Page 1

Intel® 855GME and Intel® 852GME Chipset Memory Controller Hub (MCH)

Thermal Design Guide for Embedded Applications

October 2003

Revision 1.0

Order Number: 273838-001Order Number: 273838-001

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY

ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN

INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUM ES NO LIABILIT Y WHA T SOEVER, AND INTE L DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES

RELATING T O FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER

INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life saving, life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel reserves these for

future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to the m.

®

The Intel

cause the product to deviate from published specifications. Current characterized errata are available on request.

MPEG is an international standard for video compression/decompression promoted by ISO. Implementations of MPEG CODECs, or MPEG enabled

platforms may require licenses from various entities, including Intel Corporation.

This document and the software described in it are furnished under license and may only be used or copied in accordance with the terms of the

license. The i nf orm at i o n i n t h is do cum en t i s f ur n is he d f o r i nf o rm ati o na l u s e o nl y, is subject to ch a ng e wi th out n ot ic e , an d sh o uld not be construed as a

commitment by Intel Corporation. Intel Corporation assumes no responsibility or liability for any errors or inaccuracies that may appear in this

document or any software that may be provided in association with this document. Except as permitted by such license, no part of this document may

be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the express written consent of Intel Corporation.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature may be obtained by calling

1-800-548-4725 or by visiting Intel's website at http://www.intel.com.

AlertVIEW, AnyPoint, AppChoice, BoardWatch, BunnyPeople, CablePort, Celeron, Chips, CT Connect, CT Media, Dialogic, DM3, EtherExpress,

ETOX, FlashFile, i386, i486, i960, iCOMP, InstantIP, Intel, Intel logo, Intel386, Intel486, Intel740, IntelDX2, IntelDX4, IntelSX2, Intel Create & Share,

Intel GigaBlade, Intel InBusiness, Intel Inside, Intel Inside logo, Intel NetBurst, Intel NetMerge, Intel NetStructure, Intel Play, Intel Play logo, Intel

SingleDriver, Intel SpeedStep, Intel StrataFlash, Intel TeamStation, Intel Xeon, Intel XScale, IPLink, Itanium, LANDesk, LanRover, MCS, MMX, MMX

logo, Optimizer logo, OverDrive, Paragon, PC Dads, PC Parents, PDCharm, Pentium, Pentium II Xeon, Pentium III Xeon, Performance at Your

Command, RemoteExpress, Shiva, SmartDie, Solutions960, Sound Mark, StorageExpress, The Computer Inside., The Journey Inside,

TokenExpress, Trillium, VoiceBrick, Vtune, and Xircom are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United

States and other countri es.

*Other names and brands may be claimed as the property of others.

Copyright © Intel Corporation, 2003

855GME and Intel® 852GME Chipset Memory Controller Hub (MCH) may contain design defects or errors known as errata which may

2

Page 3

Contents

Contents

1 Introduction....................................................................................................................................6

1.1 Document Objective ....................................... ...... ...... ....... ...... ....................................... ......6

1.2 Terminology..........................................................................................................................6

1.3 Reference Documents..........................................................................................................7

2 Mechanical Reference...................................................................................................................8

2.1 Intel® 855GME and Intel® 852GME Chipset MCH Package ...............................................8

3 Computational Fluid Dynamics (CFD) Modeling ......................................................................10

3.1 855GM MCH Thermal Model..............................................................................................10

3.2 Thermal Design Power (TDP) Values.................................................................................11

3.3 Maximum Temperature Specification .................................................................................11

3.4 Modeling Assumptions........................................................................................................11

3.5 Modeling Results – 855GME MCH.....................................................................................12

3.6 Modeling Results – 852GME..............................................................................................13

3.7 CFD Modeling Conclusions ................................................................................................13

4 Reference Thermal Solution for 1U Applications.....................................................................14

4.1 Applications ........................................................................................................................14

4.2 Required Volumetric Keepout.............................................................................................14

4.3 Heatsink Assembly .............................................................................................................16

4.4 Mechanical Retention .........................................................................................................17

4.5 Thermal Interface Material (TIM) and Thermal Bond Line..................................................18

4.6 Solder Joint Protection........................................................................................................18

4.7 1U Reference Thermal Solution Mechanical Drawings ......................................................19

5 Reference Thermal Solution for CompactPCI* and Blade Applications.................................20

5.1 Applications ........................................................................................................................20

5.2 CompactPCI* Heatsink Thermal Performance ...................................................................20

5.3 Required Volumetric Keepout.............................................................................................21

5.4 CompactPCI* Heatsink Assembly ......................................................................................22

5.5 Mechanical Retention .........................................................................................................23

5.6 Thermal Interface Material (TIM) and Thermal Bond Line..................................................23

5.7 CompactPCI* Thermal Solution Mechanical Drawings.......................................................24

6 Temperature Measurement Metrology ......................................................................................25

6.1 Case Temperature Measurements.....................................................................................25

6.2 0 Degree Angle Attach Methodology..................................................................................25

6.3 Maximum Temperature Specification .................................................................................26

7 Thermal Management Features and Tools................................................................................27

7.1 Internal Temperature Sensor..............................................................................................27

7.2 External Temperature Sensor.............................................................................................27

7.3 TDP chipset MCH Stress Application ......................... ....... ...... ....... ...... ....... .......................2 8

7.4 Memory Thermal Management Software ...........................................................................28

7.5 Thermal Throttling...............................................................................................................29

7.5.1 Bandwidth Triggered Throttling..............................................................................29

3

Page 4

Contents

7.5.2 Temperature Triggered Throttling..........................................................................31

8 Thermal/Mechanical Applications..............................................................................................33

8.1 Thermal Interface Materials................................................................................................33

8.1.1 Estimate Thermal Resistance................................................................................33

8.2 Mechanical Loading............................................................................................................34

8.3 Thermal and Mechanical Reliability....................................................................................34

9 Summary......................................................................................................................................35

Figures

1 855GME and 852GME chipset MCH Package Dim ensio ns (mm) – Top View ......................... ...8

2 855GME and 852GME Chipset MCH Package Dimensions (mm) - Side View ...........................9

3 Package Construction Overview ................................................................................................10

4 855GM MCH Thermal Model......................................................................................................10

5 855GME MCH (4.3W) Junction Temperatures vs. Airflow .........................................................12

6 852GME Airflow Modeling Results .. ...... ....... ...... ....... ...... ...... ....... ...... ....... .................................13

7 1U Reference Thermal Solution Volumetric Keepout.................................................................15

8 1U Heatsink Assembly (Heatsink, Clip Frame, and Clip Lever) .................................................16

9 1U Heatsink Assembly Placement and Actuation ......................................................................16

10 1U Heatsink Clip Assembly ........................................................................................................17

11 1U Heatsink Clip Lateral Retention Tab Feature.......................................................................18

12 1U Heatsink Clip Frame and Lever ............................................................................................19

13 CompactPCI* Heatsink Thermal Performance...........................................................................21

14 CompactPCI* Thermal Solution Volumetric Keepout ................................................................22

15 CompactPCI* Heatsink Assembly (Heatsink, Pull-tab, and TIM) ...............................................23

16 0 Degree Angle Attach Heatsink Modifications (not to scale......................................................26

17 0 Degree Angle Attach Methodology (not to scale)....................................................................26

18 External Temperature Sensor ....................................................................................................27

19 855GME/852GME chipset MCH Bandwidth Throttling...............................................................30

20 855GME/852GME chipset MCH Temperature Throttling...........................................................31

21 Board Keep-Out Region for 1U Reference Design Heatsink and Mounting Anchor Placement 39

22 CompactPCI* Heatsink Assembly ..............................................................................................40

Tables

1 Related reference documents ......................................................................................................7

2 855GME and 852GME MCH Thermal Design Power ................................................................11

3 855GME and 852GME Chipset MCHs Maximum Temperature Value.......................................11

4 855GME and 852GME chipset MCH Maximum Case Temperature Value................................26

5 Reliability Validation ...................................................................................................................34

6 1U Reference Design Heatsink Assembly Suppliers (as referenced in Section 4) ....................36

7 CompactPCI* Reference Design Heatsink Assembly Suppliers (as referenced in Section 5)...36

8 Mechanical Drawing List.............................................................................................................38

4

Page 5

Revision History

Date Revision Description

October 2003 001 Initial public release of this document.

Contents

5

Page 6

Introduction

Introduction 1

1.1 Document Objective

This document is intended to aid system designers to properly implem ent a thermal management

design to ensure reliable and efficient operation of the Intel

memory controller hubs (MCHs). The objective of thermal management for chipset MCHs is to

ensure that the temperature of product while operating in a embedded system is maintained within

functional limits. The functional temperature limit is the range within which the electrical circui ts

within the silicon can be expected to meet specified performance requirements. Operation outside

the functional limit can degrade system performance, cause logic errors, or cause component and/

or system damage. Temperatures exceeding the maximum operating limits may result in

irreversible changes in the operating characteristics of the components. This document will provide

an understanding of th e op erat ing limits of the Intel

and suggest proper thermal design techniques based on a particular configuration.

1.2 Terminology

Term Definition

DDR Double Data Rate

Flip Chip Ball Grid Array. A package type defined by a plastic substrate on to which a die is

FCBGA

Junction

PCB Printed Circuit Board

Tcase The measured temperature of a component at the geometric center of the top of the die.

TDP

TIM

Tjunction temperature at the hottest point in the die

MCH Memory Controller Hub, also referred to as chipset MCH

OEM Original Equipment Manufacturer

mounted using an underfill C4 (Controlled Collapse Chip Connection) attach style. The

primary electrical interface is an array of solder balls attached to the substrate opposite the

die.

Refers to a P-N junction on the silicon. In this document it is used as a temperature reference

point for the hottest point on the die (e.g., θ

resistance).

Thermal Design Power. Thermal solutions should be designed to dissipate this target power

level. The thermal design power is specified as the highest sustainable power level of most or

all of the real applications expected to be run on the given product, based on extrapolations in

both hardware and software technology over the life of the component. Thermal solutions

should be designed to dissipate this target power level.

Thermal Interface Material. This material is designed to fill surface voids between the die and

heat sink surfaces in order to facilitate heat transfer.

®

855GME and Intel® 852GME chipset

®

855GME and Intel® 852GME chipset MCHs

refers to the junction to ambient thermal

j-a

6 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 7

1.3 Reference Documents

Table 1. Related reference documents

Document/Reference Title Source/Document Number

®

Intel

Pentium® M Processor For

Embedded Applications Thermal

Design Guide

®

845G/845GL/845GV chipset

Intel

MCH Thermal Design Guide

Intel® 82801DB I/O Controller Hub 4

(ICH4): Thermal and Mechanical

Design Guidelines Design Guide

http://developer.intel.com/design/intarch/designgd/273885.htm

http://developer.intel.com/design/chipsets/designex/298655.htm

http://developer.intel.com/design/chipsets/designex/298651.htm

Introduction

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 7

Page 8

Mechanical Reference

Mechanical Reference 2

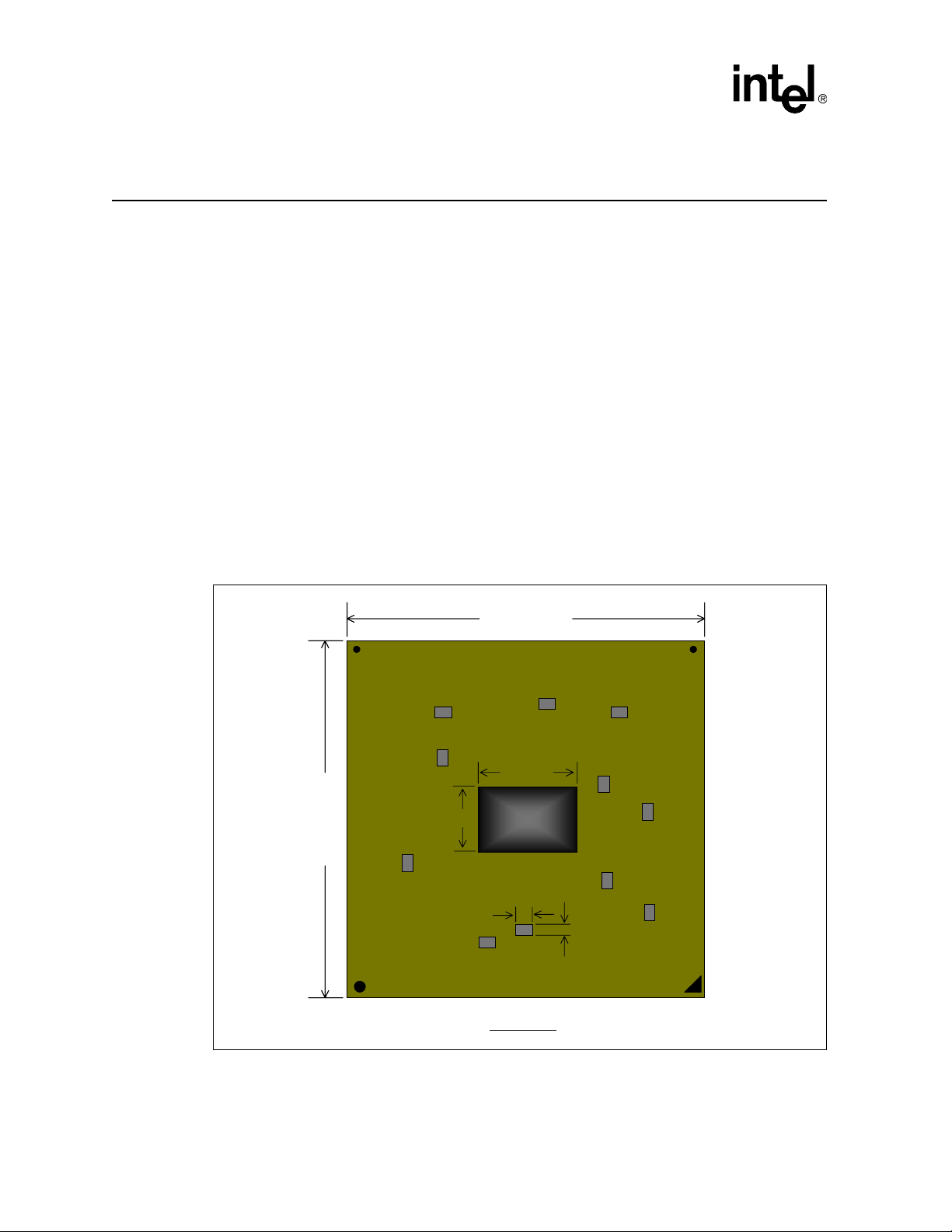

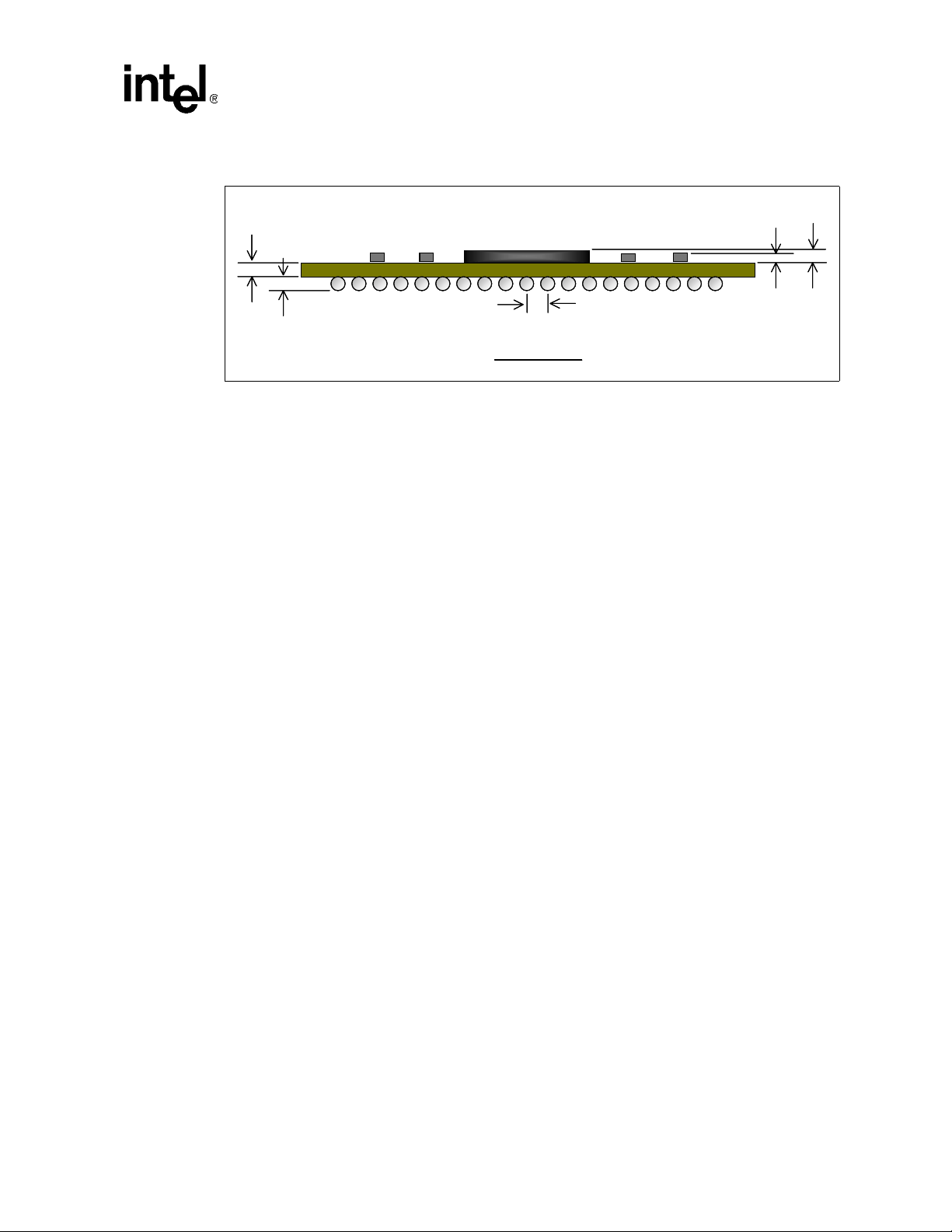

The Intel® 855GME and Intel 852GME chipset MCHs are constructed with a Flip Chip Ball Grid

Array (FCBGA) package with a size of 37.5 mm x 37.5 mm. It includes 732 solder ball lands with

a ball pitch of 1.27 mm. The chipset MCH will also include capacitors moun ted on the top of the

package. Reference drawings are shown in Figure 1 and Figure 2. The drawings are not drawn to

scale and the units shown are in millimeters.

The 855GME and 852GME MCH packages will include capacitors on the top-side. The location of

capacitors may differ between the 855GME and 852GME MCHs. Care should be taken when

applying a thermal solution onto the die in order to avoid any accidental electrical shorts.

2.1 Intel® 855GME and Intel® 852GME Chipset MCH Package

Note: The capacitor locations shown below may not be representative of the exact placement on the

855GME or the 852GME MCH.

Figure 1. 855GME and 852GME chipset MCH Package Dimensions (mm) – Top View

37.5

37.5

Capacitor

Capacitor

7.6

7.6

37.5

37.5

10.3

10.3

1.60

1.60

Die

Die

Substrate

Substrate

0.81

0.81

?

?

Top View

Top View

8 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 9

Mechanical Reference

Figure 2. 855GME and 852GME Chipset MCH Package Dimensions (mm) - Side View

1.0

1.0

0.61

0.61

0.7

0.7

1.27

1.27

Side View

Side View

0.73

0.73

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 9

Page 10

Computational Fluid Dynamics (CFD) Modeling

Computational Fluid Dynamics (CFD)

Modeling 3

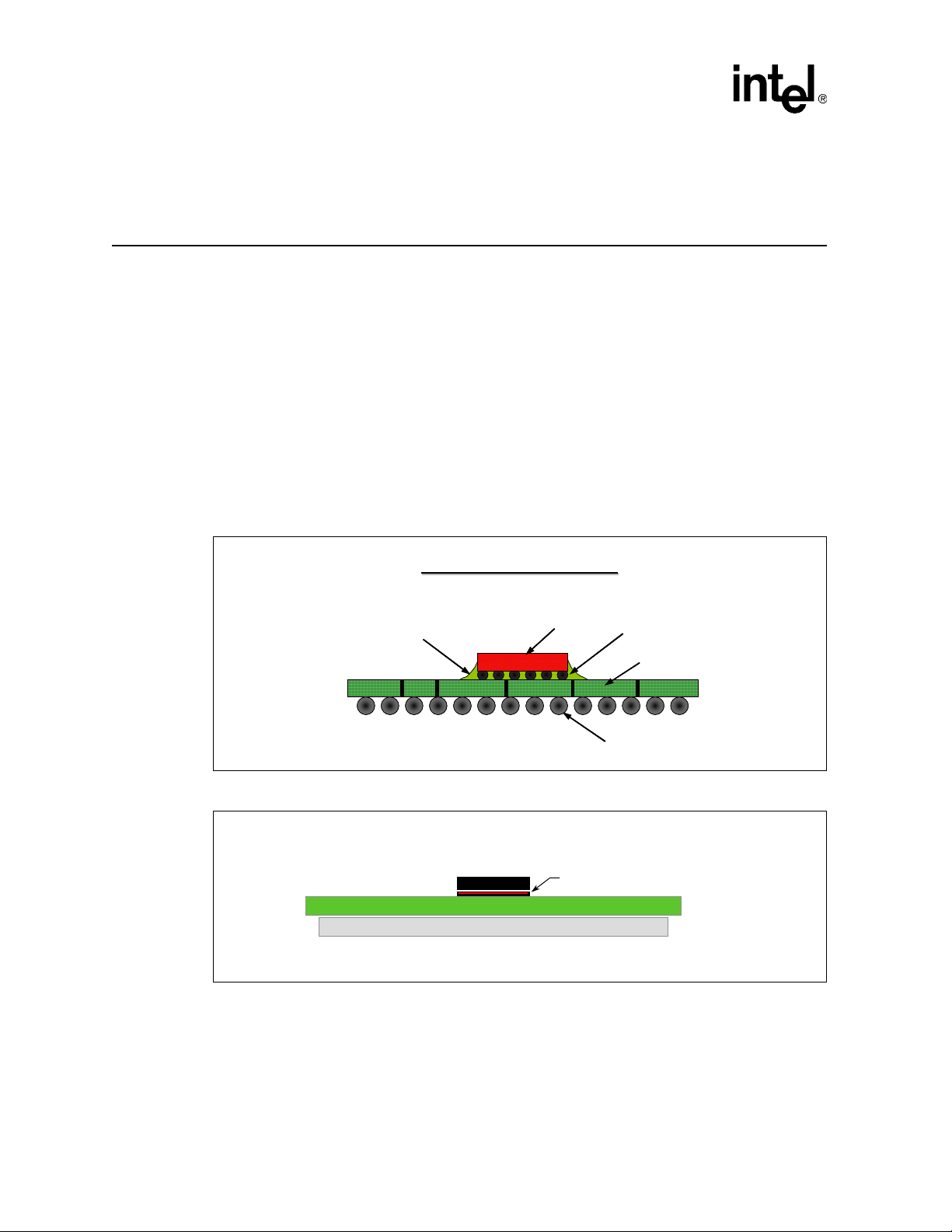

3.1 855GM MCH Thermal Model

A Computational Fluid Dynamics (CFD) thermal model of the 855GM chipset MCH has been

developed to assist in the characterization of the package thermal limits and the evaluation of

cooling methods. The thermal model used in our analysis is based on the package construction

shown in Figure 3. Simplified cuboids with the correct material properties are used to model the

primary portions of the chipset MCH package as shown in Figure 4. Contact your Intel

representative for information on obtaining the CF D model.

Note: The CFD thermal model for the 855GM MCH may als o be us ed for the 8 55GME and t he 852G ME

chipset MCHs.

Figure 3. Package Construction Overview

Underfill

Underfill

Figure 4. 855GM MCH Thermal Model

Package Overview

Package Overview

Package Overview

Package Overview

Die

Die

855GM Thermal Model

Die

Substrate

Solder Balls

C4

C4 bumps

C4 bumps

Substrate

Substrate

Solder balls

Solder balls

B1998-01

10 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 11

Computational Fluid Dynamics (CFD) Modeling

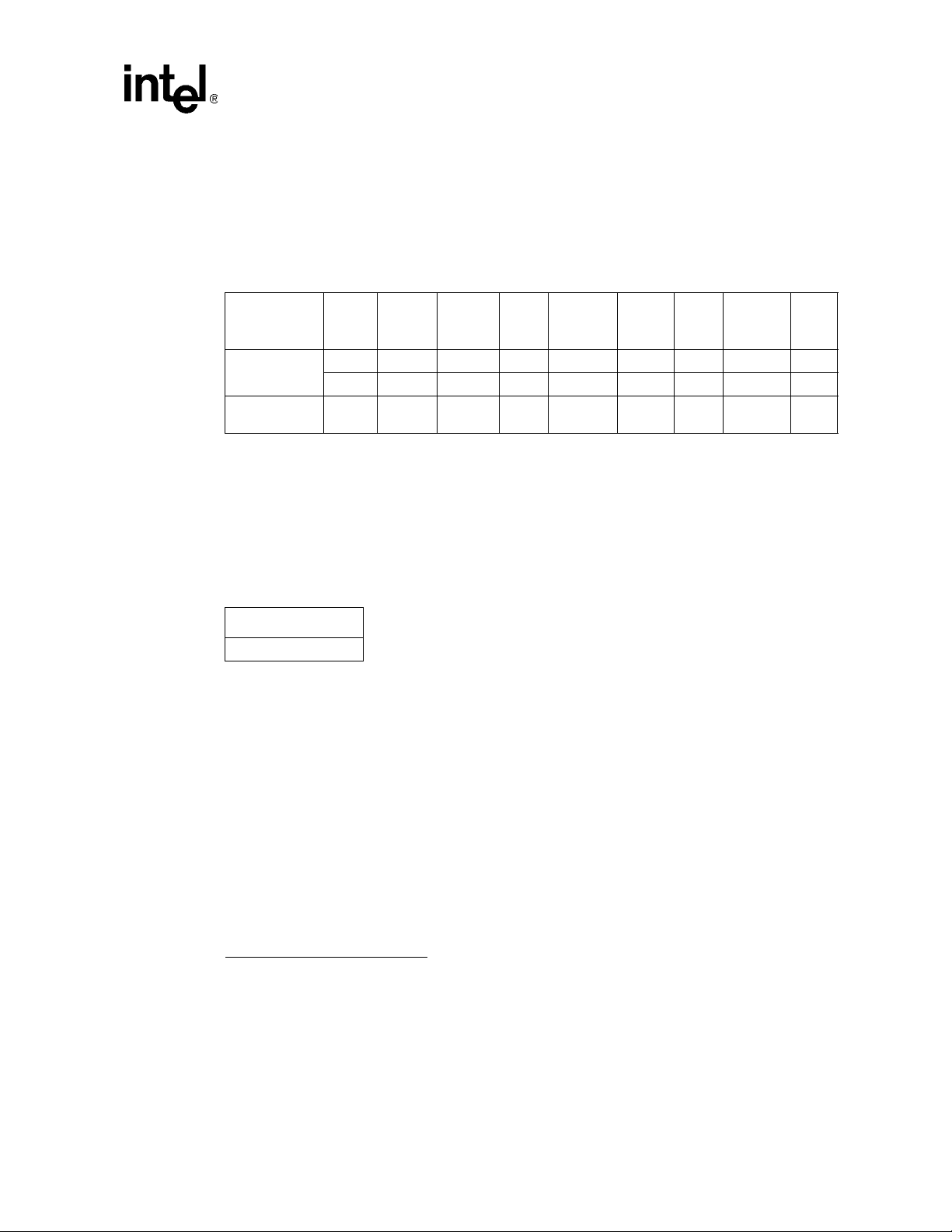

3.2 Thermal Design Power (TDP) Values

Use the following thermal design power (TDP) values when modeling based on the configuration

that is being simulated. When designing for intermediate configu r ations o n the 855GME MCH,

round up to next highest TDP value.

T able 2. 855GME and 852GME MCH Thermal Design Power

SKU Config

®

855GME

Intel

MCH

Intel® 852GME

MCH

Core

VCC (V)

Max 1.35 250 333 512 2 4 Dual 4.3

Min 1.2 133 200 256 1 1 Single 2.6

Max 1.5 266 333 512 2 4 Dual 5.7

GFX

Core

(MHz)

DDR

(MHz)

Memory

Size

(Mbytes)

# of

DIMMs

# of

Rows

3.3 Maximum Temperature Specification

Use the following table to determine the maximum junction temperature value when modeling the

855GME or 852GME chipset MCH. The junction temperature is located at the hottest part of the

die.

T a ble 3. 855GME and 852GME Chipset MCHs Maximum Temperature Value

Tj,max (°C)

110

3.4 Modeling Assumptions

Computational Fluid Dynamics (CFD) modeling is performed to provide a basis for estimating the

behavior of the Intel

configurations. Intel provides a Flotherm model of the 855GM and is available through field

sales. This model may also be used to simulate the 855GME and 852GME chipset MCHs. The

thermal model of the Intel

simulated CompactPCI* blade environment. Assumptions used in the thermal analyses are

summarized below. However, please note that they do not represent a specific design

recommendation and are mainly used as a basis for the thermal analysis.

®

855GME and Intel® 852GME chipset MCHs under varying cooling

®

855GME and Intel® 852GME chipset MCHs were analyzed in a

LVDS

Display

Settings

TDP

(W)

The following analysis was performed to evaluate the need for a heatsink to adequately cool the

855GME and 852GME chipset MCHs.

Thermal Modeling Ass umptions

:

1. Local Ambient Conditions between 40º C and 60º C. Local ambient is specified as the

temperature locally surrounding the processor. Most local ambient conditions for embedded

applications fall near the middle of that range.

2. Airflow ranges between 50 and 500 LFM.

3. The entire motherboard is modeled as an orthotropic cuboid with an effective thermal

conductivity based on the assumed copper content of the motherboard. In the analysis

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 11

Page 12

Computational Fluid Dynamics (CFD) Modeling

T

°

presented the copper content is assumed to be 10 percent of the overall volume of the

motherboard.

4. Board-to-board spacing of 0.8”, consistent with the CompactPCI* specification.

5. Tj,max for the 855GME and 852GME chipset MCHs is 110 °C.

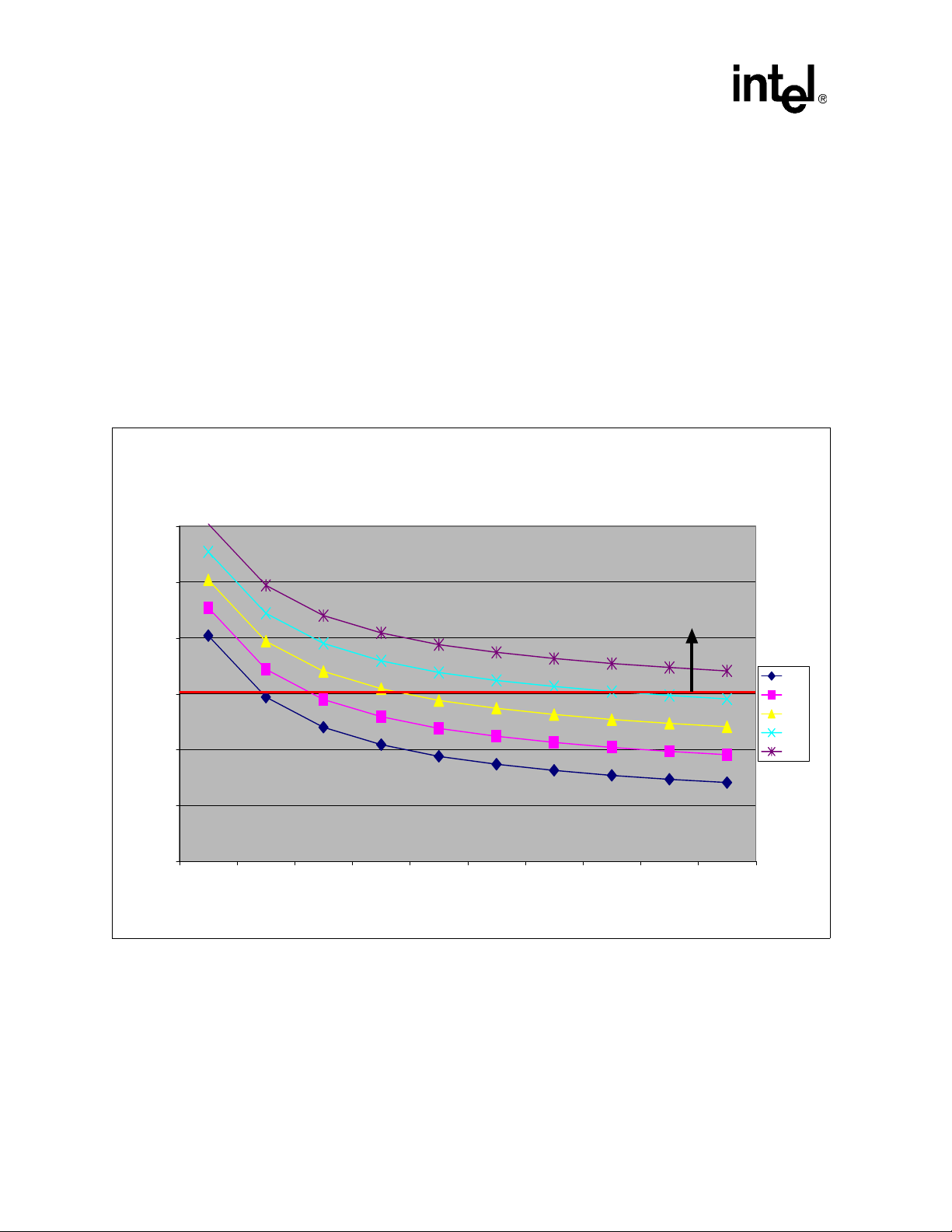

3.5 Modeling Results – 855GME MCH

Some boundary conditions evaluated will necessitate a heatsink for the 855GME chipset MCH.

See Figure 5 for a graph of junction temperature (Tj) vs. airflow (in linear feet per minute) for

various local ambient temperature conditions. A heatsink will be needed in all cases where the Tj

of the 855GME chipset MCH die is greater than 110 °C.

Figure 5. 855GME MCH (4.3W) Junction Temperatures vs. Airflow

855GM E (4.3W ) Junction Temperatures vs. Airflow

at Various Local Am bient Tem peratures

140

130

Heatsink

Required

120

40 C

110

Tj (deg C)

100

90

80

50 100 150 200 250 300 350 400 450 500

Airflow (LFM)

j max = 110

C

45 C

50 C

55 C

60 C

12 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 13

Computational Fluid Dynamics (CFD) Modeling

T

3.6 Modeling Results – 852GME

All boundary conditions evaluated will necessitate a heatsink for the 852GME chipset MCH. See

Figure 6 for a graph of junction temperature (Tj) vs. airflow for various local ambient temperature

conditions. A heatsink will be needed in all cases where the Tj of the 852GME chipset MCH die

is greater than 110 °C. Notice that a heatsink is necessary for all cases shown below.

Figure 6. 852GME Airflow Modeling Results

852GME (5.7W) Junction Temperatures vs. Airflow

at Various Local Ambient Temperatures

160

150

140

130

Tj (deg C)

120

110

100

50 100 150 200 250 300 350 400 450 500

Airflow (LFM)

3.7 CFD Modeling Conclusions

j max = 110

Heatsink

Required

40 C

45 C

50 C

55 C

60 C

°C

The 855GME chipset MCH, under many embedded configurations, will not require a heatsink.

However, if your boundary conditions are not sufficient to adequately cool the chipset MCH, Intel

offers two reference heatsink designs which are found in sections 4 and 5.

The 852GME chipset MCH will require a heatsink under almost all configurations. Refer to

sections 4 and 5 for a reference thermal solution developed by Intel. Both solutions will work with

the 852GME.

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 13

Page 14

Reference Thermal Solution for 1U Applications

Reference Thermal Solution for 1U

Applications 4

4.1 Applications

The thermal solution referenced in this chapter is valid for both the 855GME and 852GME when

the system allows for upwards of 1U (1.75” chassis) in z-height.

Note: Many boundary conditions may permit the 855GME MCH heatsink to be packaged without a

thermal solution. The 852GME will require a heatsink in most configurations. See Section 3 for

computational fluid dynamics (CFD) modeling where specific boundary conditions are analyzed.

The reference thermal solution is capable of adequately cooling the 855GME or 852GME chipset

MCHs at all boundary conditions referenced in Section 3.4.

4.2 Required Volumetric Keepout

The 1U thermal solution will require a volumetric keepout region above the chipset MCH. See

Figure 7 for a detailed side and top view of the keepout.

Appendix B, “Mechanical Drawings” contains a detailed board keep-out restriction for the

heatsink a nd mounting clips.

Note that the 1U reference thermal solution for embedded applications is exactly the same as that

referenced in the thermal design guide for the Intel® 845G chipset MCH. See Table 1 for location

of the Intel® 845G Chipset MCH Thermal Design Guide.

14 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 15

Reference Thermal Solution for 1U Applications

Figure 7. 1U Reference Thermal Solution Volumetric Keepout

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 15

Page 16

Reference Thermal Solution for 1U Applications

4.3 Heatsink Assembly

The 1U heatsink assembly includes the heatsink (with thermal interface material (TIM) and

mechanical interface gasket), the clip, and clip lever as shown in Figure 8. This clip attaches to

solder down anchors located on the system board.

Figure 9 shows the assembly placement and actuation mechanism.

Figure 8. 1U Heatsink Assembly (Heatsink, Clip Frame, and Clip Lever)

Figure 9. 1U Heatsink Assembly Placement and Actuation

16 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 17

4.4 Mechanical Retention

The heatsink is affixed to the die with a mechanical advantage clip. The clip consists of a clip

frame that interfaces to the motherboard through four through-hole mount anchors and an integral

lever (see Figure 12). The clip and lever serve three main purposes:

• Secure the heatsink in intimate contact with the die

• Ensure a thermally good baseline between the die and heatsink

• Prevent damage at the package-to-motherboard solder joint during mechanical shock events

The heatsink must maintain close contact with the die for the life of the system. The generic clip

retention mechanism design holds the heatsink to the die through a single point of contact at the

center of the heatsink. This ensures that the clip load is centered on the die, thus preventing

heatsink tilt that may be caused by unbalanced loading. The clip frame also restrains heatsink

lateral motion through tabs located between the heatsink fins (see Figure 11).

Figure 10. 1U Heatsink Clip Assembly

Reference Thermal Solution for 1U Applications

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 17

Page 18

Reference Thermal Solution for 1U Applications

Figure 11. 1U Heatsink Clip Lateral Retention Tab Feature

4.5 Thermal Interface Material (TIM) and Thermal Bond Line

A thermal interface material (TIM) is used to provide improved conductivity between the die and

heatsink. The reference thermal solution uses Chomerics* T-710, 0.127 mm (0.005”) thick,

12.7 mm x 12.7 mm (0.5” x 0.5”).

The thickness of the bond line between the heatsink and die is critical to the thermal performance

of the TIM. The bond line thickness is dep enden t on the pres sure b etween the heatsink and the die.

The clip retention mechanism is used to generate the pressure required to ensure the thermal

performance required. The generic clip frame and lever design generates more than 50-psi

pressure.

4.6 Solder Joint Protection

The generic clip design uses mechanical preload on the package to protect the solder joint against

damage under mechanical shock. The design features a rotating cam (s ee Figure 12) that generates

substantial preload between the heatsink and package. The cam has a levered handle that provides

a mechanical advantage during installation.

The preload serves to compress the solder ball array between the package and the motherboard.

The compression in the solder balls delays the onset of the tensile load under critical shock

conditions, and the magnitude of the maximum tensile load is thereby reduced. In this manner, the

critical solder balls are protected from tensile loading that may cause damage to the solder joint.

18 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 19

Reference Thermal Solution for 1U Applications

Figure 12. 1U Heatsink Clip Frame and Lever

4.7 1U Reference Thermal Solution Mechanical Drawings

Contact your field representative for additional information.

Note: The 1U reference thermal solution presented in this chapter is the same as that referenced in the

®

Intel

845G Chipset MCH Thermal Design Guide.

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 19

Page 20

Reference Thermal Solution for CompactPCI* and Blade Applications

Reference Thermal Solution for

CompactPCI* and Blade Applications 5

5.1 Applications

The thermal solution referenced in this chapter is valid for both the 855GME and 852GME chipset

MCHs when the application only allows for 0.54” of z-height above the board. Note that many

boundary conditions may permit the 855GME MCH to be packaged without a thermal solution.

The 852GME will require a heatsin k in mo st confi gurations . See Chapter 3 for computational fluid

dynamics (CFD) modeling where specific boundary conditions are analyzed.

5.2 CompactPCI* Heatsink Thermal Performance

The CompactPCI reference thermal solution is capable of adequately cooling the 855GME or

852GME chipset MCHs at most boundary conditions referenced in Section 3.4.

Figure 13 below shows the thermal performance of the heatsink on both the 855GME and

852GME MCHs at a local ambient temperature (T

ambient temperatures, shift the curve vertically upwards or downwards accordingly. Note that at

T

=60°C with 50 LFM of airflow, this heatsink may not adequately cool the 852GME. For these

LA

applications, Intel recommends the use of the 1U thermal solution presented in Ch apter 4.

) of 55 °C. For performance at other local

LA

20 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 21

Reference Thermal Solution for CompactPCI* and Blade Applications

Figure 13. CompactPCI* Heatsink Thermal Performance

Tcase Temperature (deg C)

855GME/852GME Tcase vs. Airflow for CompactPCI Heatsink

at Tem perat ur e (local ambien t) = 55 d e g C

120

110

Tcas e ma x = 105 deg C

100

90

80

70

60

50 100 150 200 250 300 350 400 450 500

Airflow (LFM)

Tcase for

855GME

(4.3W)

Tcase for

852GME

(5.7W)

5.3 Required Volumetric Keepout

The CompactPCI* thermal solution will require a volumetric keepout region above the chipset

MCH. See Figure 14 for a detailed side and top view of the keepout.

There is not a board keep-out restriction for the CompactPCI* heatsink. It uses an adhesive tape

thermal interface material for mechanical retention, and is smaller in footprint than the 855GME

and the 852GME chipset MCHs.

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 21

Page 22

Reference Thermal Solution for CompactPCI* and Blade Applications

Figure 14. CompactPCI* Thermal Solution Volumetric Keepout

5.4 CompactPCI* Heatsink Assembly

The CompactPCI heatsink assembly includes the heatsink an adhesive tape thermal interface

material, and a protective pull-tab as shown in Figure 15 on page 23.

22 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 23

Reference Thermal Solution for CompactPCI* and Blade Applications

Figure 15. CompactPCI* Heatsink Assembly (Heatsink, Pull-tab, and TIM)

Note: Thermal Interface Material (TIM) is not shown in picture.

5.5 Mechanical Retention

The heatsink is affixed to the die with an adhesive tape thermal interface material. This retention

scheme does not require board modifications and can be incorporated at any point in the design

cycle, assuming the z-height requirement is met.

5.6 Thermal Interface Material (TIM) and Thermal Bond Line

A thermal interface material (TIM) is used to provide improved conductivity between the die and

heatsink. The reference thermal solution uses Chomerics* T411 adhesive tape thermal interface

material, 15 mm x 15 mm x 0.254 mm (0. 59” x 0.59” x .01”).

The thickness of the bond line between the heatsink and die is critical to the thermal performance

of the TIM. The bond line thickness is d epend ent o n th e pres sure between th e heats ink and the die.

It is imperative that the heatsink is applied to the die with adequate force.

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 23

Page 24

Reference Thermal Solution for CompactPCI* and Blade Applications

For more information on force required and other important documentation, see the Chomerics

website at http://www.chomerics.com.

5.7 CompactPCI* Thermal Solution Mechanical Drawings

See Appendix B, “Mechanical Drawings” for a detailed drawing.

For an official electronic copy, contact Foxconn*. Contact information is available in Appendix A,

“Vendor Information”.

24 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 25

Temperature Measurement Metrology

Temperature Measurement Metrology 6

6.1 Case Temperature Measurements

Intel has established guidelines for the prop er techn iques to be us ed when measuring chip set MCH

case temperature. Section 7.3 contains information on running an application program that

emulates anticipated TDP.

The surface temperature at the geometric center of the die corresponds to the maximum Tcase.

6.2 0 Degree Angle Attach Methodology

1. Mill a 3.3 mm (0.13”) diameter hole centered on bottom of the heatsink base (see Figure 5).

The milled hole should be approximately 1.5 mm (0.06”) deep.

2. Mill a 1.3 mm (0.05”) wide slot, 0.5 mm (0.02”) deep, from the centered hole to one edge of

the heatsink. The slot should be in the direction parallel to the heatsink fins (see Figure 16 and

Figure 17).

3. Attach thermal interface material (TIM) to the bottom of the heatsink base.

4. Cut out portions of the TIM to make room for the thermocouple wire and bead. The cutouts

should match the slot and hole milled into the heatsink base.

5. Attach a 36 gauge or smaller calibrated K-type thermocouple bead or junction to the center of

the top surface of the die using a high thermal conductivity cement. During this step, make

sure there is no contact between the thermocouple cement and the heatsink base because any

contact will affect the thermocouple reading. It is critical that the thermocouple bead makes

contact with the die (see Figure 17).

6. Attach heatsink assembly to the MCH and route the thermocouple wires our through the

milled slot.

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 25

Page 26

Temperature Measurement Metrology

Figure 16. 0 Degree Angle Attach Heatsink Modifications (not to scale

Figure 17. 0 Degree Angle Attach Methodology (not to scale)

6.3 Maximum Temperature Specification

Use Table 4 to determine the maximum temperature value when performing thermal labor a to ry

testing with the 855GME or 852GME chipset MCH using the metrology described in this chapter

and the TDP Stress Application. More information about the TDP stress application may be found

in Section 7.

Table 4. 855GME and 852GME chipset MCH Maximum Case Temperature Value

Tcase,max (°C)

105

26 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 27

Thermal Management Features and Tools

Thermal Management Features and

Tools 7

7.1 Internal Temperature Sensor

The Intel 855GME and 852GME chipset MCH will include an on die temperature sensor that can

be used to protect the chipset MCH from exceeding the Tj,max specification. Upon detection that

the sensor has reached Tj,max the chipset MCH will be capable of initiating a bandwidth throttling

event that will reduce chipset MCH power and temperature. The sensor will also prove to be useful

in optimizing the thermal design for the chipset MCH by being able to provide jun c tio n

temperature during testing and evaluation of the thermal solution.

7.2 External Temperature Sensor

The chipset MCH is designed to accept an input signal from an external temperature sensor. The

external sensor can be placed in a location close to the DDR memory and upon detecting a “hot”

condition the chipset MCH would throttle the READ bandwidth. Proper placement of the sensor

would have to be determined by the OEM. The OEM would have to characterize the temperature

difference between the sensor and the DDR memory devices to determine the best placement for

the sensor. On detection of a “hot” condition a signal is communicated directly from the thermal

sensor to t he MCH via the ETS# pin as shown in Figure 18. The external thermal sensor can be

programmed via the SMBus.

Figure 18. External Temperature Sensor

ETS#ETS#

CPU

MCH-M

ICH

SMBus

THERM#

SO-DIMM’s

TS TS

Thermal Sensor on

motherboard. OEM

design dependent

SMBdata

SMBclock

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 27

Page 28

Thermal Management Features and Tools

7.3 TDP chipset MCH Stress Application

Intel provides a TDP stress software tool that can be used to validate chipset MCH thermal

solutions. The software tool will generate high memory write bandwidths to stress the chipset

MCH. The usage model for this software will include the following steps:

1. During the validation phase, OEMs will run this program on their platforms under worse case

system loading and environmental conditions. Worse case conditions might include things

such as loading the maximum number of rows for memory, setting the operating system to

maximum performance mode, an ambient environment at 55º C, and a still air environment

with no external air drafts.

2. Th e TDP stress application will remain running and the junction temperature will be

monitored until it has reached steady state. At the completion of the test, if the junction

temperature of the chipset MCH does not exceed the maximum operating temperature (110º C)

then the thermal solution can be deemed as adequate.

3. If the junction temperature exceeds the maximum operating temperature then this will provide

an indication that the thermal solution needs to be improved. Modifications to the thermal

solution should be made and the system should be retested until th e appr opriate junction

temperature can be maintained.

The TDP application will also allow the OEM to determine appropriate bandwidth WRITE throttle

settings to program into the BIOS.

7.4 Memory Thermal Management Software

The Intel Memory Thermal Management Software is a software application that allows OEMs to

generate high memory read bandwidths to stress memory. The usage model for this software will

include the following steps:

1. Preparation before testing will include placing thermocouples on each of the memory devices

of the DDR DIMMs that are to be used during validation.

2. During the validation phase, OEMs will run this program on their platforms under worse case

system loading and environmental conditions. Worse case conditions might include things

such as loading the maximum number of rows for memory, setting the operating system to

maximum performance mode, an ambient environment of 55 ºC, and a still air environment

with no external air drafts.

3. Th e pro gram will allow the OEM system designer to test at several different bandwidth

throttle settings. Some of the typical settings available for previous chipset MCHs were 65

percent, 55 percent, and 45 percent of the maximum write bandwidth. Th e OEM can begin by

running the test at one of the low bandwidth settings and monitoring the temperatures on the

DDR DIMMs. The temperatures should be allowed to reach steady state.

4. Once the temperatures are at steady state the OEM can observe the data and determine whether

any of the temperatures have exceeded the maximum allowable temperature for the memory

devices. If all the temperatures are within the allowed specification then the OEM can proceed

to the next test at a higher bandwidth setting.

5. Th is process will be repeated until the OEM tests at a bandwidth throttle setting that causes

temperature specifications to be exceeded for either the memory devices o r the bottom su rface.

This bandwidth limit will be used to determine the appropriate memory READ throttle setting

that can be programmed into the BIOS.

28 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 29

Thermal Management Features and Tools

7.5 Thermal Throttling

Both the Intel 855GME and Intel 852GME chipset MCHs are available with throttling

functionality to protect the chipset MCH from power virus conditions that can cause junction

temperatures to increase beyond maximum allowable junction temperatures. Two different

methods of thermal throttling are available on the chipset MCH: bandwidth triggered and

temperature based throttling.

There are three important things to remember about throttling:

1. It is only intended to be a safeguard to ensure that junction temperatures do not exceed

maximum specified junction temperatures.

2. chipset MCH thermal solutions must still be designed to TDP. Thro ttling is not recommended

as a method of designing the chipset MCH cooling capability to levels below TDP.

3. This mechanism was carefully designed to have minimal impact on real applications, while

safeguarding against harmful synthetic applications. However, throttling may affect

performance of the chipset MCH. Performance of the chipset MCH should be verified by

testing with benchmarks.

7.5.1 Bandwidth Triggered Throttling

Bandwidth triggered throttling will limit the max im um bandwidth that can be sustained over long

periods as a safeguard against a thermal virus. This method of thermal management will

temporarily decrease bandwidth performance of the chipset MCH when an application demands

large, sustained bandwidth levels that could cause the chipset MCH to exceed its maximum

junction temperature. However, in order to trigger bandwidth throttling, the chipset MCH

bandwidth must exceed the threshold over an entire sampling window. Most applications use high

bandwidths only in short bursts, and through application analysis, this sampling window has been

set large enough so that these applications that create short bursts in bandwidth will not see any

throttling. Only a sustained high bandwidth for a period longer than the sampling w indo w has the

potential of exceeding thermal limits, and the throttle mechanism is designed to protect the chip

against those potentially harmful applications.

Figure 19 below provides a theore tical example of h ow ban dwidth th rottling would work. In this

example, the bandwidth is set to throttle at 1100 MB/sec. The throttling value would be determined

based on the worst case operating conditions. This throttle setting is enabled upon system boot and

only one value can be set for the WRITE operatio ns of th e chips et MC H. To determine bandwidth,

the read/write operations are being monitored continuously by hardware insid e the chipse t MCH

within a one second window.

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 29

Page 30

Thermal Management Features and Tools

Figure 19. 855GME/852GME chipset MCH Bandwidth Throttling

1. The system is operating at an idle workload until an application that requires a large amount of

bandwidth is initiated. The application demands a peak bandwidth of 1200 MB/sec. for an

entire sampling window interval, and it will be reduced to the bandwidth throttle setting limit

of 1100 MB/sec. The throttle setting of 1100 MB/sec. ef fectively places a cap on the allowable

bandwidth.

Note: Applications are still allowed to exceed the 1100 MB/sec. limit in short bursts that last less than the

sampling window period.

2. Th e chi ps et MCH will continue to operate at the throttled amount of 1100 MB/sec. until the

application no longer requires this level of sustained bandwidth. In this case the junction

temperature has not increased to a temperature that is close to the maximum junction

temperature limit of 110º C. So it appears that for the brief period that the large bandwidth

level was required the chipset MCH was unnecessarily throttled. A drawback of using

bandwidth triggered throttling is that under certain conditions when the system is not operating

under worse case conditions the chipset MCH will be throttled regardle ss of the junction

temperature.

3. Once the application stops the system workload will return to a lower workload.

30 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 31

Thermal Management Features and Tools

7.5.2 Temperature Triggered Throttling

Temperature triggered throttling will limit the maximum achievable bandwidth as a safeguard

against a thermal virus only when the junction temperature reaches a specified trip point

temperature. This method of thermal throttling is an improvement over the bandwidth

triggered throttling method because the chipset MCH will only reduce bandwidth

performance when it is absolutely necessary under a preset condition.

The temperature throttle trip point is programmed into the chipset MCH at boot. If the temperature

of the chipset MCH goes beyond the trip point limit, the chipset M CH will be throttled to a

predetermined maximum throttling amount until the temperature drop s be low the same

temperature limit.

Figure 20 below provides an example of ho w temper ature triggered throttling would optimize

throttling under conditions similar to the scenario that was descr ibed in Section 7.5.1. In this

scenario the hot trip temperature is set at 100 ºC . Keep in mind that th e Tj,max specification f or the

855GME and 852GME chipset MCHs is 110 ºC and the example described in the section is only

intended to illustrate the behavior. The hot trip temperature represents the temperature setpoint at

which the chipset MCH will initiate throttling.

Figure 20. 855GME/852GME chipset MCH Temperature Throttling

1. The system is operating at an idle workload until an application that requires a large amount of

bandwidth is initiated. The application demands a peak bandwidth of 1200 MB/sec. and the

chipset MCH will sustain this bandwidth leve l until the temperature climbs above the hot trip

setting of 100 ºC.

2. During this test the chipset MCH operates at a 1200 MB/sec. bandwidth level for a period

longer than the sampling window because the junction temperature has not increased above

the hot trip point setting. In this case the chipset MCH is demonstrati ng better bandwidth

performance while operating under the same application as in the bandwidth triggering case.

This is clearly a preferred method of throttling the chipset MCH only when it is absolutely

necessary.

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 31

Page 32

Thermal Management Features and Tools

3. Once the application stops the system workload will return to its idle level of 200 MB/sec. In

this example, the chipset MCH never required any thermal throttling. The method will

potentially allow for large, brief bursts of bandwidth loading without impeding chipset MCH

performance.

32 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 33

Thermal/Mechanical Applications

Thermal/Mechanical Applications 8

8.1 Thermal Interface Materials

Use of a Thermal Interface Material (TIM) between the chipset MCH package and the thermal

enhancement is highly recommended to reduce the thermal resistance b etween the package an d the

thermal enhancement device. A reduction in the thermal resistance at this interface creates a larger

effective thermal conductivity through the interface that improves the thermal capability of the

package.

Common types of interface materials include elastomers and phase change materials. These types

of materials can easily conform to fill small air gaps that are left between the two interfaces that are

mated together. These air gaps can act as insulators and will increase the thermal resistance. An

interface material can assist in filling these voids and reducing the thermal resistance at the

interface. The total thermal resistance through the interface would consist of the three main

resistances:

1. Thermal interface material resistance (θ

2. Contact resistance between the top of the chipset MCH package and the bottom of the ther mal

interface material (θ

3. Contact resistance between the top of the thermal interface material and the bottom of the heat

spreader or heat sink (θ

contact-top

)

contact-bottom

TIM

)

8.1.1 Estimate Thermal Resistance

The thermal resistance of a material can be estimated by using the expression in Equation 1.

The expression provides a result in units of ºC/W. If adequate force is applied onto the thermal

interface material, it can be assumed the contact resistances are negligible. This is a valid

assumption when using the reference design described in Section 4.

Equation: Thermal resistance of a material

θ

TIM

θ

= Thermal Resistance through the material (ºC/W)

TIM

L = thickness of the material (m)

)

L

=

kA

k = thermal conductivity of material (W/m-ºC)

A = cross sectional area of the material (m

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 33

2

)

Page 34

Thermal/Mechanical Applications

8.2 Mechanical Loading

The pressure applied to the surface of the 855GME or 852GME MCH package should not exceed

100 psi.

If the pressure on the surface of the chipset MCH package is exceeded, problems may arise. The

solder ball joints between the package and the motherboard may be subjected to fractures that

could result in a loss or degradation of electrical signals from the chipset MCH. Also, the die may

be exposed to warpage or, at unusually high levels of stress, cracking.

If a large compressive load is applied to the die surface precautions should be taken to help

alleviate some of the load. One manner of doing this is to provide some backing support for the

motherboard directly underneath the chipset MCH. Standof fs can be used between the motherboard

and the chassis to add rigidity to the motherboard under the chipset MCH and reduce the amount of

board flexure under larg e loads.

8.3 Thermal and Mechanical Reliability

Recommendations for thermal mechanical reliability testing are shown in Table 5. These should be

considered as genera l guideline s. The user should define validation testing requireme nts based on

anticipated use conditions.

Table 5. Reliability Validation

(1)

Test

Mechanical Shock

Random Vibration

Power Cycling (for

active solutions)

Thermal Cycling

Humidity

NOTES:The above tests should be performed on a sample size of at least 12 assemblies from 3 different lots

of material.

Additional Pass/Fail Criteria may be added at the discretion of the user.

Requirement Pass/Fail Criteria

• Quantity: three drops for + and – directions in each

of three perpendicular axes (i.e., total of 18 drops).

• Profile: 50 G trapezoidal waveform, 11 ms duration,

170 in/s minimum velocity change.

• Setup: Mount sample board on test fixture

• Duration: 10 min/axis, three axes

• Frequency Range: 5 Hz to 500 Hz

• Power Spectral Density (PSD) Profile: 3.13 G RMS

• 7500 on/off cycles with each cycle specified as 3

minutes on, 2 minutes off at 70 °C

• -5 °C to +70 °C, 500 cycles Visual Check

• 85% relative humidity, 55 °C, 1000 hours Visual Check

Visual Check and Electrical

Functional Test

Visual Check and Electrical

Functional Test

Visual Check

(2)

34 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 35

Summary

Summary 9

The Intel® 855GME and Intel® 852GME Chipset Memory Controller Hub (MCH) Thermal Design

Guide For Embedded Applications was developed to aid in creating adequate thermal design s th at

will insure reliable and efficient operation of the 855GME and 852GME chipset MCHs in

embedded applications. The goal of this document is to pr ovide an understanding of the operating

limits of the chipset MCH in embedded environments and to recommend proper thermal design

techniques based on a particular configuration.

Computational Fluid Dynamics (CFD) analysis proved to be a useful tool in provid ing an initial

basis to determine the thermal limits of the chipset MCH under varying cooling configurations.

Developing a CFD analysis early in the d esign stage is h ighly recom mended to assist in iden tifying

potential thermal issues at the individual component and system levels.

Several new features and tools will be made available with the 855GME and 852GME chipset

MCH. The chipset MCH will have an on die temperature sensor to assist the thermal control and

validation of the thermal solution. It will also have the capability to resp ond to an input from an

external temperature sensor that is placed next the DDR DIMMs. This will allow for improved

thermal control of memory temperatures. New software tools will also be provided to validate the

thermal solution design at TDP levels and to determine read/write throttle settings.

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 35

Page 36

Vendor Information

Vendor Information A

Table 6. 1U Reference Design Heatsink Assembly Suppliers (as referenced in Section 4)

Part

Extruded

Heatsink

Interface

Materials

Attach

Hardware

Entire

Enabling

Assembly

NOTE: The above reference heatsink vendors and information are identical to that of the Intel

Pin Fin Heatsink A54515-001 Foxconn*

Chomerics Phase Change

TIM (T-710)

Mechanical Interface Material

(Poron)

Clip Frame A65066-001 Foxconn

Clip Lever A67031-001 Foxconn

Solder-Down Anchor (4

required per heatsink)

MCH Enabling Assembly

Includes:

Pin fin heatsink, thermal

interface material, mechanical

interface material, clip frame,

and clip lever (does not

include solder-down anchors)

Intel Part

Number

A61203-001 Boyd*

A13494-005 Foxconn HB96030-DW

A67625-001 Foxconn PHC029C02012

Supplier

Chomerics* 69-12-22066-T710

Supplier Part

Number

®

845G MCH.

T a ble 7. CompactPCI* Reference Design Heatsink Assembly Suppliers (as referenced in

Section 5)

Part

Entire Extruded

Heatsink Enabling

Assembly

Heatsink Only Pin Fin Heatsink N/A Foxconn 071-0000-884-1

Thermal Interface

Material Only

Pin Fin Heatsink with

attached Chomerics T411

Adhesive Tape Thermal

Interface Material and PullTab

Chomerics Adhesive Tape

TIM (T411)

Intel Part

Number

N/A Foxconn 2ZG85-001A

N/A Chomerics

Supplier

Supplier Part

Number

36 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 37

Vendor Information

Supplier Contact Information

Boyd Corporation*

• http://www.boydcorp.com

Chomerics, Inc.*

• http://www.chomerics.com

Foxconn Electronics, Inc.*

458 Lambert Rd.,

Fullerton, CA 92835

Tel: 714-626-1233

Fax: 714-738-8838

http://www.foxconn.com

37 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 38

Mechanical Drawings

Mechanical Drawings B

T able 8. Mechanical Drawing List

Drawing Description Page Number

Board Keep-out Restriction for 1U Reference Design 39

CompactPCI* Heatsink Assembly Drawing 40

38 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Page 39

Mechanical Drawings

Figure 21. Board Keep-Out Region for 1U Reference Design Heatsink and Mounting Anchor

Placement

Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications 39

Page 40

Mechanical Drawings

Figure 22. CompactPCI* Heatsink Assembly

40 Intel® 855GME and Intel® 852GME Thermal Design Guide for Embedded Applications

Loading...

Loading...