Page 1

R

Intel® 955X Express Chipset

Thermal/Mechanical Design Guide

– For the Intel® 82955X Memory Controller Hub (MCH)

April 2005

Document Number: 307012-001

Page 2

R

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY

ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN

INTEL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER, AND INTEL

DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR

WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT,

COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life saving, or life sustaining

applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel reserves these for

future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

®

The Intel

from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

∆

different processor families. See www.intel.com/products/processor_number

Intel, Pentium and the Intel logo are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other

countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2005, Intel Corporation

82955X Memory Controller Hub (MCH) may contain design defects or errors known as errata which may cause the product to deviate

Intel processor numbers are not a measure of performance. Processor numbers differentiate features within each processor family, not across

for details.

2 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 3

R

Contents

Introduction .........................................................................................................................7

1

1.1 Definition of Terms .................................................................................................8

1.2 Reference Documents............................................................................................8

2 Packaging Technology........................................................................................................9

2.1 Package Mechanical Requirements.....................................................................10

3 Thermal Specifications......................................................................................................11

3.1 Thermal Design Power (TDP)..............................................................................11

3.2 Die Case Temperature Specifications..................................................................11

4 Thermal Simulation...........................................................................................................13

5 Thermal Metrology............................................................................................................15

5.1 Die Case Temperature Measurements................................................................15

5.1.1 Zero Degree Angle Attach Methodology ..............................................15

6 Reference Thermal Solution.............................................................................................17

6.1 Operating Environment ........................................................................................17

6.2 Heatsink Performance..........................................................................................17

6.3 Mechanical Design Envelope...............................................................................18

6.4 Board-Level Components Keep-out Dimensions.................................................20

6.5 Reference Heatsink Thermal Solution Assembly.................................................21

6.5.1 Heatsink Orientation .............................................................................22

6.5.2 Extruded Heatsink Profiles ...................................................................22

6.5.3 Mechanical Interface Material...............................................................23

6.5.4 Thermal Interface Material....................................................................23

6.5.4.1 Effect of Pressure on TIM Performance..............................24

6.5.5 Heatsink Clip.........................................................................................24

6.5.6 Clip Retention Anchors.........................................................................24

6.6 Reliability Guidelines............................................................................................25

7 Appendix A: Thermal Solution Component Suppliers.......................................................27

8 Appendix B: Mechanical Drawings ...................................................................................29

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 3

Page 4

Figures

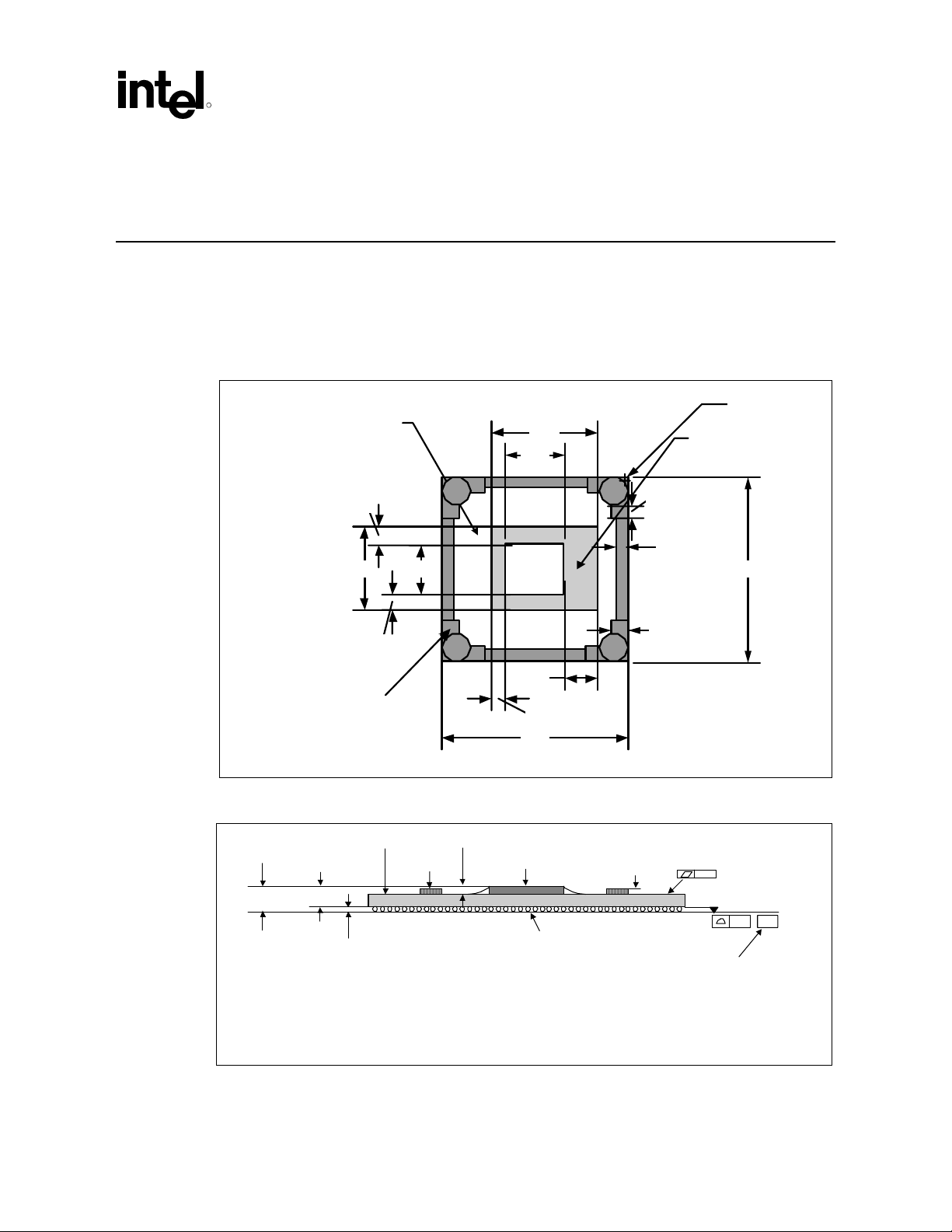

Figure 2-1. MCH Package Dimensions (Top View)............................................................9

Figure 2-2. MCH Package Dimensions (Side View)...........................................................9

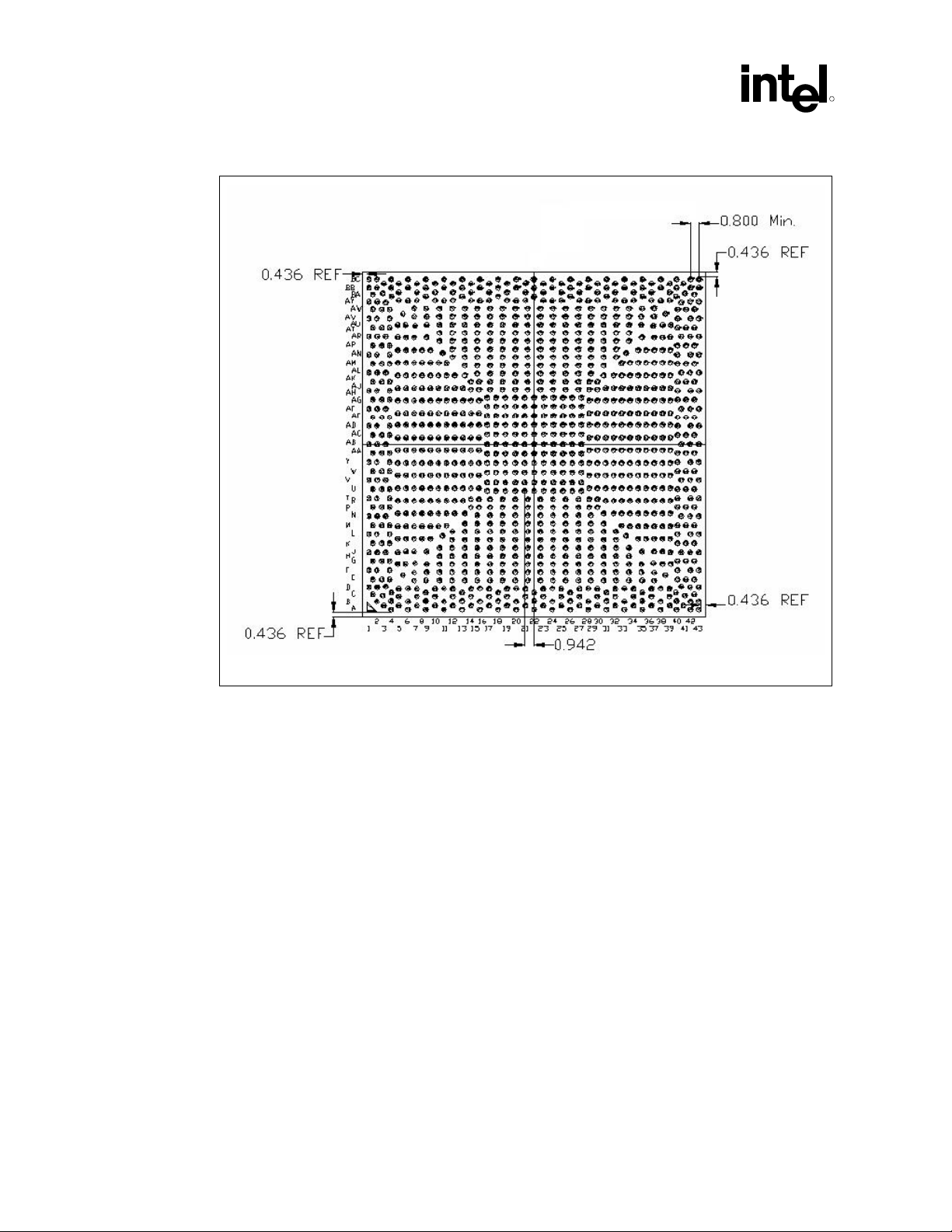

Figure 2-3. MCH Package Dimensions (Bottom View).....................................................10

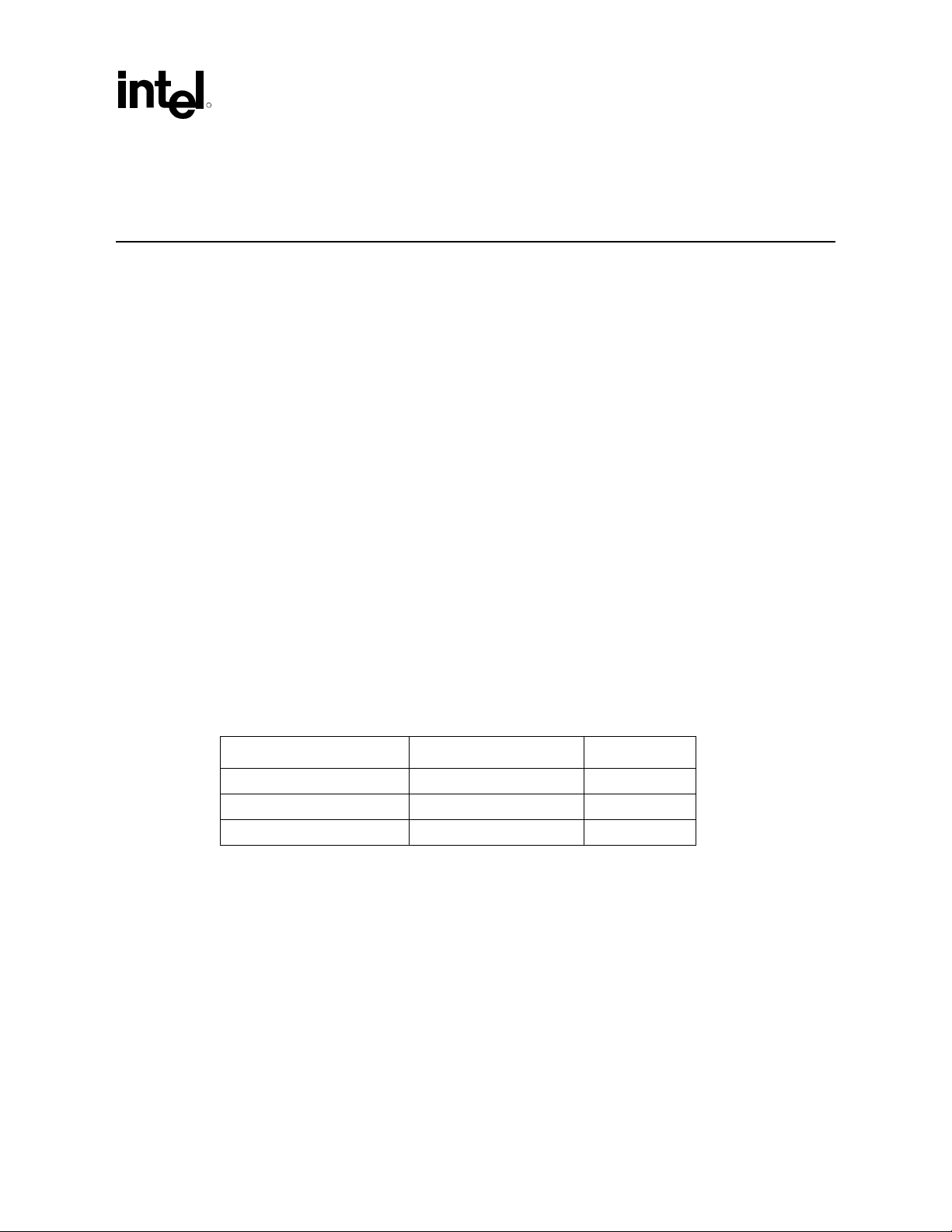

Figure 5-1. Thermal Solution Decision Flowchart.............................................................16

Figure 5-2. Zero Degree Angle Attach Methodology........................................................16

Figure 5-3. Zero Degree Angle Attach Methodology (Top View)......................................16

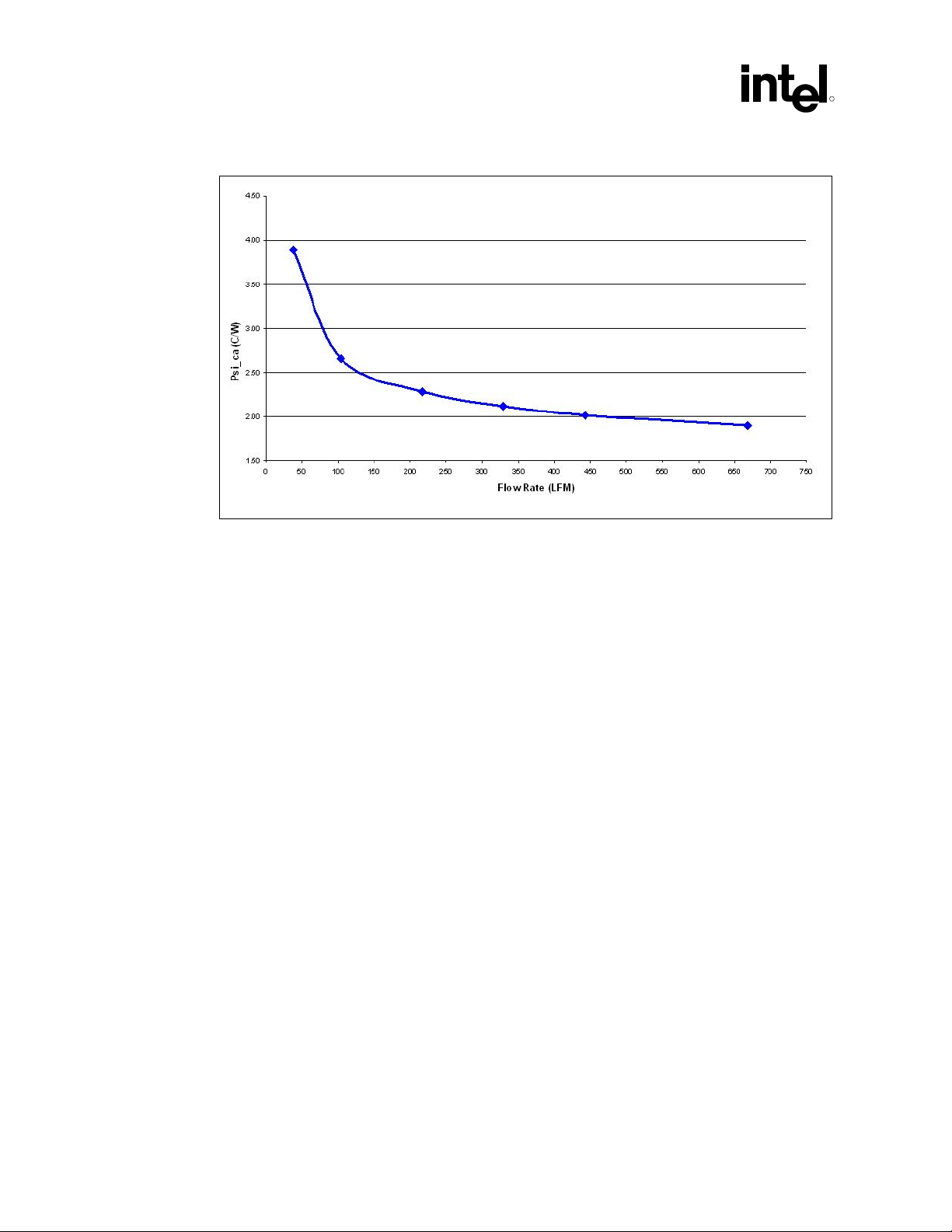

Figure 6-1. Reference Heatsink Measured Thermal Performance versus Approach

Velocity ......................................................................................................................18

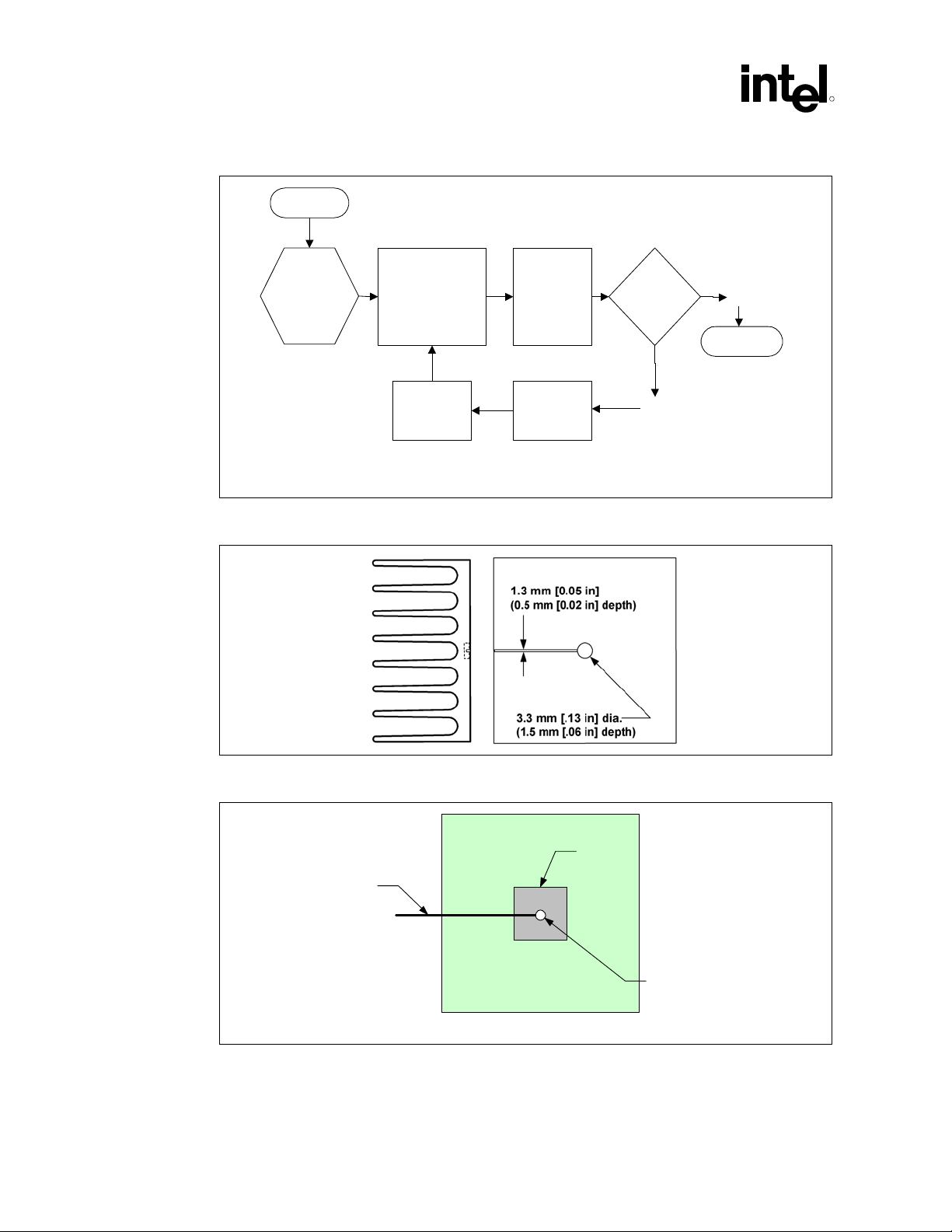

Figure 6-2. Heatsink Volumetric Envelope for the MCH...................................................19

Figure 6-3. MCH Heatsink Board Component Keep-out..................................................20

Figure 6-4. Retention Mechanism Component Keep-out Zones......................................21

Figure 6-5. Plastic Wave Soldering Heatsink Assembly...................................................22

Figure 6-6. Plastic Wave Soldering Heatsink Extrusion Profile........................................23

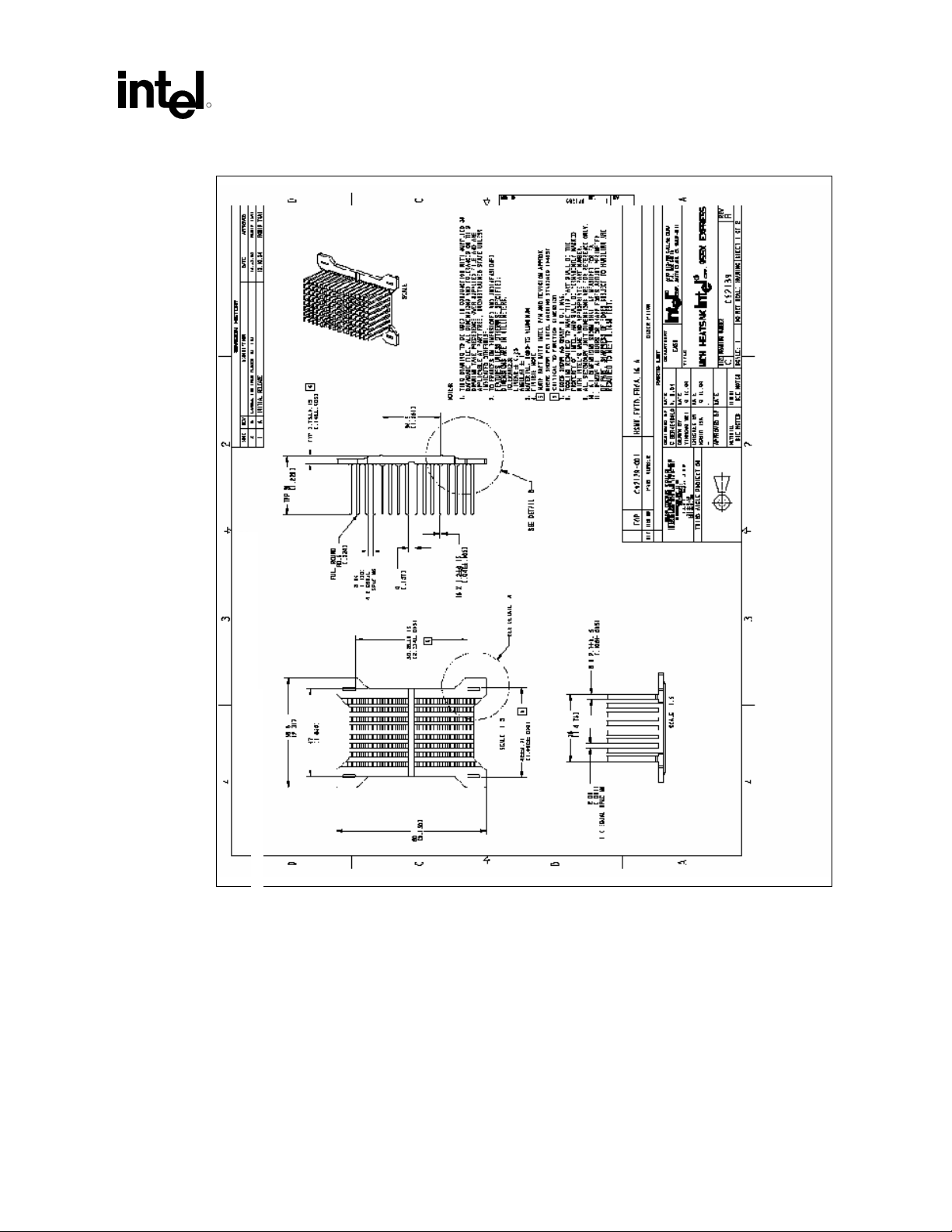

Figure 8-1. Plastic Wave Soldering Heatsink Assembly Drawing ....................................30

Figure 8-2. Plastic Wave Soldering Heatsink Drawing (1 of 2)........................................31

Figure 8-3. Plastic Wave Soldering Heatsink Drawing (2 of 2)........................................32

Figure 8-4. Plastic Wave Soldering Heatsink Ramp Clip Drawing (1 of 2).......................33

Figure 8-5. Plastic Wave Soldering Heatsink Ramp Clip Drawing (2 of 2).......................34

Figure 8-6. Plastic Wave Soldering Heatsink Wire Clip Drawing .....................................35

Figure 8-7. Plastic Wave Soldering Heatsink Solder-Down Anchor Drawing ..................36

R

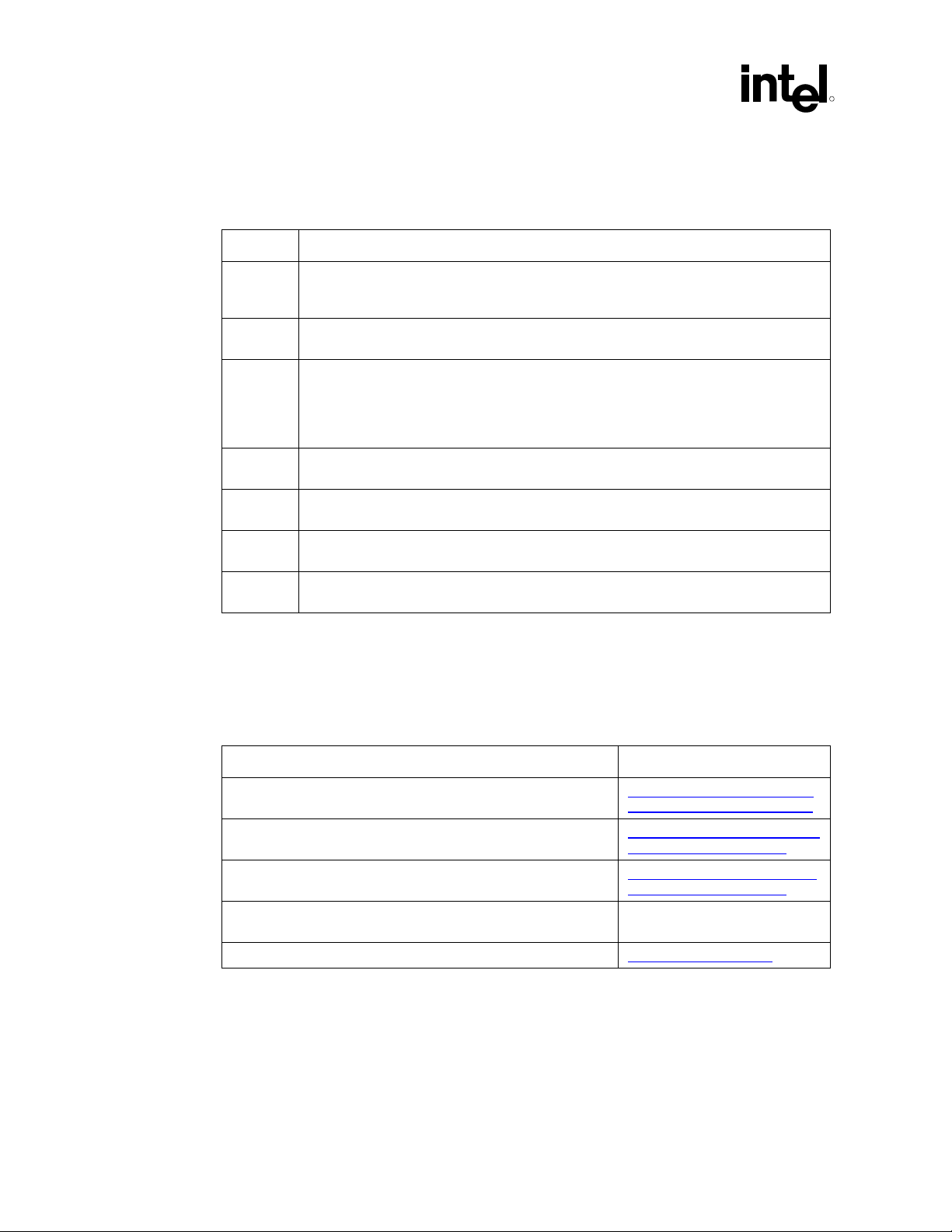

Tables

Table 3-1. MCH Thermal Specifications...........................................................................11

Table 6-1 Honeywell PCM 45F TIM Performance as a Function of Attach Pressure ......24

Table 6-2. Reliability Guidelines .......................................................................................25

Table 7-1. MCH Heatsink Thermal Solution.....................................................................27

Table 8-1. Mechanical Drawing List..................................................................................29

4 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 5

R

Revision History

Revision

Number

-001 • Initial Release. April 2005

Description Revision Date

§

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 5

Page 6

R

6 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 7

Introduction

R

1 Introduction

As the complexity of computer systems increases, so do the power dissipation requirements. Care

must be taken to ensure that the additional power is properly dissipated. Typical methods to

improve heat dissipation include selective use of ducting, and/or passive heatsinks.

The goals of this document are to:

®

• Outline the thermal and mechanical operating limits and specifications for the Intel

Express Chipset Memory Controller Hub (MCH).

• Describe a reference thermal solution that meets the specification of the 82955X MCH.

Properly designed thermal solutions provide adequate cooling to maintain the MCH die

temperatures at or below thermal specifications. This is accomplished by providing a low localambient temperature, ensuring adequate local airflow, and minimizing the die to local-ambient

thermal resistance. By maintaining the MCH die temperature at or below the specified limits, a

system designer can ensure the proper functionality, performance, and reliability of the chipset.

Operation outside the functional limits can degrade system performance and may cause

permanent changes in the operating characteristics of the component.

82955X

The simplest and most cost effective method to improve the inherent system cooling

characteristics is through careful design and placement of fans, vents, and ducts. When additional

cooling is required, component thermal solutions may be implemented in conjunction with system

thermal solutions. The size of the fan or heatsink can be varied to balance size and space

constraints with acoustic noise.

This document addresses thermal design and specifications for the 82955X MCH component

only. For thermal design information on other chipset components, refer to the respective

component datasheet. For the ICH7, refer to the Intel

®

I/O Controller Hub 7 (ICH7) Thermal

Design Guidelines.

Note: Unless otherwise specified, the term MCH refers to the Intel

®

82955X Express chipset MCH.

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 7

Page 8

Introduction

1.1 Definition of Terms

Term Description

BGA Ball grid array. A package type, defined by a resin-fiber substrate, onto which a die is

mounted, bonded and encapsulated in molding compound. The primary electrical interface is

an array of solder balls attached to the substrate opposite the die and molding compound.

BLT Bond line thickness. Final settled thickness of the thermal interface material after installation

of heatsink.

ICH7 I/O Controller Hub. Seventh generation I/O Controller Hub component that contains

additional functionality compared to previous ICH components. The I/O Controller Hub

component that contains the primary PCI interface, LPC interface, USB2, ATA-100, and

other I/O functions. It communicates with the MCH over a proprietary interconnect called

DMI.

MCH Memory Controller Hub. The chipset component that contains the processor interface, the

memory interface, and the DMI.

T

case_max

T

case_min

TDP Thermal design power. Thermal solutions should be designed to dissipate this target power

Maximum die temperature allowed. This temperature is measured at the geometric center of

the top of the package die.

Minimum die temperature allowed. This temperature is measured at the geometric center of

the top of the package die.

level. TDP is not the maximum power that the chipset can dissipate.

R

1.2 Reference Documents

The reader of this specification should also be familiar with material and concepts presented in

the following documents:

Document Title Document Number / Location

Intel® I/O Controller Hub 7 (ICH7) Thermal Design Guidelines http://developer.intel.com//desi

Intel® I/O Controller Hub 7 (ICH7) Datasheet http://developer.intel.com//design/c

Intel® 955X Express Chipset Datasheet http://developer.intel.com/design/c

BGA/OLGA Assembly Development Guide Contact your Intel Field Sales

Various system thermal design suggestions http://www.formfactors.org

§

gn/chipsets/designex/307015.htm

hipsets/datashts/307013.htm

hipsets/datashts/306828.htm

Representative

8 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 9

Packaging Technology

R

2 Packaging Technology

The 955X Express chipset consists of two individual components: the MCH and the ICH7. The

MCH component uses a 34 mm squared, 6-layer flip chip ball grid array (FC-BGA) package (see

Figure 2-1 through Figure 2-3). For information on the ICH7 package, refer to the Intel

Controller Hub 7 (ICH7) Thermal Design Guidelines.

Figure 2-1. MCH Package Dimensions (Top View)

®

I/O

Capaci tor Area,

Handling Exclusion

Zone

3.1

15.34 9.14

3.1

Handling Area

Figure 2-2. MCH Package Dimensions (Side View)

2.355 ± 0.082 mm

Substrate

1.92 ± 0.078 mm

0.84 ± 0.05 mm

Decoup

Cap

19.38

10.67

MCH

Die

6.17

2.54

34.00

Die

0. 7 mm Max

2.30

2.0

3.0

Ø5.20mm

Die

Keepout

Area

34.00

955X_Pkg_TopView

0.20 See note 4.

0.435 ± 0.025 mm

See note 3

Notes:

1. Primary datum -C- and seating plan are defined by the spherical crow ns of the solder balls (shown before motherboard attach)

2. All dimensions and tolerances conf orm to ANSI Y14.5M-1994

3. BGA has a pre-SMT height of 0.5mm and post-SMT height of 0.41-0.46mm

4. Shown before motherboard attach; FCBGA has a convex (dome shaped) orientation before reflow and is expected to have a slightly concave (bow l

shaped) orientation after reflow

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 9

Seating Plane

0.20 –C–

See note 1.

955X_Pkg_SideView

Page 10

Packaging Technology

Figure 2-3. MCH Package Dimensions (Bottom View)

R

NOTES:

1. All dimensions are in millimeters.

2. All dimensions and tolerances conform to ANSI Y14.5M-1994.

2.1 Package Mechanical Requirements

The MCH package has an exposed bare die that is capable of sustaining a maximum static normal

load of 10-lbf. The package is NOT capable of sustaining a dynamic or static compressive load

applied to any edge of the bare die. These mechanical load limits must not be exceeded during

heatsink installation, mechanical stress testing, standard shipping conditions and/or any other use

condition.

Note:

1. The heatsink attach solutions must not result in continuous stress onto the chipset package

with the exception of a uniform load to maintain the heatsink-to-package thermal interface.

2. These specifications apply to uniform compressive loading in a direction perpendicular to the

bare die top surface.

3. These specifications are based on limited testing for design characterization. Loading limits

are for the package only.

§

10 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 11

Thermal Specifications

R

3 Thermal Specifications

3.1 Thermal Design Power (TDP)

Analysis indicates that real applications are unlikely to cause the chipset MCH to consume

maximum power dissipation for sustained time periods. Therefore, to arrive at a more realistic

power level for thermal design purposes, Intel characterizes power consumption based on known

platform benchmark applications. The resulting power consumption is referred to as the Thermal

Design Power (TDP). TDP is the target power level that the thermal solutions should be designed

to. TDP is not the maximum power that the chipset can dissipate.

For TDP specifications, see Table 3-1 for the 955X Express chipset MCH. FC-BGA packages

have limited heat transfer capability into the board and have minimal thermal capability without a

thermal solution. Intel recommends that system designers plan for one or more heatsinks when

using the 955X Express chipset.

3.2 Die Case Temperature Specifications

To ensure proper operation and reliability of the MCH, the die temperatures must be at or

between the maximum/minimum operating range as specified in Table 3-1 for the 82955X MCH.

System and/or component level thermal solutions are required to maintain these temperature

specifications. Refer to Chapter 5 for guidelines on accurately measuring package die

temperatures.

Table 3-1. MCH Thermal Specifications

Parameter Value Notes

T

105 °C —

case_max

T

5 °C —

case_min

TDP

NOTE: These specifications are based on silicon characterization; however, they may be updated as further

data becomes available.

13.5 W DDR2-667

dual channel

§

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 11

Page 12

Thermal Specifications

R

12 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 13

Thermal Simulation

R

4 Thermal Simulation

Intel provides thermal simulation models of the 955X Express chipset MCH and associated user's

guides to aid system designers in simulating, analyzing, and optimizing their thermal solutions in

an integrated, system-level environment. The models are for use with the commercially available

Computational Fluid Dynamics (CFD)-based thermal analysis tool “FLOTHERM”* (version 5.1

or higher) by Flomerics, Inc. Contact your Intel field sales representative to order the thermal

models and user's guides.

§

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 13

Page 14

Thermal Simulation

R

14 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 15

Thermal Metrology

R

5 Thermal Metrology

The system designer must make temperature measurements to accurately determine the thermal

performance of the system. Intel has established guidelines for proper techniques to measure the

MCH die temperatures. Section 5.1 provides guidelines on how to accurately measure the MCH

die temperatures. The flowchart in Figure 5-1 offers useful guidelines for thermal performance

and evaluation.

5.1 Die Case Temperature Measurements

To ensure functionality and reliability, the T

maximum/minimum operating range of the temperature specification as noted in Table 3-1. . The

surface temperature at the geometric center of the die corresponds to T

requires special care to ensure an accurate temperature measurement.

Temperature differences between the temperature of a surface and the surrounding local ambient

air can introduce errors in the measurements. The measurement errors could be due to a poor

thermal contact between the thermocouple junction and the surface of the package, heat loss by

radiation and/or convection, conduction through thermocouple leads, and/or contact between the

thermocouple cement and the heatsink base (if a heatsink is used). For maximum measurement

accuracy, only the 0° thermocouple attach approach is recommended.

of the MCH must be maintained at or between the

case

5.1.1 Zero Degree Angle Attach Methodology

1. Mill a 3.3 mm (0.13 in.) diameter and 1.5 mm (0.06 in.) deep hole centered on the bottom of

the heatsink base.

2. Mill a 1.3 mm (0.05 in.) wide and 0.5 mm (0.02 in.) deep slot from the centered hole to one

edge of the heatsink. The slot should be parallel to the heatsink fins (see Figure 5-2).

3. Attach thermal interface material (TIM) to the bottom of the heatsink base.

4. Cut out portions of the TIM to make room for the thermocouple wire and bead. The cutouts

should match the slot and hole milled into the heatsink base.

5. Attach a 36 gauge or smaller calibrated K-type thermocouple bead or junction to the center of

the top surface of the die using a high thermal conductivity cement. During this step, ensure

no contact is present between the thermocouple cement and the heatsink base because any

contact will affect the thermocouple reading. It is critical that the thermocouple bead

makes contact with the die (see Figure 5-3).

6. Attach heatsink assembly to the MCH and route thermocouple wires out through the milled

slot.

. Measuring T

case

case

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 15

Page 16

Thermal Metrology

Figure 5-1. Thermal Solution Decision Flowchart

Start

R

Attach

Attach device

to board using

normal reflow

process.

thermocouples using

recommended

metrology. Se tu p the

system in the desir ed

configuration.

Select Heatsink

Figure 5-2. Zero Degree Angle Attach Methodology

Run the Power

program and

monitor the

device die

temperature.

Heatsink

Required

Tdie >

Specification?

Yes

No

End

Therm_Solution_Flow

Figure 5-3. Zero Degree Angle Attach Methodology (Top View)

Thermocouple

NOTE: Not to scale.

Wire

Substrate

§

16 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Die

Cement +

Thermocouple Bead

0_Angle_Attach_Method

Page 17

Reference Thermal Solution

R

6 Reference Thermal Solution

Intel has developed a reference thermal solution designed to meet the cooling needs of the MCH

under operating environments and specifications defined in this document. This chapter describes

the overall requirements for the Plastic Wave Soldering Heatsink (PWSH) reference thermal

solution including critical-to-function dimensions, operating environment, and validation criteria.

Other chipset components may or may not need attached thermal solutions, depending on your

specific system local-ambient operating conditions. For information on the ICH7, refer to thermal

specification in the Intel

6.1 Operating Environment

The reference thermal solution was designed assuming a maximum local-ambient temperature of

55 °C. The minimum recommended airflow velocity through the cross section of the heatsink fins

is 350 linear feet per minute (lfm). The approaching airflow temperature is assumed to be equal to

the local-ambient temperature. The thermal designer must carefully select the location to measure

airflow to obtain an accurate estimate. These local-ambient conditions are based on a 35 °C

external-ambient temperature at sea level. (External-ambient refers to the environment external to

the system.)

®

I/O Controller Hub 7 (ICH7) Thermal Design Guidelines.

6.2 Heatsink Performance

Figure 6-1 depicts the measured thermal performance of the reference thermal solution versus

approach air velocity. Since this data was measured at sea level, a correction factor would be

required to estimate thermal performance at other altitudes.

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 17

Page 18

Reference Thermal Solution

Figure 6-1. Reference Heatsink Measured Thermal Performance versus Approach Velocity

R

6.3 Mechanical Design Envelope

While each design may have unique mechanical volume and height restrictions or implementation

requirements, the height, width, and depth constraints typically placed on the MCH thermal

solution are shown in Figure 6-2.

When using heatsinks that extend beyond the MCH reference heatsink envelope shown in

Figure 6-2, any motherboard components placed between the heatsink and motherboard cannot

exceed 2.2 mm (0.087 in.) in height.

18 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 19

Reference Thermal Solution

R

Figure 6-2. Heatsink Volumetric Envelope for the MCH

Ramp

FCBGA + Solder

Balls

Retainer

Heatsink Fin

Heatsink Base

TIM

Die

Motherboard

60.6 mm

48.0 mm

26.79 mm

2.50 mm

33.50 mm

1.90 mm

81.0 mm

67.0 mm

45.79 mm

TNB

Heatsink Fin

O

135

47.0 mm

60.92 mm

Max 2.2 mm

Component

Height

No

component

this Area

HS_Vol_Envelope_MCH

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 19

Page 20

Reference Thermal Solution

6.4 Board-Level Components Keep-out Dimensions

The location of hole patterns and keep-out zones for the reference thermal solution are shown in

Figure 6-3 and Figure 6-4.

Figure 6-3. MCH Heatsink Board Component Keep-out

60.6 mm

48.0 mm

26.79 mm

TNB

R

81.0 mm

67.0 mm

45.79 mm

Heatsink Fin

O

135

47.0 mm

Air Flow

60.92 mm

HS_Brd_Component_Keepout

Max 2.2 mm

Component

Height

No

component

this Area

20 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 21

Reference Thermal Solution

R

Figure 6-4. Retention Mechanism Component Keep-out Zones

4 x 8.76 mm

Max 1.27mm

Component

Height

4 x 5.08mm

4 x 1.84mm

8 x Ø0.97 mm Plated Thru Hole

8 x Ø1.42 mm Trace Keepout

RM_Component_KeepoutZones

4 x 8.76mm

No Components

this Area

6.5 Reference Heatsink Thermal Solution Assembly

The reference thermal solution for the MCH is a passive extruded heatsink with thermal interface.

It is attached using a clip with each end hooked through an anchor soldered to the board. Figure

6-5 shows the reference thermal solution assembly and associated components.

Full mechanical drawings of the thermal solution assembly and the heatsink clip are provided in

Appendix B. Appendix A contains vendor information for each thermal solution component.

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 21

Page 22

Reference Thermal Solution

Figure 6-5. Plastic Wave Soldering Heatsink Assembly

R

6.5.1 Heatsink Orientation

To enhance the efficiency of the reference thermal solution, it is important for the designer to

orient the fins properly with respect to the mean airflow direction. Simulation and experimental

evidence have shown that the MCH heatsink thermal performance is enhanced when the fins are

aligned with the mean airflow direction (see Figure 6-3).

6.5.2 Extruded Heatsink Profiles

The reference thermal solution uses an extruded heatsink for cooling the MCH. Figure 6-5 shows

the heatsink profile. Appendix A lists a supplier for this extruded heatsink. Other heatsinks with

similar dimensions and increased thermal performance may be available. Full mechanical drawing

of this heatsink is provided in Appendix B.

22 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 23

Reference Thermal Solution

R

Figure 6-6. Plastic Wave Soldering Heatsink Extrusion Profile

NOTE: All dimensions are in millimeters, with dimensions in braces expressed in inches.

6.5.3 Mechanical Interface Material

There is no mechanical interface material associated with this reference solution.

6.5.4 Thermal Interface Material

A TIM provides improved conductivity between the die and heatsink. The reference thermal

solution uses Honeywell PCM 45F, 0.25 mm (0.010 in.) thick, 15 mm x 15 mm

(0.59 in. x 0.59 in.) square.

Note: Unflowed or “dry” Honeywell PCM 45F has a material thickness of 0.010 inch. The flowed or

“wet” Honeywell PCM 45F has a material thickness of ~0.003 inches after it reaches its phase

change temperature.

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 23

Page 24

Reference Thermal Solution

6.5.4.1 Effect of Pressure on TIM Performance

As mechanical pressure increases on the TIM, the thermal resistance of the TIM decreases. This

phenomenon is due to the decrease of the bond line thickness (BLT). BLT is the final settled

thickness of the thermal interface material after installation of heatsink. The effect of pressure on

the thermal resistance of the Honeywell* PCM45F TIM is shown in Table 6-1. The heatsink clip

provides enough pressure for the TIM to achieve a thermal conductivity of 0.17 °C inch

Table 6-1 Honeywell PCM 45F TIM Performance as a Function of Attach Pressure

Pressure (psi) Thermal Resistance (°C × in2)/W

5 0.049

10 0.046

20 0.045

30 0.044

2

/W.

R

Note: All measured at 50 °C.

6.5.5 Heatsink Clip

The retention mechanism in this reference solution includes two different types of clips; one is

ramp clip and the other is wire clip. Each end of the wire clip is attached to the ramp clip that in

turn attaches to anchors to fasten the overall heatsink assembly to the motherboard. See

Appendix B for a mechanical drawing of the clip.

6.5.6 Clip Retention Anchors

For 955X Express chipset-based platforms that have very limited board space, a clip retention

anchor has been developed to minimize the impact of clip retention on the board. It is based on a

standard two-pin jumper and is soldered to the board like any common through-hole header. A

new anchor design is available with 45° bent leads to increase the anchor attach reliability over

time. See Appendix A for the part number and supplier information.

24 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 25

Reference Thermal Solution

R

6.6 Reliability Guidelines

Each motherboard, heatsink and attach combination may vary the mechanical loading of the

component. Based on the end user environment, the user should define the appropriate reliability

test criteria and carefully evaluate the completed assembly prior to use in high volume. Some

general recommendations are shown in Table 6-2.

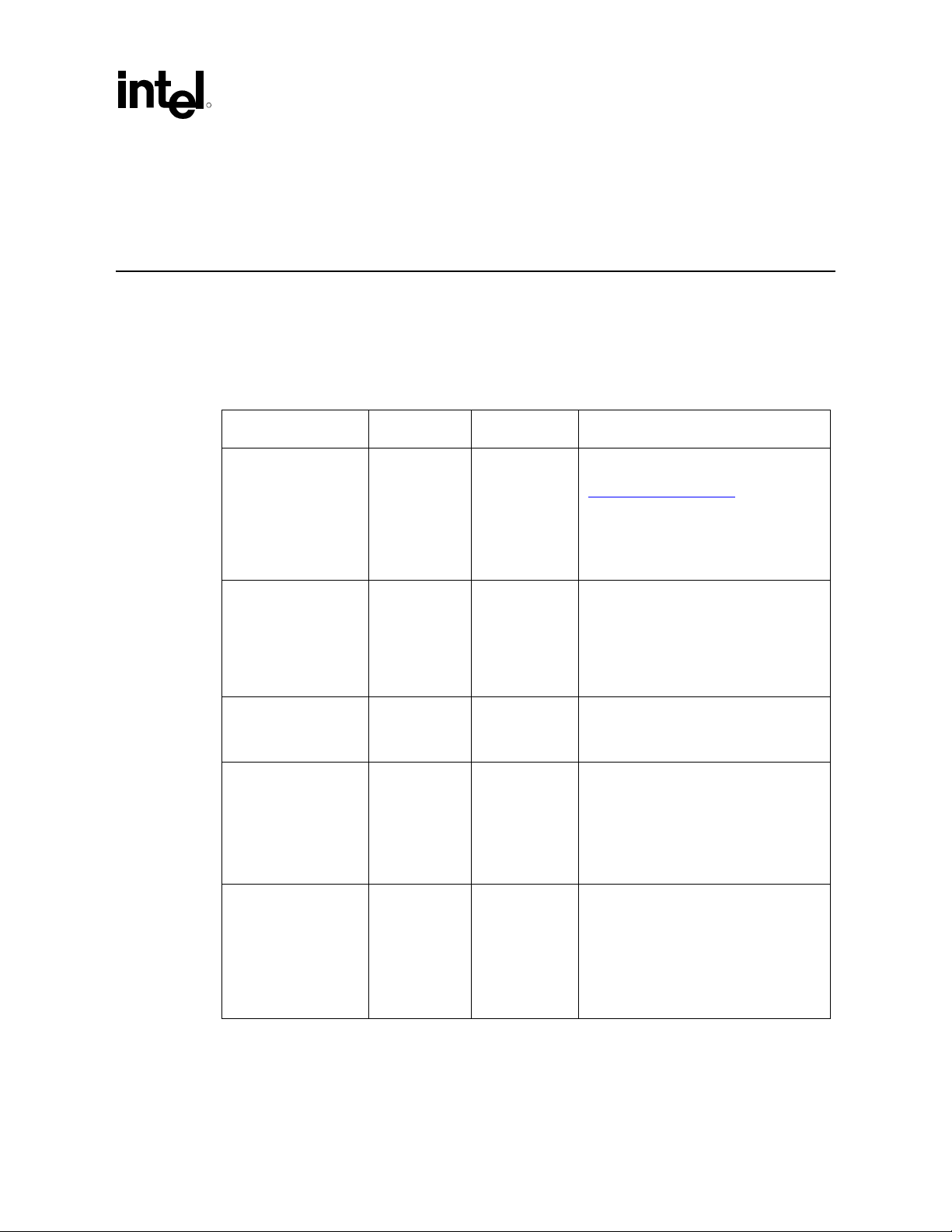

Table 6-2. Reliability Guidelines

Test1 Requirement Pass/Fail Criteria2

Mechanical Shock 50 g, board level, 11 msec, 3 shocks/axis. Visual Check and Electrical

Functional Test

Random Vibration 7.3 g, board level, 45 min/axis, 50 Hz to 2000 Hz. Visual Check and Electrical

Functional Test

Temperature Life 85°C, 2000 hours total, checkpoints at 168, 500,

1000, and 2000 hours.

Thermal Cycling –5 °C to +70 °C, 500 cycles. Visual Check

Humidity 85% relative humidity, 55 °C, 1000 hours. Visual Check

Visual Check

NOTES:

1. It is recommended that the above tests be performed on a sample size of at least twelve assemblies

from three lots of material.

2. Additional pass/fail criteria may be added at the discretion of the user.

§

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 25

Page 26

Reference Thermal Solution

R

26 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 27

Appendix A: Thermal Solution Component Suppliers

R

7 Appendix A: Thermal Solution

Component Suppliers

This list is provided by Intel solely as a convenience to customers. Intel has not tested, designed

or validated these products and does not warrant user suitability or performance in any way.

Customers are solely responsible for determining the suitability and application of these products

for their designs.

Table 7-1. MCH Heatsink Thermal Solution

Part

Heatsink Assembly

includes:

⎯ Pin-Fin Heatsink

⎯ Thermal Interface

Material

⎯ Ramp Clip

⎯ Wire Clip

Pin-Fin Heatsink

Thermal Interface

(PCM 45F)

Heatsink Ramp Clip

Heatsink Wire Clip

Intel Part

Number

C99237-001 CCI

C92139-001 CCI

C34795-001

C92140-001 CCI

C85373-001 CCI

Supplier

(Part Number)

Honeywell

PCM 45F

Contact Information

Monica Chih (Taiwan)

866-2-29952666, x131

monica_chih@ccic.com.tw

Harry Lin (CCI/ACK-USA)

714-739-5797

hlinack@aol.com

Monica Chih (Taiwan)

866-2-29952666, x131

monica_chih@ccic.com.tw

Harry Lin (CCI/ACK-USA)

714-739-5797

hlinack@aol.com

Scott Miller

509-252-2206

scott.miller4@honeywell.com

Monica Chih (Taiwan)

866-2-29952666, x131

monica_chih@ccic.com.tw

Harry Lin (CCI/ACK-USA)

714-739-5797

hlinack@aol.com

Monica Chih (Taiwan)

866-2-29952666, x131

monica_chih@ccic.com.tw

Harry Lin (CCI/ACK-USA)

714-739-5797

hlinack@aol.com

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 27

Page 28

Appendix A: Thermal Solution Component Suppliers

R

Part

Solder-Down Anchor

NOTE: The enabled components may not be currently available from all suppliers. Contact the supplier directly

to verify time of component availability.

Intel Part

Number

C85376-001 Wieson

Supplier

(Part Number)

Contact Information

Rick Lin

Deputy Manager/Project Sales

Department

Add.: 7F, No. 276, Section 1, Tatung

Road, Hsichih City, Taipei Hsien, Taiwan

Tel: 886-2-2647-1896 ext. 6342

Mobile: 886-955644008

Email: rick@wieson.com

Website: www. wieson.com

§

28 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 29

Appendix B: Mechanical Drawings

R

8 Appendix B: Mechanical Drawings

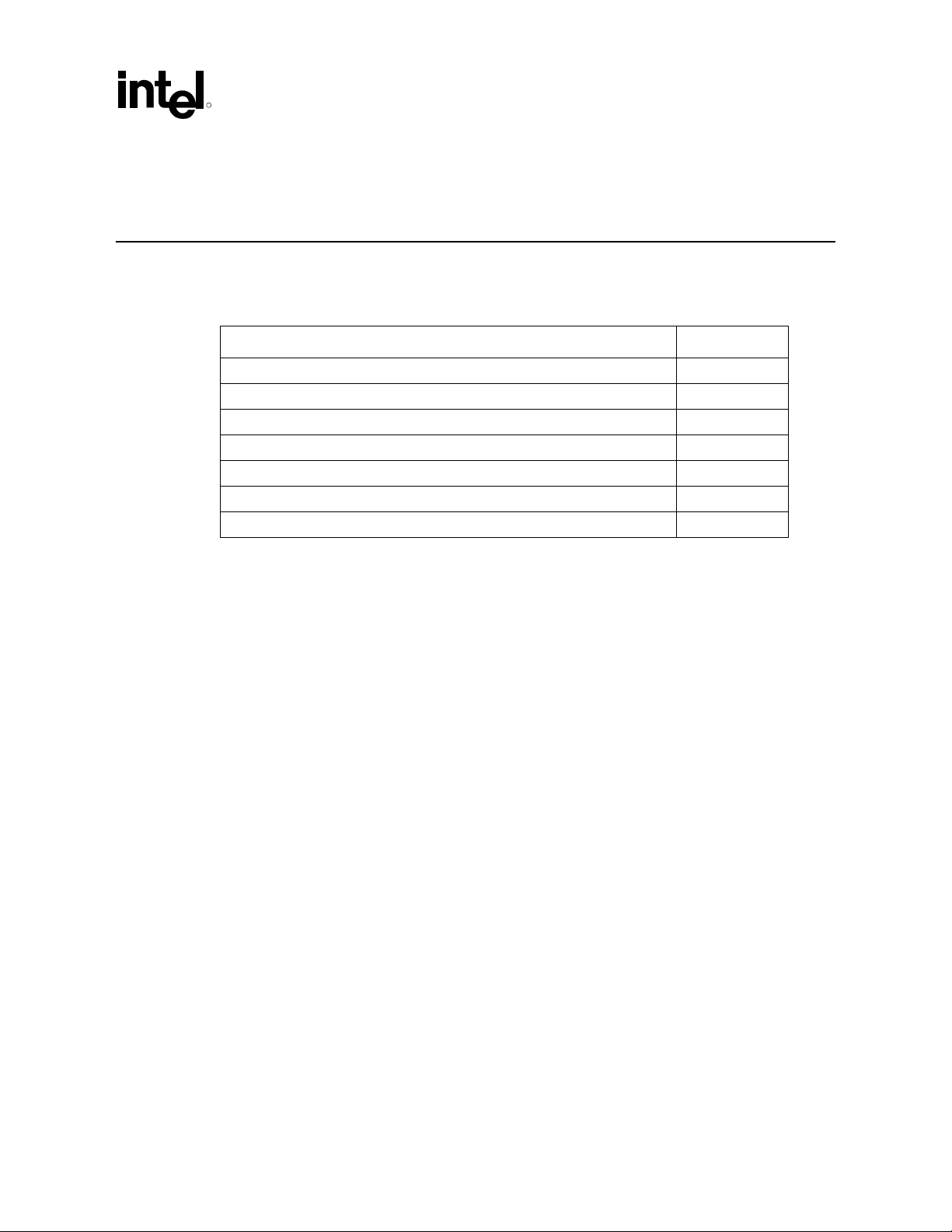

Table 8-1 lists the mechanical drawings included in this appendix.

Table 8-1. Mechanical Drawing List

Drawing Description Figure Number

Plastic Wave Soldering Heatsink Assembly Drawing Figure 8-1

Plastic Wave Soldering Heatsink Drawing (1 of 2) Figure 8-2

Plastic Wave Soldering Heatsink Drawing (2 of 2) Figure 8-3

Plastic Wave Soldering Heatsink Ramp Clip Drawing (1 of 2) Figure 8-4

Plastic Wave Soldering Heatsink Ramp Clip Drawing (2 of 2) Figure 8-5

Plastic Wave Soldering Heatsink Wire Clip Drawing Figure 8-6

Plastic Wave Soldering Heatsink Solder-Down Anchor Drawing Figure 8-7

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 29

Page 30

Appendix B: Mechanical Drawings

Figure 8-1. Plastic Wave Soldering Heatsink Assembly Drawing

R

30 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 31

Appendix B: Mechanical Drawings

R

Figure 8-2. Plastic Wave Soldering Heatsink Drawing (1 of 2)

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 31

Page 32

Appendix B: Mechanical Drawings

Figure 8-3. Plastic Wave Soldering Heatsink Drawing (2 of 2)

R

32 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 33

Appendix B: Mechanical Drawings

R

Figure 8-4. Plastic Wave Soldering Heatsink Ramp Clip Drawing (1 of 2)

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 33

Page 34

Appendix B: Mechanical Drawings

Figure 8-5. Plastic Wave Soldering Heatsink Ramp Clip Drawing (2 of 2)

R

34 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Page 35

Appendix B: Mechanical Drawings

R

Figure 8-6. Plastic Wave Soldering Heatsink Wire Clip Drawing

®

Intel

955X Express Chipset Thermal/Mechanical Design Guide 35

Page 36

Appendix B: Mechanical Drawings

Figure 8-7. Plastic Wave Soldering Heatsink Solder-Down Anchor Drawing

R

§

36 Intel

®

955X Express Chipset Thermal/Mechanical Design Guide

Loading...

Loading...