Page 1

TABLE OF CONTENTS

SECTION 1 — GENERAL INFORMATION ....................................... - 1 -

1.1 INTRODUCTION ................................................. - 1 -

1.2 PRINCIPLE OF OPERATION ....................................... - 2 -

1.3 TECHNICAL SPECIFICATIONS ..................................... - 2 -

1.4 PRECAUTIONS .................................................. - 2 -

SECTION 2 — INSTALLATION ................................................ - 4 -

2.1 INTRODUCTION ................................................. - 4 -

2.2 RheoVac MONITOR INSTALLATION/SITE SELECTION ................ - 4 -

2.2.1 Transducer Site Selection ..................................... - 4 -

2.2.2 Electronics Unit Site Selection ................................. - 4 -

2.3 MOUNTING HARDWARE INSTALLATION .......................... - 6 -

2.4 TRANSDUCER INSTALLATION .................................... - 6 -

2.5 ELECTRICAL CONNECTIONS ..................................... - 8 -

2.6 RheoVac MONITOR GROUNDING ................................. - 13 -

SECTION 3 — OPERATION .................................................. - 15 -

3.1 GENERAL INFORMATION ....................................... - 15 -

3.2 SYSTEM START-UP ............................................. - 15 -

3.3 OUTPUT SIGNALS .............................................. - 15 -

3.4 IBM-PC SOFTWARE ............................................. - 16 -

3.4.1 SOFTWARE INSTALLATION ............................... - 17 -

3.4.2 SOFTWARE OPERATION .................................. - 17 -

3.4.3 DATA PROCESSING ....................................... - 18 -

3.5 CUSTOM SOFTWARE ........................................... - 19 -

SECTION 4 — MAINTENANCE ............................................... - 21 -

4.1 GENERAL MAINTENANCE ....................................... - 21 -

4.2 CALIBRATION .................................................. - 21 -

4.3 SPARE PARTS .................................................. - 21 -

4.4 TROUBLE SHOOTING ........................................... - 21 -

SECTION 5 — CUSTOMER SERVICE ......................................... - 25 -

5.1 QUESTION ON EXISTING HARDWARE ............................ - 25 -

5.2 TROUBLE SHOOTING ........................................... - 25 -

5.3 FACTORY AND FIELD SERVICE .................................. - 25 -

5.4 QUESTIONS ON NEW EQUIPMENT ................................ - 25 -

SECTION 6 — CUSTOM INFORMATION ...................................... - 26 -

6.1 UNIT IDENTIFICATION .......................................... - 26 -

6.2 CONFIGURATION ............................................... - 26 -

6.3 SPECIAL INSTRUCTIONS ........................................ - 26 -

©Intek, Inc. 1999

Manual no. RVAC Rev. D

I:\OFFICE\WPMANUAL\RHEOVAC\RHEOVAC.RVD

Page 2

WARRANTY

Intek, Inc. warrants each RheoVac product to be free from defects in

material and workmanship under normal use and service, Intek's

obligation under this warranty being limited to making good any part or

parts thereof which shall, within one (1) year after delivery of such

product to the original purchaser, be returned to Intek with transportation

charges prepaid and which Intek's examination shall disclose to its

satisfaction to have been thus defective; this warranty being expressly in

lieu of all other warranties, express or implied and all other obligation or

liabilities on Intek's part. The purchaser will assume all responsibility

and expense for removal, decontamination and reinstallation of

equipment.

Rheotherm instruments are manufactured under United States patent numbers

4,255,968, 4,942,763, 4,949,578, 5,485,754 and 5,752,411. Intek, Rheotherm,

Rheovec, Rheomax, RheoVac and RheoSmart are registered trademarks of Intek,

Inc.

Intek, Inc.

751 Intek Way

Westerville, Ohio 43082-9057

Phone (614) 895-0301 – Fax (614) 895-0319

web site – www.intekflow.com

e-mail – techsupport@intekflow.com

Page 3

SECTION 1 — GENERAL INFORMATION

1.1 INTRODUCTION

For the first time, all necessary properties of the fluid in the condenser exhauster line are directly

measured to provide an accurate determination of air in-leakage. These properties are measured to

provide the power industry with the most advantageous and complete product for condenser system

diagnostics:

— the RheoVac

®

Air In-Leak Monitor System*

*USPNs 5,485,754; 5,752,411

The RheoVac air in-leak monitor system consists of multiple sensors configured in a single probe head

and an electronic signal conditioner and digital signal processor (DSP) unit. The sensing probe is

installed in the vacuum line between the condenser and the exhauster. The RheoVac monitor is superior

to all other methods in that it makes no assumptions about the dynamic condenser and vacuum line

®

environment. The sensor head employs the patented Rheotherm

technology to provide an accurate flow

measurement. Additionally, temperature, pressure and water vapor relative saturation measurements are

made using a high accuracy platinum resistance temperature detector (RTD), a strain gauge pressure

sensor and a specially configured and calibrated water vapor saturation sensor.

Figure 1 RheoVac Air In-Leak Monitor

- 1 -

Page 4

1.2 PRINCIPLE OF OPERATION

The principal features of the RheoVac monitor are shown in Figure 1. At the heart of the RheoVac

monitor is the Rheotherm flow transducer which uses the same patented thermal sensing technique

employed in all precision flow instruments manufactured by Intek. Two temperature sensor probes are

used — one sensor is in thermal equilibrium with the flow medium and provides a temperature and flow

signal reference, while the second sensor is located near a constant power probe heater so that its

temperature is always above that of the fluid. The temperature of the heated sensor will vary with the

stream velocity of the fluid. Hence, the measured temperature differential between the reference sensor

and heated sensor is a function of flow rate, which is approximately proportional to the logarithm of

mass flow rate (USPN 4,255,968).

The Rheotherm flow sensor is calibrated to measure the total mass flow of the water vapor/air mixture.

From the other three measurements, the RheoVac electronics converts the total mass flow signal from

the transducer into two components, air mass flow rate and water vapor mass flow rate. This unique

measurement method is disclosed in two separate patents (USPN 5,485,754 & 5,752,411).

The RheoVac monitor is fully calibrated in the factory under dynamic fluid conditions identical to those

within the power plant vacuum line. No field adjustments are required.

1.3 TECHNICAL SPECIFICATIONS

Primary Calibration Accuracy:

±1% of reading

Repeatability:

±0.5% of reading

Operating Temperature:

Electronics: !20 to 120°F

Transducer: 40 to 160°F

Never subject transducer to

temperatures above 210°F

Operating Pressure:

0 to 10 inches Hg absolute

Process Connection:

Hot tap assembly

(1½” thread-o-let must be welded to

Wetted Surface:

300 Series SS and engineering plastic

Local Display:

air in-leakage (SCFM)

Input Power:

115 Vac, 50/60 Hz (±15V)

230 Vac, 50/60 Hz (±15V)

Signal Output:

4/20 mA (for 10 parameters)

RS 232/422

Storage Temperature:

!20 to 120°F

Storage Pressure:

15 psig (maximum)

pipe for hot tap installation)

1.4 PRECAUTIONS

• Read the entire manual before installing and operating the RheoVac monitor.

• Carefully select the best location for installation of the transducer probe. Adequate straight

run and freedom from standing water in the line are vital to achieving optimal performance

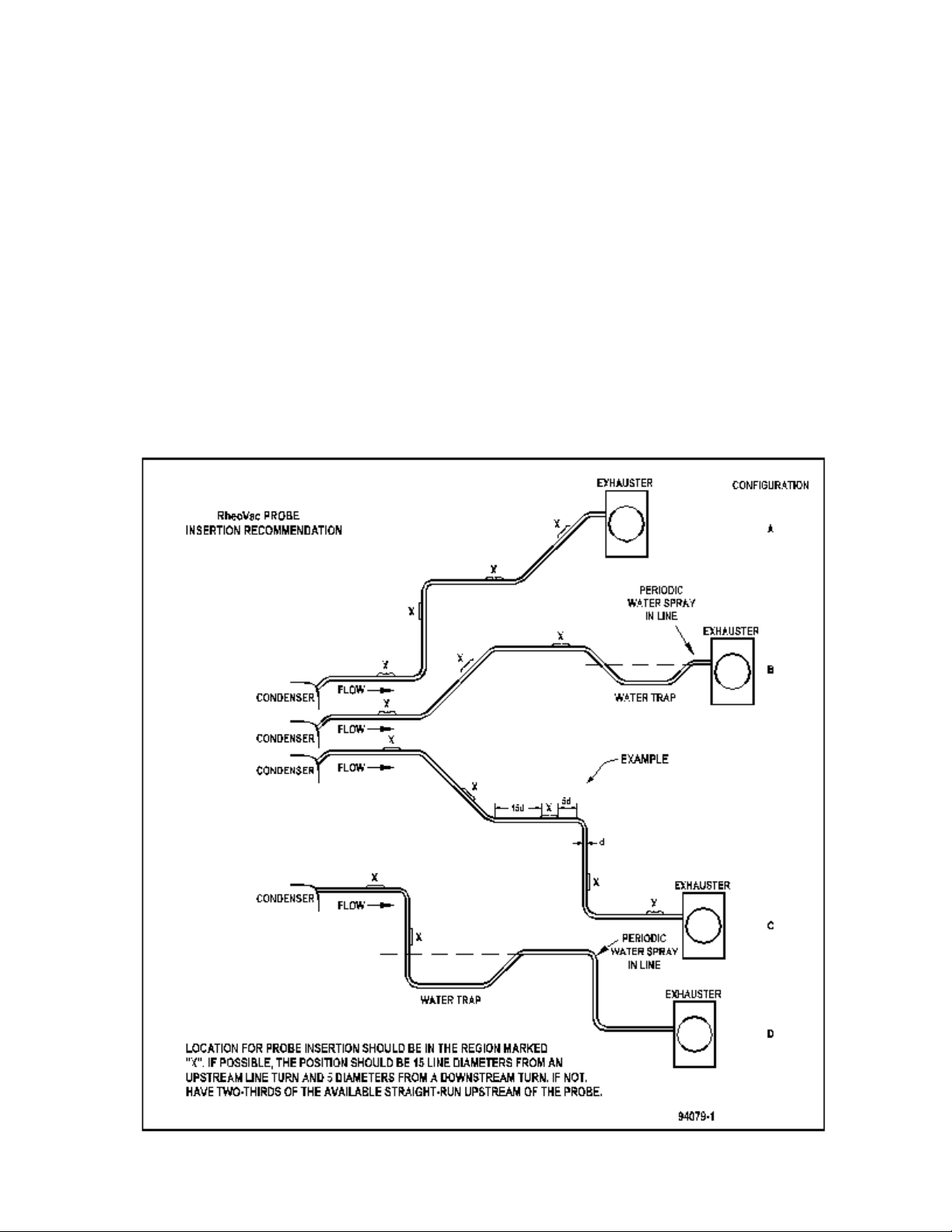

from the RheoVac monitor (See Figure 2).

• Use reasonable care in handling the transducer — the sensing components are delicate. Take

care not to bend the probes, damage the tips, or otherwise obstruct the sensing ports.

- 2 -

Page 5

• Use proper input power — check the power select switch position on the electronics. Select

either 115 Vac or 230 Vac before applying power.

• Check the transducer maximum temperature and pressure ratings — never operate a

transducer at or subject it to temperatures or pressures beyond its specified limits.

. . WARNING - Never allow live high temperature steam to flow either direction in

the exhauster line where the probe is located.

• Keep moisture out of the enclosures — once all service connections are made, make sure the

enclosure lids are tightly closed and all gaskets are in place. Seal conduit lines at the

instrument.

SECTION 2 — INSTALLATION

Figure 2 RheoVac Probe Insertion Recommendation

- 3 -

Page 6

2.1 INTRODUCTION

These instructions cover installation of the RheoVac monitor in its standard configuration. Additional

information pertaining to your unit is covered in SECTION 6 — CUSTOM INFORM A TION.

Carefully read these instructions prior to installing the equipment.

2.2 RheoVac MONITOR INSTALLATION/SITE SELECTION

2.2.1 Transducer Site Selection

# Select the installation site. The location should provide the transducer sensing area with

well-established smooth flow, uniform system temperature and pressure, and consistent nonliquid phase flow medium. Pipe sections ahead of probe, in which water can accumulate,

must be avoided. Refer to Figure 2 and select the most preferred location that fits your

vacuum line configuration. Do not install the probe beyond any “trap” sections as shown in

Figure 2, Configurations B and D. Special installation instructions unique to your unit,

where applicable, will be noted in SECTION 6.3 SPECIAL INSTRUCTIONS. Refer to

this section now to review any special instructions.

# Check installation clearance. The transducer probe is almost 3 feet long and the hot tap

assembly is about 13” long, so allow 4 feet of clearance for probe installation. Be sure there

are no obstructions around the vacuum line that will interfere with transducer insertion.

Figure 3 shows the proper insertion angle. THIS ORIENTATION IS IMPORTANT FOR

PROPER OPERATION.

# OBSERVE the selected site. It should be convenient for removal and replacing probe at any

time for service without building scaffolding or waiting for plant shutdown.

# Check operating conditions. The temperature and pressure limits of the unit should be

checked to ensure compatibility with your application.

2.2.2 Electronics Unit Site Selection

# Select the installation site. The electronics unit should be located in a dry area. The

electronics are not protected against condensed liquid water inside the enclosure.

# Check for input voltage access. The electronics unit should be located in an area with access

to a 115 Vac or 230 Vac single phase, 50-60 Hz input power source.

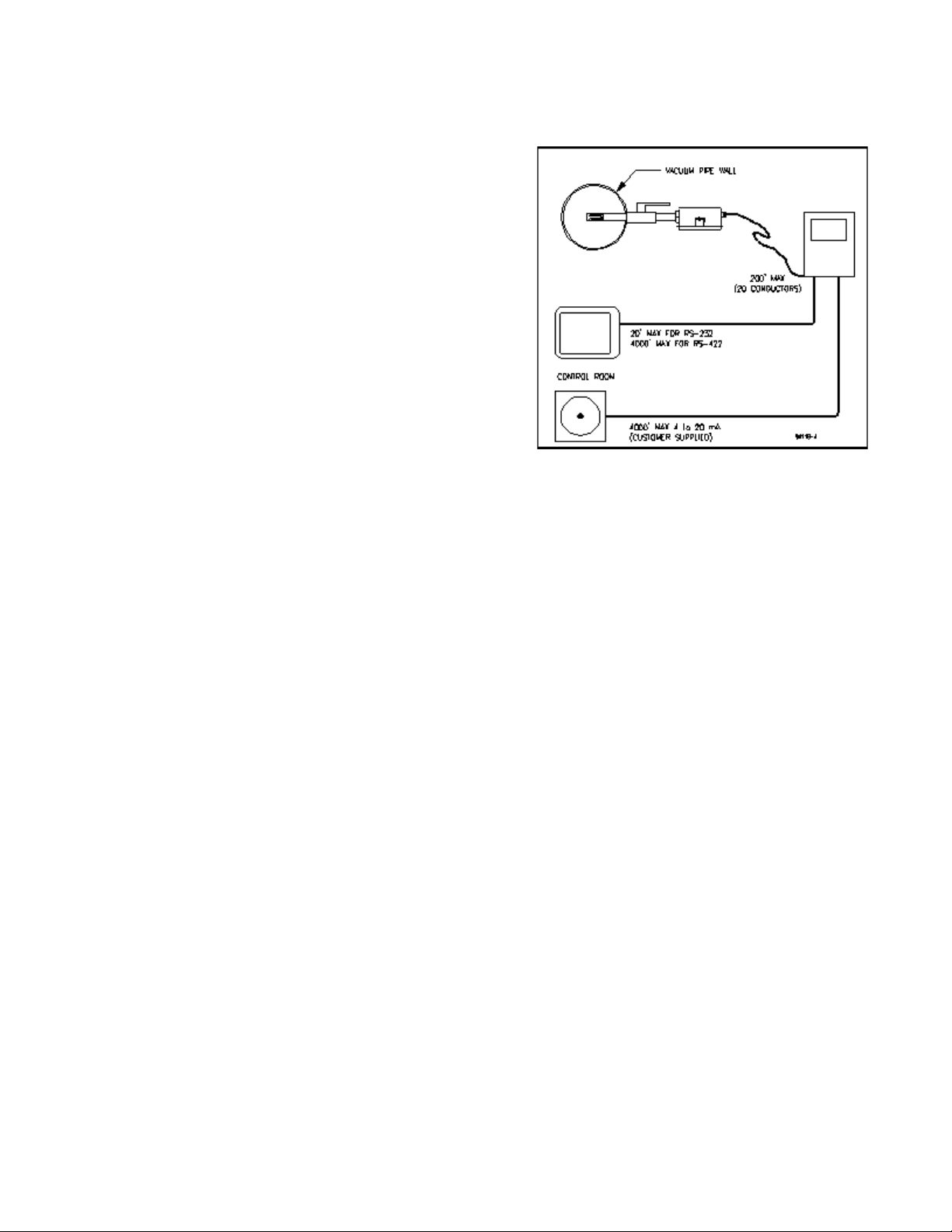

# Check cable distances. The distances from the transducer to the electronics unit and from

the electronics unit to the control room, or to the receiving equipment serial communications

port or to the analog input device, should not exceed the distances shown in Figure 4.

# Check electronics enclosure mounting area requirements. The RheoVac electronics

enclosure is NEMA 4, measuring 12"×10"×5". A detailed drawing of the mounting interface

is shown in Figure 5 (pg. 7).

# Check for accessibility to setup and use a portable computer (PC) at the site for trouble-

shooting. There should be a place to set up the PC and to open the electronics enclosure.

- 4 -

Page 7

- 5 -

Transducer Installation Detail

Page 8

2.3 MOUNTING HA RDWA RE INSTALLATION

Î Check hardware. Verify that the probe slides

through the hot tap assembly.

Ï Check installation configuration. Make sure

the probe is parallel to the floor. (see Figure 3).

Ð Check installation clearance. Verify there is a

probe insertion clearance of 4 feet from the

pipe wall.

Ñ Install the mounting hardware. Drill a 1½”

through hole and weld the thread-o-let onto

the condenser vacuum pipe (See Figure 3).

Thread the hot-tap assembly into the threado-let. Use thread tape or pipe dope to seal the

connection.

Ò It should be convenient to apply a force of

about 23 lb to remove or replace the probe

under plant operating conditions.

2.4 TRANSDUCER INSTA LLATION

Figure 4 Maximum Cable Lengths

Î Check proper installation direction. The transducer has a directional arrow on the tag and/or

etched into a metal part. Before installing the unit, note proper flow direction. This is

important to instrument operation.

Ï Check serial number. If more than one RheoVac unit has been purchased, make sure the

complete serial number of the transducer matches the complete serial number of the separate

electronics unit. The transducer and electronics are a matched set. Mismatched components

will result in erroneous readings.

Ð Verify stop clamp location (see Figure 6). A stop clamp is attached to the probe as an

indication of its insertion depth. It is important this stay in place so the sensors are in the

correct location and ensure the probes do not contact the opposite pipe wall. The clamp’s

location was determined based on your pipe diameter, as shown in SECTION 6.2, and is

marked with a groove on the probe’s shaft. Refer to this mark if the stop clamp is

inadvertently moved.

Ñ Inspect the transducer probe tips. Be sure wetted surfaces are clean before installing. If

cleaning is needed, use a damp cloth wetted with alcohol and wipe dry using a soft, lint-free

cloth. Do not immerse probe in liquid alcohol or any other liquids.

Ò Install the transducer. The instrument should be mounted through the pipe wall using the hot-

tap assembly. The transducer installs so that the two probes are side-by-side across the gas

stream. The transducer has a flow directional arrow on the transducer tag and/or marked into

the fitting. When installing under vacuum, do not allow the clamp to "slam" against the seal

nut upon opening the valve. Grasp the transducer shaft firmly before opening the ball valve.

Allow the transducer to slide through the valve by controlling the amount of grip on its shaft.

Special installation instructions, if any, will be noted in SECTION 6.

- 6 -

Page 9

Figure 5 RheoVac Electronics Enclosure

- 7 -

Page 10

2.5 ELECTRICAL CONNECTIONS

. . WARNING: Read the entire contents of this section

before powering up the unit. Improper hookup may result in

damage to this instrument or the interfacing equipment.

Î Verify/configure the input power. The input power

requirement is listed on the tag on the electronics enclosure.

Be sure the input power source to be used is properly selected

in the unit. Input power can be either 115 Vac or 230 Vac

single phase, 50-60 Hz. The power configuration may be

changed in the field. Using Figure 7, locate the power select

switch on the lower printed wiring board and slide the power

select switch to either the 115V or the 230V position. Do not

apply power to the instrument until all other connections

and optional selections have been made.

. CAUTION: The Table 1 output signals, both ! and +, are

isolated from the transducer and power ground. However,

the outputs are not isolated from each other; i.e. the 4-20 mA,

RS232/422, and status outputs are all common to each other.

All of the 4-20 mA receiver channels must have

independently isolated inputs.

Figure 6.

Transducer

Stop Clamp

Ï Check the serial communication setup. If a distance of greater than twenty feet is needed for

the serial communications, RS-422 should be used instead of RS-232 (See Figure 4). Inspect

the header pin shunt (Figure 8) at JP14 (upper board) for the proper communication type.

Consult Intek if the jumper is not configured correctly.

Figure 7 Input Power Select Switch

- 8 -

Page 11

TABLE I. Ten 4-20 mA Wire Terminal Assignment

CONFIGURATION PIN ASSIGNMENT

OUTPUT VARIABLE

DESCRIPTION

ACTUAL VOLUME F LOW [ACFM] A B B A

TOTAL MASS FLOW [lbs/hr] C D D C

WATER VAPOR MASS FLOW [lbs/hr] E F F E

RheoVac PRESSURE ["Hg] G H H G

WATER VAPOR SPECIFIC VOLUME [cu. ft/lb] I J J I

WATER to AIR MASS RATIO K L L K

RELATIVE SATURATION [%] M N N M

PARTIAL PRESSURE, WATER ["Hg] O P P O

AIR IN-LEA K [SCFM] Q R R Q

RheoVac TEMPERATURE [°F] S T T S

NOT USED U U U U

Active 4-20 mA Passive 4-20 mA

! + ! +

Ð RheoVac units have ten 4-20 mA outputs. These outputs can be configured collectively for either

passive or active transmitter. The units are shipped from the factory with the output jumpers in

the active position; i.e. the transmitter provides the current source. Figure 8 shows the locations

of the 4-20 mA select jumper, JP13 of the lower board — active position is shown.

. CAUTION: changing the passive/active jumper changes the field wiring polarity and affects

all ten 4-20 mA channels. See Table I for wire terminal identifications.

Figure 8. Output Connections and Set-up

- 9 -

Page 12

- 10 -

Monitor Wiring Detail (with 10 channel 4-20 mA output)

Page 13

Ñ Figure 9 provides the RheoVac wiring

detail for the 10 channel 4-20 mA outputs.

Table I provides the appropriate

connection identification. As stated, the

output signals are not isolated from each

other and therefore the 4-20 mA receiver

channels must be independently isolated.

A typical current output circuit is shown in

Figure 10. The current control circuitry

works by controlling the (!) side return

current through Q1 which returns current

through the isolated, but circuit-common,

ground (L1). When the 4-20mA output is

configured as active, the (+) terminal is

connected to a common 35 to 40Vdc

supply (V

jumpered to the (+) output terminal and

“B” is jumpered to the (!) terminal. For

passive mode, the “A” is not connected,

the “B” is jumpered to the (+) terminal,

and the (!) terminal is connected to

isolated circuit ground (L1).

). The circuit “A” is

unreg

Figure 10 - 4-20mA Output Circuit

The remaining outputs - RS232/422 and status, are all (!) terminated to isolated circuit

ground. A single chassis or earth ground wire should be connected to the minus of any one

and only one of the receiving devices. This prevents high or noisy common-mode “floating”

potentials between the isolated transmitter and grounded transducer circuits. Do not connect

a ground wire to each output. Again, the 4-20mA, RS232/422 and status outputs are all

common to each other and should be connected to isolated input cards.

Ò The status output located on field wiring terminal, JP7, is a digital 0-15Vdc output. This output

will go low in the event of a fault or power loss. The remaining JP7 outputs are not normally used

with the RheoVac monitor and should be left unconnected. If a non-standard option has been

ordered there will be additional notes in the SECTION 6.3 SPECIAL INSTRUCTIONS.

Ó Mount the transmitter enclosure. Install conduit such that all seals are watertight and rigidly

secure. A separate external power switch is recommended to shut the equipment off during

outages. When the vacuum system is on-line, do not turn off power to the RheoVac monitor

unless you are preparing to take the probe out of the pipe.

Ô Choose a path for the transducer to transmitter cable conduit. Route the transducer interface

cable through the conduit (See Figure 9). The cable is labeled at both ends. DO NOT CUT

OR SPLICE THE CABLE, AS THIS WILL DESTROY THE LABELING AND MAY

AFFECT THE INSTRUMENT CALIBRATION. Pull the cable through the conduit starting

at either end; coil up the remaining length outside the transmitter or transducer enclosure, or

in a cable junction box.

- 11 -

Page 14

Õ Pull wires through the conduit. Wire for power connection must be at least 24 gauge. After

pulling the wire, pot the conduit or wires near the enclosure if there is any possibility of

water from condensation or spray entering the enclosure through the conduit.

. CAUTION: The electronics are not protected against condensed liquid water inside the

enclosure. Be sure conduit interfaces are dry or sealed at the instrument to prevent

condensation that may be present in conduit lines from entering the enclosure.

Ö Make wiring connections. Power should be off at this time. Refer to Figure 9 for RheoVac

monitor wiring detail. Make power and transducer connections first on the lower circuit

board. Next connect the 4-20 mA signal wires at JP3 and the two status output wires at JP7.

There are no other terminals used on the upper board connector JP7.

. . WARNING: Verify the wiring. The equipment can be permanently damaged if not wired as

instructed in this manual.

Wire Color Label Wire Color Label Wire Color Label

Drain Wire (Black) A Red H Black/Brown Stripe O

Brown B Yellow I Green Stripe P

Orange C Purple J Black Stripe Q

Blue D Gray K Red Stripe R

White E Brown Stripe L Yellow Stripe S

Green F Orange Stripe M Purple Stripe T

Black G Blue Stripe N Gray Stripe U

× Install serial communication interface (see Figure 11, Pg. 14). Connections are made to the

serial communication receptacle with a cable with six-position RJ-11 plugs (phone type

jacks) supplied as an accessory. When using the RS-232 output, plug the RJ-11 connector

of the supplied cable into the RheoVac unit’s RS-232 receptacle. Plug the other end of the

RJ-11 cable into the provided RJ-11 to DB-9 adapter. The DB-9 adapter should then be

plugged into any standard IBM-PC compatible RS-232 port. Table II and Figure 11 provide

information on the connections.

Usually an RS-422 signal is converted to RS-232 before it is connected to a PC. The

converters do not have a standardized pin assignment, so use of the RS-422 output is less

straight-forward. The DB-9 pin out shown in Table II applies to an interface module,

QCOM-2, made by QSI Corporation. Other modules may have different wiring. Contact the

factory if you need assistance in using the RS-422 output.

Please note, the transmitter supports only one communications type at a time.

Close the lid of the enclosure. Make sure it is tight enough to make a good seal against the

gasket and ensure all other enclosure openings are completely watertight.

- 12 -

Page 15

TABLE II. RJ-1 1 t o DB-9 Module Adapt er

RS-232 CONFIGURATION RS-422 CONFIGURATION

RJ-11 Pin Out DB-9 Pin Out RJ-11 Pin Out DB-9 Pin Out

1 Tx (transmit) 1 N/C 1 Tx+ (transmit+) 1 Rx! (receive!)

2 N/C 2 Tx (transmit) 2 Tx! (transmit!) 2 Rx+ (receive+)

3 Rx (receive) 3 Rx (receive) 3 Rx+ (receive+) 3 Tx+ (transmit+)

4 N/C 4 N/C 4 Rx! (receive!) 4 N/C

5 Power (+5V) 5 Ground 5 Power (+5V) 5 Ground

6 Ground 6 Pulled high 6 Ground 6 Tx! (transmit!)

7 N/C 7 TBD

8 Pulled high 8 TBD

9 N/C 9 TBD

2.6 RheoVac SYSTEM GROUNDING

The RheoVac electrical system includes the RheoVac monitor and your data collecting inputs. In

general, it is good practice to use a single point grounding scheme to terminate the system output circuit

to a stable reference potential. Improper grounding may cause significant data noise, or in extreme cases,

damage your equipment. To simplify this task, determine which outputs you will be using and refer to

the following section for specific grounding instructions.

• RS232/422 Serial Output Only - Many PCs have non-isolated serial ports. You must

determine if your serial port is isolated. With your PC (or DCS, etc.) powered and plugged

into a grounded outlet measure both the Vdc and Vac between the local circuit’s earth ground

and pin 5 of the PC’s RS232 DB-9 connector. If the voltage is not zero the circuit needs to

be grounded. Connect a locally earth-grounded wire to the RheoVac instrument’s “OUT1”

(!) terminal of JP7 located next to the RS232/422 jack (see Figure 9). If the voltage reads

zero, no additional grounding should be attached. Additionally, we have seen noise

problems with certain laptop computers when they are connected to their external power

supplies. Some of them are not fully isolated and have signal noise levels as high as 12Vac

on the serial port GND pin. In this case, the circuit should also be grounded by connecting

a wire to the RheoVac’s “OUT1” (!) terminal.

• 4-20mA Output Only - If only a single output channel is used, it may be connected directly

to a non-isolated input channel without any additional grounding. Any additional output

connections require isolated inputs. If all inputs are isolated, regardless of how many are

used, a single channel should be grounded locally near the input card(s). In this case, connect

a locally earth-grounded wire to one of the 4-20mA (! ) terminals.

• Multiple Outputs - Review the special wiring configurations above. Connecting all of the

used outputs to isolated input devices results in one common isolated circuit. This common

circuit needs to be grounded at a single point. Choose one of the ground points listed above.

- 13 -

Page 16

- 14 -

Serial Communications Interface

Page 17

SECTION 3 — OPERATION

3.1 GENERAL INFORMATION

The RheoVac monitor is compensated and linearized for a wide range of flowing media temperatures,

pressures, and water vapor contents. However, abrupt changes in these parameters can cause the

instrument to temporarily read the flow rate improperly, which could lead to transient spikes in the flow

indication. In particular, if liquid (water) hits the probe tips, there will be high flow indications until all

the water vaporizes. This is a rare occurrence which should not happen if the transducer is properly

installed, according to instructions in SECTION 2 — INSTALLATION.

3.2 SYSTEM START-UP

The RheoVac monitor has been designed for fast warm up following turn-on of power. When power is

first turned on, no differential temperature will exist between the heated and reference probe sensors.

The transmitter is programmed to apply heat to the sensor for a set period of time or until a factory set

value is reached. Then the heater will return to normal. During this initialization period, the display will

have the message '*INTEK, INC.*' on the top line and '*(614)895-0301*', the phone number of Intek,

on the bottom. This message will then change to '*RheoVac*' and the unit's serial number. The bottom

display line will then change to 'initializing'. During this period the status output will be low (alarm

condition) and the analog outputs should be ignored. Further, no data is being transmitted over the serial

ports. The flow value will be monitored internally for stability, which will occur before the display is

set to the normal reading state. After the start-up sequence, program execution is sent to the main

instruction loop. It takes several seconds to execute the initialization sequence.

Upon a "cold" initial start-up of the RheoVac monitor, the transducer may take several minutes to give

accurate air in-leak flow measurements. During this time the probe is transitioning to thermal

equilibrium conditions under vacuum.

3.3 OUTPUT SIGNALS

Standard on all RheoVac instruments are one 2 x 20 alpha numeric LED backlit display, ten 4-20 mA

analog outputs, one 0-15V digital status port, and one serial communication port. Each process variable

is a linear, fully temperature and pressure compensated value on any of these readable outputs. All 4-20

mA output signals are scaled such that 4 mA represents 0% of the rated full scale value and 20 mA

represents 100% of the rated full scale value. The standard full scale values and definitions of all

process variables are listed in Table III.

Note: When the pressure rises above the calibrated range of 10" Hg absolute, all of the flow outputs will

indicate zero. In some instruments the display will read "General Fault Mode 6" at higher pressures,

such as one atmosphere. This is not a problem and the unit will read correctly under vacuum conditions.

Therefore, no flow rates will be reported when the generator is off-line or during hogging until the

pressure falls below 10" Hg absolute. All other variables will continue to be output normally.

- 15 -

Page 18

Table III. Process Variable Definitions and 4-20 mA Range

PROCESS VARIABLE

4-20 mA

FULL

SCALE

VALUE

PROCESS VARIABLE DEFINITION

ACTUAL VOLUME FLOW

[ACFM]

TOTAL MASS FLOW

[lbs/hr]

WATER VAPOR MASS FLOW

[lbs/hr]

RheoVac PRESSURE

[" Hg]

WATER VAPOR SPECIFIC

VOLUME [cu. ft/lb]

WATER to AIR MASS RATIO 20

RELATIVE SATURATION

[%]

PARTIAL PRESSURE, WATER

["Hg]

AIR IN-LEAK

[SCFM]

RheoVac TEMPERATURE

[°F]

10000

10000

5000

8000

30

100

10

100

210

The actual volumetric flow rate of gases leaving the condenser. It is a

measure of exhauster capacity. Decreased capacity means pump

degradation.

The total mass flow rate of the flowing gas. Note: this value is not a

measure of air in-leak. It is a measure of steam jet ejector capacity.

The water vapor component of the flowing gas being removed from the

condenser.

Absolute pressure at the RheoVac probe head. Should be equal to or less

than turbine back pressure.

The inverse density of the water vapor present in the line.

Ratio of water vapor flow rate to dry air flow rate. Defines “vacuum

quality.”

The percent concentration of wa ter vapor in the extraction line relative to

saturation.

The partial pressure of water vapor in the vacuum line.

Actual measure of air volume flow rate passing the RheoVac sensor head,

normalized to standard conditions (70°F, 29.9" HgA).

Temperature of the flow media at the RheoVac probe head.

3.4 IBM-PC SOFTWARE

IBM-PC Windows 95 compatible software has been provided. This software performs four primary

functions. It allows the user to:

• access data stored inside the RheoVac monitor over the last 24 hours

• chart all ten process variables from the RheoVac serial output (transmitted by means of

RS-232 or RS-422)

• archive the data into a general spreadsheet format

• change the line size stored inside the instrument for mass and volume flow calculations.

The best way to archive RheoVac data is with a dedicated PC or DCS serial channel. However, RheoVac

software allows data from the last 24 hours to be downloaded to a PC file. This data is stored internally

in the RheoVac instrument. The data format is TAB delimited and is easily imported to spread sheet

programs. Column headers are included in the file and are defined in Table IV. There are two additional

columns which are not shown in the table. These two columns pertain to factory calibration and

diagnostics. They are for factory use only. For continuous archiving, a computer capable of running

Windows 95 software is required. The 24-hour instrument internal record is mainly a backup for

troubleshooting or for daily data collection when continuous control room recording is not available.

3.4.1 SOFTWA RE INSTALLATION

- 16 -

Page 19

System Requirements (minimum recommended):

Windows 95, 98, or NT, 32M RAM

Pentium 100MHz, SVGA 800 x 600

One (1) RS-232 serial port w/DB-9 connector

Install the software by inserting disk 1 into an IBM-PC compatible disk drive, select that drive, and click

on the “Setup” icon. A folder, C:\RHEOVAC, will be created and seven files will be copied to this

folder. The two executable files are: “uninst.exe” and “RVMain95.exe”. The others are drivers and

configuration files and must remain in the RheoVac folder. An Excel macro file is also included for

Excel users. It quickly formats downloaded or archived data into fields with the appropriate precision

and width.

Execute the “uninst.exe” program only

If you want to move the application to a new drive or path, move only the folder contents to the new

location.

To execute the “RVMain95.exe” application the instrument must be installed with all communication

connections in place. Double click on the RVMain95 icon in the RHEOVAC folder. After several

seconds a menu will appear. The first time the application is launched, you are likely to be prompted

to check the system’s clock setting. A real-time clock has been included on-board the RheoVac monitor.

Therefore, the instrument has to be synchronized to your computer’s clock. This is done automatically

each time the software application is launched. Each download will contain a time stamp given by the

RheoVac monitor. Make sure your host computer’s clock is accurate before passing the clock setting

to the instrument. A communication error message may also occur initially. When this error occurs

initially, it usually means the software configuration file needs to learn which serial communication port

is connected to the instrument. Select the correct port when prompted, then hit the “RETRY” button.

If the error does not then go away, refer to the troubleshooting section of this manual.

3.4.2 SOFTWA RE OPERATION

Execute the “RVMain95.exe” by double clicking on the RVMain95 icon in the RHEOVAC folder. Use

this menu to choose from 24hr Data Download, Air In-Leak Monitor, or Change Line Size.

if you want to remove the entire application from your hard drive.

To select the choices from the Main Menu, left click on the button to the left of the desired option. For

help feature, right click on any button or control and pick “Description...” from the pick list.

- 17 -

Page 20

RheoVac 24hr Data Download - Selecting this choice initiates a download from the data stored

in the RheoVac instrument. This operation takes a few minutes to complete. After the data has

been transferred, you will be prompted to select a filename to store the data. The default filename

is the instrument’s serial number with an “.eep” file extension.

RheoVac Air In-Leak Monitor - Use this choice to plot selected data on single or dual charts.

This application can also be used to acquire data continuously into your computer system. The

screen shown on page 20 appears when this choice is selected. Select the rate that the RheoVac

data will be written to disk. This number represents the time between data points saved to disk.

The stored process values will be the average value of all incoming data since the last archive.

After setting the archive rate, hit the “ARCHIVE TO FILE” button. This begins data collection to

your hard drive. Any previously saved data in the selected file will be retained as new data is

appended to the end of the older data. Each file record contains a time stamp and all ten process

variables regardless of the chart configuration or group select status. The file is built in an ASCII

spreadsheet tab-delimited format and can be easily imported to spreadsheet programs such as Excel.

Archiving continues to build data into the active archive file. You should maintain the file size by

temporarily stopping the archive and renaming the data file based on your data management needs.

Intek recommends either daily or weekly data maintenance schedules.

We encourage you to send to the factory an initial week or so of data (zipped format is preferred)

via e-mail at techsupport@intekflow.com. This provides a baseline for the particular condenser

and will help us support you should future system problems arise. Our experienced support

engineers can access the “before” and “after” effects of an upset and work with you to identify and

understand the problem.

For further assistance on any feature, select help by right clicking on any button or control in the

application window and select “Description...” from the list.

Change Line Size - Use this option to update the instrument's stored line size variable for proper

volume and mass flow calculations. You should only need this option if the probe is installed in

a pipe size that is different from the value set in the instrument at the factory. Enter the new line

value, then click on “Send.”

3.4.3 DA TA PROCESSING

TABLE IV. Colum n Heading s f or Dat a Dow nloads and A rchived Dat a

O

Time

Stamp

(Time of

day)

0 1 2 3 4 5 6 7 8 9 10

Actual

Volume

Flow

(ACFM)

Total

Mass Flow

(lbs/hr)

Water

Vapor

Flow

(lbs/hr)

RheoVac

Pressure

("Hg abs)

Water

Vapor Sp.

Vol.

(Cu. ft/lb)

Water to

Air Mass

Ratio

(lb/lb)

Relative

Saturation

(%)

H

2

Partial

Pressure

("Hg abs)

Air Flow

In-Leak

(SCFM)

Probe

Temp . (°F)

Data may be retrieved from disk into any ASCII viewer or spreadsheet program. To do this, data

archiving may need to be terminated unless you open the file as read-only. Data is stored with an

appropriate number of significant digits. However, spreadsheet programs such as Excel may need you

to do additional formatting to display each field to the precision you need (e.g., Excel displays the time

- 18 -

Page 21

stamp by default in a “M/DD/YY HH:MM” format). You may prefer to reformat these cells to

“M/DD/YY HH:MM:SSp/m” to display time to the nearest second in am/pm format. Once in your

desired format, you may construct trend graphs using your spreadsheet or other analysis program. An

Excel macro file is included to automatically format the raw downloaded or archived data.

3.5 CUSTOM SOFTWA RE

Custom software may be developed by the user to receive and archive RheoVac data into a computer

system. The electronics has a serial data protocol of 9600 baud, no parity check, eight data bits and one

stop bit (i.e., 9600,N,8,1). Each transmitted group of data is sent in a standard ASCII coded format

representing each process variable value, instrument identification and status information.

The data stream consists of 13 fields, followed by a carriage return <RETURN>. The first ten fields,

nine bytes each, are the process values. Following the process variables are the RheoVac serial number,

nine bytes, the process identification tag number, 15 bytes, and the RheoVac system status, seven bytes.

The data stream is then ended by a single <RETURN> byte (ASCII code 13). The total number of bytes

transmitted in each data stream is 122 bytes including the trailing <RETURN>. This data group is sent

about once every three seconds. Table V shows the field names and number of bytes in one data stream.

TABLE V. Serial Output Data Stream

Actual

Volume

Flow

(ACFM)

9

bytes

Water

Total

Vapor

Mass

Flow

(lbs/hr)

bytes9bytes

Flow

(lbs/hr)

9

RheoVac

Pressure

("Hg abs)

9

bytes

Water

Vapor

Sp. V ol.

(Cu.

ft/lb)

9

bytes

Water to

Air Mass

Ra tio

(lb/lb)

9

bytes

Relative

Saturation

(%)

9

bytes

H2O

Partial

Pressure

("Hg abs)

9

bytes

ID

Tag

No.

Status

(°F)

Instr.

Serial

Number

Air Flow

In-Leak

(SCFM)

bytes9bytes9bytes15 bytes7bytes1byte

Probe

Temp.

9

Term.

<CR>

Each of the first ten process values are sent in the fixed decimal format of XXXX.XXXX with leading

and trailing zeros inserted to maintain the nine character length. The next three fields are ASCII text

strings followed by the <RETURN>. Example: The nine bytes for an air in-leak of 10.0 SCFM would

be: 0010.0000, or 48,48,49,48,46,48,48,48,48 ASCII.

- 19 -

Page 22

Figure 12 RheoVac Air In-leak Monitor IBM PC Display Menu for Plotting & Charting Data

- 20 -

Page 23

SECTION 4 — MAINTENANCE

4.1 GENERA L MAINTENA NCE

Precautions should be taken to insure proper performance of all sensors. Since the quantification

technique involves signal measurements, care should be exercised to prevent build-up of dirt and/or

corrosive layers on the various terminal strip connections. Periodic checks with necessary cleaning

should be performed to insure clean terminals. The joints of the sensor leads should occasionally be

inspected for corrosion or presence of moisture.

4.2 CALIBRATION

The RheoVac air in-leak instrument is calibrated at the factory in a calibration system which replicates

the condenser and vacuum line environment. The system is designed to calibrate the temperature,

pressure, water vapor relative saturation and flow sensor under the gaseous fluid conditions found within

the power plant vacuum line.

In general, calibrations should be valid over a two to five year period. Should the unit require re-ranging

or recalibration, note the serial number of the RheoVac instrument and contact the factory concerning

recalibration cost and turn around times. Refer to SECTION 5 — CUSTOM ER SERV ICE of this

manual for additional information.

4.3 SPA RE PARTS

There are no normally recommended spare parts to stock. Should a spare be needed, a complete unit

should be ordered and stocked.

Spare fuses should be available for replacement of blown fuses. Appropriate fuses to stock are:

C Slow blow 250mA Wickmann fuse, part number 3720250041 or equivalent, for the

microprocessor printed wiring board (top board);

C Slow blow 160mA Wickmann fuse, part number 3740160041 or equivalent, for the flow

meter's heater on the microprocessor printed wiring board (top board);

C Fast acting 2A Wickmann fuse, part number 3731200041 or equivalent, for the sensor

interface printed wiring board (bottom board.)

4.4 TROUBLE SHOOTING

Table VI provides a guide for plant personnel to identify causes of problems and determine appropriate

actions to resolve problems observed. If problems are encountered and factory assistance is desired, take

field check readings as identified in Table VII before contacting factory.

- 21 -

Page 24

TABLE VI. Trouble Shooting Guide

OBSERVATION PROBABLE CAUSE ACTION

'GENERAL FAULT'

'MODE 0'

‘GENERAL FAULT'

'MODE 1'

'GENERAL FAULT'

'MODE 2'

'GENERAL FAULT'

'MODE 3'

'GENERAL FAULT'

'MODE 4'

'GENERAL FAULT'

'MODE 5'

1. Shorted cable connection

2. Damaged flow sensor

1. Improper cable hookup

2. Failed A/D circuit. Short between

sensor terminals C and D of JP4 or

electronics terminals 3 and 4 of JP2

3. Damaged flow sensor

1. Cable contact corroded

2. Damaged flow sensor

1. Cable cut or not connected at all 1. Check cable for contact and continuity

1. Blown heater fuse at F1

2. Damaged flow sensor

1. Sensor's heater connection is open at

terminal H of JP4

2. Damaged flow sensor

1. Check for short in cable due to moisture

or corrosion

2. * Contact factory

1. Verify cable hookup is correct

2. Check cable connections for proper

contacts or moisture & corrosion

3. * Contact factory

1. Check both ends of cable for moisture

or corrosion

2. * Contact factory

1. Check wiring and replace fuse

2. * Contact factory

1. Check sensor heater for an open

connection

2. * Contact factory

1. Sensor at atmospheric pressure (fault

mode will disappear by the time

'GENERAL FAULT'

'MODE 6'

‘GENERAL FAULT'

'MODE 7'

Flow output saturates

high, will not

respond to flow

changes

Flow output saturates

low will not respond

to flow changes

* Record voltages in Table VII (last column) before contacting the factory. Use a high input impedance digital voltmeter for these

readings. All readings are to be taken from terminals A through U on JP4 (Dwg 94114-3, p. 10).

vacuum pressures are reached).

2. Pressure sensor not connected at

terminal L of JP4

3. Damaged pressure sensor

1. Temperature is above the specified

maximum (210°F)

2. Possible sensor damage

1. Flow rate is not within range of

calibration

2. Loose or damaged transducer cable

3. Blown heater fuse

4. Bad electronic component

1. System pressure is above 10" Hg

2. Flow rate out of range of instrument

3. Loose or damaged transducer cable

4. Bad electronic component

1. Restore operating vacuum condition or

ignore indication

2. Check pressure sensor for an open

connection

3. * Contact factory

1. Record temperature and remove sensor

from flow stream

2. * Contact factory

1. Contact factory about re-ranging

instrument

2. Fix cable / connection

3. Replace fuse

4. * Contact factory

1. Contact factory if operation above

10" Hg is required

2. Contact factory to re-range instrument

3. Fix cable connection

4. * Contact factory

- 22 -

Page 25

When using the RheoVac software on a PC, the software may give you a “Communication Error.” Use

the following table to determine the source of this message and appropriate action.

TABLE VI. Trouble Shooting Guide (software communication errors)

OBSERVATION PROBABLE CAUSE ACTION

Appears the first time

the application was

executed

Appears

intermittently after

application has been

running normally

Completely stops

working after

application was been

running normally

Canno t be made to

work at a ll with

Com3 or Com4

Works fine w ith

RS-232 but does not

work with RS-422

1. Instrument not connected to the

software defaulted serial port

2. Communication connections not made

or instrument is not powered

1. Electrical noise interfering with

communications

2. Too many applications running in

windows

3. Another application is conflicting with

this comm port or IRQ

1. Instrument has stopped communicating

2. Loose or damaged communication

connection

1. Works fine on Com1 or Com2 but does

not work on other port due to other

hardware conflicts such as a modem

1. Converter module not wired or cabled

correctly

2. Instrument jumper not set to RS-422 or

jack not plugged into RS-422

1. Change serial comm port setting and hit

“Retry”

2. Check connections and instrument

power

1. Change to RS-422 communications, reroute or shield cable

2. Close other applications until problem

self corrects

3. Change to a different comm port

1. Check instrument power or look at

instrument display for fault status

2. Check cable adapter at back of PC or at

any other splices or at instrument

1. Using windows Control Panel - System

utility, check for IRQ or I/O hardware

conflict - ADVANCED USERS ONLY

1. Review communications interface

section of manual. Supplied adapter is

for RS-232 only. Convertor connectors

may have different pinouts.

2. Move jumper or jack

If the RheoVac instrument is operating without fault mode indications but output readings are

questionable, please send to Intek by telefax or e-mail the following plant data

: turbine back pressure,

hot well temperature, load, and inlet and outlet circulation water temperatures, along with a 24 hour data

down load from the RheoVac Monitor. (See SECTION 3.4.2)

- 23 -

Page 26

TABLE VII. Field Check Readings

JP4WIRE

LABEL†

TRANSDUCER CABLE / WIRE

SIGNAL DEFINITION

EXPECTED

VOLTAGE [Vdc]

+ !

B A Flow sensor common voltage sense < 1.0V

C A Flow sensor current return 0.000V

D F Flow sensor heated RTD voltage sense Range: 5 to 40mV

E B Flow sensor heated RTD current source Range: .2 to .4V

F B Flow sensor reference RTD voltage sense Range: .2 to .4V

G B Flow sensor reference RTD current source Range: .2 to .4V

H B Flow sensor heater <10V

I Q Relative saturation sensor voltage source Range: 10 to 14V

J K Relative saturation sensor RTD differential voltage sense (+) Range: 1.0 to 1.4V

K Q Relative saturation sensor RTD offset voltage sense Range: 0 to !2V

L M Pressure sensor differential voltage sense (+) Range: 0 to 100mV

M K Pressure sensor offset voltage sense Range: 1.5 to 2.5V

*

RECORDED

VOLTAGE [Vdc]

N Q Relative saturation sensor voltage (+) Range: .5 to 5.5V

O K Pressure sensor current source Range: 3.5 to 4.5V

P K Relative saturation RTD current source Range: 1.0 to 1.4V

R Q Relative saturation heater supply Range: !2 to !4V

S Q Relative saturation heater return Range: !.7 to +.05V

T K Pressure sensor port heater supply Range: !18 to !24V

U Q Pressure sensor port heater return < .1V

*Complete this table and fax it to the factory (See SECTION 5 — CUSTOM ER SERVICE).

†Connect + lead of volt meter to + column; Connect ! lead of volt meter to ! column.

- 24 -

Page 27

SECTION 5 — CUSTOM ER SERVICE

Intek's corporate philosophy is to help solve our customer's difficult flow measurement problems. When

you purchase a RheoVac monitor you also receive Intek's outstanding customer service. For sales or

product service, call your local representative or Intek directly at (614) 895-0301 8AM to 5PM EST/EDT

weekdays or fax us anytime at (614) 895-0319. E-mail inquiries should be sent to sales@Intekflow.com

or techsupport@Intekflow.com. Our customer service staff will provide assistance promptly.

5.1 QUESTION ON EXISTING HARDWARE

To allow us to help you more quickly, please have the serial number of the equipment available before

you call.

5.2 TROUBLE SHOOTING

If you have reviewed SECTION 4.4 TROUBLE SHOOTING and have questions, please call our

experienced engineers for assistance. In many cases we can solve a problem over the phone by analysis

of the data taken on TROUBLE SHOOTING, Table VII. Please record as much of the data as possible

prior to calling.

5.3 FACTORY A ND FIELD SERVICE

If you request field service, Intek has experienced engineers available to meet your needs. The RheoVac

monitor is complex and most repairs or recalibratio ns will re quire returni ng the instrument to t he factory.

If a problem cannot be solved over the phone, with your help, we will determine if factory service or

field service will be the best solution.

To request factory service, a Return Material Authorization (RMA) or purchase order is required. Our

customer service staff will assist you with the required information to return instruments for service.

5.4 QUESTIONS ON NEW EQUIPMENT

For a new RheoVac Monitor application or any liquid or gas flow measurement need, contact the Intek

technical sales department at the above phone/fax numbers. Our staff will be pleased to answer all

questions and provide quotations.

- 25 -

Page 28

SECTION 6 — CUSTOM INFORMATION

6.1 UNIT IDENTIFICATION

Model no.:

Serial no.:

Customer identification:

6.2 CONFIGURATION

The marked (X) items denote the configuration of this unit, as originally shipped from the factory.

Pipe Connection: : Hot tap with 1½" MNPT connection

9 Other

Input Power: : 115 Vac, 50/60 Hz

Q 230 Vac, 50/60 Hz (switch)

Calibrated Ranges: Air In-Leak: 0 to 100 SCFM (4-20 mA)

Outputs Ordered:

Analog: : 10 outputs, Standard (See Table I)

Digital: Q RS-232 Q RS-422

Calibrated for customer line size of

6.3 SPECIAL INSTRUCTIONS

inches, schedule

- 26 -

Loading...

Loading...