Ingersoll-Rand P425AWIR, XP375AWIR, HP375AWIR, VHP300AWIR, P600WIR Electrical/electronic Service Manual

...

ELECTRICAL/ELECTRONIC

SERVICE MANUAL FOR

P425AWIR (7/120)

XP375AWIR (9/110)

HP375AWIR (10/105)

VHP300AWIR (14/85)

P600WIR

HP450WIR

VHP400WIR

Portable Power

P.O. Box 868 -- 501 Sanford Ave

Mocksville, N.C. 27028

www.portablepower.irco.com

Book No. 22235428 (11/03)

TABLE OF CONTENTS

SECTION1.......ManualDescription

SECTION2.......GeneralInformationAndOperationalTheory

SECTION3.......ServiceTools

SECTION4.......ElectronicSystemsTroubleshooting

Procedures And Techniques

SECTION5.......SystemSchematicDiagrams

SECTION6.......ElectronicComponent Location Drawings

SECTION7.......IndividualCircuitDiagrams

SECTION8.......ElectricalConnector Information

SECTION9.......ElectricalPartsList

SECTION10......AlertsandShutdownsList

SECTION11......RecommendedSpareParts

SECTION 12 IR Engine....

Book No. 22235428 (11/03)

1()

P425AWIR Family Electrical Manual

SECTION 1

MANUAL DESCRIPTION

Thismanualcontainsall of the information concerning the electrical and electronic systems for

theP425 Familyof compressors. It providesall information necessary to service, troubleshoot

and order parts for this machine.

It is organized into 12 sections.

Sections 2 -- 4 cover systems operation and troubleshooting procedures.

Sections 5 -- 7 have location diagrams, drawings of specific circuits and systems schematics.

Section8 hasinformation concerningthe electricalconnectors used,including removaland re-

placement.

Section 9 contains the parts list with ordering information.

Section 10 contains the list of Alerts and Shutdowns.

Section 11 contains a list of recommended spare parts for servicing.

Section 12 contains engine information.

Book No. 22235428 (11/03)

2()

P425AWIR Family Electrical Manual

SECTION 2

GENERAL INFORMATION

and

OPERATIONAL THEORY

Book No. 22235428 (11/03)

3()

P425AWIR Family Electrical Manual

GENERAL INFORMATION AND OPERATIONAL

THEORY

General

The P425 Family of machines has an electronic

monitor and control system to provide discharge air

pressure control and engine and package monitor

functions. The system uses the WEDGE controller to

perform these functions. The electrical system

connects all the necessary switches, sensors and

transducers to the WEDGE controller in order for it to

perform the monitor and control functions.

The WEDGE is attached to the control panel with four

#10 size nuts.

ThefirstfunctionoftheWEDGEcontrolleristoscanall

analog and digital inputs at a fixed interval. These

inputsarescannedevery50milliseconds. Theanalog

values are then compared against minimum and

maximum values and an ALERT or SHUTDOWN is

issued,ifavalue is outofrange. The variousALERTS

and SHUTDOWNS are listed in Section 10 of this

manual.

WEDGE Controller

The WEDGE controller is the heart of the machine

monitor and control system. It provides data

collection, alarming and control functions for

compressor operations. It is a microcontroller based

unit with analog and digital inputs and outputs.

The WEDGE controller is attached to the back of the

control panel. The LED annunciators are part of the

front panel of the WEDGE. They can be seen through

the laminate on the front of the control panel.

The second function of the WEDGE controller is

machine discharge pressure control. The WEDGE

monitorstheregulationsystemairpressureandvaries

the engine throttle to maintain the setpoint discharge

air pressure. The setpoint pressure is set using the

regulator on the separator tank.

The third function of the WEDGE controller is to

communicate with the diesel engine via the J1939

CAN network. Itretrievesdiagnosticinformation over

J1939.

Book No. 22235428 (11/03)

4()

P425AWIR Family Electrical Manual

SOLENOID VALVES

SPEED SENSOR

FUEL LEVEL SWITCH

PRESSURE TRANSDUCERS

TEMPERATURESENSORS

BATTERY STARTINGAND

CHARGING SYSTEM

W1W1

P425/P600 HARNESS SYSTEM SCHEMATIC

24VDC HEATERS

CONTROL PANEL SWITCHES

INTERFACE

ENGINE ECM DIAGNOSTIC

HOURMETER

ESTOP SWITCHES

FIGURE 2--1

W1

GAUGES

P4

W1

CONTROL PANEL HARNESS

Book No. 22235428 (11/03)

WEDGE

Controller

5()

P1

P425AWIR Family Electrical Manual

J1--34

WEDGE

CONTROLLER

J1--35

J1--24

J1--38

J1--13

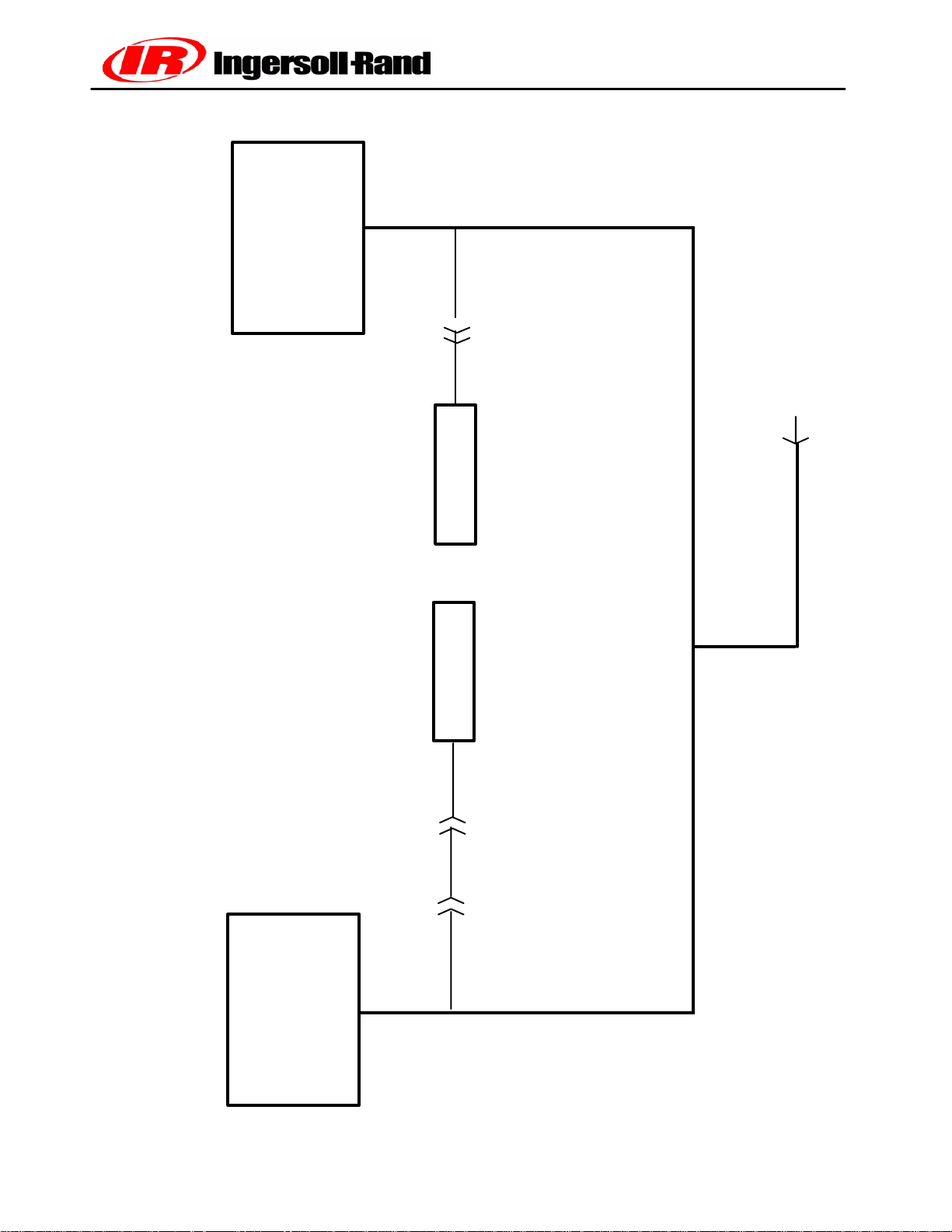

WEDGE TO ENGINE INTERFACE

IR ENGINE

CAN LO

J50--G1

CAN HI

CANSHLD

J50--J1

IR

41RD5AE

KEY SWITCH

J50--A2

61IRF8TE

ENGINE

ANALOG THROTTLE

ANALOG THROTTLE RANGE = 1.10VDC (1400RPM) TO 3.7VDC (2400 RPM)

J50--F2

FIGURE 2--2

Book No. 22235428 (11/03)

6()

CONTROLLER

P425AWIR Family Electrical Manual

WEDGE

CONTROLLER

P6

R5

R4

ENGINE DIAGNOSTICS JACK

J57

TERMINATOR

TERMINATOR

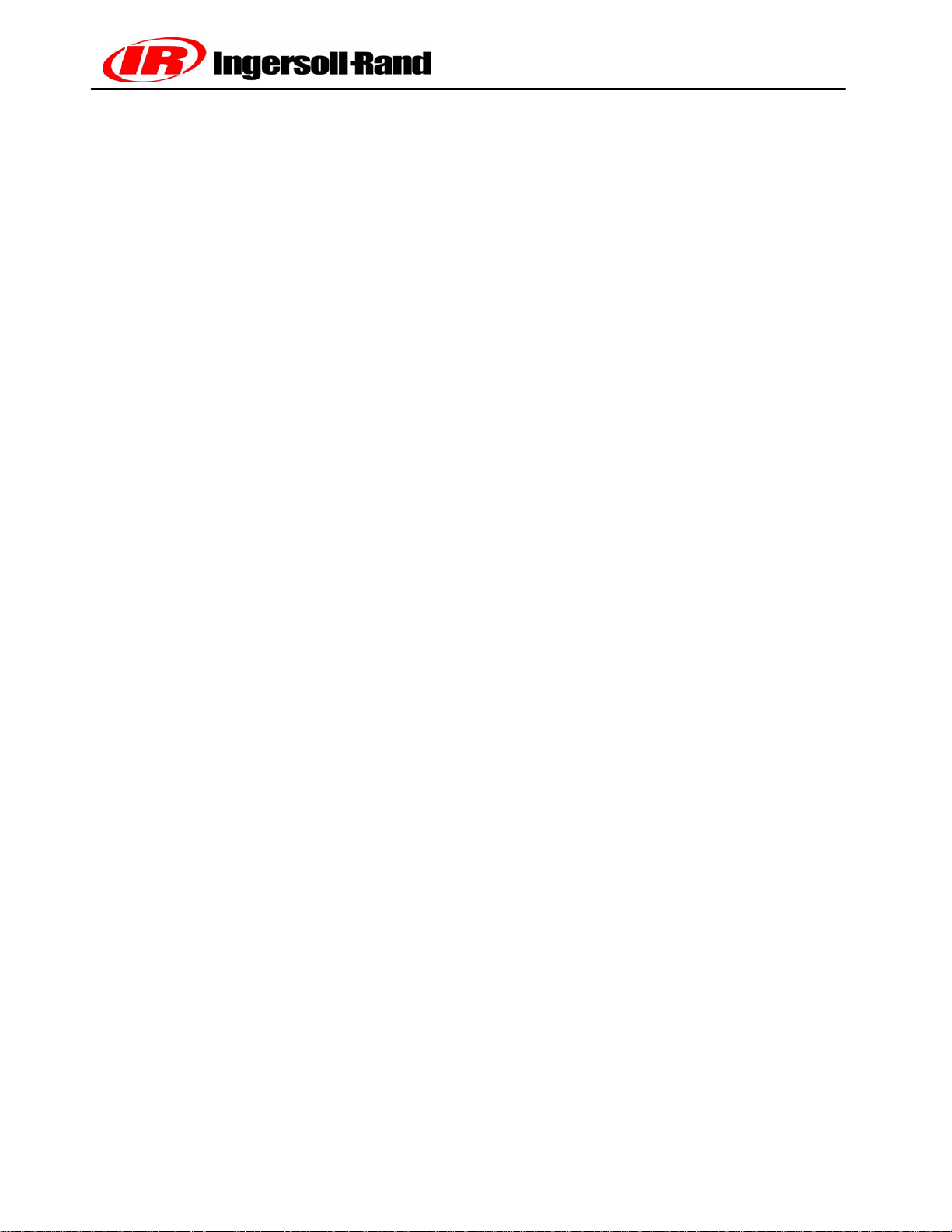

P425/P600 J1939 CAN COMMUNICATIONS SCHEMATIC

ENGINE ECM

Book No. 22235428 (11/03)

P1 1

P10

7()

FIGURE 2--3

P425AWIR Family Electrical Manual

The wedge uses an analog signal to communicate

withtheJohnDeere engine.Thissignalhasa range of

1.1V to 3.7V. This range corresponds to an engine

speed range of 1400 to 2400 RPM.

Figure 2--2 shows the signals between the engine

controller and the WEDGE controller.

Sensors and Transducers

The electronics system contains sensors and transducersthatareusedtocollectdata from the compressor. The temperature is measured by a thermistor.

Thisdeviceexhibitsa changeinresistanceasthetemperature changes. The resistance causes an input

voltage change to the WEDGE controller input and is

interpreted as a temperature change.

The electronics system also uses pressure transducerstomeasurecompressorpressurechanges. These

devices have an output signal of .45 VDC to 4.5 VDC,

corresponding to 0 psi and the maximum measured

psi for a particular device. The maximum pressure

transducer ranges are 100 or 225 psi. The 100 and

225 psi devices are gauge pressure devices. These

transducers are provided with 5 VDC excitation to

power the device. These are three wire devices: excitation, signal and ground.

Digital Inputs and Outputs

The WEDGE controller scans digital inputs such as

switch contacts. These are either “ON” (24VDC) or

“OFF” (0 VDC). These digital inputs are connected to

switches within the package such as the key start

switch, air filter switches and IQ filter switches.

The WEDGE controller provides 24 VDC digital

outputsto control solenoids,start compressor andDC

heaters. These are 24 VDC “ON” and 0 VDC “OFF”.

They are current limited and short circuit protected.

TheWEDGEvariestheanalogsignalfrom1.25to4.25

volts,correspondingto1400 to2100RPM. Thissignal

is used with the John Deere engine. The frequency

throttle signal is used with the Cummins engine and

thepulsewidth modulated signal is used with the CAT

engine.

Pressure Control

The discharge pressure is controlled by manipulating

theengine speed andcompressor inlet valveposition.

Theinletvalvepositioniscontrolledpneumaticallyand

the engine speed is determined by the WEDGE controller.The WEDGE measures the pneumatic system

regulation pressure and computes an engine throttle

setting.Thisthrottle settingissent totheengineviathe

frequencythrottle, Analog,PWM or J1939throttle, depending on which technique is used. The engine controller will control engine speed to this throttle setting.

Electronic Engine -- P425 Family of Machines

The P425 Family of machines contains an emissions

certifieddiesel engine. Inordertomeet the emissions

requirements, the engine has an electronic control

system.

The control system handles all monitor, alarm and

controlfunctions for the engine. The WEDGEcontroller communicates with the engine controller over the

J1939 CAN network.

The WEDGE controller sends throttle settings to the

engineandreceivesdiagnosticandruntimedatafrom

the engine over the J1939 CAN network. An analog

throttle interface is currently used with the engine.

Figure 2--2 shows the connections between the

WEDGE controller and the engine controller.

Controller Outputs

The WEDGE controller has four types of outputs: frequency, pulse width modulated, analog and 24VDC

digital (ON/OFF). The analog output is used as the

throttle signal to the engine.

Book No. 22235428 (11/03)

8()

P425AWIR Family Electrical Manual

J1939 Data Link

The CAN network is a single pair shielded cable

located with the W1 main harness. Figure 2--3 shows

a layout of the CAN harness or “backbone” as it is

referredto. The termination resistors(Terminator)are

important to prevent reflections on the transmission

line and must be in place for the network to function

properly.

Theenginediagnostics connectorislocatedonthe left

side of the engine. This is used to connect the engine

manufacturer’sservicetoolstotheCANnetwork. This

connector also provides 24 VDC to power these

service tools.

Electrical System

Theelectrical systemconsists of thewiring harnesses

and associated electrical devices such as relays,

switches, lights, solenoids and alarm horn. There is

one wiring harnesses in the P425 machine.

The electrical circuits are protected using ATC style

fuses. A fuse should only be replaced with one of the

same rating. Replacing a fuse with one of a large

rating could lead to harness damage. If a fault occurs

andthecircuitdoes nothavetheappropriatesizefuse,

wires could be burned in the harness and damage

other circuits.

Machine ID

Software versions 1.60 and greater use software to

setthe machine ID. Versionsless than 1.60usean ID

resistor plug, R2. The ID plug is located behind the

control panel box on the W1 harness trunk. The

resistor plugs are molded in colors for easy

identification. Refer to Section 7, Individual Circuit

Diagrams and the page entitled R @ MACHINE ID

PLUG for details.

It is recommended that all machines be upgraded to

Version1.60orgreater.Thesoftware setmachineIDis

much more reliable than the resistor plug.

P/N 22199061 W1 Chassis Main Harness

Theschematicdiagramsshow theconnectionsfor this

harness. Figure 2--1 is a system schematic showing

harnessconnectionwithdevicesandcontrollers. Section 8 includes information on connectors used in the

harness.

Book No. 22235428 (11/03)

9()

P425AWIR Family Electrical Manual

PT1:

PT2:

U1:

RT1:

RT2:

K1:

KEY ELECTRICAL COMPONENTS FUNCTION

PT1 is a 0--225 psi gauge pressure transducer that measures discharge air pressure.

PT2 is a 0--100 psi gauge pressure transducer that measures regulation system pressure.

U1 is resistive level detector that measures the fuel level in the fuel tank.

Itprovidesa continuous reading of fuel level. Italso has a switch for low fuellevel andlow fuelshutdown.

These switches connect to WEDGE.

RT1 is a 10K ohm Thermistor temperature sensor that measures separator tank temperature.

Its range is --30 to 255_ F.

RT2 is a 10K ohm Thermistor temperature sensor that measures airend discharge temperature.

Its range is --30 to 255_F.

K1 is SPST, 24VDC relay used to activate the engine starter.

K2:

K2 is a SPST, 24VDC relay used to activate the engine inlet heater.

Book No. 22235428 (11/03)

10()

P425AWIR Family Electrical Manual

CONTROL PANEL

DIAGNOSTIC SHUTDOWN (Standard)

1. Compressor Fault: Indicates shutdown due

to compressor system fault. Refer to fault

code list in Section 10.

2. Engine Fault: Indicates shutdown due to

engine fault. Refer to fault code list in Section

10.

3. Hourmeter: Indicates machine operating

hours.

4. Discharge Air Pressure Gage: Indicates

pressure in receiver tank, psi (kPa).

5. Fuel Level Gage: Indicate fuel level in tank.

CONTROLS

6. PowerSwitch: Flip“ON” to activate systems

7. Service Air Switch: After warm--up, PUSH.

Book No. 22235428 (11/03)

(Standard)

prior to starting. Flip ’off” to stop engine.

Providesfull air pressure atthe service outlet.

OPTIONAL CONTROLS

8. Engine Speed Gauge: Indicates engine

speed.

9. DischargeAirTemp.Gauge: Indicatesin_F

and _C. Normal operating range:

185_F/85_C to 248_F/120_C.

10. Engine Oil Pressure Gauge: Indicates

engine oil pressure psi (kPa).

11. Engine Water Temp Gauge: Indicates

coolant temperature with normal operating

range from 180_F/82_C to 210_F/99_C.

12. Voltmeter: Indicates battery condition.

13. Spare

14. Wait to Start Lamp

11()

P425AWIR Family Electrical Manual

OPERATIONAL INFORMATION

Power “ON” at Control Panel:

1. Key switch signal (24VDC) supplied to engine controller by WEDGE controller

Engine Start--up:

When the key is switched to the engine crank position:

1. K1 auxiliary start relay is energized.

2. Run/Start solenoid valve (L1) is opened (energized).

Note: Run/start solenoid stays open for 10 seconds after the key is released if the engine does not start.

When the engine speed reaches 600 RPM (engine start declared):

1. Engine speed is set to 1600 RPM.

When the engine speed reaches 1450 RPM:

1. Unloader solenoid valve is opened (energized), L2.

2. Run/Start solenoid valve is closed (de--energized, L1).

When the separator tank pressure reaches 50 psi:

1. Run/Start solenoid valve is opened (energized), L1.

After 5 seconds:

1. Engine speed is set to idle (1400 RPM if air end discharge temperature is approximately

150 degrees F or (if J1939 CAN is functioning) the engine coolant is 100 degrees F.

Otherwise, the engine idle stays at 1500 RPM.

Loading:

When the “Service Air” s witch is pushed:

1. Engine speed is set to 2400 RPM

When engine speed reaches 2200 RPM:

1. Run/Start solenoid valve is closed (de--energized).

After 2 seconds and if the regulation system pressure is 4 psi or greater:

1. Compressor pressure control is engaged.

Book No. 22235428 (11/03)

12()

P425AWIR Family Electrical Manual

READING AND SETTING THE DISPLAY

UNITS

The WEDGE has four choices for display units:

_F, PSI

_C, Bars

_C, kPa

_C, Kg/cm2

To determine which units the WEDGE has been configured for:

1. With the machine power off (Key turned OFF)

2. Press and hold the “Service Air” Switch

3. Turn the key switch directly to the crank position.

4. Hold these switch positions until the 4 digit LED display on the WEDGE goes blank.

5. Release “Service Air” switch, release key switch to “ON”.

Units will be displayed for 2 s econds after which the current selection will be displayed as:

_F, PSI will be displayed as “PSI”

_C, Bars will be displayed as “bAr”

_C, kPa will be displayed as “HPA”

_C, Kg/cm2 will be displayed as “H9C”

To change the units setting:

1.With theWEDGE showingthe currentsetting, pressandrelease the“Service Air”switch untilthedesired setting

appears on the display.

2. Once it appears, do not release the “Service Air” switch. Hold it in the ON position until the WEDGE restarts.

This will select units selection that was displayed.

3. Release the “Service Air” switch. The compressor is ready to start.

Book No. 22235428 (11/03)

13()

P425AWIR Family Electrical Manual

WEDGE SERVICE DIAGNOSTICS

The WEDGE controller provides a diagnostic capability that allows various internal parameters to be viewed on

the 4--digit LED display.These can be accessed with the machine stopped or while it is operating. If the machine

is stopped, the “Service Air” switch on the control panel is used to toggle through the list of parameters. If the machine is operating, the “Start” position of the key switch is used. Toview the parameters, toggle the switch or key

and a number (2--20) will appear on the LED display. After 3 seconds, it will extinguish and the parameter will be

displayed. The toggle only works in the ascending order direction, but it will wrap around and start over.

Display Parameter Remarks

2 RPM From Engine Flywheel Sensor

3 Engine RPM Filtered RPM Value

4 Reg. Sys. Pressure PSI

5 Sep. Tank Pressure PSI

6 Discharge Temperature Deg F

7 Sep. Tank Temperature Deg F

8 Engine Target RPM Wedge Signal to Engine

9 Machine Type *

10 Engine Coolant Temp. From CAN, Deg F

11 Engine Oil Temp. From CAN, Deg F

12 Engine Oil Pressure From CAN, PSI

13 Intake Manifold Temp. From CAN, Deg F

14 RPM From CAN

15 Fault Code List Cummins/CAT codes

16 Throttle Position

17 Boost Pressure

18 Engine Hours

19 Load At Speed Percent

20 Set Machine ID

Book No. 22235428 (11/03)

14()

P425AWIR Family Electrical Manual

ENTERING MACHINE ID FOR WEDGE CONTROL SYSTEMS with V1.60 or Greater Software

For machines with the WEDGE controller mounted inside the control panel/instrument panel box, the “Service

Air” switch is used to enter the machine ID. Disconnect the fuel level gauge (located in the fuel tank) before

starting the process and reconnect once the process is completed.

For machines with the WEDGE controller mounted in the engine compartment, the rocker switch beside the

WEDGE is used to enter the machine ID.

For the instructions below, the “Service Air” or rocker switch will be referred to as the “data input switch”.

1. Examine the machine data plate to confirm the machine model.

Using the machine model and the machine models list on page 2 of this document, locate the proper

machine ID.

2. Turn power to the ”ON” position. Machine must not be operating.

3. Toggle the data input switch twice and the number “2” will appear on the WEDGE 4--digit LED display.

Continue to toggle the switch until the number “9” is reached. Read the machine ID on the

display, if it matches the proper machine ID in Step 1, stop. If not, proceed to step 4.

4. Continue to toggle the switch until number “19” is reached. Push and hold the data input switch and the

number“20” willappear.Continue toholdthe switch.After 1second,the currentmachine IDwillappear in

the display. Continue to hold for 9 more seconds and a blinking “--” will appear. Release the switch.

5. Togglethedatainputswitch, thedisplaywillshow“0”.Togglethedata inputswitchuntiltheproper machine

ID appears on the display, then stop the toggle sequence.

6. Waituntil the controller performs a reset function (or power up) (approximately 10 seconds). At reset, the

controllerdisplayfirstgoesblank,thenal110annunciato rLED’slight,the4--digitLEDdisplayshowsall8’s,

thedisplay then shows the installed software version and finally the display goes blank and the engine oil

pressureand alternatorLED begin flashing.At thispoint thecontrollerhas storedthemachine IDselected

in step 5.

7. Using the data input switch, toggle to service diagnostic number “9”.

The number “9” will appear for 1 second and then the machine ID will appear. The ID should be the same

as the one entered in steps 4--6. If not, go back to step 4 and enter the ID again.

Book No. 22235428 (11/03)

15()

P425AWIR Family Electrical Manual

ESA Models/Wedge Machine

ID

Models

7/120,9/110. 10/105, 14/85 7

7/170. 10/125.14/115 8

9/230,9/270,9/300. 12/235 5

17/235,21/215 6

MSA Models/Wedge Machine

ID

Models

P425AWIR, XP375AWIR, HP375WIR 7

VHP300AWIR

P600WIR, HP450WIR, VHP400WIR 8

XP1060WCU, HP935WCU, MHP825WCU 5

VHP750WCU

XHP750WCU 6

MHP825WCAT, VHP750WCAT 2

XP1060HACAT,XP950HACAT

SHP825WCAT, XHP750WCAT. XHP650WCAT 3

HP1300CWCU,HP1600CWCU 0

XHP1170WCU 1

XHP1070AWCAT, XHP1170WCAT. XHP1170SCAT 4

HP1600WCAT 9

Machine ID

Machine ID

SIRC Models/Wedge Machine

ID

Models

P1060WCAT, XP950WCAT, HP935WCAT 2

MHP825WCAT .VHP750WCAT

XHP750WCAT 3

Book No. 22235428 (11/03)

16()

Machine ID

P425AWIR Family Electrical Manual

SECTION 3

SERVICE TOOLS

Book No. 22235428 (11/03)

17()

P425AWIR Family Electrical Manual

SERVICE TOOLS

Service Tools

The following special tools are recommended to perform service procedures in this manual. The tools can

be purchased from Ingersoll Rand or other sources as listed.

Tool Tool Description

22216691 Digital Multimeter (Fluke 87)

Used to measure electrical circuits; Volts, amps, ohms

54729660 Packard Weather--Pack Terminal Removal Tool

Used to repair Packard Electric Weather--Pack Connectors

54699632 Deutsch Terminal Removal Tool (Blue)

Used to repair Deutsch connectors

54699640 Deutsch Terminal Removal Tool (Red)

Used to repair Deutsch connectors

54699624 Deutsch Terminal Removal Tool (Yellow)\

Used to repair Deutsch connectors

22216667 Deutsch Terminal Crimp Tool (HDT--48--00)

Used to crimp Deutsch connector terminals

54729710 Electrical Contact Cleaner

Used to clean electrical contacts and connectors

54729728 PDA Service Tool

Used to load software & extract service and fault logs

54699616 Deutsch Terminal Removal Tool

Used to repair Deutsch connectors

54749544 RTD Simulator Plug

Used to test RTD circuits

54749551 Thermistor Simulator Plug

Used to test thermistor circuits for INTELLISYS controller systems

22073878 Thermistor Simulator Plug

Used to test thermistor circuits for WEDGE controller systems

54749635 Connector Repair Kit

Used to make connector repairs for Deutsch and Packard Electric Connectors

54699657 Deutsch Terminal removal Tool

Used to repair Deutsch connectors

54749643 Packard Metri--Pack Terminal Removal Tool

Used to repair Packard Electric connectors

Book No. 22235428 (11/03)

18()

P425AWIR Family Electrical Manual

22168868 Pressure Transducer Simulator

Used to test pressure transducer circuits

22147540 Test Adapter Kit Test adapters for various connectors to be

Used when making electrical measurements

22146393 Removal Tool Kit Assortment of most used Deutsch removal tools

22216675 Deutsch Crimp Tool (DTT --20--00)

Used to crimp Deutsch connector terminals

22216683 Packard Electric Crimp Tool (12155975)

Crimps 150 and 280 series pins

22255947 Packard Electric Crimp Tool (12039500)

Crimps 150 series pull to seat pins

22216709 Fluke Test Lead Set (TL20)

Contains needle probes, alligator clips, test leads

heat shrink tubing that are used on harnesses

22216725 Fluke Insulation Piercing Probe (AC--89)

Used to connect to a wire for measurements

22216733 Fluke Meter Case (C25)

Case for Fluke 87 meter including storage for test leads and probes

54740675 RS232 Heavy Duty Serial Cable

Connects lap top computer or PDA Service Tool

to WEDGE or Intellisys controller

22252969 Wire Terminal Kit

Contains a selection of terminals with

corresponding heat shrink tubing that are used on harnesses

22281588 Connector Wrench

22282107 5/32 “T” hex screwdriver wrench

22282172 1/4” Flex Shaft Nutdriver

Used to remove ECM connector on J ohn Deere engines

22252993 WEDGE Connector Kit

Includes the 40--pin connector housing and pins for the harness connector

22253009 CAN Communications Adapter

Converts RS232 to J1939 CAN, used with lap top computer

or PDA Service T 001

22253017 Adhesive Heat Shrink Assortment

Selection of most used heat shrink sizes

Book No. 22235428 (11/03)

19()

P425AWIR Family Electrical Manual

22221303 Service Tool Kit

Kit consists of the following P/N’s: 22216691 22216667

22216675 22216683 54729660 54749643 54699657

22146393 22147540 22073878 54749635 22168868

22216709 22216725 22216733 54740675

22254775 ATC Fuse Assorlment Kit

Kit contains 5, 7--1/2, 10, 15,20,25, and 30 Amp fuses

22254734 Packard Crimp Tool (12014254) Crimps Sealed

Weather Pack Connector pins

Book No. 22235428 (11/03)

20()

P425AWIR Family Electrical Manual

Tool No. Tool Description Tool Illustration

22216691

54729660 Weather--Pack Terminal Removal Tool

54699632 Deutsch Terminal Removal Tool (Blue)

54699640 Deutsch Terminal Removal Tool (Red)

Digital Multimeter

54699624 Deutsch Terminal Removal Tool (Yellow)

22216667 Deutsch Crimp Tool

Book No. 22235428 (11/03)

21()

P425AWIR Family Electrical Manual

54729710

54729728 PDA Service Tool

54699616 Deutsch Terminal Removal Tool

54749544 RTD Simulator Plug

Electrical Contact Cleaner

22073878 Thermistor Plug

54749635 Connector Repair kit

54699657 Deutsch Terminal Removal Tool

Book No. 22235428 (11/03)

22()

P425AWIR Family Electrical Manual

54749643

Packard Metri--Pack Removal Tool

22168868 Pressure Transducer Simulator

22147540 Test Adapter Kit

22146393 Removal Tool Kit

22216675 Deutsch Crimp Tool

22216683 Packard Electric Crimp Tool

Book No. 22235428 (11/03)

23()

P425AWIR Family Electrical Manual

22216709

Fluke Test Lead Set

22216725 Fluke Insulation Piercing Probe

(single probe)

22216733 Fluke Meter Case

54740675 RS232 Serial Cable

22253969 Wire Terminal Kit

Book No. 22235428 (11/03)

24()

P425AWIR Family Electrical Manual

Connector Wrenches

22281588

22282172

22282172 1/4’’ Flex Shaft Nutdriver

22252993 WEDGE Connector Kit

22253009 CAN Communications Adapter

22253017 Adhesive Heat Shrink Assortment

Book No. 22235428 (11/03)

25()

P425AWIR Family Electrical Manual

22255947

22254734 Packard Electric Crimp Tool

Packard Electric Crimp Tool

Book No. 22235428 (11/03)

26()

P425AWIR Family Electrical Manual

SECTION 4

ELECTRONIC SYSTEMS TROUBLESHOOTING

PROCEDURES AND TECHNIQUES

Book No. 22235428 (11/03)

27()

P425AWIR Family Electrical Manual

General

A thorough analysis of the problem is the key to successful troubleshooting. The more information known

about a problem, the faster and easier the problem can be solved.

Troubleshooting charts are included to act as a guide to the troubleshooting process. They are organized so

the easiest and most logical things are performed first. It is not possible to include all the solutions to problems

that can occur or list all possible problems. The charts are designed to stimulate a thinking process that will

lead to solution of the problem.

Basic Troubleshooting Steps

• Collect all facts concerning the problem

• Analyze the problem thoroughly

• Relate the symptoms to the basic electrical / electronic systems and components

• Consider any recent repairs that could relate to the problem

• Double check before replacing components

• Review the controller fault log for clues as to the problem

• Determine the cause of the problem and make a thorough repair

Book No. 22235428 (11/03)

28()

P425AWIR Family Electrical Manual

MEASURING VOLTAGE, RESISTANCE,

FREQUENCY AND DUTY CYCLE

General Measuring Guidlines:

Since the electrical system uses sealed connectors and splices, access of test points can be difficult. It is recommended that a test probe kit be used to access the signals to prevent damage to wires and connectors.

Back probing connectors and insulation piercing test probes can cause damage that can cause future failures.

Measuring Voltage:

A digital voltmeter is recommended to make measurements. Voltage measurements are made by connecting

the RED + lead to the desired signal and the BLACK lead to the common. The test lead connections must be

secure or incorrect readings will result. Use circuit common for the Black lead, not chassis ground or other

metal connection. Circuit common will be any of the BROWN wires or battery negative can be used.

IMPORTANT INFORMATION

DO NOT USE MACHINE FRAME, SHEET METAL, PIPING OR OTHER METAL COMPONENTS AS COMMON OR GROUND WHEN MAKING VOLTAGE OR FREQUENCY

MEASUREMENTS.

Measuring Resistance:

Extra care must be taken when making resistance measurements. Testprobe connections are crucial to correct readings. Ensure the test probe makes a solid connection with the wire(s) or connector pin(s) under test.

the test probe kit may help with these types of measurements. Make sure system power is turned OFF while

making resistance measurements.

Measuring Frequency:

Frequency is measured in the same manner as voltage, but the meter is set for “HZ” or frequency. Good connections are important or false readings will occur.

Measuring Duty Cycle:

To measure duty cycle, setup the meter as if measuring frequency or voltage. Select the “%” or duty cycle

function and take the measurements. As of the date of this writing, Fluke is the only known digital voltmeter

that has the duty cycle feature. The Fluke Model 87 Digital Meter has the duty cycle function.

Book No. 22235428 (11/03)

29()

P425AWIR Family Electrical Manual

Loading...

Loading...