Page 1

LC-50 FOOD WASTE DISPOSER

Installation Manual

www.insinkerator.com

The Danger signal indicates an immediately hazardous situation which, if not

avoided, will result in death or serious injury.

The Warning signal alerts you to potential hazards or unsafe practices which,

if not avoided, could result in severe personal injury or death.

The Caution signal alerts you to hazards of unsafe practices which, if not avoided,

may result in minor personal injury or property damage.

Please be certain that the person who installs or uses this appliance carefully reads

and understands the Safety Instructions contained in this manual.

Part No. 13693 - January 2008

Page 2

Table of Contents

Introduction

Clean the Drain Line ....................................................................... 3

Required Tools/Materials ................................................................

In This Package ............................................................................................ 3

Typical Installation ........................................................................................ 4

Installation with Wall Switch ...........................................................

Installation with Remote Air Switch

................................................ 4

Removing Existing Disposer ................................................................... 5-6

Installing the Disposer ............................................................................. 6-7

Electrical Connections ................................................................................. 8

Final Installation ........................................................................................... 9

3

4

Operating Instructions

Operating the Disposer ................................................................ 10

Do's and Dont's ........................................................................... 10

Operating Instructions ..................................................................

11

Troubleshooting

Troubleshooting ............................................................................ 12

For Dishwasher or Direct Water Connection ................................ 13

Warranty

FOODSERVICE DISPOSER LIMITED WARRANTY

The InSinkErator® LC-50 Foodservice disposer is warranted against defects in material and workmanship for one

year from the date of installation. The warranty includes parts and labor, provided the service is performed by an

InSinkErator Factory Authorized Service Center. This warranty does not apply if failure is due to: faulty or improper

electrical installation, faulty or improper plumbing installation, product abuse or misuse, accidental damage, grinding

elements jammed by foreign objects, clogged drain lines, or an improperly sized unit (as specified by InSinkErator).

InSinkErator Foodservice disposer accessories are included in this warranty only if they are included in the original

disposer purchase package.

2

Page 3

Introduction

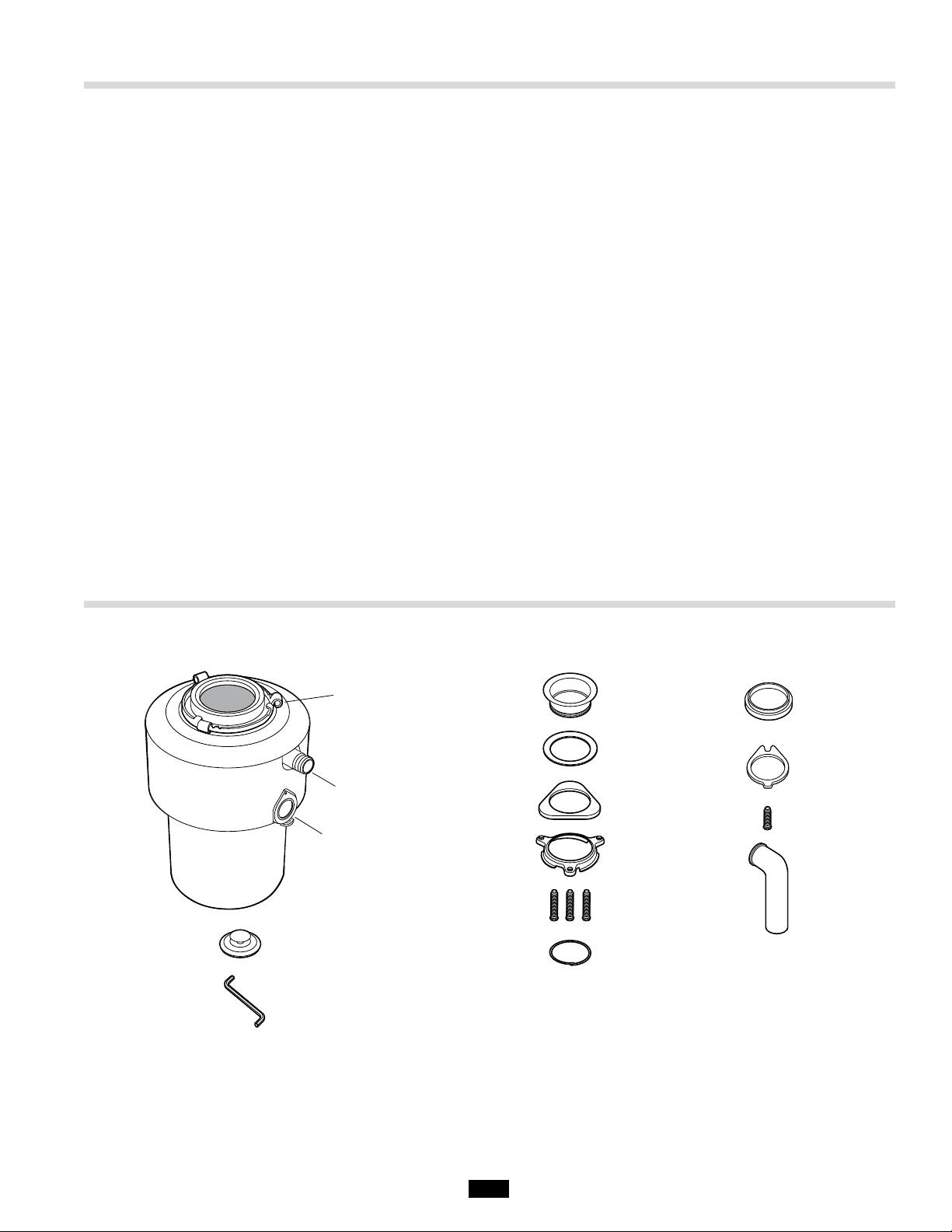

Stopper

Sink Flange

Rubber Gasket

Fiber Gasket

Metal Flange

Backup Ring

Mounting Ring

Screws

Screw

Snap Ring

Discharge Tube

Lower Mounting Ring

Mounting AssemblyDisposer Discharge Tube Assembl

y

Dishwasher Inlet

Tailpipe Mount

Wrenchette

The model LC-50 food waste disposer is designed

specifically for light foodservice use in applications

such as:

• Grocery/convenience stores

• Office/church kitchens

• Fast food restaurants

• Bed and breakfast inns

Important – These installation instructions are for the

benefit of the installing contractor. InSinkErator and/or

InSinkErator Factory Authorized Service Centers do not

make original installations. For technical information not

covered in these instructions, contact the supplier, an

InSinkErator Field Sales Representative, or InSinkErator

Foodservice Sales and Service at 1-800-845-8345.

CLEAN THE DRAIN LINE

With a drain line auger, clear away all hardened waste

material in the horizontal drain pipe running from the

drain trap to the main waste line.

REQUIRED TOOLS/MATERIALS

The following items are needed to install the disposer:

• Screwdriver

• Pipe wrench

• Hammer

The following items may be needed to install the disposer:

• Plumbing putty

• On/Off electrical switch (1/2 HP, 20A DP)

• Hacksaw

• Drain auger or rod

• Connector kit (Part #8301)

• Solenoid valve (Part #14495)

• Siphon breaker (Part #11477)

• Flow-control valve (Part #13763A)

In This Package

3

Page 4

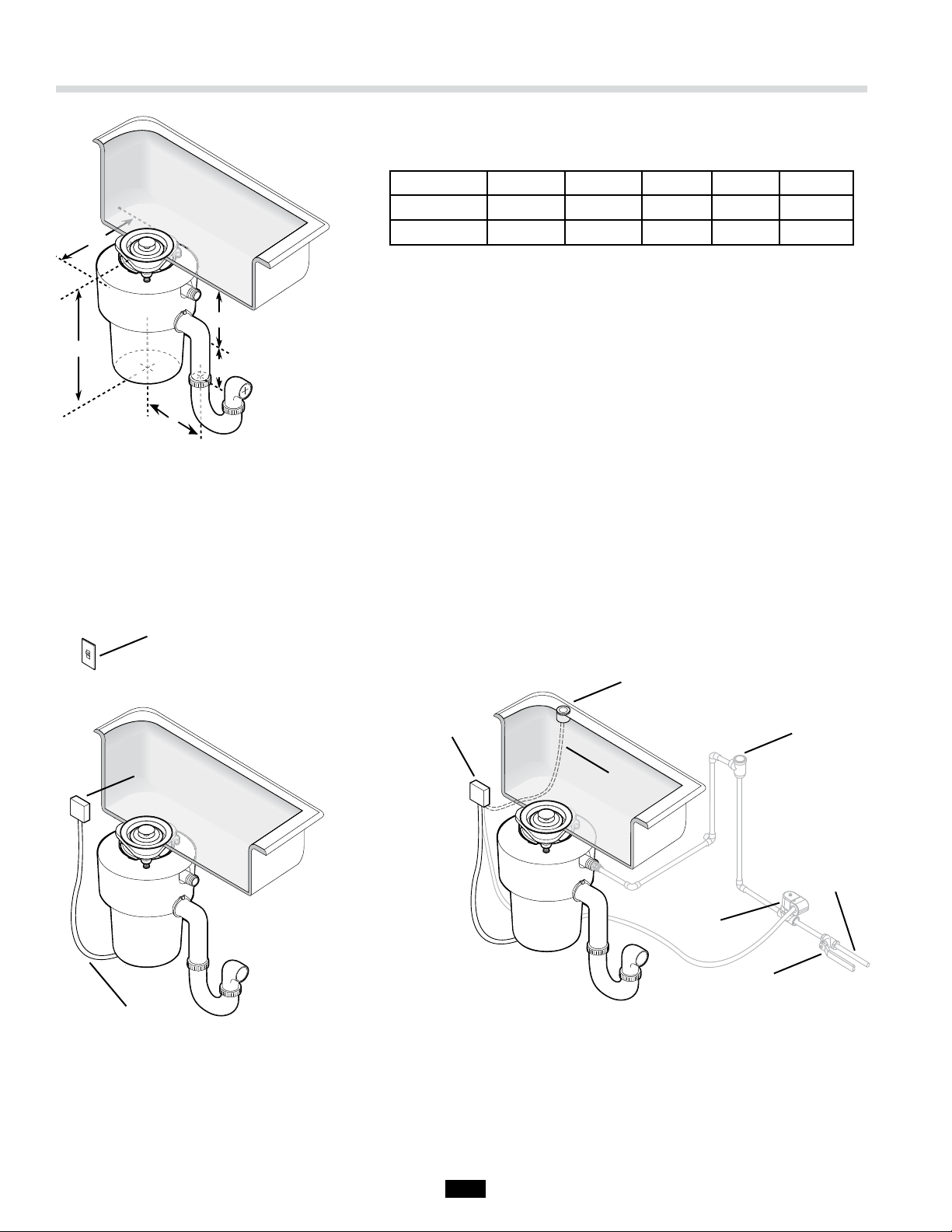

D

E

A

C*

B*

Typical Installation

Dimension A B* C* D E

Inches

Cm

B* – Distance from bottom of sink to center line of disposer outlet.

Add 1/2" (13mm) when stainless steel sinks are used.

C* – Length of discharge tube from center line of disposer outlet to

end of discharge tube.

Important – Plumb waste line to prevent standing water in

disposer motor housing.

14-9/16 6-13/16 4 8 5-3/4

37.0 17.3 10.2 20.3 14.6

INSTALLATION WITH WALL SWITCH INSTALLATION WITH REMOTE AIR

SWITCH AND OPTIONAL DIRECT

WATER CONNECTION

Push Button

Air Hose

Solenoid Valve

Water Shutoff Valve

Wall Switch

Air Switch

Power Junction

Electrical

Junction Box

Electric Supply

Syphon Breaker

OPTIONAL

DIRECT WATER

CONNECTION

Cold Water

Supply

4

Page 5

Removing Existing Disposer

1

3

2

4

ELECTRICAL SHOCK

Disconnect power before installing or servicing unit.

Test the circuit with a voltmeter or circuit tester to

ensure the power is off.

If there is no existing disposer, disconnect sink drain and skip to step 9.

FALLING HAZARD

Do not position your head or body under the

disposer. It could fall during installation.

Disconnect drain trap from waste discharge tube.

Disconnect dishwasher or direct water connection if

connected to the disposer.

With the electrical supply turned off, flip disposer

over and remove electrical cover plate. Save cable

connector if applicable.

Support disposer, insert end of wrenchette into right

side of mounting lug, and turn. Disposer will fall free.

With the electrical supply turned off, disconnect the

disposer wires from the electrical supply.

5

Page 6

Removing Existing Disposer

9

10

7

8

5

6

If the new disposer mounting is the same as the old one, you can go to step 14.

Loosen the 3 screws on the mounting assembly. Using a screwdriver, remove the snap ring.

Remove flange from sink.

Installing the Disposer

Sink Flange

Evenly apply 1/2" thick rope of plumber’s putty around

new flange.

Remove old plumber’s putty from sink with putty knife.

Press flange firmly into sink drain. Remove excess putty.

6

Page 7

> 3/8"

1-1/8"

< 3/8"

1-1/2"

13

14

15

11

12

Backup Ring

Mounting Ring

Installing the Disposer

Fiber Gasket

Optional

Insert fiber gasket, backup ring and mounting ring. Hold

in place while inserting snap ring.

Tighten screws evenly and firmly against backup flange.

Use shorter 1-1/8" screws if sink is more than 3/8"thick.

Place a weight such as the disposer on the sink flange

to hold it in place. Use a towel to prevent scratching

sink. Pull snap ring open and press firmly until it snaps

into place.

OPTIONAL: DISHWASHER OR DIRECT WATER CONNECTION ONLY

If you do not need to attach the dishwasher or direction water connection, go to step 16.

Turn disposer onto side and insert screwdriver into

dishwasher inlet.

Knock out drain plug and remove plug from inside

of disposer.

7

Page 8

Electrical Connections

19

1

2

18

16

17

ELECTRICAL SHOCK

• Disconnect power before installing or servicing

unit. Test the circuit with a voltmeter or circuit

tester to ensure the power is off.

• Use only a properly grounded and polarized

electric outlet.

• Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

• Installation must conform to all local

electrical codes.

• All control centers and disposers must

be grounded.

PERSONAL INJURY/PROPERTY DAMAGE

If the electrical installer is not experienced in

electrical installation, we recommend seeking

competent professional assistance. Disposer or

accessory damage due to improper installation is

not covered under warranty. All installations must

comply with local electrical codes.

Turn disposer over and remove electrical cover plate.

Pull out wires. DO NOT REMOVE CARDBOARD SHIELD.

Connect white to white and black to black or red

with wire nuts (not included); ground wire to green

grounding screw. Unit must be grounded for safe and

proper installation.

With electrical supply turned off, insert cable connector

(not included) and run electrical cable through access

hole on bottom of disposer. Tighten cable connector.

Push wires into disposer (do not displace cardboard

shield) and replace electrical cover plate.

8

Page 9

21

22

23

24

20

Rubber Gasket

Discharge Tube

Final Installation

Metal Flange

Screw

Rotate the disposer around. Place the rubber gasket

on the end of the discharge tube and slide on the metal

flange from the reverse end. Place assembled discharge

tube in the tailpipe mount opening and secure with

screw provided.

Turn mounting ring until all 3 mounting tabs lock over

the ridges on the slide-up ramps.

Hang disposer by aligning 3 mounting tabs with

slide-up ramps on mounting ring.

You may need to trim tube for proper fit. Reconnect

plumbing (and dishwasher or direct water connection if

used). Make sure tailpipe mount is straight.

Insert stopper into sink opening. Fill sink with water,

then test for leaks.

9

Page 10

Operating Instructions

Important – The model LC-50 is designed specifically for light commercial use. Examples of these applications

include: grocery/convenience store delis, fast food restaurants, office/church kitchens, and bed and breakfast inns.

Use of this disposer in applications other than those named above may void your warranty.

OPERATING THE DISPOSER

1. Remove stopper from sink opening and run strong flow of cold water.

2. Turn on wall switch to start disposer.

3. Slowly insert food waste into disposer and position stopper to minimize possible ejection of material while

grinding. After grinding is complete, turn disposer off and run water for a few seconds to flush drain line.

DO'S AND DON'TS

DO …

• First turn on a moderate to strong flow of cold water

and then turn on the disposer. Continue running cold

water for a few seconds after grinding is completed

to flush the drain line.

• Grind hard materials such as small bones, fruit pits,

and ice. A scouring action is created by the particles

inside the grind chamber.

• Grind peelings from citrus fruits to freshen up

drain smells.

• Use a disposer cleaner, degreaser, or deodorizer as

necessary to relieve objectionable odors caused by

grease build-up.

DON'T …

• Don't pour grease or fat down your disposer or any

drain. It can build up in pipes and cause drain

blockages. Put grease in a jar or can and dispose in

the trash.

• Don't use hot water when grinding food waste. It

is OK to drain hot water into the disposer between

grinding periods.

• Don't fill disposer with a lot of vegetable peels all at

once. Instead, turn the water and disposer on first

and then feed the peels in gradually.

• Don't grind large amounts of egg shells or fibrous

materials like corn husks, artichokes, etc., to avoid

possible drain blockage.

• Don't turn off disposer until grinding is completed and

only sound of motor and water is heard.

10

Page 11

Operating Instructions

PERSONAL INJURY

• Read all instructions before using the appliance.

• To reduce the risk of injury, close supervision is

required when an appliance is used near children.

• Do not put fingers or hands into a waste disposer.

• Turn the power switch to the off position before

attempting to clear a jam, removing an object from

the disposer or pressing reset button.

• When attempting to loosen a jam in a waste

disposer, use the self-service wrenchette.

• When attempting to remove objects from a waste

disposer, use long-handled tongs or pliers.

• To reduce the risk of injury by materials that are

expellable by a waste disposer, do not operate the

disposer without the Quiet Collar Sink Baffle

in place.

• Do not put the following into a disposer: clam or

oyster shells, caustic drain cleaners or similar

products, glass, china, or plastic, large (whole)

bones, metal (such as bottle caps, steel shot, tin

cans, or utensils), hot grease or other hot liquids.

• Do not dispose of the following in the disposer:

paints, solvents, household cleaners and

chemicals, automotive fluids, plastic wrap.

ELECTRICAL SHOCK

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

• This disposer must be properly grounded.

• Do not attach ground wire to gas supply line.

• Disconnect power before installing or

servicing disposer.

• If three-prong grounded plug is used, plug must be

inserted into three-hole ground receptacle.

• All wiring must comply with local electrical codes.

• Do not reconnect electrical current at main service

panel until proper grounds are installed.

PROPERTY DAMAGE

Do not use plumber's putty on any other disposer

connection other than sink flange. Do not use thread

sealants or pipe dope. These may harm disposer and

cause property damage.

FIRE HAZARD

Do not store flammable items such as rags, paper or

aerosol cans near disposer. Do not store or use

gasoline or other flammable vapors and liquids in

vicinity of disposer.

11

Page 12

Troubleshooting

ELECTRICAL SHOCK

Disconnect power before servicing.

Troubleshooting for problems other than what is listed below should be performed by a qualified service person.

Troubleshooting performed by untrained personnel could result in electrical shock or damage to the disposer.

Disconnect power before servicing.

PROBLEM POSSIBLE CAUSE SOLUTION

Disposer will not start. • No electrical supply.

• Turn on electrical supply.

Disposer motor stops while

grinding.

Overload protector

trips frequently.

• Disposer overload protector

is tripped.

• Disposer is jammed.

• Disposer is jammed.

• Disposer overload protector

is tripped.

• Disposer is overloaded with

food waste.

• Turn control to off position and press red reset button

on disposer.

• Turn control to off position and complete

following steps:

1. Insert one end of self-service wrenchette into center

hole on bottom of disposer. Work wrenchette back

and forth until it turns one full revolution. Remove

wrenchette.

2. Reach into disposer with tongs and remove object(s).

Allow disposer motor to cool for 3-5 minutes, then

lightly push red reset button on disposer bottom. (If

motor remains inoperative, check service panel for

tripped circuit breakers or blown fuses.)

• See "Disposer is jammed," above.

• Turn control to off position and press red reset button on

disposer. If disposer was running, allow unit to cool 3-5

minutes before pressing red reset button. Never strike

reset button with objects.

• Do not overload disposer with excessive amounts of

food waste.

12

Page 13

Troubleshooting

ELECTRICAL SHOCK

Disconnect power before servicing.

FOR OPTIONAL DISHWASHER OR DIRECT WATER CONNECTION

Troubleshooting for problems other than what is listed below should be performed by a qualified service person.

Troubleshooting performed by untrained personnel could result in electrical shock or damage to the disposer.

Disconnect power before servicing.

PROBLEM POSSIBLE CAUSE SOLUTION

Disposer will not start and

water does not flow.

Disposer will not start but

water flows.

• No electrical supply.

• Electrical disconnect switch

has been reactivated and

30-second delay has not

yet expired.

• Disposer overload protector

is tripped.

• Turn on electrical supply.

• Wait 30 seconds and try starting again.

• Turn control to off position and press red reset button

on disposer.

Disposer motor stops while

grinding, but water continues

to flow.

Water flows continuously

before controls are turned on.

Disposer runs but no

water flows.

• Disposer is jammed.

• Disposer is jammed.

• Disposer overload protector

is tripped.

• Solenoid and valve are

installed improperly.

• No water supply.

• Solenoid valve isn't opening.

• Turn control to off position and complete

following steps:

1. Insert one end of self-service wrenchette into center

hole on bottom of disposer. Work wrenchette back

and forth until it turns one full revolution. Remove

wrenchette.

2. Reach into disposer with tongs and remove object(s).

Allow disposer motor to cool for 3-5 minutes, then

lightly push red reset button on disposer bottom. (If

motor remains inoperative, check service panel for

tripped circuit breakers or blown fuses.)

• See "Disposer is jammed," above.

• Turn control to off position and press red reset button on

disposer. If disposer was running, allow unit to cool 3-5

minutes before pressing red reset button. Never strike

reset button with objects.

• Reinstall water solenoid valve with arrow on valve

pointing in direction of the water flow.

• Turn on water supply.

• Call qualified service personnel.

13

Loading...

Loading...