Page 1

Intel® Server Chassis P4000S Family

Revision 1.5

November, 2012

Enterprise Platforms and Services Marketing

Technical Product Specification

Intel order number G22850-006

Page 2

Revision History Intel® Server Chassis P4000S Family

ii

Date

Revision

Number

Modifications

July, 2010

0.5

Initial release.

December, 2010

1.0

Updated the document.

March, 2011

1.1

Added P4304XXSHCN related features.

May, 2011

1.2

Added acoustic data for P4304XXSFCN and P4304XXSHCN in section 9.3.

June, 2011

1.3

Updated figure in section 5.1.2 – Board Layout.

March, 2012

1.4

Added P4304XXSFEN, P4304XXSFDR, P4304XXSHEN, and P4304XXSHDR

related features.

November, 2012

1.5

Added S1400FP support.

Revision History

Disclaimers

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO

LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL

PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN INTEL®'S

TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL® ASSUMES NO LIABILITY

WHATSOEVER AND INTEL® DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO

SALE AND/OR USE OF INTEL® PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO

FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY

PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

A "Mission Critical Application" is any application in which failure of the Intel® Product could result, directly

or indirectly, in personal injury or death. SHOULD YOU PURCHASE OR USE INTEL®'S PRODUCTS

FOR ANY SUCH MISSION CRITICAL APPLICATION, YOU SHALL INDEMNIFY AND HOLD INTEL®

AND ITS SUBSIDIARIES, SUBCONTRACTORS AND AFFILIATES, AND THE DIRECTORS,

OFFICERS, AND EMPLOYEES OF EACH, HARMLESS AGAINST ALL CLAIMS COSTS, DAMAGES,

AND EXPENSES AND REASONABLE ATTORNEYS' FEES ARISING OUT OF, DIRECTLY OR

INDIRECTLY, ANY CLAIM OF PRODUCT LIABILITY, PERSONAL INJURY, OR DEATH ARISING IN

ANY WAY OUT OF SUCH MISSION CRITICAL APPLICATION, WHETHER OR NOT INTEL® OR ITS

SUBCONTRACTOR WAS NEGLIGENT IN THE DESIGN, MANUFACTURE, OR WARNING OF THE

INTEL® PRODUCT OR ANY OF ITS PARTS.

Intel® may make changes to specifications and product descriptions at any time, without notice. Designers

must not rely on the absence or characteristics of any features or instructions marked "reserved" or

"undefined". Intel® reserves these for future definition and shall have no responsibility whatsoever for

conflicts or incompatibilities arising from future changes to them. The information here is subject to

change without notice. Do not finalize a design with this information.

The products described in this document may contain design defects or errors known as errata which

may cause the product to deviate from published specifications. Current characterized errata are

available on request.

Contact your local Intel® sales office or your distributor to obtain the latest specifications and before

placing your product order.

Copies of documents which have an order number and are referenced in this document, or other Intel®

literature, may be obtained by calling 1-800-548-4725, or go to: http://www.intel.com/design/literature.

Intel order number G22850-006 Revision 1.5

Page 3

Intel® Server Chassis P4000S Family TPS Table of Contents

iii

Table of Contents

1. Product Overview ............................................................................................................... 1

1.1 Intel® Server Chassis P4000S Family Design Features .......................................... 1

1.2 Intel® Server Chassis P4304XXSFCN Views .......................................................... 3

1.3 Intel® Server Chassis P4304XXSHCN Views ......................................................... 4

1.4 Intel® Server Chassis P4304XXSFEN Views .......................................................... 5

1.5 Intel® Server Chassis P4304XXSHEN Views ......................................................... 6

1.6 Intel® Server Chassis P4304XXSFDR Views .......................................................... 7

1.7 Intel® Server Chassis P4304XXSHDR Views ......................................................... 8

1.8 Chassis Security .................................................................................................... 8

1.9 I/O Panel ................................................................................................................ 9

1.10 Front Bezel Features .............................................................................................. 9

1.11 Front Panel Overview ........................................................................................... 11

1.12 Back Panel Overview ........................................................................................... 11

1.13 Standard Fixed Drive Trays .................................................................................. 12

1.14 4x3.5” Hot-Swap Hard Disk Drive Cage ............................................................... 13

1.14.1 3.5” Hot-swap Hard Drive Carrier ......................................................................... 13

1.15 Peripheral Bays .................................................................................................... 14

2. Chassis Power Sub-system ............................................................................................. 15

2.1 365W Power Supply ............................................................................................. 15

2.1.1 Mechanical Overview ........................................................................................... 15

2.1.2 365W Power Supply Output Wire Harness ........................................................... 17

2.1.3 Temperature Requirements .................................................................................. 19

2.1.4 AC Input Requirements ........................................................................................ 20

2.1.5 Efficiency .............................................................................................................. 21

2.1.6 DC Output Specification ....................................................................................... 22

2.1.7 Protection Circuits ................................................................................................ 27

2.1.8 Control and Indicator Functions ............................................................................ 28

2.2 550W Power Supply ............................................................................................. 29

2.2.1 Mechanical Overview ........................................................................................... 30

2.2.2 Temperature Requirements .................................................................................. 34

2.2.3 AC Input Requirements ........................................................................................ 34

2.2.4 Efficiency .............................................................................................................. 36

2.2.5 DC Output Specification ....................................................................................... 36

2.2.6 Protection Circuits ................................................................................................ 41

2.2.7 Control and Indicator Functions ............................................................................ 42

2.3 460W Power Supply ............................................................................................. 44

2.3.1 Mechanical Overview ........................................................................................... 44

2.3.2 AC Input Requirements ........................................................................................ 47

2.3.3 Efficiency .............................................................................................................. 48

Revision 1.5 Intel order number G22850-006

Page 4

Table of Contents Intel® Server Chassis P4000S Family TPS

iv

2.3.4 DC Output Specification ....................................................................................... 49

2.3.5 Protection Circuits ................................................................................................ 53

2.3.6 Control and Indicator Functions ............................................................................ 54

2.3.7 Thermal CLST ...................................................................................................... 56

2.3.8 Power Supply Diagnostic “Black Box” .................................................................. 56

2.3.9 Firmware Uploader ............................................................................................... 57

2.4 Lower Current Common Redundant Power Distribution Board (PDB) .................. 57

2.4.1 Mechanical Overview ........................................................................................... 58

2.4.2 DC Output Specification ....................................................................................... 59

2.4.3 Protection Circuits ................................................................................................ 68

2.4.4 PWOK (Power OK) Signal .................................................................................... 68

2.4.5 PSON Signal ........................................................................................................ 69

2.4.6 PMBus* ................................................................................................................ 69

3. Chassis Cooling ............................................................................................................... 70

3.1 Cooling solution for Intel® Server Board S1200BT Series ..................................... 70

3.2 Cooling solution for Intel® Server Board S2400SC and S1400FP ......................... 71

3.3 Fan Control .......................................................................................................... 72

3.4 Fan Header Connector Descriptions ................................................................ .... 72

4. Standard Front Panel ....................................................................................................... 73

4.1 Front Panel Overview ........................................................................................... 73

4.2 Front Panel Features ............................................................................................ 73

4.3 Common Front Panel Placement.......................................................................... 74

4.3.1 Common Front Panel LED Functionality ............................................................... 74

4.4 Common Front Panel Connector List and Pinouts ................................................ 75

4.4.1 Pinouts ................................................................................................................. 75

5. 4x3.5” Hot-Swap Back Plane (HSBP) .............................................................................. 77

5.1 Overview .............................................................................................................. 77

5.1.1 Key Features ........................................................................................................ 77

5.1.2 Board Layout ........................................................................................................ 77

5.2 4x 3.5" HSBP Functional Description ................................................................... 79

5.2.1 4x3.5” HSBP Microcontroller ................................................................................ 79

5.2.2 SGPIO Functionality ............................................................................................. 80

5.2.3 I2C Functionality ................................................................................................... 80

5.2.4 SATA 6X Mode Jumper Functionality ................................................................... 81

5.2.5 HSBP LED Functionality ...................................................................................... 82

5.3 4x3.5” HSBP Connector List and Pinouts ............................................................. 82

5.3.1 Pinouts ................................................................................................................. 83

5.4 4x3.5” HSBP Cabling Requirements ................................................................ .... 84

6. System Interconnection ................................................................................................... 85

6.1 Chassis Internal Cables ....................................................................................... 85

6.1.1 Front Panel Cable ................................................................................................ 85

Intel order number G22850-006 Revision 1.5

Page 5

Intel® Server Chassis P4000S Family TPS Table of Contents

v

6.1.2 Intrusion Switch cable .......................................................................................... 85

6.1.3 USB Cable ........................................................................................................... 86

6.1.4 SATA Power Adapter Cable ................................................................................. 86

6.1.5 SATA cable for HDDs/ODD .................................................................................. 87

6.1.6 Mini SAS (MB) to 4pcs 7Pin SATA Cable with SGPIO Cable ............................... 87

6.1.7 Mini SAS (MB) to 4pcs 7Pin SATA Cable ............................................................. 88

6.1.8 I2C Cable (5pin (HSBP)--3pin (MB)) ..................................................................... 88

6.1.9 SGPIO Cable ........................................................................................................ 89

7. System-Compatible Intel® Server Boards ....................................................................... 90

8. Reliability, Serviceability, and Availability ...................................................................... 91

8.1 Mean Time between Failure ................................................................................. 91

8.2 Serviceability ........................................................................................................ 93

9. Environmental Limits ....................................................................................................... 94

9.1 System Office Environment .................................................................................. 94

9.2 System Environmental Testing ............................................................................. 94

9.3 Intel® Server Chassis P4000S Family Acoustic Level ........................................... 95

9.3.1 Intel® Server Chassis P4000S Family with Intel® Server Board S1200BTL ........... 95

9.3.2 Intel® Server Chassis P4000S Family with Intel® Server Board S1200BTS .......... 96

9.3.3 Intel® Server Chassis P4000S Family with Intel® Server Board S2400SC ............ 96

9.3.4 Intel® Server Chassis P4000S Family with Intel® Server Board S1400FP ............. 97

10. Product Regulatory Compliance ..................................................................................... 99

Appendix A: Integration and Usage Tips ............................................................................. 100

Glossary ................................................................................................................................ 101

Revision 1.5 Intel order number G22850-006

Page 6

List of Figures Intel® Server Chassis P4000S Family TPS

vi

List of Figures

Figure 1. Internal Chassis View of Intel® Server Chassis P4304XXSFCN ................................... 3

Figure 2. Internal Chassis View of Intel® Server Chassis P4304XXSHCN ................................... 4

Figure 3. Internal Chassis View of Intel® Server Chassis P4304XXSFEN ................................... 5

Figure 4. Internal Chassis View of Intel® Server Chassis P4304XXSHEN ................................... 6

Figure 5. Internal Chassis View of Intel® Server Chassis P4304XXSFDR ................................... 7

Figure 6. Internal Chassis View of Intel® Server Chassis P4304XXSHDR ................................... 8

Figure 7. ATX 2.2 I/O Aperture .................................................................................................... 9

Figure 8. Front Closed Chassis View with Front Bezel for Fixed Hard Drives Configuration ........ 9

Figure 9. Front Closed Chassis View with Front Bezel for Hot-swap Hard Drives Configuration 10

Figure 10. Front Panel Controls and Indicators ......................................................................... 11

Figure 11. Back Panel Layout (with Fixed Power Supply) ......................................................... 11

Figure 12. Back Panel Layout (with Hot-swap Power Supply) ................................................... 12

Figure 13. Fixed Drive Tray ....................................................................................................... 12

Figure 14. 4x3.5” Hot-Swap Hard Disk Drive Cage ................................................................ ... 13

Figure 15. 3.5” hot-swap hard drive carrier with 2.5” HDD Interface Bracket ............................. 13

Figure 16. Tool-less Rails Mounting 5.25-inch CD-ROM Drive .................................................. 14

Figure 17. Mechanical Drawing for 365W Power Supply Enclosure .......................................... 16

Figure 18. Output Cable Harness for 365W Power Supply ........................................................ 17

Figure 19. Differential Noise test setup ..................................................................................... 25

Figure 20. Output Voltage Timing ............................................................................................. 26

Figure 21. Turn On/Off Timing (Power Supply Signals) ............................................................. 27

Figure 22. PSON# Required Signal Characteristic .................................................................... 29

Figure 23. Mechanical Drawing for 550W Power Supply Enclosure .......................................... 30

Figure 24. Output Cable Harness for 550W Power Supply ........................................................ 31

Figure 25. Differential Noise test setup ..................................................................................... 39

Figure 26. Output Voltage Timing ............................................................................................. 40

Figure 27. Turn On/Off Timing (Power Supply Signals) ............................................................. 41

Figure 28. PSON# Required Signal Characteristic .................................................................... 43

Figure 29. Power Supply Outline Drawing ................................................................................. 44

Figure 30. Differential Noise test setup ..................................................................................... 51

Figure 31. Turn On/Off Timing (Power Supply Signals) ............................................................. 53

Figure 32. PSON# Required Signal Characteristic .................................................................... 55

Figure 33. Implementation of the Power Ok Circuits ................................................................. 56

Figure 34. Outline Drawing........................................................................................................ 58

Figure 35. Airflow Diagram ........................................................................................................ 59

Figure 36. Differential Noise test setup ..................................................................................... 67

Figure 37. Active Heatsink and Chassis Rear Fan in Intel® Server Chassis P4304XXSFCN ..... 70

Intel order number G22850-006 Revision 1.5

Page 7

Intel® Server Chassis P4000S Family TPS List of Figures

vii

Figure 38. Chassis System Fans Default location in Intel® Server Chassis P4304XXSFEN ...... 71

Figure 39. Chassis System Fans to support full length card in Intel® Server Chassis

P4304XXSFEN ................................................................................................................... 71

Figure 40. Front Panel overview ............................................................................................... 73

Figure 41. Common Front Panel LED/Button Arragement ......................................................... 74

Figure 42. 4x3.5” HSBP Board Layout ...................................................................................... 78

Figure 43. 4x 3.5" HSBP I2C Connectivity ................................................................................. 81

Figure 44. Chassis Front Panel Cable ....................................................................................... 85

Figure 45. Intrusion Switch Cable.............................................................................................. 85

Figure 46. USB Cable Drawing ................................................................................................. 86

Figure 47. SATA Power Adapter Cable ..................................................................................... 86

Figure 48. SATA cable for HDDs (450mm) ............................................................................... 87

Figure 49. Mini SAS(MB) to 4pcs 7Pin SATA cable with SGPIO Cable ..................................... 87

Figure 50. Mini SAS(MB) to 4pcs 7Pin SATA Cable .................................................................. 88

Figure 51. I2C Cable (5pin to 3pin) ............................................................................................ 88

Figure 52. SGPIO Cable ........................................................................................................... 89

Revision 1.5 Intel order number G22850-006

Page 8

List of Tables Intel® Server Chassis P4000S Family TPS

viii

List of Tables

Table 1. Intel® Server Chassis P4000S family Features .............................................................. 1

Table 2. 365W Power Supply Cable Lengths ............................................................................ 18

Table 3. P1 Main Power Connector ........................................................................................... 18

Table 4. P2 Processor#1 Power Connector .............................................................................. 19

Table 5. Peripheral Power Connectors ................................................................ ...................... 19

Table 6. SATA Power Connector .............................................................................................. 19

Table 7. Thermal Requirements ................................................................................................ 19

Table 8. Power Factor Requirements for Computer Servers ..................................................... 20

Table 9. AC Input Voltage Range .............................................................................................. 20

Table 10. AC Line Holdup Time ................................................................................................ 20

Table 11. AC Line Sag Transient Performance ......................................................................... 21

Table 12. AC Line Surge Transient Performance ...................................................................... 21

Table 13. Silver Efficiency Requirement .................................................................................... 22

Table 14. Over Voltage Protection Limits .................................................................................. 22

Table 15. Loading Conditions .................................................................................................... 22

Table 16. Voltage Regulation Limits .......................................................................................... 23

Table 17. Transient Load Requirements ................................................................................... 23

Table 18. Capacitive Loading Conditions .................................................................................. 23

Table 19. Ripples and Noise ..................................................................................................... 24

Table 20. Output Voltage Timing ............................................................................................... 25

Table 21. Turn On/Off Timing .................................................................................................... 26

Table 22. Over Voltage Protection (OVP) Limits ....................................................................... 28

Table 23. PSON# Signal Characteristic .................................................................................... 28

Table 24. PWOK Signal Characteristics .................................................................................... 29

Table 25. Power Supply Cable Lengths .................................................................................... 32

Table 26. P1 Main Power Connector ......................................................................................... 32

Table 27. P2 Processor#1 Power Connector ............................................................................ 33

Table 28. P3 Processor#1 Power Connector ............................................................................ 33

Table 29. Peripheral Power Connectors .................................................................................... 33

Table 30. SATA Power Connector ............................................................................................ 33

Table 31. Thermal Requirements .............................................................................................. 34

Table 32. Power Factor Requirements for Computer Servers ................................................... 34

Table 33. AC Input Voltage Range ............................................................................................ 35

Table 34. AC Line Holdup time ................................................................................................. 35

Table 35. AC Line Sag Transient Performance ......................................................................... 36

Table 36. AC Line Surge Transient Performance ...................................................................... 36

Table 37. Silver Efficiency Requirement .................................................................................... 36

Table 38. Over Voltage Protection Limits .................................................................................. 37

Intel order number G22850-006 Revision 1.5

Page 9

Intel® Server Chassis P4000S Family TPS List of Tables

ix

Table 39. Loading Conditions .................................................................................................... 37

Table 40. Voltage Regulation Limits .......................................................................................... 37

Table 41. Transient Load Requirements ................................................................................... 38

Table 42. Capacitive Loading Conditions .................................................................................. 38

Table 43. Ripples and Noise ..................................................................................................... 39

Table 44. Output Voltage Timing ............................................................................................... 40

Table 45. Turn On/Off Timing .................................................................................................... 40

Table 46. Over Current Limits ................................................................................................... 42

Table 47. PSON# Signal Characteristic .................................................................................... 43

Table 48. PWOK Signal Characteristics .................................................................................... 43

Table 49. DC Output Selector ................................................................................................... 44

Table 50. LED Characteristics ................................................................................................... 46

Table 51. LED Indicator States ................................................................................................. 46

Table 52. Environmental Requirements .................................................................................... 46

Table 53. AC Input Voltage Range ............................................................................................ 47

Table 54. AC Line Sag Transient Performance ......................................................................... 48

Table 55. AC Line Surge Transient Performance ...................................................................... 48

Table 56. Gold Efficiency Requirement ..................................................................................... 48

Table 57. Minimum Load Ratings .............................................................................................. 49

Table 58. Voltage Regulation Limits .......................................................................................... 49

Table 59. Transient Load Requirements ................................................................................... 49

Table 60. Capacitive Loading Conditions .................................................................................. 50

Table 61. Ripples and Noise ..................................................................................................... 51

Table 62. Timing Requirements ................................................................................................ 52

Table 63. Over Current Protection............................................................................................. 53

Table 64. Over Voltage Protection (OVP) Limits ....................................................................... 54

Table 65. PSON# Signal Characteristic .................................................................................... 54

Table 66. PWOK Signal Characteristics .................................................................................... 55

Table 67. SMBAlert# Signal Characteristics .............................................................................. 56

Tabel 68. Thermal Requirements .............................................................................................. 59

Table 69. Input Connector and Pin Assignment Diagrams ........................................................ 60

Table 70. PDB Cable Length ..................................................................................................... 60

Table 71. P1 Baseboard Power Connector ............................................................................... 61

Table 72. P0 Processor Power Connector ................................................................................ 61

Table 73. P1 Processor Power Connector ................................................................................ 61

Table 74. Power Signal Connector ............................................................................................ 62

Table 75. Aux baseboard power connector ............................................................................... 62

Table 76. P8, P9, P10, P11 Legacy Peripheral Power Connectors ........................................... 62

Table 77. P7 Legacy Peripheral Power Connectors .................................................................. 62

Table 78. SATA Peripheral Power Connectors.......................................................................... 63

Table 79. Remote Sense Connection Points ............................................................................. 63

Revision 1.5 Intel order number G22850-006

Page 10

List of Tables Intel® Server Chassis P4000S Family TPS

x

Table 80. Remote Sense Requirements.................................................................................... 63

Table 81. 12V Rail Distribution .................................................................................................. 64

Table 82. Hard Drive 12V rail configuration options .................................................................. 64

Table 83. DC/DC Converters Load Ratings ............................................................................... 65

Table 84. 5VSB Loading ........................................................................................................... 65

Table 85. Voltage Regulation Limits .......................................................................................... 65

Table 86. Transient Load Requirements ................................................................................... 66

Table 87. Capacitive Loading Conditions .................................................................................. 66

Table 88. Ripple and Noise ....................................................................................................... 66

Table 89. Output Voltage Timing ............................................................................................... 67

Table 90. PDB Over Current Protection Limits/240VA Protection .............................................. 68

Table 91. Over Voltage Protection (OVP) Limits ....................................................................... 68

Table 92. System PWOK Requirements ................................................................................... 69

Table 93. PDB addressing ........................................................................................................ 69

Table 94. Front Panel LED Functionality ................................ ................................................... 74

Table 95. Connectors for Boards .............................................................................................. 75

Table 96. Pinouts Signal Description ......................................................................................... 75

Table 97. Chassis Intrusion Pin-out ........................................................................................... 76

Table 98. 4x3.5" HSBP Microcontroller Pinouts ........................................................................ 79

Table 99. 4x3.5” HSBP SATA 6X Mode Host Jumper Block...................................................... 81

Table 100. Romley LED Functionality ....................................................................................... 82

Table 101. HDD Activity LED Functionality ............................................................................... 82

Table 102. 4x3.5” HSBP Connector List .................................................................................... 82

Table 103. 4x3.5” HSBP SGPIO Connector Pinouts ................................................................. 83

Table 104. 4x3.5” HSBP I

Table 105. 4x3.5” HSBP I

2

C (In) Connector Pinouts ................................................................. 83

2

C (Out) Connector List ..................................................................... 83

Table 106. 4x3.5” HSBP Power Connector Pinouts .................................................................. 83

Table 107. System-Compatible Intel® Server Boards ................................................................ 90

Table 108. Calculated Mean Time Between Failure – P4304XXSFCN and P4304XXSHCN ..... 91

Table 109. Calculated Mean Time Between Failure – P4304XXSFEN and P4304XXSHEN ..... 92

Table 110. Calculated Mean Time Between Failure – P4304XXSFDR and P4304XXSHDR ..... 92

Table 111. Calculated Mean Time Between Failure – P4304XXSFDN and P4304XXSHDN ..... 93

Table 112. Maximum Maintenance Procedure Times................................................................ 93

Table 113. System Office Environment Summary ..................................................................... 94

Table 114. Test Conditions at Acoustic Lab ................................................................ .............. 95

Table 115. System Configurations ............................................................................................ 95

Table 116. Declared Acoustic Data of Intel® Server Chassis P4000S family with Intel® Server

Board S1200BTL ................................................................................................................ 95

Table 117. Test Conditions at Acoustic Lab ................................................................ .............. 96

Table 118. System Configurations ............................................................................................ 96

Intel order number G22850-006 Revision 1.5

Page 11

Intel® Server Chassis P4000S Family TPS List of Tables

xi

Table 119. Declared Acoustic Data of Intel® Server Chassis P4000S family with Intel® Server

Board S1200BTS ................................................................................................................ 96

Table 120. Test Conditions at Acoustic Lab ................................................................ .............. 96

Table 121. System Configurations ............................................................................................ 97

Table 122. Declared Acoustic Data of Intel® Server Chassis P4000S family with Intel® Server

Board S2400SC ................................................................................................................. 97

Table 123. Test Conditions at Acoustic Lab ................................................................ .............. 97

Table 124. System Configurations ............................................................................................ 98

Table 125. Declared Acoustic Data of Intel® Server Chassis P4000S family with Intel® Server

Board S1400FP .................................................................................................................. 98

Revision 1.5 Intel order number G22850-006

Page 12

List of Tables Intel® Server Chassis P4000S Family TPS

xii

<This page is intentionally left blank.>

Intel order number G22850-006 Revision 1.5

Page 13

Intel® Server Chassis P4000S Family TPS Product Overview

1

Configuration

P4304XXSFCN

P4304XXSHCN

P4304XXSFEN

P4304XXSHEN

Intel® Server

Board

Support

Intel® Server

Board S1200BTL

Intel® Server

Board S1200BTS

Intel® Server Board

S1200BTL

Intel® Server Board S2400SC

Power

365W non-redundant power supply with

integrated cooling fan

550W non-redundant power supply with integrated

cooling fan.

System

Cooling

One 92x38mm fixed system rear fan

Two 92x32mm fixed system fans.

1. Product Overview

The Intel® Server Chassis P4000S family is a 4U pedestal, 22” length server chassis. Intel®

Server Chassis P4304XXSFCN and P4304XXSHCN are designed to support Intel® Server

Board S1200BTL, and S1200BTS. Intel® Server Chassis P4304XXSFEN, P4304XXSFDR,

P4304XXSHEN and P4304XXSHDR are designed to support Intel® Server Board S2400SC.

This chapter provides a high-level overview of the chassis features. Greater detail for each

major chassis component or feature is provided in the following chapters.

1.1 Intel

®

Server Chassis P4000S Family Design Features

The Intel® Server Chassis P4000S family is designed to address the entry-level market. The

Intel® Server Chassis P4000S Family make extensive use of tool-less hardware features and,

depending on configuration and upgrade features, provides redundant power supply and hot

swappable hard drives capability. The Intel® Server Chassis P4000S family comes with the

following configurations:

1. P4304XXSFCN – one 365W non-redundant PSU, one fixed 92x38mm rear system fan and

up to four 3.5” fixed hard drives

2. P4304XXSHCN – 365W non-redundant PSU and one fixed 92x38mm rear system fan up to

four 3.5” hot-swap hard drives

3. P4304XXSFEN – one 550W non-redundant PSU, two fixed 92x32mm system fans and up

to four 3.5” fixed hard drives

4. P4304XXSHEN – one 550W non-redundant PSU, two fixed 92x32mm system fans and up

to four 3.5” hot-swap hard drives

5. P4304XXSFDR – two 460W redundant PSU, two fixed 92x32mm system fans and up to four

3.5” fixed hard drives

6. P4304XXSHDR – two 460W redundant PSU, two fixed 92x32mm system fans and up to

four 3.5” hot-swap hard drives

7. P4304XXSFDN – one 460W hot-swap PSU, two fixed 92x32mm system fans and up to four

3.5” fixed hard drives

8. P4304XXSHDN – one 460W hot-swap PSU, two fixed 92x32mm system fans and up to four

3.5” hot-swap hard drives

The following table summarizes the features for all chassis combinations.

Table 1. Intel® Server Chassis P4000S family Features

Revision 1.5 Intel order number G22850-006

Page 14

Product Overview Intel® Server Chassis P4000S Family TPS

2

Configuration

P4304XXSFCN

P4304XXSHCN

P4304XXSFEN

P4304XXSHEN

Peripherals

Bays

Three (3) half height 5-1/4" bays for optical devices.

Drive Bays

Includes one fixed

drive bay.

Supports up to

four fixed hard

drives.

Includes one 4x3.5”

hot-swap hard drive

cage. Supports up

to four hot-swap

hard drives.

Includes one fixed drive bay.

Supports up to four fixed

hard drives.

Includes one 4x3.5” hotswap hard drive cage.

Supports up to four hotswap hard drives.

Expansion

Slots

Up to six PCI cards (depends on board features).

Front Panel

Power Button with LED, Reset Button, NMI Button, ID Button with LED, Four NIC LEDs, Hard drive

activity LED, System status LED, two USB ports, Optional front serial port/VGA port.

Appearance

Color: Cosmetic black (GE 701 or equivalent), service Intel® blue, hot swap Intel® green.

Support for Intel® standard front panel or LCD.

Dimensions

Pedestal

with Front

Bezel

17.24 in (438 mm) x 6.81 in (173mm) x 22.05 in (560 mm) (Height X Width X Depth).

Optional

Accessory

Kits

Zephyr flash storage, RMM4-lite modules, TPM module, and dedicated NIC module.

Configuration

P4304XXSFDR

P4304XXSHDR

P4304XXSFDN

P4304XXSHDN

Intel® Server

Board

Support

Intel® Server Board S2400SC

Intel® Server Board S1400FP

Intel® Server Board S2400SC.

Power

Two 460W redundant power supply with

integrated cooling fan.

One 460W hot-swap power supply with integrated

cooling fan.

System

Cooling

Two 92x32mm fixed system fans.

Peripherals

Bays

Three (3) half height 5-1/4" bays for optical devices.

Drive Bays

Includes one fixed

drive bay.

Supports up to

four fixed hard

drives.

Includes one 4x3.5”

hot-swap hard drive

cage. Supports up

to four hot-swap

hard drives.

Includes one fixed drive bay.

Supports up to four fixed

hard drives.

Includes one 4x3.5” hotswap hard drive cage.

Supports up to four hotswap hard drives.

Expansion

Slots

Up to Six (6) PCI cards (depends on board features).

Front Panel

Power Button with LED, Reset Button, NMI Button, ID Button with LED, Four NIC LEDs, Hard drive

activity LED, System status LED, two USB ports, Optional front serial port/VGA port.

Appearance

Color: Cosmetic black (GE 701 or equivalent), service Intel® blue, hot swap Intel® green.

Support for Intel® standard front panel or LCD.

Dimensions

Pedestal

with Front

Bezel

17.24 in (438 mm) x 6.81 in (173mm) x 22.05 in (560 mm) (Height X Width X Depth).

Optional

Accessory

Kits

Zephyr flash storage, RMM4-lite modules, TPM module, dedicated NIC module.

Intel order number G22850-006 Revision 1.5

Page 15

Intel® Server Chassis P4000S Family TPS Product Overview

3

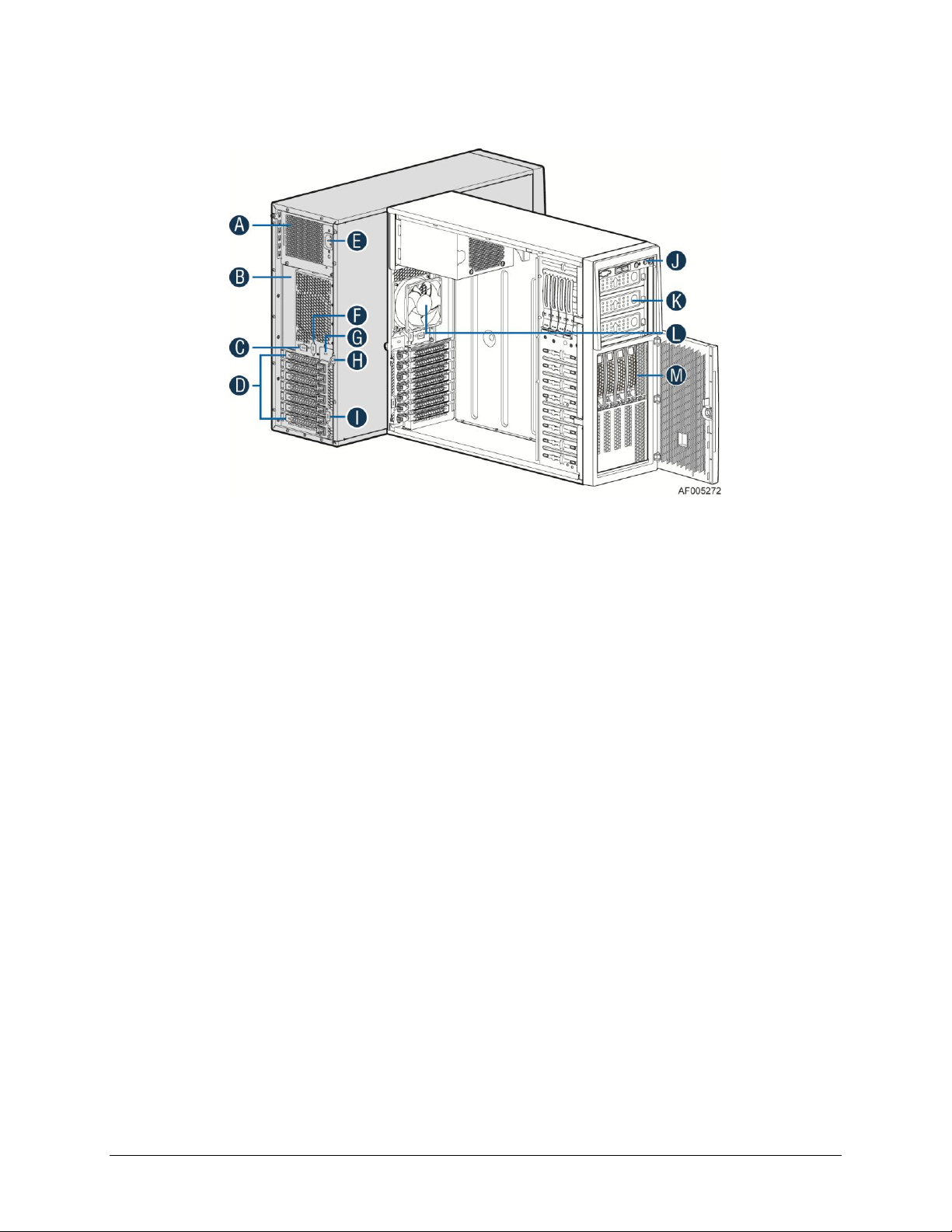

1.2 Intel

®

Server Chassis P4304XXSFCN Views

A. 365W Fixed Power supply

B. I/O Ports

C. Alternate RMM4 Knockout

D. PCI Add-in Board Slot Covers

E. AC Input Power Connector

F. Serial Port Knockout

G. A Kensington* Cable Lock Mounting Hole

H. Padlock Loop

I. Alternate RMM4 Knockout

J. Front Control Panel

K. Alternate 5.25” Peripheral Bays

L. 92x38mm System Rear Fan

M. Fixed Hard Drive Bays

Figure 1. Internal Chassis View of Intel® Server Chassis P4304XXSFCN

Revision 1.5 Intel order number G22850-006

Page 16

Product Overview Intel® Server Chassis P4000S Family TPS

4

1.3 Intel

®

Server Chassis P4304XXSHCN Views

A. 365W Fixed Power Supply

B. I/O Ports

C. Alternate RMM4 Knockout

D. PCI Add-in Board Slot Covers

E. AC Input Power Connector

F. Serial Port Knockout

G. A Kensington* Cable Lock Mounting Hole

H. Padlock Loop

I. Alternate RMM4 Knockout

J. Front Control Panel

K. 5.25” Peripheral Bays

L. 92x38mm System Rear Fan

M. 4x3.5” Hot-swap HDD Cage

Figure 2. Internal Chassis View of Intel® Server Chassis P4304XXSHCN

Intel order number G22850-006 Revision 1.5

Page 17

Intel® Server Chassis P4000S Family TPS Product Overview

5

1.4 Intel

®

Server Chassis P4304XXSFEN Views

A. 550W Fixed Power supply

B. I/O Ports

C. Alternate RMM4 Knockout

D. PCI Add-in Board Slot Covers

E. AC Input Power Connector

F. Serial Port Knockout

G. A Kensington* Cable Lock Mounting Hole

H. Padlock Loop

I. Alternate RMM4 Knockout

J. Front Control Panel

K. Alternate 5.25” Peripheral Bays

L. CPU Zone System Fan

M. Fixed Hard Drive Bays

N. PCI Zone System Fan

Figure 3. Internal Chassis View of Intel® Server Chassis P4304XXSFEN

Revision 1.5 Intel order number G22850-006

Page 18

Product Overview Intel® Server Chassis P4000S Family TPS

6

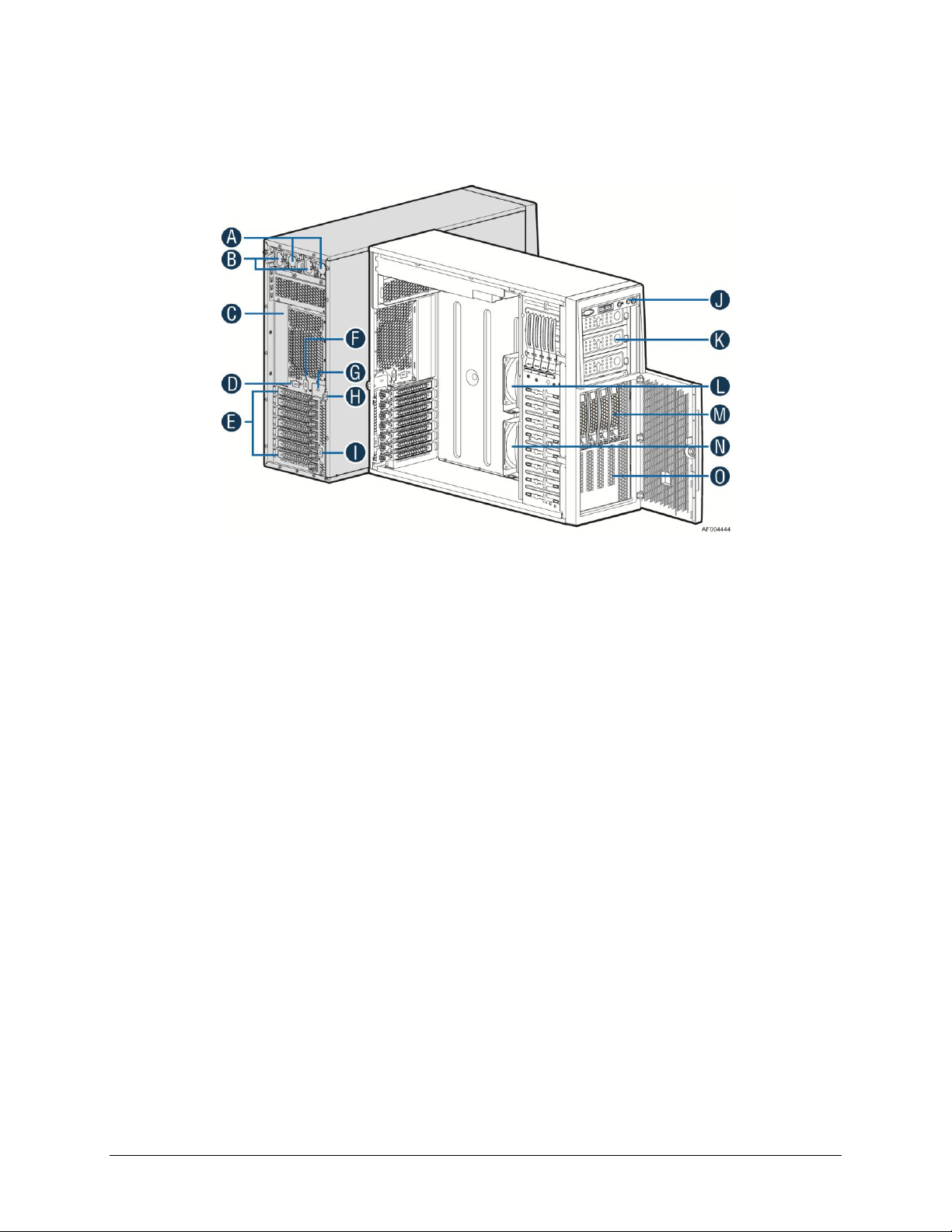

1.5 Intel

®

Server Chassis P4304XXSHEN Views

A. 550W Fixed Power supply

B. I/O Ports

C. Alternate RMM4 Knockout

D. PCI Add-in Board Slot Covers

E. AC Input Power Connector

F. Serial Port Knockout

G. A Kensington* Cable Lock Mounting Hole

H. Padlock Loop

I. Alternate RMM4 Knockout

J. Front Control Panel

K. Alternate 5.25” Peripheral Bays

L. CPU Zone System Fan

M. 4x3.5” Hot-swap HDD Cage

N. PCI Zone System Fan

O. Hot-swap HDD EMI Shield

Figure 4. Internal Chassis View of Intel® Server Chassis P4304XXSHEN

Intel order number G22850-006 Revision 1.5

Page 19

Intel® Server Chassis P4000S Family TPS Product Overview

7

1.6 Intel

®

Server Chassis P4304XXSFDR Views

A. 460W Redundant Power Supply (Two)

B. AC Input Power Connector (Two)

C. I/O Ports

D. Alternate RMM4 Knockout

E. PCI Add-in Board Slot Covers

F. Serial Port Knockout

G. A Kensington* Cable Lock Mounting Hole

H. Padlock Loop

I. Alternate RMM4 Knockout

J. Front Control Panel

K. Alternate 5.25” Peripheral Bays

L. CPU Zone System Fan

M. Fixed Hard Drive Bays

N. PCI Zone System Fan

Figure 5. Internal Chassis View of Intel® Server Chassis P4304XXSFDR

Revision 1.5 Intel order number G22850-006

Page 20

Product Overview Intel® Server Chassis P4000S Family TPS

8

1.7 Intel

®

Server Chassis P4304XXSHDR Views

A. 460W Redundant Power Supply (Two)

B. AC Input Power Connector (Two)

C. I/O Ports

D. Alternate RMM4 Knockout

E. PCI Add-in Board Slot Covers

F. Serial Port Knockout

G. A Kensington* Cable Lock Mounting Hole

H. Padlock Loop

I. Alternate RMM4 Knockout

J. Front Control Panel

K. Alternate 5.25” Peripheral Bays

L. CPU Zone System Fan

M. 4x3.5” Hot-swap HDD Cage

N. PCI Zone System Fan

O. Hot-swap HDD EMI Shield

Figure 6. Internal Chassis View of Intel® Server Chassis P4304XXSHDR

1.8 Chassis Security

A variety of chassis security options are provided at the system level:

A removable padlock loop at the rear of the system access cover can be used to prevent

access to the microprocessors, memory, and add-in cards. A variety of lock sizes can be

accommodated by the 0.270-inch diameter loop.

A Kensington* cable lock mounting hole is provided on the rear chassis I/O panel.

A chassis intrusion switch is provided, allowing server management software to detect

unauthorized access to the system side cover.

Intel order number G22850-006 Revision 1.5

Page 21

Intel® Server Chassis P4000S Family TPS Product Overview

9

I/O Aperture

Baseboard

Datum 0,0

5.196 ± 0.0106.250 ± 0.008

1.750 ± 0.008

(0.650)

(0.150)

0.100 Min keepout around opening

R 0.039 MAX, TYP

In hot-swap hard drives configuration, a door lock is provided on the front bezel assembly

with the door to prevent access to the hot-swap hard drives and the interior of the chassis.

Note: See the technical product specification appropriate to the server board for a description of

BIOS and management security features for each specific supported platform. Technical

product specifications can be found at http://www.intel.com/p/en_US/support.

1.9 I/O Panel

All input/output (I/O) connectors are accessible from the rear of the chassis. The SSI E-bay

3.61-compliant chassis provides an ATX 2.2-compatible cutout for I/O shield installation. Boxed

Intel® server boards provide the required I/O shield for installation in the cutout. The I/O cutout

dimensions are shown in the following figure for reference.

Figure 7. ATX 2.2 I/O Aperture

1.10 Front Bezel Features

There are two types of front bezel assembly in the Intel® Server Chassis P4000S family:

1. Front bezel assembly for fixed hard drives configuration.

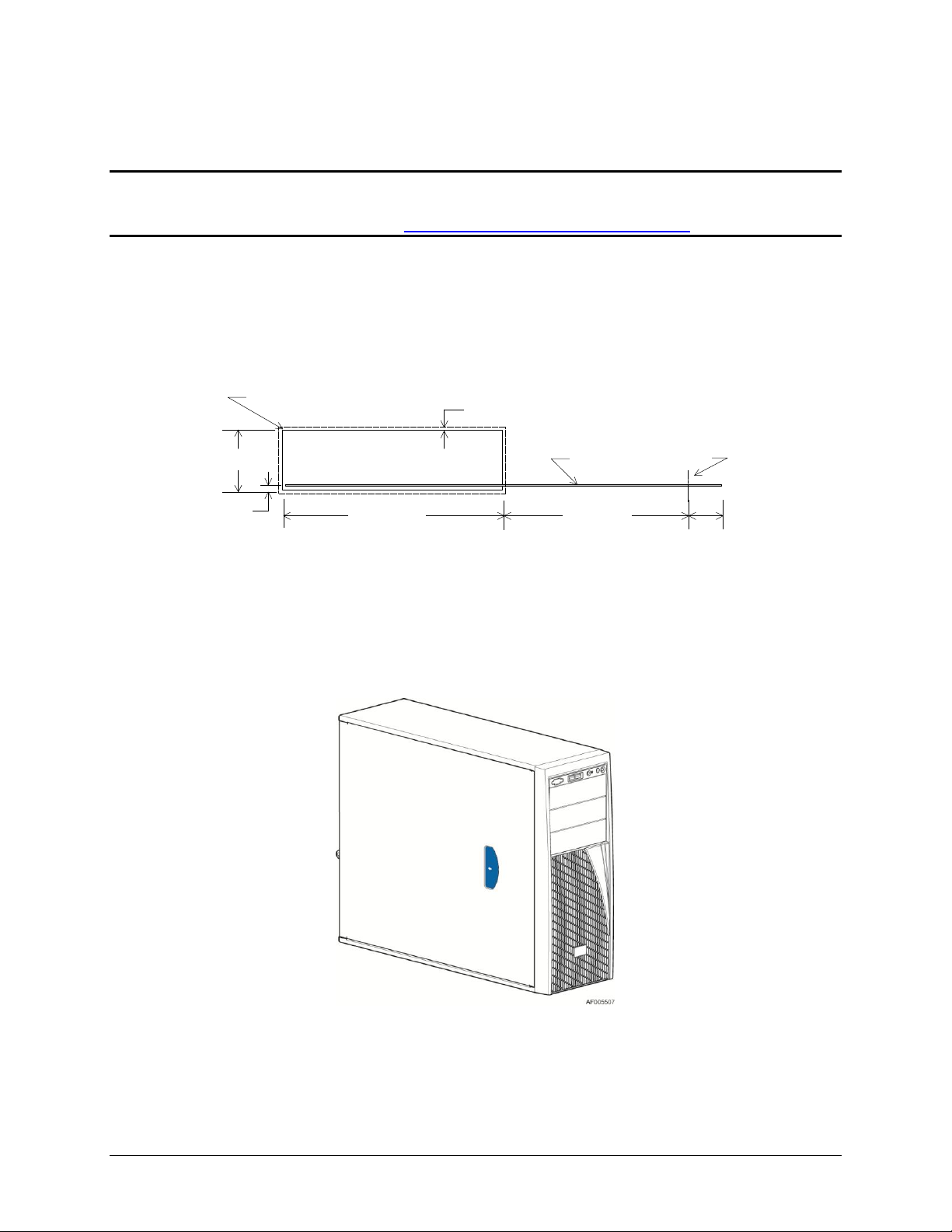

Figure 8. Front Closed Chassis View with Front Bezel for Fixed Hard Drives Configuration

Revision 1.5 Intel order number G22850-006

Page 22

Product Overview Intel® Server Chassis P4000S Family TPS

10

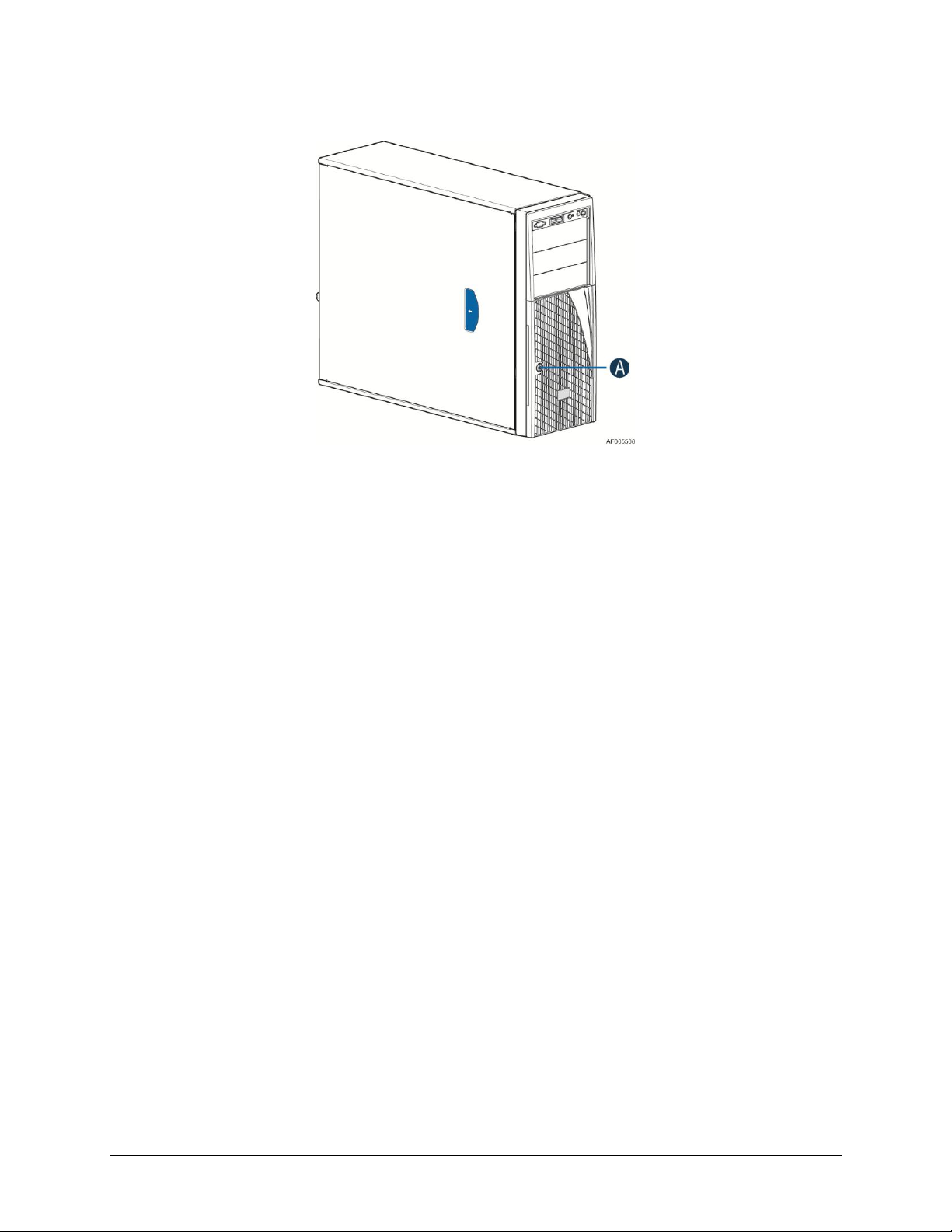

2. Front bezel assembly with the door for hot-swap hard drives configuration.

A. Security Lock

Figure 9. Front Closed Chassis View with Front Bezel for Hot-swap Hard Drives Configuration

Both two pedestal front bezel are constructed of molded plastic and attaches to the front of the

chassis with three clips on the right side and two snaps on the left. The snaps at the left attach

behind the access cover, thereby preventing accidental removal of the bezel. The bezel can

only be removed by first removing the server access cover. This provides additional security to

the hard drive and peripheral bay area.

For the front bezel assembly for fixed hard drives configuration, removing the bezel, there is an

EMI shield covering the fixed hard drives bay area.

For the front bezel assembly for hot-swap hard drives configuration, the bezel includes a keylocking door that covers the drive cage area and allows access to hot swap drives when a hot

swap drive cage is installed.

The peripheral bays are covered with plastic snap-in cosmetic pieces that must be removed to

add peripherals to the system. Front panel buttons and lights are located above the peripheral

bays.

Intel order number G22850-006 Revision 1.5

Page 23

Intel® Server Chassis P4000S Family TPS Product Overview

11

A

Fixed Power Supply

F

Serial-B Port (Optional)

B

IO Connectors

G

Kensington* Cable Lock Mounting Hole

C

RMM4 NIC Port (Optional)

H

Padlock Loop

D

Add in PCI-e cards

I

RMM4 NIC Port (Optional)

E

Power Connector

1.11 Front Panel Overview

The following figure shows the layout of the Front Control Panel of Intel® Server Chassis

P4000S:

Figure 10. Front Panel Controls and Indicators

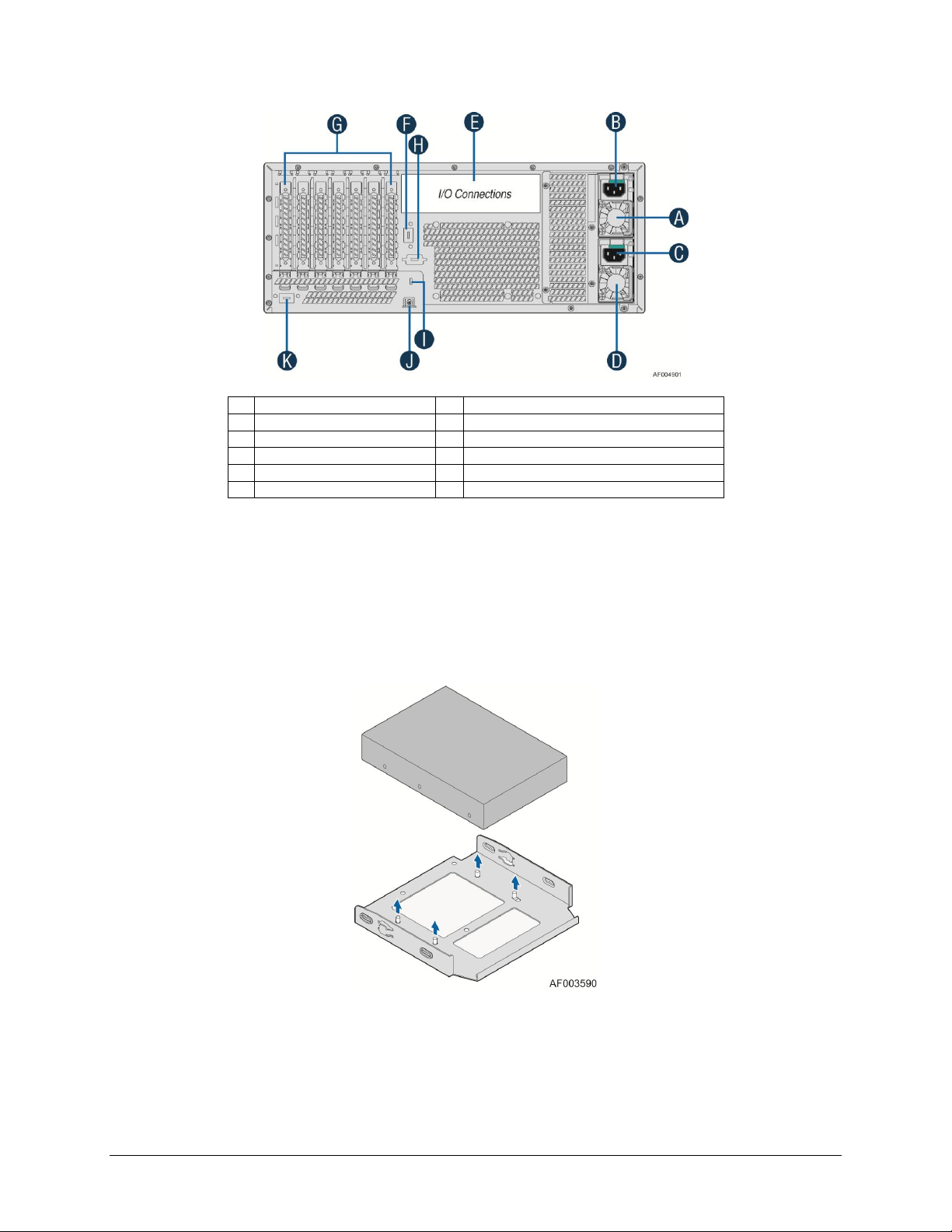

1.12 Back Panel Overview

The following figure shows the layout of Back Panel with fixed power supply and hot-swap

redundant power supplies:

Figure 11. Back Panel Layout (with Fixed Power Supply)

Revision 1.5 Intel order number G22850-006

Page 24

Product Overview Intel® Server Chassis P4000S Family TPS

12

A

Hot-swap Power Supply

G

Add in PCI-e cards

B

Power Connector

H

Serial-B Port (Optional)

C

Power Connector

I

Kensington* Cable Lock Mounting Hole

D

Hot-swap Power Supply

J

Padlock Loop

E

IO Connectors

K

RMM4 NIC Port (Optional)

F

RMM4 NIC Port (Optional)

Figure 12. Back Panel Layout (with Hot-swap Power Supply)

1.13 Standard Fixed Drive Trays

Intel® Server Chassis P4000S family supports four 3.5” fixed Hard Disk Drive trays. You can

secure each of the four drives on the drive trays with screws, and install the drive trays in the

chassis without a tool.

Intel order number G22850-006 Revision 1.5

Figure 13. Fixed Drive Tray

Page 25

Intel® Server Chassis P4000S Family TPS Product Overview

13

1.14 4x3.5” Hot-Swap Hard Disk Drive Cage

The Intel® Server Chassis P4000S family supports 4x3.5” hot-swap hard drive cage, which can

support up to four hot-swap hard drives.

Figure 14. 4x3.5” Hot-Swap Hard Disk Drive Cage

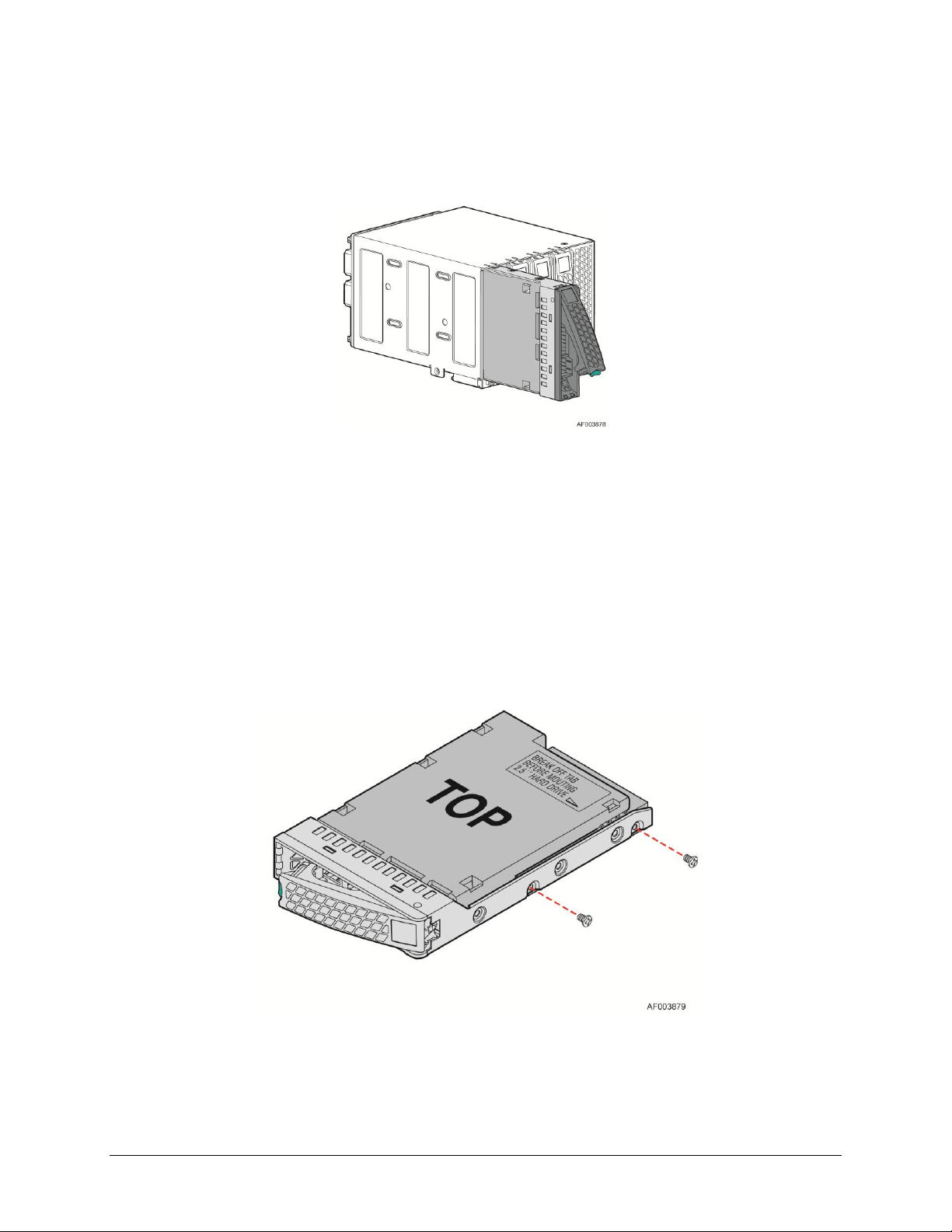

1.14.1 3.5” Hot-swap Hard Drive Carrier

Each hard drive must be mounted to a hot-swap drive carrier, making insertion and extraction of

the drive from the chassis very simple. Each drive carrier has its own dual-purpose latching

mechanism used to both insert and extract drives from the chassis and lock the carrier in place.

Each drive carrier supports a light pipe providing a drive status indicator, located on the

backplane, to be viewable from the front of the chassis.

The 3.5” hot-swap hard drive carrier has a 2.5” HDD interface bracket pre-installed. The 2.5”

HDD interface bracket is used to install the 2.5” hard drive on the 3.5” hot-swap hard drive

carrier. When a 3.5” hard drive is to be installed, the 2.5” HDD interface bracket should be

removed.

Figure 15. 3.5” hot-swap hard drive carrier with 2.5” HDD Interface Bracket

Revision 1.5 Intel order number G22850-006

Page 26

Product Overview Intel® Server Chassis P4000S Family TPS

14

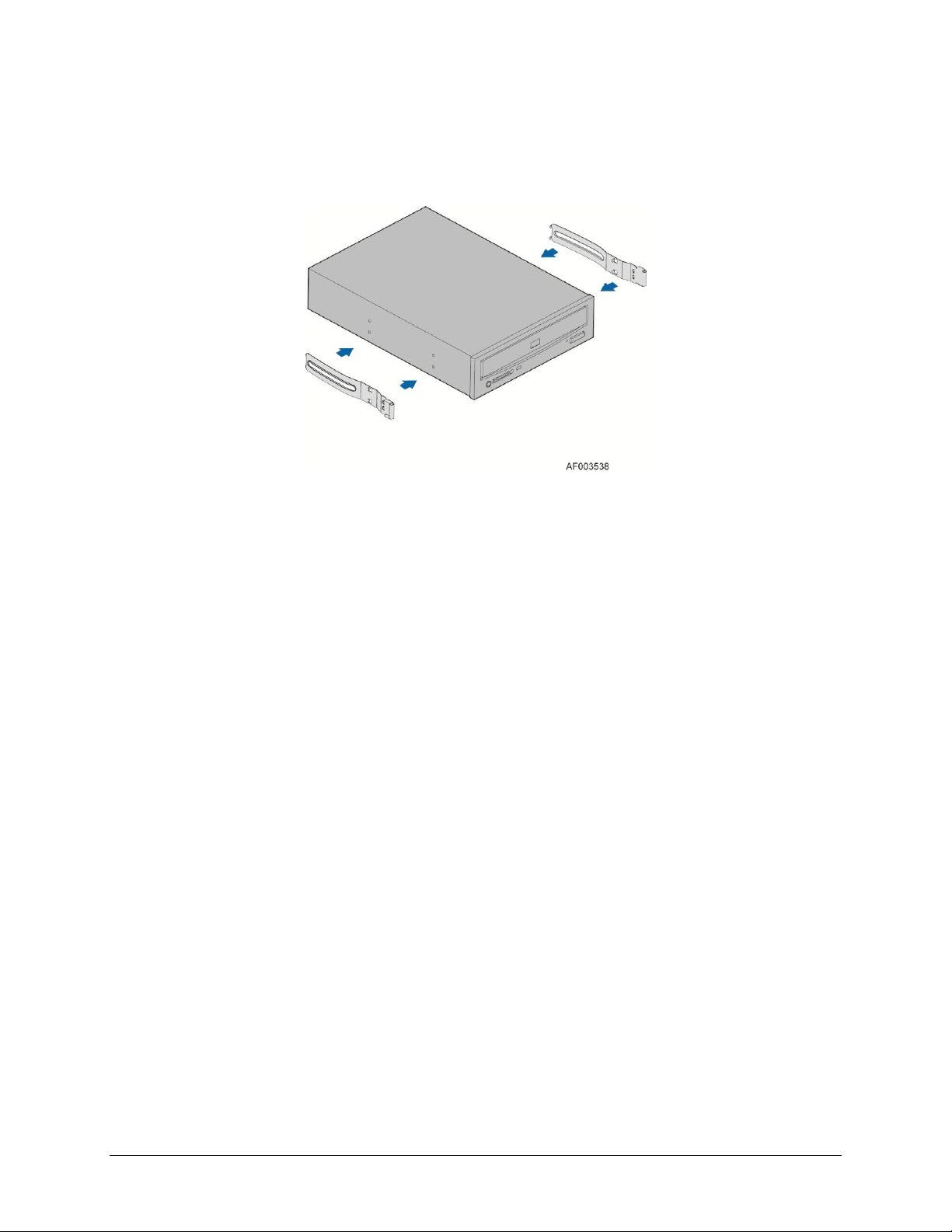

1.15 Peripheral Bays

Three 5.25-in half-height drive bays are available for CD/DVD-ROM or tape drives as well as

one 3.5-inch removable media drive bay. Drive installation is tool-less and requires no screws.

Figure 16. Tool-less Rails Mounting 5.25-inch CD-ROM Drive

Intel order number G22850-006 Revision 1.5

Page 27

Intel® Server Chassis P4000S Family TPS Chassis Power Sub-system

15

2. Chassis Power Sub-system

2.1 365W Power Supply

This 365W power supply specification defines a non-redundant power supply that supports

pedestal entry server systems. The 365W power supply has 6 outputs; 3.3V, 5V, 12V1, 12V2,

-12V, and 5Vsb. The power supply has an AC input and be power factor corrected.

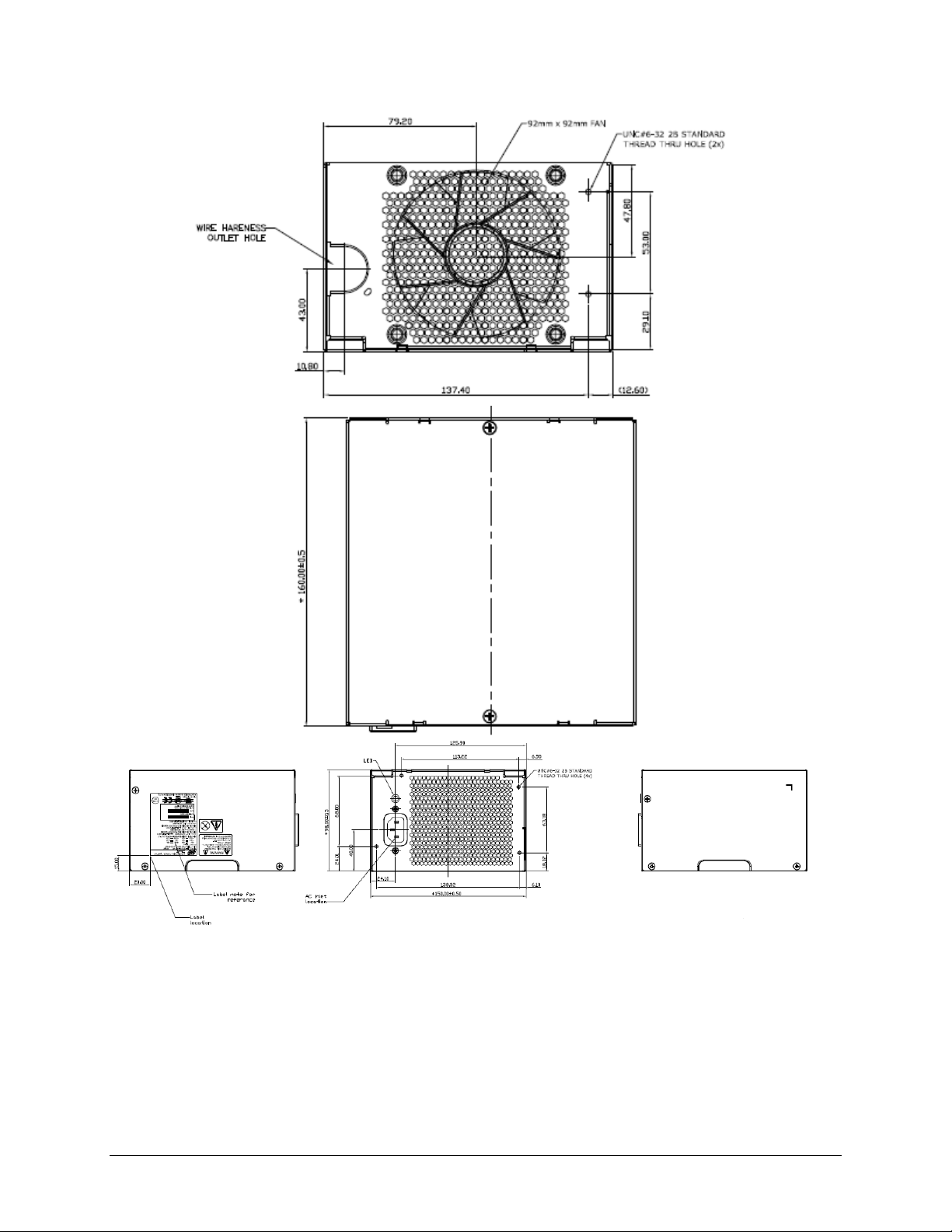

2.1.1 Mechanical Overview

The power supply size is 98mm x 150mm x 160mm (H x W x D) and has a wire harness for the

DC outputs. The AC plugs directly into the external face of the power supply.

Revision 1.5 Intel order number G22850-006

Page 28

Chassis Power Sub-system Intel® Server Chassis P4000S Family TPS

16

Figure 17. Mechanical Drawing for 365W Power Supply Enclosure

Intel order number G22850-006 Revision 1.5

Page 29

Intel® Server Chassis P4000S Family TPS Chassis Power Sub-system

17

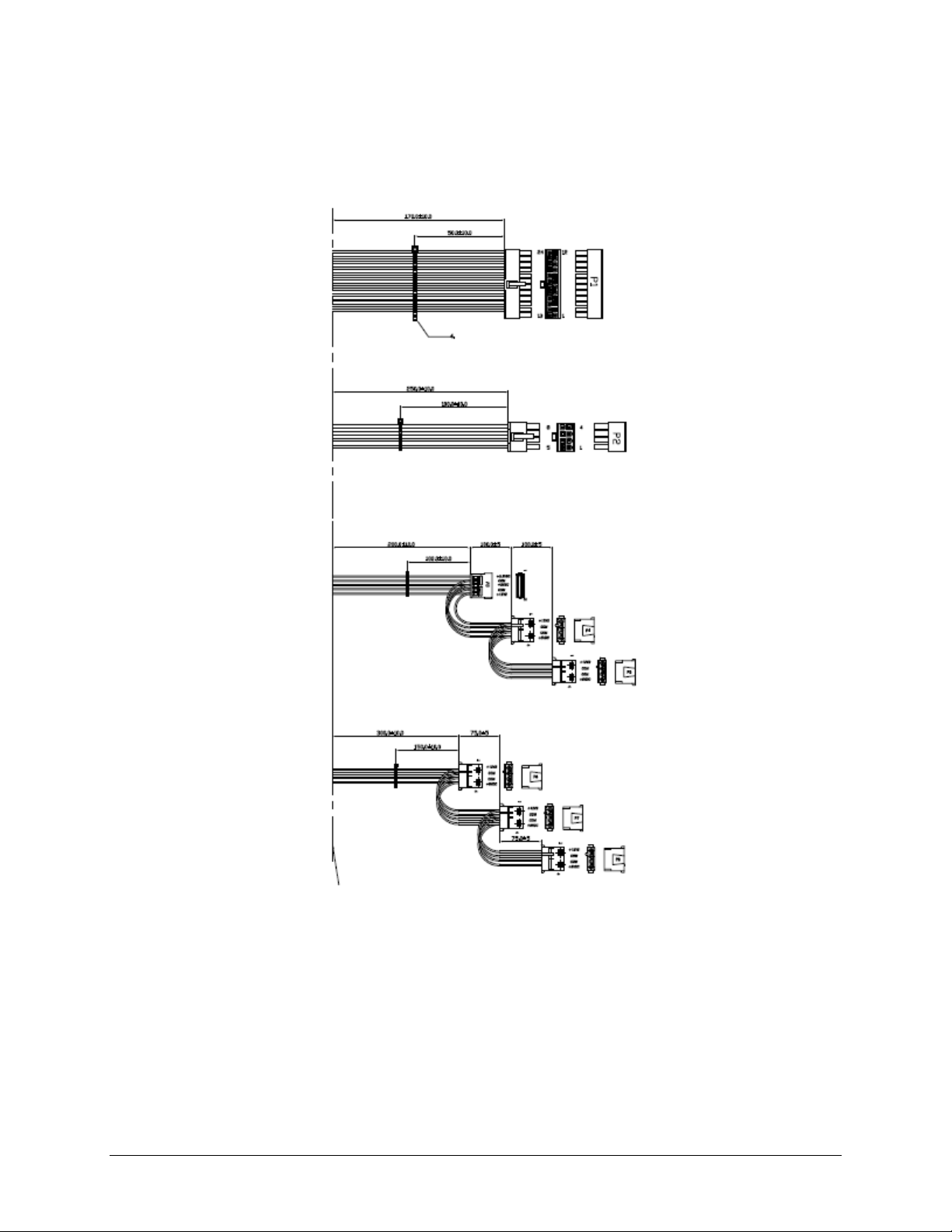

2.1.2 365W Power Supply Output Wire Harness

Listed or recognized component appliance wiring material (AVLV2), CN, rated min 85°C,

300VDC shall be used for all output wiring.

Figure 18. Output Cable Harness for 365W Power Supply

Revision 1.5 Intel order number G22850-006

Page 30

Chassis Power Sub-system Intel® Server Chassis P4000S Family TPS

18

From

Length (mm)

To connector #

No of pins

Description

Power Supply cover exit

hole

290

P1

24

Baseboard Power Connector

Power Supply cover exit

hole

250

P2 8 Processor Power Connector

Power Supply cover exit

hole

230

P3 5 SATA Power Connector

Extension from P3

100

P4 5 SATA Power Connector

Extension from P4

100

P5 4 Peripheral Power Connector

Power Supply cover exit

hole

300

P6 4 Peripheral Power Connector

Extension from P6

75

P7 4 Peripheral Power Connector

Extension from P7

75

P8 4 Peripheral Power Connector

PIN

SIGNAL

18 AWG COLOR

PIN

SIGNAL

18 AWG COLOR

1

+3.3 VDC

Orange

13

+3.3 VDC

Orange

2

+3.3 VDC

Orange

14

-12 VDC

Blue

3

COM

Black

15

COM

Black

4

+5 VDC*

Red

16

PSON#

Green

5

COM

Black

17

COM

Black

6

+5 VDC

Red

18

COM

Black

7

COM

Black

19

COM

Black

8

PWR OK

Gray

20

Reserved

N.C.

9

5VSB

Purple

21

+5 VDC

Red

10

+12V2

Yellow/Black

22

+5 VDC

Red

11

+12V2

Yellow/Black

23

+5 VDC

Red

12

+3.3 VDC

Orange

24

COM

Black

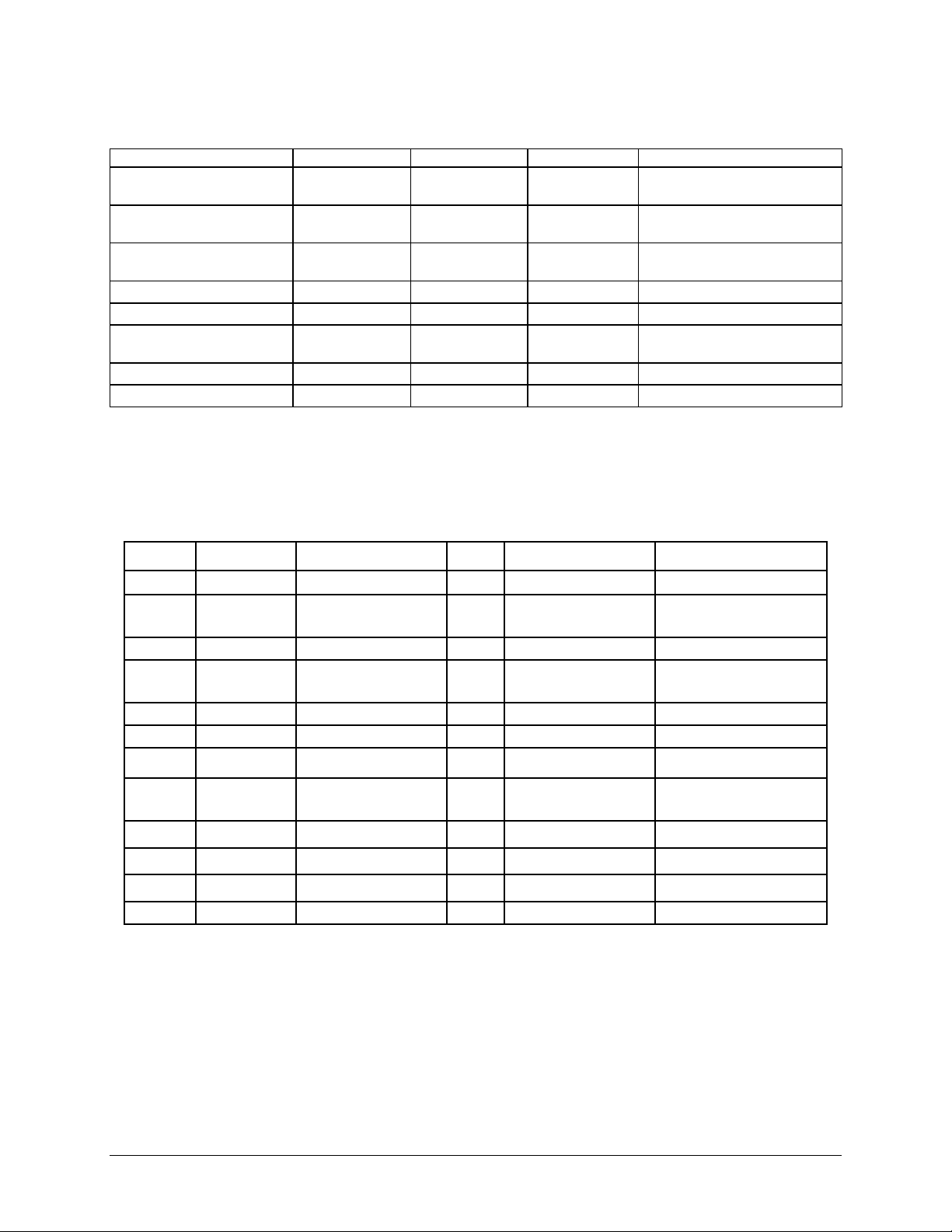

Table 2. 365W Power Supply Cable Lengths

2.1.2.1 Main power connector (P1)

Connector housing: 24- Pin Molex* Mini-Fit Jr 39-01-2245 (94V2) or equivalent

Contact: Molex* Minifit Jr, Crimp 5556 or equivalent

Table 3. P1 Main Power Connector

Intel order number G22850-006 Revision 1.5

Page 31

Intel® Server Chassis P4000S Family TPS Chassis Power Sub-system

19

PIN

SIGNAL

18 AWG COLOR

PIN

SIGNAL

18 AWG COLOR

1

COM

Black

5

+12V1

Yellow

2

COM

Black

6

+12V1

Yellow

3

COM

Black

7

+12V1

Yellow

4

COM

Black

8

+12V1

Yellow

Pin

Signal

18 AWG Color

1

+12V2

Yellow/Black

2

COM

Black

3

COM

Black

4

+5 VDC

Red

Pin

Signal

18 AWG Color

1

+3.3V

Orange

2

COM

Black

3

+5VDC

Red

4

COM

Black

5

+12V2

Yellow/Black

ITEM

DESCRIPTION

MIN

MAX

UNITS

Top

Operating temperature range.

0

50

C

T

non-op

Non-operating temperature range.

-40

70

C

Altitude

Maximum operating altitude.

3000

meters

2.1.2.2 Processor/Memory Power Connector (P2)

Connector housing: 8- Pin Molex* 39-01-2085 (94V2) or equivalent

Contact: Molex*, Mini-Fit Jr, HCS, 44476-1111 or equivalent

Table 4. P2 Processor#1 Power Connector

2.1.2.3 Peripheral Power Connectors (P4,5,6,7,8)

Connector housing: Amp 1-480424-0 or equivalent

Contact: Amp 61314-1 contact or equivalent

Table 5. Peripheral Power Connectors

2.1.2.4 SATA Hard Drive Power Connectors (P3)

Connector housing: JWT A3811H00-5P (94V2) or equivalent

Contact: JWT A3811TOP-0D or equivalent

Table 6. SATA Power Connector

2.1.3 Temperature Requirements

The power supply shall operate within all specified limits over the Top temperature range.

Table 7. Thermal Requirements

Revision 1.5 Intel order number G22850-006

Page 32

Chassis Power Sub-system Intel® Server Chassis P4000S Family TPS

20

Output power

20% load

50% load

100% load

Power factor

0.8

0.9

0.95

PARAMETER

MIN

RATED

VMAX

Start up VAC

Power Off

VAC

Voltage (110)

90 V

rms

100-127 V

rms

140 V

rms

85VAC +/4VAC

70VAC +/5VAC

Voltage (220)

180 V

rms

200-240 V

rms

264 V

rms

Frequency

47 Hz

50/60

63 Hz

Loading

Holdup time

75%

12msec

2.1.4 AC Input Requirements

2.1.4.1 Power Factor

The power supply meets the power factor requirements stated in the Energy Star® Program

Requirements for Computer Servers. These requirements are stated below:

Table 8. Power Factor Requirements for Computer Servers

Tested at 230Vac, 50Hz and 60Hz and 115VAC, 60Hz.

Tested according to Generalized Internal Power Supply Efficiency Testing Protocol Rev 6.4.3.

This is posted at http://efficientpowersupplies.epri.com/methods.asp.

2.1.4.2 AC Inlet Connector

The AC input connector is an IEC 320 C-14 power inlet. This inlet is rated for 10A/250VAC.

2.1.4.3 AC Input Voltage Specification

The power supply operates within all specified limits over the following input voltage range.

Harmonic distortion of up to 10% of the rated line voltage does not cause the power supply to

go out of specified limits. Application of an input voltage below 85VAC does not cause damage

to the power supply, including a blown fuse.

Table 9. AC Input Voltage Range

Notes:

1. Maximum input current at low input voltage range shall be measured at 90VAC, at max. load.

2. Maximum input current at high input voltage range shall be measured at 180VAC, at max. load.

3. This requirement is not to be used for determining agency input current markings.

2.1.4.4 AC Line Dropout/Holdup

An AC line dropout is defined to be when the AC input drops to 0VAC at any phase of the AC

line for any length of time. During an AC dropout the power supply meets dynamic voltage

regulation requirements. An AC line dropout of any duration does not cause tripping of control

signals or protection circuits. If the AC dropout lasts longer than the holdup time the power

supply recovers and meets all turn on requirements. The power supply meets the AC dropout

requirement over rated AC voltages and frequencies. A dropout of the AC line for any duration

does not cause damage to the power supply.

Table 10. AC Line Holdup Time

Intel order number G22850-006 Revision 1.5

Page 33

Intel® Server Chassis P4000S Family TPS Chassis Power Sub-system

21

AC Line Sag (10sec interval between each sagging)

Duration

Sag

Operating AC Voltage

Line Frequency

Performance Criteria

0 to 1/½ AC

cycle

95%

Nominal AC Voltage ranges

50/60Hz

No loss of function or performance

> 1 AC cycle

>30% Nominal AC Voltage ranges

50/60Hz

Loss of function acceptable, self

recoverable

AC Line Surge

Duration

Surge

Operating AC Voltage

Line Frequency

Performance Criteria

Continuous

10%

Nominal AC Voltages

50/60Hz

No loss of function or performance

0 to ½ AC

cycle

30%

Mid-point of nominal AC

Voltages

50/60Hz

No loss of function or performance

2.1.4.5 AC Line Fuse

The power supply has one line fused in the single line fuse on the line (Hot) wire of the AC

input. The line fusing is acceptable for all safety agency requirements. The input fuse is a slow

blow type. AC inrush current does not cause the AC line fuse to blow under any conditions. All

protection circuits in the power supply do not cause the AC fuse to blow unless a component in

the power supply has failed. This includes DC output load short conditions.

2.1.4.6 AC Line Leakage Current

The maximum leakage current to ground for each power supply is 3.5mA when tested at

240VAC.

2.1.4.7 AC Line Transient Specification

AC line transient conditions are defined as “sag” and “surge” conditions.

“Sag” conditions are

also commonly referred to as “brownout”, these conditions is defined as the AC line voltage

dropping below nominal voltage conditions. “Surge” is defined to refer to conditions when the AC

line voltage rises above nominal voltage.

The power supply meets the requirements under the following AC line sag and surge conditions.

Table 11. AC Line Sag Transient Performance

Table 12. AC Line Surge Transient Performance

2.1.4.8 Power Recovery

The power supply recovers automatically after an AC power failure. AC power failure is defined

to be any loss of AC power that exceeds the dropout criteria.

2.1.5 Efficiency

The following table provides the required minimum efficiency level at various loading conditions.

These are provided at three different load levels; 100%, 50% and 20%. Output shall be loaded

according to the proportional loading method defined by 80 Plus in Generalized Internal Power

Supply Efficiency Testing Protocol Rev 6.4.3. This is posted at

http://efficientpowersupplies.epri.com/methods.asp.

Revision 1.5 Intel order number G22850-006

Page 34

Chassis Power Sub-system Intel® Server Chassis P4000S Family TPS

22

Loading

100% of maximum

50% of maximum

20% of maximum

Minimum Efficiency

85%

88%

85%

Parameter

Min

Max.

Peak

Unit

5V

0.3

10.0

A

12V1

0.7

16.0

18.0

A

12V2

1.5

16.0

18.0

A

3.3V

0.5

18.0

A 12V

0.0

0.5 A

5Vstby

0.0

2.5

3.0

A

3.3V

5.0V

12.0V

12.0V

12.0V

5.0V

Total

Power

12V

Power

3.3V/5V

Power

Load1

10.8

2

16

10.5

0

0.3

365

318

46

Load2

18

4.1

7.6

16 0 0.3

365

283

80

Load3

18

4.1

16

7.6 0 0.3

365

283

80

Load4

13.6

7

10.2

12

0.5

2.5

365

266

80

Load5

0.5

0.3

0.7

1.5 0 0.3

31

26

3

Load6

16 4 0.7

2.6 0 0.3

114

40

73

Load7

1.2

2.7

14.5

7.1 0 1

282

259

17

Table 13. Silver Efficiency Requirement

The power supply passes with enough margins to make sure in production all power supplies

meet these efficiency requirements.

2.1.5.1 Standby Efficiency

When in standby mode; the power supply draws less than 1W AC power with 100mA of

5Vstandby load. This shall be tested at 115VAC/60Hz and 230VAC/50Hz.

2.1.6 DC Output Specification

2.1.6.1 Output Power/Currents

The following table defines the minimum power and current ratings. The power supply meets

both static and dynamic voltage regulation requirements for all conditions.

Table 14. Over Voltage Protection Limits

Notes:

1. Max. combined power for all output shall not exceed 365W.

2. Peak combined power for all outputs shall not exceed 385W.

3. Max. combined power of 12V1 and 12V2 shall not exceed 318W.

4. Max. combined power on 3.3V and 5V shall not exceed 80W.

5. Peak power and current loading shall be supported for a minimum of 12 second.

2.1.6.2 Cross Loading

The power supply maintains voltage regulation limit when operated over the following cross

loading conditions.

Table 15. Loading Conditions

Intel order number G22850-006 Revision 1.5

Page 35

Intel® Server Chassis P4000S Family TPS Chassis Power Sub-system

23

PARAMETER

TOLERANCE

MIN

NOM

MAX

UNITS

+3.3V

- 5%/+5%

+3.14

+3.30

+3.46

V

rms

+5V

- 5%/+5%

+4.75

+5.00

+5.25

V

rms

+12V1

- 5%/+5%

+11.40

+12.00

+12.60

V

rms

+12V2

- 5%/+5%

+11.40

+12.00

+12.60

V

rms

- 12V

- 10%/+10%

- 13.20

-12.00

-10.80

V

rms

+5VSB

- 5%/+5%

+4.75

+5.00

+5.25

V

rms

Output

Step Load Size

(See note 2)

Load Slew Rate

Test capacitive Load

+3.3V

6.0A

0.5 A/sec

970 F

+5V

4.0A

0.5 A/sec

400 F

12V1+12V2

18.0A

0.5 A/sec

2200 F

1,2

+5VSB

0.5A

0.5 A/sec

20 F

Output

MIN

MAX

Units

+3.3V

250

5000

F

+5V

400

5000

F

+12V

500

8000

F

2.1.6.3 Standby Output

The 5VSB output is present when an AC input greater than the power supply turn on voltage is

applied.

2.1.6.4 Voltage Regulation

The power supply output voltages stay within the following voltage limits when operating at

steady state and dynamic loading conditions. These limits include the peak-peak ripple/noise.

These shall be measured at the output connectors.

Table 16. Voltage Regulation Limits

2.1.6.5 Dynamic Loading

The output voltages remain within limits specified for the step loading and capacitive loading

specified in the table below. The load transient repetition rate is tested between 50Hz and 5kHz

at duty cycles ranging from 10%-90%. The load transient repetition rate is only a test

specification. The step load may occur anywhere within the minimum load to the maximum

load conditions.

Table 17. Transient Load Requirements

Notes:

1. Step loads on each 12V output may happen simultaneously.

2. The +12V should be tested with 2200F evenly split between the four +12V rails.

3. This will be tested over the range of load conditions in section 2.1.6.2.

2.1.6.6 Capacitive Loading

The power supply is stable and meets all requirements with the following capacitive loading

ranges.

Table 18. Capacitive Loading Conditions

Revision 1.5 Intel order number G22850-006

Page 36

Chassis Power Sub-system Intel® Server Chassis P4000S Family TPS

24

Output

MIN

MAX

Units

-12V

1

350

F

+5VSB

20

350

F

+3.3V

+5V

+12V 1

+12V 2

-12V

+5VSB

50mVp-p

50mVp-p

120mVp-p

120mVp-p

200mVp-p

50mVp-p

2.1.6.7 Grounding

The output ground of the pins of the power supply provides the output power return path. The

output connector ground pins are connected to the safety ground (power supply enclosure). This

grounding is well designed to ensure passing the maximum allowed Common Mode Noise

levels.

The power supply is provided with a reliable protective earth ground. All secondary circuits are

connected to protective earth ground. Resistance of the ground returns to chassis does not

exceed 1.0 m. This path may be used to carry DC current.

2.1.6.8 Residual Voltage Immunity in Standby mode

The power supply is immune to any residual voltage placed on its outputs (Typically a leakage

voltage through the system from standby output) up to 500mV. There is neither additional heat

generated, nor stressing of any internal components with this voltage applied to any individual

or all outputs simultaneously. It also does not trip the protection circuits during turn on.

The residual voltage at the power supply outputs for no load condition does not exceed 100mV

when AC voltage is applied and the PSON# signal is de-asserted.

2.1.6.9 Common Mode Noise

The Common Mode noise on any output does not exceed 350mV pk-pk over the frequency

band of 10Hz to 20MHz.

The measurement is made across a 100Ω resistor between each of DC outputs, including

ground at the DC power connector and chassis ground (power subsystem enclosure).

The test set-up shall use a FET probe such as Tektronix* model P6046 or equivalent.

2.1.6.10 Ripple/Noise

The maximum allowed ripple/noise output of the power supply is defined in below Table 19. This

is measured over a bandwidth of 10Hz to 20MHz at the power supply output connectors. A 10F

tantalum capacitor in parallel with a 0.1F ceramic capacitor is placed at the point of

measurement.

Table 19. Ripples and Noise

Intel order number G22850-006 Revision 1.5

Page 37

Intel® Server Chassis P4000S Family TPS Chassis Power Sub-system

25

AC HOT

POWER SUPPLY

AC NEUTRAL

V

OUT

RETURN

V

AC GROUND

LOAD

SCOPE

LOAD MUST BE

ISOLATED FROM

THE GROUND OF

THE POWER

SUPPLY

10uF

.1uF

GENERAL NOTES:

1. LOAD THE OUTPUT WITH ITS MINIMUM

LOAD CURRENT.

2. CONNECT THE PROBES AS SHOWN.

3. REPEAT THE MEASUREMENTS WITH THE

MAXIMUM LOAD ON THE OUTPUT.

SCOPE NOTE:

USE A TEKTRONIX 7834 OSCILLOSCOPE WITH 7A13 AND

DIFFERENTIAL PROBE P6055 OR EQUIVALENT.

Item

Description

MIN

MAX

UNITS

T

vout_rise

Output voltage rise time from each main output.

2

50

ms

Output rise time for the 5Vstby output.

1

25

ms

T

vout_on

All main outputs must be within regulation of

each other within this time.

50

ms

T

vout_off

All main outputs must leave regulation within this

time.

400

ms

The test set-up shall be as shown below:

Figure 19. Differential Noise test setup

Note: When performing this test, the probe clips and capacitors should be located close to the

load.

2.1.6.11 Timing Requirements

These are the timing requirements for the power supply operation. The output voltages rise from

10% to within regulation limits (T

from 1 to 25ms. The +3.3V, +5V and +12V1, +12V2 output voltages should start to rise

approximately at the same time. All outputs must rise monotonically. Each output voltage

reach regulation within 50ms (T

output voltage fall out of regulation within 400ms (T

shows the timing requirements for the power supply being turned on and off from the AC input,

with PSON held low and the PSON signal, with the AC input applied.

Revision 1.5 Intel order number G22850-006

) within 2 to 50ms, except for 5VSB - it is allowed to rise

vout_rise

) of each other during turn on the power supply. Each

vout_on

Table 20. Output Voltage Timing

) of each other during turn off. Table 21

vout_off

Page 38

Chassis Power Sub-system Intel® Server Chassis P4000S Family TPS

26

Item

Description

Min.

Max.

Units

T

sb_on_delay

Delay from AC being applied to 5VSB being