Page 1

FOOD WASTE DISPOSERS

SERVICE

MANUAL

COMMERCIAL DISPOSERS

(INCLUDES WIRING DIAGRAMS)

SEE PREFACE FOR MODEL REFERENCE

N-SINK-ERATOR DIVISION

EMERSON ELECTRIC CO.

4700 21st STREET, RACINE, Wl 53406

Page 2

TABLE OF CONTENTS

SECTION Page No.

1.

PREFACE 1

SECTION Page No.

11. ROTOR SHREDDER 28

2. PRIOR TO REPAIR 2

3. HOW TO USE THIS MANUAL 3

4. LIMITED WARRANTY 4

5.

INSTALLATION-REMOVAL-OPERATION

6. PROBLEM-CAUSE-SOLUTION 15

7. TERMINAL BOX AND TRIM SHELL 23

8. BODY AND COVER 24

9. BOTTOM COVER AND FAN 25

10. STATIONARY SHREDDER 26

12. UPPER AND LOWER

END BELL Bearing Replacement

13. ROTOR AND SHAFT 35

14. STATOR AND LOWER END BELL 37

5

15. JAMMED DISPOSER CONDITIONS 41

16. WIRING DIAGRAMS 43

ELECTRICAL CONNECTION DIAGRAMS 47

17.

18. "WATER TO START" SYSTEMS 61

29

29

Page 3

PREFACE SECTION 1

IN-SINK-ERATOR manufactures commercial food waste disposers from

1/2 horsepower through 10 horsepower.

The basic assembling or disassembling of all SS Series models is

identical. However, electrical connections do vary depending on the

disposer specifications, power supply and electrical controls. You will

find disposers with single-voltage, dual-voltage and tri-voltage motors

and for either a single or three phase power supply. Electrical

connections for various electrical controls that may be used with the

disposer are shown in this manual. Standard electrical connections are

also included.

The method of mounting the disposer is uniform throughout models as

is the mounting bolt circle diameter.

Basic models covered in this manual:

Above serial number 70,000:

SS-50

SS-75

SS-100

SS-125

SS-150

SS-200

Above serial number 130,000:

SS-300

SS-500

SS-750

SS-1000

This manual may be used for general referral for disassembly on SS

series models prior to models shown above.

Models shown here are Basic Model Numbers, (i.e. SS-150) which

includes several motor variances. The specification decal on the motor

trim cover will reveal the Complete Model Number, (i.e. SS-150-24

denoting the motor is 115/208/230 Volt, Single Phase).

Whenever new replacement parts are used/ordered, you must know the

Complete Model Number, serial number, motor voltage and phase

found on the specifications decal. You Must use correct parts sheet for

specific model you are servicing.

1

Page 4

SECTION 2 PRIOR TO REPAIRS

Prior to diagnosing a problem, one must give consideration to the

following items so that proper service adjustments are accomplished

intelligently and without delay or "call-backs".

• Obtaining complete information on the phone will help the service

technician before he arrives at the job site.

• Apparent electrical problems may actually be caused by a

mechanical problem (I.E. worn bearings can cause a unit to hum

and not run).

• Commercial disposers may be controlled by various types of starting

controls and electrical accessories.

• Has someone else been on the job "attempting" repairs?

• A "cheater" test cord can be used to by-pass all electrical starting

and/or electrical controls to run the disposer "direct".

• Do the electrical specifications of the disposer match the electrical

power supply? Are the motor lead connections proper for the power

supply as well as the starting controls?

• What is the age of the disposer? Any previous problems? Is it sized

properly?

• Always make certain you have and use the correct wiring diagram(s)

for the job and use the correct parts sheets.

• The only place (repeat-only place) to obtain the correct model

number is from the disposer specifications plate.

• You may have to adjust the water supply to the correct recommended G.P.M.

• If the problem is electrical, are there electrical problems with other

kitchen equipment?

• If you contact the factory for help, all of the above must have been

considered.

Page 5

SECTION 4

LIMITED WARRANTY

IN-SINK-ERATOR's Assurance of Quality Warrants its New

Commercial Disposers as Follows:

What Equipment Is Covered by This Warranty?

All IN-SINK-ERATOR Commercial Disposers and Accessories

produced and furnished by IN-SINK-ERATOR.

What are the IN-SINK-ERATOR Disposer and Accessories

Warranted Against?

Against defects in workmanship or material only. Parts wear Is not

considered a defect.

How Long Are the Disposer and Accessories Warranted?

The disposer and accessories are warranted for one year from date

of installation.

Are Service Labor Charges Included in This Warranty?

Yes. During the first year following installation, in the extended

areas of established commercial service, IN-SINK-ERATOR will

provide service labor necessary to repair or replace defective parts,

providing such labor is performed by an IN-SINK-ERATOR

Factory Authorized Service Center.

How to Obtain Service?

Please call the nearest IN-SINK-ERATOR Factory Authorized

Service Center when service is needed. For the location of your

nearest Factory Authorized Service Center call toll free 1-800558-5700 (except Canada) - (in Wisconsin call 1-800-922-2331).

What Conditions Are Not Covered by This Warranty?

This warranty does not apply if failure of commercial disposers to

operate is due to: Faulty or improper electrical installations, faulty

or improper plumbing installations, abuse, accidental damage,

grinding elements jammed by foreign objects, clogged drain lines,

unit improperly sized for application according to factory recommendations or disposer being in storage longer than 18 months

from date of manufacture.

This Warranty Is Valid In the 50 States and Canada Only, as

Written In Its Entirety and no Other Warranty Applies.

4

Page 6

INSTALLATION-REMOVAL-OPERATION SECTION 5

IMPORTANT

These installation instructions are for the benefit of the installing

contractor. The IN-SINK-ERATOR Company or any of its

Authorized Service Centers do not make original installations. For

technical information not covered In the following instructions,

contact the Factory.

These electrical and plumbing instructions were written under the assumption

that the installer is competent and experienced in these areas. If the installer is

not experienced in these areas, we recommend that competent Professional

assistance be sought. Improper installa tions resulting in damage to the disposer

or accessories are not covered by the warranty.

All installations are to be in accordance with local plumbing and electrical

codes.

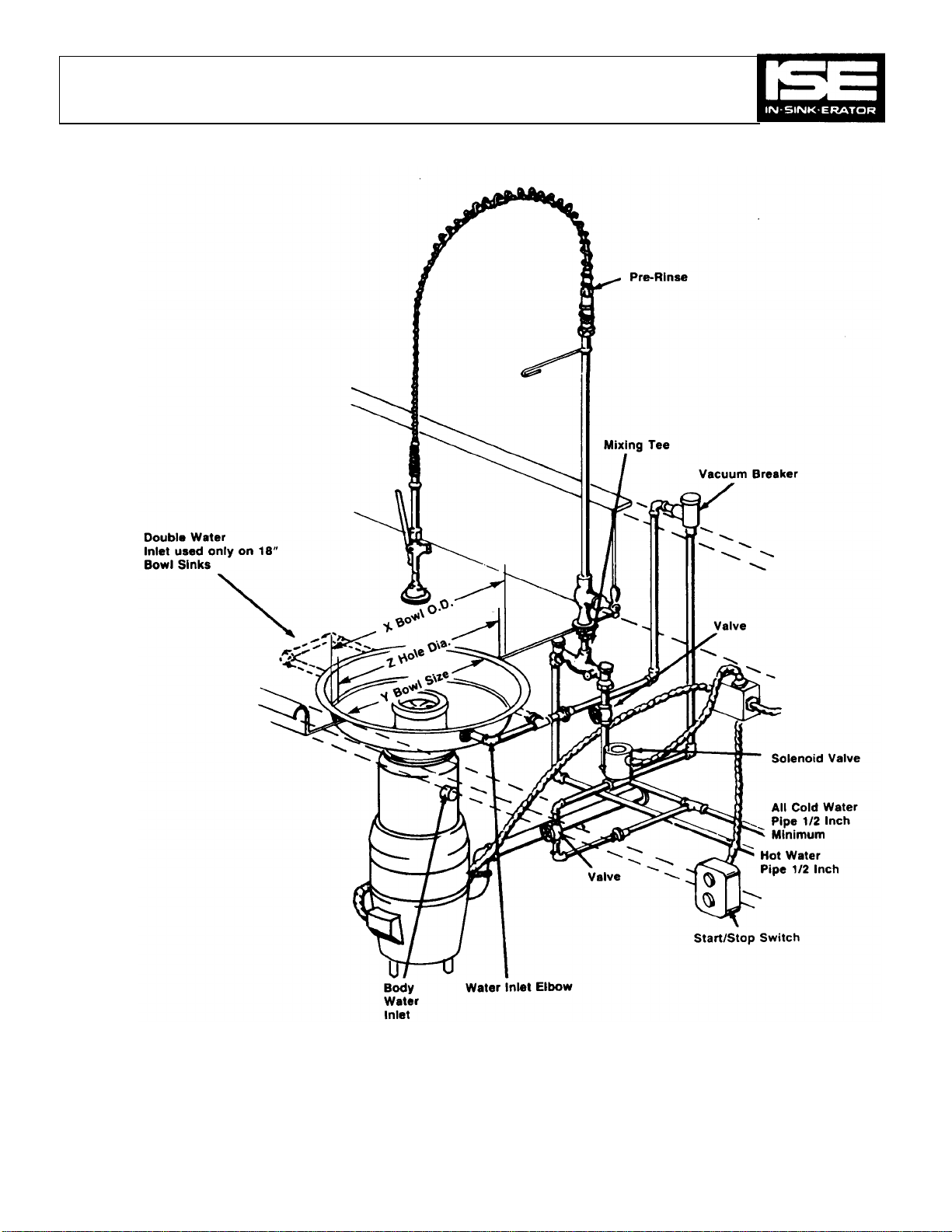

GENERAL PLUMBING INSTRUCTIONS

1. Before installing the new IN-SINK-ERATOR Disposer, properly clean

out the waste lines to the connecting main sewer.

2. Recessed thread fittings (sanitary fittings) should be used throughout,

and all pipe ends should be carefully reamed and free of burrs.

3. Use as few elbows and tees as possible. Be sure that the fittings used

are of the long sweep type.

4. All horizontal drain lines should have a minimum of 1/4" fall per foot.

A 2" pipe (minimum) is recommended for models with the following

horsepower: 1/2, 3/4, 1, 1-1/4, 1- 1/2 and 2. A 3" pipe (minimum) is

recommended for models of these horsepowers: 3, 5, 7-1/2 and 10.

5. Keep horizontal runs as short as possible to reduce the possibility of

plumbing stoppages.

6. Do not connect into a grease trap, drum trap or interceptor.

7. IN-SINK-ERATOR Disposers from 1/2 through 1-1/4 H.P. are equipped

with a drain outlet designed for a slip joint connection to a standard 11/2" "P" trap (not furnished). Connect the trap with a branch waste line

running directly into a 4" stack. IN-SINK-ERATOR Disposers from 11/2 to 2 H.P. have an outlet flange with 2" internal pipe threads (N.PT.)

assembled to the disposer. IN-SINK-ERATOR Disposers from 3

through 10 H.P. have an outlet flange with 3" internal pipe threads

(N.P.T.) assembled to the disposer. Connect "P" traps as close as

possible to the outlet flange.

IMPORTANT

Recommended cold water requirements.

1/2 through 1-1/4 H.P. 5 GPM

1-1/2 through 2 H.P. 8 GPM

3 through 10 H.P. 10 GPM

5

Page 7

all H.P. The top of the swirling water

et. Too much water

can overload motor and reduce grinding efficiency. Water volume

can be controlled by a properly rated flow control valve or a hand

At no time should hot water be connected directly to disposer or

se assembly is installed, tempered hot water is

over bottom flange of

bottom

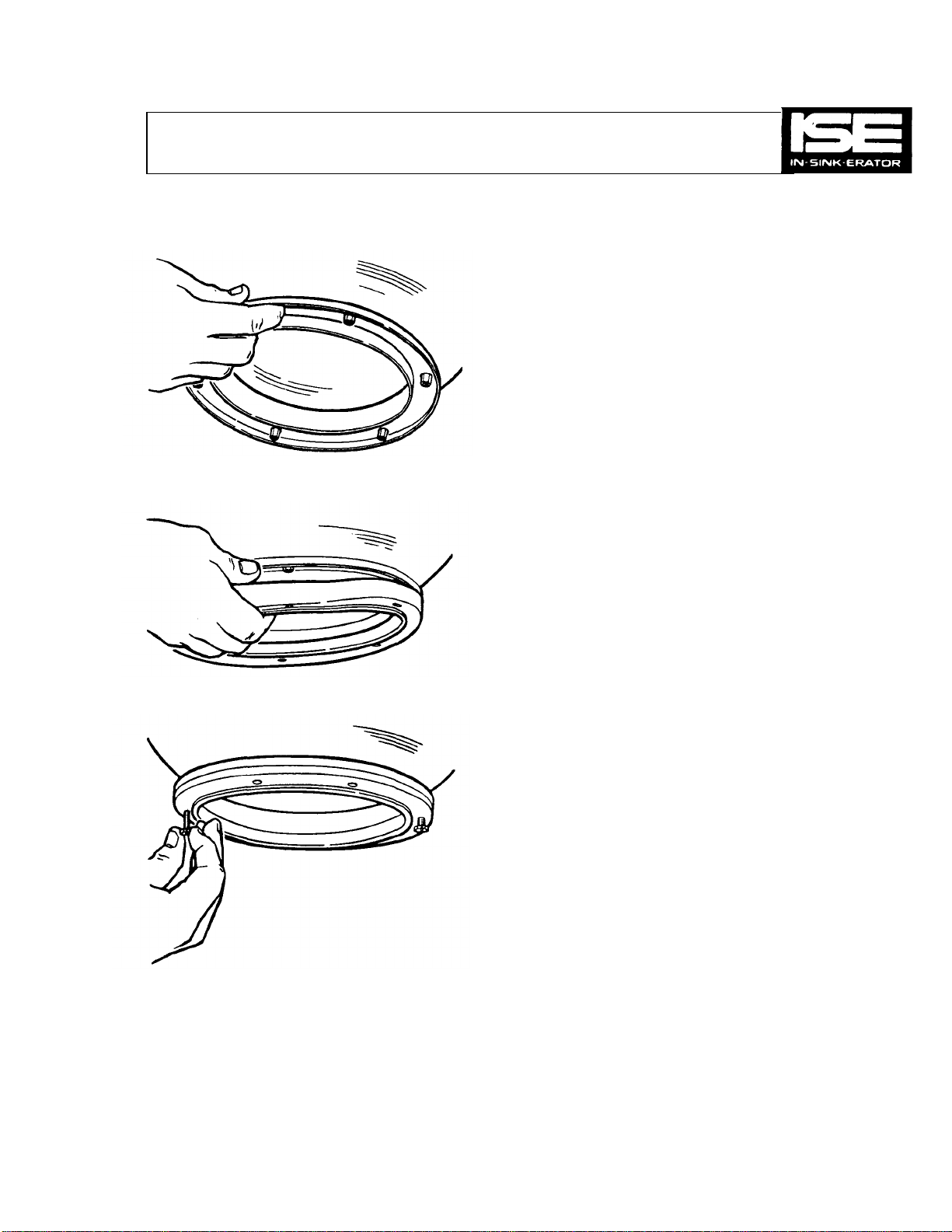

Position mounting flange down over outside of mounting gasket.

Threaded fasteners in mounting flange will fit into recesses in top

capscrews from bottom of mounting gasket into

any two opposite threaded fasteners in the mounting flange (see

d mounting gasket together at

capscrew location while assembling capscrews. Make about three

SECTION 5

8. Water volume adjustment —

should occasionally crest to the body water inl

operated valve.

9.

bowl sink. If pre-rin

acceptable.

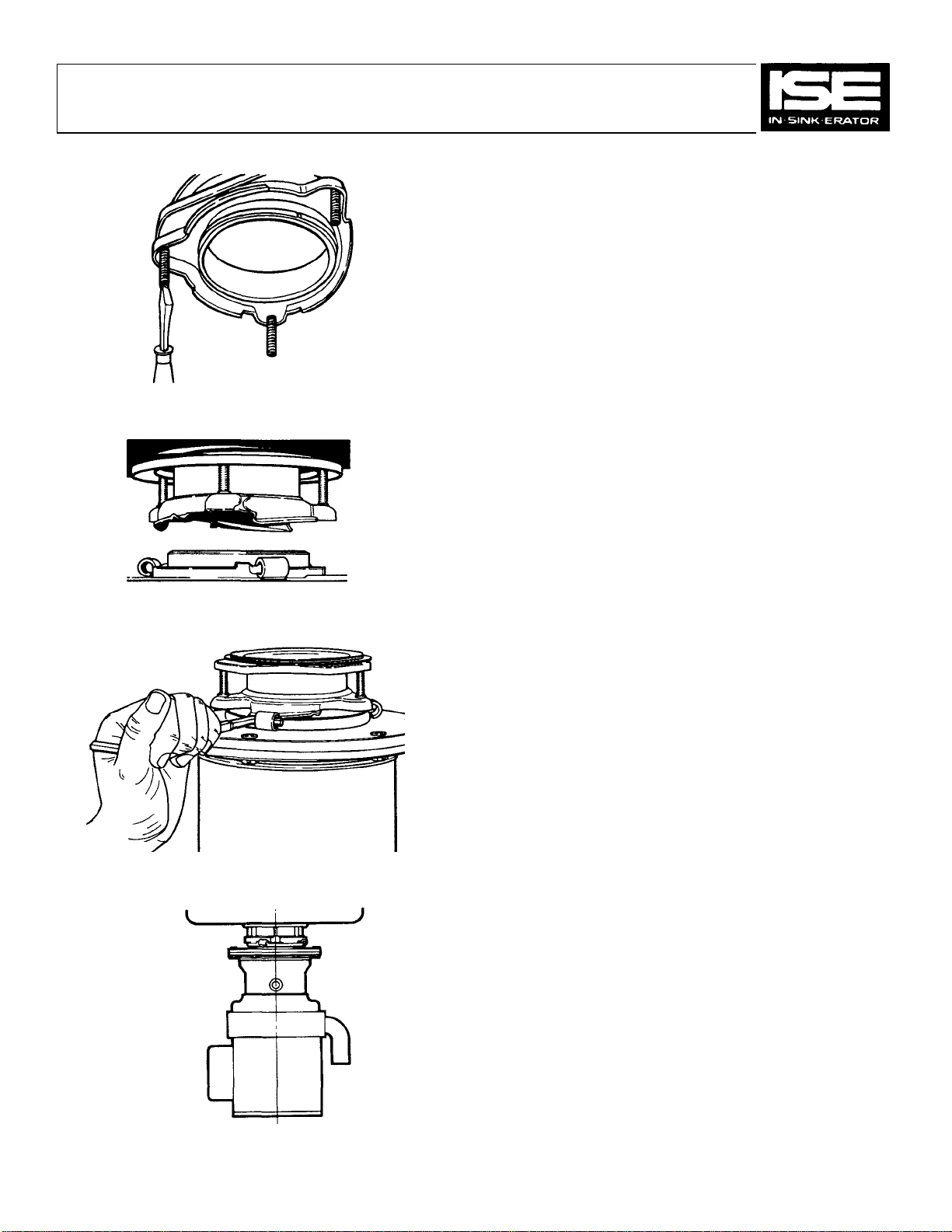

Figure 5-1.

INSTALLATION OF DISPOSER BASE UNIT

TO SINK BOWL OR COLLAR ADAPTOR

1. Slip the mounting flange (see Figure 5-1)

bowl sink or collar adaptor, and then fit mounting gasket to

flange (see Figure 5-2). Top side is marked on mounting gasket.

NOTE

Figure 5-2.

Mounting flange, mounting gasket and capscrews are packed and

shipped with each bowl sink or collar adaptor.

2.

(

of mounting gasket.)

3. Assemble two (2)

Figure 5-3.

6

Figure 5-3). Hold mounting flange an

full turns.

Page 8

sink nozzle(s). When disposer is fitted to a bowl sink, it is not necessary

See Step8, General

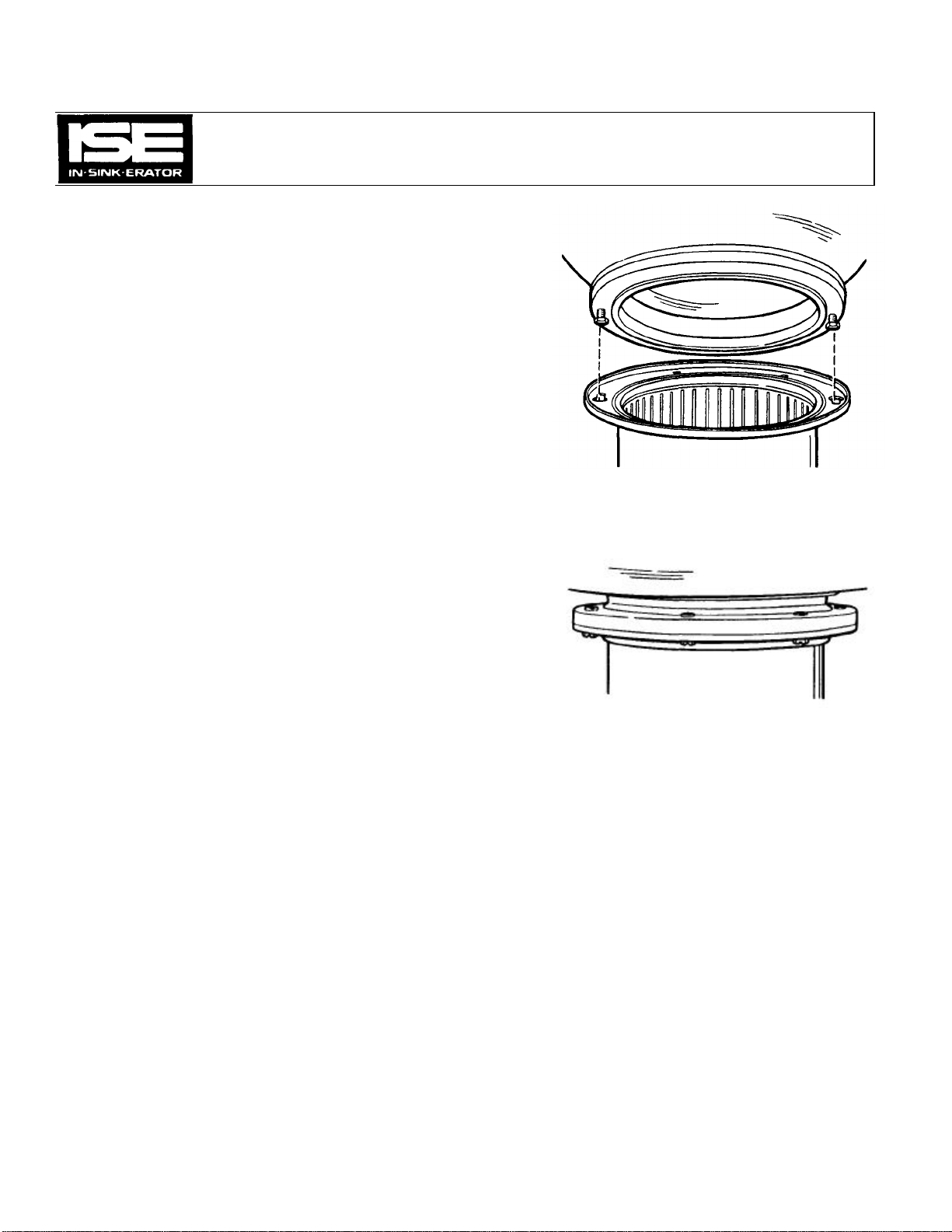

Figure

5-4. Figure

5-5.

SECTION 5

4. Raise disposer and engage capscrew heads in keyhole slots in

disposer body flange and turn disposer (see Figure 5-4). The

disposer will now hang by itself. Assemble four remaining

capscrews but do not tighten (see Figure 5-5).

For 3 H.P. through 10 H.R, unit is floor supported.

5. Turn disposer into position, line up the plumbing connections and

tighten the capscrews in disposer mounting. Capscrews are to be

tightened until edges of mounting flanges come together.

6. Make plumbing and electrical connections to the disposer per local

codes.

7. DISPOSER MOUNTED TO BOWL SINK: Connect cold water to bowl

to connect disposer body water inlet (see Figure 5-6).

Plumbing Instructions, for recommended cold water requirements.

8. DISPOSER MOUNTED TO COLLAR ADAPTOR: Connect cold water

to body water inlet. See Step 8, General Plumbing Instructions, for

recommended cold water requirements.

9. In connecting an IN-SINK-ERATOR to a septic tank, consult codes for

required size of tank and for the proper seeding (starting) of tank for

trouble-free installation.

Removal

1. Removal is the reverse of installation.

7

Page 9

SECTION 5

Figure 5-6.

8

Page 10

NOTE

For special mounting adaptor installation, refer to instructions packed

with adaptor.

INSTALLATION OF DISPOSER BASE UNIT TO No. 5 SINK

FLANGE MOUNTING (Standard 3-1/2" — 4" Sink Opening)

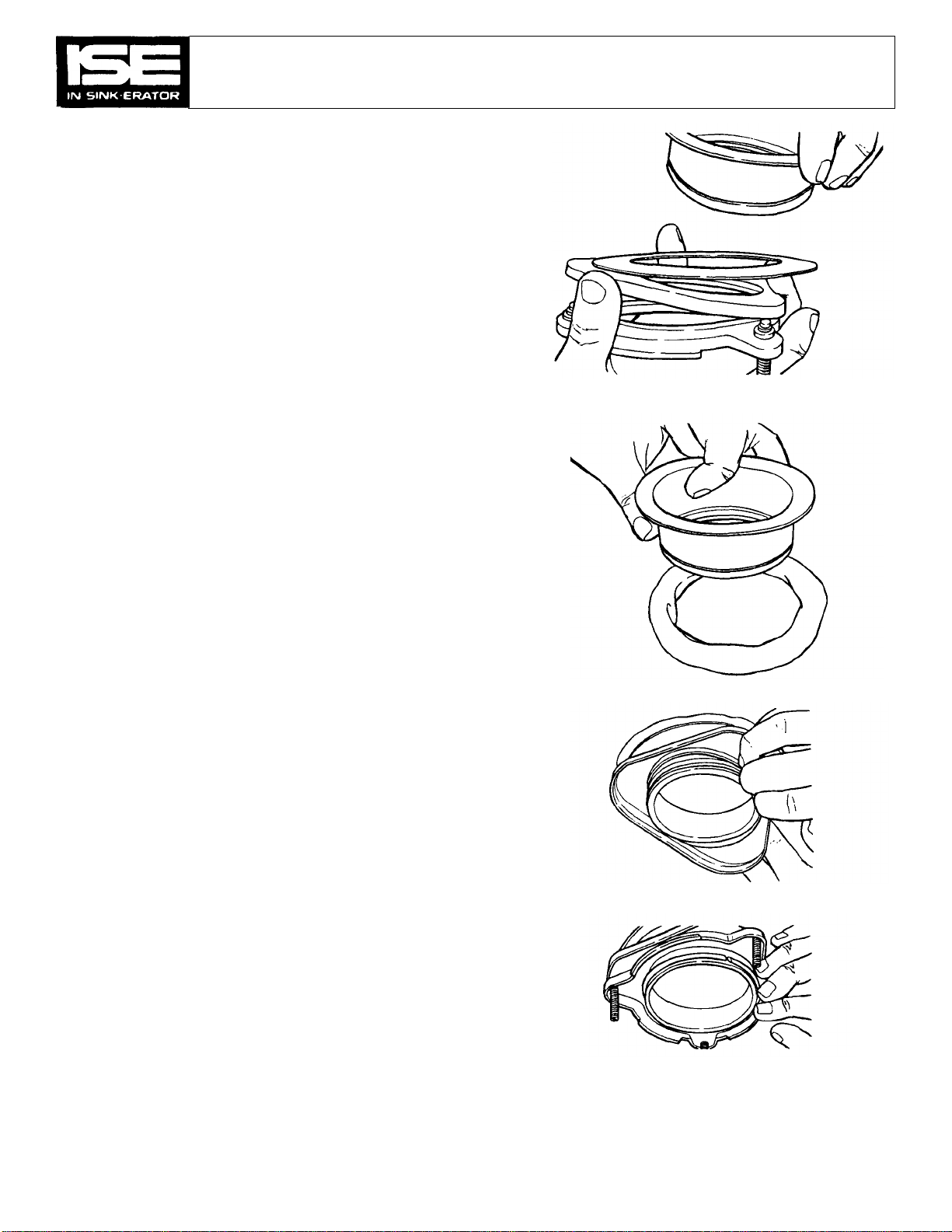

1. Unscrew the 3 mounting screws on the sink flange mounting

assembly until flush with mounting ring surface. Pry out the snap

ring holding the sink sleeve and separate all parts (see Figure 5-7).

2. To install stainless steel sink flange, form a ring of top grade oil

base putty around sink opening. Use putty that always remains

pliable. Insert sink flange into sink opening (see Figure 5-8).

3. From underneath sink, place fibre gasket over sink flange, up

against bottom of sink. Follow fibre gasket with steel back up ring,

flat side up (see Figure 5-9). Follow with upper mounting ring

having three set screws flush with top of mounting ring. Place these

parts above groove in sink flange and insert spring steel snap-lock

ring into groove (see Figure 5-10).

SECTION 5

Figure 5-7.

Figure 5-8.

Figure 5-9.

Figure 5-10.

9

Page 11

With a screwdriver tighten the three mounting screws evenly until

fibre gasket and back up ring draw up snugly against underside of

bolts provided.

for sequence of assembling parts to top of

lower mounting

(having lugs) is positioned with lugs located to right of back up

When mounting rings are positioned, hold unit up and turn lower

upported.

Insert service wrench in lug from left side and continue to turn

quarter turn)

until the two mounting lugs meet and snap into position (see

that will permit proper alignment for

degrees for easy

Make cold water connection to disposer body water inlet (see

General Plumbing Instructions, for

SECTION 5

Figure 5-11.

4.

sink. Sink flange will now be securely in place (see Figure 5-11).

5. Attach adaptor flange to top of disposer with six (6)

See Figures 5-1 to 5-5

disposer.

6. Raise disposer to sink mounting assembly so that

screws on upper mounting ring. See Figure 5-12.

7.

mounting assembly to right (clockwise) until unit is self s

lower mounting assembly to right (approximately one-

Figure 5-12.

Figure 5-13.

Figures 5-13 and 5-14).

8. Swivel unit to a position

installation of a trap. Unit can be turned 360

installation.

9.

Figure 5-6). See Step 8,

recommended cold water requirements).

REMOVAL

1. Removal is the reverse of installation.

Figure 5-14.

10

Page 12

SECTION 5

fl

oor clearance is not sufficient.

Disposer motor phase, single or three phase, must be the same as power

as

overload protection. Therefore, any starting switches furnished that have

Figure

5-15.

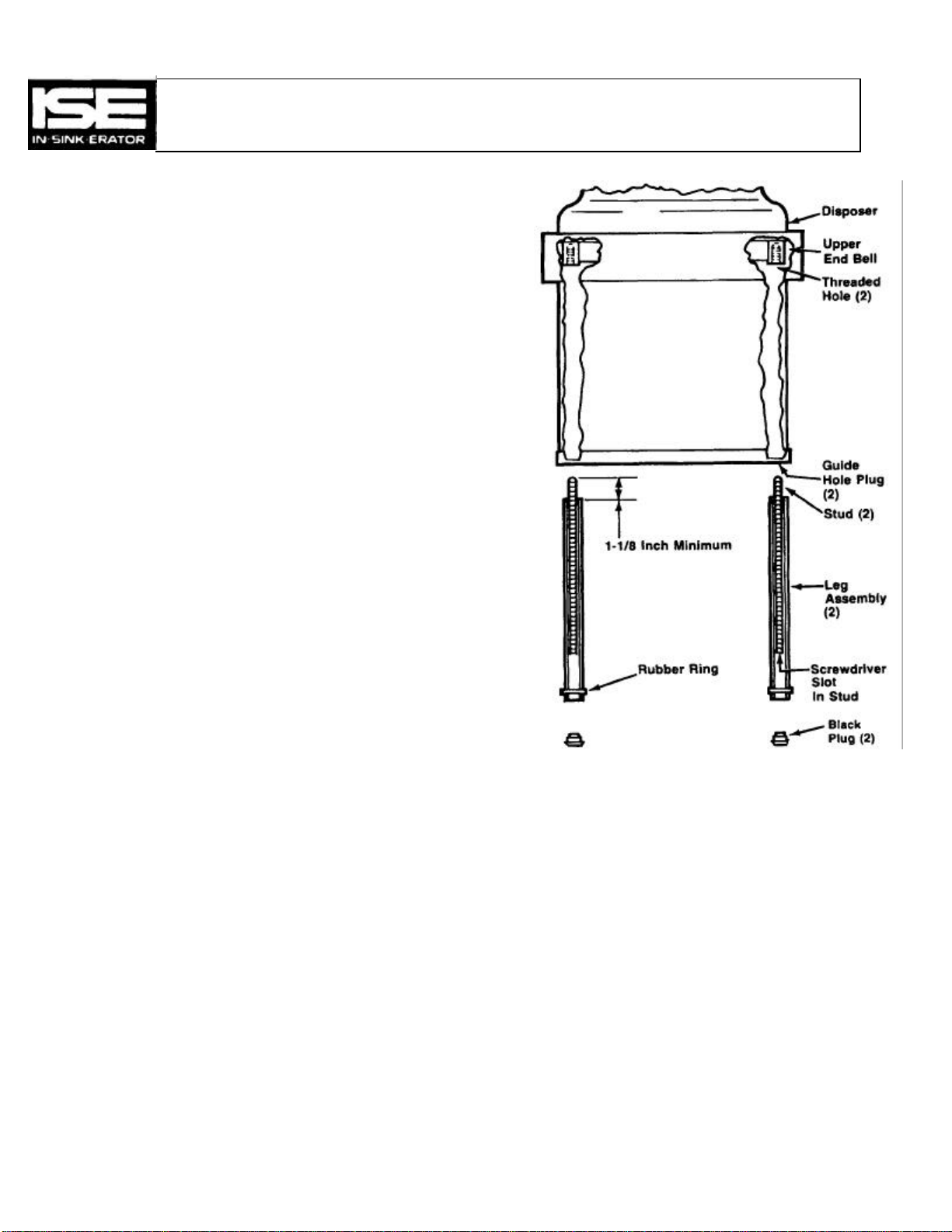

DISPOSER LEG INSTALLATION — See Figure 5-15.

1. Pry the two guide hole plugs from the bottom of the disposer.

2. Place the leg assemblies in the guide holes at the bottom of disposer.

Screw the threaded studs into the threaded holes in the upper end bell and

tighten with screwdriver. It will be necessary to demount the disposer if

3. Push the black plug into the bottom of leg tube and adjust to proper

length.

4. Push the rubber ring on each leg up securely against the bottom of the

disposer to maintain leg adjustment.

GENERAL ELECTRICAL INFORMATION

Disposers shipped from the factory are NOT connected for a specific

voltage. Please refer to the STANDARD MOTOR CONNECTION

WIRING DIAGRAMS in the disposer terminal box for correct voltage

connections.

The standard disposer voltages are 115/208/230 volts for single phase

electrical power and 208/230/460 volts for three phase electrical power.

NOTE

source and line phase. Disposer wiring connection voltage must be the ie

the voltage of the line or power supply.

CAUTION

ALL ELECTRICAL CONNECTIONS SHOULD BE MADE TO

CONFORM TO LOCAL CODES. BE CERTAIN THAT ALL

IN-SINK-ERATOR DISPOSERS ARE CAREFULLY AND

PERMANENTLY GROUNDED.

The motor connection wiring diagrams for the 1/2 through 10 H.P. models

are found inside of the disposer terminal box at the front of the disposer.

NOTE

All IN-SINK-ERATOR disposers are equipped with built-in thermal

provisions for heaters will not be supplied with heaters.

11

Page 13

SECTION 5

ELECTRICAL INSTALLATION 1/2 Through 10 H.P.

The following simple steps are required to complete the electrical

connections to the IN-SINK-ERATOR Disposer.

1.

2. Pull the terminal box out of the stainless steel trim shell.

3.

4. Connect the grounding wire to the ground screw.

5. Connect incoming wires to motor lead wires.

Be certain that the wiring connections are the same as those on the Motor

Control Wiring Diagram for your group of controls (see Section 16).

6.

BE CAREFUL NOT TO PINCH WIRES WHEN REPLACING THE

TEERMINAL BOX.

Complete Electrical Information Located Inside Disposer Terminal Box.

Remove the screw at the center of the terminal box in front of the

disposer.

Assemble an electrical conduit connector to the hole in the extension plate at the bottom of the exposed wiring compartment.

NOTE

Replace terminal box in position in the trim shell.

CAUTION

NOTE

12

TESTING — ALL MODELS

1. Check to be sure disposer is free of all objects.

2. Turn on disposer and determine that cutting elements revolve and

that water flows automatically.

3. Test mounting assembly and plumbing connections for leaks.

4. If disposer fails to operate: (A) Check wiring connections. (B)

Determine if built-in thermal overload protector has tripped —

reset by hand only. Refer to operator's instruction sheet.

CAUTION

IF DISPOSER STOPS, DO NOT LOOK FOR CAUSE UNTIL

STARTING NTROL IS TURNED "OFF".

NOTE

No lubrication is necessary as all bearings are permanently lubricated.

Page 14

5.

SECTION 5

OPERATING INSTRUCTIONS

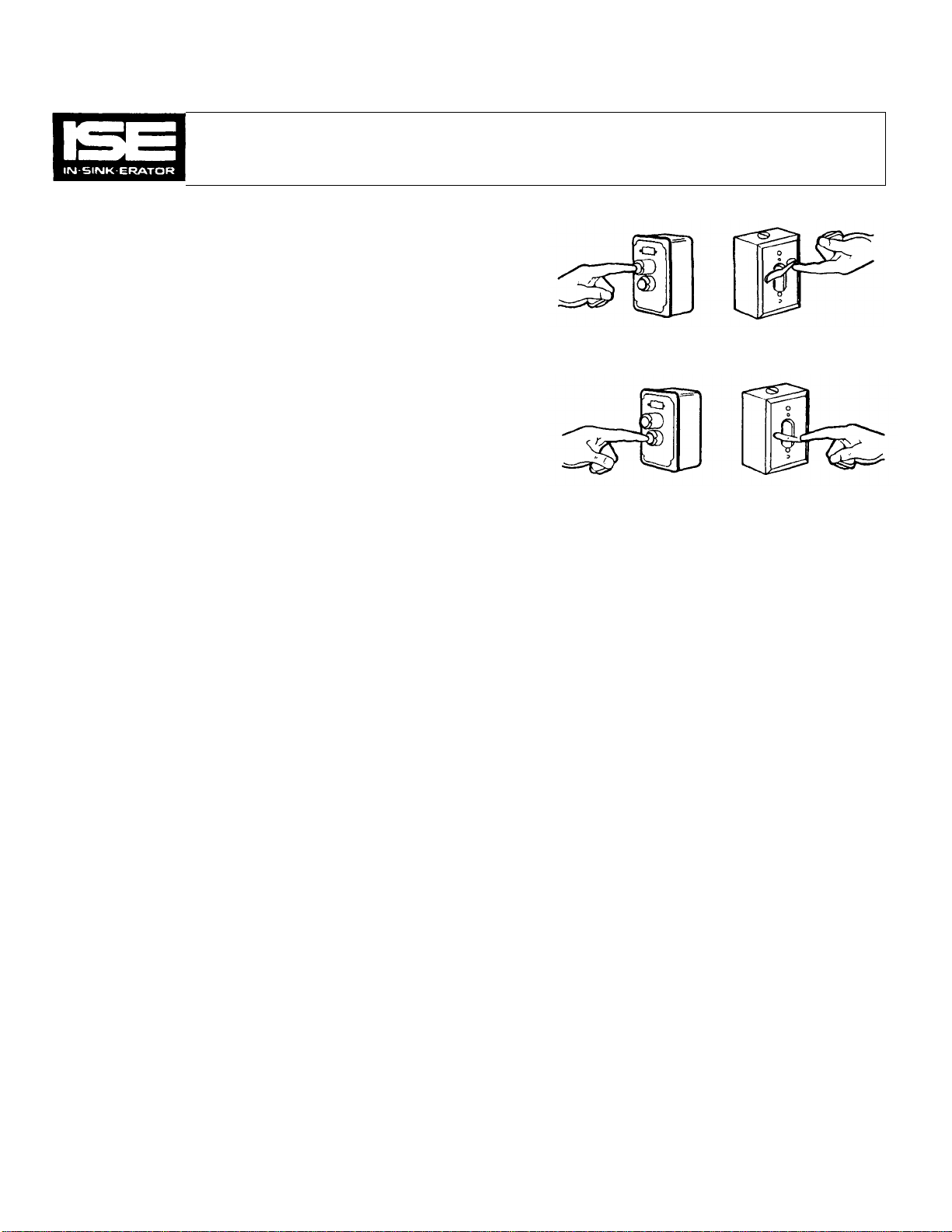

1. PUSH THE START BUTTON on the switch to put the disposer in

operation (see Figure 5-16). Before you start feeding food waste into

the disposer, make sure that a steady stream of water is flowing into

the disposer.

2.

Don't feed garbage into disposer until unit is started and water

running.

3. FEED THE GARBAGE into the disposer in a steady, continuous flow.

4. Don't overload disposer with excess amounts of garbage and water.

The unit will consume food waste faster when you feed it steadily.

Figure 5-16.

Recommended cold water requirements.

IMPORTANT

1/2 through 1-1/4 H.P 5 GPM

1-1/2 through 2 H.P. 8 GPM

3 through 10 H.P. 10 GPM

Don't touch the water valve after the correct flow of water is achieved

by adjusting plumbing valves. Grinding efficiency will be decreased if

the water swirl is more than one half way up the disposer body.

6. Don't put your hands into disposer while it is in operation.

7. Don't stop disposer with garbage in it, let it run for approximately

three minutes to clear itself of all ground garbage. This will help maintain a clean and odor-free unit and avoid drainline stoppage.

8. Do not operate without factory recommended safety guards.

9. Push the STOP BUTTON on the switch to stop the disposer's operation (see Figure 5-17).

10. To prevent accidents, make sure the disposer is shut off before you

leave it.

Figure 5-17.

13

Page 15

SECTION 5

Overloading or the presence of a foreign object (metal) can cause

Jammed

IF THE DISPOSER STOPS, ALWAYS TURN THE STARTING

THE "OFF" POSITION BEFORE LOOKING

which may have tripped and stopped electrical current to the motor

Figure 5-18.

DISPOSER JAM

1.

the disposer to jam and must be cleared (see section 15,

Disposer).

CAUTION

CONTROL TO

FOR THE CAUSE OF THE DISPOSER STOPPAGE.

2. Once the jammed condition is cleared, locate the red reset button

which can be found in the lower front of the disposer (see Figure 5-

18). This is a sensitive electrical control (overload safety switch)

to prevent motor burn-out. WAIT 3 to 5 minutes to allow motor to

cool down. Then press the red button hard, possibly with two

thumbs, to reset the safety switch.

NEVER strike the red button with an object.

14

Page 16

water runs O.K.

Starting switch on sink inoperative.

PROBLEM-CAUSE-SOLUTION

PROBLEM POSSIBLE CAUSE SOLUTION

Unit will not start —

Motor dead —

no sound —

Overload protector tripped, open.

Overload protector burned out, open

circuit.

Stator burned out, open.

Reset overload protector, allow 5 minutes cool down, then press red

button hard using both thumbs.

Test and replace overload protector.

Test and replace stator, also inspect for pinched (grounded/shorted)

motor lead wires.

Section 6

Will not start —

Motor dead —

water does not run.

Motor hums —

Water runs ok —

disposer will not run.

Jammed grind elements.

Water in motor.

No Electric power to disposer.

No electrical power.

Jammed grind elements.

Start switch in motor (single phase units).

Motor parts binding.

Clear jam and reset overload protector, (see Section 15, Jammed

Disposer Conditions).

See "Water in motor".

Check terminal box motor connections for power with volt meter.

Inspect for unconnected wires.

Check for blown fuses or tripped circuit breaker in main electrical

supply panel.

Power supply not connected to starting switch on sink.

Remove cover from switch and check operation.

Clear jam — (see Section 15, Jammed Disposer Conditions).

Switch contacts not making contact or burned off. Replace start

switch.

Motor thru bolts loose — tighten. Lower end bell misaligned —

remove and reassemble.

15

Rotor drag.

Start windings (on single phase units) open.

Capacitor (single phase units only).

Voltage.

Improper wiring at motor and/or starting switch or

solenoid valve.

Rotor shaft pulling into and binding against stator core. Check I.D. of

stator core and O.D. or rotor shaft core for score marks. Check for

worn bearings and replace If necessary.

Check and replace if needed.

Weak — test — (see Section 14, Capacitor Testing), replace if

necessary.

Low or improper voltage to disposer. Check power supply at

disposer.

Using correct wiring diagram, check, trace and make proper wiring

connections.

Page 17

Centrifugal actuator on motor shaft (single

SECTION 6

PROBLEM POSSIBLE CAUSE SOLUTION

Motor hums — water

runs ok — disposer will

not run. (Continued)

Motor starts — runs then

trips overload protector.

Single phasing (three phase units only). One or two windings open. Check stator windings, replace if

open. Also check for shorts and grounds.

Inspect, adjust, replace centrifugal actuator if necessary.

phase units only) stuck or loose spring.

Doesn't allow motor switch to open.

Motor switch contacts (single phase units

only) welded/burned closed.

Stator windings shorted. Test stator for circuitry using proper motor winding

Water in motor Inspect motor parts. Also lower bearing area of

Improper use of disposer. Potential jam — (see Section 15, Jammed Disposer

Voltage Marginal (low) power supply. Unbalanced power supply

Wiring connection improper. Make proper connection per wiring diagram.

Overloaded electrical power supply line. Connect to another circuit. Disposer motor should be

Overload protector. May be weak, improperly connected or wrong overload.

Replace motor switch.

diagrams.

upper end bell for leaking water. Repair with new

bearing/seal kit. Replace other parts if necessary.

See "Water in motor".

Conditions), operator overloading unit — explain correct

use.

(three phase only). Cannot be corrected by service

technician.

connected to its own separate circuit.

Test O.D. Check for correct connections using wiring

diagram arid parts sheet.

Runs slow and stops when

food waste is put in

disposer.

Heater Coils. Incorrectly rated heater coils in magnetic starter. To be

Voltage connections Low voltage power supply with high voltage

16

corrected or bypassed by electrician.

motor connections.

Reconnect motor lead connections using wiring

diagram.

Page 18

SECTION 6

PROBLEM POSSIBLE CAUSE SOLUTION

Trips overload protector,

circuit breaker or blows

fuses immediately on

starting disposer.

Stator Direct short in motor windings — test with ohmmeter.

Motor lead connections Check and correct connections. Also check for bare motor lead

wires. Insulate where required.

Disposer motor runs ok,

but little or no water.

Starting Control (Switch) Improperly wired — check and correct.

Improper Voltage Check disposer electrical specifications, power supply and

motor lead connections.

Improper fuse or circuit breaker Check — corrections to be made by electrician.

Overload protector Weak or incorrect part — replace.

Water supply valve shut off. Open water valve in water supply line and adjust for

correct/recommended G.P.M.

Water solenoid valve malfunction. Check solenoid —

• Coil weak, marginal voltage or wiring for low voltage.

Low water pressure. Must be increased — responsibility of equipment owner.

• Bleeder hole in diaphragm out of position. Disassemble,

reposition and reassemble.

Dirty — Disassemble valve, clean thoroughly and reassemble

Coil — Burned out (open) — replace valve. No electric power

to valve coil — trace circuit for cause.

Water in motor Seals in bearing/seal area worn. Replace parts using new bearing and seal kit.

Time delay relay. Improperly installed or defective "load" circuit. Check for

proper connections and "load" with volt meter.

Upper end bell. Cracked or eroded — replace upper end bell.

See "Water leaks at grind chamber area".

Cleaning abuse. Kitchen cleaning crew used water hose for cleanup and "hosed

down" the disposer, driving water into the motor.

17

Page 19

id drain connections and use of disposer

SECTION 6

PROBLEM POSSIBLE CAUSE SOLUTION

Noisy Worn Bearings. Replace bearings.

Vibrates excessively. Excessive water entering disposer.

Rotor core on motor shaft. Rotor core slips — not tight on shaft. Replace motor shaft.

Disposer Remove unit from sink and trap. Rest unit on floor, hold

Installation The quality of material, design and installation of the sink,

Overloading disposer with hard food

waste or non-biodegradable material.

securely and run. If unit is at fault, it can now be corrected.

drain line, adjacent walls, fasteners, etc. may be less than

described for disposer operation.

Securing the table, sol

legs may help dampen any magnified grinding noise.

Adjust water flow to disposer. See Section 5 for

recommended G.P.M. If unit is installed in a pot sink with

number 5 mounting assembly, drain water from sink before

turning on disposer.

Do not overload disposer with excessive amounts of

hard food waste (bones). Do not grind nonbiodegradable material.

Leaks Water.

IMPORTANT NOTE

REVIEW BEFORE DIAGNOSING ANY LEAKING CONDITION.

Leaks from one area may be seen at a totally different area of the disposer.

EXAMPLE: The water from a leaking mounting assembly or from a cracked stationary shredder can run down the outside of the

disposer and drip from the bottom of the unit giving an impression of "water leaking from the motor".

Whenever diagnosing any leaking problem, review all possibilities listed before making conclusions or repairs.

Water leaks at mounting Loose mounting screws. Tighten all mounting screws. Tighten locking ring if

or waste discharge. mount is a number 5 mounting assembly.

Pinched or broken gasket. Replace gasket.

Water in the motor. See "Water in motor".

18

Page 20

ean out drain lines from disposer to main sewer. Vent lines

minute post

SECTION 6

PROBLEM POSSIBLE CAUSE SOLUTION

Water leaks at grind

chamber area or center of

unit.

Stationary shredder gasket pinched,

misfitted or broken.

Replace gasket.

Syphon breaker leaks. Loose plumbing connections. Tighten plumbing connections.

Water inlet connection loose in body. Replace with new body, or totally remove inlet connector

from body and use plumbing fittings (nipple, el, nuts, rubber

gaskets) to repair.

Lower body cover. Tighten bolts holding lower body cover to upper end bell

(compress stationary shredder gasket). If this fails to secure

the leak, the "rivnuts" in the lower body cover have

separated enough, not allowing compression of the gasket.

Replace lower body cover.

Stationary shredder. Cracked or broken, allows water leaks to the outside of the

unit and runs down the outside of the motor. Replace

stationary shredder.

Installed improperly. Syphon breakers must be installed 6 inches above the "flood

plane" which is the top working surface of the sink —

reinstall.

Plumbing connections backwards — reinstall.

"Poppet" in syphon breaker worn, cracked or missing —

replace with new syphon breaker.

"Poppet" in syphon breaker sticking — disassemble, clean

and reassemble.

Does not drain or drains

slowly. Water in disposer

after being shut off

(possibly some food

waste also).

or

Frequent drain line

blockage.

19

Drain line blockage.

Center line of disposer waste outlet is

below center line of drain line.

Improper drain line slope. Horizontal drain line require minimum of 1/4" fall per foot.

Grind elements. Worn or piece broken away — allows large chunks to enter

Cl

may also require cleaning. Instruct user to use 3

flush. Possibly install a time delay relay.

Check for proper water flow — could be too little water

being used.

Plumbing adjustment required to drain line.

drain line. Replace grind element(s).

Page 21

Discontinue this practice. Food waste disposers are designed

lties when introduced

SECTION 6

PROBLEM POSSIBLE CAUSE SOLUTION

disposer during

operation.

Splashing from bowl. Spray nozzles not installed properly. Spray nozzles should be "pointed" downward approximately

Excessive water entering disposer and/or

excessive water pressure.

Adjust water entering unit to proper recommended G.P.M. Splashing — from

If water pressure cannot be adjusted, install a safety baffle,

silver guard and/or cover.

15 to 20 degrees.

Water runs continuously

after disposer is turned

off.

Excessive wear on

grinding elements.

Solenoid valve.

Normal. Normal if a time delay relay is being used. Water may run a

Time Delay Relay. Time delay may be defective and not shutting down. Initiate

Disposer undersized. Reduce use. Replace disposer with proper size.

Highly abrasive material being ground in

abundance.

Non-biodegradable material being ground.

Installed backwards — arrow on solenoid valve must point

down stream.

Valve not closing — dirty — disassemble and clean.

Bleeder hole in diaphragm out of position. Disassemble and

reset diaphragm.

High water pressure — pressure must be reduced.

few seconds to 10 minutes depending on time delay setting.

Used for post flush.

circuit always active and not shutting down. Check circuitry

with volt meter.

Do not grind abrasive material such as glass, crockery,

ceramic or clam shells.

to grind food waste. Other materials should be considered

trash and cause waste treatment difficu

into drain lines.

Will not grind.

Excessive water entering disposer. Adjust water supply to proper recommended G.P.M.

Insufficient grinding time. Do not turn off unit until all food waste has been ground

Worn grinding elements. Replace cutting elements or reverse direction of motor if

Plugged teeth in stationary shredder. See Section 15, Jammed Disposer Conditions.

20

away with a 3 minute flush.

reversing controls are not used. (Three phase — "flip flop"

any two of the three power leads at the motor.) (Single phase

— "flip flop" wires Number 2 and 5 in the disposer motor

terminal box.)

Page 22

seal

nent sleeve

Make certain the sleeve is fully down to the snap ring by driving

ing and seal

Identify all controls used on the installation. Review appropriate

PROBLEM POSSIBLE CAUSE SOLUTION

New bearings and seal kit

binds rotor shredder when

assembled.

Disposer hums but does

not start.

or

Loose after assembly.

Misassembled.

Disassemble bearing/seal kit. Can be reused, but new lower

is required.

Reread bearing/seal kit instructions and follow closely. Use all

parts in the kit. Make absolutely certain the upper end bell

bearing cavity is totally free of grit, dirt, score marks, burrs and

grease. Also the permanent snap ring in the I.D. of the bearing

cavity.

Some motor shafts (lower horsepower) have a perma

pressed on that surrounds a snap ring on the shaft. The lower

seal rides on the sleeve which also acts as a thrust spacer. The

sleeve must be firmly against the snap ring.

it with a brass rod and hammer or with an arbor press.

SECTION 6

Disposer runs O.K. only

when using "cheater" cord

and bypassing all controls.

Disposer and/or electrical

controls are wrong for the

available power supply.

Reassemble per instructions.

Check to make certain you are using the correct bear

kit for the disposer model and any other new parts.

Controls

wiring/electrical diagrams. Inspect controls visually and with

Ohm and/or Volt Meters.

Ordered wrong or sent in error. Explain to manager and suggest contacting his supplier.

21

Page 23

DISPOSER SIZING CHART

Up to

100 SS-75 SS-50 ------

------

--------

SECTION 6

Hotels Restaurants Hospitals Cafeterias Commissaries

Persons Soiled

Per Meal Dish Table

Vegetable Salad Pot Meat

Prep.Area Prep.Area Sink Prep.Area

100-150 SS-100 SS-75 SS-50 SS-50 -------150-175 SS-85 SS-100 SS-75 SS-50 SS-150

175-200 SS-150 SS-150 SS-75 SS-75 SS-150

200-300 SS-200 SS-150 SS-75 SS-75 SS-300

300-750 SS-300 SS-150 SS-75 SS-75 SS-300

750-1500 SS-500 SS-300 SS-150 SS-150 SS-500

1500-2500 (2) SS-500 SS-300 SS-150 SS-150 SS-500

2500-over Contact your Food Service Consultant or In-Sink-Erator

FOR SPECIAL APPLICATIONS, SUCH AS SUPERMARKETS OR OTHER HEAVY, CONTINUOUS

VOLUME INSTALLATIONS, SELECT MODELS SS-750 OR SS-1000

Additional IN-SINK-ERATOR units or a disposer larger than indicated in the chart may be necessary in the following

instances: if large amounts of fibrous, hard or bulky materials are in the mixed wastes, if there is an occasional need for

increased capacity, due to special occasions, or if waste volume is expected to grow.

22

Page 24

TERMINAL BOX AND TRIM SHELL SECTION 7

lear

REMOVAL

1. Place unit on bench upside down.

2. Remove terminal box retaining screw (see Figure 7-1).

3. Remove terminal box (see Figure 7-2).

4. Remove two trim shell retaining screws (see Figure 7-3).

5. Turn unit so waste outlet is facing away from you.

6. Grasp trim shell with both hands. Spread shell wide enough to

allow it to clear bottom cover. Angle upper edge of shell towards

yourself so opening in shell will pass over terminal connection

area (see Figure 7-4). Continue to lift shell and angle it towards

yourself until shell is in a horizontal position. Remove the trim

shell.

ASSEMBLY

1. Place unit on bench upside down with waste outlet facing away

from you.

2. Grasp trim shell with both hands, holding trim shell in a

horizontal position. Insert leading lower edge of trim shell in

space between terminal connection and upper shroud. Raise shell

to a vertical position, at the same time spreading it so it will c

the bottom cover.

NOTE

Use care so as not to damage lead wires in terminal box area.

3. Install two trim shell retaining screws.

4. Assemble terminal box cover to unit.

5. Install terminal box retaining screw.

Figure 7.1.

Figure 7.2.

Figure 7-3.

6. Place unit on bench in upright position.

Figure 7-4.

23

Page 25

2.

stationary shredder. With terminal box facing you, the water inlet

SECTION 8

Figure 8-1.

BODY AND COVER

REMOVAL

1. Disassemble as outlined in Section 7.

2. Using a socket wrench and a long extension or a long

screwdriver, reach up under the cover and remove the slotted

head capscrews securing the body and cover to the end bell (see

Figure 8-1).

3. Lift the body and cover assembly off of the unit.

INSPECTION AND ASSEMBLY

1. Inspect body shredder seal. If damaged or deteriorated, replace it.

Place unit on bench in upright position.

3. Position body and cover assembly on motor assembly, making

sure locating tabs are lined up with the locating grooves in the

boss should be to your right.

4. Place capscrew in socket wrench. Insert wrench up under cover

and guide cap-screw to capscrew hole. Thread capscrew about

one-half way in. Follow same procedure with remaining

capscrews until all are partially threaded. At this point you can

complete the threading and tightening process.

5. Reassemble according to Section 7.

24

Page 26

BOTTOM COVER AND FAN SECTION 9

Remove three motor thru bolts retaining bottom cover (see Figure

lifted off.

With a rawhide or plastic mallet, tap on the fan hub until the end of

Bottom cover wilt only fit one way. Be sure to align motor thru bolt

es in bottom cover with motor thru bolt holes in lower end belt,

and align leg access holes in bottom cover with threaded recess in

or thru bolts between bottom

cover and motor thru bolt hole in lower end belt. After this is done,

Figure

9-1. Figure

9-2.

REMOVAL

1. Disassemble according to Section 7.

2.

9-1). Between bottom cover and lower end bell are three spacer

tubes (see Figure 9-2). Retain these as they must be used for

reassembly. After thru bolts are removed, bottom cover can be

3. Remove snap ring from motor shaft to remove jam.

4. Using two wide, flat screwdrivers, place one on each side of the

shaft under the fan. Pry up on fan until it moves up on shaft

approximately 1/8" (see Figure 9-3).

5. Lift up and off.

INSPECTION AND ASSEMBLY

1. Inspect fan bore prior to reassembly. A locking rib should be

evident in fan bore. If it is not, the fan should be replaced.

2. Place fan on shaft, being sure that flat surfaces of fan bore line up

with flat surfaces on shaft.

3.

the shaft and fan hub are even. Then place one thumb on each side

of the fan hub and press down firmly. The locking rib in the fan

bore will seat itself in the locking groove on the shaft.

4. Install snap ring.

5. Place bottom cover on unit.

NOTE

hol

end belt.

6. After bottom cover is aligned, motor thru bolts can be inserted.

NOTE

Be sure spacer tubes are placed on mot

thru bolts can be threaded into upper end bell.

7. Reassemble according to Section 7.

25

Figure 9-3.

Page 27

Scribe mark the stationary shredder and the upper end bell (see

(or a "crow

A puller that works very well for removing the stationary grind ring

can be fabricated from the measurements shown on the diagram in

shredder with a ball peen or steel

SECTION 10

STATIONARY SHREDDER

REMOVAL FROM UNIT

1. Disassemble as per Section 7 and Section 8.

IMPORTANT

Figure 10-1).

2. Place a short section of pipe (approximately 1-1/4" long) over the

rotor shredder mounting nut. This center piece is to be used as a

fulcrum point. Place the flat end of service tool #6462

bar") under the protruding edges located in the wall of the

stationary grind ring. Rest the #6462 tool on the center fulcrum

point.

NOTE

Figure 10-1.

Figure 10-2.

Figure 10-2. This tool is not available from ISE.

Insert the "L" shaped lip of the shredder puller into the groove

beneath the rectangular grinding elements. Use an Alien wrench to

turn the threaded rod clockwise. As the threaded rod is turned down

against the outer shoulder on the upper end bell, the stationary

shredder will be pulled free of the upper end bell.

3. A mallet is now used to strike downward on tool #6462 (see Figure

10-3). Two or three sharp blows will raise the grind ring up and out

of position.

NOTE

Never strike the grind ring or rotor

hammer. Either babbitt, nylon, leather or wood mallets must be used.

Figure 10-3.

26

Page 28

Proper alignment of the scribe marks is important, as the upper body

grooves in the shredder do not line up with the locating tabs on the

INSPECTION AND ASSEMBLY

Prior to reinstalling the stationary shredder, we suggest that it be

carefully inspected. If cracked, chipped, or broken, or if excessive

wear is evident, then stationary shredder should be replaced.

To assure a trouble-free installation, the bottom surface of the

stationary shredder and the stationary shredder recess in the end bell

must be cleaned of all old mastic and dirt, so as to allow the

stationary shredder to fit squarely in the upper end frame.

See Figure 10-4.

1. Apply a coating of water resistant silicone sealant across the

bottom of the stationary shredder to form a seal with the upper

end bell.

2. Position the stationary shredder in the upper end bell, being sure

the scribe marks are aligned.

NOTE

SECTION 10

Figure 10-4

will not fit over the stationary shredder when assembling if the

body.

3. Strike fairly hard alternately on the upper rim of the stationary

shredder until it is seated fully in the upper end bell (see Figure

10-5).

NOTE

Never strike the stationary shredder with a steel hammer. Either

babbitt, nylon, leather or wood mallets must be used.

Reassemble according to Section 7 and Section 8.

Figure 10-5.

27

Page 29

SECTION 11

Place a pry tool under one edge of the rotor shredder and a similar

tool under the opposite edge of the rotor shredder. Work the tools

Prior to reassembly, the rotor shredder should be carefully inspected

rizontal bars on the top surface

of the shredder show signs of excessive wear or are broken, the rotor

Figure

11-1.

ROTOR SHREDDER

REMOVAL

1. Disassemble as per Section 7, 8 and 10.

2. Hold the rotor shredder with a vise-grip or a channel lock pliers so

it will not turn. With a socket wrench or box end wrench, remove

the mounting nut, steel washer and fibre gasket (see Figure 11-1).

NOTE

Mounting nut has right hand threads.

3.

alternately until rotor shredder is pried off of the keys which

position the shredder on the shaft (see Figure 11-2).

INSPECTION AND INSTALLATION

to determine if it is reusable. If the ho

shredder should be replaced.

1. Place rotor shredder on shaft and align keyways in shredder with

keys on shaft. After keys are lined up, tap shredder down until it is

fully seated.

2. Install new fibre gasket, steel washer and self locking hex

mounting nut.

3. Hold rotor shredder with vise-grip or channel lock pliers so it will

not turn. With a socket or box end wrench, tighten mounting nut

firmly. Then reassemble as per Section 7, Section 8 and Section

10.

Figure 11-2.

Page 30

UPPER AND LOWER END BELL

REMOVAL FROM UNIT

1. Disassemble as outlined in Sections 7, 8, 10 and 11.

TRI-LIP SEAL REMOVAL

Review Figures 12-1 and 12-15 before proceeding.

1. Remove the two exposed woodruff keys (13) and slide the shield

(1) up and free from the shaft (15) (see Figure 12-1).

2. Pull the sleeve (4) up and off the shaft.

3. Remove six (or twelve depending on size of disposer) screws (2)

allowing the tri-lip seal (3) to be pulled free from the upper end

bell (10). Remove the third woodruff key (14) from the shaft.

4. The "0" Ring (5) and the centrifugal moisture shield (6) can now

be pulled up and free from the shaft. The bearing area is now

exposed.

SECTION 12

5. Scribe mark upper end bell and stator and lower end bell and

stator (see Figure 12-2).

6. Using the stationary shredder as a "stand", stand unit upside down

and remove bottom cover and fan as outlined in Section 5. The

upper bearing will probably slide off the shaft onto the work

Figure 12-1.

1. Shield 8. Bearing Cone and Cup

2. Screw 9. Bearing Spacer

3. Lip Seal 10. End Bell

4. Sleeve 11. Thrust Washer

5. 0-Ring 12. Oil and Water Retainer

Centrifugal Moisture

6.

Shield

7. Bearing Cone and Cup

13. Woodruff Key (2)

14. Woodruff Key

15.

Rotor and Shaft Assembly

Figure 12-2.

29

Page 31

SECTION 12

Figure

12-3.

7.

Lay unit on its side and tap upper end bell alternately on opposite

sides with a nylon or rawhide mallet until upper end bell is

disengaged (see Figure 12-3).

8.

Turn unit right side up using the stationary shredder as a stand.

9.

Pull upper end bell (10) out and free of rotor and shaft (15).

CAUTION

THE MOTOR SHAFT MIGHT PULL AWAY WITH THE

UPPER END BELL. DO NOT ALLOW IT TO DROP.

REMOVAL OF BEARINGS AND OIL AND WATER

RETAINER

1.

Remove the upper tapered roller bearing, (see Figure 12-4) and

the cone spacer (see Figure 12-5). If they are to be reused, we

suggest they be wrapped in a clean rag or paper to prevent

contamination by dirt or dust. If they are not to be reused, discard

them. Place end bell on bench upside down.

2.

Use a pry bar to remove the oil and water retainer (see Figure 12-

6). Discard old seal.

Figure 12-4.

Figure 12-5.

Figure 12-8.

30

Page 32

them, proceed as follows: Lay end bell upside

Do nor attempt to remove the large snap ring installed in the center of

SECTION 12

NOTE

SS-300 AND SS-500 OVER SERIAL NO. 70,000 AND MODEL

SS-750 AND SS-1000 UNITS ONLY: Located between the oil and

water retainer and the lower tapered roller bearing is a steel thrust

washer. Remove and retain this, as it must be reinstalled at time of

reassembly (see Figure 12-7).

3. Remove lower tapered roller bearing. If it is to be reused, place

with upper bearing. If not to be reused, discard it (see Figure 12-8).

4. It is not necessary to remove either the upper or lower outer cups

unless a new bearing set is to be installed in the end bell. If it is

necessary to remove

down on bench. Insert a mild steel rod through the lower outer cup

at an angle so that the lower end of the rod will rest on the upper

cup backface (see Figure 12-9). Tap the rod gently with a hammer

and the upper outer cup will become dislodged. Turn the end bell

upright and remove the lower outer cup in the same manner (see

Figure 12-10).

Figure 12-7.

NOTE

the end bell. This part is pressed in at the factory and should not, nor

cannot, be removed without damaging the end bell.

BEARING AND BEARING CONE ASSEMBLY

1. If the existing bearings are suitable for reuse, proceed to Bearing

Cleaning and Lubrication and skip Upper and Lower Bearing Cup

Assembly.

If new bearing cups and cones are being installed, lubricate the

bearings as indicated in Cleaning and Lubrication and install the

bearing cones as indicated in Bearing Cup Assembly.

Figure 12-8.

Figure 12-9.

31

Figure 12-10.

Page 33

SECTION 12

compatible with the disposer design and operating conditions. Do

fill the space between the rollers and the cage. Any

2.

n the palm of

Make sure the grease gets

deep in between the roller and the cage and not just on the outside

ciently packed, smear the

Figure

12-11.

BEARING CLEANING AND LUBRICATION

Clean old grease and dirt from the bearings by washing the bear-

1.

ings with kerosene or mineral spirits.

After the bearing has been washed and cleaned, it should be dried

thoroughly. Inspect bearing cones and bearing cups carefully. If

they show evidence of corrosion, pitting, scoring or any other

signs of damage or wear, discard complete bearing set.

Replacement parts are available in an Upper End Bell Bearing

and Seal Kit. Parts included in kit are shown in Figure 12-11.

Do not attempt to use old cones with new cups or vice-versa. The

double tapered roller bearings are machined as a matched set and

they will not "mate" with other bearing set cones or cups.

Use only Texaco Kafram #390 grease or Texaco BRB grease to

lubricate the bearings. This type of grease has been chosen to be

not use any substitutes for the two types of grease specified.

The bearings must be packed with grease. A mechanical grease

packer will do a good job of packing the bearing cones. These

packers wilt also keep the grease clean and free of shop dirt and

dust. The grease is forced through the bearing cone from one end

to the other to

excess grease present should be smeared on the outside of the

rollers and cage.

Figure 12-12.

If a mechanical grease packer is not available, proceed as follows:

Place an amount of the Texaco Kafram #390 grease i

your hand. Holding the bearing in the other hand, wipe the large

end Into the grease (see Figure 12-12).

of these parts. After the rollers are suffi

excess grease on the outside of the rollers and cage.

32

Page 34

Once assembly of the bearings, seal (bearing/seal kit), upper end

bell, rotor shaft and rotor shredder is started, continue and complete

earing cups are property

minute drying time Is

1.

4.

Figure

12-13.

UPPER AND LOWER BEARING CUP ASSEMBLY

NOTE

without interruption. This will Insure the b

positioned while the Loctite hardens. A 30

required for the Loctite to harden. Therefore, do not run the unit until

30 minutes after this assembly.

1. Prior to assembly, the cup recess in the end bell must be thoroughly

cleaned to remove all traces of grease, dirt and mastic. A clean rag soaked

with paint thinner will remove all of this residue. It is very important that

the entire cavity is completely free of any burrs. Crocus cloth may be

required to smooth the area. After the end bell has been cleaned, wipe

with a clean rag. Also clean the outside diameter of the bearing cup in the

same manner to remove all oil, grease or dirt. Be sure it is also wiped dry

with a clean rag. Coat the cup recess in the end bell with Loctite and insert

the bearing cup. Press cup in firmly so it will be seated fully in the recess.

Turn the end bell over and repeat this process with the remaining bearing

cup.

SECTION 12

LOWER BEARING AND OIL AND WATER RETAINER ASSEMBLY

Place end bell on bench in upside down position. Insert the lower tapered

roller bearing (8) into outer cup (see Figure 12-1). Now place and center

the steel thrust washer on the bearing. Place the oil and water retainer (12)

squarely into end bell recess. Using a wood block and a nylon or rawhide

mallet, tap the seal into the end bell recess until it is flush with the casting

(see Figure 12-13).

NOTE

Upper tapered roller bearing will be assembled later.

LOWER END BELL, STATOR AND ROTOR SHAFT ASSEMBLY

1. Support the motor assembly firmly so the end bell can be reinstalled.

Holding the end bell (10) with both hands, guide it down over the rotor

shaft being careful not to damage the shaft threads. (Thrust washer could

shift causing interference). Line up the scribe marks. Tap alternately on

opposite sides with a mallet until it is seated fully in the stator.

2. Stand the unit upside down and reinstall the fan, bottom cover and motor

thru bolts. Turn assembly right side up.

3. The cone spacer is machined to properly space the two tapered roller

bearings when they are installed in the end bell. It is not interchangeable

with any other cone spacer. If new bearings are installed, the new cone

spacer furnished with the bearing set must be used.

Install upper tapered roller bearing in end bell recess. Be sure bearing

has sufficient lubrication. If not, clean and grease bearing as outlined in

Greasing procedure.

33

Page 35

oo tight, replace it. We recommend

down far enough so it rests on the centrifugal moisture shield (see

Proper sequence of assembly of the spacer sleeve and seal must be

until after

have the upward deflection or configuration as shown In the cutaway

view. Other

wise a malfunction potential will exist (see

Figure

12-15).

lip seal, coat the machined face and

Figure

12-14.

Figure

12-15.

SECTION 12

5. The centrifugal moisture shield is designed to fit snugly on the

shaft, but not tight. Place it on the rotor shaft to determine its

proper fit. If it is too loose or t

this procedure prior to reassembly of the centrifugal moisture

shield into the end bell. There is no way of determining its proper

fit once the end bell is assembled and fined to the motor assembly.

6. Install "O" Ring (5) onto the shaft. Be sure the "O" Ring is pushed

Figure 12-1).

7. Install woodruff key (14) into the shaft keyway. Be sure key is

seated fully in keyway. If It is necessary to tap the key into place,

use a soft metal drift such as copper or brass, not steel. After the

key is fully seated, install the spacer sleeve (4).

NOTE

followed exactly as outlined. Do not install the lip seal (3)

the stainless steel sleeve (4) is installed. The lips of the seal must

34

NOTE

Just prior to Installing the trigroove of the upper end bell filling the machined groove with a

waterproof silicone sealer — all around (see Figure 12-14).

Also fill the formed groove in the bottom of the seal flange with

silicone sealer — all around.

Do not use excessive amount of sealer. Do not use substitutes.

8. Install the lip seal (3) over the spacer sleeve (4) and down into the

recess in the upper bell. Line up the screw holes and install the

retaining screws (2).

NOTE

The lip seal has been packed with a special lubricant. Do not remove it.

9. Install the trash excluder shield (1) and the two rotor shredder

woodruff keys (13).

10. Reassemble the unit completely.

11. Figure 12-15 shows assembled bearings, seals, rotor, shredder

and rotor shaft in upper end bell.

REASSEMBLE END BELL TO UNIT

1. Support the motor assembly firmly so the end bell can be

reinstalled. Holding the end bell with both hands, guide it down

over the rotor shaft, being careful not to damage the shaft

thread's. Line up the scribe marks. Tap alternately on opposite

sides with a mallet until it is seated fully. Then reassemble as

outlined in Sections 7, 8,9, 10 and 11.

Page 36

7, 8, 9, 10,11

1.

phenolic ring will also become free and can be removed. The base

pry tools opposite each other under the centrifugal switch base. By

.

ROTOR AND SHAFT

REMOVAL FROM UNIT

1. Disassemble unit completely as outlined in Sections

and 12.

2. After the unit has been disassembled as outlined above, it is a

simple matter to remove the rotor and shaft assembly. Grasp the

exposed portion of the shaft firmly and lift up and out of stator

(see Figure 13-1).

3. After rotor and shaft have been removed, remove the pre-load

spring from the lower end bell bearing cavity (see Figure 13-2).

ROTOR AND SHAFT DISASSEMBLY

The rotor and shaft assembly has only two moving parts on it that

can be removed and replaced. One part is the lower bearing and the

other part is the centrifugal switch assembly (found on single phase

units only). There should be no necessity of removing either part

unless they are inoperative or damaged. The balance of the rotor and

shaft assembly is not to be disassembled in the field. If either the

rotor or shaft is damaged, it will be necessary to replace the

1. Press the lower bearing off in an arbor press, supporting the rotor

and shaft by the bearing (see Figure 13-3). If bearing is worn or

damaged, discard it.

SECTION 13

Figure 13-1.

2. To remove the centrifugal switch (single phase units only), it is

first necessary to remove the lower bearing as described in Step

Remove the two centrifugal switch springs. After they are

removed, the two centrifugal switch actuating arms and the

portion of the centrifugal switch remaining on the shaft can be

removed by prying with two screwdrivers or pry tools. Place the

rocking the base portion of the centrifugal switch with the pry

tools, it can be loosened enough to remove it. It should then be

discarded.

Figure 13-2

35

Figure 13-3.

Page 37

To assemble the centrifugal switch (single phase units only), place

from the end of the shaft to the face of the

assembly, being careful not to damage centrifugal switch or motor

Lower bearing will seat itself into the

SECTION 13

Figure 13-4.

ROTOR AND SHAFT REASSEMBLY

1.

the rotor and shaft in an upside down position in an arbor press.

Support the shaft firmly so as not to damage the bearing journals

or mounting nut threads. Place the new centrifugal switch on the

shaft in an assembled condition. Do not disassemble it. Gently

apply pressure to the centrifugal switch until it "opens" or

collapses. Then proceed to press the switch onto the shaft, taking

care not to press it on too far (see Figure 13-4). With the

centrifugal switch pressed on to the proper depth, the correct

dimension is 2-61/64"

phenolic ring. This measurement must be made when the

centrifugal switch is in the "open" or collapsed condition. A

tolerance of 1/64" plus or minus is allowed.

2. To replace the lower bearing on the shaft, use an arbor press. Use

a hollow tube the diameter of the inner race and press bearing on

until it seats on shoulder of rotor shaft (see Figure 13-5).

REASSEMBLY TO UNIT

Figure 13-5.

Figure 13-6

1. Reinstall the pre-load spring into the lower end bell bearing

cavity. Pre-load spring should be installed with spring feet

bottoming in cavity (see Figure 13-6).

2. Prior to reassembly of rotor and shaft assembly into stator

housing, examine the centrifugal switch assembly, lower bearing

and woodruff keyways. If components need replacing or if

woodruff keyways are distorted, replace parts as previously

outlined.

3. Grasp rotor and shaft assembly firmly by upper bearing journal.

Lower the rotor and shaft assembly gently into the stator

windings (see Figure 13-7).

lower bearing cavity, at which time rotor and shaft will be in

place. Complete reassembly as outlined in Sections 7, 8, 9, 10, 11

and 12.

Figure 13-7.

36

Page 38

STATOR AND LOWER END BELL SECTION 14

its only) is held in place in the

terminal box mounting bracket by a spring clip. Insert a screwdriver blade

between the clip and bottom of capacitor and by prying gently, the

DO NOT TOUCH CAPACITOR TERMINALS. CHARGED

CAPACITOR CAN CAUSE SEVERE SHOCK WHEN BOTH

TERMINALS ARE TOUCHED. A CHARGED CAPACITOR WILL

REMOVAL FROM UNIT

1. Disassemble unit as outlined in Sections 7 and 9. Scribe mark upper end

bell and stator housing and lower end bell and stator housing (see Figure

14-1).

2. Lay unit on its side and tap on bottom surface of upper end bell until

upper end bell and stator housing separate (see Figure 14-2). At this point,

stand unit upside down and lift stator and lower end bell assembly straight

up and off.

STATOR AND LOWER END BELL DISASSEMBLY

The stator assembly and the lower end bell assembly contain all the electrical

components of the disposer. In the event replacement of one or more of these

components is required, proceed as follows:

1. The capacitor (used on single phase un

Figure 14-1.

capacitor will be released (see Figure 14-3).

CAUTION

DO NOT TOUCH CAPACITOR TERMINALS AS ELECTRICAL

SHOCK MAY OCCUR.

This will allow access to the terminals so the lead wires can be unsoldered,

allowing removal or replacement of the capacitor. After lead wires are

resoldered, reinstall the capacitor.

2. Capacitor Testing

CAUTION

HOLD AN ELECTRICAL CHARGE UNTIL IT IS DISCHARGED

AND OR SHORTED OUT. HANDLE CAPACITOR CAREFULLY

UNTIL IT IS KNOWN THE CAPACITOR IS FULLY DISCHARGED.

Figure 14-2.

Figure 14-3.

37

Page 39

SECTION 14

Figure 14-4.

Figure 14-5.

Before inspecting and testing, make sure the capacitor is fully

a.

discharged by using a jumper wire with a high resistance (1000 ohm)

resistor to short out and or discharge the capacitor (see Figure 14-4).

An insulated screwdriver can also be used but is not recommended

because possible damage to the capacitor may occur (see Figure 14-

5). A sharp crack and spark will occur if the capacitor is fully or

partially charged when performing this procedure.

b. To test the capacitor, use an ohmmeter (set on highest ohm scale).

Place the meter probes on capacitor terminals (see Figure 14-6).

1. If meter does not move, capacitor is open. Replace capacitor.

2. If meter needle Jumps to 0 (zero) and stays there, capacitor is snorted

within itself. Replace capacitor.

3. If meter needle jumps to 0 (zero) and slowly moves back toward

infinity (8), capacitor is good.

The overload protector is held in place in the terminal box mounting

4.

bracket by an overload clamp and two retaining screws. To remove the

overload protector, remove the two screws and the overload clamp (see

Figure 14-7). At this point, the overload protector is available for

removal and or replacement. If the overload protector is to be removed

to allow further disassembly of the terminal box mounting bracket, be

sure to mark or identify the lead wires as they are unsoldered from the

overload protector. This will enable you to solder them to the proper

terminals upon reassembly.

If the overload protector is just being replaced, unsolder the lead wires,

one at a time, and resolder to the replacement overload to assure

connecting to the proper terminals.

Refer to "Wiring Diagrams" for correct connections.

Figure 14-6.

Figure 14-7.

38

Page 40

SECTION 14

Figure

14-8

.

5. Overload Switch Check

a. Make certain the red button is pressed in fully.

b. Use an ohmmeter to check continuity (see Figure 14-8).

1. Three phase overload protectors have six (6) terminals.

2. Single phase overload protectors have three (3) terminals.

An ohmmeter reading should show continuity between all terminals,

including the center post.

Whenever the overload protector is tripped open, the ohmmeter will

show no continuity between any and all terminals, including the center

post.

If the overload needs replacing, be absolutely certain the new overload

protector is correct. Refer to parts lists for correct numbers.

See Diagrams 1, 2, 3, 4 and 5 of Section 16.

6. The terminal box mounting bracket should not have to be removed from

the stator unless the stator is to be replaced or unless the terminal box

mounting bracket is damaged. To disassemble the mounting bracket from

the stator, remove the overload protector, capacitor (single phase units

only) and the four mounting screws. The mounting bracket will become

free. To reinstall, reverse above procedure (see Figure 14-9).

7. To replace the lower end bell, separate it from the stator and disconnect

the lead wires connected to the starting switch (see Figure 14-10).

Remove the two screws retaining the starting switch and end bell will be

free for removal. To reinstall, reverse above procedure.

Figure 14-9.

Figure 14-10.

39

Page 41

.

SECTION 14

Figure 14-11.

8. To remove and replace starting switch (used on single phase units only)

proceed as outlined in Step 6 (see Figure 14-11).

9. To replace the stator, disassemble stator and lower end bell assembly as

described previously.

10

Stator Testing

a. Use an ohmmeter to check/test continuity.

b. Each winding should be checked individually.

c. Make certain no electrical components are in the circuit you are

testing.

d. Check for:

1. Opens

2. Shorts (between coils)

3. Grounds

e. Refer to and use correct wiring diagram when testing. See Diagrams

1, 2, 3, 4 and 5 of Section 16.

NOTE

Check the motor wiring diagram that corresponds to the voltage and phase of

the motor that is being tested. This will help to identify the proper leads to be

used for checking the desired stator winding.

40

Page 42

JAMMED DISPOSER CONDITIONS

Figure

15-1.

A jammed condition may be described as disposer:

1. Hums but will not turn/start.

2. Starts and stops abruptly.

3. Starts hard, may run and trip overload.

4. Cannot turn rotor shredder by hand.

The causes would be:

1. Foreign object/material such as silverware, cleaning rag, cooking utensil,

tin foil wrappings, mop strings, etc. entered the disposer and wedged

tightly between grinding elements.

2. Excessive material such as plastic straws, cigarette filters, bits of tin foil,

cocktail mixing sticks, etc can become chewed up and packed in the

vertical teeth of the stationary shredder. Eventually they may swell and

start to bind on the outside diameter of the rotating shredder causing the

motor to overload. Lack of sufficient post flush contributes greatly to this

problem.

SECTION 15

3. Disposer was turned off before all material was ground away or disposer

was heavily overloaded before or during the grinding operation.

Clearing the jam may require:

1. Using the 18" jam release bar (I.S.E. part No. 4173B) (see Figure 15-1).

a. The notches on the ends of the jam bar are different. Determine which

end should enter the disposer to engage the lug on the rotor shredder.

Clamp vise grips or adjustable pliers to the bar as shown. While

pushing downward on the bar, turn the vice grips to move the rotor

shredder. Looking into the disposer with a flashlight will help

determine which direction the shredder was turning so that you can

unjam the unit by turning the jam bar in the opposite direction.

b. Remove the object(s) and reset the overload protector if

necessary.

c. If using the jam bar was unsuccessful, the disposer requires removal and

disassembly down to and possibly removal of the stationary shredder.

2. Cleaning the vertical grinding teeth of the stationary shredder.

a. Use an awl and scrape each individual tooth clean or disassemble the

unit down to the shredders and clean the teeth.

41

Page 43

WIRING DIAGRAMS SECTION 16

Motor Lead Connections

The following five (5) wiring diagrams will be used for all SS Model commercial disposers for:

•

Proper motor lead connections.

•

Checking continuity, grounds, opens and shorts.

•

Replacing electrical component motor parts.

For your information and to determine which wiring diagram to use, check the specification decal on the disposer to determine if it is a single, dual or

tri-voltage motor.

Commercial disposers produced since April 1985 have tri-voltage motors and are designated as such on the specification decal.

115/208/230 Volts Single Phase (7 Leads)

208/230/460 Volts Three Phase (12 Leads)

Commercial disposers produced prior to April 1985 have single or dual voltage motors. The motor voltage is designated on the specification decal.

115/230 Volts Single Phase (7 Leads)

208 Volts Single Phase (7 Leads)

230/460 Volts Three Phase (12 Leads)

208 Volts Three Phase (3 Leads)

Wiring diagrams/connections remained the same except for the 208 volt three phase motors. The single voltage 208 volt three phase motor is the only

motor with three leads. Therefore, if you are diagnosing such a motor, you must use diagram 5 only. In all other cases, use the appropriate diagram

corresponding to the voltage indicated.

These connections are the same as the STANDARD MOTOR CONNECTION WIRING DIAGRAMS found in the terminal box.

See Section 17 for "ELECTRICAL CONNECTION DIAGRAMS" for electrical controls.

43

Page 44

SECTION 16

CHECK: Electrical specifications of the motor and power (voltage and phase) must match. Wiring connections must correspond.

Important Note: Do Not use these motor lead connections whenever motor leads are connected to an optional motor reversing control

(switch). Refer to "Electrical Connection Diagrams" in Section 17 for proper motor lead connections.

115 Volts

60 Hz

Single Phase

DIAGRAM 1

208/230 Volts

60 Hz

Single Phase

DIAGRAM 2

44

Page 45

SECTION 16

CHECK: Electrical specifications of the motor and power (voltage and phase) must match. Wiring connections must correspond.

Important Note: Do Not use these motor lead connections whenever motor leads are connected to an optional motor reversing control (switch).

Refer to "Electrical Connection Diagrams" in Section 17 for proper motor lead connections.

208/230 Volts

60 Hz

Three Phase

12 Lead Motor

(also see diagram 5)

DIAGRAM 3

460 Volts

60 Hz

Three Phase

DIAGRAM 4

45

Page 46

SECTION 16

CHECK: Electrical specifications of the motor and power (voltage and phase) must match. Wiring connections must correspond.

Important Note: Do Not use these motor lead connections whenever motor leads are connected to an optional motor reversing control (switch). Refer

to "Electrical Connection Diagrams" in Section 17 for proper motor lead connections.

208 Volts

60 Hz

Three Phase

Single Voltage

Motor Only

3 Lead Motor

Review Sheet 1

(also see diagram 3)

DIAGRAM 5

46

Page 47

SECTION 17

ELECTRICAL CONNECTION DIAGRAMS

The following "Electrical Connection Diagrams" are used to:

• Connect Electrical Controls to a Disposer Motor

• Add, Remove or Bypass Electrical Controls

• Diagnose Improperly Wired Installations

• Reconnect Removed Controls or Wires

Servicing commercial disposers involves basic knowledge of electrical controls and their function. It is possible that a disposer may fail to start or

may trip the overload protector or circuit breaker because of faulty electrical connections in the control itself.

Isolating all of the controls from the disposer motor can be done with a bypass cord (see Figure A). When using the cord, the motor connections

should be the same as when using a manual on/off switch. Using the bypass cord will allow the service technician to determine quickly if the

disposer or the controls are faulty.

If on a new or rewired installation the fault is in the controls, check all wiring connections to make certain they are correct for the electrical controls

installed. Check twice.

If any electrical control requires replacing, it can be ordered from IN-SINK-ERATOR by description. You must furnish complete motor

specifications, type of control and any numbers found on the control. Electrical controls vary depending on the size of the disposer and in some

cases, a special control may be found.

ELECTRICAL CONNECTION DIAGRAMS FOR ELECTRICAL CONTROLS

INDEX OF CONTROLS DIAGRAM NO.

STARTING (ON-OFF) SWITCH-MANUAL 1 2 3 4

REVERSING SWITCH-MANUAL-SINGLE PHASE 5 6 7 8

REVERSING SWITCH-MANUAL-THREE PHASE 9 10 11 12 13 14 15

MAGNETIC STARTER-WITH START/STOP BUTTONS 21 22 23 24

MAGNETIC STARTER-REMOTE CONTROL TYPE 15 16 17 18 19 20

TIME DELAY RELAYS 2 4 7 8 12 13 14 19 20 23 24

PRESSURE SWITCHES 3 17 22

FLOW INTERLOCK SWITCH 16 21

PUSH BUTTON CONTROL STATIONS 18 19 20

WATER SOLENOID VALVE ALL

There are special designed installations requiring additional or specific types of controls or combinations. Wiring diagrams for those do not appear

on these sheets. If help is needed, call the factory for engineering assistance.

47

Page 48

SECTION 17

Switch (Locate Approx. 3' From End Of Cord)

Alligator Clips Fastened to Each Wire End

8 Required

Figure A

48

Page 49

SECTION 17

Broken lines indicate leads to be supplied by installing electrician.

· Use STANDARD MOTOR CONNECTION WIRING DIAGRAMS in disposer motor terminal box or see Section 17 "WIRING DIAGRAMS".

STARTING (ON-OFF) SWTICH — MANUAL

All Voltages

Do Not Use L3 and T3

For Single Phase

Applications.

STARTING (ON-OFF) SWITCH — MANUAL W/TIME DELAY RELAY

DIAGRAM 1

All Voltages Except 460

Volts

Do Not Use L3 and T3 For

Single Phase Applications.

DIAGRAM 2

Page 50

All Voltages

For Single Phase

SECTION 17

Broken lines indicate leads to be supplied by installing electrician.

* Use STANDARD MOTOR CONNECTION WIRING DIAGRAMS in disposer motor terminal box or see Section 17 "WIRING DIAGRAMS".

STARTING (ON-OFF) SWITCH — MANUAL W/PRESSURE SWITCH

1/2 H.P. Through 5 H.P.

Do Not Use

L3 and T3

STARTING (ON-OFF) SWITCH — MANUAL W/TIME DELAY RELAY

Applications.

DIAGRAM 3

460 Volts

Three Phase

50

DIAGRAM 4

Page 51

115

Volts

Broken lines indicate leads to be supplied by installing electrician.

REVERSING SWITCH — MANUAL SINGLE PHASE

SECTION 17

Single Phase

REVERSING SWITCH — MANUAL SINGLE PHASE

DIAGRAM 5

208/230 Volts

Single Phase

DIAGRAM 6

51

Page 52

SECTION 17

Broken lines indicate leads to be supplied by installing electrician.

REVERSING SWITCH — MANUAL SINGLE PHASE W/TIME DELAY RELAY

115 Volts

Single Phase

REVERSING SWITCH — MANUAL SINGLE PHASE W/TIME DELAY RELAY

DIAGRAM 7

208/230 Volts

Single Phase

DIAGRAM 8

52

Page 53

Broken lines indicate leads to be supplied by installing electrician.

REVERSING SWITCH — MANUAL THREE PHASE

SECTION 17

208/230 Volts

Three Phase

12 Lead Motor

(also see Diagram 10)

REVERSING SWITCH — MANUAL THREE PHASE

DIAGRAM 9

208 Volts

Three Phase

Only For Single

Voltage Motor

3 Lead Motor

DIAGRAM 10

53

Page 54

SECTION 17

Broken lines indicate leads to be supplied by installing electrician.

REVERSING SWITCH — MANUAL THREE PHASE

460 Volts

Three Phase

REVERSING SWITCH — MANUAL THREE PHASE W/TIME DELAY RELAY

DIAGRAM 11

460 Volts

Three Phase

DIAGRAM 12

54

Page 55