Page 1

Current Probe and Power Supply

USER MANUAL

GW INSTEK PART NO. 82CP-425P0M01

ISO-9001 CERTIFIED MANUFACTURER

Page 2

November 2010 edition

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will Corporation.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve its products and therefore

reserves the right to change the specifications, equipment, and

maintenance procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng City, Taipei County 236, Taiwan.

Page 3

TABLE OF CONTENTS

Table of Contents

SAFETY INSTRUCTIONS .................................. 5

Safety Symbols ....................................................................... 5

PRECAUTIONS ................................................. 7

Preliminary Check ............................................................... 7

OVERVIEW ..................................................... 13

Current Proble Overview ................................................... 13

Features ............................................................................ 13

Names of Parts(Current Probe) ......................................... 14

External view ......................................................................... 14

Parts of the Sensor ............................................................ 15

Names of Parts(Power supply) .......................................... 17

MEASURE PROCEDURE .................................................... 20

Preparations for Measurement (Current Probe)................. 20

Demagnetizing and Zero Adjustment ................................... 22

Measurement Procedure (Current Probe) .......................... 24

Preparations (Power supply) ............................................. 30

Measurement Procedure (Power supply) ........................... 31

APPENDIX ...................................................... 32

Fuse Replacement (for GCP-206P only) ............................. 32

Change the power supply voltage setting .......................... 34

Current Probe Specifications ............................................. 35

Model-specific specifications ............................................... 35

Common specifications (for GCP-530 and GCP-1030) ....... 36

Power Supply Specifications .............................................. 39

Model-specific specifications ............................................... 39

Common specifications (for GCP-206P and GCP-425P)..... 40

3

Page 4

TABLE OF CONTENTS

4

Page 5

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

Safety Symbols

This manual contains information and warnings essential for safe

operation of the device and for maintaining it in safe operating

condition. Before using the device, be sure to carefully read the

following safety notes.

symbol printed on the device indicates that

The

the user should refer to a corresponding topic in the

manual (marked with the

the relevant function.

symbol) before using

In the manual, the

important information that the user should read

before using the device.

Indicates that application around or removal from

live lines is only permitted on condition that the

lines are insulated.

Indicates a grounding terminal

Indicates AC (Alternating Current)

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates a fuse.

symbol indicates particularly

5

Page 6

GCP Series User Manual

The following symbols in this manual indicate the relative

importance of cautions and warnings.

DANGER

WARNING

CAUTION

NOTE

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a

significant hazard that could result in serious injury

or death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to the

device.

Indicates advisory items related to performance or

correct operation of the device.

(Measurement categories) EN 61010-1:2001 specifies the

measurement categories and their requirements as follows. The

device falls under category I.

• Measurement category IV is for measurement performed at the

source of a low-voltage installation.

• Measurement category III is for measurement performed in a

building installation.

• Measurement category II is for measurement performed on

circuits directly connected to a low voltage installation.

• Measurement category I is for measurements performed on

circuits not directly connected to Mains.

6

Page 7

PRECAUTIONS

PRECAUTIONS

Follow these precautions to ensure safe operation

and to obtain the full benefits of the various

functions.

Preliminary Check

Before using the device the first time, verify that it operates normally

to ensure that the no damage occurred during storage or shipping. If

you find any damage, contact your dealer.

• To avoid short circuits and potentially life-

DANGER

threatening hazards, never attach the GCP-530 or

GCP-1030 to a circuit that operates at more than

300V, or over bare conductors.

• When conductors being measured carry in excess

of the safe voltage level (SELV-E) and not more

than 300 V, to prevent short circuits and electric

shock while the core section is open, make sure

that conductors to be measured are insulated with

material conforming to

(1) Measurement CategoryⅠ,

(2) Basic Insulation Requirements for Working

Voltages of 300 V, and

(3) Pollution Degree 2.

For safeties sake, never use this sensor on bare

conductors. The core and shield case are not

insulated.

7

Page 8

GCP Series User Manual

Un-insulated

(core and

shield case)

• Be careful to avoid damaging the insulation

surface while taking measurements.

• This instrument is made for use with the GCP-

206P or GCP-425P POWER SUPPLY. It is possible

to use a power supply other than the GCP-206P or

GCP-425P, provided that the connector and pin

assignments match, and that voltage and other

electrical specifications are satisfied. In the interest

of safety, make sure that the power supply has a

protective earthing with double- insulation

construction.

• Make sure that the waveform measuring

equipment connected to this device's output

terminal (BNC) is equipped with a protective

earthing with double-insulation construction.

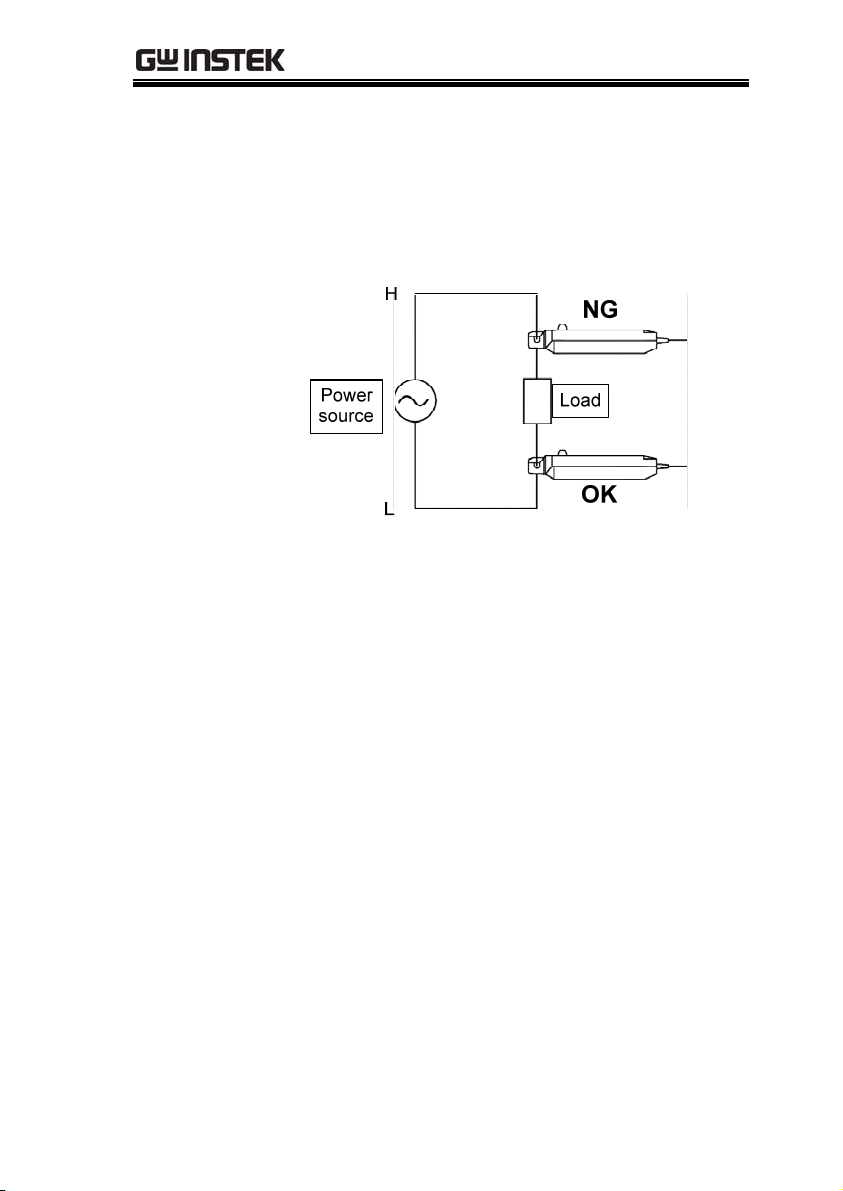

• If the waveform measuring instrument being

connected to the output terminal (BNC) on this

device is equipped with any other measurement

terminals, take the following precautions to ensure

that the other instrument does not form a bridge

between the probe and any hazardous live of a

part.

1. Isolate the terminal to which the probe is

connected from other terminals on the measuring

instrument using basic insulation conforming to

the measurement category, working voltage, and

pollution degree requirements of the circuit being

tested.

8

Page 9

PRECAUTIONS

2. If basic insulation requirements cannot be met

between the terminal to which this device is

connected and other terminals of the measuring

instrument, make sure that the voltage input to

the measurement terminal does not exceed the

safe voltage level (SELV- E).

3. Read and observe all warnings and precautions

relating to electrical safety for the measuring

instrument being connected to the probe.

Refer to the following standards regarding the

meanings of underlined terms.

IEC61010-1

IEC61010-031

IEC61010-2-032

• Be sure to observe all operating precautions for the

waveform monitoring instrument (oscilloscope or

recorder) and other measurement instruments to

which this device is connected.

• When using a measurement instrument that does

not provide isolation between its input terminals

and chassis or other input terminals, please pay

attention to the following points. If a signal is

applied to an input terminal other than that to

which this device is connected, do not connect the

ground-side terminal to any non-ground potential.

Otherwise, short-circuit current will flow through

the GCP-206P or GCP-425P or this device from the

ground terminal, which could cause an electrical

accident or damage.

9

Page 10

GCP Series User Manual

WARNING

CAUTION

• Do not allow the device to get wet, and do not take

measurements with wet hands. This may cause an

electric shock.

• To avoid electric shock when measuring live lines,

wear appropriate protective gear, such as insulated

rubber gloves, boots and a safety helmet.

• To avoid damage to the device, protect it from

physical shock when transporting and handling.

Be especially careful to avoid physical shock from

dropping.

• This device should be installed and operated

indoors only, between 0 and 40°C (32 to 104°F) and

80% RH or less.

• Do not store or use the device where it could be

exposed to direct sunlight, high temperature or

humidity, or condensation. Under such conditions,

the device may be damaged and insulation may

deteriorate so that it no longer meets

specifications.

• This device is not designed to be entirely

waterproof or dustproof. To avoid damage, do not

use it in a wet or dusty environment.

10

Page 11

PRECAUTIONS

• The sensor head is a precision assembly including

a molded component, a ferrite core, and a Hall

effect element. It may be damaged if subjected to

sudden changes in ambient temperature, or

mechanical strain or shock, and therefore great

care should be exercised in handling it.

• The matching surfaces of the sensor head are

precisely ground, and should be treated with care.

If these surfaces are scratched, performance may

be impaired.

• To avoid damaging the sensor cables, do not bend

or pull the sensor cable and power supply cable.

• To clean the device, wipe it gently with a soft cloth

moistened with water or mild detergent. Never

use solvents such as benzene, alcohol, acetone,

ether, ketones, thinners or gasoline, as they can

deform and discolor the case.

• When the power is on, keep the core section of the

sensor closed, except when clamping them onto

the conductor to be measured. The facing surface

of the core section can be scratched while it is

open.

• Keep the clamp jaws and core slits free from

foreign objects, which could interfere with

clamping action.

• Keep the sensor head closed when not in use, to

avoid accumulating dust or dirt on the mating core

surfaces, which could interfere with clamp

performance.

• Avoid stepping on or pinching the cable, which

could damage the cable insulation.

• Keep the cables well away from heat sources, as

bare conductors could be exposed if the insulation

melts.

11

Page 12

GCP Series User Manual

NOTE

• Correct measurement may be impossible in the

presence of strong magnetic fields, such as near

transformers and high-current conductors, or in

the presence of strong electromagnetic fields such

as near radio transmitters.

• When sending the device for repair, carefully to

prevent damage in transit. Include cushioning

material so the instrument cannot move within the

package. Be sure to include details of the problem.

12

Page 13

OVERVIEW

OVERVIEW

Current Proble Overview

This device can be directly connected to a BNC input connector of a

waveform measuring instrument such as an oscilloscope or recorder,

and by clamping on a conductor to be measured, allows the current

waveform to be easily captured.

Features

•

Highly accurate current detection

• Easy current measurement

• Broadband frequency characteristics DC to 50 MHz(for GCP-530)

• Broadband frequency characteristics DC to 100 MHz(for GCP-1030)

• Compact and permits measurement of low current levels

• Easy protect function at excessive input

13

Page 14

GCP Series User Manual

Names of Parts(Current Probe)

External view

14

Page 15

OVERVIEW

Parts of the Sensor

Opening lever

X

Operating lever for opening the sensor head.

Always use this lever to open the sensor head.

Sensor head

Y

Demagnetizing

Z

switch

(DEMAG)

Zero

[

adjustment

dial (ZERO

ADJ)

Coarse

\

adjustment

trimmer

This clamps the conductor being measured, and

carries out the actual current measurement. It is a

precision assembly including a molded

component, a ferrite core, and a Hall effect

element. It may be damaged if subjected to

sudden changes in ambient temperature, or

mechanical strain or shock, and therefore great

care should be exercised in handling it.

This demagnetizes the core if it has been

magnetized by switching the power on and off, or

by an excessive input. Always carry out

demagnetizing before measurement. The

demagnetizing process takes about one second.

During demagnetizing, a demagnetizing

waveform is output.

Use the zero adjustment dial to correct for the

effect of a voltage offset or temperature drift on

the device. When beginning measurement, after

demagnetizing always carry out zero adjustment.

Use this only when adjustment is not possible

within the range of the zero adjustment dial.Use a

nonconductive screwdriver (e.g. ceramic driver)

for adjustment.

Output

]

connector

Power plug

^

The current waveform of the measured conductor

is output at a constant rate (0.1 V/A).

Connect to the BNC input connector of the

waveform measuring instrument.

Connect this to the GCP-206P or GCP-425P

POWER SUPPLY receptacle to supply power to

the sensor terminator.

15

Page 16

GCP Series User Manual

DANGER

NOTE

To avoid electric shock, do not touch the portion

beyond the protective barrier during use.

• The output of this device is terminated

internally. Use a high-impedance input to the

measuring instrument. With an input

impedance of 50Ω, accurate measurement is not

possible.

• If using BNC-banana plug adapters or similar to

connect to input terminals other than BNC

connectors, make sure the polarity is correct.

• Turn the collar until it clicks, and check that it is

locked securely.

16

Page 17

OVERVIEW

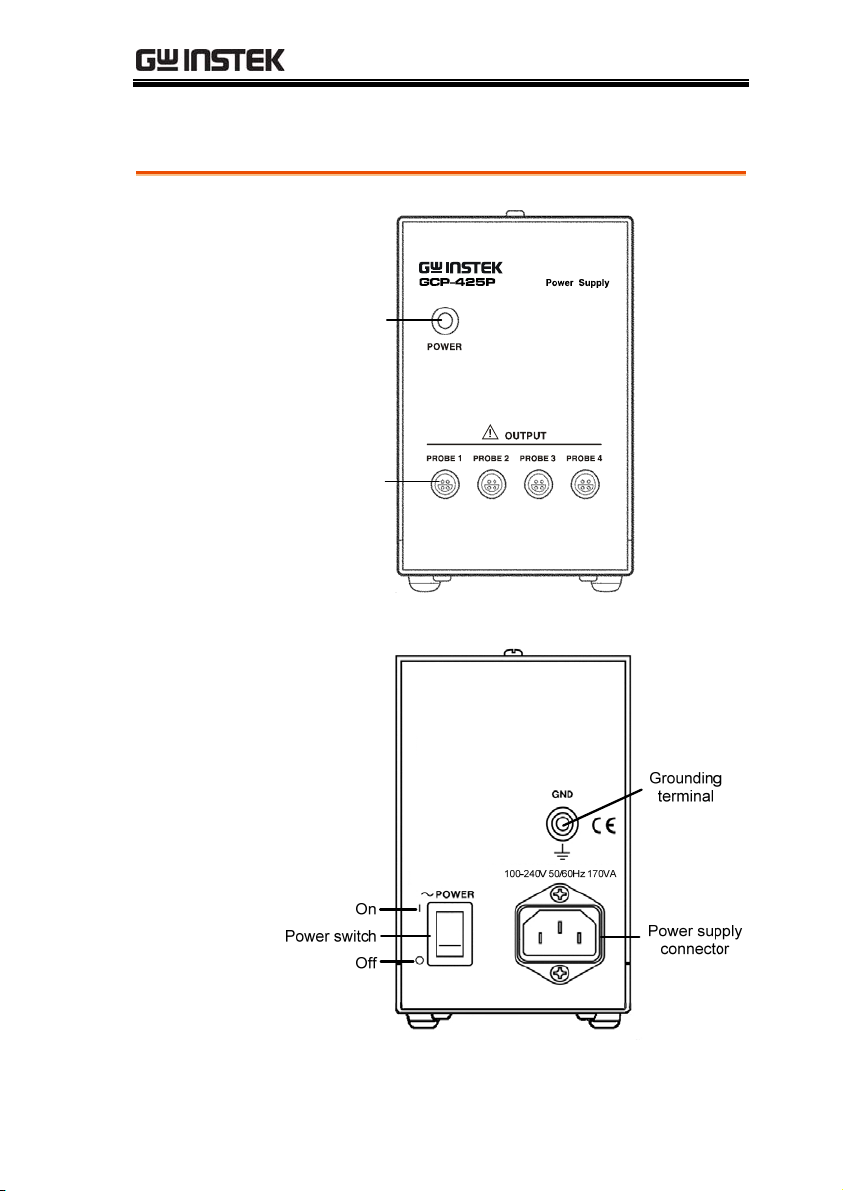

Names of Parts(Power supply)

Front view

Rear View

Power

Power

indicator

indicator

Power

Power

supply

supply

receptacles

receptacles

GCP-425P

GCP-425P

17

Page 18

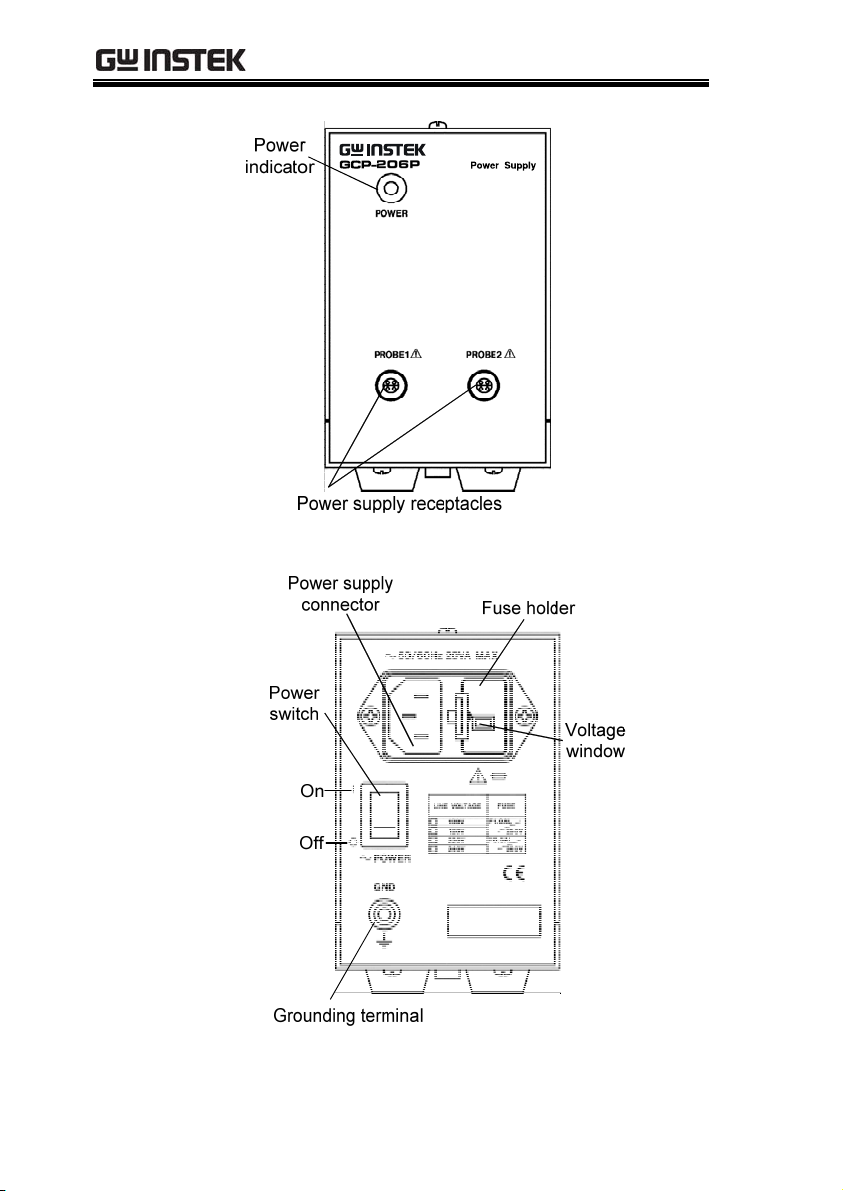

Front view

GCP Series User Manual

GCP-206P

Rear View

18

GCP-206P

Page 19

OVERVIEW

Power Supply

Receptacle

19

Page 20

GCP Series User Manual

MEASURE PROCEDURE

Preparations for Measurement (Current

Probe)

Procedure

CAUTION

NOTE

1. Have the GCP-206P or GCP-425P POWER

SUPPLY, and oscilloscope or recorder for

waveform measurement ready.

Before turning on the power, make sure that the

voltage of the power supply being used matches the

supply voltage indicated on the rear panel of the

GCP-206P or GCP-425P

The output of this device is terminated internally.

Use a high-impedance input to the measuring

instrument. With an input impedance of 50Ω,

accurate measurement is not possible.

2. Turn the power switch off and connect the

power cord.

3. Connect the power plug of the GCP-530 or GCP1030 to the power receptacle of the GCP-206P or

GCP-425P.

20

Page 21

OVERVIEW

4. Turn the GCP-206P or GCP-425P power switch

21

Page 22

GCP Series User Manual

Demagnetizing and Zero Adjustment

Procedure

CAUTION

1. With the waveform measurement instrument

input at ground, adjust the trace to the zero

position.

2. Set the input coupling of the waveform

measurement instrument to DC.

3. Connect the output connector of the GCP-530 or

GCP-1030 to the input connector of the

waveform measurement instrument. Turn the

collar until it clicks, and check that it is locked

securely.

• When disconnecting the output connector, be

sure to release the lock before pulling off the

connector. Forcibly pulling the connector

without releasing the lock, or pulling on the

cable, can damage the terminator.

• If using BNC-banana plug adapters or similar to

connect to input terminals other than BNC

connectors, make sure the polarity is correct.

22

Page 23

OVERVIEW

• Do not demagnetize while the GCP-530 or GCP-

1030 is clamping a conductor to be measured.

Demagnetizing causes current to flow into the

conductor, which may damage parts in the

circuit to be measured.

• Check that the conductor being measured is not

clamped when supplying power to the GCP-530

or GCP-1030 for the same reason. Demagnetized

waveforms are generated when supplying

electric power.

4. Without clamping the conductor to be

measured, press the opening lever until the

"UNLOCK" indication disappears, and check

that the sensor head is properly closed.

5. Press the demagnetizing switch (DEMAG) on

the terminator.

6. Turn the zero adjustment dial on the terminator,

to adjust the trace to the zero position.

7. If zero adjustment is not possible in step 6, turn

the coarse adjustment trimmer to bring the trace

within the range of adjustment by the zero

adjustment dial.

23

Page 24

GCP Series User Manual

Measurement Procedure (Current Probe)

Procedure

1. Check that the system is safe, and that the

preparations described in the preceding section

have been carried out.

2. Pull the sensor opening lever, so that the sensor

head opens.

3. Align the sensor so that the current direction

indication corresponds to the direction of

current flow through the conductor to be

measured, and clamp so that the conductor is in

the center of the sensor aperture.

4. Press the opening lever on the sensor head until

the "UNLOCK" indication disappears, and check

that the opening lever is firmly locked and the

sensor head securely closed.

24

Page 25

OVERVIEW

NOTE

Fig. 1

5. It is now possible to monitor the current

waveform. The output rate of the GCP-530 or

GCP is 0.1 V/A. The current sensitivity can be

derived from the voltage sensitivity of the

waveform measurement instrument. For

example, if the voltage sensitivity is

10mV/division, the current sensitivity is

100mA/division.

• When using the GCP-530 or GCP-1030, note that

two current probes may not be used

simultaneously with the GCP-425P POWER

SUPPLY, depending on the current to be

measured.

• The current consumption of current probes

depends on the current to be measured. Confirm

that the total current consumption of the current

probes do not exceed the rated output current of

the GCP-425P. See Fig. 1.

600

500

400

300

200

100

0

01020304050

AC(f=50Hz)

DC

Current (A)

Current consumption* vs. current to be

measured(typical)

*The sum total of a positive and negative current

consumption

25

Page 26

CAUTION

GCP Series User Manual

• The maximum continuous input range is based

on heat that is internally generated during

measurement. Never input current in excess of

this level. Exceeding the rated level may result in

damage to the probe.

• The maximum continuous input range varies

according to the frequency of the current being

measured. See the figures 3 on page 37 .

• If excess current is input, generated heat activates

a built-in safety function that blocks normal

output. If this happens, remove the input

immediately (remove the sensor from the

conductor being measured, or reduce the input

current to zero). Wait until the sensor has had

sufficient time to cool before resuming operation.

• Even if the input current does not exceed the

rated continuous maximum, continuous input for

an extended period of time may result in

activation of the safety circuit to prevent damage

resulting from heating of the sensor.

• At high ambient temperatures, the built-in safety

circuit may activate at current input levels below

the rated continuous maximum.

• Continuous input of current exceeding the rated

maximum or repeated safety circuit activation

will degrade performance of the safety circuit,

possibly resulting in damage to the device.

• The maximum input range is indicated by the

continuous maximum input range. It is also

indicated by another product specification

Maximum peak current: Noncontinuous 50 A

peak. This means that the upper limit of the

waveform response is 50 A peak. Make sure that

the input does not exceed the continuous

maximum input range in rms.

26

Page 27

OVERVIEW

• Do not place any unclamped conductor with an

electric current of a frequency of 10 kHz or more

near the sensor head. Current flowing in the

conductor nearby may heat up the sensor head

and cause its temperature to rise, leading to

damage to the sensor. For example, when one

side of a go-and-return conductor is clamped and

the other side is also placed near the sensor head

as shown in the diagram, even if the electric

current is lower than the consecutive maximum

current, electric currents in both sides will heat

up the wires and raise the temperature, thereby

causing damage to the sensor.

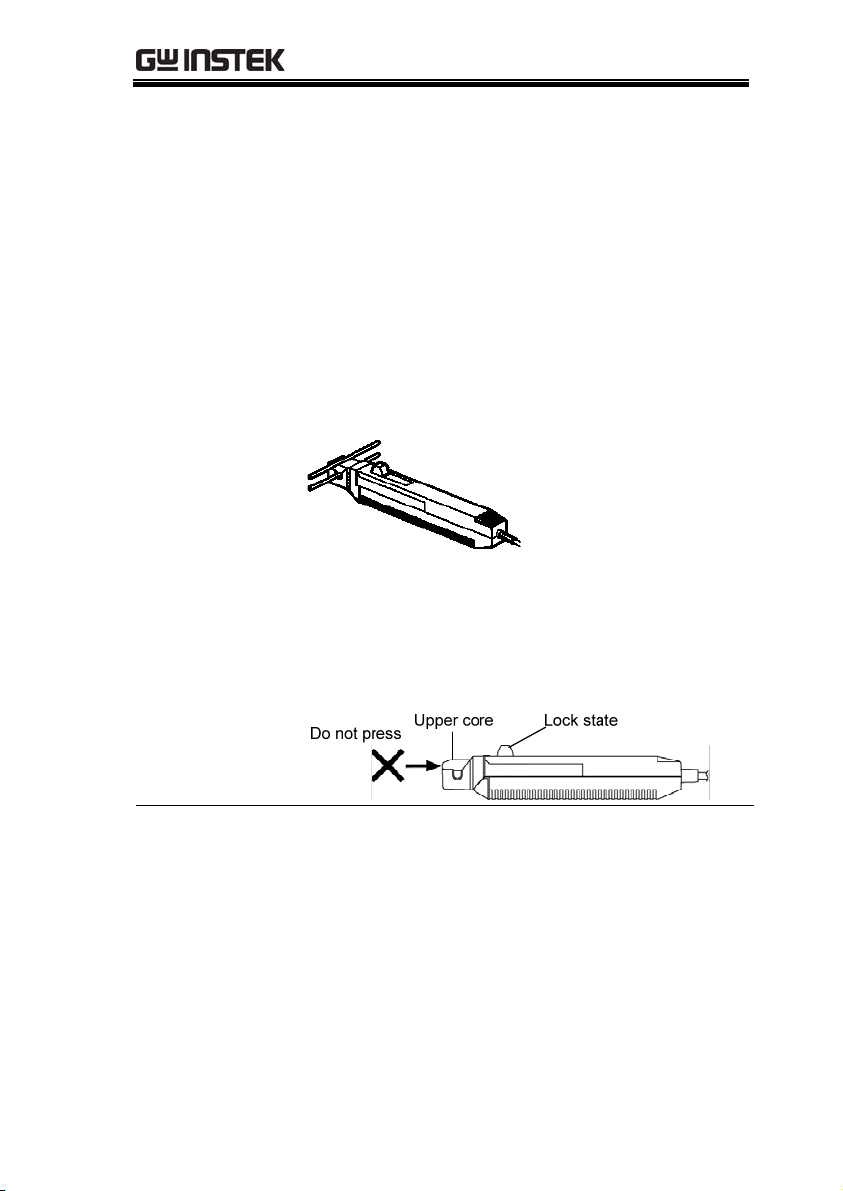

• When opening the sensor head of the probe, be

sure to operate with the opening lever. If an

upper core is forced to open, when the sensor

head is locked, the open-close mechanism can be

damaged.

NOTE

• The output of this device is terminated internally.

Use a waveform measurement instrument with

an input impedance of at least 1 MΩ.

• Immediately after powering on, this device may

be subject to an appreciable offset drift due to the

effect of self-heating. To counteract this, allow the

device to warm up for about 30 minutes before

carrying out measurement.

27

Page 28

GCP Series User Manual

• Depending on the measured current frequency,

however some sound may be produced by

resonance, it has no effect on measurements.

• When performing continuous measurements, it is

necessary to be aware that the offset voltage

drifts, depending on factors such as the ambient

temperature.

• Under certain circumstances, oscillation may

occur if the probe is connected to the GCP-206P

or GCP-425P POWER SUPPLY while the power

supply is on. This does not indicate a

malfunction. Oscillation can be stopped and

operation restored to normal by opening and

closing the sensor head.

• Depending on the measured current frequency,

however some sound may be produced by

resonance,it has no effect on measurement.

• The measurement may be affected by the position

within the clamp aperture of the conductor being

measured. The conductor should be in the center

of the clamp aperture.

• When carrying out measurement, press the

opening lever until the "UNLOCK" indication

disappears, and check that the sensor head is

properly closed. If the sensor head is not properly

closed, accurate measurement will not be

possible.

28

Page 29

OVERVIEW

• At high frequencies, common mode noise may

affect measurements taken on the high voltage

side of circuits. If this occurs, reduce the

frequency range of the waveform measuring

instrument, or clamp onto the low voltage side of

the circuit, as appropriate.

• Accurate measurement may be impossible in

locations subject to strong external magnetic

fields, such as transformers and high-current

conductors, or in locations subject to strong

external electric fields, such as radio transmission

equipment.

29

Page 30

GCP Series User Manual

Preparations (Power supply)

Procedure

WARNING

DANGER

1. Turn the power switch off and connect the

power cord. To ensure safety, connect the power

cord to a properly grounded outlet.

2. Connect the power plug of the sensor to be used

to the power receptacle of the GCP-206 or GCP425P.

3. Turn the GCP-206 or GCP-425P power switch

on, and check that the front panel power

indicator lights.

Before turning the device on, make sure the supply

voltage matches that indicated on its power

connector. Connection to an improper supply

voltage may damage the device and present an

electrical hazard.

• To avoid accidents, when using other

measurement devices with this one, observe the

usage precautions described for each device.

• To avoid electric shock or damage, when

connecting the current probe to a measurement

device that does not have its input terminals

isolated from the chassis, or to an device that

does not have it input terminals isolated from

one another and signals are applied to other

terminals, do not connect the grounding terminal

to any point that is not at ground potential.

Otherwise, if the grounding terminal is

connected to a point that is not at ground

potential, a short circuit will occur.

30

Page 31

OVERVIEW

Measurement Procedure (Power supply)

NOTE

• Make sure the sum of the current consumption of

the connected current probe(s) does not exceed the

rated output current of the GCP-425P (See Fig.1)

on page 25.

• When using the GCP-425P with Model GCP-530 or

GCP-1030 Current Probe, in general only one

current probe may be connected. However,

depending on the current level of the object under

test, two current probes may be connected

simultaneously.

• The current consumption of a current probe is

dependent upon the current level of the object

under test.

31

Page 32

GCP Series User Manual

APPENDIX

The power supply fuse for the GCP-425P, and the

power supply voltage selector, are housed in the

power input socket on the rear panel.

Fuse Replacement (for GCP-206P only)

Procedure

1. Turn the power switch off, and then disconnect

the power cord.

2. Using a flat screwdriver, pry the catch which

holds the fuse holder into the power input

socket as shown in the figure, and then remove

the fuse holder.

32

Page 33

APPENDIX

3. Remove the fuse on the fuse holder and replace

with a new one of the same rating and

specification.

4. Insert the fuse holder back into the power input

socket to finish the replacement of fuse.

33

Page 34

GCP Series User Manual

Change the power supply voltage setting

Procedure

1. Repeat steps 1-2 in the “Fuse replacement”

section on page 32.

2. Remove the voltage selector from the fuse

holder, rotate it to the desired supply voltage

value and then insert back into the fuse holder.

The voltage vaule will appear in the voltage

window. Check the setting value again.

3. Insert the fuse holder back into the power input

socket to finish setting the supply voltage

setting.

34

Page 35

APPENDIX

Current Probe Specifications

Accuracy is guaranteed at 23°C~+5°C (72°F±9°F) after the power has

been on for 30 minutes.

Model-specific specifications

GCP-530 GCP-1030

Frequency range DC to 50 MHz (-3 dB)

(Characteristics shown in Fig.

2A)

Rise time 7 ns or less 3.5 ns or less

Maximum rated

power

Weight Approx. 230g(8.1oz) Approx. 240g(8.5oz)

Accessories Instruction manual, Soft case Instruction manual, Carrying

Fig. 2A

Frequency

characteristics

(Typical

characteristics)

5.6 VA 5.3 VA

DC to 100 MHz (-3 dB)

(Characteristics shown in Fig.

2B)

case

Amplitude [dB, 0dB=1V]

Fig. 2B

Frequency

characteristics

(Typical

characteristics)

35

Page 36

GCP Series User Manual

Common specifications (for GCP-530 and GCP-1030)

GCP-530 GCP-1030

Operating

temperature and

humidity range

Rated Supply

voltage

Maximum Peak

Current Input

Maximum

Continuous Input

Range

Output Voltage

Rate

Amplitude Accuracy +1.0% rdg. ±1 mV ; up to 30 Arms

Noise Equivalent to 2.5 mArms or less (for 20 MHz band

Input Impedance (Characteristics shown in Fig.4A and 4B)

Te mp e ra t ur e

Coefficient for

Sensitivity

Storage

Temperature and

Humidity Range

Location for Use Indoor, altitude up to 2000 m (6562 feet)

Effect of External

Magnetic Fields

Maximum Rated

Vol tag e

Diameter of

Measurable

Conductors

Guaranteed

Accuracy Period

Cable Lengths Sensor cable Approx. 1.5 m (59.0"),

0 to 40°C (32 to 104°F), 80 % RH or less (no

condensation)

12 V 0.5 V

Non-continuous 50 Apeak

30 Arms (Derating according to frequency shown in Fig. 3A

and 3B)

0.1 V/A

+2.0% rdg. ; over 30 Arms to 50 Apeak (DC, and 45 to 66

Hz, input within continuous maximum input range)

measuring instrument)

±2% or less (During input of 50 Hz 30 Arms within range of

0 to 40°C (32 to104°F)

-10 to 50°C (14 to 122°F), 80 % RH or less (no

condensation)

Equivalent to a maximum of 20 mA (DC and 60 Hz,

Magnetic field of 400 A/m)

300 V, CAT Ⅰ(insulated conductor)

5 mm dia. 0.2" dia.

1 year (Opening/closing up to 10,000 times)

Power supply cable Approx. 1 m (39.4")

36

Page 37

APPENDIX

External

dimensions

Fig.3 Derating

according to

frequency (For GCP

-530)

Fig.3 Derating

according to

frequency (For GCP

-1030)

Sensor:

Approx. 175(W)×18(H)×40(D)mm

Approx. 6.89"(W)×0.71"(H)×1.58"(D)(excluding

protrusions)

Terminator:

Approx. 55(W)×27(H) ×18(D) mm

Approx. 2.17"(H) ×1.06"(W)×0.71"(D)

30

20

10

0

10 100 1k 10k 100k 1M 10M 100M

Frequency [Hz]

37

Page 38

GCP Series User Manual

M

Fig.4 Input

impedance (For

GCP-530)

Fig.4 Input

impedance (For GC

P-1030)

10

1

100m

10m

Input inpedance[Ω]

1m

100 1k 10k 100k 1M 10M 100

Frequency [Hz]

38

Page 39

APPENDIX

Power Supply Specifications

Model-specific specifications

Cable Lengths Sensor cable Approx. 1.5 m (59.0"),

GCP-425P GCP-206P

Number of power

supply connectors

Rated output

current

Ripple voltage 50 mVp-p or less 3 mVp-p or less (at rated

Load influence Within output voltage limits

Maximum rated

power

Dimensions Approx.

Weight Approx.1.2 kg (42.3 oz.) Approx. 1.1 kg( 38.8 oz)

Accessories Instruction Manual, Power

Rated supply

voltage

Power supply

voltage influence

Power supply cable Approx. 1 m (39.4")

4 2

±2.5 A (sum total of all

channels)

indicated above for current

output in the range 0 to ±2.5

A

170 VA 20 VA

80W × 119H × 200D mm

3.15"W × 4.69"H × 7.87"D

cord

100 to 240V AC (50/60Hz)

(Voltage fluctuations of ±10%

from the rated supply voltage

are taken into account.)

Within output voltage limits

indicated above for the rated

power supply voltage,

10%

600 mA (sum total of all

channels and all output

output current)

Within output voltage limits

indicated above for current

output in the range 0 to 600

73W x 110H x 186D mm

2.87"W x 4.33"H x 7.32"D

Power cord, Instruction

manual, Spare fuse

F1.0 AL/250 V, 20 mm x 5

mm dia. (for 100 V and 120 V

models) or F0.5 AL/250 V, 20

mm x 5 mm dia. (for 220 V

and 240 V models

100 V AC (120, 220, and 240

V require specification)

(Voltage fluctuation of 10%

from the rated supply voltage

are taken into account.)

voltages)

mA

Approx.

39

Page 40

GCP Series User Manual

Rated supply

frequency

50/60 Hz

Common specifications (for GCP-206P and GCP-425P)

Compatible

sensors

Output voltage

Te mp e ra t ur e

influence

Operating temperature and humidity

range

Storage

temperature and

humidity range

Location for use

Standards applying Indoor, altitude up to 2000 m (6562 feet)

GCP-530, GCP-1030 Current Probe

12 V 0.5 V

Within output voltage limits indicated above for ambient

temperature in the range 0 to 40°C (32 to 104°F)

0 to 40°C(32 to 104°F), 80%RH or less (no condensation)

-10 to 50°C(14 to 122°F), 80%RH or less (no condensation)

40

Loading...

Loading...