Page 1

Multi-Parameter Monitor

Model MPM-1 Technical Manual

Page 2

Multi-Parameter Monitor

Model MPM-1

Technical Manual

1 Introduction

1.1 Disclaimer and Warnings......................................................................... 1-2

1.2 System Overview ..................................................................................... 1-4

1.3 Technical Specifications .......................................................................... 1-7

1.4 Limited Warranty................................................................................... 1-10

1.5 Contact Information ............................................................................... 1-11

2 Operation

2.1 General Operation.................................................................................... 2-2

2.2 Principles of Operation ............................................................................ 2-9

3 Testing and Preventive Maintenance

3.1 Operational Testing.................................................................................. 3-2

3.2 Battery Replacement.............................................................................. 3-26

3.3 Bedside Monitor Calibration.................................................................. 3-27

4 Troubleshooting

4.1 Introduction.............................................................................................. 4-2

4.2 Power Supply Malfunctions..................................................................... 4-3

4.3 LCD Malfunctions ................................................................................... 4-4

4.4 Error Messages......................................................................................... 4-5

4.5 Cabling and Interfacing Problems ........................................................... 4-7

5 Technical Notes

40201–C MPM-1 Technical Manual

Page 3

1 Introduction

1.1 Disclaimer and Warnings..................................................................................... 1-2

1.2 System Overview ................................................................................................. 1-4

1.3 Technical Specifications ...................................................................................... 1-7

1.4 Limited Warranty............................................................................................... 1-10

1.5 Contact Information ........................................................................................... 1-11

40201–C

1-1 MPM-1 Technical Manual

Page 4

1.1 Disclaimer and Warnings

PROPRIETARY INFORMATION

INFORMATION CONTAINED IN THIS TECHNICAL MANUAL IS

PROPRIETARY TO INTEGRA NEUROSCIENCES AND MAY BE USED

ONLY FOR THE PURPOSE OF PERFORMING OPERATIONAL CHECKS.

THE PURCHASE OR POSSESSION OF THIS MANUAL DOES NOT

CONFER, TRANSFER OR LICENSE ANY OTHER RIGHTS TO THIS

INFORMATION. ANY OTHER USE OR DISCLOSURE AND/OR

REPRODUCTION (BY ANY METHOD) OF THE INFORMATION

CONTAINED HEREIN IS STRICTLY PROHIBITED UNLESS WRITTEN

PERMISSION IS OBTAINED FROM INTEGRA NEUROSCIENCES.

AUTHORIZED SERVICE

This manual is intended for use by biomedical personnel to perform operational

checks. Any adjustments or procedures that exceed the scope of this manual

should be referred to Integra NeuroSciences.

Integra NeuroSciences does not condone or approve of service activity on its

products by anyone other than Integra NeuroSciences personnel; and Integra

NeuroSciences is not responsible for any unauthorized repairs.

DEFINITION OF DANGER, CAUTION AND NOTE

Danger – means there is the possibility of injury or death to you or others.

Caution – means there is the possibility of damage to the unit or other property.

Note – indicates points of particular interest for more efficient and convenient

operation.

SAFETY CONSIDERATIONS

Danger – Risk of explosion if used in the presence of flammable anesthetics.

Caution – Do not autoclave or immerse the MPM-1 as damage may occur. If the

MPM-1 is exposed to liquids, turn off the unit, remove the power cord

and thoroughly dry the unit before reapplying power.

Caution – Do not use solvents or cleaning agents as they could damage the plastic

exterior of the MPM-1.

Caution – To reduce the risk of electric shock do not remove the cover. Refer

servicing to qualified personnel.

Caution – Read Directions for Use before connecting to bedside patient monitors.

Caution – Grounding reliability can only be achieved when connected to Hospital

Grade Receptacle.

Caution – Where the integrity of the external PROTECTIVE EARTH

CONDUCTOR arrangement is in doubt, the equipment shall be

operated from its internal electrical power source (battery).

40201–C

1-2 MPM-1 Technical Manual

Page 5

Caution – This equipment should not be used with high frequency surgical

equipment.

Caution – Integra NeuroSciences Catheters are for single use only. Do not

attempt to re-sterilize or reuse. Integra NeuroSciences cannot assume

any responsibility for damage caused by re-sterilized Catheters. Used

catheters should be considered as a potential biohazard. Follow all

established laws and regulations pertaining to the handling and disposal

of biohazardous materials.

Caution – The MPM-1 contains Static Sensitive Devices. Observe proper ESD

precautions when working with Static Sensitive Devices.

SHIPPING INSTRUCTIONS

A shipping container is available. To insure proper preparation and shipping,

contact Integra NeuroSciences for instructions.

APPLICABILITY

This Technical Manual is applicable to the Multi-Parameter Monitor with

waveform display, Model MPM-1. Contact Integra NeuroSciences for

information for equipment not covered in this manual.

Integra NeuroSciences reserves the right to change specifications and procedures without

notice.

40201–C

1-3 MPM-1 Technical Manual

Page 6

1.2 System Overview

1

2

3 7

4 8

5 9

Figure 1-1 International Front Panel

1

6 6

7 2

3

4 8

5 9

10

11

Figure 1-2 Domestic Front Panel

1. START/STOP – Press to turn MPM-1 on or off.

2. SCALE – Press to change scale of pressure waveform on MPM-1 Display.

3. CAL STEP - Used to calibrate or check correlation of external bedside monitor.

4. SYS/DIAS – Press to toggle between the CPP-ICP-ICT display and the

SYSTOLIC-ICP-DIASTOLIC display.

5. TREND – Press to graphically display the last 12 or 24 hours of ICP and/or CPP

values.

6. LCD DISPLAY – Displays ICP waveform, numerical values and trend data.

7. SILENCE ALARM – Press to silence the alarm for 3 minutes.

8. UP and DOWN – Press the button(s) to set the desired alarm limit value.

9. ALARM DISABLED INDICATOR – Illuminates whenever the ICP alarm limit is

set to OFF. Flashes when alarm is temporarily silenced.

10. AC POWER INDICATOR - Illuminates when MPM-1 is connected to ~AC

power. The battery will charge whenever this indicator is illuminated.

11. LOW BATTERY INDICATOR – Illuminates when MPM-1 is operating on

Battery power and less than fifteen minutes battery life remains.

10

11

40201–C

1-4 MPM-1 Technical Manual

Page 7

12

13

14

15

16

17

19

18

Figure 1-3 Rear Panel

12. COMBINATION CORD WRAP, HANDLE, and BED RAIL MOUNT

13. DFU POCKET – Storage location for the Directions for Use booklet.

14. BEDSIDE MONITOR CONNECTOR – Used for connection to the bedside

monitor.

15. EQUIPOTENTIAL CONNECTOR – Used as the connection point for

equipotential systems.

16. ICP ISOLATED ANALOG CONNECTOR – Used for data acquisition needs.

Provides 1V/100 mmHg output suitable for computer ADC’s or a strip chart

recorder.

17. RS232 CONNECTOR – Used for data acquisition needs. Please contact Integra

NeuroSciences for details on use of this digital data.

18. AC CONNECTOR – Attachment point for the ~AC power cord. Automatically

selects input ~AC voltage of 100, 115 or 230 Volts. Must be plugged into an AC

source whenever it is desired to maintain a charge on the internal battery.

19. POLE CLAMP – Used to secure the MPM-1 to an equipment pole.

40201–C

1-5 MPM-1 Technical Manual

Page 8

20a

20c

20b

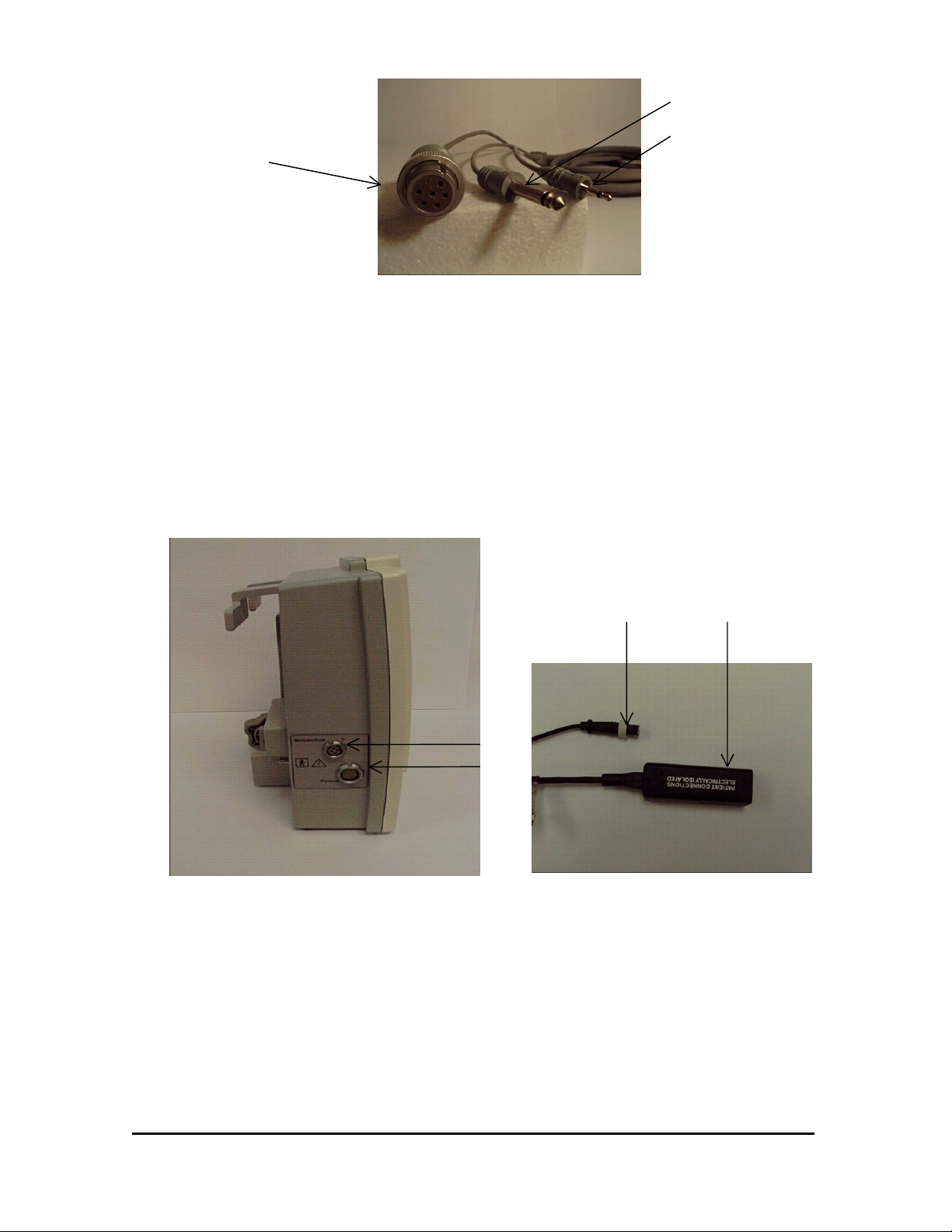

Figure 1-4 Bedside Monitor Cable

20. BEDSIDE MONITOR CONNECTOR – Used for connection to the bedside

monitor.

20a. ICT data to Bedside Monitor (Standard Phone Plug)

20b. ICP Waveform to Bedside Monitor (6-Pin Cannon Connector)

20c. Arterial Pressure Data to MPM-1 (Miniature Phone Plug)

22a 21a

22

21

Figure 1-5 ICP & ICT Connectors

Figure 1-6 Preamp Cable

21. ICP CONNECTION – Attachment point for the Preamp Cable Connector.

21.a ICP Catheter to Preamp connection.

22. TEMPERATURE CONNECTION – Attachment point for the Temperature Cable

Connector.

22.a ICT Catheter temperature connection.

40201–C

1-6 MPM-1 Technical Manual

Page 9

1.3 Technical Specifications

INTRACRANIAL PRESSURE (ICP)

Sensor Type: Fiber-optic pressure transducer

Range: -10 to +250 mmHg

Resolution: 1mmHg for LCD display

0.125 mmHg for Patient Monitoring Systems

Linearity: See individual catheter specifications.

Hysteresis: See individual catheter specifications.

Freq. Response: 120 Hz nominal, 100 Hz minimum (3dB down)

1.32 mSec for analog output

Accuracy: ± 1 mmHg

Reference Pressure: Atmospheric

INTRACRANIAL TEMPERATURE (ICT)

Sensor Type: Thermistor transducer

Display Range: 16.7°C to 42.2°C (65°F to 108°F)

Accuracy: ± 0.3°C (0.5°F) [30ºC - 40ºC]

MEAN CEREBRAL PERFUSION PRESSURE (CPP)

Type: Calculated

Range: 0 to 200 mmHg

Resolution: 1 mmHg

Accuracy: ± 1 mmHg

ALARMS

Audible: 2kHz ± 1kHz signal, ON 0.5 seconds and OFF 0.5 seconds

at full amplitude

High ICP Alarm: 0 to 250 mmHg, 1 mmHg increments

Low CPP Alarm: 0 to 150 mmHg, 1 mmHg increments

Alarm Silence: 3 minutes

40201–C

1-7 MPM-1 Technical Manual

Page 10

MONITOR INPUTS

“Trapezoidal” pre-amplifier input connection for Integra NeuroSciences ICP

catheters

Isolated 3-wire thermistor based TDC input for Integra NeuroSciences ICP/ICT

catheters.

Isolated Arterial Pressure (AP) for bed side patient monitoring systems. (1V/100

mmHg)

MONITOR OUTPUTS

Analog ICP for patient monitoring systems. (5µV/V/mmHg) (6-Pin CANNON

WK-6 connector)

Analog ICT for patient monitoring systems. (Standard 3-wire YSI 400 interface)

(Switchcraft ¼” Plug connector)

Analog ICP for data recording. (1V/100 mmHg) (Switchcraft Model 750

connector)

RS-232 Serial data port. Contact Integra NeuroSciences for details. (9 pin DB9

male connector)

DISPLAY

Type: Backlit TFT active matrix LCD panel

Parameters displayed: Pressure Waveform

CPP, ICP, ICT (Main Screen)

Systolic, ICP, Diastolic (Systolic/Diastolic Screen)

12 and 24 hour Trend Information (ICP and CPP)

BATTERY

Type: Rechargeable, sealed lead acid

Charge Time: 8-10 hours to full charge

Operation Time: 1-2 hour from full charge

POWER REQUIREMENTS

100-230 V, 50/60 Hz, 50 VA

MONITOR OPERATING LIMITS

Temperature: 15°C to 40°C (59°F to 104°F)

Pressure: 700 hPa to 1060 hPa (20.67 inHg to 31.30 inHg)

Humidity: 20% to 95% RH

40201–C

1-8 MPM-1 Technical Manual

Page 11

SHIPPING/STORAGE LIMITS

Temperature: 0°C to 50°C (32°F to 122°F)

Pressure: 500 hPa to 1060 hPa (14.76 inHg to 31.30 inHg)

Humidity: 20% RH to 95% RH non-condensing

PHYSICAL DIMENSIONS

Size: 274 mm H x 216 mm W x 89 mm D

(10.8” x 8.5” x 3.5”)

Weight: 4.4 kg (9.8 lbs.)

IEC-60601-1

Class of Equipment: Class 1

Protection Against Fluids: Ordinary

40201–C

1-9 MPM-1 Technical Manual

Page 12

1.4 Limited Warranty

INTEGRA NEUROSCIENCES warrants that each new INTEGRA NEUROSCIENCES

product is free from defects in material and workmanship under normal use and service

for a period of two (2) years (except as otherwise expressly provided as to accessory

items) from the date of delivery by INTEGRA NEUROSCIENCES to the first purchaser

but not beyond the “Expiration” date stated on any product labeling. Surgical

instruments are guaranteed to be free from defects in material and workmanship when

used normally for their intended purpose. Any covered product which is placed by

INTEGRA NEUROSCIENCES under a lease, rental or installment purchase agreement

and which requires repair service during the term of such placement agreement shall be

repaired in accordance with the terms of such agreement. If any such defect occurs

during the warranty period or term of such placement agreement, the purchaser should

communicate directly with the INTEGRA NEUROSCIENCES home office. If returned

to INTEGRA NEUROSCIENCES at its home office, repair or replacement will be

carried out at INTEGRA NEUROSCIENCES' sole discretion, at INTEGRA

NEUROSCIENCES' expense, subject to the terms of this warranty and applicable

agreements. The defective product should be returned promptly, properly packaged and

postage prepaid. Loss or damage in return shipment to INTEGRA NEUROSCIENCES

shall be at CUSTOMER’s risk.

IN NO EVENT SHALL INTEGRA NEUROSCIENCES BE LIABLE FOR ANY

INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES IN CONNECTION

WITH THE ACQUISITION OR USE OF ANY INTEGRA NEUROSCIENCES

PRODUCT. Further, this warranty shall not apply to, and INTEGRA

NEUROSCIENCES shall not be responsible for, any loss arising in connection with the

purchase or use of any INTEGRA NEUROSCIENCES product which has be repaired by

anyone other than an authorized INTEGRA NEUROSCIENCES service representative or

altered in any way so as, in INTEGRA NEUROSCIENCES' judgment, to affect its

stability or reliability, or which has been subject to misuse, negligence or accident, or

which has been used otherwise than in accordance with the instructions furnished by

INTEGRA NEUROSCIENCES. This limited warranty is exclusive and in lieu of all

other warranties, express or implied, and of all other obligations or liabilities on

INTEGRA NEUROSCIENCES' part and INTEGRA NEUROSCIENCES neither

assumes nor authorizes any representative or other person to assume for it any other

liability in connection with INTEGRA NEUROSCIENCES products.

INTEGRA NEUROSCIENCES DISCLAIMS ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR OF FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION OR

WARRANTY OF QUALITY, OTHER THAN THOSE EXPRESSLY SET FORTH IN

THE PRODUCT LABELING, INCLUDING THE APPLICABLE USER

INFORMATION. The foregoing shall not relieve INTEGRA NEUROSCIENCES from

strict tort liability, if otherwise applicable under governing law, for damages for personal

injury caused by a product defect that made the product unreasonably dangerous at the

time it was sold or placed.

40201–C

1-10 MPM-1 Technical Manual

Page 13

1.5 Contact Information

Customer Service Department

Integra NeuroSciences

105 Morgan Lane

Plainsboro, New Jersey 08536

(800) 997-4868 (USA/Canada)

(609) 275-0500 (International)

(609) 275-5363 (FAX)

CE Mark obtained in 1998

Authorized Representative:

MedPass International Limited

Windsor House

Barnett Way, Barnwood

Gloucester GL4 3RT, United Kingdom

40201–C

1-11 MPM-1 Technical Manual

Page 14

2 Operation

2.1 General Operation................................................................................................ 2-2

2.2 Principles of Operation ........................................................................................ 2-9

2.2.1 The Camino Catheter...................................................................... 2-10

2.2.2 Board 1 – Digital Board ................................................................. 2-12

2.2.3 Board 2 – Analog Board................................................................. 2-13

2.2.4 Board 3 – Power Supply, AC Input................................................ 2-18

2.2.5 Board 4 – Power Supply, DC Output............................................. 2-19

40201–C

2-1 MPM-1 Technical Manual

Page 15

2.1 General Operation

1. Turn on the MPM-1 by pressing the

START/STOP button on the front

panel. The MPM-1 will display the

“Camino Logo”(Figure 2-1).

2. Connect the Preamp Cable to the

MPM-1 by inserting the two cable

connectors in the appropriate

receptacle (Figure 2-2). Note the

red alignment marks on the cable

connectors and the side panel.

Temperature

Tran

sducer

Figure 2-1 Camino Logo

3. Select the desired Camino Pressure

Monitoring kit. Specific Directions

For Use may be found in the User

information insert provided with

each Pressure Monitoring Kit.

Pressure

Transducer

Figure 2-2 Preamp Cable to MPM-1

Figure 2-3 Catheter to Preamp Cable

40201–C

2-2 MPM-1 Technical Manual

Page 16

4. Remove the Catheter from the kit

tray, and firmly connect the

Transducer Connector(s) into the

Preamp Connector(s) (Figure 2-3).

(If a pressure only catheter is used,

then the temperature connector will

remain unconnected). After a short

system test, the MPM-1 Display

will change to the ICP/ICT display

(Figure 2-4).

5. Before inserting the Catheter into

the patient, ensure that the MPM-1

Display indicates an ICP Pressure

of “0 mmHg”. If not, use the tool

from the Catheter Kit to turn the

zero adjustment (Figure 2-5) on the

bottom side of the Transducer

Connector until the ICP Pressure

indicates “0 mmHg”. Also, ensure

that the temperature is a reasonable

value, such as room temperature,

before insertion of the Catheter into

the patient.

6. After the Catheter has been inserted

into the patient, (see the catheter

Directions For Use for proper

insertion technique) select the

appropriate scale by repeatedly

pressing the SCALE button on the

MPM-1 front panel (Figure 2-6).

Figure 2-4 CPP/ICP/ICT Display

Zero

Adjustment

Figure 2-5 ICP Catheter Transducer

Scale

Button

40201–C

Figure 2-6 Scale Button

2-3 MPM-1 Technical Manual

Page 17

7. If the MPM-1 is connected to an

external bedside monitor, the

CAL STEP button (Figure 2-7)

may be used to calibrate or

balance the bedside monitor. Each

press advances to the next mmHg

value in the following series: 0,

20, 40, 100, 200 and back to 0.

The CAL STEP momentarily

interrupts normal pressure signal

on both the MPM-1 and on the

external bedside monitor. Press

the CAL STEP button repeatedly

until 0 mmHg is displayed on the

MPM-1. While keeping the button

depressed to maintain 0,

simultaneously zero the bedside

monitor, then release the CAL

STEP button. Within a few

seconds, the MPM-1 will return to

the pressure display. Note that the

CAL STEP button may be used at

any time, and does not affect the

transducer calibration.

8. Press the SYS/DIAS button to

toggle between CPP, ICP, ICT

and SYS, ICP, DIAS displays

(Figure 2-8).

Cal Step

Button

Figure 2-7 CAL STEP Button

40201–C

Figure 2-8 SYS/DIAS Display

2-4 MPM-1 Technical Manual

Page 18

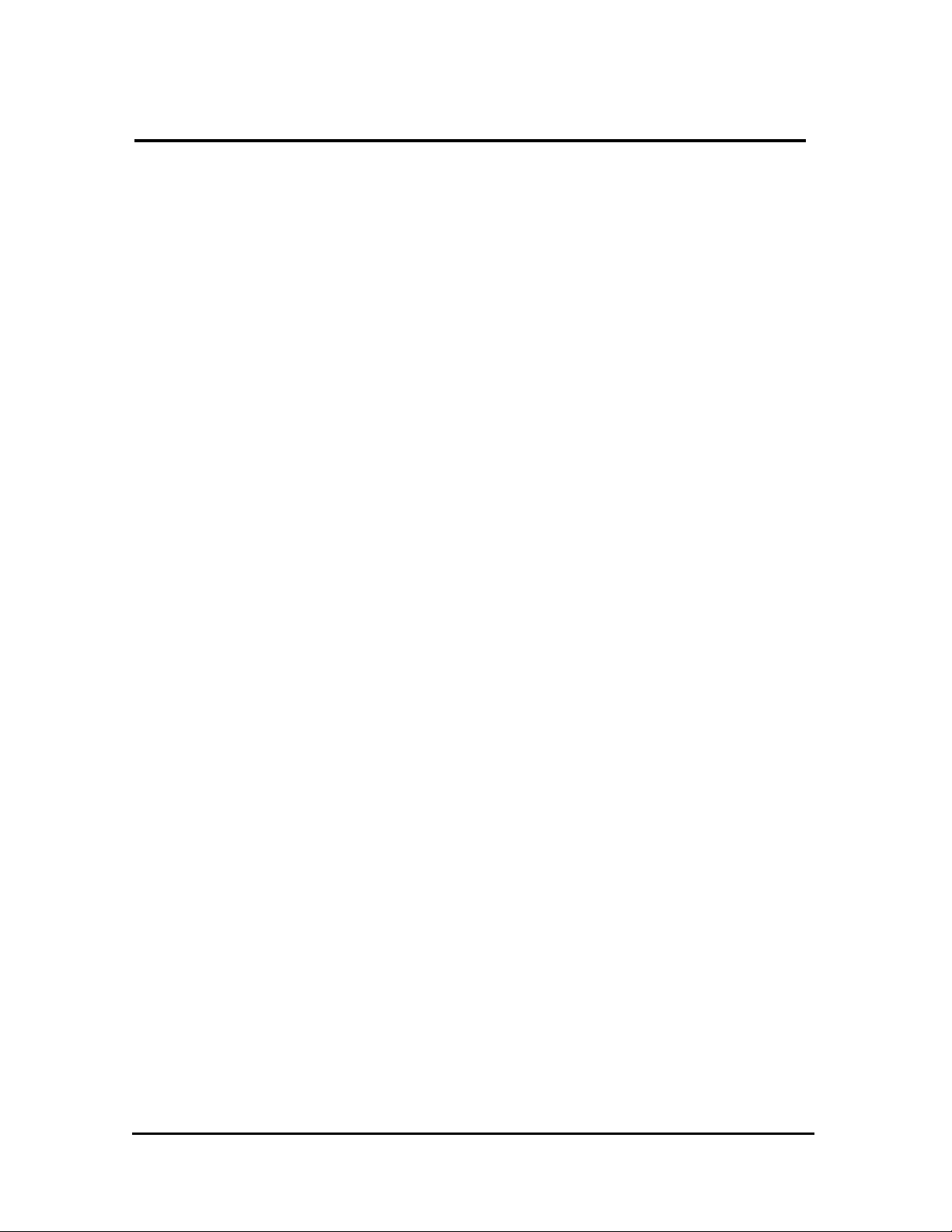

9. Press the TREND button to

display the mean ICP and CPP

value recorded during the

preceding 12 hours (Figure 2-9).

With the next press of the trend

button, the mean ICP and CPP for

the preceding 24 hours will be

displayed (Figure 2-10). Press

again to return to the pressure

display. To clear trend, turn

MPM-1 off momentarily.

NOTE - The trend information will

be lost if the MPM-1 is turned off

or if the battery discharges

completely and the MPM-1 turns

itself off.

NOTE - ICT and CPP values will

ONLY be displayed when using the

appropriate Catheter and/or bedside

monitor input connections.

NOTE - When not in use, the

MPM-1 must be connected to ∼AC

power to maintain battery charge.

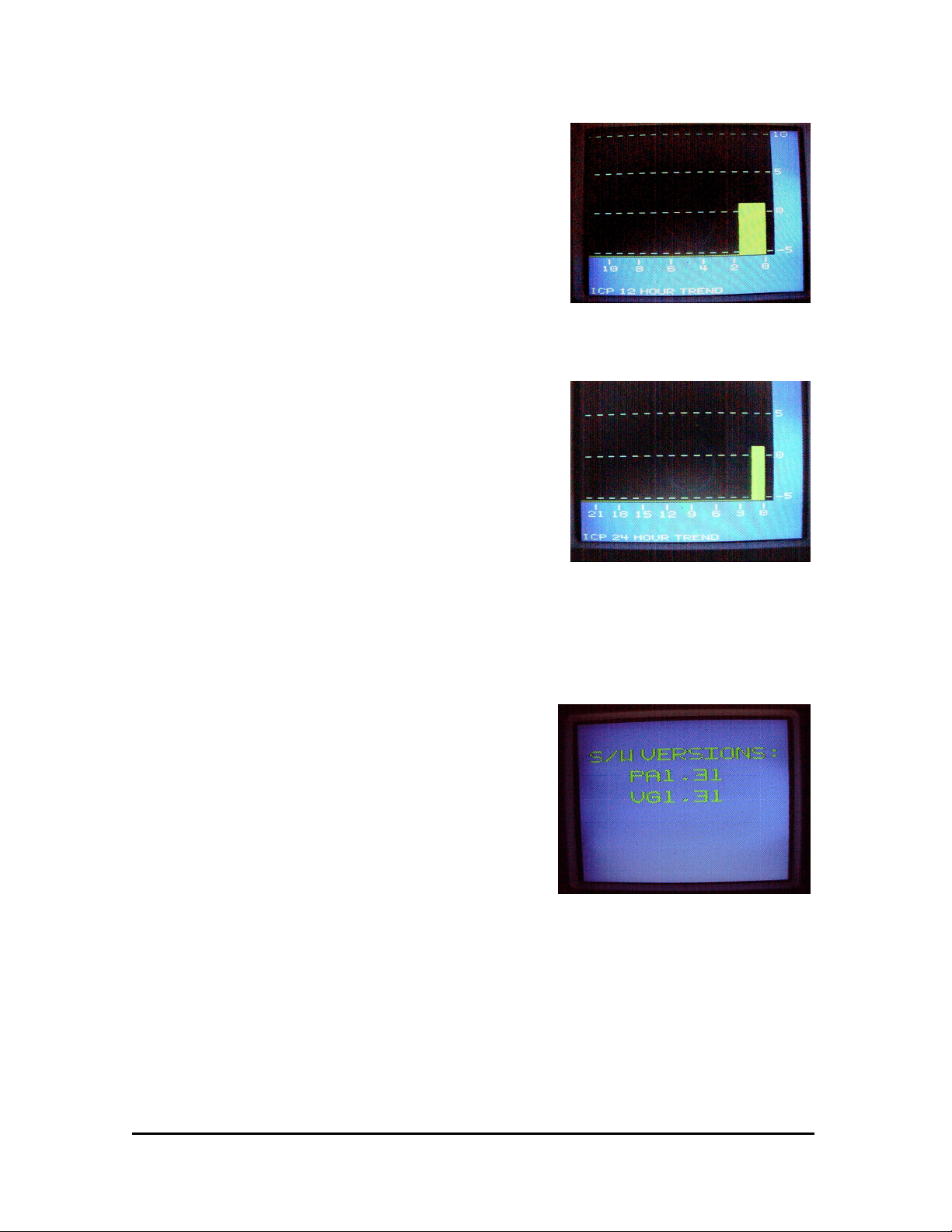

TO DISPLAY THE MPM-1

SOFTWARE VERSION

• Make sure that the MPM-1 is

powered off.

• Connect the Pre-Amp cable.

• Insert a catheter to Pre-Amp cable.

• Press and hold the DOWN button.

• While keeping the DOWN button

depressed, power on the MPM-1

by pressing the START/STOP

button.

• Hold the DOWN button until the

SOFTWARE VERSION appears

on the screen (Figure 2-11).

• Wait approximately 5 seconds for

the graph screen to appear.

Figure 2-9 12 Hour Trend

Figure 2-10 24 Hour Trend

Figure 2-11- Software Version Display

40201–C

2-5 MPM-1 Technical Manual

Page 19

TO CHANGE THE GRAPH MODE

This feature is available on software

version 1.29 and later.

• The graph mode can be either LINE

or FILL (Figure 2-12).

• The initial default graph mode is

FILL.

• The graph mode is saved every time

Directions:

• Make sure the MPM-1 is powered

off.

• Press and hold the SYS/DIAS

button depressed, power on the

MPM-1 by pressing the

START/STOP button.

• Hold the SYS/DIAS button until the

graph screen appears.

• Repeat the above to revert to the

FILL Graph Mode.

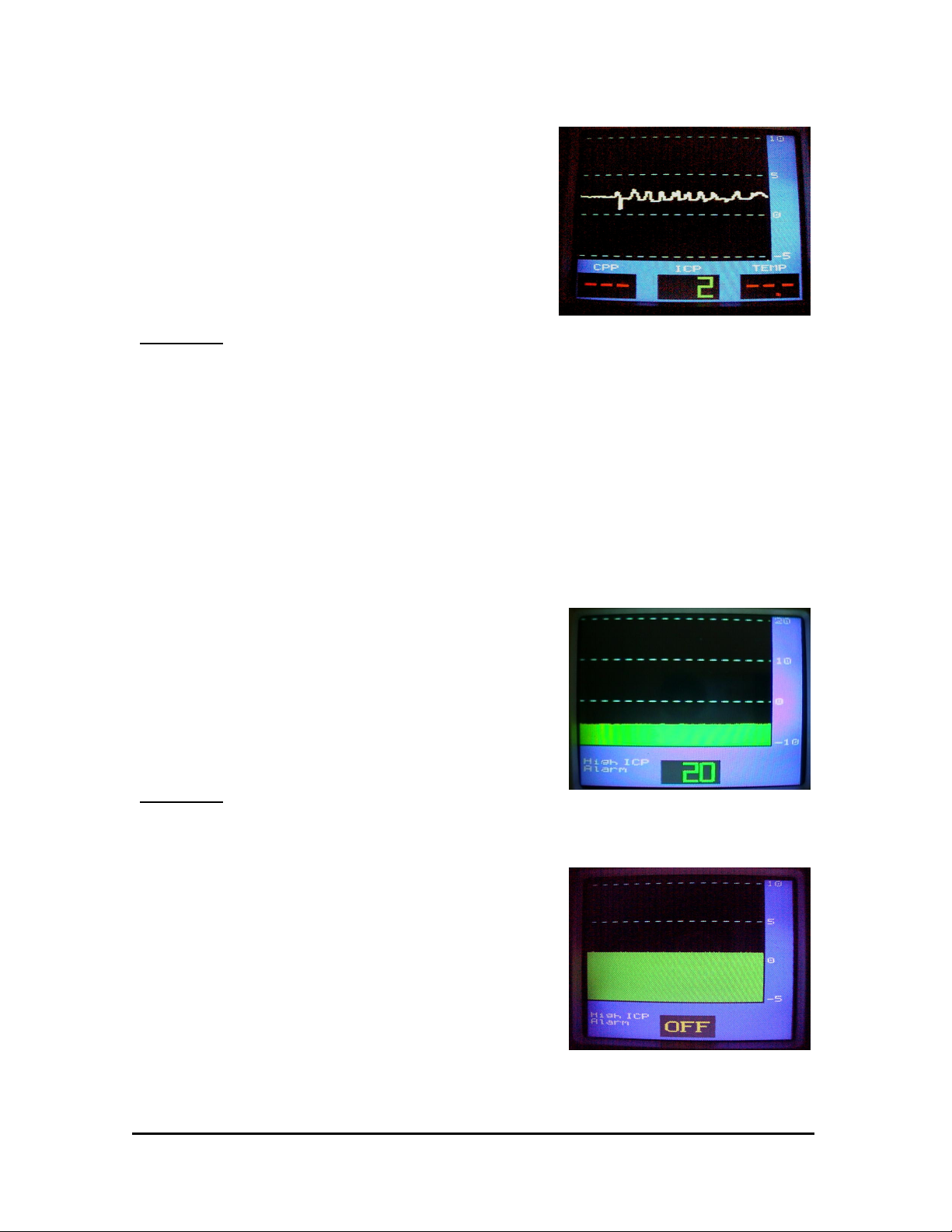

TO SET HIGH ICP ALARM

• The initial default ICP ALARM is

set to OFF. After that, the level is

saved every time it is set.

• Reminder: The alarm sounds and

the ICP parameter blinks when ICP

goes higher than the set point.

Directions:

• While the MPM-1 is on, press the

UP or DOWN button, view the

Alarm Select Screen.

• Press the UP button to select the

High ICP ALARM (Figure 2-13).

• Press the UP or DOWN button to

set the ICP ALARM to the desired

level.

• Wait approximately 5 seconds for

ICP ALARM to be set.

• Pressing the DOWN button until

the word “OFF” appears disables

this alarm (Figure 2-14).

Figure 2-12 Line Graph Mode Display

Figure 2-13 High ICP Alarm

Figure 2-14 High ICP Alarm, OFF Mode

40201–C

2-6 MPM-1 Technical Manual

Page 20

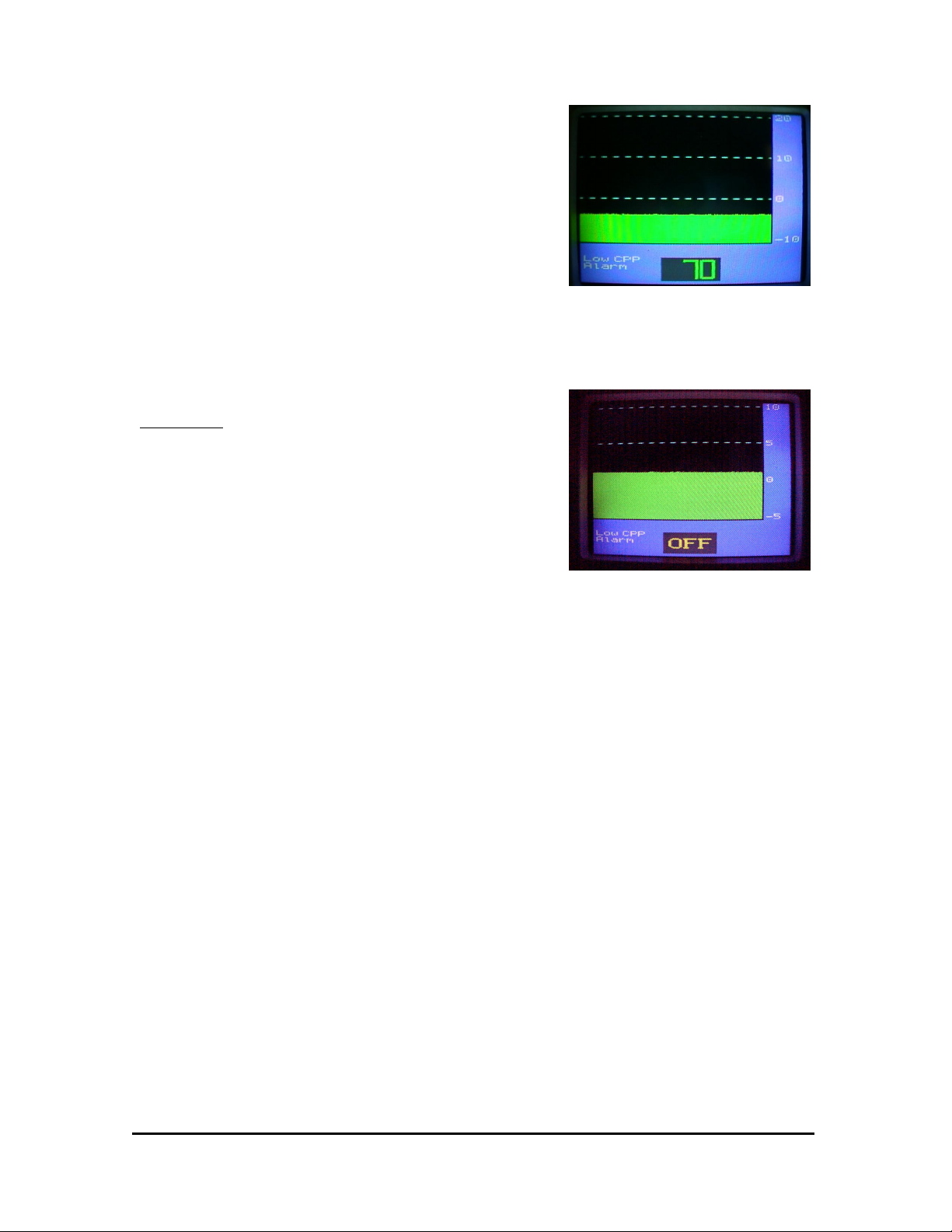

TO SET LOW CPP ALARM

This feature is available on software

version 1.31 and later.

• The initial default CPP ALARM

level is OFF. After that, the CPP

ALARM level is saved every time

it is set.

• Reminder: The alarm sounds and

the CPP parameter blinks when

CPP goes lower than the set point.

Directions:

• While the MPM-1 is on. Press the

UP or DOWN button, view the

Alarm Select Screen.

• Press the DOWN button to select

the Low CPP ALARM (Figure 2-

15).

• Press the UP or DOWN button to

set the CPP ALARM to the desired

level.

• Wait approximately 5 seconds for

CPP ALARM to be set.

• Pressing the DOWN button until

the word “OFF” appears disables

this alarm (Figure 2-16).

Figure 2-15 Low CPP Alarm

Figure 2-16 Low CPP Alarm, OFF Mode

40201–C

2-7 MPM-1 Technical Manual

Page 21

TO SILENCE THE ALARM

• The initial default CPP ALARM

and ICP ALARM levels are OFF.

After that, the CPP ALARM and

ICP ALARM levels are saved in

memory every time they are set.

Directions:

• Press the SILENCE ALARM

button. The ALARM DISABLED

INDICATOR will flash and

whichever parameter, ICP or CPP,

was in alarm mode will now be

silenced for 3 minutes and that

parameter will flash on the screen

(Figure 2-17).

NOTE: The parameter that is in alarm

mode will blink (even if it has been

silenced). If both alarms were in alarm

mode when the SILENCE ALARM

button was pressed, both alarms will be

silenced. If one parameter (ICP or CPP)

has been silenced and the other

parameter goes into its alarm mode

during the 3 minute silence period, the

silence alarm mode is disabled (the

alarm sounds).

BOTH ALARMS OFF

• As a warning, the ALARM

DISABLED INDICATOR will be

ON (and the alarms will be

disabled) when both of the alarms

have been set to OFF.

Silence

Alarm

Button

Alarm

Disabled

Indicator

Figure 2-17 Alarm Button & Indicator

40201–C

2-8 MPM-1 Technical Manual

Page 22

2.2 Principles of Operation

The Integra NeuroSciences Multi-Parameter Monitor with Waveform Display (MPM-1)

is a compact, portable device for use with Integra NeuroSciences 110-4 series of

Pressure/Temperature and Pressure Transducer-Tipped Catheters. Pressure and/or

Temperature are measured at the Catheter tip, eliminating the need for external

transducers, fluid, pressure tubing, and flush devices. The MPM-1 displays Intracranial

Pressure (ICP), Intracranial Temperature (ICT), and calculates Cerebral Perfusion

Pressure (CPP)

Note – CPP = MEAN ARTERIAL PRESSURE – MEAN INTRACRANIAL

PRESSURE

The MPM-1 provides a continuous display of the ICP waveforms, as well as mean ICP,

CPP and ICT, or mean ICP, systolic and diastolic values. A continuous record of ICP and

CPP values over the most recent 24-hour period is stored in memory, and can be

displayed on command as a TREND, either as the most recent 12 or 24-hour period.

Although the MPM-1 is intended to be a stand-alone system, it also conveniently

connects to hospital bedside monitoring systems. Outputs for ICP and ICT are available

for use with patient bedside monitors. An isolated analog output provides a continuous

ICP waveform for hard copy documentation or data acquisition. An input to receive

Mean Arterial Pressure from a compatible patient bedside monitor is available for use

when it is desired to have a CPP reading.

A built-in rechargeable battery permits monitoring during patient transport.

Internally, the MPM-1 consists of four printed circuit board assemblies:

Board 1 – Digital Board

Board 2 – Analog Board

Board 3 – Power Supply, AC Input

Board 4 – Power Supply, DC Output

40201–C

2-9 MPM-1 Technical Manual

Page 23

2.2.1 The Camino Catheter

Intracranial Pressure (ICP)

A fiber optic device, that consists of four fibers, measures intracranial pressure. Light

from an LED source is transmitted down one fiber, called the sender. The light is

reflected off the polished surface of a mechanical bellows and is collected by another

fiber, called the receiver. The reflected light, referred to as SIGNAL, is collected by a

photo-detector.

The other pair of fibers have the same characteristics and length. They are mounted

similarly and exposed to the same light source but the light is not reflected off the

polished bellows surface. Instead, the light is looped around from the sender, back to the

receiver. The light received from this dummy path, termed REFERENCE, is compared

to the light received from the SIGNAL path, forming a ratio. If light from the LED is

increased or decreased, both paths are affected, thus for a given pressure, the ratio of the

two paths does not change.

REFERENCE JUNCTION

BELLOWS

SEND/RECEIVE FIBERS

40201–C

2-10 MPM-1 Technical Manual

Page 24

The transducer has a close to linear response for the pressure range of –20 to 300 mmHg.

However, the catheter response must be linearized in order to get the required resolution

from the transducer. This is accomplished by applying a known pressure to the catheter

during manufacture and recording the resultant output pressure. This pressure is used to

construct a lookup table that the microprocessor in the MPM uses to correct the pressure.

This process is called linearization correction.

Due to manufacturing variations, the ratio of the amount of reflected light from the

bellows displacement to the reference is not the same for all transducers. In order to

normalize the output of each transducer, the transducer response is rescaled so that the

output to displacement ratio is the same for all transducers. This process is a slope

correction.

When linearization and slope corrections are accomplished, CHARACTERIZATION of

the transducer is complete. These corrections are encoded in resistor values that are

measured by the instrument. These values are translated into correction factors that are

then applied to the SIGNAL and REFERENCE outputs of the transducer.

Intracranial Temperature (ICT)

Intracranial temperature (ICT) is measured by an electrically isolated thermodilution style

thermistor, placed directly behind the bellows region of the catheter. The thermodilution

thermistor is a cardiac industry standard for temperature measurement, and the variation

is quite linear over the region of 30 – 40 °C (normal body temperature is 37 °C).

40201–C

2-11 MPM-1 Technical Manual

Page 25

2.2.2 Board 1 – Digital Board

Board 1 performs the Digital functions of the MPM-1.

The digital section of the MPM-1 consists of two Zilog Z180 processors with their PSD,

SRAM and Flash RAM arranged in twin kernel configurations. The Programmable

System Device (Wafer Scale Integration, PSD412) provides 64K EPROM and 2K

SRAM, memory and I/O space decoding, as well as certain logic functions (glue logic).

Also there is an external 32K SRAM for other temporary scratchpad and memory

functions. These processor systems are linked together with a 12 bit parallel port to

transfer data. The basic functions of these processor systems are as follows:

Pressure Processor System (consisting of Z180 U5, PSD U4 and SRAM U34):

• establishes communication with the catheter, reading the code resistors, then writes to

the DACs on the Analog Board the corresponding values for that catheter.

• guards that the Reference Loop is maintained (catheter is not disconnected, nor

inoperational).

• receives intracranial pressure, arterial pressure, intracranial temperature and

membrane switch status data via its serial link from Board 2.

• transmits data via the same serial link to the ICT Output, PMIO and Isolated Analog

port

• linearizes (straightens) intracranial pressure data received with an algorithm based on

information received from the catheter Curve 1, 2 code resistors.

• communicates the received (modified) pressure data, with handshake, to the Video

processor.

Video Processor System (consisting Z180 U24, PSD U25, Flash RAM U19, Dual Port

RAM U21 and FPGA 8282 U26):

• interrogates most of the membrane switch inputs and takes appropriate action

• performs averaging of all data received and making it available for placement onto

the LCD.

• computes CPP with Arterial Pressure data and ICP data.

• writes data to all stationary locations on the LCD screen such as mean ICP, CPP, etc.

• writes the first vertical line of pressure data received, then waits for a NTSC screen

interrupt to write again, thus constantly refreshing the screen. As averaged data

becomes available, this entire screen is written one vertical pixel line to the right and

a new vertical line of pressure data is inserted to the left—this creates the animated

display image.

Isolated Power Supply (consisting of U23, T2-T4, Q2):

• A current-mode, flyback topology switching regulator with isolation transformers

provide isolated power for all electrical functions requiring low leakage and isolation

from potential electrical faults.

40201–C

2-12 MPM-1 Technical Manual

Page 26

2.2.3 Board 2 – Analog Board

Board 2 performs the Analog functions of the MPM-1.

Pressure

The pulsed output (representing raw Pressure) received from the PAC-1 preamplifier is

conditioned by a scaling circuit with a ZERO DAC (digital-to-analog converter), then

filtered to DC, and scaled with a SPAN DAC. This results in a 0 to 200mV output as

pressure varies from 0 to 250 mmHg. Any catheter manufactured by Integra

NeuroSciences is first characterized (the DAC levels are determined). When this

particular catheter is used in any MPM-1 monitor, the DAC settings are reproduced by its

analog pressure circuitry. Thus each catheter is “normalized,” producing a consistent and

accurate pressure output. This analog signal must now be routed to an ADC (analog-todigital converter) which converts the analog level to a digital representation that can be

used by the microprocessor. In order to adequately use the ADC with its 4 volts of input

range, another scaling circuit follows this 0 to 200mV circuit to produce 1.172 to 3.125

volts, respectively. This optimally fits the ADC range allowing the ADC to output 1200

to 3200 counts, respectively. This 2000 count span from 0 to 250 mmHg is a sensitivity

of 8 counts per mmHg (approximately 8 mV per mmHg).

Reference

The output of the Reference signal is essentially a mirror image of the Pressure signal

discussed above. Its purpose is to faithfully produce an output that contains no pressure

signal but otherwise emulates the Pressure signal path. The Reference signal is employed

in a servo balancing scheme to carefully control the LED light output to minimize

semiconductor temperature coefficients and other error producing variables.

LED Drive

The LED (located in the catheter) is pulsed by the LED Drive at an approximately 1.3

kHz rate, with an ON time that is 1/16 of the OFF time, i.e., it is ON for about 83

microseconds and OFF for 1.25 milliseconds. This allows for a chopper amplifier style

sampling of signals at a higher frequency followed by low-pass filtering and the

implementation of a unique method of subtracting dark currents and unwanted signals.

The end result is a drift-free system that produces an output with a large signal-to-noise

ratio.

Code Resistor Circuit

A 245 microampere current source is connected to each of 9 precision resistors one at a

time, and the subsequent voltage (Ohms Law, Vout = Current x Resistance) is read by the

ADC which enables the microprocessor to adjust DACs and certain parameters. As it

was discussed in the Pressure

duplicate the DACs of the manufacturing characterizing equipment. These code resistors

contain the information needed to setup the DACs and the software curve-fitting

algorithm coefficients.

description, the DACs are adjusted for any MPM-1 to

40201–C

2-13 MPM-1 Technical Manual

Page 27

ZAD Circuit

A 4 milliampere current source is connected to the ZERO potentiometer located in the

catheter. Prior to placement of the catheter into the patient the nurse adjusts this

potentiometer to achieve ZERO. This is a necessary system adjustment that allows

catheters and monitors with normal variations to come together and operate correctly.

ICT Signal Connection

The analog signal from the IntraCranial Temperature measurement circuit is routed to the

ADC for measurement and subsequent readout on the LCD display.

Arterial Pressure Signal Connection

The analog signal from the external Arterial Pressure circuit is routed to the ADC for

calculation of CPP (CPP = AP, mean – ICP, mean).

Reference Voltages

The +7 volt supply from Board 1 is used to produce a precision +4 volt supply needed for

the ADC reference and a –2 volt supply needed for Pressure offset bias and Reference

servo command.

PMIO

The Patient Monitor Input/Output (PMIO) connects the MPM-1 to the bedside monitor.

The bedside monitor “views” the MPM-1 as an external transducer. In the bedside

monitor industry the typical input is from a transducer arranged as a Wheatstone Bridge

which can be imagined as 4 resistors of equal value connected in a diamond shape. The

top two resistors are connected to the excitation voltage provided by the bedside monitor

and the lower two resistors are connected to the bedside monitor common. The center

connections, by virtue of equal resistance value and by voltage dividing action produce

an output of zero volts

. By replacing one of the lower resistors with a strain gage of

equal resistance, an output, linear to changes in the strain gage resistance with pressure, is

obtained. By changing the excitation voltage higher or lower, a corresponding higher or

lower gain of the signal is achieved. With this arrangement, the output is automatically

positioned at the origin (no offset) and gain is a linear function of the excitation voltage.

In the case of the MPM-1, the PMIO circuitry emulates

an external transducer. Isooptical couplers enable the linearized pressure signal from the microprocessor to be

output digitally, with isolation

. This digital signal is converted by the DAC to an analog

signal, then appropriately scaled by the excitation signal (with an offset that moves with

gain), and is split from single-ended into a differential output. The desired result is to

have proportionate gain by increasing the excitation signal without increasing the relative

offset provided by the pressure. The output can be described as follows:

counts

.

...

V

out

5106V

exc

512

4096

150

This equation implements the medical specification for transducers used with bedside

monitors--5µV/Vexc/mmHg, that is, 5µV output per 1 volt of excitation for 1 mmHg,

except it additionally describes the pressure/ADC count scale used by the MPM-1.

40201–C

2-14 MPM-1 Technical Manual

Page 28

Solving for 0 mmHg which would be Vout = 0 volts, the counts must be equal to

150*4096/512 = 1200 counts. Similarly, at the rate of 8 counts per mmHg, 2000 counts

would be added to 1200 counts for a total of 3200 counts which reduces the amount in

the parenthesis to 250, thus 250 would be taken times 5µV times the Vexc voltage used.

As an example, for 5 volts excitation voltage and 200 mmHg of pressure, the differential

output would be 5 mV. Note that at the special point of 1200 counts (0 mmHg), the

output remains at zero regardless of excitation voltage therefore this circuit satisfies the

above desired result of proportionate gain without undue influence from the normal

offset.

Isolated Analog Output

The Isolated Analog Output provides an isolated, analog output to a printer, or to a

computer ADC that is a function of linearized pressure from the microprocessor, centered

at the origin (no offset), at 1V/100 mmHg. The purpose of isolation is to insure that a

“dirty” printer or computer connection would not cause harm to the patient. The output is

0 volts for 0 mmHg and 2.5 volts for 250 mmHg. This pressure signal processor is

output digitally to the Iso Analog ADC, which is followed by an offset and gain signal

conditioning circuit. Finally, a special IC provides galvanic isolation, which performs the

same function as in the PMIO above.

Arterial Pressure

The Arterial Pressure circuit interfaces the bedside monitor with the MPM-1 providing an

arterial pressure value (in volts) needed for CPP calculations. The microprocessor

computes:

CPP = AP, mean – ICP, mean

This circuit provides high impedance buffering in order to not load the bedside monitor

arterial pressure output. Additionally, it provides a low- pass filtered output to the MPM1 ADC using a 2-pole active Butterworth filter with a cutoff frequency of 10 Hz. Since

the bedside monitor is unknown and may be electrically “dirty”, an IC that provides

isolation is used to preclude any current carrying paths to the patient. A simple low-pass

pole at 159 Hz follows this isolation circuit to eliminate bucket-charge noise spikes.

40201–C

2-15 MPM-1 Technical Manual

Page 29

Additionally, this circuit provides voltage translation from the bedside monitor to the

MPM-1. The electrical descriptions are:

Output of the Bedside Monitor

:

1V/100 mmHg with its output centered at the origin for zero arterial pressure or,

y

= 0.01 x1

1

where y

is the output in volts and x1 is the arterial pressure in mmHg

1

measured by the bedside monitor from an external source

Input of the MPM-1 Arterial Pressure Circuit

x

= 128 y1 – 150 (or y1 = 0.007812 x2 + 1.172)

2

where y

is the input in volts and x2 is AP in mmHg used by the

1

:

microprocessor in CPP calculations

ICT Input

• The ICT Input circuit receives a voltage from a thermistor located in the tip of the

temperature/pressure catheter and provides appropriate offset and gain for accurate

temperature measurement.

• The thermistor is a custom device built/tested with a “pad” resistor enabling the

thermistor manufacturer to state a narrow range of resistances over the range of 30°40° C. The linear ICT input circuit is calibrated at these two points during Final Test

of the monitor to minimize error, which, in turn, allows the MPM-1 specification to

be ± 3.0°C over this range.

• The thermistor has a characteristic that an increasing temperature causes its resistance

decrease

to

. The thermistor (placed on top) and pad resistor (placed on bottom) are

connected in series forming a voltage divider where the voltage at the center point

with respect to common

increases

with an increase in temperature.

• When +1.0000 volt is applied as an excitation voltage, the above center point output

varies from .3498 volts to .4376 volts for a temperature of 30° to 40° C, respectively.

This excitation level, which would cause thermistor self-heating errors in air, was

chosen because the application is, in fact, in fluid. Using this level produces a signal

output much higher than noise or thermocouple errors.

• This thermistor output is defined as:

40201–C

y (in volts) = .0048779 x (in °F) - 0.0696849 {°F }

y (in volts) = .0087802 x (in °C) + .0864079 {°C }

2-16 MPM-1 Technical Manual

Page 30

• In order to optimize the +4.0 volt ADC input range, the extreme displayed

temperatures of 59 °F (15°C) to 113 °F (45°C) were chosen to have 0 to 3.78 volts,

respectively. This essentially provides a 70 mV (126 mV) change for each degree °F

(°C) displayed. This uses the entire ADC range and enables the use of a convenient

software lookup constant.

• To provide an extremely stable and precise output with negligible input loading an

instrumentation amplifier was used. Calibration during manufacturing is also easier

with the unity/full gain feature of an instrumentation amplifier.

• Because the thermistor is patient connected, an IC that provides isolation is used to

preclude any current carrying paths to the patient.

• This ICT Input circuit output is defined as:

y (in volts) = .070 x (in °F) – 4.13 {°F }

y (in volts) = .126 x (in °C) – 1.89 {°C }

ICT Output

• The ICT Output circuit interfaces the MPM-1 to the bedside monitor providing a

continuous set of resistance values for temperatures from 15° to 45° C. This emulates

a standard 3-wire YSI 400 thermistor resistance. In essence, the bedside monitor is

performing a thermistor meter function of type YSI 400 with digital readout on its

screen and the MPM-1 is producing a varying resistance output as a function of

patient temperature in similar fashion to a true YSI 400 thermistor. This approach

was used because theYSI 400 series thermistor input plug-in module is a bedside

monitor standard.

• This unusual configuration was necessary in order to maintain isolation between the

MPM-1 and the bedside monitor, yet allow a temperature readout on the MPM-1

LCD display

and

the bedside monitor (in some cases the bedside monitor may be

remotely located).

• Since this circuit connects an unknown bedside monitor that may be electrically

“dirty” to the MPM-1, the ICT Output circuitry is isolated by virtue of ISO-optical

couplers and an isolated power supply.

• The ICT Output circuitry consists of a processor controlled serial-to-parallel

converter followed by latches that control eight solid-state switches, each connected

to its precision resistor which is connected in parallel with a fixed 3500 ohm resistor.

The switches are arranged in a kind of ladder form allowing binary closing. The

switches are

normally open

, thus there is approximately 3500 ohms presented to the

output terminals for the lowest temperature readout of 15° C. As the measured

temperature increases, successive switches are closed in a

binary fashion creating 256

unique states of resistance values. The resistance is thereby reduced for increasing

temperatures. The selection of the precision resistance values is a one-time effort

requiring the use of a curve-fitting computer program.

• Due to the inherent internal resistance of the solid-state switches, several gangs of

switches are used in parallel (to reduce series switch resistance and minimize system

error) for the last two rungs of the ladder where the output resistance is rapidly

approaching that of the solid-state switch internal resistance.

40201–C

2-17 MPM-1 Technical Manual

Page 31

2.2.4 Board 3 – Power Supply, AC Input

The AC Input Board of the Power Supply provides "Off-line" conversion from the

MAINS (AC Line) to +16.5 volts of isolated, regulated power for Board 4.

Input requirements:

• 90 VAC (low-line Japan) to 264 VAC (high-line Europe).

Output drives 3 separate loads:

• The monitor circuitry (when the monitor when ON).

• A dummy load which minimally loads this supply (when the monitor is OFF).

• The battery charging circuit.

Features:

• Power is taken directly from the LINE, hence the term “Off-line” converter.

• Fixed frequency, current mode pulse width modulator topology.

• Isolation from the LINE exceeds 4500 VAC for safety.

• Output noise is in ‘sync’ with the master clock to minimize beat frequency noise.

• Output level is controlled by an isolated optocoupler with bandgap reference.

40201–C

2-18 MPM-1 Technical Manual

Page 32

2.2.5 Board 4 – Power Supply, DC Output

The DC Output Board of the Power Supply provides DC-DC conversion from the source

to +5V for Logic and LCD, +15V for LED Drive, +9V and -8V for OpAmps. This

power is extracted from either of two sources, the 16.5 volts from Board 3 or the nominal

12 volts from the lead acid battery.

Input requirements:

• 16.5 volts from Board 3 (if AC power is available and connected).

• 12 volts, nominal, from the battery (10.8 volts, minimum).

Outputs:

• +5 volts for Logic and LCD.

• +15 volts for LED drive.

• +9 volts for Operational Amplifiers.

• -8 volts for Operational Amplifiers.

Features:

• AC LED is illuminated when AC power is connected.

• BATTERY LOW lamp is illuminated (whenever the unit is ON and using battery

power) and the battery is discharged to less than 11.8 volts, warning that the battery

charge is depleted.

• Long shelf life for fully charged battery (less than 10 uA leakage current).

• 5 volt output controlled by bandgap reference; other outputs track this output given

nominal loading.

• Output noise is in ‘sync’ with master clock to minimize beat frequency noise

• Shutdown of Board 4 supply automatically occurs when the battery is discharged to

less than 10.8 volts.

• Battery charging is current limited to about 330mA protecting both the battery and

preventing overheating of the voltage regulator.

• Battery charging is maintained at two different, constant-voltage levels, nominally

14.4 volts and 13.8 volts, depending on the use and condition of the battery.

• Battery charging is temperature compensated, -4mV/degree C/cell.

40201–C

2-19 MPM-1 Technical Manual

Page 33

3 Testing and Preventive Maintenance

3.1 Operational Testing - Introduction....................................................................... 3-2

3.1.1 AC and Low Battery Indicator ..................................................................... 3-3

3.1.2 Battery Charger, Condition of Battery ......................................................... 3-4

3.1.3 Front Panel Checks....................................................................................... 3-6

3.1.4 Software Version.......................................................................................... 3-8

3.1.5 ICP Input Checkout (Graduated Drainage Bag)........................................... 3-9

3.1.6 ICP Input Checkout (Pressure Gauge) ....................................................... 3-12

3.1.7 ICP Input Checkout (Pressure Simulator).................................................. 3-15

3.1.8 High ICP Alarm Checkout ......................................................................... 3-16

3.1.9 Arterial Pressure Test ................................................................................. 3-17

3.1.10 Low CPP Alarm Test ................................................................................. 3-18

3.1.11 ICP Output Test.......................................................................................... 3-20

3.1.12 ICT Input Test ............................................................................................ 3-21

3.1.13 ICT Output Test.......................................................................................... 3-22

3.1.14 Isolated Analog Output Test....................................................................... 3-23

3.1.15 Ground Continuity Test.............................................................................. 3-24

3.1.16 Chassis Leakage Test ................................................................................. 3-25

3.2 Battery Replacement.......................................................................................... 3-26

3.3 Bedside Monitor Calibration.............................................................................. 3-27

40201–C

3-1 MPM-1 Technical Manual

Page 34

3.1 Operational Testing - Introduction

Operational testing procedures verify that the MPM-1 is in good operating condition and

accurate to significant levels. It can be a first step in locating a problem.

These tests can be performed in any order and individual tests may be selected for

performance from the entire series of tests. None of these operational testing procedures

require disassembly of the MPM-1.

If any performance parameter is not met, or an obvious malfunction occurs, the MPM-1

should be returned to Integra NeuroSciences for service.

Table 3-1 Recommended Tools and Test Equipment

Equipment Description Characteristics

DC Power supply 0-9VDC

Multimeter, Digital 1 mV minimum reading

Safety Tester BioTek Model 170 or equivalent

Cables

Pressure

Source

Catheter Integra Part Number 110-4BT

1 - 620Ω Resistor

2 - 10KΩ Resistors

1 - 10KΩ, 10 turn potentiometer

Power Cord Integra Part Number 60-006 or 60-007

Pre-Amp Integra Part Number PAC-1

PMIO Integra Part Number PMIO-MPM

Isolated Analog Output A 3.5mm phone plug at one end; the other

end to connect to a voltmeter (i.e., Fluke

79 using a double banana plug - See

Figure 3-26).

IV Bag, Tubing, Ruler, Y

Hemostasis

Pressure Gauge, Syringe,

Tubing, Male Luer, 4-way

stopcock with Luer Lock

Electronic Pressure Simulator 0 – 250 mm Hg (minimum)

Gauge 0 – 250 mmHg (minimum)

40201–C

3-2 MPM-1 Technical Manual

Page 35

3.1.1 AC and Low Battery Indicator

Low

Battery

Indicator

Figure 3-1 Front Panel Power Indicators

~AC

Indicator

1. Connect one end of the AC power cord to the back of the MPM-1. Connect the

other end of the AC power cord to a wall receptacle.

Note – The MPM-1 should have normal connections to its battery.

2. Check that the ~AC indicator is illuminated (Figure 3-1).

3. Disconnect power cord. Check that the ~AC indicator turns off.

4. Let the MPM-1 run on battery power until the LOW BATTERY INDICATOR

illuminates.

Note – Discharging a fully charged battery takes approximately 1-2 hours.

5. Connect the power cord to the MPM-1 and wall receptacle. Let the monitor charge

the battery for 8-10 hours to full charge.

6. Disconnect Power Cord.

7. Let the MPM-1 run briefly on battery power. Check that the LOW BATTERY

INDICATOR does not illuminate.

40201–C

3-3 MPM-1 Technical Manual

Page 36

3.1.2 Battery Charger, Condition of Battery

1. Disconnect power cord from MPM-1 and remove battery (follow Section 3.2 MPM-

1 Battery Replacement).

Negative

Spade Lug

Positive

Spade Lug

Figure 3-2 Battery Spade Lug Connectors

2. Connect power cord to MPM-1. Connect power cord to wall receptacle. Measure

the voltage across the spade lug connectors that connect to the battery. At room

temperature (20°C, 68°F), voltage will read approximately 13.8 volts.

Note – If room temperature is warmer, the voltage will be lower. If room

temperature is cooler, the voltage will be higher.

40201–C

3-4 MPM-1 Technical Manual

Page 37

Resistor

Figure 3-3 Spade Lugs with 620Ω Resistor

3. Disconnect the power cord from the wall receptacle. Connect a 620Ω resistor to the

spade lug connectors. Reconnect the power cord to the wall receptacle. Measure

the voltage across the resistor. At room temperature (20°C, 68°F), voltage will read

approximately 14.4 volts.

Note – If room temperature is warmer, the voltage will be lower. If room

temperature is cooler, the voltage will be higher.

4. If 13.8V and 14.4V are found, the charger is working properly.

5. With a properly working battery charger, reinstall battery and recharge the battery

for more than 12 hours, preferably 24 hours.

6. Operate the MPM-1 from battery power only. Operation should last 1 hour and 30

minutes (nominal) ± 20 minutes. If less, charge an additional day. If performance

improves so that operation time is greater than 1 hour and 10 minutes, battery is

acceptable. Repeat charge/discharge cycle a total of two more times if necessary to

improve operation time to acceptable levels.

7. Replace battery if operation is less than 1 hour and 10 minutes, and three

charge/discharge cycles does not improve operation time.

40201–C

3-5 MPM-1 Technical Manual

Page 38

Temperature

3.1.3 Front Panel Checks

ICP

Figure 3-4 Pre-Amp Cable to MPM-1

1. Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

2. Using a good catheter, firmly connect the pressure transducer connector to the Pre-

Amp cable (PAC-1). Do not connect the temperature transducer connector if you

are using a 110-4BT or 110-4HMT model catheter.

Zero Adjust

Figure 3-5 ICP Catheter Transducer

3. Turn on the MPM-1 by pressing the START/STOP button on the front panel. After

a short system test, the MPM-1 will display the “Integra Neurosciences Camino”

logo, then change to the CPP-ICP-ICT display. Ensure that the MPM-1 display

indicates an ICP Pressure of “0 mmHg”. If not, use the tool from the Catheter Kit to

turn the zero adjustment on the bottom side of the Transducer Connector until the

ICP Pressure indicates “0 mmHg”.

40201–C

3-6 MPM-1 Technical Manual

Page 39

Note – At this point, the MPM-1 should not be displaying a numerical value for

CPP and ICT. Both should read “---“ in red.

Start/Stop

Scale

Cal Step

Sys/Dias

Trend

Alarm Silence

Up/Down

Figure 3-6 Front Panel Controls

4. Make sure that the buttons function properly. The following table summarizes the

function of each button.

Table 3-2 Membrane Switch Functions

BUTTON

MPM

FUNCTION

START/STOP

SCALE

CAL STEP

Turns off and on

Changes Scale

Changes Bedside

Monitor Calibration

Pressure

SYS/DIAS

TREND

Changes Display

Displays last 12

hours / 24 hours of

ICP and CPP values

UP/DOWN

Sets or disables the

ICP and/or CPP

alarm

SILENCE

ALARM

Silences alarms for

three minutes

40201–C

3-7 MPM-1 Technical Manual

Page 40

3.1.4 Software Version

Figure 3-7 Typical Software Version Display

1. Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

2. Using a good catheter, firmly connect the pressure transducer connector to the Pre-

Amp cable (PAC-1). Do not connect the temperature transducer connector if you are

using a 110-4BT or 110-4HMT model catheter.

3. Depress DOWN ARROW button and hold while powering the MPM-1. Wait until

the current software version appears. System should display the most current software

version (call Integra NeuroSciences for current software version). If earlier software

version is displayed, the monitor should be returned to Integra NeuroSciences for

upgrade.

4. Release the DOWN ARROW button, and the MPM-1 should change to the CPP-

ICP-ICT display.

5. Turn off monitor.

40201–C

3-8 MPM-1 Technical Manual

Page 41

3.1.5 ICP Input Checkout (Graduated Drainage Bag)

I.V.

Bag

Tubing

Pre-Amp

Cable

Catheter

Figure 3-8 Graduated Drainage Bag Setup

Note: Before beginning this test, assure that MPM-1 is off, and it is not connected to any

cables.

1. Connect one end of AC cord to the wall and other end into MPM-1 on the back.

2. Connect Pre-Amp cable and a functional Camino catheter.

3. Fill half of the I.V. bag with water.

Pole

Ruler

MPM-1

40201–C

3-9 MPM-1 Technical Manual

Page 42

Catheter’s

tip

Y

Hemostasis

Figure 3-9 Y Hemostasis

4. Connect one end of tubing to the I.V. bag and other end to a Y hemostasis valve.

5. Insert the tip of the catheter into the Y Hemostasis valve through the duckbill valve.

Water

Level

End

cap

Figure 3-10 0 mmHg Position

6. Open the valve from the I.V. bag and remove the end cap from the Y Hemostasis

valve. Let water flow until tubing and Y Hemostasis valve fill with water.

7. Make sure that air bubbles are not present, then replace end cap.

8. Make sure that the water level (see red arrow) from the I.V. bag and the tip of the

catheter are at the same level. The MPM-1 should display 0 mmHg. In this example,

the catheter’s tip and the water are leveled with the 10-inch mark of the ruler.

40201–C

3-10 MPM-1 Technical Manual

Page 43

9. Turn on MPM-1 and make sure that it reads 0 mmHg. If not, zero adjust catheter.

Figure 3-11 7 mmHg position

Figure 3-12 18 mmHg position

10. Raise the I.V. bag 4 inches. The water level should be leveled with the 6-inch mark of

ruler.

Note: 1 inch H

O = 1.8683 mmHg.

2

11. The MPM-1 should read 7 ± 1 mmHg.

12. Raise I.V. bag for another 6 inches, and the MPM-1 should read 18 ± 1 mmHg.

13. End of test.

40201–C

3-11 MPM-1 Technical Manual

Page 44

3.1.6 ICP Input Checkout (Pressure Gauge)

Syringe

Pressure

Gauge

Tubing

Catheter

MPM-1

Pre-Amp

Cable

Figure 3-13 Pressure Gauge Setup

Note: Before beginning this test, assure that MPM-1 is off, and it is not connected to any

cables.

1. Connect one end of AC cord to the wall and other end into MPM-1 on the back.

2. Connect Preamp cable and a functional Camino catheter.

3. Turn on MPM-1 and make sure that it reads 0 mmHg. If not, zero adjust catheter.

Male

Luer

Vent

Tube

Figure 3-14 Catheter Vent Tube

4. Insert the male luer into the vent tube of catheter.

40201–C

3-12 MPM-1 Technical Manual

Page 45

To

pressure

gauge

4 way

stopcock

with luer

lock

From

catheter’s

vent tube

Figure 3-15 Syringe Connection

5. Connect the other end, coming from the catheter’s vent tube, to the 4 way stopcock

with luer lock.

6. Ensure the syringe’s plunger is firmly seated.

7. Connect the 4 way stopcock to the pressure gauge and syringe.

8. Confirm that the pressure gauge and MPM-1 read 0 mmHg.

40201–C

3-13 MPM-1 Technical Manual

Page 46

Figure 3-16 20 mmHg

Figure 3-17 100 mmHg

9. Once the pressure gauge and MPM-1 are zero adjusted, pull on the syringe’s plunger

until the pressure gauge reads 20 mmHg. The MPM-1 will settle and should display

the same simulated pressure value within ± 2 mmHg.

10. Repeat the same test for the following pressures: 40, 60, 100, 250 and back to 0

mmHg.

Table 3-3 Acceptable Range of Pressure

Applied Pressure MPM-1 Reading

0 mmHg 0 mmHg

20 mmHg 18 to 22 mmHg

40 mmHg 38 to 42 mmHg

60 mmHg 57 to 63 mmHg

100 mmHg 94 to 106 mmHg

250 mmHg 233 to 267 mmHg

40201–C

3-14 MPM-1 Technical Manual

Page 47

3.1.7 ICP Input Checkout (Pressure Simulator)

1. Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

2. Using a functional Camino catheter, firmly connect the pressure transducer

connector to the Pre-Amp cable (PAC-1). Do not connect the temperature

transducer connector if you are using a 110-4BT or 110-4HMT model catheter.

Catheter

Tip

Tubing

Male Luer

Loc

k

Figure 3-18 Pressure Simulator

Pressure

Simulator

3. Connect tip of catheter to pressure simulator using silicon tubing. Make sure that the

catheter tip fits firmly in the silicon tubing.

4. Turn the MPM-1 and the pressure simulator on and set the MPM-1 at the highest

sensitivity scale of –5 to +10 mmHg.

5. Adjust the Pressure Simulator to 0 mmHg, and zero adjust the catheter.

6. Set pressure simulator to 20 mmHg. Wait 15 seconds. The MPM-1 system will

settle and should display the same simulated pressure value within ± 2 mmHg.

Check for leaks in the set-up if the readings do not agree.

7. Repeat the same test for the following pressures: 40, 60, 100, 250 and back to 0

mmHg.

Table 3-4 Acceptable Range of Pressure

Applied Pressure MPM-1 Reading

0 mmHg 0 mmHg

20 mmHg 18 to 22 mmHg

40 mmHg 38 to 42 mmHg

60 mmHg 57 to 63 mmHg

100 mmHg 94 to 106 mmHg

250 mmHg 233 to 267 mmHg

40201–C

3-15 MPM-1 Technical Manual

Page 48

3.1.8 High ICP Alarm Checkout

1. Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

2. Using a functional Camino catheter, firmly connect the pressure transducer

connector to the Pre-Amp cable (PAC-1). Do not connect the temperature

transducer connector if you are using a 110-4BT or 110-4HMT model catheter.

3. Provide pressure to the catheter using any of the methods discussed in sections

3.1.5, 3.1.6 or 3.1.7.

Figure 3-19 High ICP Alarm

4. Turn on the MPM-1 and set the High ICP Alarm to 4 mmHg by pressing the UP-

ARROW.

5. Set the pressure source to 10 mmHg. The MPM-1 should display approximately 10

± 2 mmHg. After approximately 5 seconds, the alarm speaker should beep.

6. Silence the alarm by pressing the SILENCE ALARM button. The ALARM

DISABLED INDICATOR and ICP parameter should flash.

7. Wait approximately 3 minutes, and the alarm should resume beeping.

8. Decrease simulated pressure to 0 mmHg, and the alarm should silence.

9. Set High ICP Alarm to “OFF”.

40201–C

3-16 MPM-1 Technical Manual

Page 49

3.1.9 Arterial Pressure Test

1. Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

2. Using a functional Camino catheter, firmly connect the pressure transducer

connector to the Pre-Amp cable (PAC-1). Zero adjust the catheter. Do not connect

the temperature transducer connector if you are using a 110-4BT or 110-4HMT

model catheter.

3. Connect a PMIO cable to the rear connector of MPM-1, but do not connect to an

external bedside monitor.

4. Using a power supply, provide 1.000 ± 0.001 volts to the Arterial Pressure

connector (see Figure 3-20).

_

+

Figure 3-20 Arterial Pressure Connector

Note: AP = 1V/100 mmHg.

5. Turn on MPM-1. Wait until the CPP-ICP-ICT display appears. CPP parameter

should read 100 mmHg ± 1 mmHg since AP = 100 mmHg and ICP = 0 mmHg.

Note: CPP = AP-ICP.

40201–C

3-17 MPM-1 Technical Manual

Page 50

3.1.10 Low CPP Alarm

1. Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

2. Using a functional Camino catheter, firmly connect the pressure transducer

connector to the Pre-Amp cable (PAC-1). Zero adjust the catheter. Do not connect

the temperature transducer connector if you are using a 110-4BT or 110-4HMT

model catheter.

3. Connect tip of catheter to a pressure source. Make sure that tip of catheter fits firmly

to the pressure source with no leaks.

4. Connect a PMIO cable to rear connector of MPM-1, but do not connect to an

external bedside monitor.

6. Using a power supply, provide 1.000 ± 0.001 volts to the Arterial Pressure

Connector (see Figure 3-20).

5. Turn on MPM-1.

Figure 3-21 Low CPP Alarm

7. Set the LOW CPP ALARM to 4 mmHg by pressing the DOWN-ARROW. Set

pressure source to 98 mmHg. The CPP parameter should display 2 mmHg since

CPP = (100-98) mmHg. This value is lower than the value set in the alarm mode.

After approximately 5 seconds, the alarm speaker should beep.

8. Silence the alarm by pressing the SILENCE ALARM button. The ALARM

DISABLED INDICATOR and the CPP parameter should flash. Wait

approximately 3 minutes, and the alarm should resume beeping.

9. Decrease the value from pressure source to 92 mmHg. The alarm should silence

since now CPP = 8 mmHg which is greater than the value set in the alarm mode.

10. Increase simulated pressure to 98 mmHg (CPP = 2 mmHg), and the alarm should

resume beeping.

40201–C

3-18 MPM-1 Technical Manual

Page 51

11. Set LOW CPP ALARM to “OFF” by pressing the DOWN-ARROW. The alarm

should silence, and at this point the SILENCE ALARM INDICATOR will

illuminate since both alarm parameters, HIGH ICP ALARM and LOW CPP

ALARM, are set to “OFF”.

12. Set pressure source to 0 mmHg. Turn off MPM-1.

13. Disconnect power supply from AP connector.

40201–C

3-19 MPM-1 Technical Manual

Page 52

3.1.11 ICP Output Test

1. Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

2. Using a functional Camino catheter, firmly connect the pressure transducer connector

to the Pre-Amp cable (PAC-1).

3. Connect a PMIO cable to the rear connector of MPM-1, but do not connect to an

external bedside monitor.

5

(- PS) 4

(- DMM) 3

Figure 3-22 PMIO Connector

6

1 (+ PS)

2 (+ DMM)

4. Set power supply to 5 ± 0.001 volts and connect “+” and “-” leads to pins “1” and

“4” of the six pin cannon connector, respectively.

5. Connect the “+” and “-” leads of the Digital Multimeter (DMM) to pins “2” and

“3” of the six pin cannon connector, respectively.

6. Turn on monitor, and wait until the CPP-ICP-ICT display appears.

7. Press and hold the CAL STEP to produce 0 mmHg on the display. The DMM

should read less than .010 mVDC offset from 0 volts. The following table shows

simulated pressures by pressing and holding the CAL STEP button, and expected

voltages at pins “2” and “3”.

8. Turn off MPM-1. Remove power supply and DMM leads from PMIO cable

connector.

Table 3-5 Simulated Pressure & Voltage

Simulated Pressure (mmHg) Simulated Voltage (mVDC)

0

20

40

100

200

0.000 ± .001 mVDC

0.500 ± .001 mVDC

1.000 ± .001 mVDC

2.500 ± .001 mVDC

5.000 ± .001 mVDC

40201–C

3-20 MPM-1 Technical Manual

Page 53

3.1.12 ICT Input Test

2

(Vin)

1

(1Volt)

Figure 3-23 Temperature Transducer Connector

1. Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

2. Using a functional Camino catheter, firmly connect the pressure transducer connector

to the Pre-Amp cable (PAC-1).

3. Connect the leads of the Digital Multimeter (DMM) to pins 1 (1 Volt) and 3 (GND)

of Pre-Amp cable (PAC-1) temperature connector (Figure 3-23). Note: The ICT

parameter should be reading “---“ up to this point.

3

(GND)

4. Turn on the monitor, and the DMM should read 1.0000 ± 0.0001 VDC.

5. Turn off MPM-1, and remove DMM leads from temperature connector.

10KΩ

2

Vin

.350V = 30.0°C

.438V = 40.0°C

10KΩ

3

GND

Figure 3-24

Temperature Transducer

Connector Test Circuit Diagram

10KΩ

Adjust this pot for the

voltages at Pin

2 above.

1

1 Vol

t

6. Connect two 10KΩ resistors and a 10KΩ potentiometer to the temperature transducer

connector as shown in Figure 3-24. Connect the leads of the Digital Multimeter

(DMM) to pins 2 (Vin) and 3 (GND).

7. Turn on MPM-1, and adjust the 10KΩ potentiometer to produce a reading on the

DMM of 0.350 VDC. The monitor should display 30.0 ± 0.3°C.

8. Adjust the 10KΩ potentiometer to produce a reading on the DMM of 0.438 VDC.

The monitor should display 40.0 ± 0.3°C.

9. Turn off MPM, and remove all components from the temperature connector.

40201–C

3-21 MPM-1 Technical Manual

Page 54

3.1.13 ICT Output Test

+

__

Figure 3-25 ICT Output Connector

1. Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

2. Using a functional Camino catheter, firmly connect the pressure transducer connector

to the Pre-Amp cable (PAC-1).

3. Connect a PMIO cable to the rear connector of MPM-1, but do not connect to an

external bedside monitor.

4. Connect the Digital Multimeter (DMM) leads to Switchcraft ¼” connector and set

DMM to ohms.

5. Press and hold the UP arrow, then press and release the START/STOP button. Do

not release the UP arrow until the MPM-1 displays “STUCK KEYBOARD” in red

color. The DMM should read a resistance value between 3465.9Ω and 3608.1Ω. The

nominal value is 3537.0Ω.

6. Press and release the UP arrow, and the resistance value will change to the next value

shown in Table 3-6. Repeat this step until all resistance values are verified.

Table 3-6 Output Temperature Resistances

LOW Ω NOMINAL Ω HIGH Ω

3465.9 3537.0 3608.1

3431.7 3501.4 3571.1

3398.1 3466.5 3534.8

3332.6 3398.2 3463.8

3208.5 3269.3 3330.1

2984.7 3037.3 3089.8

2635.7 2676.4 2717.1

2121.7 2141.8 2161.9

1525.1 1535.4 1545.7

4. Disconnect DMM, and turn off monitor.

40201–C

3-22 MPM-1 Technical Manual

Page 55

3.1.14 Isolated Analog Output Test

Connect a Pre-Amp cable to the ICP and Temperature connections of MPM-1.

Using a functional Camino catheter, firmly connect the pressure transducer connector to

the Pre-Amp cable (PAC-1).

Isolated

Cable

Figure 3-26 Isolated Analog Connector

Isolated

Analog

Connector

1. Connect one end of cable to the isolated analog output of the MPM-1, and the other

end to a Digital Multi Meter (DMM).

2. Turn ON the MPM-1, and wait until the CPP-ICP-ICT display appears.

3. Press and hold CAL STEP. Verify that the MPM-1 and DMM display “0 mmHg”

and “0.000 ± .001 mV” respectively. The following table shows simulated pressures

and voltages by pressing and holding the CAL STEP button.

Table 3-7 Isolated Analog Voltage Output

MPM-1 DISPLAY

(mmHg)

Multi-Meter Display

(VDC)

0 0.0

20 0.2

40 0.4

100 1.0

200 2.0

6. Turn off MPM-1 once pressures and voltages are verified. Remove analog cable

and DMM.

40201–C

3-23 MPM-1 Technical Manual

Page 56

3.1.15 Ground Continuity Test

Note – This procedure assumes use of a Bio-Tek Model 170 safety tester. If a different

safety tester is used, check safety tester’s instructions for proper operation.

1. Plug the Bio-Tek Model 170 safety tester into an A.C. outlet.

2. Ensure that only the two "OK" neon lamps on the Bio-tek front panel illuminate.

3. Turn the Model 170 on using the On/Off switch.

4. The Model 170 display should indicate LINE VOLTAGE of 120 ± 10 volts for

domestic units and 220 ± 10 volts for international units.

5. Connect one end of the AC power cord to the back of the MPM-1. Connect the other

end of the AC power cord to the Model 170.

6. Turn the GROUND switch on the Model 170 to the NORMAL position.

7. Turn the Model 170 function selector to GROUND WIRE RESISTANCE position.

8. Set the Model 170 POLARITY switch to OFF.

9. Connect the Model 170 ground probe to the equipotential plug on the back panel of

the MPM instrument.

10. Check that the Model 170 display indicates less than 0.10 ohms.

11. If resistance read is higher than 0.10 ohm, check for damaged power cord or bad

power cord connections. If the problem cannot be solved, return unit to Integra

NeuroSciences for service.

40201–C

3-24 MPM-1 Technical Manual

Page 57

3.1.16 Chassis Leakage Test

Note – This procedure assumes use of a Bio-Tek Model 170 safety tester. If a different

safety tester is used, check safety tester’s instructions for proper operation.

1. Plug the Bio-Tek Model 170 safety tester into an A.C. outlet.

2. Ensure that only the two "OK" neon lamps on the Bio-tek front panel illuminate.

3. Turn the Model 170 on using the On/Off switch.

4. The Model 170 display should indicate LINE VOLTAGE of 120 ± 10 volts for

domestic units and 220 ± 10 volts for international units.

5. Connect one end of the AC power cord to the back of the MPM-1. Connect the other

end of the AC power cord to the Model 170.

6. Turn the GROUND switch on the Model 170 to the NORMAL position.

7. Turn the Model 170 function selector to CHASSIS LEAKAGE position.

8. Touch the equipotential plug on the MPM back panel with the Model 170 probe.

9. Check

following POLARITY switch positions:

NORMAL

REVERSE

10. Set the Model 170 GROUND switch to OPEN.

11. Set the Model 170 POLARITY switch to OFF. Disconnect the instrument.

12. If the chassis leakage is found higher than specified above, return unit to Integra

NeuroSciences for service.

that the Model 170 display indicates less than 12 micro amperes for the

Ensure that the display reads less than or equal to 120 micro amperes for domestic

units (MPM-1-6).

Ensure that the display reads less than or equal to 180 micro amperes for

international units (MPM-1-7).