Page 1

TABLE OF CONTENTS

SECTION 1 GENERAL INFORMATION ....................................... - 1 -

1.1 INTRODUCTION ................................................. - 1 -

1.2 PRINCIPLE OF OPERATION ....................................... - 2 -

1.3 TECHNICAL SPECIFICATIONS .................................... - 2 -

1.4 PRECAUTIONS .................................................. - 2 -

SECTION 2 INSTALLATION ................................................ - 4 -

2.1 INSTALLATION ................................................. - 4 -

2.2 RheoVac SYSTEM INSTALLATION/SITE SELECTION ................. - 4 -

2.2.1 Probe Site Selection .......................................... - 4 -

2.2.2 Electronics Unit Site Selection ................................. - 5 -

2.3 MOUNTING HARDWARE INSTALLATION .......................... - 6 -

2.4 PROBE INSTALLATION AND ORIENTATION ........................ - 6 -

2.5 ELECTRICAL CONNECTIONS ..................................... - 8 -

SECTION 3 OPERATION .................................................. - 14 -

3.1 GENERAL INFORMATION ....................................... - 14 -

3.2 SYSTEM START-UP ............................................. - 14 -

3.3 PORTABLE USB DATA STORAGE DEVICE/Warranty ................. - 14 -

3.4 DISPLAY ....................................................... - 15 -

3.5 COMMUNICATIONS ............................................ - 15 -

3.6 DATA PROCESSING ............................................. - 16 -

3.7 CUSTOM SOFTWARE ........................................... - 17 -

SECTION 4 MAINTENANCE .............................................. - 18 -

4.1 GENERAL MAINTENANCE ....................................... - 18 -

4.2 CALIBRATION ................................................. - 18 -

4.3 SPARE PARTS .................................................. - 18 -

4.4 TROUBLESHOOTING ............................................ - 18 -

4.5 HARDWARE AND SOFTWARE MODIFICATIONS AND UPGRADES . . . - 20 -

SECTION 5 CUSTOMER SERVICE ......................................... - 21 -

5.1 QUESTIONS ON EXISTING HARDWARE ........................... - 21 -

5.2 TROUBLESHOOTING ............................................ - 21 -

5.3 FACTORY AND FIELD SERVICE .................................. - 21 -

5.4 QUESTIONS ON NEW EQUIPMENT ............................... - 21 -

5.5 CONDENSER SERVICES ......................................... - 21 -

SECTION 6 CUSTOM INFORMATION ...................................... - 22 -

6.1 UNIT IDENTIFICATION .......................................... - 22 -

6.2 CONFIGURATION ............................................... - 22 -

6.3 SPECIAL INSTRUCTIONS ........................................ - 22 -

Appendix A - RheoVac Model 950 User Interface Software

Appendix B - RheoVac Model 950 Networking

Intek, Inc. 2007

Manu al no. RV950 Rev. D

I:\OFFICE\WPMANU AL\RV950 Rev D.wpd

Page 2

WARRANTY

Intek, Inc. warrants each RheoVac product to be free from defects in

material and workmanship under normal use and service, Intek's

obligation under this warranty being limited to making good any part or

parts thereof which shall, within one (1) year after delivery of such

product to the original purchaser, be returned to Intek with transportation

charges prepaid and which Intek's examination shall disclose to its

satisfaction to have been thus defective; this warranty being expressly in

lieu of all other warranties, express or implied and all other obligation or

liabilities on Intek's part. The purchaser will assume all responsibility

and expense for removal, decontamination and reinstallation of

equipment.

RheoVac instruments are manufactured under United States patent numbers

4,255,968, 5,485,754, 5,752,411 and 6,526,755. Intek, Rheotherm, Rheovec,

Rheomax, RheoVac and RheoSmart are registered trademarks of Intek, Inc.

Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

Intek, Inc.

751 Intek Way

Westerville, Ohio 43082-9057

Phone (614) 895-0301 Fax (614) 895-0319

web site www.intekflow.com

e-mail techsupport@intekflow.com

Page 3

SECTION 1 — GENERAL INFORMATION

1.1 INTRODUCTION

For the first time, all necessary properties of the gases in the condenser exhauster line are directly

measured to provide an accurate determination of air in-leakage and condenser performance related

parameters. These properties are measured to provide the power industry with the most advantageous

and complete product for condenser system diagnostics:

the RheoVac®System*

*USPNs 4,255,648; 5,485,754; 5,752,411; 6,526,755

A model 950 RheoVac system consists of one, two or three probes reporting to a central signal

conditioner and processor unit. The sensing probe, consisting of multiple sensors configured in a single

probe head, is installed in the vacuum line between the condenser and the exhauster. The RheoVac

system is superior to all other methods in that it makes no assumptions about the dynamic condenser and

vacuum line environment. The sensor head employs the patented Rheotherm

an accurate mass flow measurement. Additionally, temperature, pressure and water vapor relative

saturation measurements are made using a high accuracy platinum resistance temperature detector

(RTD), a strain gauge pressure sensor and a specially configured and calibrated water vapor saturation

sensor.

®

technology to provide

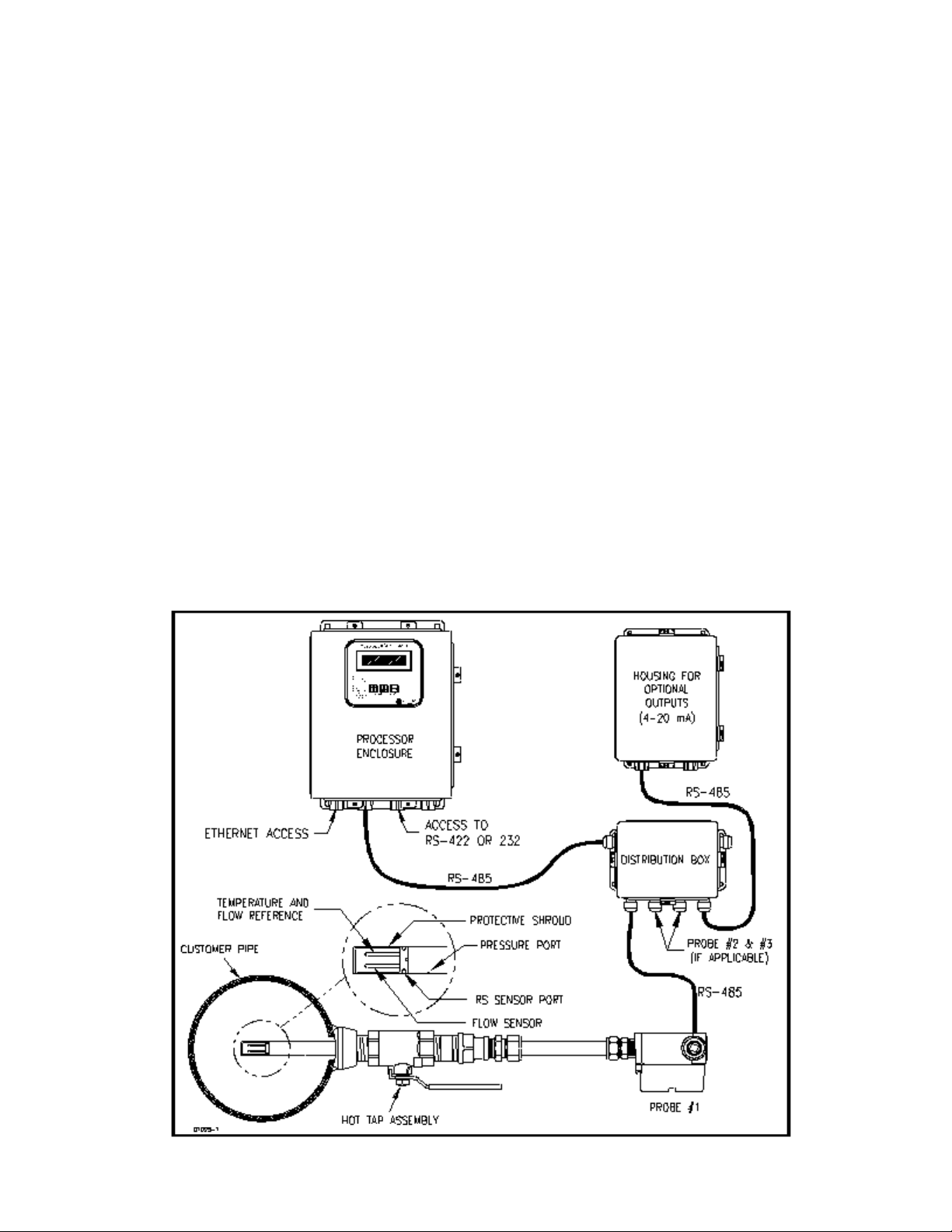

Figure 1 RheoVac Model 950

- 1 -

Page 4

1.2 PRINCIPLE OF OPERATION

The principal features of the RheoVac system are shown in Figure 1. At the heart of the RheoVac

system is the Rheotherm mass flow transducer, which uses the same patented thermal sensing technique

employed in all precision flow instruments manufactured by Intek. Two temperature sensors are used

one sensor is in thermal equilibrium with the flow medium and provides a temperature and flow signal

reference, while the second sensor is located near a constant power heater so that its temperature is

always above that of the fluid. The temperature of the heated sensor will vary with the stream velocity

of the fluid. Hence, the measured temperature differential between the reference sensor and heated

sensor is a function of flow rate, which is approximately proportional to the logarithm of mass flow rate

(USPN 4,255,968).

The Rheotherm flow sensor is calibrated to measure the total mass flow of the gaseous water vapor/air

mixture. From the other three measurements, the RheoVac electronics converts the total gas mass flow

signal from the probe into two components, air mass flow rate and water vapor mass flow rate. This

unique measurement method is disclosed in two separate patents (USPN 5,485,754 & 5,752,411).

The RheoVac system is fully calibrated in the factory under dynamic fluid conditions identical to those

within the power plant vacuum line. No field adjustments are required.

1.3 TECHNICAL SPECIFICATIONS

Primary Calibration Accuracy:

±5% Total Mass Flow

Repeatability:

±0.5% of reading

Operating Temperature:

Electronics: 40 to 120°F (5 to 49°C)

Probe: 40 to 160°F (5 to 71°C)

Never subject probe to temperatures

above 210°F (99°C)

Operating Pressure:

0.5 to 30 inches Hg absolute

15 psi maximum

Process Connection:

Hot tap assembly

(1½” thread-o-let must be welded to

pipe for hot tap installation)

Wetted Surface:

300 Series SS and engineered plastic

1.4 PRECAUTIONS

Read the entire manual before installing and operating the RheoVac system.

Local Display:

Back-lit LCD

Selectable display of air in-leakage and 6

of the other output parameters

Input Power:

100-250 Vac, 50/60 Hz

Signal Output:

RS-232/RS-422/Serial Modbus, Ethernet

Eight 4-20mA signals (optional)

Data Access:

Ethernet

Storage Temperature:

!20 to 120°F (-29 to 49°C)

Storage Pressure:

15 psig (maximum)

Local Keypad:

Parameter scrolling

Metric/English units

Carefully select the best locations for installation of the probes. Access, installation clearances,

freedom from standing water, and straight-run should all be considered when selecting a probe

location.

- 2 -

Page 5

Use reasonable care in handling the probe the sensing components are delicate. Do not

bend the probes, damage the tips, or obstruct the sensing ports. If shipping the unit, make sure

the probe is adequately protected from foreign objects and damage.

Use proper input power it must be between 100 and 250 Vac (nominal 120/240 Vac) at

50/60 Hz (60 Hz nominal).

Confirm the line and environmental temperature is always below the probe and electronics

ratings never operate a probe at or subject it to temperatures or pressures beyond its

specified limits. (See Section 1.3)

.. WARNING - Never allow live high temperature steam to flow either direction in the

exhauster line where a probe is located. This can happen if steam jet ejectors are

operated incorrectly.

.. WARNING - Do not allow the instrument’s RS sensor (or separate RS probe) to come

into contact with liquid water, water mist, or fog – these conditions may be present in

your condenser vent line due to design configuration. The RS sensor measures relative

saturation up to 100% but may fail under the above wet condition. Intek provides design

services to improve condenser venting and reduce or eliminate entrained liquid water and

excess condenser back pressure.

Keep moisture out of the enclosures once all service connections are made, make sure the

enclosure lids are tightly closed and all gaskets are in place. Seal all conduit lines.

.. WARNING - Be sure to power up your RheoVac instrument system and probe(s) for

at least 30 minutes before inserting probes into the vent line hot taps. DO NOT leave

probe in vent line unpowered or when flooding the condenser.

- 3 -

Page 6

SECTION 2 — INSTALLATION

2.1 INSTALLATION

These instructions cover installation of RheoVac instruments in their standard configuration. Additional

information pertaining to your unit is covered in SECTION 6 CUSTOM INFORMATION . Carefully

read these instructions prior to installing the equipment. Also, see preceding SECTION 1.4.

2.2 RheoVac SYSTEM INSTALLATION/SITE SELECTION

The RheoVac 950 can be configured with one, two or three probes. A three probe system is intended

to be installed so that one probe is in each of the two exhaust lines coming out of the condenser (A side

and B side). The third probe should go in the header pipe that runs to the exhauster(s). Other

installation arrangements of multiple probes should be discussed with the factory.

2.2.1 Probe Site Selection

# The location for each probe should provide the probe sensing area with well-established

smooth flow, uniform system temperature and pressure, and consistent non-liquid phase flow

medium. Pipe sections ahead of a probe, in which water can accumulate, must be avoided.

Refer to Figure 2 and select the most preferred location for each probe. Do not install the

probes beyond any “trap” sections as shown in Figure 2, Configurations B and D. Special

installation instructions unique to your unit, where applicable, will be noted in SECTION

6.3 SPECIAL INSTRUCTIONS. Refer to this section now to review special instructions.

Figure 2 RheoVac Probe Insertion Recommendation

- 4 -

Page 7

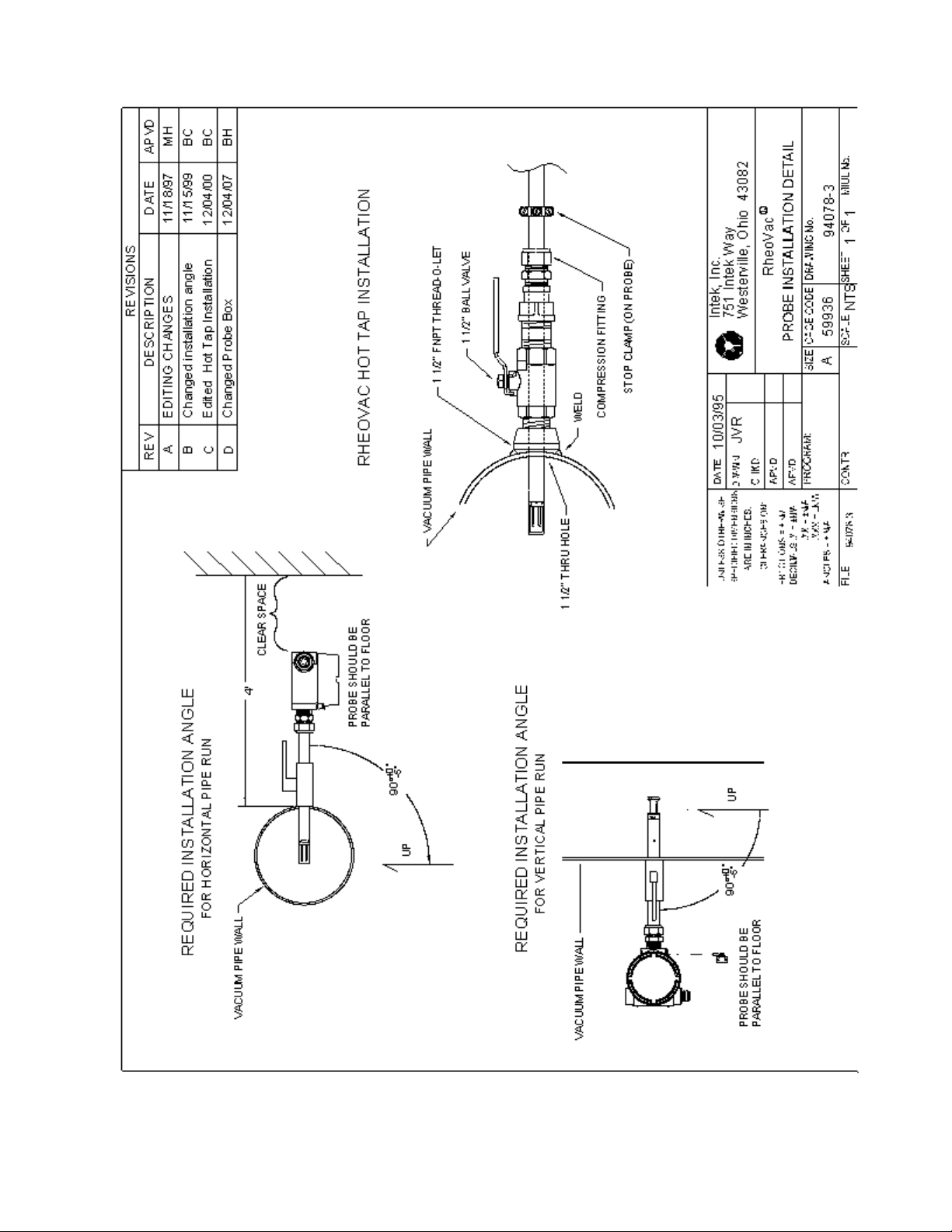

# Check installation clearance. Each transducer probe is almost 3 feet (0.9m) long and the hot

tap assembly is approximately 13 inches (0.33m) long, therefore, allow minimum clearance

of 4 feet (1.3m) for probe installation. Be sure there are no obstructions around the vacuum

line that will interfere with probe insertion. Figure 3 shows the proper insertion angle. THIS

ORIENTATION IS IMPORTANT FOR PROPER OPERATION.

# Observe the selected sites. They should be convenient for the removal and replacement of

probes at any time for service without building scaffolding or waiting for plant shutdown.

# Check operating conditions. The temperature and pressure limits (see Technical

Specifications; Section 1.3) of the unit should be checked to ensure compatibility with your

application.

# Gases in the air removal line should be free of liquid water, mist or fog. Wetness in the line

will result in erroneous readings from the instrument. If wet conditions exist in the air

removal line, there is either air removal section damage or design flaws which adversely

affect condenser performance. Consult Intek for assistance in evaluating the severity of the

problem and possible remedies.

2.2.2 Electronics Unit Site Selection

The Model 950 typically has two or three electronics enclosures (see Figure 1). The processor

enclosure and other electronics boxes should be installed in a convenient location and should be

kept away from direct sources of heat, such as uninsulated steam lines, or moisture. The

maximum temperature rating of electronics is 120°F; ensure that this temperature will not be

exceeded. Once the wiring connections are made, close and latch down the box lid to protect the

contents from damage and debris. All these enclosures should be located in a dry area and should

be kept clamped shut during normal operation. Do not allow water to get into the enclosures. If

installed outdoors, build a roof over all enclosures to prevent eventual water infiltration.

A. Processor Enclosure: This 12x10 NEMA 4 enclosure houses the display and central

processing unit. Input power (100-250 Vac, 50/60 Hz) is connected inside this enclosure.

This enclosure should be installed in a convenient location and should be kept away from

direct sources of high heat, such as uninsulated steam lines.

B. Distribution Box: This 8x6 NEMA 4 enclosure is typically located near the probe that is

closest to the processor enclosure unit. It is connected to the main processor with an RS-485

bus DeviceNet™ cable, which can be hundreds of feet long. The probe and transmitter RS485 cable connections are also made within this box. The probe and transmitter cable

lengths should be 15 ft. or less, if possible.

C. Transmitter Box (optional): This 10x8 NEMA 4 enclosure contains terminals for accessing

the eight 4-20mA signals. It can be located in or near the control room so that the 4-20 wires

do not have to be run from the plant floor. An RS-485 DeviceNet cable runs from the

distribution box to the transmitter box. (There are restrictions on how this can be done, so

check manual Section 6, or contact the factory.)

- 5 -

Page 8

2.3 MOUNTING HARDWARE INSTALLATION

Î Check hardware. Verify that the probe slides through the hot tap assembly.

Ï Check installation configuration. Make sure the probe is parallel to the floor (see Figure 4).

Be sure location is accessible for probe removal and maintenance.

Ð Check installation clearance. Verify there is a minimum probe insertion clearance of 4 feet

(1.3m) between pipe surface and any obstruction.

Ñ Install the mounting hardware. Drill a 1½” through-hole, center the thread-o-let over the

hole and weld it onto the condenser vacuum pipe (see Figure 4). Thread the hot-tap

assembly into the thread-o-let. Use thread tape or pipe dope to seal the connection.

(Alternate: weld thread-o-let to pipe wall, then drill a 1¼" hole in pipe wall using a hot-tap

drill.)

Ò It may be necessary to apply a force of about 23 lb (102 Newtons) to remove or replace the

probe under plant operating conditions.

2.4 PROBE INSTALLATION AND ORIENTATION

Î Check proper installation direction. Each probe has a directional

arrow on the junction box. Before installing the unit, note proper

flow direction. This is important to instrument operation.

Ï Check serial number (S/N). If more than one RheoVac unit has been

purchased, make sure the first five digits of the serial numbers of the

probe(s) match the first five digits of the serial number of the main

processor unit. The electronics and up to three probes are a matched

set. Mismatched components will not work correctly. The dash

number on the probe S/N is the probe number shown on the display.

Record the probe number and installation location for future

reference.

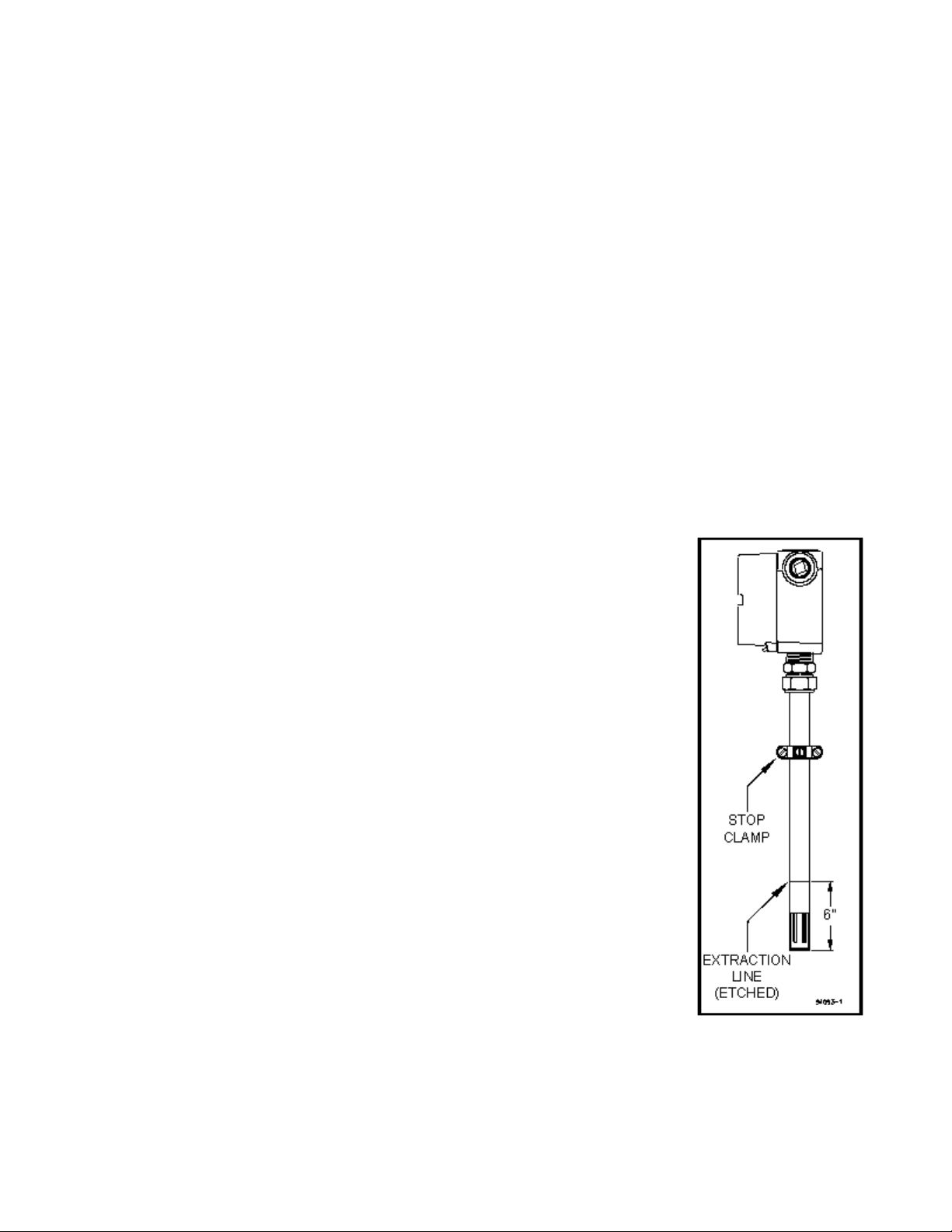

Ð Verify stop clamp location (see Figure 3). A stop clamp is attached

to each probe as an indication of its insertion depth. It is important

that the stop clamp is securely in place to position the sensors in the

correct location and to ensure that the probes do not contact the

opposite pipe wall. Contact with the pipe wall could damage the

probe. The clamp’s location was determined based on your

submitted pipe diameter, as shown in SECTION 6.2, and is marked

with a groove on each probe shaft. Refer to this mark if a stop clamp

is inadvertently moved. The two metal probe tips should be in the

middle of the pipe.

Figure 3

Probe Stop Clamp

- 6 -

Page 9

Figure 4 Transducer Installation Detail

- 7 -

Page 10

Ñ Inspect the probe tips. Be sure wetted surfaces are clean before installing. If cleaning is

needed, use a damp cloth wetted with alcohol and wipe dry using a second dry, soft, lint-free

cloth. Do not immerse probes in alcohol or any other liquids. This may damage the probe

sensors.

Ò Be sure to power up your RheoVac instrument system and probe(s) for at least 30 minutes

before inserting probes into the vent line hot taps. DO NOT leave probe in vent line

unpowered or when flooding the condenser.

Ó Install each probe. The probe should be mounted through the pipe wall using the hot-tap

assembly. The probe installs so that the two sensor tips are side-by-side across the gas stream.

The probes have a flow directional arrow on the junction box. When installing under vacuum,

do not allow the clamp to "slam" against the seal nut upon opening the valve. Grasp the probe

firmly, with hand against the seal nut, before opening the ball valve. Allow the probe shaft to

slide slowly through the valve by controlling the amount of grip on the probe shaft. Special

installation instructions, if any, will be noted in SECTION 6.

Ô Prior to inserting probe, loosen the compression nut on the thermocouple connector of the hot

tap and clean the inner surface of the thermocouple connector to ensure it is free of particles

that may cause probe damage.

2.5 ELECTRICAL CONNECTIONS

. IMPORTANT . Inspect and VERIFY these electrical connections carefully. Improper

connection could damage electronic components and sensor function. If additional holes need to

be drilledin the processor enclosure, remove the electronicssubassembly (mounted ona mounting

plate) and temporarily store inside an ESD bag in a safe, clean place. Do not drill with electronics

boards inside the enclosure.

A. Main Processor Unit (see Figure 5)

1. Sensor Power and Communication Line

box using the RS-485 Communications/Power cable. Follow indicated connector color code.

[communications

2. Main Power

circuit. An external disconnect switch should be used for disconnecting power to the

: white (A), blue (B) and shield (SH); power: 24Vdc, red (+), and black (!)]

: Connect main power terminals to a dedicated 100-250Vac, single phase, 15 amp

: Connect the distribution box to this main processor

system during outages. Power connection wires should be at least 18 gauge and comply with

accepted wiring codes. SW1 is used for cycling power to reset.

3. Serial Communication

: Connector JP3 is the RS-232 serial communication interface. This

interface should only be used for distances of 20 feet or less, such as to a laptop computer. A

20 foot serial cable with a DB-9 connector can be shipped upon request (see Figure 9 and

Table I below). An RS-422 serial communication interface is present for long data

communications when configured without 4-20 mA outputs.

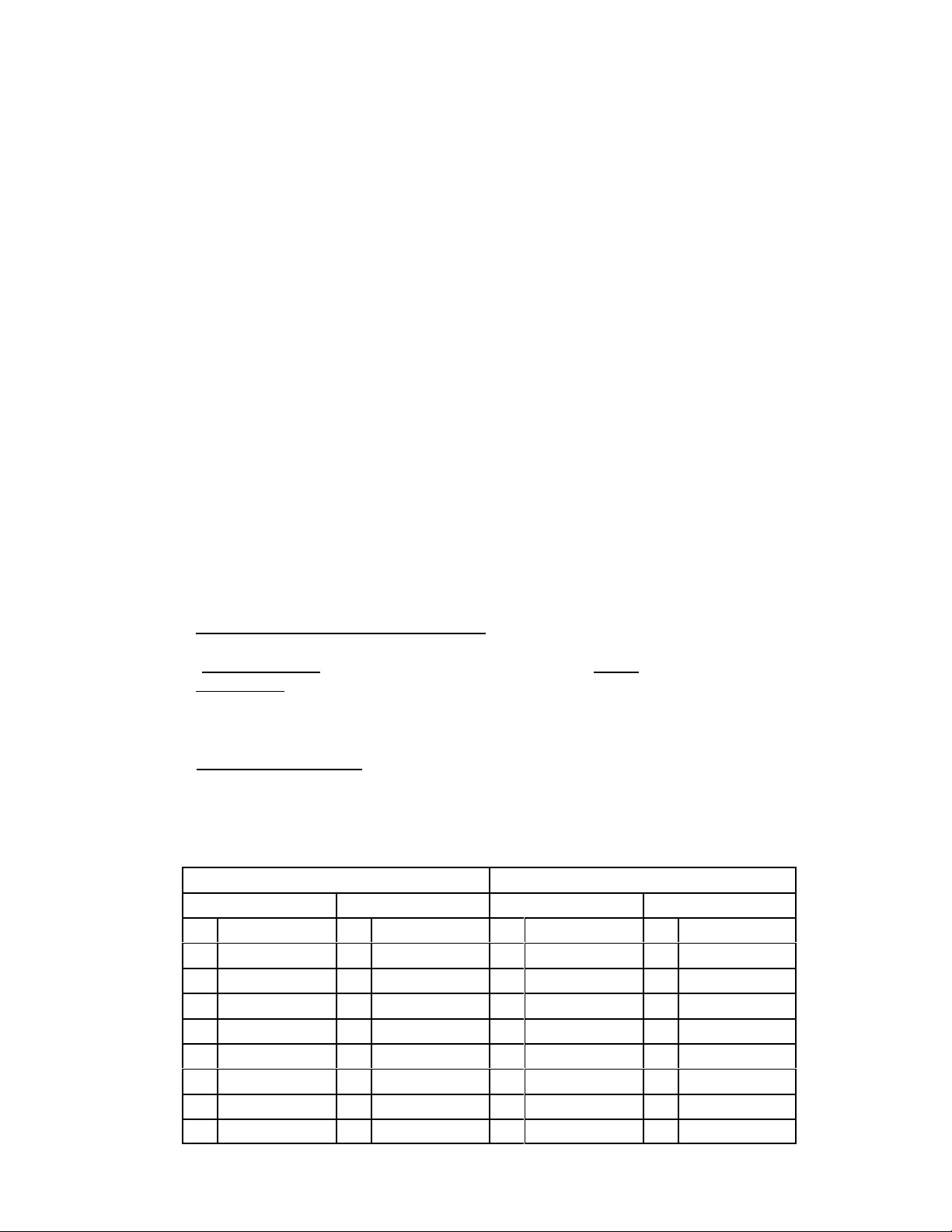

Table I RJ-11 to DB-9 Module Adapter

RS-232 CONFIGURATION RS-422 CONFIGURATION

RJ-11 Pin Out DB-9 Pin Out RJ-11 Pin Out DB-9 Pin Out

1 Tx (transmit) 1 N/C 1 Tx+ (transmit+) 1 Rx

2 N/C 2 Tx (transmit) 2 TxS (transmitS) 2 Rx+ (receive+)

3 Rx (receive) 3 Rx (receive) 3 Rx+ (receive+) 3 Tx+ (transmit+)

4 N/C 4 N/C 4 RxS (receiveS) 4 N/C

5 Power (+5V) 5 Ground 5 Power (+5V) 5 Ground

6 Ground 6 Pulled high 6 Ground 6 Tx

7 N/C 7 7 TBD

8 Pulled high 8 8 TBD

9 N/C 9 9 TBD

S (receiveS)

S (transmitS )

- 8 -

Page 11

Figure 5 Output Connections and Set-up

- 9 -

Page 12

4. Network Connection

Ethernet Cat 5 crossover cable is supplied with the unit.

B. Distribution Box (see Figure 6)

1. Connect the RS-485 wires (blue, white and shield) and 24Vdc power (red and black) from

the main processor unit.

2. Install ½” liquid-tight conduit between the distribution enclosure and the probes unless ½”

rigid conduit is used for long distance runs. Use a minimum of 6 feet of liquid tight at the

probes.

3. The probe connector comes with an adapter which allows the attachment of the ½” flexible

conduit connector.

4. Connect the probes to the distribution enclosure using the manufacturer supplied four

conductor shielded cable. Probe cable connections are shown in Figure 6.

5. Optional - Connect the transmitter box to the distribution box using a RS-485 cable.

: The Ethernet connection at JP1 is an RJ-45 style jack. A 10 foot

Figure 6 Distribution Box

- 10 -

Page 13

C. Probe - .. CAUTION - Do not cross thread connection. The probe is supplied with a

convenient plug-in connector. The male side of the connector comes installed in the probe

junction box. The female side is usually shipped loose and must be installed onto the RS485 cable once it is run from the Distribution Box to the probe. A separate instruction sheet

comes with the connector, showing the wiring connections.

D. Transmitter Box (optional) - For driving eight (8) remote 4-20 mA analog signals from one

RS-485 input port. (See Figure 8)

1. Connect the RS-485 communications/power cable from the distribution box (RS-485: white

and blue wires; 24Vdc power: red and black wires).

2. Connect up to eight (8) signal wire pairs to the indicated terminals for isolated 4-20mA

outputs.

3. Figure 8 provides the RheoVac wiring detail for

the 8 channel 4-20 mA outputs. Table II

provides the appropriate connection

identification. Model 950 transmitters are

configured as active (transmitter sources the

current) when shipped. To change to the passive

mode (receiver to source the current), extract

each small 4-20 board, find the JP1 pins, and

move the two jumpers from the "Act" pins to the

"Pass" pins (two positions to the right of factory

settings). Figure 7 shows the current output

TABLE II - Optional 4-20m A Configuration

Channel

1 Actual volume flow

2 Total mass flow

3 Water vapor flow

4 Pressure

5 Water vapor/A ir mass ratio

6 Relative saturation

7 Air in-leak

8 Temperature

Output Parameter

circuit. The figure also illustrates the active

mode and the passive mode configurations.

Figure 7 4-20 mA

Output Circuit

- 11 -

Page 14

Figure 8 Optional Transmitter Box

Figure 9 Serial Communications Interface

- 12 -

Page 15

E. Cable Connection from Probe to Distribution Box

The RheoVac probes require special connectors to be installed on the supplied DeviceNet

type 5711 cable sections that go from the Distribution Box(es) to the probes. The probes

have the male mating connectors already installed. These connectors will use either the

“backshell nut” or “conduit connector” (see Figure 10) depending on whether the cable is

installed in a liquid-tight conduit. When installing without conduit, use the backshell nut;

when using liquid-tight conduit, use the conduit connector with o-ring.

1. Slide all of the appropriate parts onto the cable as shown.

2. Strip the cable conductors as shown. The connector (Turck p/n B4151-0/9) has 5 retention

screws to hold the wires in place. The use of crimp pins on the wires will greatly increase

connection reliability.

3. Loosen all 5 retention screws (do not completely remove).

4. Insert the wires, in accordance with color-coding shown (see Figure 6, insert).

5. Tighten the retention screws on each wire.

6. Reassemble the connector parts (Figure 10).

Figure 10 Probe Connector Assembly

- 13 -

Page 16

SECTION 3 — OPERATION

3.1 GENERAL INFORMATION

The RheoVac system is calibrated, compensated, and linearized for a wide range of flowing media

temperatures, pressures, and water vapor contents. However, abrupt changes in these parameters can

cause the instrument to temporarily read the flow rate improperly, which could lead to transient spikes

in the flow indication. In particular, if liquid (water) hits the probe tips, there will be high flow

indications until all the water vaporizes. If liquid (water) is present for extended periods, the

performance of the instrument will be compromised or the sensors can be damaged. See SECTION 2

INSTALLATION.

3.2 SYSTEM START-UP

Verify wiring from SECTION 2.5 is correct. With all power off, place the power OFF/ON switch,

SW1, to “ON.” Close the main processor enclosure lid. While watching the main processor display,

apply power to the instrument. After about twenty seconds the display should initialize to “Health

Check in Progress” followed by additional initialization status messages. Within two minutes the

display should indicate “Air In-Leak.”

Upon a "cold" initial start-up of the RheoVac system, the probe may take several minutes to give

accurate readings. During this time, the probe is transitioning to thermal equilibrium conditions under

vacuum.

3.3 PORTABLE USB DATA STORAGE DEVICE/Warranty Registration Instructions

Intek’s warranty program is stated at the front of the manual. To validate warranty, return the portable

USB Data Storage Device after the RheoVac instrument has been in operation with the unit on-line for

one week.

To return the portable USB Data Storage Device to Intek:

Î Locate portable USB Data Storage Device in the main electronics enclosure (see Figure 5).

Ï Grasp bracket and carefully remove portable USB Data Storage Device.

Ð Place portable USB Data Storage Device in the pre-addressed, padded envelope provided

by Intek and mail.

The initial data stored in the device is used to verify proper operation of the RheoVac instrument and

is required to provide baseline data for future technical support.

.. CAUTION Do not attempt to use non-Intek approved USB flash drives with the RheoVac

instrument.

- 14 -

Page 17

3.4 DISPLAY

The RheoVac 950 has a 2x20 alphanumeric scroll-through display that shows seven parameters for each

probe. The display shows Air In-leakage, W/A Mass Ratio, Total Mass Flow, Temperature, Pressure,

Relative Saturation, or Actual Volume Flow (as well as Time/Date, Software Version, or Serial

Number). To change the displayed parameter, press the Scroll Up or Down arrows. The display units

can be changed from English or Metric units by pressing the Units button.

If the Model 950 has two or three probes the display will show two or three serial numbers at a time,

one for each probe. The numbers will be in order, from the lowest serial number to the highest, reading

from left to right on the display. Example: 02611-1, 02611-2 and 02611-3.

3.5 COMMUNICATIONS

Typical RheoVac 950 instruments have an Ethernet port, two serial communications choices (RS-232

or RS-422) and eight 4-20mA output signals for each probe. Each process variable is a linear, fully

temperature and pressure compensated value on any of these readable outputs. All 4-20 mA output

signals are scaled such that 4 mA represents 0% of the rated full scale value (except temperature, which

is 0°C) and 20 mA represents 100% of the rated full scale value (temperature is 100°C). The standard

full scale values and definitions of all process variables are listed in Table III.

Table III. Process Variable Definitions and 4-20 mA Range*

4-20 mA

PROCESS VARIABLE

FULL

SCALE

VALUE

ACTUAL VOLUME FLOW

ACFM [m

TOTAL MASS FLOW

lbs/hr [kg/hr]

WATER VAPOR MASS FLOW

lbs/hr [kg/hr]

RheoVac PRESSURE

" Hg [mm Hg]

WATER VAPOR SPECIFIC

VOLUME [cu. ft/lb]

WATER to AIR M AS S RATIO 20 Ratio of w ater va por flo w rate t o dry a ir flow r ate. D efines “ vacuum quality .”

RELATIVE SATURATION

PARTIAL PRESSURE, WATER

"Hg [mm Hg]

AIR IN-LEAK

SCFM [nm

RheoVac TEMPERATURE

[%]

°F [°C]

3

/hr]

3

/hr]

5000

[8,500]

10000

[4,536]

8000

[3,629]

30

[762]

N/A The inv erse density of th e water v apor pres ent in the lin e. Not su pplied as 4-20m A output.

100 The percent concentration of water vapor in the extraction line relative to saturation.

N/A The pa rtial pressure of w ater vapo r in the vac uum line. Not su pplied as 4-20m A outpu t.

100

[169.9]

212

[100]

The actual volumetric flow rate of gases leaving the condenser. It is a measure of exhauster

capacity. Decreased capacity means pump degradation.

The total m ass flow rate of the flo wing gas. N ote: this va lue is n ot a me asure o f air in-le ak.

It is a measure of total vapor and air removal and exhauster operating capacity.

The water v apor comp onent of the flowing ga s being remo ved from the c ondenser.

Absolute pressure at the RheoVac probe head. Should be equal to or less than turbine back

pressure.

Actual meas ure of air volume flow rate passing the RheoVac sensor head, normalized to

standard conditions (70°F, 29.9" HgA).

4 mA = 0°C /32°F 20 m A = 100°C/21 2°F

Temperature of the flow med ia at the RheoVac pro be he ad.

* See Custom Information section (Section 6) for custom units of measure.

PROCESS VARIABLE DEFINITION

Communication with the RheoVac unit using Intek supplied software is discussed in Appendix A of this

manual.

- 15 -

Page 18

3.6 DATA PROCESSING

TABL E IV. Column Headings for Data Downloads and Archived Data*

O

Time

Stamp

(Time of

day)

012345678910

Actual

Volume

Flow

(ACFM)

Total Mass

Flow

(lbs/hr)

Water

Vapor

Flow

(lbs/hr)

RheoVac

Pressure

("Hg abs)

Water

Vapor Sp.

Vol.

(Cu. ft/lb)

Water to

Air Mass

Ratio

(lb/lb)

Relative

Saturation

(%)

H

2

Partial

Pressure

("Hg abs)

Air Flow

In-Leak

(SCFM)

Probe

Temp. (°F)

* See Custom Information section (Section 6) for custom units of measure.

A very important part of understanding your condenser system comes from evaluating the data that is

created and stored by the RheoVac instrument. The ability to evaluate data has been greatly enhanced

with the RheoVac Model 950 by providing nearly unlimited data storage capacity. A data file is created

for each calender day that the monitor is operating. The ability to review stored data has been invaluable

when troubleshooting condenser problem s.

The importance of reviewing graphed data cannot be overstated. Reviewing data for normal operating

conditions will greatly decrease the time needed to troubleshoot problem conditions when they arise. To

simplify the graphing process, an Excel add-in has been created by the technical support team at Intek

and is included with your RheoVac user software. This Excel add-in graphing utility, called

RheoGraph, is an automated graphing macro that imports and graphs RheoVac data files.

The RheoGraph utility is contained in a self-extracting zip file called “InstallRheoGraph.exe” on the

User Interface software CD. Executing the file will begin the menu driven installation process. The

default installation path is to C:\RheoVac, do not change this path nam e during installation. The file

RheoGraph.xla will be copied to the installation folder along with help files, sample data, and a readme

text file. Microsoft Excel is required for the add-in to function.

Executing RheoGraph.xla will launch Excel and the graphing menu will appear. Selecting Auto will

prompt the user to enter Company, Plant, and Unit info, which will be placed in the graph titles. Then

the user is prompted to browse to the data file to be graphed. The data will be inserted into a spreadsheet

page and four graph pages will then be automatically added as separate tabs in the workbook. When the

graphs are complete, macro execution terminates.

Several advanced features are available by selecting Advanced on the Auto Start menu. For additional

help, use the keyboard arrow keys to set focus on any button, then press F1. The following is an example

of one of the graphs made by RheoGraph showing air in-leak and water vapor to air mass ratio.

- 16 -

Page 19

3.7 CUSTOM SOFTWARE

Custom software may be developed by the user to receive and archive RheoVac data into a computer

system. The electronics has a serial data protocol of 9600 baud, no parity check, eight data bits and one

stop bit (i.e., 9600,N,8,1). Each transmitted group of data is sent in a standard ASCII coded format

representing each process variable value, instrument identification and status information.

The data stream consists of 13 fields, followed by a carriage return <RETURN>. The first ten fields,

nine bytes each, are the process variables. Following the process variables are the RheoVac serial

number, nine bytes, the process identification tag number, 15 bytes, and the RheoVac system status,

seven bytes. The data stream is then ended by a single <RETURN> byte (ASCII code 13). The total

number of bytes transmitted in each data stream is 122 bytes per probe including the trailing

<RETURN>. This data group is sent approximately once every three seconds. Table V shows the field

names and number of bytes in one data stream.

TABLE V. Serial Output Data Stream**

(°F)

Instr.

Serial

Numbe

9

bytes

ID

Status

Tag

No.

r

15

9

bytes

7

bytes

Term.

<CR>

1

byte

Actual

Volume

Flow

(ACFM)

9

bytes

Total

Mass

Flow

(lbs/hr)

9

bytes

Water

Vapor

Flow

(lbs/hr)

9

bytes

RheoVac

Pressure

("Hg abs)

9

bytes

Water

Vapor

Sp. V ol.

3

/16)

(ft

9

bytes

Water to

Air Mass

Ratio

(lb/lb)

9

bytes

Relative

Saturation

(%)

9

bytes

H2O

Partial

Pressure

("Hg abs)

9

bytes

Air Flow

** See Custom Information section (Section 6) for custom units of measure.

In-Leak

(SCFM)

9

bytes

Probe

Temp.

bytes

Each of the first ten process values are sent in the fixed decimal format of XXXX.XXXX with leading

and trailing zeros inserted to maintain the nine character length. The next three fields are ASCII text

strings followed by the <RETURN>. Example: The nine bytes for an air in-leak of 10.0 SCFM would

be: 0010.0000, or 48,48,49,48,46,48,48,48,48 ASCII.

- 17 -

Page 20

SECTION 4 — MAINTENANCE

4.1 GENERAL MAINTENANCE

Precautions should be taken to insure proper performance of all sensors. Since the quantification

technique involves signal measurements, care should be exercised to prevent build-up of dirt and/or

corrosive layers on the various terminal strip connections. Periodic checks with necessary cleaning

should be performed to insure clean terminals. The joints of the sensor leads should occasionally be

inspected for corrosion or presence of moisture.

4.2 CALIBRATION

The RheoVac instrument is calibrated at the factory in a calibration system which replicates the

condenser and vacuum line environment. The system is designed to simulate the temperature, pressure,

water vapor relative saturation and flow rate under the gaseous fluid conditions found within the power

plant vacuum line.

In general, calibrations should be valid over a two year period if the probe is well maintained. Should

the unit require re-ranging or recalibration, note the serial number of the RheoVac instrument and

contact the factory concerning recalibration cost and turn around times. Refer to SECTION 5

CUSTOMER SERVICE of this manual for additional information.

4.3 SPARE PARTS

It is advantageous to have a spare probe. Should a spare probe be desired, it can be ordered and stored

for installation at any time. A spare probe will come with a parameter disk for uploading from a laptop.

Spare fuses should be available for replacement of blown fuses. Appropriate fuses to stock are:

500 mA fuse, slow blow, Wickmann part number 3720500041 or equivalent, for probes.

1 A fuse, slow blow, Wickmann part number 372110041 or equivalent, for the main electronics.

There are no other normally recommended spare components to stock.

To replace the fuse in the main electronics: locate the AC Power Input board (shown in Figure 5) in the

lower right hand corner of the main electronics box. Slide the power switch to the “OFF” position to

disable power to the electronics. The fuses are shown at locations F1 and F2 (spare). Gently pull the

fuse(s) from their sockets and gently insert the replacement 1 Amp fuse(s) as appropriate. Slide the

power switch back to the “ON” position to enable power to the electronics. Close hinged lid and verify

display backlight is on. Clamp close the enclosure lid, and tighten the latch screws.

4.4 TROUBLESHOOTING

Table VI provides a guide for plant personnel to identify causes of problems and determine appropriate

actions to resolve problems observed. If problems are encountered and factory assistance is desired,

please contact the factory.

- 18 -

Page 21

MESSAGE CODE

Description/Symptom

TABLE VI. Troubleshooting Guide

PROBABLE CAU SE

ACTION

MSG-0

Communications not

being received from

probe(s)

MSG-1

Invalid data received

from probe(s)

MSG-2

Flow sensor heater

“OFF”

MSG-3

Relative saturation

sensor power “OFF”'

MSG-4

RS heater “FF”

MSG-5

Pressure sensor heater

“FF”

MSG-6

Temperature alarm

(above 210°F/99°C)

MSG-7

Wet probe

1. Improper cable hookup

2. Blown main fuse

3. Failed RS-485 circuit

4. Damaged flow sensor

1. Failed RS-485 communications

component

1. Blown heater fuse

2. Failed electronic component

1. Probe temperature too high

1. Com ponent failure 1. Contact factory

1. Problem with pressure port

circuitry

1. Steam in exhaust pipe

1. This usually indicates a condenser

design or operation problem that

requires corrective action

2. Hogging mode during start-up

1. Verify plug-in connector properly mated

2. Check all cable connections

3. Check F1 fuse on probe board

4. Contact factory

1. Check wiring

2. Contact factory

1. Contact factory

1. Ch eck to be su re probe tem perature is

<160°F

2. Contact factory

1. Contact factory

1. Remove probe or cool line ASAP!

Once line h as cooled down and probe is

reinstalled, check unit for proper function

1. Contact factory

MSG-8

RS sensor problem

Mass flow output

saturates high, will not

respond to flow changes

Mass flow output

saturates low, will not

respond to flow changes

1. RS sensor has failed 2. Contact factory

1. Flow rate is not within range of

calibration

2. Blown heater fuse

3. Failed electronic component

1. Flow rate is not within range of

calibration

2. Failed electronic component

1. Contact factory about re-ranging

instrument

2. Replace fuse

3. Contact factory

1. Contact factory about re-ranging

instrument

2. Contact factory

When using the RheoVac software on a PC, the software may give you a “Communication Error or

Message.” Use the Table VII to determine the source of this message and appropriate action.

Note: If the RheoVac instrument is operating without message indications but output readings are

questionable, please send to Intek by telefax or e-mail the following plant data

: turbine back pressure,

hot well temperature, load, and inlet and outlet circulation water temperatures, along with at least 24

hours of data from the RheoVac instrument/probe for the same time period.

- 19 -

Page 22

TABLE VII. Troubleshooting Guide (software communication errors)

OBSERVATION PROBABLE CAU SE ACTION

1. Instrument not connected to the software

Appears the first time the

application was executed

Appears intermittently

after application has

been running normally

Completely stops

working after application

was been running

normally

Cannot be made to work

at all with Com3 or

Com4

Note: Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

defaulted serial port

2. Communication connections not made

or instrument is not powered

1. Electrical noise interfering with

communications

2. Too many applications running in

windows

3. Another application is conflicting with

this comm port or IRQ

1. Instrument has stopped communicating

2. Loose or damaged communication

connection

1. Works fine on Com1 or Com2 but does

not work on other port due to other

hardware conflicts such as a modem

1. Change serial comm port setting and hit

“Retry”

2. Check connections and instrument power

1. Change to RS-422 communications, reroute or shield cable

2. Close other applications until problem

self corrects

3. Change to a different comm port

1. Check instrument power or look at

instrument display for fault status

2. Check cable adapter at back of PC or at

any other splices or at instrument

1. Using Windows Control Panel - System

utility, check for IRQ or I/O hardware

conflict - ADVANCED USERS ONLY

4.5 HARDWARE AND SOFTWARE MODIFICATIONS AND UPGRADES

Note: The workgroup setting of the identification tab in Network Neighborhood Properties must be set

to WORKGROUP which is the Windows 98 default setting. A Cat5 crossover network cable is required

for proper Ethernet network communication to the RheoVac instrument.

4.5.1 UPDATING SOFTWARE

Normally, updating the main software residing on the RheoVac Model 950 should not need to be done

by the user. However, software improvements or other factors may necessitate a user installation or

upgrade of a new main program. When this is required, instructions will be supplied.

4.5.2 REPLACING PROBES

If it is necessary to replace one of the probes, a new probe and diskette (with probe-specific calibration

data) can be ordered from Intek.

4.5.3 ADDING ADDITIONAL PROBES (maximum total probes is 3)

Each RheoVac Model 950 can communicate with up to three probes simultaneously. Additional probes

can be easily added to systems that have fewer than three probes.

Each additional probe will be shipped with a set of calibration files that must be installed on the

RheoVac instrument. Refer to drawings for mechanical and electricalconnections. Specific instructions

will be supplied with the probe(s).

- 20 -

Page 23

SECTION 5 — CUSTOMER SERVICE

Intek's corporate philosophy is to help solve our customers’ difficult flow measurement problems.

When you purchase a RheoVac system you also receive Intek's outstanding customer service. For sales

or product service, call your local representative or Intek directly at (614) 895-0301 8AM to 5PM

EST/EDT weekdays or fax us anytime at (614) 895-0319. E-mail inquiries should be sent to

sales@Intekflow.com or techsupport@Intekflow.com. Our customer service staff will provide

assistance promptly.

5.1 QUESTIONS ON EXISTING HARDWARE

To allow us to help you more quickly, please have the serial number of the equipment available before

you call.

5.2 TROUBLESHOOTING

If you have reviewed SECTION 4.4 TROUBLESHOOTING and have questions, please call our

experienced engineers for assistance. In many cases we can solve a problem over the phone. Please

provide as complete a description as possible of the problems encountered.

5.3 FACTORY AND FIELD SERVICE

If you request field service to help with condenser performance problems, Intek has, for a fee,

experienced engineers available to meet your needs. For RheoVac instrument related questions, if a

problem cannot be solved over the phone, with your help, we will determine if factory service or field

service will be the best solution. Be sure to carefully pack the instrument/electronics; extra care should

be taken to protect the probes from damage in shipment.

To request factory service on your instrument, a Return Material Authorization (RMA) and purchase

order is required. Our customer service staff will assist you with the required information to return

instruments for service.

5.4 QUESTIONS ON NEW EQUIPMENT

For a new RheoVac system or any liquid or gas flow meter or flow switch need, contact the Intek

technical sales department at the above phone/fax numbers. Our staff will be pleased to answer all

questions and provide our recommended solutions or instruments.

5.5 CONDENSER SERVICES

Intek has developed unique solutions for plants experiencing problems with dissolved oxygen, heat rate

and excessive back pressure. We provide comprehensive condenser diagnostic and report services.

Plant and RheoVac data is automatically transmitted to Intek and results are published via online

reporting and regular hard copy reports. For a quotation, please call us at the numbers listed above.

- 21 -

Page 24

SECTION 6 — CUSTOM INFORMATION

6.1 UNIT IDENTIFICATION

Model no.:

Serial no.:

Customer identification:

6.2 CONFIGURATION

The marked (X) items denote the configuration of this unit, as originally shipped from the factory.

Pipe Connection: : Hot tap with 1½" MNPT connection

Input Power:

Outputs:

Analog: 9 8 outputs (4-20mA) for each probe

Digital:

: 100-250 Vac, 50/60 Hz

: Ethernet

9 RS-232/RS-422

Data Access:

Portable Data Storage: : Portable USB Data Storage Device

Enclosures shipped: Cables Shipped:

: Ethernet communication

: Processor Box : 5711 interconnect cable (RS485) -

: Distribution Box : Cat5 Ethernet cable - 10 ft.

9 Transmitter Box 9 RS232 communication - 20 ft.

Software: Windows compatible RheoVac 950 software on CD - Version

Calibrated for customer line size of inches, schedule

6.3 SPECIAL INSTRUCTIONS

- 22 -

Page 25

APPENDIX A - RheoVac® Instrument User Interface Software

A.1 INTRODUCTION

User Interface Software (UIS) is provided on CD-ROM with every RheoVac instrument. This

software is used to communicate with the RheoVac unit from a User Interface Computer (UIC).

Some of the functions of the software can be performed using a serial cable, while all functions are

available using an Ethernet connection. An Ethernet crossover cable is provided with each RheoVac

instrument for the purpose of connecting a UIC directly to the RheoVac unit. The network functions

are also capable of being used from any network computer if the RheoVac instrument is connected

directly to the same network. In this case, the supplied crossover cable is not used; rather a straight,

high noise-immune Ethernet cable with RJ-45 plug is used (supplied by customer).

Most details regarding use of the software can be found in the active help files from the pull down

Help menu when using the software.

A.2 SOFTWARE INSTALLATION

A User Interface Computer (UIC) is required to access stored data and real time data of all

parameters. A laptop is suggested for easy access to the main processor unit. Intek does not supply

UICs but recommends the following System Requirements (minimum recommended):

Minimum System Requirements:

Windows 98, Windows NT, Windows 2000 or Windows XP Operating Systems

Pentium III, 400 MHZ processor with 128 MB RAM

SVGA 800 x 600 display

One CD-ROM drive

One 10/100 Ethernet Port

Recommended (Optional):

One 3.5 inch floppy disk drive (probe recalibration data files can be provided on diskette)

One RS-232 serial port with DB-9 connector

The User Interface Software should be installed onto the User Interface Computer. Install the

software by inserting the CD-ROM supplied with the manual into the CD-ROM drive and follow

the on screen prompts. A folder, C:\RHEOVAC will be created and files will be copied to this

folder. The executable file is RheoVac User Interface.exe and the others are drivers and

configuration files that must remain in the RHEOVAC folder. If a previous version of User

nd

Interface Software is on the UIC, you will need to launch the installer a 2

time.

A.3 USER INTERFACE SOFTWARE (UIS) SELECTION

After installation, the user interface is initiated by selecting [START\PROGRAMS\RHEOVAC\

RHEOVAC USER INTERFACE]. The main menu appears, prompting for a selection of RS-232

Serial Communication or Ethernet Communication Utility. A list of functions for each utility

appears below the green selection buttons.

I:\OFFICE\WPMANUAL\RV950 APPENDIX A3.wpd January 29, 2007

- A1 -

Page 26

Make sure the proper cable connection has been made and select the desired communication type

by clicking on either green button.

Figure A - Initial UIS computer Screen

A.4 RS-232/422 COMMUNICATION

This function requires a serial cable and connector, available on request, to connect the UIC and the

RheoVac instrument electronics. This connection allows the user to view real time data of important

parameters in a convenient gauge screen layout. From this gauge screen, the user may choose to

graph a single parameter for all probes, graph all parameters for a single probe, or archive data

directly to the UIC. The archive rate can also be adjusted. These are the only functions available

using serial communication. No commands or updates can be sent to the RheoVac instrument using

this communication method.

A.5 ETHERNET COMMUNICATION

User interface using Ethernet connection allows the user to: synchronize the RheoVac clock with

the UIC clock, retrieve stored data

1

, update files1, change line size, and access data. These network

access utilities are performed from a user interface computer (UIC) connected directly (peer-to-peer)

to the RheoVac unit using a crossover network cable or from a network computer when the RheoVac

instrument is connected to a network (LAN/WAN)2 using a straight Ethernet cable.

Each RheoVac instrument is identified by a unique network ID. The ID begins with the letter “R”

followed by the first five digits of the serial number found on the unit. (RheoVac Model 950 devices

which have not been serviced by the factory since 2005 may use the serial numbers or “RheoVac

1

File transfer can also be accomplished using Windows Explorer or Network Neighborhood

2

Specific network set-up at Intek may be required.

I:\OFFICE\WPMANUAL\RV950 APPENDIX A3.wpd January 29, 2007

- A2 -

Page 27

950" network ID). The user must select the network ID from the pull down menu following the

selection of Ethernet Communication utility from the Main Menu. If the Network ID is not in the

list, select Add New ID and enter the correct six character Network ID. When a new ID is added

to the list, it will be saved as the default for later use. Selecting the correct ID will initiate

communication with the RheoVac instrument. Software features, in addition to those detailed above,

are described within the User Interface Software itself.

A.6 SOFTWARE OPERATION

1. Set Clock

(available with Ethernet connection only): Initiating this action will reset the

RheoVac time clock to agree with the time on your UIC. Make sure the UIC has the

correct time before proceeding.

2. Change Line Size (available with Ethernet connection only): Use this option to update

the instrument’s stored line size variable for proper volume and mass flow calculations.

You should only need this option if the probe is installed in a pipe size that is different

from the value set in the instrument at the factory. In Ethernet Communication, click on

the Line Size tab. On the pull down menu for pipe size, click on the new value, then click

on Save. Click Load to verify that the change was saved by the instrument.

3. Update Files

recalibration, or some other change in the RheoVac operating software is needed, this tab

will be used. Do not use it until then. Instructions will be supplied at that time.

4. Retrieve Data

accessed via Ethernet connection from the

The

RheoVac software creates a new data file each day. The file name is in the

(available with Ethernet connection only): If the probes are ever returned for

(available with Ethernet connection only): Stored data can be easily

RheoVac instrument to the UIC.

following format:

MMDDYY - P.dat

where MM = two digit month

DD = two digit day

YY = two digit year

P = probe designator (1, 2, or 3)

.dat = file extension

These data files are stored in tab delimited text format. See SECTION 3.5 to process data.

To copy a file for analysis, you must access the files on the RheoVac instrument. Open

Windows Explorer on the UIC. Type \\Network ID\RHEOVAC\DATA (Network ID is

generally “R” plus the first 5 digits of the serial number; see section A.5) on the address

line and press enter. Be careful not to alter any support files in this data folder. Use

the copy/paste functions (copy - Ctrl C; paste - Ctrl V) to put data files (.dat) on the

UIC.

5. Monitor Data

(available with Ethernet or RS-232 connection): Once RS-232 or Ethernet

is selected, the first screen, Figure B, shows the most recent value for each parameter.

I:\OFFICE\WPMANUAL\RV950 APPENDIX A3.wpd January 29, 2007

- A3 -

Page 28

Click on the small graph image to view a historical graph of that parameter. Se l ec t

from all available probes by clicking on the Probe S/N menu.

Figure B - User Interface Software Data Monitor Feature

To do real-time graphing, select from the graph menu. The screen shown in Figure C

appears.

Figure C - User Interface Software Graph Feature

I:\OFFICE\WPMANUAL\RV950 APPENDIX A3.wpd January 29, 2007

- A4 -

Page 29

This screen can be divided into four parts:

1. The Chart (or charts)

2. The X-Axis Controls

3. The Legend

4. The User Menu

These four parts work together in the following ways: As soon as the software is opened and valid

communication is established, the data collected for each probe is plotted on the chart(s). The

newest data points are displayed on the right of the chart and push older data points to the left, much

like many old-style strip chart recorders.

The horizontal scroll bar immediately below the chart(s) can be used to select which data points (i.e.,

data from a specific timestamp) from the chart are displayed on the legend below. Data points can

be selected either by clicking-and-dragging the scroll bar pointer or by simply single-clicking a spot

on the scroll bar.

The four buttons below and to the left of the scroll bar labeled 30 min, 1 hour, 2 hour, and 4 hour

can be used to quickly set the x-axis range of the chart(s) and the scroll bar. When using these

buttons keep in mind that the maximum x-axis value is always used as a reference and only the

minimum displayed x-axis value will be changed. You can also change both the minimum and

maximum x-axis value by double-clicking them with your mouse and entering a new value with

your keyboard. Changing the range of the chart (X or Y axis) changes only the data that is displayed

and does not delete or alter the data in any way.

The blue block (time/date) to the right of the 4 hour button displays the timestamp for the data point

currently being pointed to by the horizontal scroll bar. If the scroll bar is in the right-most position,

this value will automatically update when new data is received from the connected instrument.

The legend at the bottom of the screen displays the value of the data being pointed to by the scroll

bar and also is used to control where each data parameter is plotted. To access this feature singleclick on any parameter in the legend. Two things will happen. First, the background color of the

selected parameter will change in the legend, and second, the parameter will disappear from the

chart if you are in single-chart mode or jump from one chart to the other if you are in dual-chart

mode.

Single-chart and dual-chart modes are the first two selections available in the chart user menu. Also

available in the chart menu are selections to choose between manual and auto scaling for the y-axis

and to reset the maximum x-axis value to the most recently collected data point.

The legend menu is used to select which parameter or which probe is displayed. If a parameter is

chosen from this menu, that parameter will be displayed for all probes connected to the instrument.

If a probe is selected, then all parameters for that probe will be displayed.

The archive menu is used to set the rate that data will be archived to the hard disk of the computer

on which the user has installed the User Interface Software. These selections have no effect on the

data that is stored every minute on the hard disk of the RheoVac instrument itself. Data archived

I:\OFFICE\WPMANUAL\RV950 APPENDIX A3.wpd January 29, 2007

- A5 -

Page 30

to the user’s hard disk is stored in the “C:\RHEOVAC\DATA\” directory. The data is subdivided

into folders for each probe. A new file for each probe will be created each day that data is archived.

A.7 WARRANTY REGISTRATION/TECHNICAL SUPPORT

Sending Data to Intek: IMPORTANT

If the instrument is equipped with a portable USB data storage device as shown in Figure 5 (in the

main manual), remove this storage device after one week of operation and send to "Intek, Inc., 751

Intek Way, Westerville, OH 43082" to activate/secure warranty registration. This storage device

is programmed to capture the initial baseline data recorded by the RheoVac instrument.

The following paragraph is applicable to RheoVac 950 instrument users only:

The availability of plant data for periods corresponding to the RheoVac data are important to proper

diagnostic evaluation. Plant data of interest to the factory for the same time period are: turbine back

pressure, hotwell temperature, load, and inlet and outlet circulation water temperatures. The plant

data is necessary for correlating RheoVac measured data. The availability of this information at the

factory is very important to Intek’s ability to assist you in troubleshooting your instrument and/or

to respond to inquiries. This provides a baseline for the system and will help us support you should

future system problems arise. Our experienced support engineers can access the “before” and “after”

effects of an upset and work with you to identify and understand the problem, and develop solutions.

Additionally, most air removal piping conditions that are detrimental to probe operation can be

diagnosed before probe damage occurs. For this reason, we require a data download one week after

RheoVac system is placed into service. The download activates the one year warranty service.

the

Alternately, you may send to the factory an initial week or so of data (zipped format is preferred). The

simplest way is to copy all data files and the ‘event.log’ file to your UIC and send it via email to

techsupport@intekflow.com.

Note: Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

I:\OFFICE\WPMANUAL\RV950 APPENDIX A3.wpd January 29, 2007

- A6 -

Page 31

APPENDIX B - RheoVac Model 950 Networking

B.1 INTRODUCTION

Use these instructions when making a peer-to-peer Ethernet connection between the RheoVac 950 and

the User Interface Computer (UIC), or an Ethernet connection between the RheoVac 950 and a Local

Area Network (LAN). Locate the section that covers your operating software.

B.2 WINDOWS 98 OR WINDOWS ME OPERATING SYSTEM

1. Ethernet Cable

:

a. UIC Connection: use CAT5 network crossover cable (supplied by Intek) to connect the

Ethernet port of the UIC to the Ethernet port on the RheoVac 950.

b. LAN Connection: use CAT5 straight high noise-immune Ethernet cable (not supplied)

with RJ45 plug to connect the Ethernet port of the LAN to the Ethernet port of the

RheoVac 950.

2. Workgroup Identification

: Unless otherwise requested, the Workgroup identification for the

RheoVac 950 will be WORKGROUP, which is the Windows 98 default setting. To check/set

the workgroup name: Right click on the Network Neighborhood icon on the UIC desktop.

Select Properties from the menu that appears. Select the Identification tab of the Network

dialog box that appears. Verify that Workgroup is WORKGROUP.

3. Check for Installed Network Components

: Right click on the Network Neighborhood icon

on the UIC or LAN computer desktop. Select Properties from the menu that appears. Select

the Configuration tab of the Network dialog box that appears. In the list under “The

following network components are installed” there should be all three of the following: Client

for Microsoft Networks, Ethernet adapter, and NetBEUI (with the Ethernet adapter identified

on the same line next to it). Each will have a different icon associated with it; the ‘Client’

icon looks like a computer screen, the ‘Adapter’ icon looks like an adapter card, and the

‘NetBEUI’ protocol icon looks like a cable in a “T” shape. If these components are not

installed, one or more of the following installations may be necessary. Note: The Windows

installation disk may be needed.

a. Installing Client for Microsoft Networks: If Client for Microsoft Networks is not in the

list of “The following network components are installed,” then do the following:

i. Click the Add button next to the list.

ii. The Select Network Component Type dialog box will appear.

iii. Select Client from the list then click the Add button.

iv. Select Microsoft from the Manufacturers list.

v. Select Client for Microsoft Networks in the Network Clients list.

b. Installing NetBEUI: If the NetBEUI (with the Ethernet adapter identified on the same line

next to it) is not in the list of “The following network components are installed,” then do

the following:

i. Search the installed network components list for the installed Ethernet adapter.

ii. Select the Ethernet adapter and click the Add button below the list.

iii. Select Protocol from the Select Network Component Type dialog box.

iv. Click the Add button next to the list.

v. The Select Network Protocol dialog box will appear.

vi. Select Microsoft from the Manufacturers list.

vii. Select NetBEUI from the Network Protocols list.

I:\OFFICE\WPMANUAL\RV950 Appendix B2.wpd March 1, 2006

-B1-

Page 32

4. Networking with the RheoVac 950: If all of the items above are completed successfully, the

UIC or LAN computer should be able to network with the RheoVac 950. To search for the

RheoVac 950 from the UIC or LAN computer:

Method 1

a. Open Network Neighborhood.

b. Each RheoVac instrument is identified by a unique Network ID. The ID is “R” plus the

first five digits of the serial number found on the unit. (RheoVac Model 950 devices

which have not been serviced by the factory since August, 2003 may use the serial

numbers or “RheoVac 950” as the Network ID).

c. Look for the Network ID of your RheoVac 950. If the expected Network ID (see previous

paragraph) does not show up in the list, then type in the appropriate Address line (either

“\\RHEOVAC 950” or “\\R” and the first five digits of the serial number) and click the Go

button. This may take several seconds and then a RHEOVAC folder will appear, which

is the hard drive of the RheoVac 950.

d. Open the RHEOVAC folder then open the DATA folder. The \\Network ID

\RHEOVAC\DATA folder contains all the stored data. Use copy/paste functions (copy -

Ctrl C; paste - Ctrl V) to save the data files to the UIC or LAN computer.

Method 2

a. Open My Computer

b. Type in the Address line: \\Network ID (Network ID is defined above) and click the Go

button. This may take several seconds and then a RHEOVAC folder will appear, which

is the hard drive of the RheoVac 950.

c. Open the RHEOVAC folder then open the DATA folder. The \\Network ID\

RHEOVAC\DATA folder contains all the stored data. Use copy/paste functions to save

the data files to the UIC or LAN computer.

B.3 WINDOWS NT OR WINDOWS 2000 OPERATING SYSTEM

1. Ethernet Cable

:

a. UIC Connection: use CAT5 network crossover cable (supplied by Intek) to connect the

Ethernet port of the UIC to the Ethernet port on the RheoVac 950.

b. LAN Connection: use CAT5 straight high noise-immune Ethernet cable (not supplied)

with RJ45 plug to connect the Ethernet port of the LAN to the Ethernet port of the

RheoVac 950.

2. Workgroup Identification

: Unless otherwise requested, the Workgroup identification for the

RheoVac 950 will be WORKGROUP. To check/set the workgroup name: Right click on the

My Computer icon on the UIC or LAN computer desktop. Select Properties from the menu

that appears. Select the Network Identification tab of the System Properties dialog box that

appears. Verify that Workgroup is WORKGROUP.

3. Check for Installed Network Components

: Click the Start button, select Settings, select

Network and Dial-up Connections. Or, right click My Network Places and select

Properties. Highlight the Local Area Connection that represents the Ethernet adapter. Right

click on Local Area Connection and select Properties. Under “Components checked are

used by this connection:” look for Client for Microsoft Networks and NetBEUI Protocol.

If these components are not installed, one or more of the following installations may be

I:\OFFICE\WPMANUAL\RV950 Appendix B2.wpd March 1, 2006

-B2-

Page 33

necessary. Note: The Windows installation disk may be needed as well as administrator

security rights.

a. Installing Client for Microsoft Networks: If Client for Microsoft Networks is not in the

list of “The following network components are installed,” then do the following:

i. Click the Install button below the list.

ii. The Select Network Component Type dialog box will appear.

iii. Select Client from the list then click the Add button.

iv. Select Microsoft from the Manufacturers list.

v. Select Client for Microsoft Networks in the Network Client list.

vi. Click OK.

b. Installing NetBEUI: If the NetBEUI (with the Ethernet adapter identified on the same line

next to it) is not in the list of “The following network components are installed,” then do

the following:

i. Click the Install button below the list.

ii. The ‘Select Network Component Type’ dialog box will appear.

iii. Select Protocol and click the Add button.

iv. The ‘Select Network Protocol’ dialog box will appear.

v. Select NetBEUI from the Network Protocol list.

vi. Click OK.

4. Networking with the RheoVac 950

UIC or LAN computer should be able to network with the RheoVac 950. To search for the

RheoVac 950 from the UIC or LAN computer:

a. Open My Computer

b. Each RheoVac instrument is identified by a unique Network ID. The ID is “R” plus the

first five digits of the serial number found on the unit. (RheoVac Model 950 devices

purchased prior to August, 2003 may use the serial numbers or “RheoVac 950” as the

Network ID.)

c. Look for the Network ID of your RheoVac 950. If the expected Network ID (see previous

paragraph) does not show up in the list, then type in the appropriate Address line (either

‘\\RHEOVAC 950’ or ‘\\’ and the first five digits of the serial number) and click the Go

button. This may take several seconds and then a RHEOVAC folder will appear, which

is the hard drive of the RHEOVAC 950.

d. Open the RHEOVAC folder and then open the DATA folder. The \\Network ID\

RHEOVAC\DATA folder contains all the stored data. Use copy/paste functions (copy Ctrl C; paste - Ctrl V) to save the data files to the UIC or LAN computer.

B.4 WINDOWS

1. Ethernet Cable

XP OPERATING SYSTEM

:

a. UIC Connection: use CAT5 network crossover cable (supplied by Intek) to connect the

Ethernet port of the UIC to the Ethernet port on the RheoVac 950.

b. LAN Connection: use CAT5 straight high noise-immune Ethernet cable (not supplied)

with RJ45 plug to connect the Ethernet port of the LAN to the Ethernet port of the

RheoVac 950.

2. Workgroup Identification

RheoVac 950 will be WORKGROUP. To check/set the workgroup name: Click the Start

button and select Control Panel. Right click on the System icon and select Open. Select

the Computer Name tab. Verify that Workgroup is WORKGROUP. Use the Change button

to type in a new Workgroup if needed.

: If all of the items above are completed successfully, the

: Unless otherwise requested, the Workgroup identification for the

I:\OFFICE\WPMANUAL\RV950 Appendix B2.wpd March 1, 2006

-B3-

Page 34

3. Check for Installed Network Components: Click the Start button and select Control Panel.

Right click on the Network Connections icon and select Open. Or, click the Start button,

select Connect To, then select Show all connections. Highlight the Local Area Connection

that represents the Ethernet adapter. Right click the icon and select Properties. In the new

window that pops up, under “This connection uses the following items:,” look for Client for

Microsoft Networks, NWLink NetBIOS, and NWLink IPX/SPX/NetBios protocols. If these

components are not installed, one or more of the following installations may be necessary.

Note: The Windows installation disk may be needed as well as administrator security rights.

a. Installing Client for Microsoft Networks: If Client for Microsoft Networks is not in the

list of “This connection uses the following components:,” then do the following:

i. Click the Install button below the list.

ii. The Select Network Component Type dialog box will appear.

iii. Select Client from the list then click the Add button.

iv. Select Microsoft from the Manufacturers list.

v. Select Client for Microsoft Networks in the Network Client list.

vi. Click OK.

b. Installing NWLink NetBIOS: If NWLink NetBIOS is not in the list of “This connection

uses the following components:,” then do the following:

i. Click the Install button below the list.

ii. The Select Network Component Type dialog box will appear.

iii. Select Protocol and click the Add button.

iv. The Select Network Protocol dialog box will appear.

v. Select NWLink NetBIOS from the Network Protocol list.

vi. Click OK.

c. Installing NWLink IPX/SPX/NetBIOS: If NWLink IPX/SPX/NetBIOS is not in the list

of “This connection uses the following components:,” then do the following:

i. Click the Install button below the list.

ii. The Select Network Component Type dialog box will appear.

iii. Select Protocol and click the Add button.

iv. The Select Network Protocol dialog box will appear.

v. Select NWLink IPX/SPX/NetBIOS from the Network Protocol list.

vi. Click OK.

4. Networking with the RheoVac 950

: If all of the items above are completed successfully, the

UIC or LAN computer should be able to network with the RheoVac 950. To search for the

RheoVac 950 from the UIC or LAN computer:

a. Open My Computer.

b. Each RheoVac instrument is identified by a unique Network ID. The ID is “R” plus the

first five digits of the serial number found on the unit. (RheoVac Model 950 devices

purchased prior to August, 2003 will use the Network ID “RheoVac 950.”)

c. Look for the Network ID of your RheoVac 950. If the expected Network ID (see previous

paragraph) does not show up in the list, then type in the appropriate Address line (either

‘\\RHEOVAC 950’ or ‘\\’ and the first five digits of the serial number) and click the Go

button. This may take several seconds and then a RHEOVAC folder will appear, which

is the hard drive of the RheoVac 950.

d. Open the RHEOVAC folder and then open the DATA folder. The \\Network ID\

RHEOVAC\DATA folder contains all the stored data. Use copy/paste functions (copy Ctrl C; paste - Ctrl V) to save the data files to the UIC or LAN computer.

I:\OFFICE\WPMANUAL\RV950 Appendix B2.wpd March 1, 2006

-B4-

Loading...

Loading...