Page 1

INSTALLATION, CARE AND USE MANUAL

The Model LC-50 food waste disposer is designed specifically for light commercial use in applications such as:

• Grocery/convenience stores

• Fast food restaurants

• Office/church kitchens

• Bed and breakfast inns

This manual clearly describes the installation procedure, operating instructions, maintenance instructions, and safety instructions.

Following this manual will help you enjoy all the benefits from using a

food waste disposer in your operation.

TOOLS AND MATERIALS YOU WILL NEED

? Screwdriver

? Pipe wrench

? Hammer

? Plumber's putty (1/4 Ib.)

? Wire nuts (2 - size 54)

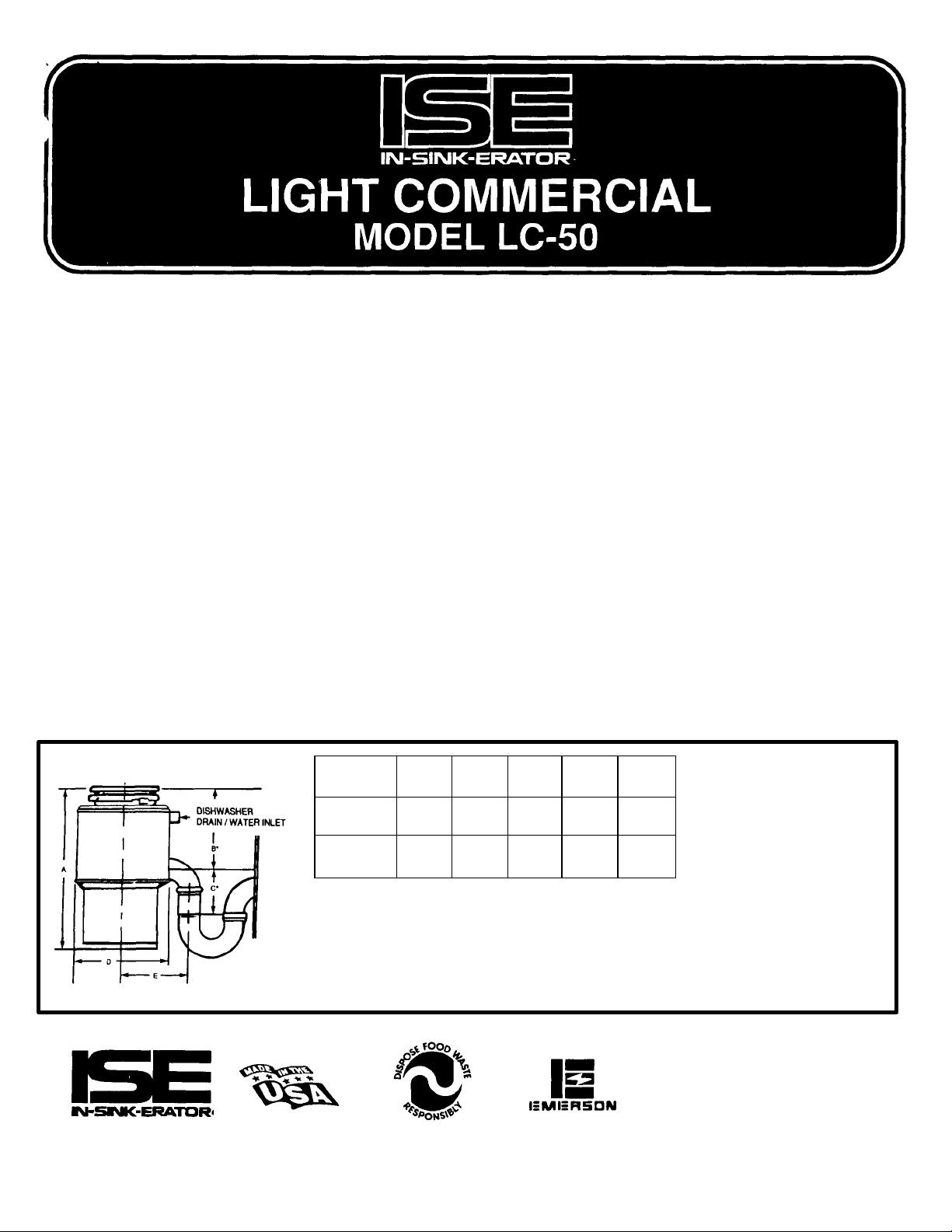

INSTALLATION DIMENSIONS

Dimension A B* C* D E

TOOLS AND MATERIALS YOU MAY NEED

? Plumber's drain auger or rod

? On-off electrical switch (1/2 H.P., 15-20 amps)

? Hack saw

? Worm gear clamp

? Copper wire (12 or 14 gauge)

? Connector kit (Part #8301)

? Solenoid valve (Part #11475)

? Syphon breaker (Part #11477)

? Flow control valve (Part #11033D)

Inches

Cm

14 9/16 6 13/16 4 8 5%

37.0 17.3 10.2 20.3 14.6

B* - Distance from bottom of sink to center line of disposer outlet. Add '/z" when stainless steel

sinks are used.

C* - Length of discharge tube from center line of disposer outlet to end of discharge tube.

IMPORTANT: Plumb waste line to prevent standing water in disposer motor housing.

For Service Information Call Toll Free 1-800-558-5712 (U.S.) or 1-414-554-5432 (Canada)

IN-SINK-ERATOR DIVISION

EMERSON ELECTRIC CO.

4700 21st STREET, RACINE, WIS. 53406

Page 2

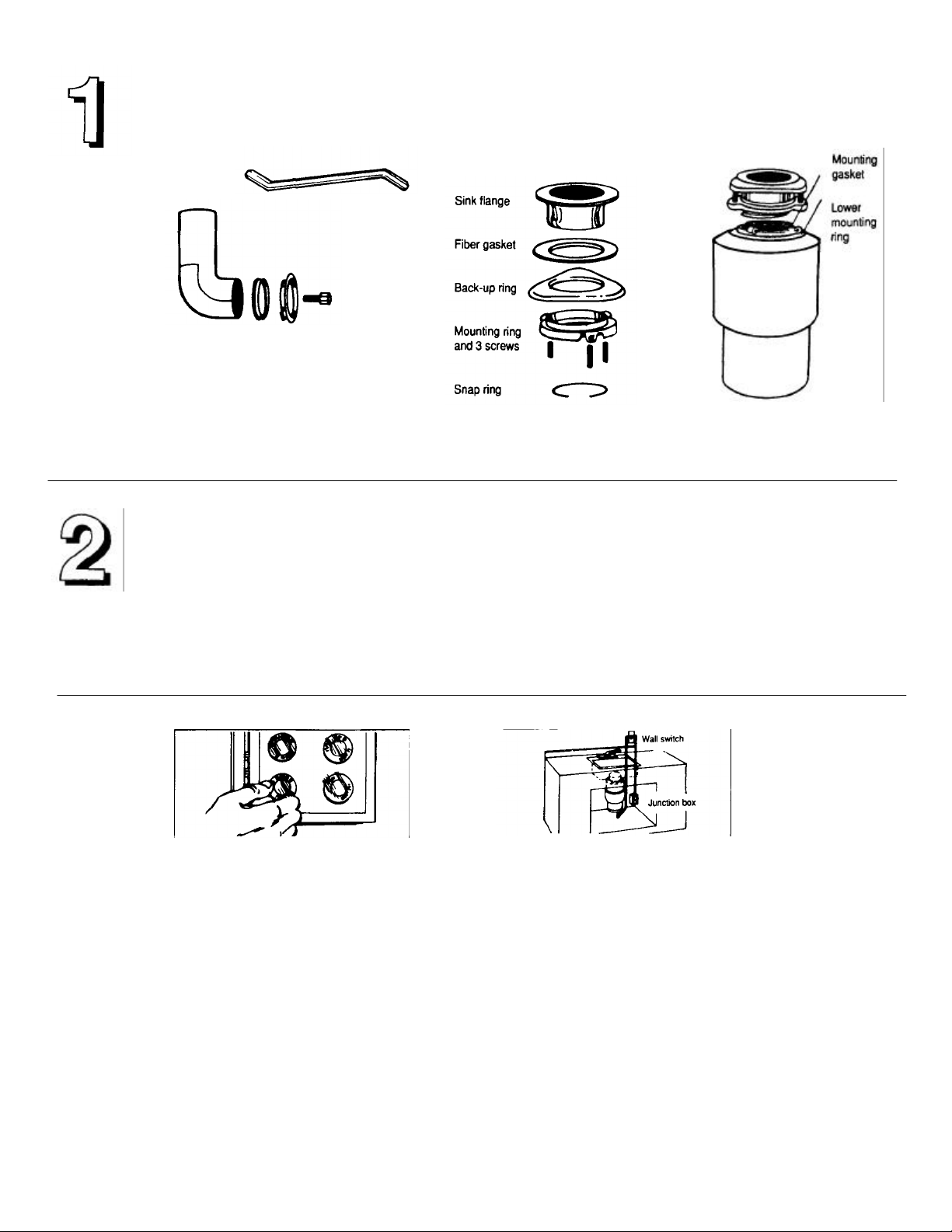

CHECK THE PARTS AGAINST THE DRAWINGS BELOW AND MAKE SURE

EVERYTHING IS THERE

THE MOUNTING

ASSEMBLY CONSISTING

OF:

SELF-SERVICE

"WRENCHETTE”

DISCHARGE TUBE, GASKET,

METAL FLANGE AND

SCREWS

THE DISPOSER ITSELF

CLEANING YOUR SINK'S DRAIN LINE

We recommend cleaning the line before connecting your new disposer. You can do the job yourself with a drain

auger. Remove the drain trap and, using the auger, clean out the horizontal drain pipe that runs from the trap to the

main waste pipe. Make certain that the auger removes the hardened material that forms at the intersection of the

horizontal pipe and the main waste pipe.

ELECTRICAL SUPPLY

First, remove the fuse or open the circuit

breaker on the circuit you plan to use for your

disposer. Use a separate 15 or 20 amp, 120

volt circuit for the disposer. If you are

replacing a unit, skip to step 4. Next, use 1520 amp, 120 volt cable to make a connection

from the junction box to the on-off switch.

NOTE: See 10&11 for final electrical connections.

Install a junction box and switch. (Obtain 1/2

H.P., 15-20 amp rated on-off switch and

electrical wiring locally.) Position the switch in

any convenient location, and connect to

junction box. All wiring must comply with

local electrical codes. 14 gauge size wire is the

smallest permissible for use with a 15 amp

circuit, and 12 gauge is the smallest

permissable for use with a 20 amp circuit.

Page 3

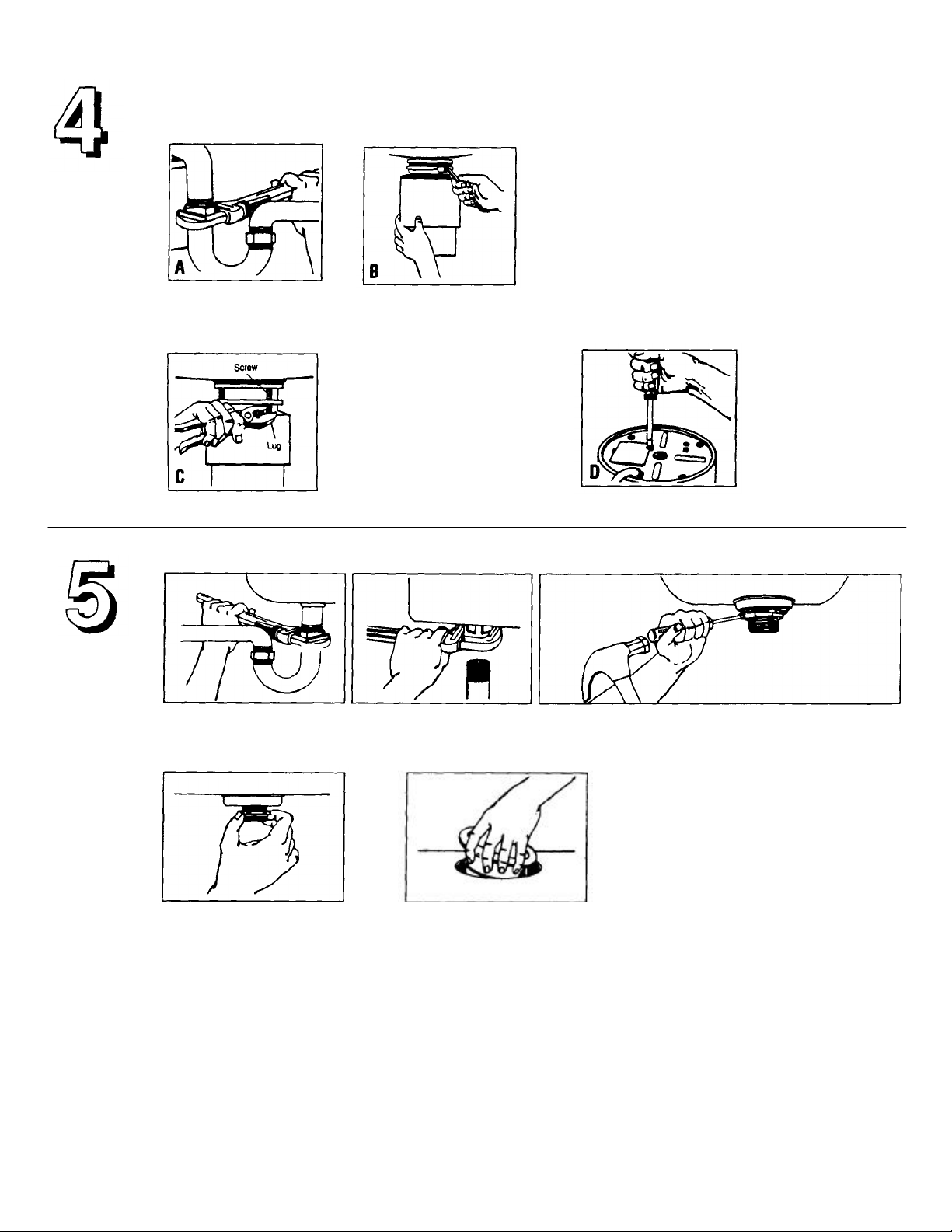

REPLACING AN OLD DISPOSER

FIRST, TURN OFF ELECTRICAL POWER at the service panel (fuse box or circuit breaker box). If the mounting is the same as your new

disposer's mounting, you can use the existing mounting. Follow instructions A, B, D and E, Step 4, then go on to Step 6.

IF YOUR OLD DISPOSER HAS A DIFFERENT MOUNTING THAN

YOUR NEW ONE, GO ON TO INSTRUCTION C.

If your old disposer has the same mounting as your new one, insert the

end of your "wrenchette" or screwdriver into the right side of one of the

disposer mounting ring lugs at the top of the disposer. Then, turn the

"wrenchette" or screwdriver to the left (counter-clockwise) until the lug

lines up with one of the sink mounting assembly screws.

Use a pipe wrench to

disconnect the drain line

where it attaches to the

disposer discharge tube.

CAUTION: Be sure to hold the disposer with one hand while performing this step or

it may fall when the mounting ring is disconnected from the sink mounting assembly.

GO TO INSTRUCTION D.

If your old disposer has a different

mounting than your new one, use a pliers

or adjustable wrench to remove the nuts

on the mounting ring. Then remove old

disposer. (Some disposers have to be

removed by taking off a clamp or by

twisting the disposer to remove it from its

mounting. Easy to figure out.)

Once the disposer is off, turn

it upside down and remove the

electrical plate.

INSTALLING A FIRST-TIME DISPOSER

Use a wrench to loosen the nut at

the top of the "P"-trap.

The nut should be loosened

enough that you can spin it off by

hand.

Next, remove the nut at the top of

the sink strainer and remove the

extension pipe.

Now, push the strainer assembly

up through the sink hole and

remove it.

Now, remove the large-diameter nut at the base of the strainer by placing

the tip of your screwdriver on the edge of the nut. (There are usually

ridges to hold your screwdriver.)

Page 4

CLEAN THE OLD SEALANT FROM THE RIM OF THE

Make a nice fat snake of

Apply this roll under the rim of

Then, place the sink flange into

SINK HOLE

Use your screwdriver or a putty knife to scrape away all traces of

the old putty or caulking from the edge of the sink drain hole. Make

sure you get this as clean as possible so that you'll have a good,

water-tight seal for your new disposer sink flange.

SEPARATE THE PARTS IN THE MOUNTING ASSEMBLY

First, remove the mounting

assembly from the lower mounting

ring. Holding the mounting assembly

with one hand, insert your

Then, loosen the screws on the

mounting assembly until they are

just level with the surface of the

mounting ring.

Now, use a screwdriver to pry off

the snap ring.

wrenchette or screwdriver into one

of the lugs of the lower mounting

ring and turn it to the left

(counterclockwise) with your other

hand.

The assembly will now come apart. Set it aside and move to the next

step.

APPLY PUTTY TO THE SINK FLANGE

plumber's putty by rolling it

between your hands.

the sink flange.

the sink drain hole and push

down making sure it sits evenly

in the putty.

Page 5

ATTACH THE UPPER MOUNTING ASSEMBLY

Simply attach the third green

If you don't have a ground supply

First, working from under the sink, slip the

fiber gasket and next the metal back-up

ring (flat side up) up and over the sink

flange.

Hold the fiber gasket and metal back-up

ring in place with one hand and place the

mounting ring with its three screws onto the

sink sleeve.

Tighten the three mounting screws with your screwdriver until the whole mounting

assembly is seated evenly and tightly against the sink.

ELECTRICAL CONNECTIONS

Remove the electrical plate from the bottom of the disposer and

pull out the two electrical wires. The ground screw is also

under the plate.

Connect the wires from the switch to the disposer wires. In

making this connection, electrical wire nuts can be used or

wires may be securely soldered together. Be sure to connect

white to white and black to black. Wrap wire connections with

electrical tape and put wires inside of disposer housing. Check

for proper grounding, then replace the electrical cover.

Now, push the fiber gasket, metal backup

ring and the mounting ring further up on

the sink sleeve. Slide the snap ring onto

the sink sleeve until it pops into place in

the groove on the sleeve.

GROUNDING THE DISPOSER

WARNING: IF NOT PROPERLY GROUNDED, a hazard of electrical shock may exist. DO NOT reconnect electrical current at main service

panel until proper ground is installed. For your safety, DO NOT ground to a gas supply pipe.

wire to the green ground screw

on the unit.

conductor, buy a length of copper

wire from your hardware store that

is no smaller in size than the

supply wire and attach one end to

the green ground screw on the

unit.

If you have a water meter in your home, check the meter to see if there is a wire that comes

across it. If there is no wire, your cold water pipe is NOT GROUNDED. To properly ground it, add

a #6 copper wire as shown for 200 amp service or less. Use (Underwriters Laboratories Inc.,

listed for the U.S.A.) ground clamps to attach wire to pipe.

Attach the other end of this ground wire to the METAL cold

water pipe. NOTE: Be sure that this cold water pipe is

continuous METAL pipe from the sink to the ground. Use

(Underwriters Laboratories Inc., listed for the U.S.A.) ground

clamp to attach wire to pipe. If any doubt, or if NON-METAL

pipe is used in your home water connections or if plastic pipe

is used In your water supply pipe, you will need a qualified

electrician to install a proper ground.

Page 6

OPTIONAL STEP

If you do NOT plan to use this

step, go to step 13.

from an overhead faucet. As an option, the

water/dishwasher drain inlet can be used for direct water

The model LC-50 is designed to be used with water

A. Preparing the water/dishwasher drain inlet

Lay the disposer on its side and insert the tip of

your screwdriver into the water/drain inlet

opening at an angle.

B. Connecting direct water line or dishwasher drain hose to the disposer. This is done after step 13.

Remove the clamp or fittings

from the end of your dishwasher

drain hose. (Dishwasher

application only.)

Slide large end of adaptor over

inlet tube of disposer. Fasten

the adaptor to the disposer with

a proper size clamp.

connections, or as a connection for your dishwasher drain.

Tap the end of the screwdriver with a

hammer until the molded plug pops out.

MAKE SURE YOU TAKE THE LOOSE

PLUG OUT OF YOUR DISPOSER.

Then determine the outside diameter

of dishwasher drain line and cut

rubber adaptor to correct size. (Most

commercial water lines are 1/2" so

no cuts are necessary.)

Slip the remaining clamp over the

water line or dishwasher drain hose

and back two or three inches. Now,

slip the drain hose or water line into

the adaptor. Then slide clamp into

position and tighten.

NOTE: Both types of connections are recommended to be used with an In-Sink-Erator Connection kit, part number 8301 (shown above).

IMPORTANT: It you connect your dishwasher drain hose to the disposer, the discharge water must go through an air gap. Direct water

connections require a solenoid valve (Part #11475), and a syphon breaker (Part #11477). If your water line velocity is greater than 3 GPM, it is

recommended you use a flow control valve (Part #110330). Connections should comply to local plumbing codes. Check the three clamps to make

sure all of them are tightened.

CONNECTING THE DISPOSER TO ITS MOUNTING ASSEMBLY

Lift the disposer and position it so that the

disposer's three mounting lugs are lined up

under the three sink mounting assembly screws.

Then, while holding the disposer in place, turn the lower mounting

ring with the lugs to the right until all three ears are engaged on the

mounting assembly. You will lock this ring later, after the

plumbing connections are made.

Page 7

ATTACH THE DISPOSER DISCHARGE TUBE TO YOUR SINK'S DRAIN TRAP

First, check inside the disposer

grinding chamber to remove any objects or dirt that might have dropped

in.

Turn the disposer so that the

discharge tube aligns with your

drain trap.

Rotate the disposer around and attach the discharge

tube to the disposer. First, insert the rubber washer in

the discharge opening. Then, put the metal flange

over the discharge tube and screw the tube into place

using the bolts provided.

TUBE TOO LONG? Simply cut off as

much as necessary with a hack saw,

making sure you have a clean, straight

cut.

Install the discharge tube

gasket onto the discharge

tube. Gasket must be installed

as shown to assure a leakproof installation.

TUBE TOO SHORT? If the discharge

tube doesn't reach your drain outlet,

measure the difference and buy a drain

trap extension tube.

IF IT FITS - Simply tighten the slip nut on the trap to make your connection to the

discharge tube complete. IF DOUBLE SINK EXISTS, WE RECOMMEND USE OF

SEPARATE TRAPS FOR DISPOSER AND SECOND SINK. NOTE: Be sure to

comply with all applicable plumbing codes.

LOCK DISPOSER IN PLACE AND CHECK FOR LEAKS

Place the end of your "wrenchette" or a

screwdriver into the left side of one of the

disposer mounting lugs ... at the top of the

disposer. Then, turn the "wrenchette" or

screwdriver to the right until the disposer locks

in place.

Run water slowly through the unit.Then,

place the stopper in seal position and fill

the sink with water.

Finally, remove the stopper and permit

the water to flow. check for leaks and

correct, if necessary.

Page 8

IN-SINK-ERATOR DISPOSER WARRANTY INFORMATION

following into a disposer:

possible drain blockage

MODEL LC-50 FULL 1 YEAR WARRANTY

Covers all replacement parts and repair labor to correct defects in material or workmanship for the full warranty period from the date of installation. If service is

required during the warranty period, an In-Sink-Erator Factory Authorized Service Center must be contacted to replace or repair the disposer i no charge to the

customer.

If the manufacturer determines the unit should be replaced rather than repaired, the warranty on the replacement unit will be limited to the unexpired term i the original

warranty.

If you have questions concerning your disposer, or when service is needed, please call In-Sink-Erator's Automated Service Information System at 1-80( 558-5700 for

the nearest In-Sink-Erator Factory Authorized Service Center. In Canada call 1-414-554-5432. This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

NO OTHER EXPRESS WARRANTY, WRITTEN OR ORAL APPLIES

If your disposer will not operate, follow these steps, in order:

1. Check the things you can do yourself. Be sure disposer is plugged firmly into appropriate receptacle or is properly electrically connected in some other manner. Be

sure fuses and circuit breakers are in good order. Reread instruction booklet to assure that you are using correct operating procedure. Mai unnecessary service calls

result in the service man doing what you can do yourself.

2. Check with your local authorized service center. For the location of your nearest factory authorized service center call toll free 1 -800-558-5700 or 1 -414 554-5432.

3. Write to us if a satisfactory solution is not reached in steps 1 and 2. Our address is:

IMPORTANT: The model LC-50 is designed specifically for light commercial use. Examples of these applications include: grocery/convenience store deli's, fast food

restaurants, office/church kitchens, and bed and breakfast inns. Use of this disposer in applications other than those named above may void your warranty. If you are

unsure of a potential application, call the factory at 1-800-558-5712, ext. 3536 or 3537.

HOW TO OBTAIN SERVICE

IN-SINK-ERATOR, SERVICE DEPARTMENT

4700-21st Street

Racine, Wisconsin 53406 U.S.A.

OPERATING INSTRUCTIONS

MODEL LC-50

1. Remove the stopper from the disposer sink sleeve and turn on the cold water fo//flow. (Water should remain on during complete

disposer operation.) Failure to turn on a full flow of water before turning on the disposer can cause drain blockages.

2. "Flip" the switch to the on position to start disposer. Feed food waste into the disposer white it is running. To avoid drain pipe

blockage allow water to flow sufficient time after grinding Is completed to be sure all waste is flushed away. Ground waste and

water mixture flows at the rate of 2 seconds per foot in a horizontal drain line.

NOTE: After all the food waste has been fed into the disposer place the stopper in the sink sleeve In the drain/grind

position (see Illustrations) to minimize the possible ejection of material while grinding. DO NOT INSERT HAND INTO

DISPOSER.

Stopper in drain/grind position

DO'S AND DON'TS

DO...

? use a strong flow of cold water while grinding

? grind hard materials such as bones, fruit pits, etc.

? grind citrus and melon rinds

? grind coffee grounds

? dispose of grease/fats with strong flow of cold water

? flush disposer for cleaning

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric appliances, basic precautions should always be followed, including the following:

1. Read all the instructions.

2. To reduce the risk of injury, close supervision is necessary when used near children.

3. Do not put fingers or hands into disposer.

4. Turn the power switch to the off position before attempting to clear a jam or remove an object from the disposer.

5. When attempting to loosen a jam in a waste disposer, use a self service wrenchette as described below.

6. When attempting to remove objects from a waste disposer use long-handled tongs or pliers.

7. To reduce the risk of injury by materials that may be expelled by a garbage disposer place the stopper in the drain/grind position when grinding. Do not put the

a. Clam and oyster shells

b. Drain cleaner

c. Glass, china, plastic or plastic wrap

d. Large whole bones

e. Metal objects

Continued on next page.

DON'T...

• use hot water while grinding food waste

• turn off disposer or water until grinding is complete

• grind extremely fibrous materials like corn husks, artichokes, etc. to avoid

• grind plastic, plastic wrap, glass, cardboard, metal, clam and oyster shells,

or large whole bones

Page 9

Safety Instructions continued.

8. When not operating a disposer, leave the stopper in place to reduce the risk of objects falling into the disposer.

9. Before pressing red reset button, (see Fig. 4), be sure the wall switch Is In the off position.

10. GROUNDING INSTRUCTIONS FOR PERMANENTLY CONNECTED UNITS: This appliance must be connected to a permanent metal ground, per

National Electric Code, and in accordance with all local codes.

DANGER - Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician or serviceman if you

are in doubt as to whether the appliance is property grounded.

SAVE THESE INSTRUCTIONS

TROUBLE SHOOTING

Loud noises while your disposer is operating are usually caused by the accidental entry of a spoon, bottle cap, or similar object. To correct this, turn off the

disposer switch and water. After grinding disc has stopped turning, investigate.

Motor stops while your disposer is operating. This can be caused by overloading the unit. First, check the cause of the overload - often some foreign material

is in the disposer. To avoid personal Injury turn off the disposer switch and water. Remove object as previously explained. If motor remains inoperative,

check your fuse box and replace any blown fuses, or look for a tripped circuit breaker.

NOTE: If the water does not drain as readily as you think it should and food waste tends to float or take too long to grind, don't reduce water How to solve this

problem. It is very likely that the drain line is partially clogged. To save the cost of a service call, use applications of a disposer safe cleanser and degreaser

until drain runs smoothly. If you see no improvement after several applications, a drain auger should be used to remove the blockage. Like any precision

machine, your disposer was built to perform a particular job. If unusual demands are placed on it, service interruptions are possible. These service

interruptions, mentioned below, are usually not serious and in most cases, can be remedied without calling a service man.

TO FREE JAMS FROM FOREIGN OBJECTS

To save the cost of a service call to free a jam. The accidental entry of foreign material will cause any disposer to jam occasionally. To free jammed material, follow

thesesteps to avoid personal Injury:

1. Turn off disposer and shut off cold water.

2. Insert one end of your Self Service Wrench provided with your disposer, into the center hole of the bottom of the disposer as shown.

3. Work the wrench back and forth until it moves freely for at least one complete revolution. Remove wrench before restarting disposer.

4. Wait 3 to 5 minutes to allow disposer motor to cool and then push red reset button, (Fig. 4). Before pressing red reset button be sure the wall switch

is In the off position.

Follow this procedure to save the cost of a service call to free a tight jam.

Be sure wall switch is turned off. Use a flashlight to determine the direction the unit was running at the time of the jam. A pry bar or tool should be inserted through the sink

opening into the disposer. The end then must be placed alongside the grinding protrusion near the outside edge of the grinding disc. Be sure to place the pry tool on the proper

side of the protrusion so when pressure is applied the grinding disc will move in the proper direction to unjam the disposer (see figure 5).

Do not drop or hammer on pry bar.

Lose Your Self Service Wrenchette?

If you should ever lose your Self Service Wrench just write to us and a replacement will be sent at no charge.

WRITE TO: WRENCHETTE

c/o IN-SINK-ERATOR

SERVICE DEPT.

4700 21st Street

Racine, Wisconsin 53406

For Service Information Call Toll Free 1-800-558-5712 (U.S.) or 1-414-554-5432 (Canada)

Loading...

Loading...