Page 1

CONDENSER

MONITORING SYSTEM

with

RheoVac® and Rheotherm® Instruments

Installation & Operation Manual

Page 2

Intentionally left blank

Page 3

TABLE OF CONTENTS

SECTION 1 - GENERAL INFORMATION ...............................................................................................1

1.1 INTEK’S POWER INDUSTRY SERVICES ................................................................................................................ 1

1.2 PURPOSE AND FUNCTION ....................................................................................................................................... 2

1.3 TECHNICAL SPECIFICATIONS – check custom page to determine which components apply to your CMS .......... 3

1.3.1 Main Electronics (SCADA, RTU and HMI) ......................................................................................................... 3

1.3.2 RheoVac Multi-Sensor Probe (MSP) .................................................................................................................... 3

1.3.3 Rheotherm Cooling Water Flow and Fouling (CWFF) Meters ............................................................................. 4

1.3.4 Pressure/Temperature (PT) Probe ......................................................................................................................... 4

1.3.5 Thermocouple (TC) Temperature Sensors and Arrays ......................................................................................... 4

1.3.6 High Spatial Density Temperature Sensors and Arrays ........................................................................................ 5

1.4 WARNINGS , PRECAUTIONS AND RECOMMENDATIONS ........................................................... 6

SECTION 2 - INSTALLATION .................................................................................................................7

2.1 HARDWARE INSTALLATION .................................................................................................................................. 7

2.1.1 RheoVac Multi-Sensor Probes .............................................................................................................................. 7

2.1.2 PT Probes ............................................................................................................................................................ 10

2.1.3 Rheotherm CWFF Meters and Temperature Sensors .......................................................................................... 10

2.2 ELECTRICAL CONNECTIONS................................................................................................................................ 11

2.2.1 Main Electronics – contains the SCADA and HMI components ........................................................................ 12

2.2.2 Satellite Electronics (only provided with systems that have several instruments) .............................................. 13

2.2.3 Distribution Box (see Figure 6) – For distributing RS485 communication and 24VDC .................................... 13

2.2.4 4-20mA Transmitter Box (optional) – For driving eight (8) remote 4-20 mA analog signals ............................ 14

2.2.5 RheoVac MSP and PT Probe Connector Assembly ............................................................................................ 16

2.2.6 Rheotherm CWFF Meters and Temperature Sensors Connections ..................................................................... 17

SECTION 3 - USER INTERFACE AND DATA RETRIEVAL ..............................................................18

3.1 MENUS ....................................................................................................................................................................... 18

3.1.1 Compressing Data (to USB Stick) ...................................................................................................................... 18

3.1.2 Change Line Size (i.e., pipe diameter) ................................................................................................................ 20

3.1.3 Reboot ................................................................................................................................................................. 21

3.1.4 Cancel ................................................................................................................................................................. 21

3.2 UPLOADING TO INTEK’S SECURE FTP SITE FOR DATA EVALUATION ...................................................... 22

SECTION 4 - COMMUNICATION METHODS .....................................................................................24

4.1 ANALOG OUTPUT ................................................................................................................................................... 24

4.2 MODBUS .................................................................................................................................................................... 24

4.2.1 Modbus TCP ....................................................................................................................................................... 26

4.2.2 Serial Modbus ..................................................................................................................................................... 26

4.2.3 Modifying the Modbus Configuration File ................................................................................................ ......... 28

4.2.4 Modbus Troubleshooting .................................................................................................................................... 29

4.3 OPC – (OLE for Process Control) ............................................................................................................................... 30

4.3.1 Connecting .......................................................................................................................................................... 30

4.3.2 Adding Process Variables ................................................................................................................................... 30

SECTION 5 - TROUBLESHOOTING .....................................................................................................31

5.1 COMMON ISSUES .................................................................................................................................................... 33

SECTION 6 - MAINTENANCE GUIDE..................................................................................................34

6.1 WATERBOX INSTRUMENTS .................................................................................................................................. 34

6.2 CALIBRATION .......................................................................................................................................................... 34

6.3 SOFTWARE UPDATES ................................................................ ................................................................ ............. 34

6.4 ADDING/REPLACING SENSORS/INSTRUMENTS .............................................................................................. 34

SECTION 7 - CUSTOMER SERVICE .....................................................................................................35

7.1 TROUBLESHOOTING .............................................................................................................................................. 35

7.2 FACTORY AND FIELD SERVICE ................................................................ ................................ ........................... 35

7.3 CONSULTING SERVICES ........................................................................................................................................ 35

7.4 CONDENSER MANAGEMENT AND RheoVac/CMS TRAINING ......................................................................... 36

SECTION 8 - CUSTOM INFORMATION ...............................................................................................37

8.1 UNIT IDENTIFICATION AND CONFIGURATION ............................................................................................... 37

8.2 SPECIAL INFORMATION ........................................................................................................................................ 37

September 2013 i © Intek, Inc. 2013

Revision D

Page 4

WARRANTY

Intek, Inc. warrants each Rheotherm, RheoVac and CMS product to be free

from defects in material and workmanship under normal use and service;

Intek's obligation under this warranty being limited to making good any

part or parts thereof which shall, within one (1) year after delivery of such

product to the original purchaser, be returned to Intek with transportation

charges prepaid and which Intek's examination shall disclose to its

satisfaction to have been thus defective; this warranty being expressly in

lieu of all other warranties, express or implied and all other obligation or

liabilities on Intek's part. The purchaser will assume all responsibility and

expense for removal, decontamination and reinstallation of equipment.

Rheotherm flow meters are manufactured under United States patent numbers 4,255,968, 4,942,763, 4,949,578 and 5,445,018.

Rheotherm circulating water flow and fouling meters are patent pending in the USA. RheoVac instruments are manufactured

under United States patent numbers 4,255,968, 5,485,754, 5,752,411 and 6,526,755. CMS products incorporate Rheotherm and

RheoVac technology as well as technology under US patent numbers 6,526,755, 7,065,970, 7,926,277 and international patents.

Intek, Rheotherm, and RheoVac are registered trademarks of Intek, Inc.

September 2013 ii © Intek, Inc. 2013

Revision D

Page 5

SECTION 1 - GENERAL INFORMATION

1.1 INTEK’S POWER INDUSTRY SERVICES

Intek manufactures RheoVac condenser and air in-leak monitors, Rheotherm circulating water

flow and fouling meters, flow meters, flow switches, as well as specialty temperature and pressure

measurement instruments. These specialty instruments for the power industry provide continuous

monitoring of critical steam surface condenser parameters important to plant thermal performance and

life cycle.

The data from these instruments have been used to gain a unique comprehensive understanding

of steam surface condensers and the condensation process. This understanding has enabled Intek to help

customers troubleshoot condensers with greater speed and accuracy than ever before. Intek has

expanded service offerings and developed an online information website for steam surface condensers,

available at www.MyCondenser.com.

Intek has also taken advantage of its aerospace design tools and design expertise for the purpose

of retrofitting condensers to maximize performance and improve condensate chemistry. Intek has

transformed underperforming condensers into some of the best performing condensers in the world.

The condenser services team under Dr. Joseph Harpster’s leadership has also sought to educate

the industry by contributing volumes of material to ASME and EPRI regarding proper condenser

measurement and steam flow dynamics. Intek conducts a unique Condenser Operations and

Management Workshop for continuing education purposes. Tutorials and case studies are also available

at www.MyCondenser.com for registered users.

Intek is The Gateway to

Improved Condenser Performance, Fast Response Maintenance and Optimized Operations

September 2013 1 © Intek, Inc. 2013

Revision D

Page 6

1.2 PURPOSE AND FUNCTION

The Condenser Monitoring System (CMS) integrates unique instruments allowing

comprehensive examination of condenser performance. These unique instruments are specifically

designed to provide direct measurement of performance degradation mechanisms and data that exceed

the requirements of instrumentation outlined in ASME PTC 12.2. A complete system will provide data

used to derive information for quantifying specific degradation mechanisms such as microfouling,

macrofouling, cooling water flow, waterbox fill, air binding, low vacuum equipment capacity and

condensate inundation. This information can also be used to evaluate the cooling water system changes,

fouling control systems, waterbox eductors, vacuum equipment, and new or refurbished condenser

commissioning. In essence, this system puts a microscope on your condensing heat exchanger and

empowers engineers with direct measurements to organize actionable effort.

Illustration of the Condenser Monitoring System (CMS)

Used for comprehensive online continuous heat exchanger performance measurement and monitoring

September 2013 2 © Intek, Inc. 2013

Revision D

Page 7

1.3 TECHNICAL SPECIFICATIONS – check custom page to determine which

components apply to your CMS

1.3.1 Main Electronics (SCADA, RTU and HMI)

Input Power:

100-250 VAC, 50/60 Hz (UPS recommended)

Digital Communication:

TCP/IP:

Windows File Share (SMB)

OPC

Modbus

Web Interface

Wireless (optional)

All TCP/IP options are enabled by default

Serial:

RS-232 (Modbus) (optional)

Analog Communication:

4-20mA signals (optional)

Temperature Environment:

Operating: 40 to 120°F (5 to 49°C)

Storage: -20 to 158°F (-29 to 70°C)

Local Display (optional):

LCD Screen

or

2 x 20 alphanumeric LCD – displays output parameters and diagnostic messages

Parameter scrolling

Wireless Handheld Tablet (optional)

1.3.2 RheoVac Multi-Sensor Probe (MSP)

Typical Calibration Accuracy:

±5% of total mass flow

Repeatability:

±1.5% of reading

Operating Temperature:

Electronics: 40 to 120°F (5 to 49°C)

Probe: 40 to 158°F (5 to 70°C)

Never subject probe to temperatures above 210°F (99°C)

(high temperature protection optional, up to 450°F)

Operating Pressure:

0.5 to 10 inches Hg absolute

15 psia maximum

Storage Temperature:

-20 to 185°F (-29 to 85°C)

Storage Pressure:

15 psig (maximum)

Process Connection:

Ball valve assembly (1½" thread-o-let must be welded to pipe for installation)

Wetted Surface:

300 Series SS and engineered plastic (depending on model)

September 2013 3 © Intek, Inc. 2013

Revision D

Page 8

1.3.3 Rheotherm Cooling Water Flow and Fouling (CWFF) Meters

Primary Calibration Accuracy:

Better than ±2% of reading

Flow Range:

2-20 ft/s (extended range optional)

Repeatability:

±0.5% of reading

Operating Temperature:

Electronics: 40 to 120°F (5 to 49°C)

Sensor: 40 to 140°F (5 to 60°C)

Operating Pressure:

60 psi (1000 psi optional)

Storage Temperature:

-20 to 140°F (-29 to 60°C)

Storage Pressure:

60 psig (maximum)

Wetted Surface:

300 Series SS (material options available)

Neoprene, Polyolefin (cable included)

1.3.4 Pressure/Temperature (PT) Probe

Accuracy:

±0.02 inches HgA for pressure

±0.1°F for temperature

Repeatability:

±0.5% of reading

Operating Temperature:

Electronics: 40 to 120°F (5 to 49°C)

Probe: 40 to 300°F (5 to 149°C)

Operating Pressure:

0.5 to 10 inches Hg absolute

15 psia maximum

Storage Temperature:

-20 to 185°F (-29 to 85°C)

Storage Pressure:

15 psig (maximum)

Process Connection:

Ball valve assembly (1½" thread-o-let must be welded to pipe for installation)

Wetted Surface:

300 Series SS

1.3.5 Thermocouple (TC) Temperature Sensors and Arrays

Temperature range:

40-175°F (higher temperature components optional)

Accuracy:

±0.2°F

Repeatability:

±0.1°F

Wetted Surface:

300 Series SS and thermoplastics

September 2013 4 © Intek, Inc. 2013

Revision D

Page 9

1.3.6 High Spatial Density Temperature Sensor Arrays

Operating Temperature:

40 to 185°F (5 to 85°C)

Accuracy:

±0.15°F

Repeatability:

±0.1°F

Wetted Surface:

Proprietary

September 2013 5 © Intek, Inc. 2013

Revision D

Page 10

1.4 WARNINGS , PRECAUTIONS AND RECOMMENDATIONS

WARNING — Never operate any instruments at or subject them to temperatures or

pressures beyond the specified limits. (See Section 1.3)

Use reasonable care in handling the RheoVac and PT probes. Do not bend the probes, damage

the tips, or obstruct the sensing ports. If moving or shipping the unit, make sure the probe is

adequately protected from foreign objects and damage during handling and shipping; save and

reuse factory provided custom probe protector and shipping boxes.

Keep the USB memory stick disconnected during normal operations to extend memory lifetime.

All instruments should be serviced on a 1 or 2 year cycle to ensure all instruments are within

specifications and electronics are maintained with appropriate software/hardware updates.

Use the USB stick to retrieve data after the system has been online and flow has been established

for at least 48 hrs. E-mail data to Intek for evaluation.

Intek recommends using the RJ-45 network connection for all data traffic (as opposed to serial

and 4-20 mA communication).

RheoVac probes and PT probes:

WARNING — Be sure to power up your RheoVac probe(s) for at least 30 minutes before

inserting probes into the vent line. DO NOT leave probe in vent line without power or

when flooding the condenser.

WARNING — Never allow live high temperature steam to flow either direction in the

exhauster line where a RheoVac probe is located. This can happen if steam jet ejectors are

operated incorrectly.

WARNING — Do not allow RheoVac or PT probes to come into contact with liquid water,

including water from condenser flooding (hydro testing) and entrained liquid water.

Entrained liquid water is an indicator of poor condenser venting and may be present in

your condenser vent line due to design configuration. See EPRI’s “Air In-Leakage and

Intrusion Prevention Guideline,” TR 1014125. Intek offers analysis and design services to

improve condenser venting and reduce or eliminate entrained liquid water and excess

condenser back pressure.

Recalibration every 2 years: RheoVac probes and PT probes should be returned to the factory

for inspection and calibration service every two years.

Rheotherm CWFF and thermocouple sensor arrays:

WARNING — Ensure cleaning crews do not apply lateral pressure, “cock,” to the cleaning

guns; this can damage epoxy cladded tubesheets and the installed meters.

WARNING — Do not attempt to disassemble the meters/sensors – there are no user

serviceable components.

When cleaning condenser tubes, it is recommended to insert projectiles into the CWFF meter.

Inspect the installation on a scheduled basis or as opportunities arise to ensure the epoxy coating

is securely sealing the installed meters/sensors in place. Follow epoxy coating manufacturer’s

(Plastocor, Duromar, etc.) recommendations to touch up coat as required. Intek recommends

annual inspections, as a minimum.

September 2013 6 © Intek, Inc. 2013

Revision D

Page 11

SECTION 2 - INSTALLATION

2.1 HARDWARE INSTALLATION

2.1.1 RheoVac Multi-Sensor Probes

2.1.1.1 Selecting a Ball Valve Assembly Location (Hot Tap Compatible)

Figure 1: Recommended ball valve assembly locations

1. Select an easy to access location; location should be accessible for probe removal

and maintenance.

2. Adhere to locations shown in Figure 1.

3. Verify there is a minimum probe insertion clearance of 4 feet (1.3m) between pipe

surface at the tap location and any obstruction, refer to Figure 2.

4. Verify installation site is parallel to the floor, refer to Figure 2.

5. An additional ball valve assembly is required for high temperature model MSPs.

Refer to SECTION 8 -CUSTOM INFORMATION for installation instructions.

September 2013 7 © Intek, Inc. 2013

Revision D

Page 12

2.1.1.2 Ball Valve Installation

1. Be sure location is accessible for probe removal and maintenance.

2. Install mounting hardware. Drill a 1½" through-hole, center the thread-o-let over

the hole and weld it onto the condenser vacuum pipe (see Figure 2). Thread the

ball valve assembly into the thread-o-let. Use thread tape or pipe dope to seal the

connection (Alternate: weld thread-o-let to pipe wall, then drill a 1¼" hole in pipe

wall using a hot tap drill).

3. Make sure the probe installs parallel to the floor (see Figure 2).

4. Verify that the probe slides easily through the ball valve assembly and pipe

penetration hole.

Figure 2: RheoVac MSP ball valve assembly installation detail

September 2013 8 © Intek, Inc. 2013

Revision D

Page 13

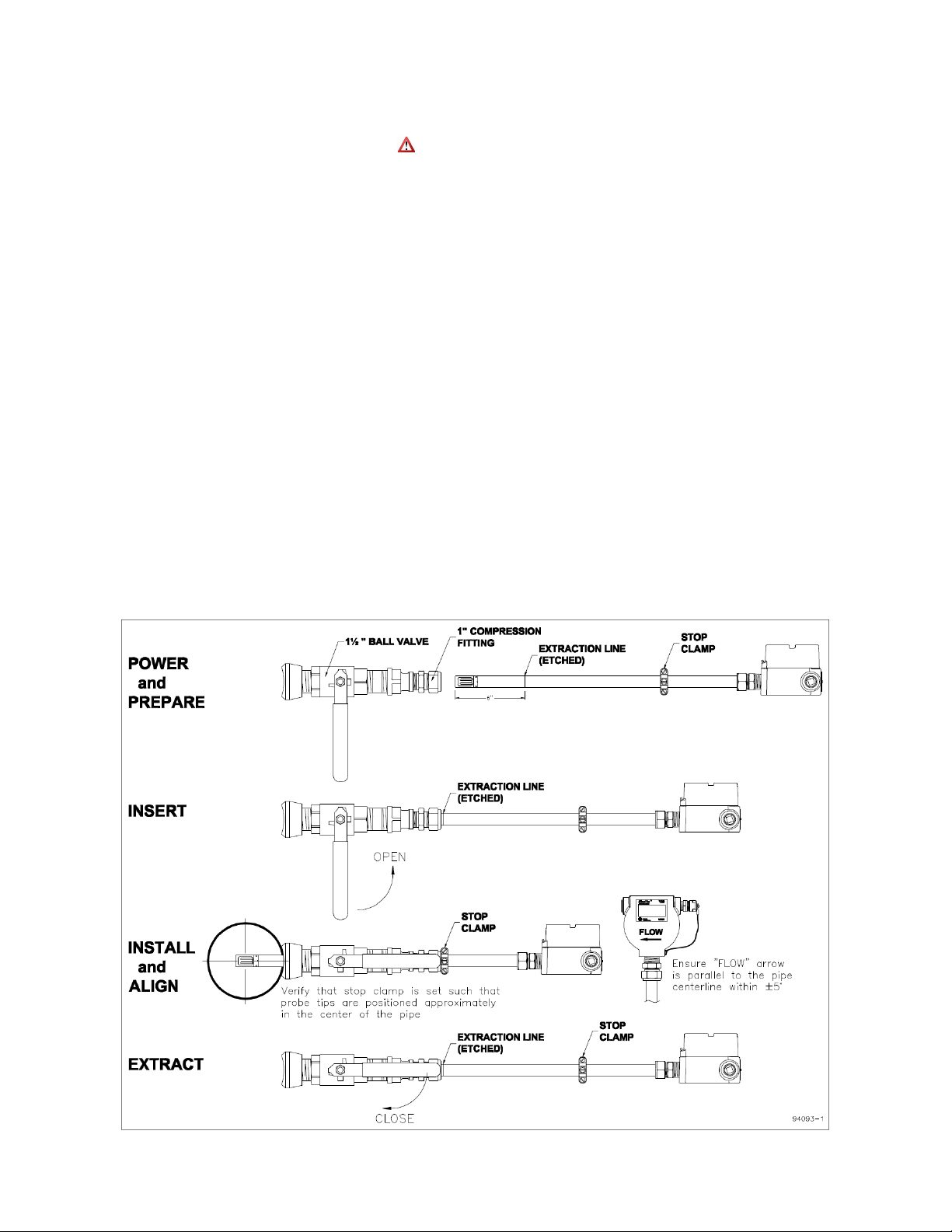

2.1.1.3 Installing/Removing Probe Instruments – refer to Figure 3

1. Power up your RheoVac MSP for at least 30 minutes before inserting probe into the

vent line ball valves. DO NOT leave probe in vent line without power or when

flooding the condenser.

2. Prepare each probe. Verify stop clamp location (see Figure 3). It is important that

the stop clamp is securely in place which determines the position of the multisensor assembly and ensures that the probes do not contact the opposite pipe wall.

Contact with the pipe wall could damage the probe. The clamp’s location is set at

the factory and is marked with a groove on each probe shaft. This location roughly

places the thermal mass flow elements (two metal probe tips) in the center of the

pipe. Refer to this mark if a stop clamp is inadvertently moved. Loosen the

compression nut on the thermocouple connector of the ball valve assembly and

clean the inner surface of the thermocouple connector to ensure it is free of particles

that may cause probe damage.

3. Insert probe until the extraction line meets the compression nut and snug the

compression nut.

4. Install each probe. When installing under vacuum, do not allow the clamp to

“slam” against the seal nut upon opening the valve. Grasp the probe firmly, with

hand against the seal nut, before opening the ball valve.

5. Align the FLOW arrow to the direction of flow and the centerline of the pipe.

6. When removing the probe, loosen the compression nut on the thermocouple

connector of the ball valve assembly and slowly extract the probe until the

Extraction Line is visible (see Figure 3). This indicates that the probe is clear of the

ball valve. Close the ball valve, then remove the probe from the assembly.

Figure 3: Installing and removing probe instruments

September 2013 9 © Intek, Inc. 2013

Revision D

Page 14

2.1.2 PT Probes

The PT probe(s) is installed through a ball valve similar to that shown in Figure 2 and Figure 3.

Special instructions, where applicable, are provided by Intek (see SECTION 8 - CUSTOM

INFORMATION).

2.1.3 Rheotherm CWFF Meters and Temperature Sensors

These instruments are installed by Intek Inc. or under Intek Inc.’s supervision. The installation

ensures proper seating/anchoring of the sensors in the selected locations. Wiring is fully coated using

epoxy coating that is proven for underwater application.

September 2013 10 © Intek, Inc. 2013

Revision D

Page 15

2.2 ELECTRICAL CONNECTIONS

A typical system with a model 950 RheoVac MSP is shown in Figure 4. Additional instruments

can be connected to the RS-485 bus per the EIA-485 standard.

Figure 4: Typical system configuration with one RheoVac MSP

IMPORTANT — Inspect and VERIFY these electrical connections carefully. Improper

connection could damage electronic components and sensor function. If additional holes need to be

drilled in the processor enclosure, remove the electronics subassembly (mounted on a mounting plate)

and temporarily store inside an ESD bag in a safe, clean place. Do not drill with electronics boards

inside the enclosure.

September 2013 11 © Intek, Inc. 2013

Revision D

Page 16

2.2.1 Main Electronics – contains the SCADA and HMI components

RS-232 CONFIGURATION

RS-422 CONFIGURATION

RJ-11 Pin Out

DB-9 Pin Out

RJ-11 Pin Out

DB-9 Pin Out

1

Tx (transmit)

1

N/C

1

Tx+ (transmit+)

1

Rx- (receive-)

2

N/C

2

Tx (transmit)

2

Tx- (transmitS)

2

Rx+ (receive+)

3

Rx (receive)

3

Rx (receive)

3

Rx+ (receive-)

3

Tx+ (transmit+)

4

N/C 4 N/C

4

Rx- (receive-)

4

N/C

5

Power (+5V)

5

Ground

5

Power (+5V)

5

Ground

6

Ground

6

Pulled high

6

Ground

6

Tx- (transmit-)

7

N/C 7 7 TBD

8

Pulled high 8 8 TBD

9

N/C 9 9 TBD

1. Transmitter(s) Power/COM: A DeviceNet 5711 cable is used all probe/sensor/4-20mA

transmitters. The color code for this cable is: RS-485 communications: white (A), blue

(B) and shield (SH); power: 24Vdc, red (+), and black ().

2. Main Power: Power connection wires should be at least 18 AWG. Connect main power

terminals to a dedicated 120 or 240 VAC, single phase, 15-amp circuit. A main power

switch is provided near the input power terminals.

3. Network Communication (Recommended): An Ethernet connection (RJ-45 style jack) is

provided. Intek recommends using this connection for all data transmissions because:

a. More measured data is accessible through the network connection.

b. Software and calibration file updates can be done remotely.

4. Serial Communication: Connector JP3 on the CPU interface PWA (printed wiring board

#08017-1) is the RS-232 and RS-422 serial communication interface. The configuration

information for a RJ-11 to DB-9 adapter is shown in Table 1 and Figure 5.

Table 1: RJ-11 to DB-9 Module Adapter

Figure 5: Serial communication interface

September 2013 12 © Intek, Inc. 2013

Revision D

Page 17

2.2.2 Satellite Electronics (only provided with systems that have several instruments)

1. Transmitter(s) Power/COM: A DeviceNet 5711 cable is used for RS485 communication

and power for all transmitters. The color code for this cable is: RS-485 communications:

white (A), blue (B) and shield (SH); power: 24Vdc, red (+), and black ().

2. Power: Power connection wires should be at least 18 AWG. Connect power terminals to a

dedicated 120 or 240 VAC, single phase, 15-amp circuit. A power switch is provided near

the input power terminals.

2.2.3 Distribution Box (see Figure 6) – For distributing RS485 communication and 24VDC

1. Connect the provided DeviceNet 5711 cable from the main processor unit to screw

terminal, JP1. The color code for this cable is: RS-485 communications: white (A), blue

(B) and shield (SH); power: 24Vdc, red (+), and black ().

2. Install ½" conduit between the distribution box and probes. Intek recommends 6 feet of

liquid-tight conduit between conduit and probes to minimize stress at the connector.

3. An adapter is provided which allows attachment of ½" flexible conduit to the connector.

4. Connect the probes to the distribution enclosure using the manufacturer supplied

DeviceNet 5711 cable to the screw terminals labeled JP3 to JP6 (refer to Figure 6).

5. For systems with multiple distribution boxes, screw terminal JP2 will be used to connect

to the JP1 screw terminal on the next distribution box in the series.

6. If no additional distribution boxes are used, ensure the outgoing termination resistor (JP7

or JP8) is enabled.

Figure 6: Distribution Box

September 2013 13 © Intek, Inc. 2013

Revision D

Page 18

2.2.4 4-20mA Transmitter Box (optional) – For driving eight (8) remote 4-20 mA analog

signals

The 4-20mA transmitter component is optional, see Figure 7. Note: Intek recommends using the

network connection for all data transmissions and communications with the RheoVac MSP.

1. Connect the DeviceNet 5711 cable. The color code for this cable is: RS-485

communications: white (A), blue (B) and shield (SH); power: 24Vdc, red (+), and black

().

2. Connect up to eight (8) signal wire pairs to the indicated terminals for isolated 4-20mA

outputs.

3. CMS 4-20mA transmitters are configured as active (transmitter sources the current) when

shipped. To change to the passive mode (receiver to source the current), extract each

small 4-20 board, find the JP1 pins, and move the two jumpers from the “Act” pins to the

“Pass” pins (two positions to the right of factory settings). Figure 8 shows the current

output circuit. Figure 8 also illustrates the active mode and the passive mode

configurations.

4. Refer to Section 4.1 for general information on standard transmitter channel-to-

instrument output mapping. Refer to SECTION 8 - CUSTOM INFORMATION for

transmitter channel-to-instrument 4-20mA outputs mapping.

Figure 7: Optional 4-20mA Transmitter Box

September 2013 14 © Intek, Inc. 2013

Revision D

Page 19

Q1

R1

75 Ohm

R1

75 Ohm

10 Ohm

R2

Q1

Vdd

Terminal

Isolated Circuit Isolated Circuit

from RheoVac Supply

Terminal

Active Configuration Passive Configuration

05026-1

CAUTION: Do not move config.

jumpers if instrument is powered.

RFL2N05

or Equiv.

RFL2N05

or Equiv.

Figure 8: 4-20 mA output circuit

September 2013 15 © Intek, Inc. 2013

Revision D

Page 20

2.2.5 RheoVac MSP and PT Probe Connector Assembly

1"

3/8"

1

2

3

CAUTION — Do not cross thread connection. The probe is supplied with a convenient plugin connector; the male side of the connector is installed in the probe junction box. The female side must

be installed onto the supplied DeviceNet™ type 5711 cable once it is run from the Distribution Box to

the probe. The wiring detail for the female plug-in connector (Turck p/n B4151-0/9) is shown in Figure

9. These connectors will use either the “backshell nut” or “conduit connector” depending on whether the

cable is installed in a liquid-tight conduit. When installing without conduit, use the backshell nut; when

using liquid-tight conduit, use the conduit connector with o-ring.

1. Slide all of the appropriate parts onto the cable as shown.

2. Strip the cable conductors as shown. The connector has 5 retention screws to hold the

wires in place. The use of crimp pins on the wires will greatly increase connection

reliability.

3. Loosen all 5 retention screws (do not completely remove).

4. Insert the wires, in accordance with color-coding shown (see Figure 9, insert).

5. Tighten the retention screws on each wire.

6. Reassemble the connector parts.

Figure 9: Probe connector assembly

September 2013 16 © Intek, Inc. 2013

Revision D

Page 21

2.2.6 Rheotherm CWFF Meters and Temperature Sensors Connections

These instruments are installed by Intek Inc. or under Intek Inc.’s supervision. Special

instructions, where applicable, are provided by Intek (see SECTION 8 - CUSTOM INFORMATION).

Electrical terminations, cable routing diagrams and more are provided in the CMS Installation

Instructions document.

September 2013 17 © Intek, Inc. 2013

Revision D

Page 22

SECTION 3 - USER INTERFACE AND DATA RETRIEVAL

This section presents the standard interface options and typical operations to retrieve data from

the system.

3.1 MENUS

The standard Main Electronics enclosure for the system serves as a SCADA RTU and HMI. The

standard enclosure has a 2x20 alphanumeric display and a 3-button access menu. Larger systems have a

standard LCD display and optional touch screen interfaces. Pressing all three buttons

(Left+Right+Enter) brings up the 3-button menu. The 3-button menu has the following selections:

Compress Data – Compresses data to the USB stick, if present, for data collection and transfer

Change Line Size – Change the line size of connected RheoVac MSPs. Typically, the factory

sets this to the specified line size on the order. If a probe is moved to a different location, the user

must check for line size and re-set this data as needed to ensure accurate measurement.

Shutdown – Provides option to Shutdown or Reboot the system

Cancel – Exit the 3-button menu

3.1.1 Compressing Data (to USB Stick)

The data stored in your CMS can be downloaded to a USB memory device, which is provided in

the instrument’s main electronics enclosure. Intek recommends having this USB stick disconnected from

the main electronics during normal operations. All the data is stored by the instrument on its internal

flash drive. Follow these steps when data needs to be retrieved and stored on the USB memory stick:

1. Insert the USB memory stick in the USB port, as shown. (Figure 10)

Figure 10: USB stick installation

2. On the front panel keypad, press all three buttons (Left+Right+Enter) at the same time and

release. Compress Data is the default selection, alternately, you can use the arrow keys and

Enter to navigate the menu. With Compress Data highlighted as shown in Figure 11 either wait

for the timer to reach zero or press enter to compress the entire CMS folder and save it to the

USB stick. No other user interaction is required. Figure 12 shows the screens that will follow as

data is compressed and copied to the USB memory stick.

September 2013 18 © Intek, Inc. 2013

Revision D

Page 23

LCD

Alphanumeric

LCD

Alphanumeric

Figure 11: 3-Button Menu with Compress Data Highlighted

Figure 12: Compressing and copying screens

3. The file saved to the USB stick is automatically named based on the date of the download. The

above example is shown in Figure 13.

Figure 13: D-drive explorer view of zip file

4. Copy the CMS_(serial number)_(MMDDYY).zip file to a computer for analysis. For data

plotting, tools are available at www.MyCondenser.com. For further support email data and

questions to techsupport@intekflow.com; a service contract or order may be required. The file

may also be uploaded to Intek’s server for review by Intek engineers. See Section 3.2 for

uploading instructions.

September 2013 19 © Intek, Inc. 2013

Revision D

Page 24

3.1.2 Change Line Size (i.e., pipe diameter)

LCD

Alphanumeric

LCD

Alphanumeric

The CMS instruments are configured at the factory for the line size specified. This is shown in

SECTION 8 - CUSTOM INFORMATION. If the probe is moved to a pipe with a different diameter

then it is important to change the line size so that the instrument will adjust the measured velocity and

report the correct volumetric flow rate. This is accomplished using the “Change Line Size” option.

The change line size menu can be accessed through the 3 button menu. Use Left and Right to

scroll through the options until Change Line Size is highlighted as shown in Figure 14. Then either wait

for the timer to expire or press Enter.

Figure 14: 3-Button menu with change line size highlighted

Left or Right - cycle between probes or line sizes depending on which one is selected.

Enter + Left or Enter + Right - switch whether Probes or Line Size is selected.

Left + Right - save and exit.

Left + Right + Enter - exit without saving.

The LCD screen is shown in Figure 15 and the 2x20 alphanumeric Select Probe and Select Line

Size options are shown in Figure 16.

Figure 15: Change line size LCD dialog

Figure 16: Change line size 2x20 alphanumeric menu

September 2013 20 © Intek, Inc. 2013

Revision D

Page 25

3.1.3 Shutdown

The Shutdown command can be accessed through the 3 button menu. Use left and right to scroll

through the options until Shutdown is highlighted. Then either wait for the timer to expire or press

enter. Then select either Shutdown, Reboot, or Cancel by pressing the enter button. A confirmation

message will appear, press enter to accept. If using the LCD, the main application window will close and

system diagnostics will run before the system reboots. If using the 2x20 alphanumeric, the screen will

display Rebooting until the diagnostic software starts. The entire reboot process should take less than

eight minutes to complete.

3.1.4 Cancel

The Cancel command can be accessed through the 3 button menu. Use left and right to scroll

through the options until Cancel is highlighted. Then either wait for the timer to expire or press enter.

Cancel will close the 3-button menu.

September 2013 21 © Intek, Inc. 2013

Revision D

Page 26

3.2 UPLOADING TO INTEK’S SECURE FTP SITE FOR DATA EVALUATION

The following instructions can be used to logon to Intek, Inc.’s Secure File Server to upload or

download software, files, pictures, etc. An account must first be set-up to permit secure file data transfer.

1. Open any internet browser, i.e., Internet Explorer, Mozilla Firefox, Google Chrome, etc. Type

http://sftp.intekflow.com into the address bar and hit enter. The following screens are shown

using Internet Explorer.

2. To access your Private folder, please use the User ID and Password when you registered and

set up your private account. Click the Login button.

3. Click OK at the Welcome screen.

4. To upload a file, click the Upload button at the bottom of the screen.

September 2013 22 © Intek, Inc. 2013

Revision D

Page 27

5. Browse to the file to upload, and then click the Upload button. Click the Close button when

finished.

6. For downloading, highlight (single left click) the file to download and click the Download

button at the bottom of the screen.

7. Click the Save button and select where to store the file.

8. When finished, click the Logout button at the top right of the screen.

September 2013 23 © Intek, Inc. 2013

Revision D

Page 28

SECTION 4 - COMMUNICATION METHODS

Address

Type

Description

20 – 3999

PT

Read 16 bit registers (“input registers”)

4000 – 7999

FM

Read 16 bit registers (“input registers”)

8000 – 11999

TC

Read 16 bit registers (“input registers”)

12000 – 15999

RV

Read 16 bit registers (“input registers”)

16000 – 19999

CC

Read 16 bit registers (“input registers”)

20000 – 23999

MA

Read 16 bit registers (“input registers”)

Address

Variable

Description

24 - 25

Temperature

Temperature measured by the first referenced PT Probe

The CMS system supports Modbus TCP (Modbus over Ethernet), RS232/422 serial Modbus and

OPC communication protocols. Analog 4-20mA outputs can be supplied as an option. Note: Intek

recommends using the network connection for all data transmissions and CMS communications.

4.1 ANALOG OUTPUT

All 4-20 mA output signals are linearly scaled such that 4 mA represents 0% of the rated full

scale value (except temperature, which is 0°C) and 20 mA represents 100% of the rated full scale value

(temperature is 100°C). See SECTION 8 - CUSTOM INFORMATION for custom outputs.

4.2 MODBUS

Modbus is a communication protocol that can be used to read process variables from the CMS

system. This section demonstrates the basics of Modbus communication with the CMS.

Registers - Modbus stores variables in memory locations referred to as registers. Modbus is

capable of storing variables as coils, discrete inputs, input registers, and holding registers. The CMS

conserves memory space by not supporting coils or discrete inputs. This creates more space for holding

and input registers whose type definition fits more closely with the CMS process variables. This

modification does not affect the formation of a Modbus request packet, which is demonstrated in the

packet section. However, if an attempt to poll the removed register banks is made a timeout error will

occur.

Table 2: CMS input registers

CMS process variables are stored as IEEE 751 floating point numbers unless specified otherwise.

Therefore, multiple registers must be used to account for the size of the floating point variables. Modbus

protocol specifies that multiple registers containing floating point values are transmitted with the most

significant byte of the register first.

Table 3: Multiple register example

September 2013 24 © Intek, Inc. 2013

Revision D

Page 29

Basic Function Codes - The Modbus packet structure is determined by the function code being

Function

Hex Code

Read Holding Registers

03

Read Input Registers

04

Read Exception Status

07

Write Multiple Registers

10

Write Holding Register

06

Code

Description

01

Invalid function code – function code not supported by device

02

Invalid data address – address defined by the start address and

number of registers is out of valid range

03

Invalid data value – number of registers = 0 or > 125

Type

Byte Length

Example

Device address

1 Byte (1 – 247)

0x01

Function code

1 Byte (Function code + 0x80)

0x83

Exception code

1 Byte

0x01

performed. Some of the basic commands that CMS supports are shown in Table 4.

Table 4: Modbus function codes

Exception Packet Definition - If an error is detected in one of the following packet definitions a

certain error code is applied and sent back in an exception response.

Table 5: Modbus error codes

Table 6: Modbus exception response

September 2013 25 © Intek, Inc. 2013

Revision D

Page 30

4.2.1 Modbus TCP

IP Layer

IP Header

Trailer

TCP Layer

TCP Header

Trailer

Modbus Layer

Modbus Packet

Modbus TCP is a way to communicate a Modbus packet over Ethernet. CMS implements a class

0 Modbus TCP communication standard. The CMS communicates Modbus TCP using port 502 with a

configurable IP address. Modbus TCP communication can be broken down into three different layers,

IP/Ethernet, TCP, and Modbus Protocol.

Table 7: Communication layers

The IP Header and Trailer dictate what IP address should receive the TCP Layer. The TCP layer

contains which port to establish communication and the transmitted data. The transmitted data is a

standard Modbus packet. There is no need for a slave address or CRC in Modbus TCP because these are

handled by the IP and TCP Layers. Modbus TCP also allows for specification of a unit identifier in the

Modbus Packet. The unit identifier functionality is not supported by CMS and should be defaulted to 1.

Connecting – To connect to the Modbus TCP server open any Modbus TCP client and enter the

IP address of the CMS system. CMS uses the standard Modbus TCP port of 502. Allow at least 5

seconds for the CMS to initialize the Modbus connection. The minimum poll rate supported by CMS is

1 second.

4.2.2 Serial Modbus

4.2.2.1 Modbus server global settings

A number of global settings are used to configure the CMS serial Modbus server. Many of these

settings can be adjusted by the end user to facilitate integration of a CMS with an existing Modbus

network. Table 8 lists the CMS serial Modbus global settings and their default values.

The settings can be modified in two ways: either by modifying a configuration file within the

CMS, (contact Intek for instructions), or by sending a properly formatted Modbus Function 06 message

to write the address listed in Table 8.

Process variables (PVs) for each instrument are produced by the CMS serial Modbus server.

These values take one of the two formats: multiplied integer or single float. The “Conversion Mode”

(Register 0009) setting listed in Table 8 determines the data format used for the PVs. In multiplied

integer mode, the CMS data values are multiplied by a power of ten specified in a set of additional

registers. The resulting values are then transmitted as 16-bit unsigned integers. In single float mode, all

of the data values are converted into a 4-byte hexadecimal string corresponding to their single-precision

float representation.

September 2013 26 © Intek, Inc. 2013

Revision D

Page 31

Table 8: Modbus server global settings

Address

Description

Allowed Values

Default

Format

Read Only?

0001

Restart Modbus Server

Write ‘1’ to restart

0

16-bit unsigned

No

0002

CMS Serial Port

Set to ‘0’ internally by

CMS System

0

16-bit unsigned

Yes

0003

Baud Rate

2400,4800,9600,14400,

19200 bps

9600

16-bit unsigned

No

0004

Data Bits

7 or 8

8

16-bit unsigned

No

0005

Stop Bits

0 = 1 stop bit

1 = 1.5 stop bits

2 – 2 stop bits

2

16-bit unsigned

No

0006

Parity

0 = No Parity

1 = Odd Parity

2 = Even Parity

3 = Mark Parity

4 = Space Parity

0

16-bit unsigned

No

0007

Modbus Address

1 – 255

1

16-bit unsigned

No

0008

Communication Mode

0 = RTU

1 = ASCII

0

16-bit unsigned

No

0009

Conversion Mode

0 = Multiplied Integer

1 = Single Float

1

16-bit unsigned

No

0010

Number of Probes

1 – 255

1

16-bit unsigned

Yes

Address

Description

Allowed Values

Default

Read Only?

8001

Multiplier power for TC1-1

0 – 3

16-bit unsigned

No

12005

Multiplier power for RheoVac MSP Actual Volume Flow

0 – 3

16-bit unsigned

No

12007

Multiplier power for RheoVac MSP Total Mass Flow

0 – 3

16-bit unsigned

No

12009

Multiplier power for RheoVac MSP Water Vapor Flow

0 – 3

16-bit unsigned

No

4.2.2.2 Modbus data settings (Multiplied Integer Mode)

The values listed in Table 9 are examples of how the Modbus server stores “Multiplied Integer”.

“Multiplied Integer” mode can be enabled by writing a “0” to register 09. The address for the multiplier

is the holding register equivalent of the input register parameter it is multiplying. These register values

determine the power of 10 that is used to multiply each parameter (effectively shifting the decimal point)

before it is transmitted as a 16-bit unsigned integer.

Table 9: Modbus example data holding registers

4.2.2.3 Modbus data registers (Multiplied Integer Mode)

When in Multiplied Integer Mode, the CMS data values are multiplied by a power of ten

specified in the registers listed in Table 9. The resulting values are then transmitted as 16-bit unsigned

integers. Each value therefore needs only 1 register (2 bytes) of allocated space. In this mode, the data

registers are allocated in pairs, with each data value followed by the multiplication power corresponding

to it. For example, assuming all multiplier registers are set to 3, the RheoVac MSP Pressure is

transmitted as follows:

RheoVac MSP Pressure (probe reading) = 1.257

Input Register 12011 (RheoVac MSP Pressure) = 1257

Holding Register 12011 (Multiplier Value) = 3

All other instruments can be calculated the same way substituting the correct address in place of

12011. The addresses for each instrument can be found in SECTION 8 - CUSTOM INFORMATION.

September 2013 27 © Intek, Inc. 2013

Revision D

Page 32

4.2.2.4 Modbus data registers (Single Float Mode)

In Single Float mode, all of the data values are converted into the 4-byte, big-endian

hexadecimal string corresponding to their single-precision float representation. The Modbus client

program must be capable of converting these 4-byte values back into single-precision float values. If the

client software is unable to make this conversion, the Multiplied Integer mode must be used. Data in the

Single Float mode is transmitted as follows:

RheoVac Pressure (probe reading) = 1.257

Single-Float Hex Representation = 0x3FA0E560

Input Register 12011 (high word) = 0x3FA0

Input Register 12012 (low word) = 0xE560

The full list of addresses for each MSP probe can be found in SECTION 8 - CUSTOM

INFORMATION.

4.2.3 Modifying the Modbus Configuration File

To modify the configuration file, the CMS must be attached to a local network. Once connected,

Windows Explorer can be used to browse into the CMS similar to a PC. Using the Network ID or IP

(see SECTION 8 - CUSTOM INFORMATION) of the CMS, the Modbus settings file can be found at

the following location:

\\<Network ID or IP of the CMS>\CMS\init\serial.ini

Figure 17 shows a sample serial.ini file. The Modbus settings are listed under the section titled

“[Modbus]”. The multiplied Integer settings can be found in the file MDBSInts.dat. The first column is

the starting register and the second is the power of 10. These values can be changed to fit the needs of

the existing serial Modbus network. Once the changes have been made and the file has been saved in its

current location, the CMS must be rebooted by simultaneously pushing all the keypad buttons to activate

the “Reboot System” function for the changes to take effect.

CAUTION: Modifying any of the other settings in this file could result in undesired behavior.

Figure 17: Sample serial.ini file

September 2013 28 © Intek, Inc. 2013

Revision D

Page 33

4.2.4 Modbus Troubleshooting

Problem

Cause

Solution

No response from CMS

1. System not set for Modbus

communication

2. Incorrect Modbus settings

3. Improper wiring

1. Verify settings in serial.ini file, see Table 8

2. Verify wiring connections

Not enough data

resolution in Multiplied

Integer mode

1. Non-optimal multiplier values set

1. Change the multiplier values in the

MDBSInts.dat file

Multiplier values are

changing

1. The CMS has overflow protection

built in. When [process

variable]*[multiplier value]

exceeds 65535, the instrument

automatically lowers the multiplier

value to retain a usable output.

1. Request the multiplier value along with process

data rather than hard coding the multiplier value

in the client software

2. Lower the multiplier value for each process

variable that reaches the overflow state

3. Use single precision float mode instead of

multiplied integer mode

September 2013 29 © Intek, Inc. 2013

Revision D

Page 34

4.3 OPC – (OLE for Process Control)

FM/12345-1/PV1/Label

Flow

FM/12345-1/PV1/Units

FPS

FM/12345-1/PV1/Value

21.4

CMS is equipped with an OPC data server which can publish its process variables across an

Ethernet network. The CMS software is compliant with OPC version 2.0. When using OPC we

recommend the use of a NTP network time server to ensure the CMS time is synchronized with the

client system.

4.3.1 Connecting

The following information can be used to connect and view the process variables using an OPC

Client. Please be sure to properly configure any firewall to allow OPC communication.

OPC Server Name = OPC_Intek-exe

Remote Machine Name = <CMS IP> or <CMS Network Name>

Client DCOM Settings

Authentication Level: None

Impersonation Level: Identify

Security: Default

4.3.2 Adding Process Variables

Once connected to the CMS system there will be a tree view of the available process variables

organized by instrument type. Select or expand the type of instrument you would like to view outputs

from (FM, PT, RV, TC, MA, etc). Then select or expand the specific instrument you would like to

monitor. Each instrument contains at least one process variable denoted by PV#. PV# will then have a

series of sub values either Label, Units, and/or Value depending on the instrument type. These sub

values can be added to a group or viewed individually to get the current outputs of the desired

instrument. Other variable options are available and vary by client. Please consult your OPC client

manual for more specific settings.

A flow meter (FM) outputs two process variables marked as PV1 and PV2. An example to view

the current information for PV1 flow meter 12345-1 is shown in Table 10. A complete list of all OPC

published variables can be found in SECTION 8 - CUSTOM INFORMATION.

Table 10: Process variable example

September 2013 30 © Intek, Inc. 2013

Revision D

Page 35

SECTION 5 - TROUBLESHOOTING

MESSAGE CODE

Description/Symptom

PROBABLE CAUSE

ACTION

OUTPUT ERROR

CODES

Global Message Codes

MSG-0

Communications not

being received from

probe(s)

1. Improper cable hookup

2. Blown main fuse

3. Failed RS-485 circuit

4. Damaged flow sensor

1. Verify plug-in connector is

properly mated

2. Check F1 fuse on probe board

3. Check all cable connections

4. Contact factory

-99

MSG-1

Invalid data received

from probe(s)

1. Failed RS-485

communications component

1. Check wiring

2. Contact factory

N/A

RheoVac MSP Messages Codes

MSG-2

Flow sensor heater

“OFF”

1. Blown heater fuse

2. Failed electronic component

1. Contact factory

N/A

MSG-3

RS sensor power

“OFF”

1. Probe temperature too high

2. Liquid water on probe tips

1. Check that probe temperature is

<160°F

2. Contact factory

N/A

MSG-4

RS heater “OFF”

1. Component failure

1. Contact factory

N/A

MSG-5

Circuit issue

1. Problem with circuitry

1. Contact factory

N/A

MSG-6

Temperature alarm

(above 210°F/99°C)

1. Steam in exhaust pipe

1. Remove probe or cool line

ASAP!

2. Once line has cooled down and

probe is reinstalled, check unit

for proper function

N/A

MSG-7

Wet probe

1. Liquid water on probe tip

1. Remove probe ASAP!

2. Contact factory

N/A

MSG-8

RS sensor problem

1. RS sensor problem

1. Remove from line, allow 24 hrs

with power on to dry out RS

sensor, reinsert probe

2. Contact factory

N/A

MSG-9 or (CalX)

Calibration expired

1. Probe calibration is expired

1. Contact factory for recalibration

N/A

Mass flow output

saturates high, will not

respond to flow changes

1. Flow rate is not within range

of calibration

2. Blown heater fuse

3. Failed electronic component

1. Contact factory about re-ranging

instrument

2. Contact factory

N/A

Mass flow output

saturates low, will not

respond to flow changes

1. Flow rate is not within range

of calibration

2. Failed electronic component

1. Contact factory about re-ranging

instrument

2. Contact factory

N/A

The CMS will identify problems by alternately flashing a message code and the serial number of

the instrument affected. Table 11 provides a guide to identify causes of problems and determine

appropriate actions to resolve the observed problems. If problems are encountered and factory assistance

is desired, please contact the factory.

Table 11: Troubleshooting/message code guide (diagnostic messages)

September 2013 31 © Intek, Inc. 2013

Revision D

Page 36

MESSAGE CODE

Description/Symptom

PROBABLE CAUSE

ACTION

OUTPUT ERROR

CODES

PT Probe Message Codes

MSG-2

Reserved

MSG-3

Reserved

MSG-4

Reserved

MSG-5 or (CalX)

Calibration Expired

1. Probe Calibration Expired

1. Contact factory for

Recalibration

N/A

Flow Meter Message Codes

MSG-2

Reserved

MSG-3

Reserved

MSG-4

Reserved

MSG-5

Sensor Issue

1. No sensor communication

2. Irregular sensor data

1. Contact factory

-101

Thermocouple Message Codes

Open

TC Circuit Open

1. Loose connection

2. Broken wire

1. Check wiring at the electronics

2. Contact factory

-500

Under

TC Value Under Range

1. Temperature below 32°F

1. Contact factory

-501

Over

TC Value Over Range

1. Temperature above 212°F

1. Contact factory

-502

Error

General Error

1. Loose connection

2. Component failure

1. Check wiring at the electronics

2. Contact factory

-504

MA (4-20mA DAQ) Message Codes

Open

MA Circuit Open

1. Loose connection

2. Broken wire

1. Check wiring at the electronics

2. Contact factory

-500

Under

MA Value Under Range

1. Output below range

1. Contact factory

-501

Over

MA Value Over Range

1. Output above range

2. Contact factory

-502

Error

General Error

1. Loose connection

2. Component failure

1. Check wiring at the electronics

2. Contact factory

-504

September 2013 32 © Intek, Inc. 2013

Revision D

Page 37

5.1 COMMON ISSUES

Modbus/OPC client loses communication on/after midnight

The CMS system is designed to perform an automatic daily maintenance reboot. It takes

approximately 5-8 minutes for the system to return to normal operation. We recommend that digital

communication clients use an extended timeout value of 8 minutes or greater to prevent midnight reboot

timeouts.

Modbus/OPC data is not updating

The digital outputs update once every minute. Requesting data faster than one minute will result

in duplicate data points. Intek recommends setting the poll or scan rate of data acquisition system to one

minute.

September 2013 33 © Intek, Inc. 2013

Revision D

Page 38

SECTION 6 - MAINTENANCE GUIDE

This section provides a guide for typical operations interaction with the components of the CMS.

6.1 WATERBOX INSTRUMENTS

Intek recommends, at a minimum, annual inspection of the CWFF meter IDs and integrity

of the coatings. CMS instruments are installed into cooling water systems that have widely varying

debris controls and water chemistry controls. It is important to schedule maintenance inspections of the

CWFF meter IDs and integrity of the coatings. It may be convenient to conduct these inspections at the

same time as regular waterbox cleanings.

The CWFF meters should be cleaned during each waterbox cleaning. A wet standard bottle brush

can be used to remove mud and dirt. If scale is present then acetic acid (vinegar) can be used with the

bottle brush to remove the scale. Thoroughly flush with fresh water after cleaning, do not allow acetic

acid to remain in tubes. Never use abrasive tools to clean the meters.

If repair of coating/recoating is necessary, ensure that the surface to be coated is thoroughly

cleaned using appropriate means for removing dirt, grease and debris in accordance with coating

manufacturer’s recommendations. Apply repair coating in accordance with manufacturer’s

recommendations.

Intek offers services to repair, recoat and clean waterbox instruments.

6.2 CALIBRATION

All instruments are calibrated at the factory using NIST traceable standards. The waterbox

sensors can be checked in the field and adjusted with factory equipment. RheoVac vent line condenser

and air in-leak monitors can only be calibrated at the factory. Recommended recalibration schedule is

every 2 years for all instruments. The CMS user interface and calibration files can be updated via

uploads from a USB memory device. Contact the factory for details at (614) 895-0301 or

techsupport@intekflow.com.

6.3 SOFTWARE UPDATES

CMS systems are custom configured for the end user’s system and intended purpose. Display

changes, computation changes, calibration updates and general software updates are readily

accomplished using USB file transfers. For specific instructions along with software updates, contact the

factory for details at (614) 895-0301 or techsupport@intekflow.com.

6.4 ADDING/REPLACING SENSORS/INSTRUMENTS

The CMS delivers 24V to power instrument electronics and RS-485 for instrument

communication. Flow, pressure, temperature, humidity/dew point and multi-sensor instruments can be

added to the system if desired. Contact the factory for specifics at (614) 895-0301, or

sales@intekflow.com.

September 2013 34 © Intek, Inc. 2013

Revision D

Page 39

SECTION 7 - CUSTOMER SERVICE

Intek’s corporate philosophy is to help solve our customers’ difficult flow measurement

problems. When you purchase a CMS system you also receive Intek’s dedicated customer service. For

sales or product service, call your local representative or Intek directly at (614) 895-0301 8AM to 5PM

EST/EDT weekdays or fax us anytime at (614) 895-0319. E-mail inquiries should be sent to

sales@intekflow.com or techsupport@intekflow.com. Our customer service staff will provide assistance

promptly. To allow us to help you more efficiently, please have the complete serial number of the

equipment available.

7.1 TROUBLESHOOTING

If you have reviewed SECTION 5 TROUBLESHOOTING and have questions, please call our

experienced engineers for assistance. In many cases we can solve a problem over the phone. Please

provide as complete a description as possible of the problems encountered.

7.2 FACTORY AND FIELD SERVICE

If you request field service to help with condenser performance problems, Intek has, for a fee,

experienced engineers who can be assigned to meet your needs. For CMS instrument related questions,

if a problem cannot be solved over the phone, with your help, we will help you to determine if factory

service or field service will be the best solution.

To request factory service on your instrument, a Return Material Authorization (RMA) and

purchase order is required. Our customer service staff will assist you with the required information to

return equipment for service. Use reasonable care in handling the RheoVac and PT probes. Do not bend

the probes, damage the tips, or obstruct the sensing ports. If moving the unit, make sure the probe is

adequately protected from foreign objects and damage during handling. When returning

instruments/probes for factory service, be sure to carefully pack the instrument/electronics; extra care

should be taken to protect the probes from damage in shipment. When possible, use the factory supplied

PVC probe protection tube and custom shipping box for MSP and PT probes.

7.3 CONSULTING SERVICES

Intek has developed unique solutions for plants experiencing problems with dissolved oxygen,

heat rate and excessive backpressure. We provide comprehensive condenser diagnostic and analysis

services. Plant and CMS data can be transmitted to Intek for analysis and results are provided via

electronic means or hard copy reports. Please call us to discuss your observations, concerns, and needs.

Intek has many years of experience helping customers solve their complex condenser problems.

Intek's monitoring services ensure plants have expert assistance with collecting, interpreting, and

reporting on condenser operations. In many cases, excess backpressure problems can be predicted before

they have a limiting effect on power production. Contact your Intek sales team for a quotation to meet

your specific needs, sales@intekflow.com.

For information on Intek’s power plant instruments and services, such as a new CMS system,

liquid or gas flow meter or flow switches, circulating water flow and fouling meters or condenser

inspection, analysis, or monitoring services, contact the Intek technical sales department by

phone/fax/email. Our staff will be pleased to answer all questions and provide information on our

recommended solutions, instruments, or services, sales@intekflow.com.

September 2013 35 © Intek, Inc. 2013

Revision D

Page 40

7.4 CONDENSER MANAGEMENT AND RheoVac/CMS TRAINING

Intek conducts Condenser Operations and Management workshops to educate professionals on

RheoVac and Rheotherm instrumentation as well as condenser operations and fundamentals. At these

workshops, degraded condenser performance is discussed including root cause analysis for poor

performance and condensate chemistry issues. Approaches to diagnose problems and develop solutions

are presented and discussed.

Several training tools and reference materials can be found on our website,

www.MyCondenser.com. Tutorials can be found in the help menu, included are presentations on

condenser theory, instrumentation, case studies, and services offered by Intek. Posted case studies show

events and conditions captured by the RheoVac MSP condenser monitoring instruments and how the

instrument helped troubleshoot or solve upset conditions. Case studies include information on pump

issues, air in-leakage events, steam jet air ejector problems, and general condenser performance

troubleshooting. Case studies captured by the Rheotherm Circulating Water Flow and Fouling Meters

are also presented and discussed. Macrofouling, thermal stratification, circulating water pump

degradation, and identification of condenser design deficiencies are highlighted.

September 2013 36 © Intek, Inc. 2013

Revision D

Page 41

SECTION 8 - CUSTOM INFORMATION

This section contains information unique to the system delivered to the customer. It contains a

record of the system components, information important to the installation of equipment and setup of

data communication.

8.1 UNIT IDENTIFICATION AND CONFIGURATION

Model no.:

Serial no.:

Customer identification:

The marked (X) items denote the configuration of this unit as originally shipped from the factory.

Input Power: 100-250 VAC, 50/60 Hz

Outputs:

Digital: Ethernet Modbus

Serial Modbus

OPC

Time Server IP:

Analog: 4-20mA Output (see Section 4.1)

Wireless: WiFi Transmitter

Tablet HMI: CMS Manual and condenser documents in:

(See tablet manual for special information and instructions)

Data Access:

Ethernet Network ID:

Ethernet IP:

Portable Data Storage: Portable USB Data Storage Device

Enclosures: Cables:

Main Electronics Box: DeviceNet 5711 Cable (RS485):

Satellite Electronics Box: Cat5 Ethernet X-Over Cable - 10 ft

Distribution Box:

4-20mA Transmitter Box:

Ball Valve Assemblies: 1 ½" ball valve assembly:

Software: Windows OS; CMS system software version :

Summary of instruments included in this system:

Rheotherm CWFF: Tube size: Sch:

RheoVac Multi-Sensor Probes: Pipe size: Sch:

PT Probes:

Temperature Instruments:

MA Instruments:

P Instruments:

Other:

September 2013 37 © Intek, Inc. 2013

Revision D

Page 42

8.2 SPECIAL INFORMATION

Below is a list of special information, attached to this document, which is relevant to customer

specific equipment.

System configuration/layout recommendations

High temperature RheoVac MSP installation instructions

Wireless tablet manual

Special information included

MODBUS register definition, example value(s) and units list

OPC register definition, example value(s) and units list

4-20mA channel definition, example value(s) and units list

Drawings of custom enclosures

Custom system wiring diagrams

Important Information has been reviewed with the customer and is included in this manual.

Engineering: Date:

Sales: Date:

September 2013 38 © Intek, Inc. 2013

Revision D

Loading...

Loading...