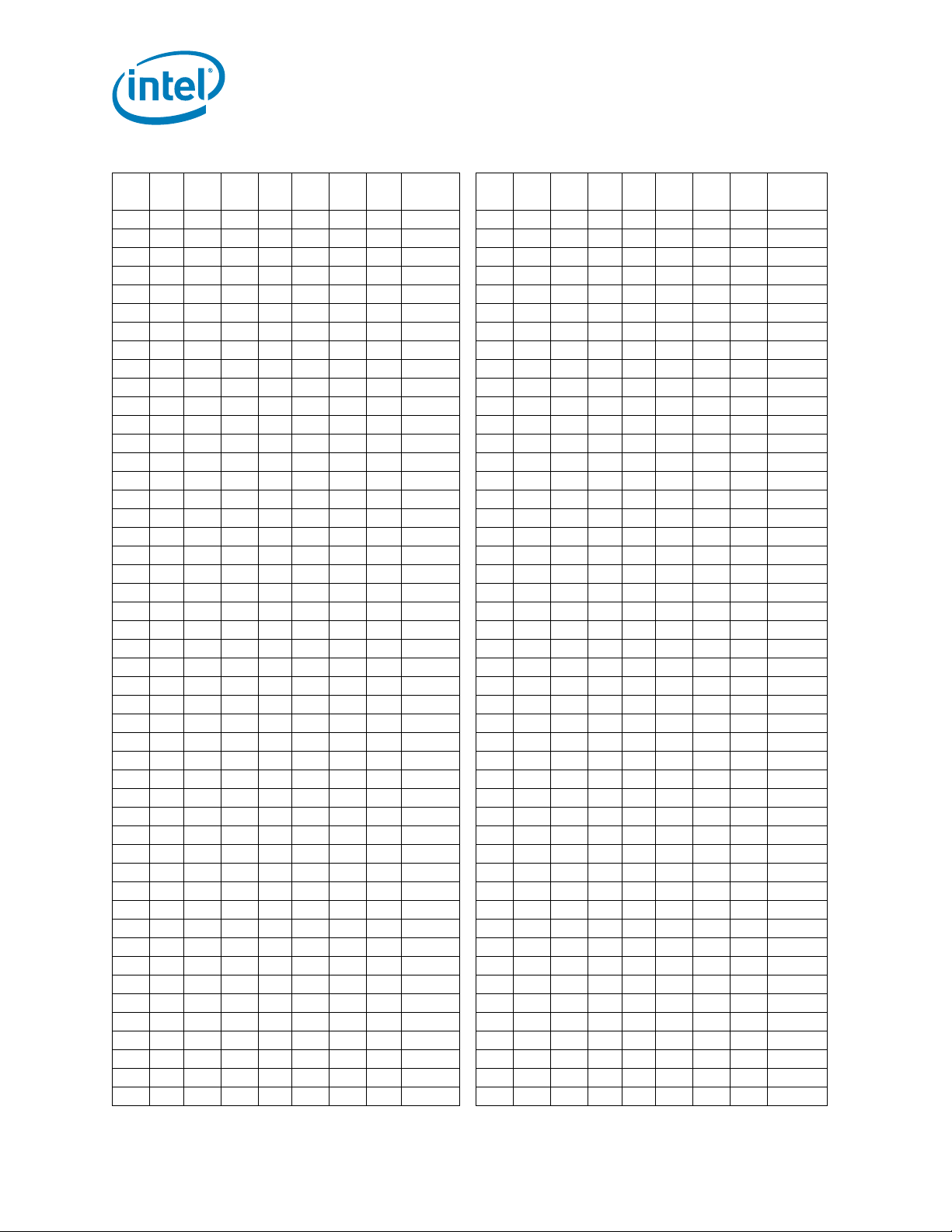

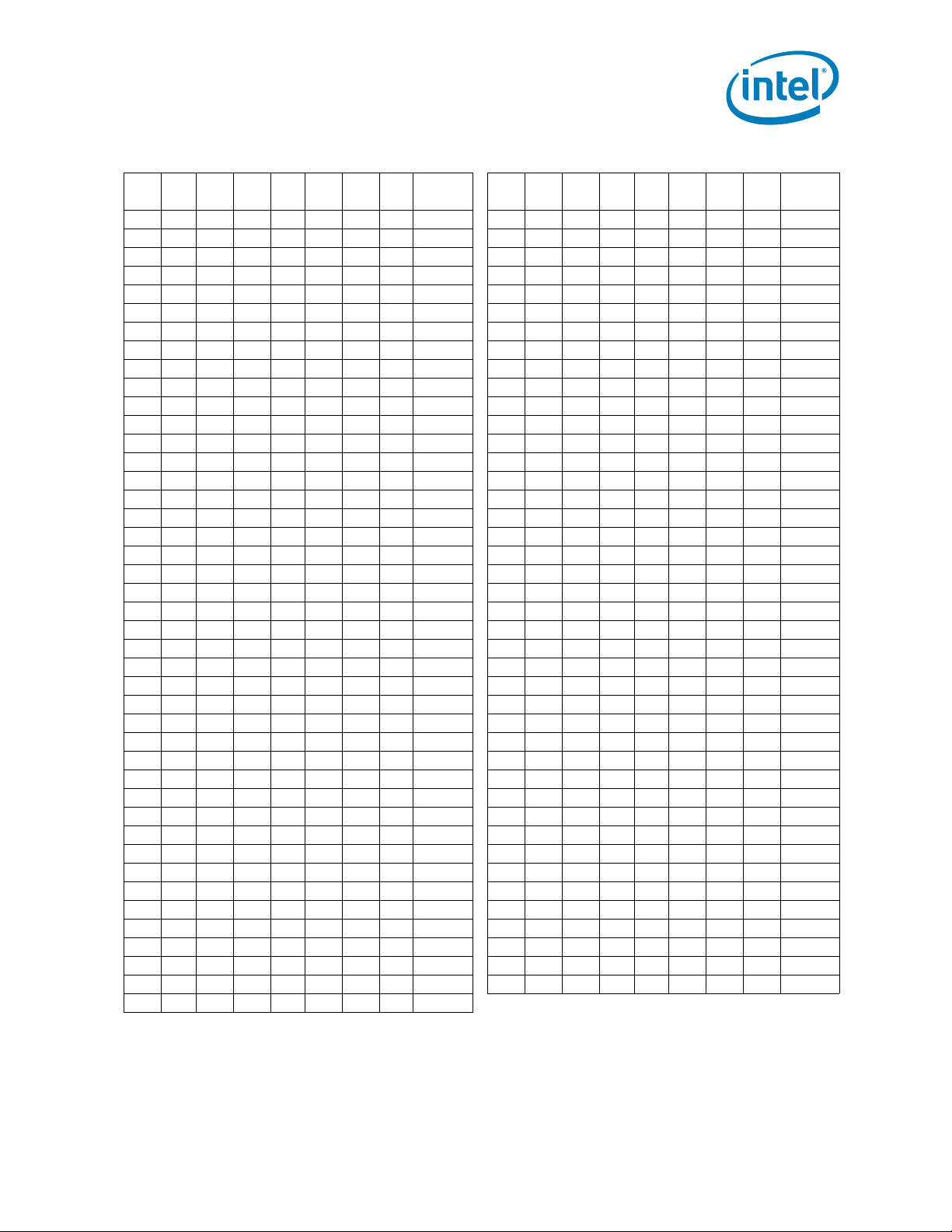

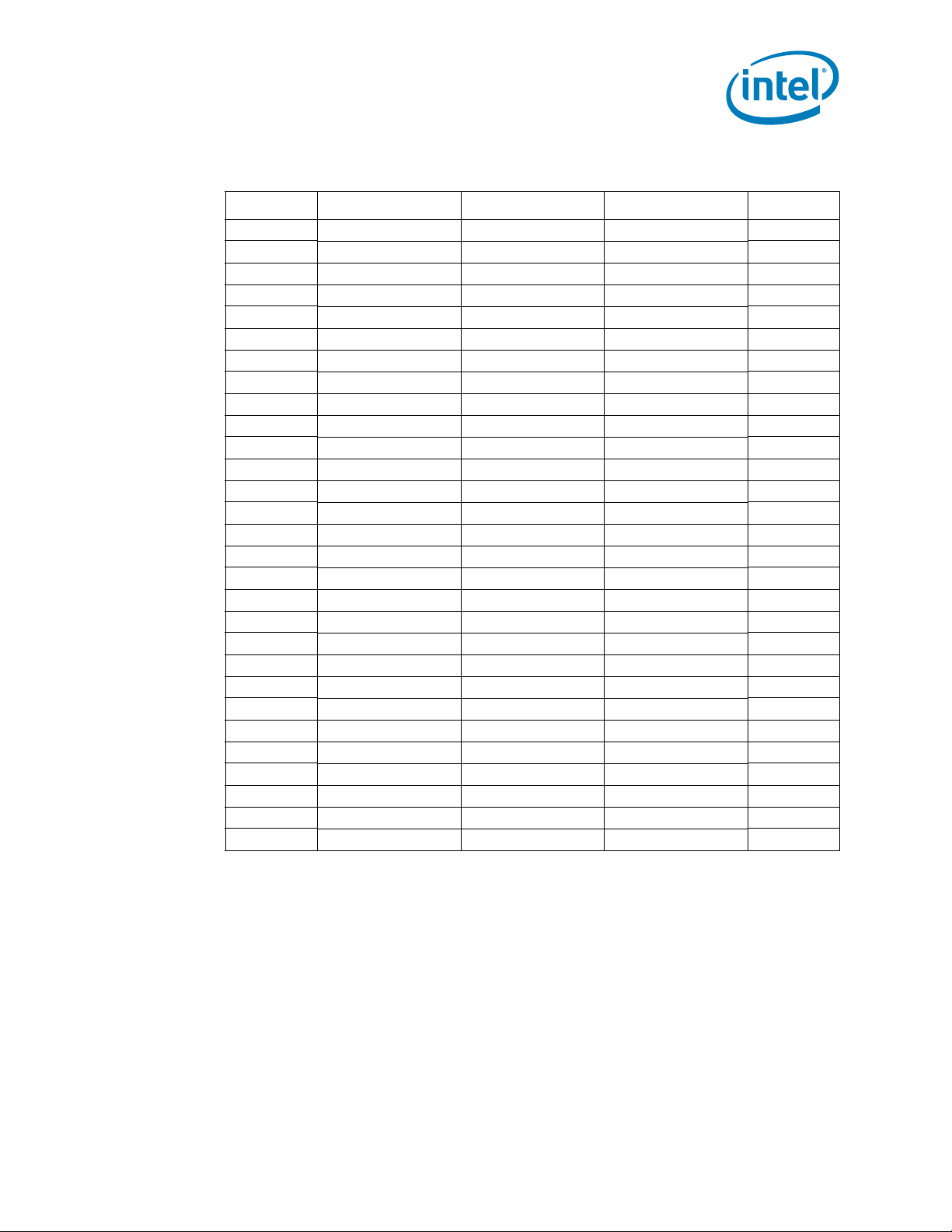

Table 2-1. Voltage Identification Definition (Sheet 1 of 2)

VID7VID6VID5VID4VID3VID2VID1VID

V

CC_MAX

0

0 0 0 0 0 0 0 0 OFF 0 1 0 1 1 0 1 1 1.04375

0 0 0 0 0 0 0 1 OFF 0 1 0 1 1 1 0 0 1.03750

0 0 0 0 0 0 1 0 1.60000 0 1 0 1 1 1 0 1 1.03125

0 0 0 0 0 0 1 1 1.59375 0 1 0 1 1 1 1 0 1.02500

0 0 0 0 0 1 0 0 1.58750 0 1 0 1 1 1 1 1 1.01875

0 0 0 0 0 1 0 1 1.58125 0 1 1 0 0 0 0 0 1.01250

0 0 0 0 0 1 1 0 1.57500 0 1 1 0 0 0 0 1 1.00625

000001

000010

1 1 1.56875 0 1 1 0 0 0 1 0 1.00000

0 0 1.56250 0 1 1 0 0 0 1 1 0.99375

0 0 0 0 1 0 0 1 1.55625 0 1 1 0 0 1 0 0 0.98750

0 0 0 0 1 0 1 0 1.55000 0 1 1 0 0 1 0 1 0.98125

0 0 0 0 1 0 1 1 1.54375 0 1 1 0 0 1 1 0 0.97500

0 0 0 0 1 1 0 0 1.53750 0 1 1 0 0 1 1 1 0.96875

0 0 0 0 1 1 0 1 1.53125 0 1 1 0 1 0 0 0 0.96250

0 0 0 0 1 1 1 0 1.52500 0 1 1 0 1 0 0 1 0.95626

0 0 0 0 1 1 1 1 1.51875 0 1 1 0 1 0 1 0 0.95000

0 0 0 1 0 0 0 0 1.51250 0 1 1 0 1 0 1 1 0.94375

0 0 0 1 0 0 0 1 1.50625 0 1 1 0 1 1 0 0 0.93750

0 0 0 1 0 0 1 0 1.50000 0 1 1 0 1 1 0 1 0.93125

0 0 0 1 0 0 1 1 1.49375 0 1 1 0 1 1 1 0 0.92500

0 0 0 1 0 1 0 0 1.48750 0 1 1 0 1 1 1 1 0.91875

0 0 0 1 0 1 0 1 1.48125 0 1 1 1 0 0 0 0 0.91250

0 0 0 1 0 1 1 0 1.47500 0 1 1 1 0 0 0 1 0.90625

0 0 0 1 0 1 1 1 1.46875 0 1 1 1 0 0 1 0 0.90000

0 0 0 1 1 0 0 0 1.46250 0 1 1 1 0 0 1 1 0.89375

0 0 0 1 1 0 0 1 1.45625 0 1 1 1 0 1 0 0 0.88750

0 0 0 1 1 0 1 0 1.45000 0 1 1 1 0 1 0 1 0.88125

0 0 0 1 1 0 1 1 1.44375 0 1 1 1 0 1 1 0 0.87500

0 0 0 1 1 1 0 0 1.43750 0 1 1 1 0 1 1 1 0.86875

0 0 0 1 1 1 0 1 1.43125 0 1 1 1 1 0 0 0 0.86250

0 0 0 1 1 1 1 0 1.42500 0 1 1 1 1 0 0 1 0.85625

0 0 0 1 1 1 1 1 1.41875 0 1 1 1 1 0 1 0 0.85000

0 0 1 0 0 0 0 0 1.41250 0 1 1 1 1 0 1 1 0.84374

0 0 1 0 0 0 0 1 1.40625 0 1 1 1 1 1 0 0 0.83750

0 0 1 0 0 0 1 0 1.40000 0 1 1 1 1 1 0 1 0.83125

0 0 1 0 0 0 1 1 1.39375 0 1 1 1 1 1 1 0 0.82500

0 0 1 0 0 1 0 0 1.38750 0 1 1 1 1 1 1 1 0.81875

0 0 1 0 0 1 0 1 1.38125 1 0 0 0 0 0 0 0 0.81250

0 0 1 0 0 1 1 0 1.37500 1 0 0 0 0 0 0 1 0.80625

0 0 1 0 0 1 1 1 1.36875 1 0 0 0 0 0 1 0 0.80000

0 0 1 0 1 0 0 0 1.36250 1 0 0 0 0 0 1 1 0.79375

0 0 1 0 1 0 0 1 1.35625 1 0 0 0 0 1 0 0 0.78750

0 0 1 0 1 0 1 0 1.35000 1 0 0 0 0 1 0 1 0.78125

0 0 1 0 1 0 1 1 1.34375 1 0 0 0 0 1 1 0 0.77500

0 0 1 0 1 1 0 0 1.33750 1 0 0 0 0 1 1 1 0.76875

0 0 1 0 1 1 0 1 1.33125 1 0 0 0 1 0 0 0 0.76250

0 0 1 0 1 1 1 0 1.32500 1 0 0 0 1 0 0 1 0.75625

0 0 1 0 1 1 1 1 1.31875 1 0 0 0 1 0 1 0 0.75000

VID7VID6VID5VID4VID3VID2VID1VID

0

V

CC_MAX

16 Datasheet, Volume 1

Page 17

Electrical Specifications

Table 2-1. Voltage Identification Definition (Sheet 2 of 2)

VID7VID6VID5VID4VID3VID2VID1VID

V

CC_MAX

0

0 0 1 1 0 0 0 0 1.31250 1 0 0 0 1 0 1 1 0.74375

0 0 1 1 0 0 0 1 1.30625 1 0 0 0 1 1 0 0 0.73750

0 0 1 1 0 0 1 0 1.30000 1 0 0 0 1 1 0 1 0.73125

0 0 1 1 0 0 1 1 1.29375 1 0 0 0 1 1 1 0 0.72500

0 0 1 1 0 1 0 0 1.28750 1 0 0 0 1 1 1 1 0.71875

0 0 1 1 0 1 0 1 1.28125 1 0 0 1 0 0 0 0 0.71250

0 0 1 1 0 1 1 0 1.27500 1 0 0 1 0 0 0 1 0.70625

0 0 1 1 0 1 1 1 1.26875 1 0 0 1 0 0 1 0 0.70000

0 0 1 1 1 0 0 0 1.26250 1 0 0 1 0 0 1 1 0.69375

0 0 1 1 1 0 0 1 1.25625 1 0 0 1 0 1 0 0 0.68750

0 0 1 1 1 0 1 0 1.25000 1 0 0 1 0 1 0 1 0.68125

0 0 1 1 1 0 1 1 1.24375 1 0 0 1 0 1 1 0 0.67500

0 0 1 1 1 1 0 0 1.23750 1 0 0 1 0 1 1 1 0.66875

0 0 1 1 1 1 0 1 1.23125 1 0 0 1 1 0 0 0 0.66250

0 0 1 1 1 1 1 0 1.22500 1 0 0 1 1 0 0 1 0.65625

0 0 1 1 1 1 1 1 1.21875 1 0 0 1 1 0 1 0 0.65000

0 1 0 0 0 0 0 0 1.21250 1 0 0 1 1 0 1 1 0.64375

0 1 0 0 0 0 0 1 1.20625 1 0 0 1 1 1 0 0 0.63750

0 1 0 0 0 0 1 0 1.20000 1 0 0 1 1 1 0 1 0.63125

0 1 0 0 0 0 1 1 1.19375 1 0 0 1 1 1 1 0 0.62500

0 1 0 0 0 1 0 0 1.18750 1 0 0 1 1 1 1 1 0.61875

0 1 0 0 0 1 0 1 1.18125 1 0 1 0 0 0 0 0 0.61250

0 1 0 0 0 1 1 0 1.17500 1 0 1 0 0 0 0 1 0.60625

0 1 0 0 0 1 1 1 1.16875 1 0 1 0 0 0 1 0 0.60000

0 1 0 0 1 0 0 0 1.16250 1 0 1 0 0 0 1 1 0.59375

0 1 0 0 1 0 0 1 1.15625 1 0 1 0 0 1 0 0 0.58750

0 1 0 0 1 0 1 0 1.15000 1 0 1 0 0 1 0 1 0.58125

0 1 0 0 1 0 1 1 1.14375 1 0 1 0 0 1 1 0 0.57500

0 1 0 0 1 1 0 0 1.13750 1 0 1 0 0 1 1 1 0.56875

0 1 0 0 1 1 0 1 1.13125 1 0 1 0 1 0 0 0 0.56250

0 1 0 0 1 1 1 0 1.12500 1 0 1 0 1 0 0 1 0.55625

0 1 0 0 1 1 1 1 1.11875 1 0 1 0 1 0 1 0 0.55000

0 1 0 1 0 0 0 0 1.11250 1 0 1 0 1 0 1 1 0.54375

0 1 0 1 0 0 0 1 1.10625 1 0 1 0 1 1 0 0 0.53750

0 1 0 1 0 0 1 0 1.10000 1 0 1 0 1 1 0 1 0.53125

0 1 0 1 0 0 1 1 1.09375 1 0 1 0 1 1 1 0 0.52500

0 1 0 1 0 1 0 0 1.08750 1 0 1 0 1 1 1 1 0.51875

0 1 0 1 0 1 0 1 1.08125 1 0 1 1 0 0 0 0 0.51250

0 1 0 1 0 1 1 0 1.07500 1 0 1 1 0 0 0 1 0.50625

0 1 0 1 0 1 1 1 1.06875 1 0 1 1 0 0 1 0 0.50000

0 1 0 1 1 0 0 0 1.06250 1 1 1 1 1 1 1 0 OFF

0 1 0 1 1 0 0 1 1.05625 1 1 1 1 1 1 1 1 OFF

0 1 0 1 1 0 1 0 1.05000

VID7VID6VID5VID4VID3VID2VID1VID

0

V

CC_MAX

Datasheet, Volume 1 17

Page 18

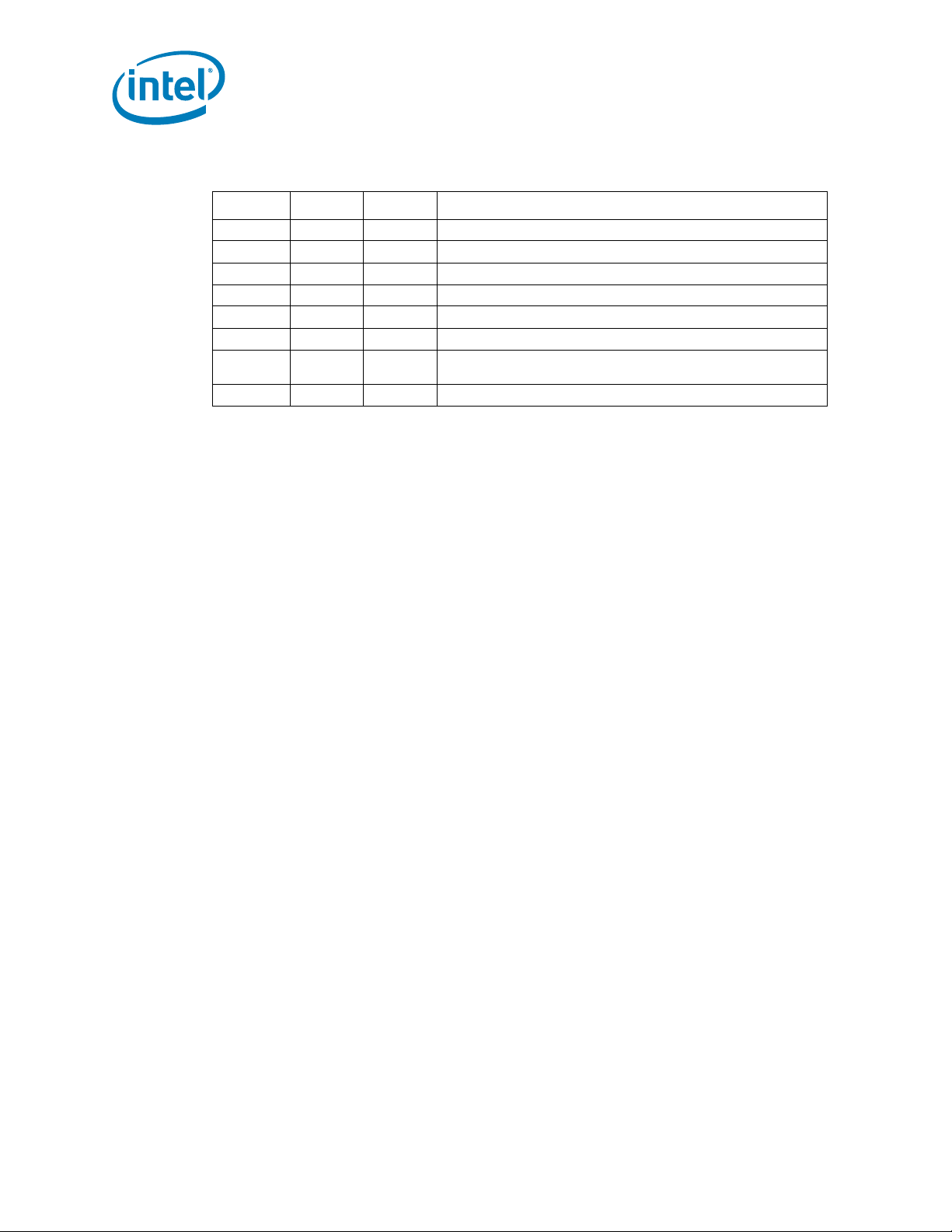

Table 2-2. Market Segment Selection Truth Table for MS_ID[2:0]

Notes:

MSID2 MSID1 MSID0 Description

0 0 0 Reserved

0 0 1 Reserved

0 1 0 Reserved

0 1 1 Reserved

1 0 0 Reserved

1 0 1 Reserved

®

Intel

110

1 1 1 Reserved

1. The MSID[2:0] signals are provided to indicate the market segment for the processor and may be used for

future processor compatibility or for keying.

Core™ i7-900 desktop processor Extreme Edition series and

®

Core™ i7-900 desktop processor series on 32-nm process

Intel

2.6 Reserved or Unused Signals

All Reserved (RSVD) signals must remain unconnected. Connection of these signals to

VCC, V

result in component malfunction or incompatibility with future processors. See

Chapter 4 for a land listing of the processor and the location of all Reserved signals.

TTA

, V

TTD

, V

DDQ

, V

, VSS, or to any other signal (including each other) can

CCPLL

Electrical Specifications

1

For reliable operation, always connect unused inputs or bi-directional signals to an

appropriate signal level, except for unused integrated memory controller inputs,

outputs, and bi-directional pins that may be left floating. Unused active high inputs

should be connected through a resistor to ground (V

). Unused outputs may be left

SS

unconnected; however, this may interfere with some Test Access Port (TAP) functions,

complicate debug probing, and prevent boundary scan testing. A resistor must be used

when tying bi-directional signals to power or ground. When tying any signal to power or

ground, a resistor will also allow for system testability.

18 Datasheet, Volume 1

Page 19

Electrical Specifications

2.7 Signal Groups

Signals are grouped by buffer type and similar characteristics as listed in Table 2-3. The

buffer type indicates which signaling technology and specifications apply to the signals.

All the differential signals, and selected DDR3 and Control Sideband signals have OnDie Termination (ODT) resistors. There are some signals that do not have ODT and

need to be terminated on the board. The signals that have ODT are listed in Table 2-4.

Table 2-3. Signal Groups (Sheet 1 of 2)

Signal Group Type Signals

System Reference Clock

Differential Clock Input BCLK_DP, BCLK_DN

Intel QPI Signal Groups

Differential Intel QPI Input

Differential Intel QPI Output

DDR3 Reference Clocks

Differential DDR3 Output

1,2

QPI_DRX_D[N/P][19:0], QPI_CLKRX_DP,

QPI_CLKRX_DN

QPI_DTX_D[N/P][19:0], QPI_CLKTX_DP,

QPI_CLKTX_DN

DDR{0/1/2}_CLK[D/P][3:0]

DDR3 Command Signals

Single ended CMOS Output

Single ended Asynchronous Output DDR{0/1/2}_RESET#

DDR3 Control Signals

Single ended CMOS Output

DDR3 Data Signals

Single ended CMOS Bi-directional DDR{0/1/2}_DQ[63:0]

Differential CMOS Bi-directional DDR{0/1/2}_DQS_[N/P][7:0]

TAP

Single ended TAP Input TCK, TDI, TMS, TRST#

Single ended GTL Output TDO

Control Sideband

Single ended Asynchronous GTL Output PRDY#

Single ended Asynchronous GTL Input PREQ#

Single ended GTL Bi-directional CAT_ERR#, BPM#[7:0]

Single Ended Asynchronous Bi-directional PECI

Single Ended Analog Input COMP0, QPI_CMP[0], DDR_COMP[2:0]

Single ended

Single ended Asynchronous GTL Output THERMTRIP#

Single ended CMOS Input/Output

Asynchronous GTL Bidirectional

DDR{0/1/2}_RAS#, DDR{0/1/2}_CAS#,

DDR{0/1/2}_WE#, DDR{0/1/2}_MA[15:0],

DDR{0/1/2}_BA[2:0]

DDR{0/1/2}_CS#[5:4], DDR{0/1/2}_CS#[1:0],

DDR{0/1/2}_ODT[3:0], DDR{0/1/2}_CKE[3:0]

PROCHOT#

VID[7:6]

VID[5:3]/CSC[2:0]

VID[2:0]/MSID[2:0]

VTT_VID[4:2]

Datasheet, Volume 1 19

Page 20

Notes:

Table 2-3. Signal Groups (Sheet 2 of 2)

Signal Group Type Signals

Single ended CMOS Output VTT_VID[4:2]

Single ended Analog Input ISENSE

Reset Signal

Single ended Reset Input RESET#

PWRGOOD Signals

Single ended Asynchronous Input VCCPWRGOOD, VTTPWRGOOD, VDDPWRGOOD

Power/Other

Power VCC, VTTA, VTTD, VCCPLL, VDDQ

Asynchronous CMOS Output PSI#

Sense Points VCC_SENSE, VSS_SENSE

Other SKTOCC#, DBR#

1. Refer to Chapter 5 for signal descriptions.

2. DDR{0/1/2} refers to DDR3 Channel 0, DDR3 Channel 1, and DDR3 Channel 2.

Electrical Specifications

1,2

Table 2-4. S ignals with ODT

• Q PI_DRX_ DP[19:0], QPI_DRX_DN[19:0], QPI_DTX_DP[19:0], QPI_DTX_DN[19:0], QPI_CLKRX_D[N/P],

QPI_CLKTX_D[N/P]

• D DR{0/1/2}_DQ[63:0], DDR{0/1/2}_DQS_[N/P][7:0], DDR{0/1/2}_PAR_ERR#[0:2], VDDPWRGOOD

• BCLK_ITP_D[N/P]

•PECI

• BPM#[7:0], PREQ#, TRST#, VCCPWRGOOD, VTTPWRGOOD

Note:

1. Unless otherwise specified, signals have ODT in the package with 50 pulldown to V

2. PREQ#, BPM[7:0], TDI, TMS and BCLK_ITP_D[N/P] have ODT in package with 35 pullup to V

3. VCCPWRGOOD, VDDPWRGOOD, and VTTPWRGOOD have ODT in package with a 10 k to 20 k pulldown

4. TRST# has ODT in package with a 1 k to 5 k pullup to V

5. All DDR signals are terminated to VDDQ/2

6. DDR{0/1/2} refers to DDR3 Channel 0, DDR3 Channel 1, and DDR3 Channel 2.

7. While TMS and TDI do not have On-Die Termination, these signals are weakly pulled up using a 1–5 k

8. While TCK does not have On-Die Termination, this signal is weakly pulled down using a 1–5 kresistor to

.

to V

SS

resistor to V

V

.

SS

.

TT

TT

All Control Sideband Asynchronous signals are required to be asserted/de-asserted for

at least eight BCLKs for the processor to recognize the proper signal state. See

Section 2.11 for the DC specifications. See Chapter 6 for additional timing

requirements for entering and leaving the low power states.

2.8 Test Access Port (TAP) Connection

Due to the voltage levels supported by other components in the Test Access Port (TAP)

logic, it is recommended that the processor be first in the TAP chain and followed by

any other components within the system. A translation buffer should be used to

connect to the rest of the chain unless one of the other components is capable of

accepting an input of the appropriate voltage. Two copies of each signal may be

required with each driving a different voltage level.

.

SS

.

TT

20 Datasheet, Volume 1

Page 21

Electrical Specifications

2.9 Platform Environmental Control Interface (PECI) DC Specifications

PECI is an Intel proprietary interface that provides a communication channel between

Intel processors and chipset components to external thermal monitoring devices. The

processor contains a Digital Thermal Sensor (DTS) that reports a relative die

temperature as an offset from Thermal Control Circuit (TCC) activation temperature.

Temperature sensors located throughout the die are implemented as analog-to-digital

converters calibrated at the factory. PECI provides an interface for external devices to

read the DTS temperature for thermal management and fan speed control. More

detailed information may be found in the Platform Environment Control Interface

(PECI) Specification.

2.9.1 DC Characteristics

The PECI interface operates at a nominal voltage set by V

specifications shown in Table 2-5 is used with devices normally operating from a V

interface supply . V

nominal levels will vary between processor families. All PECI

TTD

devices will operate at the V

system. For specific nominal V

Table 2-5. PECI DC Electrical Limits

Symbol Definition and Conditions Min Max Units Notes

V

V

hysteresis

V

V

I

source

I

sink

I

leak+

I

leak-

C

V

noise

Note:

1. V

2. The leakage specification applies to powered devices on the PECI bus.

Input Voltage Range -0.150 V

in

Hysteresis 0.1 * V

Negative-edge threshold voltage 0.275 * V

n

Positive-edge threshold voltage 0.550 * V

p

High level output source

= 0.75 * V

(V

OH

Low level output sink

= 0.25 * V

(V

OL

High impedance state leakage to V

= VOL)

(V

leak

High impedance leakage to GND

= VOH)

(V

leak

Bus capacitance per node N/A 10 pF

bus

Signal noise immunity above 300 MHz 0.1 * V

supplies the PECI interface. PECI behavior does not affect V

TTD

TTD

TTD

. The set of DC electrical

TTD

level determined by the processor installed in the

TTD

levels, refer to Table 2-7.

TTD

V

TTD

TTD

TTD

TTD

)

)

TTD

-6.0 N/A mA

0.5 1.0 mA

N/A 100 µA 2

N/A 100 µA 2

TTD

TTD

N/A V

0.500 * V

0.725 * V

min/max specifications.

TTD

TTD

N/A V

V

V

p-p

TTD

1

Datasheet, Volume 1 21

Page 22

2.9.2 Input Device Hysteresis

Minimum V

P

Maximum V

P

Minimum V

N

Maximum V

N

PECI High Range

PECI Low Range

Valid Input

Signal Range

Minimum

Hysteresis

V

TTD

PECI Ground

The input buffers in both client and host models must use a Schmitt-triggered input

design for improved noise immunity. Use Figure 2-2 as a guide for input buffer design.

Figure 2-2. Input Device Hysteresis

Electrical Specifications

2.10 Absolute Maximum and Minimum Ratings

Table 2-6 specifies absolute maximum and minimum ratings, which lie outside the

functional limits of the processor. Only within specified operation limits can functionality

and long-term reliability be expected.

At conditions outside functional operation condition limits, but within absolute

maximum and minimum ratings, neither functionality nor long-term reliability can be

expected. If a device is returned to conditions within functional operation limits after

having been subjected to conditions outside these limits, but within the absolute

maximum and minimum ratings, the device may be functional, but with its lifetime

degraded depending on exposure to conditions exceeding the functional operation

condition limits.

At conditions exceeding absolute maximum and minimum ratings, neither functionality

nor l ong-term reliability can be expected. Moreover, if a device is subjected to these

conditions for any length of time then, when returned to conditions within the

functional operating condition limits, it will either not function or its reliability will be

severely degraded.

Although the processor contains protective circuitry to resist damage from ElectroStatic Discharge (ESD), precautions should always be taken to avoid high static

voltages or electric fields.

22 Datasheet, Volume 1

Page 23

Electrical Specifications

.

Table 2-6. Processor Absolute Minimum and Maximum Ratings

Symbol Parameter Min Max Unit Notes

V

CC

V

TTA

V

TTD

V

DDQ

V

CCPLL

T

CASE

T

STORAGE

Notes:

1. For functional ope ratio n, all processor electri cal, signal quality, mechanical and thermal specifications must

be satisfied.

2. Excessive overshoot or undershoot on any signal will likely result in permanent damage to the processor.

3. V

Processor Core voltage with respect to V

Voltage for the analog portion of the integrated

memory controller, QPI link and Shared Cache

with respect to V

Voltage for the digital portion of the integrated

memory controller, QPI link and Shared Cache

with respect to V

Processor I/O supply voltage for DDR3 with

respect to V

Processor PLL voltage with respect to V

Processor case temperature See

Storage temperature See

TTA

and V

should be derived from the same VR.

TTD

SS

SS

SS

SS

SS

-0.3 1.4 V

-0.3 1.4 V 3

-0.3 1.4 V 3

-0.3 1.8 V

-0.3 2.0 V

Chapter 6

Chapter 6

See

Chapter 6

See

Chapter 6

1, 2

C

C

2.11 Processor DC Specifications

The processor DC specifications in this section are defined at the processor

pads, unless noted otherwise. See Chapter 4 for the processor land listings and

Chapter 5 for signal definitions. Voltage and current specifications are detailed in

Table 2-7. For platform planning, refer to Table 2-8 that provides V

transient tolerances. This same information is presented graphically in Figure 2-3.

The DC specifications for the DDR3 signals are listed in Table 2-11. Control Sideband

and Test Access Port (TAP) are listed in Table 2-12 through Table 2-15.

Table 2-7 through Table 2-15 list the DC specifications for the processor and are valid

only while meeting specifications for case temperature (T

“Thermal Specifications”), clock frequency, and input voltages. Care should be taken to

read all notes associated with each parameter.

static and

CC

as specified in Chapter 6,

CASE

Datasheet, Volume 1 23

Page 24

2.11.1 DC Voltage and Current Specification

Notes:

Table 2-7. V oltage and Curre nt Specificat ions

Symbol Parameter Min Typ Max Unit Notes

VID VID range 0.8 1.375 V

V

for processor core

CC

3.46 GHz

3.33 GHz

3.33 GHz

3.20 GHz

for processor

I

CC

3.46 GHz

3.33 GHz

3.33 GHz

3.20 GHz

See Table 2-8 and Figure 2-3 V

See Table 2-10 and Figure 2-4 V

See Table 2-9 and Figure 2-4 V5

1.71 1.8 1.89 V

——

——5A

——23A

——1A

V

CC

V

TTA

V

TTD

V

DDQ

V

CCPLL

I

CC

I

TTA

I

TTD

I

DDQ

I

S3

DDQ

I

CC_VCCPLL

Processor

Number

i7-990X

i7-980X

i7-980

i7-970

Voltage for the analog portion of the

integrated memory controller, QPI link

and Shared Cache

Voltage for the digital portion of the

integrated memory controller, QPI link

and Shared Cache

Processor I/O supply voltage for DDR3 1.425 1.5 1.575 V

PLL supply voltage (DC + AC

specification)

Processor

Number

i7-990X

i7-980X

i7-980

i7-970

Current for the analog portion of the

integrated memory controller, QPI link

and Shared Cache

Current for the digital portion of the

integrated memory controller, QPI link

and Shared Cache

Processor I/O supply current for DDR3 — — 6 A

Processor I/O supply current for DDR3

while in S3

PLL supply current (DC + AC specification) — — 1.1 A

Electrical Specifications

1

2

3,4

5

145

145

A

6

145

145

7

1. Unless otherwise noted, all specifications in this table are based on estimates and simulations or empirical

data. These specifications will be updated with characterized data from silicon measurements at a later date

2. Each processor is programmed with a maximum valid voltage identification value (VID), which is set at

manufacturing and can not be altered. Individual maximum VID values are calibr ated during manufacturing

such that two processors at the same frequency may have different settings wit hin the VID range. Not e that

this differs from the VID employed by the processor during a power management event (Adaptive Thermal

Monitor, Enhanced Intel SpeedStep

3. The voltage specification requirements are measured across VCC_SENSE and VSS_SENSE lands at the

socket with a 100 MHz bandwidth oscilloscope, 1.5 pF maximum probe capacitance, and 1 M minimum

impedance. The maximum length of ground wire on the probe should be less than 5 mm. Ensure external

noise from the system is not coupled into the oscilloscope probe.

4. Refer to Table 2-8 and Figure 2-3 for the minimum, typical, and maximum V

processor should not be subjected to any V

5. See Table 2-9 for details on VTT Voltage Identification. See Table 2-10 and Figure 2-4 for details on the VTT

Loadline

6. I

7. This specification is based on a processor temperature, as reported by the DTS, of less than or equal to

specification is based on the V

CC_MAX

CONTROL

–25.

T

®

Technology, or Low Power States).

and ICC combination wherein VCC exceeds V

CC

loadline. Refer to Figure 2-3 for details.

CC_MAX

allowed for a given current. The

CC

CC_MAX

for a given current.

24 Datasheet, Volume 1

Page 25

Electrical Specifications

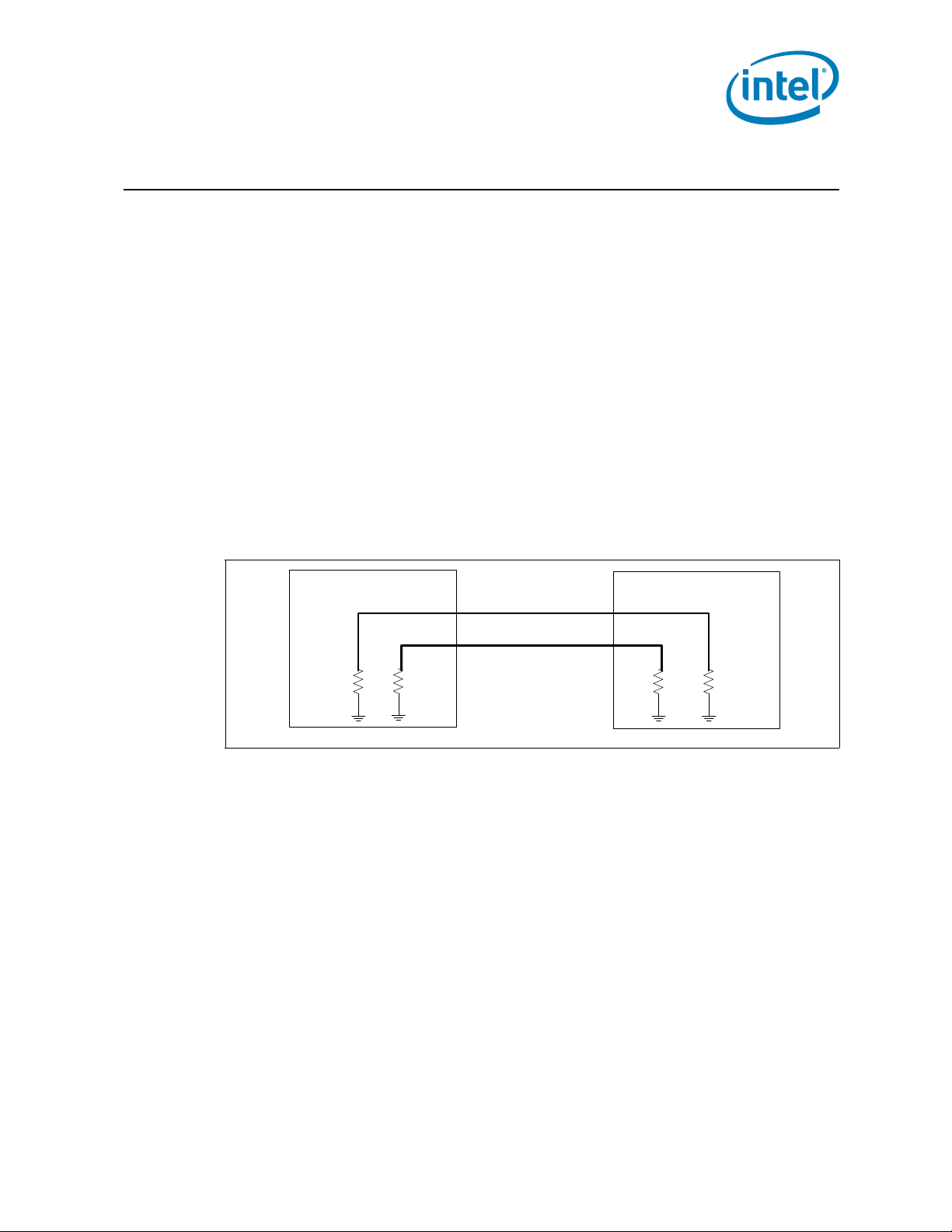

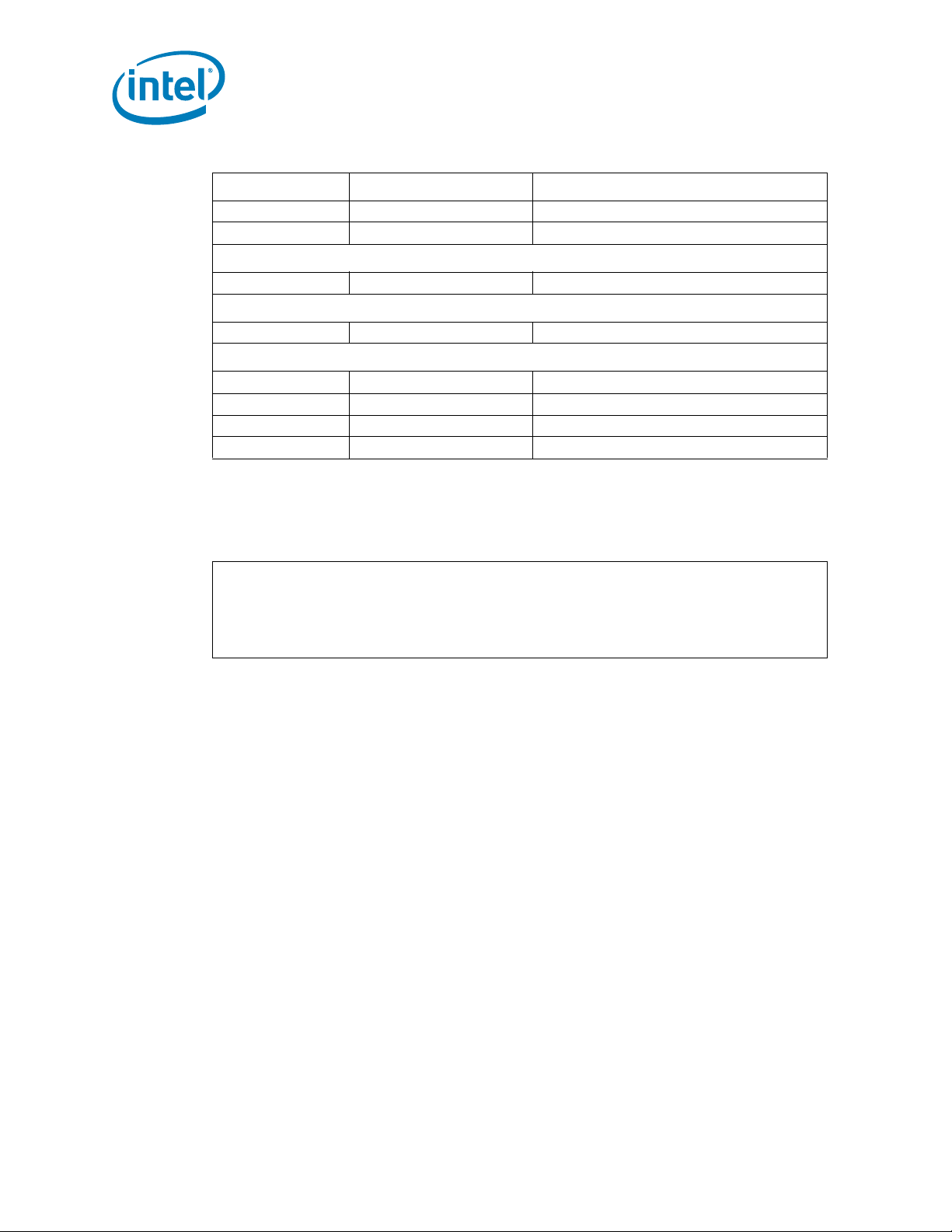

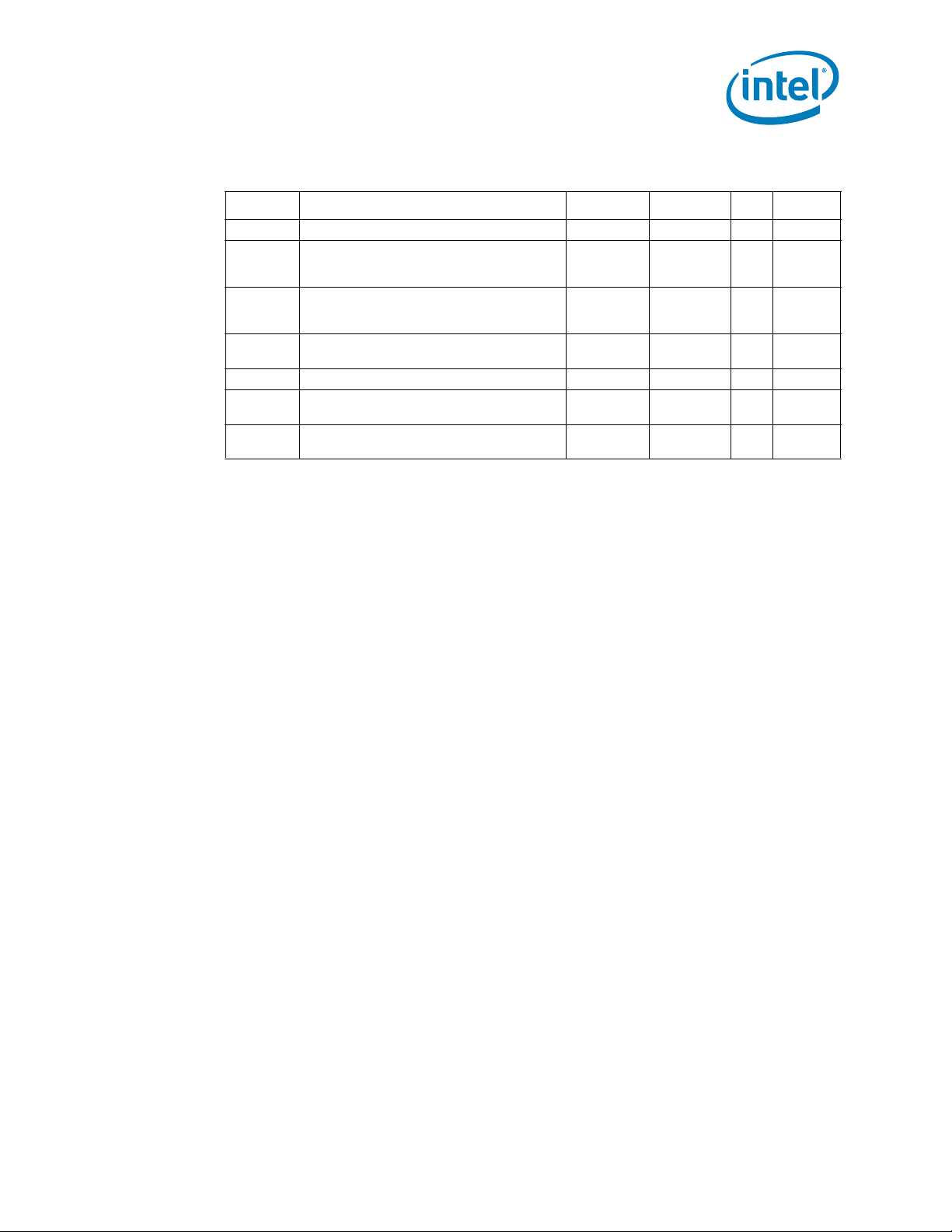

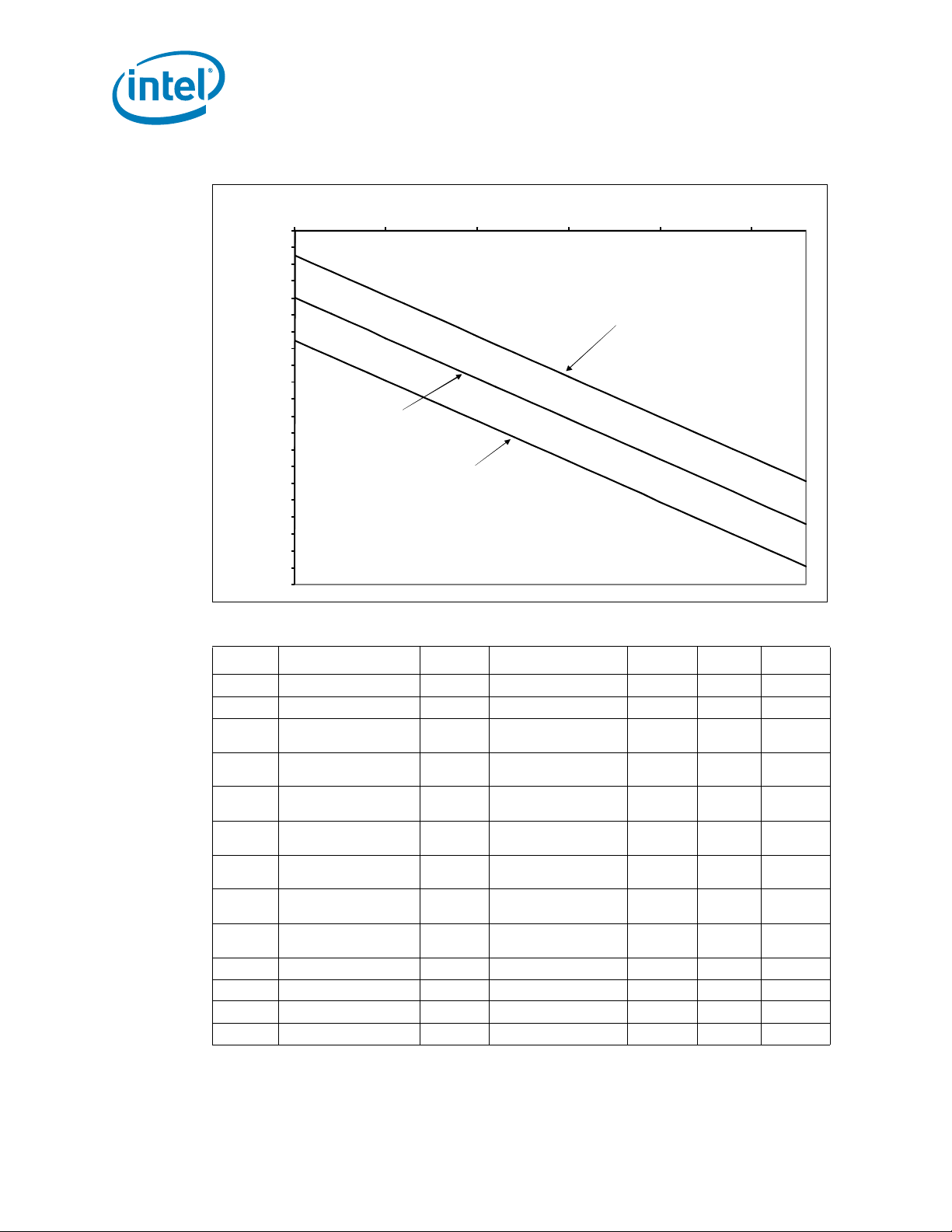

Table 2-8. VCC Static and Transient Tolerance

ICC (A) V

0 VID – 0.000 VID – 0.019 VID – 0.038 1, 2, 3

5 VID – 0.004 VID – 0.023 VID – 0.042 1, 2, 3

10 VID – 0.008 VID – 0.027 VID – 0.046 1, 2, 3

15 VID – 0.012 VID – 0.031 VID – 0.050 1, 2, 3

20 VID – 0.016 VID – 0.035 VID – 0.054 1, 2, 3

25 VID – 0.020 VID – 0.039 VID – 0.058 1, 2, 3

30 VID – 0.024 VID – 0.043 VID – 0.062 1, 2, 3

35 VID – 0.028 VID – 0.047 VID – 0.066 1, 2, 3

40 VID – 0.032 VID – 0.051 VID – 0.070 1, 2, 3

45 VID – 0.036 VID – 0.055 VID – 0.074 1, 2, 3

50 VID – 0.040 VID – 0.059 VID – 0.078 1, 2, 3

55 VID – 0.044 VID – 0.063 VID – 0.082 1, 2, 3

60 VID – 0.048 VID – 0.067 VID – 0.086 1, 2, 3

65 VID – 0.052 VID – 0.071 VID – 0.090 1, 2, 3

70 VID – 0.056 VID – 0.075 VID – 0.094 1, 2, 3

75 VID – 0.060 VID – 0.079 VID – 0.098 1, 2, 3

78 VID – 0.062 VID – 0.081 VID – 0.100 1, 2, 3

85 VID – 0.068 VID – 0.087 VID – 0.106 1, 2, 3

90 VID – 0.072 VID – 0.091 VID – 0.110 1, 2, 3

95 VID – 0.076 VID – 0.095 VID – 0.114 1, 2, 3

100 VID – 0.080 VID – 0.099 VID – 0.118 1, 2, 3

105 VID – 0.084 VID – 0.103 VID – 0.122 1, 2, 3

110 VID – 0.088 VID – 0.107 VID – 0.126 1, 2, 3

115 VID – 0.092 VID – 0.111 VID – 0.130 1, 2, 3

120 VID – 0.096 VID – 0.115 VID – 0.134 1, 2, 3

125 VID – 0.100 VID – 0.119 VID – 0.138 1, 2, 3

130 VID – 0.104 VID – 0.123 VID – 0.142 1, 2, 3

135 VID – 0.108 VID – 0.127 VID – 0.146 1, 2, 3

140 VID – 0.112 VID – 0.131 VID – 0.150 1, 2, 3

(V) V

CC_Max

(V) V

CC_Typ

(V) Notes

CC_Min

Notes:

1. The V

overshoot specifications.

2. This table is intended to aid in reading discrete points on Figure 2-3.

3. The loadlines specify voltage limits at the die measured at the VCC_SENSE and VSS_SE NSE land s. Voltage

regulation feedback for voltage regulator circuits must also be taken from processor VCC_SENSE and

VSS_SENSE lands. Refer to the Voltage Regulator Down (VRD) 11.1 Design Guidelines for socket load line

CC_MIN

and V

loadlines represent static and transient limits. See Section 2.11.2 for VCC

CC_MAX

guidelines and VR implementation.

Datasheet, Volume 1 25

Page 26

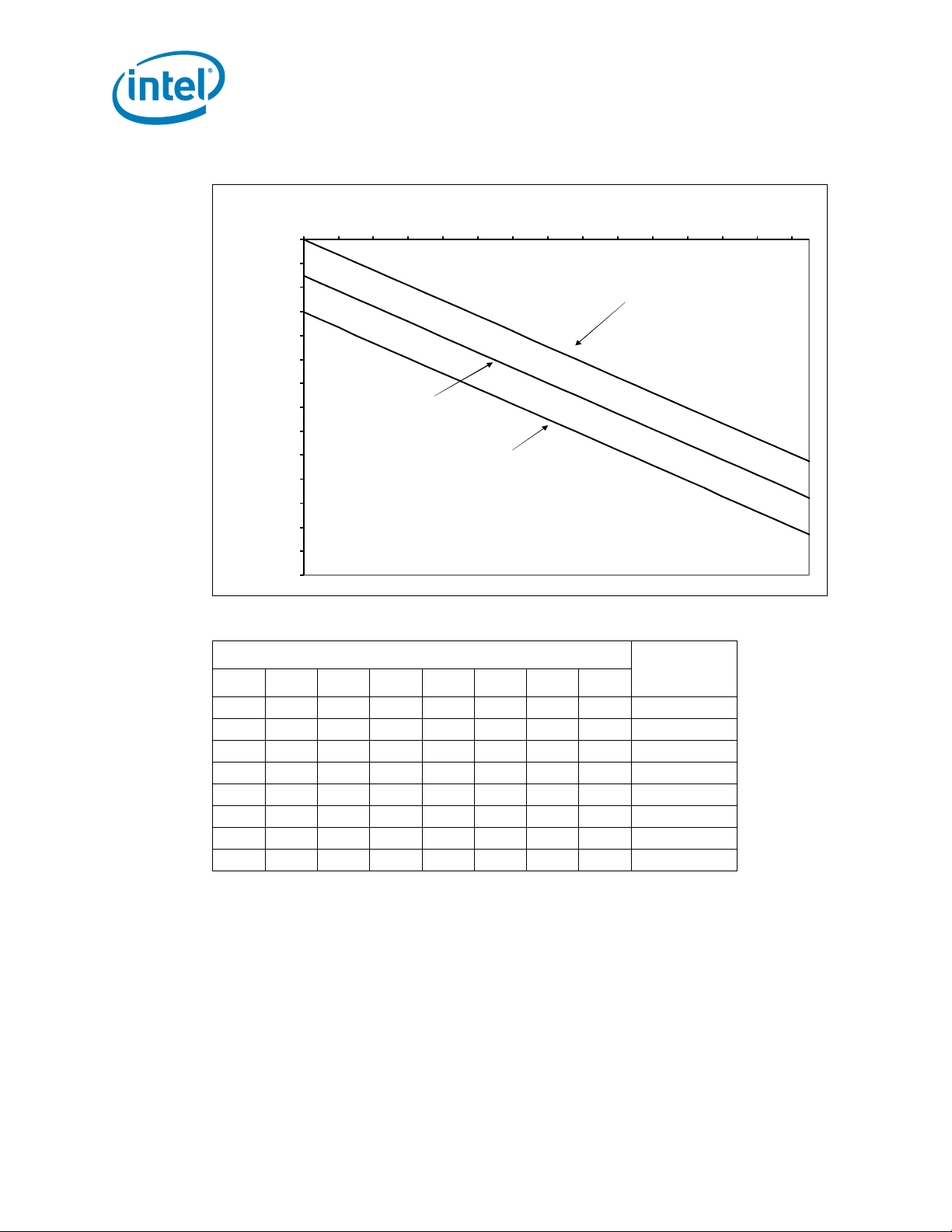

Figure 2-3. VCC Static and Transient Tolerance Load Lines

VID - 0.000

VID - 0.013

VID - 0.025

VID - 0.038

VID - 0.050

VID - 0.063

VID - 0.075

VID - 0.088

VID - 0.100

VID - 0.113

VID - 0.125

VID - 0.138

VID - 0.150

VID - 0.163

VID - 0.175

0 102030405060708090100110120130140

V

c

c

V

Icc [ A ]

Vcc Maximum

Vcc Typica l

Vcc Mini mu m

Electrical Specifications

Table 2-9. VTT Voltage Identification (VID) Definition

VTT VR - VID Input

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0

01000010 1.220V

01000110 1.195V

01001010 1.170V

01001110 1.145V

01010010 1.120V

01010110 1.095V

01011010 1.070V

01011110 1.045V

Notes:

1. The associated voltage with the VTT_VID codes listed in this table do not match the Voltage RegulatorDown (VRD) 11.1 Design Guidelines, they include a +20 mV offset.

2. This is a typical voltage. See Table 2-10 for VTT_Max and VTT_Min voltage.

26 Datasheet, Volume 1

V

TT_Typ

Page 27

Electrical Specifications

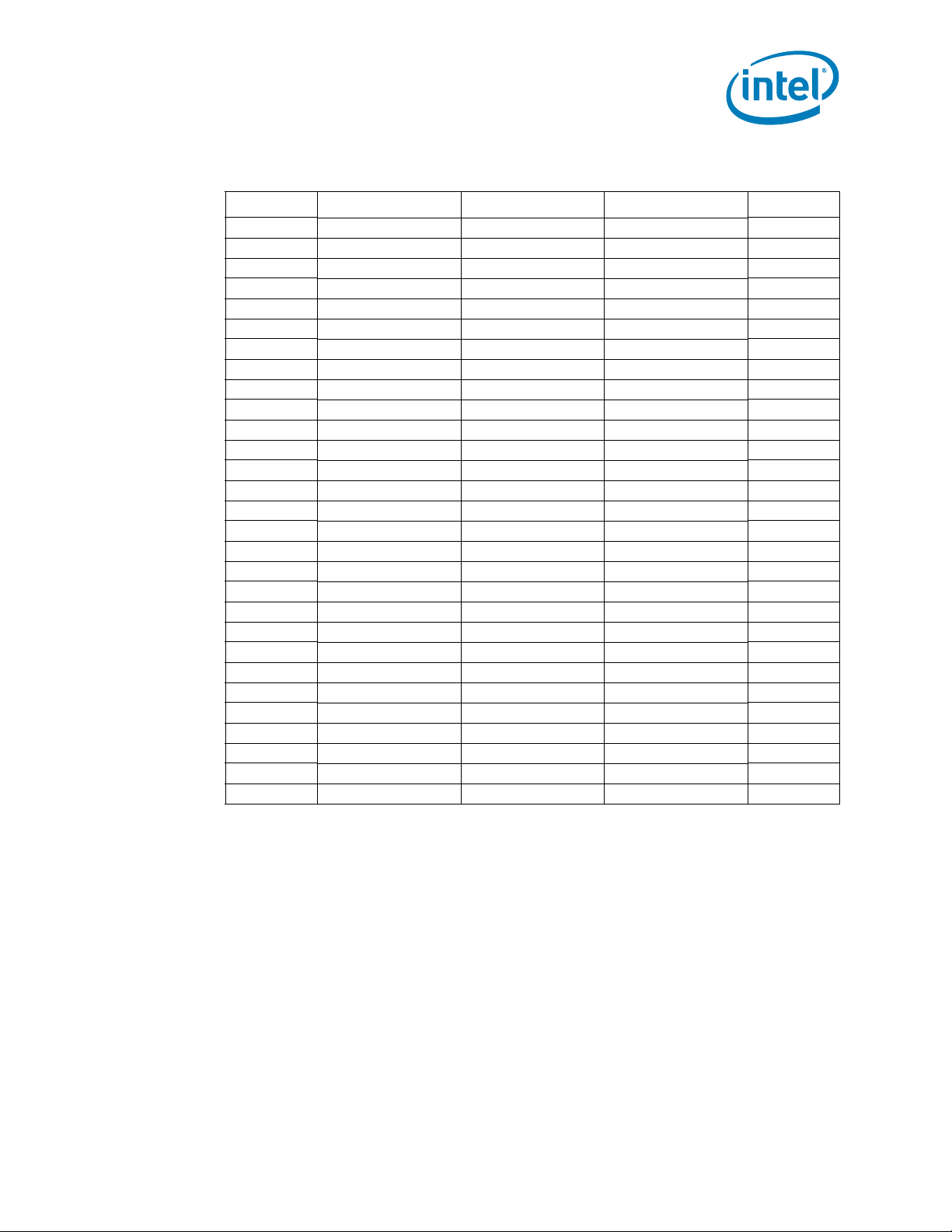

Notes:

Table 2-10. VTT Static and Transient Tolerance

(A) V

I

TT

0 VID + 0.0315 VID – 0.0000 VID – 0.0315

1 VID + 0.0255 VID – 0.0060 VID – 0.0375

2 VID + 0.0195 VID – 0.0120 VID – 0.0435

3 VID + 0.0135 VID – 0.0180 VID – 0.0495

4 VID + 0.0075 VID – 0.0240 VID – 0.0555

5 VID + 0.0015 VID – 0.0300 VID – 0.0615

6 VID – 0.0045 VID – 0.0360 VID – 0.0675

7 VID – 0.0105 VID – 0.0420 VID – 0.0735

8 VID – 0.0165 VID – 0.0480 VID – 0.0795

9 VID – 0.0225 VID – 0.0540 VID – 0.0855

10 VID – 0.0285 VID – 0.0600 VID – 0.0915

11 VID – 0.0345 VID – 0.0660 VID – 0.0975

12 VID – 0.0405 VID – 0.0720 VID – 0.1035

13 VID – 0.0465 VID – 0.0780 VID – 0.1095

14 VID – 0.0525 VID – 0.0840 VID – 0.1155

15 VID – 0.0585 VID – 0.0900 VID – 0.1215

16 VID – 0.0645 VID – 0.0960 VID – 0.1275

17 VID – 0.0705 VID – 0.1020 VID – 0.1335

18 VID – 0.0765 VID – 0.1080 VID – 0.1395

19 VID – 0.0825 VID – 0.1140 VID – 0.1455

20 VID – 0.0885 VID – 0.1200 VID – 0.1515

21 VID – 0.0945 VID – 0.1260 VID – 0.1575

22 VID – 0.1005 VID – 0.1320 VID – 0.1635

23 VID – 0.1065 VID – 0.1380 VID – 0.1695

24 VID – 0.1125 VID – 0.1440 VID – 0.1755

25 VID – 0.1185 VID – 0.1500 VID – 0.1815

26 VID – 0.1245 VID – 0.1560 VID – 0.1875

27 VID – 0.1305 VID – 0.1620 VID – 0.1935

28 VID – 0.1365 VID – 0.1680 VID – 0.1995

(V) V

TT_Max

1

(V) V

TT_Typ

(V) Notes

TT_Min

1. The ITT listed in this table is a sum of I

2. The loadlines specify voltage limits at the die measured at the VTT_SENSE and VSS_SENSE_VTT lands. Voltage

regulation feedback for voltage regulator circuits must also be taken from the processor VTT_SENSE and

TTA

and I

TTD

.

VSS_SENSE_VTT lands.

Datasheet, Volume 1 27

Page 28

Figure 2-4. VTT Static and Transient Tolerance Load Line

-0.2125

-0.2000

-0.1875

-0.1750

-0.1625

-0.1500

-0.1375

-0.1250

-0.1125

-0.1000

-0.0875

-0.0750

-0.0625

-0.0500

-0.0375

-0.0250

-0.0125

0.0000

0.0125

0.0250

0.0375

0.0500

0 5 10 15 20 25

V

t

t

V

Itt [A] (sum of Itta and Ittd)

Vtt Maximum

Vtt Typical

Vtt Mini mu m

Electrical Specifications

Table 2-11. D DR3 Signal Group DC Specificati ons

Symbol Parameter Min Typ Max Units Notes

V

Input Low Voltage — — 0.43*V

IL

V

Input High Voltage 0.57*V

IH

V

V

R

R

28 Datasheet, Volume 1

R

R

R

DDR_COMP0

DDR_COMP1

DDR_COMP2

Notes:

1. Unless otherwise noted, all specifications in this table apply to all processor frequencies.

2. V

Output Low Voltage

OL

Output High Voltage

OH

DDR3 Clock Buffer On

ON

Resistance

DDR3 Command Buffer

ON

ON

ON

ON

I

LI

On Resistance

DDR3 Reset Buffer On

Resistance

DDR3 Control Buffer On

Resistance

DDR3 Data Buffer On

Resistance

Input Leakage Current N/A N/A ± 1 mA

COMP Resistance 99 100 101 5

COMP Resistance 24.65 24.9 25.15 5

COMP Resistance 128.7 130 131.30 5

is defined as the maximum voltage level at a receiving agent that will be interpreted as a logical low

IL

value.

DDQ

—

—

V

(R

21 — 31 7

16 — 24

25 — 75

21 — 31

21 — 33

——V3

(V

/ 2)* (R

DDQ

(R

ON+RVTT_TERM

– ((V

DDQ

/(RON+R

ON

ON

/ 2)*

DDQ

VTT_TERM

/

))

))

DDQ

—V

—V4

V2,4

1

Page 29

Electrical Specifications

3. VIH is defined as the minimum voltage level at a receiving agent that will be interpreted as a logical high

value.

and VOH may experience excursions above V

4. V

IH

signal quality specifications.

5. COMP resistance must be provided on the system board with 1% resistors. DDR_COMP[2:0] resistors are

to V

6. This is the pull down driver resistance.

SS

Table 2-12. RESET# Signal DC Specifications

Symbol Parameter Min Typ Max Units Notes

V

Input Low Voltage — — 0.40 * V

IL

V

Input High Voltage 0.80 * V

IH

I

Input Leakage Current — — ± 200 A3

LI

Notes:

1. Unless otherwise noted, all specifications in this table apply to all processor frequencies.

2. The V

3. For Vin between 0 V and V

4. V

referred to in these specifications refers to instantaneous V

TTA

and VOH may experience excursions above VTT.

IH

. Measured when the driver is tristated.

TTA

Table 2-13. TAP Signal Group DC Specifications

Symbol Parameter Min Typ Max Units Notes

V

Input Low Voltage — — 0.40 * V

IL

V

Input High Voltage 0.75 * V

IH

V

V

Ron Buffer on Resistance 10 — 18

Notes:

1. Unless otherwise noted, all specifications in this table apply to all processor frequencies.

2. The V

3. For Vin between 0 V and V

4. V

Output Low Voltage

OL

Output High Voltage V

OH

I

Input Leakage Current — — ± 200 A3

LI

referred to in these specifications refers to instantaneous V

TTA

and VOH may experience excursions above VTT.

IH

. Measured when the driver is tristated.

TTA

——

TTA

. However, input signal drivers must comply with the

DDQ

V2

V2

V

)

TTA

TTA

TTA

——V2,4

.

TTA

TTA

——V2,4

V

* RON /

TTA

+ R

(R

ON

sys_term

——V2,4

.

TTA

1

1

2

Datasheet, Volume 1 29

Page 30

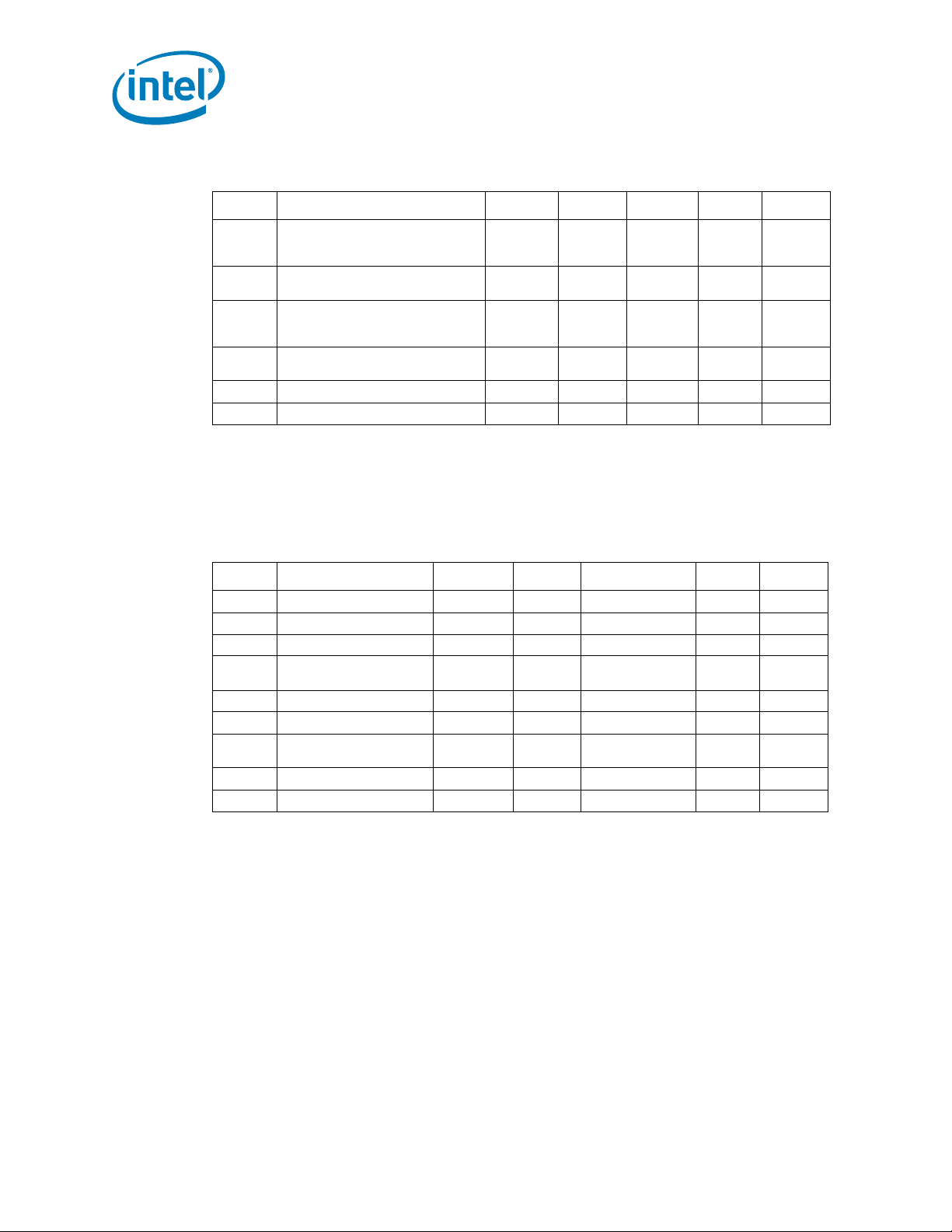

Table 2-14. P WRG OOD Signal Group DC Specificati ons

Symbol Parameter Min Typ Max Units Notes

Input Low Voltage for

V

VCCPWRGOOD and VTTPWRGOOD

IL

Signals

Input Low Voltage for

V

IL

VDDPWRGOOD Signal

Input High Voltage for

VCCPWRGOOD and VTTPWRGOOD

V

IH

Signals

Input High Voltage for

V

IH

VDDPWRGOOD Signal

Ron Buffer on Resistance 10 — 18

I

Input Leakage Current — — ± 200 A3

LI

Notes:

1. Unless otherwise noted, all specifications in this table apply to all processor frequencies.

2. The V

3. For Vin between 0 V and V

4. V

5. This specification applies to VCCPWRGOOD and VTTPWRGOOD

6. This specification applies to VDDPWRGOOD

referred to in these specifications refers to instantaneous V

TTA

and VOH may experience excursions above VTT.

IH

. Measured when the driver is tristated.

TTA

— — 0.25 * V

— — 0.29 V 6

0.75 * V

0.87

TTA

Electrical Specifications

1

TTA

V2,5

——V2,5

——V6

.

TTA

Table 2-15. Control Sideband Signal Group DC Specifications

Symbol Parameter Min Typ Max Units Notes

V

Input Low Voltage — — 0.64 * V

IL

V

Input Low Voltage — — 0.61 * V

IL

V

Input High Voltage 0.76 * V

IH

V

V

Output Low Voltage

OL

Output High Voltage V

OH

TTA

——

TTA

Ron Buffer on Resistance 10 — 18

Ron

Buffer on Resistance for

VID[7:0]

I

Input Leakage Current — — ± 200 A3

LI

—100 —

COMP0 COMP Resistance 49.4 49.9 50.40 5

Notes:

1. Unless otherwise noted, all specifications in this table apply to all processor frequencies.

2. The V

3. For Vin between 0 V and V

4. V

5. COMP resistance must be provided on the system board with 1% resistors. COMP0 resistors are to V

referred to in these specifications refers to instantaneous V

TTA

and VOH may experience excursions above VTT.

IH

. Measured when the driver is tristated.

TTA

——V2

——V2,4

V

* RON / (RON

TTA

+ R

sys_term

TTA

1

TTA

TTA

)

V2

V2

V2,4

.

.

SS

30 Datasheet, Volume 1

Page 31

Electrical Specifications

Time

Example Overshoot Waveform

Voltage (V)

VID

VID + V

OS

T

OS

V

OS

TOS: Overshoot time above VID

V

OS

: Overshoot above VID

2.11.2 VCC Overshoot Specification

The processor can tolerate short transient overshoot events where VCC exceeds the VID

voltage when transitioning from a high-to-low current load condition. This overshoot

cannot exceed VID + V

OS_MAX

VID). These specifications apply to the processor die voltage as measured across the

VCC_SENSE and VSS_SENSE lands.

(V

OS_MAX

is the maximum allowable overshoot above

Table 2-16. V

Overshoot Specifications

CC

Symbol Parameter Min Max Units Figure Notes

V

OS_MAX

T

OS_MAX

Magnitude of V

Time duration of V

CCP

overshoot above VID — 50 mV 2-5

overshoot above VID — 25 µs 2-5

CCP

Figure 2-5. VCC Overshoot Example Waveform

2.11.3 Die Voltage Validation

Core voltage (VCC) overshoot events at the processor must meet the specifications in

Table 2-16 when measured across the VCC_SENSE and VSS_SENSE lands. Overshoot

events that are < 10 ns in duration may be ignored. These measurements of processor

die level overshoot should be taken with a 100 MHz bandwidth limited oscilloscope.

Datasheet, Volume 1 31

Page 32

Electrical Specifications

Notes:

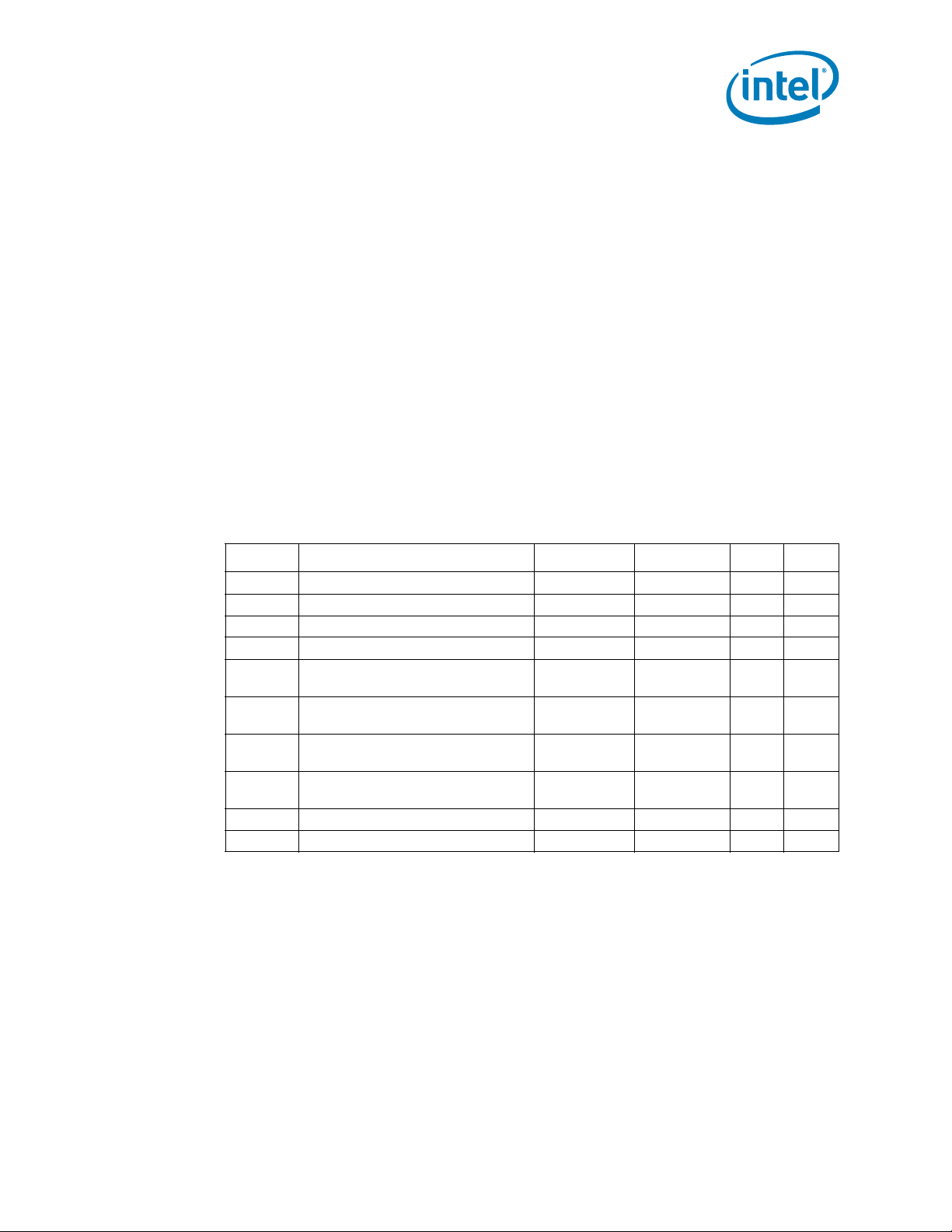

2.12 Intel® QuickPath Interconnect (Intel® QPI) Specifications

The processor Intel QPI specifications in this section are defined at the processor pins.

Routing topologies are dependent on the processors supported and the chipset used in

the design. In most cases, termination resistors are not required as these are

integrated into the processor silicon.

Table 2-17. Intel

®

QuickPath Interconnect (Intel QPI) Specifications

Symbol Parameter Min Nom Max Unit Notes

UIavg

T

slew-rise-fall-pin

Average UI size at “x” GT/s

(Where x= 4.8 GT/s, 6.4 GT/s, etc.)

Defined as the slope of the rising or

falling waveform as measured between

±100 mV of the differential transmitter

output, for any data or clock.

0.999 *

nominal

1000/f

1.001 *

nominal

10 — 25 V / nsec

psec

Defined as:

Z

TX_LOW_CM_DC

± (max(Z

min(Z

expressed in%, over full range of Tx

TX_LOW_CM_DC

TX_LOW_CM_DC)) /ZTX_LOW_CM_DC

) –

-6 0 6

% of

Z

TX_LOW_CM_DC

single ended voltage

Z

RX_LOW_CM_DC

Defined as: ±(max(Z

min(Z

TX_LOW_CM_DC)) /ZTX_LOW_CM_DC

expressed in%, over full range of Tx

single ended voltage

TX_LOW_CM_DC

) –

-6 0 6

% of

Z

TX_LOW_CM_DC

# of UI over which the ey e mask voltage

N

MIN-UI-Validation

Z

TX_HIGH_CM_DC

Z

RX_HIGH_CM_DC

Z

TX_LINK_DETECT

T

Refclk-Tx-Variability

L

D+/D-RX-Skew

T

CLK_DET

T

CLK_FREQ_DET

BER

Lane

TX

EQ-error

and timing specification needs to be

validated

Single ended DC impedance to GND for

either D+ or D- of any data bit at Tx

Single ended DC impedance to GND for

either D+ or D- of any data bit at Tx

Link Detection Resistor

Phase variability between reference Clk

(at Tx input) and Tx output.

Phase skew between D+ and D- lines for

any data bit at Rx

Time taken by clock detector to observe

clock stability

Time taken by clock frequency detector

to decide slow vs operational clock after

stable clock

Bit Error Rate per lane valid for 4.8 GT/s

and 6.4 GT/s

% error in Tx equalization setting as

measured by errors in DC levels when

sending a steady “1”.

1,000,000 ——