Page 1

Intel® 945G/945GZ/945GC/

945P/945PL Express Chipset

Family

Thermal and Mechanical Design Guidelines (TMDG)

- For the Intel® 82945G/82945GZ/82945GC Graphics Memory

Controller Hub (GMCH) and Intel® 82945P/82945PL Memory

Controller Hub (MCH)

February 2008

Document Number: 307504-004

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR

IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT

AS PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY

WHATSOEVER, AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL

PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY,

OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS OTHERWISE AGREED IN WRITING BY INTEL, THE INTEL PRODUCTS ARE NOT DESIGNED NOR INTENDED FOR ANY

APPLICATION IN WHICH THE FAILURE OF THE INTEL PRODUCT COULD CREATE A SITUATION WHERE PERSONAL INJURY OR

DEATH MAY OCCUR.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel

reserves these for future definition and shall ha ve no responsibility whatsoever for conflicts or incompatibilities arising from

future changes to them.

The Intel

errata, which may cause the product to deviate from published specifications. Current characterized errata are available on

request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Intel, Pentium, and the Intel log o are trademarks of Intel Corporation in the U.S. and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2005–2008, Intel Corporation. All rights reserved.

®

82945G/82945GZ/82945GC GMCH and Intel® 82945P/82945PL MCH may contain design defects or errors known as

2 Thermal and Mechanical Design Guidelines

Page 3

Contents

1 Introduction.....................................................................................................7

1.1 Terminology ..........................................................................................8

1.2 Reference Documents .............................................................................9

2 Product Specifications......................................................................................11

2.1 Package Description..............................................................................11

2.1.1 Non-Grid Array Package Ball Placement......................................11

2.2 Package Loading Specifications...............................................................12

2.3 Thermal Specifications ..........................................................................13

2.4 Thermal Design Power (TDP)..................................................................13

2.4.1 Methodology...........................................................................14

2.4.2 Application Power....................................................................14

2.4.3 Specifications .........................................................................14

3 Thermal Metrology..........................................................................................15

3.1 Case Temperature Measurements...........................................................15

3.1.1 Thermocouple Attach Methodology.............................................15

3.2 Airflow Characterization ........................................................................16

4 Reference Thermal Solution..............................................................................19

4.1 Operating Environment .........................................................................19

4.1.1 ATX Form Factor Operating Environment ....................................19

4.1.2 Balanced Technology Extended (BTX) Form Factor Operating

Environment...........................................................................

4.2 Mechanical Design Envelope...................................................................21

4.3 Thermal Solution Assembly....................................................................21

4.4 Environmental Reliability Requirements...................................................24

Appendix A Enabled Suppliers ...........................................................................................25

Appendix B Mechanical Drawings.......................................................................................27

20

Thermal and Mechanical Design Guidelines 3

Page 4

Figures

Figure 1. (G)MCH Non-Grid Array......................................................................12

Figure 2. 0° Angle Attach Methodology (top view, not to scale)..............................16

Figure 3. 0° Angle Attach Heatsink Modifications (generic heatsink side and bottom

view shown, not to scale)...........................................................................

Figure 4. Airflow Temperature Measurement Locations .........................................17

Figure 5. Processor Heatsink Orientation to Provide Airflow to (G)MCH Heatsink on an

ATX Platform............................................................................................

Figure 6. Processor Heatsink Orientation to Provide Airflow to (G)MCH Heatsink on a

Balanced Technology Extended (BTX) Platform..............................................

Figure 7. ATX GMCH Heatsink Installed on Board.................................................22

Figure 8. Balanced Technology Extended (BTX) GMCH Heatsink Installed on Board...23

Figure 9. (G)MCH Package Drawing ...................................................................28

Figure 10. (G)MCH Component Keep-Out Restrictions for ATX Platforms .................29

Figure 11. (G)MCH Component Keep-Out Restrictions for Balanced Technology

Extended (BTX) Platforms ..........................................................................

Figure 12. (G)MCH Reference Heatsink for ATX Platforms – Sheet 1 .......................31

Figure 13. (G)MCH Reference Heatsink for ATX Platforms – Sheet 2 .......................32

Figure 14. (G)MCH Reference Heatsink for ATX Platforms – Anchor ........................33

Figure 15. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 1..34

Figure 16. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 2..35

Figure 17. (G)MCH Reference Heatsink for ATX Platforms – Wire Preload Clip ..........36

Figure 18. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX)

Platforms.................................................................................................

Figure 19. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX)

Platforms – Clip........................................................................................

Figure 20. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX)

Platforms – Heatsink Assembly ...................................................................

16

20

21

30

37

38

39

Tables

Table 1. (G)MCH Loading Specifications..............................................................12

Table 2. (G)MCH Case Temperature Specifications .............................................13

Table 3. (G)MCH Thermal Design Power Specifications........................................14

Table 4. Reference Thermal Solution Environmental Reliability Requirements.........24

Table 5. (G)MCH ATX Intel Reference Heatsink Enabled Suppliers.........................25

Table 6. (G)MCH Balanced Technology Extended (BTX) Intel Reference Heatsink

Enabled Suppliers .....................................................................................

4 Thermal and Mechanical Design Guidelines

26

Page 5

Revision History

Revision

Number

-001 • Initial Release May 2005

-002 • Added Intel® 82945PL specifications October 2005

-003 • Added Intel® 82945GZ specifications December

-004 • Added Intel® 82945GC specifications February 2008

Description Date

2005

§

Thermal and Mechanical Design Guidelines 5

Page 6

6 Thermal and Mechanical Design Guidelines

Page 7

Introduction

1 Introduction

As the complexity of computer systems increases, so do power dissipation

requirements. The additional power of next generation systems must be properly

dissipated. Heat can be dissipated using improved system cooling, selective use of

ducting, and/or active/passive heatsinks.

The objective of thermal management is to ensure that the temperatures of all

components in a system are maintained within functional limits. The functional

temperature limit is the range within which the electrical circuits can be expected to

meet specified performance requirements. Operation outside the functional limit can

degrade system performance, cause logic errors, or cause component and/or system

damage. Temperatures exceeding the maximum operating limits may result in

irreversible changes in the operating characteristics of the component. The goal of this

document is to provide an understanding of the operating limits of the Intel

82945G/82945GZ/82945GC Graphics and Memory Controller Hub (GMCH) and Intel

82945P/82945PL Memory Controller Hub (MCH), and discuss a reference thermal

solution.

®

®

The simplest and most cost-effective method to improve the inherent system cooling

characteristics of the (G)MCH is through careful design and placement of fans, vents,

and ducts. When additional cooling is required, component thermal solutions may be

implemented in conjunction with system thermal solutions. The size of the fan or

heatsink can be varied to balance size and space constraints with acoustic noise.

This document presents the conditions and requirements to properly design a cooling

solution for systems that implement the 82945G/82945GZ/82945GC GMCH or

82945P/82945PL MCH. Properly designed solutions provide adequate cooling to

maintain the (G)MCH case temperature at or below thermal specifications. This is

accomplished by providing a low local-ambient temperature, ensuring adequate local

airflow, and minimizing the case to local-ambient thermal resistance. By maintaining

the (G)MCH case temperature at or below those recommended in this document, a

system designer can ensure the proper functionality, performance, and reliability of

these components.

Note: Unless otherwise specified, the information in this document applies to the Intel

82945G/82945GZ/82945GC Graphics and Memory Controller Hub (GMCH) and the

®

82945P/82945PL Memory Controller Hub (MCH). The term (G)MCH refers to the

Intel

82945G GMCH, 82945GZ GMCH, 82945GC GMCH, 82945P MCH, and 82945PL MCH.

®

Note: Unless otherwise specified, ICH7 refers to the Intel

82801GB ICH7 and 82801GR

ICH7R I/O Controller Hub 7 components.

®

Thermal and Mechanical Design Guidelines 7

Page 8

1.1 Terminology

Term Description

BGA Ball Grid Array. A package type defined by a resin-fiber substrate where a die is

mounted and bonded. The primary electrical interface is an array of solder balls

attached to the substrate opposite the die and molding compound.

FC-BGA Flip Chip Ball Grid Array. A package type defined by a plastic substrate where a

die is mounted using an underfill C4 (Controlled Collapse Chip Connection)

attach style. The primary electrical interface is an array of solder balls attached

to the substrate opposite the die. Note that the device arrives at the customer

with solder balls attached.

Intel® ICH7 Intel® I/O Controller Hub 7. The chipset component that contains the primary

PCI interface, LPC interface, USB, ATA, and/or other legacy functions.

GMCH Graphic Memory Controller Hub. The chipset component that contains the

processor and memory interface and integrated graphics device.

MCH Memory Controller Hub. The chipset component that contains the processor

and memory interface. It does not contain an integrated graphics device.

Introduction

TA The measured ambient temperature locally to the component of interest. The

ambient temperature should be measured just upstream of airflow for a

passive heatsink or at the fan inlet for an active heatsink.

TC The measured case temperature of a component. For processors, TC is

measured at the geometric center of the integrated heat spreader (IHS). For

other component types, it is generally measured at the geometric center of the

die or case.

T

The maximum case/die temperature with an attached heatsink. This

C-MAX

temperature is measured at the geometric center of the top of the package

case/die.

T

The minimum case/die temperature with an attached heatsink. This

C-MIN

temperature is measured at the geometric center of the top of the package

case/die.

TDP Thermal Design Power . TDP is specif ied as the highest sustainable power level

of most or all of the real applications expected to be run on the given product,

based on extrapolations in both hardware and software technology over the life

of the component. Thermal solutions should be designed to dissipate this target

power level.

TIM Thermal Interface Material. TIM is the thermally conductive material installed

between two surfaces to improve heat transfer and reduce interface contact

resistance.

lfm Linear Feet per Minute. Unit of airflow speed.

Ψ

Case-to-ambient thermal characterization parameter (Psi). This is a measure of

CA

thermal solution performance using total package power. It is defined as (T

) / Total Package Power. Heat source size should always be specified for Ψ

T

A

C

measurements.

–

8 Thermal and Mechanical Design Guidelines

Page 9

Introduction

1.2 Reference Documents

Document Comments

Intel® 945G/945GZ/945P/945PL Express Chipset Family

Datasheet

Intel® I/O Controller Hub 7 (ICH7) Datasheet http://developer.intel.com//de

Intel® I/O Controller Hub 7 (ICH7) Thermal Design Guidelines http://developer.intel.com//de

Intel® Pentium® 4 Processor 670, 660, 650, 640, and 630 and

®

Pentium® 4 Processor Extreme Edition Datasheet

Intel

http://developer.intel.com/des

ign/chipsets/datashts/307502.

htm

sign/chipsets/datashts/30701

3.htm

sign/chipsets/designex/30701

5.htm

http://developer.intel.com

/design/pentium4/datashts

/306382.htm

Intel® Pentium®4 Processors 570/571, 560/561,

550/551,540/541, 530/531 and 520/521 Supporting HyperThreading Technology Datasheet

Intel® Pentium® D Processor 840, 830 and 820 Datasheet http://developer.intel.com

http://developer.intel.com

/design/Pentium4/datashts

/302351.htm

/design/PentiumD//datasht

s/307506.htm

Intel® Pentium® 4 Processor on 90 nm Process in the 775–

Land LGA Package Thermal and Mechanical Design Guidelines

http://developer.intel.com

/design/Pentium4/guides/3

02553.htm

Intel® Pentium® D® Processor and Intel® Pentium® Processor

Extreme Edition 830 Thermal and Mechanical Design Guidelines

http://developer.intel.com/

design/pentiumXE/designe

x/306830.htm

LGA775 Socket Mechanical Design Guide http://developer.intel.com/

design/pentium4/guides/3

02666.htm

Various System Thermal Design Suggestions http://www.formfactors.or

g

§

Thermal and Mechanical Design Guidelines 9

Page 10

Introduction

10 Thermal and Mechanical Design Guidelines

Page 11

Product Specifications

2 Product Specifications

This chapter provides the package description and loading specifications. The chapter

also provides component thermal specifications and thermal design power descriptions

for the (G)MCH.

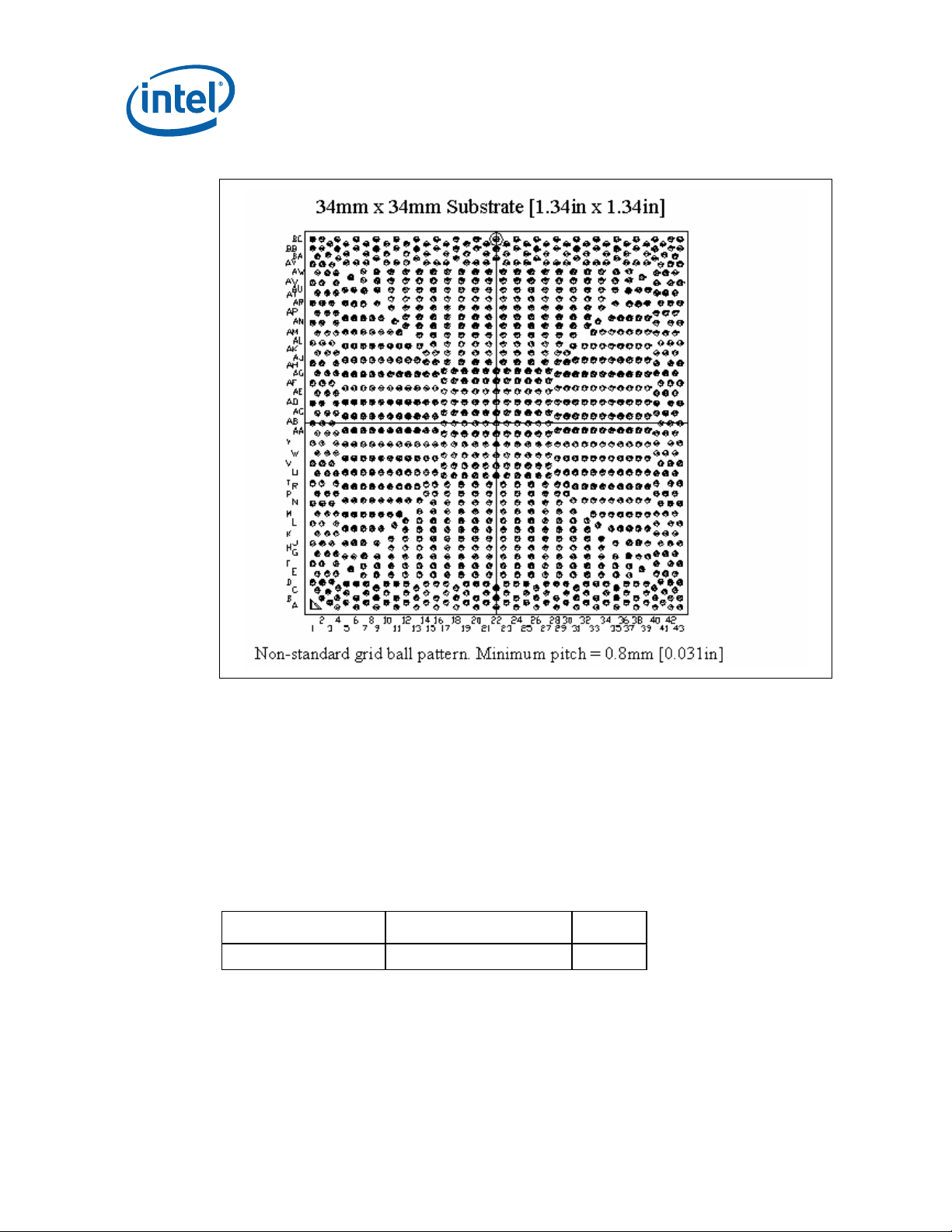

2.1 Package Description

The (G)MCH is available in a 34 mm [1.34 in] x 34 mm [1.34 in] Flip Chip Ball Grid

Array (FC-BGA) package with 1202 solder balls. The die size is currently 9.6 mm

[0.378in] x 10.6 mm [0.417in]. A mechanical drawing of the package is shown in

Figure 9, Appendix B.

2.1.1 Non-Grid Array Package Ball Placement

The (G)MCH package uses a “balls anywhere” concept. The minimum ball pitch is

0.8 mm [0.031 in], but ball ordering does not follow a 0.8-mm grid. Board designers

should ensure correct ball placement when designing for the non-grid array pattern.

For exact ball locations relative to the package, contact your Field Sales

Representative.

Thermal and Mechanical Design Guidelines 11

Page 12

Figure 1. (G)MCH Non-Grid Array

Product Specifications

2.2 Package Loading Specifications

Table 1 provides static load specifications for the chipset package. This mechanical

maximum load limit should not be exceeded during heatsink assembly, shipping

conditions, or standard use conditions. Also, any mechanical system or component

testing should not exceed the maximum limit. The chipset package substrate should

not be used as a mechanical reference or load-bearing surface for the thermal and

mechanical solution.

Table 1. (G)MCH Loading Specifications

Parameter Maximum Notes

Static 15 lbf 1,2,3

NOTES:

1. These specifications apply to uniform compressive loading in a direction normal to the

(G)MCH package.

2. This is the maximum force that can be applied by a heatsink retention clip. The clip must

also provide the minimum specified load on the (G)MCH package.

3. These specif ications are based on limited testing for design characterization. Loading limits

are for the package only.

12 Thermal and Mechanical Design Guidelines

Page 13

Product Specifications

2.3 Thermal Specifications

To ensure proper operation and reliability of the (G)MCH, the temperature must be at

or below the maximum value specified in

thermal enhancements are required to dissipate the heat generated and maintain the

(G)MCH within specifications. Chapter

case temperature measurements.

The (G)MCH must also operate above the minimum case temperature specification

listed in Table 2.

Table 2. (G)MCH Case Temperature Specifications

Parameter Value

3 provides the thermal metrology guidelines for

Table 2. System and component level

T

C-MAX

T

0 °C

C-MIN

NOTE: Thermal specifications assume an attached heatsink is present.

82945G/82945GZ/82945GC GMCH: 99 °C

82945P/82945PL MCH : 103°C

2.4 Thermal Design Power (TDP)

Thermal design power (TDP) is the estimated power dissipation of the (G)MCH based

on normal operating conditions including V

case power intensive applications. This value is based on expected worst-case data

traffic patterns and usage of the (G)MCH and does not represent a specific software

application. TDP attempts to account for expected increases in power due to variation

in (G)MCH current consumption due to silicon process variation, processor speed,

DRAM capacitive bus loading and temperature. However, since these variations are

subject to change, the TDP cannot ensure that all applications will not exceed the TDP

value.

The system designer must design a thermal solution for the (G)MCH such that it

maintains T

specification is a requirement for a sustained power level equal to TDP, and that

MAX

below T

C

for a sustained power level equal to TDP. Note that the T

C-MAX

the case temperature must be maintained at temperatures less than T

operating at power levels less than TDP. This temperature compliance is to ensure

(G)MCH reliability over its useful life. The TDP value can be used for thermal design if

the (G)MCH thermal protection mechanisms are enabled. Intel chipsets incorporate a

hardware-based fail-safe mechanism to help keep the product temperature within

specifications in the event of unusually strenuous usage above the TDP power limit.

and T

CC

while executing real worst-

C-MAX

C-MAX

C-

when

Thermal and Mechanical Design Guidelines 13

Page 14

2.4.1 Methodology

2.4.1.1 Pre-Silicon

To determine TDP for pre-silicon products in development, it is necessary to make

estimates based on analytical models. These models rely on extensive knowledge of

the past chipset power dissipation behavior along with knowledge of planned

architectural and process changes that may affect TDP. Knowledge of applications

available today and their ability to stress various components of the chipset is also

included in the model. Since the number of applications available today is beyond

what Intel can test, only real world high-power applications are tested to predict TDP.

The values determined are used to set specific data transfer rates. The projection for

TDP assumes (G)MCH operation at T

account for process variation.

2.4.1.2 Post-Silicon

Once the product silicon is available, post-silicon validation is performed to assess the

validity of pre-silicon projections. Testing is performed on both commercially available

and synthetic high power applications and power data is compared to pre-silicon

estimates. Post-silicon validation may result in a small adjustment to pre-silicon TDP

estimates.

Product Specifications

. The TDP estimate also includes a margin to

C-MAX

2.4.2 Application Power

Designing to the TDP can ensure that a particular thermal solution meets the cooling

needs of future applications. Testing with currently available commercial applications

has shown that the components may dissipate power levels below the published TDP

specification in Section

2.4.3. Intel strongly recommends that thermal engineers

design to the published TDP specification to develop a robust thermal solution that will

meet the needs of current and future applications.

2.4.3 Specifications

The (G)MCH is estimated to dissipate the Thermal Design Power values provided in

Table 3 when using two DIMMs of 667 MHz (553 MHz for the 82945PL/82945GZ) dual

channel DDR2 with a 1066 MHz (800 MHz for the 82945PL/82945GZ/82945GC)

processor system bus speed. For the 82945G/82945GZ/82945GC GMCH, the graphics

core is assumed to run at 400 MHz. FC-BGA packages have limited heat transfer

capability into the board and have minimal thermal capability without thermal

solutions. Intel requires that system designers plan for an attached heatsink when

using the (G)MCH.

Table 3. (G)MCH Thermal Design Power Specifications

Component System Bus Speed Memory Frequency TDP Value

82945G GMCH

82945GZ GMCH

82945GC GMCH

82945P MCH

82945PL MCH

1066 MHz 667 MHz

800 MHz 533 MHz

800 MHz 667 MHz

1066 MHz 667 MHz

800 MHz 533 MHz

§

22.2 W

22.2 W

22.2 W

15.2 W

15.2 W

14 Thermal and Mechanical Design Guidelines

Page 15

Thermal Metrology

3 Thermal Metrology

The system designer must measure temperatures to accurately determine the thermal

performance of the system. Intel has established guidelines for proper techniques of

measuring (G)MCH component case temperatures.

3.1 Case Temperature Measurements

To ensure functionality and reliability, the (G)MCH is specified for proper operation

when T

surface temperature at the geometric center of the die corresponds to T

T

C

Temperature differences between the temperature of a surface and the surrounding

local ambient air can introduce error in the measurements. The measurement errors

could be due to a poor thermal contact between the thermocouple junction and the

surface of the package, heat loss by radiation and/or convection, conduction through

thermocouple leads, or contact between the thermocouple cement and the heatsink

base (if a heatsink is used). To minimize these measurement errors a thermocouple

attach with a zero-degree methodology is recommended.

is maintained at or below the maximum temperature listed in Table 2. The

C

requires special care to ensure an accurate temperature reading.

. Measuring

C

3.1.1 Thermocouple Attach Methodology

1. Mill a 3.3 mm [0.13 in] diameter hole centered on bottom of the heatsink base.

The milled hole should be approximately 1.5 mm [0.06 in] deep.

2. Mill a 1.3 mm [0.05 in] wide slot, 0.5 mm [0.02 in] deep, from the centered hole

to one edge of the heatsink. The slot should be in the direction parallel to the

heatsink fins (see

3. Attach thermal interface material (TIM) to the bottom of the heatsink base.

4. Cut out portions of the TIM to make room for the thermocouple wire and bead.

The cutouts should match the slot and hole milled into the heatsink base.

5. Attach a 36 gauge or smaller calibrated K-type thermocouple bead or junction to

the center of the top surface of the die using a high thermal conductivity cement.

During this step, make sure no contact is present between the thermocouple

cement and the heatsink base because any contact will affect the thermocouple

reading. It is critical that the thermocouple bead makes contact with the

die (see

6. Attach heatsink assembly to the (G)MCH and route thermocouple wires out

through the milled slot.

Figure 2).

Figure 3).

Thermal and Mechanical Design Guidelines 15

Page 16

Thermal Metrology

Figure 2. 0° Angle Attach Methodology (top view, not to scale)

Figure 3. 0° Angle Attach Heatsink Modifications (generic heatsink side and bottom

view shown, not to scale)

3.2 Airflow Characterization

Figure 4 describes the recommended location for air temperature measurements

measured relative to the component. For a more accurate measurement of the

average approach air temperature, Intel recommends averaging temperatures

recorded from two thermocouples spaced about 25 mm [1.0 in] apart. Locations for

both a single thermocouple and a pair of thermocouples are presented.

16 Thermal and Mechanical Design Guidelines

Page 17

Thermal Metrology

Figure 4. Airflow Temperature Measurement Locations

Airflow velocity should be measured using industry standard air velocity sensors.

Typical airflow sensor technology may include hot wire anemometers.

Figure 4

provides guidance for airflow velocity measurement locations. These locations are for

a typical JEDEC test setup and may not be compatible with chassis layouts due to the

proximity of the processor to the (G)MCH. The user may have to adjust the locations

for a specific chassis. Be aware that sensors may need to be aligned perpendicular to

the airflow velocity vector or an inaccurate measurement may result. Measurements

should be taken with the chassis fully sealed in its operational configuration to achieve

a representative airflow profile within the chassis.

§

Thermal and Mechanical Design Guidelines 17

Page 18

Thermal Metrology

18 Thermal and Mechanical Design Guidelines

Page 19

Reference Thermal Solution

4 Reference Thermal Solution

The reference component thermal solution for the (G)MCH for ATX platforms uses two

ramp retainers, a wire preload clip, and four custom MB anchors. The Intel Balanced

Technology Extended (BTX) reference design uses a Z-clip attach for the (G)MCH

heatsink. This chapter provides detailed information on operating environment

assumptions, heatsink manufacturing, and mechanical reliability requirements for the

(G)MCH.

4.1 Operating Environment

The operating environment of the (G)MCH will differ depending on system

configuration and motherboard layout. This section defines operating environment

boundary conditions that are typical for ATX and BTX form factors. The system

designer should perform analysis on the platform operating environment to assess any

impact to thermal solution selection.

4.1.1 ATX Form Factor Operating Environment

In ATX platforms, an airflow speed of 0.76 m/s [150 lfm] is assumed to be present

25 mm [1 in] in front of the heatsink air inlet side of the attached reference thermal

solution. The system integrator should note that board layout may be such that there

will not be 25mm [1in] between the processor heatsink and the (G)MCH. The potential

for increased airflow speeds may be realized by ensuring that airflow from the

processor heatsink fan exhausts in the direction of the (G)MCH heatsink. This can be

achieved by using a heatsink providing omni directional airflow, such as a radial fin or

“X” pattern heatsink. Such heatsinks can deliver airflow to both the (G)MCH and other

areas like the voltage regulator, as shown in

placement should ensure that the (G)MCH heatsink is within the air exhaust area of

the processor heatsink.

Note that heatsink orientation alone does not ensure that 0.76 m/s [150 lfm]

airflow speed will be achieved. The system integrator should use analytical or

experimental means to determine whether a system design provides adequate airflow

speed for a particular (G)MCH heatsink.

The local ambient air temperature, T

assumed to be 47 °C. The thermal designer must carefully select the location to

measure airflow to get a representative sampling. These environmental assumptions

are based on a 35 °C system external temperature measured at sea level.

, at the (G)MCH heatsink in an ATX platform is

A

Figure 5. In addition, the (G)MCH board

Thermal and Mechanical Design Guidelines 19

Page 20

Reference Thermal Solution

Figure 5. Processor Heatsink Orientation to Provide Airflow to (G)MCH Heatsink on an

ATX Platform

Airflow Direction

Airflow Direction

Airflow Direction

Airflow Directio n

Airflow Direction

Airflow Directio n

(G)MCH Heatsink

Airflow Direction

Airflow Direction

TOP VIEW

Omi Direc t ional Flow

Processor Heatsink

(Fan Not Shown)

Proc_HS_Orient_ATX

Other methods exist for providing airflow to the (G)MCH heatsink, including the use of

system fans and/or ducting, or the use of an attached fan (active heatsink).

4.1.2 Balanced Technology Extended (BTX) Form Factor Operating Environment

The operating environment for the (G)MCH in typical BTX systems has not been

profiled. This section provides operating environment conditions based on what has

been exhibited on the Intel micro-BTX reference design. On a BTX platform, the

(G)MCH obtains in-line airflow directly from the processor thermal module. Since the

processor thermal module provides lower inlet temperature airflow to the processor,

reduced inlet ambient temperatures are also often seen at the (G)MCH as compared to

ATX. An example of how airflow is delivered to the (G)MCH on a BTX platform is

shown in

Figure 6.

The local ambient air temperature, TA, at the (G)MCH heatsink in the Intel micro-BTX

reference design is predicted to be ~45 °C. The thermal designer must carefully select

the location to measure airflow to get a representative sampling. These environmental

assumptions are based on a 35 °C system external temperature measured at sea

level.

Note: The local ambient air temperature is a projection based on anticipated power

increases on a 2005 platform and may be subject to change in future revisions of this

document.

20 Thermal and Mechanical Design Guidelines

Page 21

Reference Thermal Solution

Figure 6. Processor Heatsink Orientation to Provide Airflow to (G)MCH Heatsink on a

Balanced Technology Extended (BTX) Platform

Balanced Technology

Airflow Direction

(G)MCH

Extended (BTX) Thermal

Module Assembly Over

Processor

Top View

Proc_HS_Orient

4.2 Mechanical Design Envelope

The motherboard component keep-out restrictions for the (G)MCH on an ATX platform

are included in

restrictions for the (G)MCH on a BTX platform are included in

System integrators should ensure no board or chassis components would intrude into

the volume occupied by the (G)MCH thermal solution.

Appendix B, Figure 10. The motherboard component keep-out

4.3 Thermal Solution Assembly

The reference thermal solution for the (G)MCH for an ATX platform is shown in

Figure 7 and Appendix B and is an aluminum extruded heatsink that uses two ramp

retainers, a wire preload clip, and four custom motherboard anchors. The heatsink is

attached to the motherboard by assembling the anchors into the board, placing the

heatsink over the (G)MCH and anchors at each of the corners, and securing the plastic

ramp retainers through the anchor loops before snapping each retainer into the fin

gap. The assembly is then sent through the wave process. Post wave, the wire preload

clip is assembled using the hooks on each of the ramp retainers. The clip provides the

mechanical preload to the package. A thermal interface material (Chomerics* T710) is

pre-applied to the heatsink bottom over an area that contacts the package die.

The reference thermal solution for the (G)MCH for a BTX platform is shown in

Figure 8. The heatsink is aluminum extruded and uses a Z-clip for attach. The clip is

secured to the system motherboard via two solder-down anchors around the (G)MCH.

The clip helps to provide a mechanical preload to the package via the heatsink. A

thermal interface material (Chomerics* T710) is pre-applied to the heatsink bottom

over an area in contact with the package die.

Figure 11.

The ATX reference thermal solution differs from the BTX reference solution because a

BTX platform requires a Support and Retention Mechanism (SRM) that helps to meet

the mechanical requirements listed in

Thermal and Mechanical Design Guidelines 21

Table 4.

Page 22

Figure 7. ATX GMCH Heatsink Installed on Board

Reference Thermal Solution

22 Thermal and Mechanical Design Guidelines

Page 23

Reference Thermal Solution

Figure 8. Balanced Technology Extended (BTX) GMCH Heatsink Installed on Board

Thermal and Mechanical Design Guidelines 23

Page 24

Reference Thermal Solution

4.4 Environmental Reliability Requirements

The environmental reliability requirements for the reference thermal solution are

shown in

plans should be defined by the user based on anticipated use conditions and resulting

reliability requirements.

Table 4. Reference Thermal Solution Environmental Reliability Requirements

Table 4. These should be considered as general guidelines. Validation test

Test1 Requirement Pass/Fail

Mechanical

Shock

Random

Vibration

Thermal

Cycling

Unbiased

Humidity

NOTES:

1. The above tests should be performed on a sample size of at least 12 assemblies from 3

different lots of material.

2. Additional Pass/Fail Criteria may be added at the discretion of the user.

• 3 drops for + and - directions in each of 3

perpendicular axes (i.e., total 18 drops).

• Profile: 50 G trapezoidal waveform, 11 ms duration,

4.3 m/s [170 in/s] minimum velocity change.

• Setup: Mount sample board on test fixture. Include

550 g processor heatsink.

• Duration: 10 min/axis, 3 axes

• Frequency Range: 5 Hz to 500 Hz

• Power Spectral Density (PSD) Profile: 3.13 g RMS

• -40 °C to +85 °C, 900 cycles Thermal

• 85 % relative humidity / 55 °C, 500 hours Visual Check

Criteria2

Visual\Electrical

Check

Visual/Electrical

Check

Performance

§

24 Thermal and Mechanical Design Guidelines

Page 25

Enabled Suppliers

Appendix A Enabled Suppliers

Current suppliers for the Intel® 945G/945GZ/945GC/945P/945PL Express chipset

(G)MCH reference thermal solution are listed in

Table 5. (G)MCH ATX Intel Reference Heatsink Enabled Suppliers

Table 5 and Table 6.

Supplier Intel Part

CCI (Chaun Choung

Technology Corp)

WiesonElectronic Co.

Foxconn/HonHai

Precision

Foxconn/HonHai

Precision

Number

C85366-001

(heatsink)

C85370-001

(ramp

retainer)

C85373-001

(wire clip)

C85376-001

(anchor)

C85366-001

(heatsink)

C85370-001

(ramp

retainer)

C85373-001

(wire clip)

C85376-001

(anchor)

Vendor Part

Number

00C863501A

334C863501A

334C863502A

G2100C888-143 Rick Lin - +886 (-2) -

2Z802-016

3EE77-002

3KS02-066

2Z802-015 Jack Chen – (714) 626-1233

Contact Information

Monica Chih - +886 (-2) 29952666

monica_chih@ccic.com.tw

Harry Lin - (714) 739-5797

hlinack@aol.com

26471896 ext.6342

rick@wieson.com.tw

Jack Chen – (714) 626-1233

Jack.chen@foxconn.com

Jack.chen@foxconn.com

Note: These vendors and devices are listed by Intel as a convenience to Intel's general

customer base, but Intel does not make any representations or warranties whatsoever

regarding quality, availability, reliability, functionality, or compatibility of these

devices. This list and/or these devices may be subject to change without notice.

Thermal and Mechanical Design Guidelines 25

Page 26

Enabled Suppliers

Table 6. (G)MCH Balanced Technology Extended (BTX) Intel Reference Heatsink

Enabled Suppliers

Supplier Intel Part

CCI (Chaun

Choung

Technology

Corp.)

AVC (Asia Vital

Components)

Foxconn/HonHai

Precision

Number

C57359-001 00C863401A Monica Chih - +886 (-2) -

C57359-001 S909700001 David Chao - +886 (-2) -2299-

C57359-001 2Z802-010 Jack Chen – (714) 626-1233

Vendor Part

Number

§

Contact Information

29952666

monica_chih@ccic.com.tw

Harry Lin - (714) 739-5797

hlinack@aol.com

6930 x619

david_chao@avc.com.tw

Jack.chen@foxconn.com

26 Thermal and Mechanical Design Guidelines

Page 27

Mechanical Drawings

Appendix B Mechanical Drawings

The following table lists the mechanical drawings available in this document.

Drawing Name Page

(G)MCH Package Drawing 28

(G)MCH Component Keep-Out Restrictions for ATX Platforms 29

(G)MCH Component Keep-Out Restrictions for Balanced Technology Extended

(BTX) Platforms

(G)MCH Reference Heatsink for ATX Platforms – Sheet 1 31

(G)MCH Reference Heatsink for ATX Platforms – Sheet 2 32

(G)MCH Reference Heatsink for ATX Platforms – Anchor 33

(G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 1 34

(G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 2 35

(G)MCH Reference Heatsink for ATX Platforms – Wire Preload Clip 36

. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX)

Platforms

(G)MCH Reference Heatsink for Balanced Technology Extended (BTX)

Platforms – Clip

(G)MCH Reference Heatsink for Balanced Technology Extended (BTX)

Platforms – Heatsink Assembly

Number

30

37

38

39

NOTE: Unless otherwise specified, all figures in this appendix are dimensioned in millimeters.

Dimensions shown in brackets are in inches.

Thermal and Mechanical Design Guidelines 27

Page 28

Mechanical Drawingss

Figure 9. (G)MCH Package Drawing

28 Thermal and Mechanical Design Guidelines

Page 29

.345[]

4X 8.76

NO COMPONENTS THIS AREA

.345[]

4X 8.76

DETA IL A

SCALE 8

0.97 .038[]

8X 1.42[.056] TRACE KEEPOUT

8X PLATED THRU HOLE

.200[]

4X 5.08

.072[]

4X 1.84

EAST

2.9134[]

DETAIL A

74

2.398[]

60.92

1 HOLE PLACEMENT FABRICAT ION

NOTES:

TOLERANCE PER INTEL 454979, CLASS 1,2,3

2. HEATSINK COMPONENT HEIGHT NOT TO EXCEED

38.1MM ABOVE MOTHERBOARD SURFA CE.

MAX 25 [1.000]

COMPONENT HEIGHT

MAX 1.27 [.050]

COMPONENT HEIGHT

COMPONENT CENTER

(NON-MCH COMP ONENT S)

.1575[]

4

135

1.85[]

47

Thermal and Mechanical Design Guidelines 29

2.386[]

1.055[]

1.890[]

60.6

26.79

48

NORTH

1.803[]

45.79

2.638[]

67

3.189[]

81

Mechanical Drawings

Figure 10. (G)MCH Component Keep-Out Restrictions for ATX Platforms

Page 30

Mechanical Drawingss

.073[]

4X 1.85

.165[]

4X 4.19

8X 1. 42[. 0 56] TRA CE KEE POUT

8X P L AT ED THRU HO L E0.97 .038[]

N O C O MPON EN T S T H IS AR EA

.345[]

4X 8.76

.200[]

4X 5.08

D ETAIL A

D E TAIL A

SCALE 8

.083[]

4X 2.1

COM PONENT CENTER

MAX 1 .7 8 [.07 0 ] C O MPON EN T H EIG H T

.100[]

.225[]

2X 2.54

2X 5.72

.130[]

2X 3.3

1 . H O L E PLAC EMENT FABR IC AT IO N

NOTES:

.090[]

DETAIL B

2X 2.29

TOLE RANCE PER INTEL 454 979, CLASS 1,2, 3

2. HEATS INK COM PONENT HEIGHT NO T TO EX CEED

26.9 M M A BOVE MOT HERB O ARD SURFACE .

SCALE 5

MAX 1 .2 7[.0 5 0 ] C O MPON EN T H EIGH T

B

1.900[]

48.26

2. 2 00[]

55.8 8

2.44 0[]

61.98

Figure 11. (G)MCH Component Keep-Out Restrictions for Balanced Technology Extended (BTX) Platforms

DETAIL B

SCALE 4

1.83 0[]

46.4 8

30 Thermal and Mechanical Design Guidelines

Page 31

NOT E S: 1. THIS DRAW I NG TO B E USE D IN CO NJUNCT IO N W IT H SUP PLIED 3D

5 MA RK P ART W IT H INT EL P/N A ND REV ISIO N APP RO X

DATA BAS E F ILE. ALL DIME NSIO NS AND T O LERANCES O N TH IS

DRAWING TA KE PRECEDENCE OVER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS

INDICAT ED O T HE RW ISE .

2. TO LERANCE S O N D IME NSIO NE D AND UNDIM E NSIO NE D

FEATURES UNLESS OTHERWISE SPECIFIED:

DIME NSIO NS ARE I N MILLIM ET ERS .

TOLERANCES:

6 CRITICA L TO F UNCTIO N DIME NSIO N

LINE AR 0.25

ANG ULAR 1

3. M AT E RI AL: 6063-T 5 A LUM IN UM

4. FINISH: NO NE

WHERE SHOW N PER INTEL MARKING STANDARD 164997

7. EDG ES SHO W N AS SHARP R 0.1 MAX.

8. TO O LING REQ UIRED T O M AKE T HIS PA RT S HALL BE T HE

PROPERTY O F INTEL, AND SHALL BE PERMANENTLY MARKED

WIT H INTEL'S NAME AND APPROPRIATE PART NUMBER.

9. ALL SECO NDARY UNIT DIM ENSIO NS ARE FO R RE F ERENCE O NLY.

10. ALL DIMENSIONS SHOWN SHALL BE MEASURED FOR FAI

11. REMO VE ALL BURRS O R SHARP EDGES ARO UND PERIMETER

OF P ART. SHARPNESS OF EDGE S SUBJECT TO HANDLING ARE

REQ UIRED T O M EET UL1439 TEST.

.005[]

.148

TYP 63.7 5 0.15

1.398[]

TYP 35.5

FULL RO UND

2.307[]

1.850[]

47

2X 58.6

SEE DETAIL B

SEE DETAIL B

1.201[]

30.5

SPACING

14X E Q UA L

.157[]

4

659.28

.005[]

2X

0.15

2.334

.005[]

.047

16X 1.2 0.15

SEE DE TA IL A

SEE DE TA IL A

.005[]

1.890

2X 648 0.15

.005[]

.106

8X 2. 7 0. 15

1.417[]

36

SPA CING

7X E Q U A L

3.150[]

2X 80

Mechanical Drawings

Figure 12. (G)MCH Reference Heatsink for ATX Platforms – Sheet 1

Thermal and Mechanical Design Guidelines 31

Page 32

Mechanical Drawingss

.02 4[]

2X 60.6

TYP 135

.020[]

R0. 5

66.72 0.15

.005[]

.265

NO B URR ALL ARO UND

61.5 0.15

.039[]

TYP R 1

.003[]

.108

.1575[]

TYP 62.75 0.1

TYP 4

DETA IL B

SCALE 5

TYP DETAIL A

SCALE 5

TYP.

.005[]

.059

Figure 13. (G)MCH Reference Heatsink for ATX Platforms – Sheet 2

.630[]

16

0.1 [.003]

2X 15

2.5984[]

66

.591[]

1.004[]

25.5

CH OM ER ICS:

69-12-22350-T 710

4X 45 X 1 [.039]

BOTT OM VIEW

5

32 Thermal and Mechanical Design Guidelines

Page 33

2X CHAMF ER ALL ARO UND

CONTACT TO INSULATOR INTERFACE

AT SUPPLIERS OPTIO N

+.000

-.002

0

-0.07

.025

0.64

[]

.003[]

.030

2X 60.77 0.1

.005[]

.300

7.62 0.15

NOT ES: 1. THIS DRAW ING T O BE USED IN CO NJUNCTIO N W IT H SUPP LIED 3D

DATA BASE FILE. ALL DIMENSIO NS A ND TO LERANCES O N THIS

DRAWING T AKE PRECEDENCE OVER SUPPLIED F ILE AND ARE

APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS

INDICATED O T HERW ISE .

2. TOLERA NCES O N DIME NSIO NED AND UNDIMENS IO NED

FEA TURES UNLESS O THE RW ISE SP ECIF IED:

DIMENSIONS ARE IN MILLIMET ERS.

FO R FE AT URE SIZ ES < 10MM: LINEAR .07

45 X 0.2 M IN

2X 45 2

.005[]

.098

2.5 0.15

2X 3.94 0.15

FO R FE AT URE SIZ ES > 10MM: LINEAR .08

ANG LES: 0.5

3. M AT E RIA LS:

.005[]

.155

.001[]

.020

2X 0.5 0.0 5

6 CRITICAL TO F UNCTIO N DIM ENSIO N

INSULATO R: PO LYCARBO NAT E T HERM O PLAST IC, UL 94V -0, BLACK (739)

(REF. G E LEXAN 3412R-739)

CONTACT: BRASS O R EQUIVALENT UPON INT EL APPRO VAL

CON TA CT F INIS H: .000050u" M IN. NICK EL UNDER P LAT ING ;

SO LDE R T A ILS , 0.000100" M IN T IN O NLY SO LD ER (LE AD F RE E).

5. MARK W IT H INTE L P/N AND REVISIO N PE R INTEL MA RKING

STANDARD 164997; PER SEC 3.8 (POLYETHYLENE BAG)

7. ALL DIMENS IONS SHO W N SHALL BE M EASURE D FO R FA I

8. NO T E RE M O VE D

9. DEG AT E: F LUSH T O 0.35 BELO W S T RUCTUR AL TH ICKNE SS

(GAT E W ELL OR G A TE RECESS A CCEPT ABLE)

10. F LAS H: 0. 15 MA X .

11. SIN K: 0.25 M AX .

12. EJECTOR MARKS: FLUSH TO -0.25

13. PARTING LINE MISM AT CH NOT TO E XCEED 0.25.

14. EJECTIO N PIN BO SSE S, G AT ING , AND TO O LING INSERT S REQ UIRE

INTEL'S APPRO VAL PRIO R T O TO O L CONS TRUCT IO N.

ALL EJECTION PIN BOSSES AND GATE FEATURES SHOWN

ARE F O R REF E RENCE O NLY.

15. EDGES SHOW N AS SHARP R 0.1 M AX.

16. TOO LING REQ UIRED TO M AKE THIS P ART S HALL BE THE

PROPERTY OF INTEL, AND SHALL BE PERMANENTLY MARKED

WITH INTEL'S NAME AND APPROPRIATE PART NUMBER.

17. ALL S ECO NDARY UNIT DIM ENSIO NS A RE F OR RE FERE NCE O NLY.

.004[]

.399

2X 10.13 0.12

+.000

-.002

0

-0.07

.025

0.64

[]

65.08 0.12

.004[]

.200

.030[]

.157[]

2X 4

Mechanical Drawings

Figure 14. (G)MCH Reference Heatsink for ATX Platforms – Anchor

2X 0.75

65.21 0.12

.004[]

.205

.004[]

.308

4X 67.83 0.12

Thermal and Mechanical Design Guidelines 33

Page 34

Mechanical Drawingss

5 MARK PART W ITH INTEL P/N, REVISION, CAVITY NUMBER

NOTES: 1. THIS DRA W ING T O B E USE D IN CO NJUNCT IO N W IT H S UPPLIED 3D

DATABASE FILE. ALL DIM ENSIONS AND T OLERANCES O N THIS

670.49

DRAWING TAKE PRECEDENCE OVER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCO NSTRAINED STATE UNLESS

INDICAT E D O T HERW ISE.

2. TO LERANCES O N DIM ENSIO NE D AND UNDIME NSIO NED

FEATURES UNLESS OT HERWISE SPECIFIED:

DIME NSIO NS ARE IN MILLIM ET ERS.

FO R FEATURE SIZES < 10MM : LINEAR .07

2.775[]

661.51

2.422[]

FO R FEATURE SIZES BETWEEN 10 AND 25 M M: LINEAR .08

FO R FEATURE SIZES BETWEEN 25 AND 50 M M: LINEAR .10

FO R FEATURE SIZES > 50MM : LINEAR .18

ANG LES: 0.5

3. MAT ERIA L:

A) TYPE: ENVIRONMENTALLY CO MPLIANT THERMOPLASTIC O R

EQ UIV ALENT UPO N IN TE L APP RO VAL (REF . G E LEX AN 500ECR-739)

B) CRITICAL MECHANICAL MATERIAL PROPERTIES

FO R EQUIVALENT M ATERIAL SELECTION:

TE NSILE YIELD ST RENG T H (AST M D638) > 57 MPa

TENSILE ELO NGATION AT BREAK (ASTM D638) >= 46%

F LEX URA L M O D ULUS (AS T M D638) 3116 M Pa 10%

SO F T ENING T EM P (VICAT , RAT E B ): 154 C

C) CO LOR: APPROXIMATING BLACK, (REF GE 739)

6 CRIT ICAL TO F UNCT IO N DIM ENS IO N

D) REG RIND: 25% PE RMIS SIB LE.

E) VO L UM E - 1. 73e+ 03 C UB IC -M M (RE F )

W E IG HT - 2.16 G RAM S (REF )

AND DATE CO DE APPROX W HERE SHOWN PER INTEL M ARKING

ST A NDA RD 164997

7. ALL DIMENSIO NS SHOWN SHALL BE M EASURED F OR FAI

8. NOT E REM O VED

9. DEGA TE: FLUSH T O 0.35 BELOW ST RUCT URAL THICKNES S

(G AT E W E LL OR G A TE RECE SS A CCEP TA BLE)

10. F LAS H: 0. 15 MA X .

11. SIN K: 0. 25 MA X.

12. EJECTOR MARKS: FLUSH TO -0.25

13. PARTING LINE MISM A TCH NO T TO E XCEE D 0.25.

14. EJECTION PIN BOSSES, GATING, AND TOO LING INSERTS REQUIRE

INTEL'S APPROVAL PRIO R TO T OO L CONSTRUCT ION.

ALL EJECTION PIN BOSSES AND GATE FEATURES SHOWN

ARE FO R REFERENCE ONLY.

15. EDGES SHOW N AS SHARP R 0.1 MAX.

16. TO OLING REQUIRED TO M AKE THIS PART SHALL BE THE

PROPERTY OF INTEL, AND SHALL BE PERMANENTLY M ARKED

W ITH INTEL'S NAME AND APPROPRIATE PART NUMBER.

17. ALL S ECO NDARY UNIT DIM ENSIO NS A RE F O R REF ERENCE O NLY.

Figure 15. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 1

5

62 0.05

SEE DETAIL C

SEE DETAIL C

1.100[]

.118[]

3

2X 27.95

1.225[]

2X 31.1

.001[]

.079

SEE DETAIL ASEE DETAIL A

34 Thermal and Mechanical Design Guidelines

Page 35

.157[]

4

65.56

.219[]

DET AIL C

SCALE 10

.114[]

2X 62.9

.252[]

6.4

.227[]

2X 65.76

SECT IO N B-B

.047[]

1.19

60.5

61.75

.020[]

.069[]

63.15

.108[]

.124[]

2.75

B

64. 7 5

.187[]

.205[]

5.2

2X DET AIL A

SCALE 20

.258[]

6.55

.118[]

3

B

Mechanical Drawings

Figure 16. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 2

Thermal and Mechanical Design Guidelines 35

Page 36

Mechanical Drawingss

A2

.019[]

0.5

1. 8 3 5

46.6

A

FA R SIDE

A2

TYP R1.8

A3

FAR SI DE

A3

NOTES: 1. THIS DRAWING T O BE USED IN CORRELATION WITH SUPPLIED 3D

DATA BAS E F ILE. ALL DIMENS IO NS AND T O LERA NCES O N T HIS

DRAWING T AKE PRECEDENCE O VER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCO NSTRAINED ST ATE UNLESS

.071[]

INDICAT ED O THE RW ISE .

2. TO LERANCE S O N DIM ENSIO NE D AND UNDIM ENSIO NE D

FEATURES UNLESS OTHERWISE SPECIFIED:

DIME NSIO NS ARE IN M ILLIME TE RS.

TO LERA NCES : LINEAR 0.25

ANGLES: 1

3. M A T E RI AL:

A) TYPE: ASTM A228 MUSIC WIRE 1.8 0.1M M 4

4 CRIT ICAL TO F UNCT ION DIME NSIO N

PLATING : ELECTRO-LESS NICKEL OR EQUIVALENT UPON

INTEL APPROVAL.

B) CRITICAL M ECHANI CAL MAT E RIAL PRO PE RTIE S

FOR EQUIVALENT MATERIAL SELECTIO N:

TENS ILE YIELD ST RENG T H (AST M D638) > 965 MPa

FLE X URA L M O D ULUS (A S T M D638) 210 G P a 10%

5. MARK W IT H INT EL P/N AND REV ISIO N P ER INT EL M ARK ING

STANDARD 164997; PER SEC 3.8 (POLYETHYLENE BAG)

6. REM O VE ALL SHARP EDGES AND BURRS.

7. ALL DIMENSIO NS SHO W N SHA LL BE M EAS URED FO R F AI

8. ALL SECO NDARY UNIT DIM ENSIO NS ARE F O R REF ERE NCE O NLY.

A

SECTION A-A

.104[]

2.65

A

A1

.019[]

2.431

61.74 0. 5

1.459[]

37.06

.019[]

.760

19.3 0.5

Figure 17. (G)MCH Reference Heatsink for ATX Platforms – Wire Preload Clip

.019[]

1.075

27.3 0.5

A

2X 90

A2 A3

427. 7

1.090[]

36 Thermal and Mechanical Design Guidelines

Page 37

N OT ES:

.953[]

3 . CRITICAL TO FUNCTION DIMENSIONS

1. PROCUREMENT SPECIFICATION A02160 SHALL APPLY

2. REMOVE ALL BURRS AND SHARP EDGES

.009[]

.118

3 0.25

.591[]

()15

24.2

3

.007[]

.118

3 0.2

R0 TO 0.5[.020]

.046[]

C

2.20[]

()55.88

1.30[]

()33

Mechanical Drawings

Figure 18. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX) Platforms

16X 1.17

R0 TO FULL

1.885[]

47.88

15X EQUAL SPACES

B

.08[]

()1.94

FULL R

2X 7.25 0.2

A

.007[]

.285

.046[]

2X 1.17

3

.007[]

.134

3.4 0.2

.748[]

19

.047[]

2X 1.2

0.08 [.003]

0.25 [.009] B C

.748[]

19

Thermal and Mechanical Design Guidelines 37

Page 38

10.0

WITHIN

W IR E TER MIN ATION

.161[]

Mechanical Drawingss

4.1

.990[]

25.14

A

4 CRIT ICAL T O FUNCTION DIMENSIONS

NOTES:

1. REMOVE ALL SHAR P EDGES AND BU RR S

2. MATERIAL: ASTM A228 MUSIC WIRE 1.8 MM STOCK

3. TOTAL WI RE LENGTH = 121. 9 M M

5. PLATING: ELEC TRO-LESS NICKEL

.404[]

()10.27

VIEW A

.150[]

3.8

4

A2

SECTION B-B

SCALE 10:1

FAR SI DE

A1

B2X 90

.071[]

()1.80

27.3

Figure 19. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX) Platforms – Clip

F AR S IDE

F AR SIDE

A2

A3

B

1.075[]

1.390[]

35.3

.039[]

2.465

62.6 1

1.030[]

2X 26.16

DE TA IL C

SCALE 8:1

A

47.36

.071[]

4X R 1 .8

A

A1

.150[]

()3.80

.051[]

1.3

1.865[]

.049[]

.349

8.87 1.25

4

R

A3

SEE DETAIL C

A

TYP

38 Thermal and Mechanical Design Guidelines

Page 39

B

NO TES:

1. THIS DRAWING TO BE USED IN CON JU NCTION WITH SUPPLIED 3D

DATABASE FILE. ALL DIMENS IONS AND TO LERANCES ON THIS

DRAW I NG TAKE PRECEDENCE OVER SUPPLIED FIL E AN D AR E

APPLI CA BL E AT PAR T FREE, UNCO NSTRAINED STATE UNLESS

3

5 .ASSEMBLY TO BE MARKED W ITH IN TEL P/ N APPR OX. WHER E SH OWN.

INDICATED OTHERWISE.

2. FINISH: NONE

3. ALL SECONDARY UNIT DIMENSIONS ARE FOR REFERENCE ONLY. TOLERANCES

SHAL L BE C ALCUL ATED FROM PRIMARY UNI TS TO AVOID TRUN C ATION ERRORS.

4. I TEMS WITHOUT INTEL PAR T NUMBER SH AL L BE MANAGED

AND PR O CURED BY SUPP L I ER

6. ATTACH THER MAL I N TERFACE MATERIAL WHERE SH OWN. R EMO VABLE PROTECTIVE

BARRI ER APPL I ED OVER INTERFACE MATERI AL.

.748[]

2.200[]

()19

()55.88

C

1.299[]

()33

.748[]

()19

0.25 [.009] A B C

1

2

5

Mechanical Drawings

Figure 20. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX) Platforms – Heatsink Assembly

Thermal and Mechanical Design Guidelines 39

Loading...

Loading...