Page 1

Intel® Xeon® Processor 3500 Series

Thermal / Mechanical Design Guide

March 2009

Document Number: 321461-001

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED,

BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS

PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER,

AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING T O SALE AND/OR USE OF INTEL PRODUCT S INCLUDING

LIABILITY OR WARRANTIES RELA TING T O FITNES S FOR A PARTICULAR PURPOSE, MERCHANT ABILITY, OR INFRINGEMENT OF ANY

PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life savin g, or

life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel

reserves these for future definition and shall have no responsibility whatsoev er for conflicts or incompatibilities arising from future

changes to them.

The Intel® Xeon® Processor 3500 Series and LGA1366 socket may contain design defects or errors known as errata which may

cause the product to deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Intel, the Intel logo, Intel, Pentium, Core and Core Inside are trademarks of Intel Corporation in the U.S. and other countries.

* Other brands and names may be claimed as the property of others.

Copyright © 2009, Intel Corporation.

2 Thermal and Mechanical Design Guide

Page 3

Contents

1Introduction..............................................................................................................7

1.1 References.........................................................................................................8

1.2 Definition of Terms..............................................................................................8

2 LGA1366 Socket ......................................................................................................11

2.1 Board Layout....................................................................................................13

2.2 Attachment to Motherboard................................................................................14

2.3 Socket Components...........................................................................................14

2.3.1 Socket Body Housing..............................................................................14

2.3.2 Solder Balls...........................................................................................14

2.3.3 Contacts ...............................................................................................15

2.3.4 Pick and Place Cover...............................................................................15

2.4 Package Installation / Removal ......... ..................................................................16

2.4.1 Socket Standoffs and Package Seating Plane..............................................16

2.5 Durability.........................................................................................................17

2.6 Markings..........................................................................................................17

2.7 Component Insertion Forces ...............................................................................17

2.8 Socket Size ......................................................................................................17

2.9 LGA1366 Socket NCTF Solder Joints.....................................................................18

3 Independent Loading Mechanism (ILM)...................................................................19

3.1 Design Concept.................................................................................................19

3.1.1 ILM Cover Assembly Design Overview.......................................................19

3.1.2 ILM Back Plate Design Overview...............................................................20

3.2 Assembly of ILM to a Motherboard.......................................................................20

4 LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications .23

4.1 Component Mass...............................................................................................23

4.2 Package/Socket Stackup Height ..........................................................................23

4.3 Socket Maximum Temperature............................................................................23

4.4 Loading Specifications.................................... .. .. .. ......................... .. .. .................24

4.5 Electrical Requirements......................................................................................24

4.6 Environmental Requirements .................................................................. ............25

5 Sensor Based Thermal Specification Design Guidance..............................................27

5.1 Sensor Based Specification Overview...................................................................27

5.2 Sensor Based Thermal Specification.....................................................................28

5.2.1 TTV Thermal Profile................................................................................28

5.2.2 Specification When DTS value is Greater than TCONTROL ............................29

5.3 Thermal Solution Design Process.........................................................................30

5.3.1 Boundary Condition Definition..................................................................30

5.3.2 Thermal Design and Modelling.................................................................. 31

5.3.3 Thermal Solution Validation.....................................................................32

5.4 Fan Speed Control (FSC) Design Process..............................................................33

5.4.1 Fan Speed Control Algorithm without TAMBIENT Data .................................34

5.4.2 Fan Speed Control Algorithm with TAMBIENT Data......................................35

5.5 System Validation .............................................................................................36

5.6 Specification for Operation Where Digital Thermal Sensor Exceeds TCONTROL.... .......37

6 ATX Reference Thermal Solution..............................................................................39

6.1 Operating Environment............................... ... .. .. ................................................39

6.2 Heatsink Thermal Solution Assembly....................................................................40

6.3 Geometric Envelope for the Intel

6.4 Reference Design Components................................................... .. .. .....................42

®

Reference ATX Thermal Mechanical Design ...........41

Thermal and Mechanical Design Guide 3

Page 4

6.4.1 Extrusion...............................................................................................42

6.4.2 Clip.......................................................................................................43

6.4.3 Core .....................................................................................................44

6.5 Mechanical Interface to the Reference Attach Mechanism ........................................44

6.6 Heatsink Mass and Center of Gravity....................................................................46

6.7 Thermal Interface Material.............................................................................. .. ..46

6.8 Absolute Processor Temperature..........................................................................46

7 Thermal Solution Quality and Reliability Requirements ............................................47

7.1 Reference Heatsink Thermal Verification ...............................................................47

7.2 Mechanical Environmental Testing........................................................................47

7.2.1 Recommended Test Sequence ..................................................................47

7.2.2 Post-Test Pass Criteria.............................................................................48

7.2.3 Recommended BIOS/Processor/Memory Test Procedures .............................48

7.3 Material and Recycling Requirements....................................................................48

A Component Suppliers...............................................................................................49

B Mechanical Drawings ...............................................................................................51

C Socket Mechanical Drawings....................................................................................65

D Processor Installation Tool ......................................................................................71

Figures

1-1 Processor Thermal Solution & LGA1366 Socket Stack.................................................... 7

2-1 LGA1366 Socket with Pick and Place Cover Removed ......................................... .. ........11

2-2 LGA1366 Socket Contact Numbering (Top View of Socket)............................................12

2-3 LGA1366 Socket Land Pattern (Top View of Board) ......................................................13

2-4 Attachment to Motherboard.................................................... ... .. ........................... ..14

2-5 Pick and Place Cover................................................................................................15

2-6 Package Installation / Removal Features .... ................................................................16

2-7 LGA1366 NCTF Solder Joints.....................................................................................18

3-1 ILM Cover Assembly................................................................................................20

3-2 ILM Assembly.........................................................................................................21

3-3 Pin1 and ILM Lever..................................................................................................22

4-1 Flow Chart of Knowledge-Based Reliability Evaluation Methodology ................................26

5-1 Comparison of Case Temperature vs. Sensor Based Specification...................................28

5-2 Thermal Profile ..................... .. ........................... ... .. ........................... .. .. .. ...............29

5-3 Thermal solution Performance...................................................................................30

5-4 Required YCA for various TAMBIENT Conditions...................................... .. ...................31

5-5 Thermal Solution Performance vs. Fan Speed..............................................................33

5-6 Fan Response Without TAMBIENT Data.......................................................................34

5-7 Fan Response with TAMBIENT Aware FSC...................................................................35

6-1 ATX Heatsink Reference Design Assembly...................................................................40

6-2 ATX KOZ 3-D Model Primary (Top) Side......................................................................41

6-3 RCBF5 Extrusion .....................................................................................................42

6-4 RCBF5 Clip.............................................................................................................43

6-5 Core......................................................................................................................44

6-6 Clip Core and Extrusion Assembly..............................................................................45

6-7 Critical Parameters for Interface to the Reference Clip..................................................45

6-8 Critical Core Dimensions ..........................................................................................46

B-1 Socket / Heatsink / ILM Keepout Zone Primary Side (Top)............................................52

B-2 Socket / Heatsink / ILM Keepout Zone Secondary Side (Bottom) ...................................53

B-3 Socket / Processor / ILM Keepout Zone Primary Side (Top)...........................................54

B-4 Socket / Processor / ILM Keepout Zone Secondary Side (Bottom)..................................55

B-5 Reference Design Heatsink Assembly (1 of 2)..............................................................56

4 Thermal and Mechanical Design Guide

Page 5

B-6 Reference Design Heatsink Assembly (2 of 2).............................................................57

B-7 Reference Fastener Sheet 1 of 4...............................................................................58

B-8 Reference Fastener Sheet 2 of 4...............................................................................59

B-9 Reference Fastener Sheet 3 of 4...............................................................................60

B-10 Reference Fastener Sheet 4 of 4 ...............................................................................61

B-11 Reference Clip - Sheet 1 of 2.......................................... ............................ .. ............62

B-12 Reference Clip - Sheet 2 of 2.......................................... ............................ .. ............63

C-1 Socket Mechanical Drawing (Sheet 1 of 4)..................................................................66

C-2 Socket Mechanical Drawing (Sheet 2 of 4)..................................................................67

C-3 Socket Mechanical Drawing (Sheet 3 of 4)..................................................................68

C-4 Socket Mechanical Drawing (Sheet 4 of 4)..................................................................69

D-1 Processor Installation Tool .......................................................................................72

Tables

1-1 Reference Documents.................................................................................................8

1-2 Terms and Descriptions ..............................................................................................8

4-1 Socket Component Mass................................ .. ............................ ........................... ..23

4-2 1366-land Package and LGA1366 Socket Stackup Height............................................... 23

4-3 Socket and ILM Mechanical Specifications....................................................................24

4-4 Electrical Requirements for LGA1366 Socket................................................................25

5-1 Thermal Solution Performance above TCONTROL..........................................................37

6-1 Processor Thermal Solution Requirements & Boundary Conditions...................................39

7-1 Use Conditions (Board Level).....................................................................................47

A-1 Reference Heatsink Enabled Components....................................................................49

A-2 LGA1366 Socket and ILM Components........................................................................49

A-3 Supplier Contact Information.....................................................................................49

B-1 Mechanical Drawing List............................................................................................51

C-1 Mechanical Drawing List............................................................................................65

Thermal and Mechanical Design Guide 5

Page 6

Revision History

Revision

Number

-001 • Initial release March 2009

Description Revision Date

§

6 Thermal and Mechanical Design Guide

Page 7

Introduction

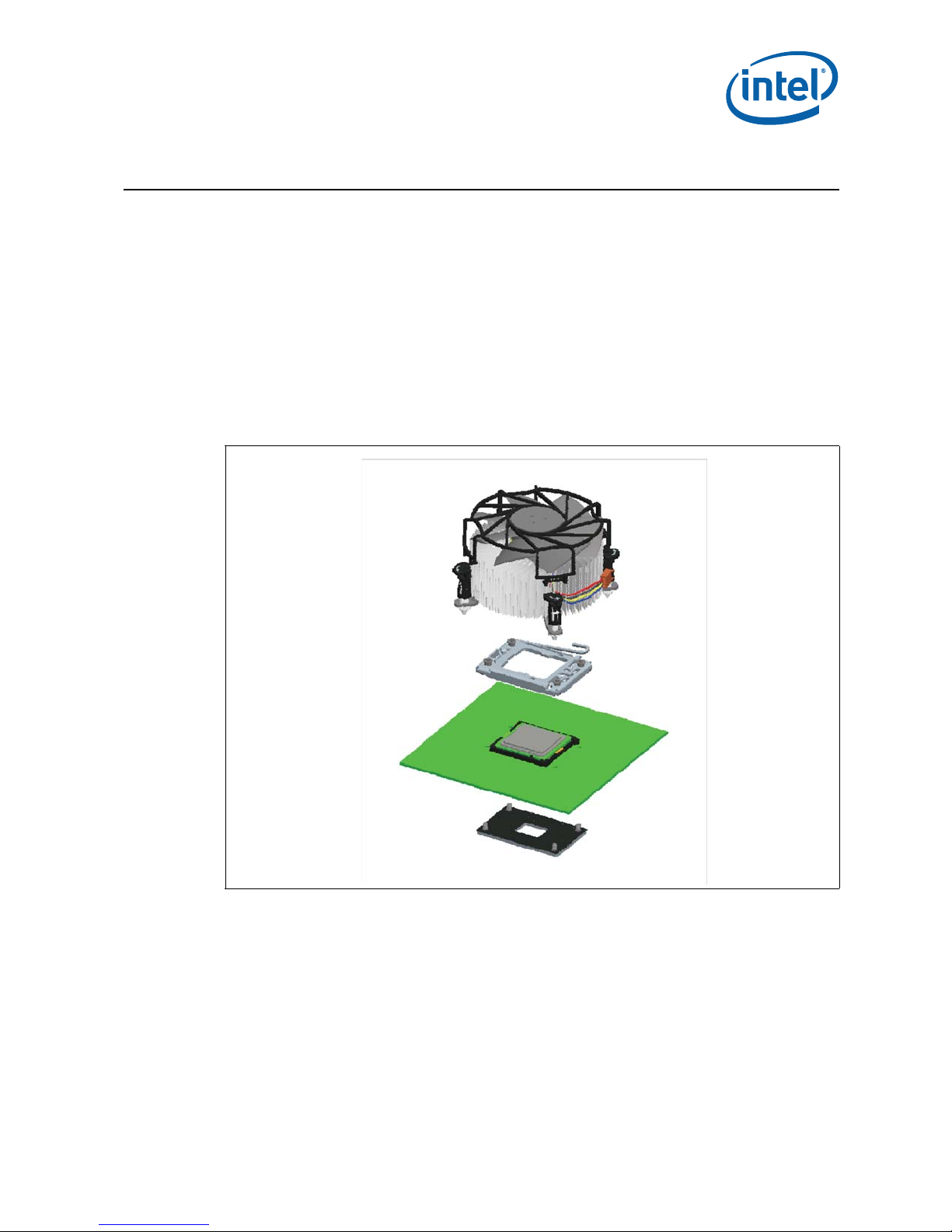

1 Introduction

This document provides guidelines for the design of thermal and mechanical solutions

for the:

• Intel® X eon® Processor 3500 Series

Unless specifically required for clarity , this document will use “processor” in place of the

specific product names. The components described in this document include:

• The processor thermal solution (heatsink) and associated retention hardware.

• The LGA1366 socket and the Independent Loading Mechanism (ILM) and back

plate.

Figure 1-1. Processor Thermal Solution & LGA1366 Socket Stack

The goals of this document are:

• To assist board and system thermal mechanical designers.

• To assist designers and suppliers of processor heatsinks.

Thermal profiles and other processor specifications are provided in the appropriate

processor Datasheet.

Thermal/Mechanical Design Guide 7

Page 8

1.1 References

Material and concepts available in the following documents may be beneficial when

reading this document.

Table 1-1. Reference Documents

Document Location Notes

Intel® Xeon® Processor 3500 Series Processor Datasheet,

Volume 1

Intel® Xeon® Processor 3500 Series Processor Datasheet,

Volume 2

Intel® Xeon® Processor 3500 Series Processor Specification

Update

Notes:

1. Available electronically

1.2 Definition of Terms

Table 1-2. Terms and Descriptions (Sheet 1 of 2)

Term Description

Bypass Bypass is the area between a passive heatsink and any object that can act to form a

DTS Digital Thermal Sensor reports a relative die temperature as an offset from TCC

FSC Fan Speed Control

IHS Integrated Heat Spreader: a component of the processor package used to enhance the

ILM Independent Loading Mechanism provides the force needed to seat the 1366-LGA land

IOH Input Output Hub: a component of the chipset that provides I/O connections to PCIe,

LGA1366 socket The processor mates with the system board through this surface mount, 1366-contact

PECI The Platform Environment Control Interface (PECI) is a one- wire in terface that pro vides

Ψ

CA

Ψ

CS

Ψ

SA

T

CASE

T

CASE_MAX

TCC Thermal Control Circuit: Thermal monitor uses the TCC to reduce the die temperature

T

CONTROL

duct. For this example, it can be expressed as a dimension away from the outside

dimension of the fins to the nearest surface.

activation temperature.

thermal performance of the package. Component thermal solutions interface with the

processor at the IHS surface.

package onto the socket contacts.

drives and other peripherals

socket.

a communication channel between Intel processor and chipset components to external

monitoring devices.

Case-to-ambient thermal characterization parameter (psi). A measure of thermal

solution performance using t otal package power. Defined as (T

Package Power. Heat source should always be specified for Ψ measurements.

Case-to-sink thermal characterization parameter. A measure of thermal interface

material performance using total package po wer. Defined as (T

Package Power.

Sink-to-ambient thermal characterization parameter. A measure of heatsink thermal

performance using total package power. Defined as (T

The case temperature of the TTV measured at the geometric center of the topside of the

IHS.

The maximum case temperature as specified in a component specification.

by using clock modulation and/or operating frequency and input voltage adjustment

when the die temperature is very near its operating limits.

T

control.

is a static value below TCC activation used as a trigger point for fan speed

CONTROL

Introduction

321332 1

321344 1

321333 1

– TLA) / Total

CASE

– TS) / Total

CASE

– TLA) / Total Package Power.

S

8 Thermal/Mechanical Design Guide

Page 9

Introduction

Table 1-2. Terms and Descriptions (Sheet 2 of 2)

Term Description

TDP Thermal Design Power: Thermal solution should be designed to dissipate this target

Thermal Monitor A power reduction feature designed to decrease temperature after the processor has

Thermal Profile Line that defines case temperature specification of the TTV at a given power level.

TIM Thermal Interface Material: The thermally conductive compound between the heatsink

T

AMBIENT

T

SA

power level. TDP is not the maximum power that the processor can dissipate.

reached its maximum operating temperature.

and the processor case. This material fills the air gaps and voids, and enhances the

transfer of the heat from the processor case to the heatsink.

The measured ambient temperature locally surrounding the proces sor. The ambient

temperature should be measured just upstream of a p assive he atsink or at the fan inle t

for an active heatsink.

The system ambient air temperature external to a system chassis. This temperature is

usually measured at the chassis air inlets.

§

Thermal/Mechanical Design Guide 9

Page 10

Introduction

10 Thermal/Mechanical Design Guide

Page 11

LGA1366 Socket

2 LGA1366 Socket

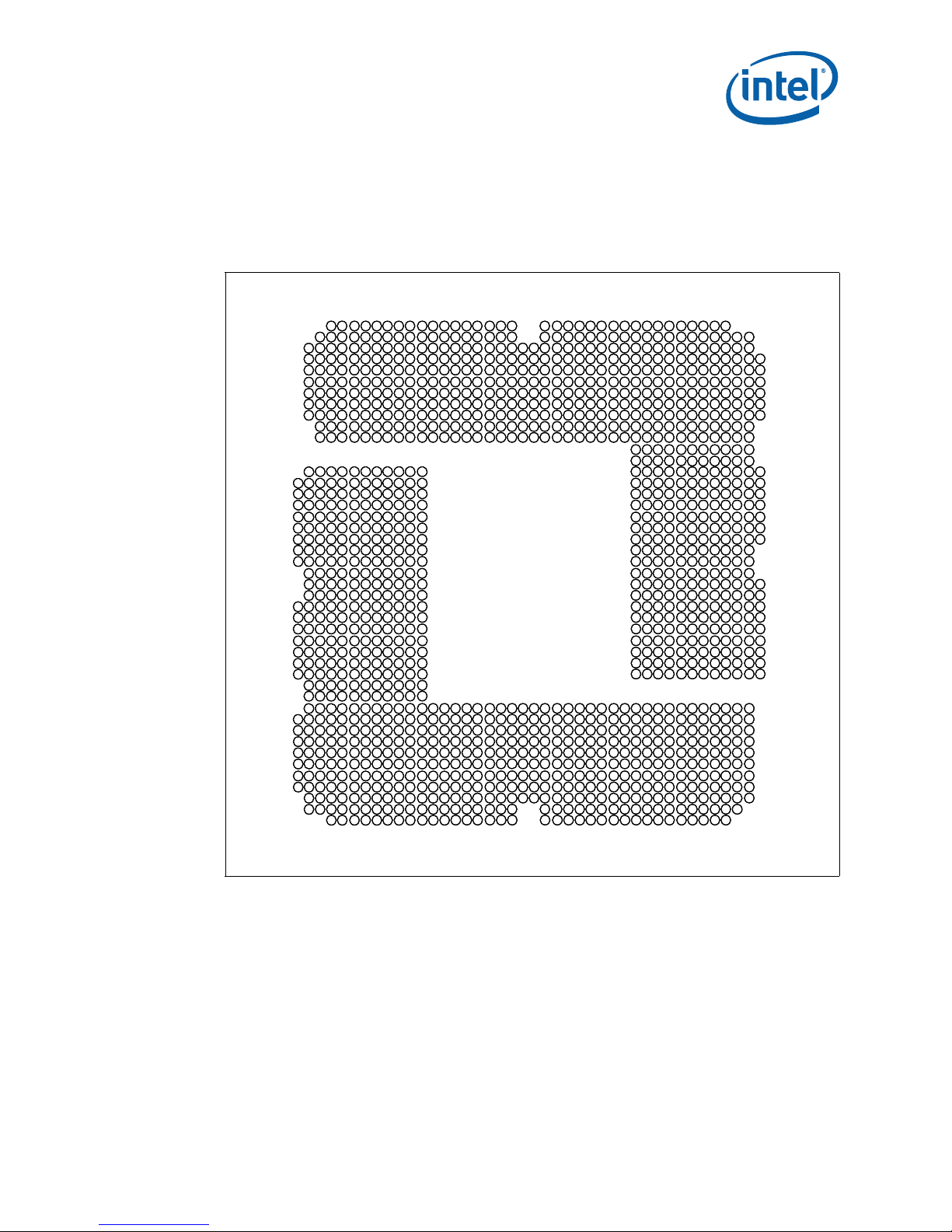

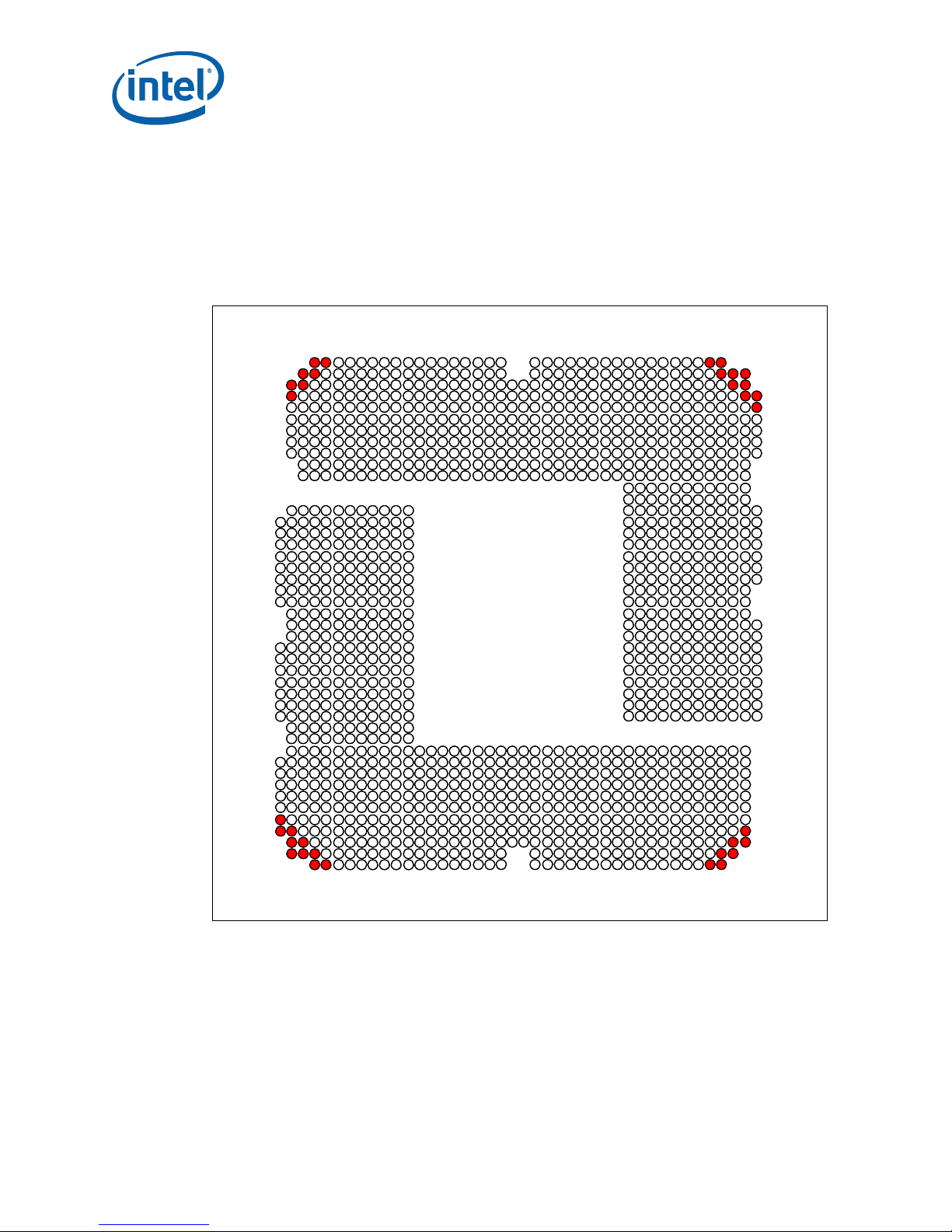

This chapter describes a surface mount, LGA (Land Grid Array) socket intended for

Intel® Xeon® Processor 3500 Series. The socket provides I/O, power and ground

contacts. The socket contains 1366 contacts arrayed about a cavity in the center of the

socket with lead-free solder balls for surface mounting on the motherboard.

The socket has 1366 contacts with 1.016 mm X 1.016 mm pitch (X by Y) in a

43x41 grid array with 21x17 grid depopulation in the center of the array and selective

depopulation elsewhere.

The socket must be compatible with the package (processor) and the Independent

Loading Mechanism (ILM). The design includes a back plate which is integral to having

a uniform load on the socket solder joints. Socket loading specifications are listed in

Chapter 4.

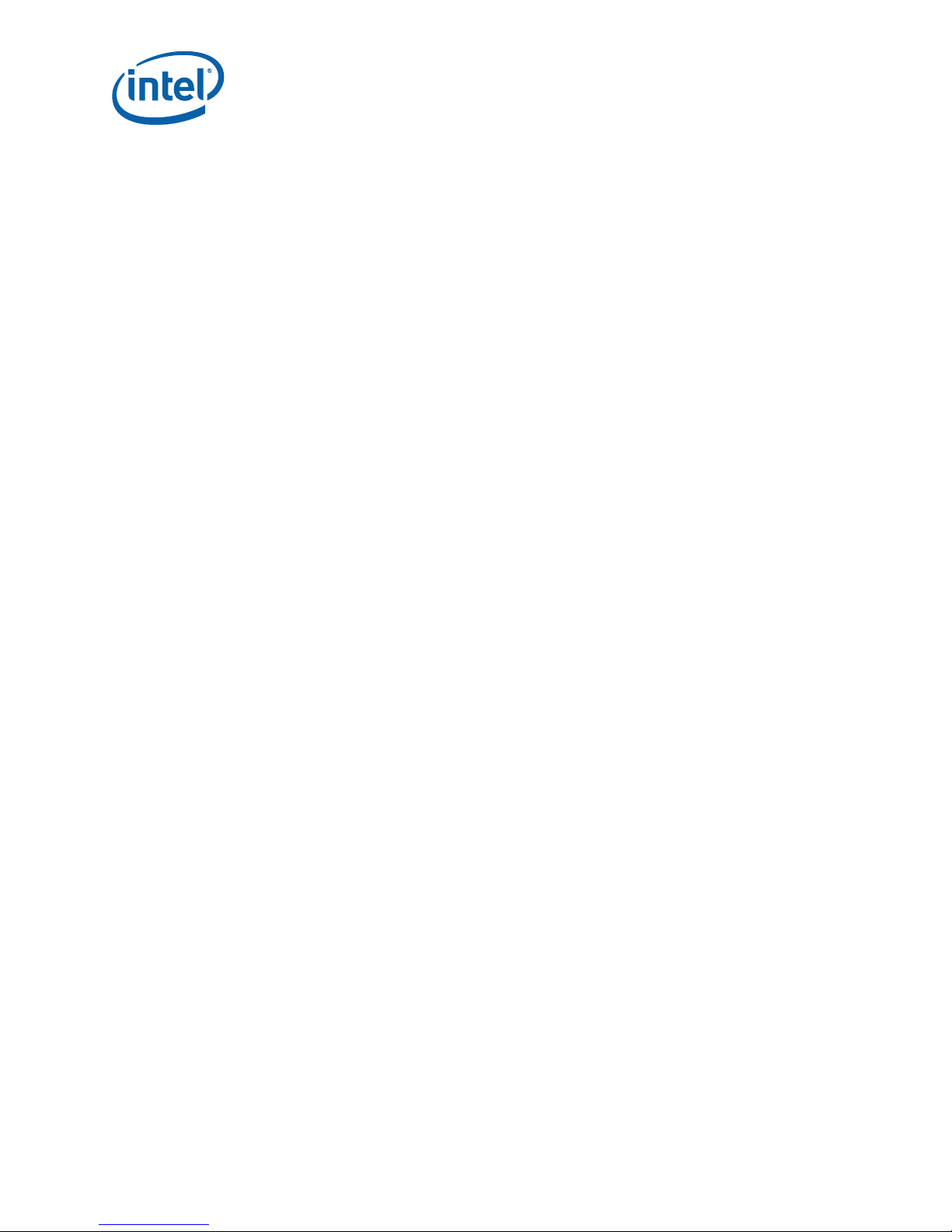

Figure 2-1. LGA1366 Socket with Pick and Place Cover Removed

package socket

package

cavity

cavity

socket

Thermal/Mechanical Design Guide 11

Page 12

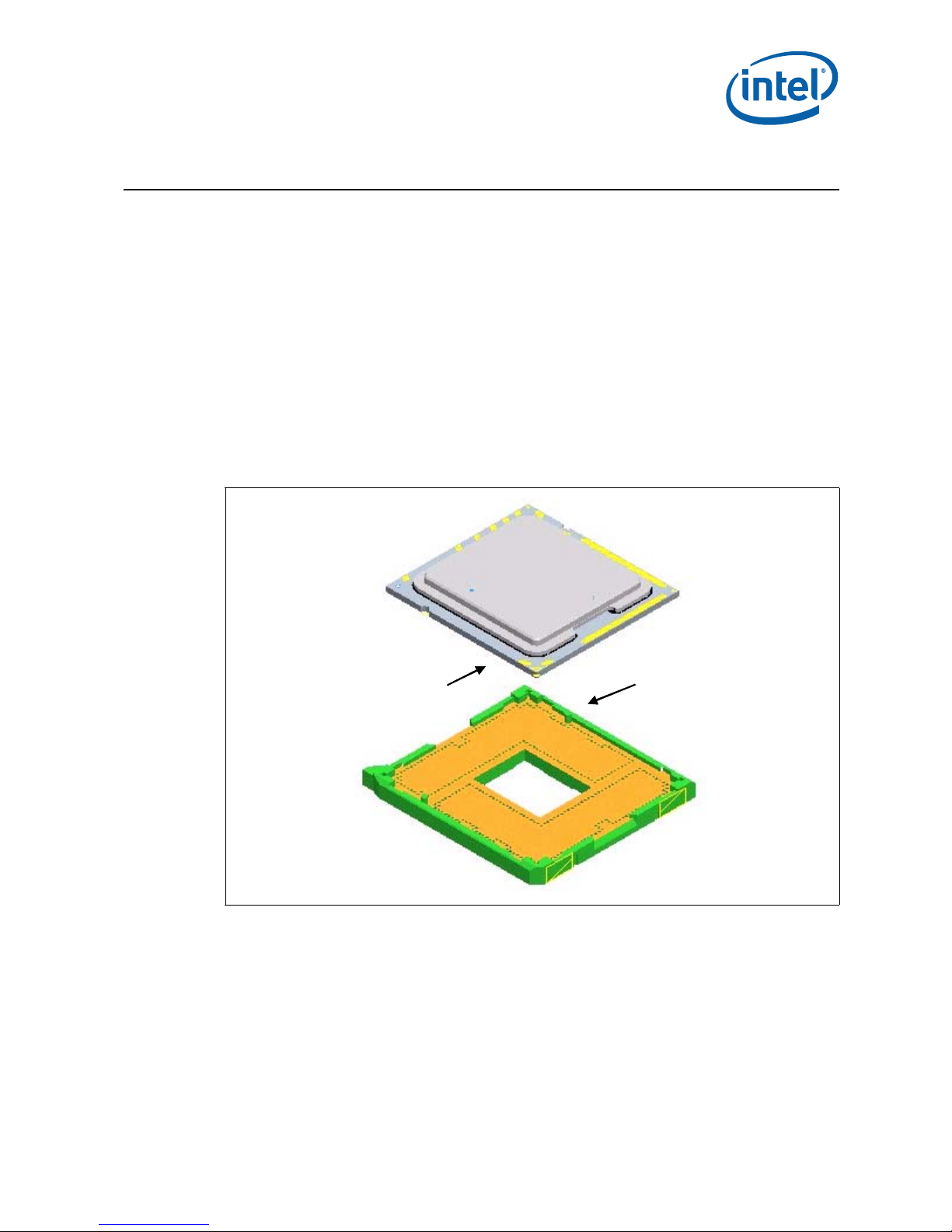

Figure 2-2. LGA1366 Socket Contact Numbering (Top View of Socket)

AP

AN

AM

AL

AK

AJ

AH

AG

AF

AE

AD

AC

AB

AA

Y

W

V

U

T

R

P

N

M

L

K

J

H

G

F

E

D

C

B

A

31 29 27 25 23 21 19 17 15 13 11 9 7 5

32 30 28 26 24 22 20 18 16 14 12 10 8 6 4

AR

AU

AT

LGA1366 Socket

BA

AY

AW

AV

43 41 39 37 35 33 31 29 27 25 23 21 19 17 15 13

42 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12

BA

AY

AW

AV

AU

AT

AR

AP

AN

AM

AL

AK

AJ

AH

AG

AF

AE

AD

AC

AB

AA

Y

W

V

U

T

R

P

N

M

L

K

J

H

G

F

E

D

C

B

A

12 Thermal/Mechanical Design Guide

Page 13

LGA1366 Socket

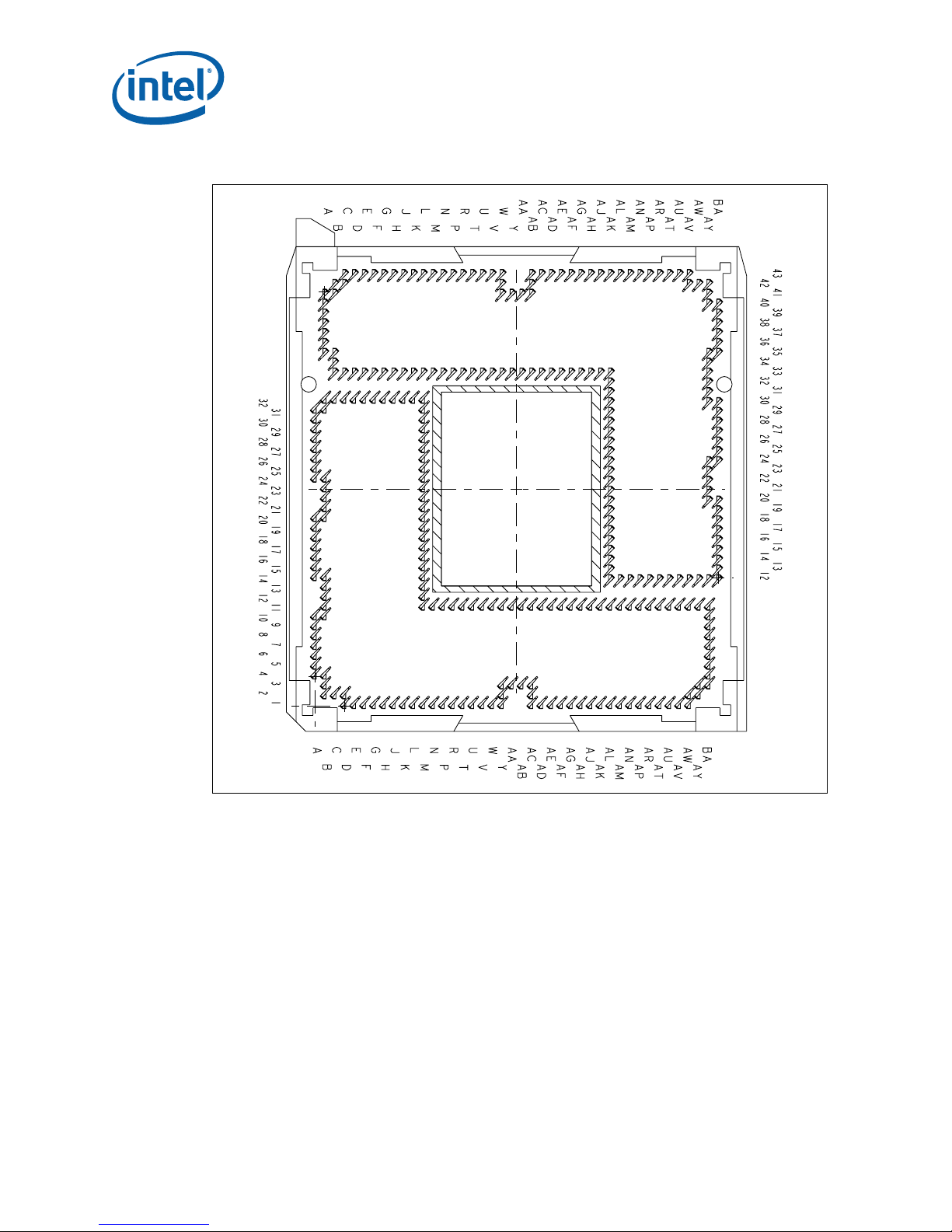

2.1 Board Layout

The land pattern for the LGA1366 socket is 40 mils X 40 mils (X by Y), and the pad size

is 18 mils. Note that there is no round-off (conversion) error between socket pitch

(1.016 mm) and board pitch (40 mil) as these values are equivalent.

Figure 2-3. LGA1366 Socket Land Pattern (Top View of Board)

A C E G J L N R U W AA AC AE AG AJ AL AN AR AU AW BA

B D F H K M P T V Y AB AD AF AH AK AM AP AT AV AY

32

32

31

31

30

30

29

29

28

28

27

27

26

26

25

25

24

24

23

23

22

22

21

21

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

A C E G J L N R U W AA AC AE AG AJ AL AN AR AU AW BA

B D F H K M P T V Y AB AD AF AH AK AM AP AT AV AY

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

Thermal/Mechanical Design Guide 13

Page 14

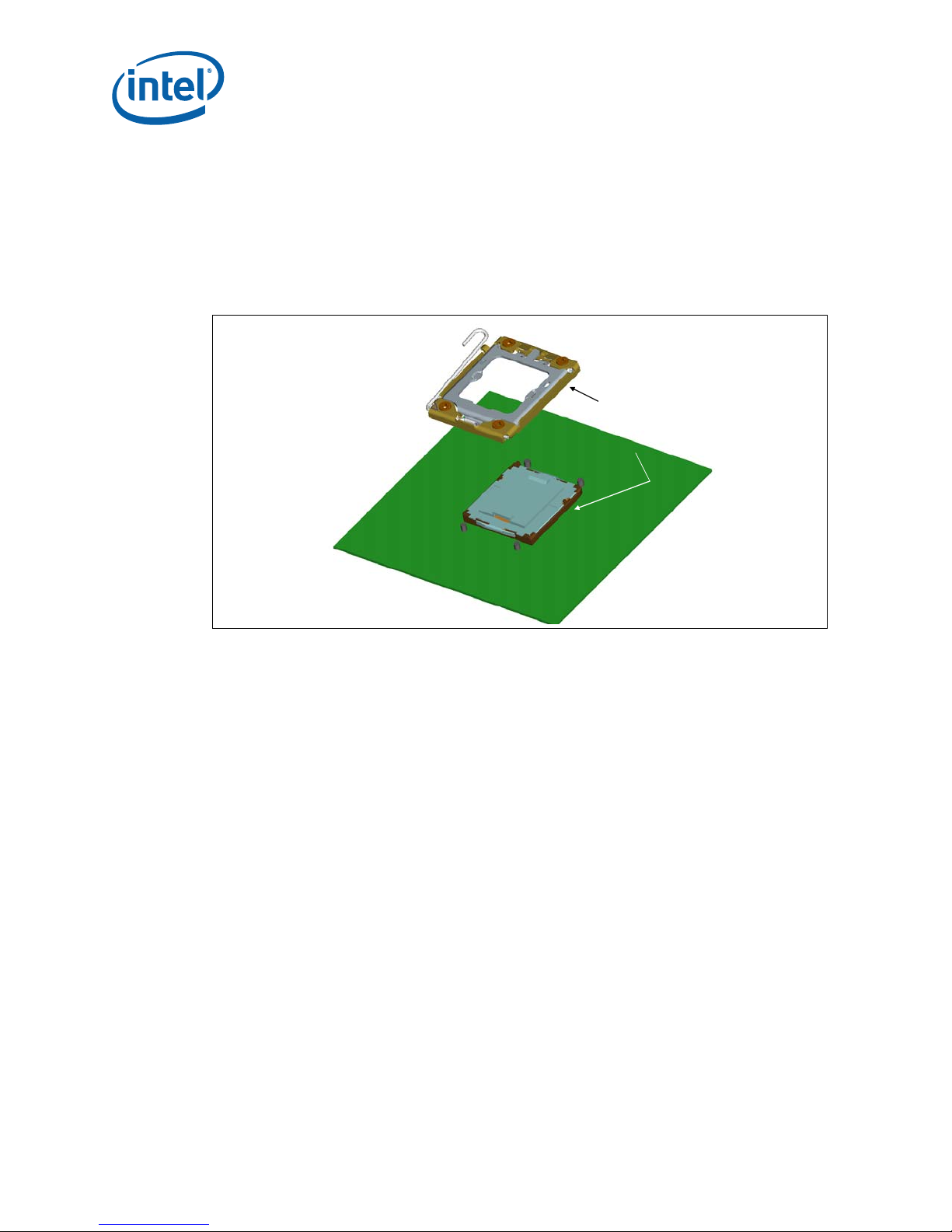

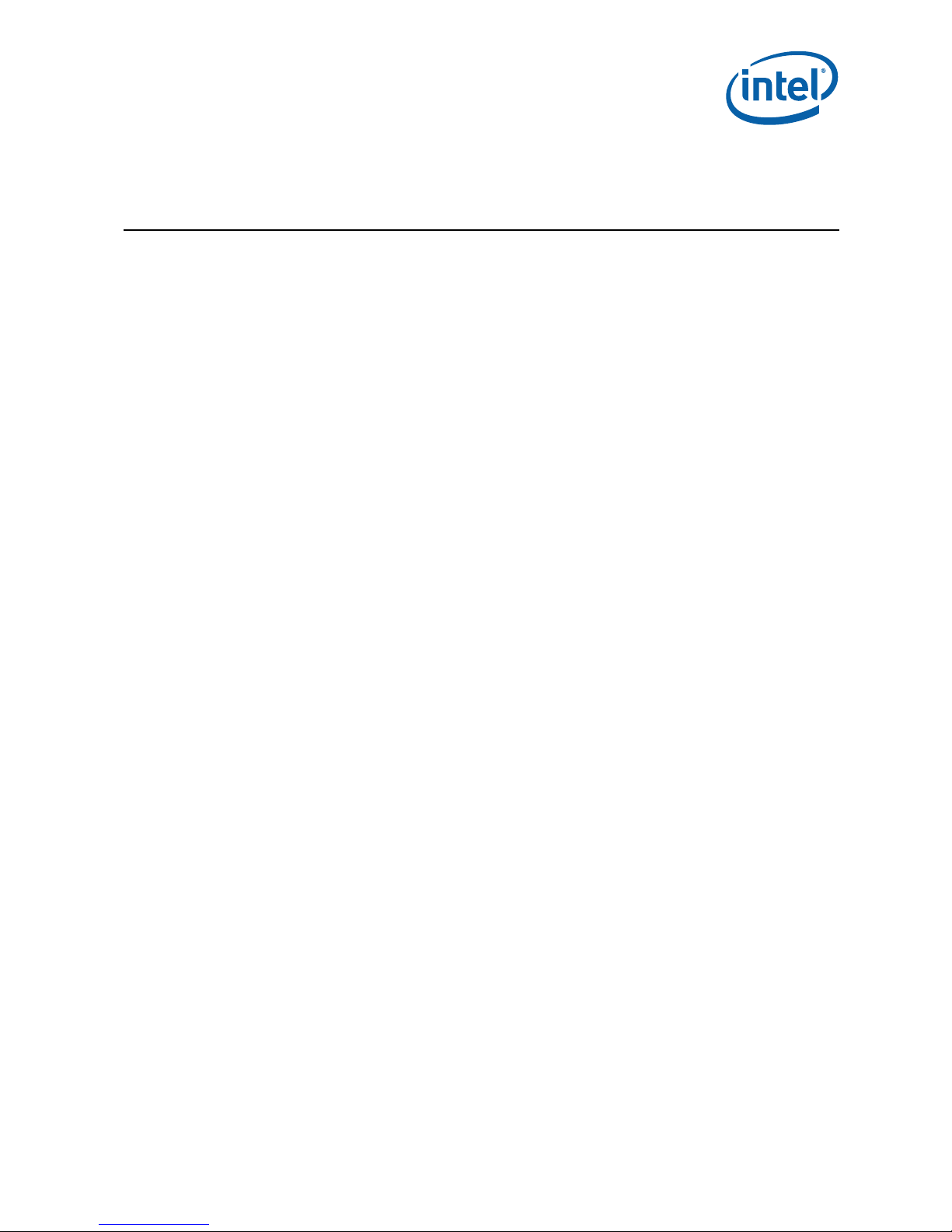

2.2 Attachment to Motherboard

The socket is attached to the motherboard by 1366 solder balls. There are no additional

external methods (that is, screw, extra solder, adhesive, and so on) to attach the

socket.

As indicated in Figure 2-4, the Independent Loading Mechanism (ILM) is not present

during the attach (reflow) process.

Figure 2-4. Attachment to Motherboard

LGA1366 Socket

ILM

LGA 1366 Socket

2.3 Socket Components

The socket has two main components, the socket body and Pick and Place (PnP) cover,

and is delivered as a single integral assembly. Refer to Appendix C for detailed

drawings.

2.3.1 Socket Body Housing

The housing material is thermoplastic or equivalent with UL 94 V -0 flame rating capable

of withstanding 260 °C for 40 seconds (typical reflow/rework). The socket coefficient of

thermal expansion (in the XY plane), and creep properties, must be such that the

integrity of the socket is maintained for the conditions listed in Chapter 7.

The color of the housing will be dark as compared to the solder balls to provide the

contrast needed for pick and place vision systems.

2.3.2 Solder Balls

A total of 1366 solder balls corresponding to the contacts are on the bottom of the

socket for surface mounting with the motherboard.

The socket has the following solder ball material:

• Lead free SAC (SnAgCu) solder alloy with a silver (Ag) content between 3% and

4% and a melting temperature of approximately 217 °C. The alloy must be

compatible with immersion silver (ImAg) motherboard surface finish and a SAC

alloy solder paste.

The co-planarity (profile) and true position requirements are defined in Appendix C.

14 Thermal/Mechanical Design Guide

Page 15

LGA1366 Socket

2.3.3 Contacts

Base material for the contacts is high strength copper alloy.

For the area on socket contacts where processor lands will mate, there is a 0.381 μm

[15 μinches] minimum gold plating over 1.27 μm [50 μinches] minimum nickel

underplate.

No contamination by solder in the contact area is allowed during solder reflow.

2.3.4 Pick and Place Cover

The cover provides a planar surface for vacuum pick up used to place components in

the Surface Mount Technology (SMT) manufacturing line. The cover remains on the

socket during reflow to help prevent contamination during reflow. The cover can

withstand 260 °C for 40 seconds (typical reflow/rework profile) and the conditions

listed in Chapter 7 without degrading.

As indicated in Figure 2-5, the cover remains on the socket during ILM installation, and

should remain on whenever possible to help prevent damage to the socket contacts.

Cover retention must be sufficient to support the socket weight during lifting,

translation, and placement (board manufacturing), and during board and system

shipping and handling.

The covers are designed to be interchangeable between socket suppliers. As indicated

in Figure 2-5, a Pin1 indicator on the cover provides a visual reference for proper

orientation with the socket.

Figure 2-5. Pick and Place Cover

ILM

Installation

Pin 1 Pin 1

Pick and

Place Cover

Thermal/Mechanical Design Guide 15

Page 16

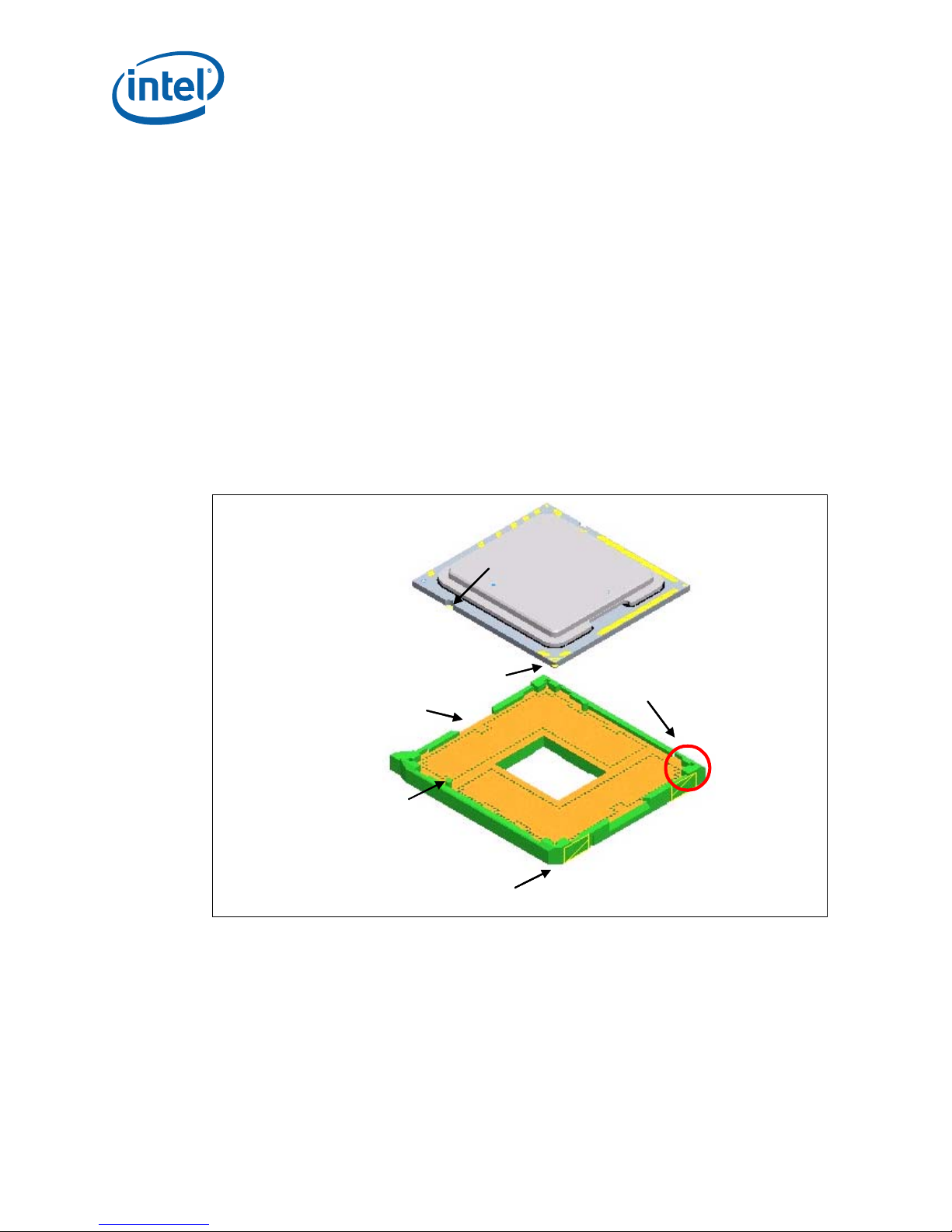

2.4 Package Installation / Removal

As indicated in Figure 2-6, access is provided to facilitate manual installation and

removal of the package.

To assist in package orientation and alignment with the socket:

• The package Pin1 triangle and the socket Pin1 chamfer provide visual reference for

proper orientation.

• The package substrate has orientation notches along two opposing edges of the

package, offset from the centerline. The socket has two corresponding orientation

posts to physically prevent mis-orientation of the package. These orientation

features also provide initial rough alignment of package to socket.

• The socket has alignment walls at the four corners to provide final alignment of the

package.

See Appendix D for information regarding a tool designed to provide mechanical

.

Figure 2-6. Package Installation / Removal Features

assistance during processor installation and removal.

LGA1366 Socket

orientation

orientation

notch

notch

alignment

Pin1 triangle

Pin1 triangle

access

access

orientation

orientation

post

post

Pin1 chamfer

Pin1 chamfer

alignment

walls

walls

2.4.1 Socket Standoffs and Package Seating Plane

Standoffs on the bottom of the socket base establish the minimum socket height after

solder reflow and are specified in Appendix C.

Similarly, a seating plane on the topside of the socket establishes the minimum

package height. See Section 4.2 for the calculated IHS height above the motherboard.

16 Thermal/Mechanical Design Guide

Page 17

LGA1366 Socket

2.5 Durability

The socket must withstand 30 cycles of processor insertion and removal. The max

chain contact resistance from Table 4-4 must be met when mated in the 1st and 30th

cycles.

The socket Pick and Place cover must withstand 15 cycles of insertion and removal.

2.6 Markings

There are three markings on the socket:

• LGA1366: Font type is Helvetica Bold - minimum 6 point (2.125 mm).

• Manufacturer's insignia (font size at supplier's discretion).

• Lot identification code (allows traceability of manufacturing date and location).

All markings must withstand 260 °C for 40 seconds (typical reflow/rework profile)

without degrading, and must be visible after the socket is mounted on the

motherboard.

LGA1366 and the manufacturer's insignia are molded or laser marked on the side wall.

2.7 Component Insertion Forces

Any actuation must meet or exceed SEMI S8-95 Safety Guidelines for Ergonomics/

Human Factors Engineering of Semiconductor Manu facturing Equipment, example Table

R2-7 (Maximum Grip Forces). The socket must be designed so that it requires no force

to insert the package into the socket.

2.8 Socket Size

Socket information needed for motherboard design is given in Appendix C.

This information should be used in conjunction with the reference motherboard keep-

out drawings provided in Appendix B to ensure compatibility with the reference thermal

mechanical components.

Thermal/Mechanical Design Guide 17

Page 18

2.9 LGA1366 Socket NCTF Solder Joints

Intel has defined selected solder joints of the socket as non-critical to function (NCTF)

for post environmental testing. The processor signals at NCTF locations are typically

redundant ground or non-critical reserved, so the loss of the solder joint continuity at

end of life conditions will not affect the overall product functionality. Figure 2-7

.

Figure 2-7. LGA1366 NCTF Solder Joints

identifies the NCTF solder joints.

A C E G J L N R U W AA AC AE AG AJ AL AN AR AU AW BA

B D F H K M P T V Y AB AD AF AH AK AM AP AT AV AY

32

32

31

31

30

30

29

29

28

28

27

27

26

26

25

25

24

24

23

23

22

22

21

21

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

A C E G J L N R U W AA AC AE AG AJ AL AN AR AU AW BA

B D F H K M P T V Y AB AD AF AH AK AM AP AT AV AY

LGA1366 Socket

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

18 Thermal/Mechanical Design Guide

§

Page 19

Independent Loading Mechanism (ILM)

3 Independent Loading

Mechanism (ILM)

The Independent Loading Mechanism (ILM) provides the force needed to seat the

1366-LGA land package onto the socket contacts. The ILM is physically separate from

the socket body. The assembly of the ILM to the board is expected to occur after wave

solder. The exact assembly location is dependent on manufacturing preference and test

flow.

Note: The ILM has two critical functions: deliver the force to seat the processor onto the

socket contacts and distribute the resulting compressive load evenly through the socket

solder joints.

Note: The mechanical design of the ILM is integral to the overall functionality of the LGA1366

socket. Intel performs detailed studies on integration of processor package, socket and

ILM as a system. These studies directly impact the design of the ILM. The Intel

reference ILM will be “build to print” from Intel controlled drawings. Intel recommends

using the Intel Reference ILM. Custom non-Intel ILM designs do not benefit from Intel's

detailed studies and may not incorporate critical design parameters.

3.1 Design Concept

The ILM consists of two assemblies that will be procured as a set from the enabled

vendors. These two components are ILM cover assembly and back plate.

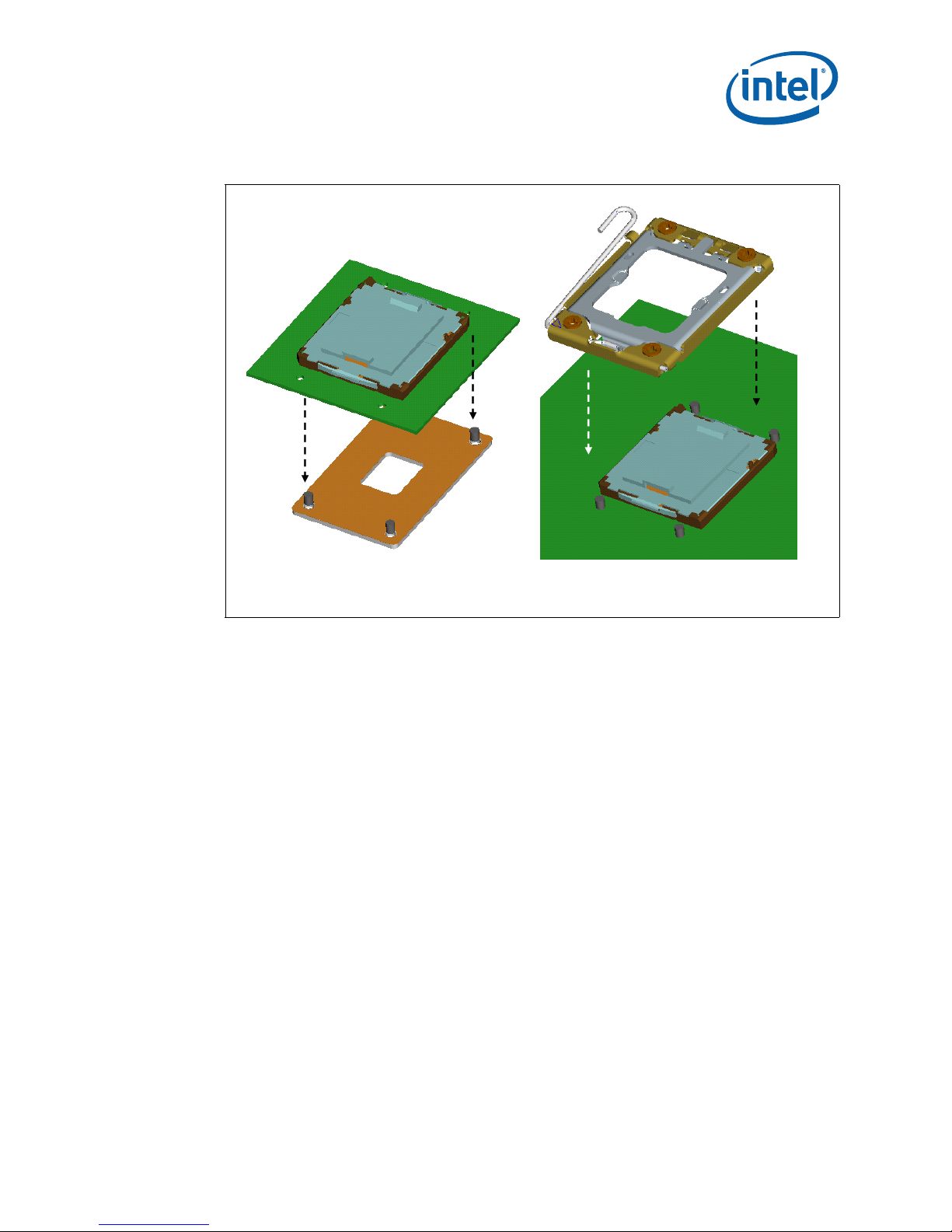

3.1.1 ILM Cover Assembly Design Overview

The ILM Cover assembly consists of four major pieces: load lever, load plate, frame and

the captive fasteners.

The load lever and load plate are stainless steel. The frame and fasteners are high

carbon steel with appropriate plating. The fasteners are fabricated from a high carbon

steel. The frame provides the hinge locations for the load lever and load plate.

The cover assembly design ensures that once assembled to the back plate and the load

lever is closed, the only features touching the board are the captive fasteners. The

nominal gap of the frame to the board is ~1 mm when the load plate is closed on the

empty socket or when closed on the processor package.

When closed, the load plate applies two point loads onto the IHS at the “dimpled”

features shown in Figure 3-1. The reaction force from closing the load plate is

transmitted to the frame and through the captive fasteners to the back plate. Some of

the load is passed through the socket body to the board inducing a slight compression

on the solder joints.

Thermal/Mechanical Design Guide 19

Page 20

Figure 3-1. ILM Cover Assembly

Load Lever

Load Lever

Load Plate

Load Plate

Independent Loading Mechanism (IL M )

Captive Fastener (4x)

Captive Fastener (4x)

Frame

Frame

3.1.2 ILM Back Plate Design Overview

The back plate for single processor workstation products consists of a flat steel back

plate with threaded studs for ILM attach. The threaded studs have a smooth surface

feature that provides alignment for the back plate to the motherboard for proper

assembly of the ILM around the socket. A clearance hole is located at the center of the

plate to allow access to test points and backside capacitors. An insulator is pre-applied.

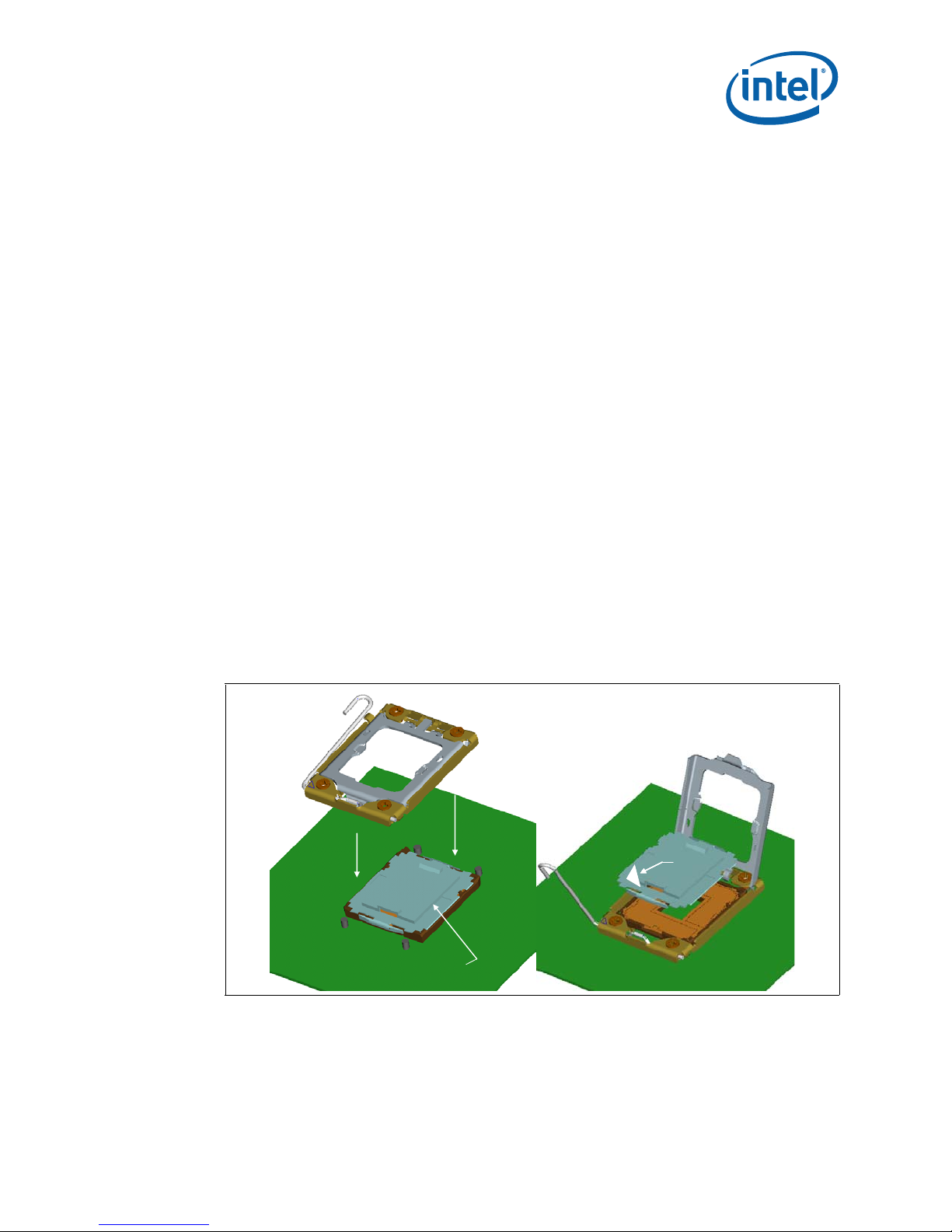

3.2 Assembly of ILM to a Motherboard

The ILM design allows a bottoms up assembly of the components to the board. In

step 1, (see Figure 3-2), the back plate is placed in a fixture. Holes in the motherboard

provide alignment to the threaded studs. In step 2, the ILM cover assembly is placed

over the socket and threaded studs. Using a T20 Torx* driver fasten the ILM cover

assembly to the back plate with the four captive fasteners. Torque to 8 ± 2 inchpounds. The length of the threaded studs accommodate board thicknesses from

0.062” to 0.100”.

20 Thermal/Mechanical Design Guide

Page 21

Independent Loading Mechanism (ILM)

.

Figure 3-2. ILM Assembly

Socket Body Reflowed on board

Socket Body Reflowed on board

Socket Body with Back Plate on board

Socket Body with Back Plate on board

Step 1 Step 2

Step 1 Step 2

Thermal/Mechanical Design Guide 21

Page 22

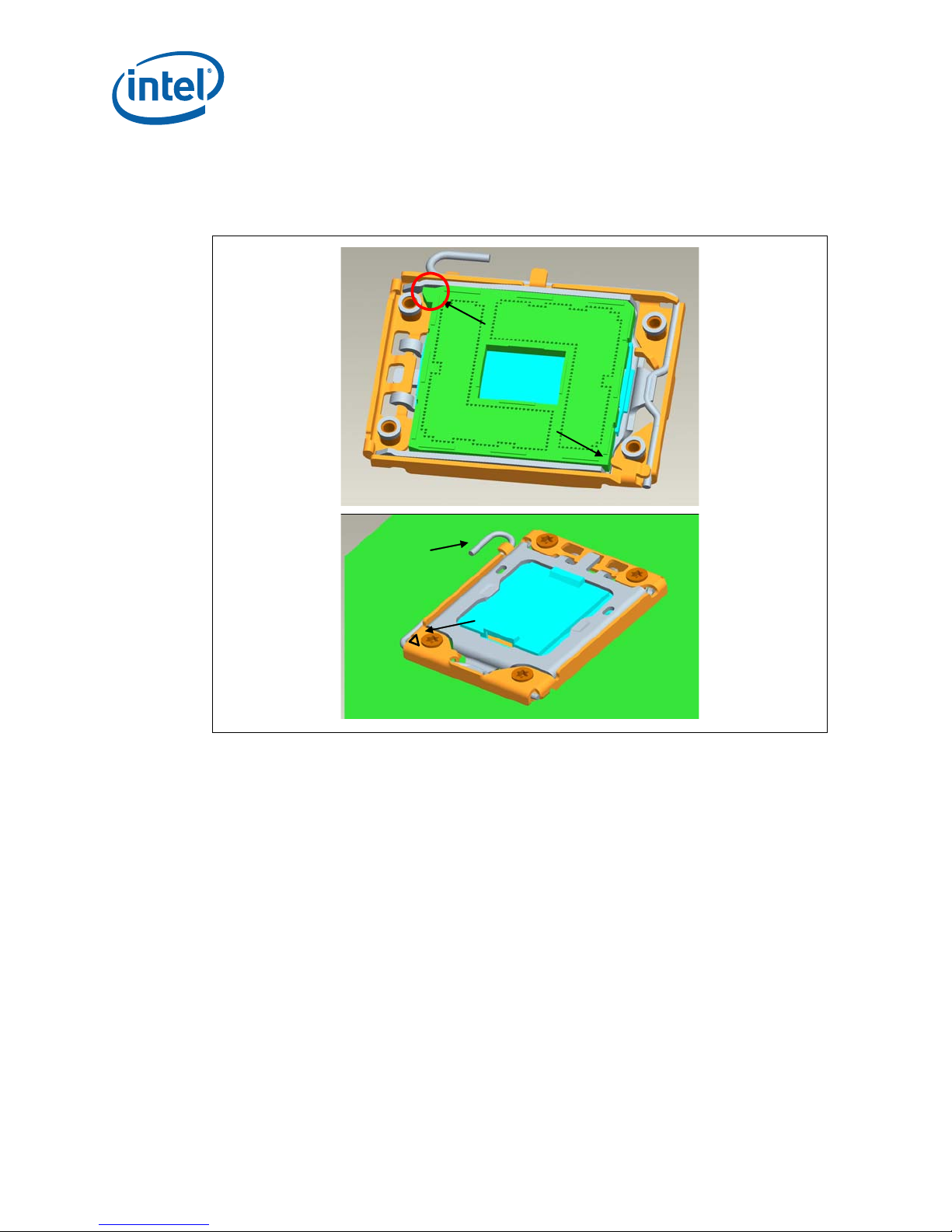

As indicated in Figure 3-3, socket protrusion and ILM key features prevent 180-degree

rotation of ILM cover assembly with respect to the socket. The result is a specific Pin 1

orientation with respect to the ILM lever.

Figure 3-3. Pin1 and ILM Lever

Independent Loading Mechanism (IL M )

Protrusion

ILM Key

ILM

Lever

Pin 1

§

22 Thermal/Mechanical Design Guide

Page 23

LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications

4 LGA1366 Socket and ILM

Electrical, Mechanical, and

Environmental Specifications

This chapter describes the electrical, mechanical, and environmental specifications for

the LGA1366 socket and the Independent Loading Mechanism.

4.1 Component Mass

Table 4-1. Socket Component Mass

Component Mass

Socket Body, Contacts and PnP Cover 15 g

ILM Cover 43 g

ILM Back Plate 51 g

4.2 Package/Socket Stackup Height

Table 4-2 provides the stackup height of a processor in the 1366-land LGA package and

LGA1366 socket with the ILM closed and the processor fully seated in the socket.

Table 4-2. 1366-land Package and LGA1366 Socket Stackup Height

Integrated Stackup Height (mm)

From Top of Board to Top of IHS

Notes:

1. This data is provided for information only, and should be derived from: (a) the height of the s ocke t seating

plane above the motherboard after reflow, given in Appendix C, (b) the height of the package, from the

package seating plane to the top of the IHS, and accounting for its nominal variation and tolerances that

are given in the corresponding processor datasheet.

2. This value is a RSS calculation.

7.729 ± 0.282 mm

4.3 Socket Maximum Temperature

The power dissipated within the socket is a function of the current at the pin level and

the effective pin resistance. To ensure socket long term reliability, Intel defines socket

maximum temperature using a via on the underside of the motherboard. Exceeding the

temperature guidance may result in socket body deformation, or increases in thermal

and electrical resistance which can cause a thermal runaway and eventual electrical

failure. The guidance for socket maximum temperature is listed below:

• Via temperature under socket < 96 °C

Thermal/Mechanical Design Guide 23

Page 24

LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications

4.4 Loading Specifications

The socket will be tested against the conditions listed in Chapter 7 with heatsink and

the ILM attached, under the loading conditions outlined in this chapter.

Table 4-3 provides load specifications for the LGA1366 socket with the ILM installed.

The maximum limits should not be exceeded during heatsink assembly, shipping

conditions, or standard use condition. Exceeding these limits during test may result in

component failure. The socket body should not be used as a mechanical reference or

load-bearing surface for thermal solutions.

Table 4-3. Socket and ILM Mechanical Specifications

Parameter Min Max Notes

Static compressive load from ILM cover to

processor IHS

Heatsink Static Compressive Load 0 N [0 lbf] 266 N [60 lbf] 1, 2, 3

Total Static Compressive Load

(ILM plus Heatsink)

Dynamic Compressive Load

(with heatsink installed)

Pick and Place Cover Insertion / Removal force N/A 10.2 N [2.3 lbf]

Load Lever actuation force N/A 38.3 N [8.6 lbf] in the

470 N [106 lbf] 623 N [140 lbf] 3, 4, 7

470 N (106 lbf) 890 N (200 lbf) 3, 4

N/A 890 N [200 lbf] 1, 3, 5, 6

vertical direction

10.2 N [2.3 lbf] in the

lateral direction.

Notes:

1. These specifications apply to uniform compressive loading in a direction perpendicular to the IHS top

surface.

2. This is the minimum and maximum static force that can be applied by the heatsink and it’s retention

solution to maintain the heatsink to IHS interface. This does not imply the Intel reference TIM is validated

to these limits.

3. Loading limits are for the LGA1366 socket.

4. This minimum limit defines the compres sive forc e require d to electrically seat the processor onto the sock et

contacts.

5. Dynamic loading is defined as an 11 ms duration average load superimposed on the static load

requirement.

6. Test condition used a heatsink mass of 550 gm [1.21 lb] with 50 g acceler ation measured at h eatsink mass.

The dynamic portion of this specification in the product application can have flexibility in specific values, but

the ultimate product of mass times acceleration should not exceed this dynamic load.

7. Conditions must be satisfied at the beginning of life and the loading system stiffness for non-reference

designs need to meet a specific stiffness range to satisfy end of life loading requirements.

4.5 Electrical Requirements

LGA1366 socket electrical requirements are measured from the socket-seating plane of

the processor to the component side of the socket PCB to which it is attached. All

specifications are maximum values (unless otherwise stated) for a single socket

contact, but includes effects of adjacent contacts where indicated.

24 Thermal/Mechanical Design Guide

Page 25

LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications

Table 4-4. Electrical Requirements for LGA1366 Socket

Parameter Value Comment

Mated loop inductance, Loop

Mated partial mutual inductance, L

Maximum mutual capacitance, C.

Socket Average Contact R esistance

(EOL)

Max Individual Contact Resistance

(EOL)

Bulk Resistance Increase

Dielectric Withstand Voltage

Insulation Resistance

<3.9nH

NA

<1 pF

15.2 mΩ

≤ 100 mΩ

≤ 3 mΩ

360 Volts RMS

800 MΩ

The inductance calculated for two contacts,

considering one forward conductor an d one return

conductor. These values must be satisfied at the

worst-case height of the socket.

The inductance on a contact due to any single

neighboring contact.

The capacitance between two contacts

The socket average contact resistance target is

derived from average of every chain contact

resistance for each part used in testing, with a

chain contact resistance defined as the resistance

of each chain minus resistance of shorting bars

divided by number of lands in the daisy chain.

The specification listed is at room temperature

and has to be satisfied at all time.

Socket Contact Resistance: The resistance of

the socket contact, solderball, and interface

resistance to the interposer land.

The specification listed is at room temperature

and has to be satisfied at all time.

Socket Contact Resistance: The resistance of

the socket contact, solderball, and interface

resistance to the interposer land; gaps included.

The bulk resistance increase per contact from

24 °C to 107 °C

4.6 Environmental Requirements

Design, including materials, shall be consistent with the manufacture of units that meet

the following environmental reference points.

The reliability targets in this chapter are based on the expected field use environment

for these products. The test sequence for new sockets will be developed using the

knowledge-based reliability evaluation methodology, which is acceleration factor

dependent. A simplified process flow of this methodology can be seen in Figure 4-1.

Thermal/Mechanical Design Guide 25

Page 26

LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications

Figure 4-1. Flow Chart of Knowledge-Based Reliability Evaluation Methodology

Establish the

market/expected use

environment for the

technology

Develop Speculative

stress conditions based on

historical data, content

experts, and literature

search

Freeze stressing

requirements and perform

additional data turns

Perform stressing to

validate accelerated

stressing assumptions and

determine acceleration

factors

A detailed description of this methodology can be found at:

ftp://download.intel.com/technology/itj/q32000/pdf/reliability.pdf.

§

26 Thermal/Mechanical Design Guide

Page 27

Sensor Based Thermal Specification Design Guidance

5 Sensor Based Thermal

Specification Design Guidance

The introduction of the sensor based thermal specification presents opportunities for

the system designer to optimize the acoustics and simplify thermal validation. The

sensor based specification utilizes the Digital Thermal Sensor information accessed

using the PECI interface.

This chapter will review thermal solution design options, fan speed control design

guidance & implementation options and suggestions on validation both with the TTV

and the live die in a shipping system.

5.1 Sensor Based Specification Overview

Create a thermal specification that meets the following requirements:

• Use Digital Thermal Sensor (DTS) for real-time thermal specification compliance.

• Single point of reference for thermal specification compliance over all operating

conditions.

• Does not required measuring processor power & case temperature during

functional system thermal validation.

• Opportunity for acoustic benefits for DTS values between T

CONTROL

and -1.

The current specification based on the processor case temperature has some notable

gaps to optimal acoustic design. When the ambient temperature is less than the

maximum design point, the fan speed control system (FSC) will over cool the processor.

The FSC has no feedback mechanism to detect this over cooling. This is shown in the

top half of Figure 5-1.

The sensor based specification will allow the FSC to be operated at the maximum

allowable silicon temperature or T

acoustics for operation above T

for the measured ambient. This will provide optimal

J

CONTROL

. See lower half of Figure 5-1.

Thermal/Mechanical Design Guide 27

Page 28

Sensor Based Thermal Specification Design Guidance

Figure 5-1. Comparison of Case Temperature vs. Sensor Based Specification

Ta = 43.2 C

Ta = 43.2 C

Tcontrol

Tcontrol

Ta = 30 C

Ta = 30 C

Ψ-ca = 0.292

Ψ-ca = 0.292

TDP

Power

Power

Current Sp ecification (Case Temp)

Current Sp ecification (Case Temp)

Ψ-ca = 0.362

Ψ-ca = 0.362

Tcontrol

Tcontrol

Ta = 30 C

Ta = 30 C

TDP

Ψ-ca = 0.292

Ψ-ca = 0.292

TDP

Power

Power

Sensor Based Specification (DTS Temp)

Sensor Based Specification (DTS Temp)

TDP

5.2 Sensor Based Thermal Specification

The sensor based thermal specification consists of two parts. The first is a thermal

profile that defines the maximum TTV T

thermal profile defines the boundary conditions for validation of the thermal solution.

The second part is a defined thermal solution performance (Ψ

DTS value as reported over the PECI bus when DTS is greater than T

defines the operational limits for the processor using the TTV validated thermal

solution.

5.2.1 TTV Thermal Profile

For the sensor based specification the only reference made to a case temperature

measurement is on the TTV. Functional thermal validation will not require the user to

apply a thermocouple to the processor package or measure processor power.

Note: All functional compliance testing will be based on fan speed response to the reported

DTS values above T

will be necessary.

CONTROL

. As a result no conversion of TTV T

as a function of TTV power dissipation. The

CASE

) as a function of the

CA

CONTROL

to processor T

CASE

. This

CASE

28 Thermal/Mechanical Design Guide

Page 29

Sensor Based Thermal Specification Design Guidance

As in previous product specifications, a knowledge of the system boundary conditions is

necessary to perform the heatsink validation. Section 5.3.1 will provide more detail on

defining the boundary conditions. The TTV is placed in the socket and powered to the

recommended value to simulate the TDP condition. See Figure 5-2 for an example of

the processor TTV thermal profile.

Figure 5-2. Thermal Profile

70.0

65.0

60.0

55.0

TTV Tcase in C

50.0

45.0

40.0

0 102030405060708090100110120130

y = 43. 2 + 0. 19 * P

TTV Power (W)

Note: This graph is provided as a reference. Please refer to the appropriate processor

datasheet for the specification.

5.2.2 Specification When DTS value is Greater than T

The product specification provides a table of ΨCA values at DTS = T

DTS = -1 as a function of T

AMBIENT

(inlet to heatsink). Between these two defined

CONTROL

CONTROL

and

points, a linear interpolation can be done for any DTS value reported by the processor.

A copy of the specification is provided as a reference in Table 5-1 of Section 5.6.

The fan speed control algorithm has enough information using only the DTS value and

T

AMBIENT

to command the thermal solution to provide just enough cooling to keep the

part on the thermal profile.

As an example, the data in Table 5-1 has been plotted in Figure 5-3 to show the

required Ψ

required Ψ

at 25, 30, 35, and 39 °C T

CA

which means lower fan speeds and reduced acoustics from the processor

CA

thermal solution.

In the prior thermal specifications this region, DTS values greater than T

defined by the processor thermal profile. This required the user to estimate the

processor power and case temperature. Neither of these two data points are accessible

in real time for the fan speed control system. As a result, the designer had to assume

the worst case T

Thermal/Mechanical Design Guide 29

AMBIENT

AMBIENT

. The lower the ambient, the higher the

CONTROL

, was

and drive the fans to accommodate that boundary condition.

Page 30

Figure 5-3. Thermal solution Performance

Sensor Based Thermal Specification Design Guidance

5.3 Thermal Solution Design Process

Thermal solution design guidance for this specification is the same as with previous

products. The initial design must take into account the target market and overall

product requirements for the system. This can be broken down into several steps:

• Boundary condition definition

• Thermal design / modelling

•Thermal testing

5.3.1 Boundary Condition Definition

Using the knowledge of the system boundary conditions (e.g., inlet air temperature,

acoustic requirements, cost, design for manufacturing, package and socket mechanical

specifications and chassis environmental test limits) the designer can make informed

thermal solution design decisions.

The thermal boundary conditions for an ATX tower system are as follows:

•T

EXTERNAL

•T

RISE

•T

AMBIENT

Based on the system boundary conditions, the designer can select a T

to use in thermal modelling. The assumption of a T

the required Ψ

assumed T

Figure 5-4 shows a number of satisfactory solutions for the processor.

= 35 °C. This is typical of a maximum system operating environment

= 4 °C. This is typical of a chassis compliant to CAG 1.1

= 39 °C (T

needed to meet TTV T

CA

AMBIENT

AMBIENT

can utilize a design with a higher ΨCA, which can have a lower cost.

= T

EXTERNAL

CASEMAX

+ T

RISE

)

AMBIENT

at TDP. A system that can deliver lower

AMBIENT

and ΨCA

has a significant impact on

30 Thermal/Mechanical Design Guide

Page 31

Sensor Based Thermal Specification Design Guidance

Note: If the assumed T

thermal solution performance may not be sufficient to meet the product requirements.

The results may be excessive noise from fans having to operate at a speed higher than

intended. In the worst case this can lead to performance loss with excessive activation

of the Thermal Control Circuit (TCC).

Figure 5-4. Required Ψ

for various T

CA

AMBIENT

is inappropriate for the intended system environment, the

AMBIENT

Conditions

Note: If an ambient of greater than 43.2 °C is necessary based on the boundary conditions a

thermal solution with a Ψ

lower than 0.19 °C/W will be required.

CA

5.3.2 Thermal Design and Modelling

Based on the boundary conditions the designer can now make the design selection of

the thermal solution components. The major components that can be mixed are the

fan, fin geometry , heat pipe or air cooled solid core design. There are cost and acoustic

trade-offs the customer must make.

To aide in the design process Intel provides TTV thermal models. Please consult your

Intel Field Sales Engineer for these tools.

Thermal/Mechanical Design Guide 31

Page 32

Sensor Based Thermal Specification Design Guidance

5.3.3 Thermal Solution Validation

5.3.3.1 Test for Compliance to the TTV Therm al Profile

This step is the same as previously suggested for prior products. The thermal solution

is mounted on a test fixture with the TTV and tested at the following conditions:

• TTV is powered to the TDP condition

• Thermal solution fan operating at full speed

•T

AMBIENT

at the boundary condition from Section 5.3.1

The following data is collected: TTV power, TTV T

CASE

, and T

AMBIENT

, and used to

calculate ΨCA, which is defined as:

Ψ

= (TTV T

CA

CASE

– T

AMBIENT

) / Power

This testing is best conducted on a bench to eliminate as many variables as possible

when assessing the thermal solution performance. The boundary condition analysis as

described in Section 5.3.1 should help in making the bench test simpler to perform.

5.3.3.2 Thermal Solution Characterization for Fan Speed Control

The final step in thermal solution validation is to establish the thermal solution

performance,ΨCA and acoustics as a function of fan speed. This data is necessary to

allow the fan speed control algorithm developer to program the device. It also is

needed to asses the expected acoustic impact of the processor thermal solution in the

system.

The characterization data should be taken over the operating range of the fan. Using

the RCHF5 as the example the fan is operational from 600 to 3500 RPM. The data was

collected at several points and a curve was fit to the data see Figure 5-5. Taking data at

6 evenly distributed fan speeds over the operating range should provide enough data to

establish a 3-variable equation. By using the equation from the curve fitting a complete

set of required fan speeds as a function of Ψ

reference thermal solution characterization are provided in Table 5-1.

The fan speed control device may modulate the thermal solution fan speed (RPM) by

one of two methods a pulse width modulation (PWM) signal or varying the voltage to

the fan. As a result the characterization data needs to also correlate the RPM to PWM or

voltage to the thermal solution fan. The fan speed algorithm developer needs to

associate the output command from the fan speed control device with the required

thermal solution performance as stated in Table 5-1. Regardless of which control

method is used, the term RPM will be used to indicate required fan speed in the rest of

this document.

be developed. The results from the

CA

Note: When selecting a thermal solution from a thermal vendor, the characterization data

should be requested directly from them as a part of their thermal solution collateral.

32 Thermal/Mechanical Design Guide

Page 33

Sensor Based Thermal Specification Design Guidance

Figure 5-5. Thermal Solution Performance vs. Fan Speed

0.50

5.9

5.4

0.40

0.30

4.9

4.4

3.9

Psi-ca

0.20

0.10

3.4

2.9

Bels (BA)

2.4

0.00

1.9

600 1100 1600 2100 2600 3100 3600

RPM

Psi-ca Syst em (BA)

Note: This data is taken from the validation of the RCBF5 reference processor thermal

solution. The Ψ

vs. RPM data is available in Table 5-1 at the end of this chapter.

CA

5.4 Fan Speed Control (FSC) Design Process

The next step is to incorporate the thermal solution characterization data into the

algorithms for the device controlling the fans.

As a reminder, the requirements are:

• When the DTS value is at or below T

with prior processors.

•When DTS is above T

Ψ

vs. RPM to achieve the necessary level of cooling.

CA

This chapter discusses two implementations. The first is a FSC system that is not

provided the T

current T

acoustic benefit by operating the processor closer to the thermal profile. But only the

T

AMBIENT

performance.

In the development of the FSC algorithm it should be noted that the T

expected to change at significantly slower rate than the DTS value. The DTS value will

be driven by the workload on the processor and the thermal solution will be required to

respond to this much more rapidly than the changes in T

An additional consideration in establishing the fan speed curves is to account for the

thermal interface material performance degradation over time.

Thermal/Mechanical Design Guide 33

AMBIENT

AMBIENT

aware FSC system can fully use the specification for optimized acoustic

. Either method will result in a thermally compliant solution and some

CONTROL

information and a FSC system that is provided data on the

, FSC algorithms will use knowledge of T

CONTROL

, the fans can be slowed down; just as

and

is

AMBIENT

AMBIENT

AMBIENT

.

Page 34

Sensor Based Thermal Specification Design Guidance

5.4.1 Fan Speed Control Algorithm without T

In a system that does not provide the FSC algorithm with the T

designer must make the following assumption:

• When the DTS value is greater than T

CONTROL

derived in Section 5.3.1.

This is consistent with our previous FSC guidance to accelerate the fan to full speed

when the DTS value is greater than T

specification at DTS = T

CONTROL

CONTROL

can reduce some of the over cooling of the processor

and provide an acoustic noise reduction from the processor thermal solution.

In this example the following assumptions are made:

•T

AMBIENT

= 39 °C

• Thermal Solution designed / validated to a 39 °C environment

•T

CONTROL

= -20

• Reference processor thermal solution (RCFH5)

•Below T

CONTROL

For a processor specification based on a T

equal to or greater than T

the fan speed is slowed down as in prior products

CASE

CONTROL

, the fan speed must be accelerated to full speed. For

the reference thermal solution full speed is 3500 RPM (dashed line in Figure 5-6). The

DTS thermal specification defines a required Ψ

2500 RPM. This is much less than full speed even if the assumption is a

T

AMBIENT

where DTS values are less than T

acceleration of the fans from T

= 39 °C (solid line in Figure 5-6). The shaded area displayed in Figure 5-6 is

CONTROL

CONTROL

. For simplicity, the graph shows a linear

– 10 to T

for simple fan speed control algorithms.

the T

AMBIENT

. As will be shown below, the DTS thermal

thermal profile, when the DTS value is

and therefore the fan speed is

CA

CONTROL

as has been Intel’s guidance

AMBIENT

Data

information, the

AMBIENT

is at boundary condition

As the processor workload continues to increase, the DTS value will increase and the

FSC algorithm will linearly increase the fan speed from the 2500 RPM at DTS = -20 to

full speed at DTS value = -1.

Figure 5-6. Fan Response Without T

AMBIENT

Data

34 Thermal/Mechanical Design Guide

Page 35

Sensor Based Thermal Specification Design Guidance

5.4.2 Fan Speed Control Algorithm with T

In a system where the FSC algorithm has access to the T

capable of using the data the benefits of the DTS thermal specification become more

striking.

As will be demonstrated below, there is still over cooling of the processor, even when

compared to a nominally ambient aware thermal solution equipped with a thermistor.

An example of these thermal solutions are the RCFH5 or the boxed processor thermal

solutions. This over cooling translates into acoustic margin that can be used in the

overall system acoustic budget.

In this example the following assumptions are made:

•T

AMBIENT

• Thermal Solution designed / validated to a 39 °C environment

•T

CONTROL

• FSC device has access to T

• Reference processor thermal solution (RCFH5)

•Below T

For a processor specification based on a T

equal to or greater than T

for the T

would be about 2500 RPM at 35 °C. This is graphically displayed as the dashed line in

Figure 5-7.

This is an improvement over the ambient unaware system but is not fully optimized for

acoustic benefit. The DTS thermal specification required Ψ

speed in this scenario is 1450 RPM. This is less than thermistor controlled speed of

2500 RPM - even if the assumption is a T

in Figure 5-7.

The shaded area displayed in Figure 5-7 is where DTS values are less than T

For simplicity, the graph shows a linear acceleration of the fans from T

T

CONTROL

As the processor workload continues to increase, the DTS value will increase and the

FSC algorithm will linearly increase the fan speed from the 1450 RPM at DTS = -20 to

2250 RPM at DTS value = -1.

= 35 °C

= -20

thermal profile, when the DTS value is

CASE

, the fan speed is accelerated to maximum fan speed

AMBIENT

= 35 °C. This is graphically displayed

CONTROL

AMBIENT

AMBIENT

the fan speed is slowed down as in prior products

CONTROL

as controlled by the thermistor in thermal solution. For the RCFH5, this

as has been Intel’s guidance for simple fan speed control algorithms.

AMBIENT

AMBIENT

and therefore the fan

CA

Data

information and is

CONTROL

CONTROL

- 10 to

.

Figure 5-7. Fan Response with T

Thermal/Mechanical Design Guide 35

AMBIENT

Aware FSC

Page 36

5.5 System Validation

System validation should focus on ensuring the fan speed control algorithm is

responding appropriately to the DTS values and T

device being monitored for thermal compliance.

Since the processor thermal solution has already been validated using the TTV to the

thermal specifications at the predicted T

chassis is not expected to be necessary.

Once the heatsink has been demonstrated to meet the TTV Thermal Profile, it should be

evaluated on a functional system at the boundary conditions.

In the system under test and Power/Thermal Utility Software set to dissipate the TDP

workload confirm the following item:

• Verify if there is TCC activity by instrumenting the PROCHOT# signal from the

processor. TCC activation in functional application testing is unlikely with a

compliant thermal solution. Some very high power applications might activate TCC

for short intervals this is normal.

• Verify fan speed response is within expectations - actual RPM (Ψ

with DTS temperature and T

• Verify RPM vs. PWM command (or voltage) output from the FSC device is within

expectations.

• Perform sensitivity analysis to asses impact on processor thermal solution

performance and acoustics for the following:

— Other fans in the system.

— Other thermal loads in the system.

AMBIENT

Sensor Based Thermal Specification Design Guidance

data as well as any other

) is consistent

CA

AMBIENT

AMBIENT

, additional TTV based testing in the

.

In the same system under test, run real applications that are representative of the

expected end user usage model and verify the following:

• TCC activation is not occurring.

• Verify fan speed response vs. expectations as done using Power/Thermal Utility

SW.

• Validate system boundary condition assumptions: Trise, venting locations, other

thermal loads and adjust models / design as required.

36 Thermal/Mechanical Design Guide

Page 37

Sensor Based Thermal Specification Design Guidance

5.6 Specification for Operation Where Digital Thermal

Sensor Exceeds T

Table 5-1 is provided as reference for the development of thermal solutions and the fan

speed control algorithm.

CONTROL

Table 5-1. Thermal Solution Performance above T

Ψ

T

1

AMBIENT

43.2 0.190 N/A 0.190 N/A

42.0 0.206 N/A 0.199 N/A

41.0 0.219 N/A 0.207 N/A

40.0 0.232 3250 0.215 N/A

39.0 0.245 2600 0.222 3500

38.0 0.258 2200 0.230 3150

37.0 0.271 1900 0.238 2400

36.0 0.284 1700 0.245 2500

35.0 0.297 1450 0.253 2500

34.0 0.310 1300 0.261 2100

33.0 0.323 1200 0.268 1900

32.0 0.336 1100 0.276 1700

31.0 0.349 1000 0.284 1650

30.0 0.362 900 0.292 1550

29.0 0.375 850 0.299 1450

28.0 0.388 800 0.307 1350

27.0 0.401 700 0.315 1250

26.0 0.414 700 0.322 1200

25.0 0.427 650 0.330 1100

24.0 0.440 600 0.338 1050

23.0 0.453 600 0.345 1000

22.0 0.466 600 0.353 950

21.0 0.479 600 0.361 900

20.0 0.492 600 0.368 900

19.0 0.505 600 0.376 850

18.0 0.519 600 0.384 800

DTS = T

at

CA

CONTROL

RPM for ΨCA at

2

DTS = T

CONTROL

CONTROL

5

Ψ

at

CA

DTS = -1

3

RPM for ΨCA at

DTS = -1

5

Notes:

1. The ambient temperature is measured at the inlet to the processor thermal solution

2. This column can be expressed as a function of T

Ψ

= 0.19 + (43.2 - T

CA

3. This column can be expressed as a function of T

4. This table is provided as a reference please consult the product specification for current values.

5. Based on the testing performed a curve was fit to the data in the form

Thermal/Mechanical Design Guide 37

= 0.19 + (43.2 - T

Ψ

CA

Psi_ca = (1+a*RPM)/(b+c*RPM) where

a = 0.000762, b = 0.667637, c = 004402

AMBIENT

AMBIENT

) * 0.013

) * 0.0077

by the following equation:

AMBIENT

by the following equation:

AMBIENT

§

Page 38

Sensor Based Thermal Specification Design Guidance

38 Thermal/Mechanical Design Guide

Page 39

ATX Reference Thermal Solution

6 ATX Reference Thermal

Solution

Note: The reference thermal mechanical solution information shown in this document

represents the current state of the data and may be subject to modification.The

information represents design targets, not commitments by Intel.

The design strategy is to use the design concepts from the prior Intel® Radial Curved

Bifurcated Fin Heatsink Reference Design (Intel® RCBFH Reference Design) designed

originally for the Intel® Pentium® 4 processors.

This chapter describes the overall requirements for the A TX heatsink reference thermal

solution including critical-to-function dimensions, operating environment, and

validation criteria.

6.1 Operating Environment

Table 6-1 provides the target heatsink performance for the ATX heatsink reference

thermal solution supporting the processor at several system and ambient conditions.

The exhaust air flow from the processor thermal solution is the inlet air flow to the IOH

reference thermal solution and other components such as the voltage regulator. This

airstream is assumed to be approaching the IOH heatsink at a 30° angle from the

processor thermal solution, see the Intel

®

X58 Express Chipset Thermal and

Mechanical Design Guide for more details.

Table 6-1 summarizes the boundary conditions for designing and evaluating the

processor thermal solution. In addition to the power dissipation a set of three system

level boundary conditions for the local ambient T

and external ambient will be used.

A

• Low external ambient (25 °C)/ idle power for the components (Case 3). This covers

the system idle acoustic condition.

• Low external ambient (25 °C)/ TDP for the components (Case 2). The processor

thermal solution fan speed is limited by the thermistor in the fan hub.

• High ambient (35 °C)/ TDP for the components (Case 1). This covers the maximum

.

fan speed condition of the processor thermal solution.

Table 6-1. Processor Thermal Solution Requirements & Boundary Conditions

Case

1 35 °C TDP TDP 39 °C 0.23 °C/W 756 LFM[3.8 m/S]

2 25 °C TDP TDP 30 °C 0.30 °C/W 420 LFM[2.1 m/S]

3 25 °C Idle Idle 30 °C 1.54 °C/W 163 LFM[0.83 m/S]

Notes:

1. The values in Table 6-1 are preliminary and subject to change.

2. Output airflow targets are the minimum inlet requirements for the IOH.

3. For Case 3 the minimum fan speed is projected to deliver 0.54 °C/W.

4. All measurements will be evaluated at sea level.

External

Ambient

IOH

Power

Processor

Power

T

A-Local

Target

Psi-ca

Output

Airflow

Thermal/Mechanical Design Guide 39

Page 40

ATX Reference Thermal Solution

6.2 Heatsink Thermal Solution Assembly

The reference thermal solution for the processor is an active fan solution similar to the

prior designs for the Intel® Pentium® 4 and Intel® Core™2 Duo processors. The

design uses a copper core with an aluminum extrusion. It attaches to the motherboard

with a fastener design reused from the RCBFH3 and RCFH4. The clip design is new to

span the larger size of the LGA1366. The thermal solution assembly requires no

assembly prior to installation on a motherboard. Figure 6-1 shows the reference

thermal solution assembly in an exploded view.

The first step in assembling the thermal solution is to verify the fasteners are aligned to

the mounting holes on the motherboard. The fasteners are pressed firmly to lock the

thermal solution to the motherboard.

Figure 6-1. ATX Heatsink Reference Design Assembly

Wire Guard

Impeller /

Motor Assy

Extrusion

Fastener

Base

Fastener

Cap

Clip

Core

40 Thermal/Mechanical Design Guide

Page 41

ATX Reference Thermal Solution

6.3 Geometric Envelope for the Intel® Reference ATX

Thermal Mechanical Design

Figure 6-2 shows a 3-D representation of the board component keep out for the

reference ATX thermal solution. A fully dimensioned drawing of the keepout information

is available at Figure B-1 and Figure B-2 in Appendix B. A DXF version of these

drawings is available as well as the 3-D model of the board level keep out zone is

available. Contact your field sales representative for these documents.

Figure 6-2. ATX KOZ 3-D Model Primary (Top) Side

Socket / ILM

27.0 mm

Maximum Component

Height (3 – places)

Keep In Zone

10.10 mm

Maximum

Component

Height

(4 – places)

2.50 mm Maximum

Component Height

(5 – places)

1.80 mm Maximum

Component Height

1.20 mm Maximum

Component Height

The maximum height of the reference thermal solution above the motherboard is

71.12 mm [2.8 inches], and is compliant with the motherboard primary side height

constraints defined in the ATX Specification and the microATX Motherboard Interface

Specification found at http://www.formfactors.org.

The reference solution requires a chassis obstruction height of at least 81.28 mm

[3.2 inches], measured from the top of the motherboard. This allows for appropriate

fan inlet airflow to ensure fan performance, and therefore overall cooling solution

performance. This is compliant with the recommendations found in both ATX

Specification and microATX Motherboard Interf ace Sp ec i f i c atio n do cu me nts.

.

Thermal/Mechanical Design Guide 41

Page 42

6.4 Reference Design Components

6.4.1 Extrusion

The aluminum extrusion is a 51 fin 102 mm diameter bifurcated fin design. The overall

height of the extrusion is 38 mm tall. To facilitate reuse of the core design the center

cylinder ID and wall thickness are the same as RCFH4.

Figure 6-3. RCBF5 Extrusion

ATX Reference Thermal Solution

42 Thermal/Mechanical Design Guide

Page 43

ATX Reference Thermal Solution

6.4.2 Clip

Structural design strategy for the clip is to provide sufficient load for the Thermal

Interface Material (TIM).

The clip is formed from 1.6 mm carbon steel, the same material as used in previous clip

designs. The target metal clip nominal stiffness is 376 N/mm [2150 lb/in]. The

combined target for reference clip and fasteners nominal stiffness is 260 N/mm

[1489 lb/in]. The nominal preload provided by the reference design is 191 N ± 42 N

[43 lb ± ~10 lb].

Note: Intel reserves the right to make changes and modifications to the design as necessary

to the Intel RCBF5 reference design, in particular the clip.

Figure 6-4. RCBF5 Clip

Thermal/Mechanical Design Guide 43

Page 44

6.4.3 Core

The core is the same forged design used in RCFH4. This allows the reuse of the fan

attach and if desired the same extrusion as used in RCFH4. The machined flange height

has been reduced from the RCFH4 design to match the IHS height for the Intel®

Xeon® Processor 3500 Series when installed in the LGA1366 socket. The final height of

the flange will be an output of the design validation and could be varied to adjust the